Patents

Literature

1011results about How to "High sphericity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal powder for 3D printer and preparing method thereof

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

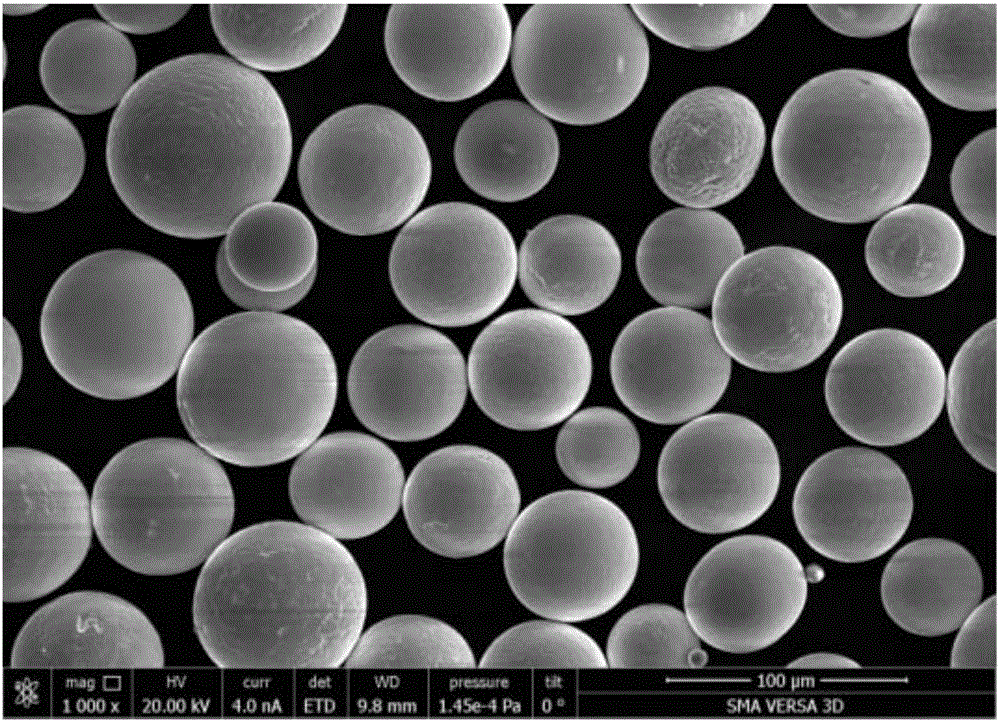

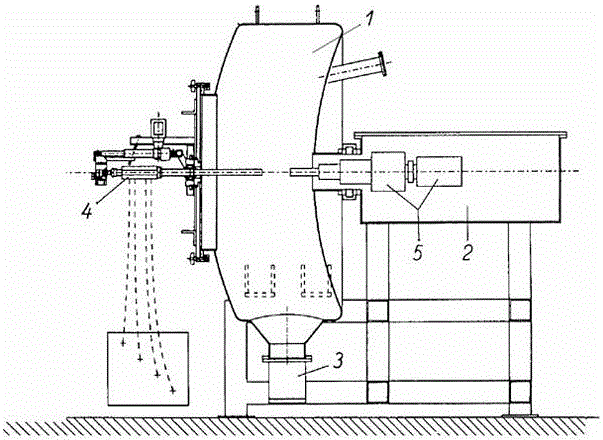

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

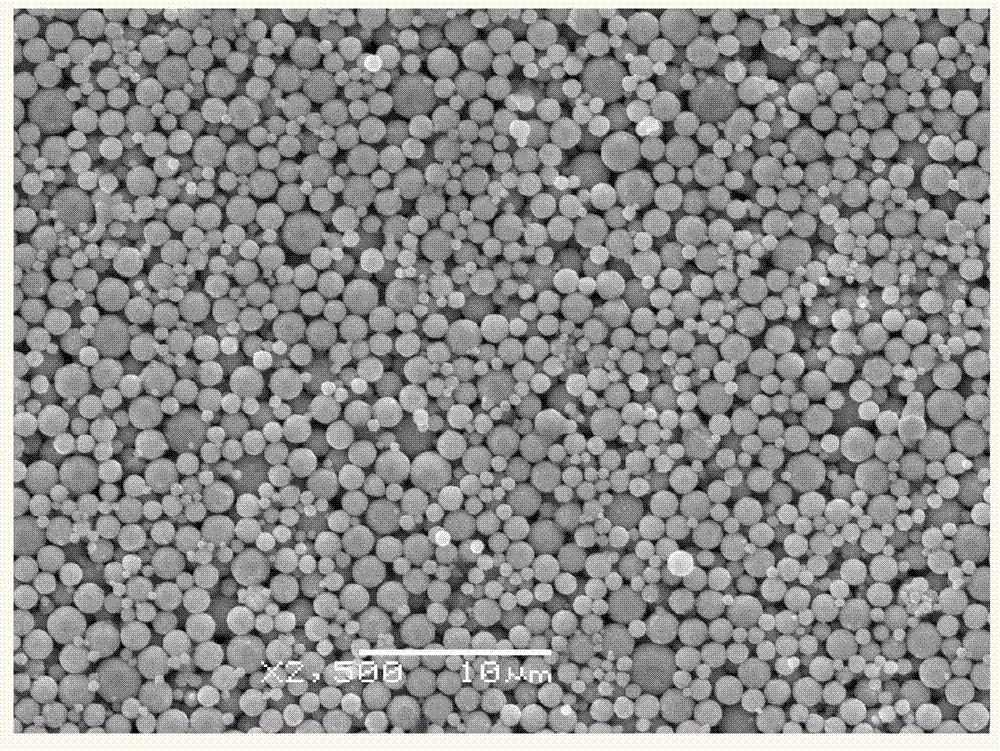

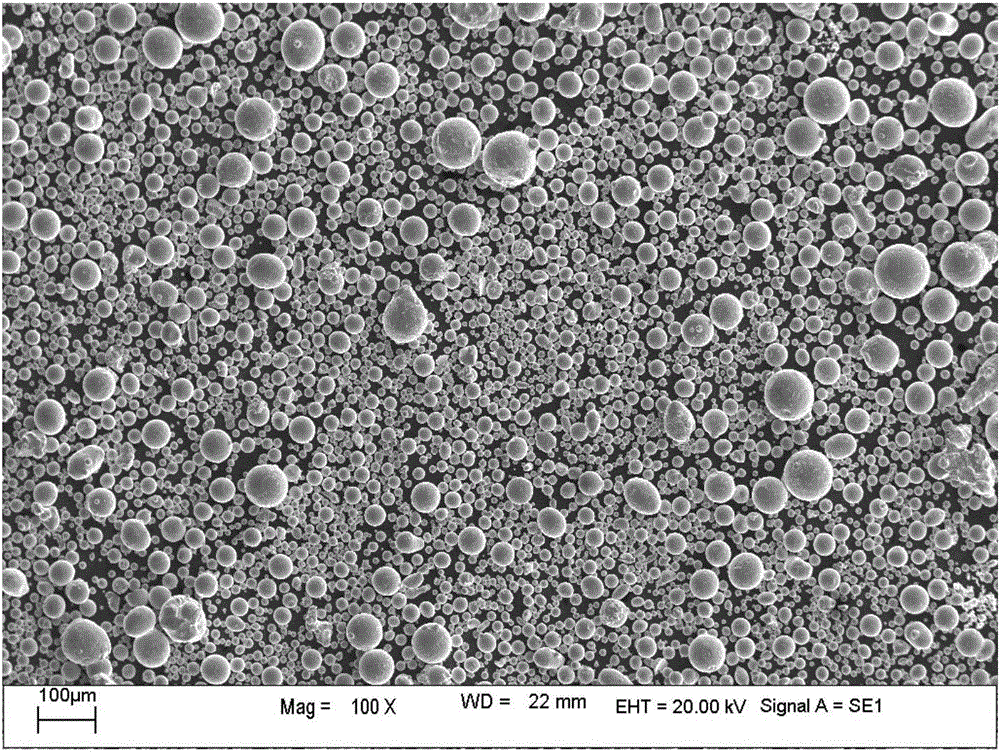

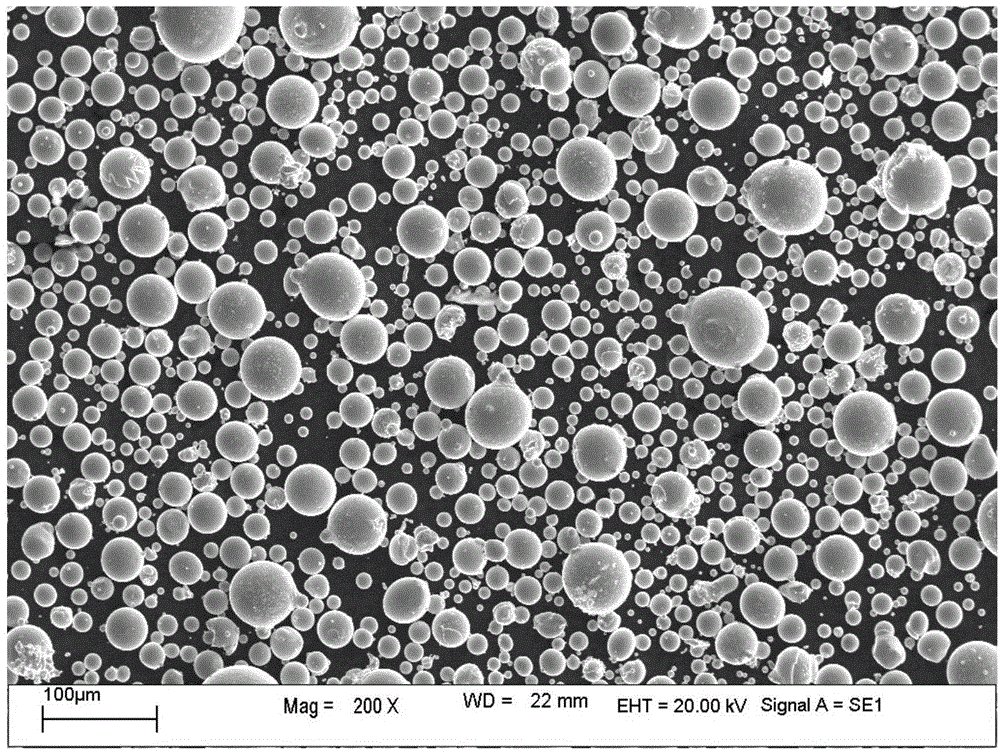

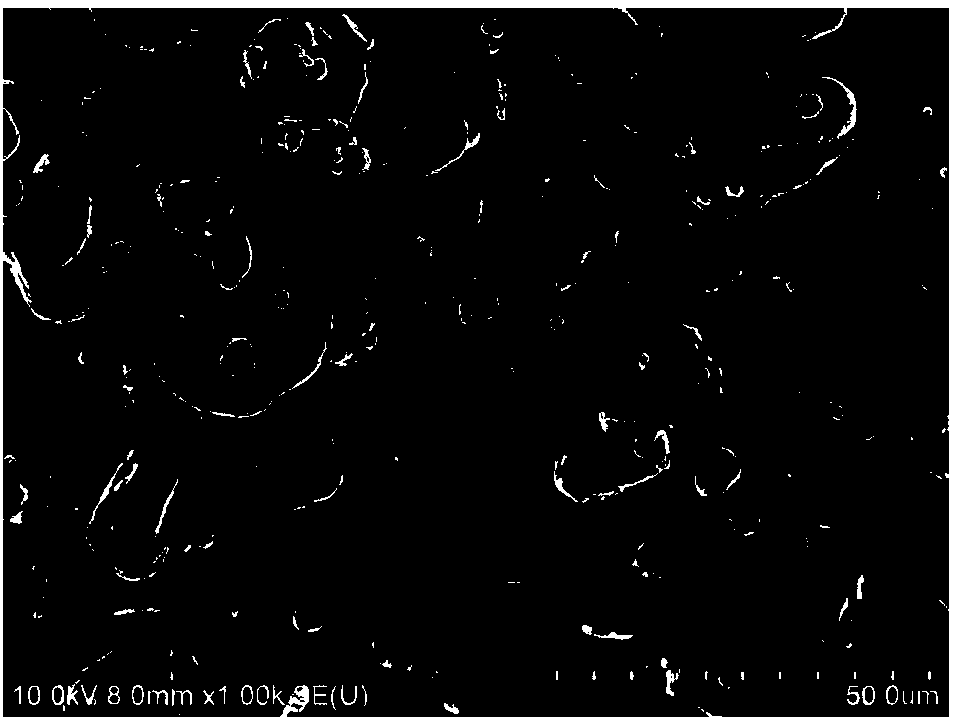

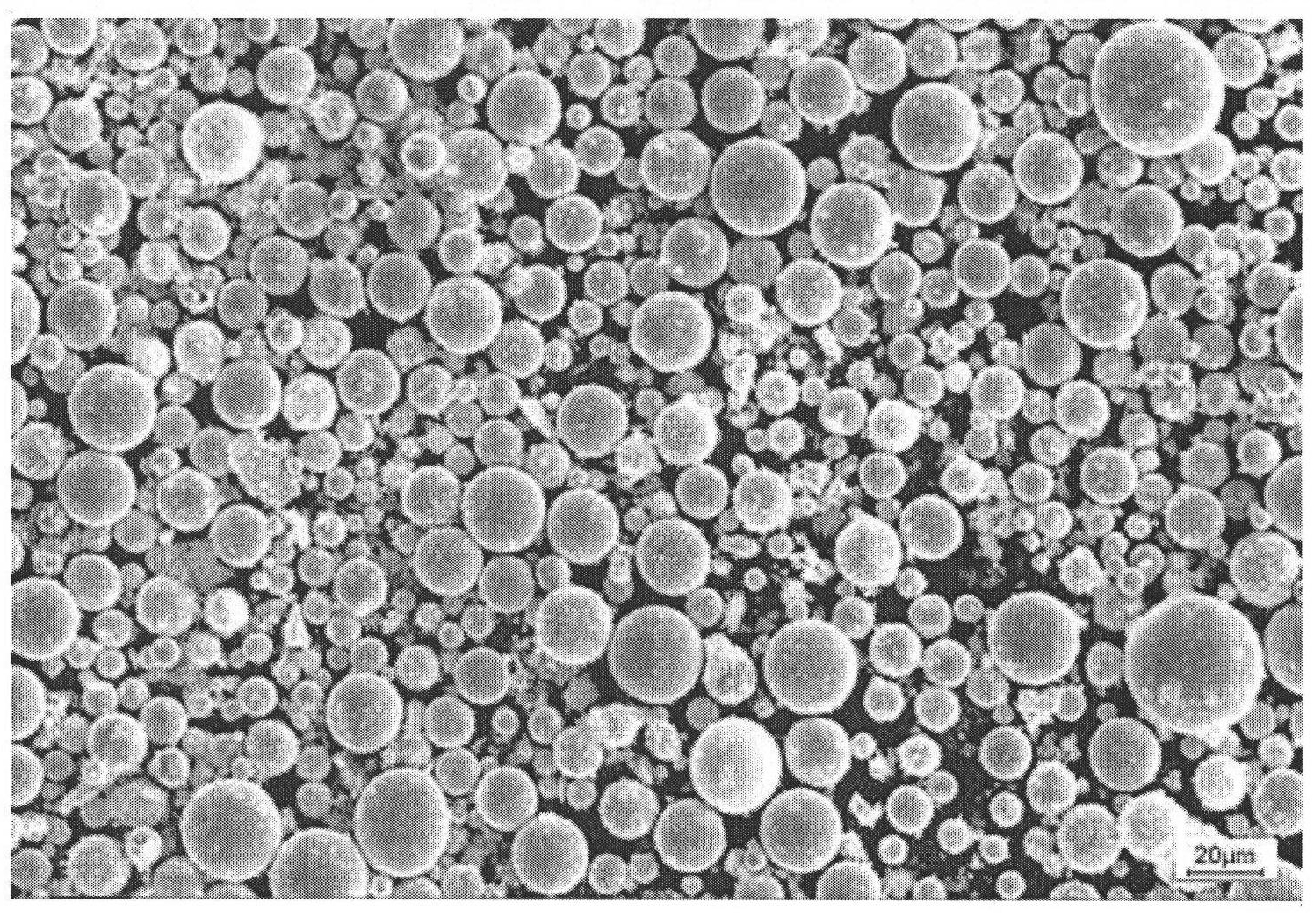

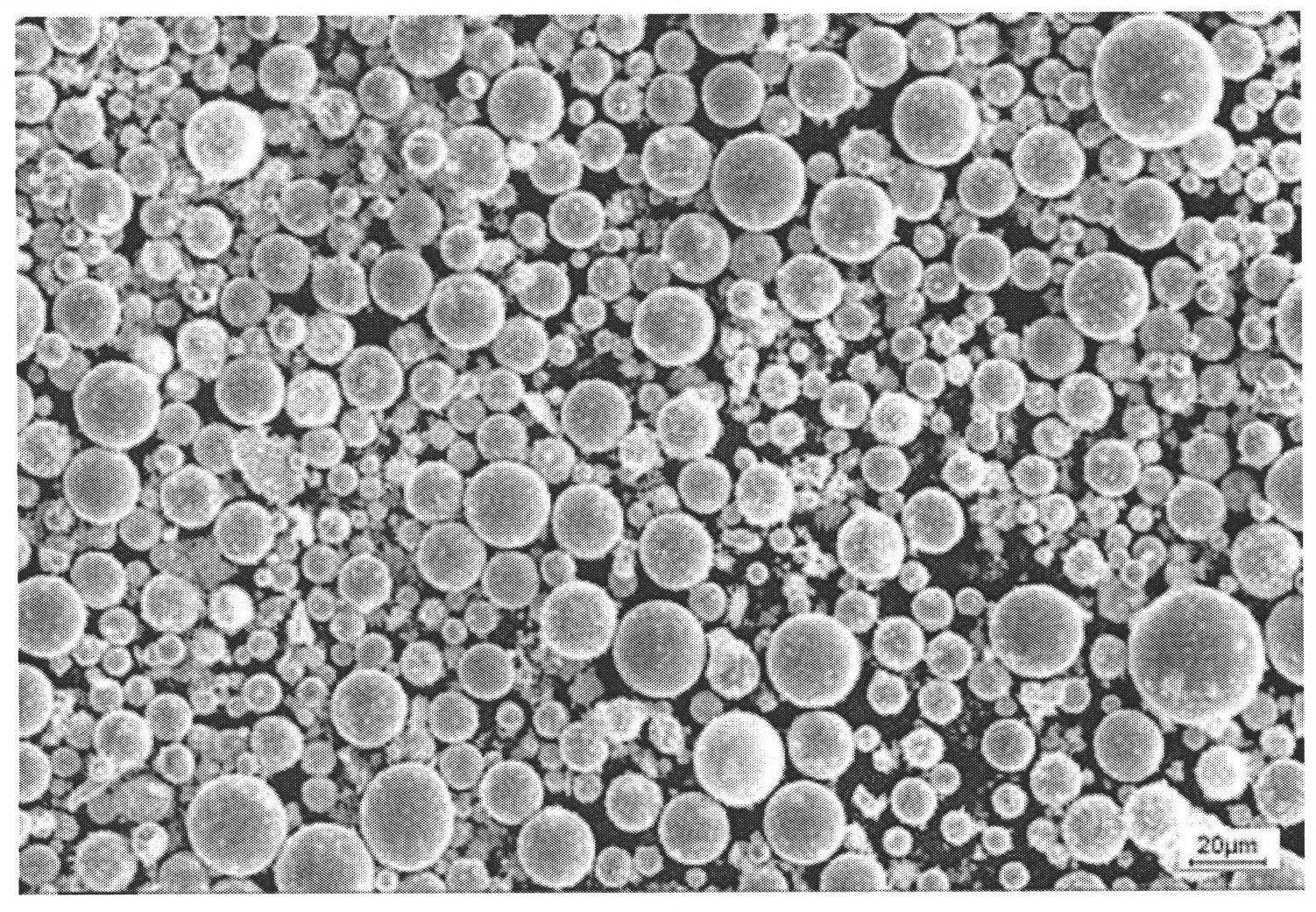

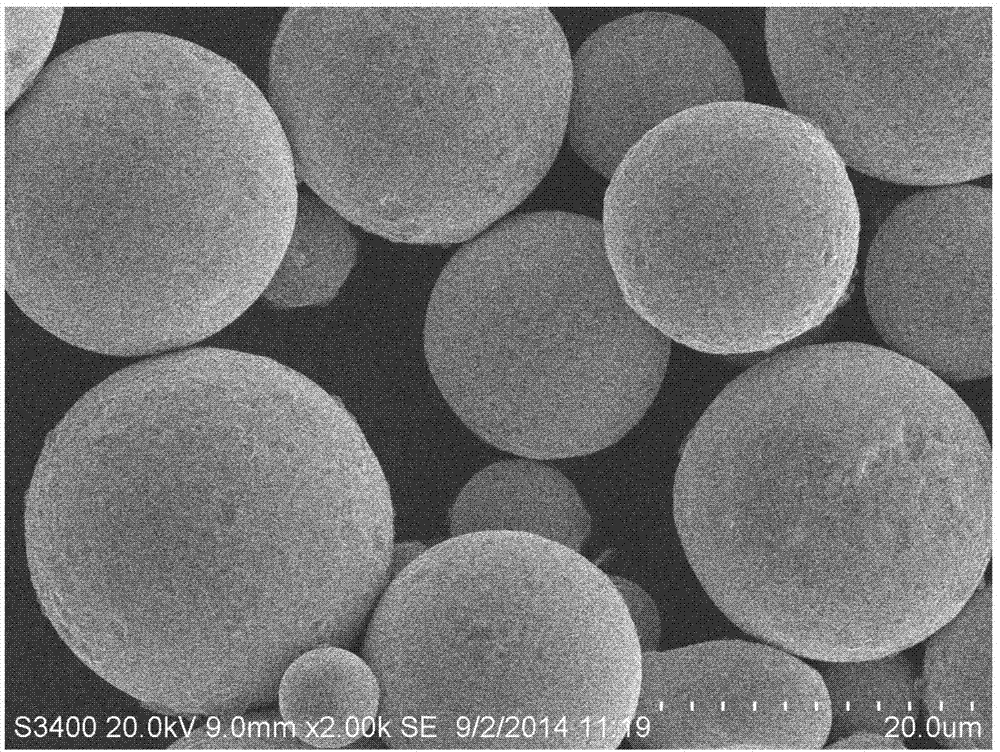

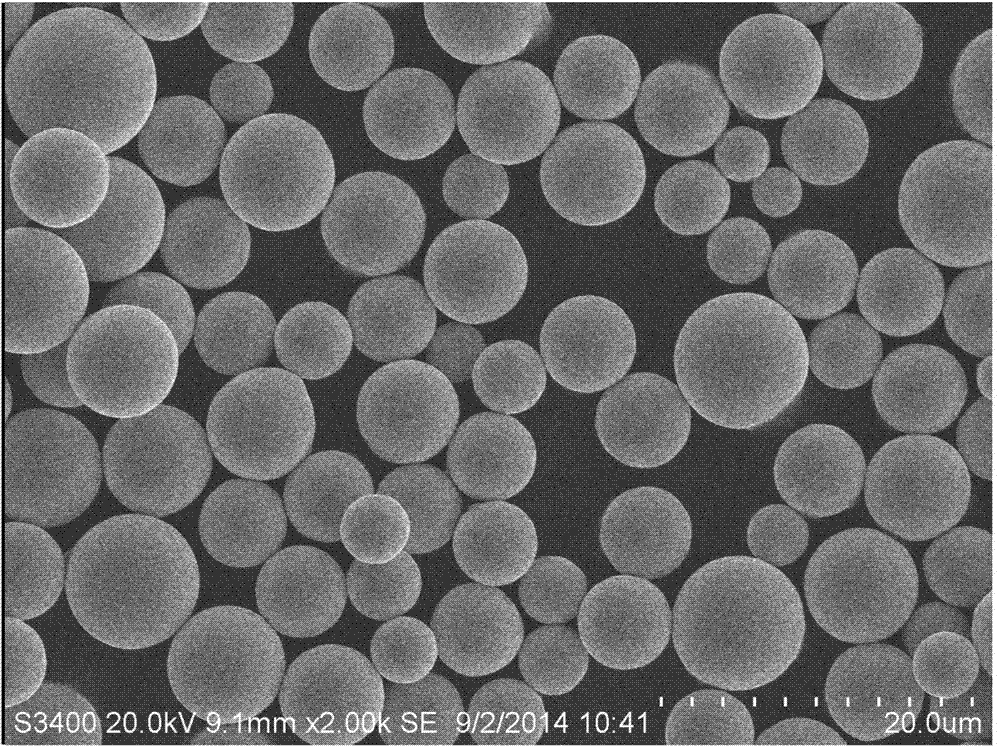

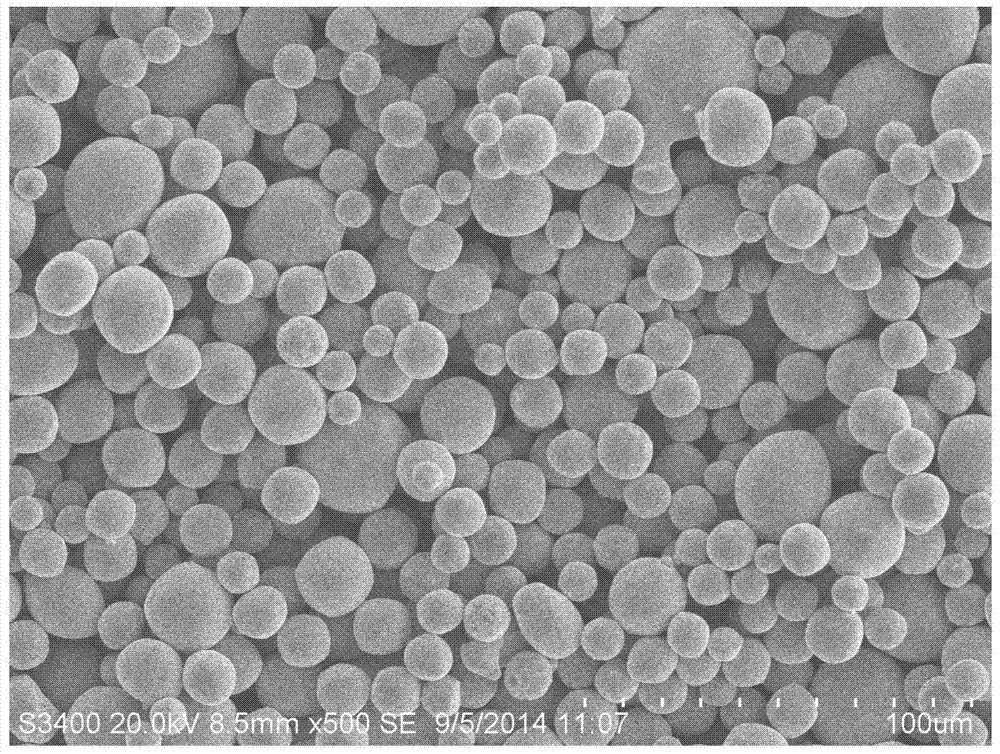

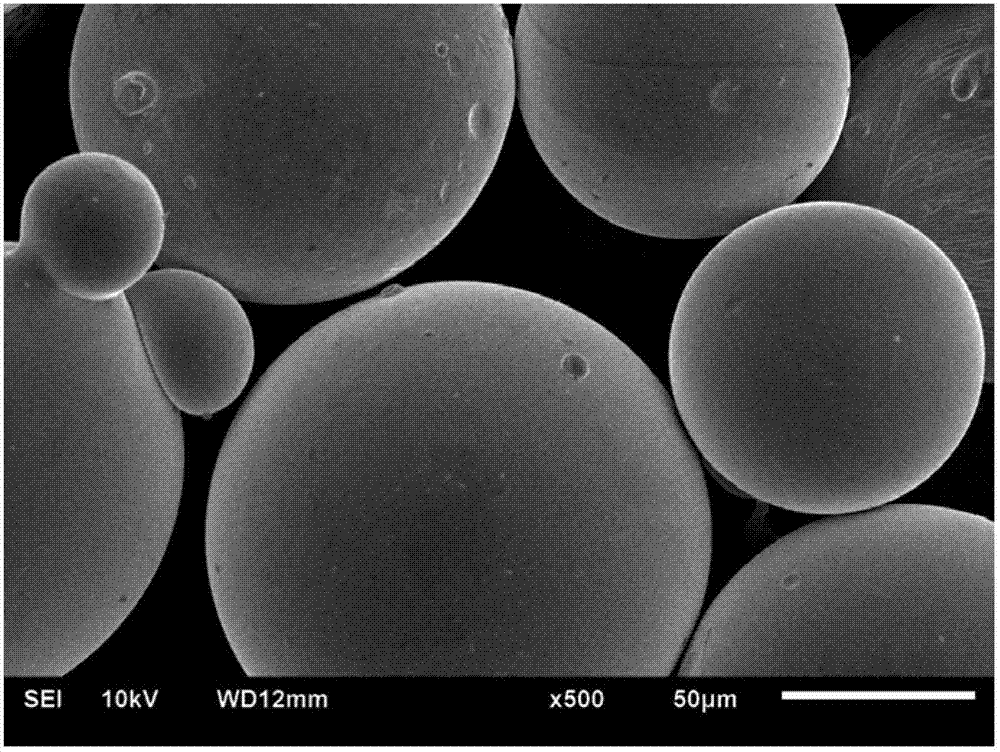

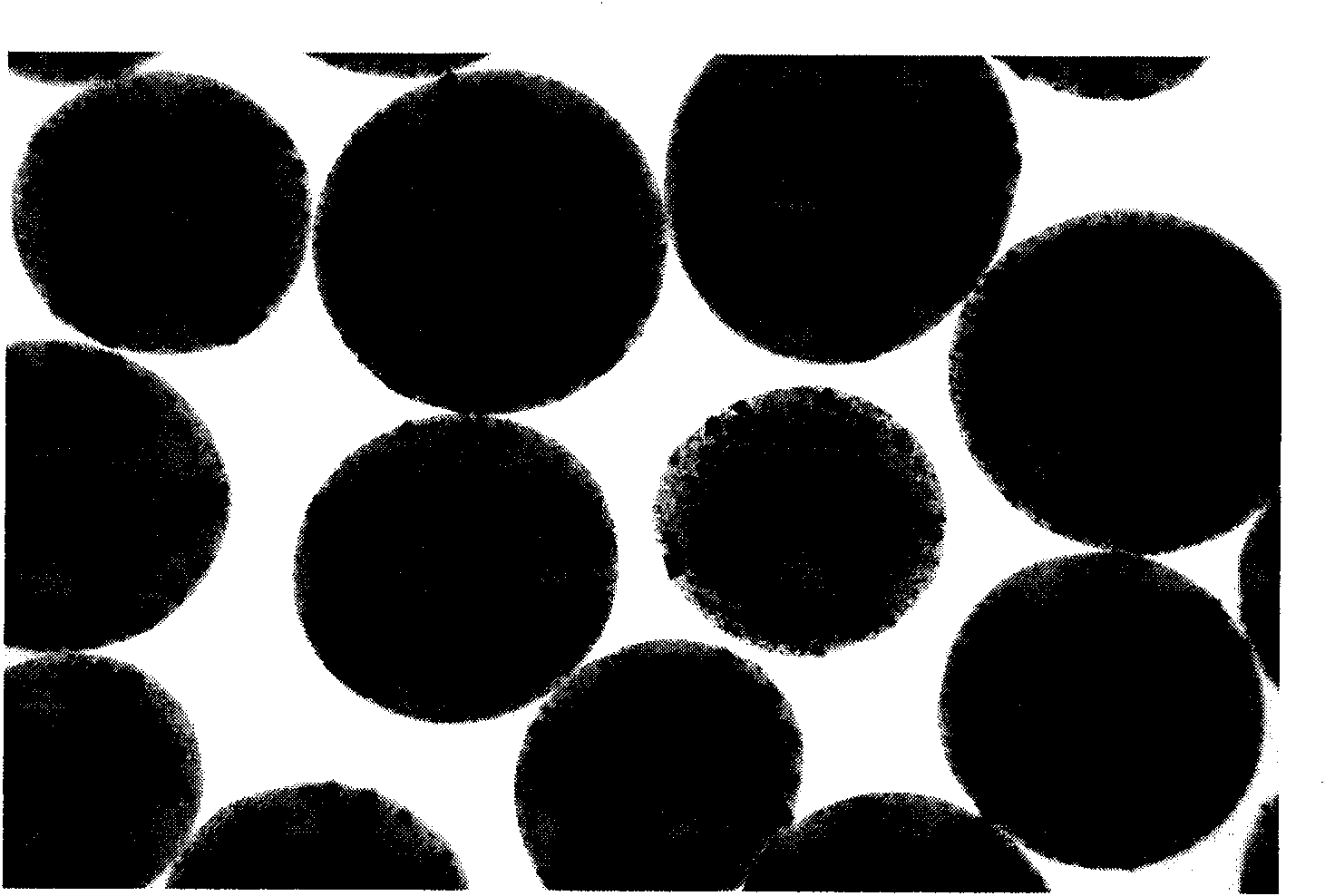

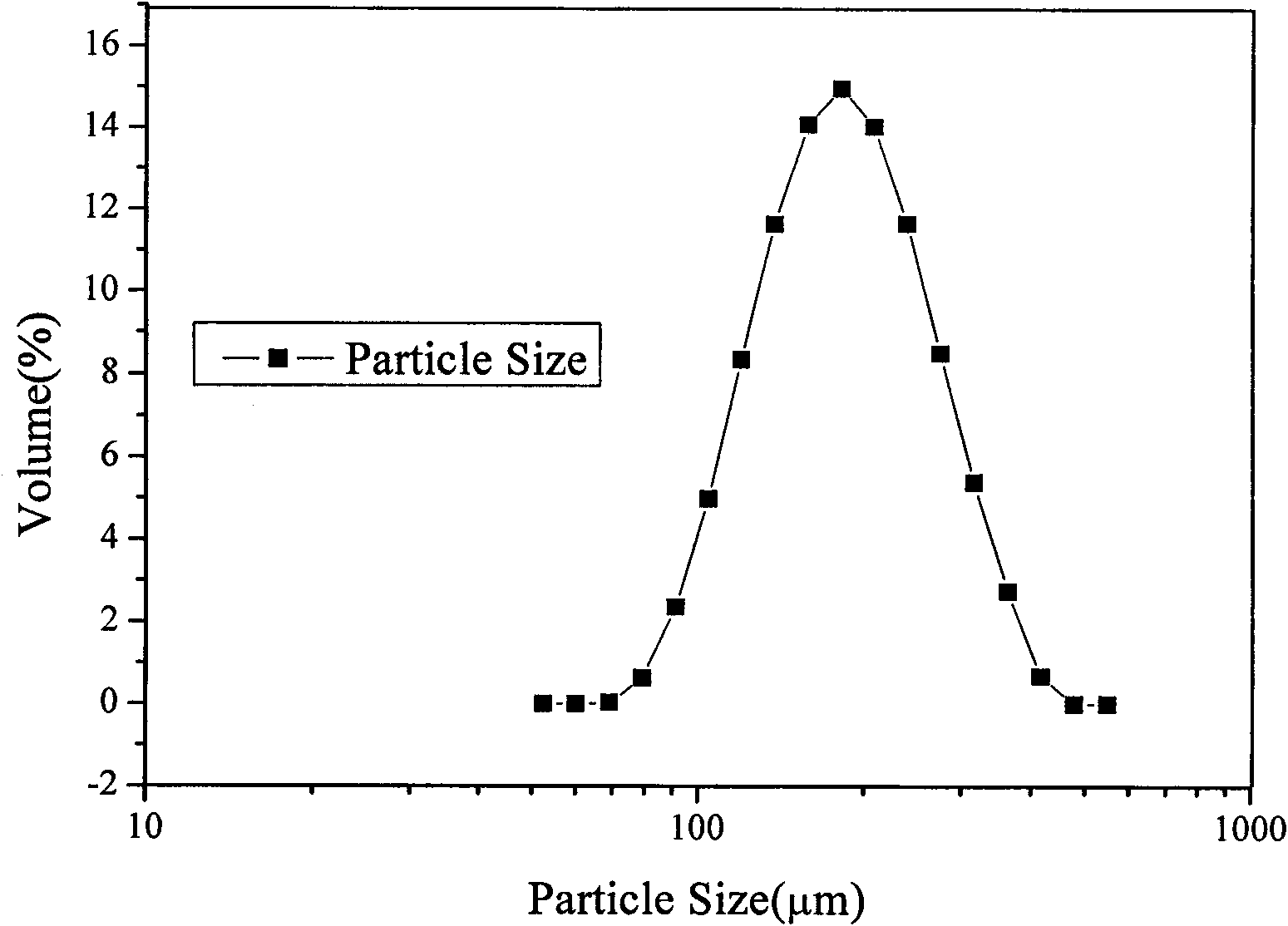

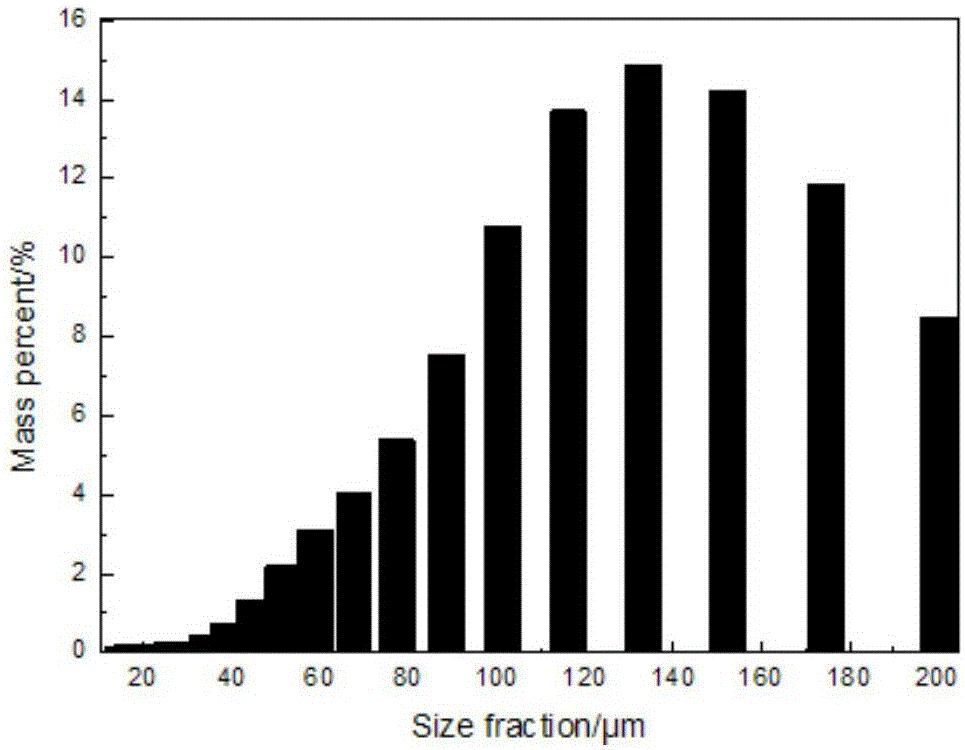

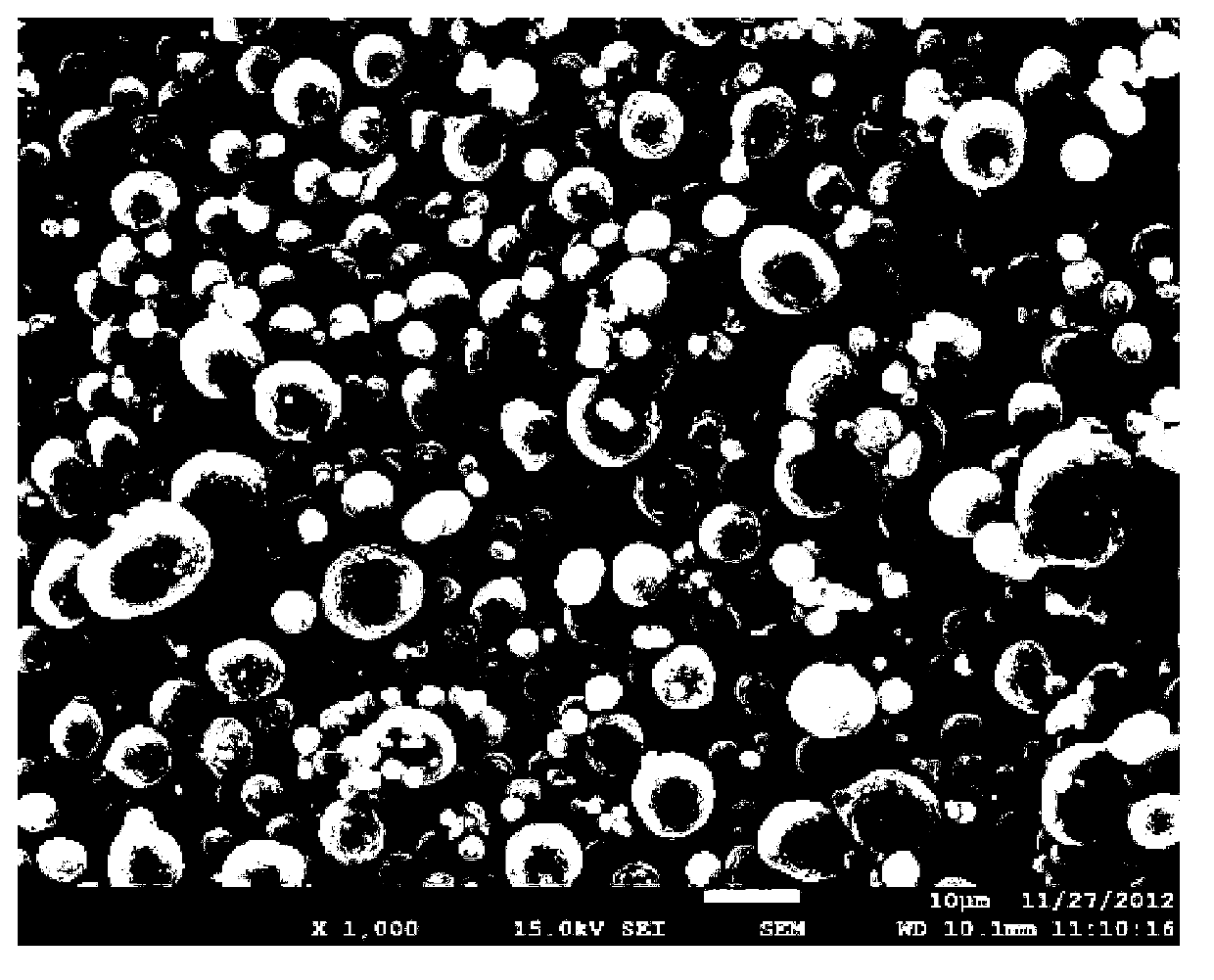

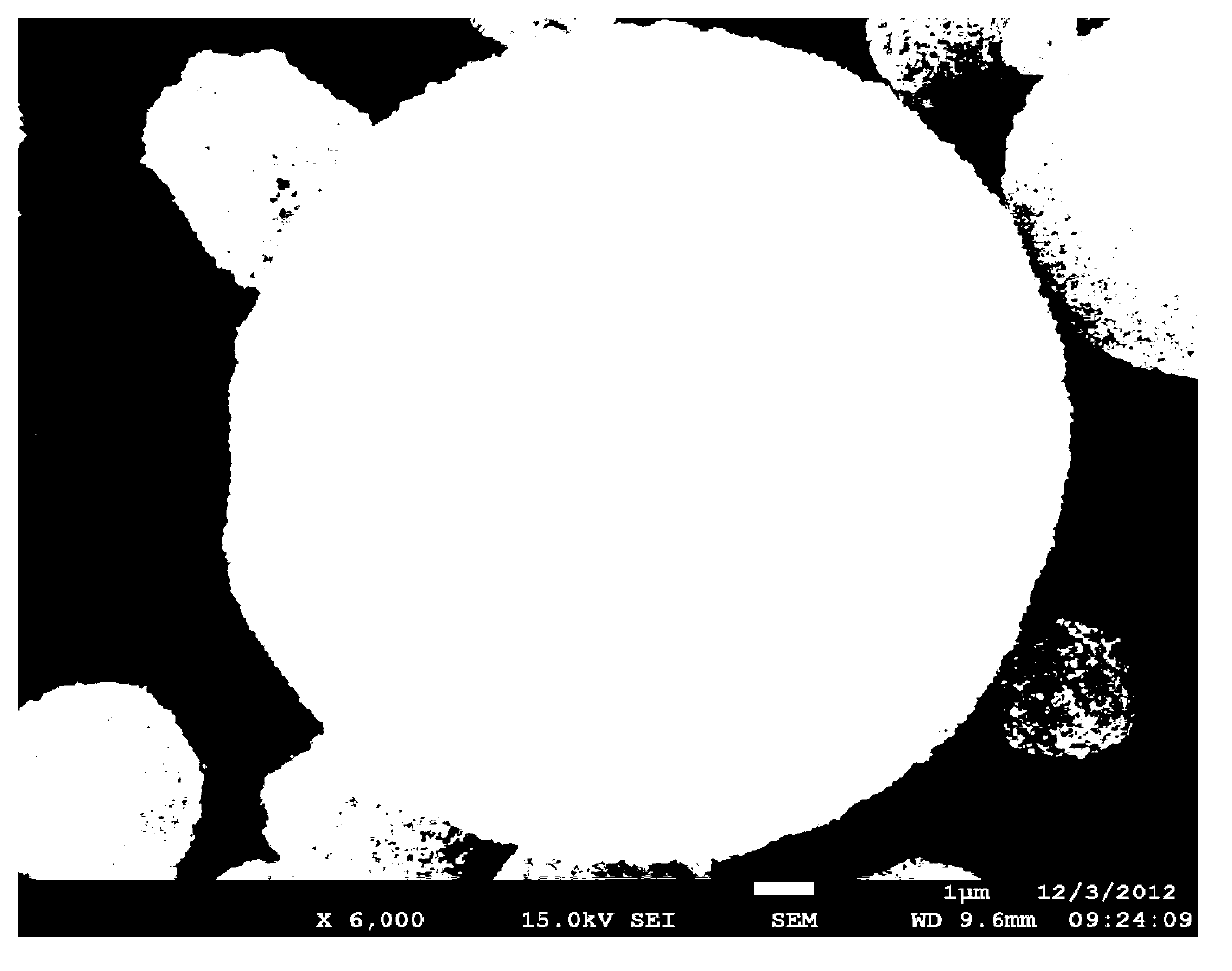

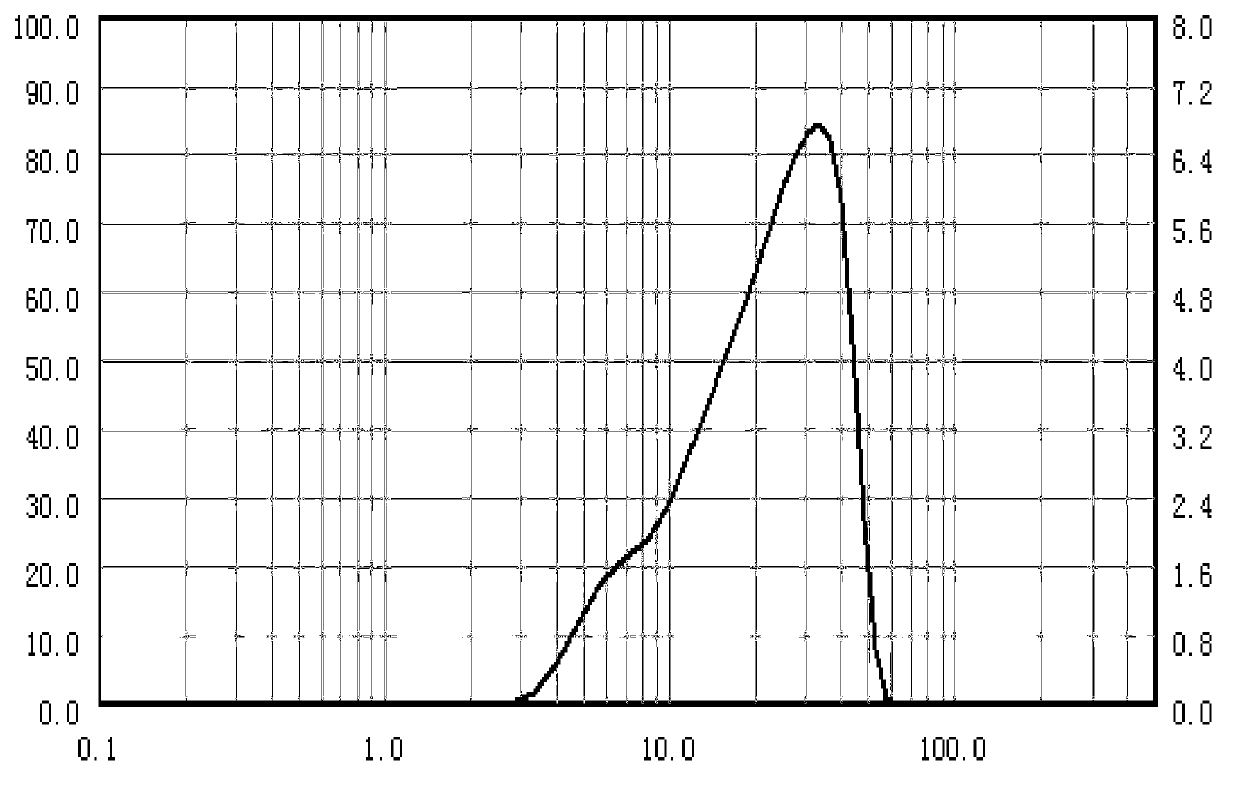

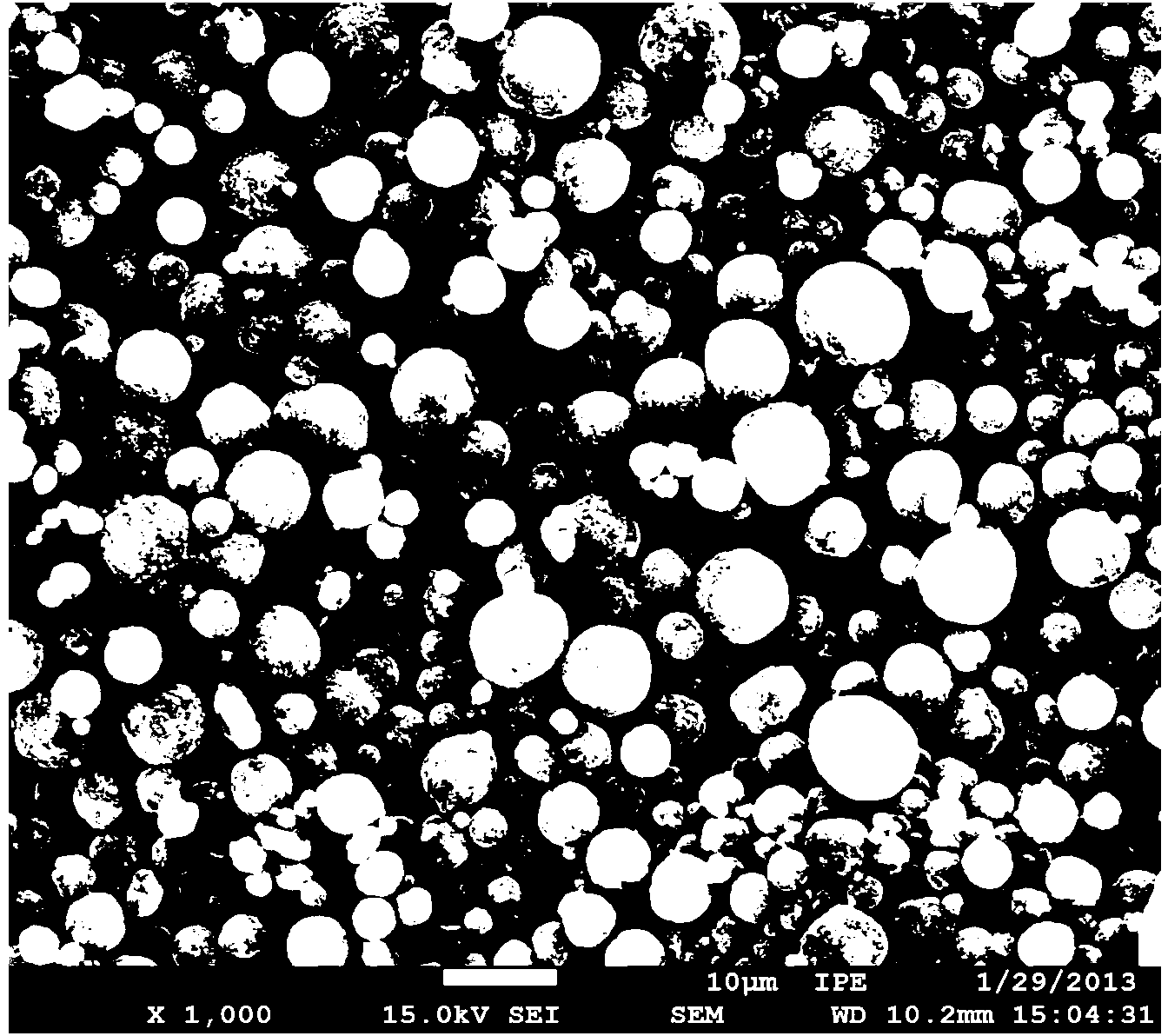

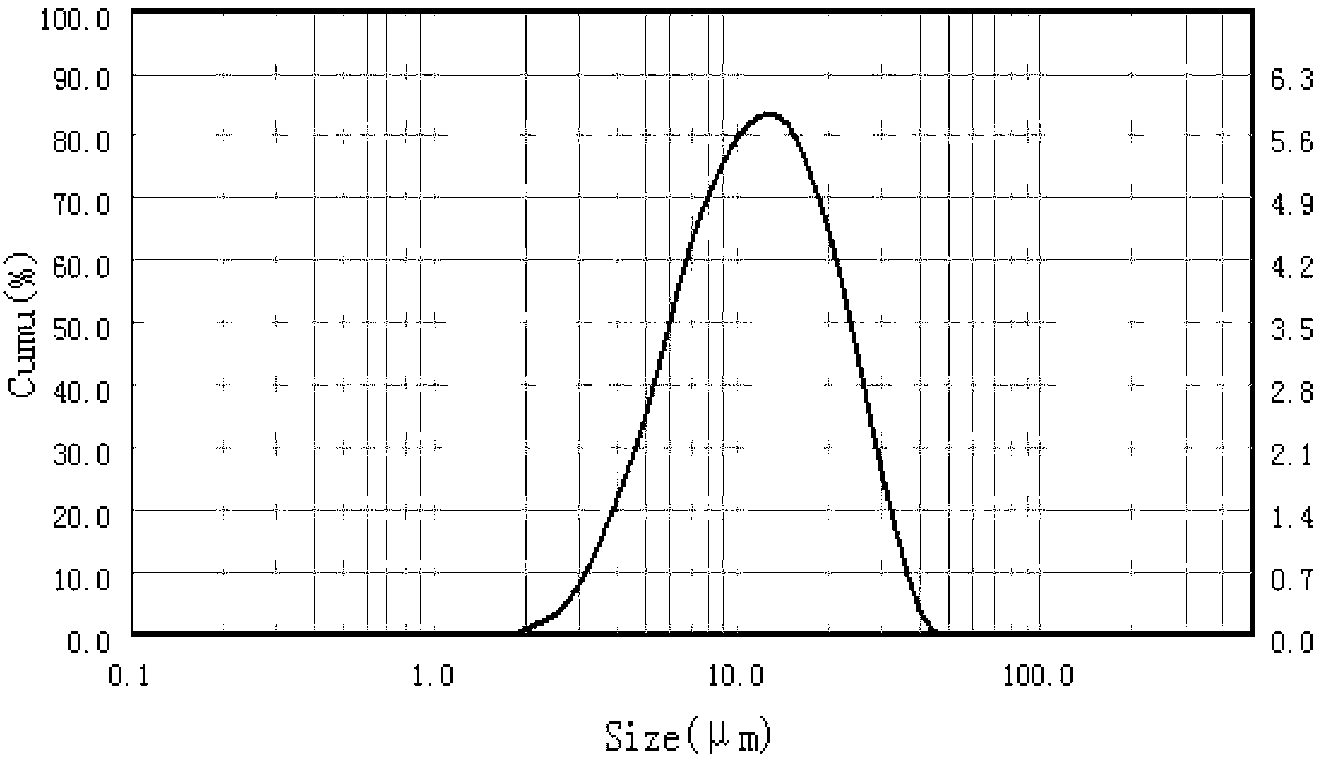

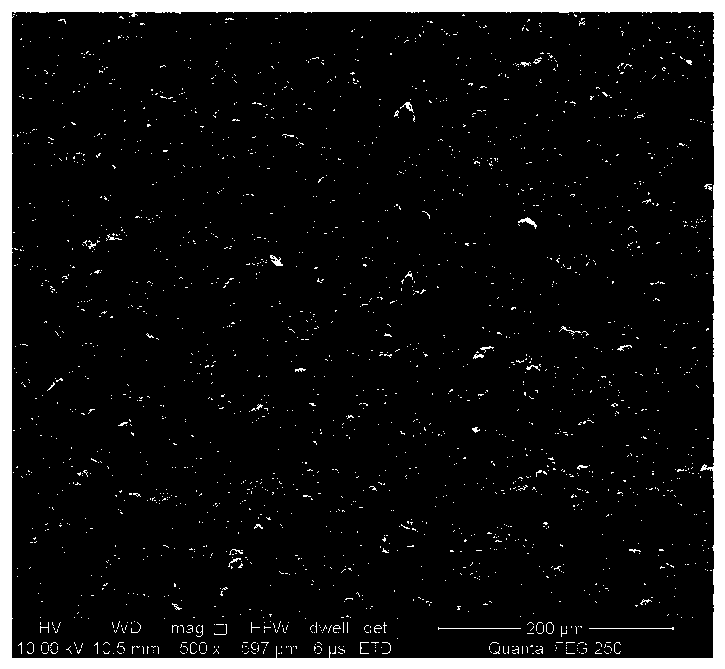

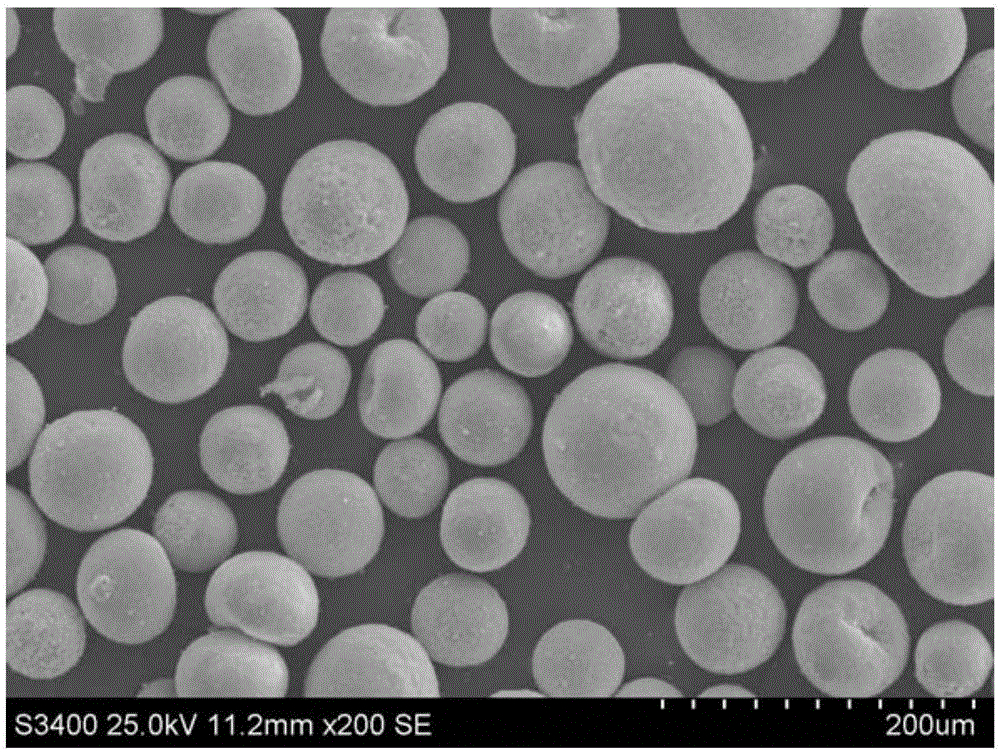

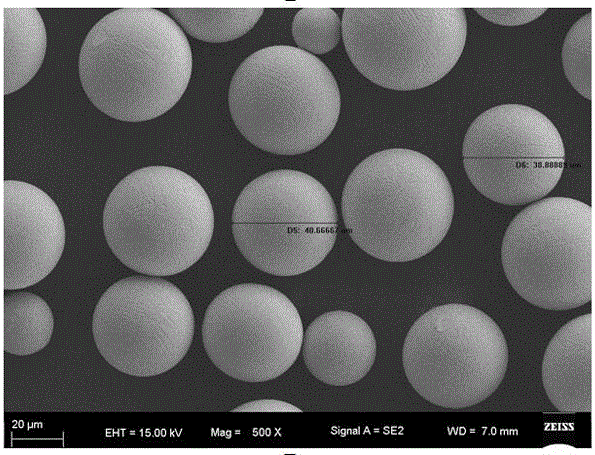

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

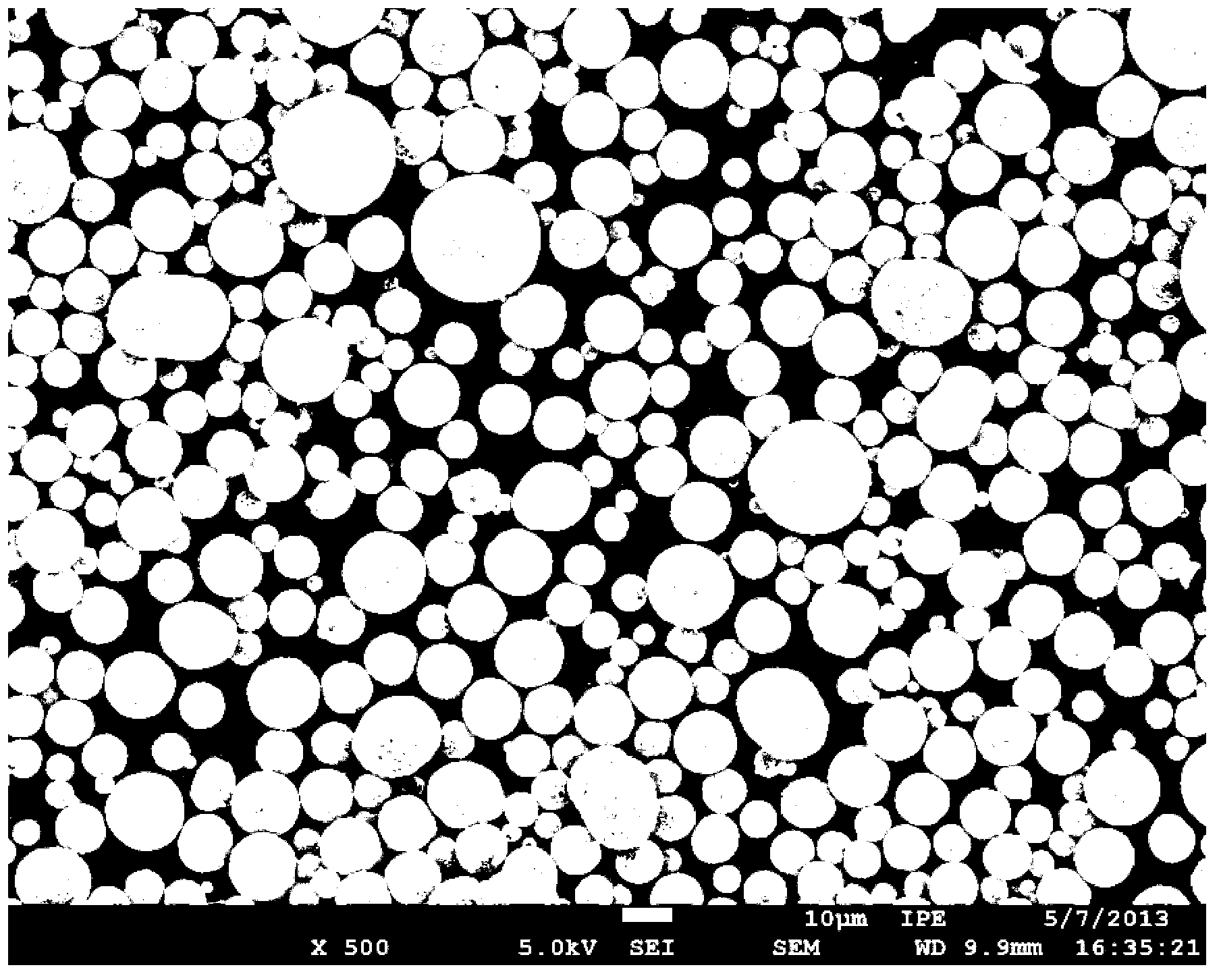

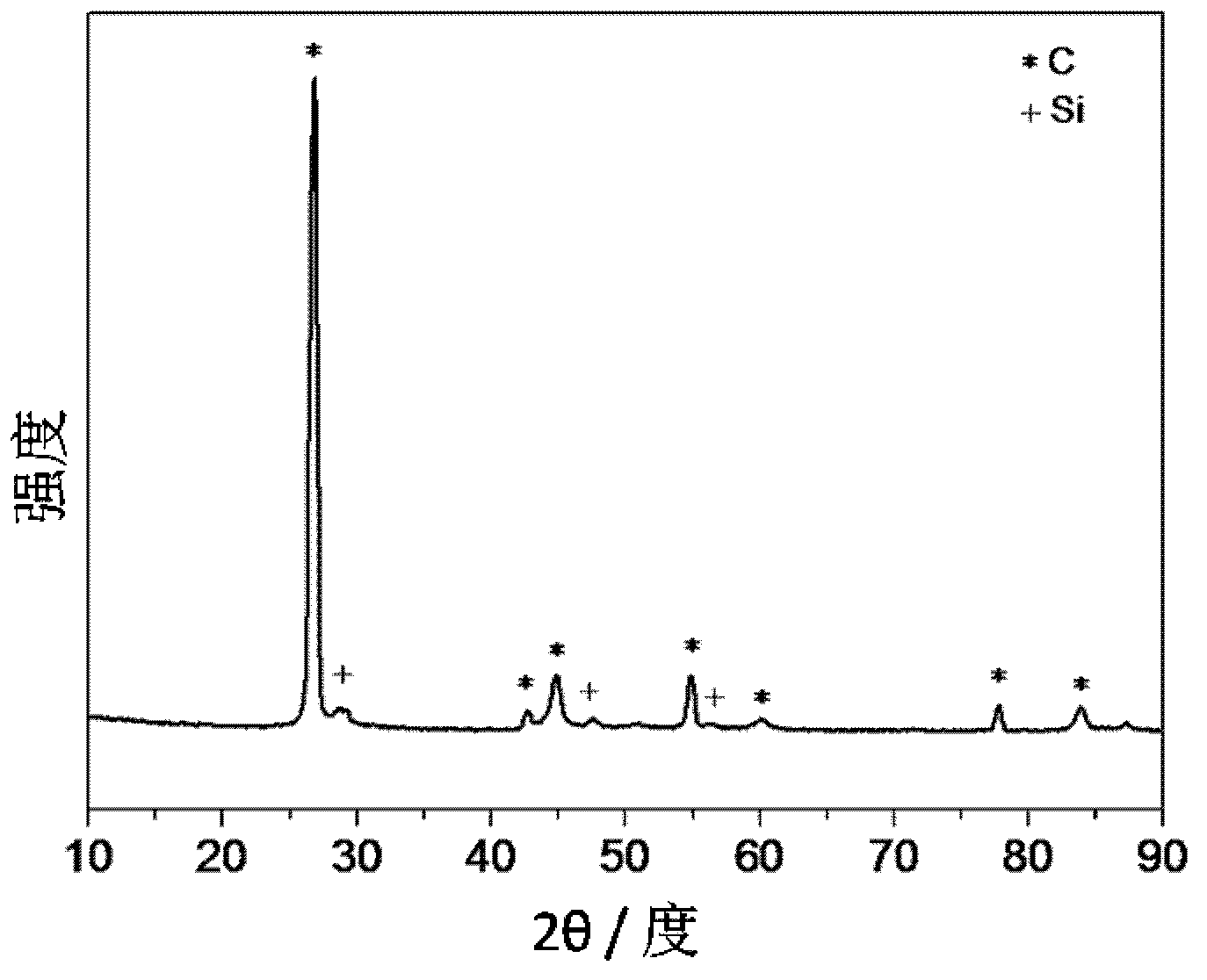

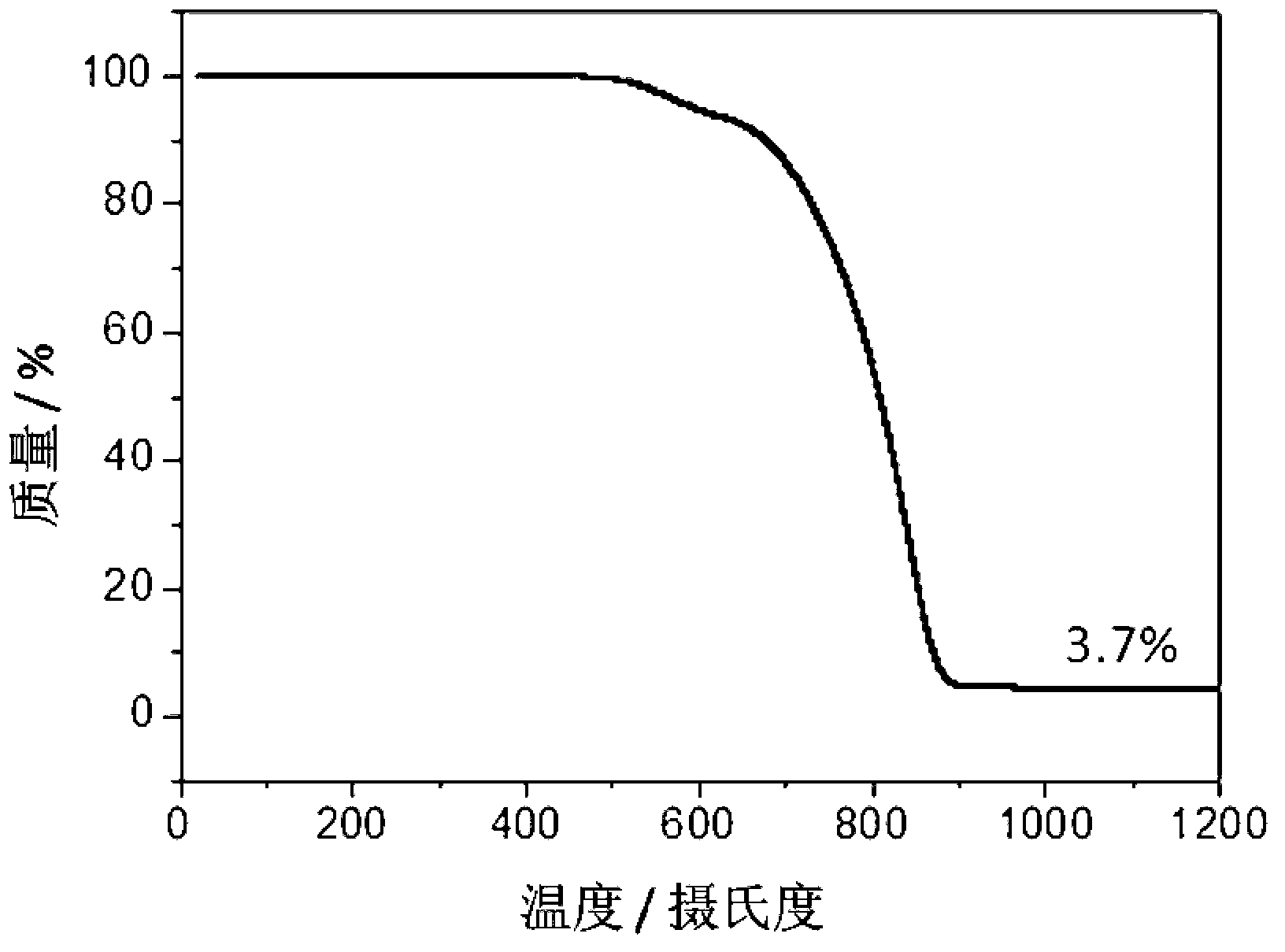

