Patents

Literature

397 results about "Radio frequency plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

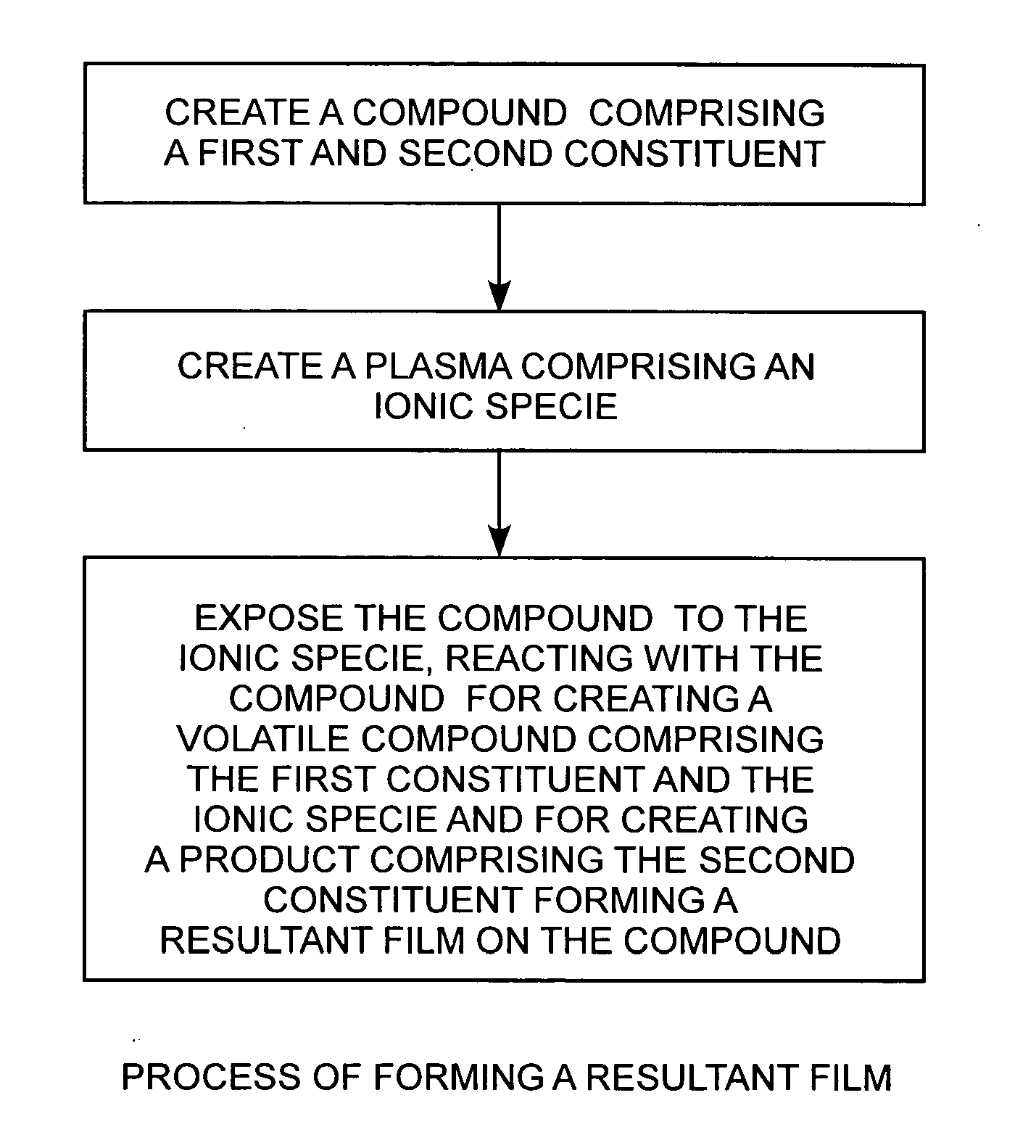

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS20060068125A1Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon filmCarbon coating

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

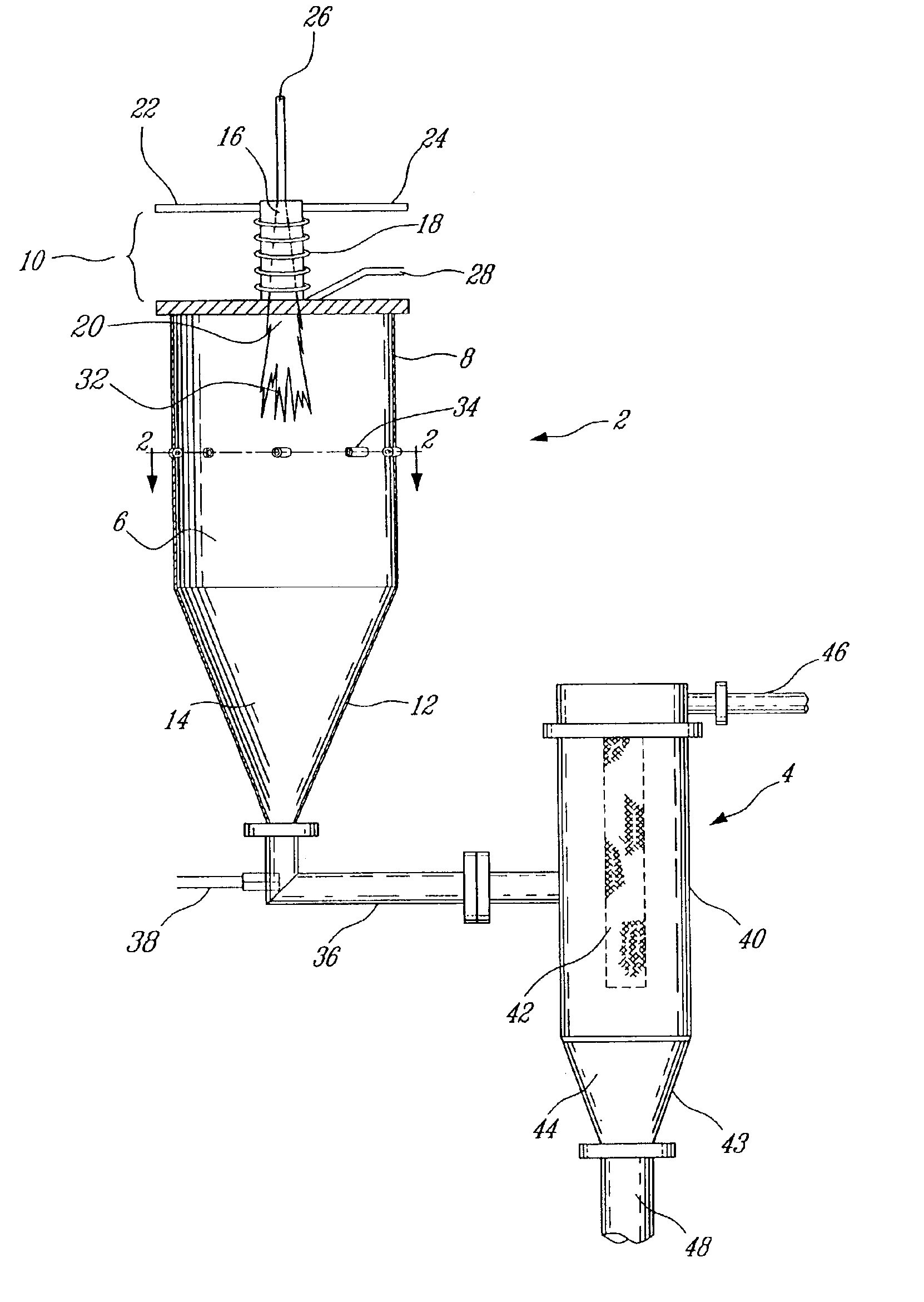

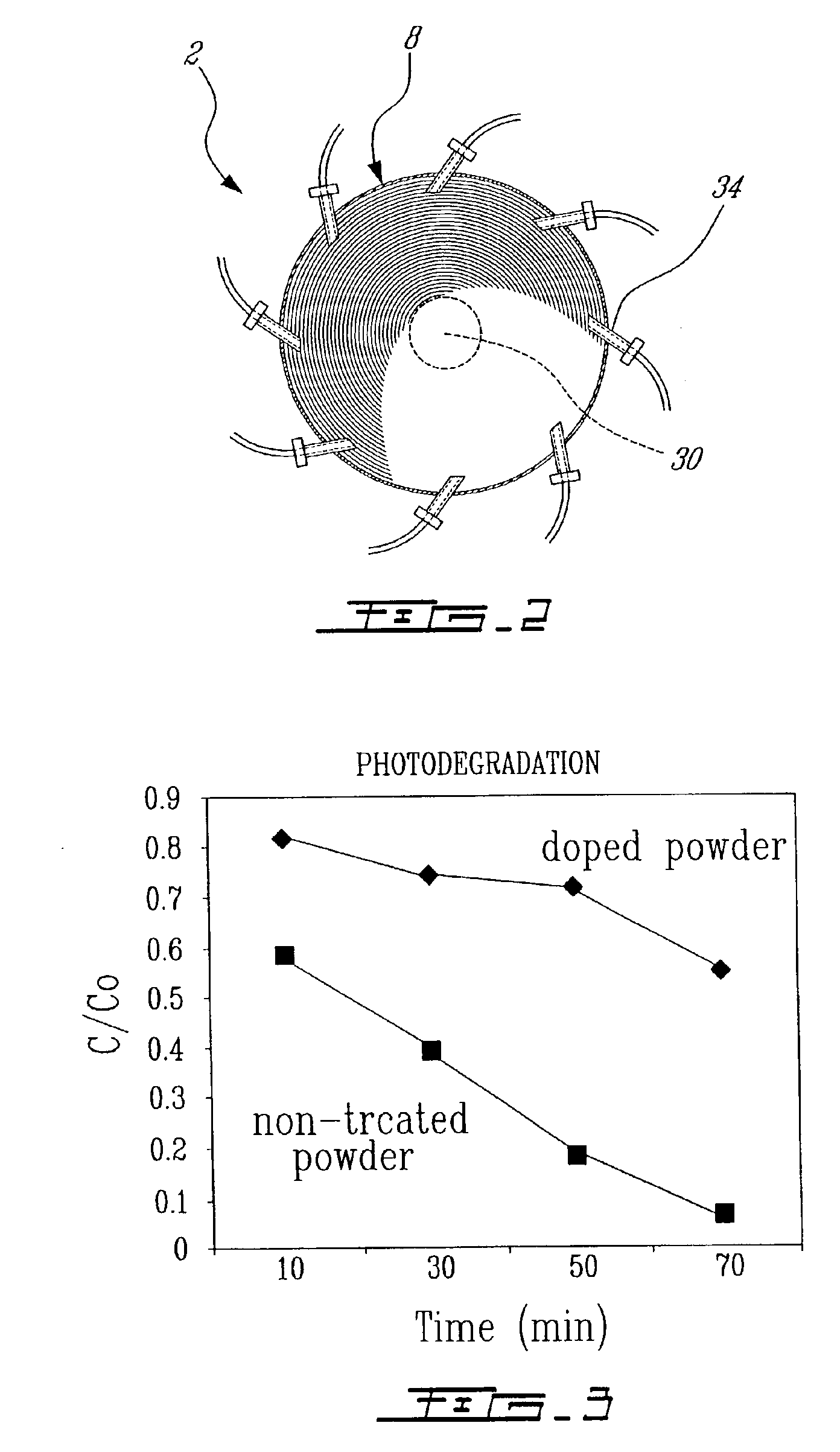

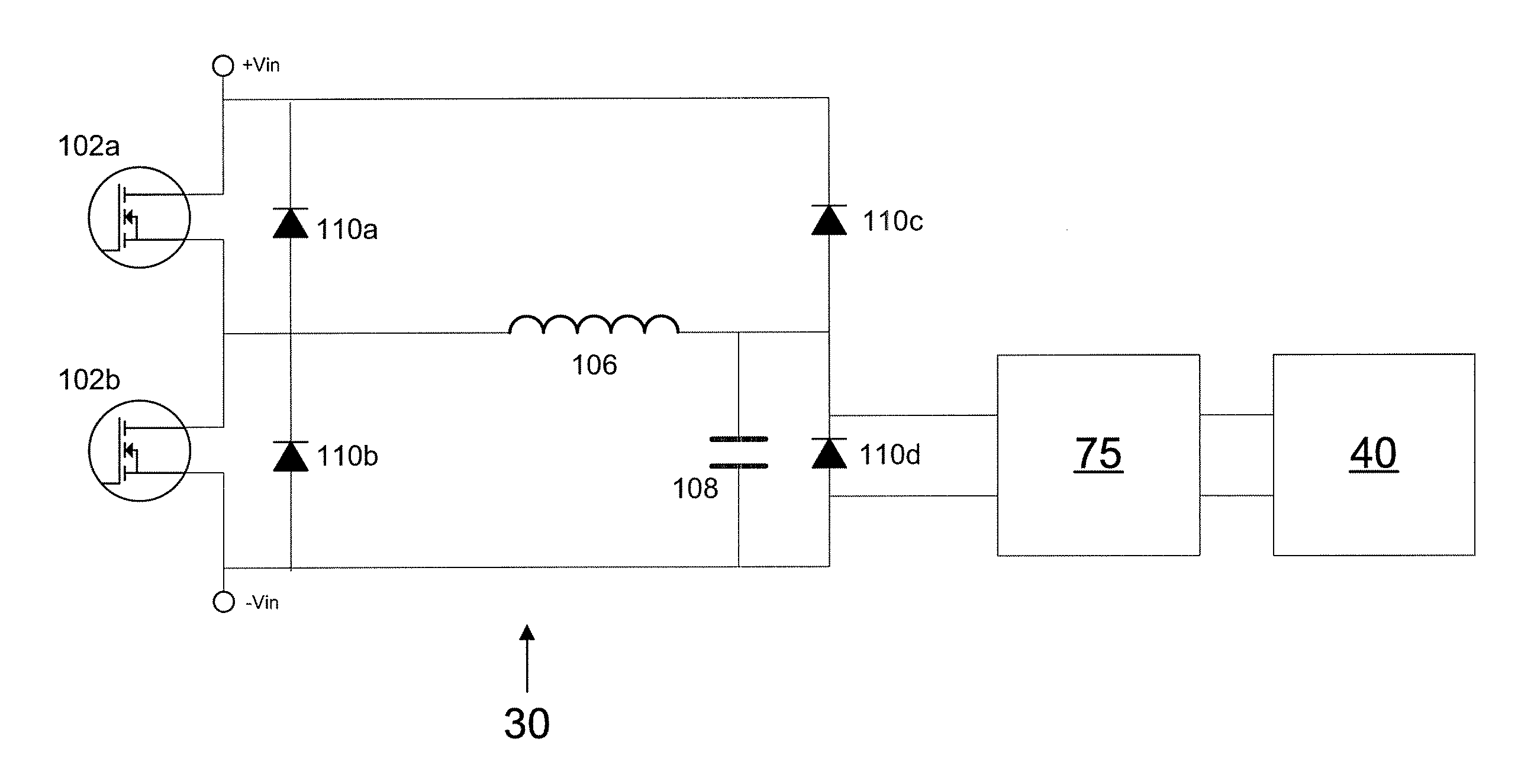

Plasma synthesis of metal oxide nanopowder and apparatus therefor

InactiveUS6994837B2Large dischargeKeep for a long timePigmenting treatmentMaterial nanotechnologyDopantPhysical chemistry

A process and apparatus for the synthesis of metal oxide nanopowder from a metal compound vapour is presented. In particular a process and apparatus for the synthesis of TiO2 nanopowder from TiCl4 is disclosed. The metal compound vapour is reacted with an oxidizing gas in electrically induced RF frequency plasma thus forming a metal oxide vapour. The metal oxide vapour is rapidly cooled using a highly turbulent gas quench zone which quickly halts the particle growth process, yielding a substantial reduction in the size of metal oxide particles formed compared with known processes. The metal compound vapour can also react with a doping agent to create a doped metal oxide nanopowder. Additionally, a process and apparatus for the inline synthesis of a coated metal oxide is disclosed wherein the metal oxide particles are coated with a surface agent after being cooled in a highly turbulent gas quench zone.

Owner:TEKNA PLASMA SYST INC

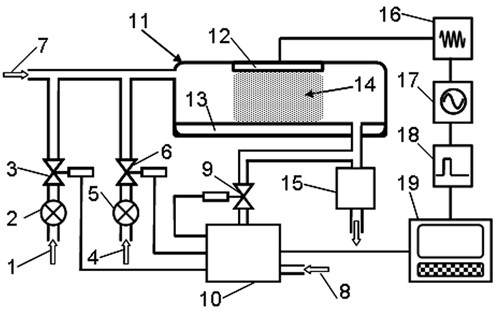

Stabilizer for switch-mode powered RF plasma

InactiveUS6046546AAvoid instabilityEffect can be causedElectric discharge tubesAc-dc conversionHarmonicInstability

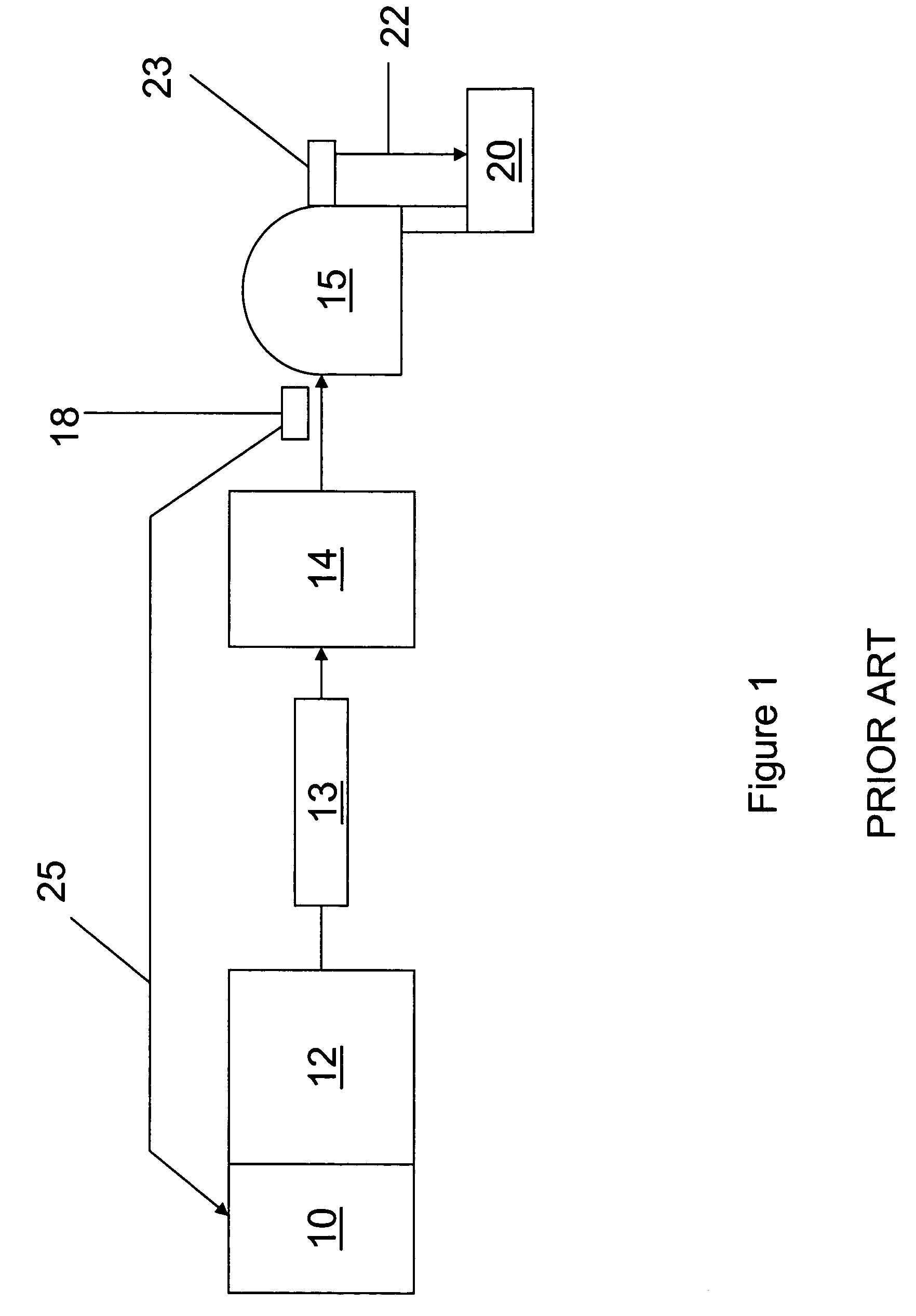

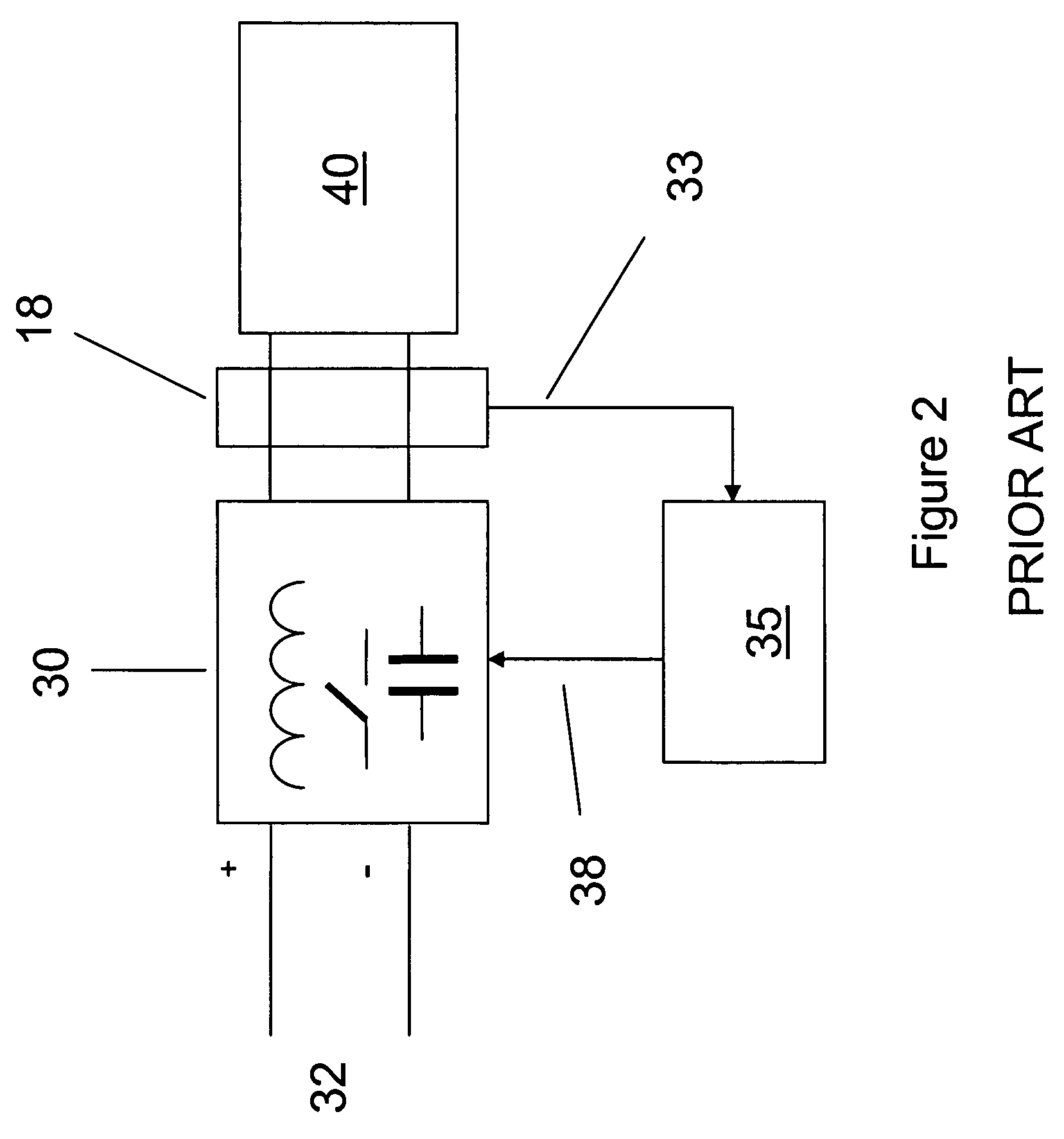

Circuitry and techniques designed to allow stable and continuous delivery of alternating power to a plasma with switch-mode power supply (16) include a variety of embodiments. Parallel, series, and other circuit elements connected across switching element (7) are tuned so that energy at other than the fundamental frequency is absorbed and dissipated. This energy may be only at the second harmonic or it may be across broad frequency ranges through selecting high impedance at the fundamental frequency and relatively low impedance at other frequencies. In overcoming instabilities, oscillations, and even changing class of operation of the switch-mode power supply, the stabilizing element absorbs the energy to avoid allowing it to affect switch (7) of power supply (16).

