Patents

Literature

42results about How to "Good surface finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

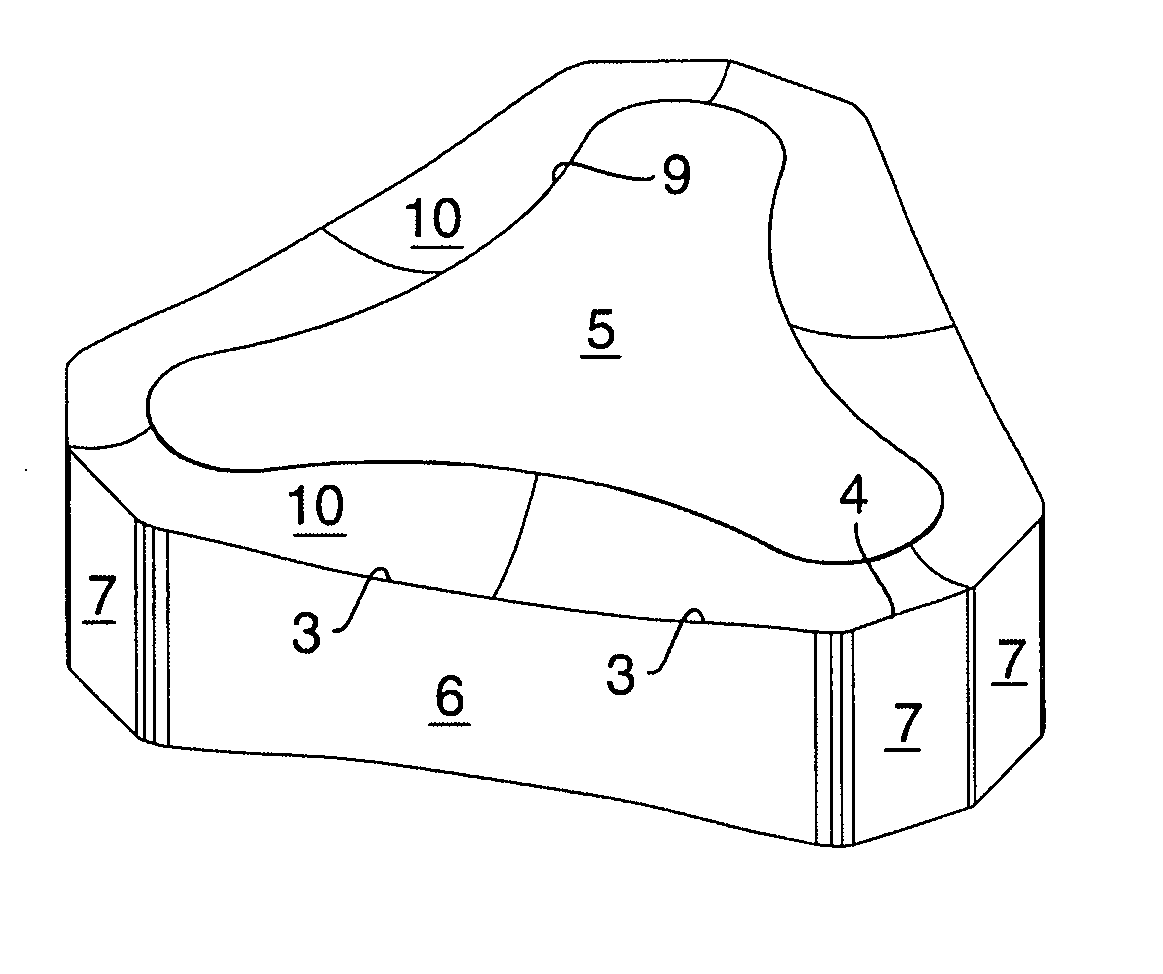

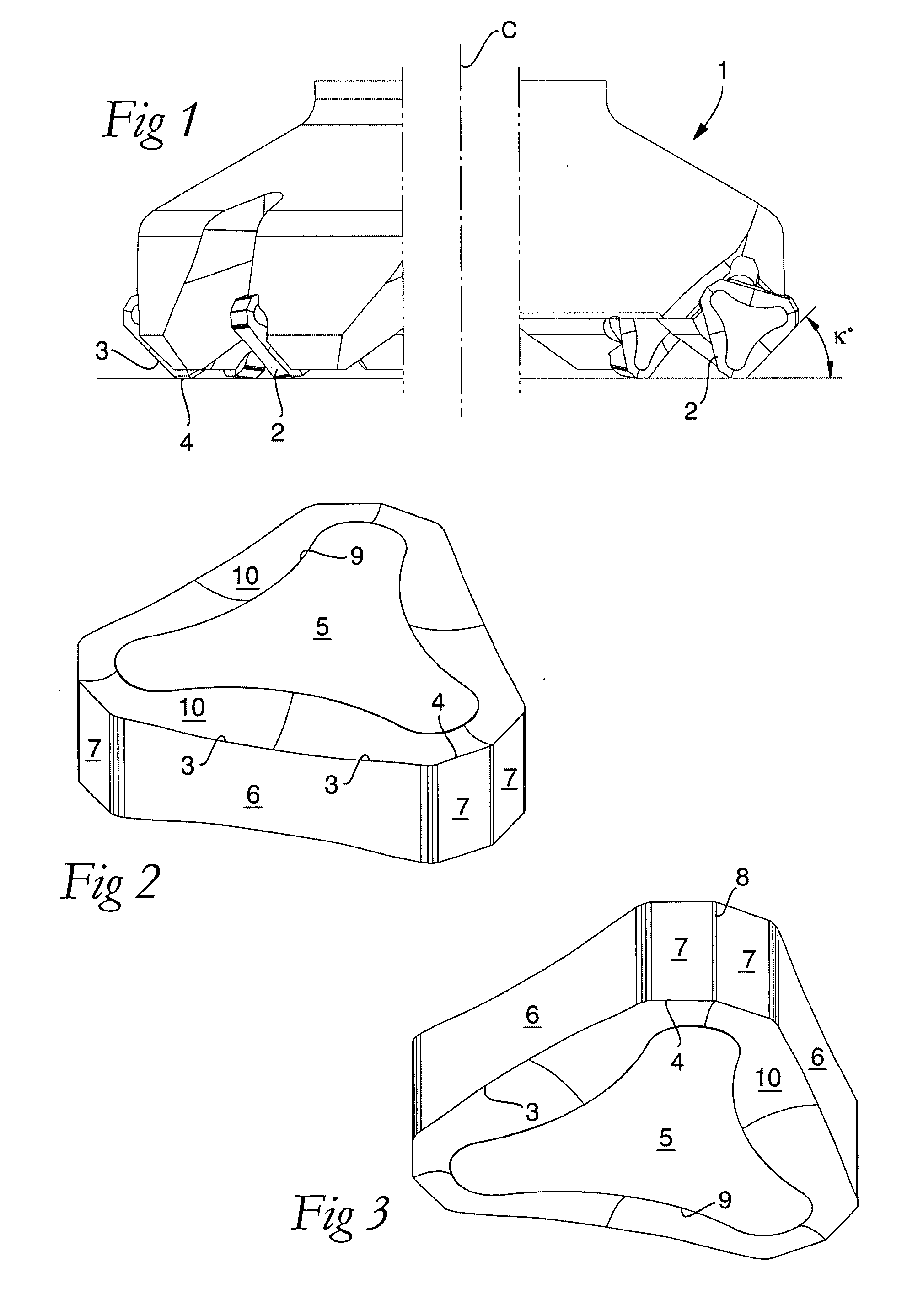

Face milling insert

ActiveUS20070297865A1Good surface finishLong service lifeTransportation and packagingMilling cuttersSwarfStructural engineering

A face-milling insert, including a chip-removing main cutting edge adjacent to a first clearance surface, and a surface-wiping secondary edge adjacent to a second clearance surface, the main cutting edge forming an angle of 45° with an imaginary straight line in the extension of the secondary edge. Adjacent to a third clearance surface, an intermediate cutting edge is formed between the main cutting edge and the secondary edge, the intermediate cutting edge being shorter than the main cutting edge and forming an angle within a range of 20-40° with the extension line. The intermediate cutting edge transforms into the adjacent edges via arched part edges adjacent to convex clearance surfaces.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Preparing method of refractory high-entropy alloy spherical powder

InactiveCN108145170AHigh sphericityGood surface finishAdditive manufacturing apparatusMolten spray coatingHigh entropy alloysThermal spraying

Owner:CENT SOUTH UNIV

Aluminum alloy welding wire surface scraping method and device

ActiveCN101513699AGood surface finishPrevents dark spots and splattersWelding/cutting media/materialsSoldering mediaWeld seamSurface finishing

