Patents

Literature

549results about How to "High antibacterial rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

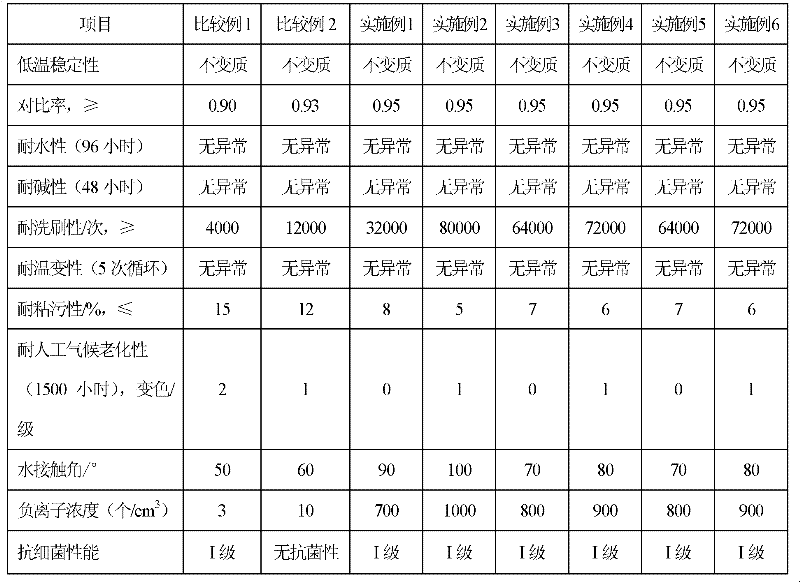

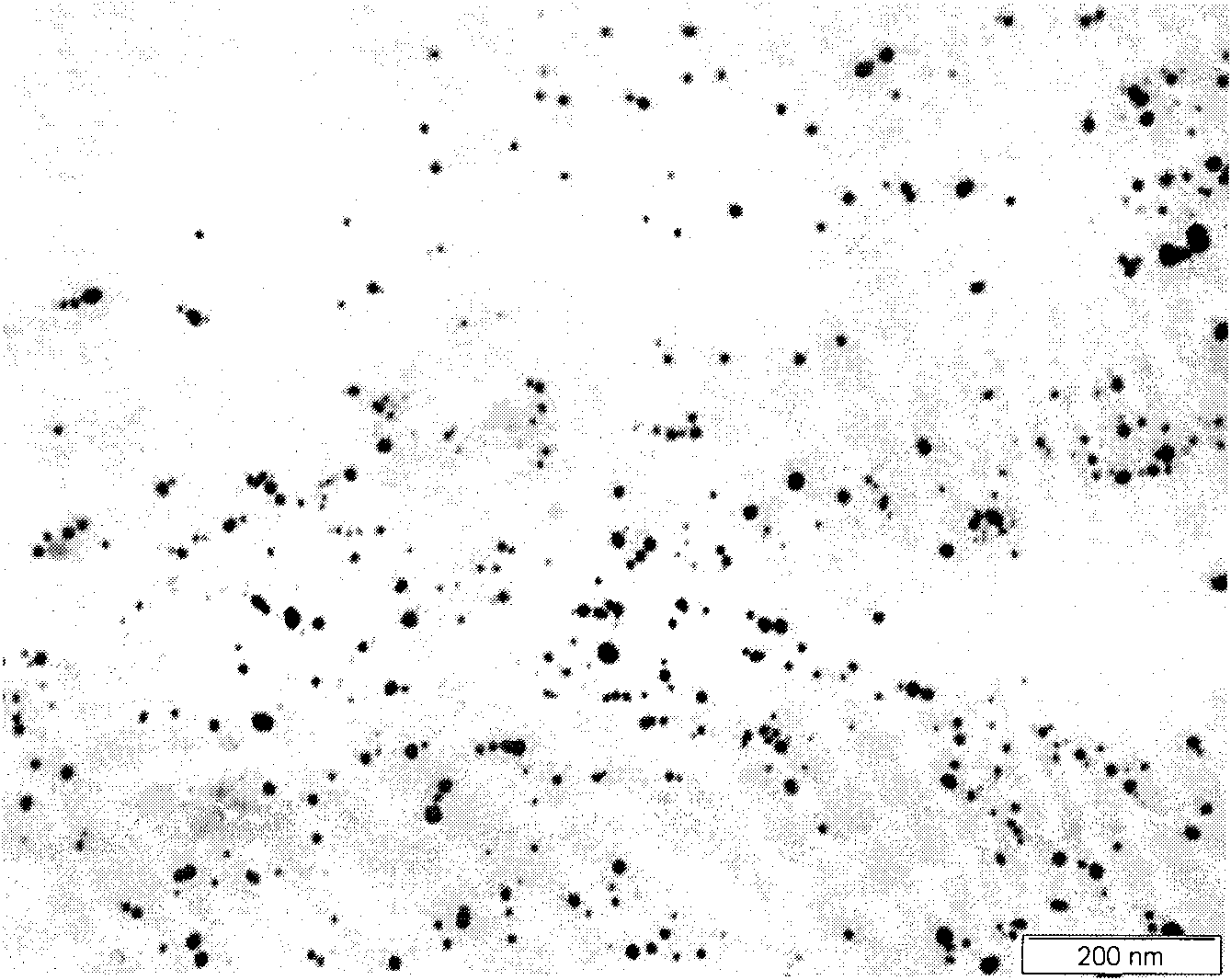

High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

ActiveCN102417748AEasy to disperseStorage stableAntifouling/underwater paintsPaints with biocidesVolatile organic compoundEmulsion

The invention relates to a paint technology, an environment-friendly technology and an antibacterial mould-proof technology, in particular to high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and a preparation method thereof. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint comprises the following components in percentage by weight: 0.5 to 5 percent of wetting dispersant, 0.01 to 20 percent of inorganic composite nano antibacterial agent concentrated pulp, 0.5 to 10 percent of hydrophobing agent, 0.5 to 10 percent of anionic powder, 0.5 to 8 percent of film-forming aid, 0.1 to 2 percent of anti-settling agent, 0.8 to 10 percent of antifreezing agent, 0.1 to 3 percent of defoaming agent, 4 to 30 percent of pigment, 0 to 30 percent of filler, 15 to 45 percent of emulsion, 0.1 to 4 percent of thickening agent, 0.1 to 3 percent of flatting agent, 0 to 3 percent of pH regulator and 0.5 to 45 percent of water. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint is mainly prepared by adding the inorganic composite nano antibacterial agent into the basic materials, so that the paint has the coating characteristic of high performance, is low is cost, and has a function of purifying air, can eliminate harmful gas volatile organic compounds (VOC), formaldehyde and the like and also has a durable and high-efficiency antibacterial mould-proof function, so that the sterilizing rate within 6 hours reaches 100 percent and the mould-proof grade reaches the first grade. By the high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and the preparation method thereof, self-cleaning performance, hydrophobicity, scrubbing resistance, dirt resistance and weather resistance of the coating are improved; and the high-efficiency and durable antibacterial and mould-proof effect is achieved.

Owner:广东腐蚀科学与技术创新研究院

Efficient antibacterial chitosan essential oil microcapsule preparation method

ActiveCN104975513AGood slow-release fragranceImprove antibacterial propertiesMicroballoon preparationVegetal fibresEscherichia coliEnvironmental resistance

The present invention provides an efficient antibacterial chitosan essential oil microcapsule preparation method, which comprises chitosan aqueous solution preparing, polyvinyl alcohol aqueous solution preparing, core material emulsion preparing, and efficient antibacterial chitosan essential oil microcapsule preparing so as to obtain the efficient antibacterial chitosan essential oil microcapsules. According to the present invention, the method has characteristics of safety and environmental protection, and the used raw materials are the natural products; and the product microcapsules are cationic, have characteristics of efficient antibacterial effect, high essential oil content and good slow release property, and can be directly used for fabric post-finishing and related function nursing products, and the bacterial inhibition rate of the obtained fabric on Staphylococcus and escherichia coli is up to 85%.

