Preparation method of 3D printable iron ion double-crosslinked alginate-polyacrylamide acrylic acid high-performance hydrogel

A technology of polyacrylamide acrylic acid and alginate, applied in the direction of additive processing, can solve problems such as affecting the biocompatibility of stents, and achieve the effects of excellent self-healing performance, short preparation period and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

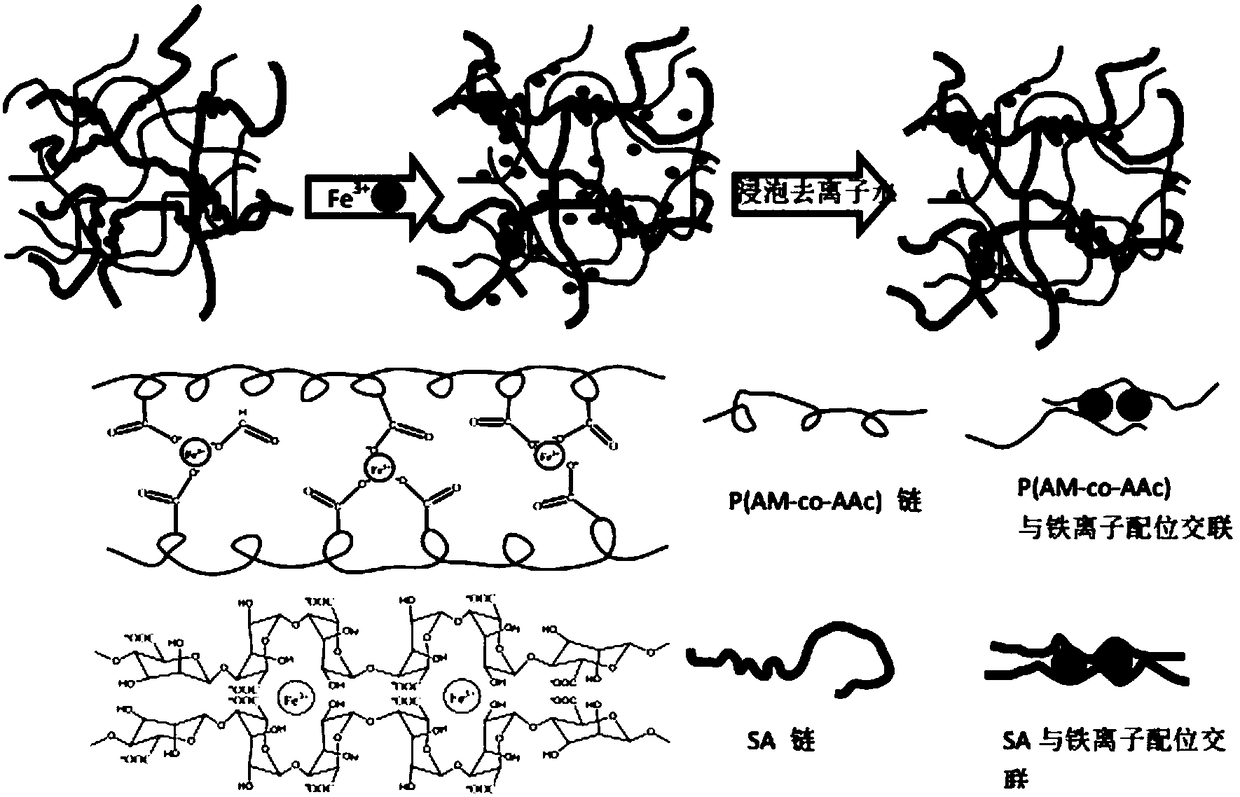

Method used

Image

Examples

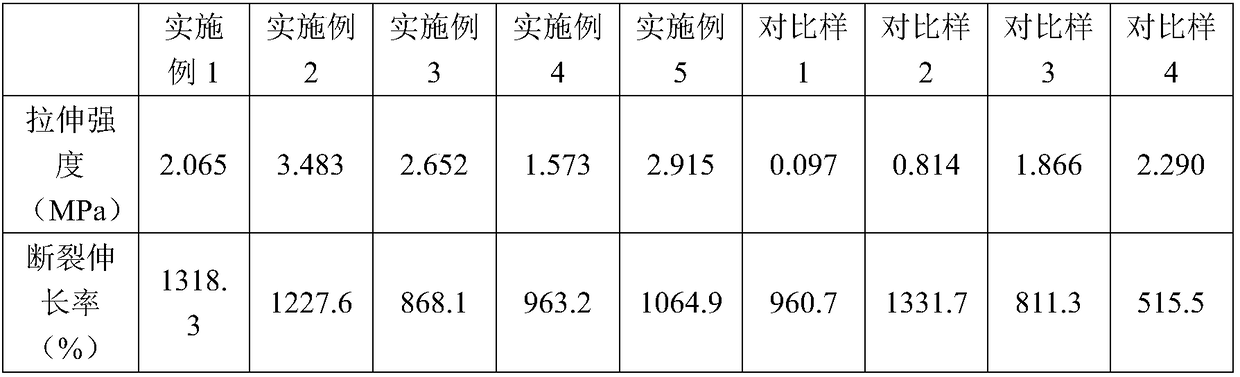

Embodiment 1

[0036] Step 1): Weigh 0.4642g of sodium alginate (SA) into 15mL of deionized water, stir at 65°C and 500RPM for 20min at high speed to dissolve to obtain a uniform SA solution.

[0037] Step 2): Weigh 9.9512g AM, 0.5045g AAc, and 0.0215g KA into 5mL deionized water, stir and dissolve at 30°C to obtain a uniform transparent aqueous solution. This solution was added to the solution in step 1), and stirred at 50°C and 500RPM for 10min in a light-proof environment, and the molar concentration of SA was 0.1172mol / L, the molar concentration of AM was 7mol / L, and the molar concentration of AAc was 0.35mol / L, KA molar concentration of 0.00735mol / L mixed solution.

[0038] Step 3): inject the mixed solution obtained in step 2) into a glass mold under the condition of shading, and place the glass mold under ultraviolet light for 5-7 hours to obtain preliminary SA / P(AM-co-AAc) hydration glue.

[0039] Step 4): Soak the preliminary hydrogel obtained in step 3) in 0.06mol / LFe 3+ In the ...

Embodiment 2

[0042] Step 1): Weigh 0.6220g of sodium alginate (SA) into 15mL of deionized water, stir at 65°C and 500RPM for 20min at high speed to dissolve to obtain a uniform SA solution.

