Patents

Literature

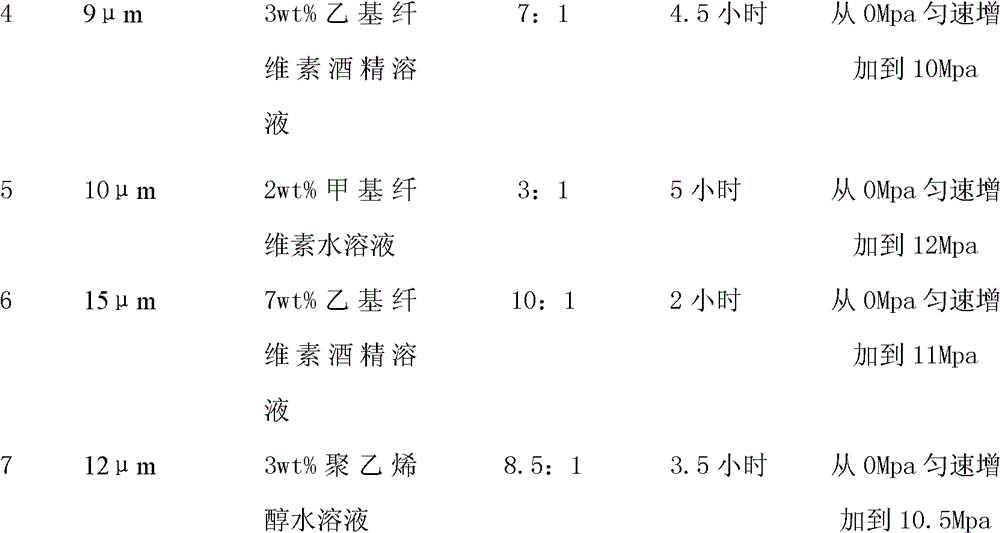

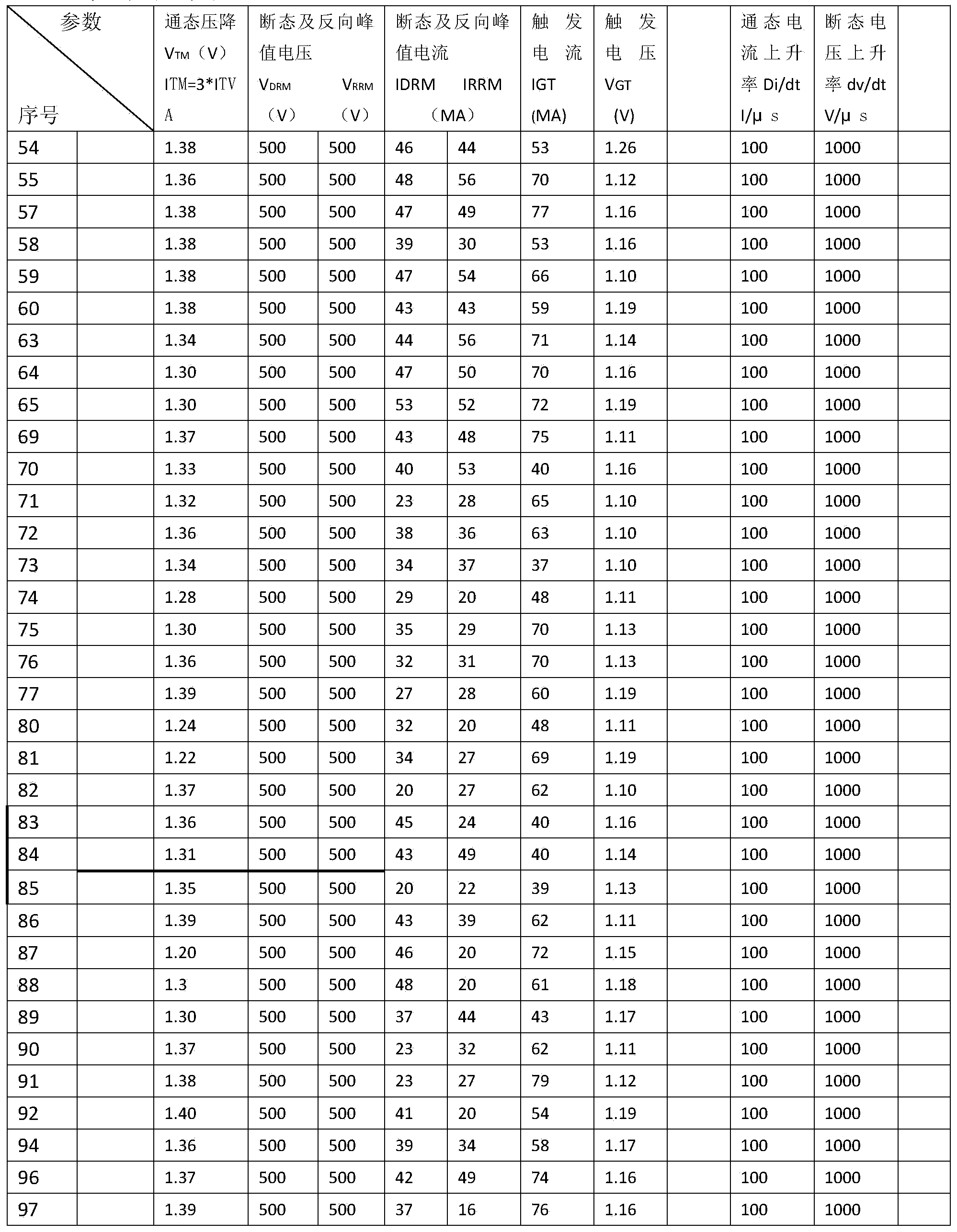

53results about How to "Reduce sintering deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

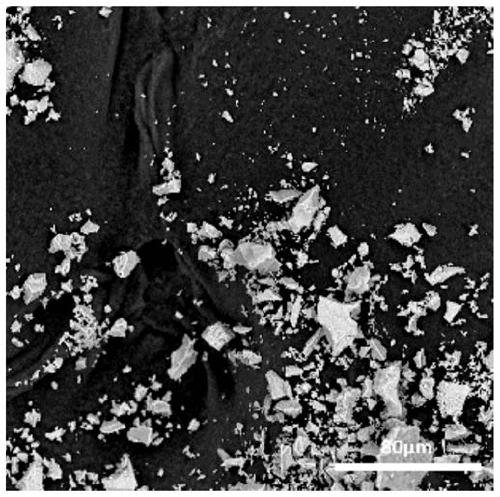

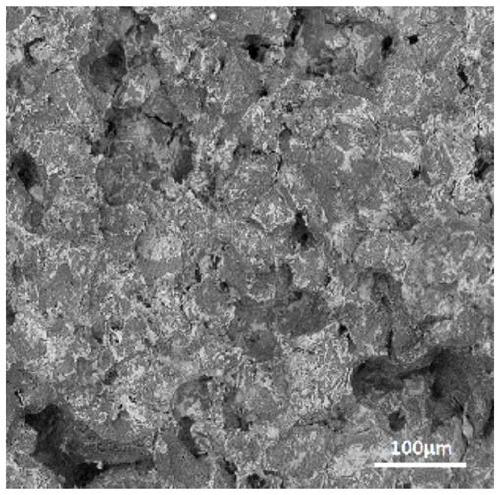

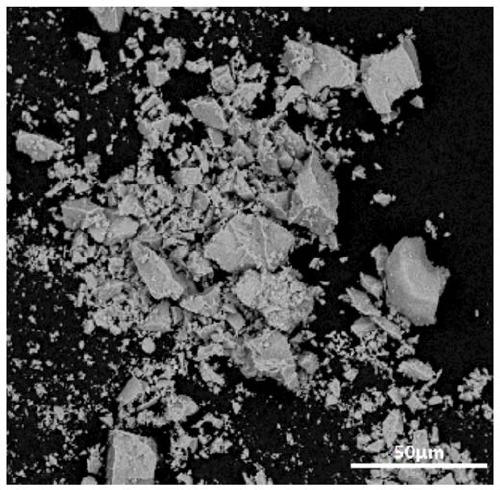

Preparation method for compact solid-phase sintered silicon carbide by using particle-size blended powder as raw material

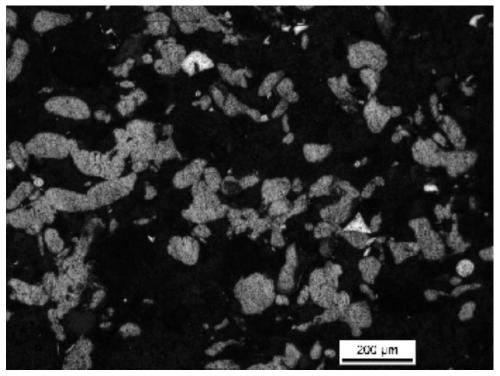

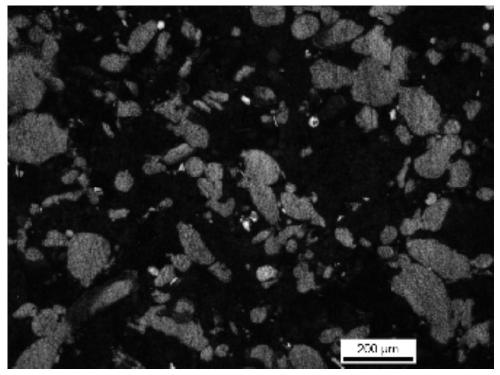

The invention relates to a preparation method for compact solid-phase sintered silicon carbide by using a particle-size blended powder as a raw material. The method comprises the following step: subjecting a compound powder of a particle-size silicon carbide blended powder and a sintering auxiliary agent to molding and sintering so as to prepare compact solid-phase sintered silicon carbide ceramic, wherein the particle-size silicon carbide blended powder comprises a micron-size silicon carbide powder, and a submicron-size silicon carbide powder and / or a nanometer-size silicon carbide powder; and a mass ratio of the micron-size silicon carbide powder to the submicron-size silicon carbide powder and / or the nanometer-size silicon carbide powder is (2-0.05): 1. According to the invention, through introduction of a micron-size powder with low cost, production cost of the solid-phase sintered silicon carbide ceramic is reduced; meanwhile, density of a ceramic body is improved; shrinkage is reduced; and the method facilitates to reducing sintering deformation or cracking of a large-size sample.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing biological medical porous implant material

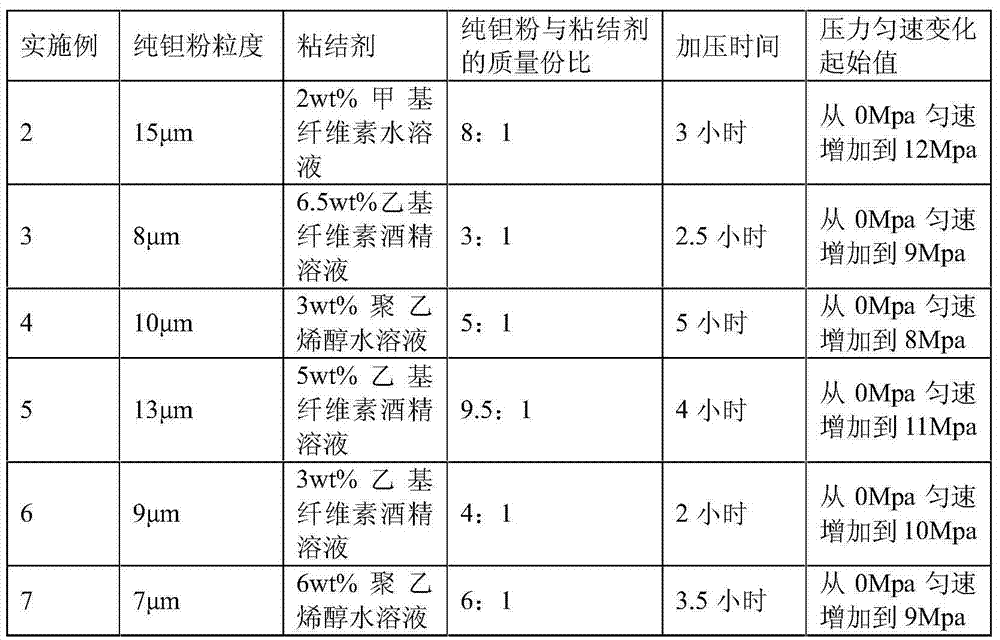

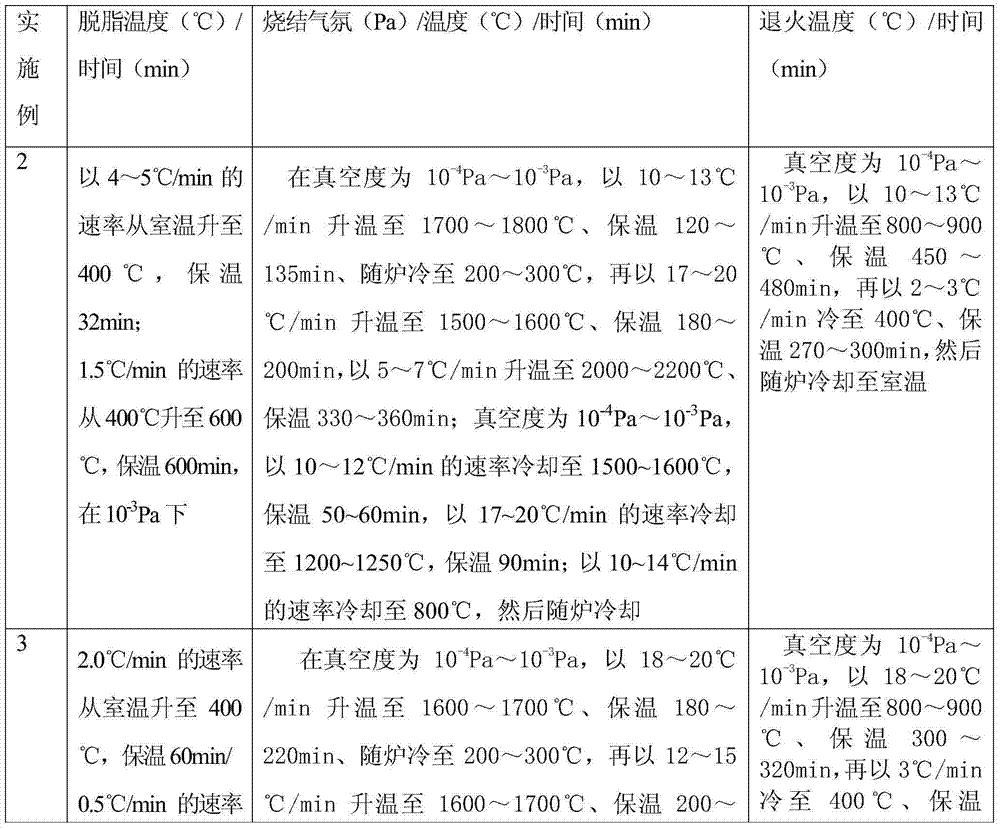

ActiveCN102796907AReduce sintering deformationStrong mechanical propertiesTransportation and packagingMetal-working apparatusBiocompatibility TestingSlurry

