Polyurethane foam modifying method

A polyurethane foam and polyurethane prepolymer technology, which is applied in the field of polyurethane foam modification, can solve the problems of unpopularity in the market, high cost and price of polyol polyol, etc., and achieve simple technical methods, improved hydrophilicity, saturated The effect of water absorption capacity and water retention capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

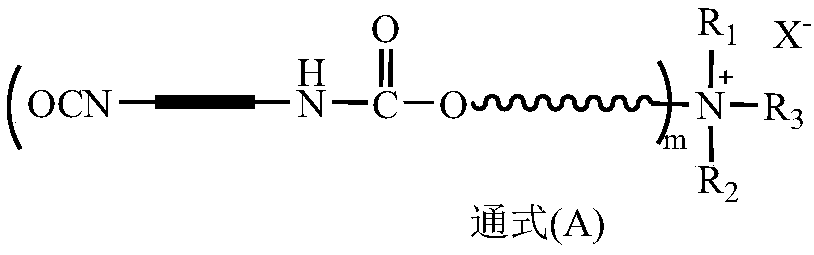

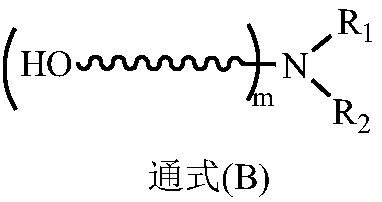

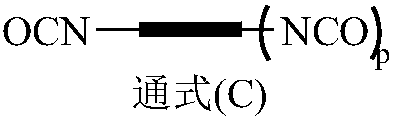

[0034] Weigh 65 grams of formula (c 1 ) N,N-dimethylaminopolyethylene glycol-600 with the structure shown in ) was dissolved in 40 grams of N,N-dimethylformamide to prepare N,N-dimethylaminopolyethylene glycol -600 N,N-dimethylformamide solution; Weigh 20 grams of 4-methoxybenzyl chloride and dissolve in 20 grams of ethyl acetate to obtain an ethyl acetate solution of 4-methoxybenzyl chloride 30 grams of toluene diisocyanate and 0.01 gram of dibutyltin dilaurate are weighed and dissolved in 26 grams of 1,4-dioxane to obtain a dioxane solution of toluene diisocyanate; the ethyl acetate solution Add to the N,N-dimethylformamide solution, control the reaction temperature at 20-25°C, stir and react for 2 hours, then add the dioxane solution into the reaction system, continue to stir and react for 2 hours, and prepare Deformation (a 1 ) solution of multifunctional polyurethane prepolymer;

[0035]

[0036] formula (a 1 ) The mass percentage content of isocyanate groups in th...

Embodiment 2

[0039] According to the method and operation steps of embodiment 1, the formula (b in embodiment 1 1 ) of the N,N-dimethylaminopolyethylene glycol-600 structure shown in the formula (b 2 ) structure shown in N,N-dimethylaminopolyethylene glycol-2000, 4-methoxybenzyl chloride is replaced by 5-chloromethyl salicylaldehyde, the formula (a 2 ) multifunctional polyurethane prepolymer. Adopt the method determination formula of embodiment 1 (a 2 ) The mass percentage of isocyanate group in the solution of multifunctional polyurethane prepolymer is 3.32%

[0040]

[0041] Adopt embodiment 1 method, use formula (a 2 ) The relative density of the multifunctional polyurethane prepolymer solution is 85Kg / m 3 Open Cell Polyurethane Soft Foam 2cm 3 Cube, the modified polyurethane foam has a saturated water absorption rate of 13.3 times its own mass and a water retention rate of 2.2 times its own mass.

Embodiment 3

[0043] According to the method and operation steps of embodiment 1, the formula (b in embodiment 1 1 ) of the N,N-dimethylaminopolyethylene glycol-600 structure shown in the formula (b 2 ) of N,N-dimethylaminopolyethylene glycol-2000, 4-methoxybenzyl chloride is replaced by 5-chloromethyl salicylaldehyde, toluene diisocyanate is replaced by diphenylmethane di Isocyanate, obtain formula (a 3 ) Multifunctional polyurethane prepolymer. Adopt the method determination formula of embodiment 1 (a 2 ) The mass percentage of isocyanate groups in the solution of the multifunctional polyurethane prepolymer is 3.18%.

[0044]

[0045] Adopt embodiment 1 method, use formula (a 3 ) The relative density of the multifunctional polyurethane prepolymer solution is 32Kg / m 3 Open Cell Polyurethane Soft Foam 2cm 3 Cube, the modified polyurethane foam has a saturated water absorption rate of 8.6 times its own mass and a water retention rate of 1.3 times its own mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com