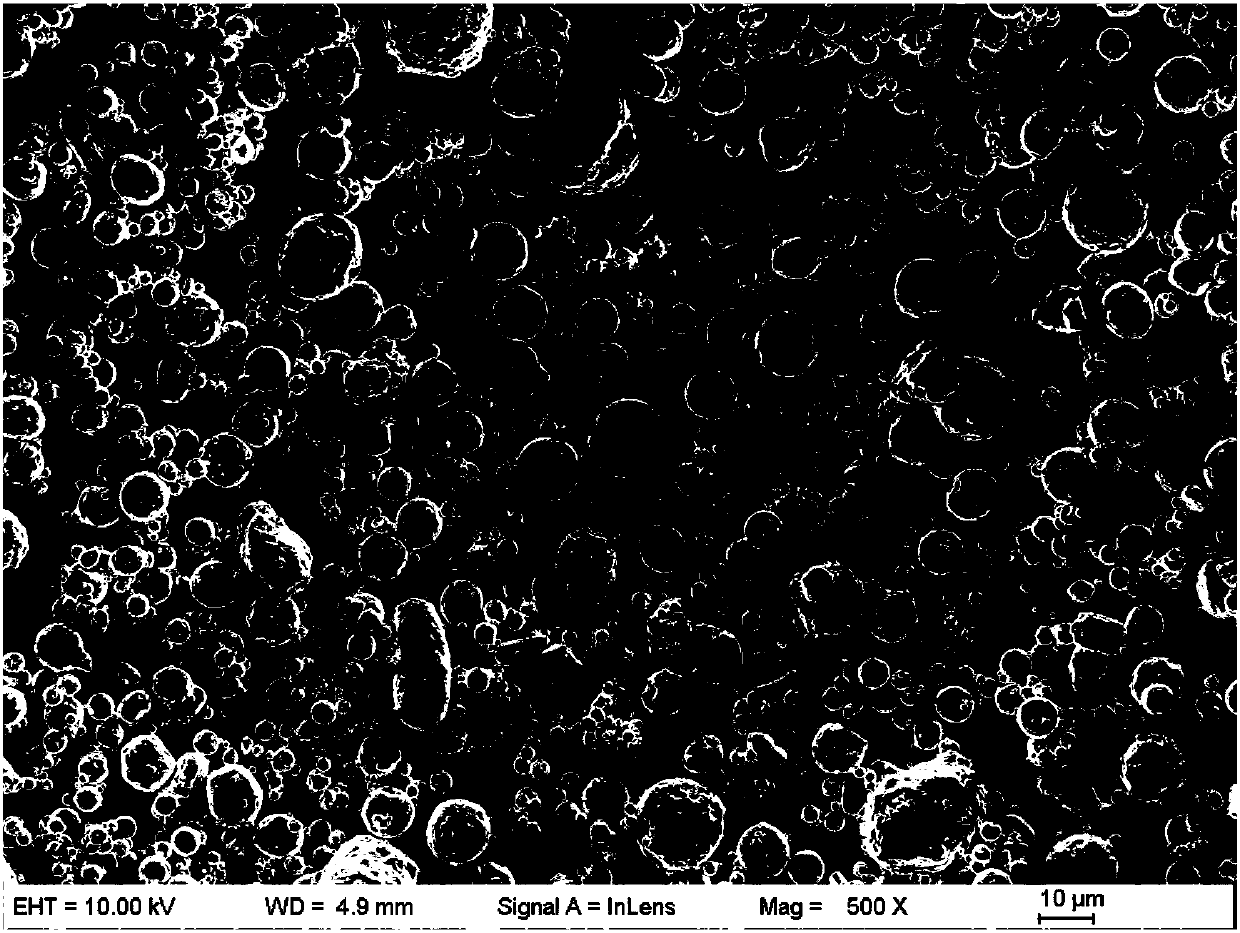

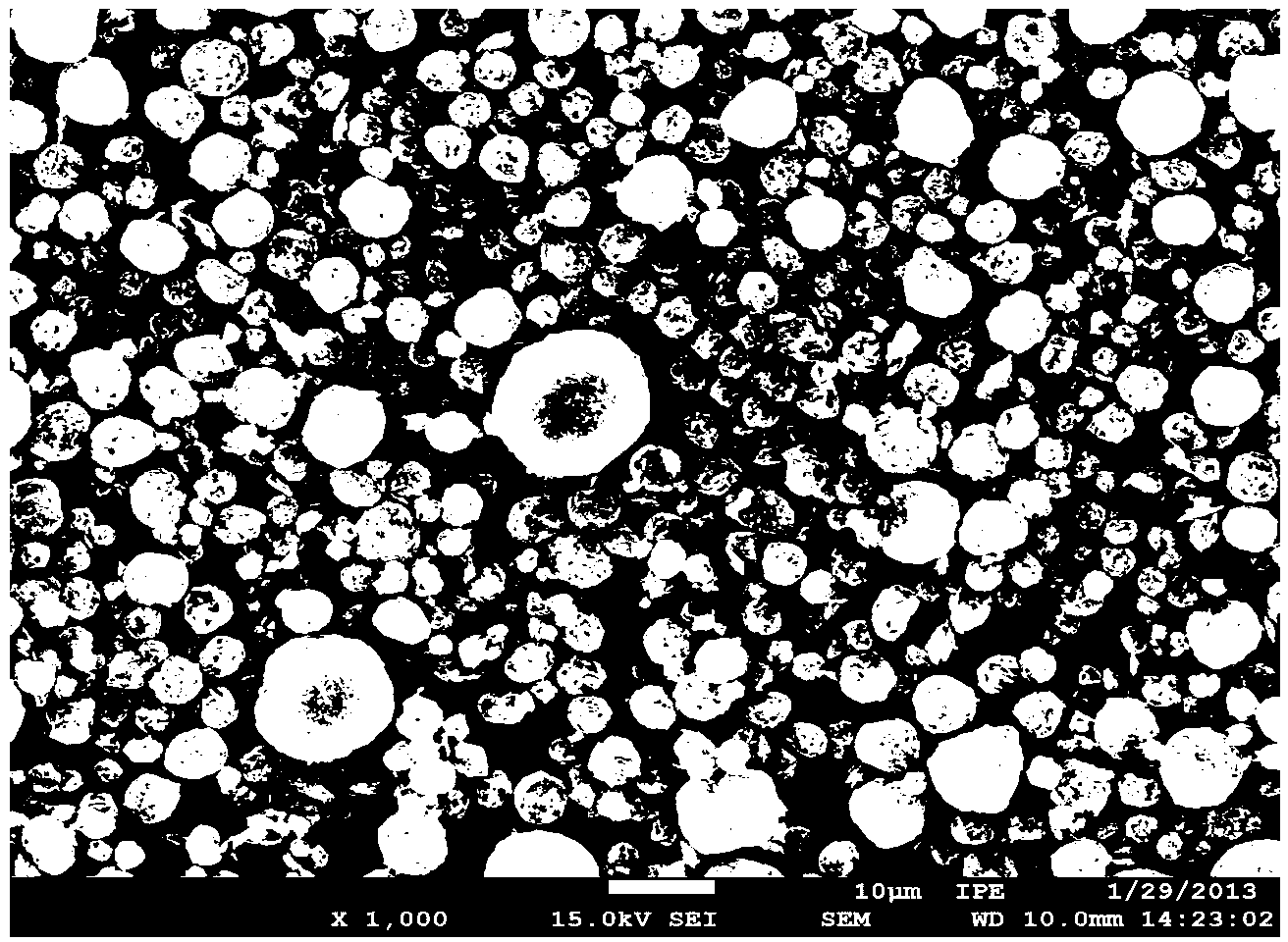

Silicon/carbon composite microsphere negative electrode material as well as preparation method and application for same

ActiveCN103311522AStable structureImprove charge and discharge cycle lifeCell electrodesSolventCarbon black

The invention relates to a silicon / carbon composite microsphere negative electrode material as well as a preparation method and an application for the same. The silicon / carbon composite microsphere negative electrode material is silicon / carbon composite microspheres internally provided with pore structures; and each microsphere comprises a matrix material of hard carbon, and an active material of silicon powder. The preparation method for the silicon / carbon composite microsphere negative electrode material comprises the following steps of: uniformly mixing silicon powder, soft carbon, carbon black, a soluble carbon-containing organic adhesive and a solvent with formula amounts to obtain a slurry; and performing spray-drying and carbonization on the slurry to obtain the silicon / carbon composite microsphere negative electrode material. The silicon / carbon composite microsphere negative electrode material provided by the invention has the advantages of being high in tap density, high in reversible capacity, good in cyclicity, good in rate capability, safe and reliable, and