Patents

Literature

181results about How to "Guaranteed biocompatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

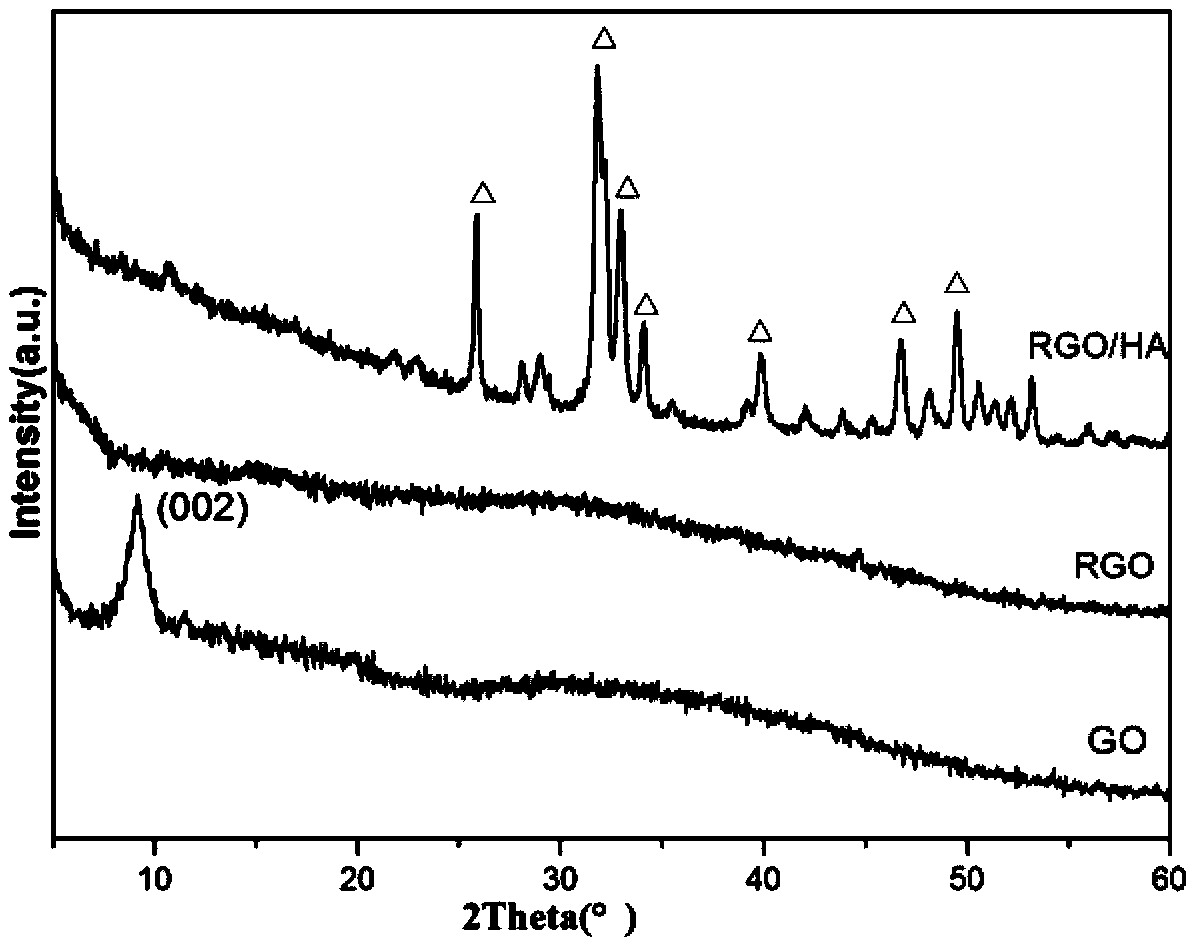

Preparation method of grapheme/hydroxyapatite composite material

InactiveCN103420364AGood biocompatibilityHigh activityCarbon compoundsPhosphorus compoundsApatitePhosphate ion

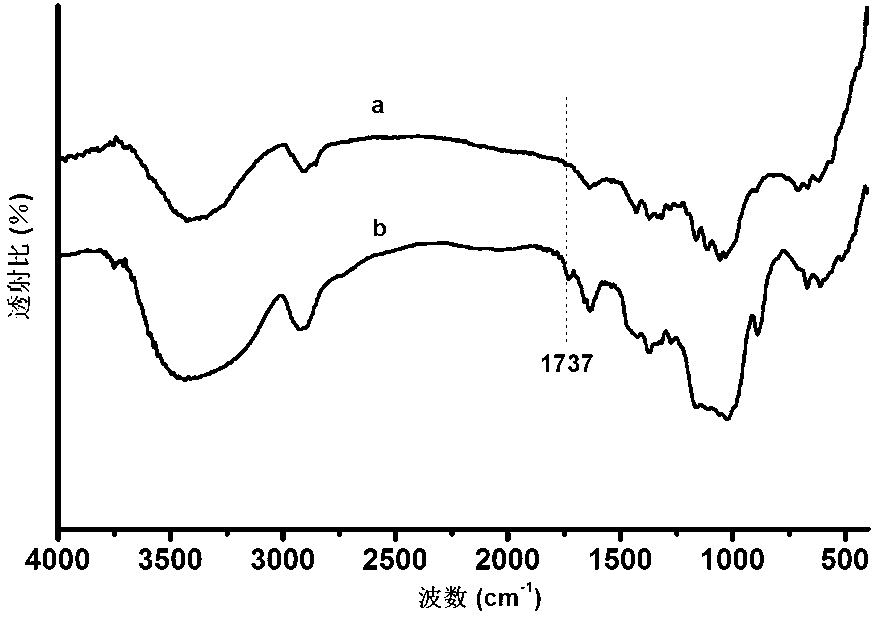

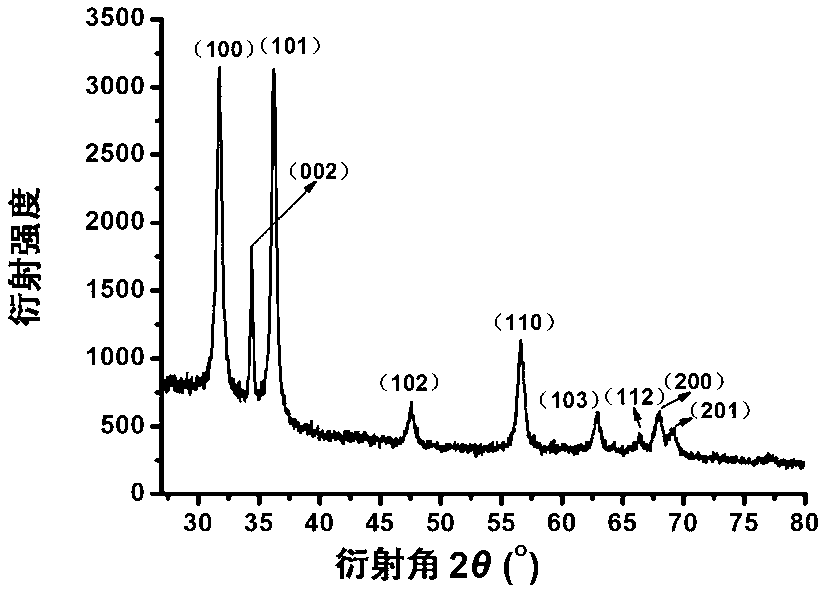

A preparation method of a grapheme / hydroxyapatite composite material comprises the following steps: uniformly mixing oxidized grapheme with the concentration of 0.5-5 mg / ml and a solution or a turbid liquid with the calcium ion concentration of 0.01-3.0 mol / L to obtain a first mixed solution; adding a solution I with the phosphate anion concentration of 0.01-2.0 mol / L to the first mixed solution according to the molar ratio of calcium to phosphorus is (1.5-2.0) to 1, and uniformly mixing the solution I and the first mixed solution under the action of magnetic mixing; adjusting the pH to be 8-14 through a pH adjusting agent to obtain a second mixed solution; transferring the second mixed solution to a reaction kettle; carrying out hydro-thermal treatment for 1-12 hours at the temperature of 160-240 DEG C; cooling the second mixed solution until the temperature of the second mixed solution is the room temperature; cleaning, freezing and drying to obtain the grapheme / hydroxyapatite composite material. The preparation method is environment-friendly, simple and beneficial to large-scale production. The prepared grapheme / hydroxyapatite composite material has the advantages of good mechanical property as well as high electrical conductivity, adsorbability, biocompatibility and osteogenic activity.

Owner:SOUTHWEST JIAOTONG UNIV

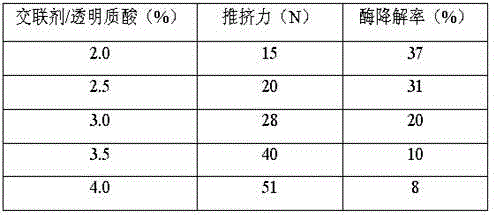

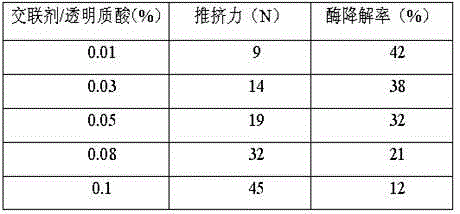

Modified sodium hyaluronate gel for injection

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

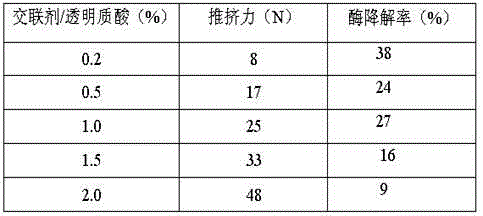

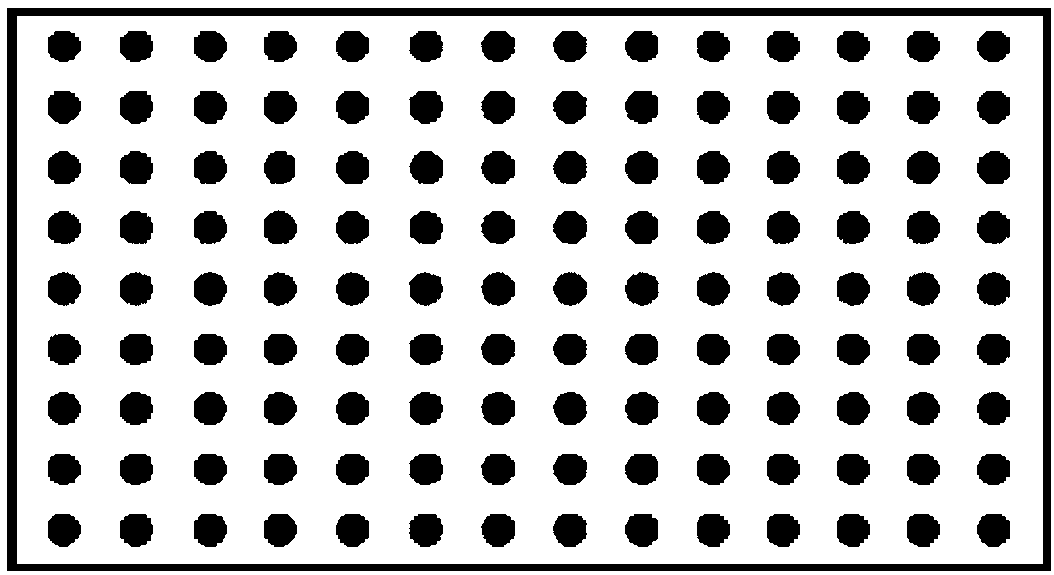

Functionalized implantable flexible electrode and application thereof

PendingCN109350847AGuaranteed biocompatibilityReduce surgical riskHead electrodesEpicardial electrodesImplantable ElectrodesPower flow

The invention relates to a functionalized implantable flexible electrode and an application thereof. The functionalized implantable flexible electrode at least comprises a function layer capable of generating a current or voltage. In the invention, through adopting the function layer which can generate the current or the voltage via triggering, the flexible electrode does not need complex line connection and device packaging and the function of a nerve stimulation device can be realized so that an operation risk and the safety risk of long-term implantation are greatly reduced, and the application field of the nerve stimulation device is expanded. The invention also provides the applications of the above functionalized wide-width implantable electrode in manufacturing an implantable artificial retina, an implantable artificial cochlea, an implantable cardiac pacemaker, and an implantable deep brain stimulator.