The invention relates to a metal welding wire manufacture method, especially to an aluminum alloy welding wire surface scraping method and device, which mainly solves problems in prior art that welding wire surface is treated by a chemical treatment method, because after chemical treatment, surface smoothness is deficient, block is easy to happen when conveying, simultaneously oil stain and chemical stain are remained on the surface, smoke is generated when the welding wire is used for welding, and black spot and splash phenomenon are appeared on and near weld seam. The method includes steps of line laying, positioning, wiping, crude scraping, fine scraping and cooling. The device includes a frame, and a positioning wheel, a wiping die, a crude scraping die, a fine scraping die and a cooling device which are connected in the frame.

Owner:杭州坤利焊接材料有限公司

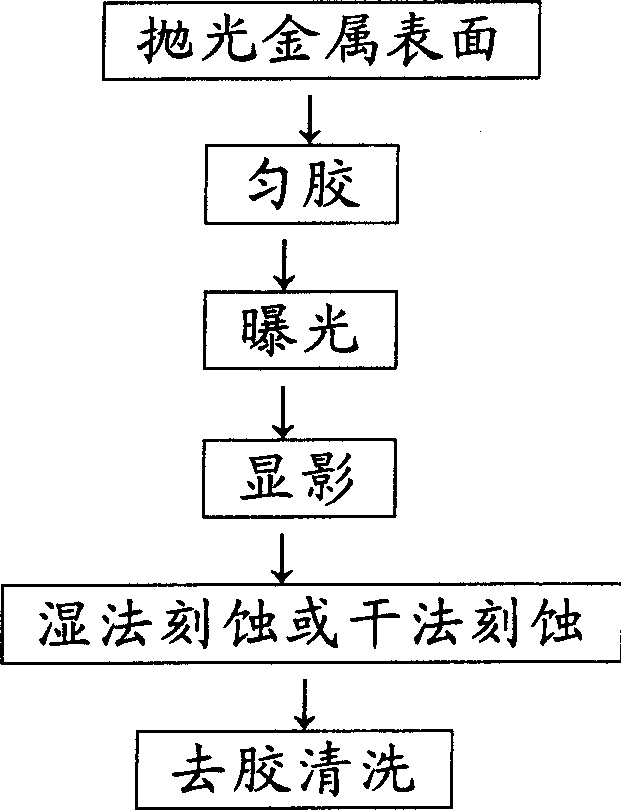

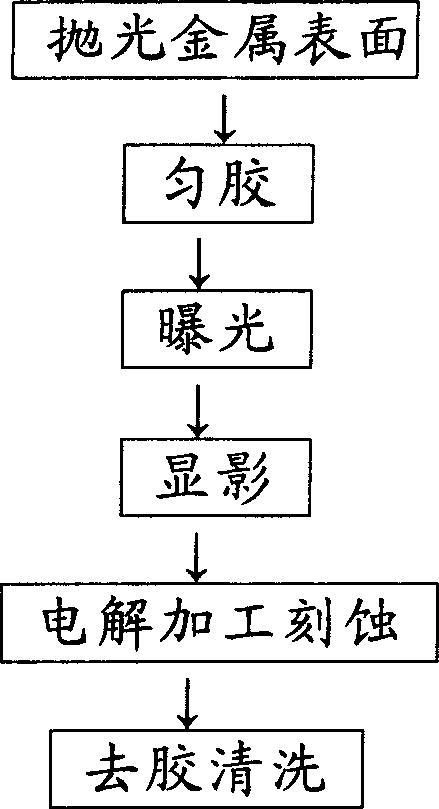

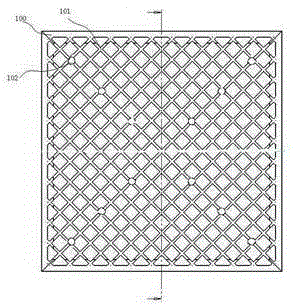

Metal grating template making process

The metal grating template making process includes photoetching comprising homogenizing photoresist, exposure, developing and other steps to form photoresist grating pattern; electrolytic etching via setting metal workpiece as positive electrode inside the electrolyte with the grating pattern side set opposite to the negative electrode to etch out the exposed the grating pattern to form grooves while protecting the photoresist masked metal surface; and taking out the metal template after reaching the required etching depth, eliminating photoresist and cleaning to obtain the metal grating template. The metal grating template making process of the present invention is simple, low in cost and fast, and etched pattern is smooth and precise.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Preparation method of anti-migration thermoplastic polyurethane elastomer

