Modified sodium hyaluronate gel for injection

A technology of sodium hyaluronate and hyaluronic acid, used in medical science, prosthesis, surgery, etc., to enhance stability and cohesion, maintain biocompatibility, and achieve good filling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

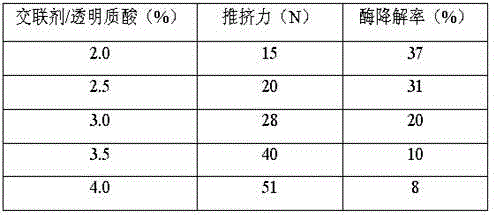

[0052] This embodiment investigates the influence of gel X with different crosslinking degrees on the properties of the gel of the invention. The preparation method is as follows:

[0053] (1) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>10), mix well, add cross-linking agent 1,4-butanediol diglycidyl ether, cross-linking agent and hyaluronic acid The acid quality ratio is shown in Table 1, stir and mix well, and react in a water bath at 35°C for 10 h to obtain gel X;

[0054] (2) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>9), mix well, add 1,4-butanediol diglycidyl ether, the mass ratio of crosslinking agent to hyaluronic acid is 0.06%, stir and mix well, and react in a water bath at 35°C for 8 hours to obtain gel Y;

[0055] (3) Mix gel X and gel Y at a ratio of 50% X-50% Y (50 g : 50 g), adjust the pH to 2~4, add 1,4-butanediol diglycidol Ether, the mass ratio of cross-linking agent to hyaluronic acid is 0.8%, react in a water bath ...

Embodiment 2

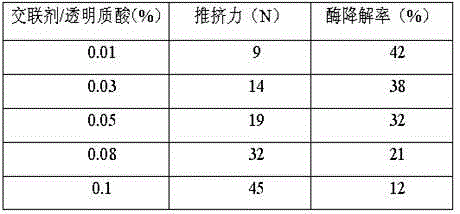

[0065] This embodiment investigates the influence of gel Y with different crosslinking degrees on the properties of the invented gel, and the preparation method is as follows:

[0066] (1) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>10), mix well, add cross-linking agent 1,4-butanediol diglycidyl ether, cross-linking agent and hyaluronic acid The acid mass ratio was 2.5%, stirred and mixed, and reacted in a water bath at 35°C for 10 h to obtain gel X;

[0067] (2) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>9), mix well, and then add 1,4-butanediol diglycidyl ether. 2, stir and mix well, and react in a water bath at 35°C for 8 h to obtain gel Y;

[0068] (3) Mix gel X and gel Y at a ratio of 50% X-50% Y (50 g : 50 g), adjust the pH to 2~4, add 1,4-butanediol diglycidol Ether, the mass ratio of cross-linking agent to hyaluronic acid is 0.8%, react in a water bath at 35°C for 6 h;

[0069] (4) Adjust the pH value of the gel to neutral w...

Embodiment 3

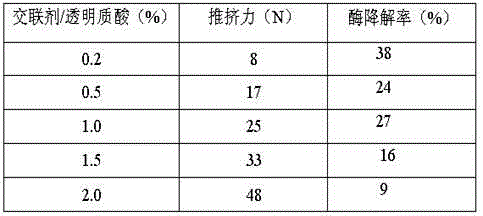

[0076] Compare the amount of crosslinker after mixing gel X and gel Y:

[0077] (1) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>10), mix well, add 1,4-butanediol diglycidyl ether, the mass ratio of crosslinking agent to hyaluronic acid is 2.5%, stirred and mixed, and reacted in a water bath at 35°C for 10 h to obtain gel X.

[0078] (2) Dissolve 5.0 g of hyaluronic acid in 50 ml of NaOH solution (pH>9), mix well, add 1,4-butanediol diglycidyl ether, the mass ratio of crosslinking agent to hyaluronic acid is 0.06% (w / w), stirred and mixed, and reacted in a water bath at 35°C for 8 h to obtain gel Y.

[0079] (3) Mix gel X and gel Y at a ratio of 50% X-50% Y (50 g : 50 g), adjust the pH value to 2~4, add different ratios of 1 as shown in Table 3, 4-Butanediol diglycidyl ether was reacted in a water bath at 35°C for 6 h.

[0080] (4) Adjust the pH value of gel X to neutral with 0.5% NaOH solution, and then dialyze the gel in phosphate buffer with neutral pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com