high in first-week coulombic efficiency; the preparation method provided by the invention is simple in process, environment-friendly, low in energy consumption and cost, and easy to realize large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

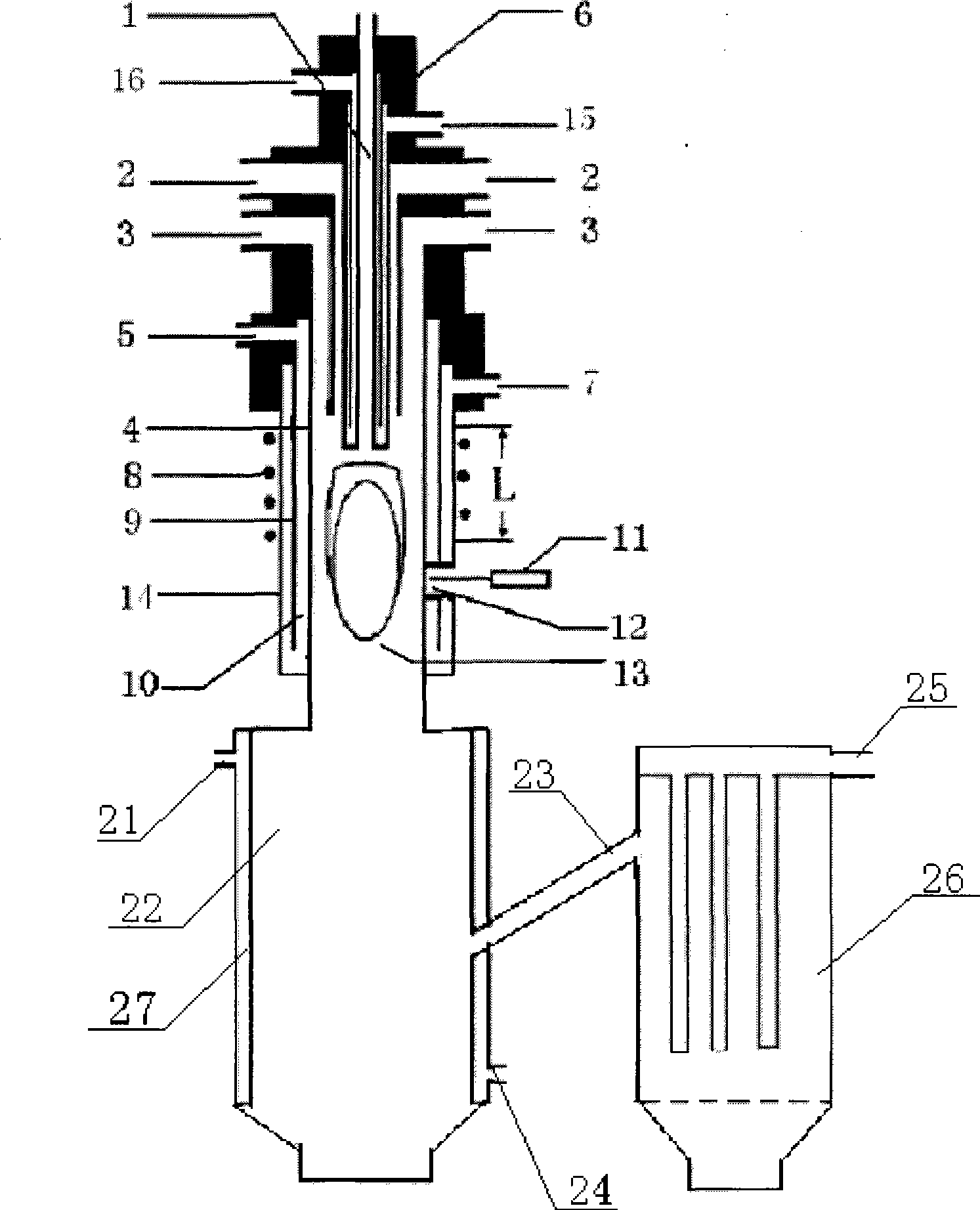

Globular titanium micro-powder or ultra-micro powder preparation device and method

The invention belongs to a process for preparing and processing powder material by taking plasma as a heat source, in particular to a process and an apparatus of metal titanium powder material for powder metallurgy, plasma spray, injection forming, gel injection molding and the like. The invention has the advantages that: the adoption of the high temperature spheroidization and rapid condensation special spheroidization technique can improve the sphericity and purity of titanium powder, and both a reactor and the titanium powder spheroidization process are cooled with circulating water, thereby ensuring the sealing performance of equipment, also reducing the use of inert gases, effectively reducing costs, improving the production efficiency and guaranteeing the purity of spherical titanium powder.

Owner:SOUTHWESTERN INST OF PHYSICS

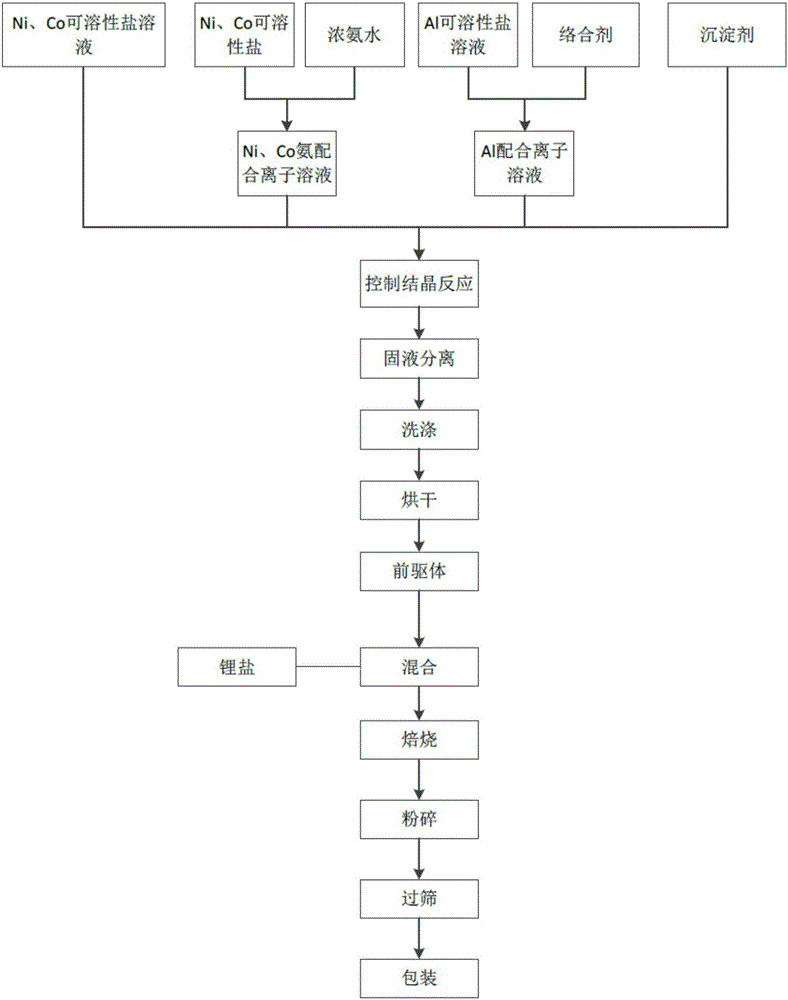

Nickel-cobalt-aluminum ternary precursor as well as preparation method thereof and preparing anode material and method

ActiveCN106299347AImprove mixing uniformityHigh tap densityCell electrodesReaction temperatureSlurry

The invention discloses a nickel-cobalt-aluminum ternary precursor as well as a preparation method thereof and a preparing anode material and a method. The preparation method comprises the following steps: dissolving soluble salts of Ni and Co into ammonia water so as to prepare a Ni and Co ammonia complex ion solution as a complexing agent solution, adding a complexing agent into an aluminum salt solution so as to prepare an Al complex ion solution as an aluminum source solution, combining and adding the Ni and Co soluble salt solution, a precipitant solution, the complexing agent solution and the aluminum source solution into a reaction kettle, controlling a reaction pH value and reaction temperature, controlling the reaction time to be at least greater than 10h, performing solid-liquid separation on slurry obtained through reaction, and washing and drying the obtained solid, thereby obtaining the nickel-cobalt-aluminum ternary precursor. A nickel-cobalt-aluminum ternary anode material can be prepared from a mixture of the precursor and a lithium salt through high-temperature thermal treatment in the presence of air or oxygen. The mixing uniformity of three elements of Ni, Co and Al can be effectively improved, and the tap density of the precursor material can be improved, and the spherical degree of granules can be increased.