Owner:SHENZHEN INST OF ADVANCED TECH

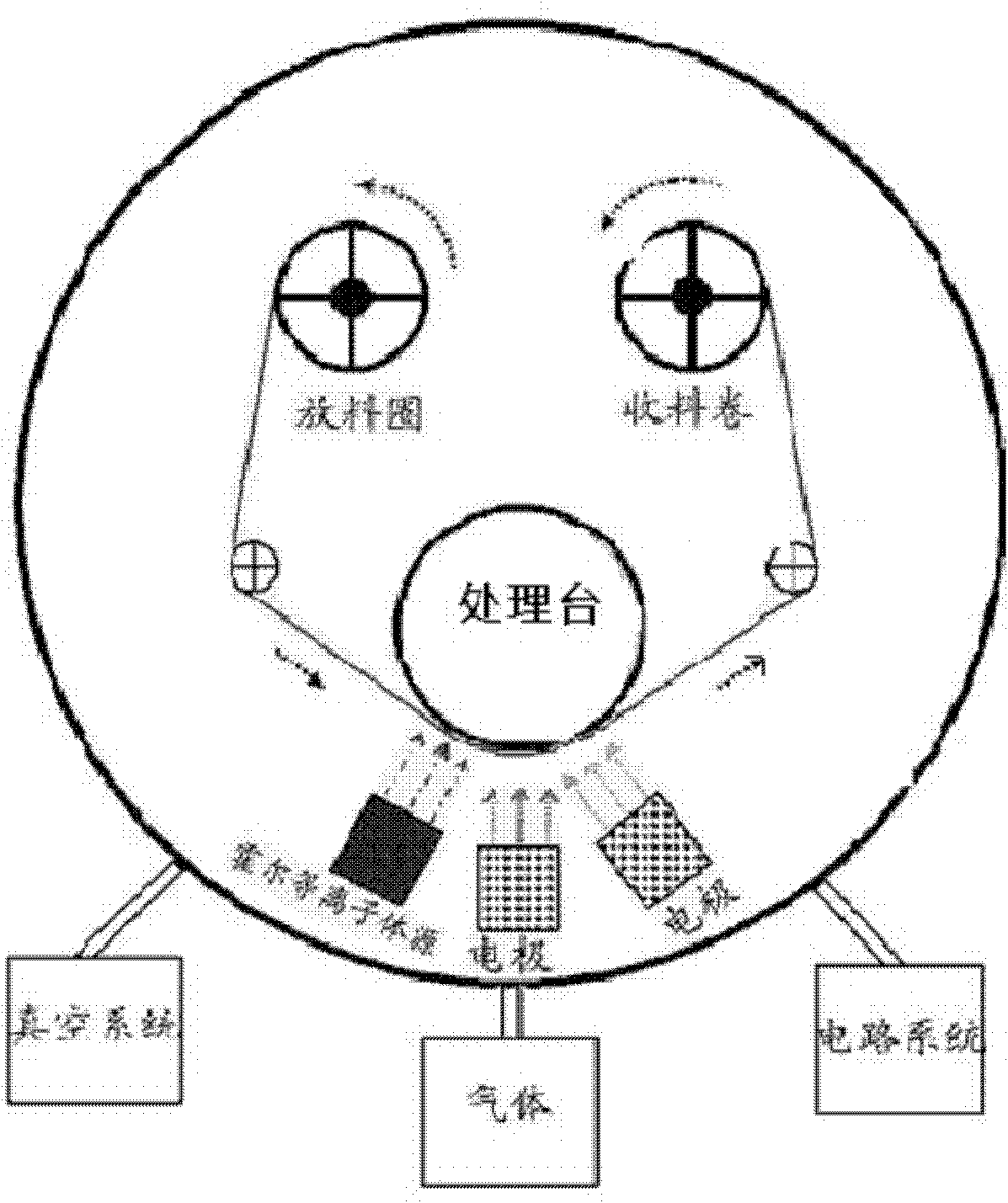

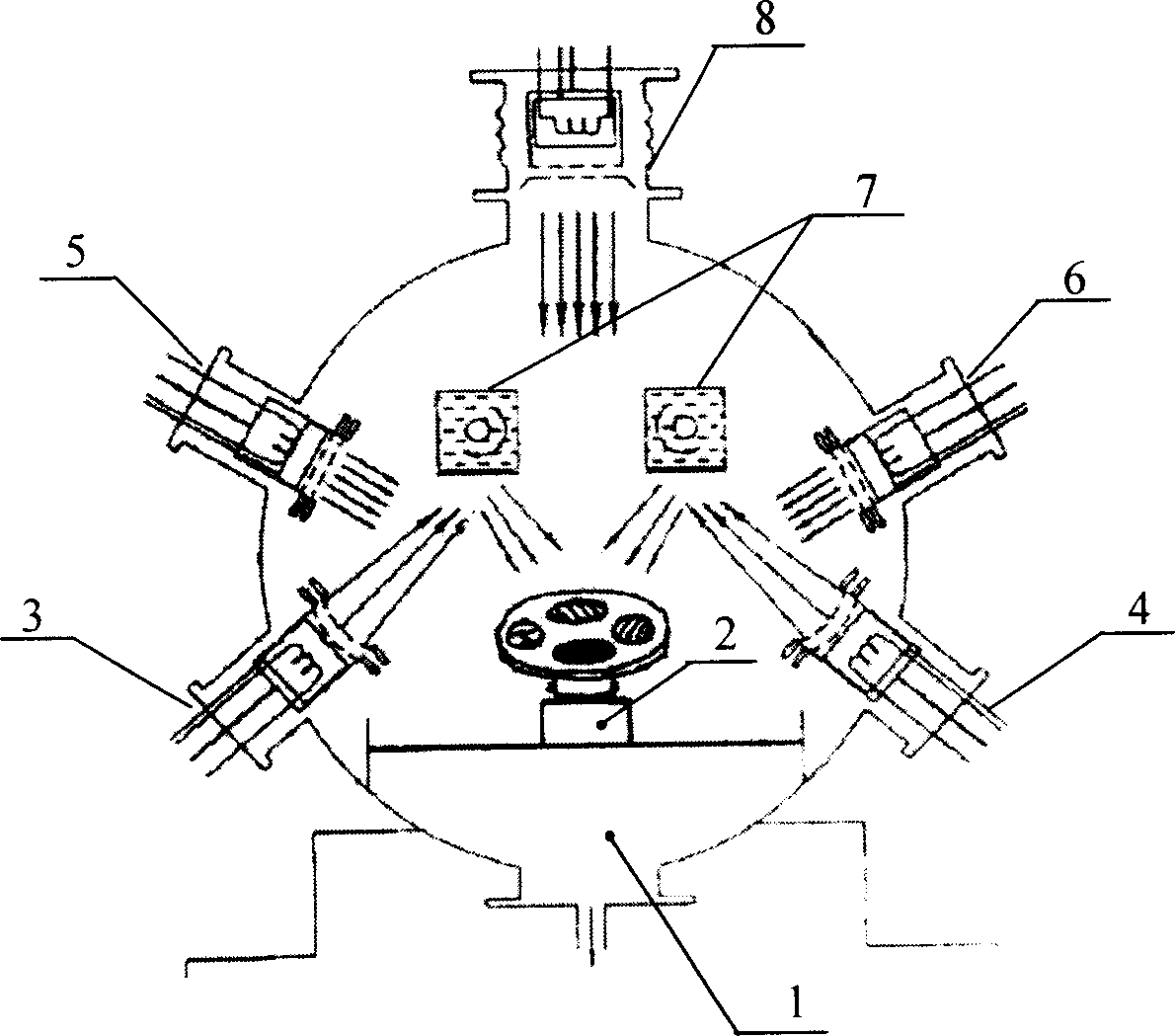

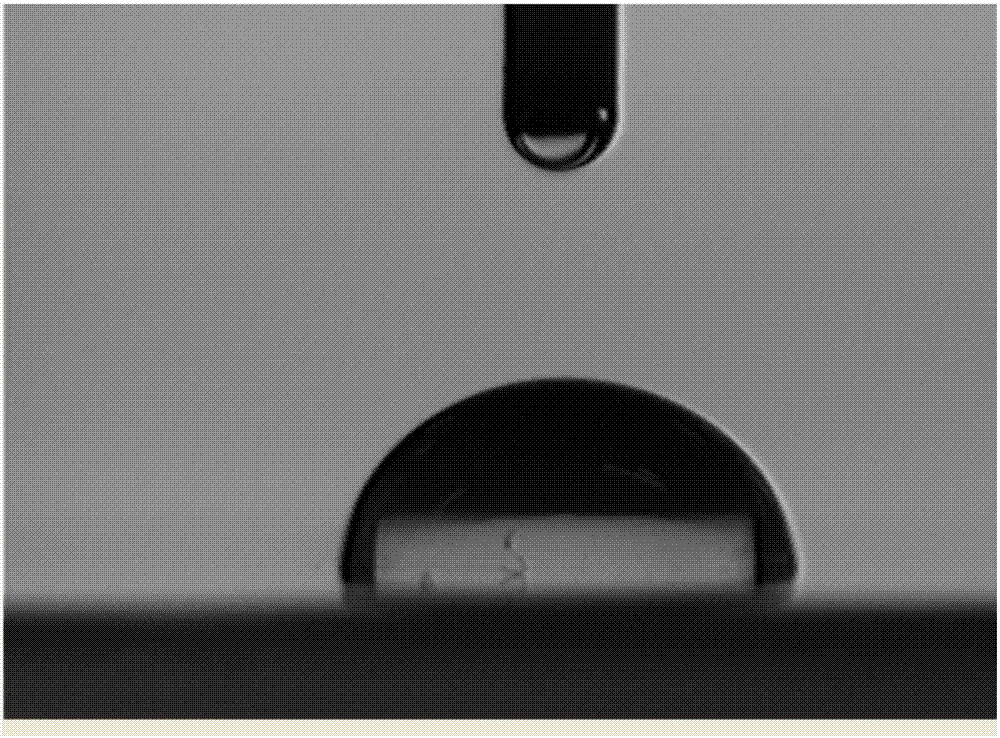

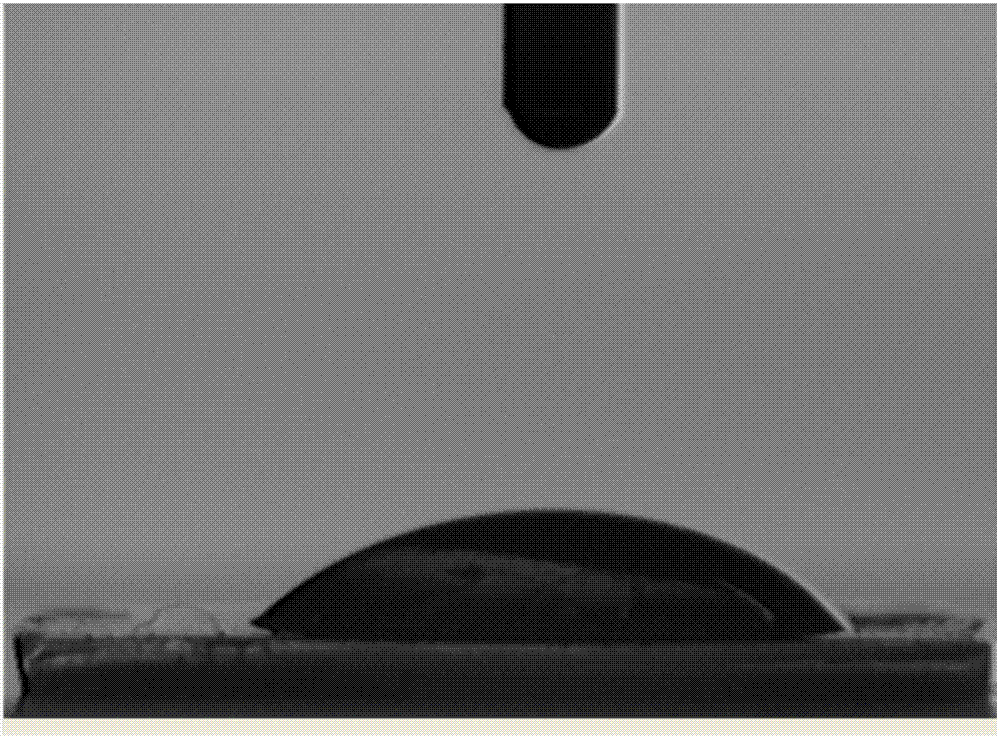

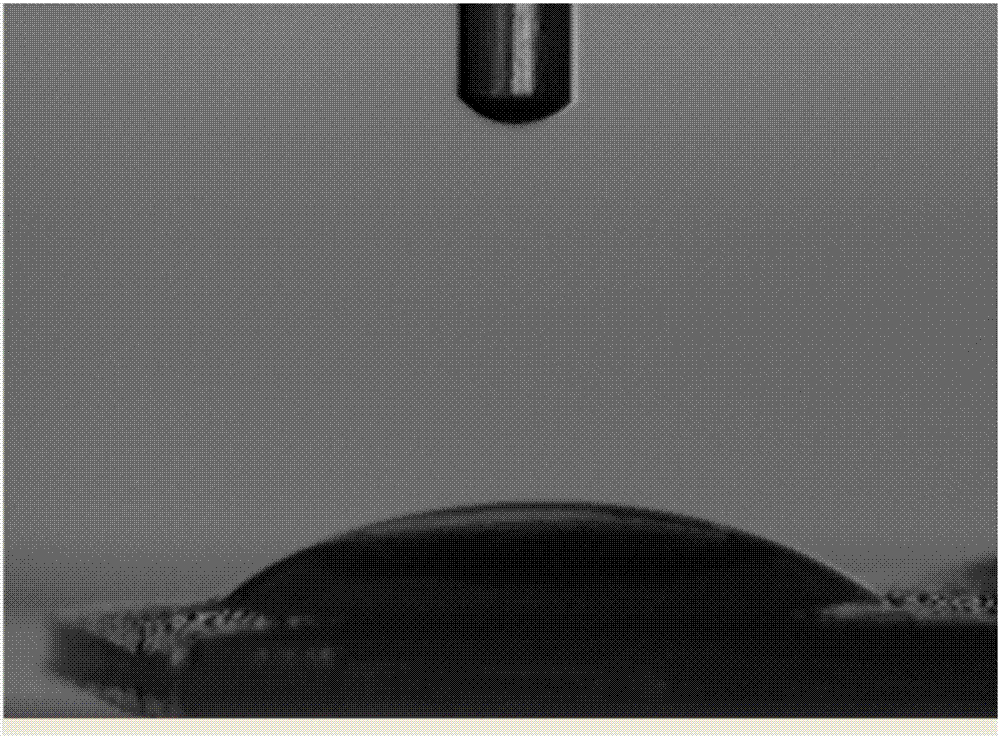

Method for preparing medical polymer material by ion implantation technique

ActiveCN103044699AChange surface structureGuaranteed biocompatibilityVacuum evaporation coatingSputtering coatingVacuum pumpingBiocompatibility Testing

The invention discloses a method for preparing a medical polymer material by an ion implantation technique; the method obtains the medical polymer material with surface infection resistance and biocompatibility by the following steps of fixing the medical polymer material on or moving the medical polymer material through a treatment table of ion implantation equipment, vacuum-pumping, introducing gas, turning on the power supply of the ion implantation equipment, and performing treatment. The method is simple in operation, and does not influence the physical-chemical structure of the material body; the treated polymer material is stable in surface structure, has long-acting and wide-spectrum infection resistance, and has cytocompatibility not lower than the inherent biocompatibility of the material itself.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

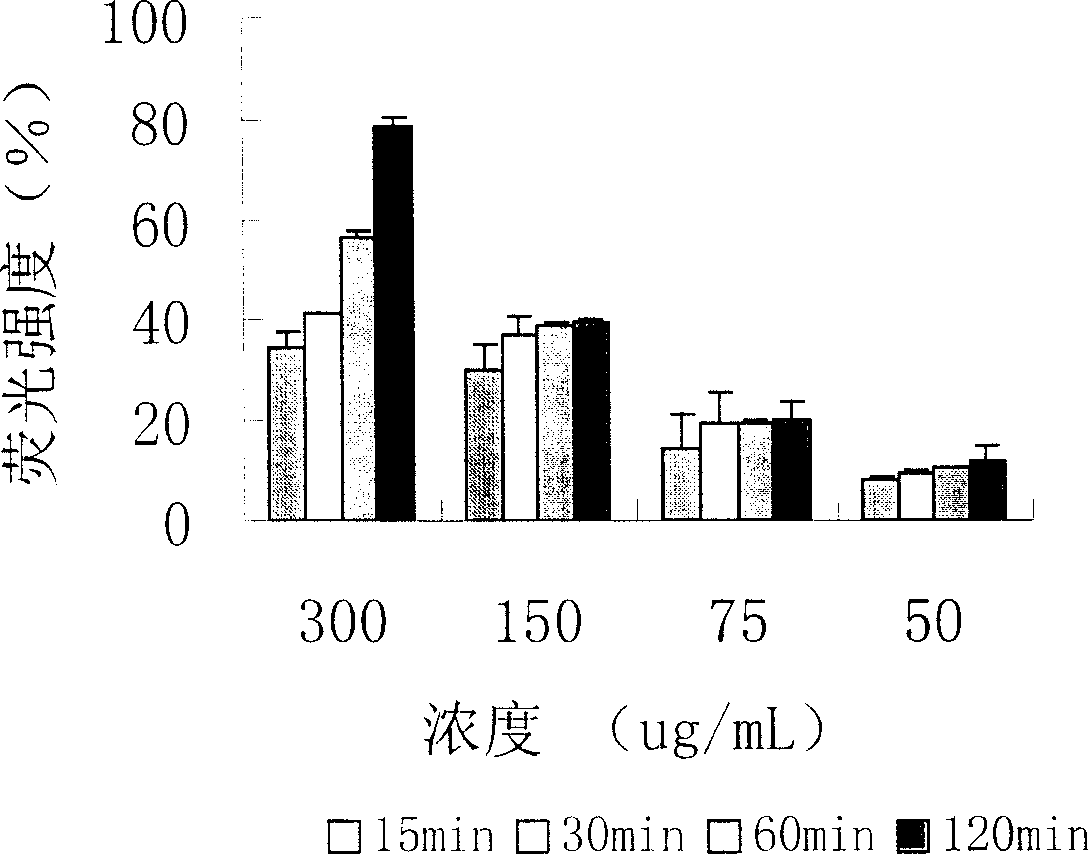

Fluorescence labeling hydrophobic modified chitin polymer, its preparation method and application

InactiveCN1718592ALow toxicityBiodegradablePharmaceutical non-active ingredientsCross-linkPolymer adhesive

A fluorescently-labeled hydrophobic modified oligochitose polymer used for preparing target medicine or fluorescent signal amplifier carrier is prepared through reaction between aqueous solution of oligochitose, fatty acid and cross-linking coupler, and reacting on isothiocyano fluorescent larbel in ice bath, darc and magnetic stirring conditions to obtain said polymer, and ultrasonically dispersing it in water to obtain its colloidal microparticles.