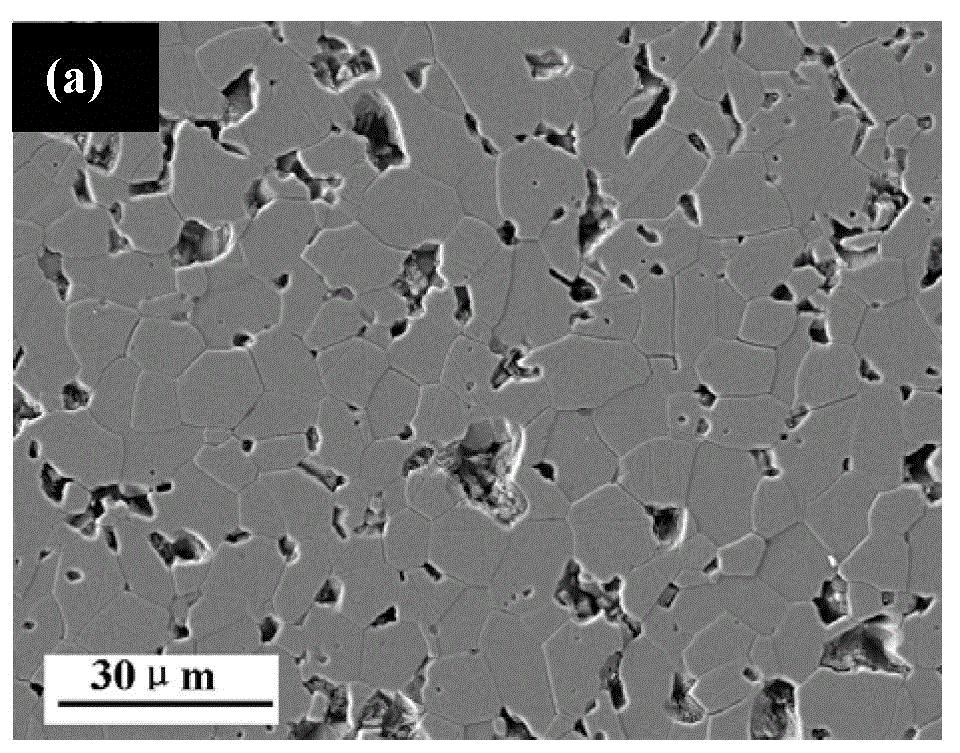

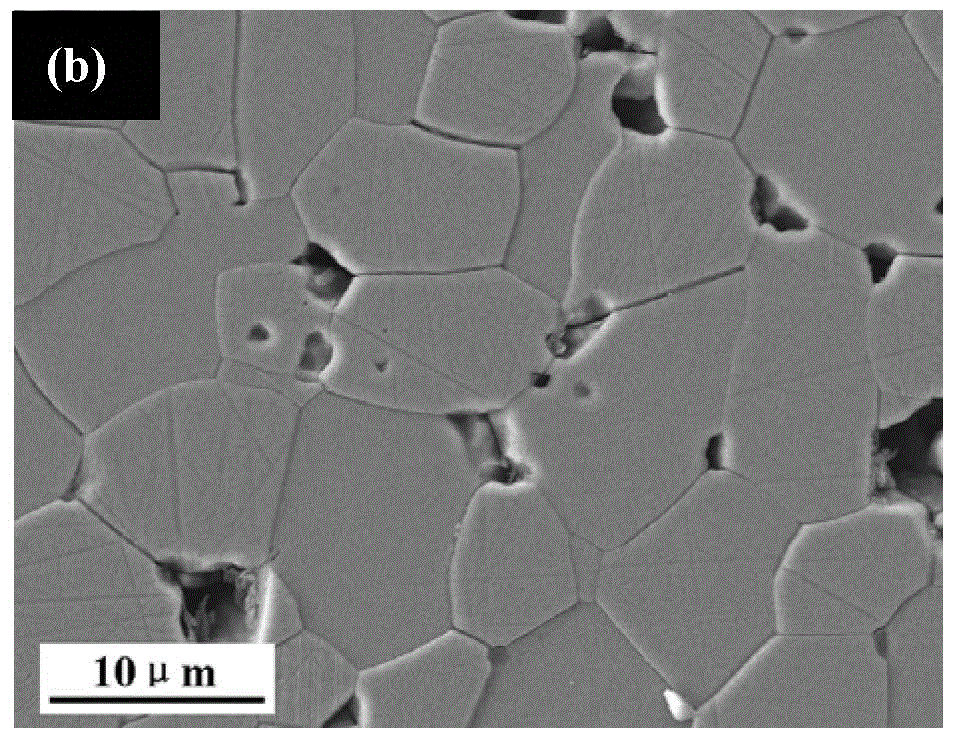

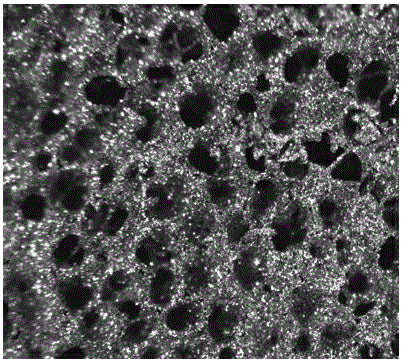

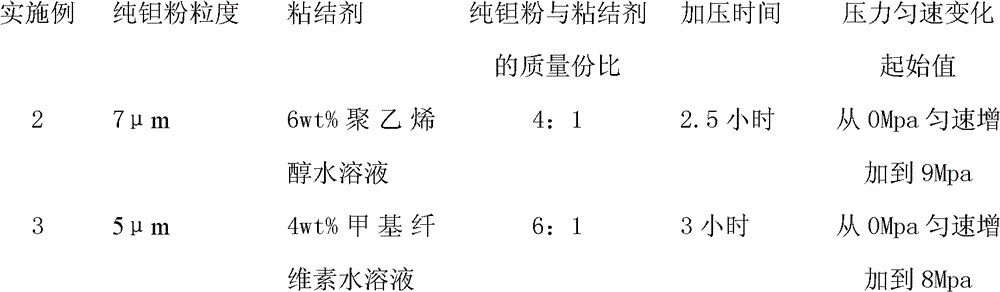

The invention discloses a method for preparing a porous tantalum biological medical implant material. The method comprises the following steps of: uniformly mixing pure tantalum powder and a binding agent to obtain tantalum powder slurry; placing a high polymer resin template support which has the porosity of 20 to 50 percent and of which pores are completely communicated in a three-dimensional way in a steel die; pouring the prepared tantalum powder into the steel die until the high polymer resin template support is immersed; slowly and uniformly applying pressure to the periphery of the steel die to ensure that the tantalum powder can be fully and completely filled into the high polymer resin template support, wherein the applied pressure is increased from 0 Mpa to10 Mpa at constant speed, and the time required by the pressure application process is 2 to 5 hours; performing chemical dissolution to remove the high polymer resin template support to obtain a green body framework of porous tantalum; and performing aftertreatment such as degreasing, sintering and the like to obtain the biological medical porous tantalum implant material. A product prepared by the method is a green body of the porous metal material of which pores are completely communicated in the three-dimensional way, and the green body is sintered to form the porous metal implant material of which the pores are completely communicated in the three-dimensional way, so that the porous metal implant material is high in biocompatibility.

Owner:CHONGQING RUNZE PHARM CO LTD

Ceramic metal composite substrate and production method thereof

The invention relates to a ceramic metal composite substrate and a production method thereof. The substrate mainly comprises an ultrathin ceramic sheet, a heat conduction glue and a metal substrate; the ceramic powder of the ultrathin ceramic sheet is a micropowder and a nanopowder mixture, and the volume proportion of nanopowder in the ceramic powder is 15-25%; and the heat conduction glue comprises, by volume, 20-30% of a one-dimensional high heat conduction material. The production method mainly comprises the following steps: making the ultrathin ceramic sheet; carrying out surface treatment on the metal substrate, coating the metal substrate with the heat conduction glue through a coating technology, and carrying out drying semi-solidification; and carrying out hot pressing on the ultrathin ceramic sheet and the glued metal substrate. The ceramic metal composite substrate has a good heat conduction performance, and has a good heat matching performance with chips, and the method has a high production efficiency, and is in favor of realizing development of the substrate to a small, light and thin direction. Tape casting makes the production efficiency of the ultrathin ceramic sheet be high; and the heat conduction glue comprises the one-dimensional high heat conduction material, so thermal resistance between the ultrathin ceramic sheet and the metal substrate is reduced.

Owner:SHANTOU UNIV

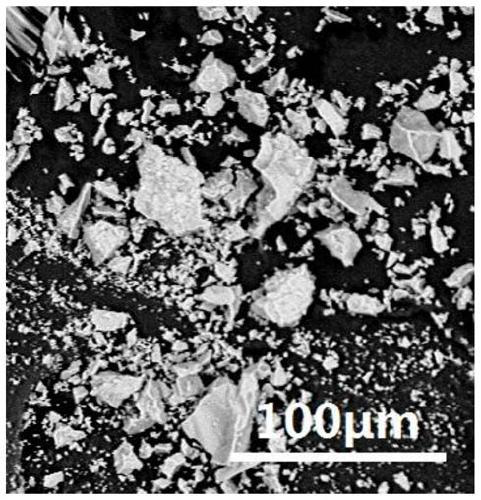

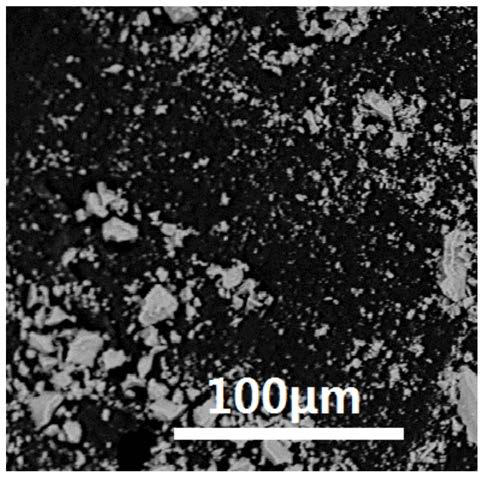

Preparation method of ultra-fine spherical nickel coated titanium composite powder

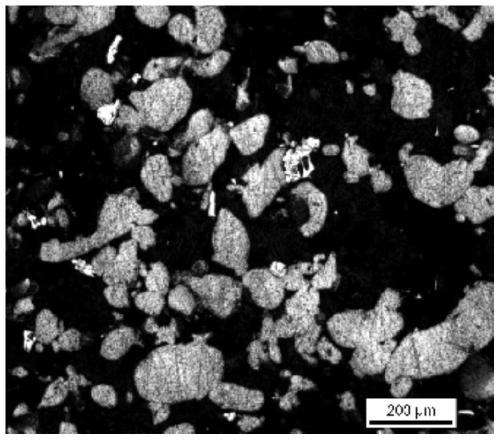

ActiveCN102179521BLow oxygenUniform thicknessLiquid/solution decomposition chemical coatingDehydrogenationVolumetric Mass Density

The invention provides a preparation method of an ultra-fine spherical nickel coated titanium composite powder, belonging to the manufacturing field of metallic powder material (compound). The preparation method comprises the following steps of: after pre-processing the raw material titanium hydride powder, firstly performing chemical nickel-plating; after radio-frequency plasma spheroidizing, performing dehydrogenation on the titanium hydride powder with large-particles; breaking the powder into ultra-fine spherical powder; and simultaneously reacting the nickel coated on the surface with titanium to obtain the spherical powder coated with nickel on the surface; and obtaining purified ultra-fine spherical nickel coated titanium composite powder after vacuum heat treatment. The preparation method has the characteristics of low oxygen content of power, uniform thickness of the nickel layer coated on the surface, high apparent density, good fluidity, short processing time, and the like,and the short procedure preparation of material is realized.