Owner:TIANJIN CHENGJIAN UNIV

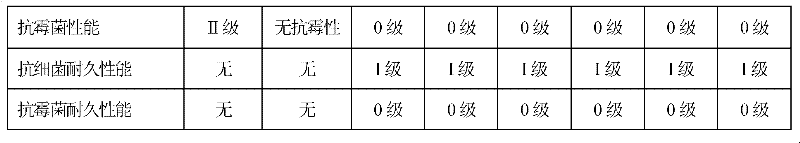

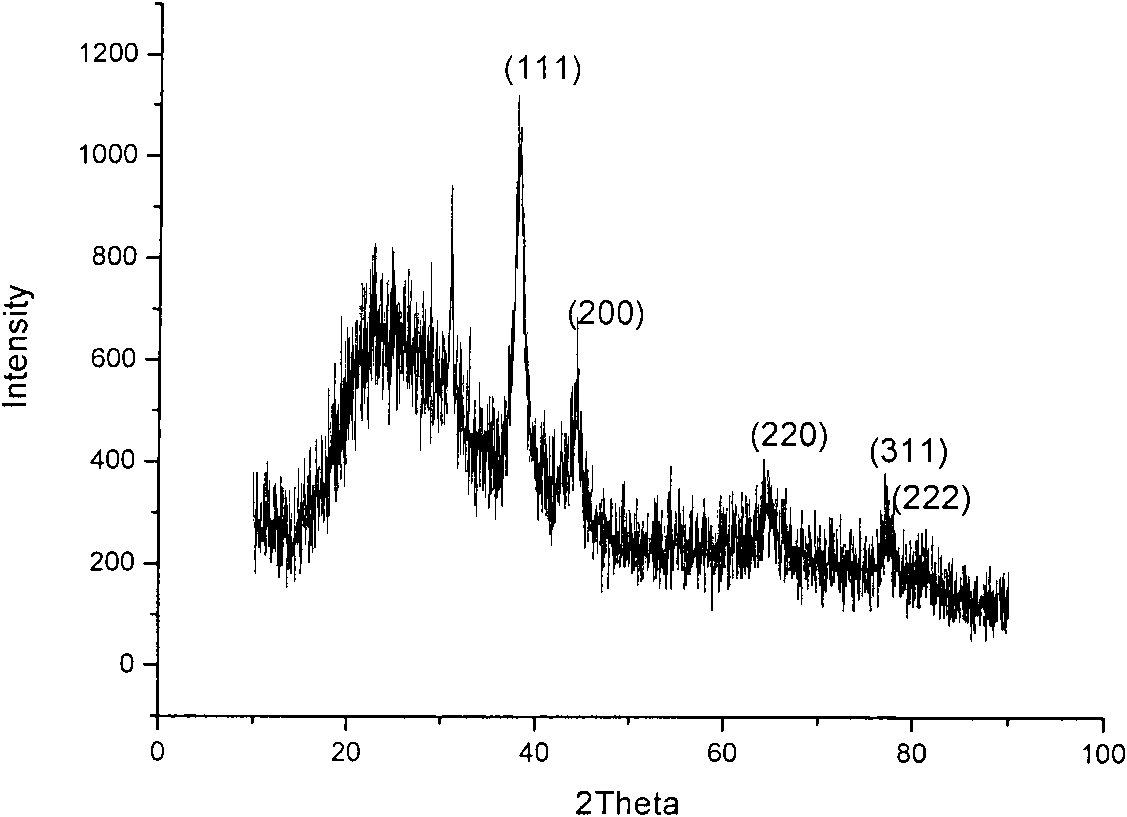

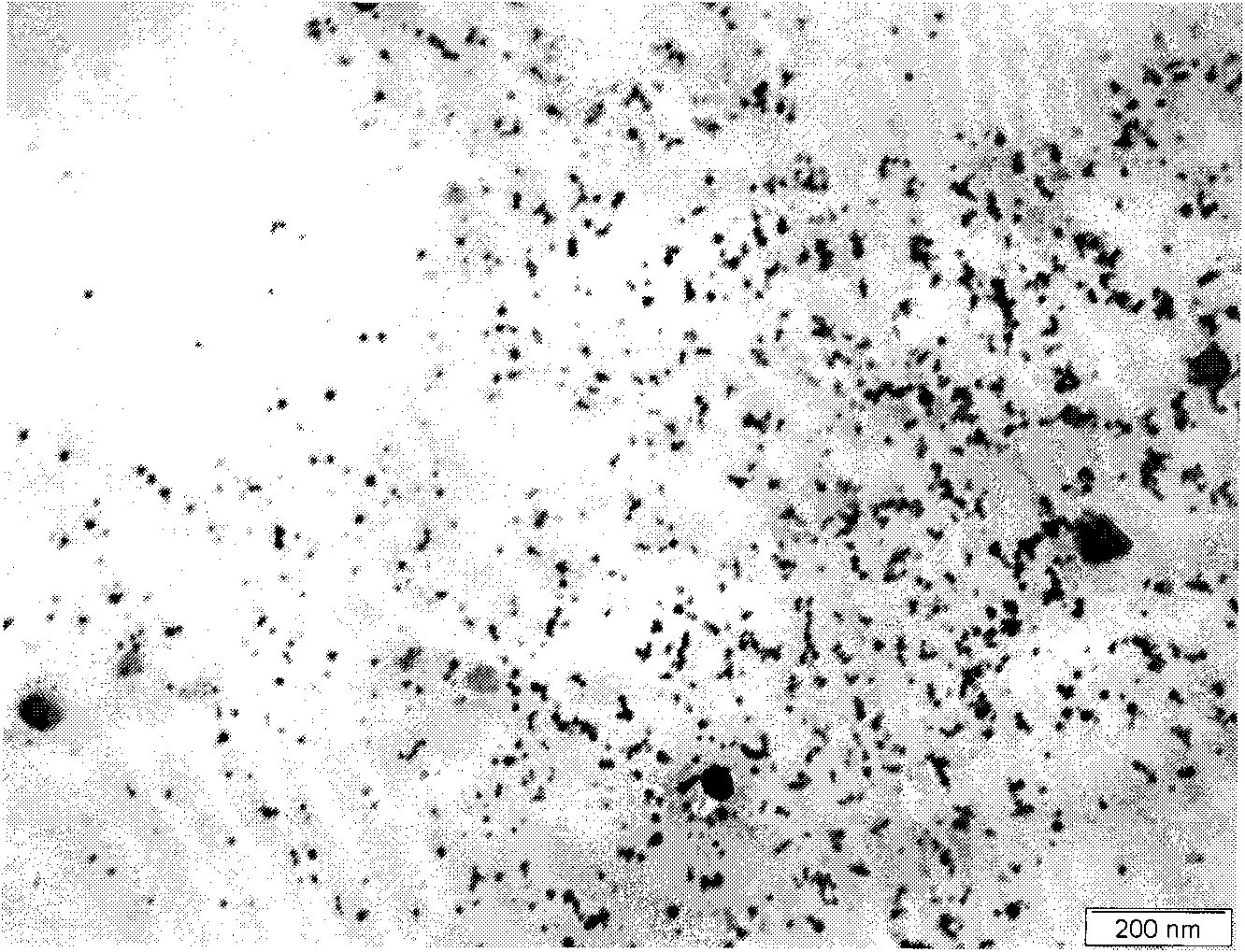

Nanometer silver collosol, preparation method and application thereof

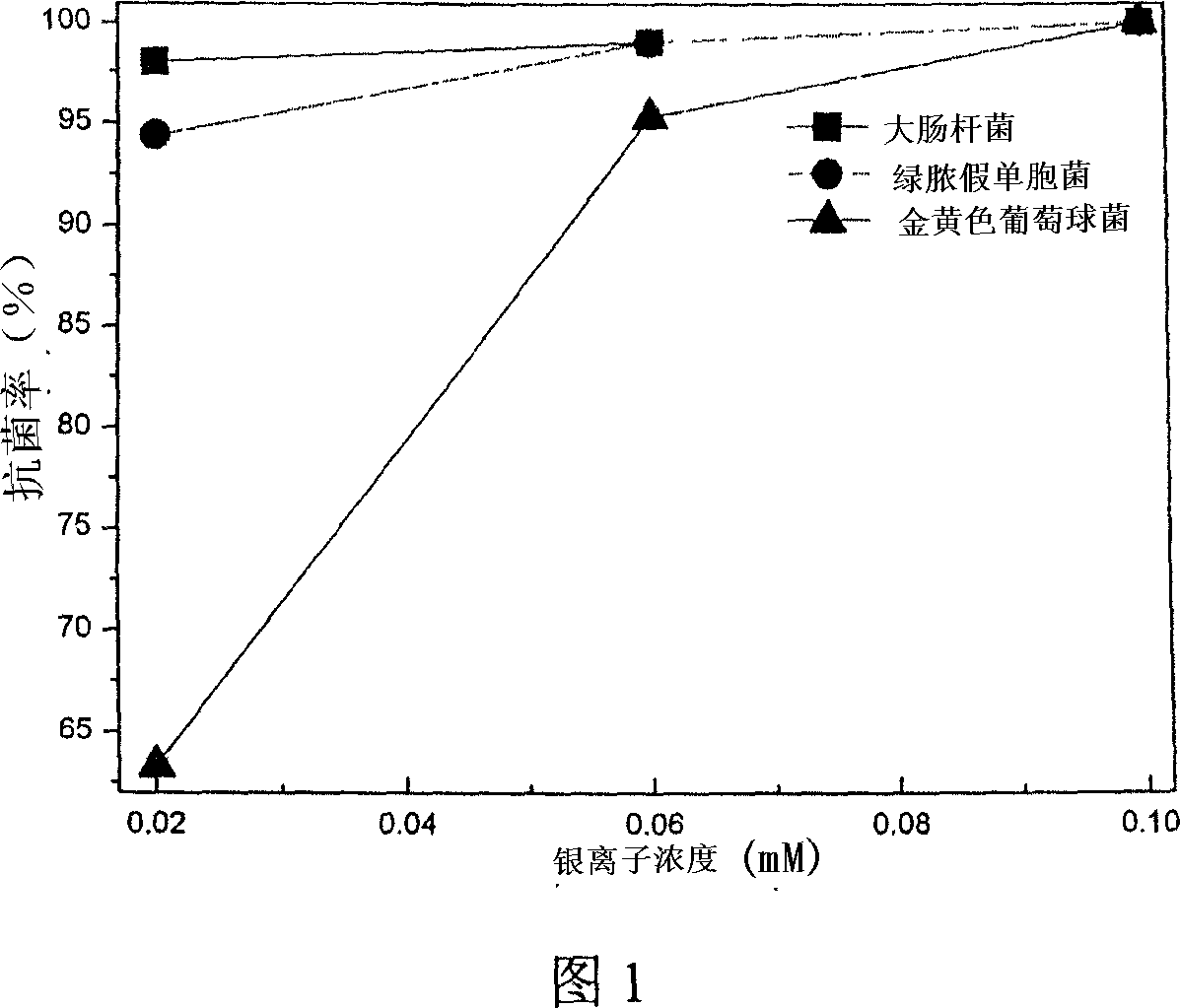

ActiveCN101633045AImprove the safety of useImprove antibacterial propertiesFibre treatmentLavatory sanitoryAlcoholFatty alcohol

The invention relates to a nanometer silver collosol, a preparation method and an application thereof. The preparation method comprising the following steps: dissolving reductor, alcohol and fatty alcohol in a closed reactor to prepare a mixed dispersion reductor solution; and then carrying out reaction between a silver salt alcohol solution and the mixed dispersion reductor solution for 6-72 hours under the temperature of 35-70 DEG C to obtain the nanometer silver collosol. The nanometer silver collosol has good antibacterial property and is very stable, safe in use and low in production cost, thereby being extensively used for the antibacterial processing of textiles and the antibacterial and deodorizing processing of shoes and having strong market competitiveness.

Owner:CHANGZHOU CHAMGO NANO MATERIALS

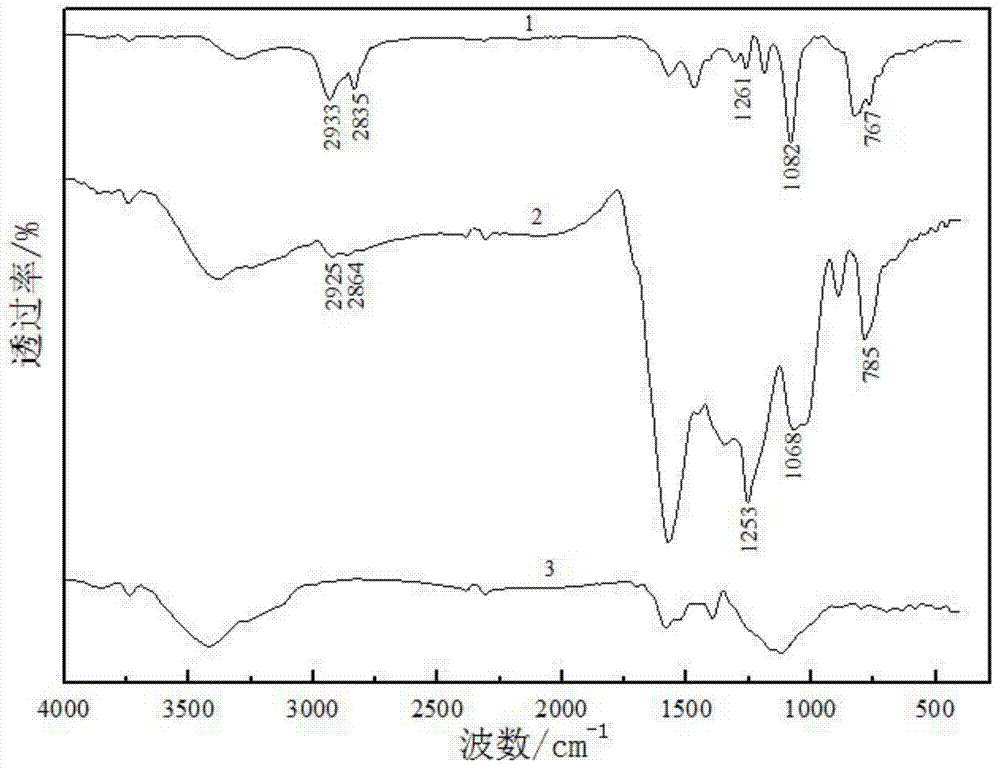

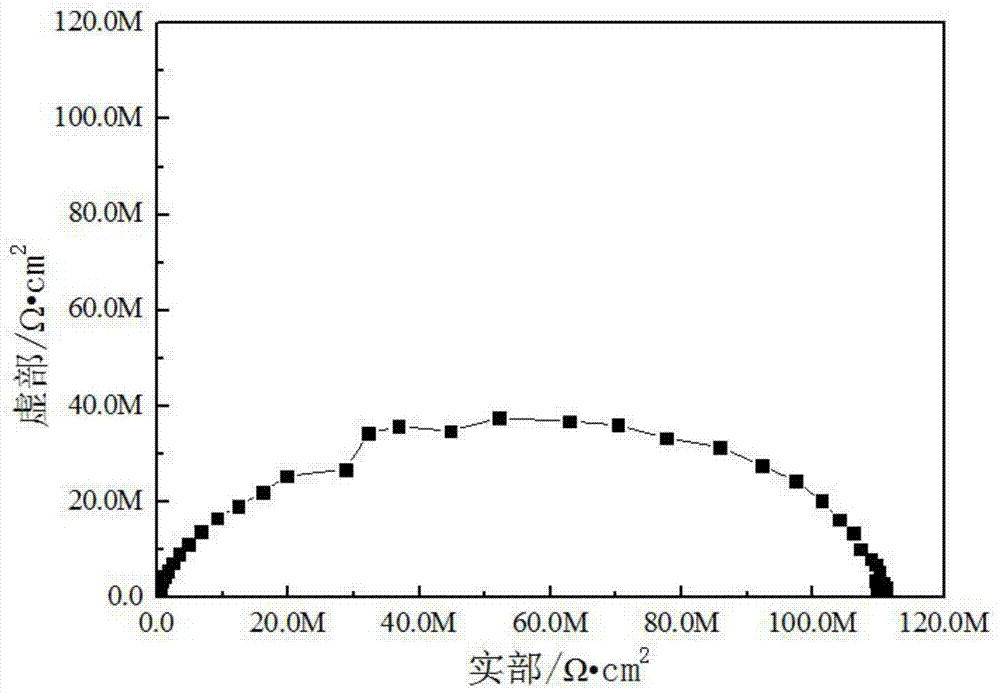

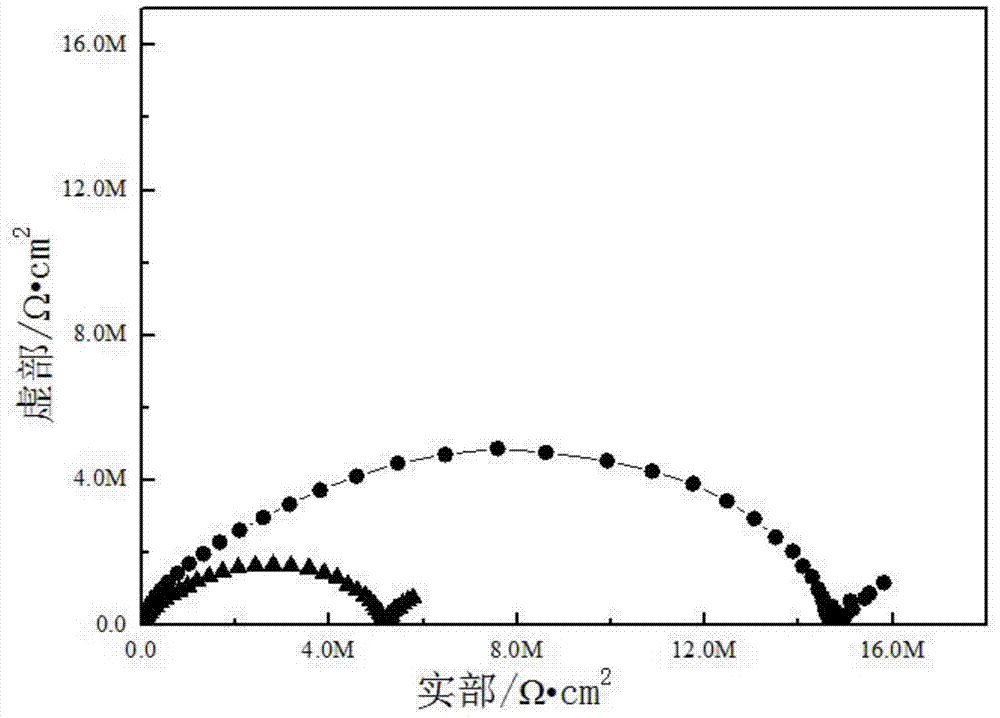

Graphene-containing marine anticorrosion antifouling coating and preparation method thereof

InactiveCN103589282AImprove anti-corrosion performanceImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesEpoxyGraphene

The invention discloses a graphene-containing marine anticorrosion antifouling coating and a preparation method thereof. Graphene having an antibacterial function is used as a filling material and is added into epoxy resin by surface modification, and the nano composite antifouling coating having antibacterial and anticorrosion properties is prepared. The graphene is added into the epoxy resin to form the marine antifouling coating; the excellent characteristics of the two materials are fully combined, so the coating has both the antifouling characteristic and the anticorrosion characteristic, that is to say, graphene and the epoxy resin are composited, so the antibacterial property of graphene and the anticorrosion property of the epoxy resin are organically combined jointly, and thus the novel antifouling coating having both the anticorrosion property and the antifouling property is developed.

Owner:TIANJIN UNIV

Antibacterial viscose containing artemisia argyi oil component and production method of antibacterial viscose

ActiveCN103556250AHigh antibacterial rateImprove durabilityArtificial filaments from viscosePolymer scienceAnti bacterial

The invention relates to antibacterial viscose containing an artemisia argyi oil component and a production method of the antibacterial viscose. The antibacterial viscose takes an artemisia argyi oil microcapsule as an antibacterial agent and a spinning solution is composed of the artemisia argyi oil microcapsule and mucilage glue, wherein the adding ratio of the artemisia argyi oil microcapsule is 10%-30% of alpha cellulose in the mucilage glue and the antibacterial property index are as follows: the antibacterial value is more than 4.0 and the sterilization value is 2.7. The production method of the antibacterial viscose containing the artemisia argyi oil component comprises the following steps: preparing artemisia argyi emulsion, preparing the artemisia argyi oil microcapsule, preparing the mucilage glue, preparing the spinning solution, and spinning and molding. The antibacterial viscose not only has the advantages of maintaining water absorption and air permeability of common viscose and being comfort to wear, but also has high antibacterial rate and good endurance; meanwhile, the antibacterial viscose has a good skin-caring effect and can be widely applied to home textile articles, underwear, sports shirts and the like.

Owner:潍坊欣龙生物材料有限公司

Antibacterial down feather and manufacturing method thereof

InactiveCN101611938APrevent mildew and insectsHigh antibacterial rateFibre treatmentDry-cleaning apparatus for textilesAntibacterial agentInflammation

The invention relates to an antibacterial down feather and a manufacturing method thereof. The manufacturing method comprises the steps of raw material stem removal, dust and sand removal, precise separation, washing, dehydration, drying, cooling and package, wherein an antibacterial agent comprises the following components in portion by weight: 6 to 10 portions of quaternary ammonium salt A, 1 to 2 portions of modified chitosan, 0.2 to 0.5 portion of silane coupling agent, 0.1 to 0.5 portion of solubilizing agent, and 0.3 to 0.6 portion of dispersing agent. The antibacterial down feather can effectively prevent mildew and attack of insects of the down feather in storage, transportation and use, and particularly when the antibacterial down feather serves as a filling material and is manufactured into articles for daily use, because of the antibacterial and bacteriostatic functions, the corresponding products have obvious functions of resisting bacteria, diminishing inflammation, deodorizing, resisting mildew, relieving itching and converging, and have no stimulation to skins, and the antibacterial rate of the obtained down feather to staphylococcus aureus bacteria reaches up to 99 percent, and after 10 times of washing, the antibacterial rate still reaches 92 percent.