Owner:ADVANCED ENERGY IND INC

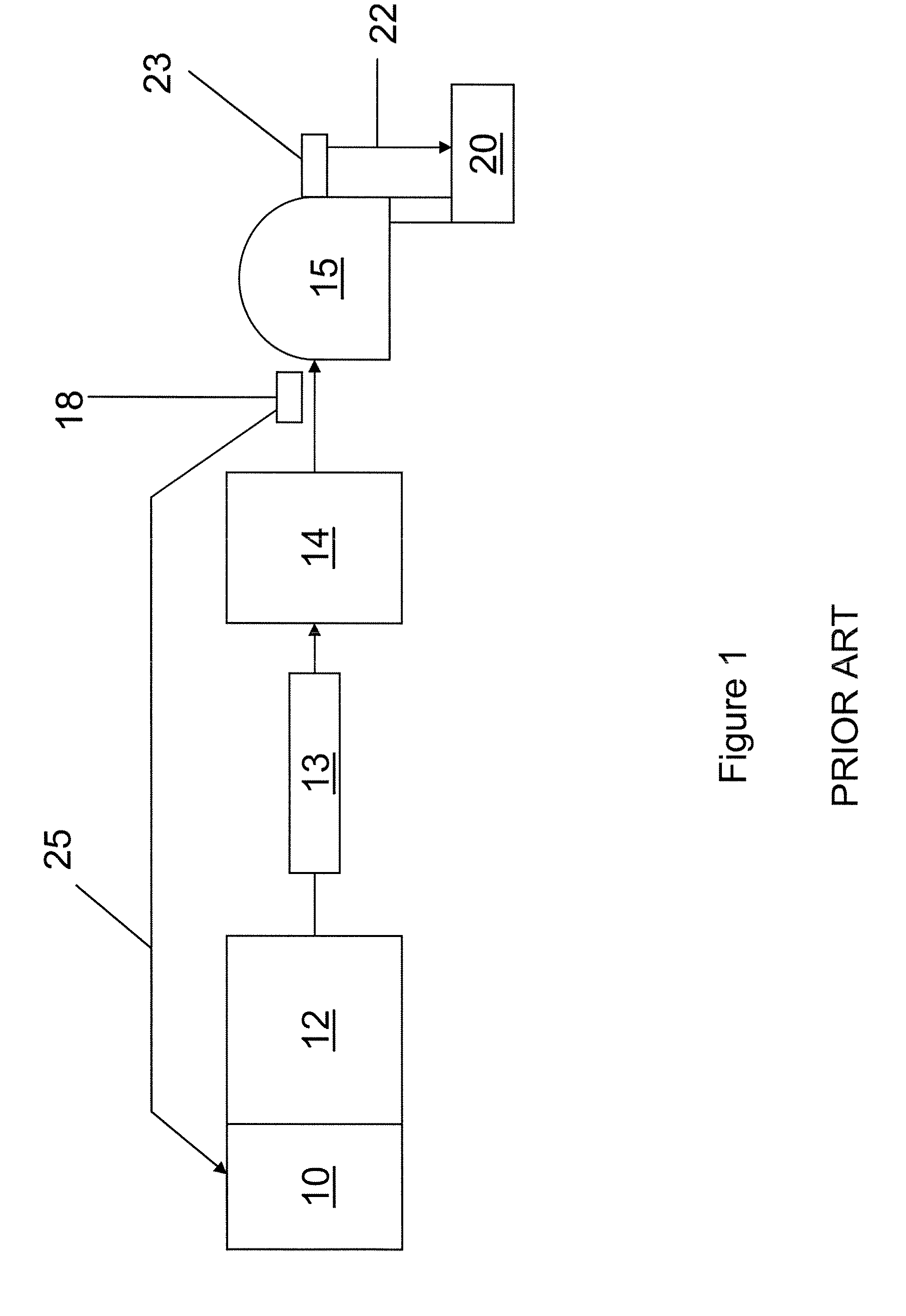

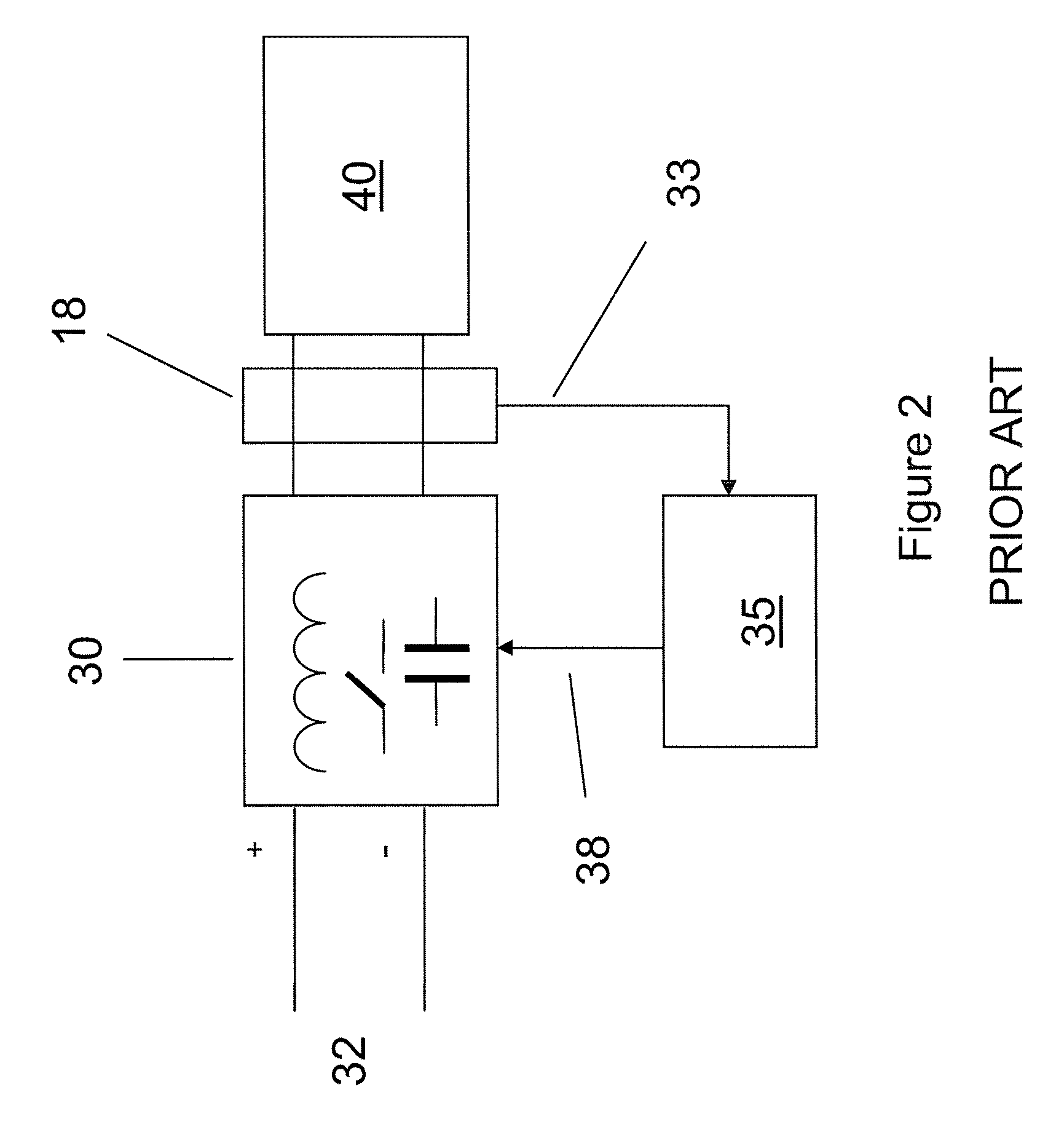

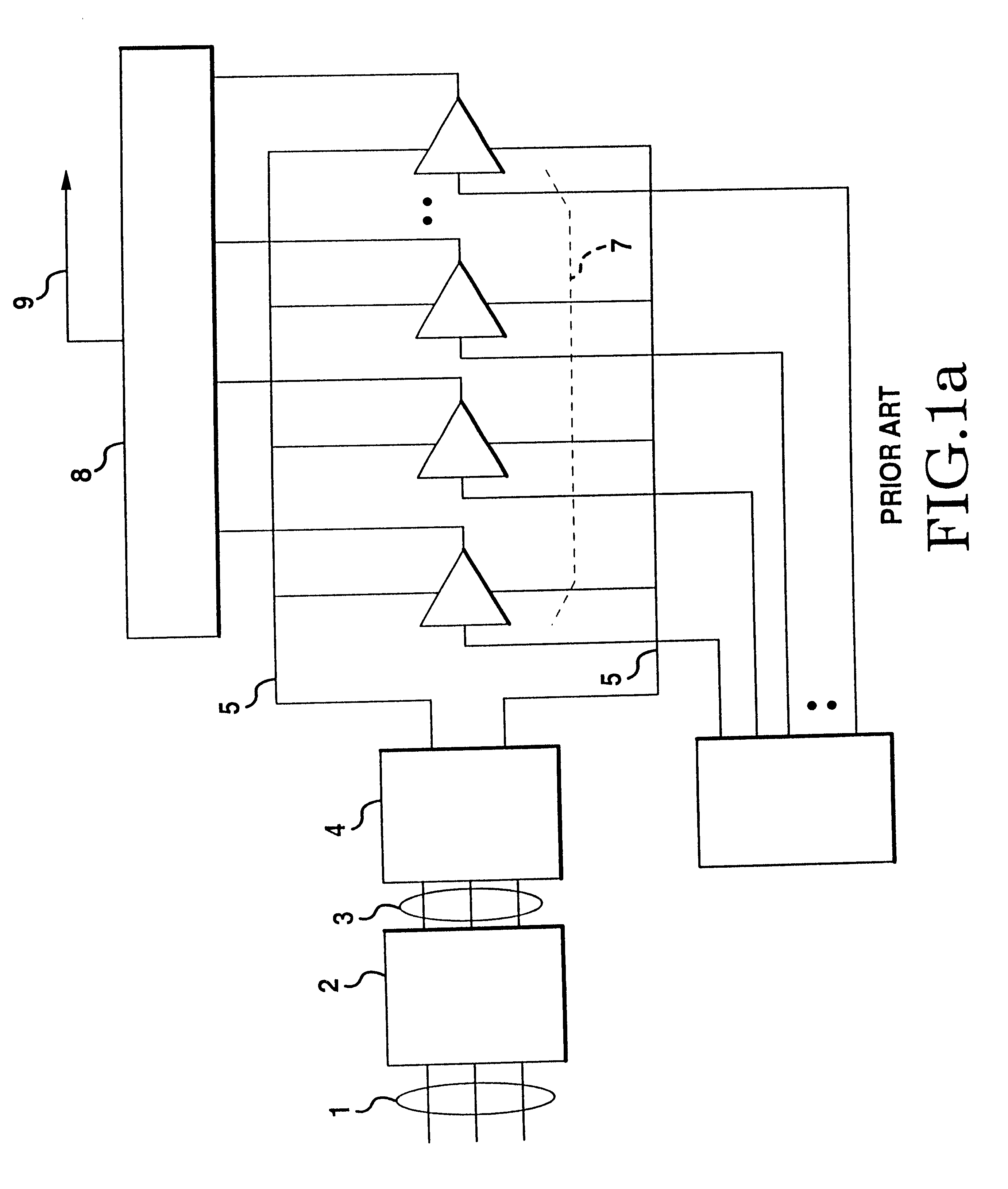

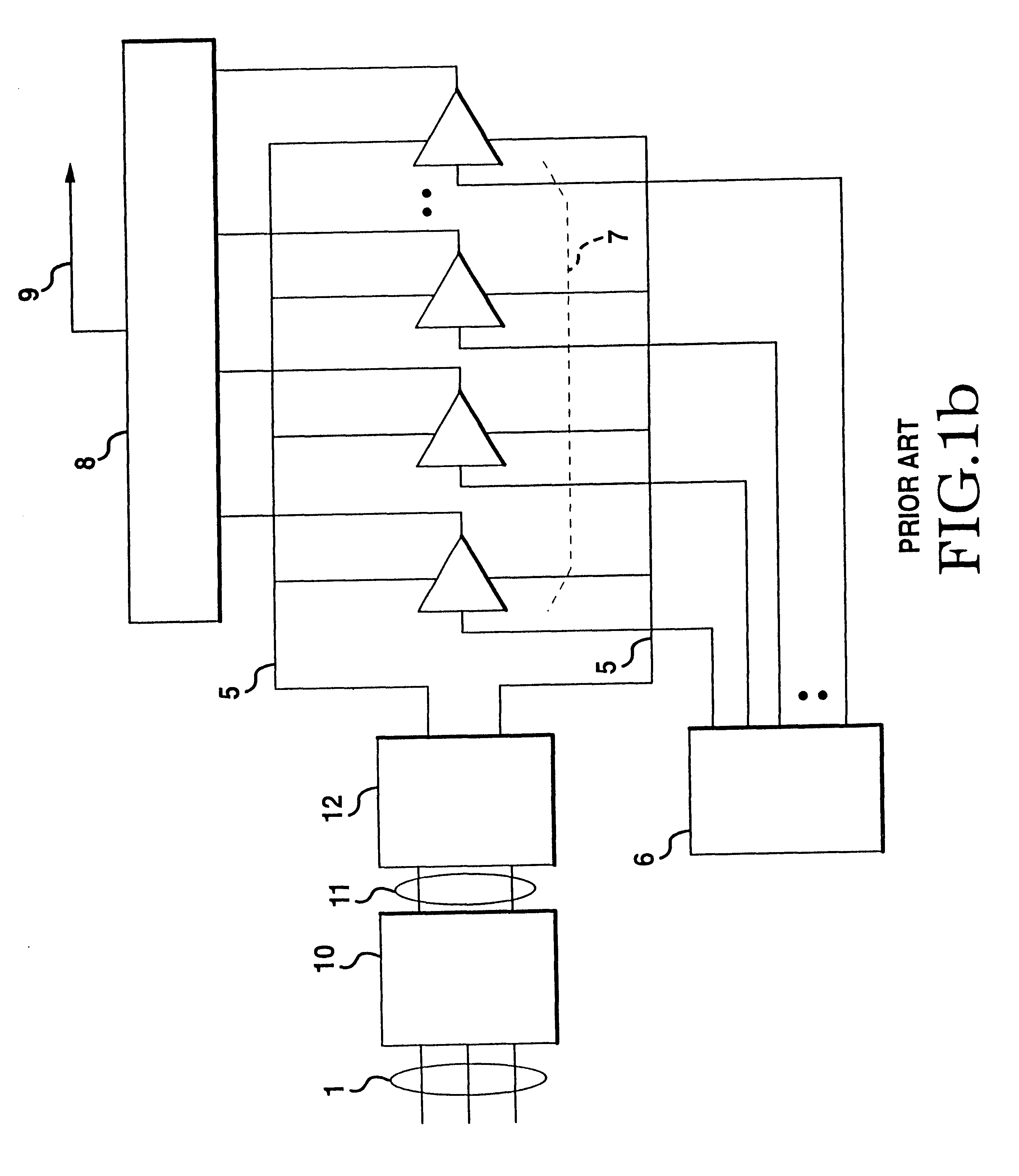

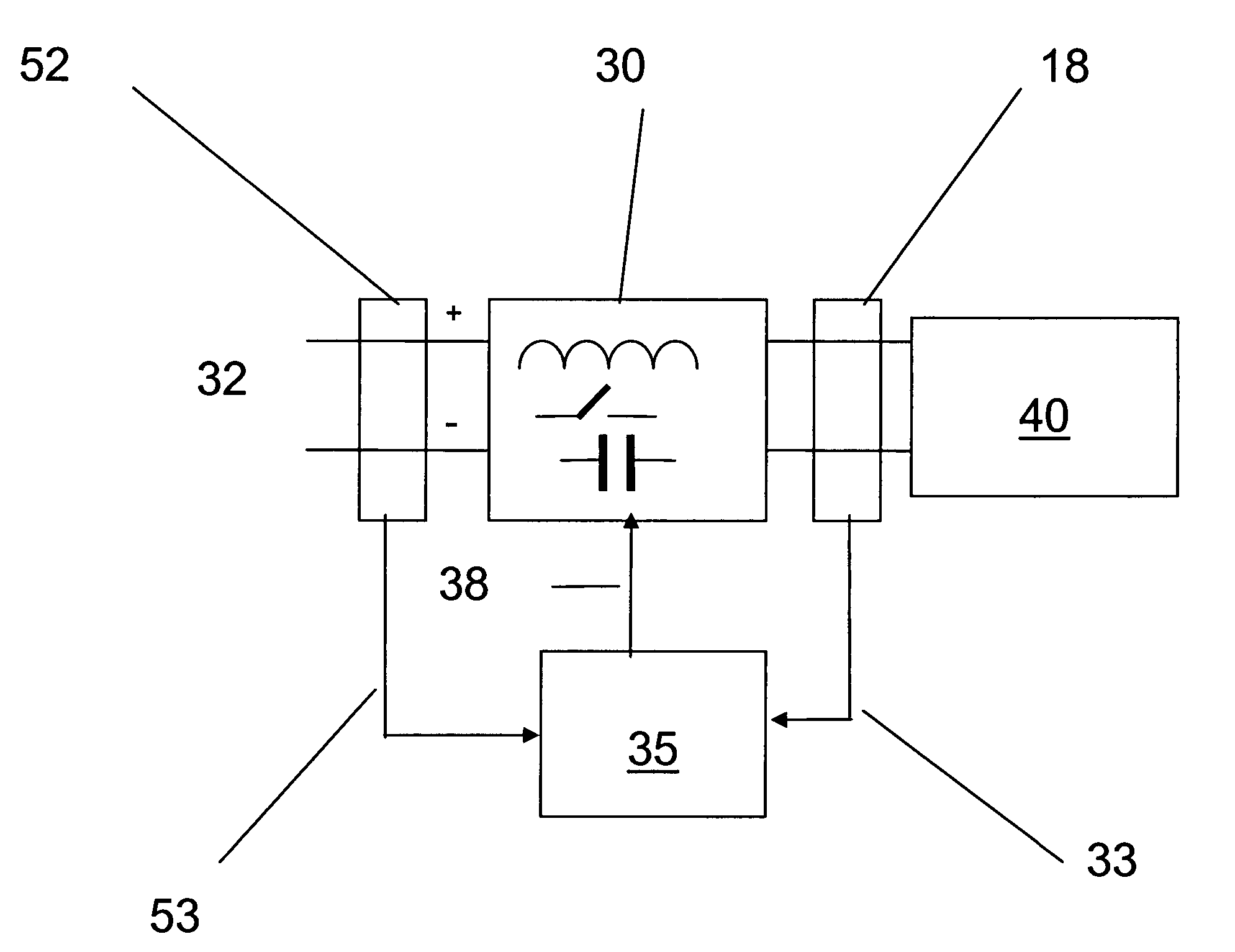

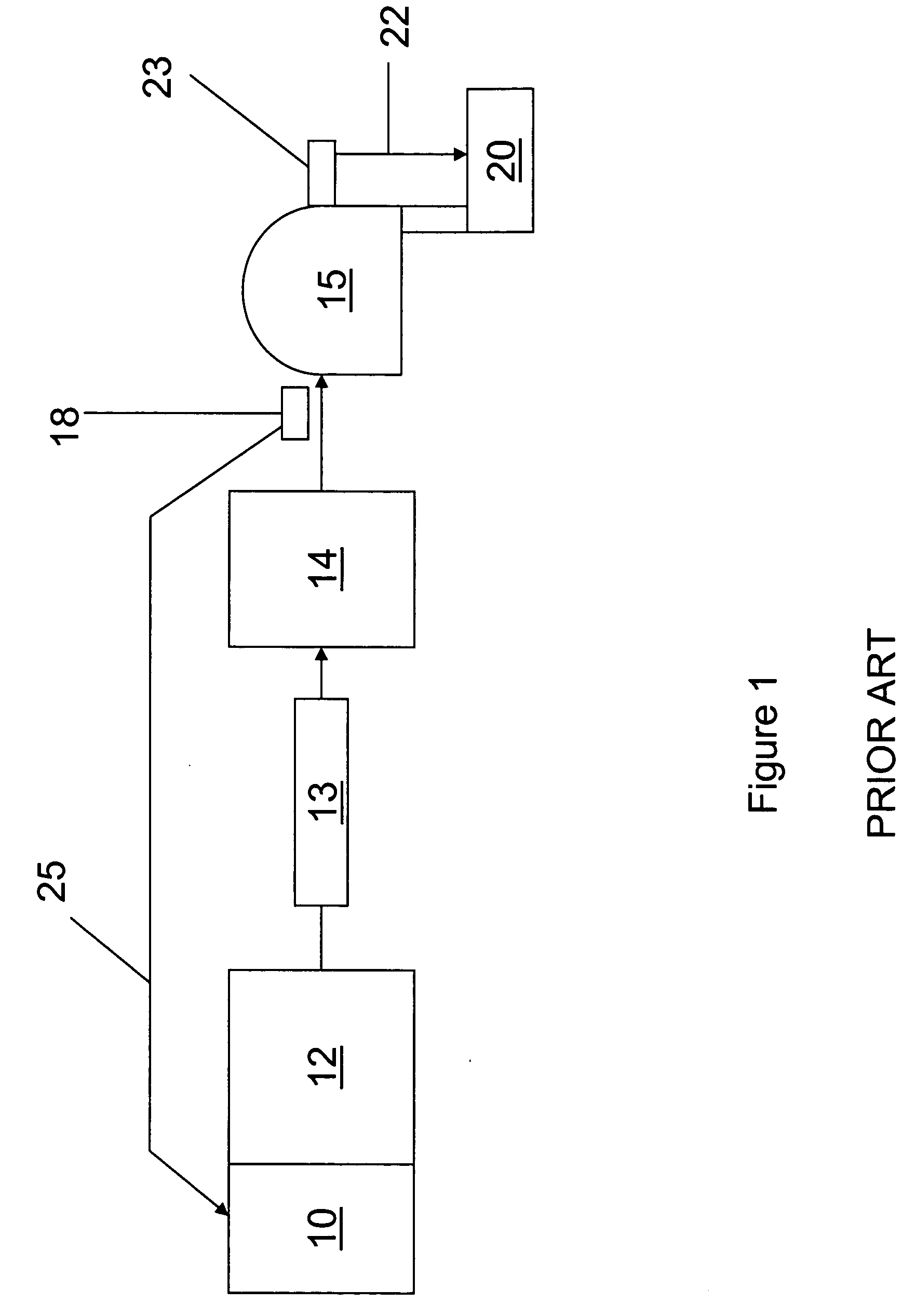

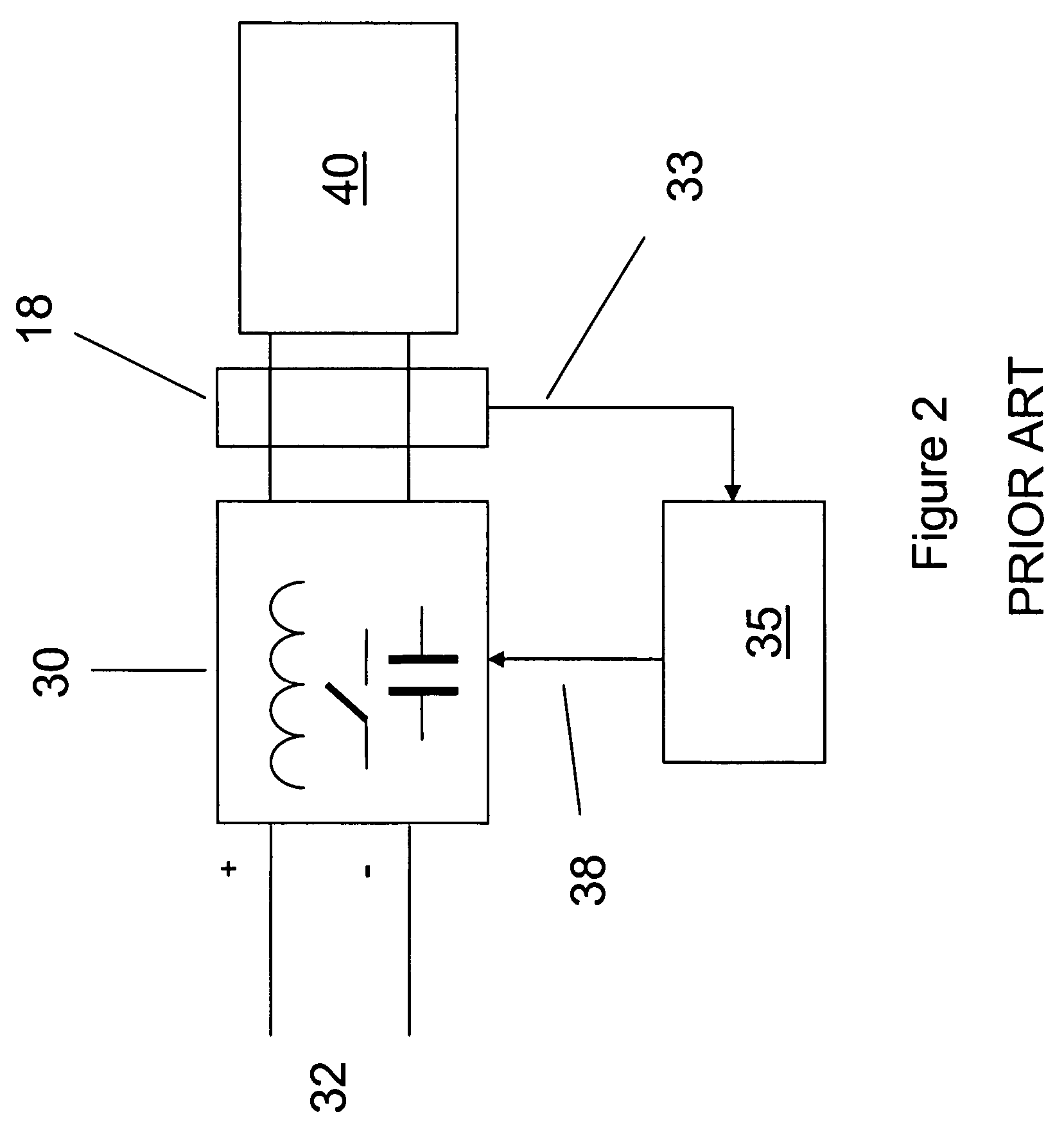

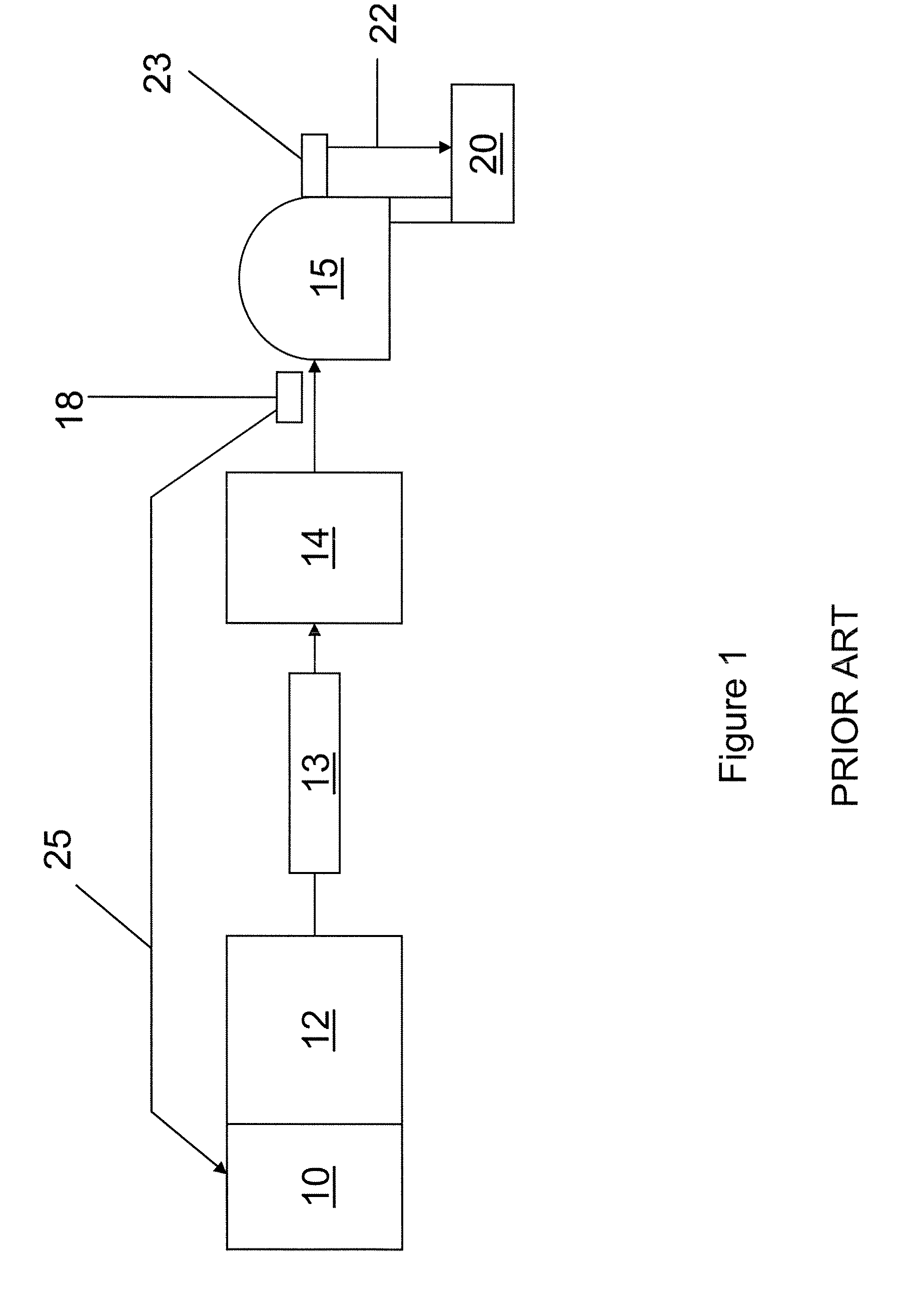

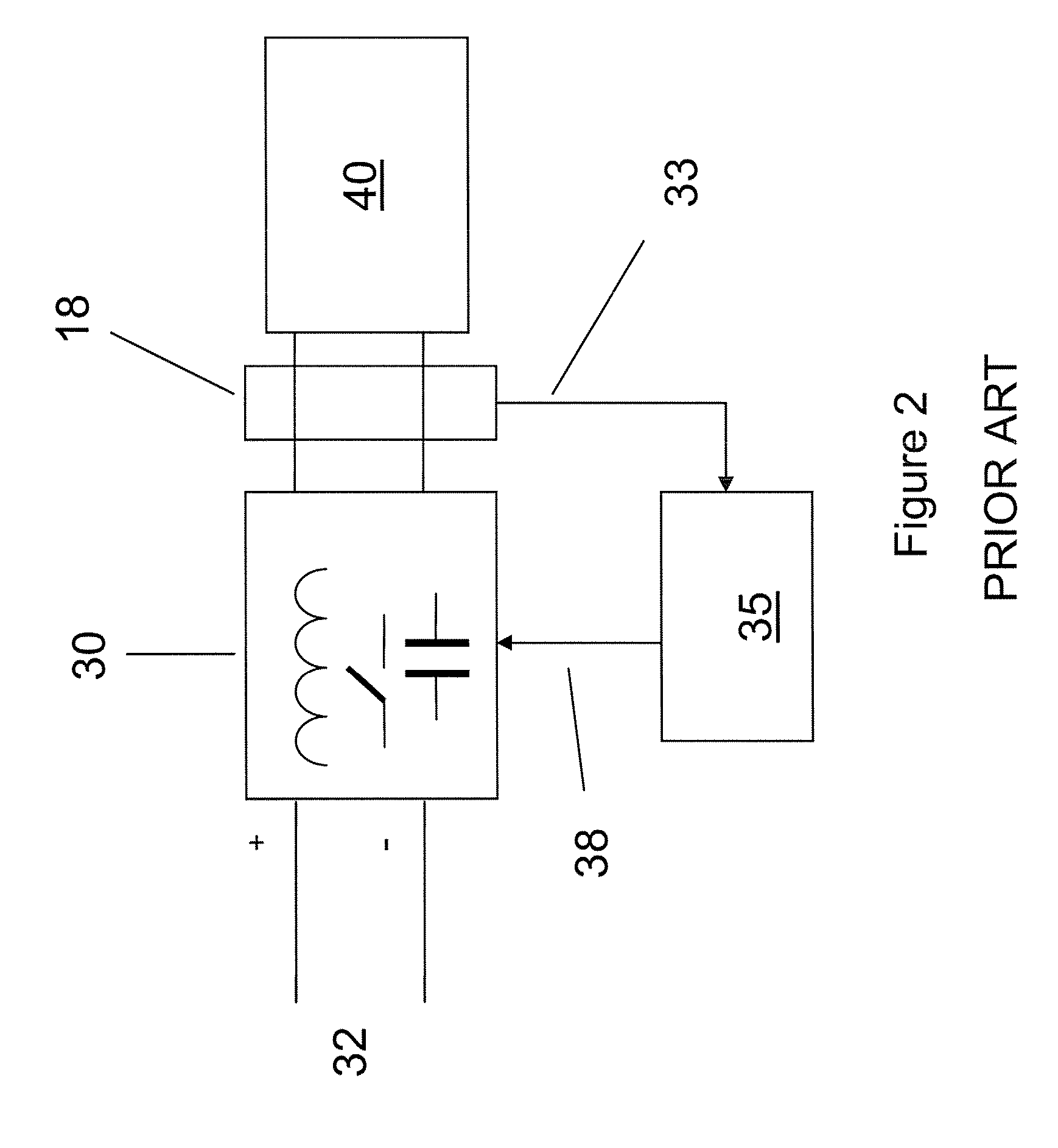

Method and apparatus for preventing instabilities in radio-frequency plasma processing

ActiveUS7755300B2Guaranteed uptimeElectric discharge tubesElectric light circuit arrangementConstant powerInstability

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up 1 MHz and above. The apparatus includes a power source, a power converter receiving power from the source, the power converter providing a constant output power controlled by varying at least one of input voltage or switching frequency, and an RF generator receiving constant power from the power converter.