Owner:TIANJIN B&M SCI & TECH

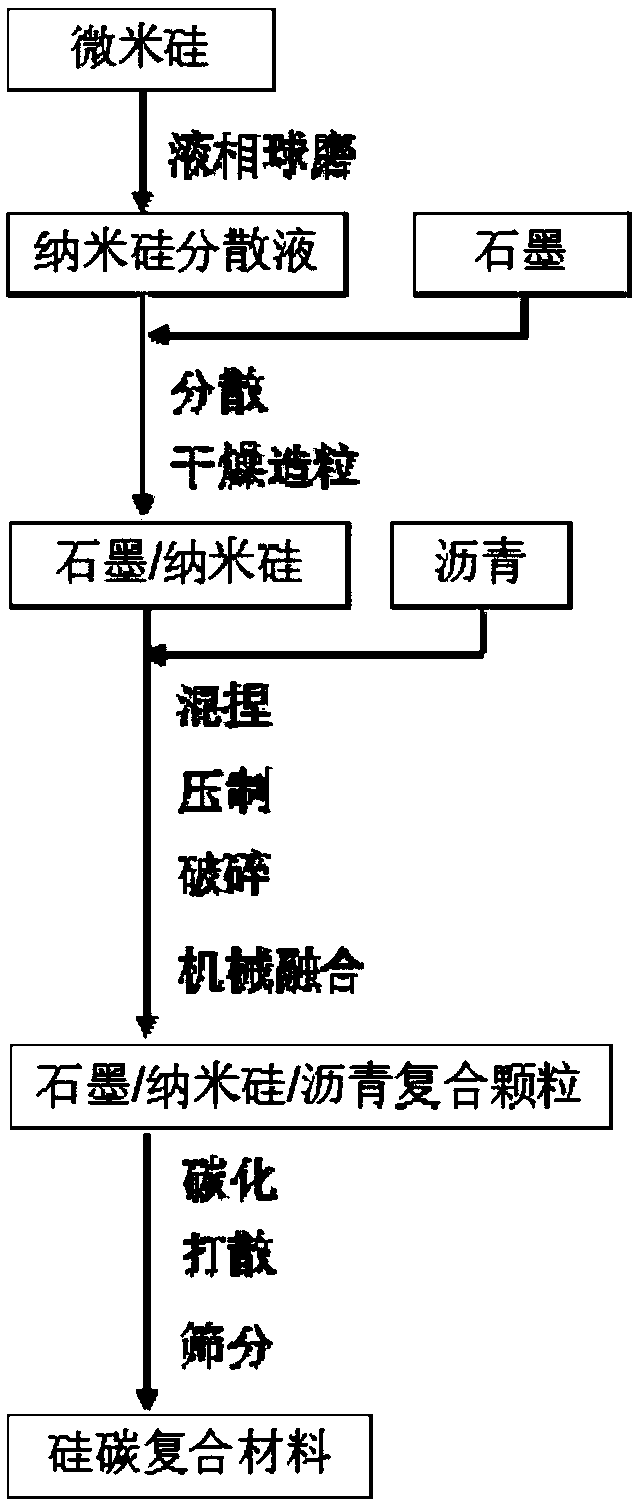

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

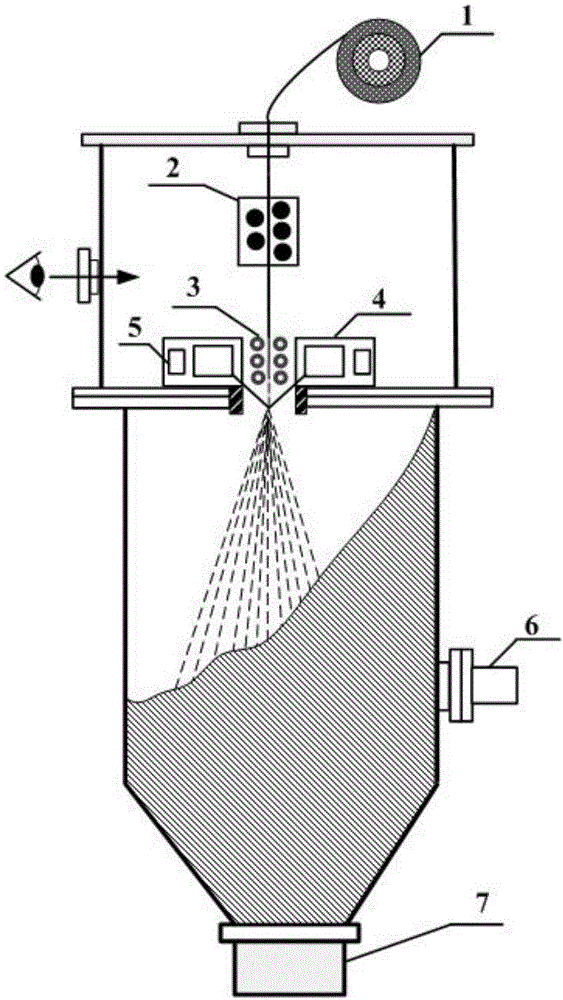

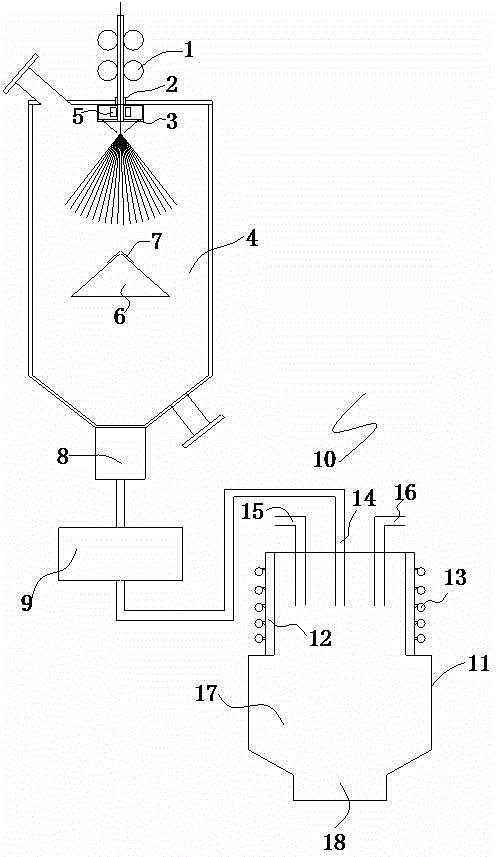

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

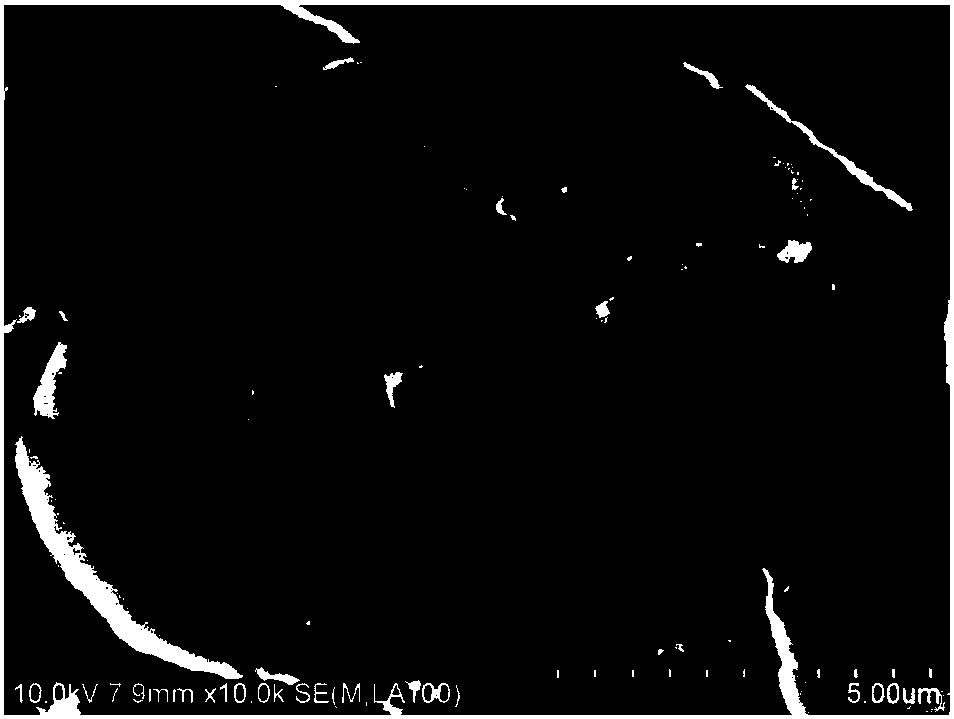

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

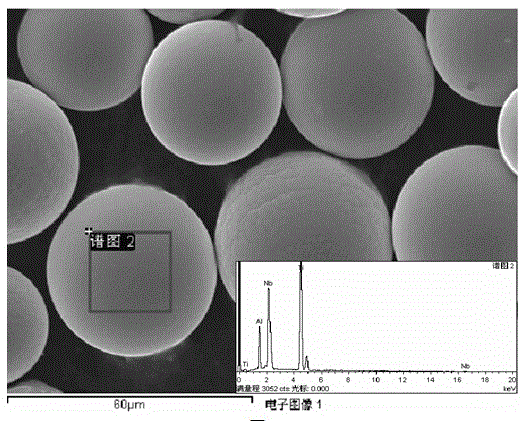

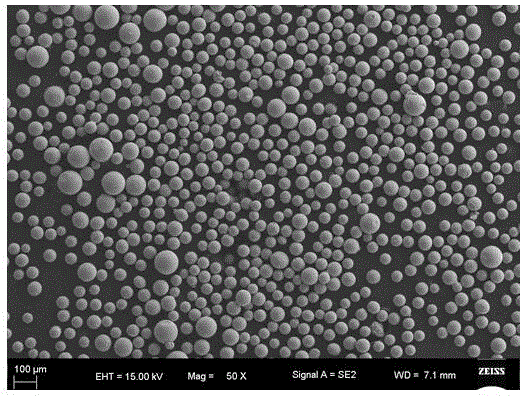

Method for largely preparing superfine spherical titanium aluminium-based alloyed powder

The invention provides a method for largely preparing superfine spherical titanium aluminium-based alloyed powder, which belongs to the technical field of powder preparation. The method comprises the following steps: smelting high-purity aluminium and titanium sponge as main raw materials and Al-Nb intermediate alloy, Ti-B alloy, tungsten powder and high-purity yttrium scraps as auxiliary raw materials into an alloy cast ingot in a vacuum consumable electrode arc skull furnace or a vacuum induction furnace; then carrying out coarse crushing and vortex airflow milling to prepare irregular superfine alloy powder; and finally carrying out plasma spheroidization of radio frequency (RF) and the like to prepare the superfine spherical titanium aluminium-based alloyed powder. The prepared alloy powder has the advantages of high purity, fine particle size, narrow particle size distribution, good uniformity, high sphericity, good flowability and the like and can meet the demands of the technical industrial production of injection forming, gel injection molding forming, thermal spraying and the like.

Owner:UNIV OF SCI & TECH BEIJING

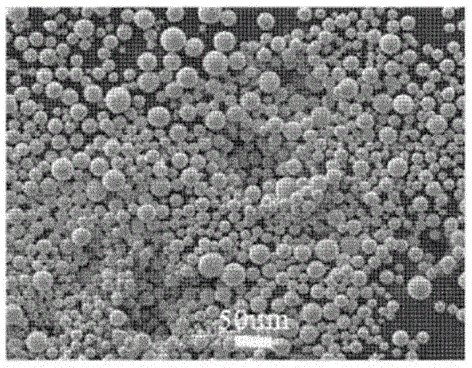

Manufacturing method of micron and nanometer metal spherical powder

ActiveCN104259469AImprove consistencyClear principleMaterial nanotechnologyRare earthSpherical shaped

The invention provides a manufacturing method of micron and nanometer metal spherical powder. The manufacturing method comprises the steps of 1 preparing metal powder; 2 preparing evenly mixed powder of the metal powder and carbon material powder or ceramic material powder; 3 performing high-temperature annealing to enable metal to be molten and solidify to form a metal ball, wherein the temperature for the high-temperature annealing is the temperature for metal melting, especially the temperature is higher than metal melting point temperature and ranges from 40 DEG C to 100 DEG C; 4 removing the carbon material powder or the ceramic material powder to obtain the micron and nanometer metal spherical powder. All metals of the metal spherical powder are elemental metals containing gold, silver, copper, aluminum, gallium, tin, zinc, lead, iron, cobalt, nickel, rare earth and the like, and alloy and compounds formed by the elemental metals are alloy and compounds formed by the metals including boron, silicon, carbon, phosphorus, germanium, nitrogen and the like and nonmetal.

Owner:NANJING UNIV

Preparation method for zirconium-based amorphous alloy as well as powder and large-sized block of zirconium-based amorphous alloy

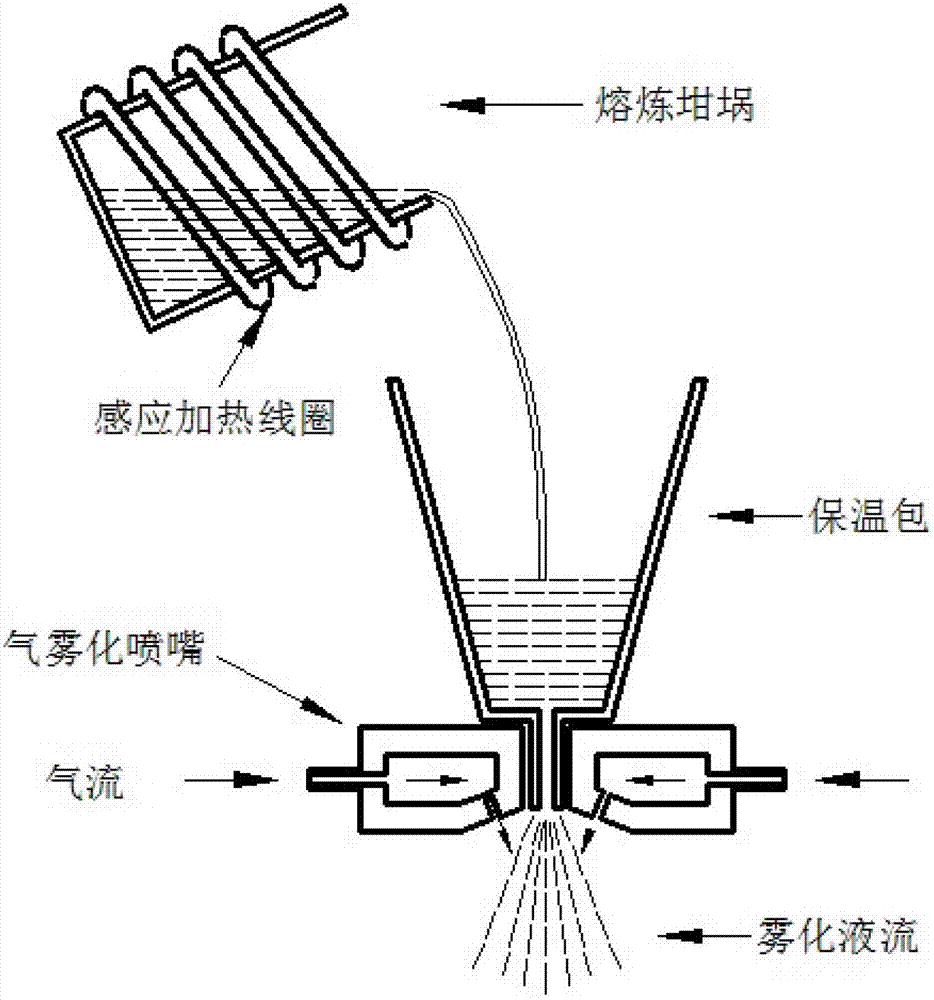

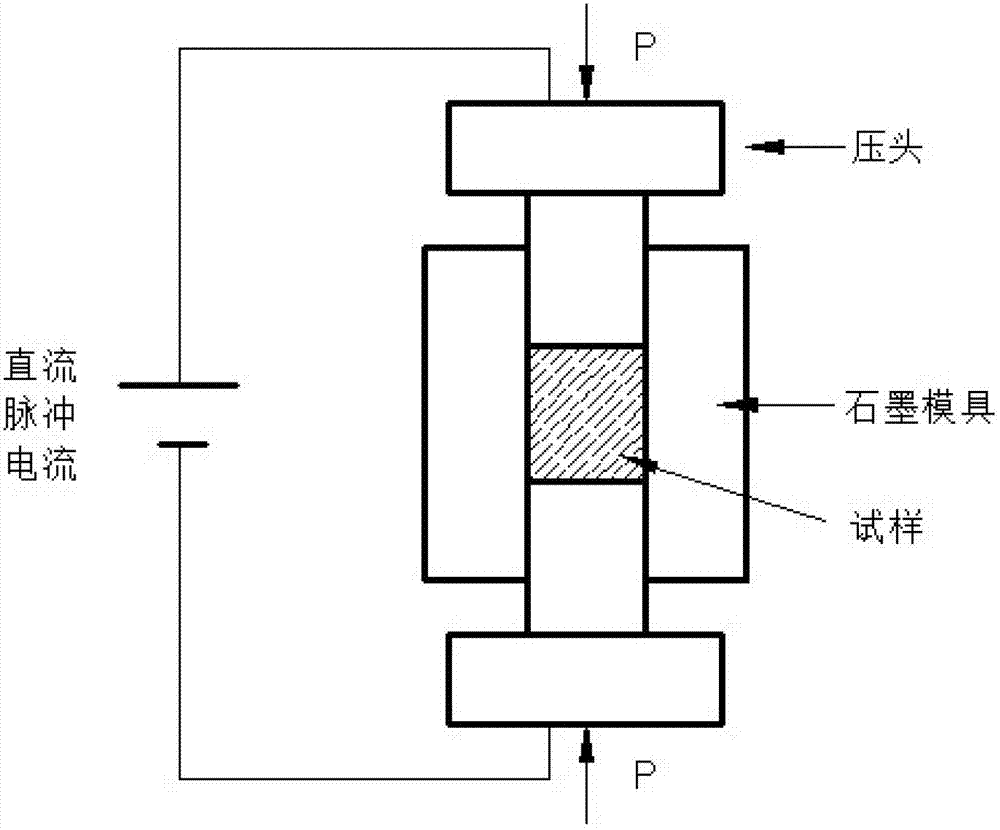

The invention relates to a preparation method for a zirconium-based amorphous alloy as well as powder and a large-sized block of the zirconium-based amorphous alloy, which belongs to the field of amorphous alloys, and is characterized by comprising the component of Zr61(Cu, Ni)27.5Al10Re1.5(at%), wherein Re is Y, La, Ce, Nd, Gd and Er, and adopting a manner of combination of the gas atomization powder milling technology and the spark plasma sintering technology. The preparation method comprises the following steps: preparing raw materials according to components of the amorphous alloy, and placing the raw materials into an induction crucible of gas atomization powder milling equipment; vacuumizing and filling inert gas for shielding; smelting to obtain an alloy solution with uniform components under the action of induction heating; pouring the alloy solution after smelting into an insulation bag at a constant speed slowly, and filling high-pressure inert gas as an atomizing medium at the same time; atomizing the alloy solution flow into small droplets under the impact of high-pressure airflow, and finally cooling to form amorphous alloy powder; collecting and screening the amorphous alloy powder; and under the protection of the inert gas, utilizing the spark plasma sintering technology to perform sintering on the amorphous alloy powder at different temperatures and pressure to obtain an amorphous alloy block.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing cellulose microsphere by taking ionic liquid as solvent

InactiveCN101612540ASolve forming problemsSolve the problem of sphericityOther chemical processesAlkali metal oxides/hydroxidesCelluloseLow speed

The invention discloses a method for preparing cellulose microspheres by taking ionic liquid as a solvent. The method comprises the steps of: 1) preparing cellulose solution as follows: dissolving the cellulose into the ionic liquid under low-speed stirring and proper temperature; 2) adding inert particles: adding proper amount of inert particles, and stirring evenly; 3) forming spheres by reversed phase suspension: adding oil phase and a surface active agent, leading the cellulose solution to be condensed into spheres by reversed phase suspension and program temperature reduction; 4) curving microspheres: adding a curving agent and curving to form the cellulose microspheres; 5) washing: using deionized water to wash and soak so as to obtain the cellulose microspheres; and 6) screening: screening in a wet state and obtaining the cellulose microspheres with a certain particle size range. The developed preparation process is simple and convenient, the used solvent is safe and non-toxic, the prepared cellulose micrsphere has porous structure and proper particle size, high sphericity and good hydropathy, can adjust density, can be used as substrate of an absorbent and has good biocompatibility.

Owner:ZHEJIANG UNIV

3D printing mould-free injection forming method through metal sizing agents

The invention provides a 3D printing mould-free injection forming method through metal sizing agents. According to the method, a 3D printing technology and an injection forming technology are combined, an injection forming process is utilized for evenly mixing metal powder and organic binding agents to form the metal sizing agents, the sizing agents are adopted as the raw materials of 3D printing, layered printing is carried out through 3D printing equipment according to a data model, layer-by-layer accumulation is carried out to obtain a metal blank, and a metal part product in a complex shape is obtained through degreasing and sintering. The method can be used for manufacturing a part including a sealed cavity, a complex inner cavity and the like, the part cannot be manufactured through a traditional injection forming mode, the metal blank is directly formed through the 3D printing technology, a mould is not needed, the cost of single part and small scale production is low, requirements for powder materials are low, process reliability is high, repeatability is high, efficiency is high, and the industrialization of manufacturing the small thin-wall metal part in the complex shape through the 3D printing technology is easy to achieve.

Owner:UNIV OF SCI & TECH BEIJING

TC21 titanium alloy powder for laser 3D printing and preparation and using methods

ActiveCN106435270AHigh sphericitySmooth surface and good fluidityAdditive manufacturing apparatusTransportation and packagingMicrometerSpray nozzle

The invention provides TC21 titanium alloy powder for laser 3D printing and preparation and using methods. The powder is prepared from, by mass, 5.5%-6.7% of Al, 1.7%-2.4% of Sn, 1.7%-2.4% of Zr, 2.4%-3.1% of Mo, 1.0%-1.8% of Cr, 1.8%-2.2% of Nb, 0.004%-0.18% of Fe, 0.004%-0.01% of C, 0.002%-0.009% of N, 0.003%-0.01% of H, 0.08%-0.1% of O and the balance Ti. The preparation method comprises the steps that TC21 titanium alloy is machined into an electrode and then rotates and goes down in a smelting chamber, gas acts on the conical tip of a titanium bar when the tip of the titanium bar is bright white, titanium alloy liquid drops are brought into an atomizing chamber through nozzles to be cooled into alloy powder, and the alloy powder is collected. The using method comprises the steps that after the alloy powder with the particle size ranging from 54 micrometers to 180 micrometers and a substrate are pretreated, the as-deposited TC21 titanium alloy with the good strength and toughness is printed by adopting a laser 3D printer, wherein the tensile strength is 1,100-1,150 Mpa, the yield strength is 1,010-1,030 Mpa, and the elongation rate is 7%-8%.

