Method for manufacturing low-power dissipation avalanche thyristor chip through open pipe daubing resource perfect diffusion

A fully-diffused, low-power technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high failure rate, short service life, low cost, etc., to reduce physical damage, improve reliability, Small effect of sintering deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

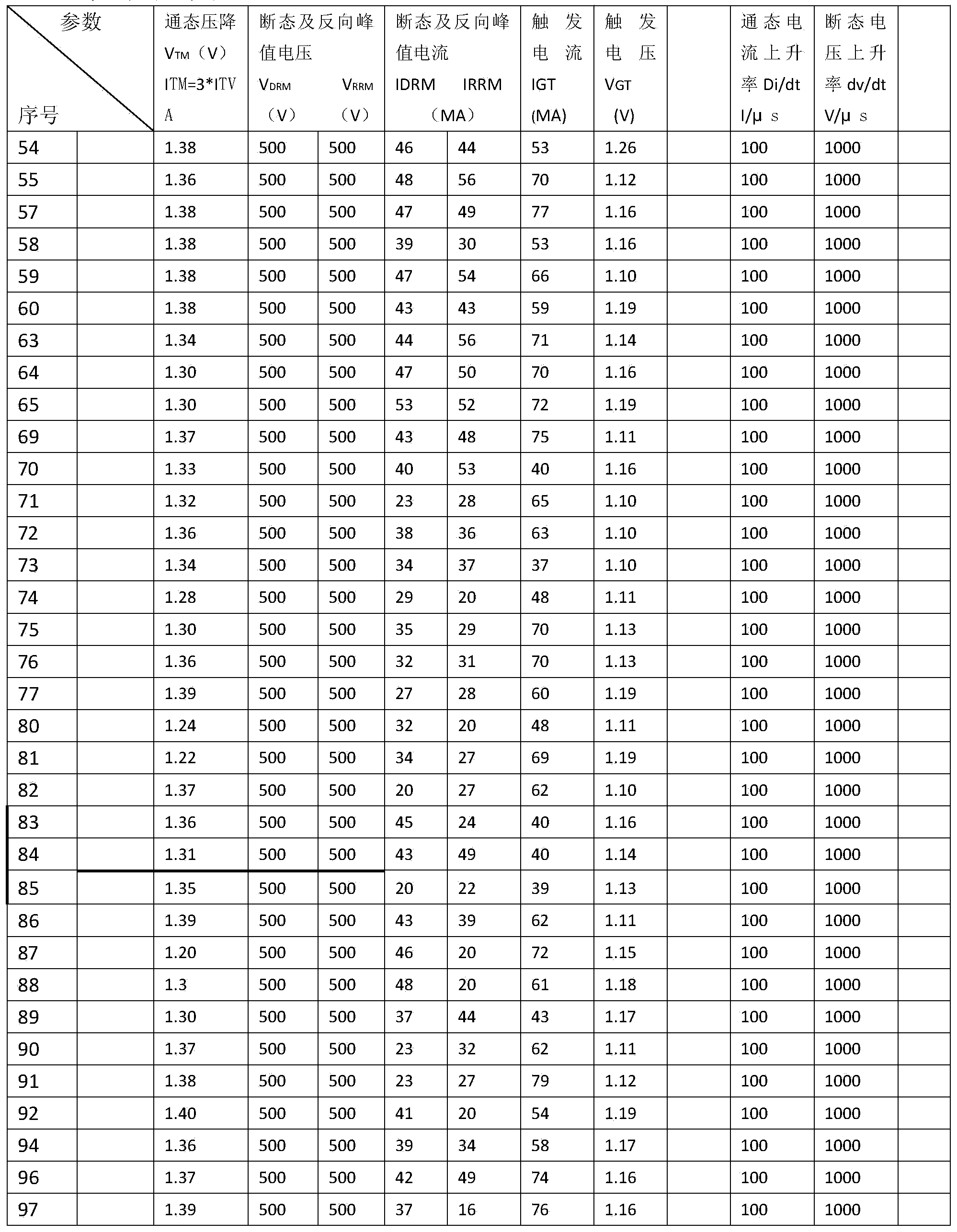

Image

Examples

Embodiment 1

[0078] [Example 1] Applying the method of the present invention to manufacture 100 avalanche thyristor chips, the manufacturing process is as follows:

[0079] The air in the process environment is double-stage and double-filtered, and the filtered air is 10 grades;

[0080] Ultrasonic desanding of silicon wafers for 1 hour, ultrasonic cleaning of hydrofluoric acid for 1 hour, rinse with deionized water at room temperature and 70°C respectively, and then ultrasonic cleaning with deionized water for 2 hours, replace deionized water every 30 minutes, and then wash with hot and cold Rinse four times alternately with deionized water;

[0081] Prepare 1# liquid, the volume ratio is ammonia water: hydrogen peroxide: deionized water = 1:2:5; prepare 2# liquid, the volume ratio is hydrochloric acid: hydrogen peroxide: deionized water = 1:2:7; Put the sanded silicon wafer into 1# solution, boil it on the heater for 5 minutes, rinse it with deionized water 10 times, replace it with cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com