Owner:ZHEJIANG UNIV

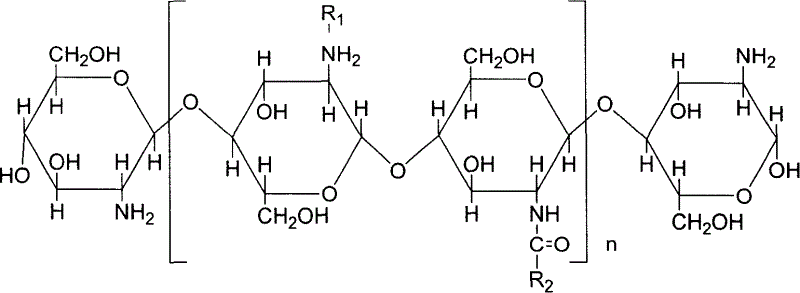

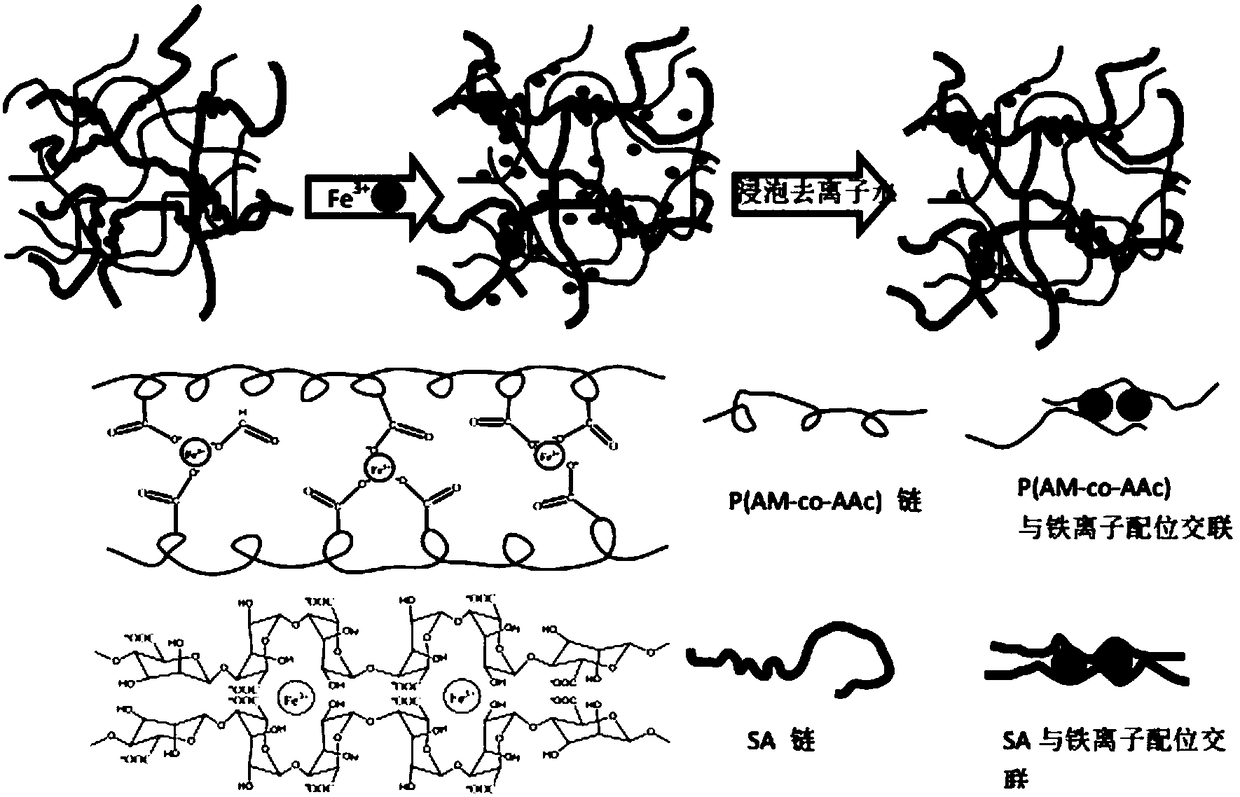

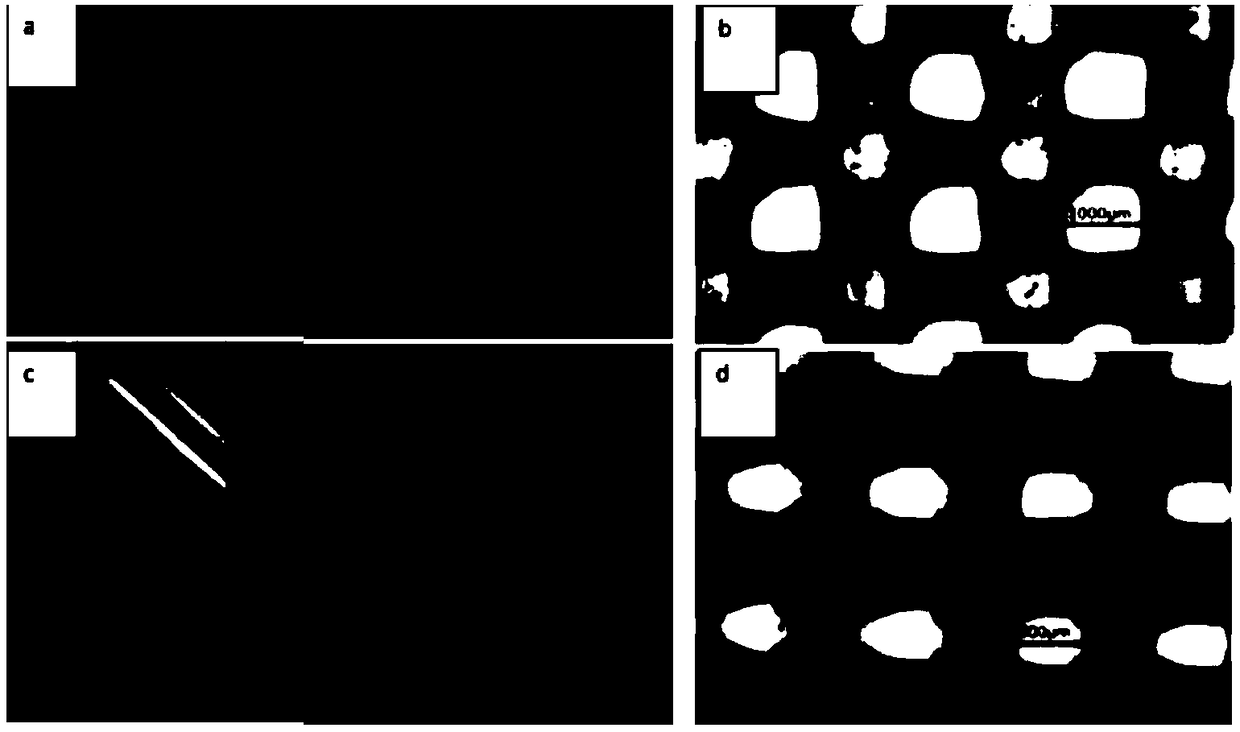

Preparation method of 3D printable iron ion double-crosslinked alginate-polyacrylamide acrylic acid high-performance hydrogel

ActiveCN108276522AImprove mechanical propertiesImprove fatigue resistanceAdditive manufacturing apparatusPorosityCross-link

The invention discloses a preparation method of 3D printable iron ion double-crosslinked alginate-polyacrylamide acrylic acid high-performance hydrogel. The method comprises the following steps: firstly, evenly mixing sodium alginate, acrylamide, acrylic acid and a photo-initiator; pre-molding by using a mould or a 3D printing way; illuminating by using an ultraviolet lamp so as to realize copolymerization between an AAc monomer and an AM monomer; after the polymerization is completed, soaking a hydrogel scaffold into an Fe3<+> solution to form ionic cross-linking; finally, soaking the productinto deionized water for balancing so as to remove the unreacted monomers. Two networks are both Fe3<+> cross-linked, so that a common cross-linking point exists between the two networks, and the hydrogel is enabled to have excellent performance. In addition, the sodium alginate has good natural high polymer with good biocompatibility, and the viscosity is adjusted by adding a small amount of adhesive in a sol state, so that the hydrogel has good anti-collapse and rapid gelation characteristics; the hydrogel can be prepared into high porosity hydrogel with various complex structures by usinga 3D printing technology.

Owner:HUBEI UNIV OF TECH

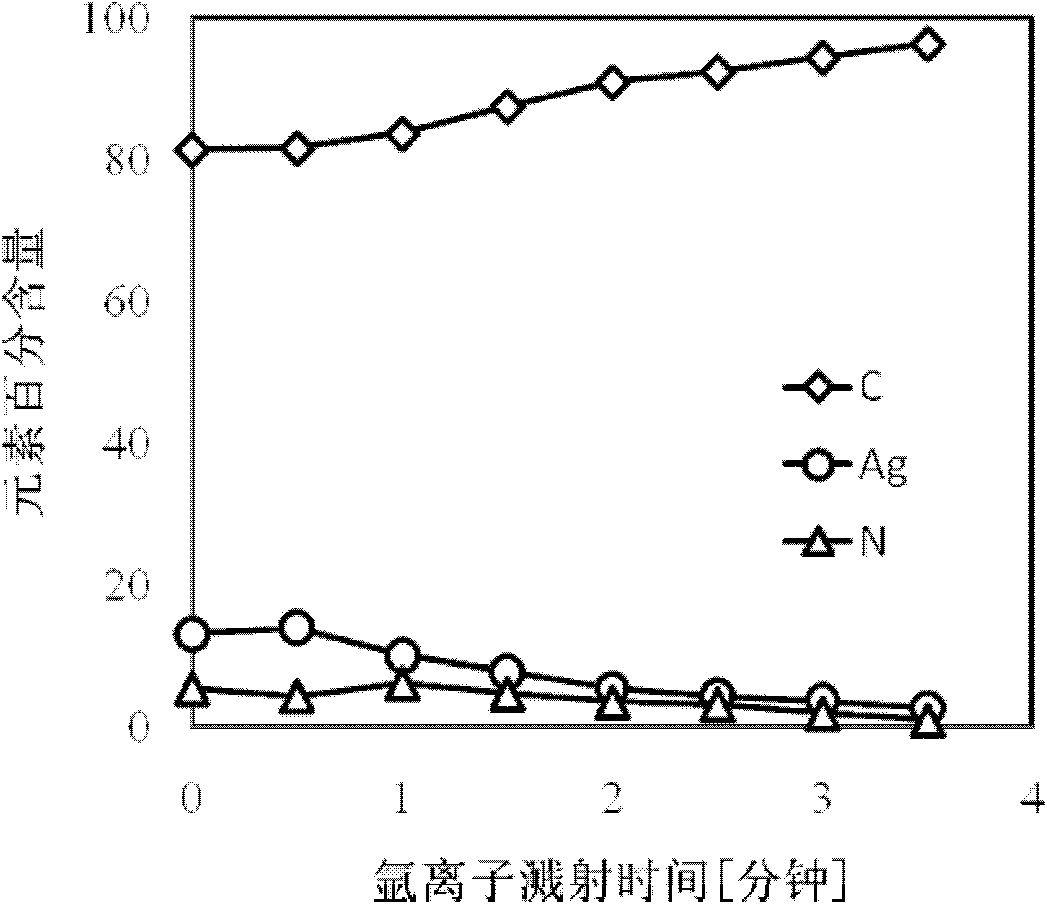

Method for preparing silver-enriched antibacterial film on pyrolytic carbon and TiN film for medical use

InactiveCN1827840AIncrease concentrationImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingSputteringHigh energy

The invention relates the method for preparing rich silver antibiotic film used for medical pyrolytic carbon and TiN film. It solves the antibiosis question. The method comprises the following steps: on the pyrolytic carbon: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d injecting silver ion: 70, 30keV energy, 2-8mA beam current, 2X1014 / cm2-3X1014 / cm2 dosage, and forming rich silver antibiotic film and antibiosis ratio being 100%; on TiN film: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d sputtering Ti target with 3keV, 80mA Ar+ ion, 20-40keV, beam current: bombarding with 2-8mA high-energy N+ ion for 10-20 minutes; 50-350eV, beam current: bombarding with 10-30mA low-energy N+ ion for 60-180 minutes to deposit, N2 air pressure being 8X10 3Pa; e injecting silver ion: 30-80keV, beam current: 2-8mA, 1X1017 / cm2-5X1018 / cm2 dosage, forming rich silver antibiotic film and antibiosis ratio being 90%. The film has the advantages of good abradability, strong adhesive force and anti-corrosion, good cell compatibility and long antibiosis time-effect. The film can be used to prepare artificial heart valve and hard tissue alternate material which is implanted in human.

Owner:TIANJIN NORMAL UNIVERSITY

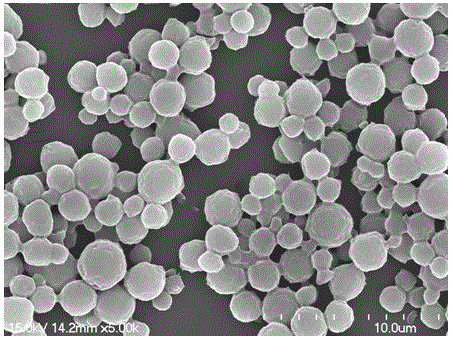

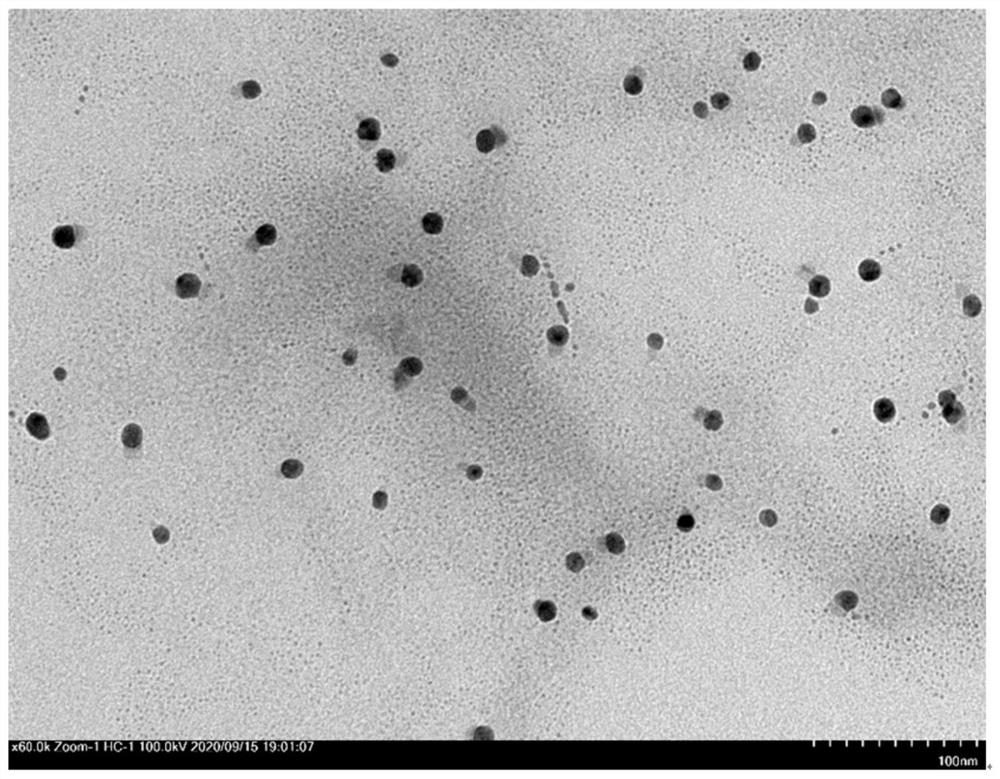

Wild antheraea pernyi silk fibroin microsphere and preparation method thereof

InactiveCN102977381AGuaranteed biocompatibilityIncrease productionCosmetic preparationsToilet preparationsDiseaseMicrosphere

The invention discloses a wild antheraea pernyi silk fibroin microsphere and a preparation method of the microsphere. The preparation method comprises the steps of degumming and dissolving tussah silk; subjecting the above processed tussah silk to dialysis treatment to obtain a solution of the wild antheraea pernyi silk fibroin; adjusting the concentration of the solution to 10-100mg / ml; adding in a citric acid solution or an acetic acid buffer solution at the temperature of 10-60 DEG C to adjust the pH value to 3-6; subjecting the resulting solution to ultrasonic oscillation and stirring treatment to obtain a suspension of the wild antheraea pernyi silk fibroin microsphere; centrifugalizing, freezing and drying the suspension to obtain the biodegradable wild antheraea pernyi silk fibroin microsphere, the diameter of which is 0.1-10mu m. The preparation method of the invention prepares the wild antheraea pernyi silk fibroin microsphere by means of in-situ self-assembly generation and is simple in process procedures; the prepared microsphere is uniform in size distribution, keeps the RGD sequence of the wild antheraea pernyi silk fibroin, promotes the cell recognition of the microsphere, improves the targeting property and bioavailability of drugs, can function as a carrier with bioactive substance to carry an enzyme drug, a nucleic acid drug, a polypeptide drug, a protein drug and the like, and can be applied to diagnosing and treating diseases and the like.

