Preparing method of refractory high-entropy alloy spherical powder

A high-entropy alloy and spherical powder technology, which is applied in metal processing equipment, melt spraying, metal material coating technology, etc., can solve the problems of high melting point of refractory high-entropy alloy, difficult preparation by atomization method, and long preparation process. , to achieve the effect of good fluidity, high sphericity and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

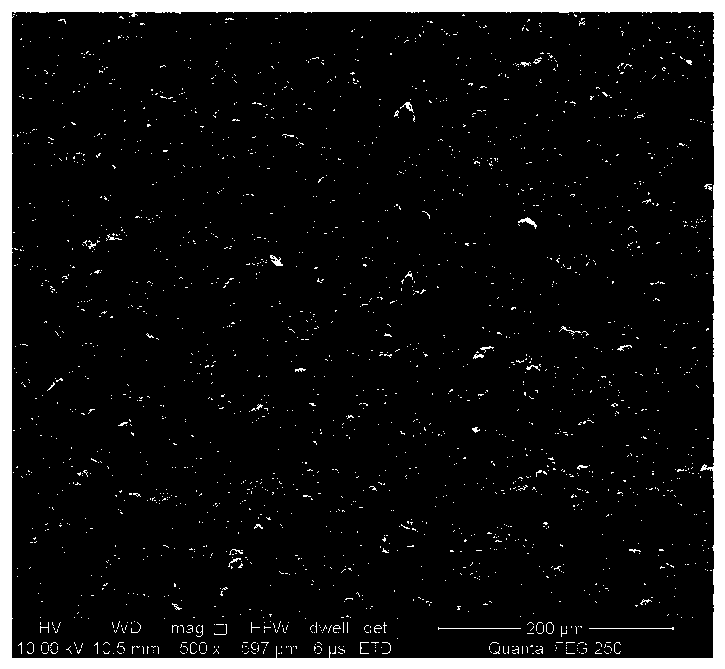

Image

Examples

Embodiment 1

[0030] A preparation method of W, Mo, Ta, Nb refractory high-entropy alloy spherical powder, comprising the following steps:

[0031] (1) Use 99.9% pure tungsten powder, molybdenum powder, tantalum powder, and niobium powder as high-entropy alloy raw materials, weigh each raw material according to the atomic percentage of 25%, and the total mass is 100g, and then add the high-entropy alloy raw material to the hard Perform ball milling in an alloy tank to obtain mechanically alloyed alloy powders. During ball milling, control the ball milling time to not less than 40 hours, rotate at a speed of 300r / min, and have a ball-to-material ratio of 10:1. Prevent cold welding phenomenon;

[0032] (2) Take the alloy powder obtained in step (1) out of the vacuum glove box and sieve it through a 200-mesh sieve. When sieving, ensure that the argon gas in the box is filled to normal pressure to prevent the alloy powder from being oxidation;

[0033] (3) Place the sieved powder obtained in ...

Embodiment 2

[0036] A kind of preparation method of Nb, Mo, Cr, Ti refractory high-entropy alloy spherical powder, comprises the following steps:

[0037] (1) Use 99.9% pure niobium powder, molybdenum powder, chromium powder and titanium powder as high-entropy alloy raw materials, weigh each raw material according to the atomic percentage of 25%, and the total mass is 100g, and then add high-entropy alloy raw materials to the hard Perform ball milling in an alloy tank to obtain mechanically alloyed alloy powders. During ball milling, control the ball milling time for not less than 24 hours, rotate at a speed of 250r / min, and have a ball-to-material ratio of 15:1. Prevent cold welding phenomenon;

[0038](2) Take the alloy powder obtained in step (1) out of the vacuum glove box and pass through a 325-mesh screen to obtain an alloy powder smaller than 45 microns. When sieving, the box must be filled with argon to normal pressure to prevent the alloy The powder is oxidized during the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com