Owner:凌颖

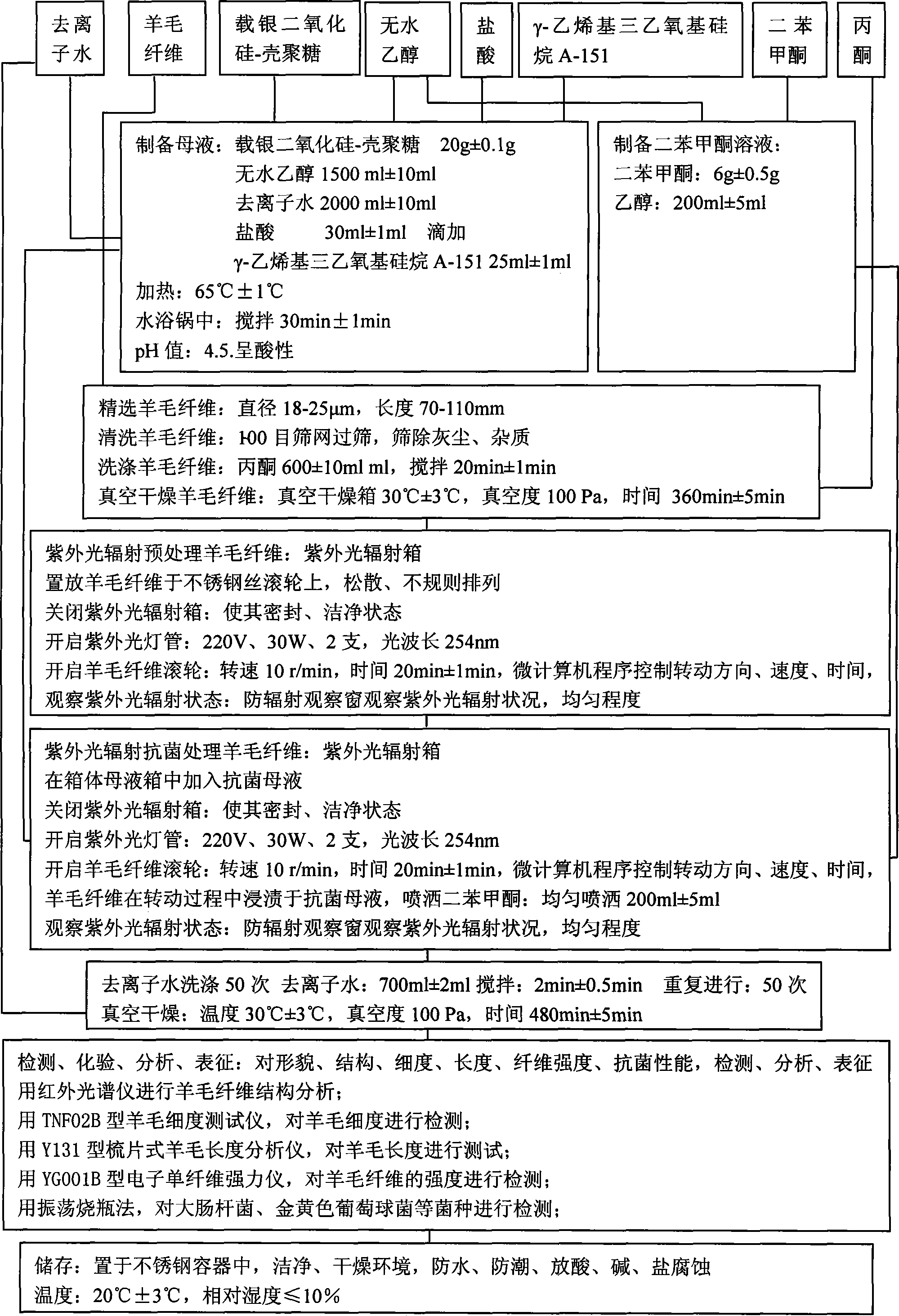

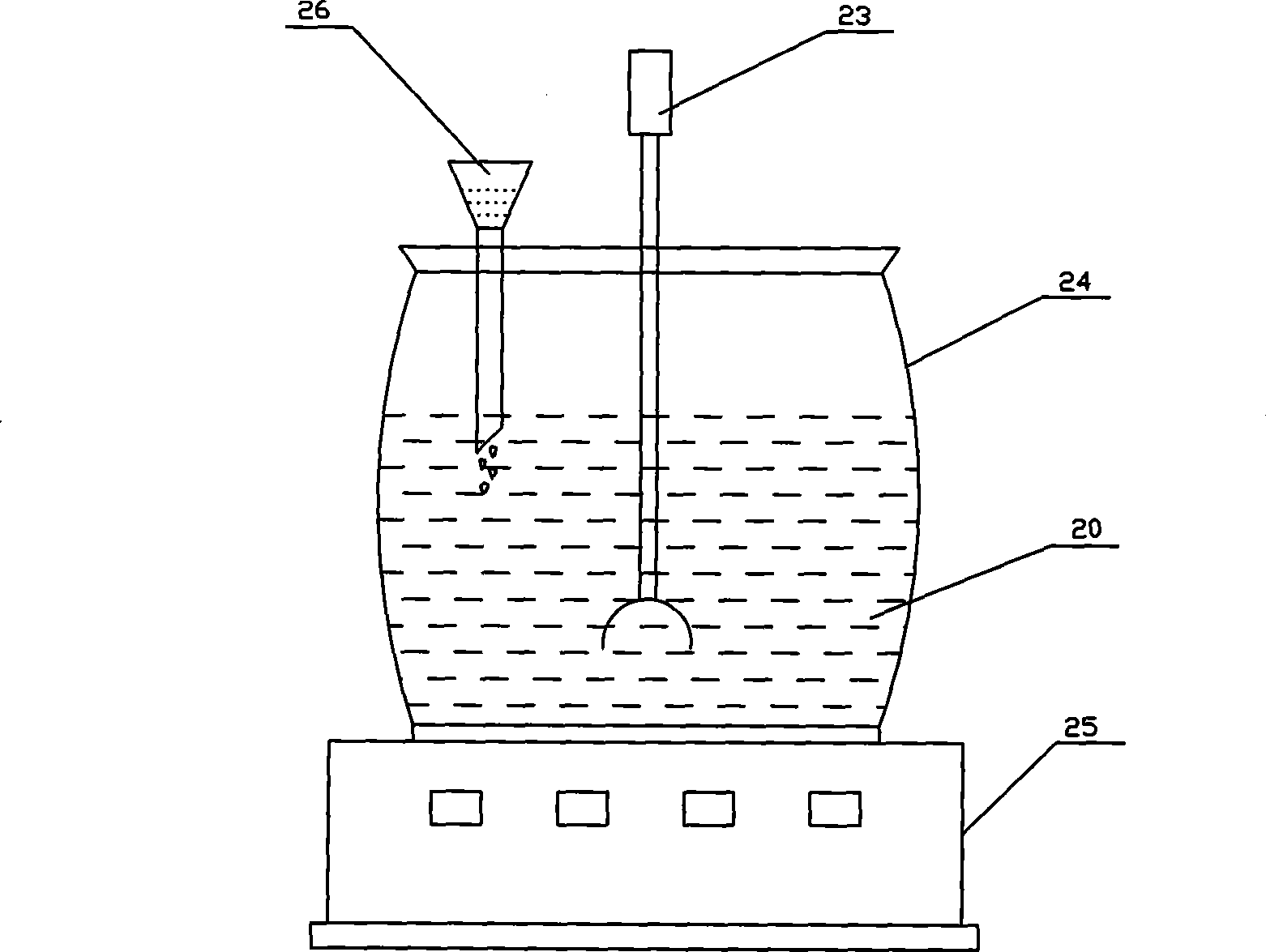

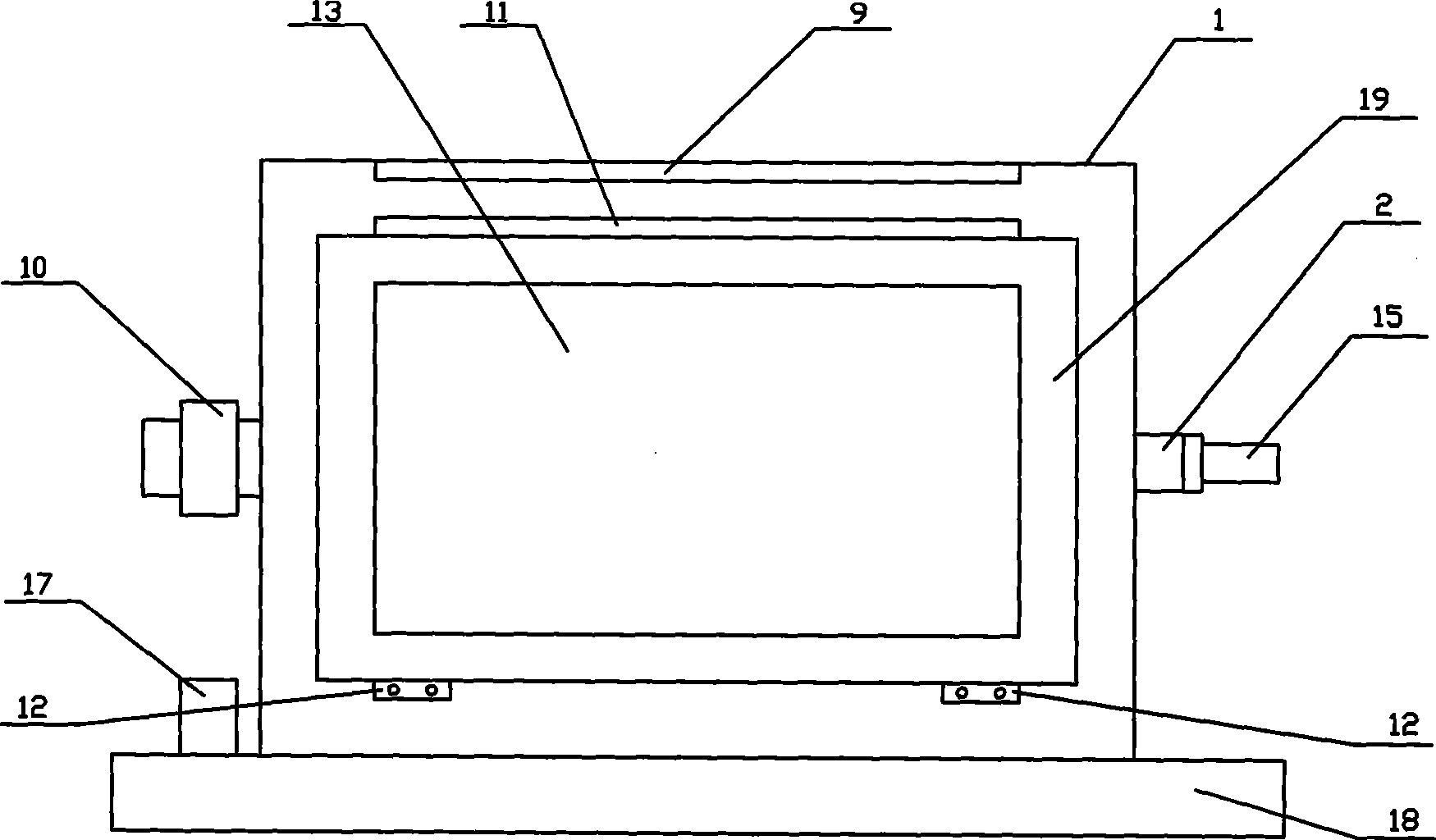

Antibacterial processing method for wool fiber

InactiveCN101413208AImprove durabilityEasy to manufacturePhysical treatmentAnimal fibresPre irradiationChemical reaction

The invention relates to an antibacterial treatment method for wool fiber, which comprises the following steps: an organic-inorganic composite antibacterial agent, namely silver-bearing silicon dioxide-chitosan is taken as an antibacterial agent and prepared into a pentabasic antibacterial mother liquor with anhydrous alcohol, deionized water, a diluted hydrochloric acid, a dispering / coupling agent and gamma-vinyltriethoxysilane A-151; the wool fiber is subjected to pre-irradiation of the ultraviolet light, and then immersed into the antibacterial mother liquor for secondary irradiation; and the wool fiber and the silver-bearing silicon dioxide-chitosan composite antibacterial agent generate chemical reaction under the action of a light trigger benzophenone and are combined by means of valence linkage to form an antibacterial film with the thickness of 200 nanometers. The antibacterial treatment method improves the persistence of antibacterial functions of the wool fiber, and the antibacterial rate of the wool fiber is still 98.6 percent after being washed for 50 times. Moreover, the antibacterial treatment method has short process flow, small number of equipment used, quick antibacterial speed, high efficiency and good effect, is easy to prepare the mother liquor, is particularly suitable for performing antibacterial treatment on the wool fiber and pashm fiber, and improves the efficiency by 90 percent compared with the prior antibacterial technology.

Owner:TAIYUAN UNIV OF TECH

Toothbrush hair having anti-bacterial and health-caring function and preparation method thereof

InactiveCN105239201ABroad spectrum antibacterialHigh antibacterial rateBristleConjugated synthetic polymer artificial filamentsChemistryPolymer

The invention provides a toothbrush hair having an anti-bacterial and health-caring function and a preparation method thereof. The toothbrush hair includes the following raw materials, by weight, 75-90% of a polymer, 3-20% of a natural anti-bacterial agent, 1.8-3% of pomegranate seed oil, and 1.2-2% of a coupling agent. The natural anti-bacterial agent is prepared from following components comprising, by weight, 75-90% of loess powder, 4-10% of an extract of commelina communis, 3.5-9% of an extract of herba houttuyniae and 2.5-6% of an extract of caryopteris incana. By means of the technical scheme, the toothbrush hair is produced through various process methods. The toothbrush hair is wide in anti-bacterial spectrum, is high and durable in efficiency and is safe to use, has excellent light-prevention, wear-resistant and aging-resistant performance, has the health-caring effect of increasing fragrance and protecting teeth, is beneficial to environment cleaning and odor eliminating, has the effects of preventing and controlling decayed tooth and periodontal diseases, is good in anti-dirt property, rebound elasticity, flexibility and hydrophobicity, is free of deformation, is long in service life, is low in production cost and is easy to popularize.