Owner:江苏金物新材料有限公司

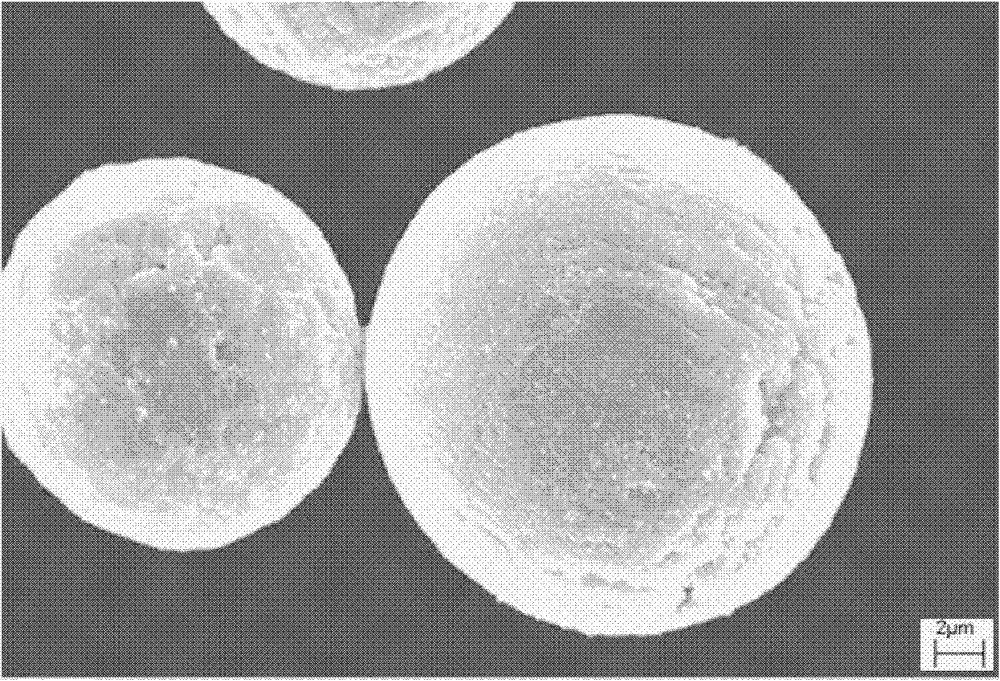

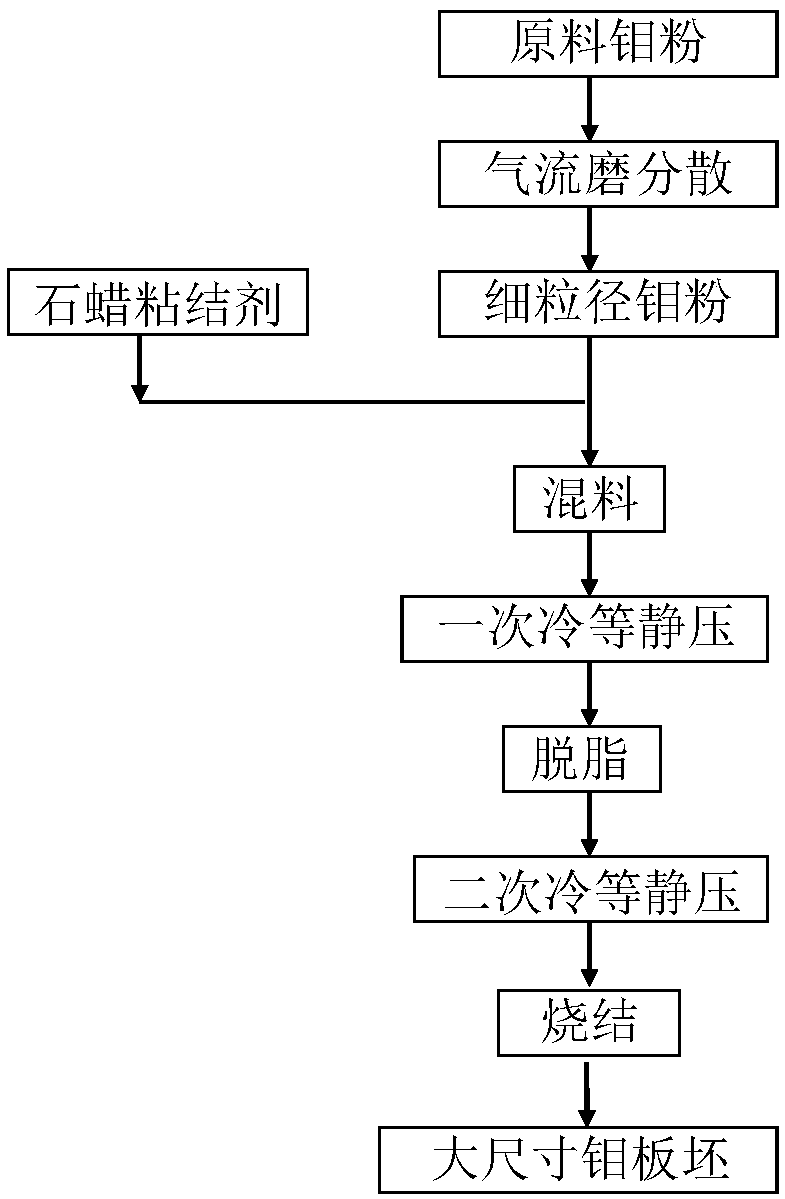

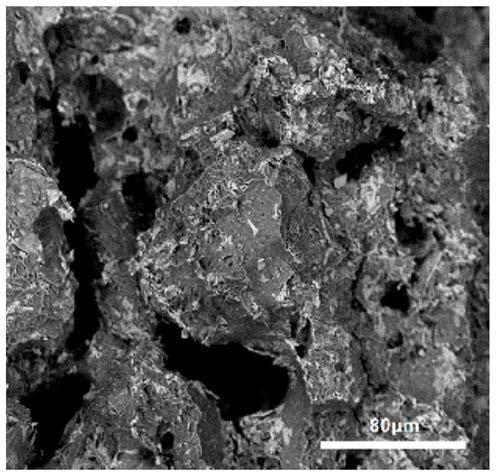

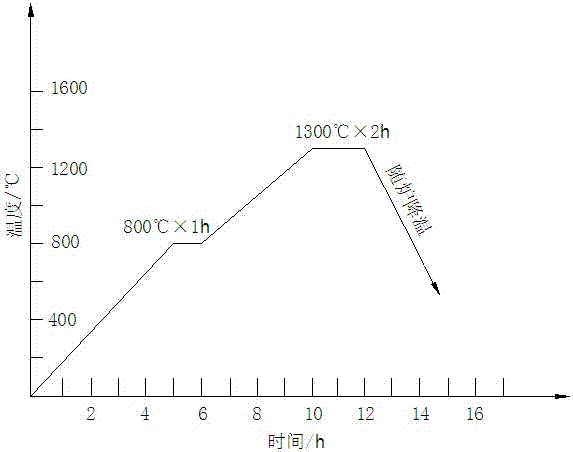

Method for preparing large-size molybdenum plate blank

ActiveCN108907211AGood dispersionUniform particle size distributionTransportation and packagingMetal-working apparatusHigh pressureMaterials science

The invention provides a method for preparing a large-size molybdenum plate blank, and belongs to the technical field of powder metallurgy. The method includes the steps that reducing molybdenum powder serves as a raw material, and small-granularity molybdenum powder which is evenly dispersed, has narrow granularity distribution and is nearly spherical is obtained through airflow milling treatment; then the small-granularity molybdenum powder and a paraffin binder are evenly mixed, and a mixture is obtained; and then by the adoption of a secondary isostatic cool pressing forming process, a degreased blank is isostatically pressed into a secondary blank under high pressure intensity. A sintering method of low-temperature slow heating and high-temperature rapid heating is adopted, specifically, slow heating is carried out at a low-temperature sintering stage, the blank is fully reduced in order to reduce the oxygen content in a blank body, and therefore the sintering activity of the blank is kept; and rapid heating is carried out at a high-temperature sintering stage, grain growth can be reduced, and after sintering is completed, the thick molybdenum plate blank with high density andhigh tissue uniformity can be obtained. By means of the preparation method, the problems that local looseness and cracks are easily generated in former large-size thick molybdenum plates are solved,the density of the prepared molybdenum plate blank reaches 99% or above, and the uniformity and the consistency of tissue of the surface and the center position of the plate blank can be guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