Owner:MKS INSTR INC

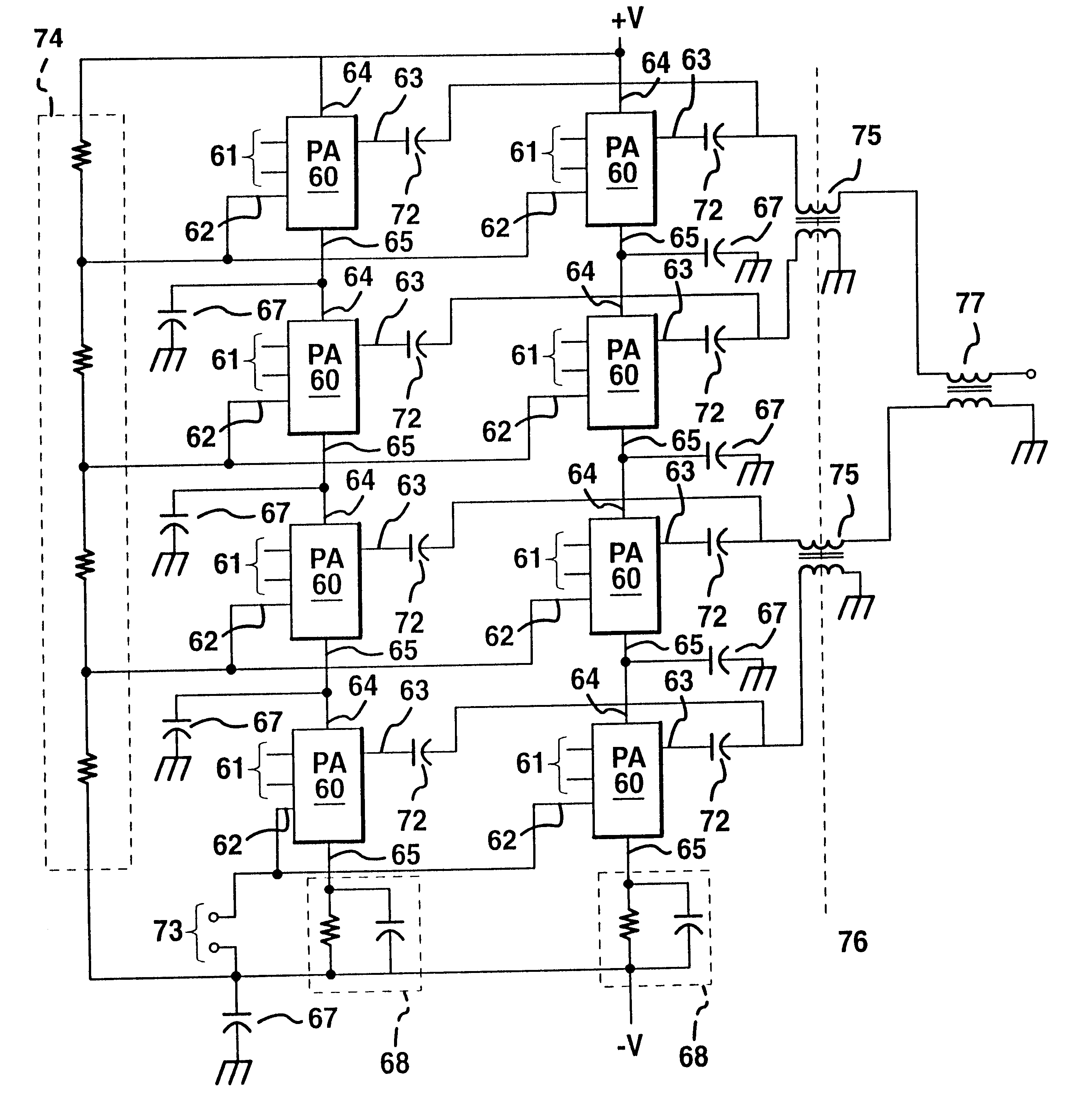

System for high power RF plasma processing

InactiveUS6384540B1Cost effectiveSimple designNegative-feedback-circuit arrangementsElectric discharge tubesAudio power amplifierSystems design

A high power radio frequency power method of amplifications described in which a variety of amplifiers (60 & 86) may be used to reduce the stress any one amplifier experiences. The power leads (64 & 65) may be arranged in a series to power each amplifier at potentials which are lower than the total potential. Outputs (63) may then be connected in a parallel fashion to combine the power output by the system. A variety of unique stabilization, drive, division, combination, and supply configurations are presented as well as the possibility of utilization and adaptation of the designs for a plasma processing system. An aspect of tiered combining is included such as may be especially appropriate for larger numbers of devices which may include switchmode amplifiers and the like.

Owner:ADVANCED ENERGY IND INC

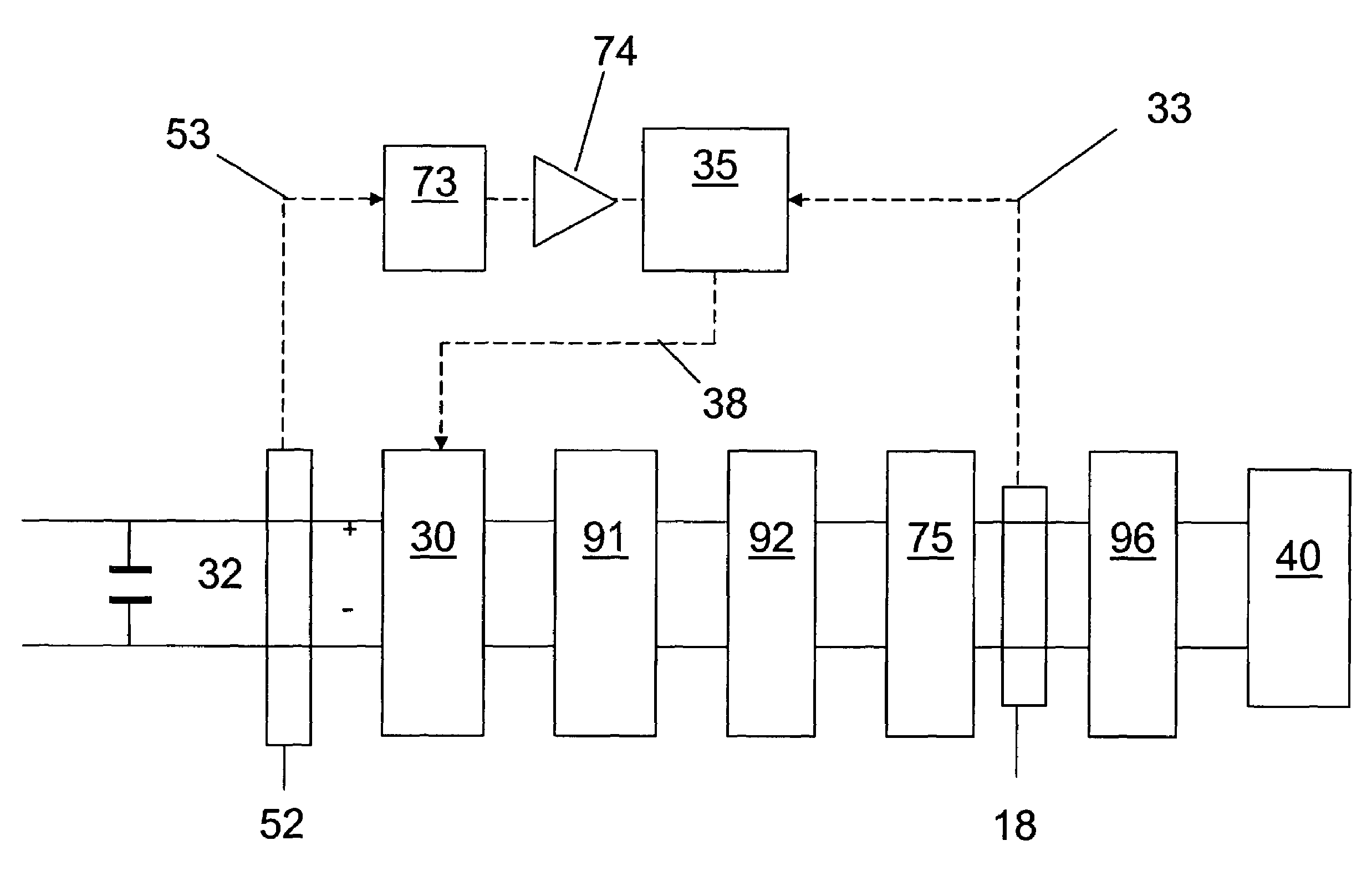

Method and apparatus for preventing instabilities in radio-frequency plasma processing

ActiveUS7304438B2Guaranteed uptimeEasy to controlElectric discharge tubesElectric arc lampsElectricityPlasma impedance

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up, uses a feedforward type of control loop to tightly regulate the power supplied to the dynamic electrical load, such as loads caused by variable and inconsistent plasma impedance. A feedback control loop can also be used in combination with the feedforward loop, but at a slower rate, to help regulate the amount of power provided to the load.

Owner:MKS INSTR INC

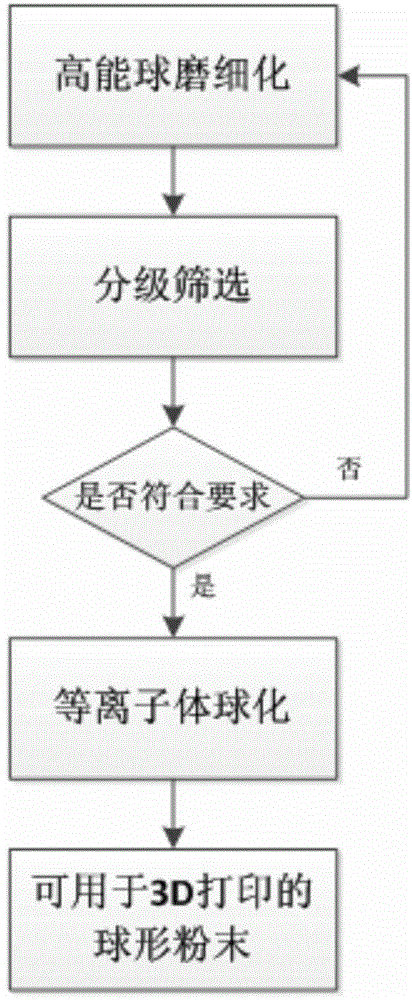

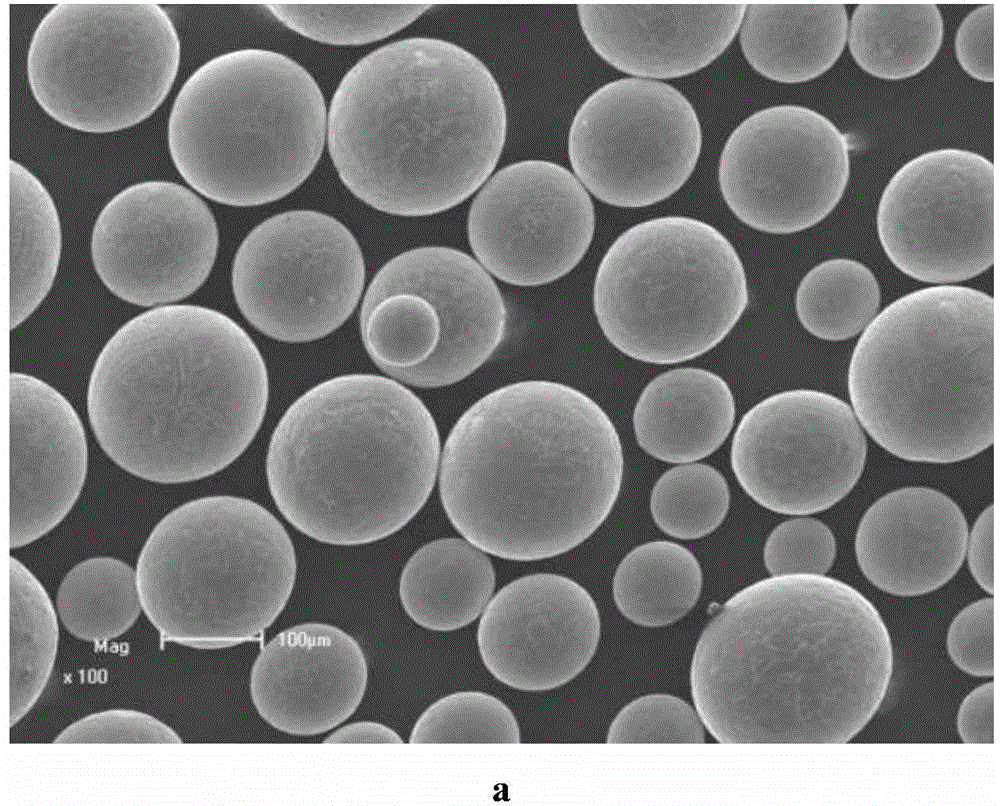

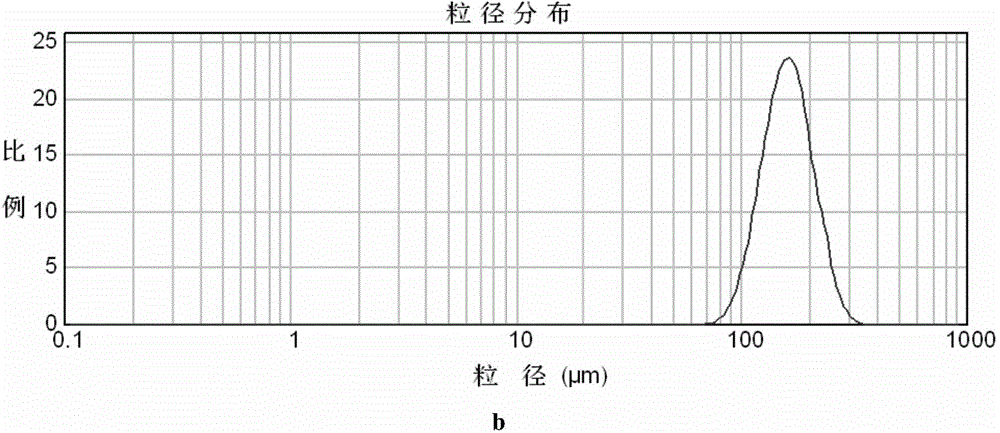

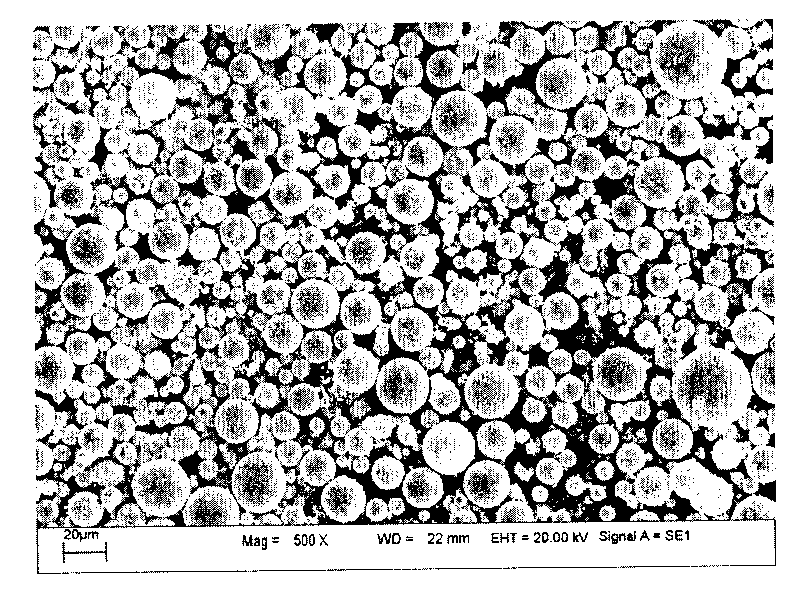

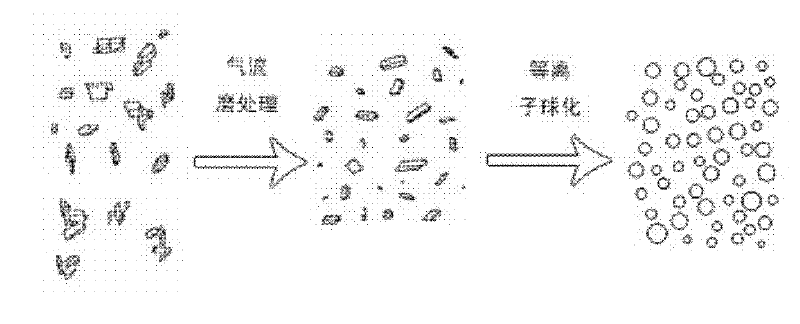

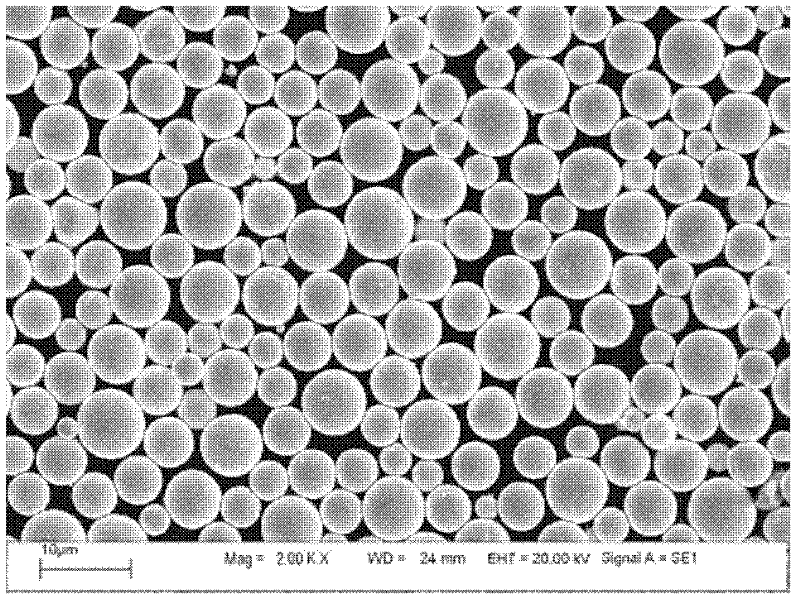

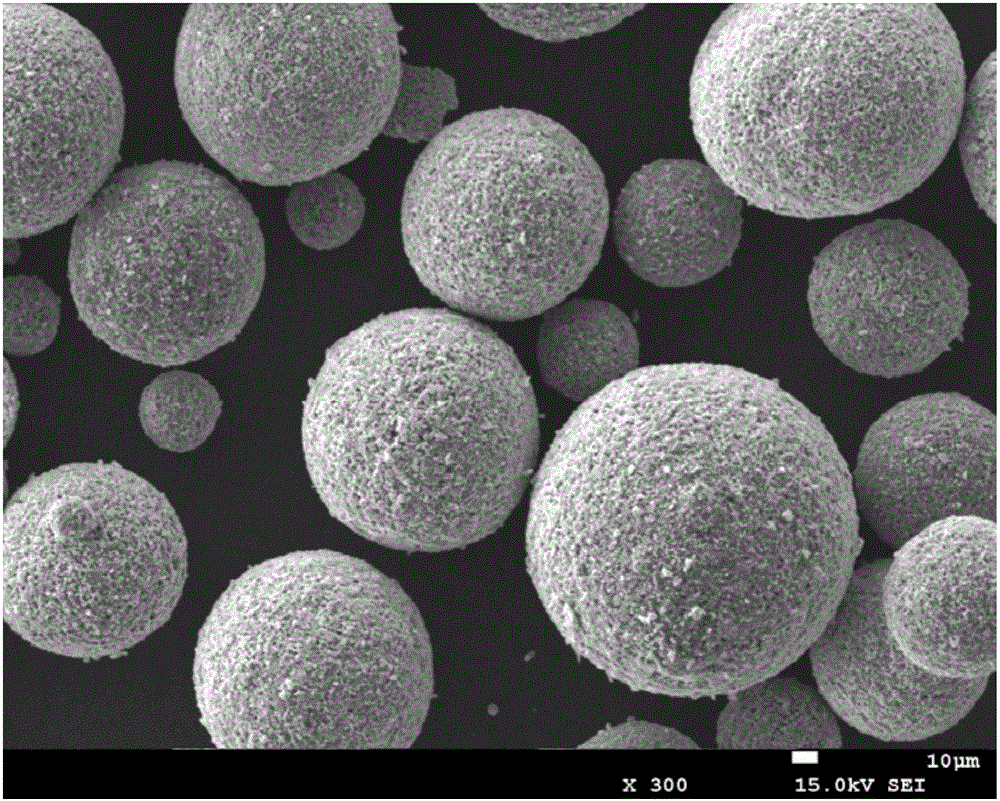

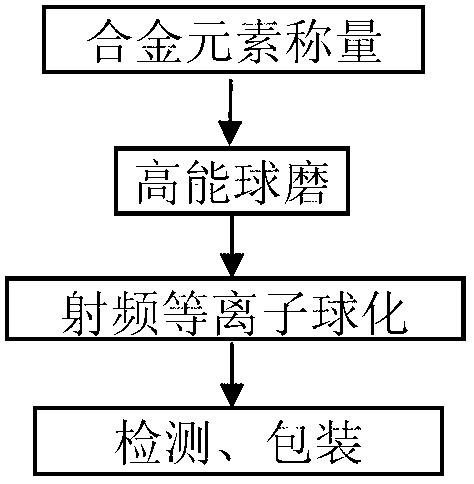

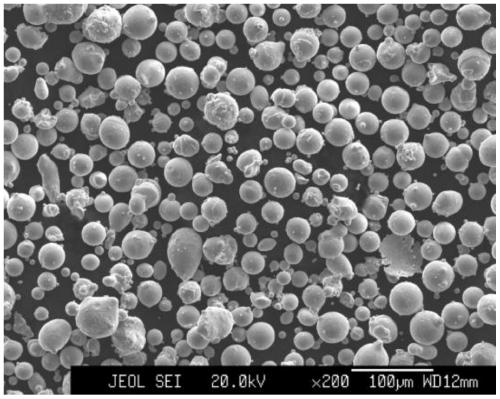

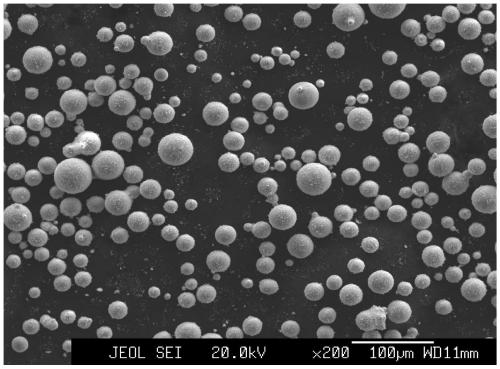

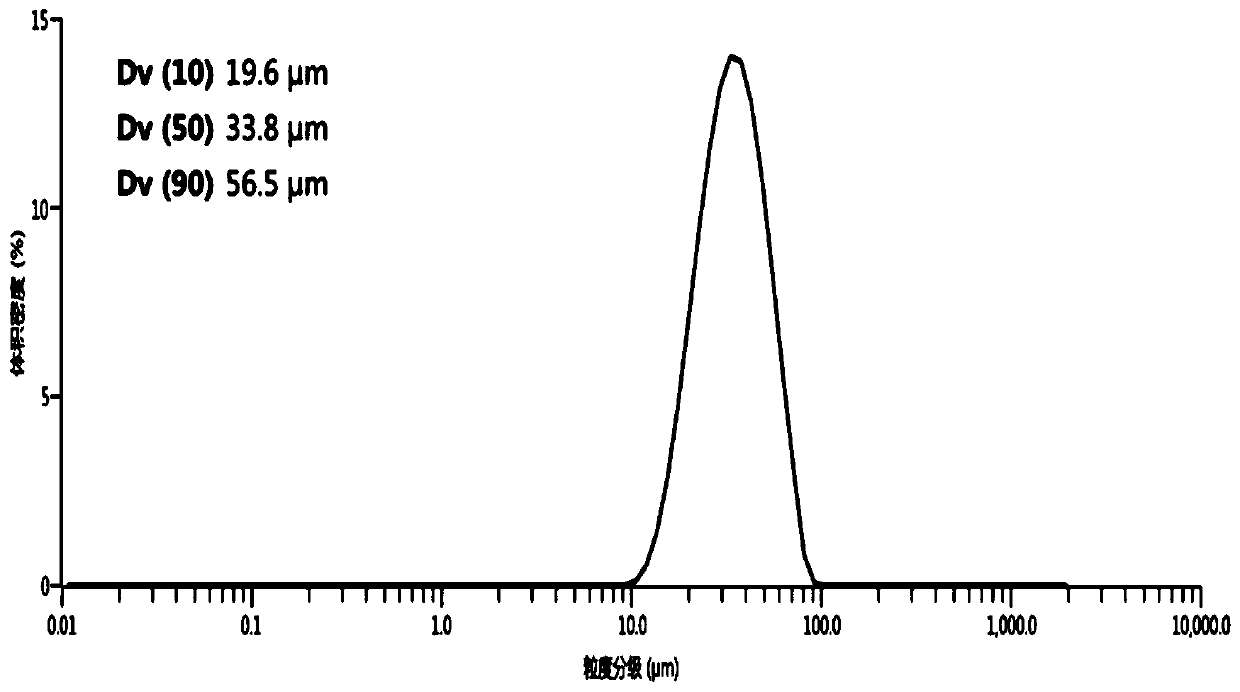

Method for preparing spherical powder material used for three-dimensional printing

The invention discloses a method for preparing a spherical powder material used for three-dimensional printing. The method includes the steps of raw material selecting, high-energy ball milling and radio-frequency plasma spherizing. Selected raw materials are metal or alloy powder in the step of raw material selecting; the step of high-energy ball milling is carried out under the argon shielding condition, petroleum ether serves as the ball milling medium, and the metal or alloy powder is aluminum alloy powder, or titanium alloy powder, or nickel-base alloy powder, or stainless steel powder or tungsten alloy powder; according to the step of radio-frequency plasma spherizing, the total gas flow is 100 L / min-200 L / min, the input power of plasma is 50 kW-100 kW, the negative pressure of a gas outlet of a system is minus 1000 Pa-minus 2000 Pa, and the powder conveying amount is 50 g / min-150 g / min. The manufactured spherical powder is high in sphericity degree, even in granularity, low in oxygen content and good in liquidity, has few defects and is suitable for three-dimensional printing. The method for preparing the spherical powder material used for three-dimensional printing has the advantage that the process is accurate and controllable.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Method and apparatus for preventing instabilities in radio-frequency plasma processing

ActiveUS20050093459A1Guaranteed uptimeEasy to controlElectric discharge tubesElectric arc lampsPlasma impedanceInstability

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up, uses a feedforward type of control loop to tightly regulate the power supplied to the dynamic electrical load, such as loads caused by variable and inconsistent plasma impedance. A feedback control loop can also be used in combination with the feedforward loop, but at a slower rate, to help regulate the amount of power provided to the load.

Owner:MKS INSTR INC

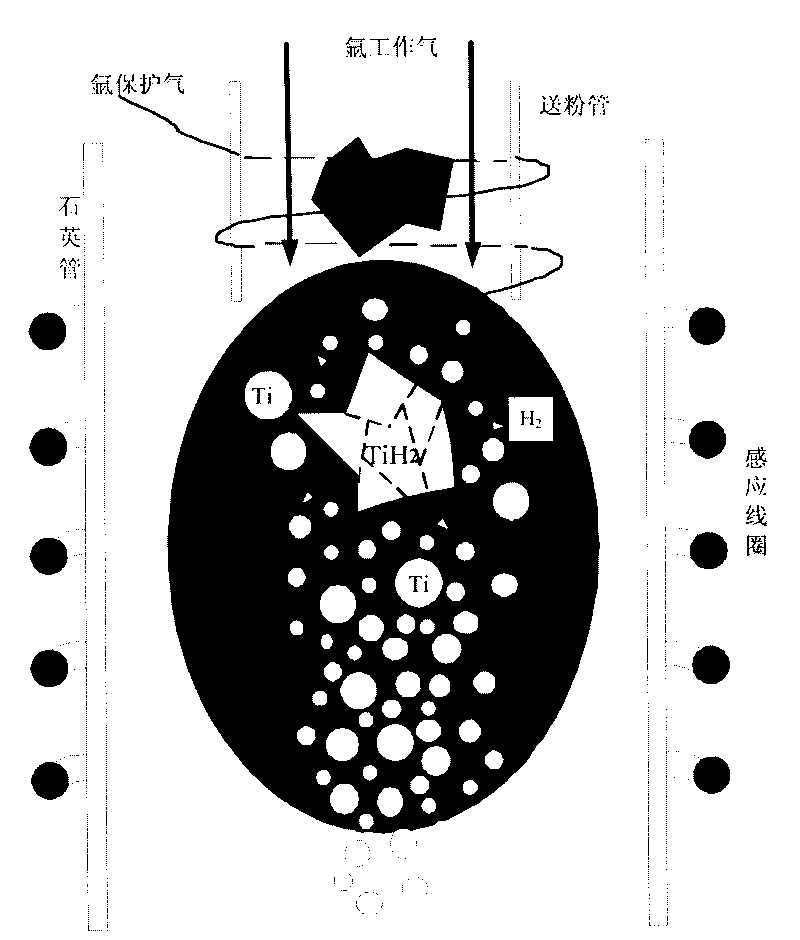

Short-flow preparation method of micro-sized spherical titanium powder

ActiveCN101716686AReduce dehydrogenation processShort processTransportation and packagingMetal-working apparatusDehydrogenationDie casting

Owner:江苏金物新材料有限公司

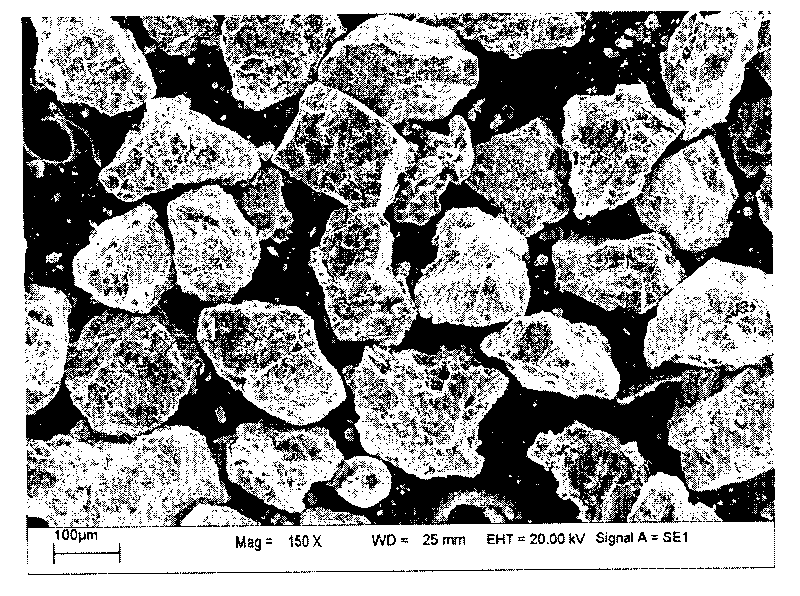

Method for manufacturing micro-fine spherical titanium powder

The invention discloses a method for manufacturing micro-fine spherical titanium powder, which includes the steps: using sponge titanium as raw materials, mixing the sponge titanium with hydrogen, holding the positive pressure of the hydrogen at 0.05-0.1MPa, preserving heat at the temperature of 650-730 DEG C, and cooling after ensuring the sponge titanium and the hydrogen to sufficiently react; crushing the hydrogenated sponge titanium with an air-stream mill, controlling the revolving speed of the air-stream mill within 1000r / min-1300r / min, and obtaining titanium hydride powder with a grain size smaller than 45 micrometers by means of crushing; and dehydrogenizing and balling the titanium hydride powder by using radio frequency plasma. The method for manufacturing the micro-fine spherical titanium powder has the advantages that the grain size of the powder and grain size distribution can be effectively controlled, and the powder is low in oxygen content, few in production procedure, low in cost, high in balling rate, fine in sphericility and suitable for industrialized popularization.

