Preparation method of biomass filtering and purifying filter material and use method thereof

A technology for filtration and purification of biomass raw materials, applied in chemical instruments and methods, filtration separation, membrane filters, etc., can solve the problems of rough processing of raw materials, complicated manufacturing process, and limited use range, etc., and achieve more fine spaces and better filtration performance Good, excellent texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing biomass filtering and purifying filter material includes the following steps:

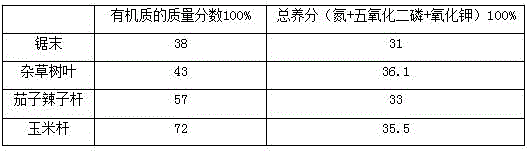

[0028] Step 1) Selection, crushing and screening: selecting biomass raw materials, the biomass raw materials including crop straw waste. Crush and screen the biomass raw materials, select 6-40 mesh as raw materials, and retain waste materials below 40 mesh for use;

[0029] Step 2) Soaking: The specific method is as follows: Take 100 kg of water, add 5 kg KOH and 0.5 kg sodium tripolyphosphate STPP, stir evenly to form an aqueous solution of the first pool of chemical agent A, and place the selected raw materials containing chemical agent A Soak the raw materials in the aqueous solution for 2 days, wash, degrease, remove impurities, and remove nutrients. After soaking, remove and spin dry. The mass ratio of the selected raw materials to the aqueous solution of chemical agent A is 1:8;

[0030] Step 3) Washing: Place the above-mentioned spin-dried raw materials in a washing t...

Embodiment 2

[0040] A method for preparing biomass filtering and purifying filter material includes the following steps:

[0041] Step 1) Selection, crushing and screening: selecting biomass raw materials, the biomass raw materials including crop straw waste. Crush and screen the biomass raw materials, select 6-40 mesh as raw materials, and retain waste materials below 40 mesh for use;

[0042] Step 2) Soaking: The specific method is as follows: Take 100 kg of water and add 8 kg of NH 4 HCO 3 And 0.3 kg of fatty alcohol polyoxyethylene ether phosphate monoester, stir evenly to form an aqueous solution of the first pool of chemical agent A, soak the selected raw materials in the aqueous solution containing chemical agent A for 3 days, and wash, degrease, and Remove impurities, remove nutrients, soak and remove and spin dry. The mass ratio of the selected raw materials to the aqueous solution of chemical agent A is 1:10;

[0043] Step 3) Washing: Place the above-mentioned spin-dried raw materials ...

Embodiment 3

[0053] A method for preparing biomass filtering and purifying filter material includes the following steps:

[0054] Step 1) Selection, crushing and screening: selecting biomass raw materials, the biomass raw materials including crop straw waste. Crush and screen the biomass raw materials, select 6-40 mesh as raw materials, and retain waste materials below 40 mesh for use;

[0055] Step 2) Soaking: The specific method is as follows: Take 100 kg of water and add 5 kg K 2 CO 3 And 0.5 kg sodium phosphate Na 3 PO 3 .12H 2 O, stir evenly to form an aqueous solution of the first pool of chemical agent A, soak the selected raw materials in the aqueous solution containing chemical agent A for 3 days, wash, degrease, remove impurities, and remove nutrients from the raw materials. Dry, where the mass ratio of the selected raw materials to the aqueous solution of chemical agent A is 1:10;

[0056] Step 3) Washing: Place the above-mentioned spin-dried raw materials in a washing tank and stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com