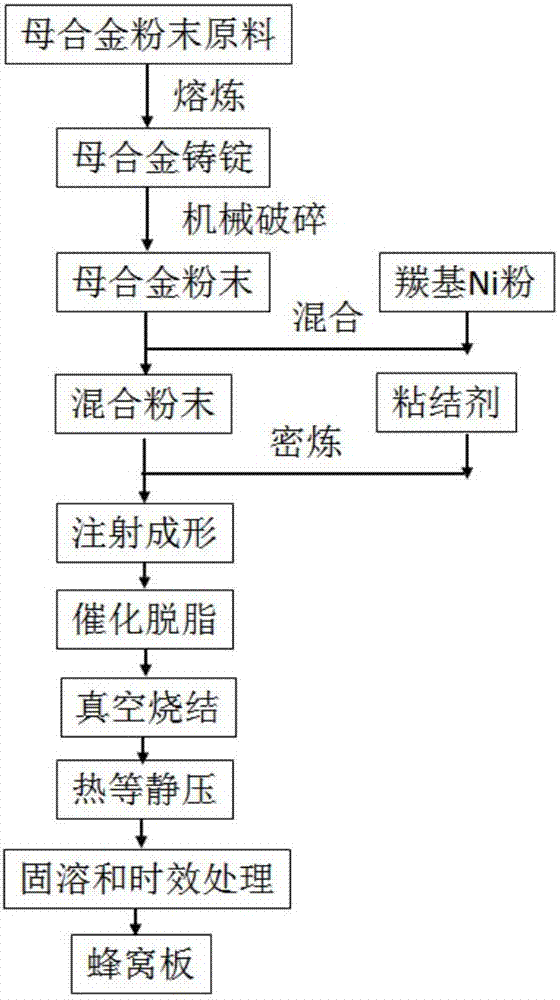

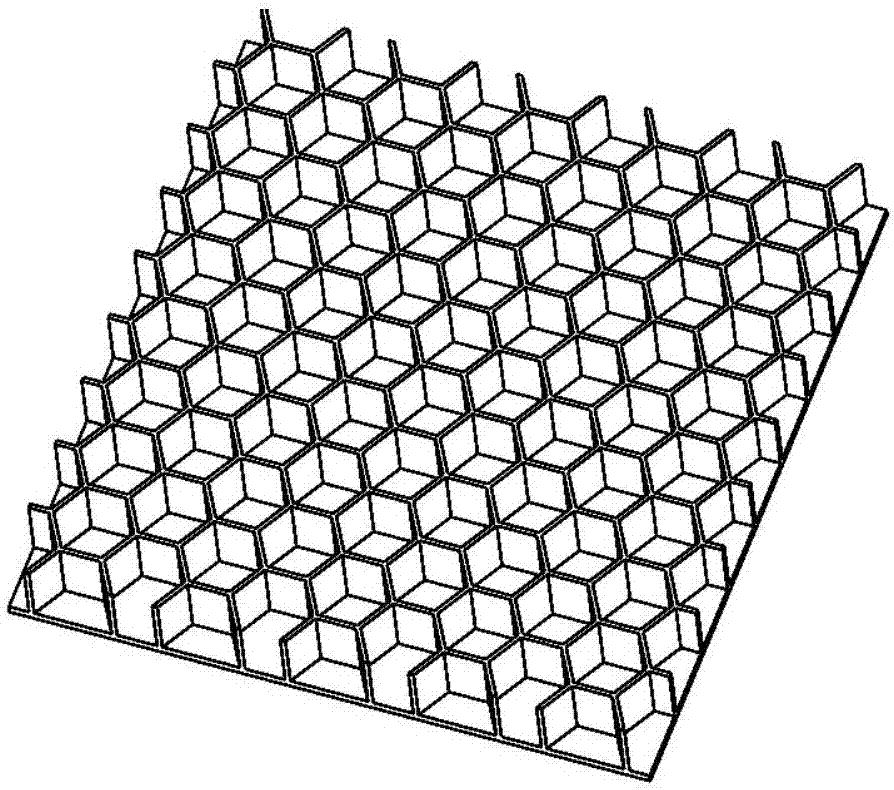

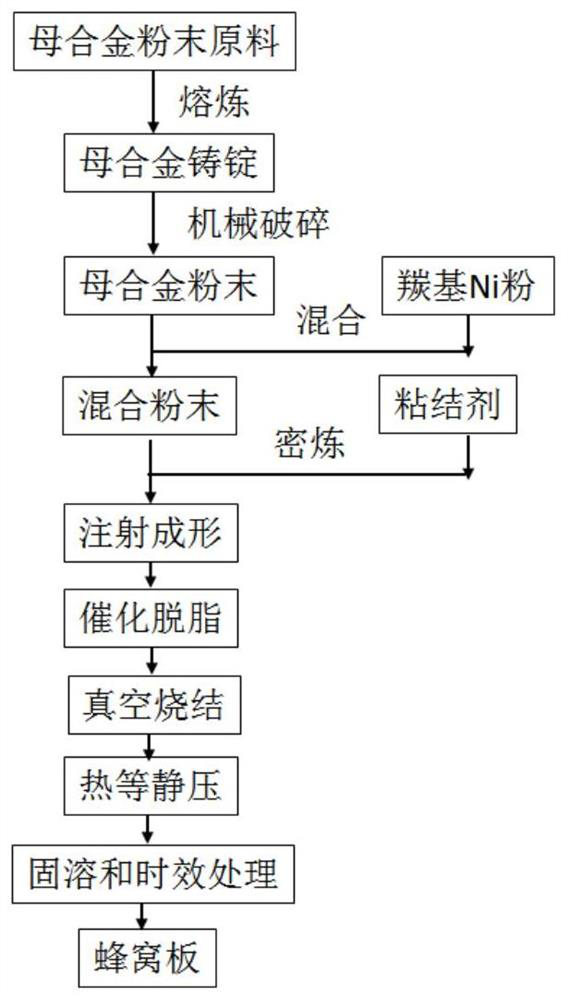

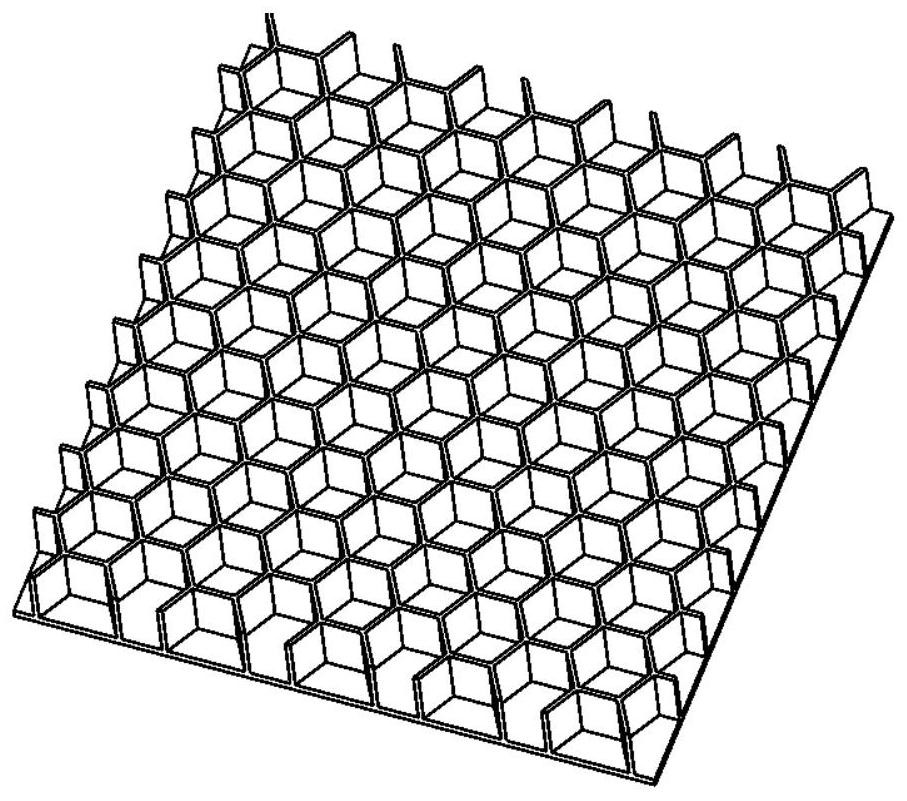

Method for preparing high-temperature alloy honeycomb insulation board based on injection forming

ActiveCN107999756AImprove mechanical propertiesLow costTransportation and packagingMetal-working apparatusHoneycombSuperalloy

The invention relates to the technical field of metal injection forming, and particularly relates to a method for preparing a high-temperature alloy honeycomb insulation board based on injection forming. The method comprises the steps of S1, preparation of mother alloy powder, S2, feeding and pelleting, S3, injection forming, S4, degreasing, S5, sintering, S6, hot isostatic pressing, S7, solid solution and aging treatment and other steps. By adopting the method for preparing the high-temperature alloy honeycomb insulation board, the defects that traditional brazing processes are complex in machining process, high in manufacturing cost and low in size precision can be effectively overcome, and the comprehensive mechanical properties of the prepared high-temperature alloy honeycomb insulation board are better than those of honeycomb boards prepared through brazing methods.

Owner:SHENZHEN ELEMENT TECH CO LTD

High efficiency and energy saving fly ash sintered brick making method

ActiveCN104129972AEasy to transformLow drying efficiencySolid waste managementBrickResource utilization

The invention provides a high efficiency and energy saving fly ash sintered brick making method. The optimization of granularity graduation of shale powder and the introduction of a single layer drying process capable of realizing large-scale continuous production solve the problems of low strength and easy deformation of green bricks in the drying process of ultrahigh-content fly ash sintered bricks, and multi-time mixing, forced mixing, heat insulation time prolongation processes further improve the product stability, so the large-scale industrial production of ultrahigh-content fly ash sintered bricks is successfully realized, the sintered bricks obtained in the invention has high yield, excellent strength and reduced weight, and energy consumed by sintering is effectively reduced. The selection of a kiln top and a hanging structure made of a sintered refractory material improves the acid corrosion resistance of a kiln body, can effectively adapt to the production of high--sulfur high-carbon fly ash sintered bricks, solves the problem of difficult utilization of fly ash from a circulating fluidized bed power plant, and improves the resource utilization rate.

Owner:西安瑞泰机械设备制造有限公司

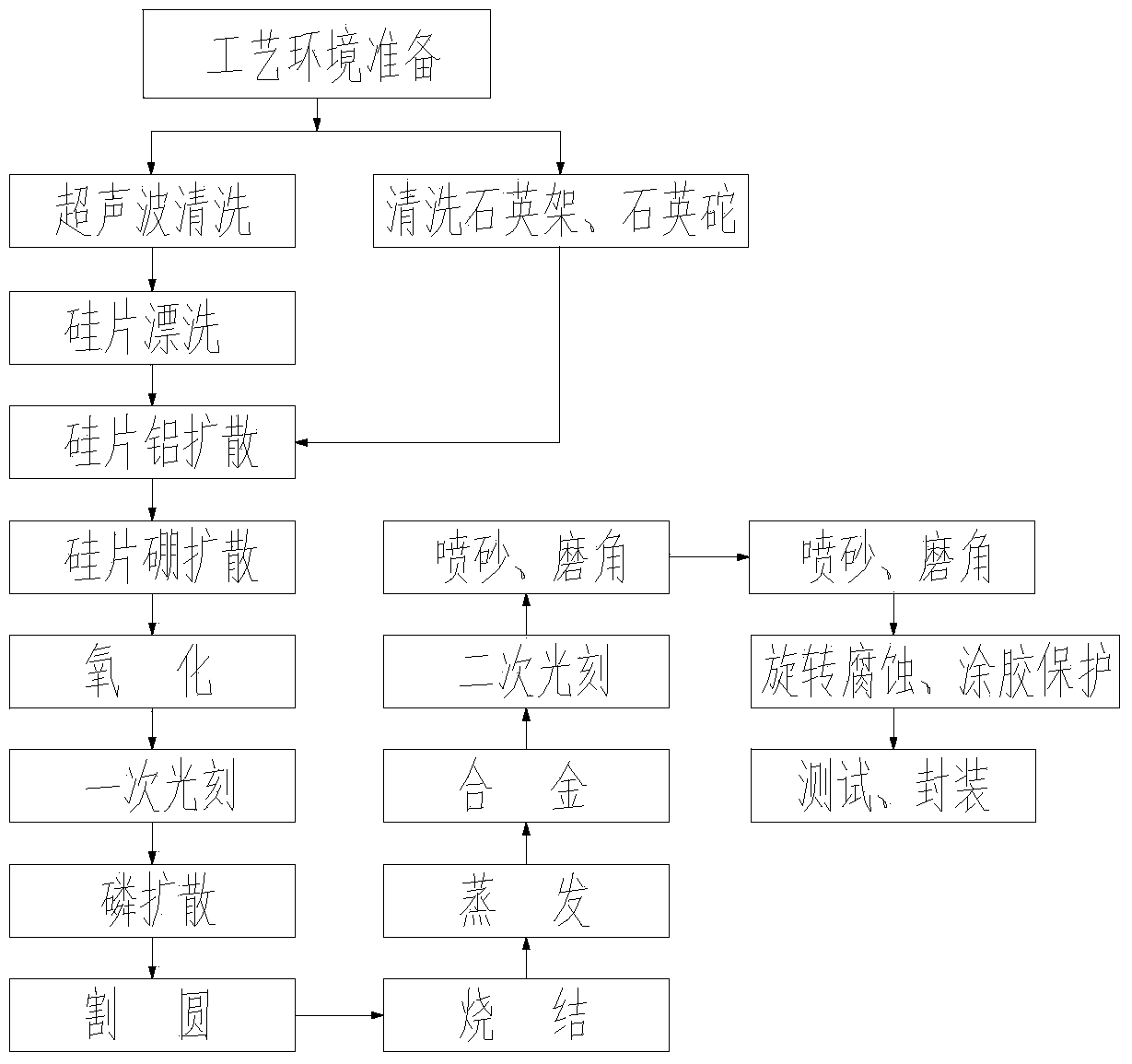

Sintering technology for high-specific gravity tungsten alloy

The invention discloses a sintering technology for a high-specific gravity tungsten alloy, which comprises the following steps of: 1) preparing materials according to a nominal composition of the high-specific gravity tungsten alloy, mixing materials according to a conventional method, and then pressing, thereby obtaining an alloy pressed blank; 2) primarily sintering the alloy pressed blank and cooling in furnace, thereby obtaining a pre-sintered blank; and 3) secondarily sintering the pre-sintered blank and cooling in furnace, thereby obtaining an alloy. According to the sintering technology for the high-specific gravity tungsten alloy, twice sintering is adopted, deformation of materials in the sintering process is reduced and the use ratio of raw materials is increased, so that the production cost of the products is lowered. By adopting the temperature of the twice sintering according to the sintering technology provided by the invention, the volume of sintering liquid phase in the tungsten alloy material is effectively controlled, the viscosity of a sintered body is increased, the mobility of the sintered body is reduced, and the sintering blank at high temperature has the capability of maintaining the shape of the original pressed blank and avoiding serious deformation.

Owner:XIAN HUASHAN TUNGSTEN PROD CO LTD

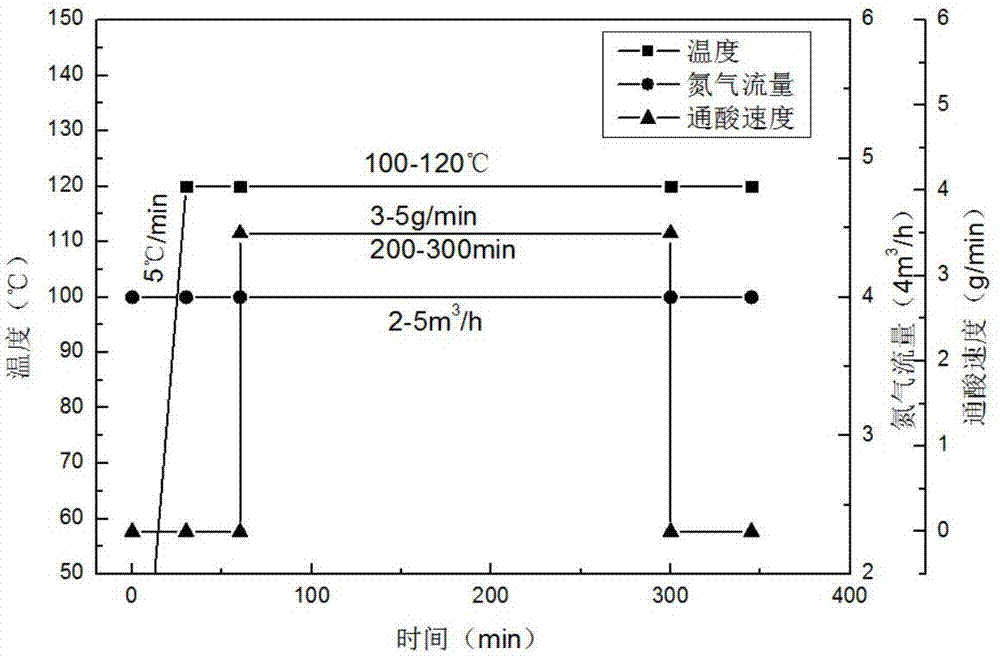

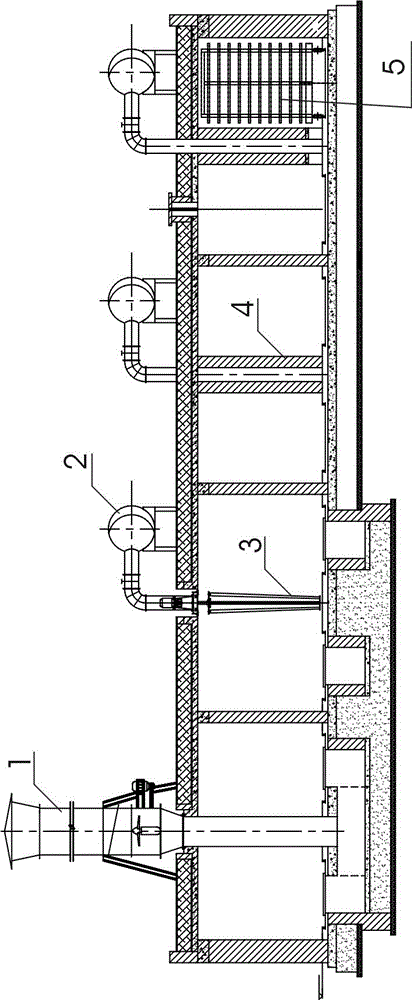

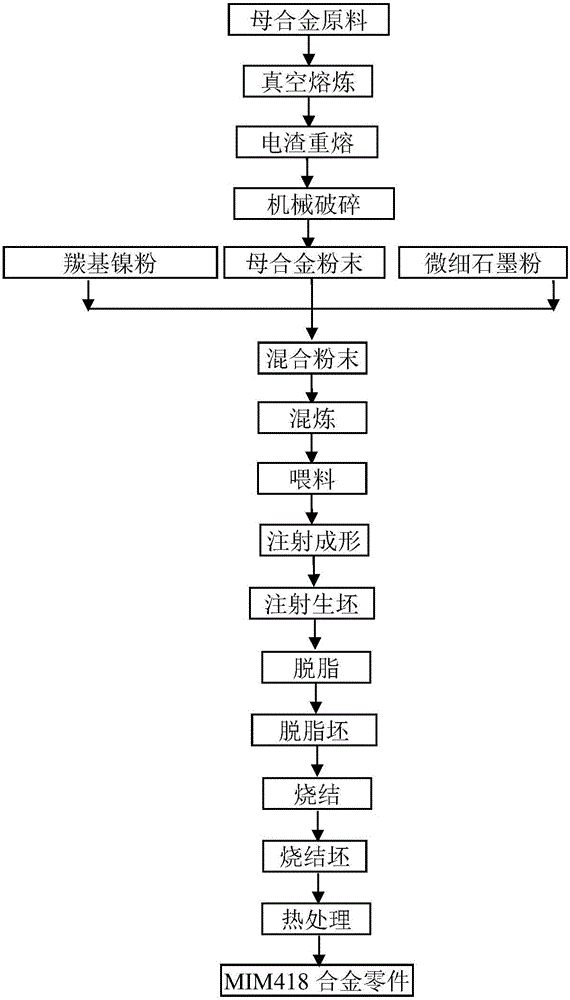

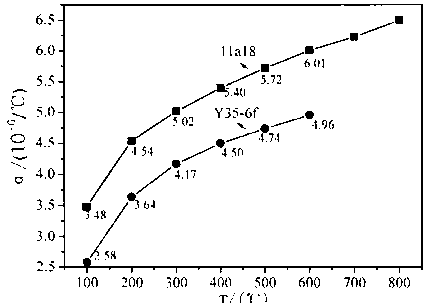

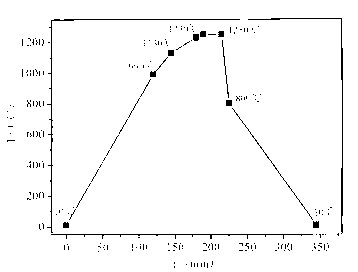

Method of preparing MIM418 alloy through low-oxygen content mother alloy method

ActiveCN106756148AReduce segregationReduce oxygen contentIncreasing energy efficiencyPolyethylene glycolSuperalloy