Owner:SUZHOU UNIV

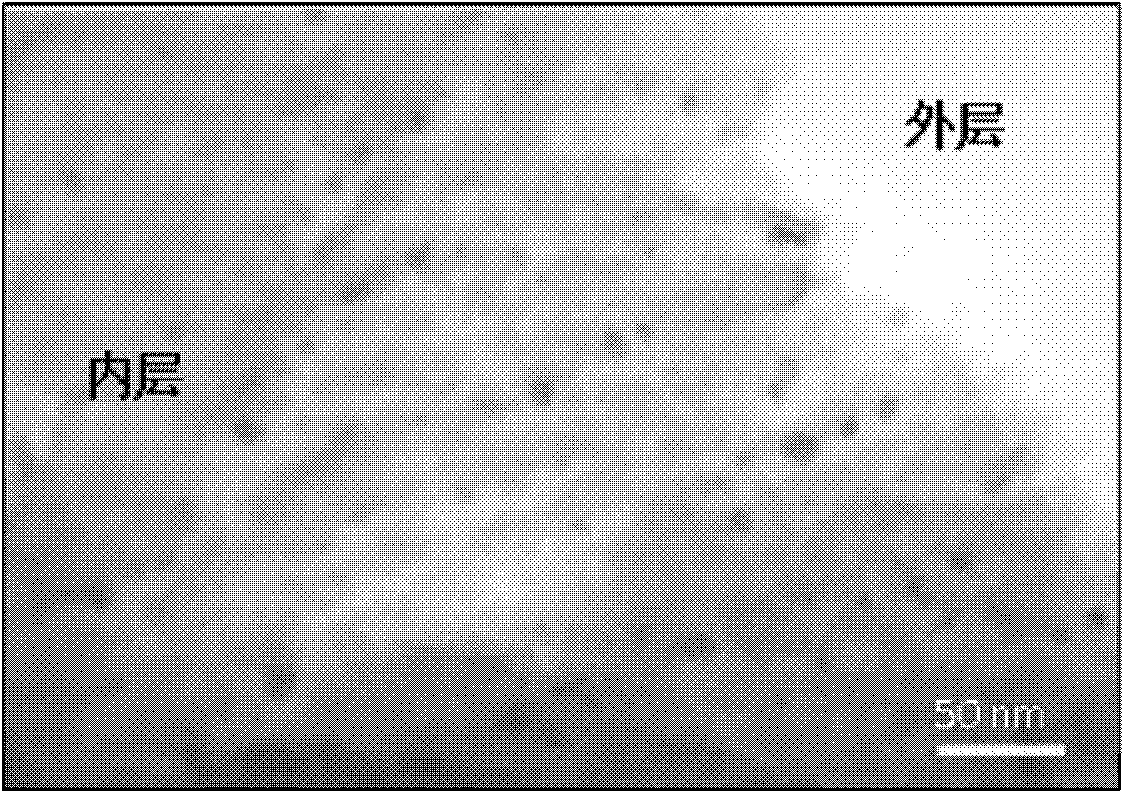

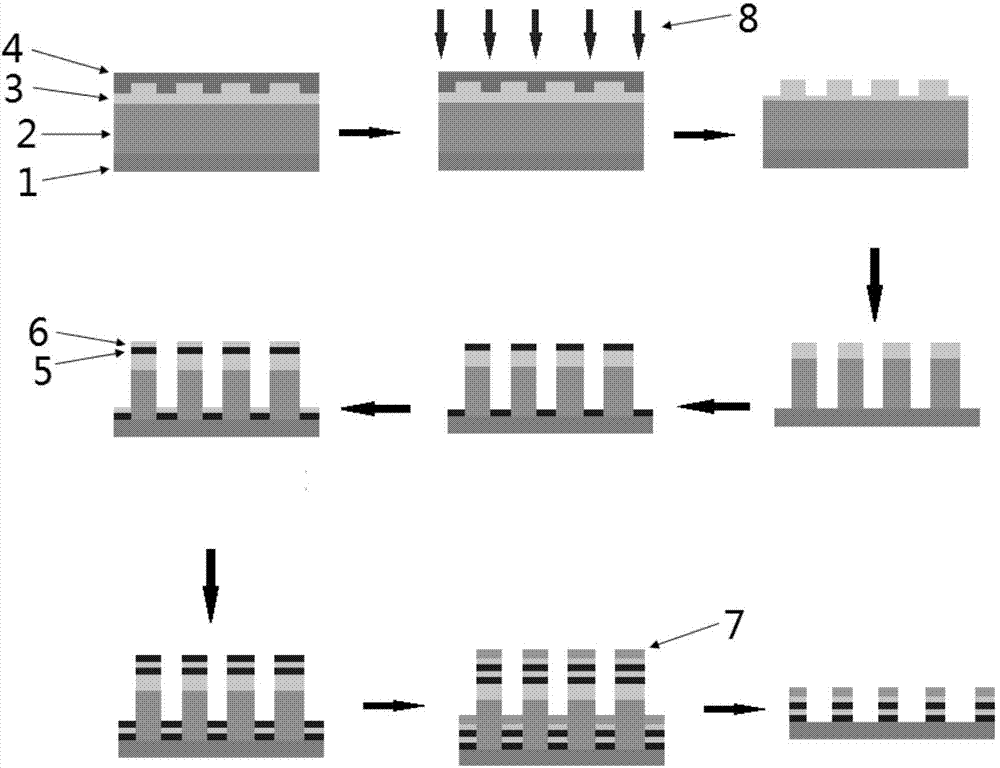

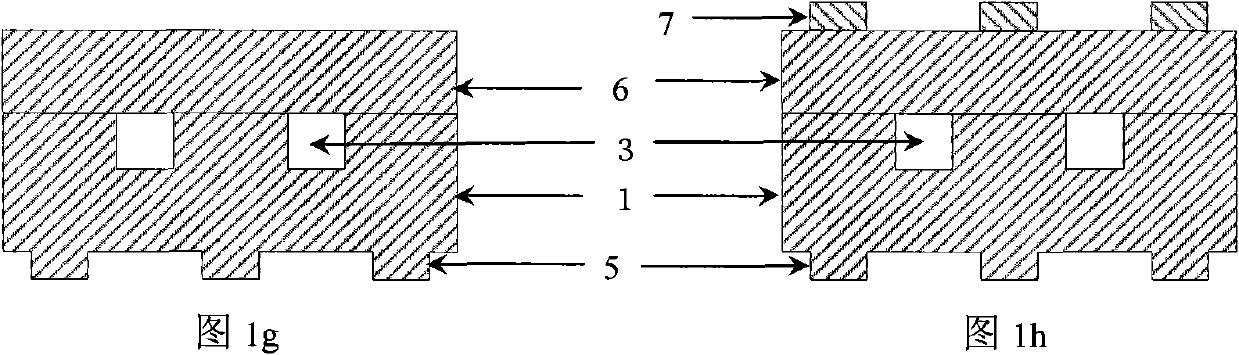

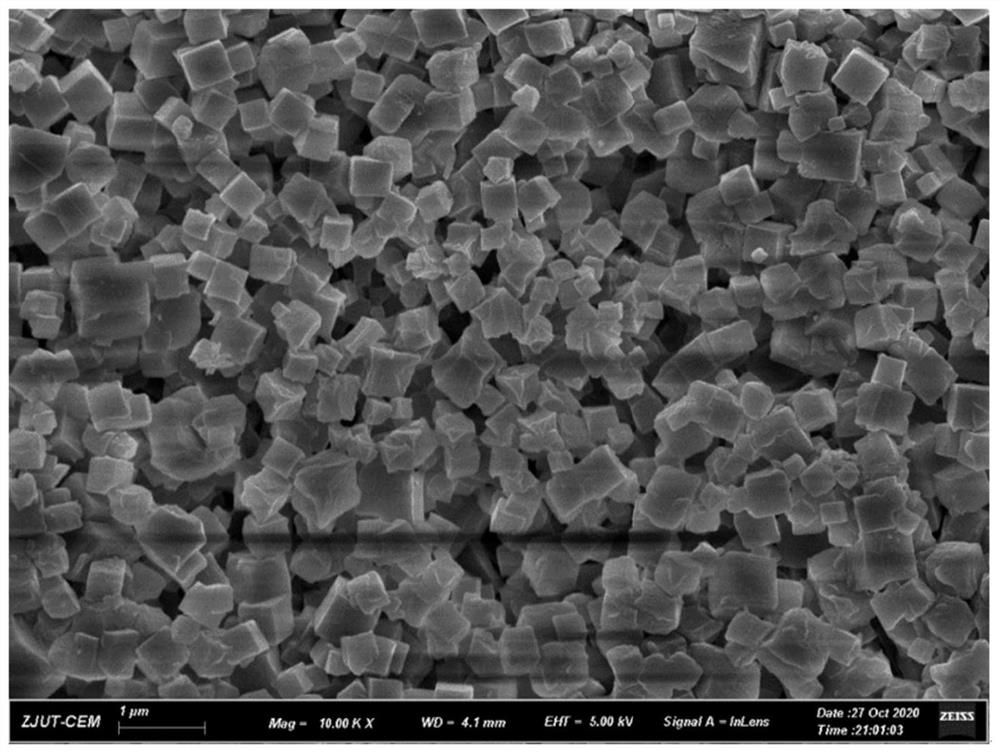

Multilayer structure surface enhanced Raman scattering base and preparation method thereof

ActiveCN103575721ACoordination compatibilityOverall structure coordinationRaman scatteringNano structuringBiocompatibility Testing

The invention belongs to the technical field of nano-imprinting and spectra, and in particular relates to a multilayer structure surface enhanced Raman scattering base and a preparation method thereof. The surface enhanced Raman scattering base is simple in process, high in efficiency, high in enhancement factor and biocompatible. The base consists of a substrate and a periodic nano columnar structure which is positioned on the substrate, wherein the nano columnar structure is a multilayer structure; the multilayer structure consists of alternation layers and a gold layer; the alternation layers consist of silver and media; the gold layer is positioned on the topmost layer. A nano-imprinting technology is used as a core technology, and a reactive ion etching process, a metal evaporation process, a silicon dioxide plating process, a metal peeling process and the like are combined to prepare a multilayer nano structure, so that the technical problems that a silver structure base is not biocompatible and a gold structure base is low in enhancement factor are solved; on the basis of ensuring biocompatibility, the enhancement factor of the base is greatly improved, the detection is efficient and sensitive, and the base can be applied to biological detection after further treatment.

Owner:WUXI IMPRINT NANO TECH

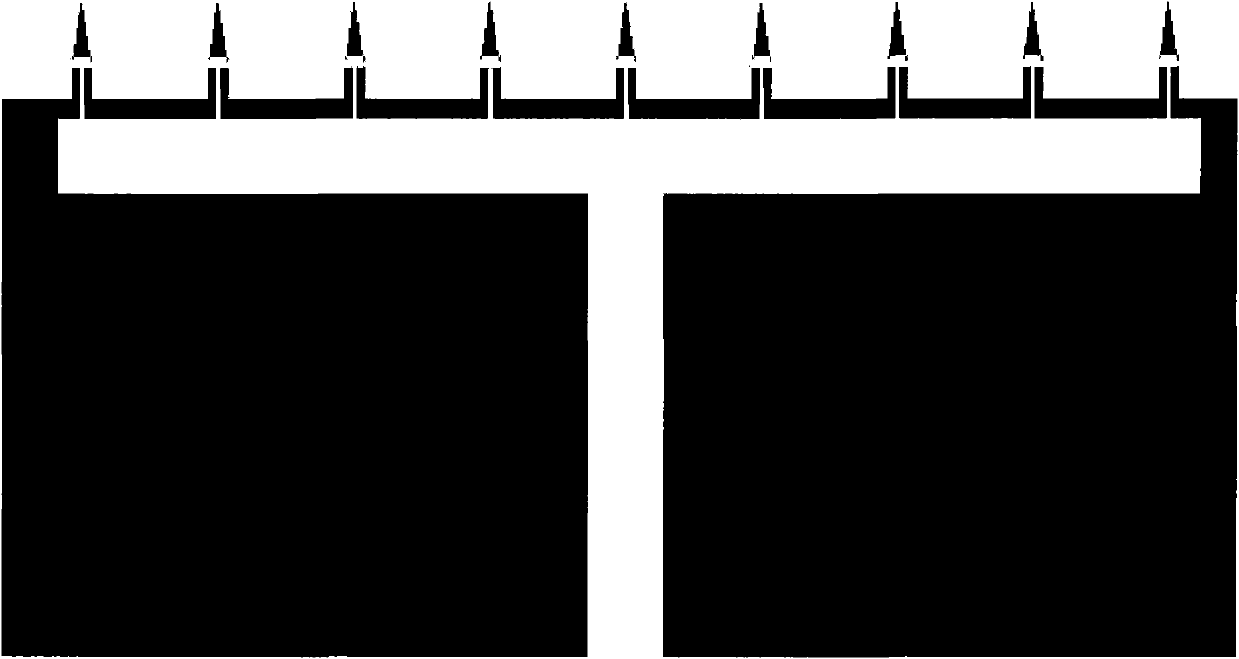

Method for preparing plane hollow microneedle for transdermal administration

InactiveCN101905856ATo achieve the purpose of sustained releasePrecise deliveryDecorative surface effectsMicroneedlesEnteral administrationChannel pattern

The invention discloses a method for preparing a plane hollow microneedle for transdermal administration, which comprises the following steps of: defining a microneedle flow channel pattern on one surface of a first metal substrate to form a trench, and defining a microneedle pattern on the other surface to form a cutting sign, wherein the central axis of the flow channel pattern is aligned with that of the microneedle pattern; bonding a second metal substrate with a trench surface of the first metal substrate; thinning a non-bonding surface of the second metal substrate, and allowing the cutting sign on the first metal substrate to align with and transfer to the non-bonding surface of the second metal substrate; and thinning a non-bonding surface of the first metal substrate, and cutting by aligning with the cutting sign on the second metal substrate to form the plane hollow microneedle. Based on the micromachining technology and by combining the conventional technology of machining and cutting at the same time, the method reduces the process difficulty, increases the using reliability of the microneedle, and is favorable for quantity production.

Owner:PEKING UNIV

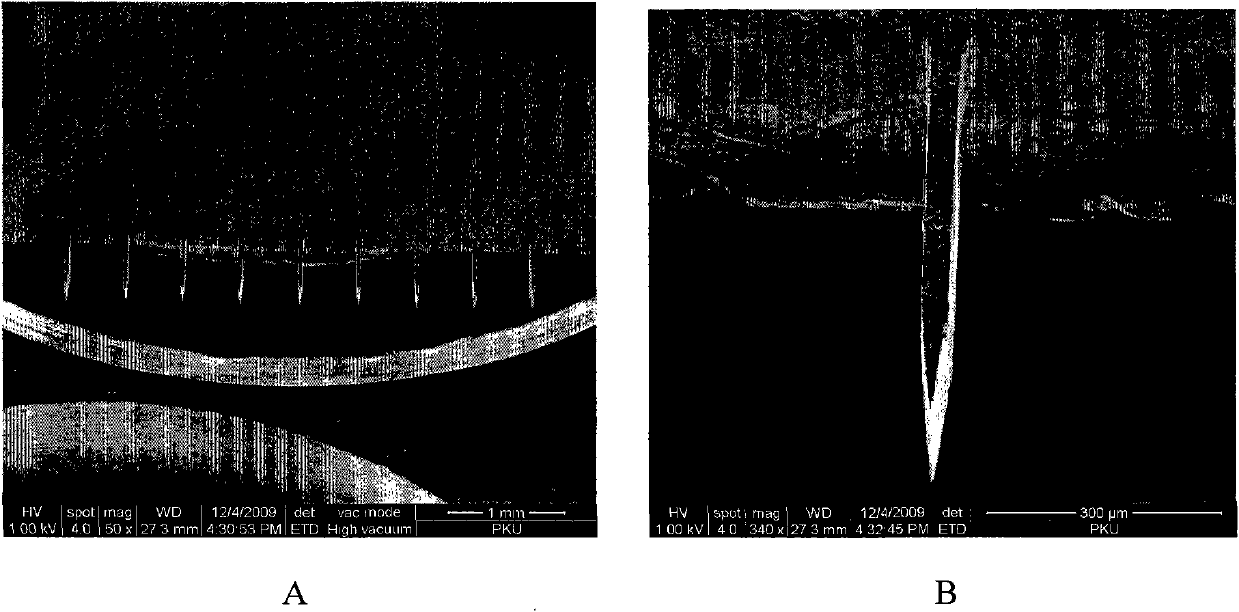

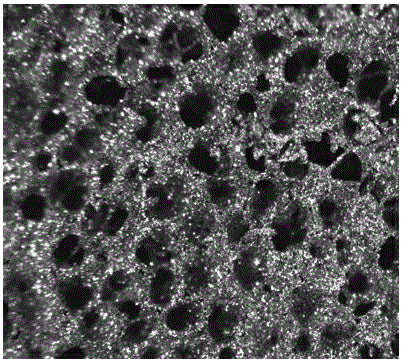

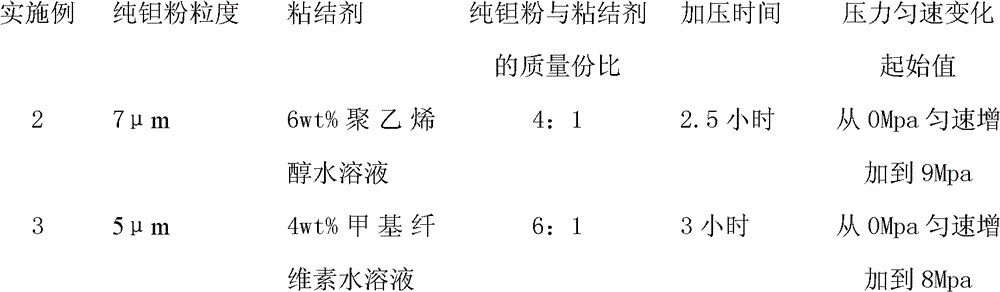

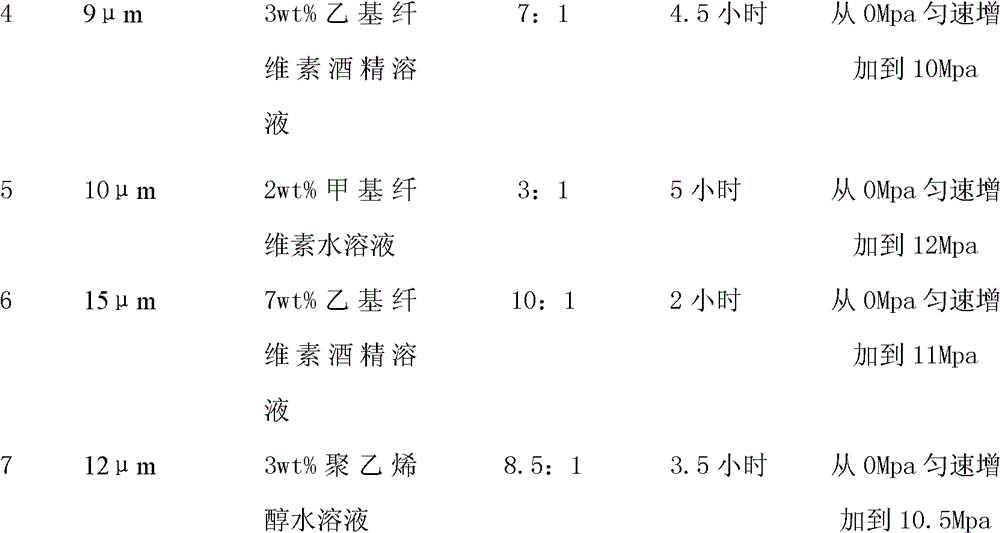

Method for preparing biological medical porous implant material

ActiveCN102796907AReduce sintering deformationStrong mechanical propertiesTransportation and packagingMetal-working apparatusBiocompatibility TestingSlurry

