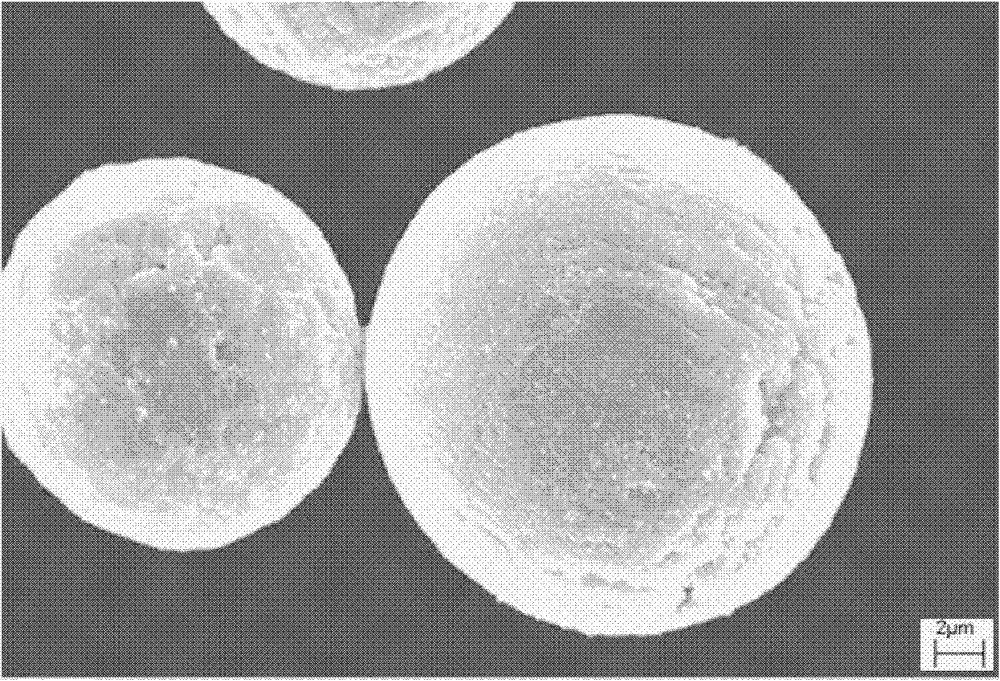

Preparation method of ultra-fine spherical nickel coated titanium composite powder

A composite powder and nickel-coated technology, which is applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problems of irregular powder shape, large deformation of sintered products, and low packing density, so as to achieve small sintering deformation , High bulk density and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 20 g of 40 μm titanium hydride powder. First soak in alcohol for 10 minutes, remove the upper solution, then soak in 10g / L stannous chloride hydrochloric acid solution for 30 minutes, remove the upper solution, wash with deionized water until neutral; finally soak it in 10g / L Soak in silver nitrate solution for 12 hours, remove the upper solution, wash with deionized water 2-3 times, filter and dry.

[0024] Weigh 30g of nickel sulfate hexahydrate, dissolve it into 1000mL solution with deionized water, and prepare a 17.68g / L nickel sulfate solution, heat it in a water bath to 64°C, slowly add 12mL of hydrazine hydrate dropwise under rapid stirring, and then add the pretreatment Slowly add 2mol / L NaOH solution to adjust the pH to 9.7, stir quickly to ensure the uniformity of titanium hydride nickel plating, and slowly add 2mol / L NaOH solution to keep the pH at 9.3~9.7, Keep the water bath temperature at 80°C. After coating for 2 hours, take out the titanium hydri...

Embodiment 2

[0028] Weigh 30 g of 50 μm titanium hydride powder. First soak in alcohol for 12 minutes to remove the upper layer solution, then soak in 11g / L stannous chloride hydrochloric acid solution for 35 minutes, remove the upper layer solution, wash with deionized water until neutral; finally soak it in 11g / L stannous chloride hydrochloric acid solution Soak in silver nitrate solution for 13 hours, remove the upper solution, wash with deionized water 2-3 times, filter and dry.

[0029] Weigh 30g of nickel sulfate hexahydrate, dissolve it into 1000mL solution with deionized water, and prepare a 17.68g / L nickel sulfate solution, heat it in a water bath to 74°C, slowly add 12mL of hydrazine hydrate dropwise under rapid stirring, and then add the pretreatment Slowly add 2mol / L NaOH solution to adjust the pH to 9.5, stir quickly to ensure the uniformity of titanium hydride nickel plating, and slowly add ammonia solution to keep the pH at 9.3~9.7, and ensure that the temperature of the wat...

Embodiment 3

[0033] Weigh 15 g of 60 μm titanium hydride powder. First soak in alcohol for 13 minutes, remove the upper solution, then soak in 8g / L stannous chloride hydrochloric acid solution for 45 minutes, remove the upper solution, wash with deionized water until neutral; finally soak it in 8g / L Soak in silver nitrate solution for 15 hours, remove the upper solution, wash with deionized water 2-3 times, filter and dry.

[0034] Weigh 30g of nickel sulfate hexahydrate, dissolve it into 1000mL solution with deionized water, and prepare a 17.68g / L nickel sulfate solution, heat it in a water bath to 80°C, slowly add 9mL of hydrazine hydrate dropwise under the condition of rapid stirring, and then add the pretreatment Slowly add 2mol / L KOH solution to the titanium hydride powder, adjust the pH to 9.0, stir quickly to ensure the uniformity of titanium hydride nickel plating, and slowly add 2mol / L KOH solution to keep the pH at 8.8~9.2, Keep the water bath temperature at 90°C. After coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com