The invention discloses a method of preparing MIM418 alloy through a low-oxygen content mother alloy method. The method comprises the following steps: first, designing to obtain a mother alloy component, wherein the liquidus temperature of the mother alloy component is far lower than that of prealloy MIM418; preparing mother alloy powder through vacuum induction melting, electroslag remelting and mechanical disruption, mixing the mother alloy powder with nickel carbonyl powder and superfine graphite powder to obtain a mixture, uniformly mixing the mixture with a polyethylene glycol based water-soluble binder, and obtaining a part blank with a complicated shape through injection forming; and then, obtaining the high-performance MIM418 alloy through degreasing, vacuum sintering and thermal treatment. According to the invention, oxide segregation is reduced, oxygen content in a finished product and the oxygen content increased in the degreasing technology are reduced. During the vacuum sintering process, sintering deforming is reduced to control size precision through adjusting the heating rates of different temperature intervals. The cost and technological energy consumption of the raw material powder are remarkably reduced, the oxygen content and inclusion content of a superalloy part are effectively reduced, the oxygen content of a finished product is lower than 200 ppm, and the prepared superalloy is close to full-compact, uniform in organization structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

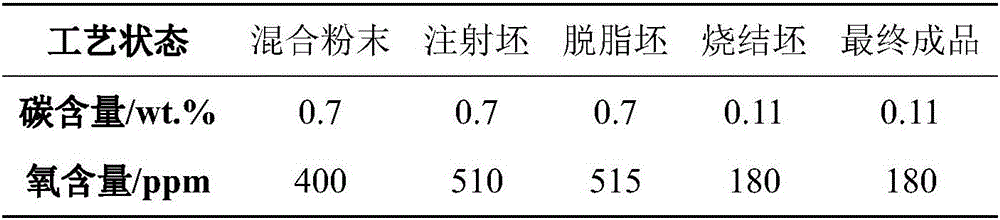

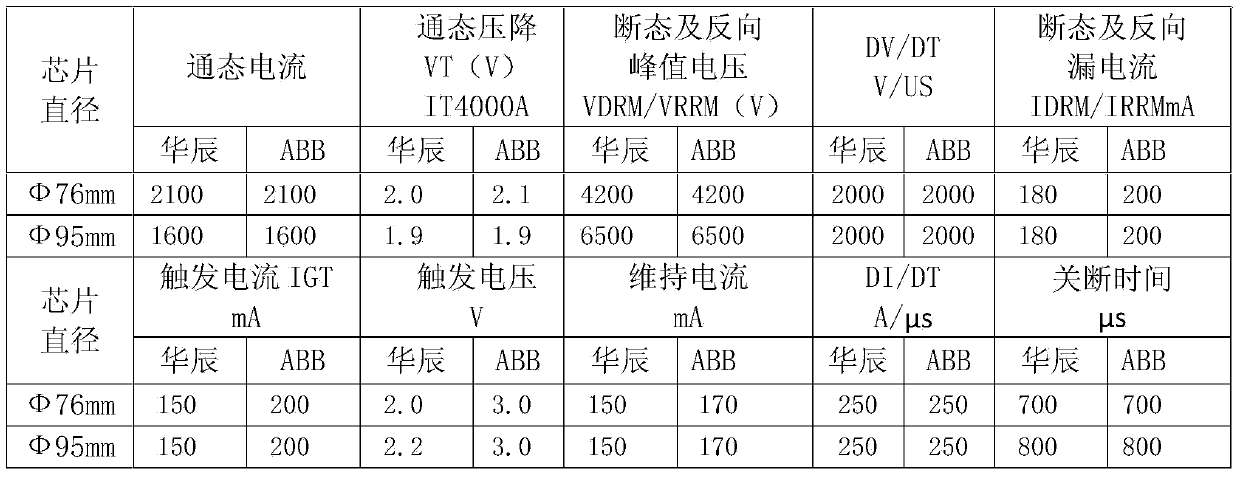

Method for manufacturing high-voltage large-power thyristor by adopting sintering process

ActiveCN103700591AReduce sintering deformationGood adhesionSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingAlloy

The invention relates to a method for manufacturing a high-voltage large-power thyristor by adopting a sintering process. The method comprises the following steps of preparing a process environment, ultrasonically washing, rinsing a silicon chip, washing a quartz frame and a quartz lead, diffusing aluminum on the silicon chip, diffusing boron on the silicon chip, oxidizing the silicon chip, performing primary photoetching, diffusing phosphorus, cutting and rounding, sintering, evaporating, forming alloy, performing secondary photoetching, shot blasting and grinding corners, performing spin etching, gluing for protection and encapsulating. Compared with the prior art, the method has the beneficial effects that the boron diffusion and the aluminum diffusion are adopted for manufacturing the chip, so that the front edge of a PN junction is enabled to be smooth; by adopting the novel sintering technology, the sintering deformation is small, firmness in binding is realized, and a diffusion parameter is stable and invariable; by adopting the ultraclean process environment and a precise washing method, the minority carrier life is long through excellent washing reagent; the diffusion is controlled by adopting a computer, and the corners are mechanically ground and blasted, so that the consistency of product parameters is guaranteed, and reliability in use can be realized; the manufacturing cost is low, the rate of finished products is high, and each technical performance can reach the level of a similar imported product.

Owner:鞍山市华辰电力器件有限公司

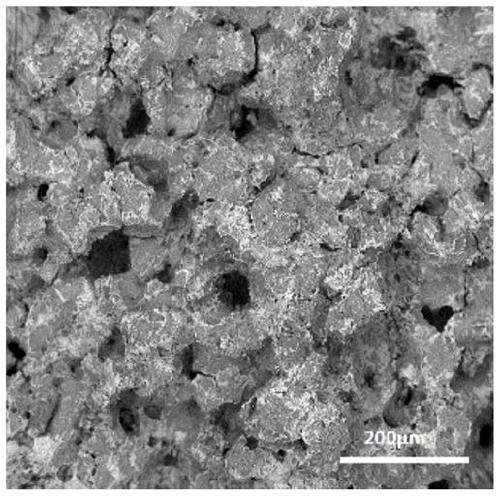

High-performance silicon carbide ceramic dehydrating element and preparation method thereof

InactiveCN107021768ASolve the problem of complex shape and high processing costReduce manufacturing costSpray GranulationBoron carbide

The invention relates to a high-performance silicon carbide ceramic dehydrating element and a preparation method thereof. The high-performance silicon carbide ceramic dehydrating element is prepared from the following components in parts by weight: 93 to 99 parts of silicon carbide ultrafine powder, 1 to 5 parts of boron carbide ultrafine powder, 1 to 5 parts of nanometer titanium boride, 0.1 to 1 part of graphene aqueous solution, 8 to 15 parts of water soluble phenol-formaldehyde resin, 5 to 10 parts of efficient dispersing agent, and 1 to 5 parts of blank enhancing agent. The preparation method comprises the following steps: circularly mixing and grinding materials; performing spray granulation; performing dry pressing; curing a green body and sintering in vacuum to obtain a final product. By adopting the high-performance silicon carbide ceramic dehydrating element and the preparation method thereof, the security and convenience are improved in a production process, and the production cost is lowered; a small amount of nanometer-grade titanium boride is introduced, so that the inside is optimized, and the product performance is improved greatly.