Owner:陆思烨

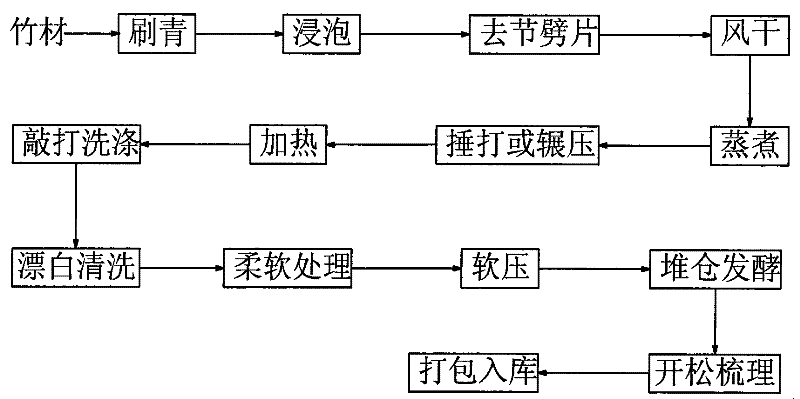

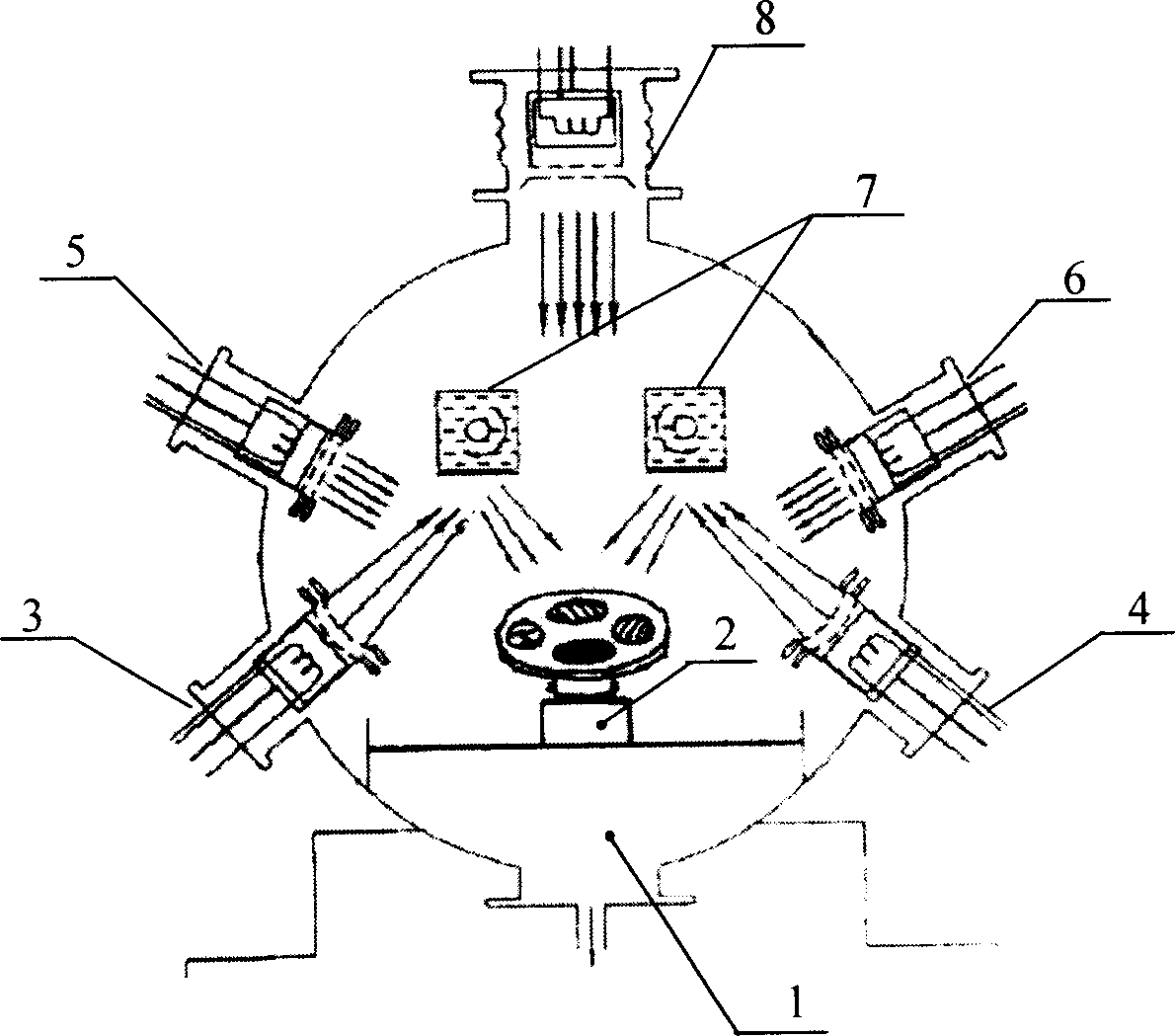

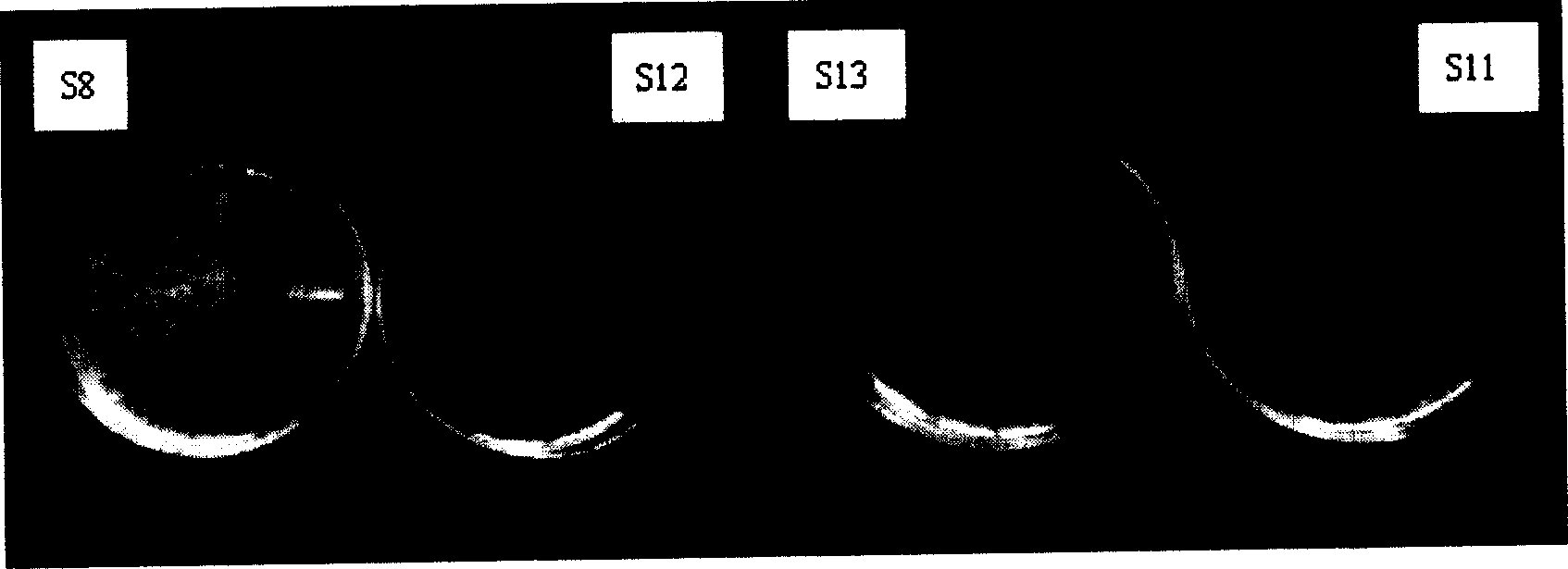

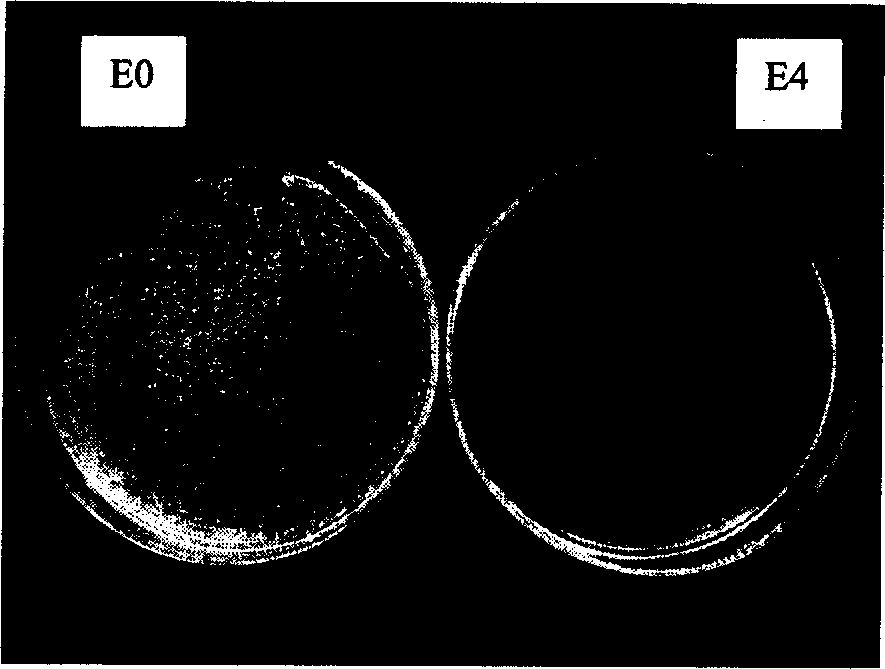

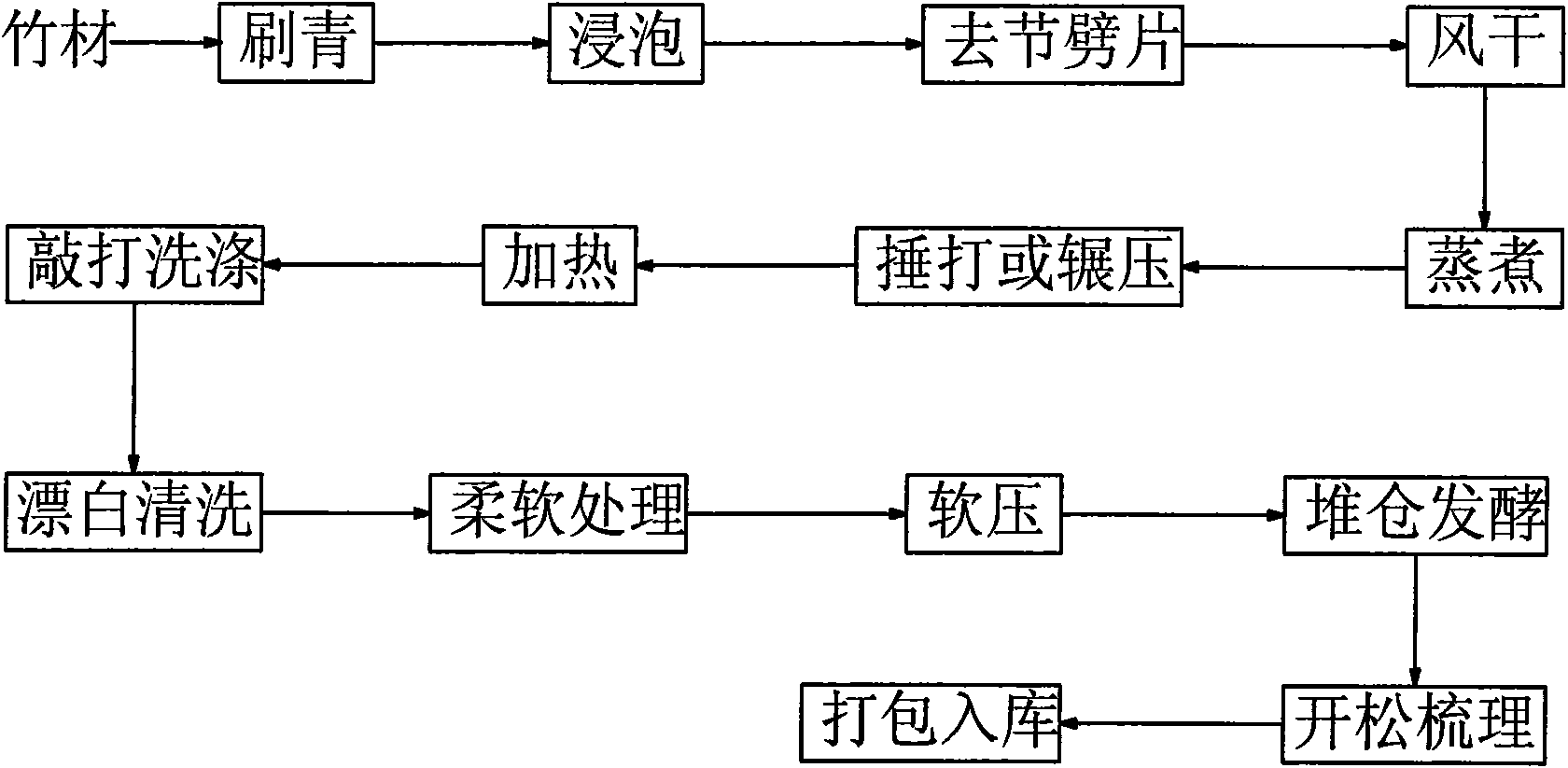

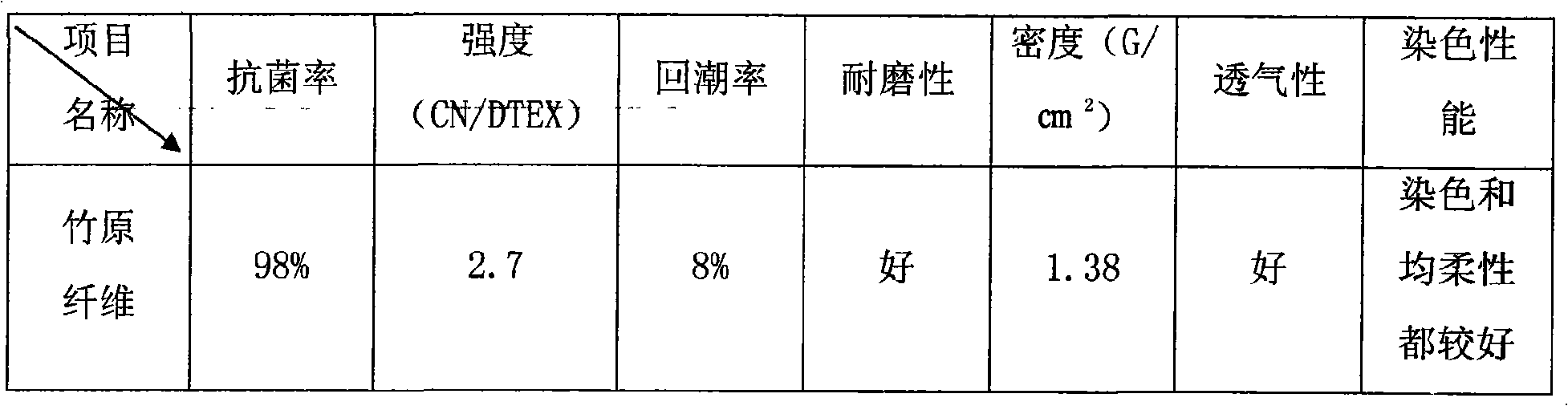

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Copper-based antimicrobial fiber and preparation method thereof

ActiveCN105671682AImprove spinnabilityGood antibacterial durabilityMelt spinning methodsConjugated synthetic polymer artificial filamentsMasterbatchCopper