The invention discloses a preparation method of an anti-migration thermoplastic polyurethane elastomer. The preparation method comprises the following steps: (1) adding heated and molten polyester polyol into a reaction kettle, and adding an antioxidant and a catalyst, and dewatering under heating and reduced pressure conditions to form a component A; (2) heating and melting diisocyanate to form a component B; (3) heating and melting a dihydric alcohol chain extending agent, and dewatering under the reduced pressure condition to form a component C; (4) reacting the components A, B and C in a double-screw extruder, and fully and uniformly mixing a reaction product with a macromolecular hindered amine light stabilizer to obtain the anti-migration thermoplastic polyurethane elastomer; (5) curing the anti-migration thermoplastic polyurethane elastomer obtained in the step (4). According to the anti-migration thermoplastic polyurethane elastomer, the smooth surface can be better kept and the physical property retention period can be better prolonged in processed products such as late-period wires and cables and films.

Owner:苏州奥斯汀新材料科技有限公司

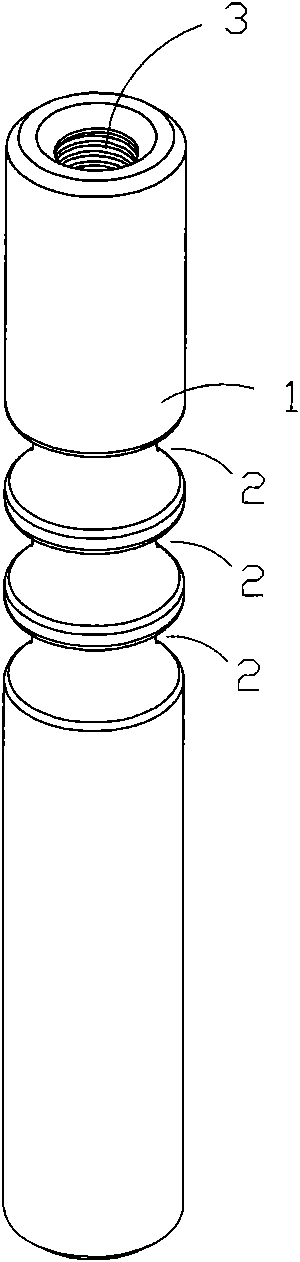

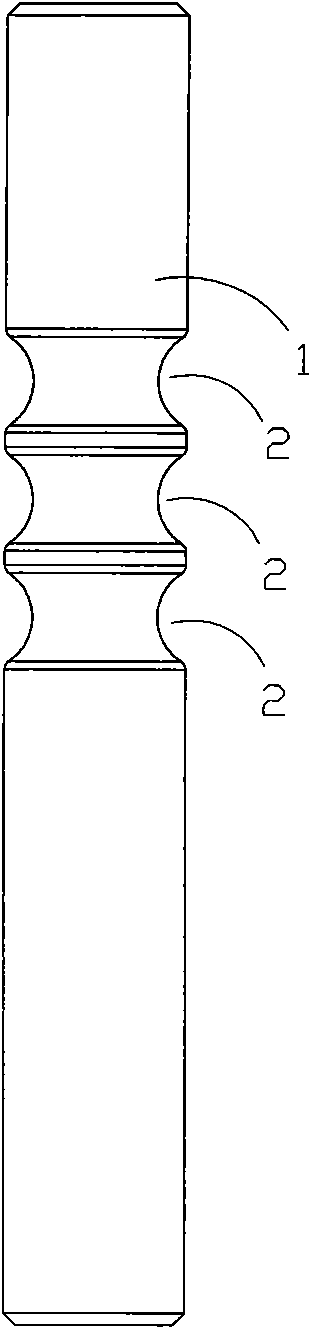

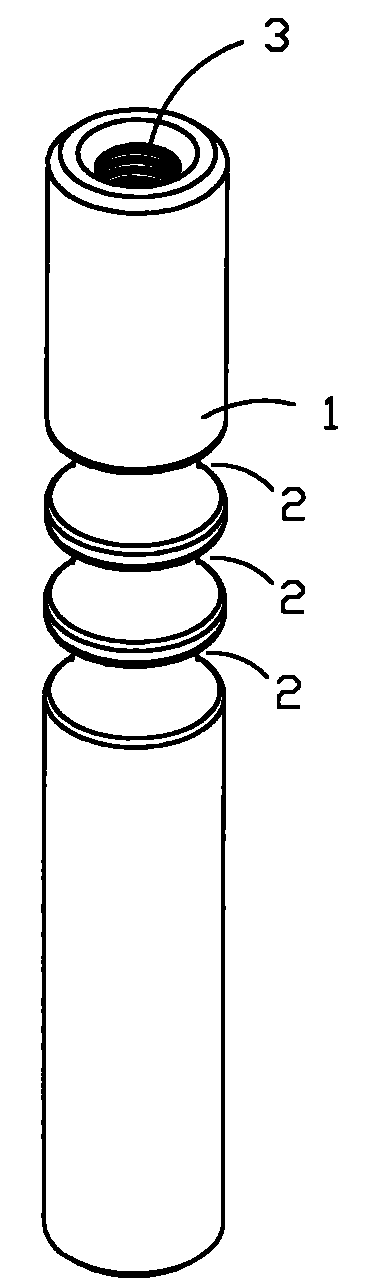

Shifting fork shaft and manufacturing method thereof

InactiveCN101922546AGood surface finishImprove reliabilityFlexible-parts wheelsGearing controlHardnessEngineering

The invention discloses a shifting fork shaft and a manufacturing method thereof. The shifting fork shaft is provided with a cylindrical working area, a plurality of shifting chutes are arranged on the working area, the axial cross section of each shifting chute is in the basic shape of a circular arc, and the surface of each shifting chute is a smooth surface ground by an elastic grinding wheel. The manufacturing method comprises the following steps: (1) selecting a steel column billet, and milling a preset amount of shifting chutes on the steel column billet; (2) quenching the billet on which the shifting chutes are milled to improve the hardness of the shifting chutes; and (3) grinding the quenched billet: concretely, grinding the shifting chutes by adopting the elastic grinding wheel, and taking the shifting chutes as the finished products of shifting fork shafts after the surfaces of the shifting chutes are changed from a rough and black state into a smooth and light-reflecting state. The product of the invention has high reliability and stability, and the process of the invention has better simplicity and convenience.