Owner:扬州北方三山工业陶瓷有限公司

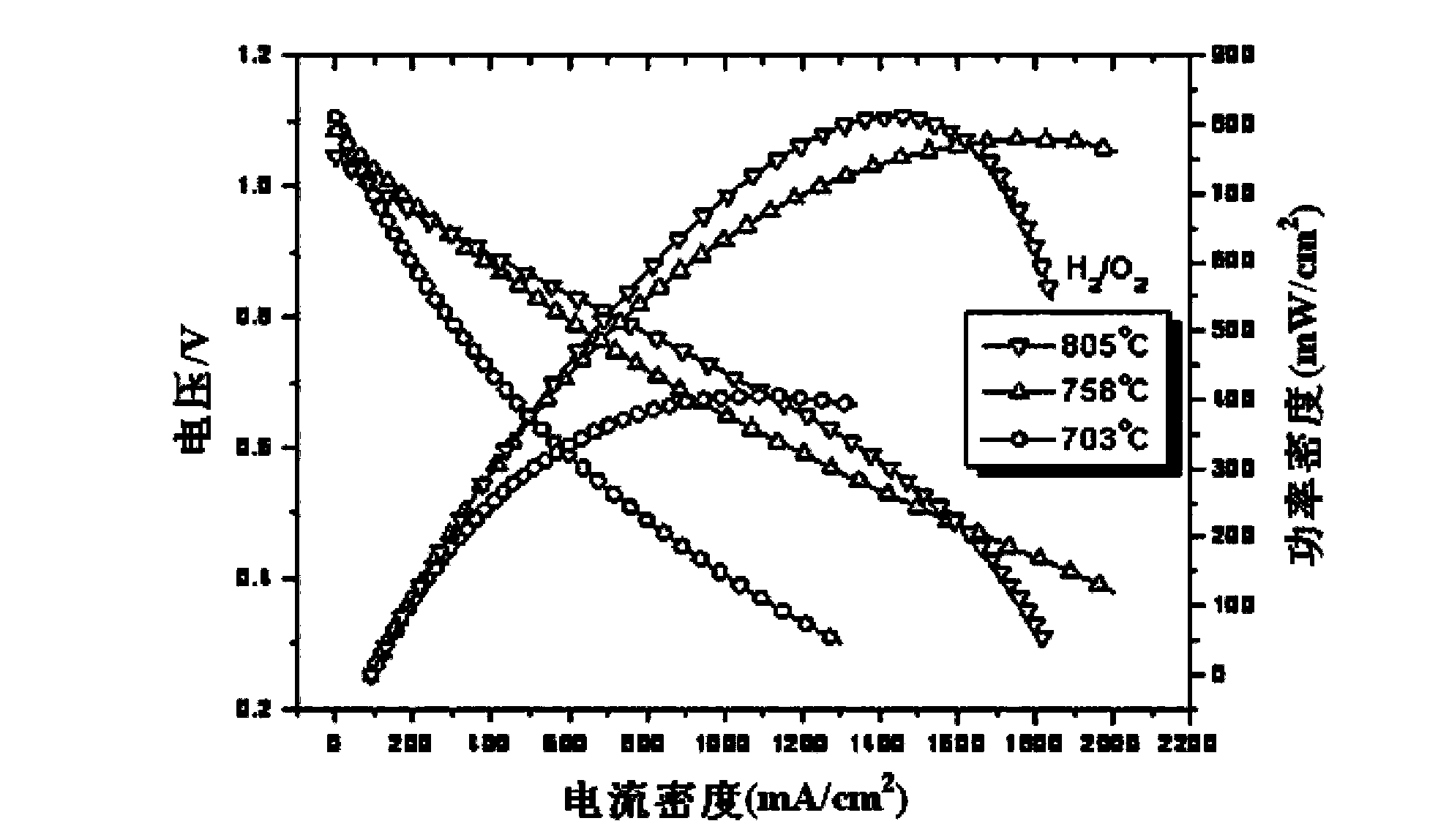

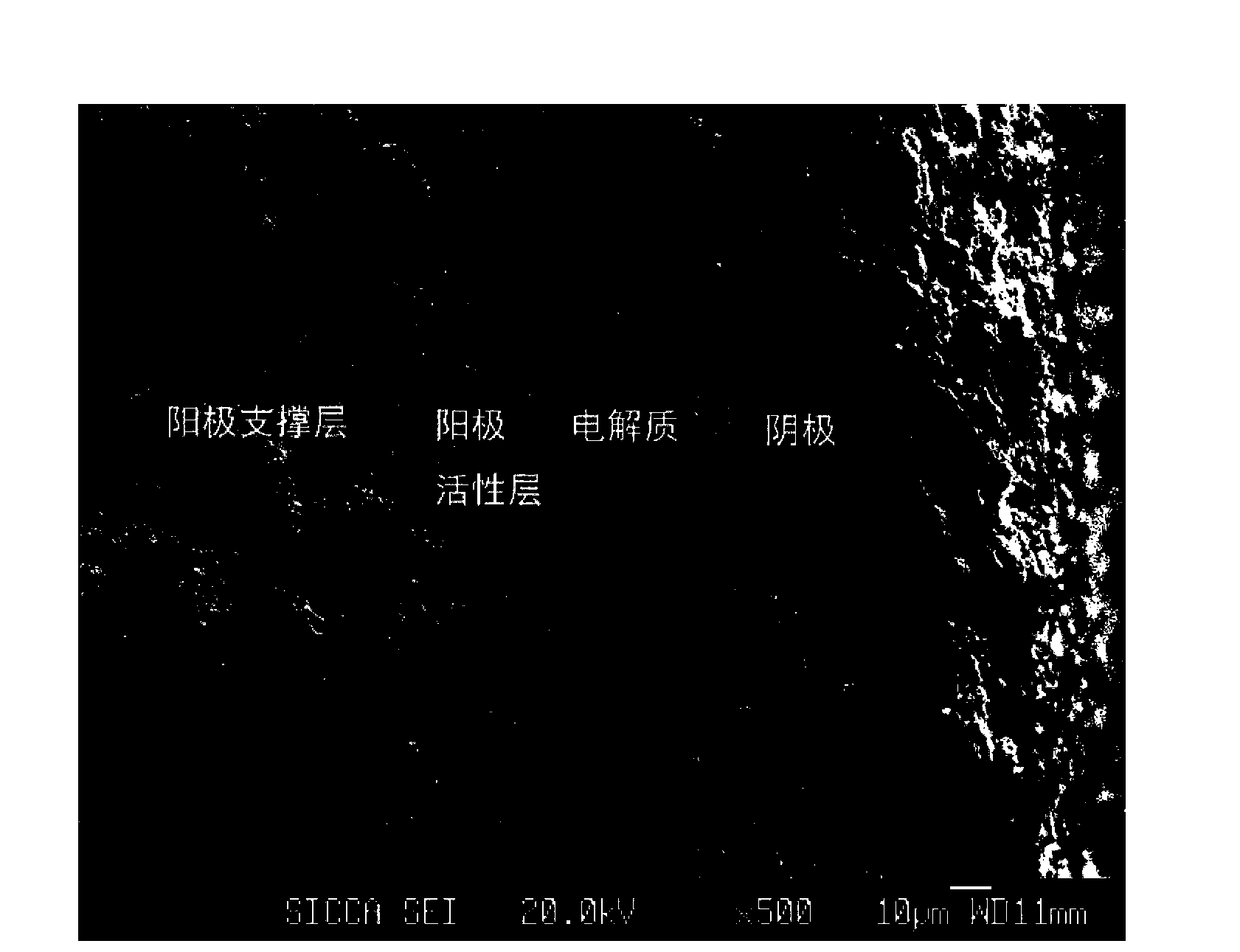

Method for producing flat-plate-type solid oxide fuel cell anode support electrolyte composite membrane

InactiveCN103811787AShrink evenlyReduce sintering deformationFinal product manufactureElectrolytesOxideSolid oxide fuel cell

The invention discloses a method for producing a flat-plate-type solid oxide fuel cell anode support electrolyte composite membrane, and the method is as follows: first, preparing each slurry material for respective preparation of an electrolyte layer, an anode active layer and / or an anode support layer, and an electrolyte slurry material for silk-screen printing; then respectively casting the electrolyte layer, the anode active layer and / or the anode support layer; then using the electrolyte slurry material for silk-screen printing of the surface of the anode support layer of a casted membrane; and finally co-sintering a dried biscuit. The preparation method provided by the invention is low in cost, strong in operability, simple in process, and suitable for mass production, the prepared composite membrane is good in flatness, a cell prepared by use of the composite membrane is high in performance, low in interface impedance, and long in cell life, and has practical value and application prospect. All functional layers are combined closely.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

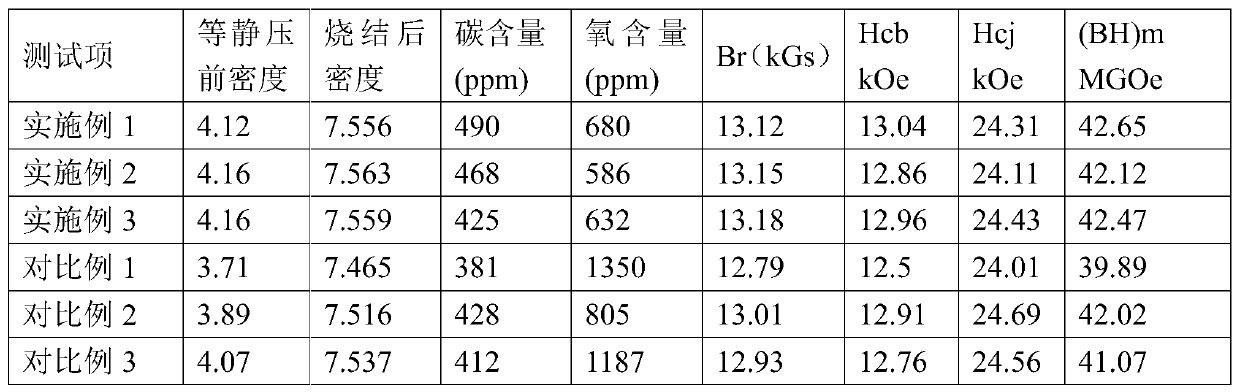

Manufacturing method of sintered neodymium iron boron

InactiveCN111739729AHigh dimensional accuracyGood dimensional stabilityMagnetic materialsPermanent magnet manufactureOrganic solventHigh density

The invention belongs to the field of sintered rare earth permanent magnet material manufacturing, and particularly relates to a manufacturing method of sintered neodymium iron boron. The preparationmethod comprises the following steps: obtaining neodymium-iron-boron alloy powder by using a conventional process; dissolving an organic matter coating agent into an organic solvent to prepare an organic matter coating solution; mixing the organic matter coating solution with neodymium-iron-boron alloy powder, and uniformly mixing, so that the surface of the powder is coated with a compact organicmatter coating film so as to achieve the effects of oxidation resistance, lubrication and bonding; and putting the powder into a mold, and carrying out magnetic field molding to directly press a high-density, high-strength and low-oxygenation green body without isostatic pressing, so that the sintered product has high dimensional precision, and the method is a near-net molding method.

Owner:JIANGXI KAIYUAN AUTOMATIC EQUIP CO LTD +1

Making method of low-deformation toughened silica-based ceramic core

ActiveCN105418058ALower sintering temperatureReduce sintering deformationCeramic shaping apparatusTurbine bladeRoom temperature

The invention belongs to the technical field of precision casting, and particularly relates to a making method of a low-deformation toughened silica-based ceramic core. Zirconium oxide is doped with different-valence metallic oxide magnesium oxide to serve as a stabilizer, ZrO2 can be maintained in a tetragonal phase or a cubic phase at room temperature, magnesium oxide is further added to a core sizing formula, a fibrous structure of the magnesium oxide can increase the toughness of a wet core when a core wet billet is pressed, drawing deformation and cracks of the core wet billet can be reduced, and the fracture rate during core trimming can be decreased. The making method of the low-deformation toughened silica-based ceramic core is not only suitable for preparing ceramic cores of large parts which are complex in shape and thin in wall, but also suitable for producing ceramic cores for equiaxial and directed hollow turbine blades. The core wet billet prepared through the making method is good in toughness, high in drawing yield, small in deformation and small in sintering deformation of the core.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

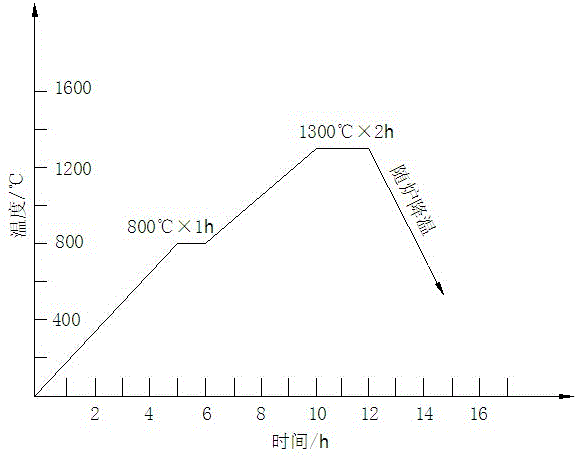

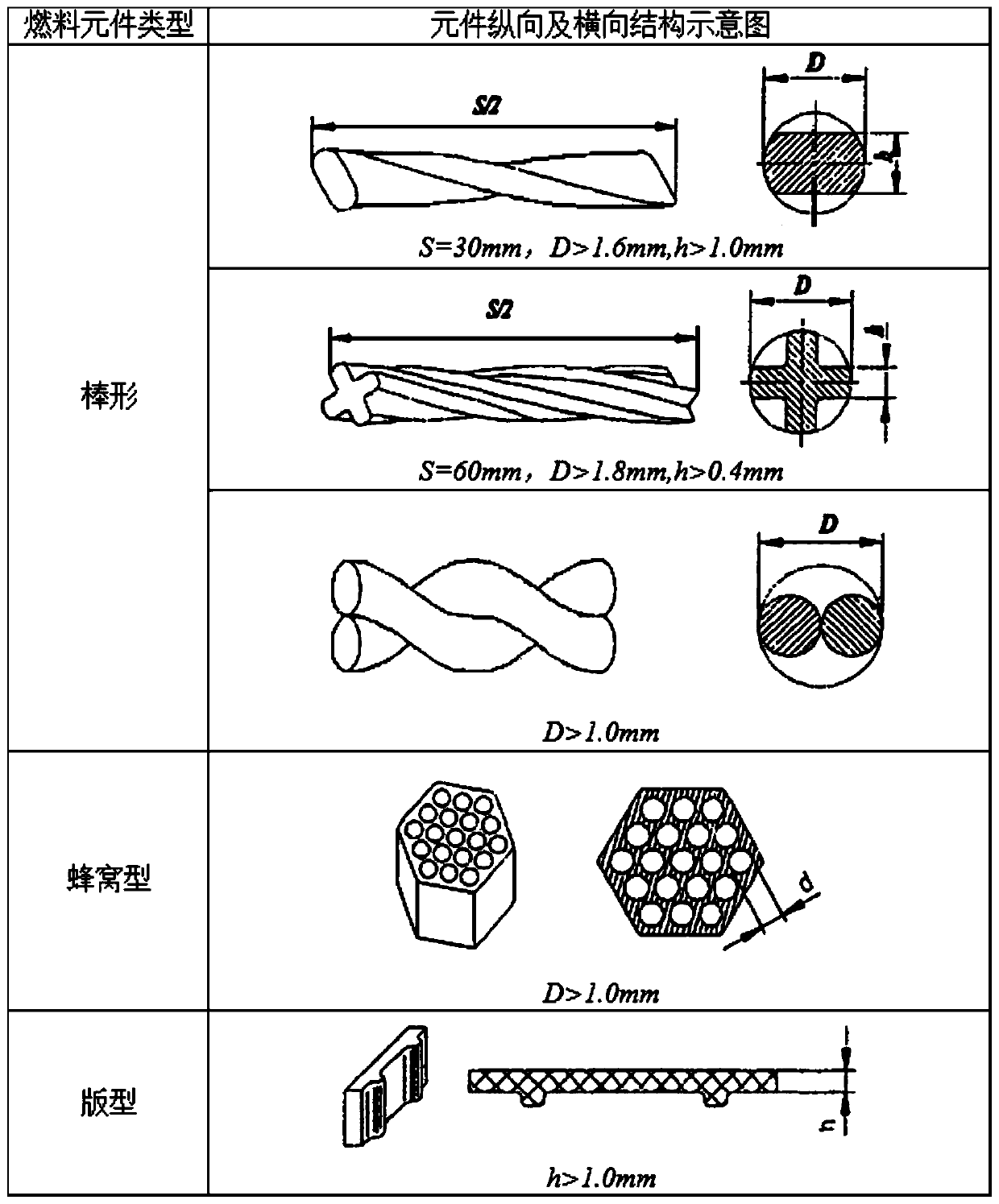

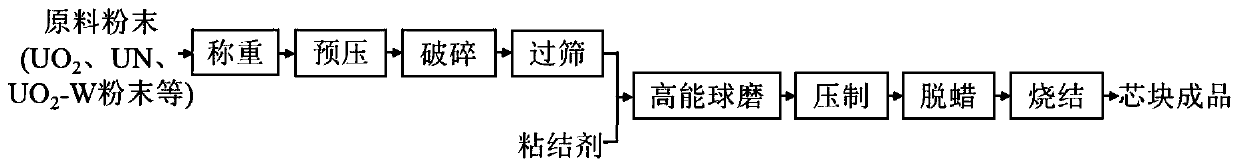

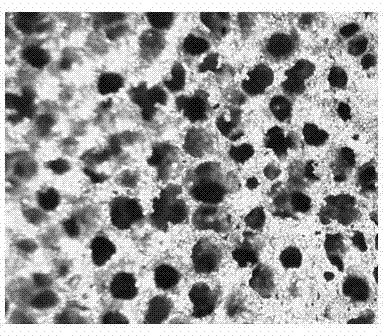

Preparation method of honeycomb fuel pellet

ActiveCN110164574AReduce grinding processIncrease productivityNuclear energy generationReactors manufactureProduction linePrill

The invention belongs to the technical field of nuclear fuel preparation, and relates to a preparation method of a honeycomb fuel pellet. The preparation method which does not include a grinding stepsequentially comprises the following steps: (1) granulating: weighing raw material powder particles, filling a mold with the raw material powder particles, pre-pressing the raw material powder particles in a hydraulic machine, crushing a pre-pressed green body, sieving the crushed green body to obtain large particles, mixing the large particles with a binder, pouring the obtained mixture into a ball mill jar, placing grinding balls in the jar, and performing high-energy ball milling; (2) pressing: sieving the obtained ball-milled powder, filling the mold with the large particles, pressing thelarge particles, and demolding the pressed large particles to obtain a pellet pressed body; and (3) sintering: dewaxing the pellet pressed body, placing the dewaxed pellet pressed body in a burning boat, and placing and sintering the burning boat in a sintering furnace to obtain the finished honeycomb fuel pellet. The preparation method of the honeycomb fuel pellet of the invention has the advantages of realization of the production of the nuclear fuel pellet with a complicated shape by using the existing nuclear fuel production line, omission of the grinding process, increase of the production efficiency and reduction of the production cost.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