Owner:WESTERN BAODE TECH CO LTD

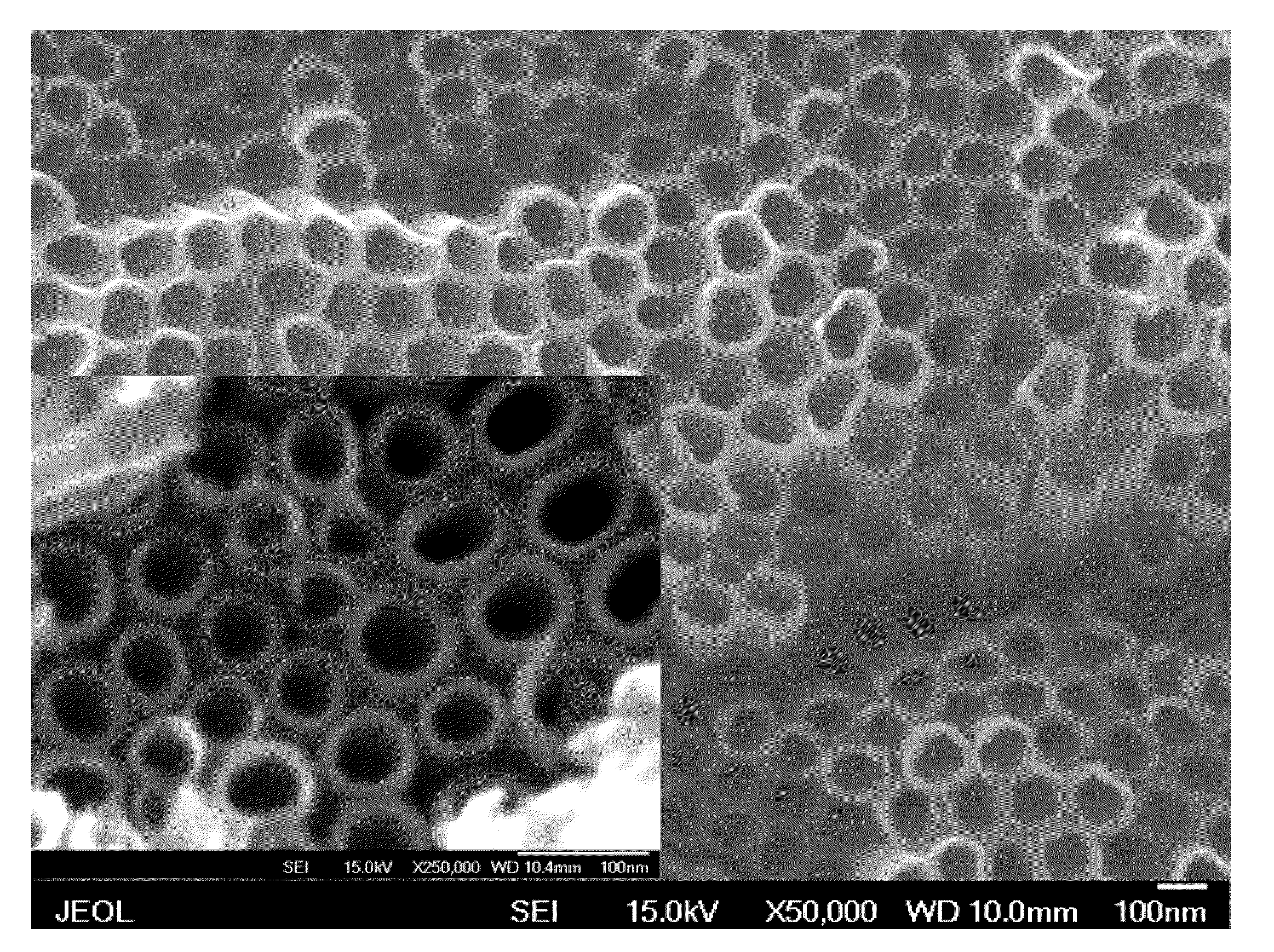

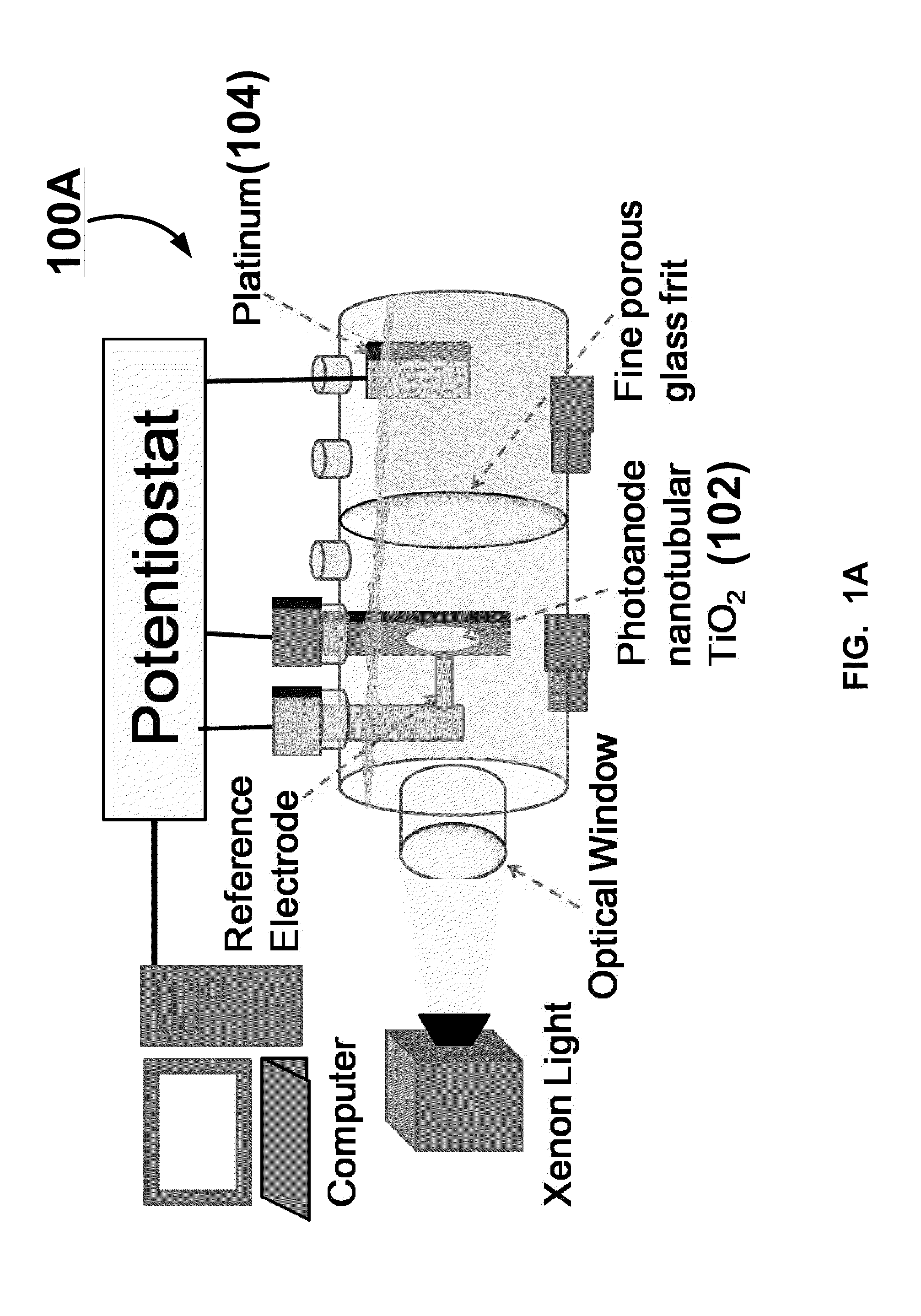

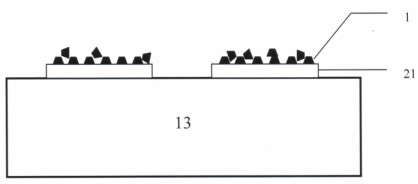

ENHANCED BONE CELLS GROWTH AND PROLIFERATION ON TiO2 NANOTUBULAR SUBSTRATES TREATED BY RADIO-FREQUENCY PLASMA DISCHARGE

A method for growing bone cells. In one aspect, the present invention provides a method for growing bone cells, comprising the steps of (a) anodizing a titanium substrate to form an array of titanium dioxide nanotubes on a surface of the titanium substrate, (b) subjecting the anodized titanium substrate to a radio frequency plasma discharge to chemically modify the array of titanium dioxide nanotubes formed on the surface of the titanium substrate, (c) seeding bone cells onto the surface of the titanium substrate that has an array of titanium dioxide nanotubes thereon after the subjecting step, and (d) incubating the seeded bone cells for a period of time effective for the cells to grow and proliferate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

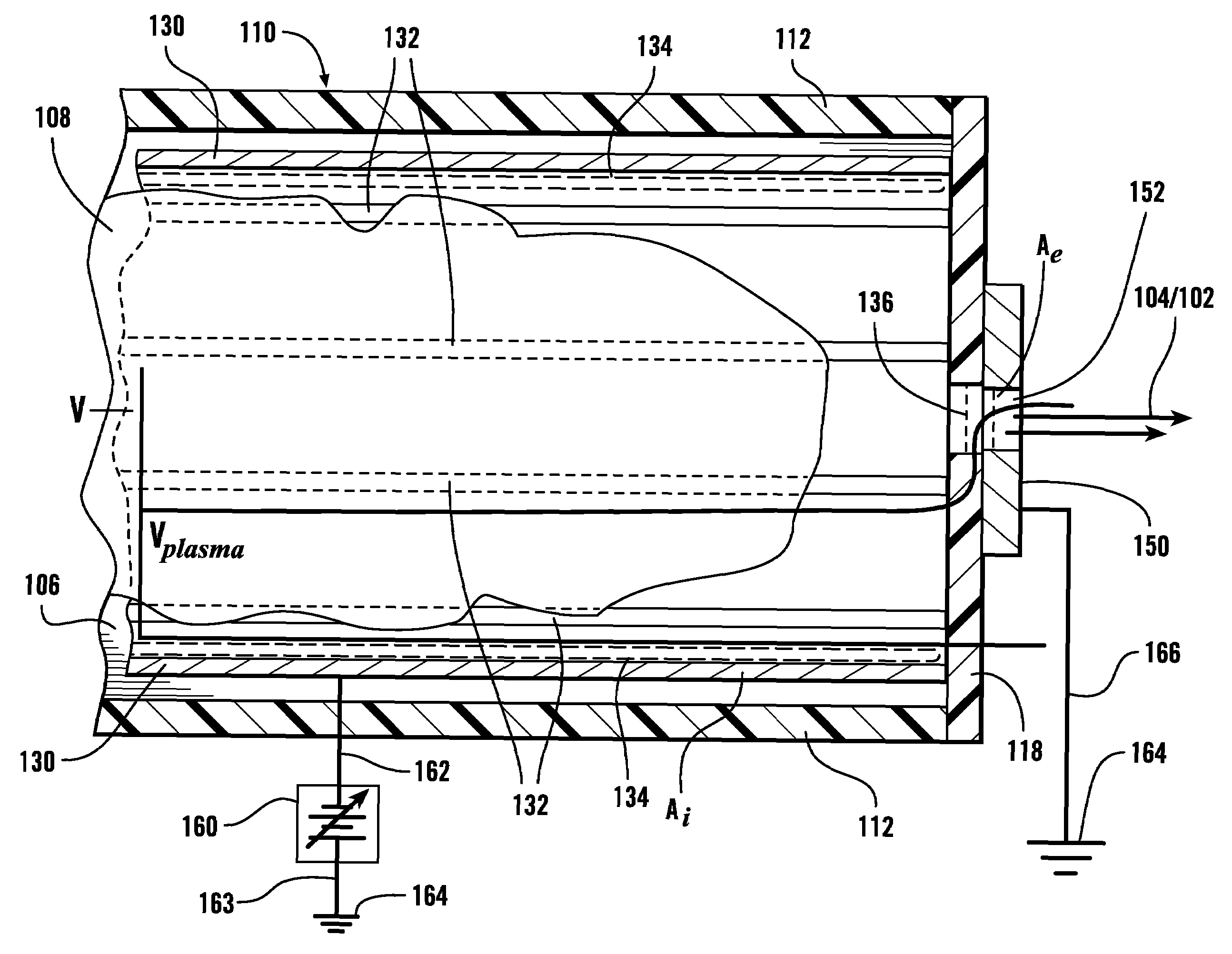

Non-ambipolar radio-frequency plasma electron source and systems and methods for generating electron beams

ActiveUS20080067430A1Reduce capacityElectric arc lampsMaterial analysis by optical meansRf fieldCapacitance

An electron generating device extracts electrons, through an electron sheath, from plasma produced using RF fields. The electron sheath is located near a grounded ring at one end of a negatively biased conducting surface, which is normally a cylinder. Extracted electrons pass through the grounded ring in the presence of a steady state axial magnetic field. Sufficiently large magnetic fields and / or RF power into the plasma allow for helicon plasma generation. The ion loss area is sufficiently large compared to the electron loss area to allow for total non-ambipolar extraction of all electrons leaving the plasma. Voids in the negatively-biased conducting surface allow the time-varying magnetic fields provided by the antenna to inductively couple to the plasma within the conducting surface. The conducting surface acts as a Faraday shield, which reduces any time-varying electric fields from entering the conductive surface, i.e. blocks capacitive coupling between the antenna and the plasma.