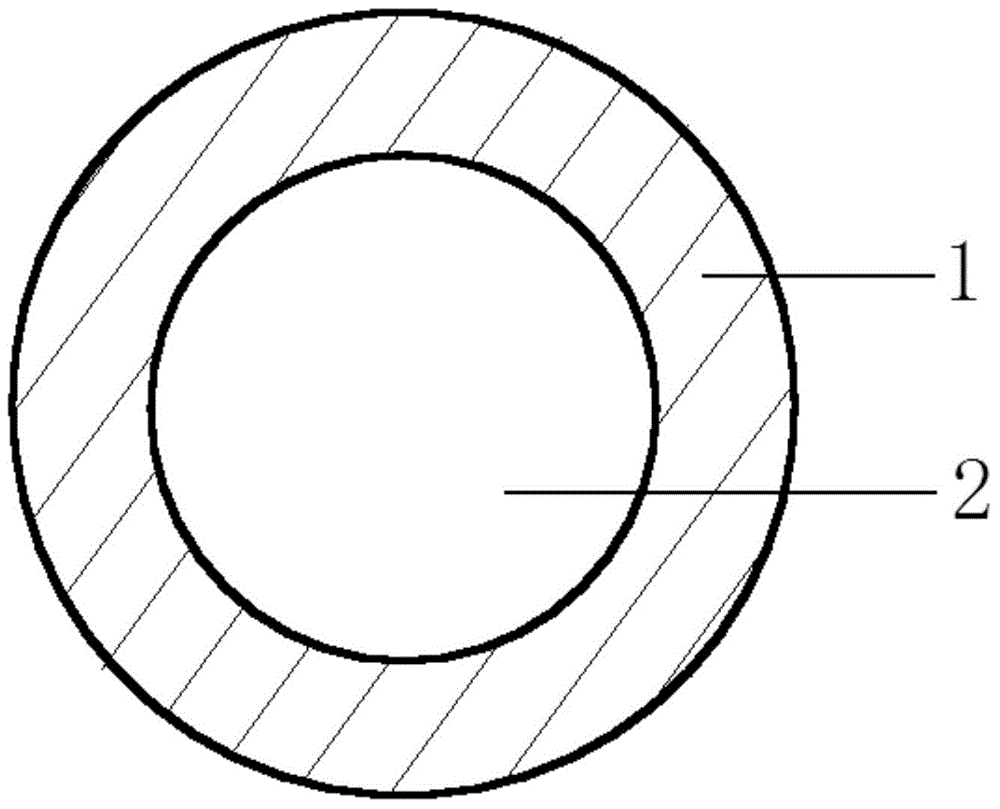

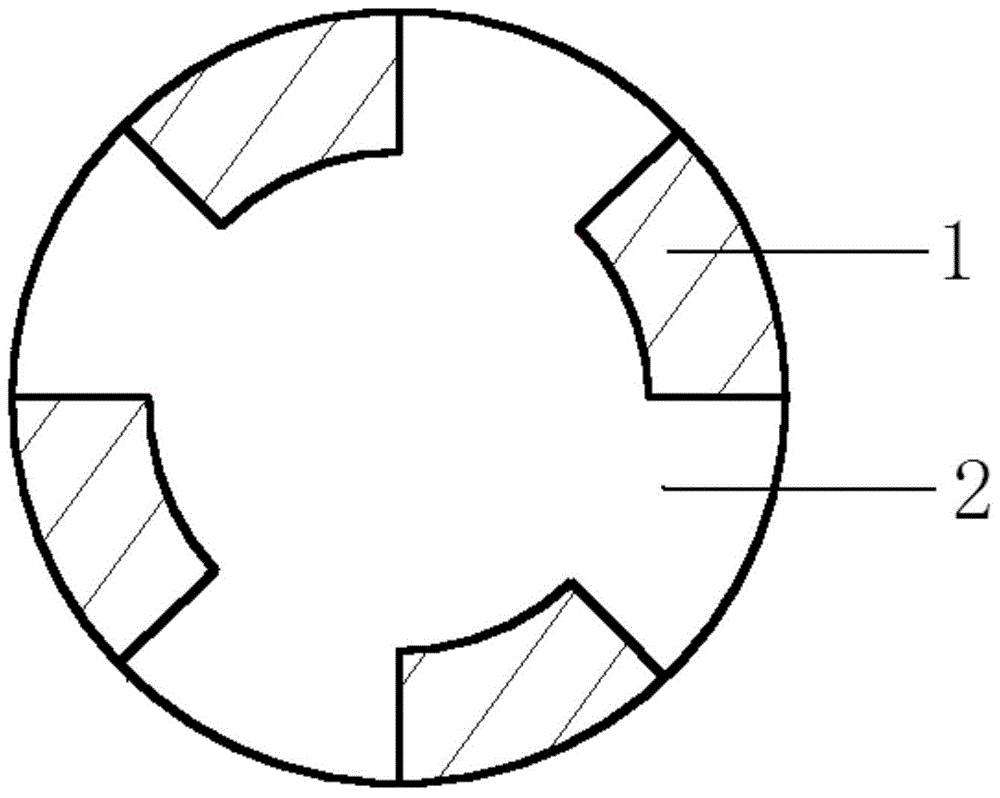

The present invention provides copper-based antimicrobial fiber and a preparation method thereof, a cross-section of the copper-based antimicrobial fiber has a skin-core structure, a skin layer comprises an antimicrobial agent and carrier resin, a core layer comprises a fiber-forming polymer, and the preparation method of the copper-based antimicrobial fiber comprises the following steps: mixing evenly carrier resin powder and antimicrobial masterbatch ingredients of copper-based antimicrobial agent powder to obtain mixed powder; adding the mixed powder into a twin-screw extruder for extruding to obtain antimicrobial masterbatch; compounding and spinning the antimicrobial masterbatch as the skin layer and the fiber-forming polymer as the core layer to obtain the copper-based antimicrobial fiber. The beneficial effects are as follows: the copper-based antimicrobial fiber produced by the method has good spinnability, cross-sectional shape uniformity, long spinning pack replacement cycle, good antimicrobial effect and good durability, and has good antimicrobial effect especially on fungi.

Owner:CTA HIGH TECH FIBER

Method for preparing multi-layer composite functional surgical dressing

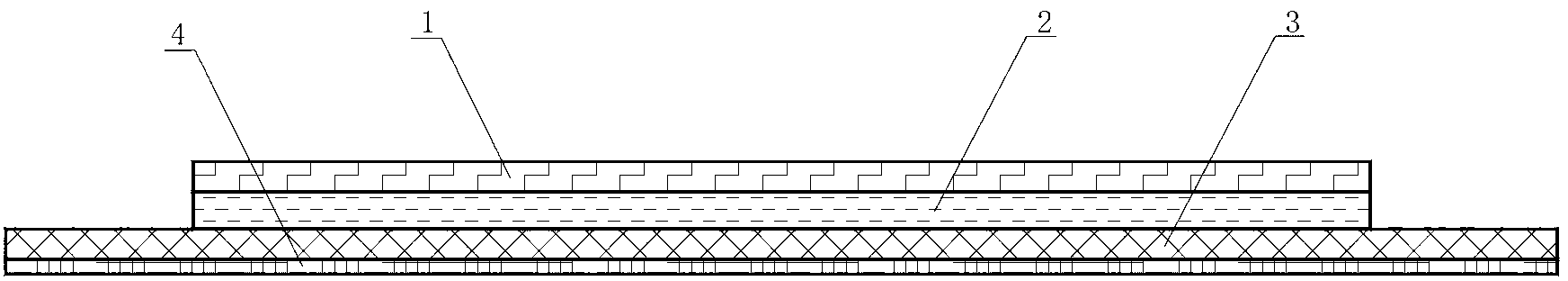

InactiveCN103239755AGuaranteed softnessChieve protectiveAdhesive dressingsAbsorbent padsPolyesterBiocompatibility Testing

The invention relates to a method for preparing a multi-layer composite functional surgical dressing. The method comprises the following steps: respectively and independently carding the fiber layers comprising a functional layer which is formed by mixing chitosan fiber or chitosan fiber and viscose and is directly contacted with the skin, a water-absorbing layer which is made of viscose and has high liquid absorption performance and a protective layer which is formed by mixing the viscose and polyester fiber and has the supporting and protecting functions so as to form a net, manufacturing a three-layer laminate with an upper functional layer, a middle water-absorbing layer and a lower protective layer by employing a water jet strengthening technology, coating a waterproof agent on the protective layer of the three-layer laminate to form a waterproof layer, and finally rolling to obtain the surgical dressing. The product has high biocompatibility and promotes healing, the antibacterial rate is up to 96.7 percent, the liquid absorption rate is 1259 percent, the waterproofing grade is up to level 5, and the surgical dressing can be used for clinical repair for operative incision, burn, scald, ulcer and other skin injury and is simple in production process, low in cost and environmentally-friendly.

Owner:DONGHUA UNIV +1

Antibacterial viscose rayon and production thereof

InactiveCN1779004AEvenly dispersedHigh antibacterial rateMonocomponent cellulose artificial filamentCelluloseAntiseptic Agent

The invention provides an antiseptic viscose fiber. It is spinned by the silver antiseptic agent and the cellulose sulphonic acid ester. The silver antiseptic agent is 0.5-5% weight of the cellulose. The product has the good antisepsis and the detergent resistance.

Owner:XINXIANG CHEM FIBER

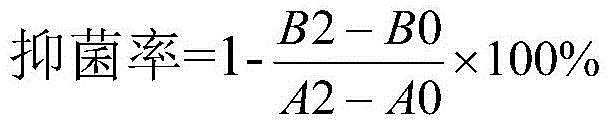

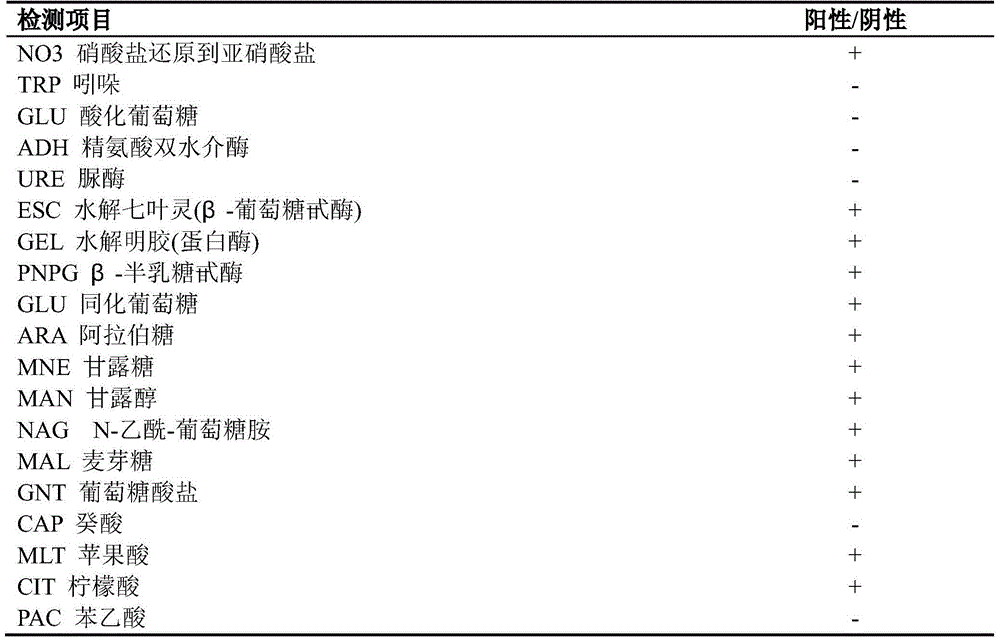

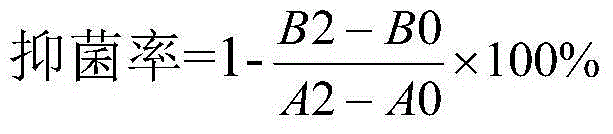

Bacillus subtilis and application thereof to livestock breeding

ActiveCN103555640AHigh antibacterial ratePromote reproductionBacteriaMicroorganism based processesHigh concentrationEscherichia coli

The invention aims to provide bacillus subtilis WL-04 and application thereof to livestock breeding. The preservation number of the bacillus subtilis WL-04 is CCTCC NO:M 2013343. The bacillus subtilis WL-04 can be used for remarkably inhibiting the growth of Escherichia coli, salmonella, clostridium pefringens and other conditional pathogenic bacteria of the intestinal canal of livestock, and particularly, the bacteriostasis rate of the bacillus subtilis WL-04 to Escherichia coli and clostridium perfingens is above 75%; the enzyme production is stable; the average activity of alpha-amylase is 22U / mL, and the average activity of neutral protease is 170U / mL; the reproduction of probiotics of intestinal canal can be promoted; high temperature for pelletizing can be endured; the influence of inverse environments with low-pH gastric fluid and high-concentration cholate is endured; the production performance of breeding animals can be effectively improved; immune organ development can be promoted. The bacillus subtilis WL-04 can be widely applied to livestock feeds as a feed additive.

Owner:山东蔚蓝生物科技有限公司 +1

Compound photocatalysis antimicrobial air filter material and preparation method thereof

InactiveCN101745271AImprove wash resistanceImprove crosslink strengthFibre treatmentFiltration separationAir filtrationPolyurethane adhesive

The invention discloses a compound photocatalysis antimicrobial coating air filter material and a preparation method thereof. The method is as follows: respectively preparing nano titanium oxide collosol, nano zinc oxide collosol and nano copper-nickel compound metallic collosol; preparing compound photocatalysis antimicrobial finishing agent; in cationic waterborne polyurethane adhesive emulsion, firstly, adding nano copper-nickel compound metallic collosol, nano titanium oxide collosol and nano zinc oxide collosol, stirring, and then adding deionized water; at room temperature, stirring and dispersing to form stable emulsion compound photocatalysis antimicrobial finishing agent; preparing finishing agent accounting for 5-15 wt% of air filter material to be treated; adding deionized water until reaching 100%; adopting a continuous padding technology to perform dip coating classification to the filter material to be treated; and drying and backing. The invention solves the problems of unfavorable nano photocatalysis antimicrobial effect, single effect and poor laundering durability, and improves the laundering durability of compound coating.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

Method for preparing silver-enriched antibacterial film on pyrolytic carbon and TiN film for medical use

InactiveCN1827840AIncrease concentrationImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingSputteringHigh energy

The invention relates the method for preparing rich silver antibiotic film used for medical pyrolytic carbon and TiN film. It solves the antibiosis question. The method comprises the following steps: on the pyrolytic carbon: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d injecting silver ion: 70, 30keV energy, 2-8mA beam current, 2X1014 / cm2-3X1014 / cm2 dosage, and forming rich silver antibiotic film and antibiosis ratio being 100%; on TiN film: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d sputtering Ti target with 3keV, 80mA Ar+ ion, 20-40keV, beam current: bombarding with 2-8mA high-energy N+ ion for 10-20 minutes; 50-350eV, beam current: bombarding with 10-30mA low-energy N+ ion for 60-180 minutes to deposit, N2 air pressure being 8X10 3Pa; e injecting silver ion: 30-80keV, beam current: 2-8mA, 1X1017 / cm2-5X1018 / cm2 dosage, forming rich silver antibiotic film and antibiosis ratio being 90%. The film has the advantages of good abradability, strong adhesive force and anti-corrosion, good cell compatibility and long antibiosis time-effect. The film can be used to prepare artificial heart valve and hard tissue alternate material which is implanted in human.

Owner:TIANJIN NORMAL UNIVERSITY

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743AHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Environment-friendly composite calcium metasilicate plate and preparation method thereof

The invention discloses an environment-friendly composite calcium metasilicate plate and a preparation method thereof. The preparation method comprises the following step: coating a nanometer titania photocatalyst aqueous suspension on a base plate of the calcium metasilicate plate in a rolling coating or spraying coating manner to obtain the environment-friendly composite calcium metasilicate plate, wherein the base plate of the calcium metasilicate plate is prepared from a silicon material, a calcium material, reinforced fibers and assistants; the nanometer titania photocatalyst aqueous suspension comprises titanium dioxide powder with the fineness of not greater than 50nm, a surface active agent, an adhesive and water. According to the preparation method, the nanometer titania photocatalyst aqueous suspension is coated on the base plate of the calcium metasilicate plate to form a water-based film; the water-based film is coated on the surface of a base material and then dried to form a membrane which can be used for highly catalyzing and degrading under the effect of light, so that indoor formaldehyde can be absorbed and degraded, and the antibacterial effect is also improved.