The invention discloses a method for preparing a porous tantalum biological medical implant material. The method comprises the following steps of: uniformly mixing pure tantalum powder and a binding agent to obtain tantalum powder slurry; placing a high polymer resin template support which has the porosity of 20 to 50 percent and of which pores are completely communicated in a three-dimensional way in a steel die; pouring the prepared tantalum powder into the steel die until the high polymer resin template support is immersed; slowly and uniformly applying pressure to the periphery of the steel die to ensure that the tantalum powder can be fully and completely filled into the high polymer resin template support, wherein the applied pressure is increased from 0 Mpa to10 Mpa at constant speed, and the time required by the pressure application process is 2 to 5 hours; performing chemical dissolution to remove the high polymer resin template support to obtain a green body framework of porous tantalum; and performing aftertreatment such as degreasing, sintering and the like to obtain the biological medical porous tantalum implant material. A product prepared by the method is a green body of the porous metal material of which pores are completely communicated in the three-dimensional way, and the green body is sintered to form the porous metal implant material of which the pores are completely communicated in the three-dimensional way, so that the porous metal implant material is high in biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of colloidal solution of nano-ZnO

InactiveCN103318945AImprove water solubilityLow viscosityMaterial nanotechnologyZinc oxides/hydroxidesHydroxypropylmethyl celluloseChemistry

The invention discloses a preparation method of a colloidal solution of nano-ZnO. The method comprises the following steps: mixing an aqueous modified cellulose solution having a concentration of 0.001-100g / L with a zinc salt solution having a concentration of 0.01-100g / L according to a volume ration of 1:10-100:1, wherein the modified cellulose is dialdehyde hydehydroxypropyl methyl cellulose obtained through the selective oxidation of the secondary hydroxyl groups in the C2 and C3 positions of hydroxypropyl methyl cellulose; and slowly adding an alkaline solution for adjusting the pH value to 8.5-11.5, and stirring at 20-90DEG C for 1-600min until reaction completion in order to obtain the colloidal solution of nano-ZnO having an average particle size of 1-100nm. The prepared nano-ZnO has the advantages of ultrahigh stability, antibiosis and ultraviolet resistance, good biocompatibility and good biodegradability, and can be applied to the coat field, the textile field, the medical health field and the like.

Owner:SUZHOU UNIV

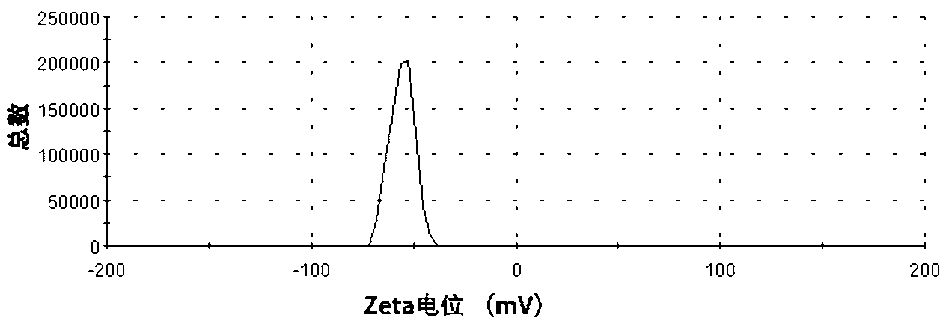

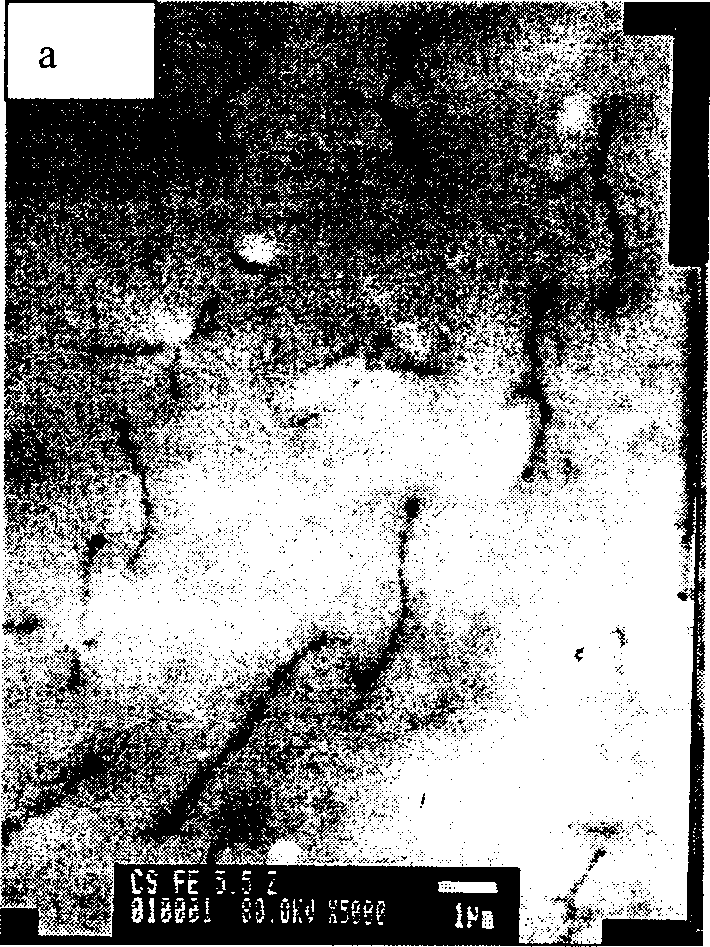

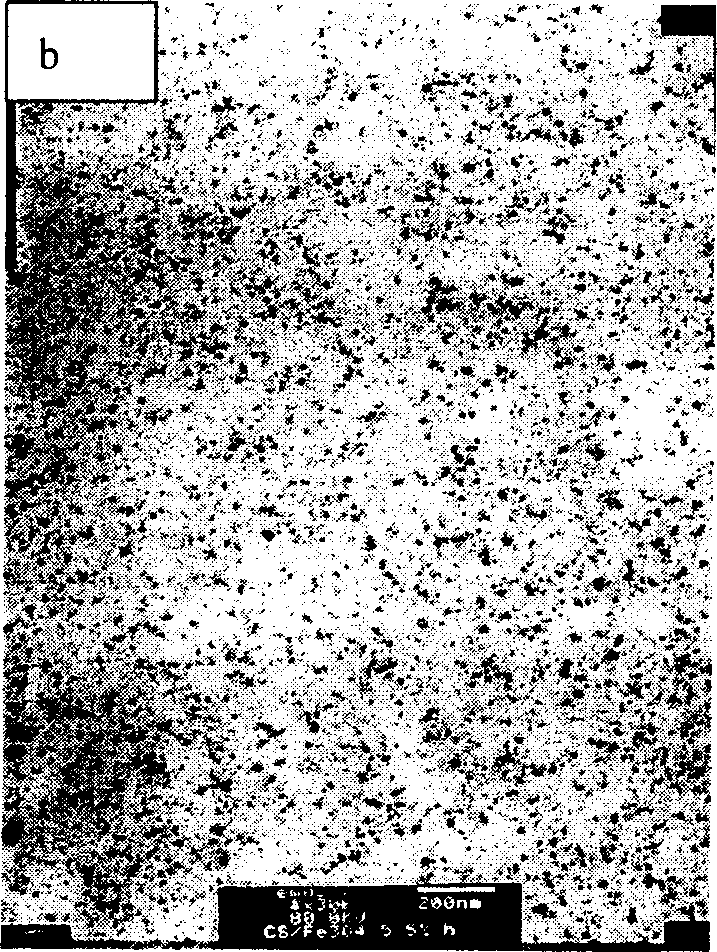

Method for preparing ordered ferriferrous oxide/chitosan nanometre composite material

The invention discloses a method for preparing ordered ferriferrous oxide / chitosan nanometre composite material comprising the following steps, making chitosan solution from chitosan powder with thin acid solution, charging FeCl2 and FeCl3 solution into the chitosan solution, forming ferriferrous oxide / chitosan precursor solution, loading the precursor solution into a mould with a layer of pure chitosan film internally, placing into freeze liquid, removing the mould and applying magnetic field onto the two ends of the gel composite material for material forming, flushing to neutral with distilled water and drying.

Owner:ZHEJIANG UNIV

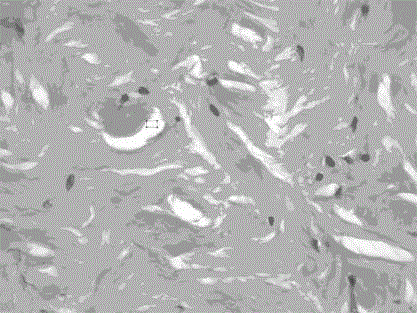

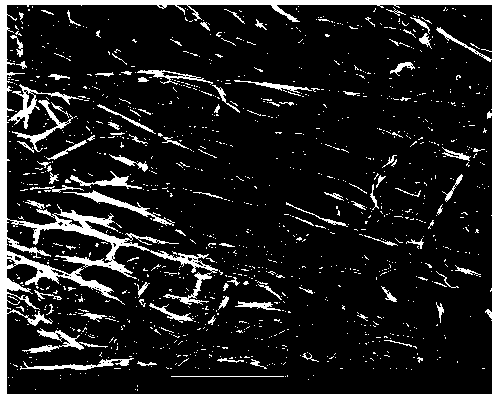

Preparing method of heterogeneous acellular dermal matrix substrate with good biocompatibility

ActiveCN105079880AProtect physical propertiesGuaranteed biocompatibilityProsthesisVirus inactivationBiocompatibility

The invention relates to a preparing method of a heterogeneous acellular dermal matrix substrate with good biocompatibility. The method concretely comprises the following steps of (1) split thickness skin graft preparation; (2) epidermis and dermis separation; (3) acellular processing; (4) cross linking; (5) virus inactivation; (6) refining; (7) Co-60 irradiation sterilization. The ecellular tissue engineering materials obtained by the method provided by the invention has the advantages that the toxicity is stable, and the cell compatibility is better.

Owner:HEBEI AINENG BIOTECH CO LTD

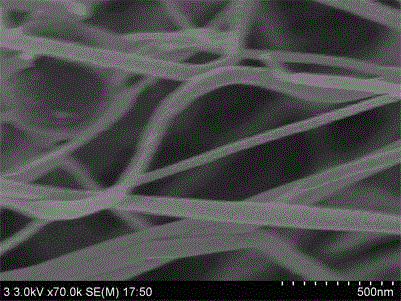

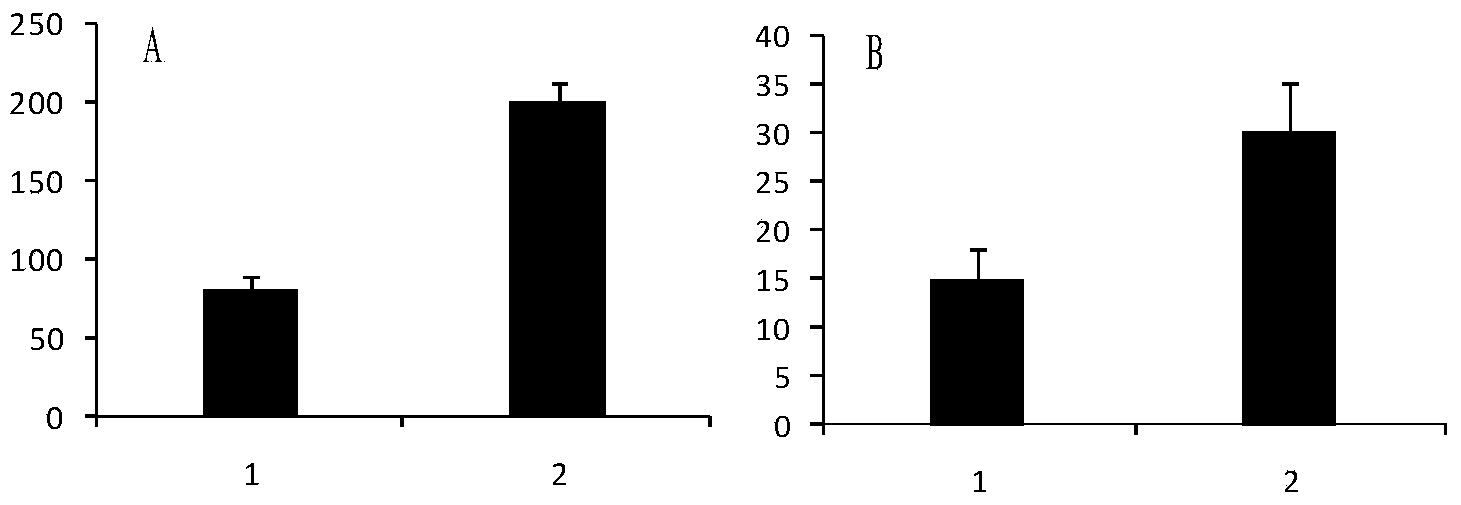

Ligament support and preparation method thereof

InactiveCN104043148AEliminate biocompatibilityAdjustable widthNon-woven fabricsProsthesisFiberNanofiber

The invention relates to a ligament support containing silk fibroin compound oriented nanofiber and a preparation method thereof, and belongs to the technical field of medical apparatus and instruments. The ligament support is prepared from oriented fiber combining silk fibroin with a medical high molecular synthetic material and has a porous three dimensional structure, the mass ratio of the silk fibroin and medical high molecular synthetic material in the compound oriented fiber is (1-20):(1-1), the diameter of the compound oriented fiber is 500nm-10000nm, the thickness of the ligament is 1mm-10mm, and the width of the ligament is 1mm-15mm. The ligament support has a uniform microstructure and good biocompatibility, provides a matrix structure for growing of ligament cells, and can be used for increasing the tensile strength of the ligament due to the compound fiber orientated structure. The ligament support is simple in preparation method and convenient to operate, the preparation process is controllable, and the preparation method is suitable for preparing the ligament supports of various sections and lengths.

Owner:WUHAN TEXTILE UNIV

Method for preparing anticoagulant composite coating

InactiveCN107456611AExcellent anticoagulant propertiesIncreased anticoagulationSurgeryPharmaceutical delivery mechanismBiocompatibility TestingPre treatment

The invention discloses a method for preparing an anticoagulant composite coating. The method for preparing the anticoagulant composite coating comprises the steps of first using a coupling agent to process the surface of a pre-processed biomedical base material to obtain a hydrophilic surface, using a specific anticoagulant composite coating to modify the biomedical base material, and obtaining a biomedical material having good anticoagulation property after drying. Studies have shown that the biomedical material modified by the anticoagulant composite coating is greatly improved in hydrophilicity and shows excellent biocompatibility. The modified material can not only maintain its original physical and mechanical properties, but also greatly extend activated partial thromboplastin time (APTT) in the coagulation test to show excellent anticoagulant properties.