Owner:WISCONSIN ALUMNI RES FOUND

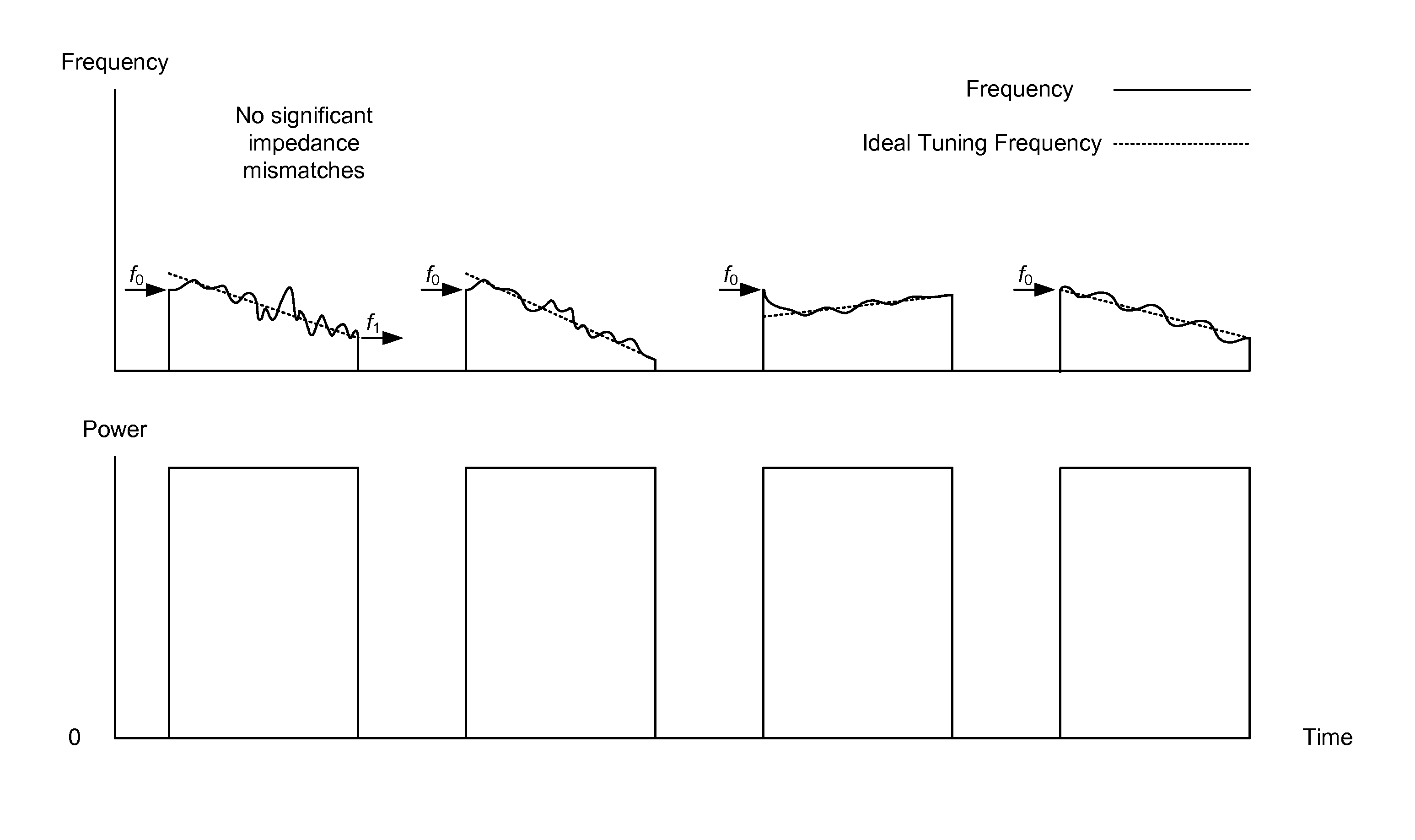

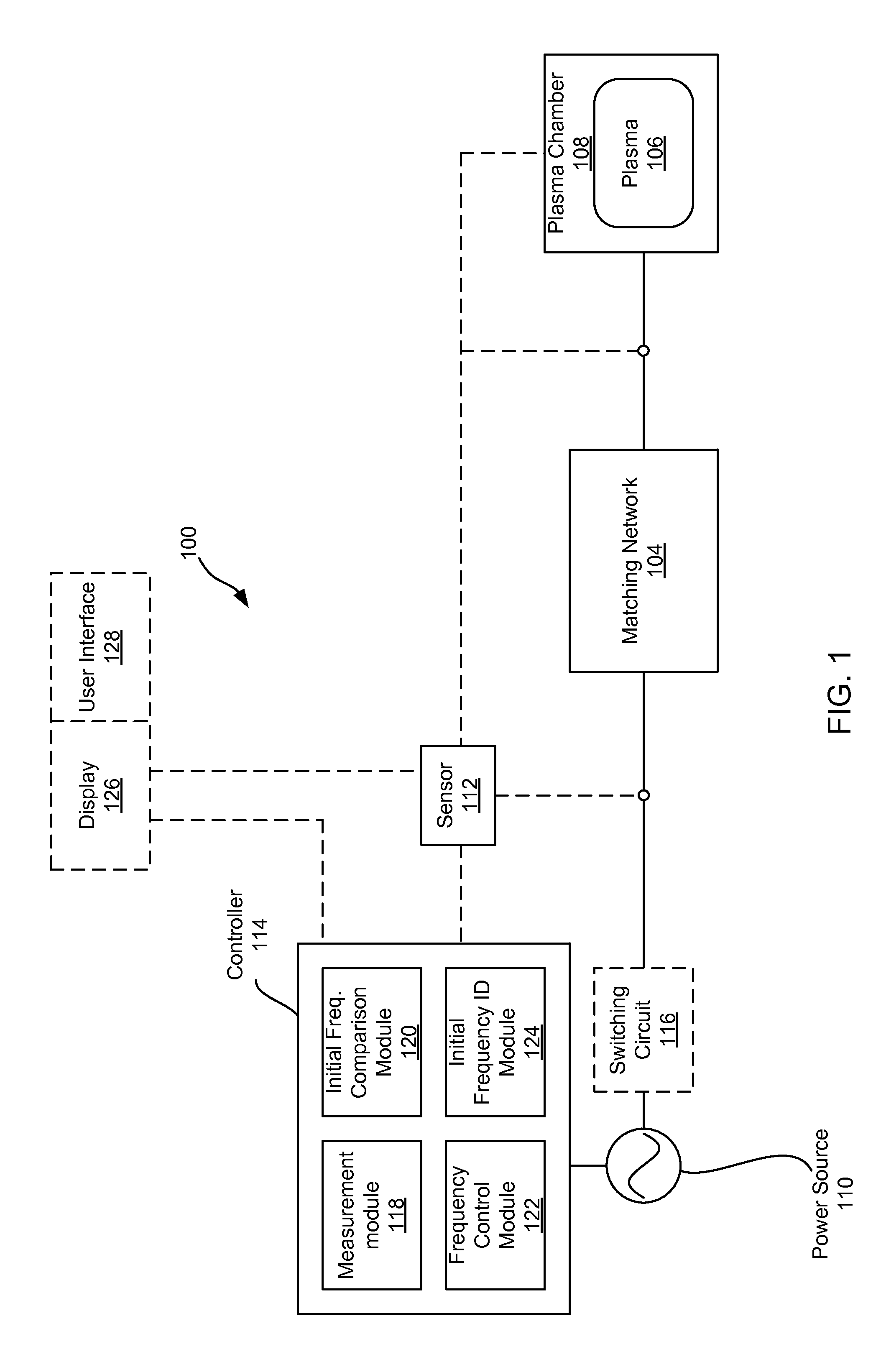

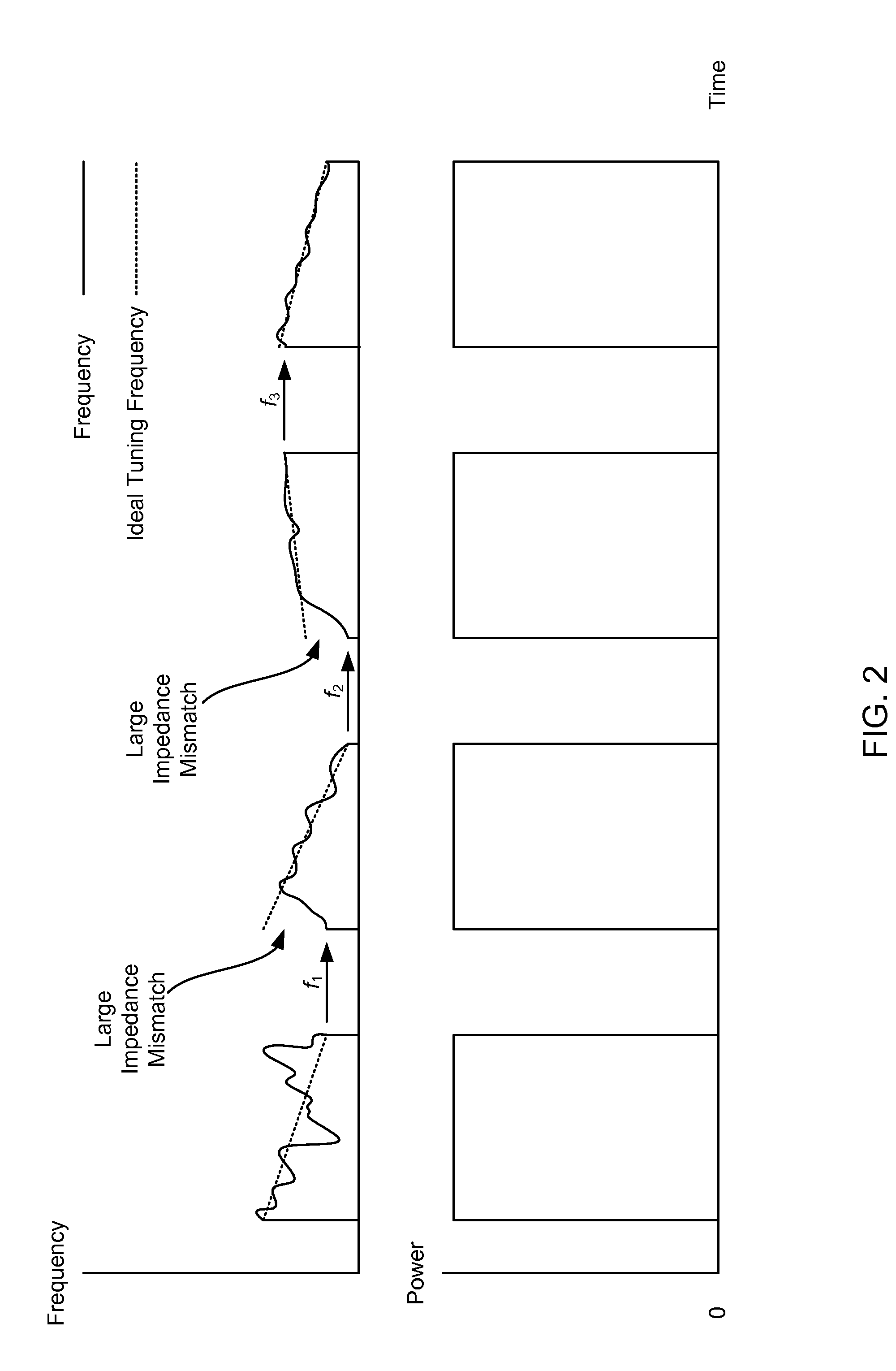

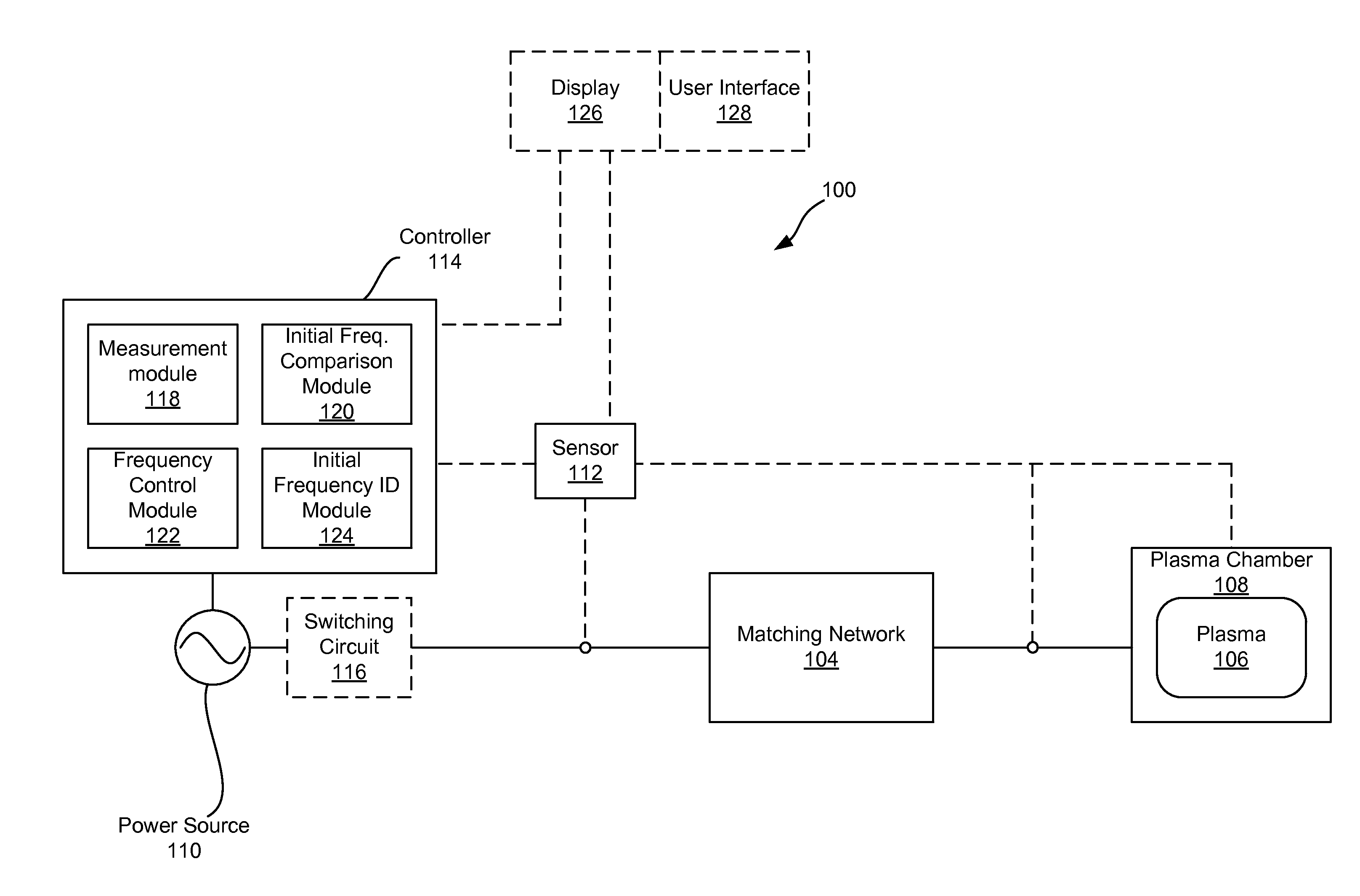

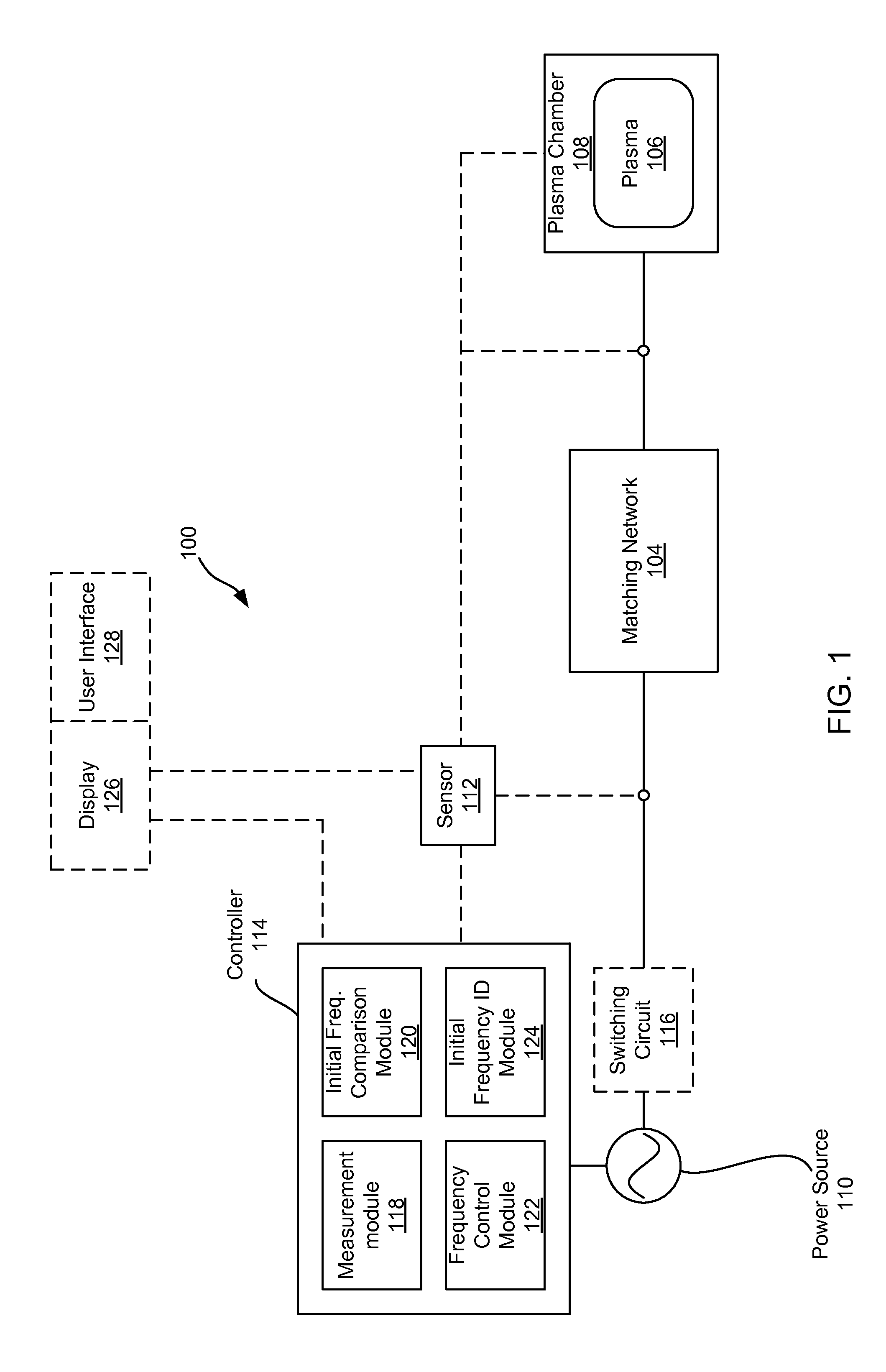

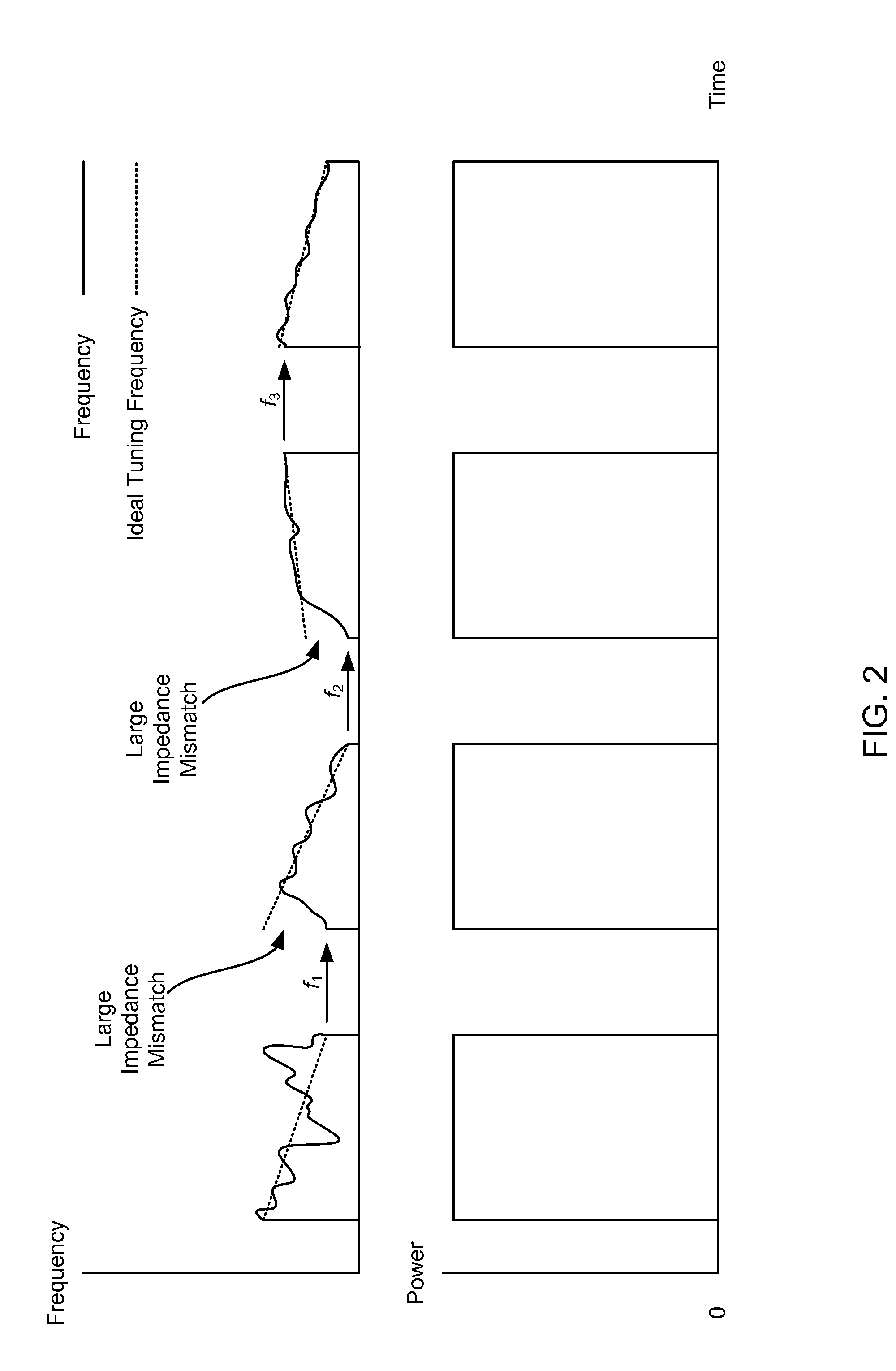

Frequency tuning for pulsed radio frequency plasma processing

This disclosure describes systems, methods, and apparatus for pulsed RF power delivery to a plasma load for plasma processing of a substrate. In order to maximize power delivery, a calibration phase using a dummy substrate or no substrate in the chamber, is used to ascertain a preferred fixed initial RF frequency for each pulse. This fixed initial RF frequency is then used at the start of each pulse during a processing phase, where a real substrate is used and processed in the chamber.

Owner:AES GLOBAL HLDG PTE LTD

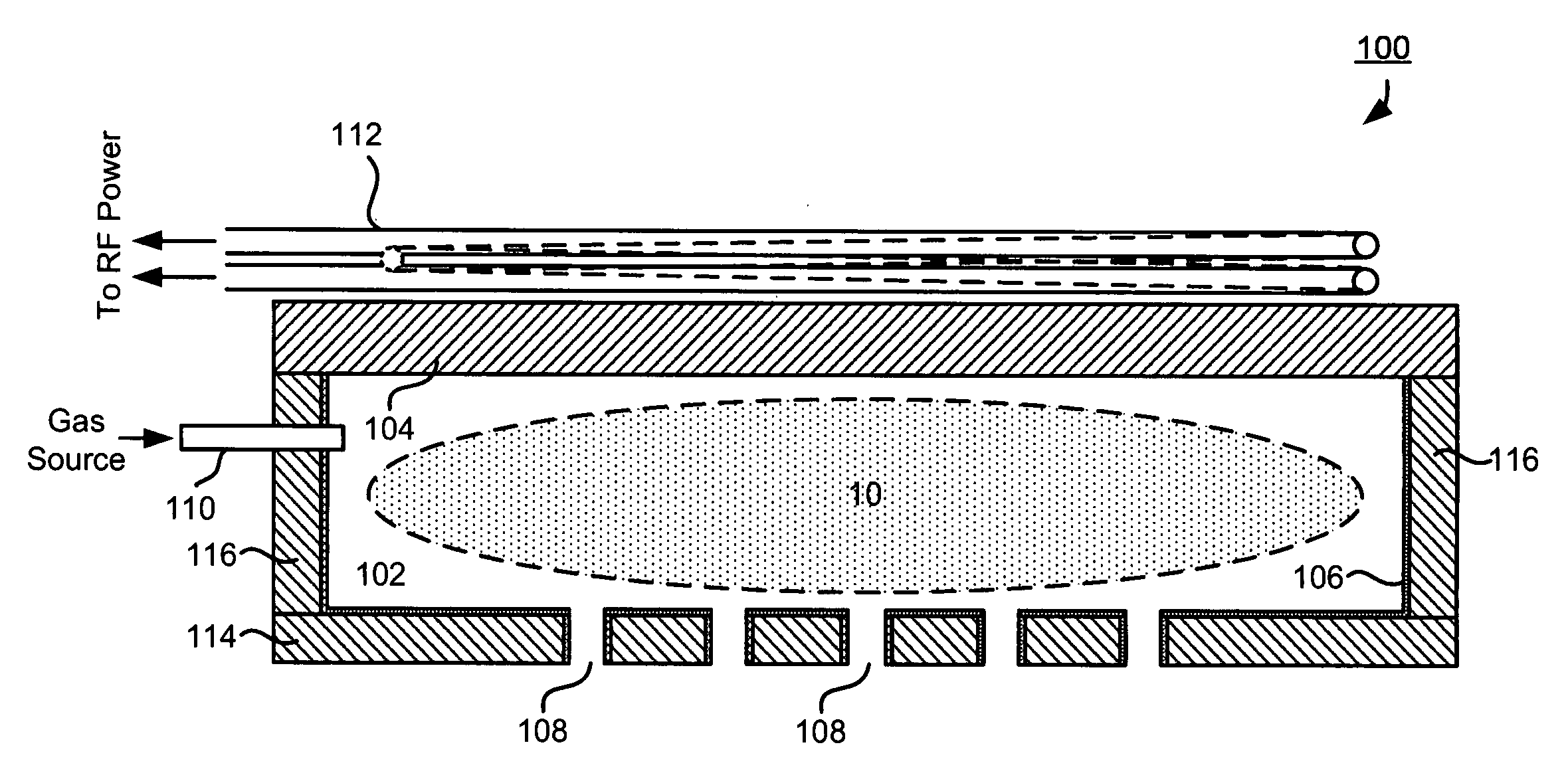

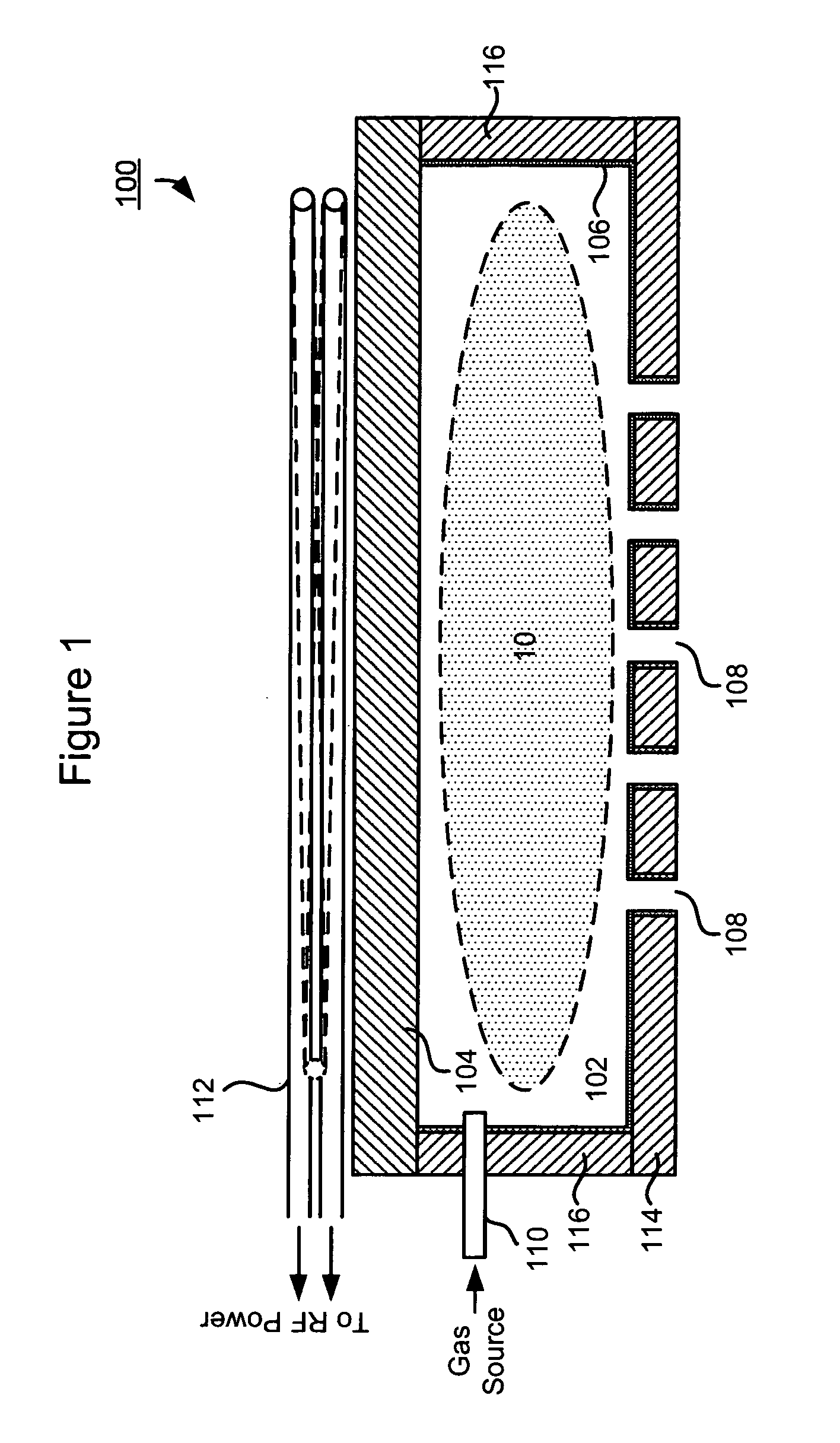

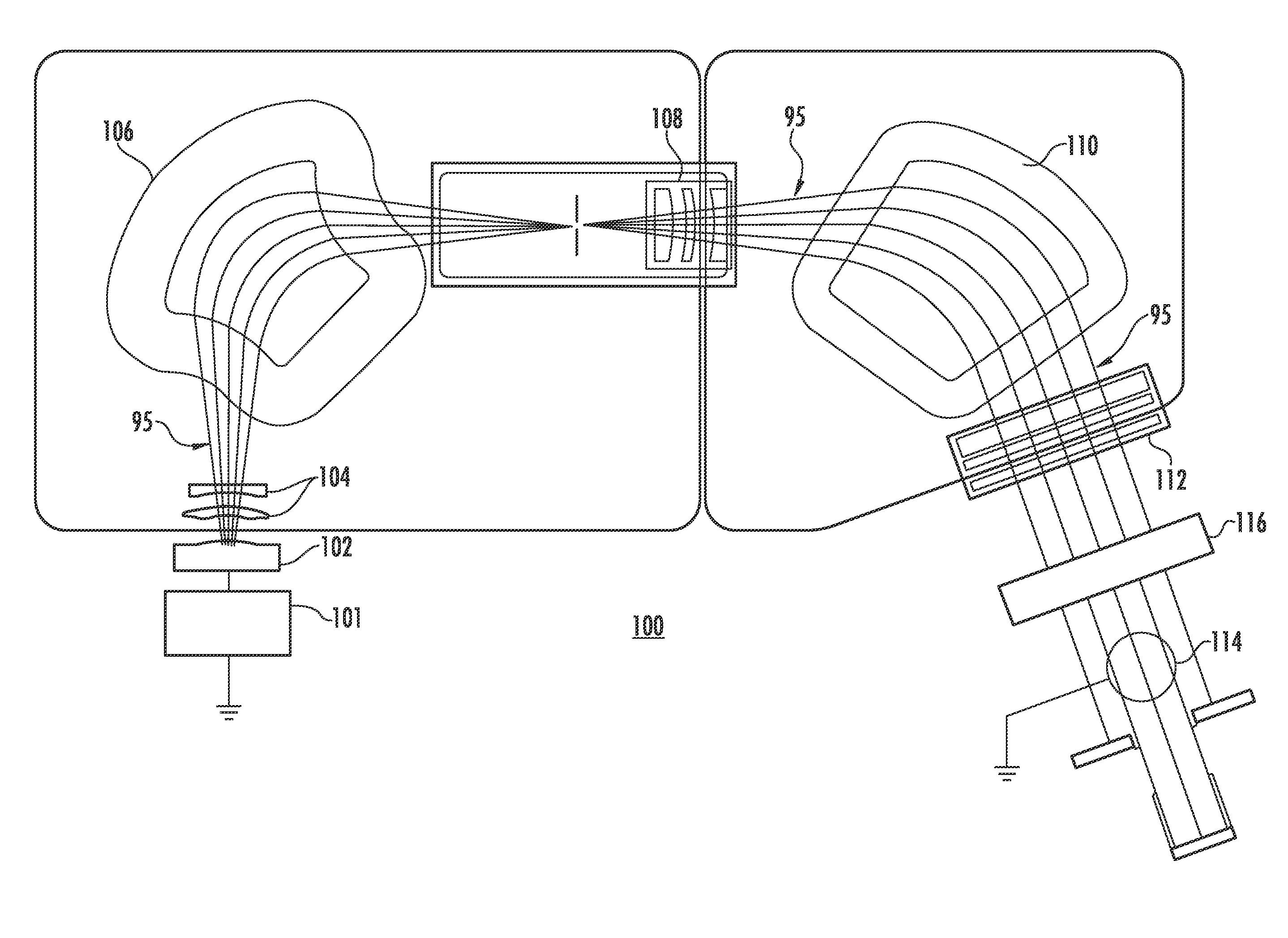

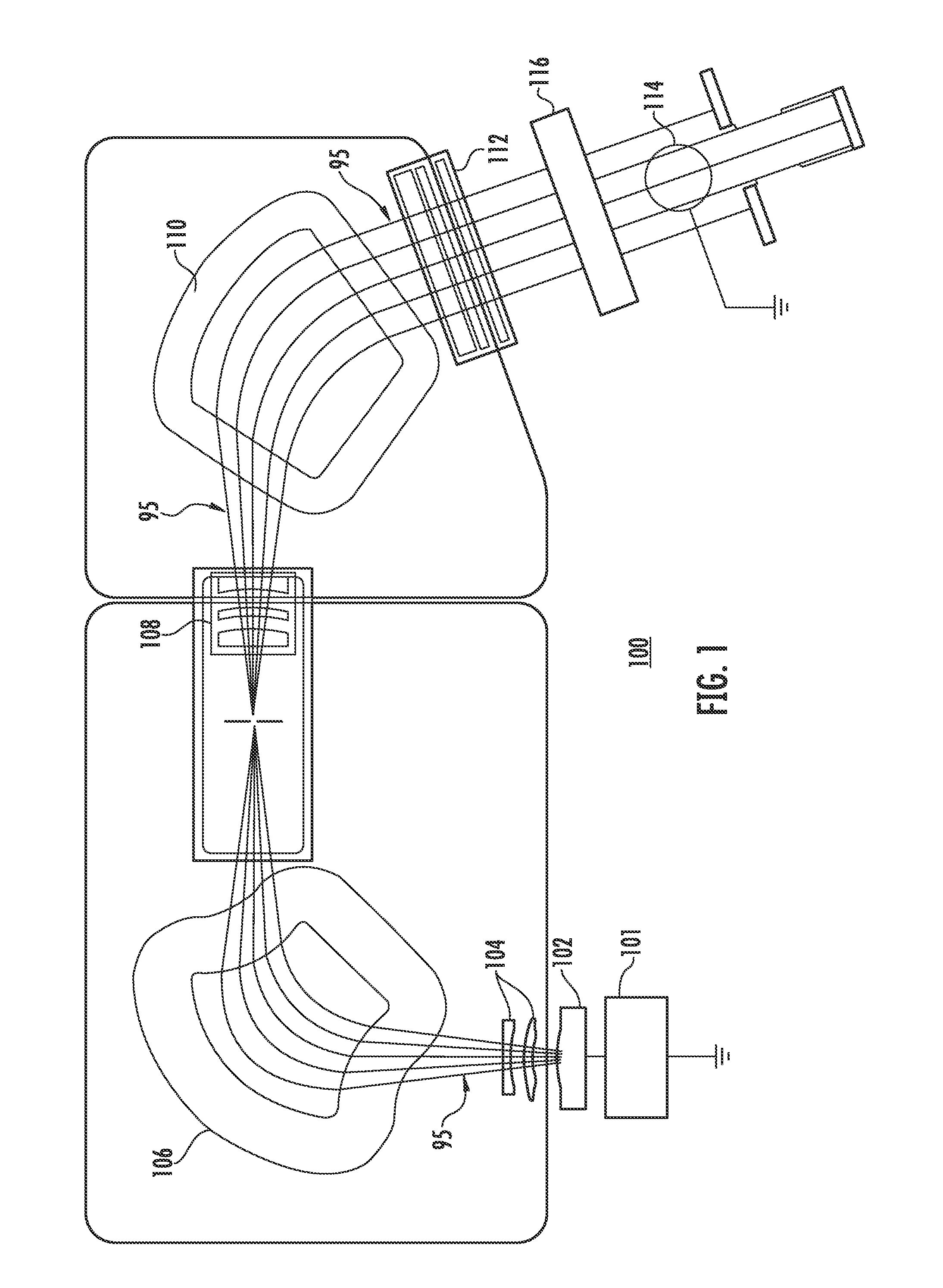

Technique for providing an inductively coupled radio frequency plasma flood gun

A technique for providing an inductively coupled radio frequency plasma flood gun is disclosed. In one particular exemplary embodiment, the technique may be realized as a plasma flood gun in an ion implantation system. The plasma flood gun may comprise: a plasma chamber having one or more apertures; a gas source capable of supplying at least one gaseous substance to the plasma chamber; and a power source capable of inductively coupling radio frequency electrical power into the plasma chamber to excite the at least one gaseous substance to generate a plasma. Entire inner surface of the plasma chamber may be free of metal-containing material and the plasma may not be exposed to any metal-containing component within the plasma chamber. In addition, the one or more apertures may be wide enough for at least one portion of charged particles from the plasma to flow through.

Owner:VARIAN SEMICON EQUIP ASSOC INC

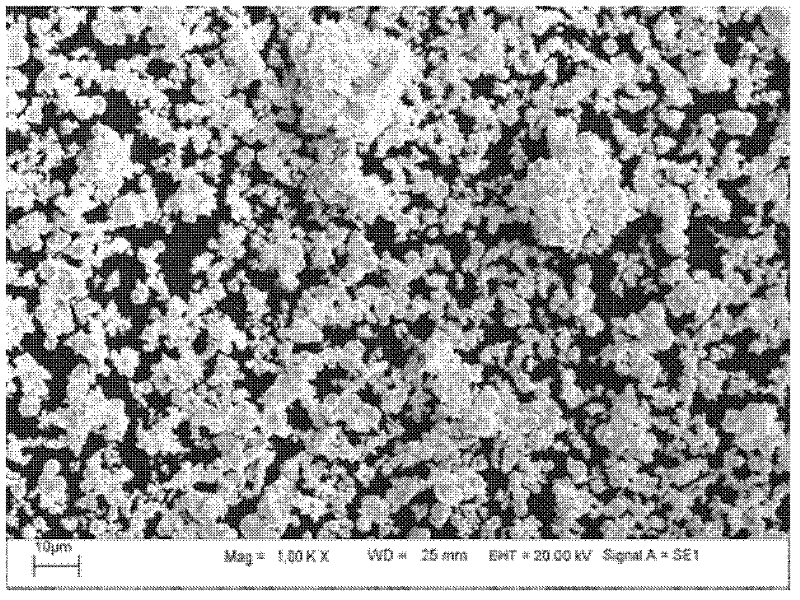

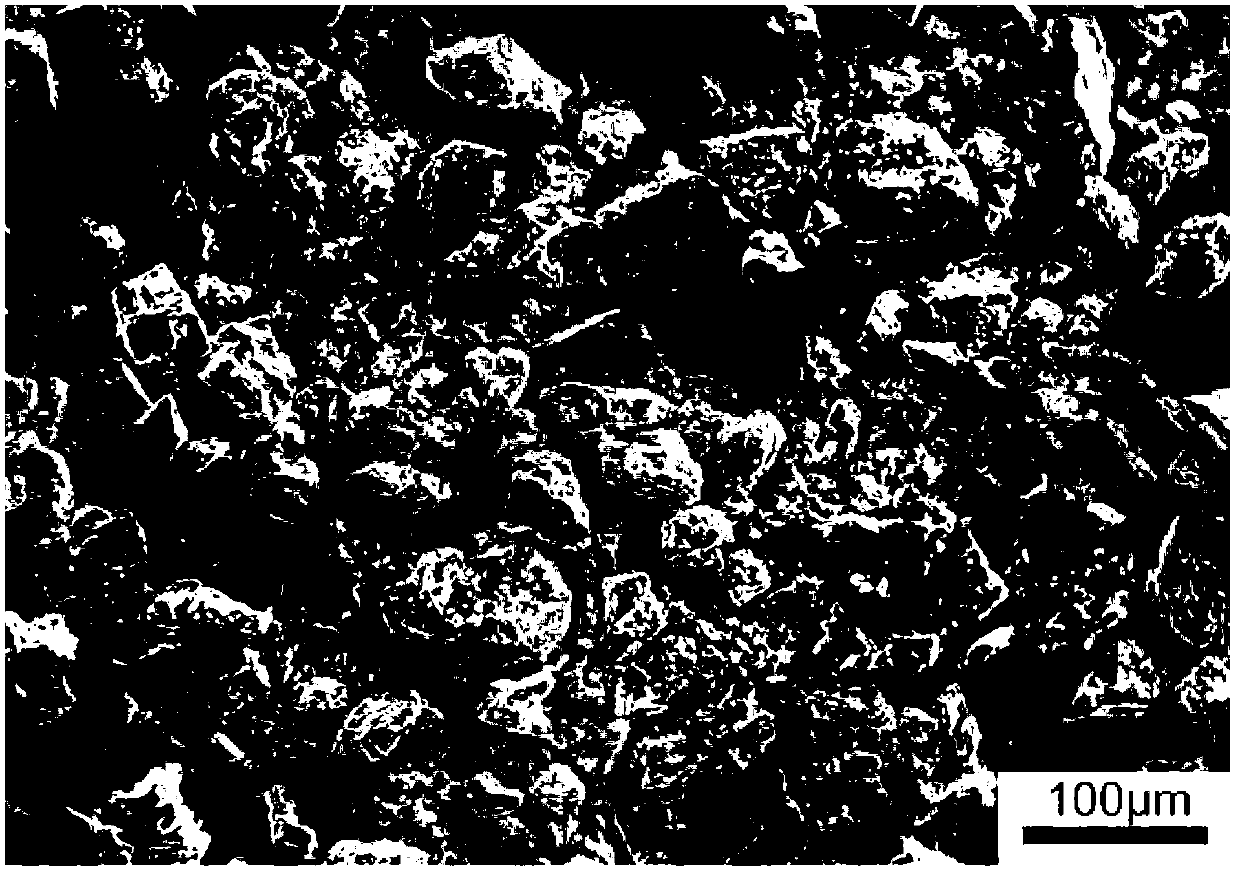

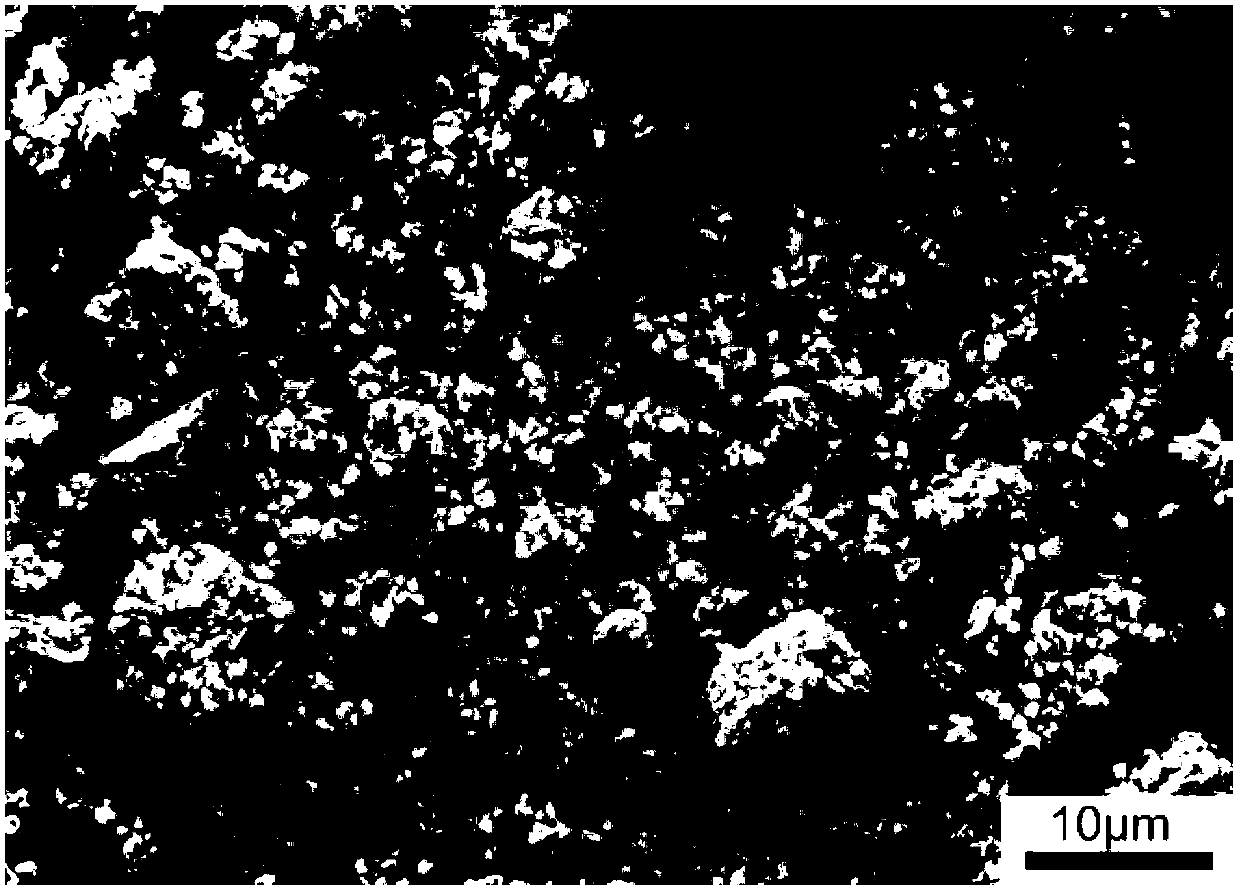

A kind of preparation method of fine spherical tungsten powder

The invention belongs to the field of powder metallurgy powder preparation and provides a preparation method of fine spherical tungsten powder. By combining the dispersion and classification of tungsten powder with spheroidization, spherical tungsten powder with a particle size below 10 μm is prepared. The specific process is: disperse and classify the irregularly shaped raw material tungsten powder through the impact of airflow, and then spheroidize the dispersed powder through a radio frequency plasma torch to obtain a fine spherical tungsten powder with a particle size below 10 μm. The invention has the advantages that the combination of airflow impact and radio frequency plasma spheroidization solves the problem that the spherical powder obtained by single radio frequency plasma spheroidization is easy to grow, and the production efficiency is high. The obtained powder has a high degree of sphericity, a particle size of less than 10 μm, a spheroidization rate of 100%, a smooth surface, uniform particle size distribution, and good dispersion.