Owner:白山市东北亚新型建筑材料有限公司

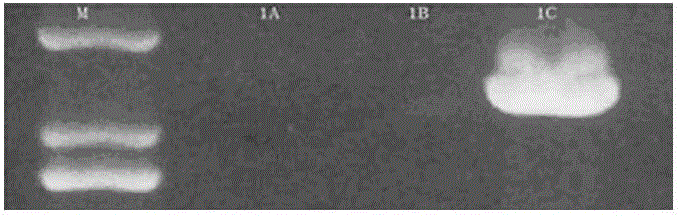

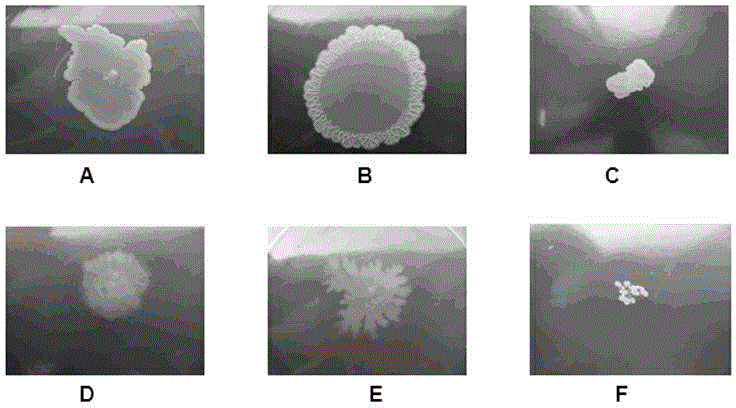

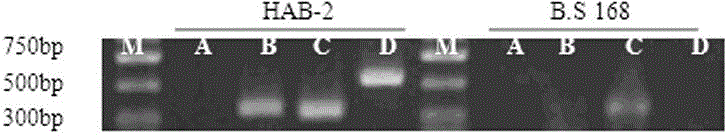

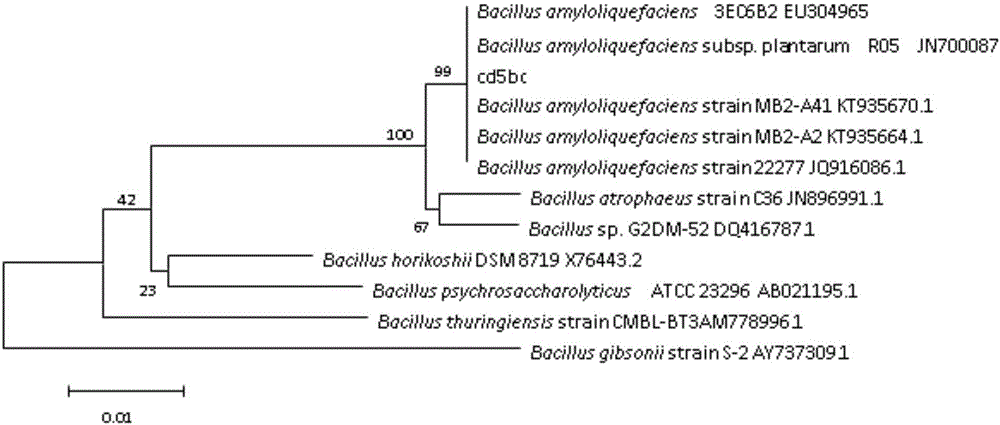

Sfp gene-deleted biocontrol bacteria as well as fermentation technology and application thereof

ActiveCN104673716AHigh research valueBroad antibacterial spectrumBiocideBacteriaBiotechnologyAntibacterial activity

The invention provides bacillus amyloliquefaciens HAB-2, which has the collection number of CCTCC M 2015070. Although the key lipopeptide synthetase gene sfp gene is deleted, the surfactin substances can still be generated, indicating that the strain has a specific and distinctive biosynthetic pathway and has a remarkably high research value. The bacillus amyloliquefaciens HAB-2 has very strong ability of inhibiting pathogenic fungi, has a wide antibacterial spectrum and can inhibit multiple kinds of pathogenic fungi while the antibacterial effect is good and the antibacterial rate is high. Further research finds that the active ingredient can be directly obtained through simple treatment on the fermentation broth of the strain, and the antibacterial active ingredient is stable and has very high activity in strong acid and strong alkaline environments; the antibacterial activity is not changed after 24 hours of ultraviolet irradiation, and high temperature does not influence the antibacterial active ingredient; and the fermentation broth of the biocontrol bacteria realizes certain growth promoting effect on a plant.

Owner:HAINAN UNIVERSITY

Antibacterial masterbatches used for plastic toys and preparation method of antibacterial masterbatches

The invention provides antibacterial masterbatches used for plastic toys and a preparation method of the antibacterial masterbatches. The antibacterial masterbatches comprises the following raw materials by weight percent: 65-85% of plastic resin, 10-25% of a natural antibacterial agent, 3-5% of cumin seed oil, 0.5-2% of polyethylene wax, and 1.5-3% of a coupling agent. According to the invention, the raw materials are prepared into the masterbatches through various processing means, the raw materials achieve synergistic interaction, and the effects of the raw materials complement each other; when applied to plastic toys, the masterbatches are wide in antibacterial spectrum, high in antibacterial rate, good in antibacterial property, and long-lasting in bacteria prevention, prevent microbes such as various harmful bacteria, moulds and viruses from breeding on toys, and have excellent aging resistance and better mechanical property, and the service life can be greatly prolonged; besides, the masterbatches slowly release fragrance and health protection components, and automatically emit far infrared rays, thereby achieving the effects of purifying the environment and eliminating peculiar smell, having the functions of self-cleaning and health care, enabling children to gain more health benefits, and having high practical value.

Owner:陆思烨

Preparation method of antibacterial and deodorant down feather and its product

The invention discloses a preparation method of an antibacterial and deodorant down feather and its product, the preparation method comprises the following steps: a)immersing the washed clean down feather in 1-2.5% (owf) of a silver-loaded nano antiseptic aqueous solution for leaching, wherein the leaching rate is 60-80%; and b)predrying, stoving, flushing, dehydrating, and drying the leached down feather, and naturally cooling to obtain the antibacterial and deodorant down feather. The antibacterial and deodorant down feather can effectively prevent milden, rot and moth eating in the process of storage, transportation and use, and the corresponded product has obvious functions for preventing bacteria and deodorization.

Owner:LUOLAI LIFESTYLE TECH CO LTD

Preparation method of graphene-containing marine anticorrosive antifouling paint

InactiveCN104974640AUniform coatingHigh antibacterial rateAntifouling/underwater paintsPaints with biocidesEpoxyGraphite

The invention discloses a graphene-containing marine anticorrosion antifouling coating and a preparation method thereof. Graphene having an antibacterial function is used as a filling material and is added into epoxy resin by surface modification, and the nano composite antifouling coating having antibacterial and anticorrosion properties is prepared. The graphene is added into the epoxy resin to form the marine antifouling coating; the excellent characteristics of the two materials are fully combined, so the coating has both the antifouling characteristic and the anticorrosion characteristic, that is to say, graphene and the epoxy resin are composited, so the antibacterial property of graphene and the anticorrosion property of the epoxy resin are organically combined jointly, and thus the novel antifouling coating having both the anticorrosion property and the antifouling property is developed.