Owner:林加伟

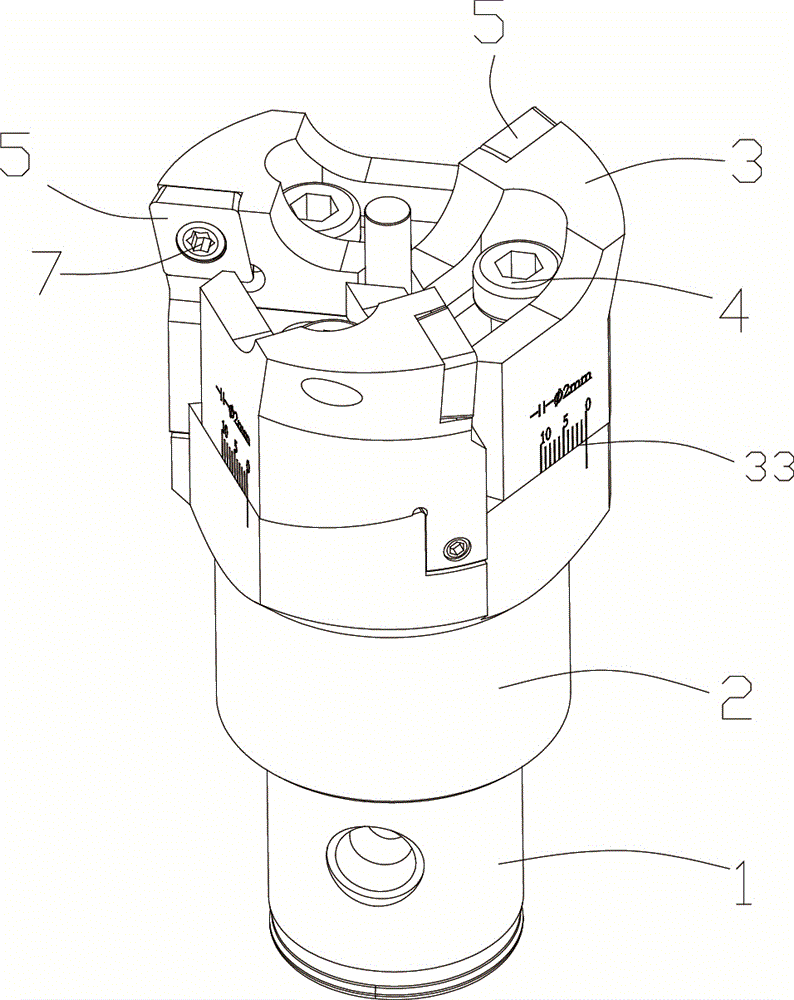

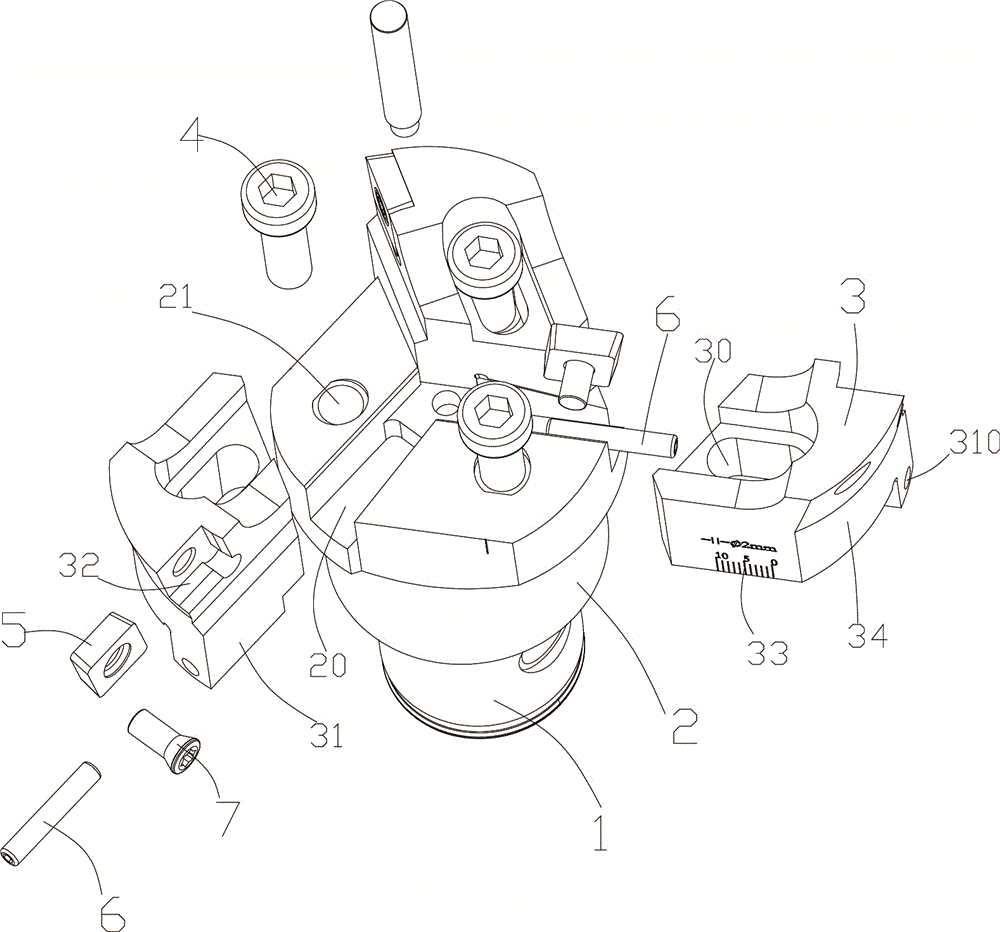

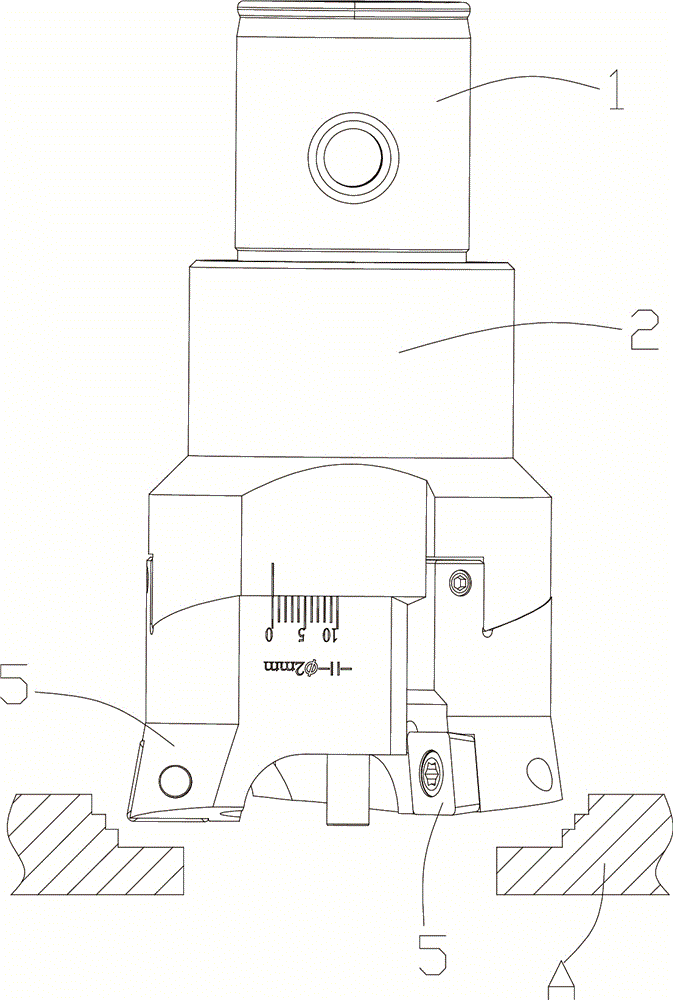

Heavy boring cutter

InactiveCN105772762AReduce wearIncrease feed rateCutting insertsTurning toolsEngineeringScrew thread

The invention discloses a heavy boring cutter and belongs to the field of machining cutters. The heavy boring cutter comprises a round handle inserted into a machine tool and a cutter bar; the cutter bar is provided with a plurality of sliding grooves, blade bases are arranged on the sliding grooves in a sliding mode and are provided with kidney-shaped holes, the cutter bar is provided with threaded holes corresponding to the kidney-shaped holes in position, fasteners penetrate through the kidney-shaped holes and are screwed into the threaded holes respectively for fixing the blade bases to the cutter bar, and blades are arranged on the blade bases. Compared with the prior art, when the heavy boring cutter is used for milling work-pieces, the blade bases on the heavy boring cutter can slide in the sliding grooves, the distance between the blade bases and the center of the cutter bar can be adjusted by adjusting a countersink screw according to the producing and machining requirements, then the diameters of bored holes can be adjusted, a higher feed rate can be realized for users, the blades are saved, the machining time is greatly shortened, the machining cost is lowered, the market prospect is wide, and the economic value is high.