Owner:NORTHEASTERN UNIV

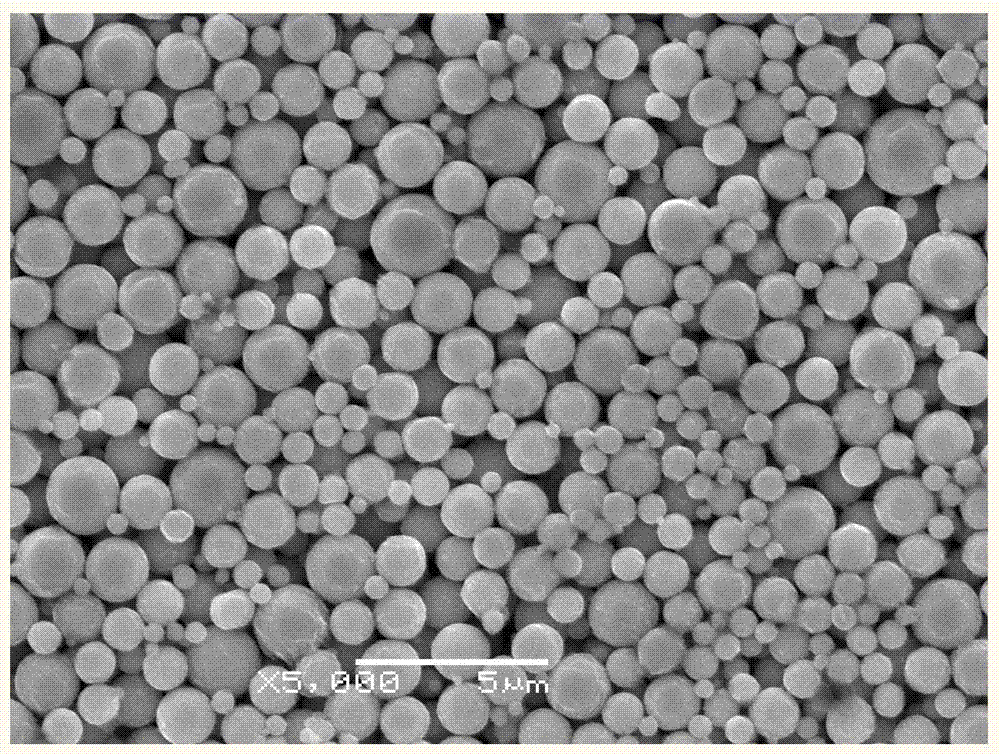

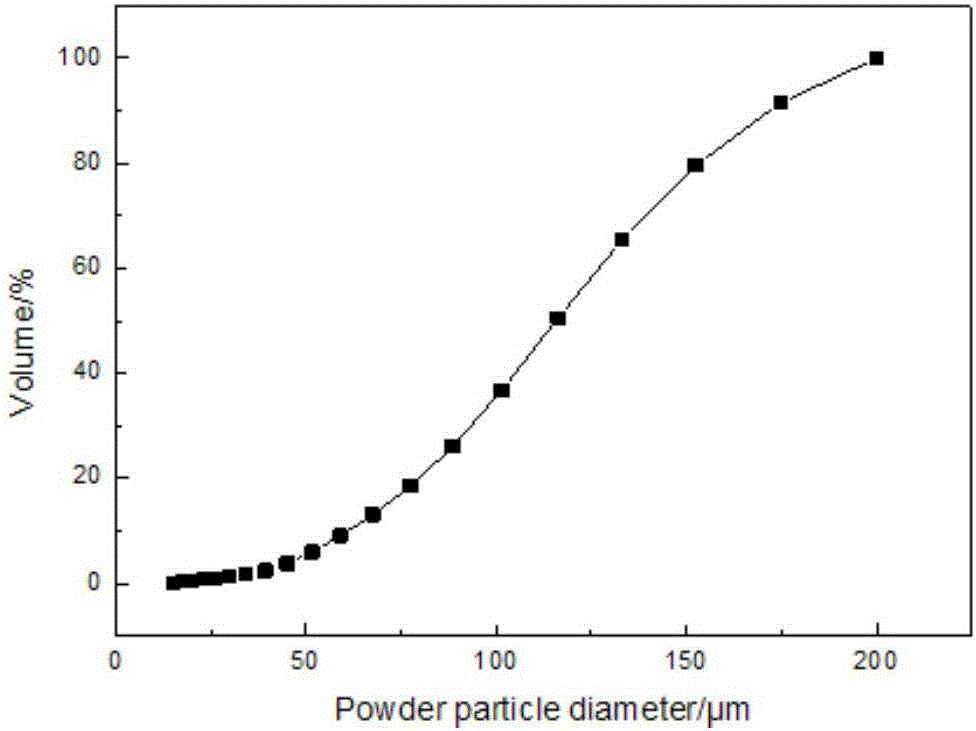

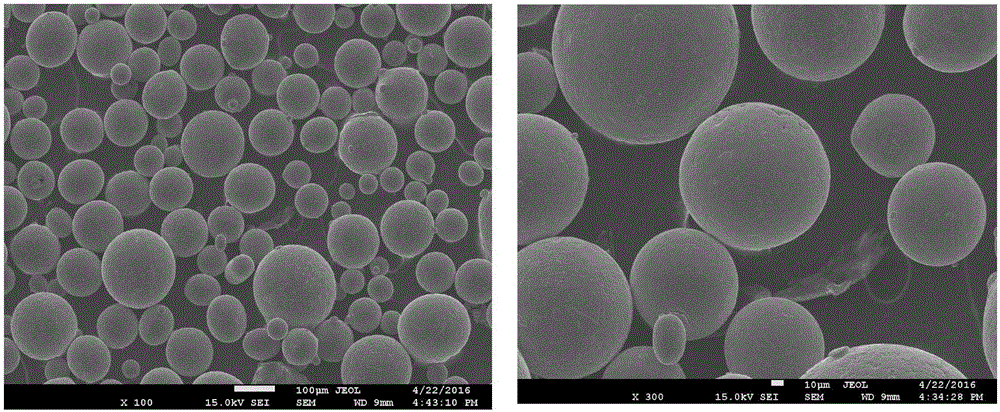

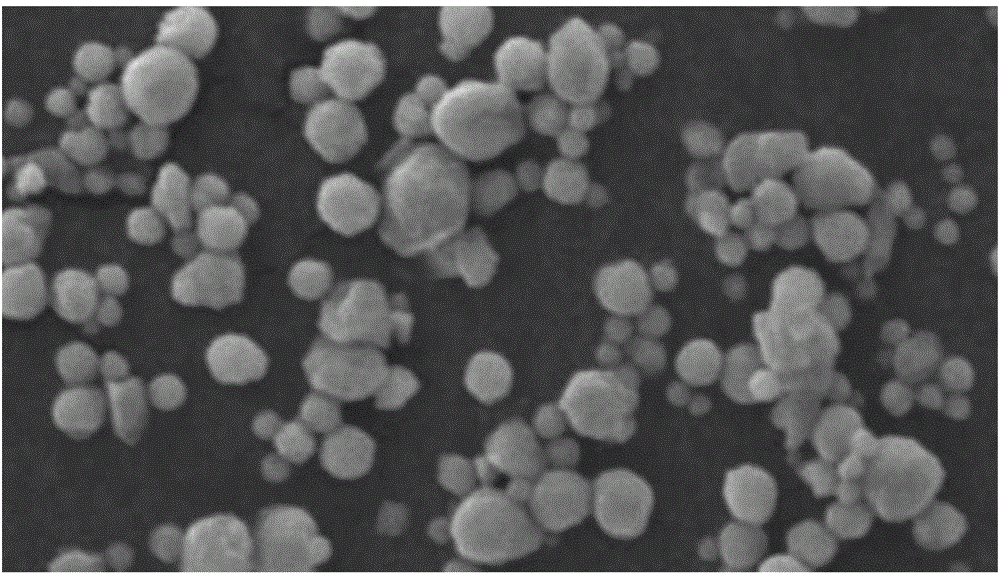

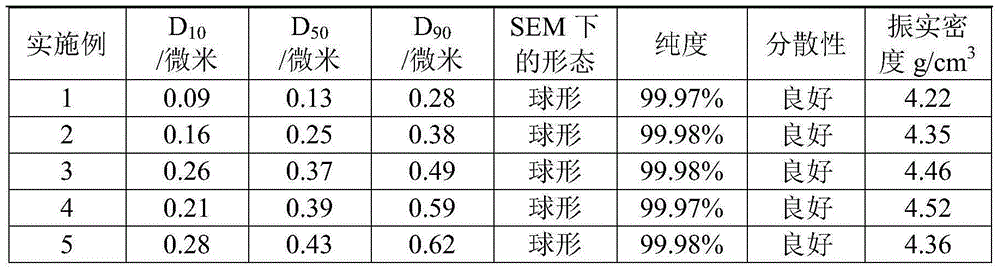

Spherical silver powder with controllable granularity and preparation method thereof

The invention relates to spherical silver powder with controllable granularity. The spherical silver powder has more than 99.9 percent of purity and more than 4.2g / cm<3> of tap density, and the granularity D90 of the spherical silver powder keeps being adjustable within an interval ranged from 0.2 mu m to 0.65 mu m based on a reaction system formula and reaction condition changes during a preparation method thereof. The preparation method of the spherical silver powder comprises the following steps of adopting soluble silver salt as raw materials, and preparing to obtain the nanoscale spherical silver powder through a hydrothermal method; adopting the nanoscale spherical silver powder as silver seed crystal, utilizing sediment reaction to induce the silver seed crystal to grow up uniformly, adjusting the growth degree of the silver seed crystal through controlling a reaction system formula and reaction conditions of the sediment reaction, and further obtaining the spherical silver powder with controllable granularity. The spherical silver powder is regular in shape, uniform in granularity, and can realize controllable granularity through process operation.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

Lithium ion battery carbon microsphere negative electrode material and preparation method thereof

ActiveCN103107319AHigh rate characteristicsLow costCell electrodesSecondary cellsSolventCarbon black

The invention relates to a preparation method of a lithium ion battery carbon microsphere negative electrode material. The method comprises: mixing carbon black, a binder and a solvent to prepare a slurry, conducting spray drying for molding, and then carrying out a high temperature treatment so as to obtain the lithium ion battery carbon microsphere negative electrode material. The lithium ion battery carbon microsphere negative electrode material provided in the invention has a high degree of sphericity and a controllable particle size, so that close packing of the negative electrode material is realized, the volume energy density of electrodes is enhanced. Meanwhile, lithium ions can be embedded from all directions, and the structural stability, the rate capability and the first coulombic efficiency of the material are improved. The carbon microspheres internally have size-controllable gaps, which make up a plurality of ion transport channels, thus being conducive to improving the charge-discharge capacity and cyclic capacity retention rate of the material. Also, the main preparation raw material is carbon black, which has wide sources, no need for breaking, and a low price. And the preparation method has the advantages of simple process, environmental friendliness, low energy consumption and cost, and is easy for large scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

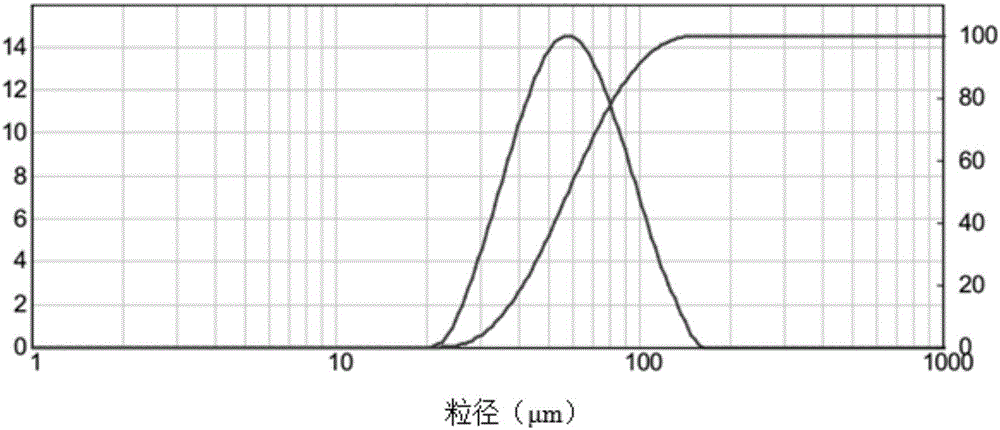

Method for preparing high-quality energetic crystal material fine particles

ActiveCN102320903AReduce crystal defectsReduced Shockwave SensitivityExplosive working-up apparatusShock waveFOX-7

The invention relates to a method for preparing high-quality energetic crystal material fine particles. Various high-quality energetic crystal material fine particle products, such as pentaerythritol tetranitrate (PETN), cyclotrimethylene trinitramine (RDX), cyclotetramethylenetetranitramine (HMX), hexanitrohexaazaisowurtzitane (CL-20), DADNE (FOX-7), ammonium perchlorate (AP), and the like can be prepared by adopting an ultrasound solvating-out crystallization method in the traditional solvating-out crystallization process. The high-quality energetic crystal material fine particle product prepared by the preparation method disclosed by the invention has subglobular particle form, narrow granularity distribution, average particle diameter of 5-50 microns or so, transparent crystals, high particle density, crystal theoretical density of more than 99.9 percent and obviously reduced shock wave sensitivity and is used for pouring or pressing PBX (Plastic-bonded explosives). The method for preparing the high-quality energetic crystal material fine particles has the advantages of simple process flow and mild reaction conditions and is suitable for mass industrialized production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

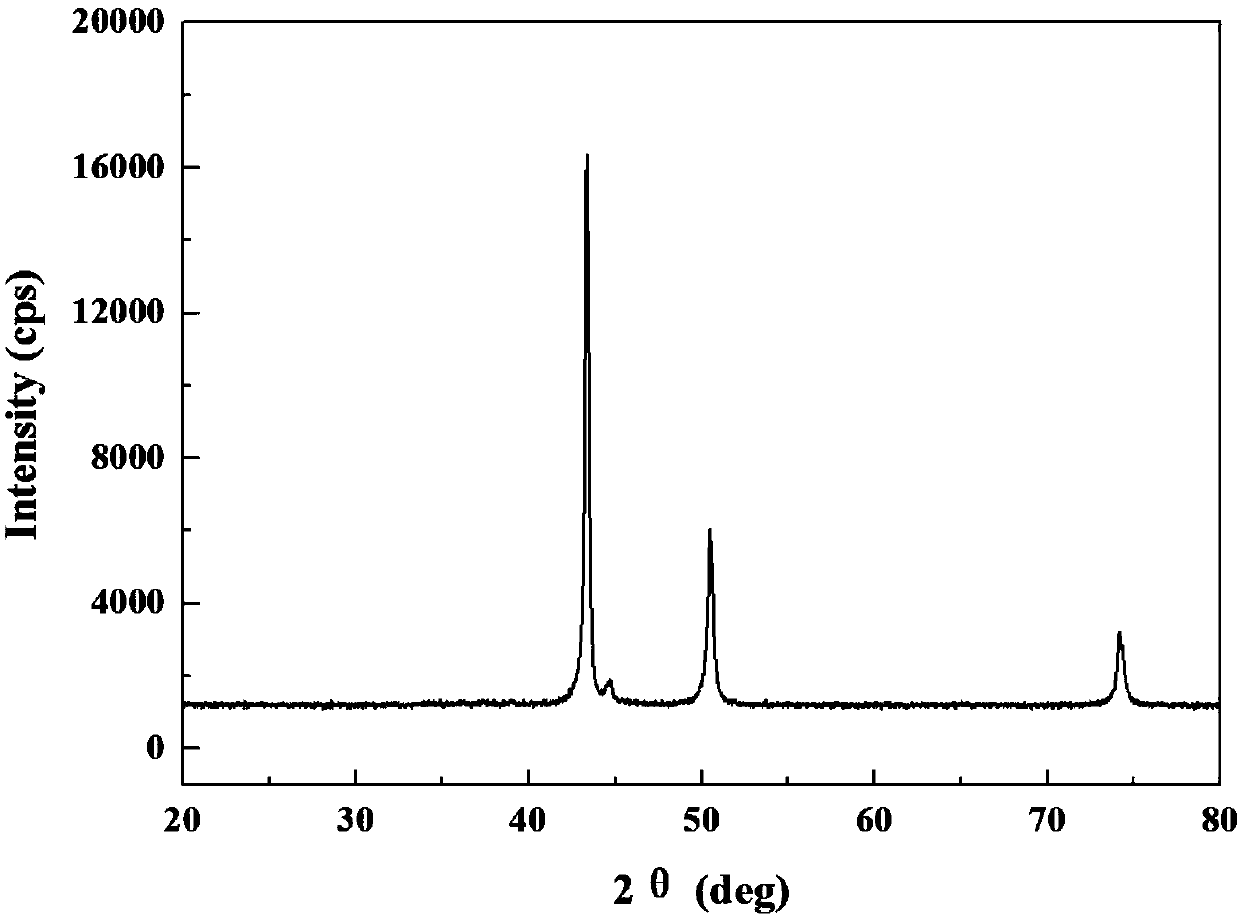

Iron-rich high-entropy alloy powder material for 3D printing and preparation method thereof

ActiveCN105950947AHigh sphericityGranularity controllableAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysGuide tube

The invention discloses an iron-rich high-entropy alloy powder material for 3D printing and a preparation method thereof. The molar ratio of the iron-rich high-entropy alloy powder material FexAlCoCrNiB0.3 is as follows: the molar weight of Fe is 2 to 3, the molar weights of Al, Co, Cr and Ni are 1, the molar ratio of B is 0.3, and B is added in an Ni-B alloy form. The iron-rich high-entropy alloy powder material is prepared through a medium frequency induction melting gas atomization one-step method, namely, a metal liquid subjected to medium frequency induction melting and refining is directly fed into a gas atomization device through a guide tube and a tundish to be atomized for powder material preparation. According to the iron-rich high-entropy alloy powder FexAlCoCrNiB0.3material prepared through the method, a phase structure is composed of solid solutions of simple face-centered cubic and body-centered cubic structures, and a product is good in degree of sphericity, controllable in particle size, uniform in components, low in oxygen content and good in fluidity; and according to the preparation method provided by the invention, the technology is simple, the energy consumption is low, the control is easy, the product quality is stable, and the method is applicable to large-scale industrial production, pollution-free to the environment, and environment-friendly in utilization.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Preparation method of spherical titanium-alloy powder for 3D printing

InactiveCN106493350AUniform particle sizeImprove liquidityAdditive manufacturing apparatusTransportation and packagingHydrogenMicrometer

The invention provides a preparation method of spherical titanium-alloy powder for 3D printing, relates to a method for manufacturing 3D printing consumables, and aims at solving the technical problems that existing Ti-6Al-4V alloy powder is nonuniform in particle size and irregular in shape, and cannot meet the usage requirement of 3D printing. The method comprises the steps that Ti powder and alloy powder of contained elements are added into a ball mill for ball milling according to components of titanium alloy, and titanium-alloy powder is obtained; and the titanium-alloy powder is screened and conveyed to thermal plasma spheroidizing equipment for plasma spheroidizing in hydrogen-containing gas, and the spherical titanium-alloy powder for 3D printing is obtained. According to the spherical titanium-alloy powder, the particle size is smaller than or equal to 100 micrometers, the spheroidization degree is larger than 95%, and the spherical titanium-alloy powder can be applied to the field of 3D printing manufacturing.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Carbon/carbon composite microsphere material, production method and lithium ion battery

ActiveCN103214245ASmall specific surface areaHigh strengthMaterial nanotechnologyCell electrodesSolventCarbon black

The invention relates to a carbon / carbon composite microsphere material, a production method and a lithium ion battery. The carbon / carbon composite microsphere material is prepared through the following steps of: grinding petroleum coke, needle coke or other soft carbon materials into particles which are less than 2 microns in granularity, and mixing the particles with a binding agent, carbon black and a solvent by a certain proportion to obtain a slurry; carrying out spray-balling and drying to obtain an initial composite microsphere, and implementing heat treatment in the atmosphere of an inert gas to obtain the carbon / carbon composite microsphere material. The carbon / carbon composite microsphere material disclosed by the invention has a good sphericity degree and a proper microporous channel, the microsphere material, serving as a negative electrode material of a lithium ion battery, is well compatible with an electrolyte solution, and simultaneously, the microsphere material has a relatively high specific capacity and an excellent circulating performance. The preparation process is environmental-friendly, simple in process, low in cost and easy for industrial promotion.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

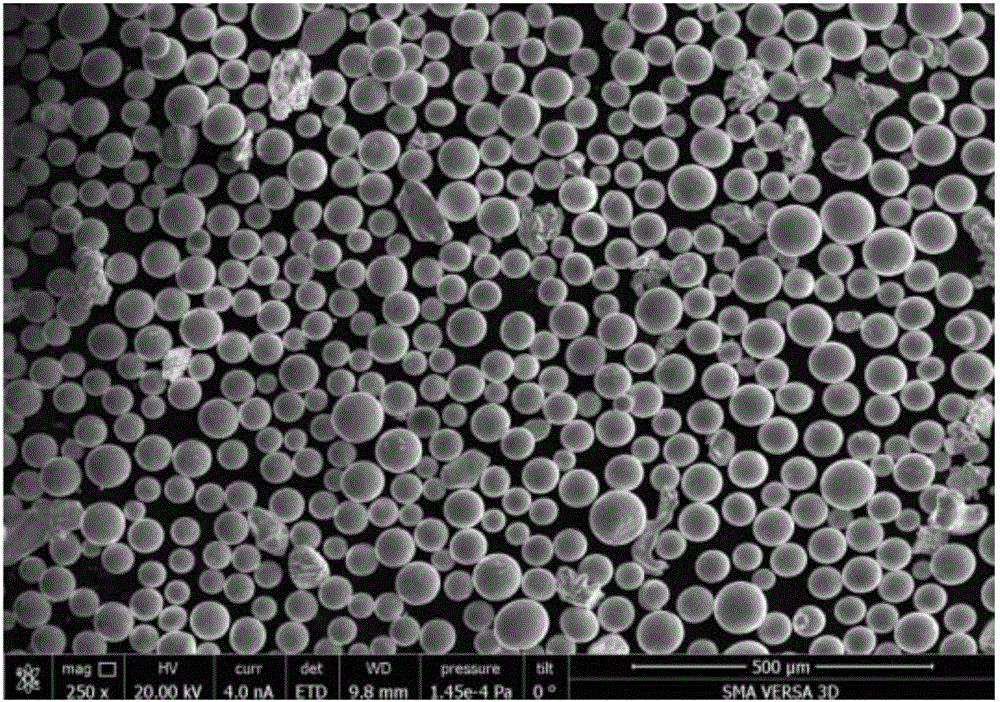

Preparing method of refractory high-entropy alloy spherical powder

InactiveCN108145170AHigh sphericityGood surface finishAdditive manufacturing apparatusMolten spray coatingHigh entropy alloysThermal spraying