Owner:BEIJING UNIV OF CHEM TECH

Tendon reinforcing repairing material and preparation method thereof

ActiveCN103480041AEasy to wrapGood biocompatibilityProsthesisCell-Extracellular MatrixBiocompatibility Testing

The invention relates to a tendon reinforcing repairing material and a preparation method of the tendon reinforcing repairing material. The repairing material takes animal original dermis as the raw material and is prepared by steps of pretreatment, preparation of a holder layer, preparation of a mechanical reinforcing layer, and preparation of a tendon reinforcing repairing material. The tendon reinforcing material comprises the holder layer and the mechanical reinforcing layer, wherein the holder layer reserves the integrity of the structure and component of an extracellular matrix to the greatest degree, and due to the introduction of the mechanical reinforcing layer, the acellular dermal matrix has better mechanical property compared with the acellular dermal matrix prepared by the traditional technology, for the biocompatibility, mechanical strength and biological activity are improved and balanced. According to the requirements of different indications on materials, the preparation method can prepare membrane materials and curl materials in different thicknesses. The tendon reinforcing repairing material is widely applicable to repairing of acute and old tendon injury.

Owner:SHAANXI RUISHENG BIOTECH

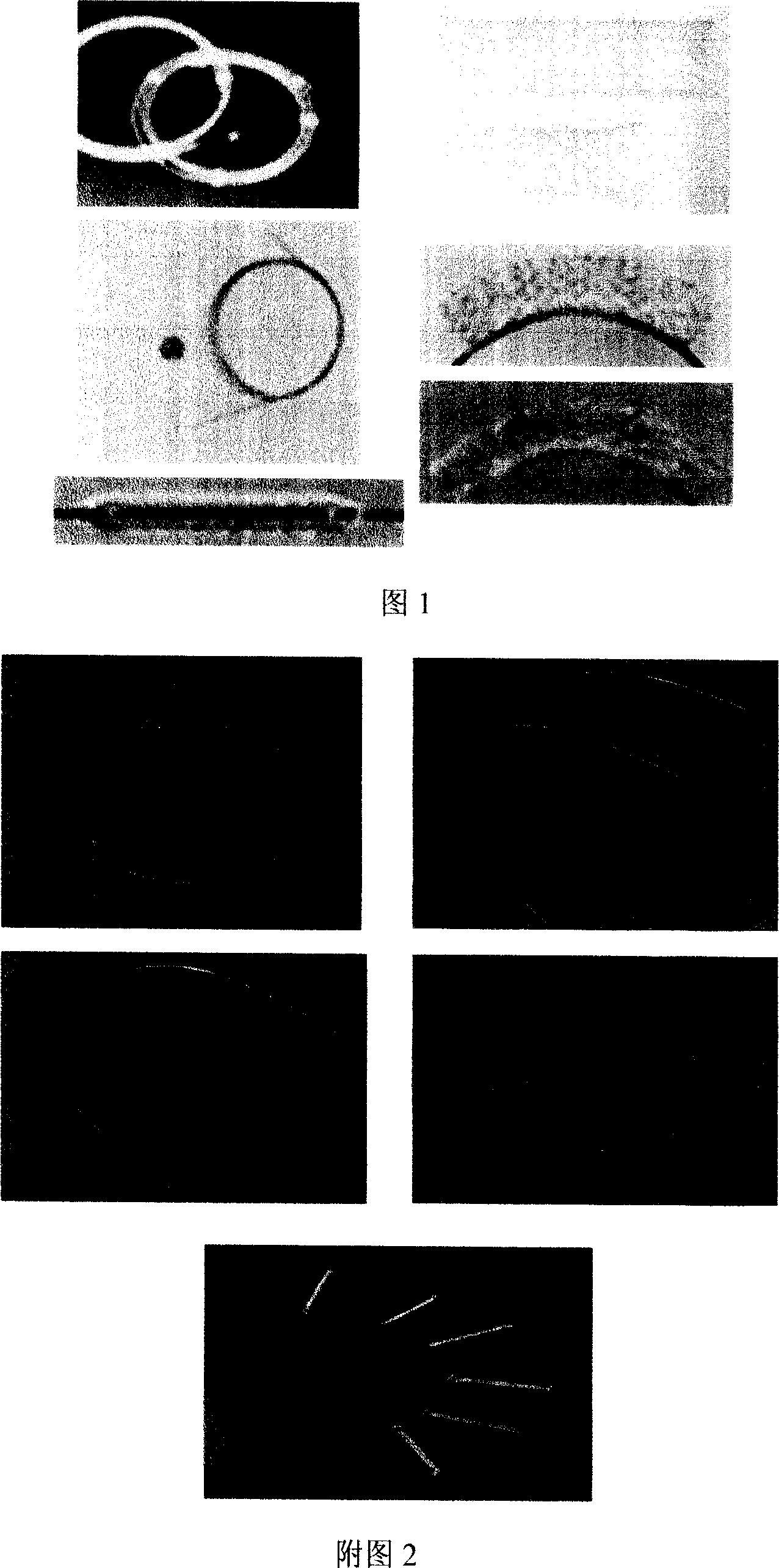

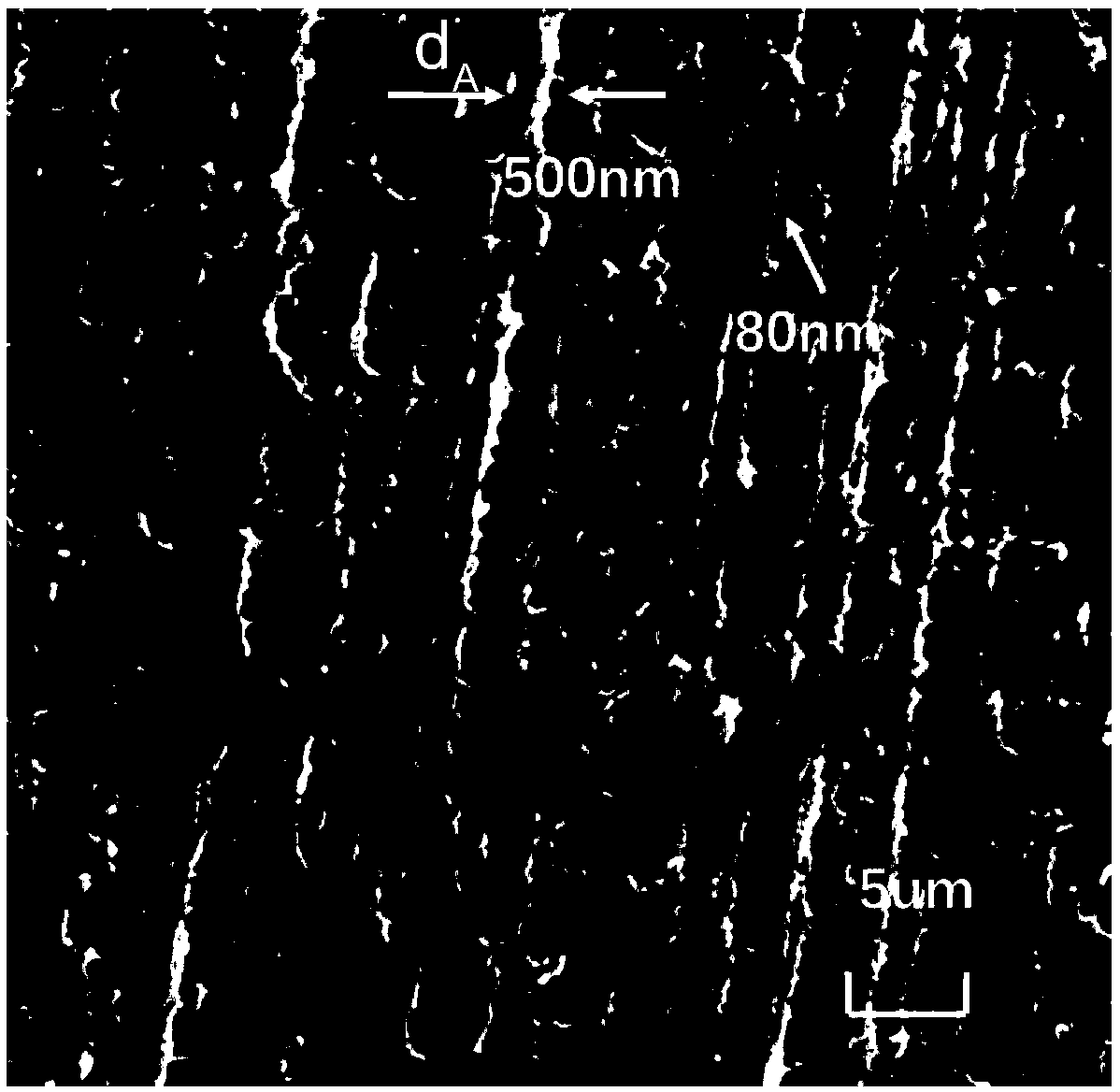

NiTi shape memory alloy bionic nano TiO2 tectorial membrane biology medical embedded material and application

InactiveCN101100738AMake sure not to be importedPrevent splashSurgeryVacuum evaporation coatingTectorial membraneShape-memory alloy

Bio-medical implanting material with biomimetic nano film and its use are both disclosed herewith. The implanting material uses NiTi shape-memory alloy as base with biomimetic nano TiO2 bio-ceramic film of 100-200nm to stop Ni ions liberated in human body liquid. It can be used as implanting device, e.g. tubular support, bone fixer, bone orthotic device, and oral orthodontic material, etc.

Owner:沈阳天贺新材料开发有限公司

Method for perstraction of fermented microbial intracellular product with non-ionic surfactant

ActiveCN102443605AChange in permeabilityDisinhibitionMicroorganism based processesEnzymesMicrobial enzymesSecondary metabolite

The invention discloses a method for perstraction of a fermented microbial intracellular product with a non-ionic surfactant. Specifically, during fermentation of a microbial intracellular product, a non-ionic surfactant micellar solution formed by addition of the non-ionic surfactant concentration or a cloud point system formed thereby is adopted as a microbial fermentation medium, by which the intracellular product can be penetrated to an extracellular environment so as to improve the product level of microbial fermentation. Simultaneously, perstraction and fermentation of the microbial intracellular product can be realized. The method of the invention is especially suitable for the fermentation process of an intracellular product, such as production of intracellular microbial enzymes, production of intracellular organic small molecule substances as well as production of intracellular oil compounds, etc. The method provided in the invention effectively eliminates intracellular product inhibition, enhances the concentration of a microbial fermentation product, and adjusts the composition of a microbial fermentation secondary metabolite, thus improving the volume yield of microbial fermentation as well as the efficiency of intracellular product fermentation, product release and other processes.

Owner:JECHO BIOPHARM CO LTD

Degradable biological composite material of phosphate containing calcium and preparation method thereof

InactiveCN101417149AGuaranteed biocompatibilityEasy to controlProsthesisCalcium EDTACalcium biphosphate

The invention provides a degradable bioactivity composite containing calcium phosphate and a preparation method thereof. The composite consists of calcium phosphate and a multiple amino acid polymer; wherein, the weight percentage of inorganic composition is not more than 50 percent and the residual substance is the multiple amino acid polymer which is formed by the polymerization of caprolactam and at least 5 other amino acids; wherein, the molar ratio of the caprolactam in the polymer is 40-90 percent and the respective molar ratio of other single amino acid is not less than 0.5 percent. During preparation, the caprolactam is mixed with all amino acids and dehydration is carried out under the protection of inert gases and stirring, and pre-polymerization composition reaction and polymerization reaction are respectively carried out at the temperature of 210-250DEG C, thus obtaining the composite. The indexes of the prepared material such as mechanic performance, degradation period and the like can be adjusted and controlled according to the use requirements.

Owner:SICHUAN UNIV

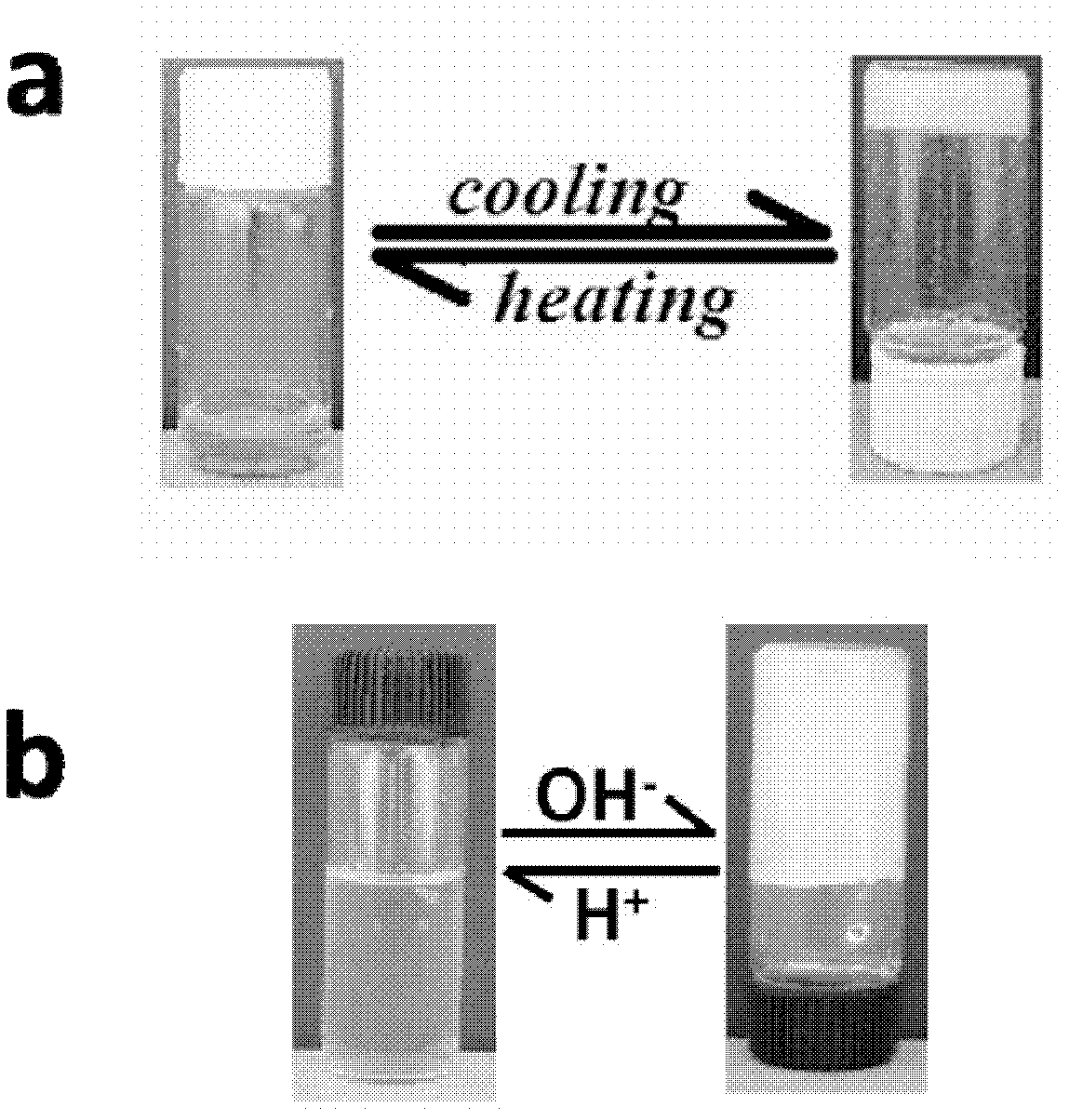

Nanogel scaffold material for culturing and desorbing type of cells and preparation method thereof