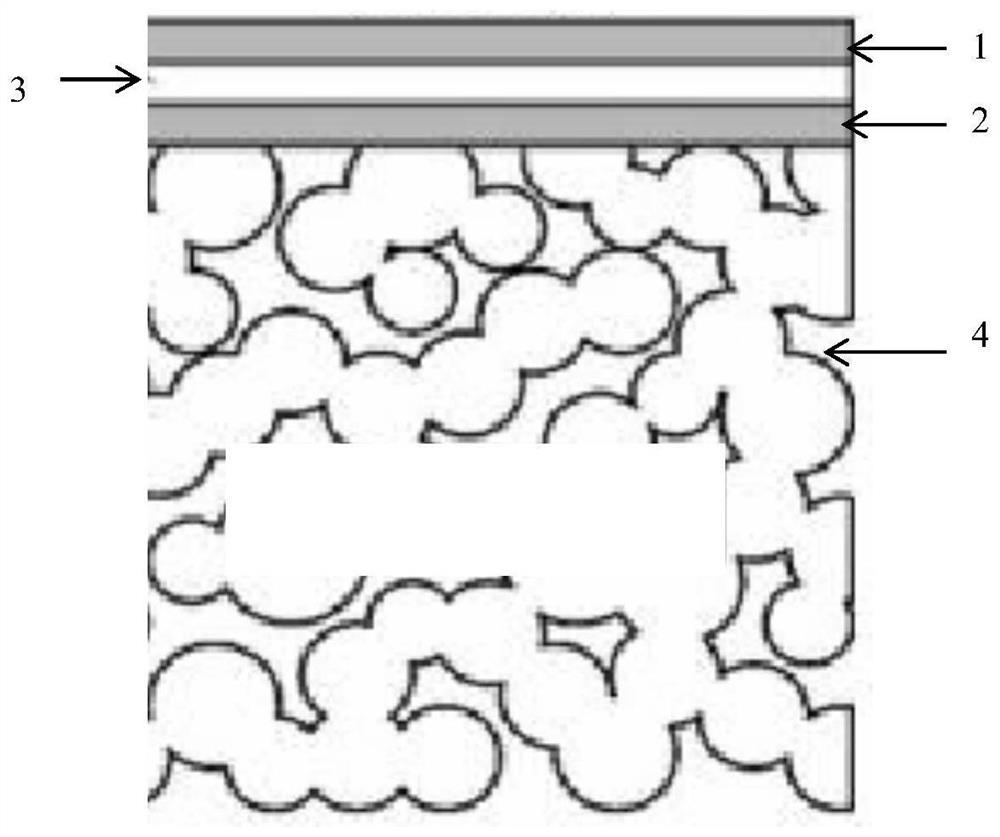

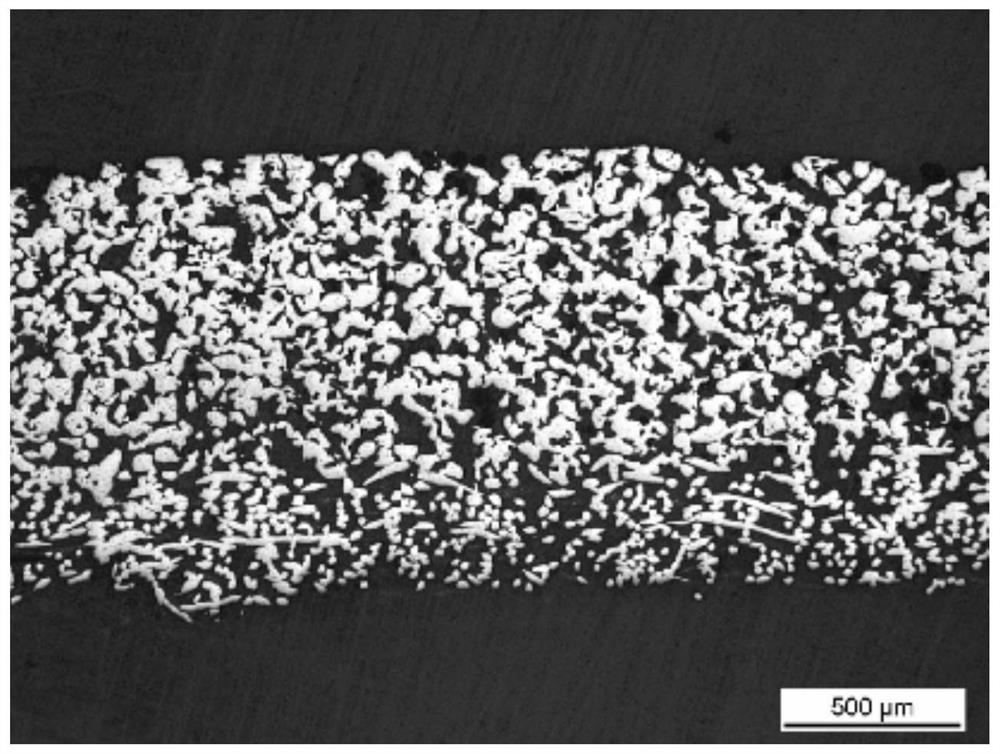

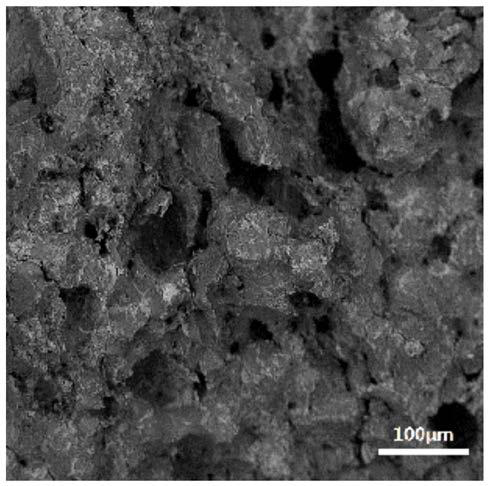

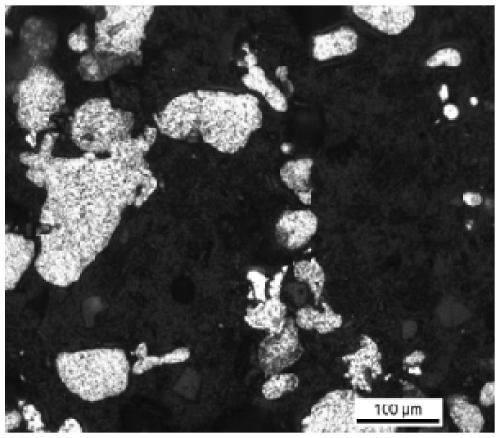

Method for preparing porous tantalum medical implant material

ActiveCN103691003AReduce sintering deformationStrong mechanical propertiesProsthesisPorous tantalumImplant material

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps: uniformly mixing pure tantalum powder and an adhesive to obtain tantalum powder slurry; putting a polymer resin template stent which has the porosity of 20-50 percent and is completely in three-dimensional connection into a steel mold, pouring the prepared tantalum powder slurry into the steel mold, and allowing the slurry to spill over the polymer resin template stent; slowly and uniformly pressurizing the periphery of the steel mold, so that the tantalum powder is fully and completely filled in the polymer resin template stent, the applied pressure is increased from 0MPa to 8-12MPa at a constant speed, and the used time in the pressurization process is 2-5 hours; removing the polymer resin template stent through chemical dissolution, thereby obtaining a porous tantalum blank framework; and finally, degreasing, sintering, cooling and performing after-treatment to obtain the biomedical porous tantalum implant material. The prepared porous tantalum implant material is high in biocompatibility and excellent in mechanical property.

Owner:CHONGQING RUNZE PHARM CO LTD

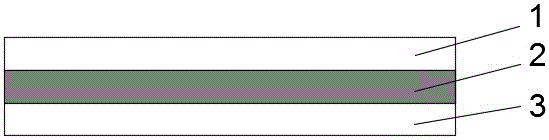

Manufacturing method of metal supporting plate for fuel cell

PendingCN113054215AReduce sintering deformationElimination of sintering deformationFinal product manufactureFuel cellsFuel cellsSlurry

The invention relates to a manufacturing method of a metal supporting plate for a fuel cell. The manufacturing method sequentially comprises the following steps: 1) adopting one of sintered stainless steel, heat-resistant steel, nickel-based alloy, cobalt-based alloy, titanium alloy and chromium-based alloy; 2) screening the powder in the step 1), wherein the particle size of the selected powder is 13-250 microns; 3) placing the powder in an inner hole of a measuring vessel, removing a redundant powder, and placing the measuring vessel on a load bearing plate; 4) sintering the load bearing plate on which the measuring vessel is placed; 5) coating an anode slurry on the upper surface of a metal substrate so as to form an anode layer on the upper surface of the metal substrate; 6) coating an electrolyte slurry on the upper surface of the anode layer to form an electrolyte coating on the surface of the anode layer; and 7) coating the cathode slurry on the upper surface of the electrolyte coating to form a cathode layer on the upper surface of the electrolyte coating so as to produce a metal support plate. Sintering deformation is eliminated, and the combination tightness between the anode layer and the metal substrate is improved.

Owner:NBTM NEW MATERIALS GRP

Hard alloy shaft sleeve and preparation method thereof

The invention discloses a hard alloy shaft sleeve and a preparation method thereof. The shaft sleeve is composed of the following raw materials: tungsten carbide, nickel, titanium carbide, cobalt powder, a tantalum-niobium solid solution and chromium powder; and the preparation method of the shaft sleeve comprises the steps of material preparation, ball milling, drying, forming, sintering, and post-processing. According to the hard alloy shaft sleeve and the preparation method thereof, by scientific and reasonable compatibility of various components of the tungsten carbide, the nickel, the titanium carbide, the cobalt powder, the tantalum-niobium solid solution and the chromium powder, an obtained hard alloy shaft sleeve has high hardness, high bending strength, the wear resistance and acid-alkali resistance of the hard alloy shaft sleeve are improved, and the service life is significantly prolonged; the preparation method of the hard alloy shaft sleeve is advantageous to product processing, the operation is easy, the preparation is convenient, the surface roughness of a sealing ring of the shaft sleeve is lower, and the method is suitable for large-scale industrial production.

Owner:成都川硬合金材料有限责任公司

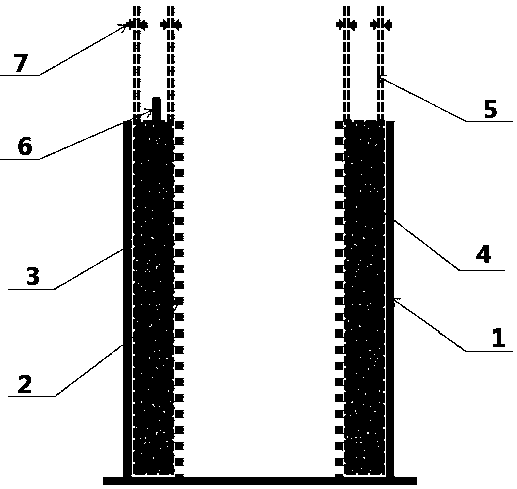

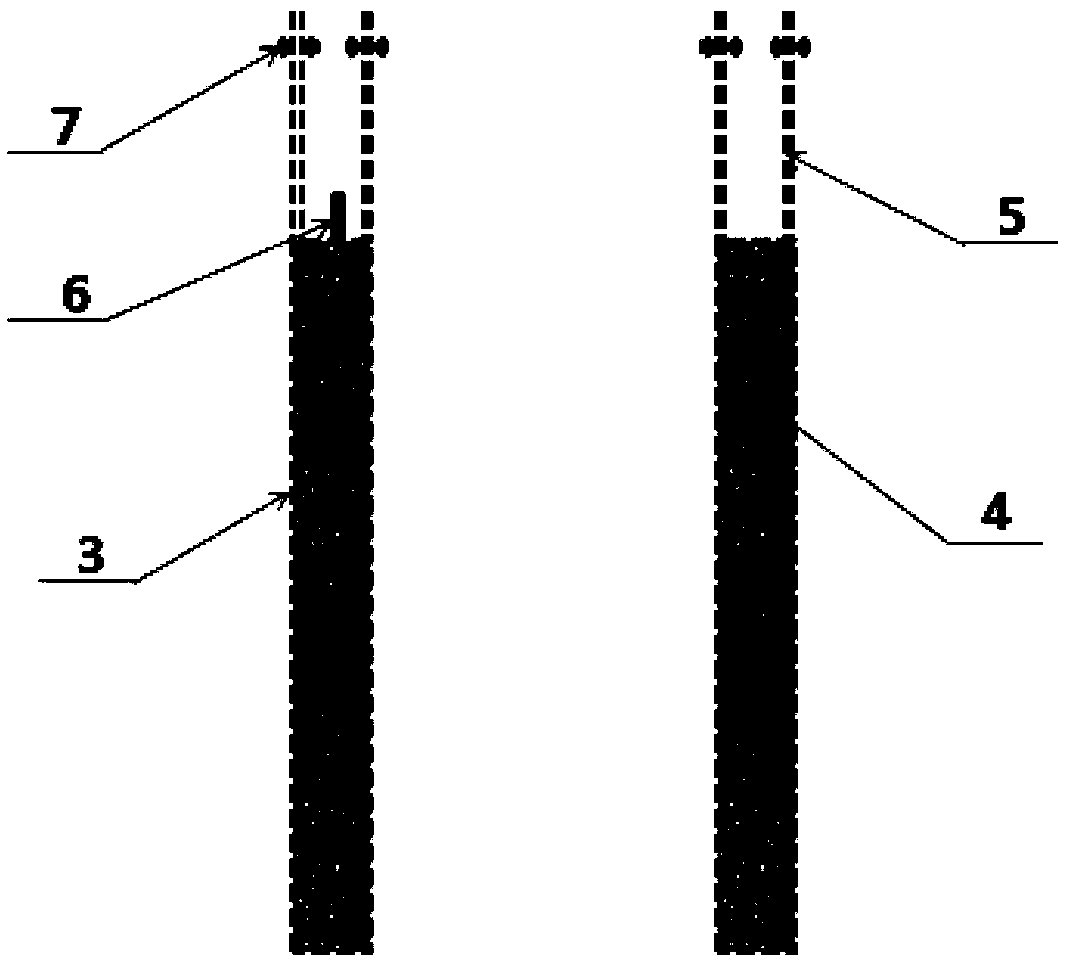

Isostatic cool pressing molding die for ceramic tube and molding method

The invention provides a isostatic cool pressing molding die for a ceramic tube and a molding method. The isostatic cool pressing molding die comprises a steel die and a die sleeve die, wherein the steel die comprises an inner steel die and an outer steel die; a die sleeve is arranged between the inner steel die and the outer steel die, and is divided into an upper die sleeve and a lower die sleeve; the length of the upper die sleeve is the same as that, higher than the steel die, of the lower die sleeve; an exhaust tube arranged on the die sleeve to vacuumize the interior of the die sleeve isprovided; and a cavity filled with ceramic powder is reserved between the lower die sleeve and the upper die sleeve.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Powder metallurgical aluminum base material and manufacturing method thereof