[0043] Step 2): Weigh 9.9512g AM, 0.5045g AAc, and 0.0215g KA into 5mL deionized water, stir and dissolve at 30°C to obtain a uniform transparent aqueous solution. This solution was added to the solution in step 1), and stirred at 50°C and 500RPM for 10min in a light-proof environment, and the molar concentration of SA was 0.157mol / L, the molar concentration of AM was 7mol / L, and the molar concentration of AAc was 0.35mol / L, KA molar concentration of 0.00735mol / L mixed solution.

[0044] Step 3): inject the mixed solution obtained in step 2) into a glass mold under the condition of shading, and place the glass mold under ultraviolet light for 5-7 hours to obtain preliminary SA / P(AM-co-AAc) hydration glue.

[0045] Step 4): Soak the preliminary hydrogel obtained in step 3) in 0.06mol / LFe 3+ In the s...

Embodiment 3

[0048] Step 1): Weigh 0.9426g of sodium alginate (SA) into 15mL of deionized water, stir at 65°C and 500RPM for 20min at high speed to dissolve to obtain a uniform SA solution.

[0049] Step 2): Weigh 9.9512g AM, 0.5045g AAc, and 0.0074g KA into 5mL deionized water, stir and dissolve at 30°C to obtain a uniform transparent aqueous solution. This solution was added to the solution in step 1), and stirred at 50°C and 500RPM for 10min in a light-proof environment, and the molar concentration of SA was 0.2381mol / L, the molar concentration of AM was 7mol / L, and the molar concentration of AAc was 0.35mol / L, KA molar concentration of 0.00735mol / L mixed solution.

[0050] Step 3): inject the mixed solution obtained in step 2) into a glass mold under the condition of shading, and place the glass mold under ultraviolet light for 5-7 hours to obtain preliminary SA / P(AM-co-AAc) hydration glue.

[0051] Step 4): Soak the preliminary hydrogel obtained in step 3) in 0.06mol / LFe 3+ In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com