Nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing as well as preparation method and application thereof

A high-entropy alloy and composite powder technology, which is applied in additive processing, metal processing equipment, transportation and packaging, etc., can solve problems such as poor powder sphericity, affecting the forming performance of powder fluidity products, and uneven dispersion of nano-ceramic particles. , to achieve high sphericity, improve forming accuracy and mechanical properties, and improve powder utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 Preparation method of nano-TiC reinforced CoCrFeNiMn high-entropy alloy composite powder for SLM / EBM additive manufacturing

[0060] 1. Method

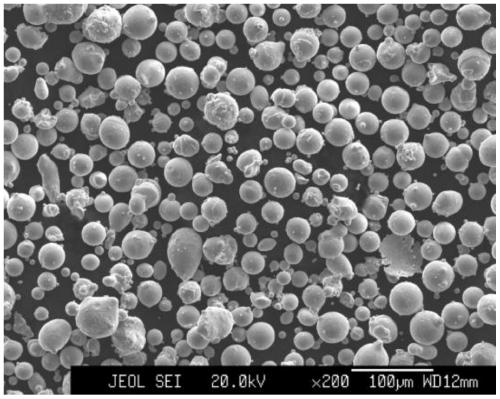

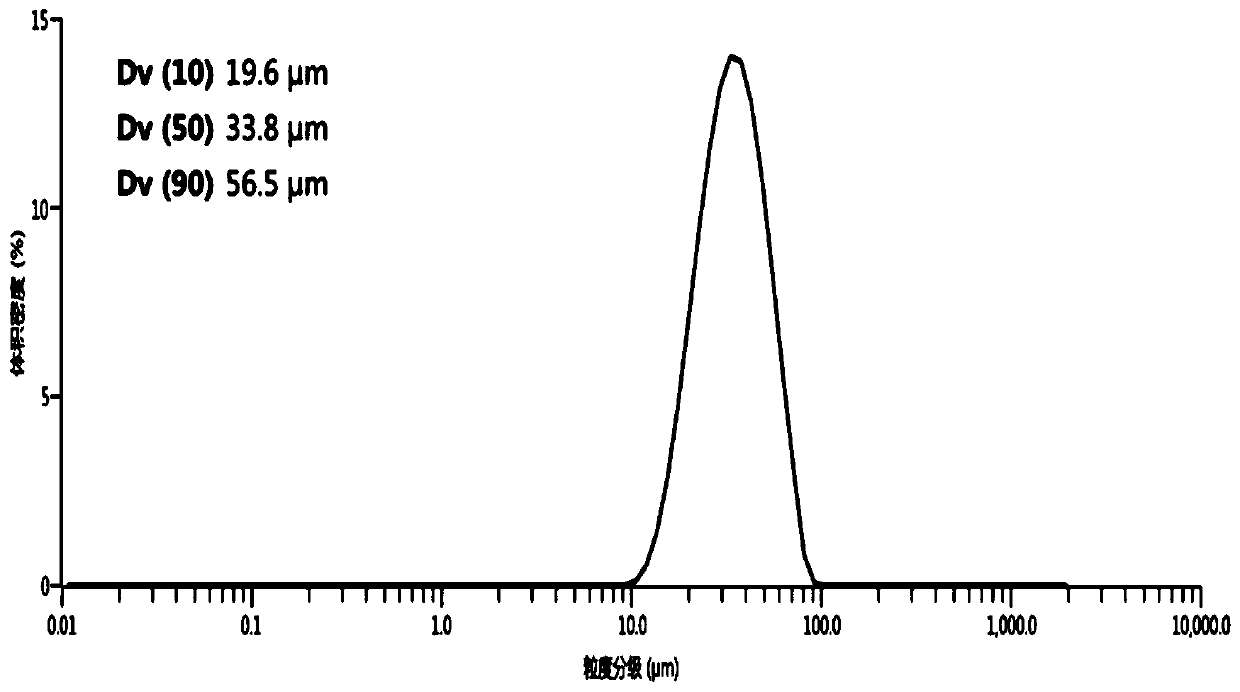

[0061] (1) Powder mixing: high entropy alloy powder CoCrFeNiMn (particle size 15 ~ 53μm, such as figure 1 shown) and nano-TiC particles (particle size is 20nm) are uniformly mixed by ultrasonic dispersion and mechanical stirring to obtain CoCrFeNiMn high-entropy alloy powder A with surface-adhered nano-TiC particles; wherein, the high-entropy alloy powder CoCrFeNiMn and nano-TiC particles by mass The mixing ratio is 9:1; the ultrasonic dispersion frequency is 18kHZ, the stirring rate of mechanical stirring is 60r / min, and the processing time is 120min.

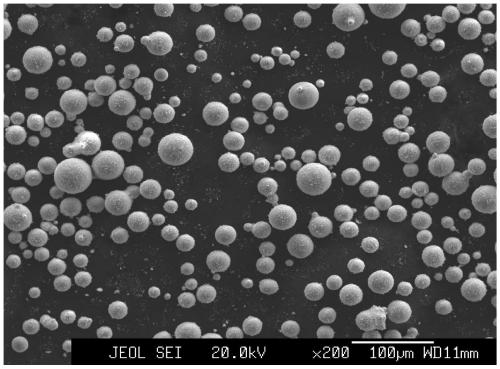

[0062] (2) Powder plasma spheroidization: the CoCrFeNiMn high-entropy alloy powder A with nano-TiC particles adhered to the surface is sprayed into the plasma torch through the carrier gas (argon gas) through the powder feeder, and under the action of high-temperatur...

Embodiment 2

[0067] Example 2 Preparation method of nano-TiN reinforced WMoNbTa high-entropy alloy composite powder for LMD additive manufacturing

[0068] 1. Method

[0069] (1) Powder mixing: irregularly shaped WMoNbTa high-entropy alloy powder (particle size 45-105 μm, such as Figure 4 shown) and nano-TiN particles (particle size is 30nm) are simultaneously processed by ultrasonic dispersion and mechanical stirring to obtain WMoNbTa high-entropy alloy powder A with nano-TiN particles attached to the surface; wherein, the irregular-shaped WMoNbTa high-entropy alloy powder and nano-TiN The particles are mixed according to the mass ratio of 22:3; the ultrasonic dispersion frequency is 30kHZ, the stirring rate of mechanical stirring is 60r / min; the time is 90min;

[0070] (2) Powder plasma spheroidization: the WMoNbTa high-entropy alloy powder A with nano-TiN particles adhered to the surface is sprayed into the plasma torch through the carrier gas (argon gas) through the powder feeder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com