Owner:UNIV OF SCI & TECH BEIJING

Metal ceramic composite alloy spherical powder and preparation method thereof

ActiveCN106270493AReduce composition segregationUniform microstructureAdditive manufacturing apparatusMolten spray coatingSpray GranulationMixed materials

The invention discloses metal ceramic composite alloy spherical powder and a preparation method thereof. The metal ceramic composite alloy spherical powder is TiCN-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-Co and at least one of Ni, Mo and Fe or TiCN-MxC-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-MxC-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-TiCN-MxC-Co and at least one of Ni, Mo and Fe. Mixed materials are dried, the powder is spherized by the aid of a roller spherizing method, a radio frequency plasma spherizing method or a spray granulation spherizing method, and the spherized powder is sintered to obtain the metal ceramic composite alloy spherical powder. The metal ceramic composite alloy spherical powder serves as a coating material, binding force between a coating and a substrate is improved, and the quality of 3D (three-dimensional) printing products can be improved when the spherical powder serves as a 3D printing material.

Owner:成都锦钛精工科技有限公司

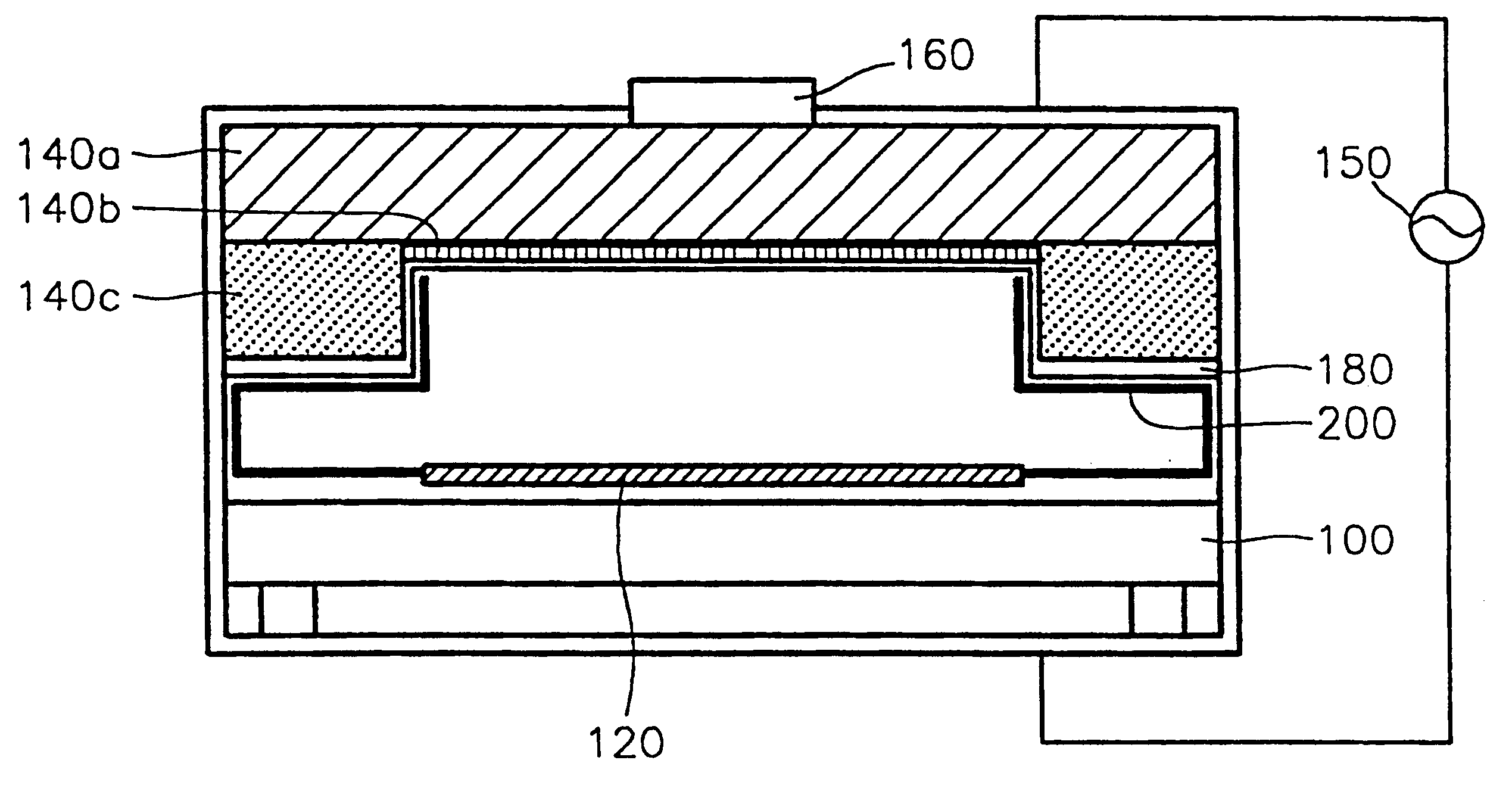

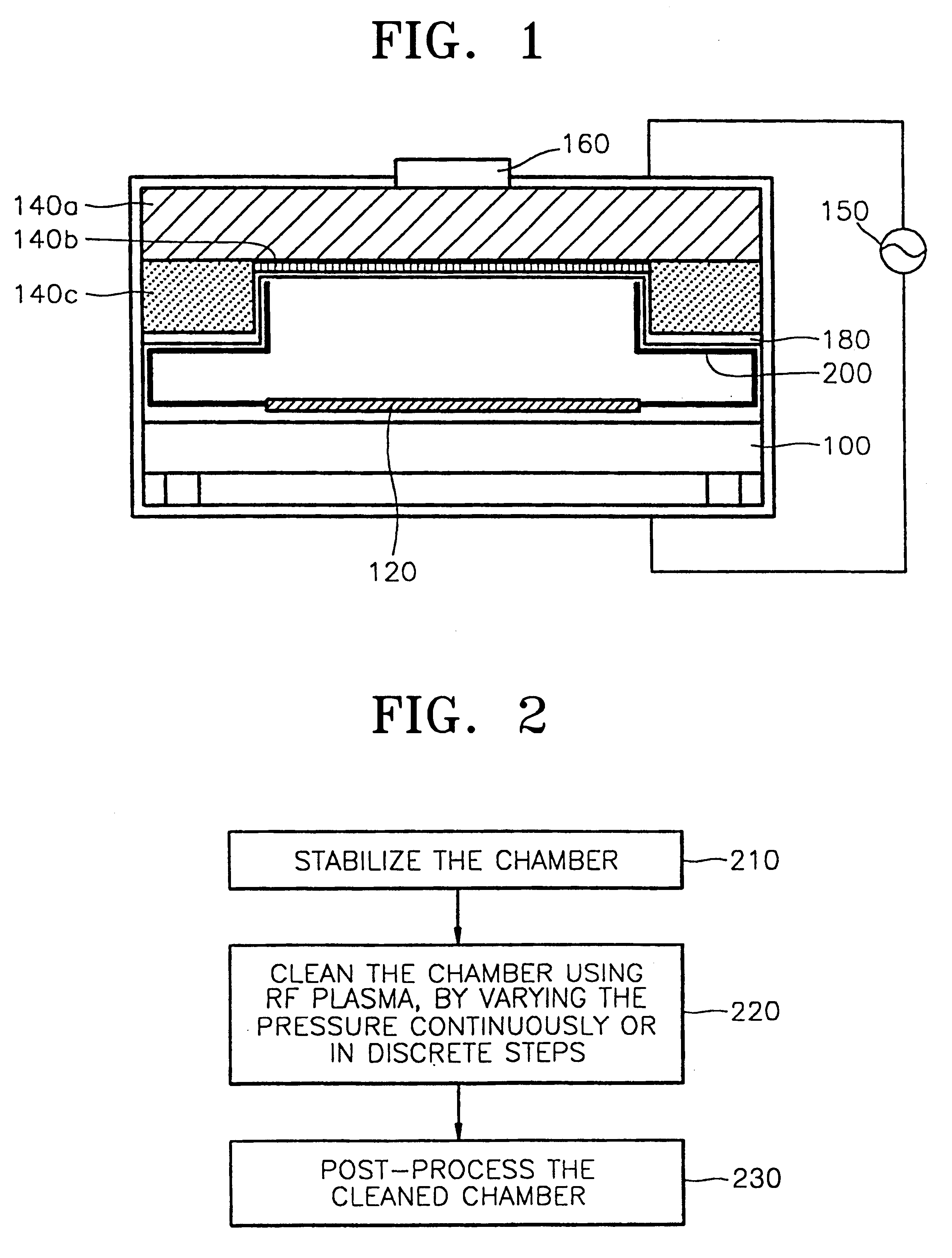

Method for cleaning inside of chamber using RF plasma

A method for cleaning the inside of a chamber using a radio frequency (RF) plasma, in which all parts within the camber can be completely cleaned. In the cleaning method, the conditions inside the chamber are stabilized. Then, impurities are cleaned from the inside of the chamber using the RF plasma, while varying the pressure in the chamber continuously or in discrete steps.

Owner:SAMSUNG ELECTRONICS CO LTD

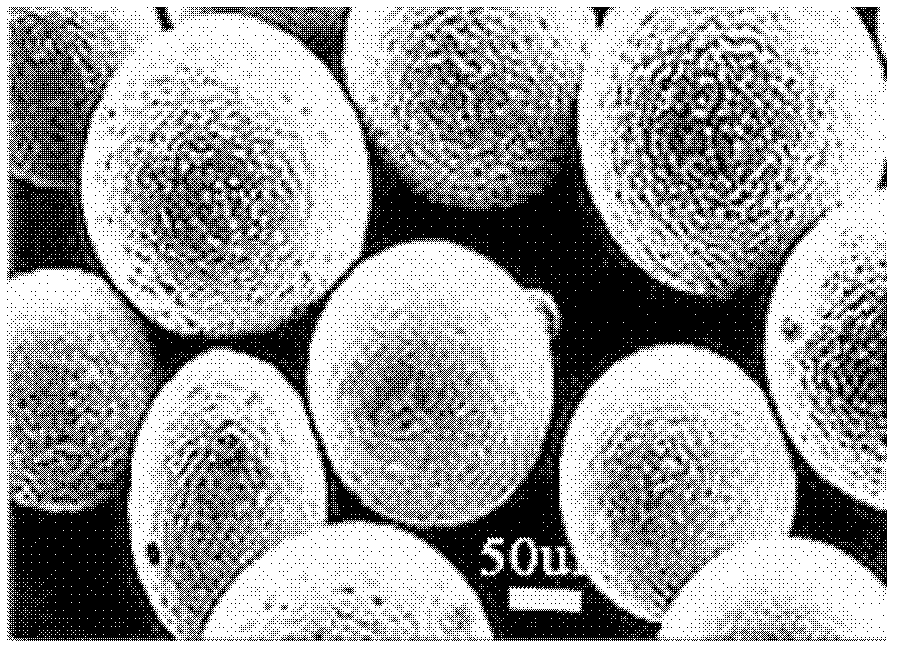

Preparation method of ultra-fine spherical nickel coated titanium composite powder

ActiveCN102179521ASolve composition segregationEasy to operateLiquid/solution decomposition chemical coatingPrillDehydrogenation

The invention provides a preparation method of an ultra-fine spherical nickel coated titanium composite powder, belonging to the manufacturing field of metallic powder material (compound). The preparation method comprises the following steps of: after pre-processing the raw material titanium hydride powder, firstly performing chemical nickel-plating; after radio-frequency plasma spheroidizing, performing dehydrogenation on the titanium hydride powder with large-particles; breaking the powder into ultra-fine spherical powder; and simultaneously reacting the nickel coated on the surface with titanium to obtain the spherical powder coated with nickel on the surface; and obtaining purified ultra-fine spherical nickel coated titanium composite powder after vacuum heat treatment. The preparation method has the characteristics of low oxygen content of power, uniform thickness of the nickel layer coated on the surface, high apparent density, good fluidity, short processing time, and the like,and the short procedure preparation of material is realized.

Owner:江苏金物新材料有限公司

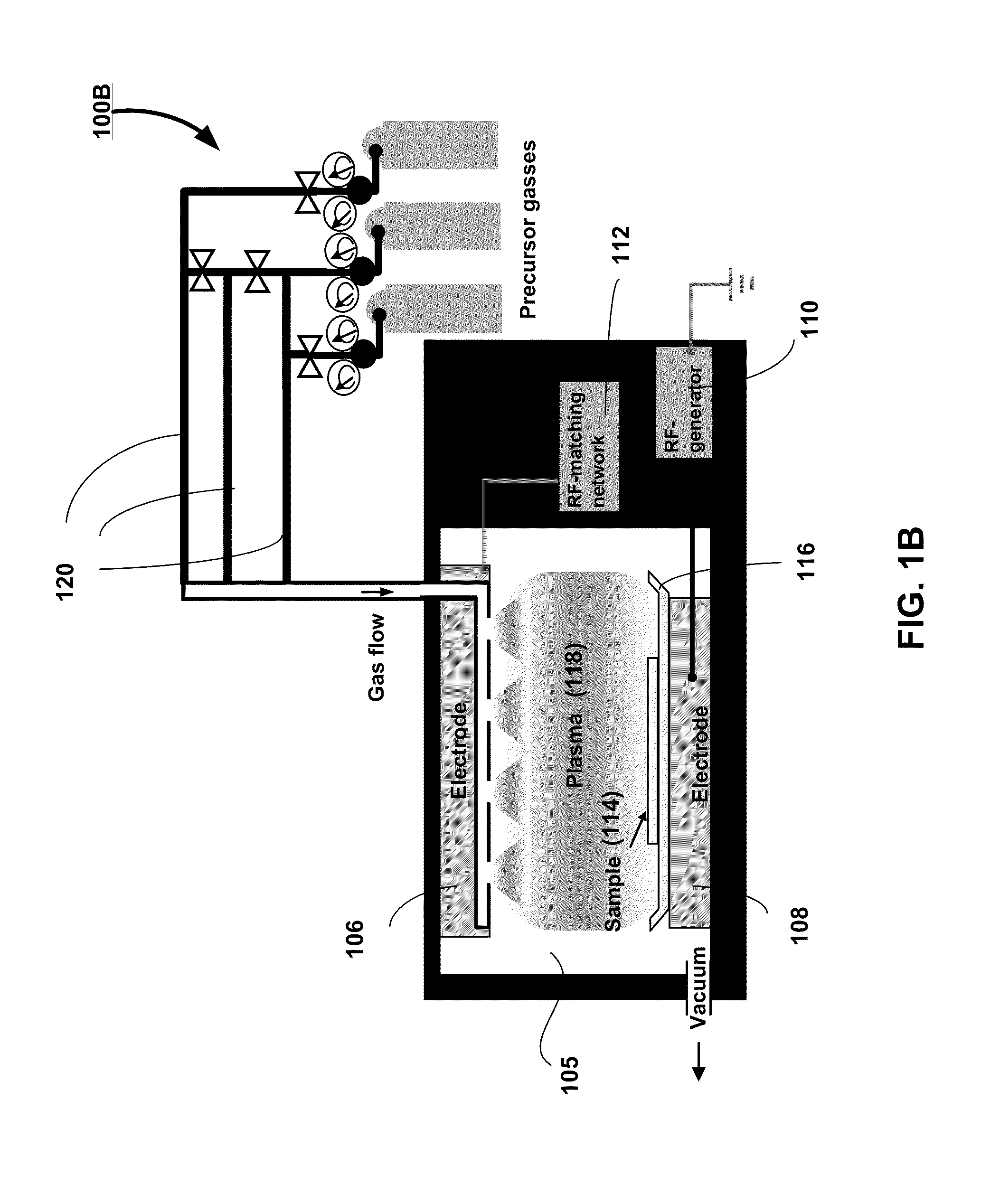

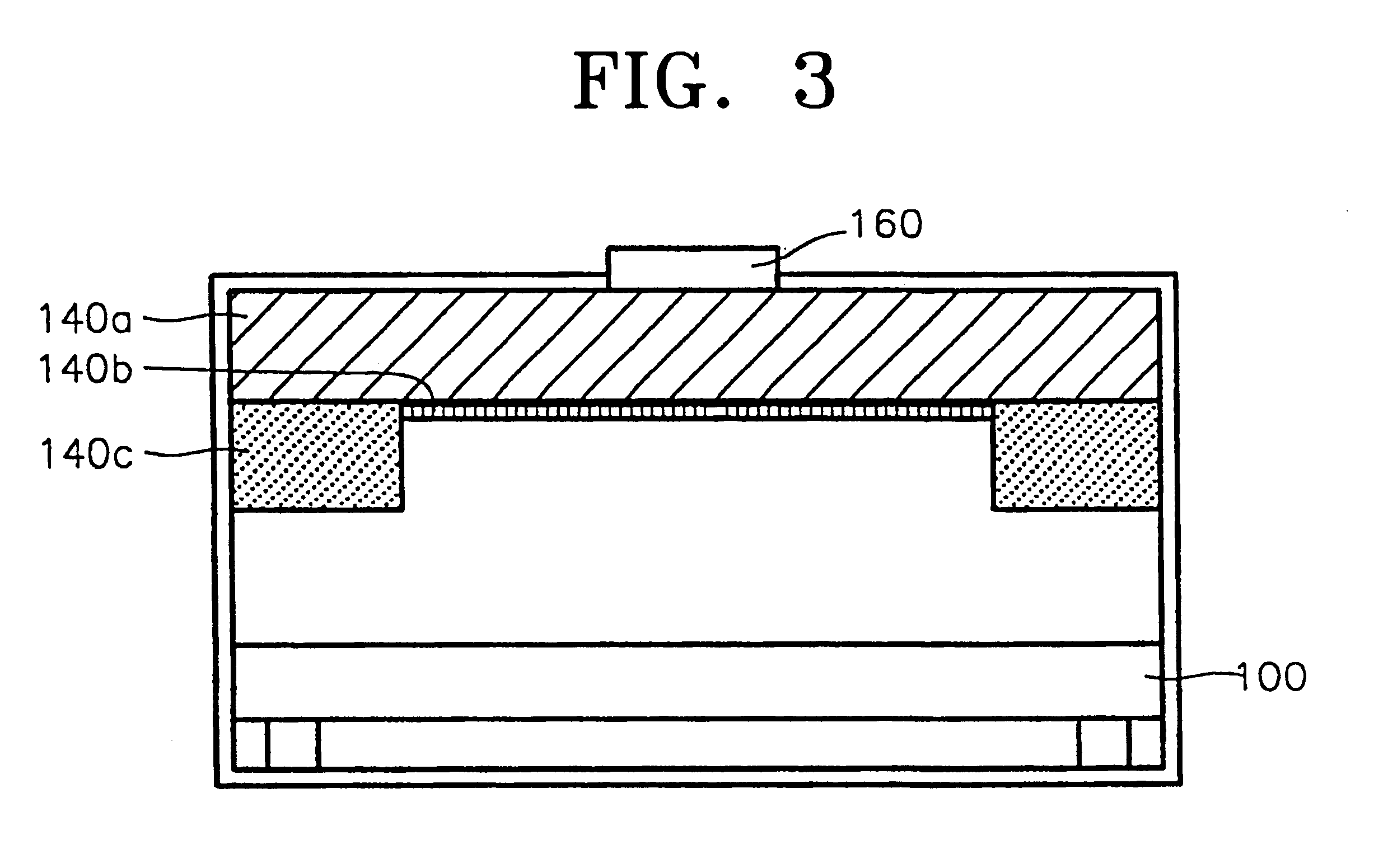

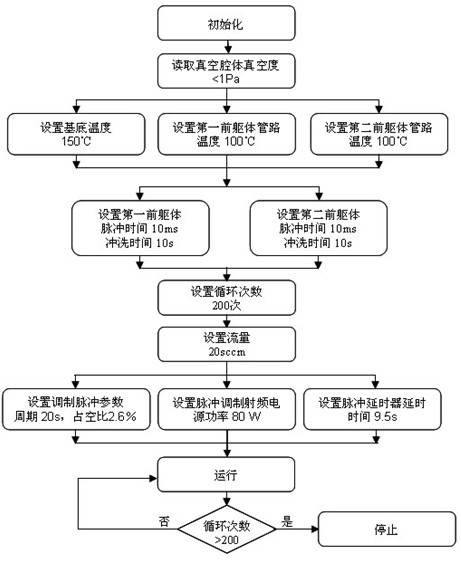

Device and method for enhancing atomic layer deposition by pulse-modulation radio frequency plasma

InactiveCN102127756AHigh activityIncrease the number of graftsChemical vapor deposition coatingIon bombardmentPhysical chemistry

The intention relates to a device and method for enhancing atomic layer deposition by pulse-modulation radio frequency plasma. The device comprises a vacuum reaction chamber, wherein a substrate is arranged at the inner bottom of the vacuum reaction chamber, and the vacuum reaction chamber is respectively connected with a vacuum mechanical pump and a precursor input pipeline. The device is characterized in that a plasma electrode is arranged at the inner top of the vacuum reaction chamber and is sequentially connected with a radio-frequency power matcher, a pulse modulation radio-frequency power supply and a pulse delay unit. In the method, plasma is generated by the pulse modulation radio-frequency power supply to assist deposition when at least one precursor is deposited. The device and method provided by the invention reduces the impact of ion bombardment on the deposited film during deposition process and prevents the temperature increase of the cavity during deposition process.