Owner:CENT SOUTH UNIV

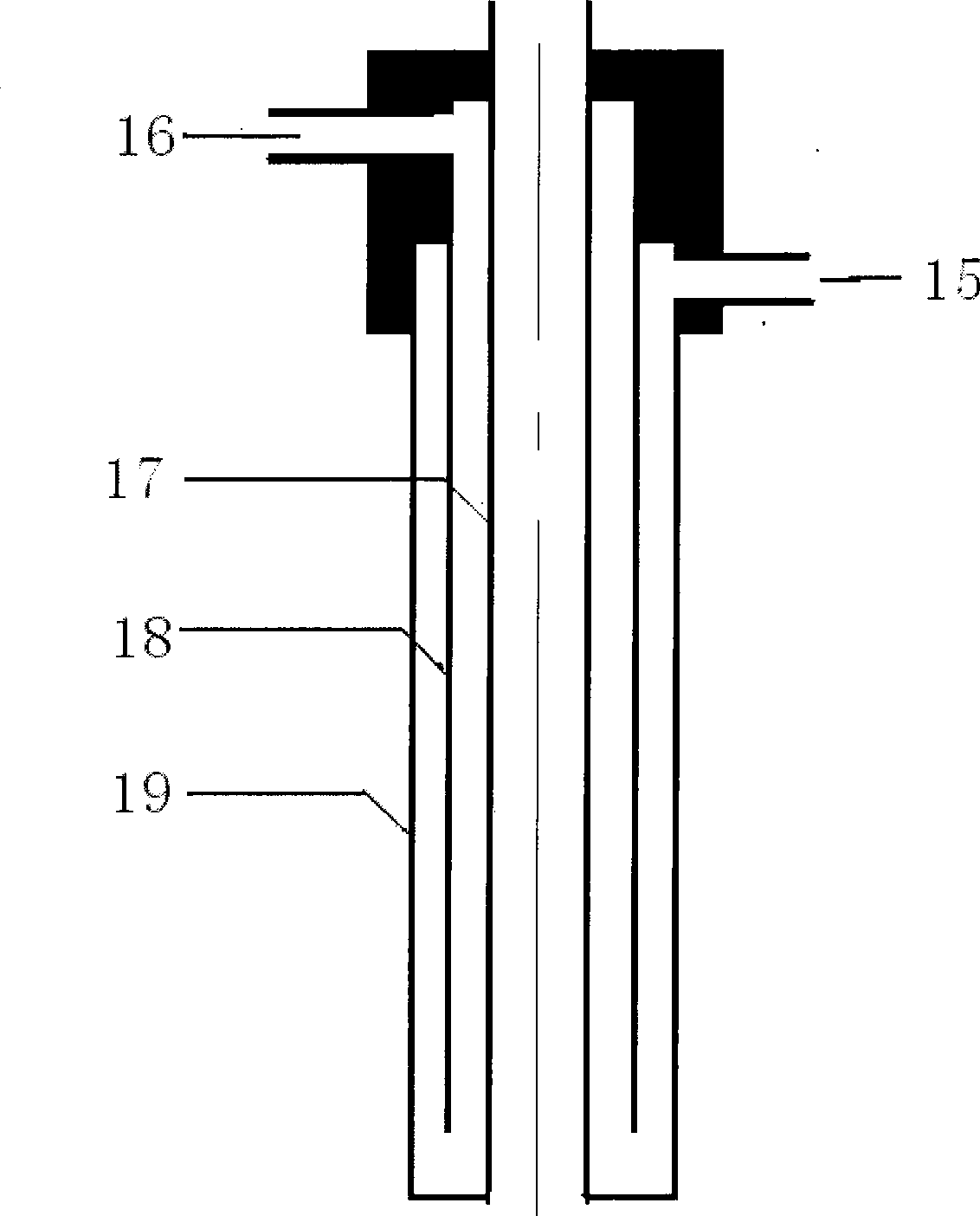

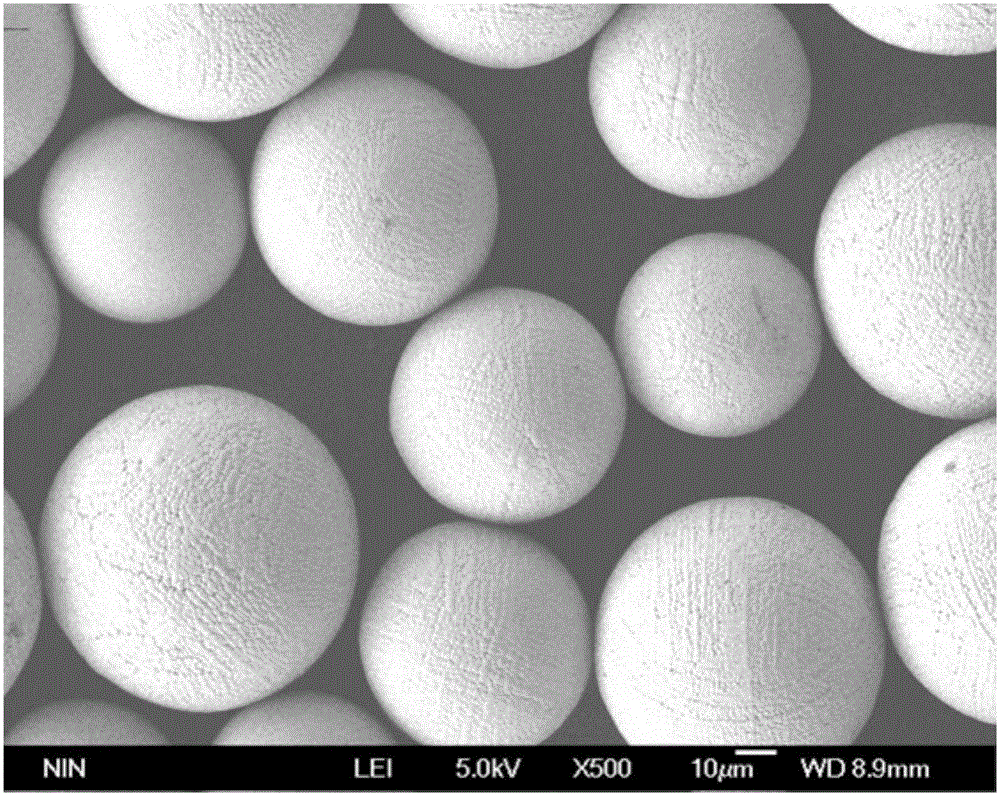

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

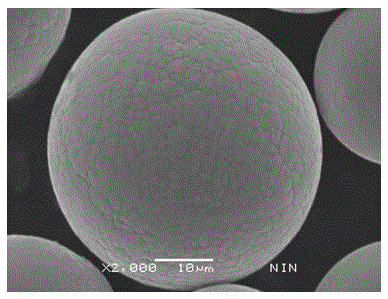

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

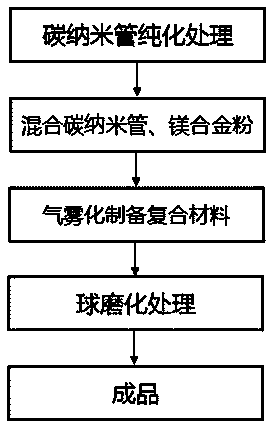

Method for enhancing laser energy absorption efficiency of metal powder material

ActiveCN104226980AUniform particle sizeHigh sphericityIncreasing energy efficiencyManufacturing cost reductionCarbon composites

The invention discloses a method for enhancing the laser energy absorption efficiency of a metal powder material. The method comprises the following steps of preparing metal powder and a carbon material, purifying the carbon material, uniformly mixing the metal powder and the purified carbon material, performing gas atomization treatment on a mixture of the metal powder and the carbon material to obtain a metal / carbon composite material, and performing ball-milling treatment on the metal / carbon composite material obtained by gas atomization, wherein the carbon material is a carbon nanotube, graphene, graphite or carbon black, and the amount of the carbon material is 0.5 to 10 percent based on the total amount. According to the method, the carbon material is added into the metal powder, gas atomization and ball-milling processes are sequentially used for treatment, and the powder material with a uniform particle size, high sphericity and laser absorption rate capable of reaching 70 percent is finally prepared, so that the laser machining efficiency of the powder material and the mechanical performance of a formed part can be greatly improved, and the manufacturing cost can be lowered.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

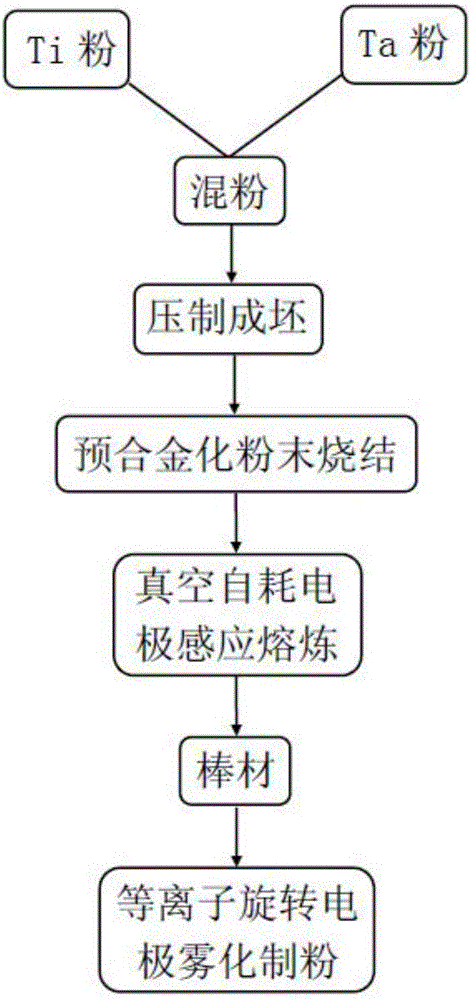

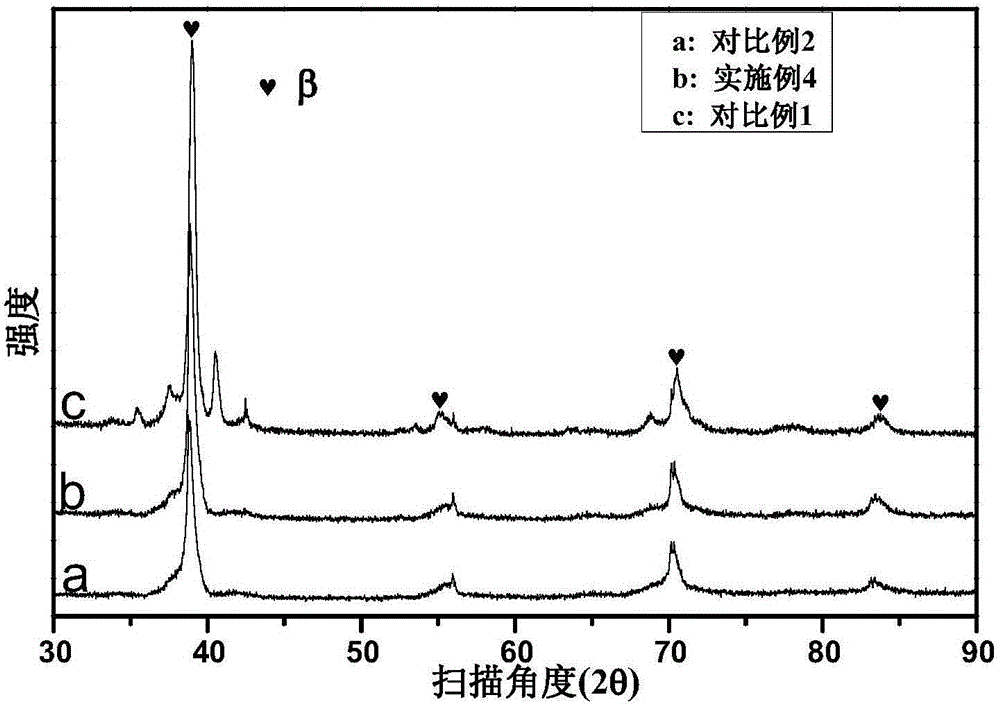

Preparation method of spherical TiTa alloy powder

ActiveCN106735280ASimple processIncrease productivityTransportation and packagingMetal-working apparatusElectric arc furnaceAlloy

The invention discloses a preparation method of spherical TiTa alloy powder. The preparation method comprises the following steps: 1, mixing Ti powder and Ta powder in a material mixing machine to obtain mixed powder; 2, pressing the mixed powder to prepare a blank; 3, pre-sintering the pressed blank; 4, putting the pressed blank into a vacuum consumable electrode electric arc furnace for smelting to obtain a sheared billet; 5, carrying out forging peeling, perforation and tapping, and machining an alloy rod finished product for atomization powdering of a plasma rotary electrode; and 6, preparing the spherical TiTa alloy powder from the alloy rod finished product in the step 5 through a plasma rotary electrode atomization process. The preparation method is simple in operation process and high in production efficiency; the pollution risk to the prepared TiTa alloy powder is reduced, and the oxygen content is less than or equal to 0.1 percent by weight; the raw materials are saved by at least 30 percent or above; the manufacturing cost of the spherical TiTa alloy powder can be effectively reduced by 50 percent; and therefore, low-cost and large-scale production of the high-quality spherical TiTa alloy powder can be met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

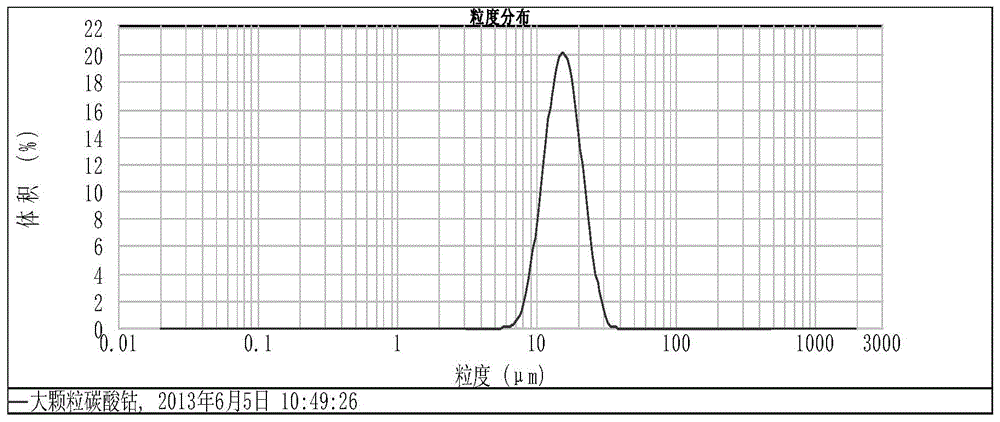

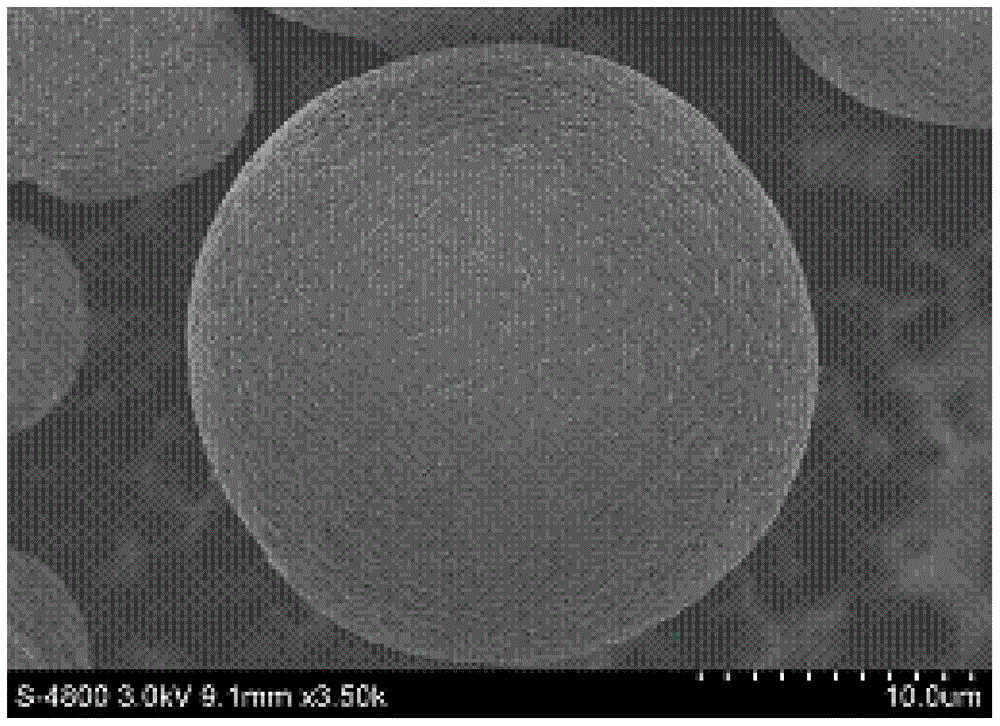

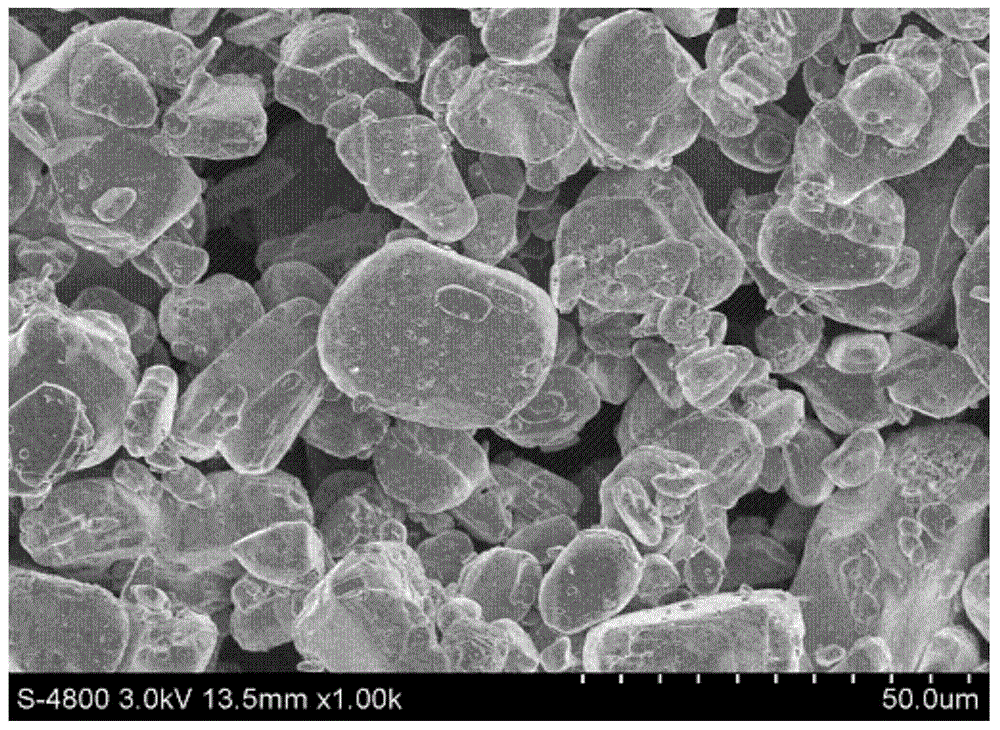

Method for continuously producing large-particle spherical cobalt carbonate

The invention relates to a method for continuously producing large-particle spherical cobalt carbonate. The method comprises the following steps: manufacturing a turbid liquid containing small-particle-size cobalt carbonate seed crystal and manufacturing a turbid liquid containing large-particle spherical cobalt carbonate, stirring the turbid liquid containing the small-particle-size cobalt carbonate seed crystal and the turbid liquid containing large-particle-size cobalt carbonate to form a mixed liquid, carrying out solid-liquid separation, washing and filter pressing to obtain a filter cake as a large-particle cobalt carbonate filter cake, drying the filter cake, and repeatedly operating to obtain the large-particle cobalt carbonate powder. According to the method disclosed by the invention, the small-particle-size cobalt carbonate seed crystal is adopted to control the particle size of the large-particle cobalt carbonate in reaction mother liquor, so that the degree of sphericity of cobalt carbonate produced by continuous production can be ensured to be high, the particle size can be stably controlled within the range of 15+ / -0.5 microns, and the consistency and the stability of the particle size of the large-particle spherical cobalt carbonate through large-scale continuous production can be realized; the method is simple in process, easy to operate and low in cost, and can provide the high-quality raw material for producing high-end lithium cobalt oxide; the carbonate is used as a precipitant, so that the environment can be optimized; the production efficiency can be improved, and the wide application prospect can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

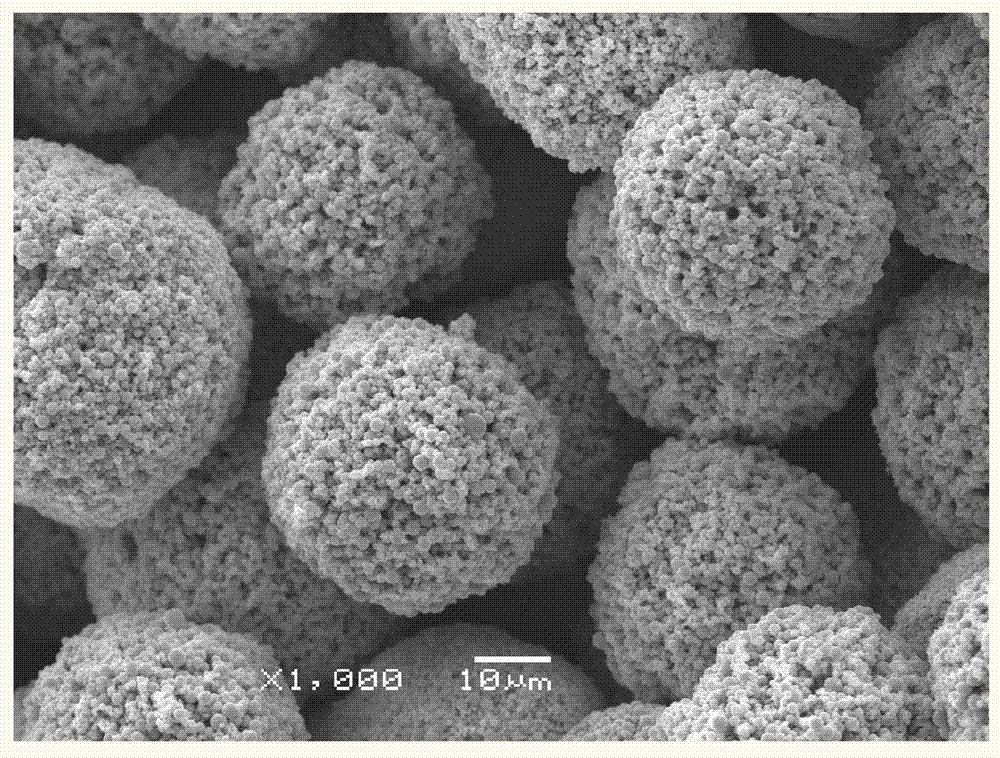

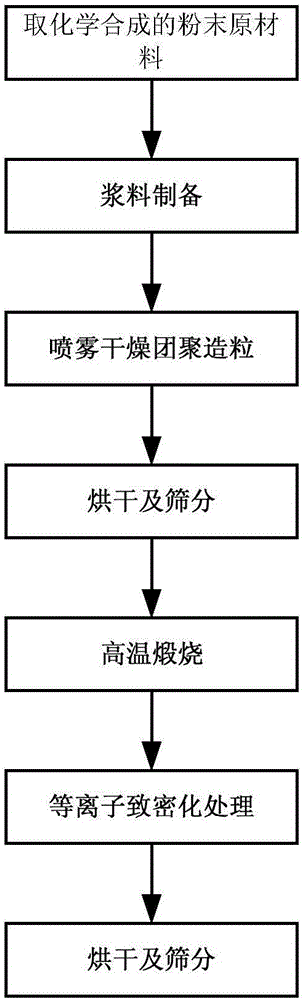

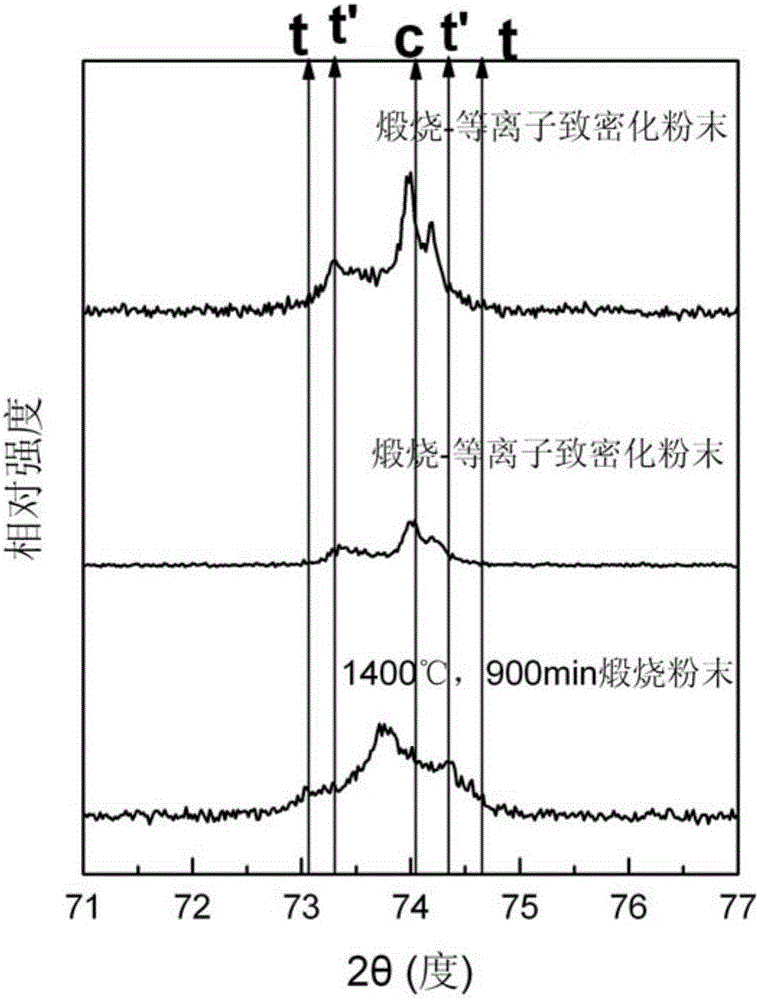

Multi-component rare earth oxide-doped modified YSZ thermal spraying powder and preparation method thereof

