Goose down based expanded silk wadding quilt and preparation method thereof

A silk quilt and goose down technology, which is applied in silk fiber production, application, household appliances, etc., can solve problems such as non-conforming to environmental protection, easy to produce bacteria in products, uneven quality, etc., and achieve good application prospects, good display performance, Taking performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

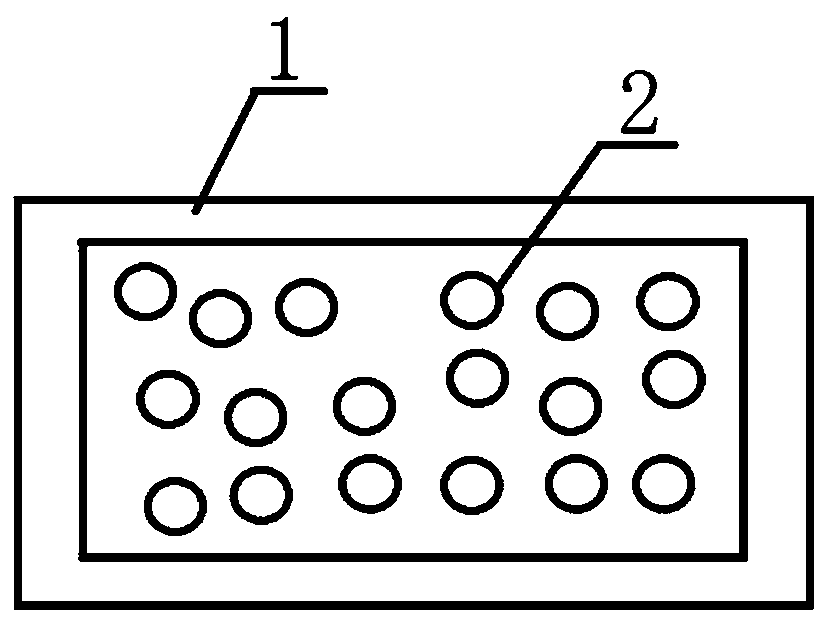

Image

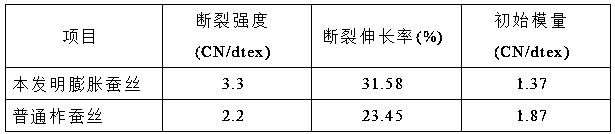

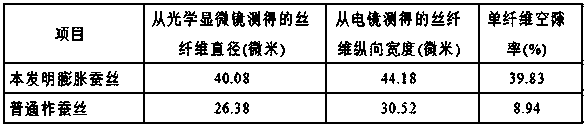

Examples

Embodiment 1

[0048] A preparation method for expanded silk quilt, comprising the steps of:

[0049] (1) Take tussah silk as raw material, after removing impurities and rinsing, add water to soak for 50 minutes, the liquor ratio is 15:1; then dehydrate and complete the cleaning; degumming the cleaned silk under high temperature and pressure; after degumming, remove it from the reaction kettle Release the degummed silk fiber solution; the pressure of high temperature and high pressure degumming is 0.2MPa, the temperature is 125°C, and the degumming time is 15 minutes; the mass concentration of the degummed silk fiber solution is 75%;

[0050](2) Add the mixed solution of turmeric extract, acetic acid and carboxymethyl cellulose into the degummed silk fiber solution, ultrasonically treat for 2 hours, then add polyurea formaldehyde and selenocystamine hydrochloride, and ultrasonically treat for 1 hour; Then dehydrate and dry to obtain processed silk; the mass ratio of degummed silk fiber, turm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com