Owner:DONGHUA UNIV +1

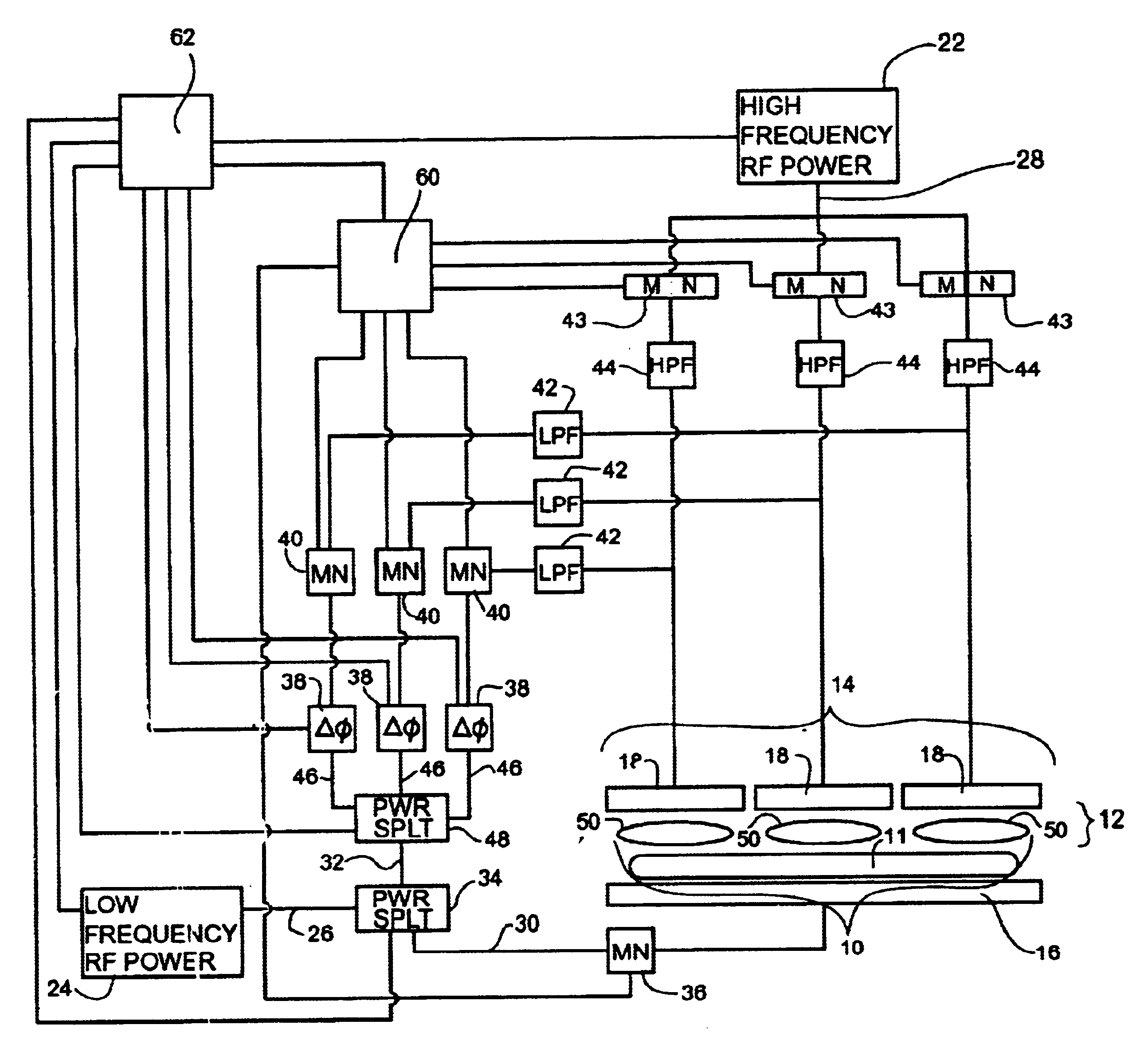

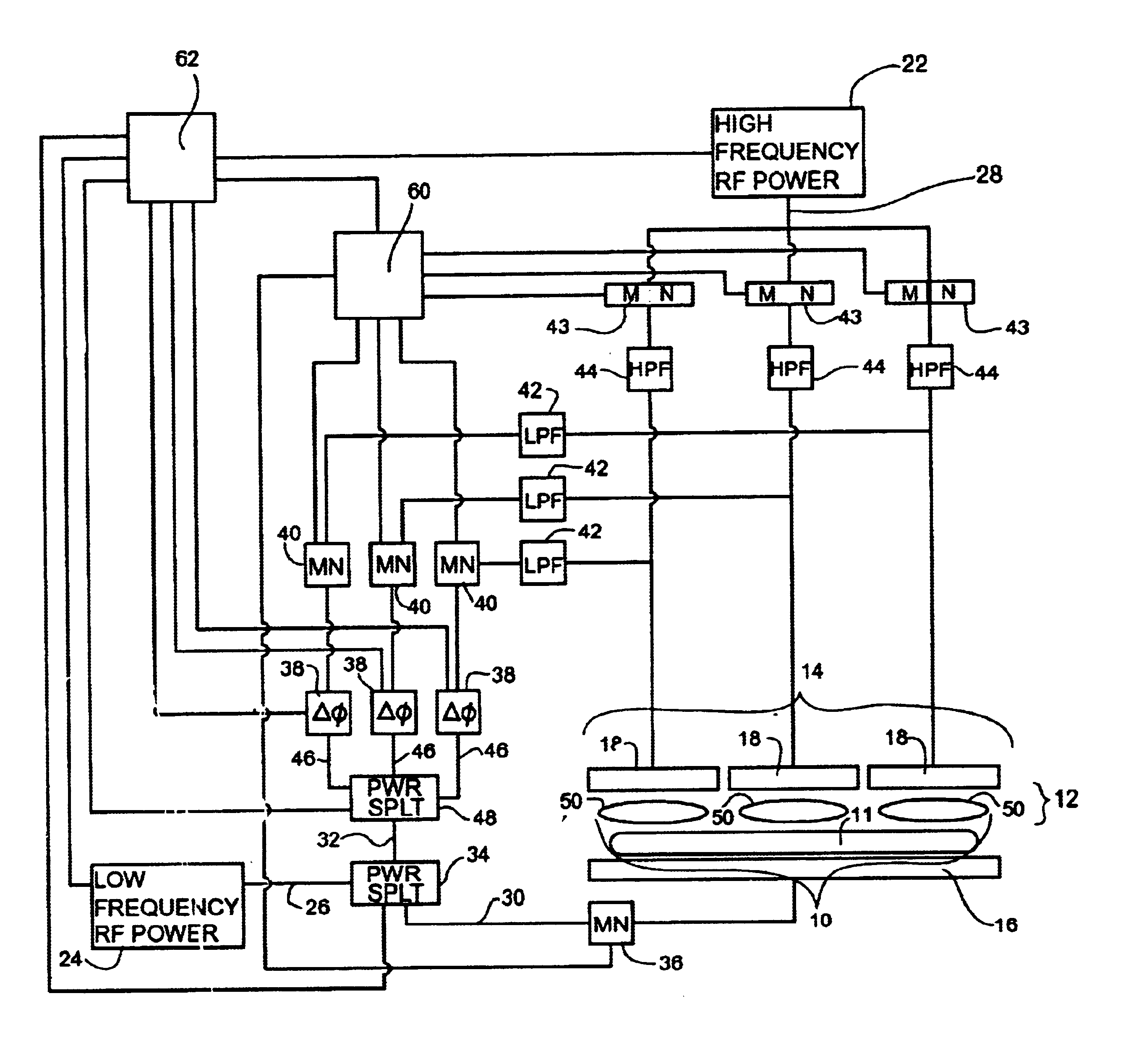

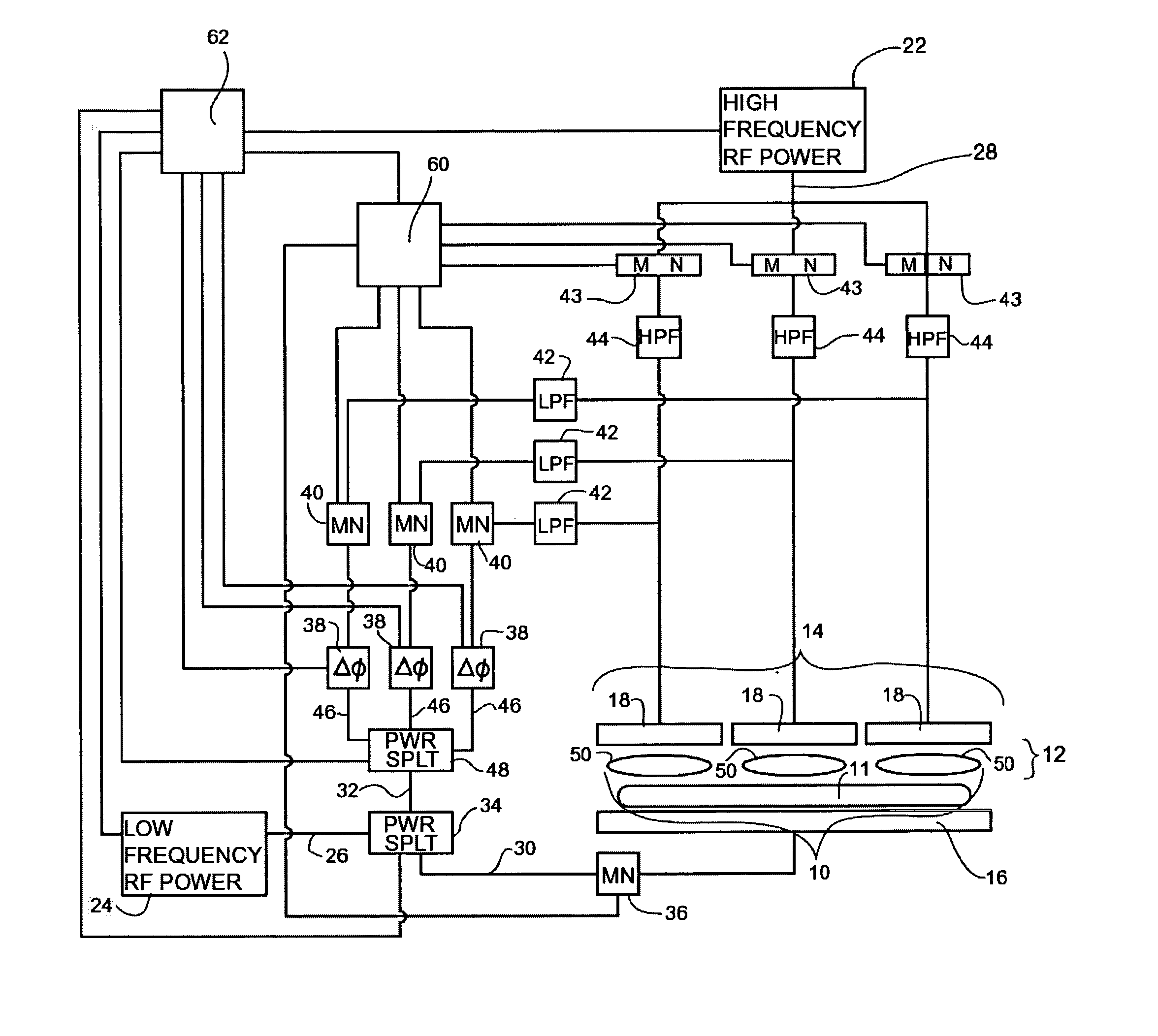

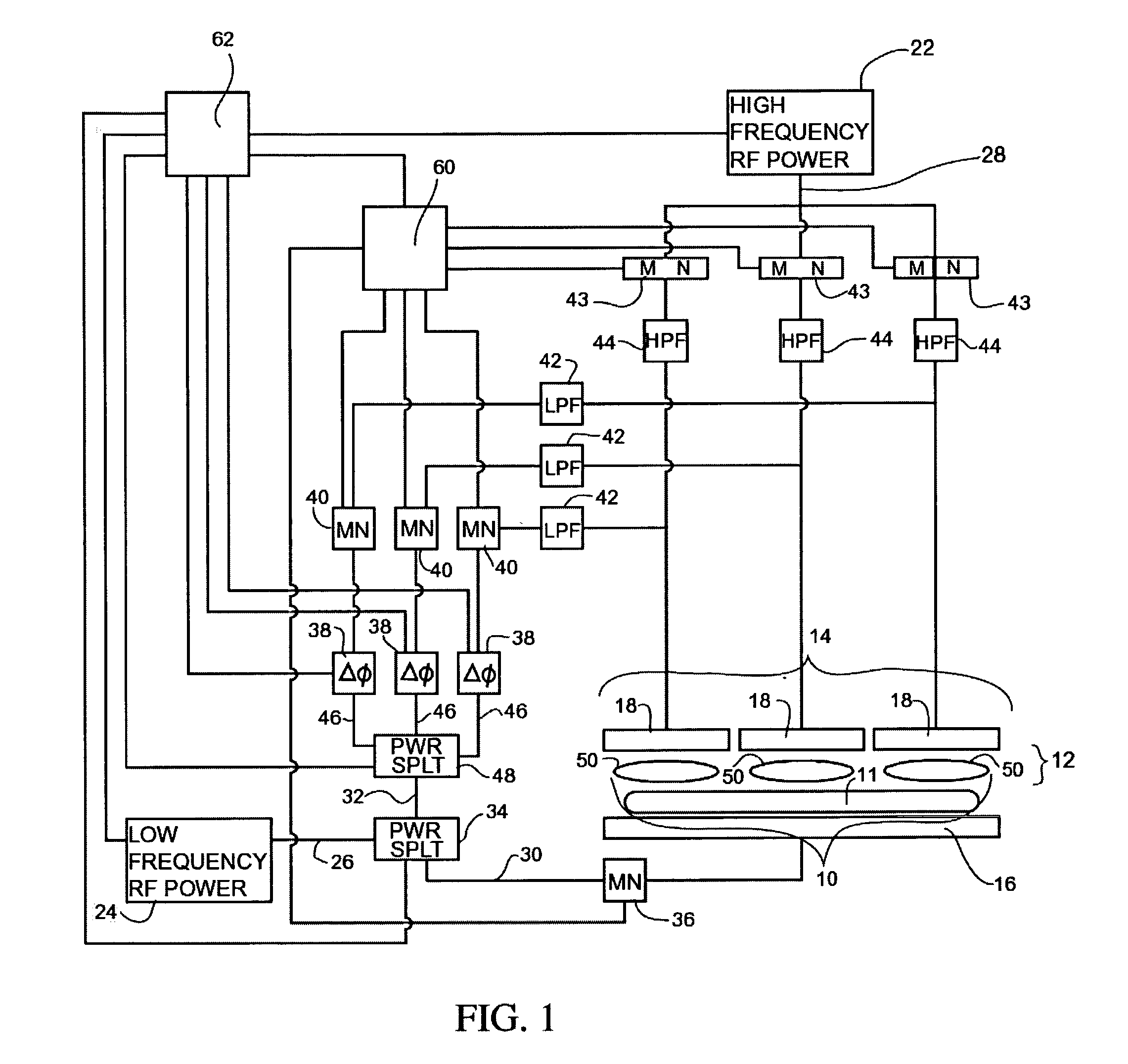

Method to affect spatial distribution of harmonic generation in a capacitive discharge reactor

The present invention provides an apparatus and a method of generating and controlling plasma formed in a capacitively coupled plasma region between a plasma electrode and a bias electrode. The plasma electrode includes a plurality of sub-electrodes that are electrically insulated from one another. Radio frequency plasma generating electric power is provided to the plasma electrode. Radio frequency bias electric power, at a lower frequency than the plasma generating radio frequency electric power, is also provided. A first portion of the bias electric power is provided to the bias electrode, and a second portion of the bias electric power is provided to the plasma electrode. At least one filter, impedance matching network, phase shifter, and power splitter are used to affect the electric power provided to the electrodes.

Owner:TOKYO ELECTRON LTD

Frequency tuning for pulsed radio frequency plasma processing

ActiveUS20150382442A1Minimize the differenceElectric discharge tubesElectric arc lampsPulsed radiofrequencyPlasma processing

This disclosure describes systems, methods, and apparatus for pulsed RF power delivery to a plasma load for plasma processing of a substrate. In order to maximize power delivery, a calibration phase using a dummy substrate or no substrate in the chamber, is used to ascertain a preferred fixed initial RF frequency for each pulse. This fixed initial RF frequency is then used at the start of each pulse during a processing phase, where a real substrate is used and processed in the chamber.

Owner:AES GLOBAL HLDG PTE LTD

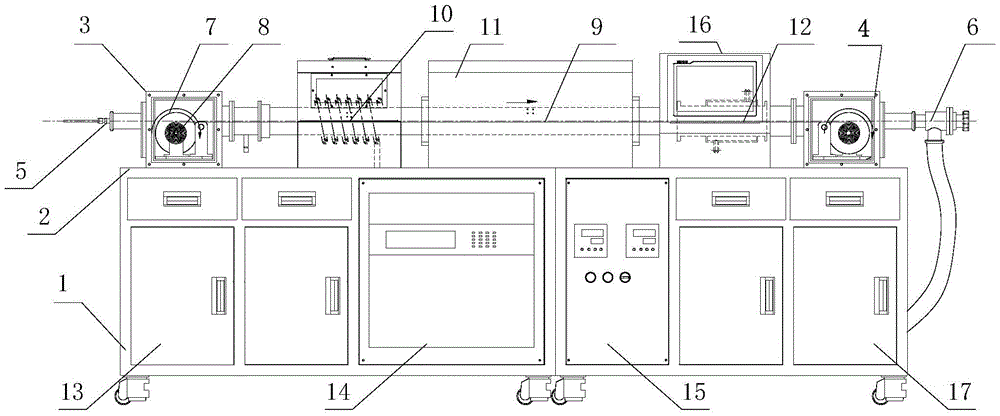

Roll-to-roll continuous grapheme film growth device and technique

The invention discloses a roll-to-roll continuous grapheme film growth device and technique. The roll-to-roll continuous grapheme film growth device comprises a machine body. The two ends of a workbench are provided with vacuum cavities correspondingly. A vacuum pipe is connected to the vacuum cavities. A radio-frequency plasma generator, a heating furnace and a liquid nitrogen cold trap are sequentially arranged at one side of one vacuum cavity. According to the device, roll-shaped copper foil is arranged in the vacuum cavities for roll-to-roll continuous preparation of large-area and high-quality grapheme. Compared with an existing method, the method for preparing the grapheme through the device has the advantages of being rapid and continuous; large-scale growth of the large-area and high-quality grapheme can be achieved.

Owner:ANHUI BEQ EQUIP TECH

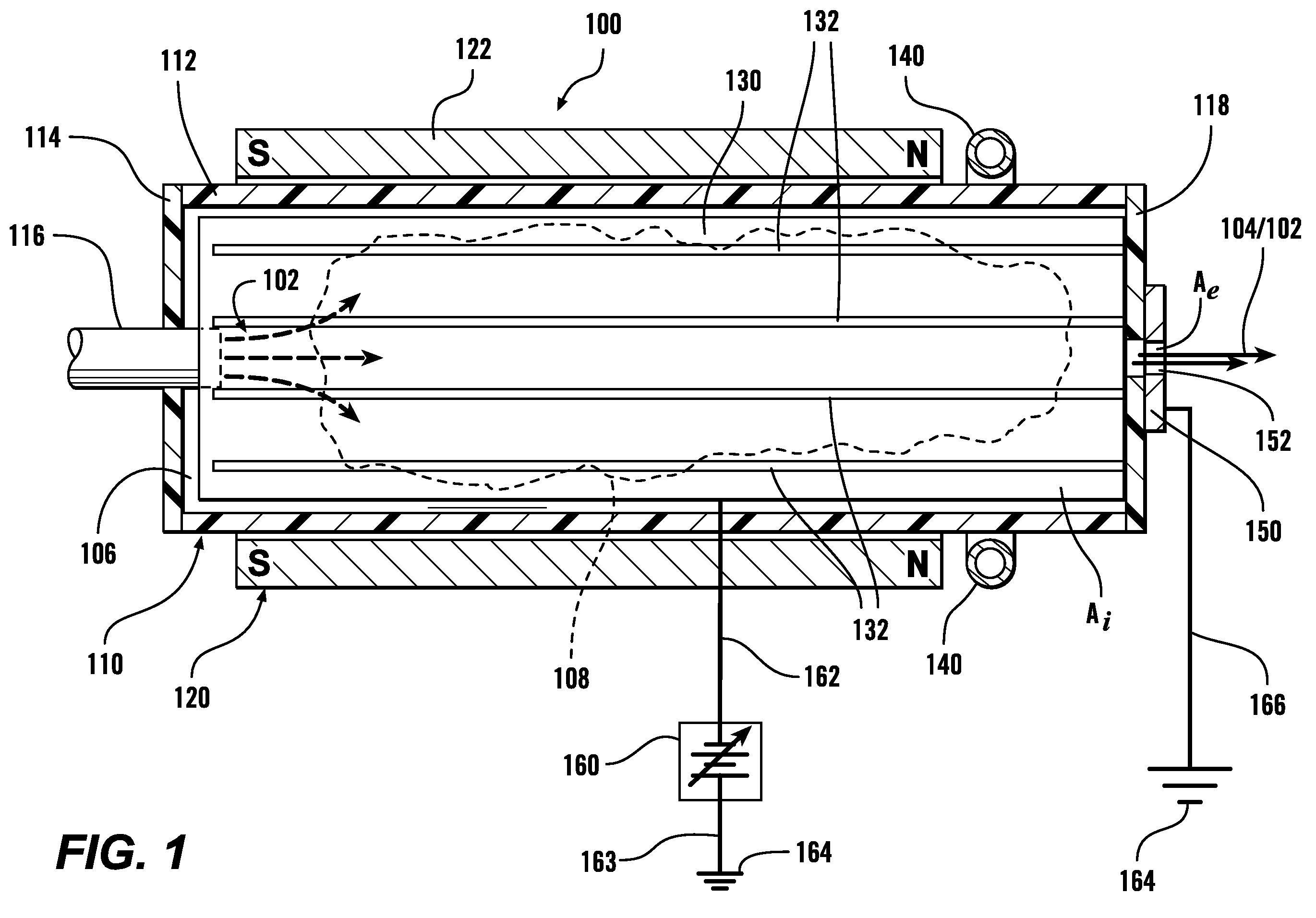

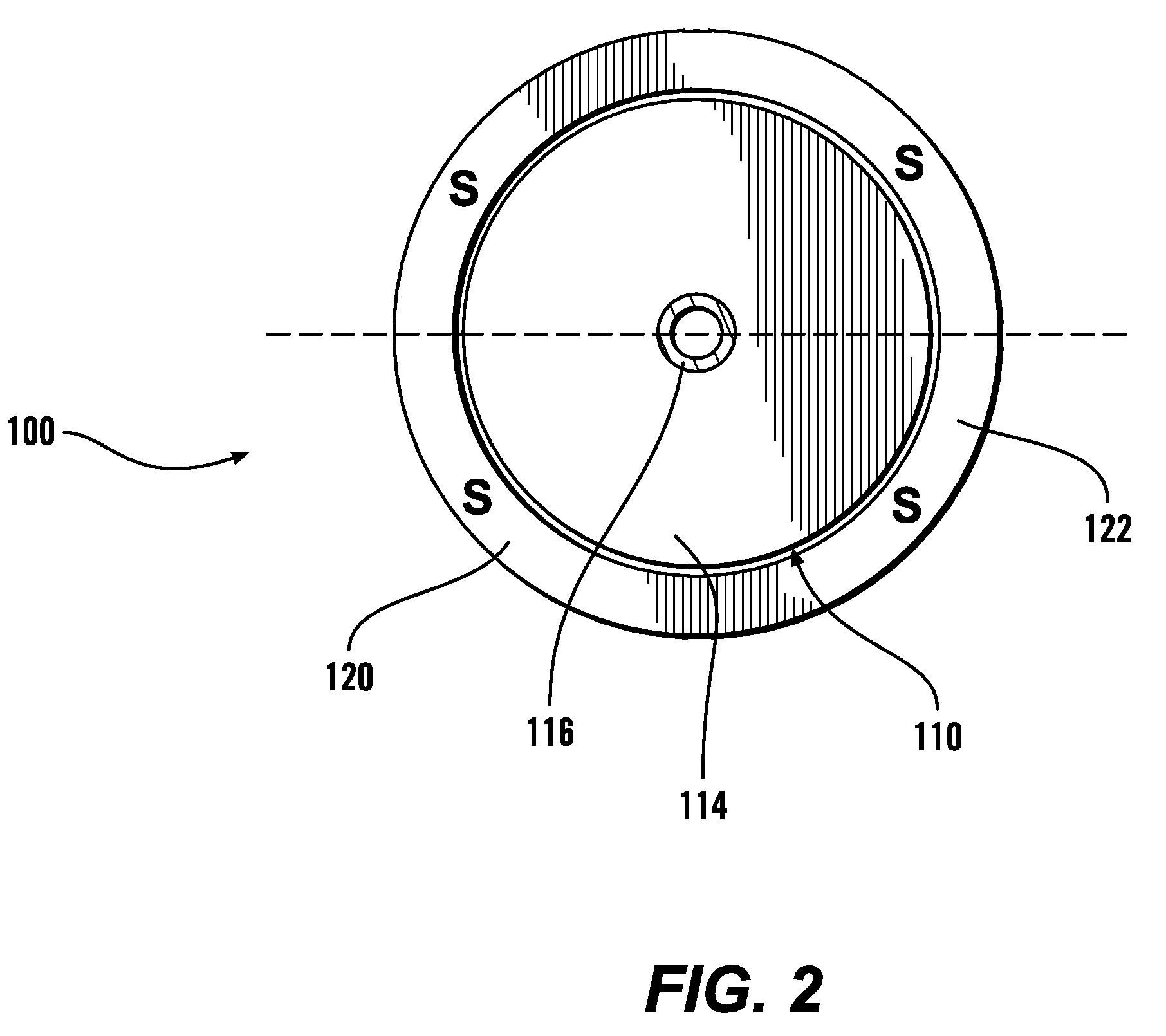

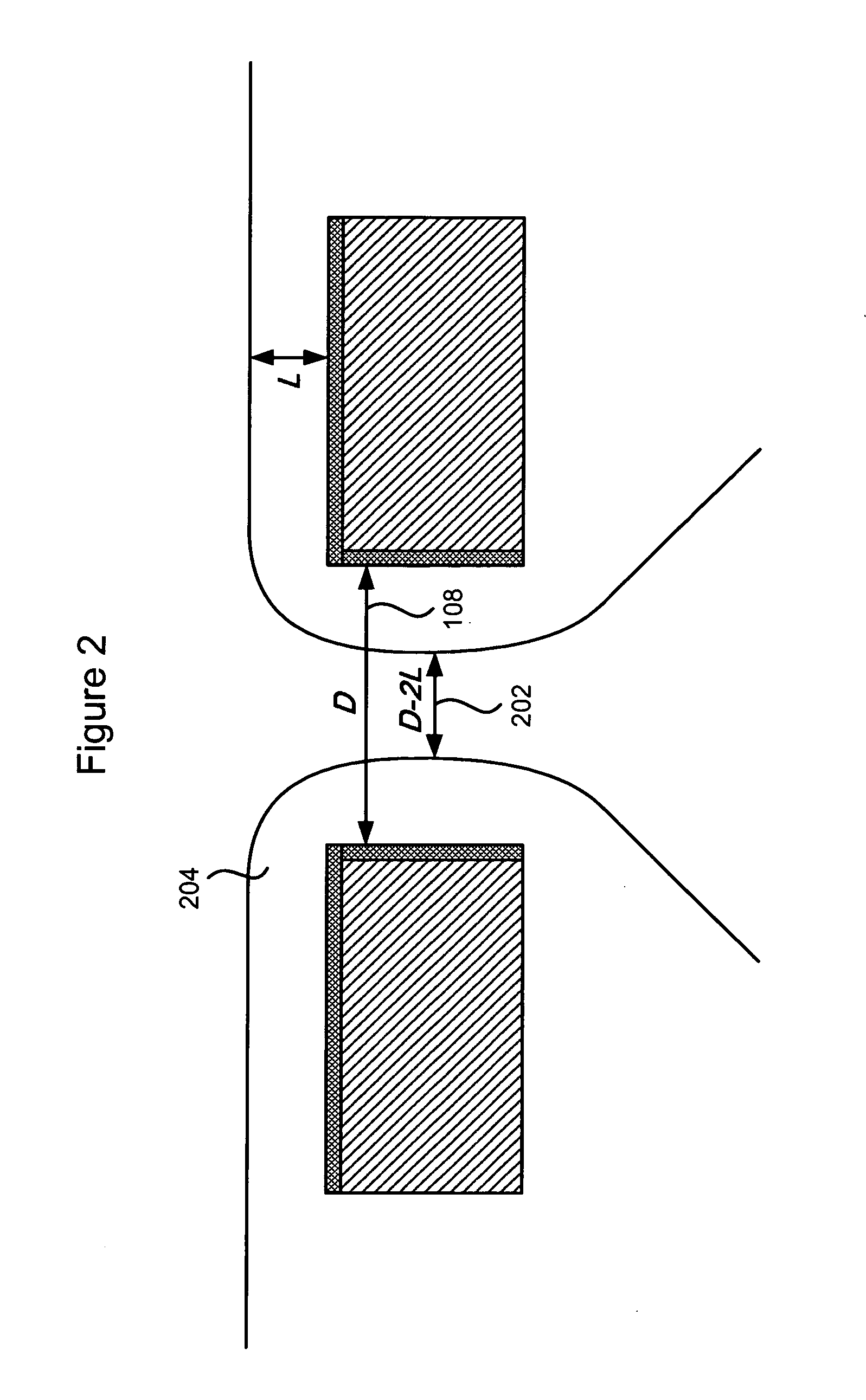

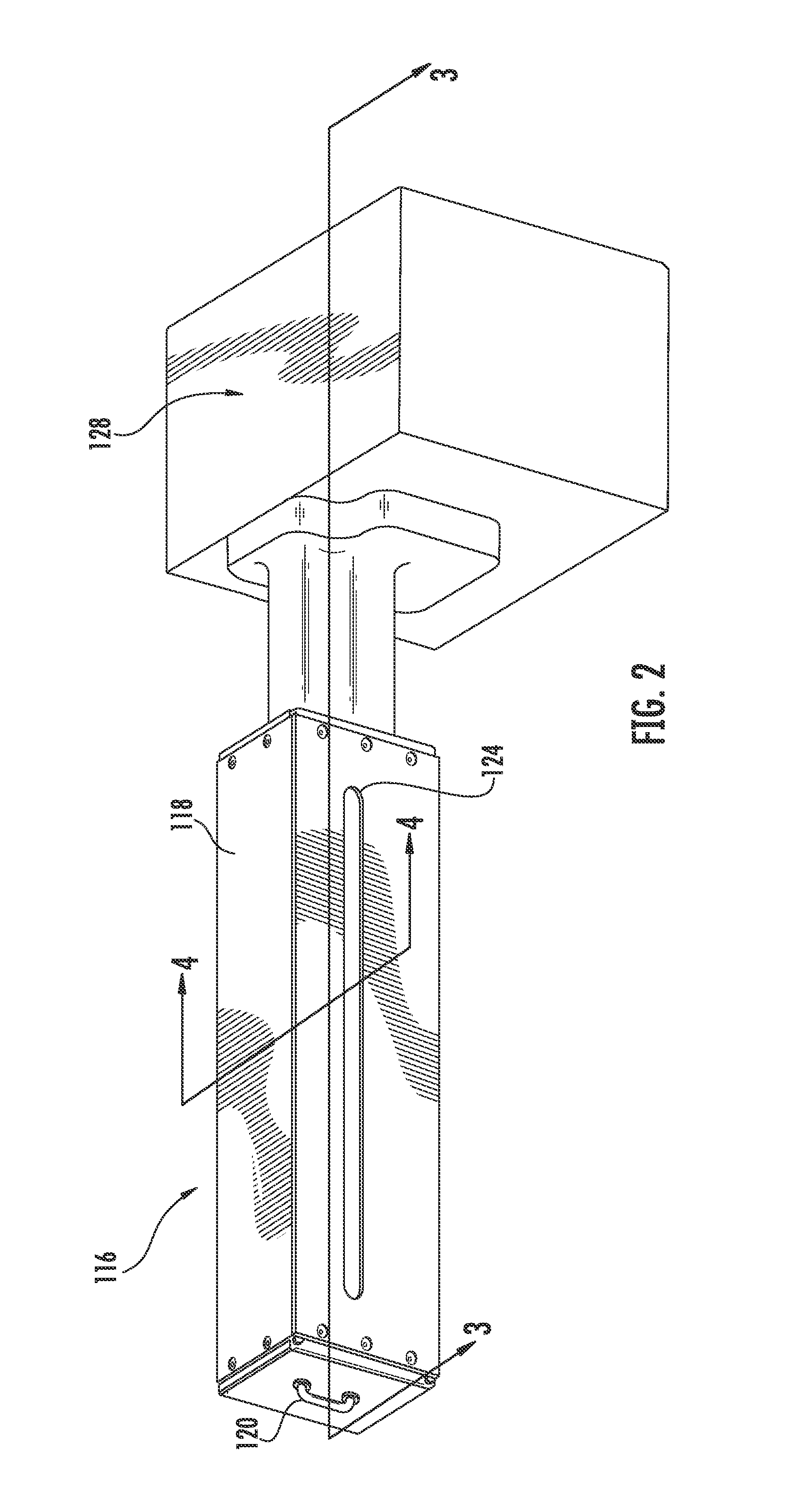

Inductively coupled plasma flood gun using an immersed low inductance fr coil and multicusp magnetic arrangement

ActiveUS20120085917A1Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsMetallic materialsInductively coupled plasma

A device is disclosed for providing an inductively coupled radio frequency plasma flood gun. In one particular exemplary embodiment, the device is a plasma flood gun in an ion implantation system. The plasma flood gun may comprise a plasma chamber having one or more apertures; a gas source capable of supplying at least one gaseous substance to the plasma chamber; a single-turn coil disposed within the plasma chamber, and a power source coupled to the coil for inductively coupling radio frequency electrical power to excite the at least one gaseous substance in the plasma chamber to generate a plasma. The inner surface of the plasma chamber may be free of metal-containing material and the plasma may not be exposed to any metal-containing component within the plasma chamber. The plasma chamber may include a plurality of magnets for controlling the plasma. An exit aperture may be provided in the plasma chamber to enable negatively charged particles of the resulting plasma to engage an ion beam that is part of the associated ion implantation system. In one embodiment, magnets are disposed on opposite sides of the aperture and are used to manipulate the electrons of the plasma.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Method to affect spatial distribution of harmonic generation in a capacitive discharge reactor

The present invention provides an apparatus and a method of generating and controlling plasma formed in a capacitively coupled plasma region between a plasma electrode and a bias electrode. The plasma electrode includes a plurality of sub-electrodes that are electrically insulated from one another. Radio frequency plasma generating electric power is provided to the plasma electrode. Radio frequency bias electric power, at a lower frequency than the plasma generating radio frequency electric power, is also provided. A first portion of the bias electric power is provided to the bias electrode, and a second portion of the bias electric power is provided to the plasma electrode. At least one filter, impedance matching network, phase shifter, and power splitter are used to affect the electric power provided to the electrodes.