Owner:NINGBO DANDERUI PRECISION MACHINERY TECH CO LTD

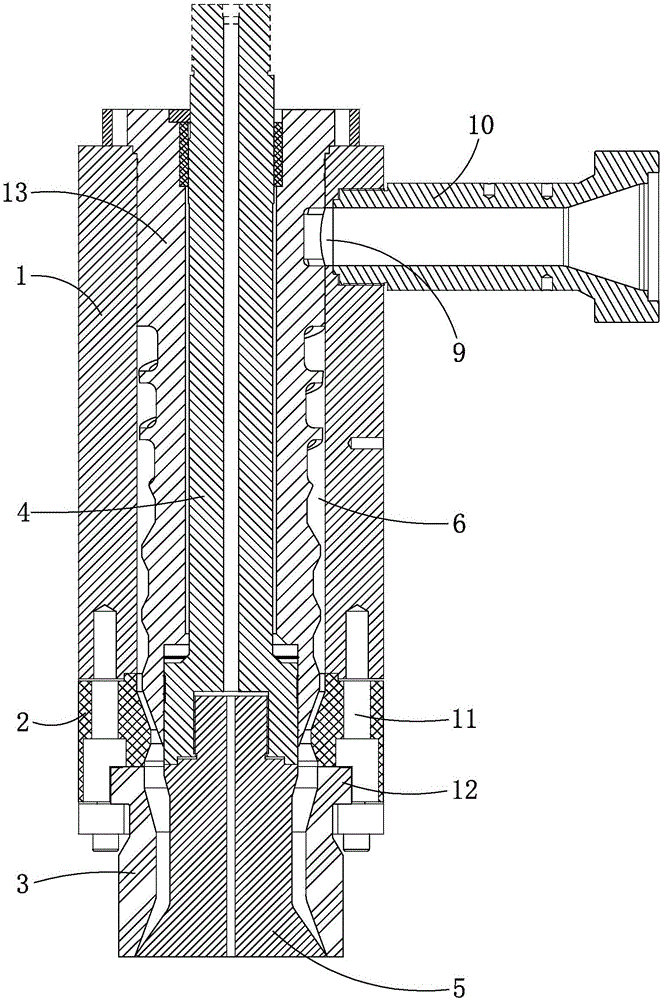

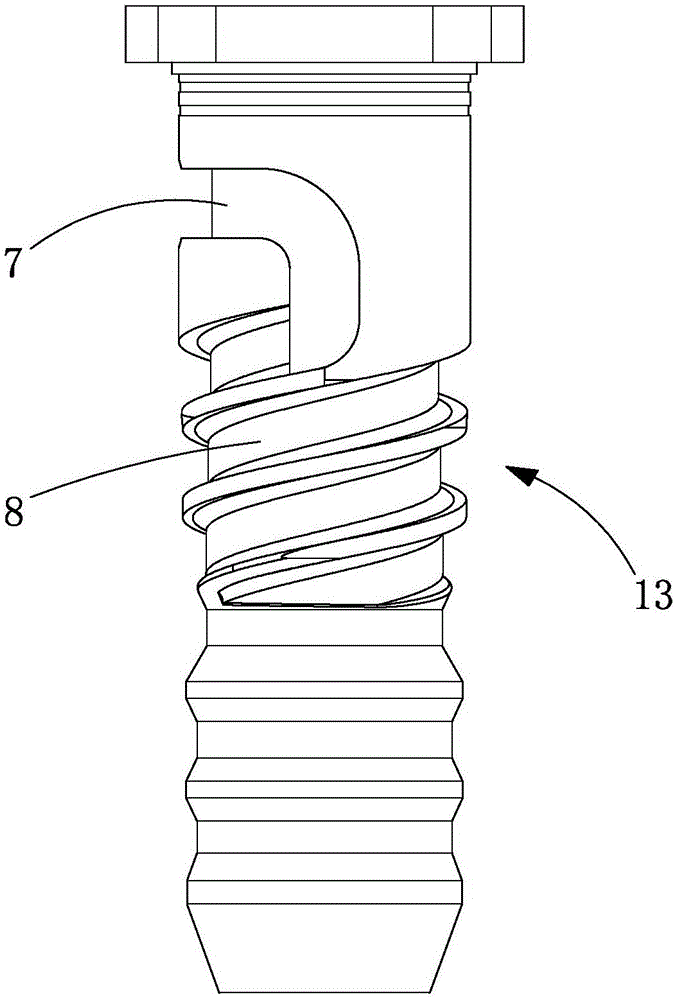

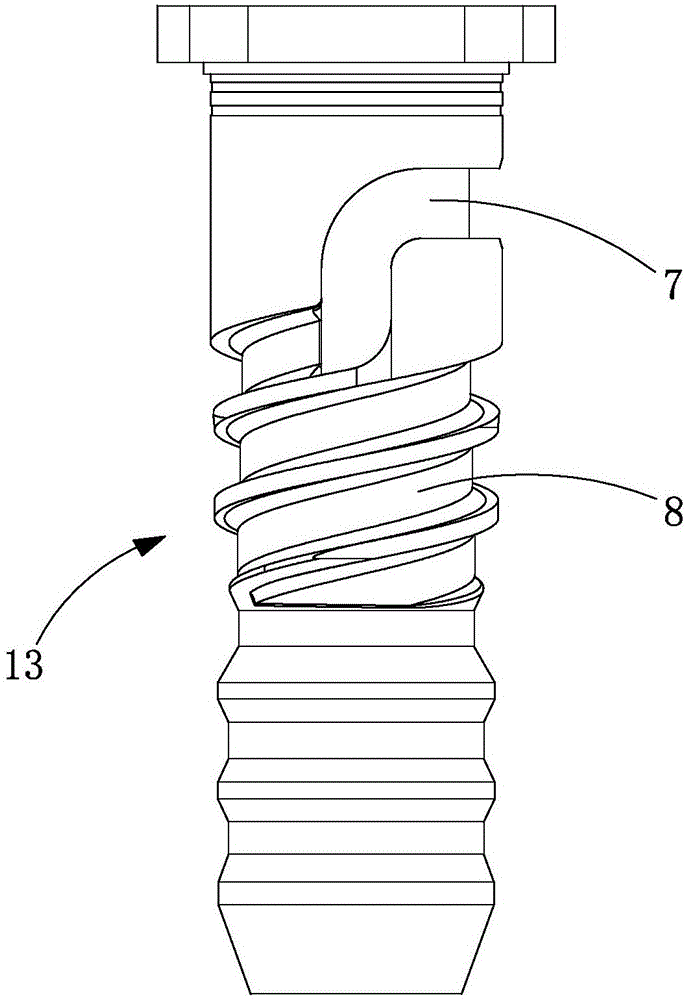

Side feeding spiral type continuous extrusion blow molding die head

The invention discloses a side feeding spiral type continuous extrusion blow molding die head. The side feeding spiral type continuous extrusion blow molding die head comprises an outer-layer structure and an inner-layer structure. The outer-layer structure comprises an outer die sleeve, an adjusting ring and an opening die, all of which are axially connected and installed in sequence. The inner-layer structure comprises a lifting rod and a core die which are axially connected and installed. The outer die sleeve, the adjusting ring and the opening die are each of an axis hollow structure. The lifting rod is collected in the outer die sleeve and the adjusting ring. The core die is collected in the opening die. The peripheral wall of the lifting rod is sleeved with a flow diverting spiral core which can axially and relatively move, and a material runner is formed between the outer wall faces of the flow diverting spiral core and the core die and the inner wall face of the outer-layer structure. A material groove is formed in the outer wall face of the flow diverting spiral core. The material groove comprises a feeding groove and multiple parallel spiral material distributing grooves, wherein all the spiral material distributing grooves