The invention relates to a powder metallurgical aluminum base material. According to the raw material powder, the powder metallurgical aluminum base material comprises, by mass percentage, 0.001%-3% of magnesium hydride powder and the balance aluminum substrate powder. The aluminum substrate powder is aluminum elementary substance powder or aluminum alloy powder or aluminum-based composite material powder. The invention further relates to a manufacturing method of the powder metallurgical aluminum base material. The manufacturing method comprises the following steps of (a) powder mixing; (b) forming; (c) sintering; and (d) thermal treatment. The powder metallurgical aluminum base material is low in sintering deformation. The manufacturing method is simple in technology and high in production efficiency, and is suitable for mass production.

Owner:NBTM NEW MATERIALS GRP

Method for reducing oxygen content of sintered neodymium iron boron material, and additive

ActiveCN110444359AAntioxidantImprove liquidityMagnetic materialsPermanent magnet manufactureCyclohexanoneMagnetic effect

The invention relates to the technical field of permanent magnet materials, and discloses a method for reducing oxygen content of a sintered neodymium iron boron material, and an additive. According to the method disclosed by the invention, magnetic powder is subjected to anti-oxidation protection by adopting a two-step method before grinding and after grinding, and different formulas (II type andII type) are adopted for the additive before grinding and after grinding, wherein the I-type additive comprises BTA, 200# solvent oil, isopropanol and cyclohexanone; and the II-type additive comprises stearate and 120# solvent oil, oleamide, terpilenol, petroleum ether and stadis (R) 450. The additive is added into the neodymium iron boron powder in a continuous spraying manner, so that the particle surfaces of the neodymium iron boron powder are uniformly coated, and the antioxidant effect of the neodymium iron boron powder is improved; the chain section of the I type additive is slightly longer, and the new section caused by airflow grinding is conveniently coated; the chain segment of the type II additive is slightly short and contains a lubricant and a polar group component, so that the static magnetic effect between the powder particles can be weakened, agglomeration between powder particles is reduced, and the orientation degree is improved.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Powder metallurgy aluminum base material and preparation method thereof

ActiveCN110216276AReduce interactionImprove mechanical propertiesHigh volume manufacturingThermal treatment

The invention relates to a powder metallurgy aluminum base material, the raw material powder comprises the following components by mass percent: 0.01-10% of calcium hydride powder and balance of aluminum base powder, wherein the aluminum base powder is aluminum elemental powder or aluminum alloy powder or aluminum base composite material powder. The invention further relates to a preparation method for the powder metallurgy aluminum base material; and the method comprises the following steps of (a) mixing powder; (b) forming; (c) sintering; and (d) thermal treatment. The powder metallurgy aluminum base material has a small amount of sintering deformation; and with the advantages of simple process and high production efficiency, the preparation method is suitable for high-volume production.

Owner:NBTM NEW MATERIALS GRP

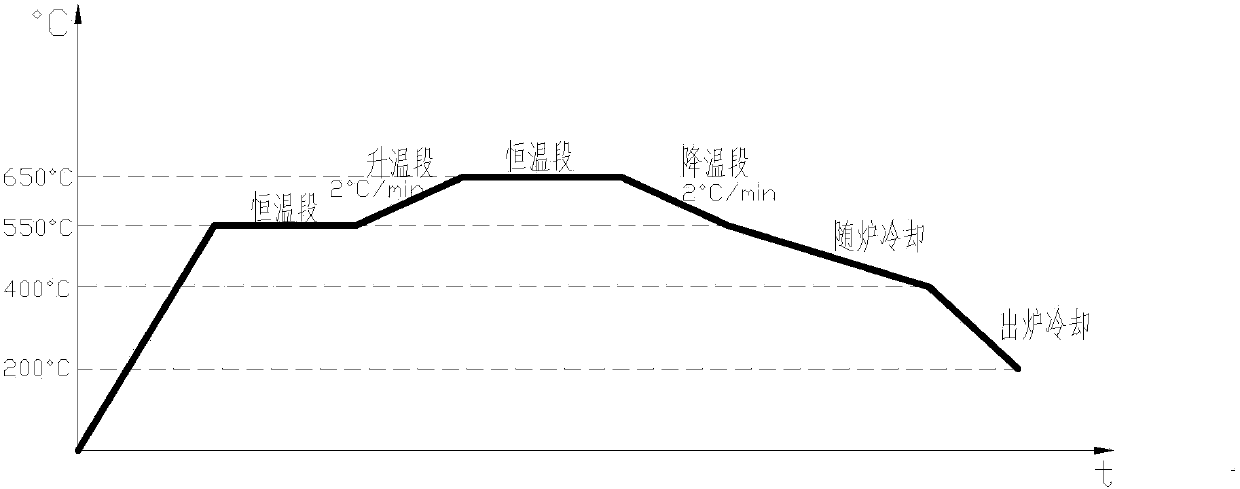

Method for manufacturing low-power dissipation avalanche thyristor chip through open pipe daubing resource perfect diffusion

ActiveCN104299901AEnsure consistencySimple processSemiconductor/solid-state device manufacturingSemiconductor devicesEvaporationAlloy

The invention relates to a method for manufacturing a low-power dissipation avalanche thyristor chip through open pipe daubing resource perfect diffusion. The method comprises the steps of (1) technological environment preparation, (2) ultrasonic cleaning, (3) silicon wafer cleaning, (4) quartz frame and quartz lead cleaning, (5) silicon wafer boron-aluminum diffusion, (6) oxidation, (7) primary photoetching, (8) phosphorus diffusion, (9) circle cutting, (10) sintering, (11) secondary photoetching and evaporation once forming, (12) alloying, (13) table face processing, and (14) testing. Compared with the prior art, the method has the advantages that boron-aluminum primary diffusion is adopted, so that PN junction leading edge smoothness and product uniformity are ensured; the secondary photoetching and evaporation once forming technology is adopted, the working procedures are simplified, the physical damage is reduced, and the rate of finished products and the product performance reliability are improved; operation is carried out in the ultra-clean technological environment, and the long minority carrier lifetime is ensured due to a special cleaning way and a high-quality cleaning reagent; it is ensured that sintering deformation is small due to the novel sintering technology, bonding is firm, and it is ensured that diffusion parameters are stable and unchangeable.

Owner:ANSHAN LIANGXI POWER TECH

Powder metallurgy aluminum-based material and preparation method thereof

ActiveCN110184487AReduce sintering deformationDimensionally stableAluminum matrix compositesPowder metallurgy

The invention relates to a powder metallurgy aluminum-based material. The powder metallurgy aluminum-based material is characterized in that raw material powder comprises the following components of,by mass, 0.01%-15% of zirconium hydride and the balance aluminum base body powder, wherein the aluminum base body powder is aluminum elementary substance powder or aluminum alloy powder or aluminum-based composite material powder. The invention further relates to a preparation method of the powder metallurgy aluminum-based material. The preparation method comprises the following steps of (a) performing powder mixing; (b) performing forming; (c) performing sintering; and (d) performing heat treatment. The powder metallurgy aluminum-based material is relatively small in sintering deformation amount; and the preparation method is simple in process, relatively high in production efficiency and suitable for mass production.

Owner:NBTM NEW MATERIALS GRP

Powder metallurgy aluminum-matrix material and preparing method thereof

ActiveCN110157930AReduce sintering deformationDimensionally stableTransportation and packagingMetal-working apparatusAluminum matrix compositesPowder metallurgy

The invention relates to a powder metallurgy aluminum-matrix material. The raw material powder comprises, by mass percent, 0.01 to 10% of hydrogenated hafnium powder and the balance aluminum-matrix powder. The aluminum-matrix powder is aluminum elemental powder or aluminum alloy powder or aluminum-matrix composite powder. The invention further relates to a preparing method of the powder metallurgyaluminum-matrix material. The method comprises the following steps of a, powder mixing, b, forming, c, sintering, and d, heat treatment. The powder metallurgy aluminum-matrix material is small in sintering deforming amount, and the preparing method is simple in process, high in production efficiency and suitable for large-batch production.

Owner:NBTM NEW MATERIALS GRP

Powder metallurgic aluminum-based material and preparation method thereof

The invention relates to a powder metallurgic aluminum-based material. Raw material powder comprises the following components in percentage by mass: 0.01%-5% of titanium hydride, and the balance of aluminum matrix powder which is aluminum elemental powder or aluminum alloy powder or aluminum-based composite material powder. The invention further relates to a preparation method for preparing the powder metallurgic aluminum-based material, and the preparation method comprises the following steps: (a) mixing powder; (b) forming; (c) sintering; and (5) thermally treating. The powder metallurgic aluminum-based material is relatively small in sintering deformation amount. The preparation method is simple in process, and is suitable for large-batch production.

Owner:NBTM NEW MATERIALS GRP

A method for manufacturing a low-deformation toughened silicon-based ceramic core

ActiveCN105418058BHigh melting pointHeat shock resistantCeramic shaping apparatusTurbine bladeRoom temperature

The invention belongs to the technical field of precision casting, and particularly relates to a making method of a low-deformation toughened silica-based ceramic core. Zirconium oxide is doped with different-valence metallic oxide magnesium oxide to serve as a stabilizer, ZrO2 can be maintained in a tetragonal phase or a cubic phase at room temperature, magnesium oxide is further added to a core sizing formula, a fibrous structure of the magnesium oxide can increase the toughness of a wet core when a core wet billet is pressed, drawing deformation and cracks of the core wet billet can be reduced, and the fracture rate during core trimming can be decreased. The making method of the low-deformation toughened silica-based ceramic core is not only suitable for preparing ceramic cores of large parts which are complex in shape and thin in wall, but also suitable for producing ceramic cores for equiaxial and directed hollow turbine blades. The core wet billet prepared through the making method is good in toughness, high in drawing yield, small in deformation and small in sintering deformation of the core.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Magnesian ceramic blank, magnesian ceramic and preparation method thereof

ActiveCN102786298BSmall coefficient of thermal expansionImprove thermal stabilitySodium BentoniteBall clay

The invention provides novel magnesian ceramic blank. The novel magnesian ceramic blank comprises, by weight percent, 60-70% of talcum, 20-25% of clay, 5-10% of feldspar, and 5-10% of alumina. The talcum is mixture of raw talcum and burnt talcum. The clay is mixture of kaolin, ball clay and bentonite. The invention further provides a preparation method of magnesian ceramic, and the magnesian ceramic prepared by the preparation method. The magnesian ceramic prepared by the magnesian ceramic blank, glaze and the preparation method is low in thermal expansion coefficient, and has improved thermal stability and formability. In addition, sintering range is wide, sintering temperature is low, and the risk of ceramic burst is lowered greatly.

Owner:HUNAN XIANFENG CERAMIC IND

A method for preparing superalloy honeycomb insulation board based on injection molding

ActiveCN107999756BImprove mechanical propertiesLow costTransportation and packagingMetal-working apparatusSuperalloyMachining process

Owner:SHENZHEN ELEMENT TECH CO LTD

A method and additive for reducing oxygen content of sintered NdFeB material

ActiveCN110444359BHigh carbon contentHas a lubricating effectMagnetic materialsPermanent magnet manufactureCyclohexanoneMetallurgy

The invention relates to the technical field of permanent magnet materials, and discloses a method and additives for reducing the oxygen content of sintered NdFeB materials. The method of the present invention adopts the pre-grinding and post-grinding two-step method to carry out anti-oxidation protection to the magnetic powder, and the pre-milling and post-grinding additives adopt different formulations (Type I and Type II), wherein the Type I additives include BTA, 200# solvent oil , isopropanol and cyclohexanone; Type II additives include stearate and 120# solvent oil, oleic acid amide, terpineol, petroleum ether and stadis (R) 450. In the present invention, the additive is added to the NdFeB powder in the form of continuous spraying, and the particle surface of the NdFeB powder is evenly coated, which improves the anti-oxidation effect of the NdFeB powder. The chain segment of the type I additive is slightly longer, It is convenient to cover the new section produced by jet milling; the chain segment of type II additive is slightly short and contains lubricant and polar group components, which can weaken the static magnetic effect between powder particles and reduce the agglomeration between powder particles, which is beneficial to improve degree of orientation.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com