Method for preparing silver-enriched antibacterial film on pyrolytic carbon and TiN film for medical use

An antibacterial film, pyrolytic carbon technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., to achieve obvious antibacterial properties, uniform thickness and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

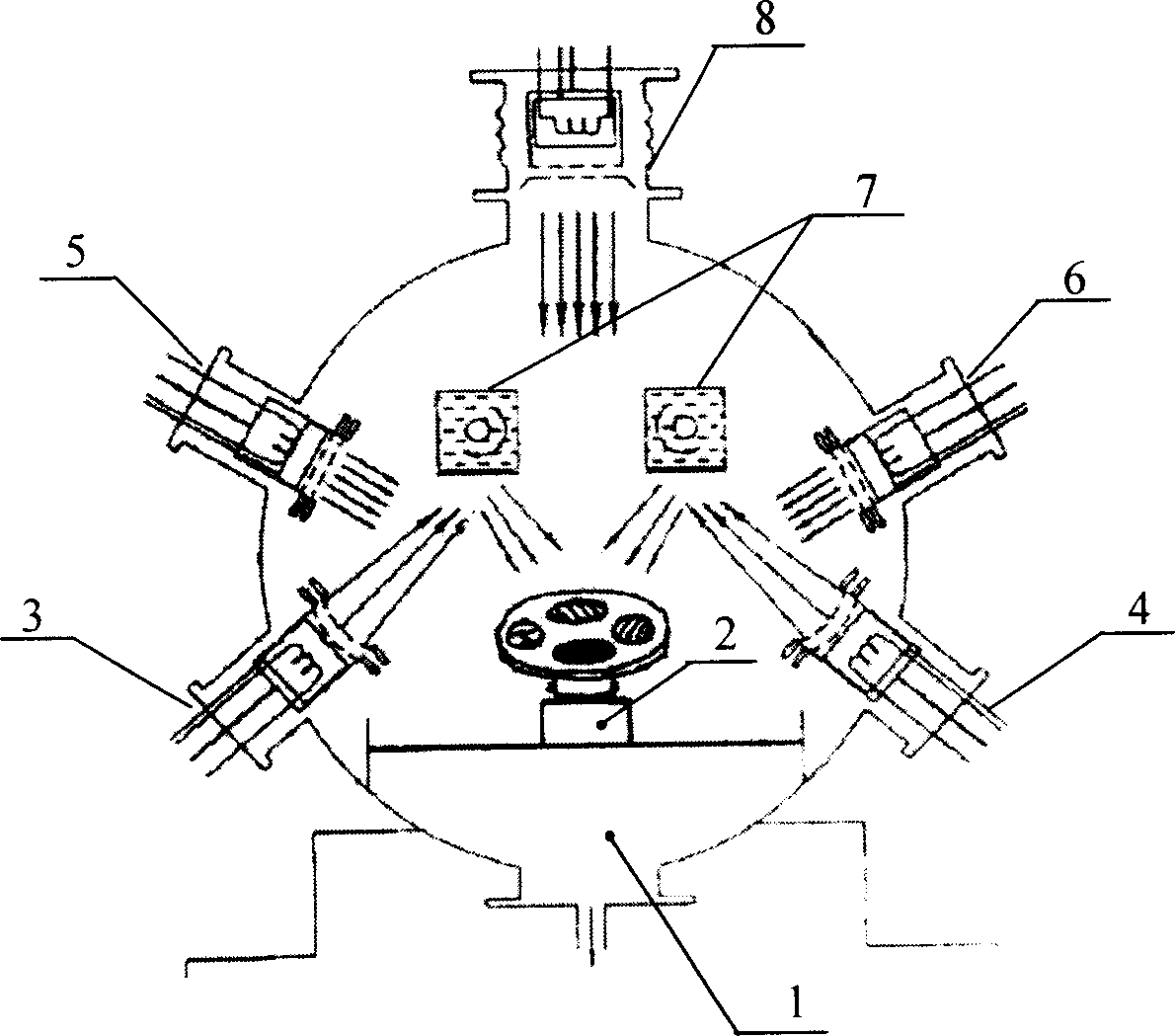

[0032] Before injection, put the polished and cleaned pyrolytic carbon sample S11 on the rotating water-cooled sample stage (2) of the multifunctional ion beam assisted deposition equipment (such as figure 1 shown in middle 2); after the vacuum unit (1) is vacuumed, the background vacuum degree is higher than 1×10 -3 Pa is sufficient; the sputtering ion source (3) and the sputtering ion source (4) are sputtered and cleaned with a nitrogen ion beam with an energy of 1KeV for 5 minutes; the MEVVA source (8) is first used with a high energy of 70keV, and the implantation dose is 2× 10 14 / cm 2 silver ions, and then use relatively low energy 30keV, the dose is 3×10 14 / cm 2 The silver ions are injected into the surface of the pyrolytic carbon material; the rotating water-cooled target stage (7) is always circulated by the chiller with 10°C tap water to cool the rotating water-cooled target stage (7) and the sample stage (2), so that the pyrolysis The carbon temperature is main...

Embodiment 2

[0033] Example 2: Pyrolytic carbon material sample S12, after sputtering and cleaning for 5 minutes, the MEVVA source (8) uses high energy 70keV, and the injection dose is 2×10 15 / cm 2 Silver ions, and then use low energy 30keV, the dose is 3×10 15 / cm 2 The surface of the pyrolytic carbon material is implanted with silver ions, and the total dosage is 5×10 15 / cm 2uniform silver-rich layer. As shown in Table 2, the antibacterial rate to Staphylococcus aureus is tested by the direct contact method, and the antibacterial rate to Escherichia coli is as shown in Table 3, all reaching 100%, and all the other are the same as in Example 1.