communicate with the feeding groove and are arranged in parallel. A material is evenly divided into circular-ring-shaped non-weld-line pipe blanks after being diverted, the circular-ring-shaped non-weld-line pipe blanks continuously enter the die head along with the molten material, and the circular-ring-shaped pipe blanks are extruded out of the opening die to form pipe blanks meeting blow molding product technology requirements.

Owner:SUZHOU JWELL PLASTIC MACHINERY CO LTD

Stainless steel passivating agent

InactiveCN106191838AExcellent anti-rustGood surface finishMetallic material coating processesWeather resistancePotassium chlorate

The invention discloses a stainless steel passivating agent which consists of the following components in parts by weight: 1-2 parts of borax anhydrous, 0.9 part of potassium chlorate, 0.7 part of silicon-calcium powder, 4.9 parts of tannic acid, 1.8 parts of hydroxyl propyl methylcellulose, 2.3 parts of fatty amine polyoxyethylene ether, 1.1 parts of ammonium hexafluorotitanate, 1.3 parts of alkyl sodium sulfovinate, 0.7 part of titanyl sulfate and 44 parts of deionized water. The stainless steel passivating agent disclosed by the invention can be used for passivating treatment of metal, so that a uniform passivating protective film is formed on the surface of the metal; and the protective film has excellent rust protection, abrasion resistance, corrosion resistance, heat resistance, cold resistance, weather resistance, and is good in surface smoothness.