Owner:TIANJIN UNIV

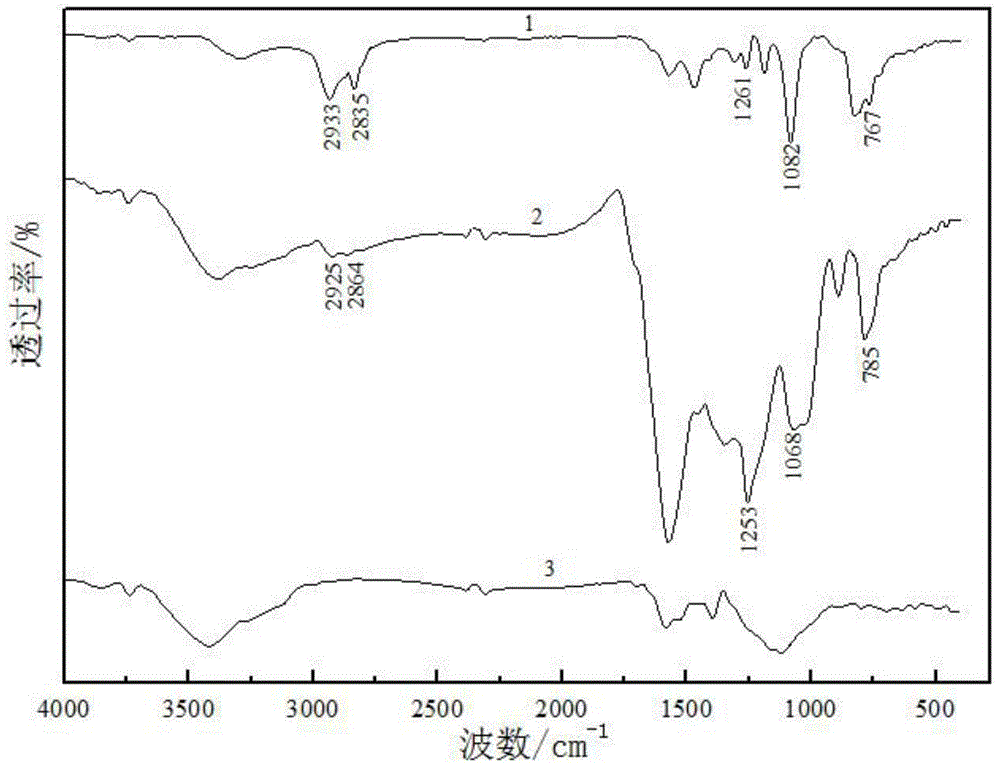

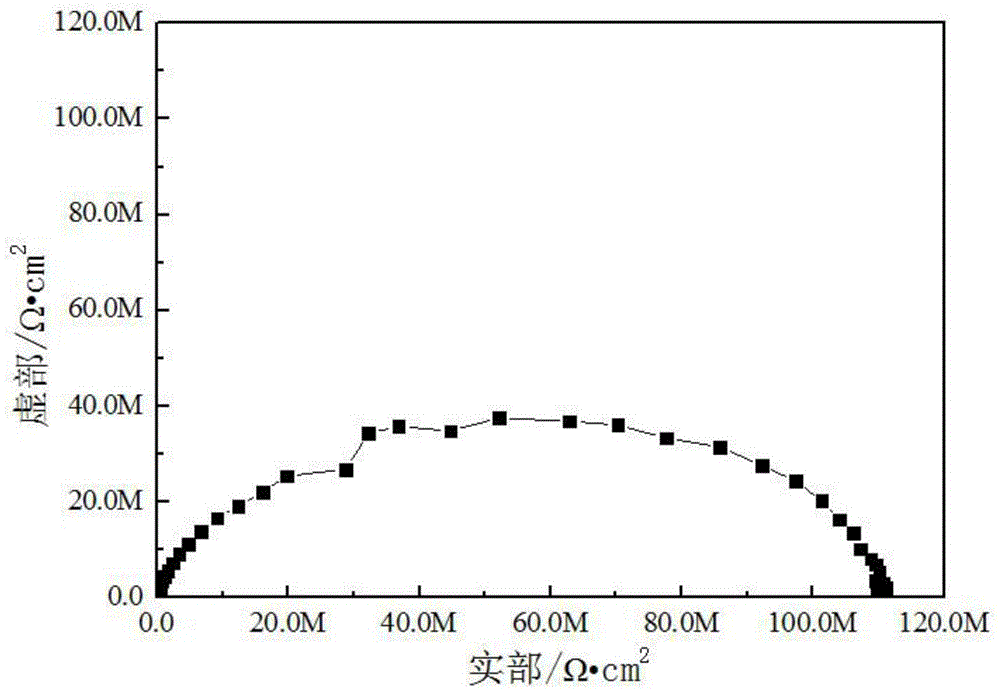

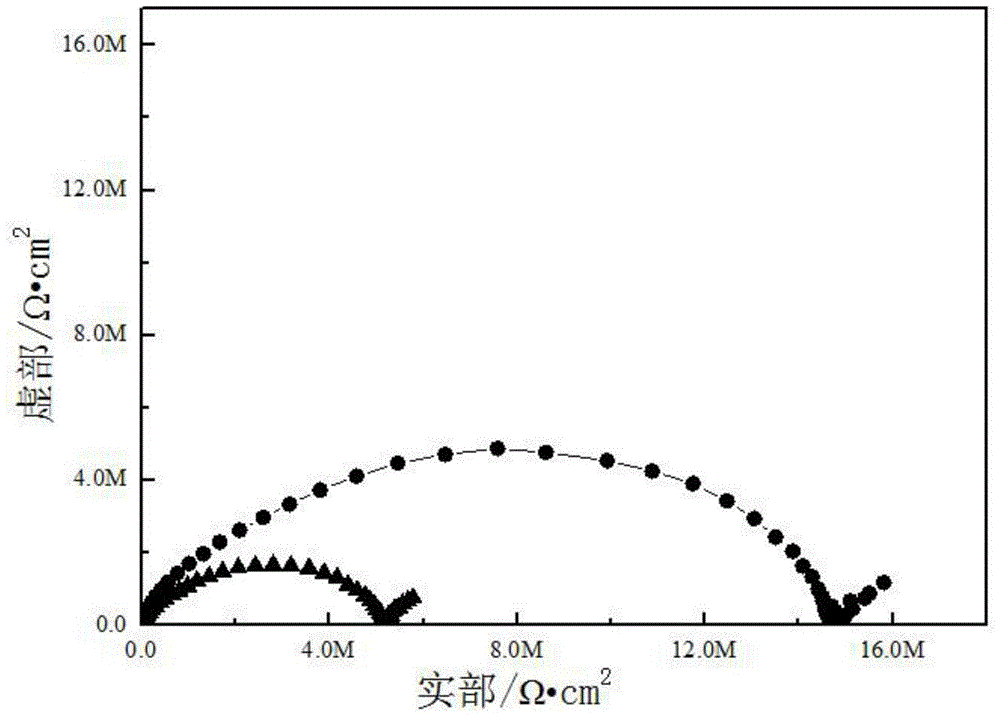

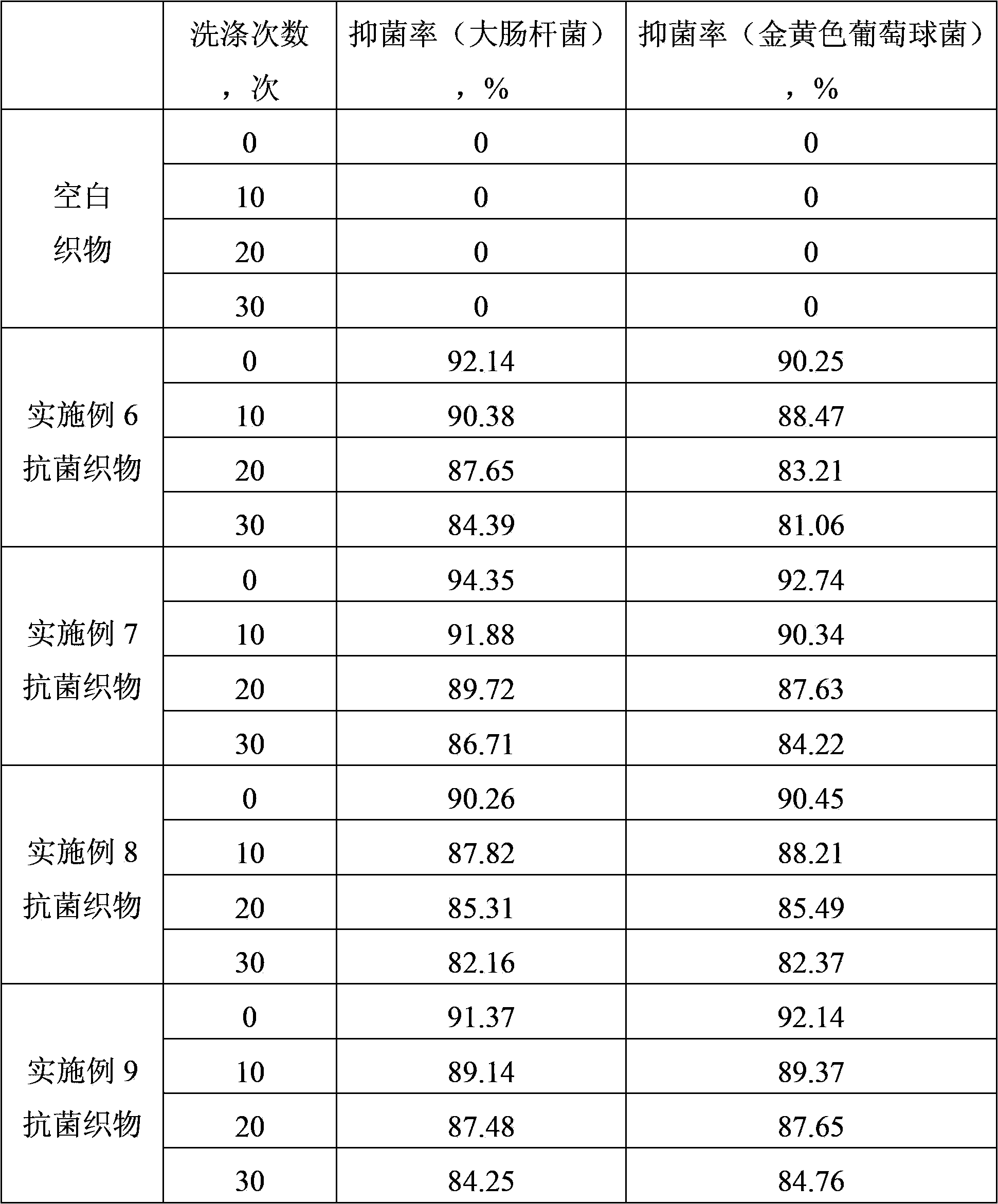

Antibacterial finishing agent, antibacterial finishing method of fabrics, and antibacterial fabrics

The invention discloses an antibacterial finishing agent, an antibacterial finishing method of fabrics, and antibacterial fabrics. The antibacterial finishing agent comprises the following components in parts by weight: 10-30 parts of 2-methyl-4-isothiazolin-3-ketone, 15-25 parts of poly(hydroxypropyl dimethyl ammonium chloride) and 30-50 parts of sodium dodecyl carboxymethyl imidazoline acetate. The antibacterial fabrics provided by the invention can be obtained by a dipping or padding finishing method. The antibacterial fabrics obtained through dipping or padding after-finishing with the antibacterial finishing agent provided by the invention have the properties of odor resistance, corrosion resistance and the like, and are high in antibacterial rate on escherichia coli and staphylococcus aureus; even after the antibacterial fabrics are washed for 30 times, the antibacterial rate of the antibacterial fabrics is still kept at a high level; therefore, the human body health is protected and the wearability of clothes is improved.

Owner:JIANGSU CHENSHI WEIYE TEXTILE TECH

Multifunctional fabric with moisture absorbing, sweat removing, antibacterial and anti-static functions as well as production method thereof

ActiveCN104389076AImprove wearing comfortGuaranteed antistatic functionWoven fabricsYarnYarnCotton fibre

The invention discloses a multifunctional fabric with moisture absorbing, sweat removing, antibacterial and anti-static functions as well as a production method thereof. The multifunctional fabric is formed by weaving of 95-99% of multifunctional blended yarn and 1-5% of stainless steel anti-static yarn or conductive fiber anti-static yarn; the multifunctional blended yarn is formed by blending of 50-80% of moisture absorbing and sweat removing fibers, 15-45% of cotton fibers and 5-10% of silver fibers; the stainless steel anti-static yarn is formed by blending of 35-45% of moisture absorbing and sweat removing fibers, 10-30% of cotton fibers, 3-7% of silver fibers and 25-40% of stainless steel fibers; the conductive fiber anti-static yarn is formed by twisting of 3-5% of organic conductive fibers and 95-97% of multifunctional blended yarn. The produced multifunctional fabric has the anti-static, moisture absorbing, sweat removing and antibacterial functions, so that the anti-static function of the fabric can be guaranteed, the air permeability of the fabric can be greatly improved, the wear comfort of the fabric is improved, and meanwhile, the fabric has the good antibacterial function.

Owner:ZHENGZHOU NO 4 COTTON TEXTILE

Nozzle tipping paper for antibiosis cigarette, preparation method thereof, and nozzle for antibiosis cigarette

InactiveCN103054188AImprove antibacterial efficacyEasy to prepareBiocideCigarette manufactureSolventChemistry

The invention discloses nozzle tipping paper for an antibiosis cigarette, a preparation method thereof and a nozzle for the antibiosis cigarette. The nozzle tipping paper for the antibiosis cigarette is prepared by evenly distributing mixed medicine extracting solution on the surface of the tipping original paper and drying the mixed medicine extracting solution. The mixed medicine extracting solution is prepared by 10-27 parts of mother chrysanthemum, 3-7 parts of jasmine, 8-14 parts of fresh lemon, 2-17 parts of violet, 0.5-2 parts of radix angelicae pubescentis and 1.5-4 parts of folium eucalypti by weight, ethanol water solution serves as the extracting solvent after mixing, and the mixed medicine extracting solution with the relative density of 1.02-1.20 is prepared through reflux extraction. By means of the nozzle tipping paper for the antibiosis cigarette, the preparation method thereof and the nozzle for the antibiosis cigarette, the problem that after a cigarette box is opened, the nozzle of the cigarette can be contaminated by microorganisms easily is fundamentally solved. The antibiosis effect is further strengthened by using flax cellosilk beams, cellulose acetate beams, the nozzle tipping paper for the antibiosis cigarette and nozzle forming paper, and the cigarette can be further provided with the aroma of natural plants.

Owner:HUBEI CHINA TOBACCO IND +1

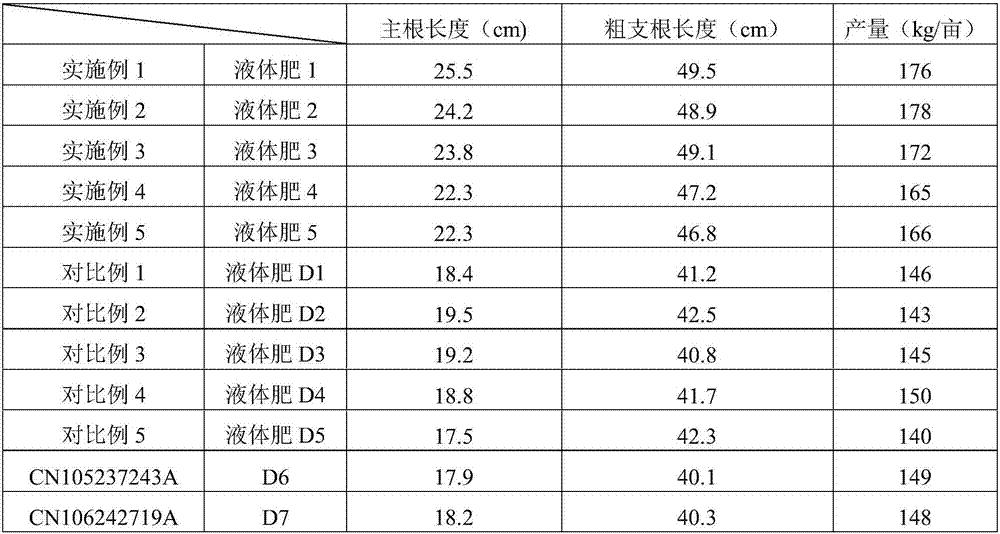

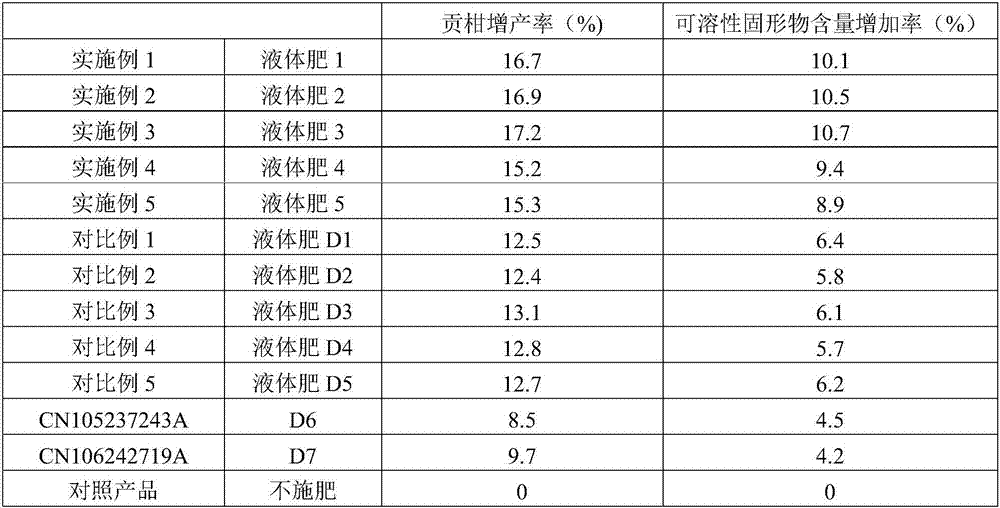

Chitosan-containing humic acid liquid fertilizer with effect of promoting rooting and fruiting

InactiveCN107011024AImprove water absorptionEffective absorptionMagnesium fertilisersAlkali orthophosphate fertiliserTrace elementOrganic matter

The invention provides a chitosan-containing humic acid liquid fertilizer with effect of promoting rooting and fruiting. The chitosan-containing humic acid liquid fertilizer is prepared from the following components in percentage by weight: 20 to 55% of massive element, 2 to 10% of trace element, 10 to 30% of organic matter, humic acid and chitosan, wherein the weight ratio of the organic matter to humic acid to chitosan is (10 to 30):(3 to 6):(0.5 to 2). The invention also provides a preparation method of the liquid fertilizer. The liquid fertilizer has the advantages that the organic matter, humic acid and chitosan are compounded with the nutrient element, the quality of the crop is improved, the content of soluble sugar in the crop is increased, the growth of capillary roots is promoted, and the ability of the crop absorbing the nutrients is enhanced.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

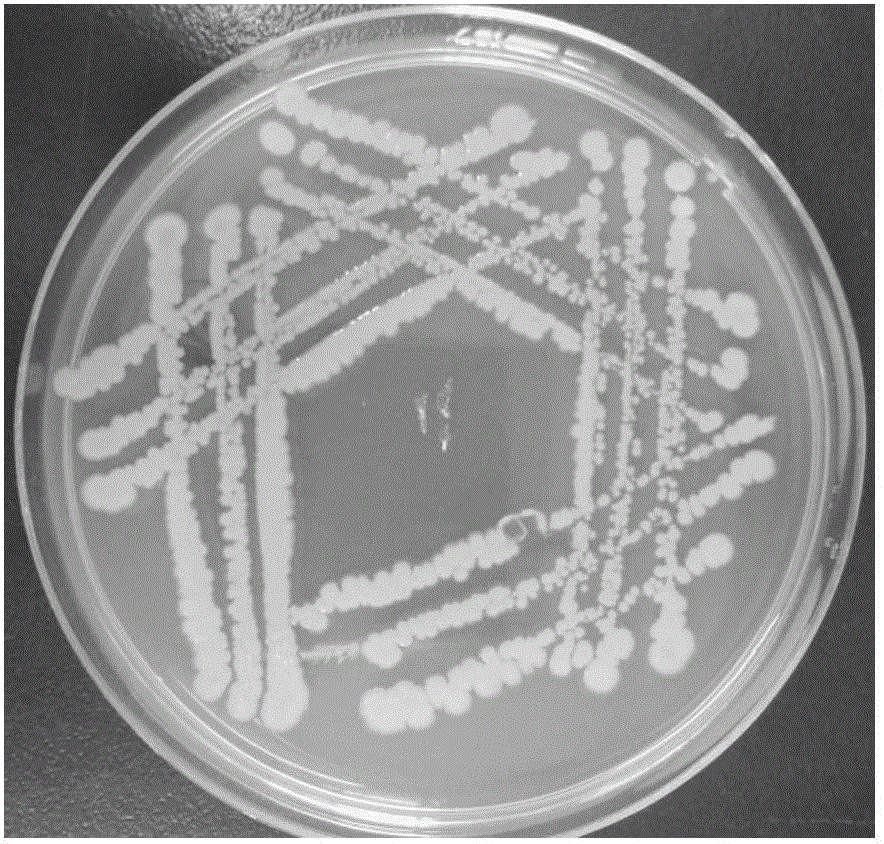

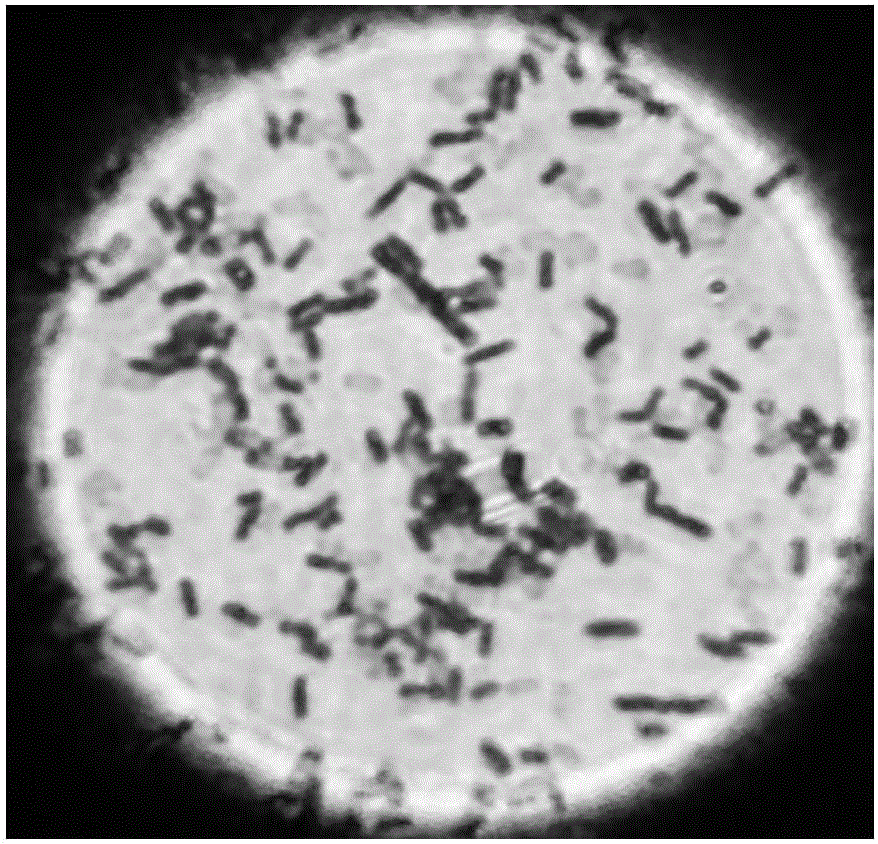

Bacillus amyloliquefaciens cd5bc and application thereof

ActiveCN105907683AGood control effectGood biological control effectBiocideBacteriaBitter gourdSclerotinia

The invention provides bacillus amyloliquefaciens cd5bc. The strain is classified and named as Bacillus amyloliquefaciens cd5bc and is preserved in China Center for Type Culture Collection, the preservation number is CCTCC NO:M 2016232, and the preservation time is April 28, 2016. The invention further provides application of the strain in the aspect of preventing and controlling crop diseases and a biocontrol preparation prepared from the strain. The strain has a very significant preventing and controlling effect on red pepper phytophthora blight, the biocontrol effect reaches up to 100% after inoculation is conducted for 15 days, and the biocontrol effect reaches up to 82.36% after inoculation is conducted for 60 days. The bacillus amyloliquefaciens cd5bc has excellent disease-resistant effects on multiple crop diseases, the bacteriostasis rates of the strain on pathogenic bacteria of red pepper sclerotinia blight, bitter gourd wilt, cucumber wilt, cucumber scabs, rice blast, a rice sheath blight disease, broad bean chocolate spots and broad bean brown spots all reach up to 70% or above, and the bacteriostasis rate of the strain on the broad bean chocolate spots and broad bean brown spots reaches up to 100%.