ActiveCN106380210AHigh sphericityImprove microstructure uniformityMolten spray coatingThermal sprayingRare earth

The invention discloses a multi-component rare earth oxide-doped modified YSZ thermal spraying powder and a preparation method thereof. A coating prepared by the above powder is obviously improved in high-temperature phase stability and resistance to high-temperature sintering performance, compared with that of the conventional 8 YSZ material. The Gd2O3-Yb2O3-Y2O3-ZrO2(HfO2) power provided in the invention is composed of 5.5-6.5 wt% of Y2O3, 2.5-3 wt% of Gd2O3, 2.5-3.5 wt% of Yb2O3, 87-89.5 wt% of ZrO2-HfO2, and 2 wt% or less of HfO2, wherein HfO2 is the associated material of the ZrO2. Raw materials are prepared through subjecting the slurry to the sparying, drying, agglomerating, granulating, drying, sieving, high-temperature calcination, plasma densification treatment, drying and sieving process. In this way, the loose density of obtained spherical thermal spraying powders is 1.8-2.3 g / cm<3>, and the fluidity of obtained spherical thermal spraying powders is smaller than 50s / 50g, wherein most of the obtained spherical thermal spraying powders are in metastable tetragonal phase. The powder is prepared through multiple different heat treatment means, so that the high-temperature stability and the performance of the spraying powder and the sprayed coating are improved. Meanwhile, the heat-shock life of a plasma sprayed coating prepared by the above powder is up to over 2300 times at 1200 DEG C, and is far higher than that of a 8 YSZ coating in the same condition.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Method for preparing ceramic tritium proliferation agent in fusion stack cladding

InactiveCN101510450AImprove bindingHigh strengthNuclear energy generationThermonuclear fusion reactorNuclear fusionSlurry

The invention relates to a method for preparing a ceramic tritium breeding agent in a fusion reactor blanket, pertaining to the nuclear fusion field, in particular to a technique for preparing the ceramic tritium breeding agent pellets in the fusion reactor blanket. The method is characterized in that: organic monomers that can generate free radical polymerization and a crosslinking agent are mixed and dissolved with water or an organic solvent to prepare a pre-mixed solution, then ceramic tritium breeding agent powder is added and an initiator and a catalyst are added after defoaming treatment so as to prepare a slurry; the slurry is dripped into a medium by using a dripping device and the medium is in the state of being heating and is exclusive to the solvent used in the slurry. After entering the medium, the dripping liquid takes the form of pellet, solidifies and maintains the shape during the dropping process; the pellet is collected, cleaned, dried and sintered into the tritium breeding agent ceramic pellet material. The formed blanket has high strength and toughness; the formed pellet has high degree of sphericity, smooth surface and good evenness; the shrinkage after drying and sintering are slight, the size of the pellet is easy to be controlled and the strength is high; additionally, the cost is relatively low and the technique is flexible.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

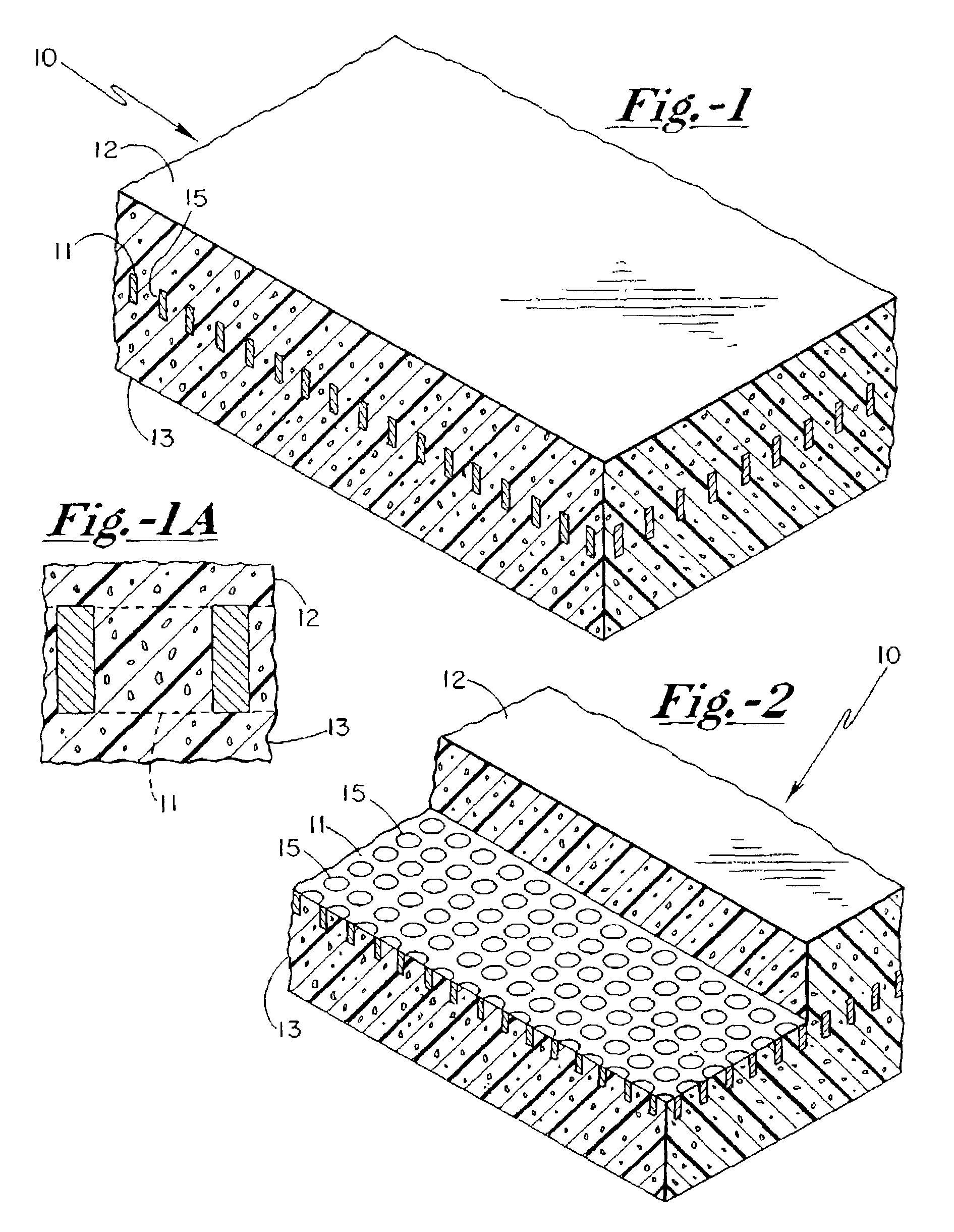

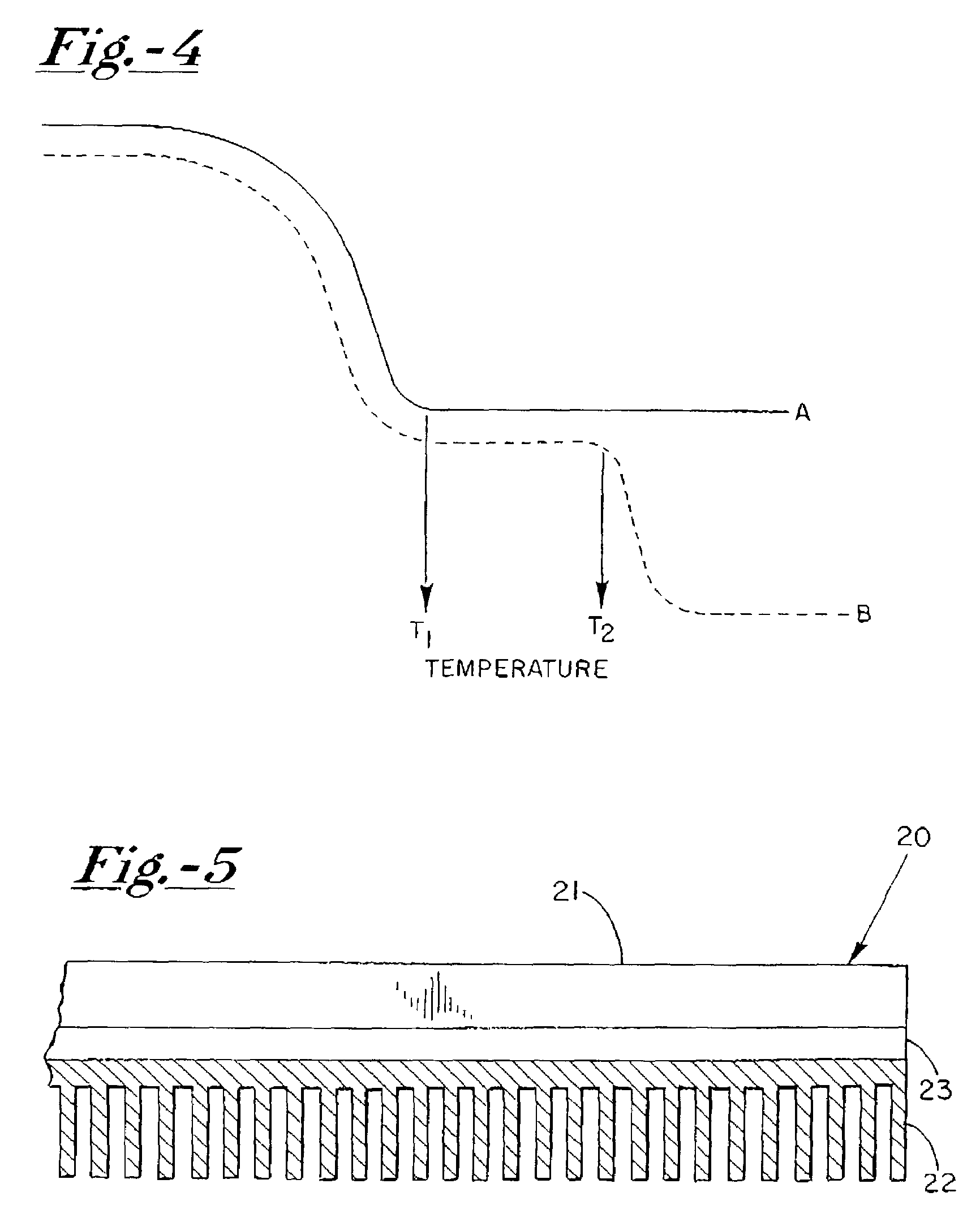

Thermal interface pad utilizing low melting metal with retention matrix

InactiveUS6984685B2Low viscosityReduction of viscous dragLayered productsSemiconductor/solid-state device detailsParticulatesWax

A stabilized thermally conductive mechanical compliant laminate pad to be interposed between opposed surfaces of a generating semi-conductor device and a heat sink, with the laminate pad comprising upper and lower laminae on opposed surfaces of a central stabilizing apertured grid. The laminae are subjected to a compressive force at an elevated temperature until portions of the laminae extend through the apertures to form a continuum. The laminae comprise a polymer matrix having a quantity of a low melting indium or gallium alloy and a thermally conductive particulate dispersed there through, with the polymer matrix being a hot wax or melt resin. With the upper and lower laminae positioned on opposed surfaces of a central stabilizing apertured grid a compressive load is applied to force portions of said laminae to pass through apertures in the mesh grid to form a continuum.

Owner:HENKEL IP & HOLDING GMBH

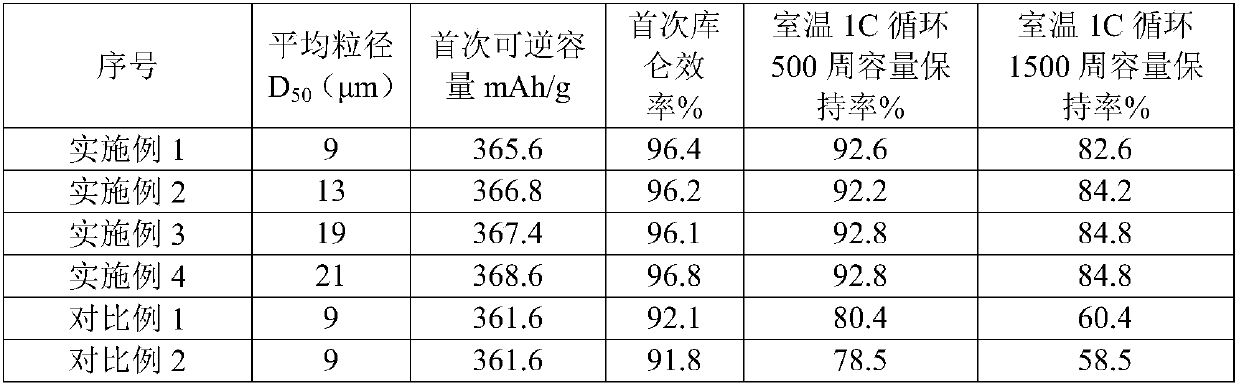

Long-life modified natural graphite cathode material as well as preparation method and use thereof

ActiveCN107814382AHigh sphericitySmooth particle surfaceCarbon compoundsCell electrodesFilling rateHigh pressure

The invention discloses a long-life modified natural graphite cathode material as well as a preparation method and use thereof. According to the preparation method, natural graphite powder and asphaltare dipped by virtue of a hot isostatic pressure machine, so that holes in graphite particles can be completely filled with asphalt at high temperature and high pressure conditions; and meanwhile, anasphalt coating layer is formed on the surface of the natural graphite powder, and graphitization is carried out so as to obtain the modified natural graphite cathode material with a core-shell structure, wherein synthetic graphite is embedded into the inside and surface of the natural graphite in situ, the filling rate of the synthetic graphite in the holes of the natural graphite is more than or equal to 94%, the surfaces of the particles are smooth, and the spheroidization degrees of the particles are high. According to the preparation method, the primary coulombic efficiency of the modified natural graphite cathode material is more than or equal to 96%, and the capacity retention ratio of the material after being circulated at a room temperature 1C for 1500 cycles is more than or equal to 80%, so that the prepared material is high in primary coulombic efficiency, long in service life and can be used for replacing synthetic graphite for producing powder battery cathode materials, and the cost is greatly lowered. The preparation method is simple in preparation process and low in cost and has relatively high practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

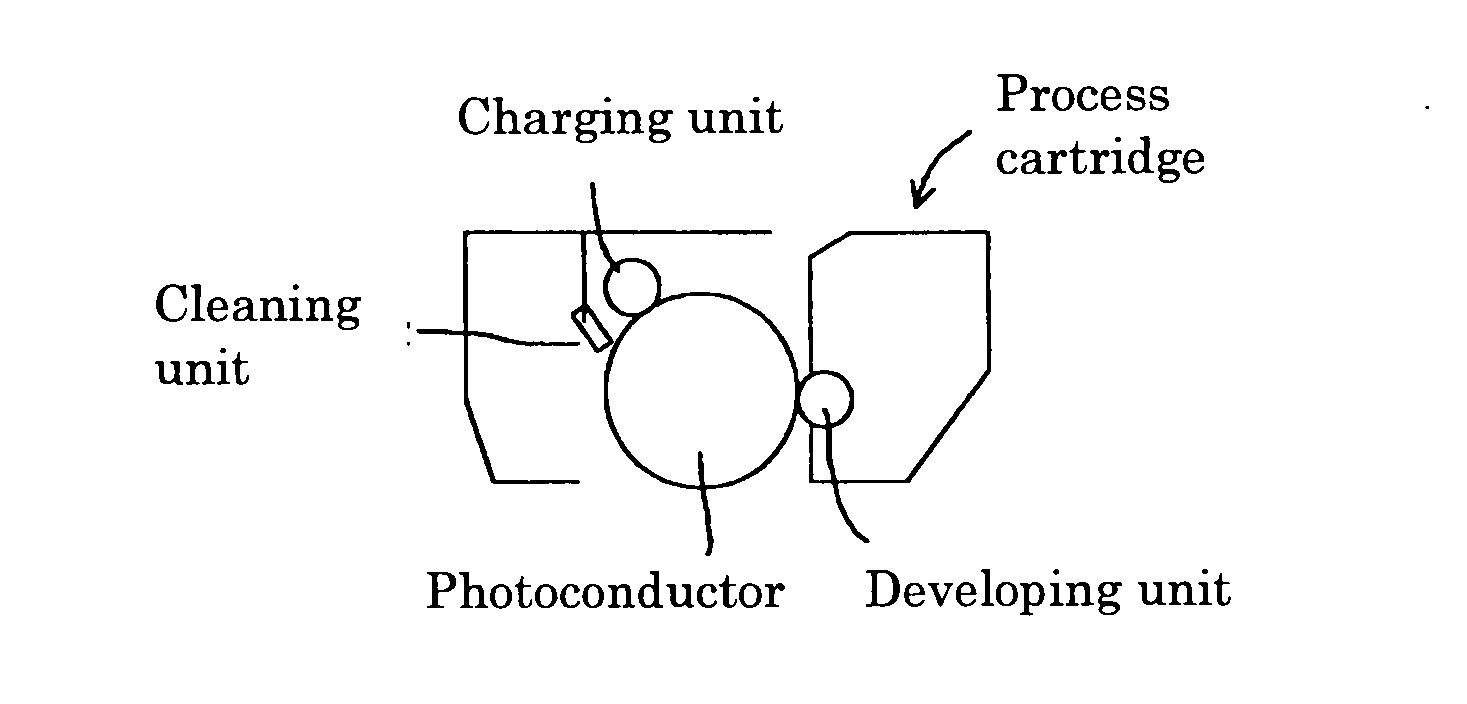

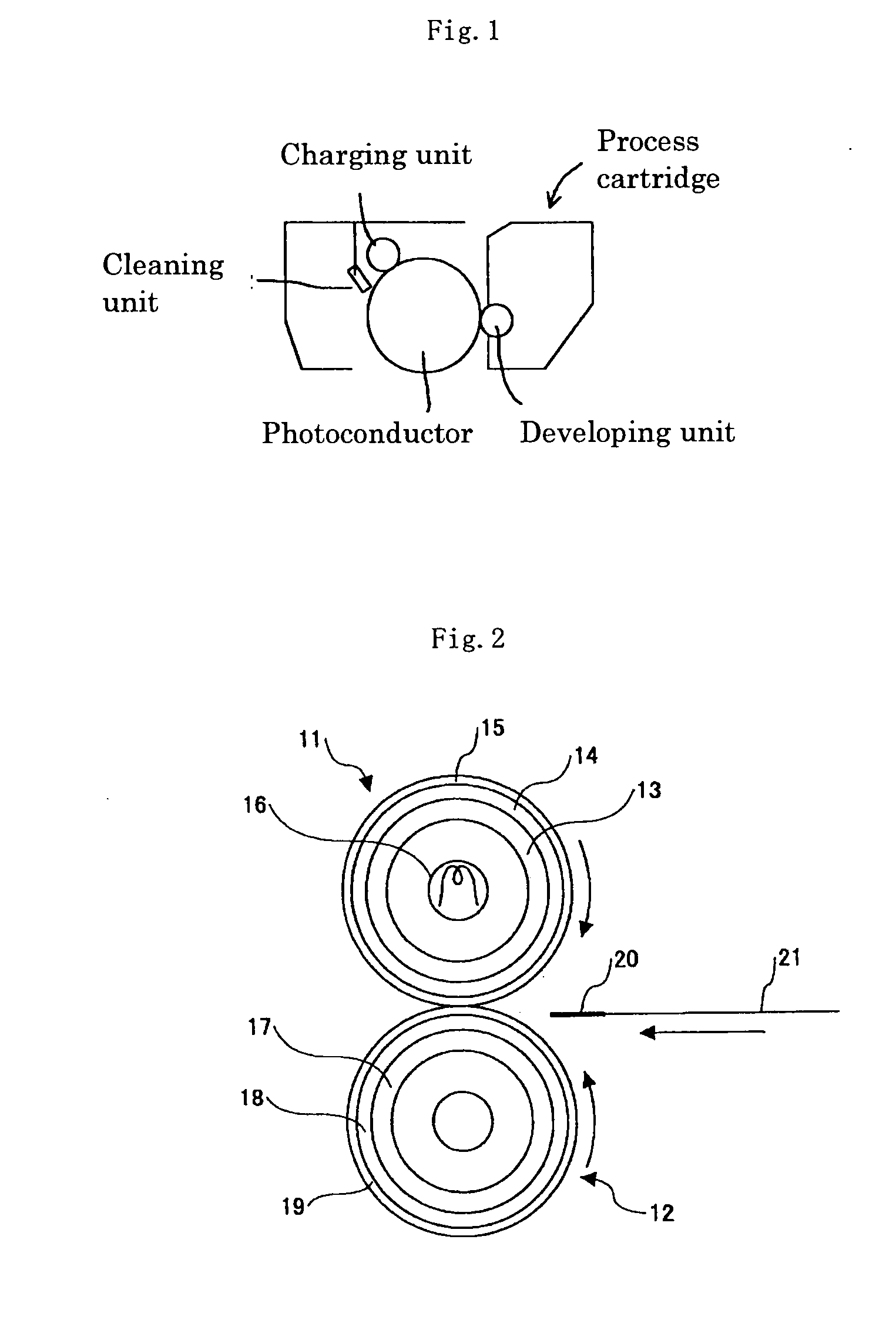

Toner and method for producing the same, toner container, developer, image forming apparatus and process cartridge

InactiveUS20080233510A1Reduce the amount requiredHigh sphericityDevelopersElectrographic process apparatusOrganic solventImage formation

Disclosed is a non-magnetic toner for use in developing electrostatic toner image, wherein the toner is produced by a toner production method that includes: dispersing in an aqueous medium an organic dispersion liquid that comprises in an organic solvent a pigment, a binder resin and / or a binder resin precursor, and a releasing agent; removing the organic solvent to prepare a dispersion slurry in which toner particles are dispersed in the aqueous medium; heating the dispersion slurry to a temperature equal to or higher than the melting point of the releasing agent; and washing the toner particles.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com