Embodiment 3

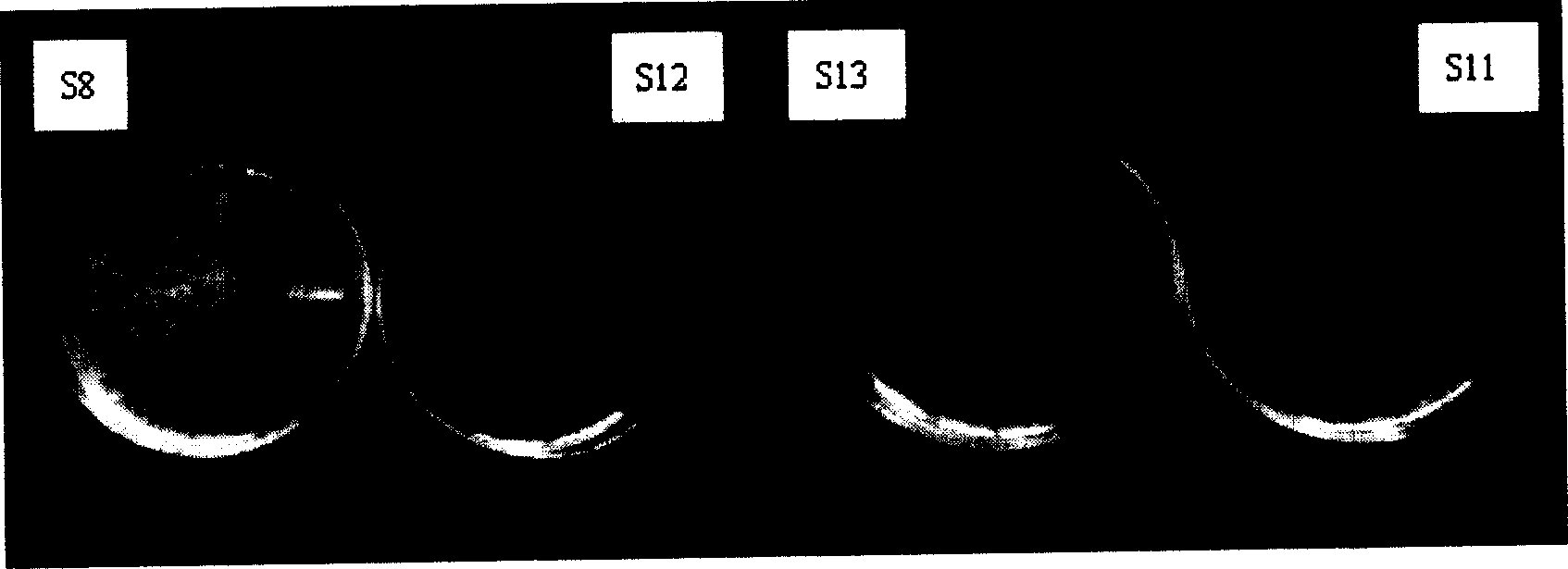

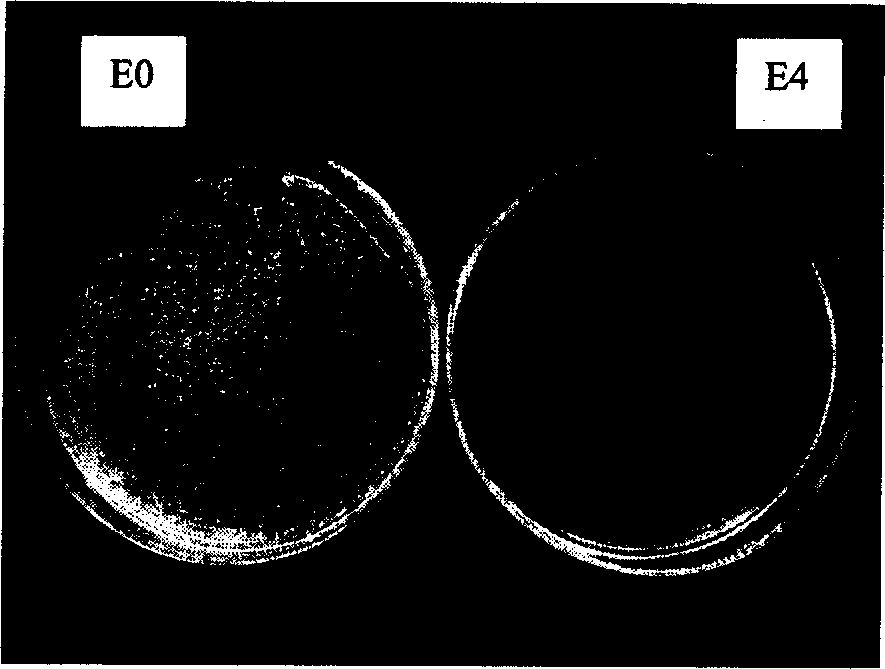

[0034] Example 3: Pyrolytic carbon sample S13, after sputtering and cleaning for 5 minutes, the MEVVA source (8) uses high energy 70keV, and the injection dose is 2×10 16 / cm 2 silver ions, then use low energy 30keV, dose 3×10 16 / cm 2 The silver ions were implanted to form a total dose of 5×10 16 / cm 2 The uniform silver-rich layer, antibacterial rate also reaches 100%, all the other are with embodiment 2. like figure 2 It is the colony pictures of pyrolytic carbon non-silver injected sample S8 and the corresponding silver injected samples S12, S13 and S11. From this, it can be seen qualitatively that S11 has obvious antibacterial properties, and the antibacterial rates of S12 and S13 both reach 100%.

[0035] Sample serial number

[0036] Sample serial number

[0037] (2) Example of forming a uniform silver-rich antibacterial film on a TiN film on a stainless steel substrate

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com