Owner:TOKYO ELECTRON LTD

Method for preparing micro spherical niobium (Nb)-wolfram (W)-molybdenum (Mo)-zirconium (Zr) alloy powder

Owner:UNIV OF SCI & TECH BEIJING

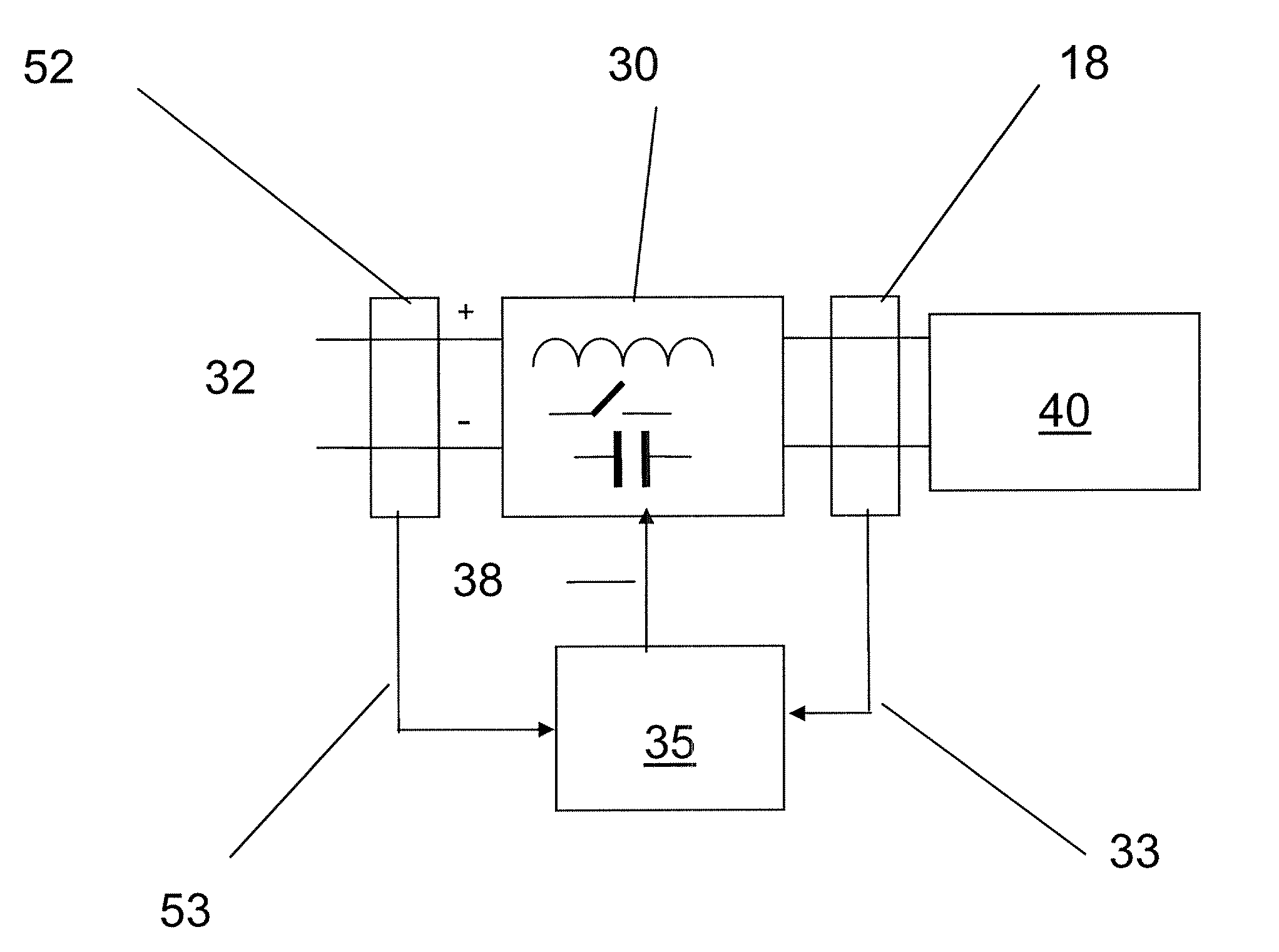

Method and Apparatus for Preventing Instabilities in Radio-Frequency Plasma Processing

ActiveUS20070075654A1Stable operation of plasmaGuaranteed uptimeElectric discharge tubesElectric light circuit arrangementConstant powerInstability

A method and apparatus for controlling a power supply to prevent instabilities due to dynamic loads in RF plasma processing systems, operating at frequencies of from 1 MHz and up 1 MHz and above. The apparatus includes a power source, a power converter receiving power from the source, the power converter providing a constant output power controlled by varying at least one of input voltage or switching frequency, and an RF generator receiving constant power from the power converter.

Owner:MKS INSTR INC

Nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing as well as preparation method and application thereof

ActiveCN111168057AImprove liquidityReduce oxygen contentAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysNanoceramic

The invention discloses nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing and a preparation method and application thereof, and belongs to the technical field of metal additive manufacturing. The preparation method of the nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing comprises the following steps of powder mixing, powderplasma spheroidizing, redundant nano ceramic particle removing, powder particle size grading and mixing. According to the preparation method, high-entropy alloy serves as matrix powder, nano ceramicparticles serve as reinforcing phase particles, high-entropy alloy powder with the nano ceramic particles evenly attached to the surface is obtained in an ultrasonic dispersion and mechanical stirringmode, and then the spherical nano ceramic particle reinforced high-entropy alloy composite powder is prepared through the radio frequency plasma spheroidizing technology; and the process for preparing the nano ceramic reinforced high-entropy alloy composite powder is simple, and the prepared powder is excellent in performance and suitable for mass production.

Owner:SOUTH CHINA UNIV OF TECH

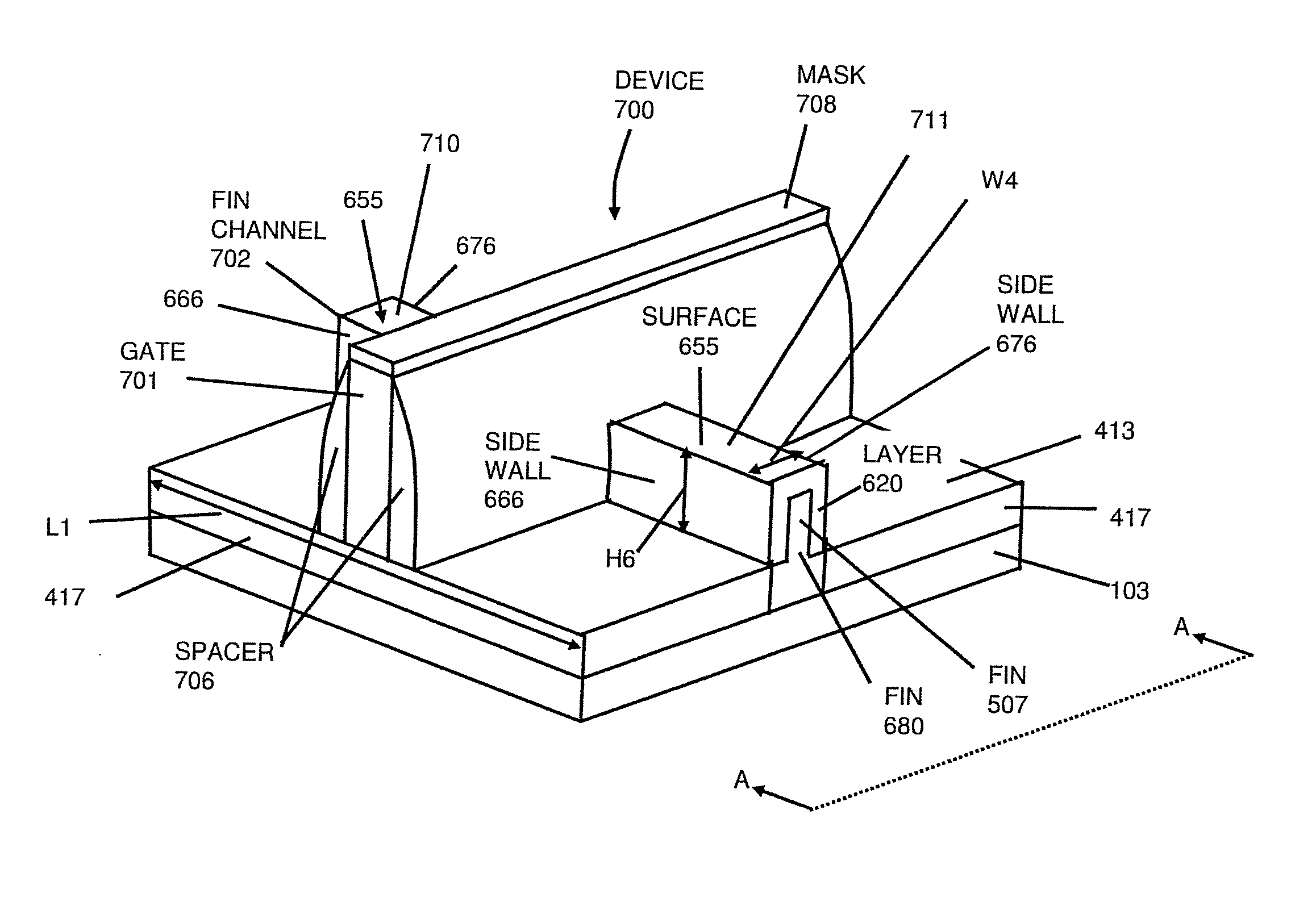

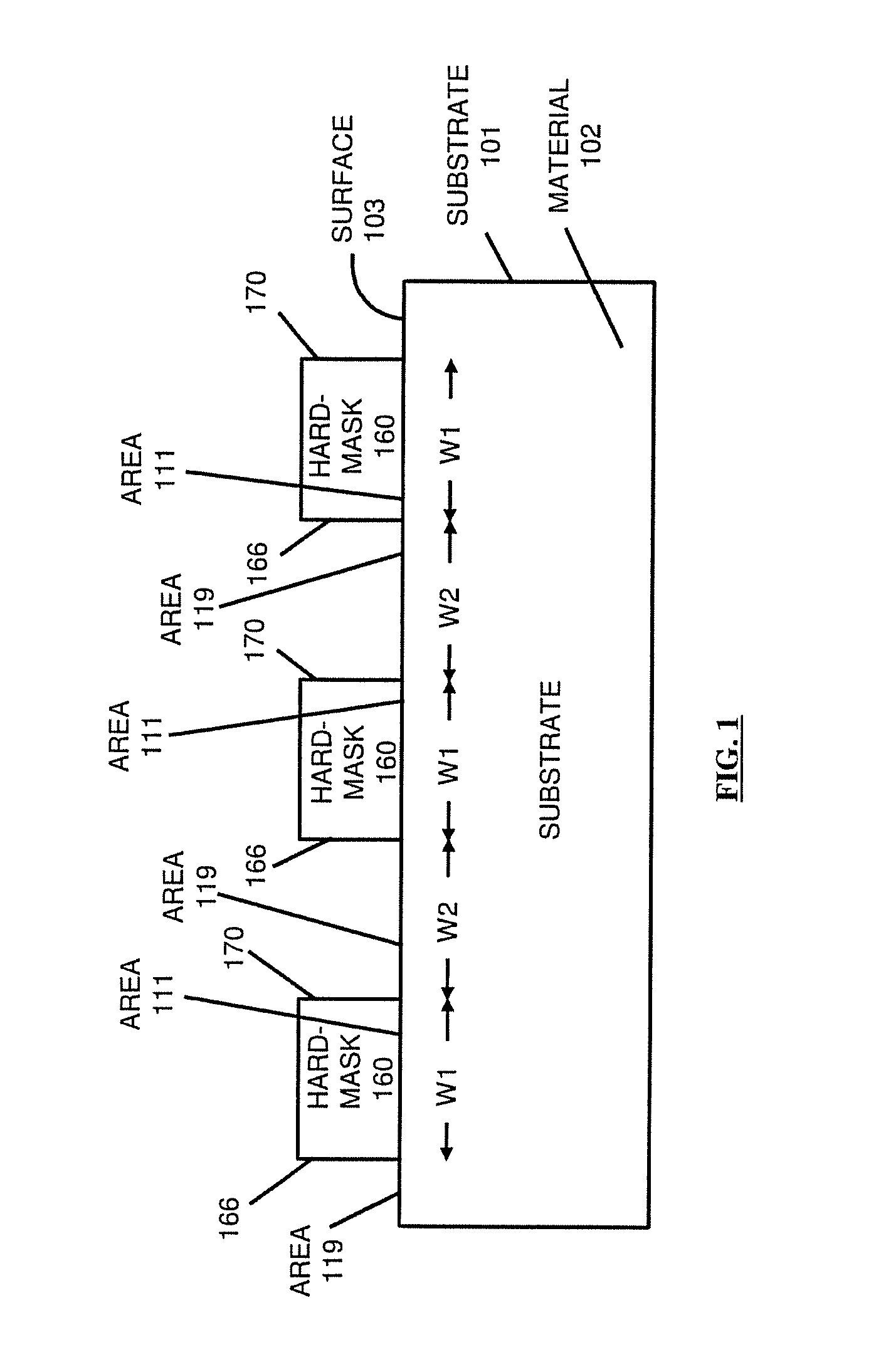

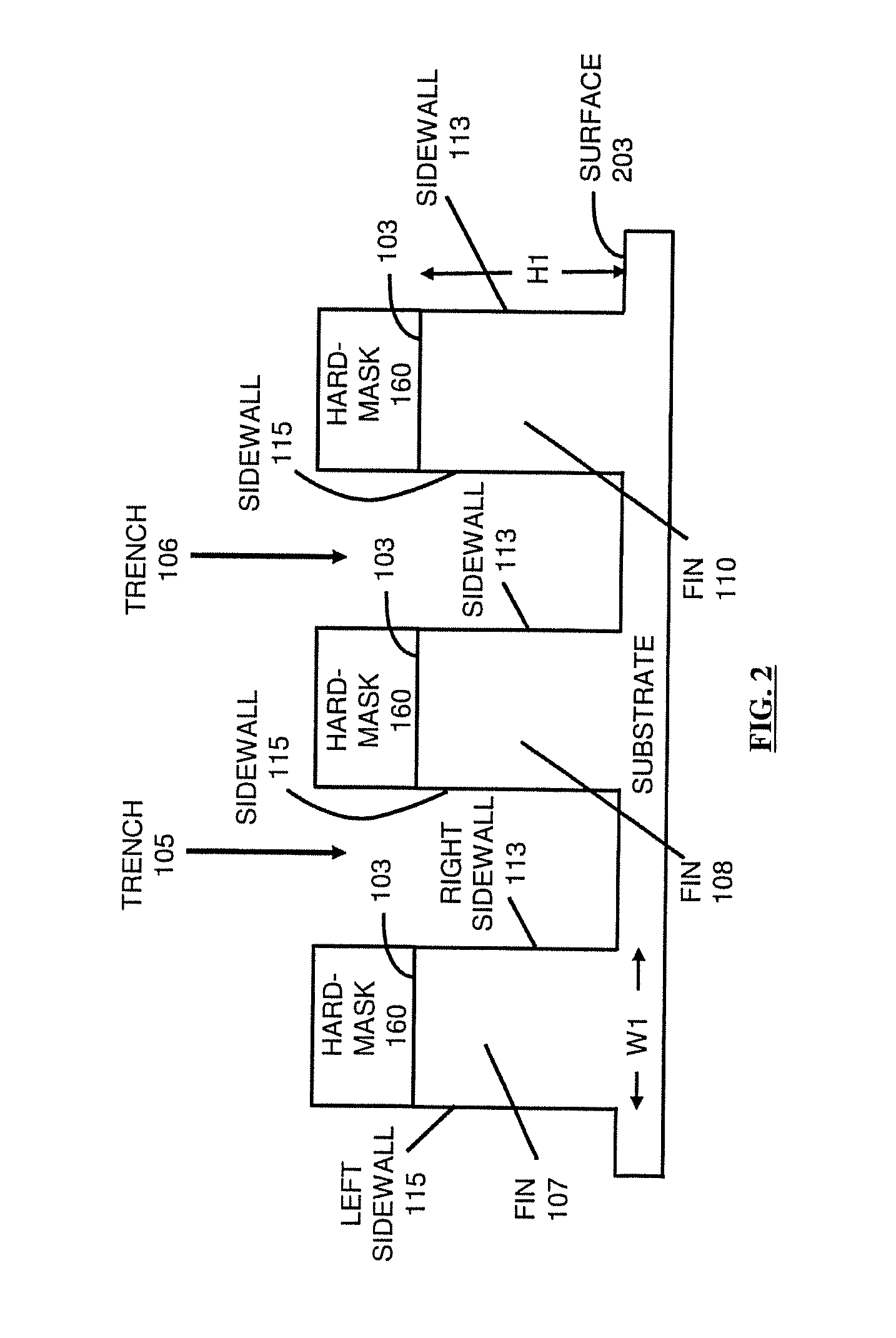

Pre-sculpting of si fin elements prior to cladding for transistor channel applications

ActiveUS20160308032A1Solid-state devicesSemiconductor/solid-state device manufacturingIon bombardmentSingle crystal

Transistor fin elements (e.g., fin or tri gate) may be modified by radio frequency (RF) plasma and / or thermal processing for purpose of dimensional sculpting. The etched, thinned fins may be formed by first forming wider single crystal fins, and after depositing trench oxide material between the wider fins, etching the wider fins using a second etch to form narrower single crystal fins having undamaged top and sidewalls for epitaxially growing active channel material. The second etch may remove a thickness of between a 1 nm and 15 nm of the top surfaces and the sidewalls of the wider fins. It may remove the thickness using (1) chlorine or fluorine based chemistry using low ion energy plasma processing, or (2) low temperature thermal processing that does not damage fins via energetic ion bombardment, oxidation or by leaving behind etch residue that could disrupt the epitaxial growth quality of the second material.

Owner:TAHOE RES LTD

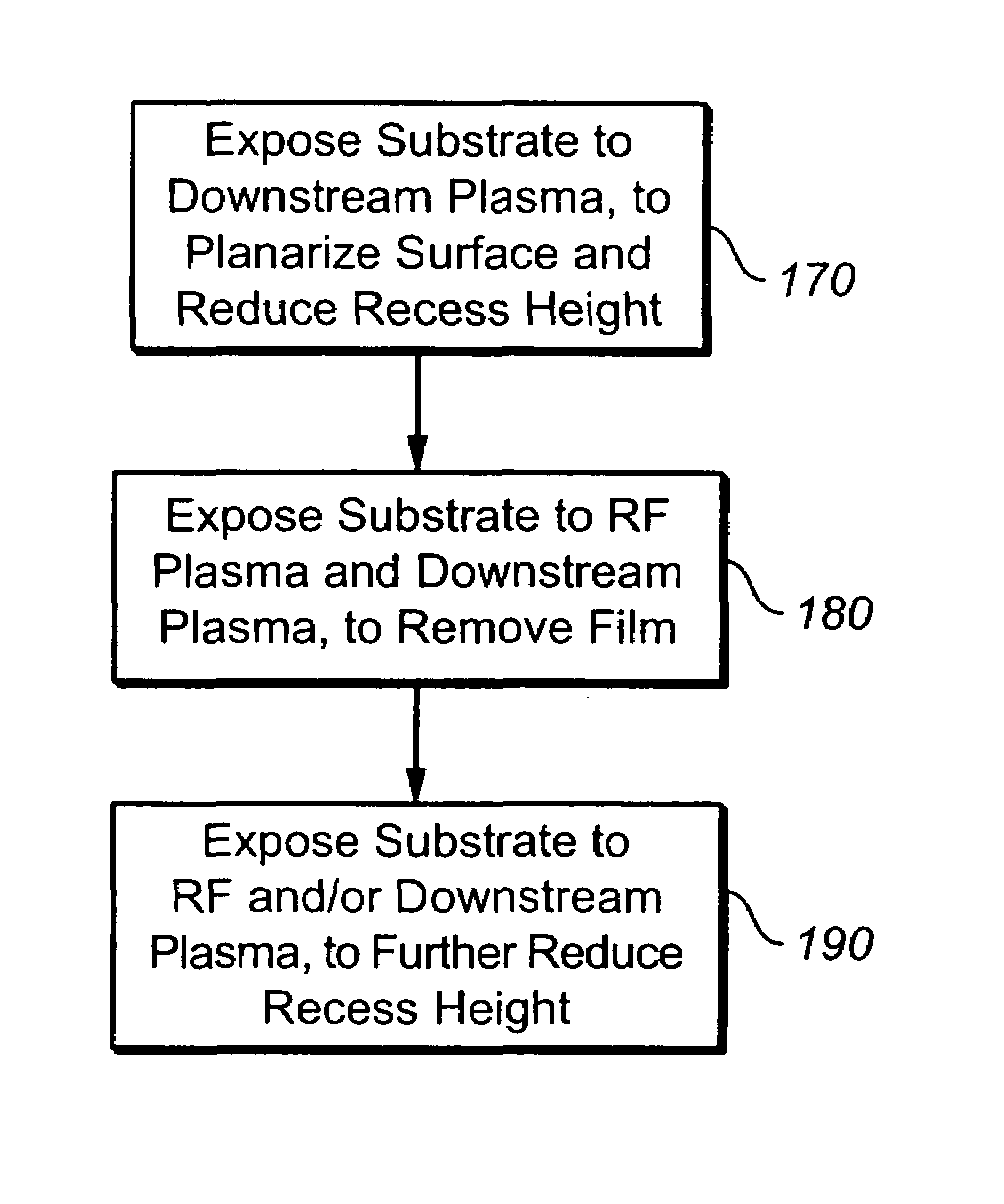

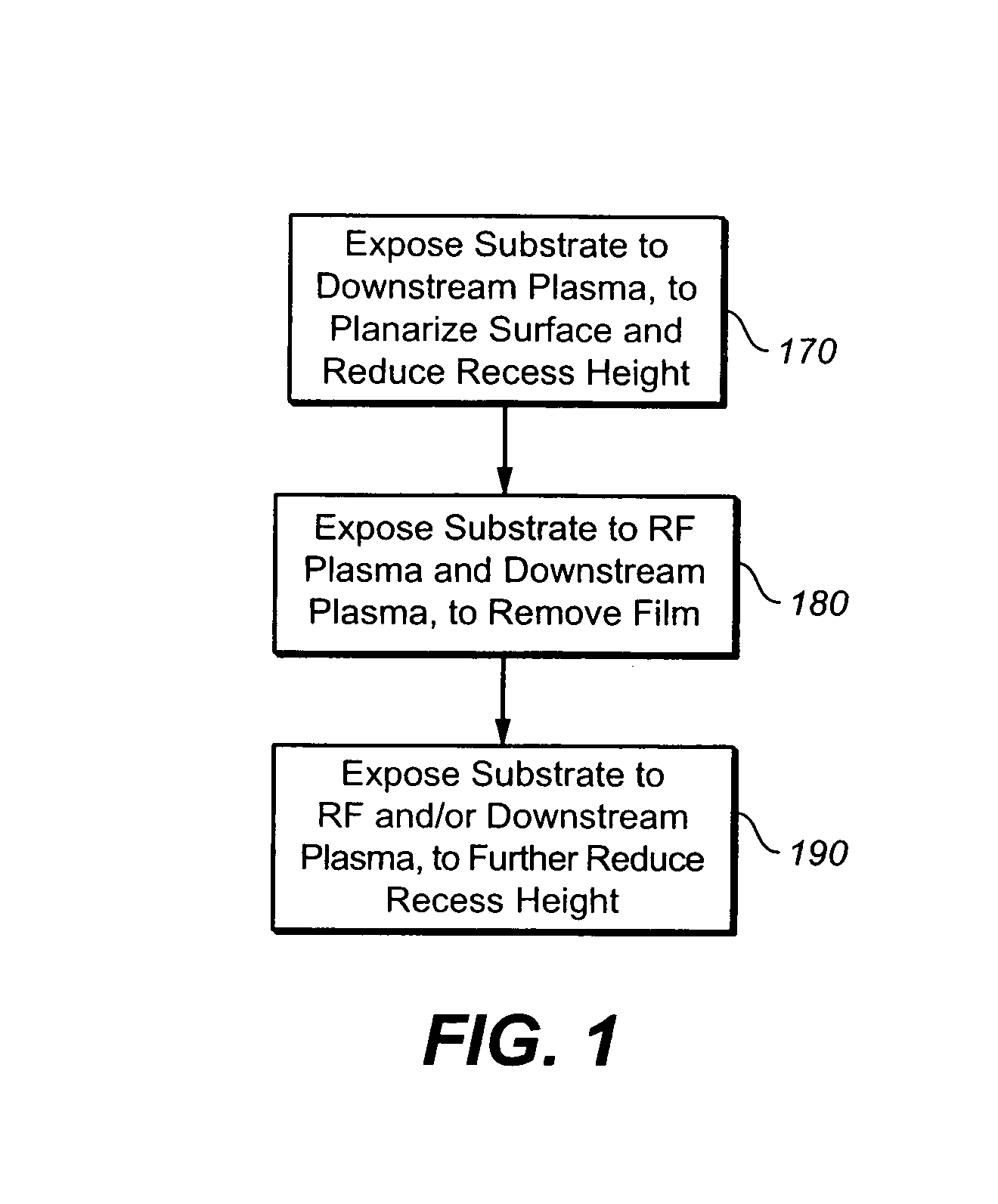

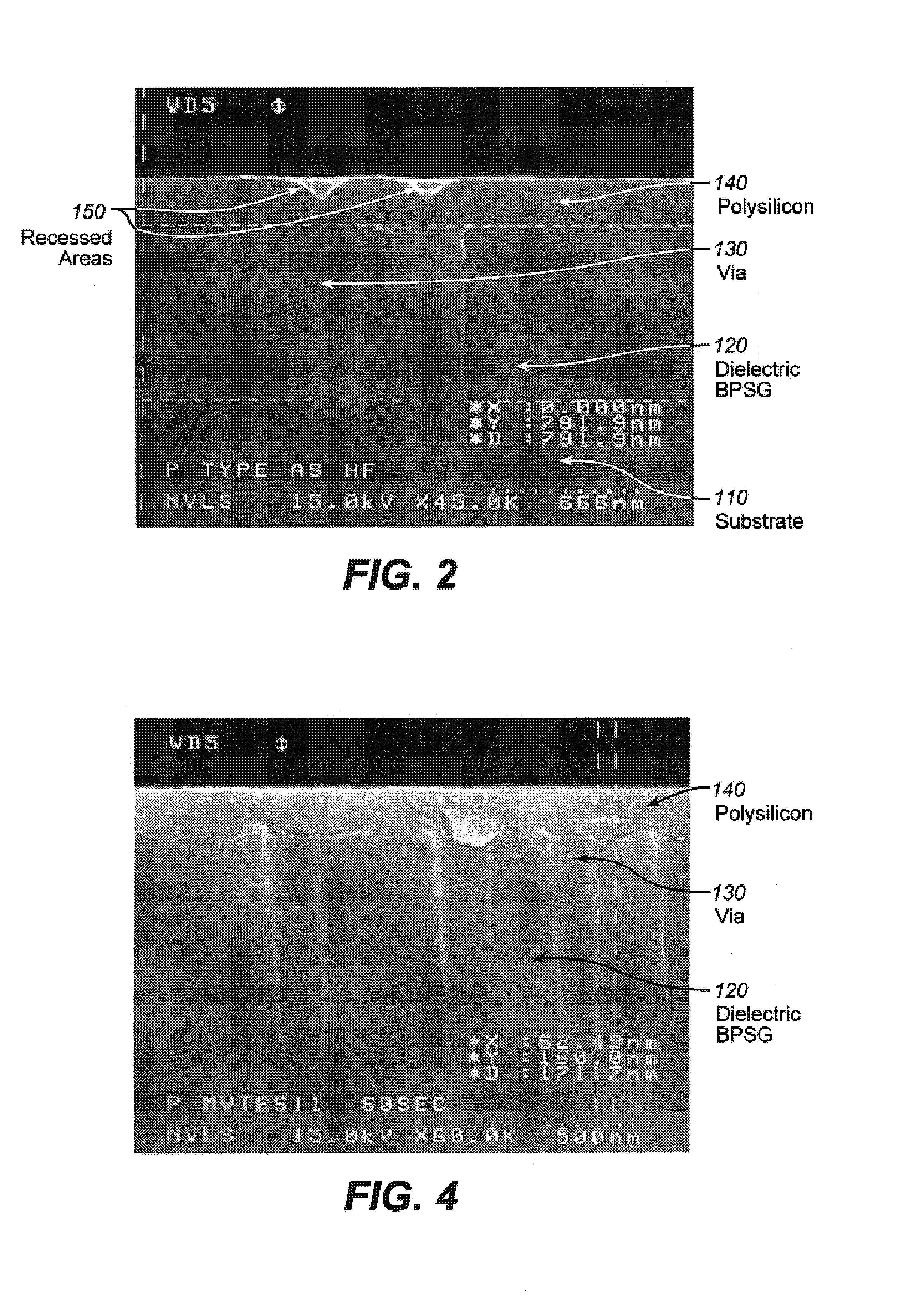

Etch back process approach in dual source plasma reactors

InactiveUS7160813B1High densityLow densityElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingTopography

A method is disclosed for removing a polysilicon layer from a semiconductor wafer, in which a downstream plasma source is used first to planarize the wafer, removing contours in the polysilicon layer caused by deposition over lithographic features, such as via holes. The planarizing process is followed by exposure to a plasma made by a direct, radio frequency plasma source, which may be in combination with the downstream plasma source, to perform the bulk etching of the polysilicon. The invention can produce planar surface topography after the top layer of the film is removed, in which the residual recess height of the polysilicon plug filling a via hole is less than about about 10 nm.

Owner:NOVELLUS SYSTEMS

Drug dispensing components

InactiveUS20050143685A1Reduce absorptionReduce frictionElectrotherapyPharmaceutical containersMedication DispenserDrug dispensing

A medicament dispenser comprising a canister and a drug dispensing valve, wherein one or more surfaces of said canister and / or valve has a fluorinated coating provided by a process comprising generating one or more fluorine-containing radical species and polymerising said radicals on said one or more surfaces, provided that the radicals are not generated by a process involving continuous wave radio frequency plasma polymerisation is disclosed.

Owner:GLAXO GROUP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com