Owner:INST OF PLANT PROTECTION SICHUAN ACAD OF AGRI SCI +1

Antiseptic biological active titanium coating and its production

InactiveCN101073675AImprove antibacterial propertiesImprove biological activityMolten spray coatingTitanium coatingCalcium biphosphate

The invention is concerned with antibiotic resistance biological activity coating and its produce method. It adopts NaOH solution and supersaturated calcium phosphate solution with Ag+ to dispose the titanium coating, makes the coating with biological activity and antibiotic resistance capability. The titanium coating with Ag+ ion is 0.01 to 0.1 mm. Dispose titanium powder on the metal basal body (for example, titanium alloy) which having been cleaned and disposed with sand blasting through vacuum plasm sprying technology with favourable technology parameters. Dip the prepared titanium coating into 3 to 10 mol NaOH solution and keep warm for 12 to 48 hours under 20 to 80 degree, take out and ultrasonic clean with deionized water for 2 to 6 times and each time is 3 to 10 minutes, dry for 12 to 48 hours with 20 to 80 degree. Dip the dried titanium coating into supersaturated calcium phosphate solution with Ag+ and keep warm for 12 to 48 hours with 20 to 37 degree and dry for 2 to 6 hours with 100 to 150 degree. The titanium coating has nice antibiotic resistance performance without obvious cytotoxicity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

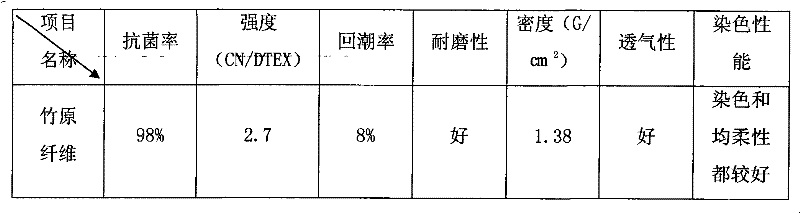

Shell fabric of blending bamboo fibers and polyesters

Owner:DAIFUNI HOUSEHOLD DECORATION PRODS FUSN CITY

Anti-bacterial high-viscosity medical glue and preparation method thereof

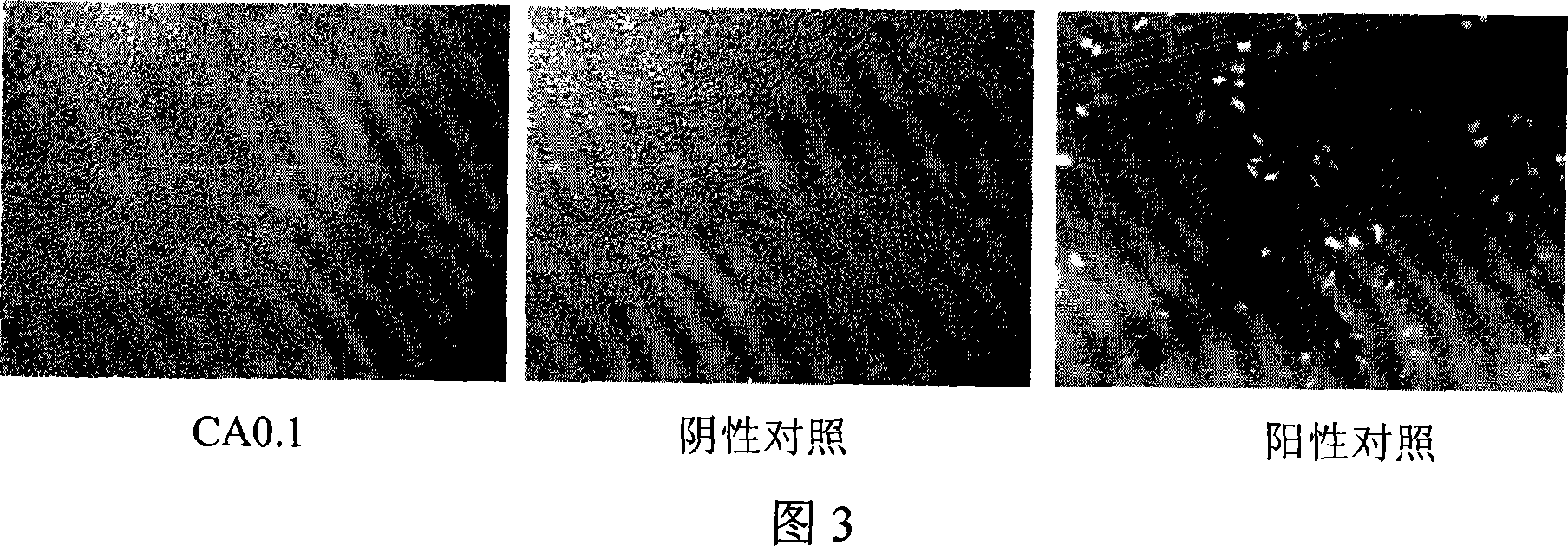

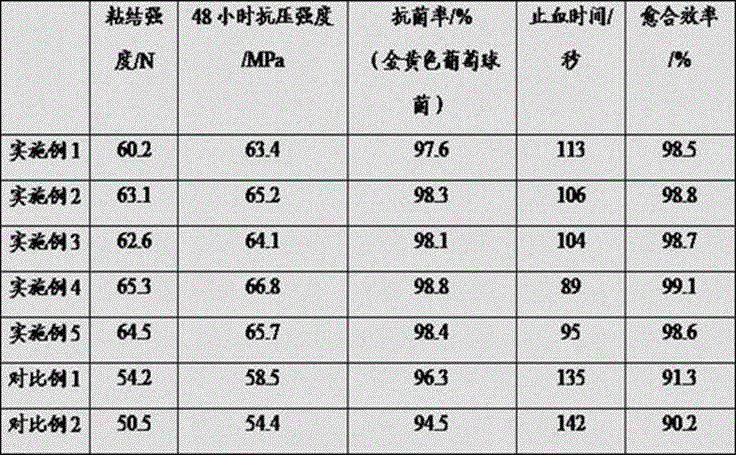

InactiveCN106039391AMeet application requirementsHigh antibacterial rateSurgical adhesivesPharmaceutical delivery mechanismIrritationAdditive ingredient

Owner:林春梅

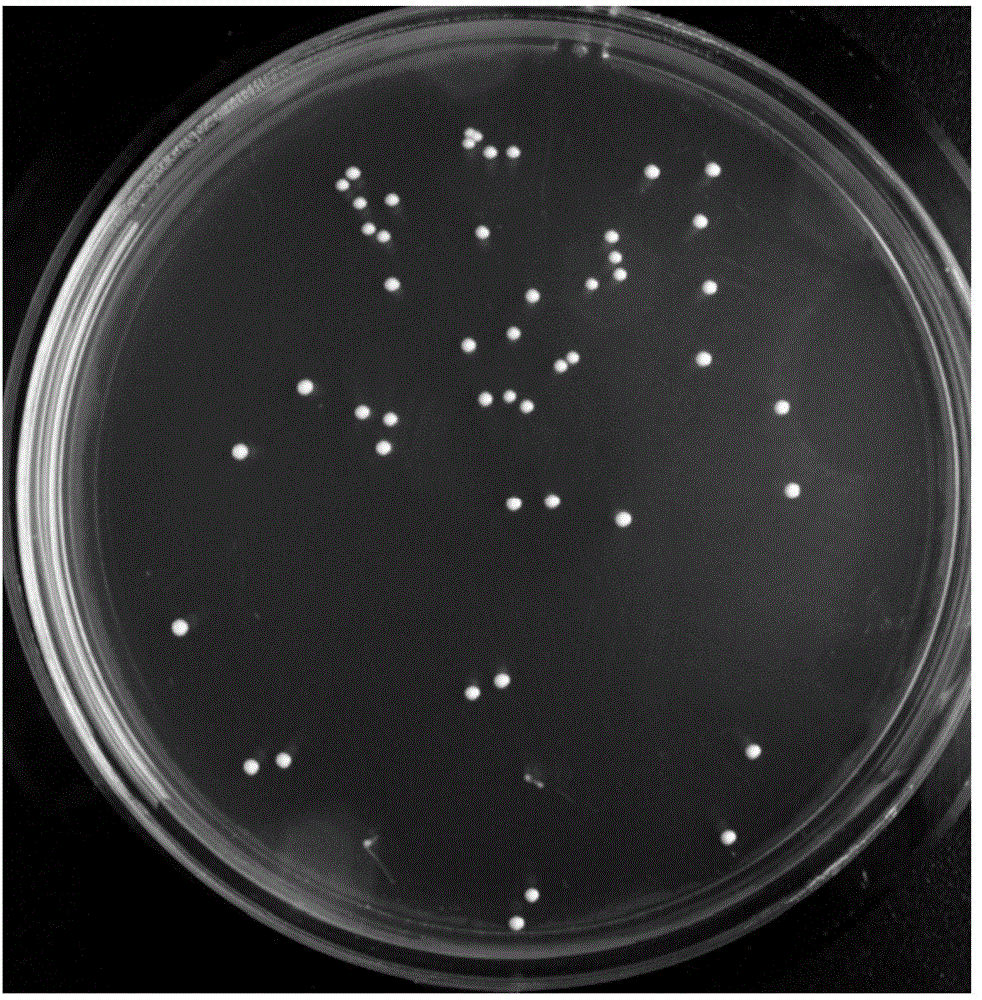

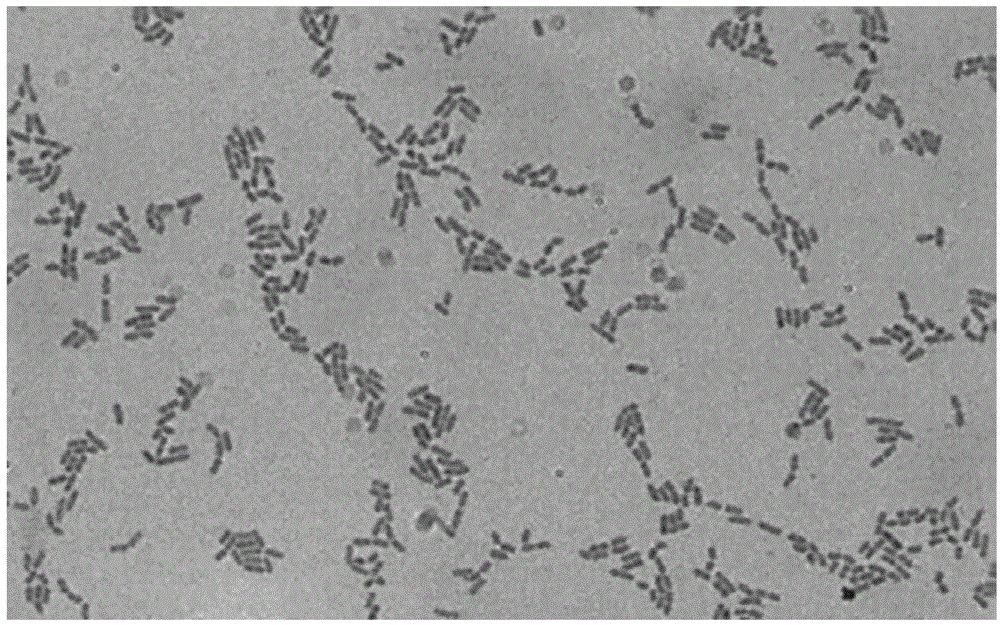

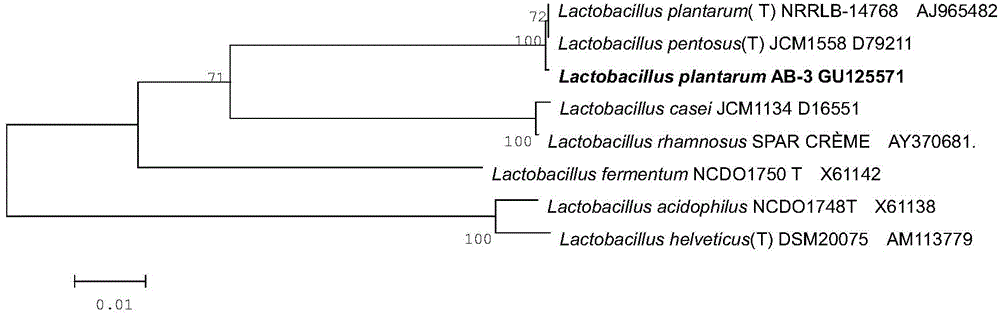

Lactobacillus plantarum AB-3 having bacteria inhibition activity and application thereof

ActiveCN104818232AGrowth inhibitionImprove thermal stabilityBiocideMilk preparationFusarium oxysporumNeutral protease

The invention provides a lactobacillus plantarum AB-3 strain having an activity of resisting phytophthora melonis kalsura, of which the accession number is CGMCC No.9655. The lactobacillus plantarum AB-3 has effective inhibition properties on escherichia coli, salmonella typhimurium and shigella flexneri, has effective inhibition properties on the phytophthora melonis kalsura, fusarium oxysporum, penicillium roqueforti and glomerella cingulata and is excellent in thermostability. A fermentation supernate of the strain shows a significantly increased bacteria inhibition rate after treatment at 100 DEG C and is enhanced in bacteria inhibition activity through enzymolysis by a neutral protease. The fermentation supernate of the strain has a storage resistance property and is excellent in bacteria inhibition activity even after normal storage for 20 days.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com