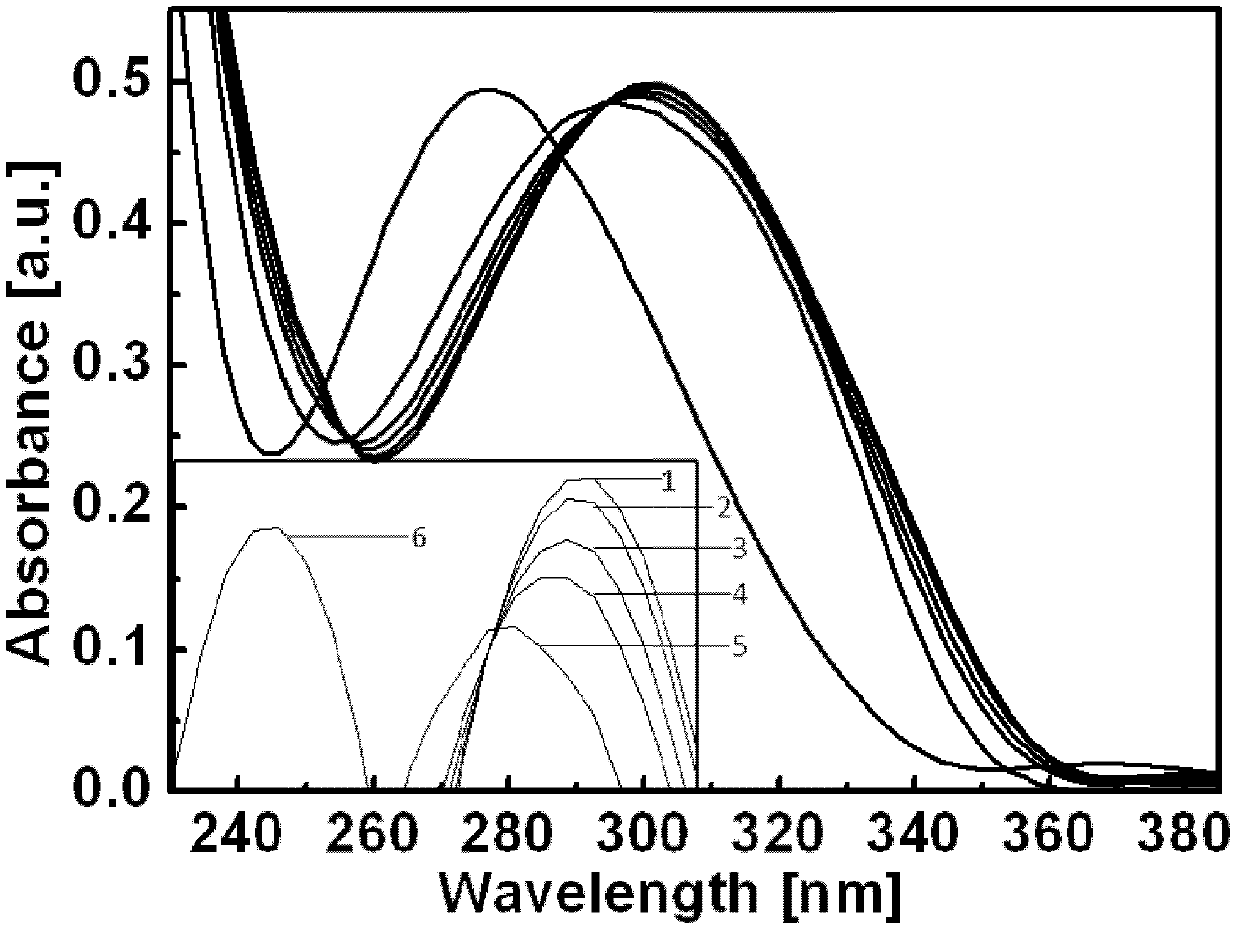

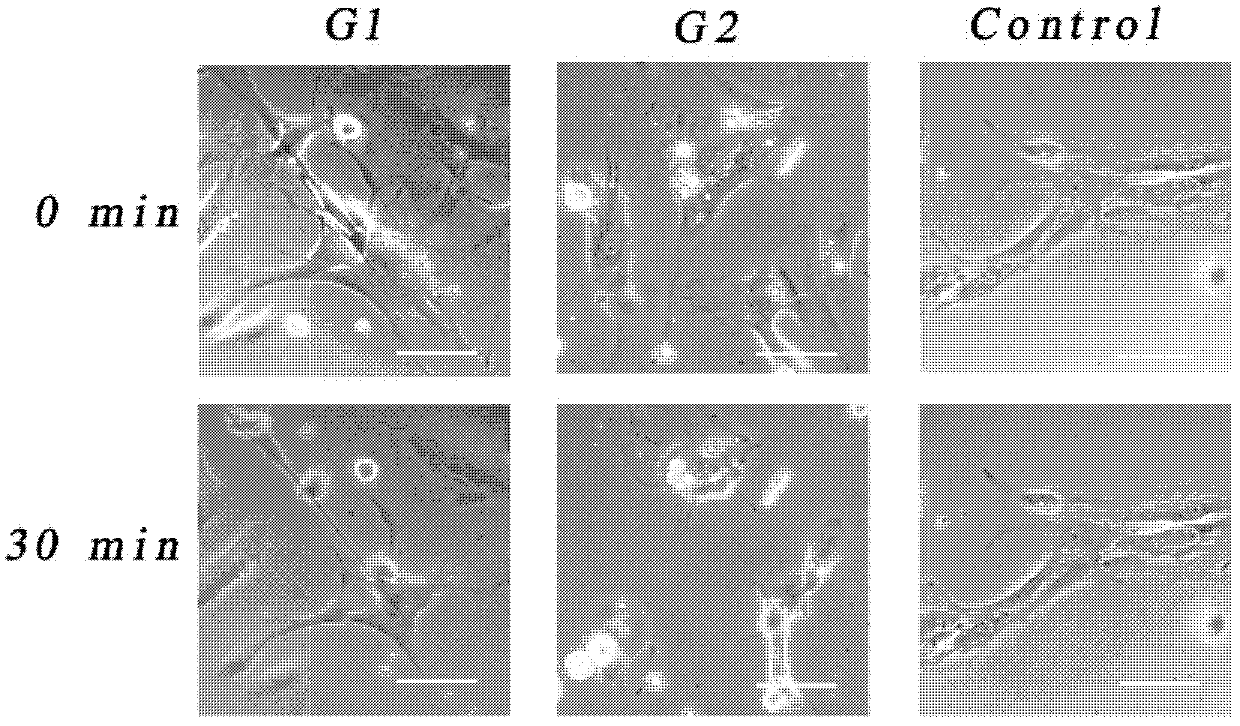

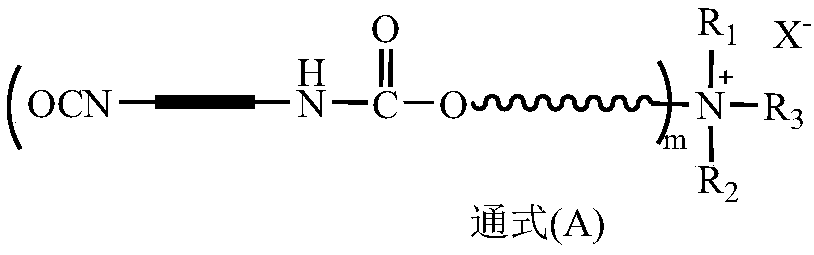

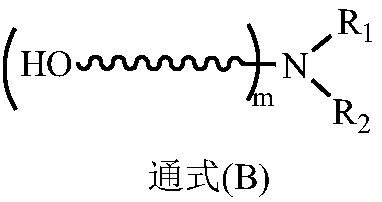

ActiveCN102533549AInduced desorptionPrevent functional impairmentPeptidesTissue/virus culture apparatusDesorptionStructural formula

The invention discloses a nanogel scaffold material for culturing and desorbing cells and a preparation method thereof. The nanogel scaffold material is formed by selfassembling low-molecular weight gel factors G1 and G2. The structural formula of the low-molecular weight gel factors is disclosed in the specification, wherein R is disclosed in the specification; when R<*> is disclosed in the specification, the low-molecular weight gel factor is G1, and when R<*> is disclosed in the specification, the low-molecular weight gel factor is G2. The preparation method of the material comprises the following steps: preparing the low-molecular weight gel factors G1 and G2; and regulating the temperature or pH value of the solvent of the low-molecular weight gel factors G1 and G2 to form the nanogel scaffold material for culturing and desorbing cells by selfassembling. The method overcomes the defect of damage to cell functions in the existing enzymolysis method and wide-range temperature change induced cell desorption, and is beneficial to adhesion, spreading and proliferation of cells on the biological material surface.

Owner:海安百优基质生物工程有限公司

Polyurethane foam modifying method

ActiveCN109467736AImprove hydrophilicityEnhanced saturated water absorption capacity and water retention capacityPrepolymerChemistry

The invention belongs to the technical field of functional high polymer materials, and particularly relates to a polyurethane foam modifying method. The polyurethane foam modifying method comprises the following steps: first step, uniformly dipping a polyurethane foam which is cleaned thoroughly in a multifunctional polyurethane prepolymer solution, wherein the use amount of the multifunctional polyurethane prepolymer solution is 5-50 times the mass of the polyurethane foam; and second step, taking out the polyurethane foam which has been saturated and adsorbs the multifunctional polyurethaneprepolymer solution, after squeezing the polyurethane foam to be dry, placing the polyurethane foam in an oven, and drying the polyurethane foam for 2-72 hours at the temperature of 20-80 DEG C to obtain the multifunctional polyurethane prepolymer modified polyurethane foam. The hydrophilicity of the obtained polyurethane foam is greatly improved, and saturation water absorbing ability and water retention ability are enhanced obviously. The mechanical property, the biocompatibility and the stability of the polyurethane foam can still be maintained, and meanwhile, the polyurethane foam furtherhas an antibacterial property.

Owner:长治学院

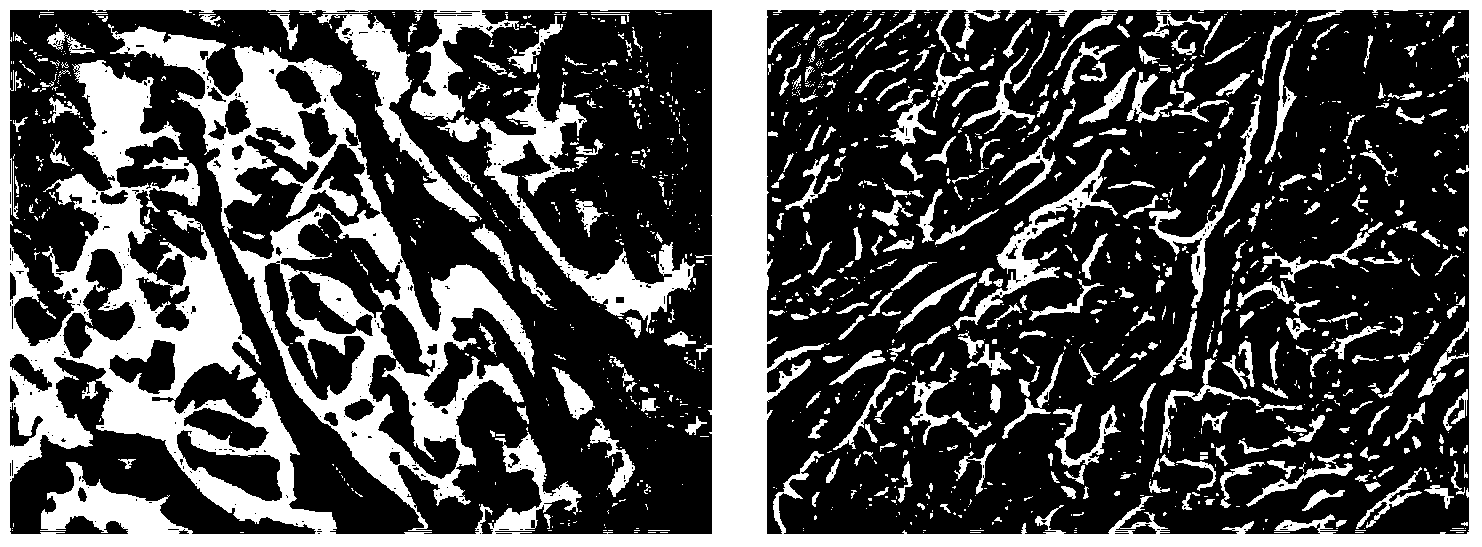

Method for preparing cornea lamina material

ActiveCN102552979AStrong ability to pass onReduce the risk of contaminationProsthesisBiocompatibility TestingStem cell culture

The invention discloses a method for preparing a cornea lamina material. The method comprises the following steps of: carrying out accellular processing on a cornea-sclera complex of a mammal eyeball, culturing an amnion epithelial stem cell, inducing and secreting TSP (Thrombospondin)-1 and co-culturing accellular cornea stroma and the amnion epithelial stem cell, sizing, packaging and sterilizing, and the like. According to an obtained cornea lamina transplanting material, the promotion and the balance among the biocompatibility, the stability, the transparency, the mechanical strength and the bioactivity are realized; the integrity of cornea collagen molecules and a lamina structure can be kept to the largest extent, and compared with that prepared with the traditional method, the accellular cornea stroma prepared according to the method disclosed by the invention is larger in tensile strength and has the moisture content and the transparency close to those of normal cornea; and various cell growth factors and the TSP-1 are gathered, and the cornea lamina material has special effects of inflammatory resistance and vascularization resistance, has the capability of greatly enhancing the bioactivity of the cornea lamina material and can be widely used for repairing complicated ocular surface coloboma such as inflammation and corneal ulcer grown in a vascularization way.

Owner:SHAANXI RUISHENG BIOTECH

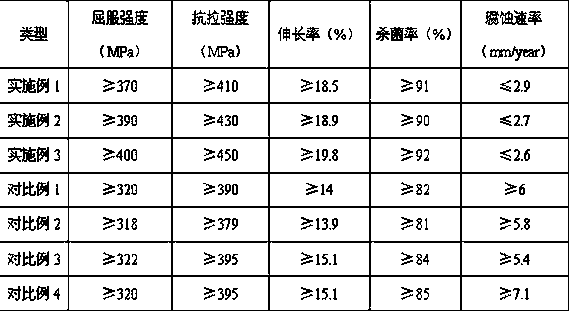

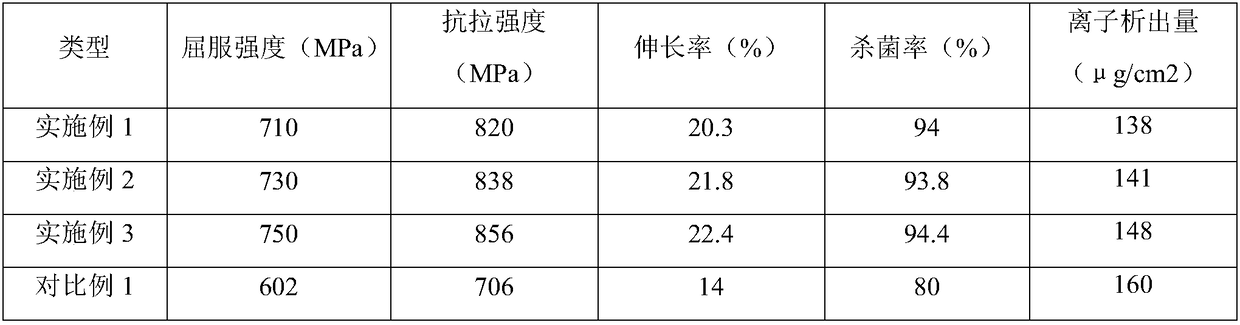

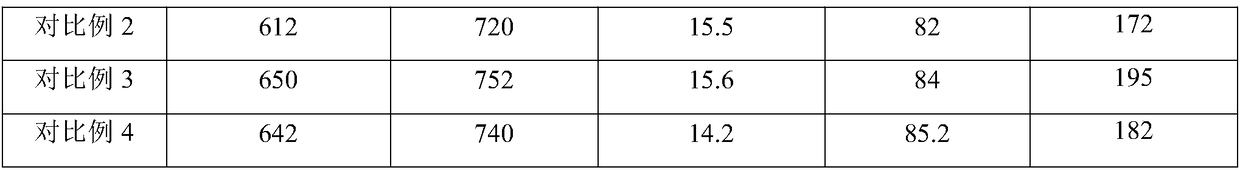

Mg alloy for being implanted in bone and preparation method of Mg alloy

InactiveCN108359868AImprove mechanical propertiesImprove corrosion resistanceSurgeryMetallic material coating processesImpurityMagnesium alloy

The invention provides a Mg alloy for being implanted in bone. The Mg alloy is characterized by comprising the following chemical components in percentage by weight: 1.5-3% of Zn, 0.6-1.1% of Mn, 0.3-0.8% of Ca, 0.3-0.45% of Si, 0.45-0.8% of Sr, 1-1.8% of Li, 2.5-3.5% of Cr, 1-2% of Cu, 1.3-1.4% of Mo, 0.01-0.08% of Sc, La and Ce, 0.1-0.8% of Nb, and the balance of Mg and inevitable impurity elements. According to the Mg alloy provided by the invention, the yield strength is higher than or equal to 370 MPa, the tensile strength is higher than or equal to 410 MPa, the elongation is higher thanor equal to 8.5%, and the sterilizing rate is higher than or equal to 90%. The above indices of the Mg alloy are obviously higher than those of other products which lack alloy elements and those of similar products which are not subjected to surface coating treatment.