Owner:常熟市虞东磷化材料有限公司

Degradable plastic film and production method thereof

A degradable plastic film and a production method thereof, relating to the technical field of plastic extrusion blow molding, comprising drying crop straw fragments with a length of 1.5-2.0 mm and mixing them with plastics and plastic additives; plastics, natural plant fibers, plastics The additives are 60-70 parts, 20-30 parts and 5-10 parts respectively, and are extruded and granulated by a twin-screw extruder; the granules are fed into a single-screw extruder for film blowing. The formed film is uniform and stable, and can replace conventional plastic bags such as polypropylene. It has good surface finish, high strength, good toughness, and comfortable hand feeling. The invention can reduce the cost of degradable plastics, and the longest degradation period is 180 days.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

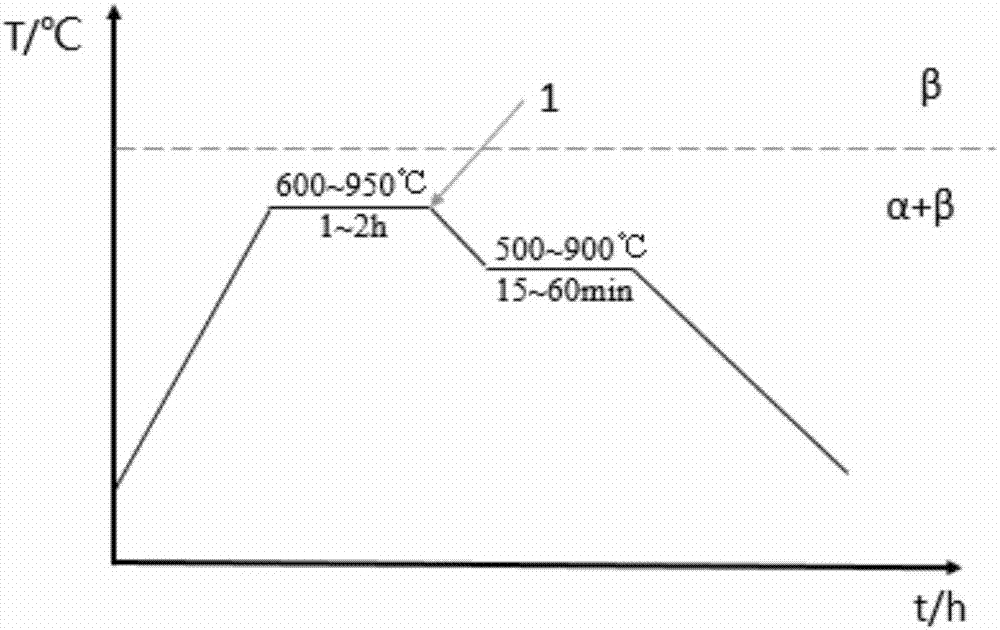

Temperature-control solidification method for Ti55 cast high-temperature titanium alloy

The invention discloses a temperature-control solidification method for Ti55 cast high-temperature titanium alloy. The method comprises the steps that a mould shell is heated in vacuum to 600-950 DEG C, the temperature is kept constant for 1-2 h, then, pouring is carried out, the metal liquid cooling speed is controlled in the solidification process, heat preservation is kept for 15-60 min at 500-900 DEG C, furnace cooling is carried out, and therefore the purpose of eliminating cracks in a casting process is achieved. Meanwhile, the obtained casting is better in surface smoothness, the mold filling performance and structure compactness of the titanium alloy casting are improved, and the cracking and deformation problems in the casting process are effectively eliminated.

Owner:重庆两航金属材料有限公司

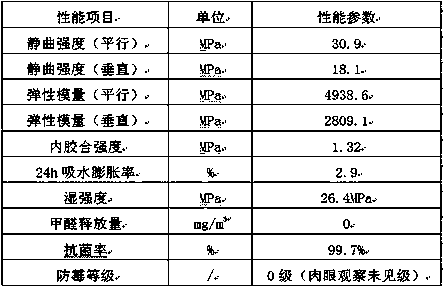

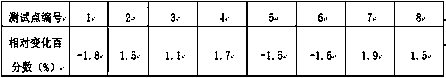

Waterproof antibacterial directional shaving board and preparation method thereof

InactiveCN110815485AThorough responseGood gluing propertiesFlat articlesDomestic articlesAnti bacterialFormaldehyde free

The invention provides a waterproof antibacterial directional shaving board. The waterproof antibacterial directional shaving board comprises an upper surface layer, a core layer and a lower surface layer, the mass ratio of the upper surface layer and the lower surface layer to the core layer is (60% to 75%):(25% to 40%), and the paving included angles between the upper surface layer and the corelayer as well as between the lower surface layer and the core layer are each 80-90 degrees. The invention further provides a preparation method of the waterproof antibacterial directional shaving board. The preparation method comprises the steps of shaving, drying, mixed spraying, drying, gluing, paving, liquid spraying and hot pressing, plate billet balancing, edge cutting, cooling, sanding and film forming. The waterproof antibacterial directional shaving board has the beneficial effects that a reaction between -NCO groups of isocyanate MDI glue in a board material of the waterproof antibacterial directional shaving board and -OH groups of shavings is complete, the gluing effect is good, and internal stress is uniformly distributed; the board material is good in overall stability, in thelong-term using or storage process, the phenomena of crack, layering, bulking and the like are avoided, and release of substances such as formaldehyde harmful to the human body is avoided; and bacterial resisting, mold preventing and insect preventing can be effectively achieved, and the antibacterial rate of the waterproof antibacterial directional shaving board reaches 99.1-99.7%.

Owner:寿光市鲁丽木业股份有限公司

Aluminum passivation agent

InactiveCN106119825AExcellent anti-rustGood surface finishMetallic material coating processesWeather resistanceMalonic acid

The invention discloses an aluminum passivation agent. The aluminum passivation agent is composed of, by weight, 1-2 parts of calcium chloride, 8.5 parts of malonic acid, 6.5 parts of organic phosphonic acid, 1.8 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 2.3 parts of hydroxypropyl cellulose, 2.1 parts of polyoxyethylene castor oil, 0.7 part of beta-naphthylamine, 1.5 parts of isodecanol polyoxyethylene ether, 1.1 parts of titanium (IV) acetylacetonate and 40 parts of deionized water. The aluminum passivation agent can be used for passivation treatment of metal, a uniform passivation protective film is formed on the surface of the metal, and the protective film has excellent antirust performance, friction resistance, corrosion resistance, heat resistance, cold resistance and weather resistance and is good in surface degree of finish.