Owner:温州市赢创新材料技术有限公司

High-strength shape-memory 3D (three dimensional) printing bioplastics and preparation method

InactiveCN106928671AImprove mechanical propertiesHigh tensile modulusAdditive manufacturing apparatusCross-linkBiocompatibility Testing

The invention discloses high-strength shape-memory 3D (three dimensional) printing bioplastics. The high-strength shape-memory 3D printing bioplastics are prepared by compounding PLLA (Poly-L-lactic acid), PCL and CaCO3, wherein the PLLA accounts for 25 to 80 percent of the total mass of the material. The PCL accounts for 17 to 72 percent of the total mass of the material, the CaCO3 accounts for 3 percent of the total mass of the material, the high-strength shape-memory 3D printing bioplastics are prepared by virtue of fused deposition molding; the PLLA and the PCL are blended, so that the mechanical strength of the PCL is improved, good biocompatibility is ensured; by virtue of machining or radiation cross-linking treatment, the PLLA has the shape memory characteristics; after the PLLA is blended and extruded with the PCL, the shape memory property of the material can also be maintained; by adding little CaCO3, not only can a capacity increasing effect be achieved and the performance degradation caused by the mixing be avoided, the mechanical strength of the material can be further improved; and moreover, the invention also discloses a preparation method of the high-strength shape-memory 3D printing bioplastics. The method is easy in operation, low in technological conditions and low in requirement on production equipment, capable of being widely popularized, and wide in application prospect.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

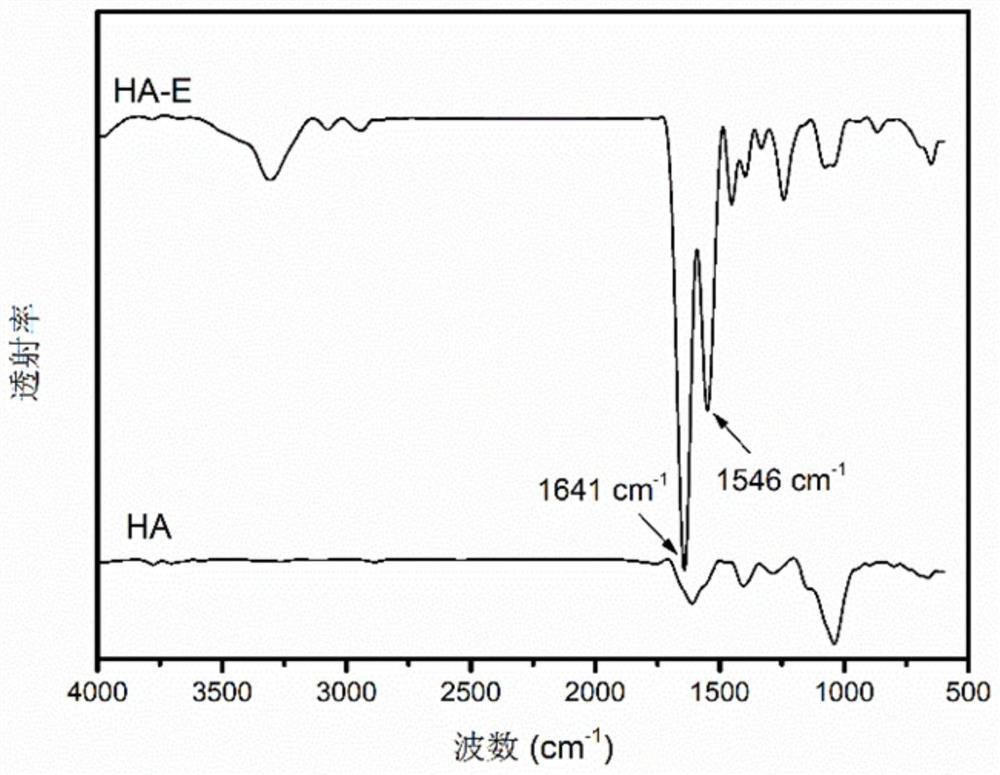

Antibacterial composite hydrogel as well as preparation method and application thereof

ActiveCN112778772AGuaranteed biocompatibilityGood biocompatibilityCapsule deliveryBandagesPhotoinitiatorComposite hydrogels

The invention discloses a preparation method of antibacterial composite hydrogel, which comprises the following steps of: dissolving a water-soluble gel base material in deionized water to obtain a base material solution; dissolving modified hyaluronic acid in the base material solution to obtain a mixed solution; and uniformly dispersing silver nanoparticles in the mixed solution, and performing curing under ultraviolet irradiation by virtue of a photoinitiator, so as to obtain the antibacterial composite hydrogel. The composite hydrogel disclosed by the invention has good biocompatibility, antibacterial property, biodegradability and mechanical property, and can be used for wound dressing.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

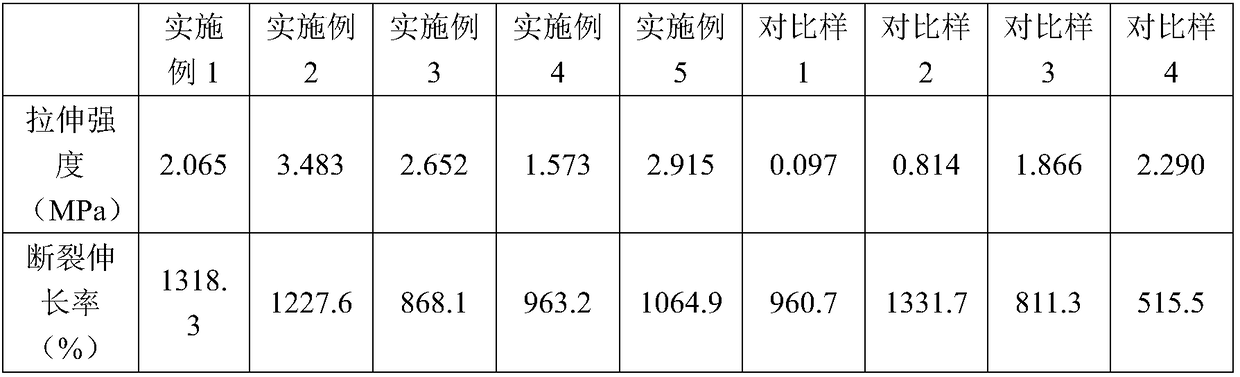

Transparent polylactic acid film as well as preparation method and application thereof

The invention belongs to the technical fields of high polymer materials and biomedical materials, and particularly relates to a transparent polylactic acid film as well as a preparation method and anapplication thereof. The invention provides a preparation method for a transparent polylactic acid film. The preparation method for the transparent polylactic acid film comprises the following steps:melting polylactic acid in an extruder to obtain a melt and extruding the melt by the extruder, cooling through an air knife, then stretching through a casting roll, dragging by a dragging roll, and carrying out film formation by winding to obtain the transparent polylactic acid film, wherein the temperature of an extrusion port film of the extruder is 150-210 DEG C; the ratio of the speed of themelt at the extrusion port film to the linear speed of the casting roll is 1: (30 to 160); the air knife is arranged between the extrusion port film and the casting roll; and the included angle formedby the air port direction of the air knife and the surface of the melt is 45-90 degrees. The preparation method is capable of preparing the transparent polylactic acid film in the case of not addingany fillers and additives; and the transparent polylactic acid film comprises orientated fibrous crystals and / or is an orientated structure as a whole, has a crystallinity degree of less than 8%, andalso has high elongation at break and tensile strength.

Owner:GUANGDONG UNIV OF TECH

Cobalt base alloy for fixing human skeletons and preparation method thereof

The invention discloses a cobalt base alloy for fixing human skeletons. The cobalt base alloy is characterized by comprising the following chemical components in percentage by weight: 22.5-24.5% of Cr, 7-8% of Ni, 11-12% of W, 3-4% of Mo, 0.5-1.5% of Ta, 0.1-0.8% of Si, 0.1-0.5% of Mn, 0.1-0.5% of Nb, 1.0-2.0% of Cu, 0.1-0.2% of N, 0.01-0.08% of Sc+La+Ce, and the balance of Co and inevitable impurity elements. The yield strength of the cobalt base alloy is not less than 710 MPa, the tensile strength is not less than 820 MPa, the elongation is not less than 20%, and the sterilization rate is not less than 93.8%; and all the indexes are obviously higher than that of other products short of alloy elements, products not performing atomized pulverization and similar products not performing surface coating treatment.

Owner:王甲林

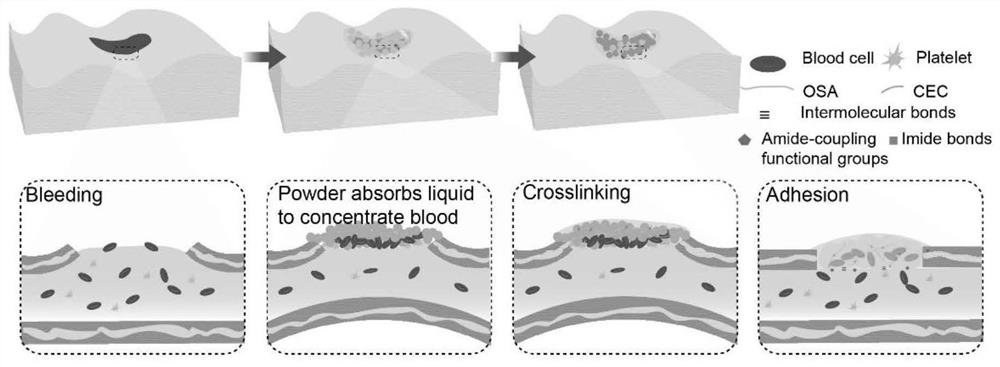

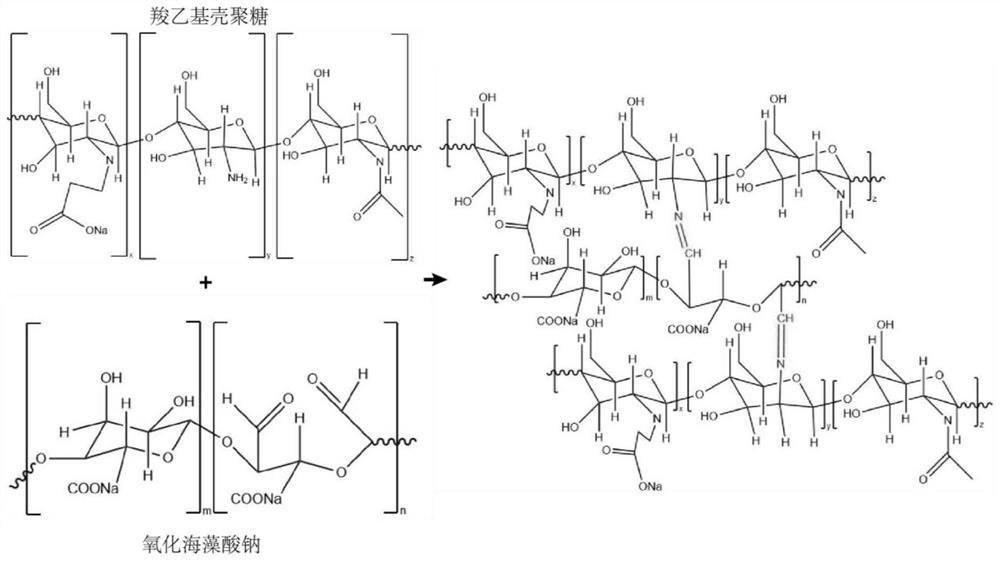

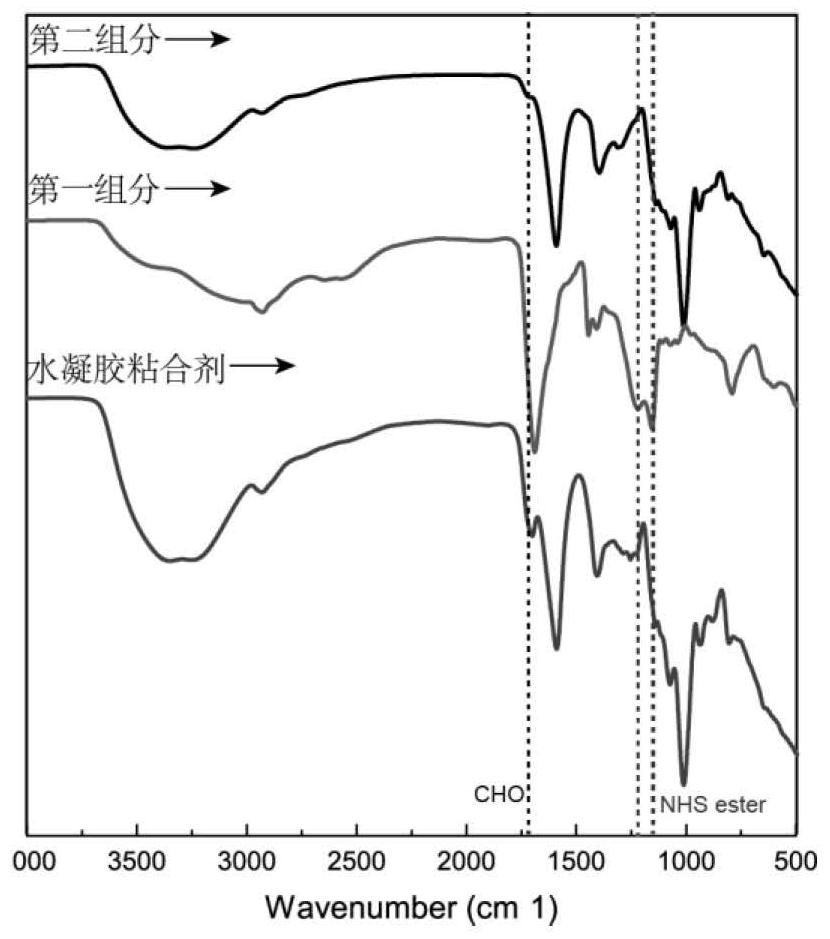

Injectable hydrogel adhesive capable of rapidly stopping bleeding as well as preparation method and application of injectable hydrogel adhesive

ActiveCN114712550ARapid hemostasisGuaranteed biocompatibilitySurgical adhesivesInorganic non-active ingredientsAdhesiveMaterials science

The invention belongs to the technical field of medical polymer materials, and discloses an injectable hydrogel adhesive capable of rapidly stopping bleeding as well as a preparation method and application of the injectable hydrogel adhesive capable of rapidly stopping bleeding. A precursor of the injectable hydrogel adhesive capable of rapidly stopping bleeding comprises a first component and a second component, and the first component simultaneously comprises a chitosan component and a polyacrylic acid hydrogel component; the second component simultaneously comprises non-aldehyde polysaccharide, dialdehyde polysaccharide and a cationic salt solution; after the first component and the second component are mixed, hydrogel can be formed through in-situ crosslinking by means of Schiff base reaction, and the hydrogel can be used as a hydrogel adhesive for rapid hemostasis. The hydrogel adhesive based on two components is obtained by improving the composition of the hydrogel adhesive and the precursor of the hydrogel adhesive, has the characteristics of being injectable and rapid in gelling, has no requirements on the position and form of a wound surface in the use process, and can effectively overcome the difficulty of the existing hemostatic material in hemostasis of irregularly-shaped and non-compressible wounds.

Owner:HUAZHONG UNIV OF SCI & TECH

Degradable biological composite material of phosphate containing calcium and preparation method thereof

InactiveCN101417149BImprove performanceGuaranteed biocompatibilityProsthesisCalcium biphosphatePhosphate

The invention provides a degradable bioactivity composite containing calcium phosphate and a preparation method thereof. The composite consists of calcium phosphate and a multiple amino acid polymer; wherein, the weight percentage of inorganic composition is not more than 50 percent and the residual substance is the multiple amino acid polymer which is formed by the polymerization of caprolactam and at least 5 other amino acids; wherein, the molar ratio of the caprolactam in the polymer is 40-90 percent and the respective molar ratio of other single amino acid is not less than 0.5 percent. During preparation, the caprolactam is mixed with all amino acids and dehydration is carried out under the protection of inert gases and stirring, and pre-polymerization composition reaction and polymerization reaction are respectively carried out at the temperature of 210-250DEG C, thus obtaining the composite. The indexes of the prepared material such as mechanic performance, degradation period and the like can be adjusted and controlled according to the use requirements.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com