Owner:常熟市虞东磷化材料有限公司

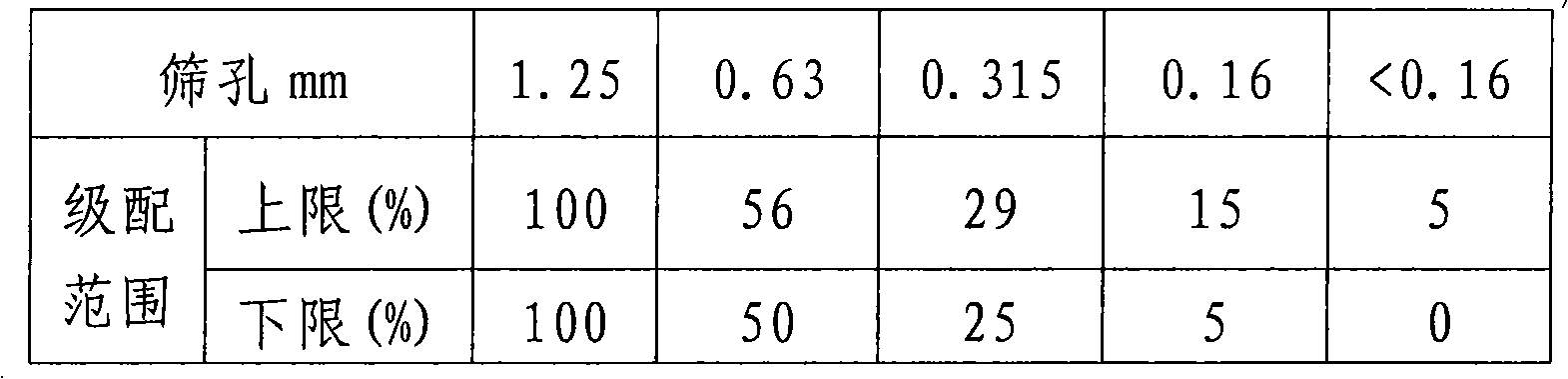

Reactive powder concrete for cable trough cover boards of railways

The invention provides reactive powder concrete (RPC) for cable trough cover boards of railways, and belongs to the technical field of building materials. In order to solve the problem of high construction cost of reactive powder concrete used for the conventional railway construction, the invention adopts a technical scheme that: the reactive powder concrete is prepared from the following raw materials in part by weight: 625 to 690 parts of cement, 1,120 to 1,200 parts of quartz sand, 140 to 162 parts of water, 295 to 320 parts of admixture special for the RPC, 85 to 140 parts of steel fiber and 33 to 38 parts of polycarboxy acid admixture with the solid content more than or equal to 30 percent through stirring, vibrating and curing. Compared with the conventional products, the reactive powder concrete can reduce cost by about 500 yuan / cubic meter.

Owner:CHINA RAILWAY NO 17 BUREAU GRP

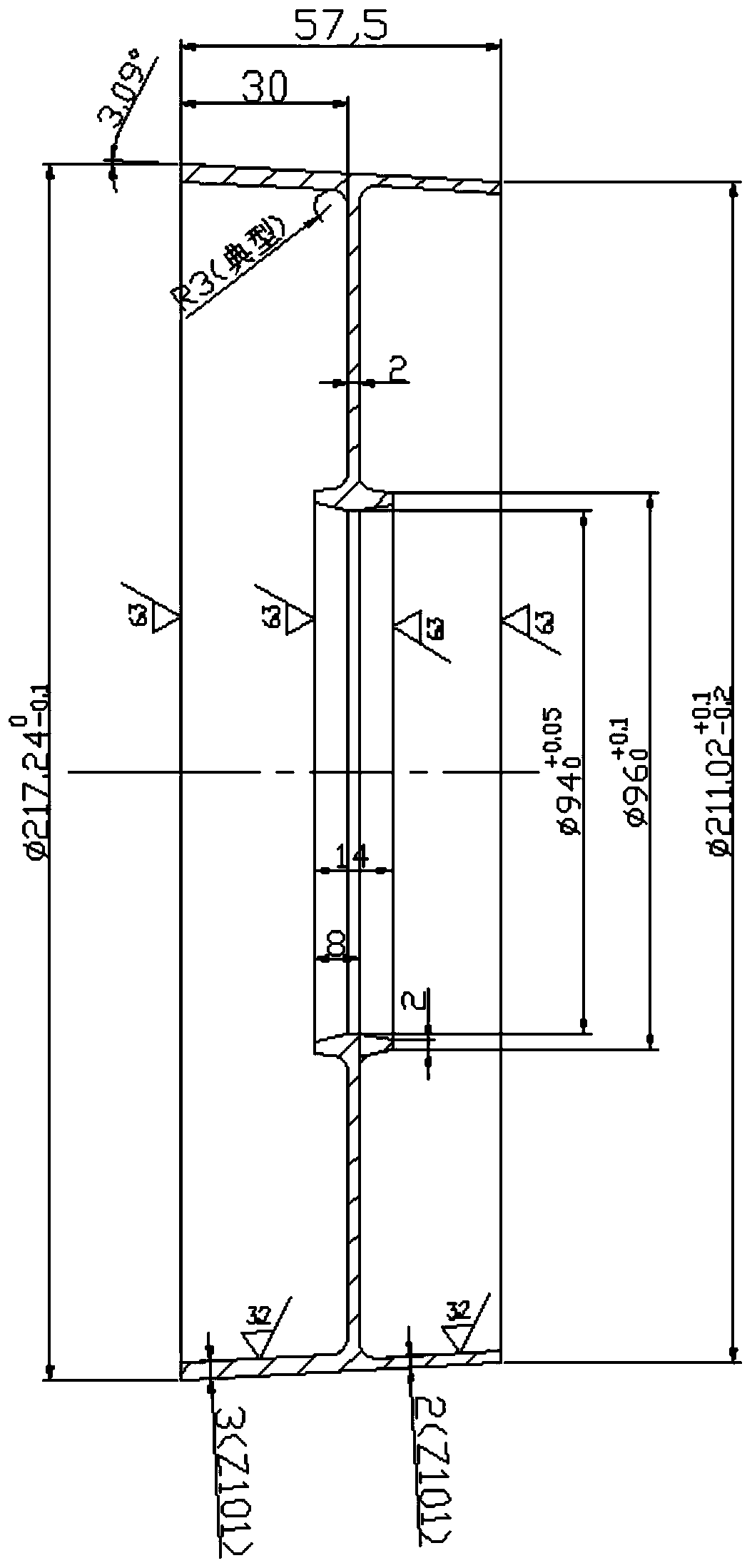

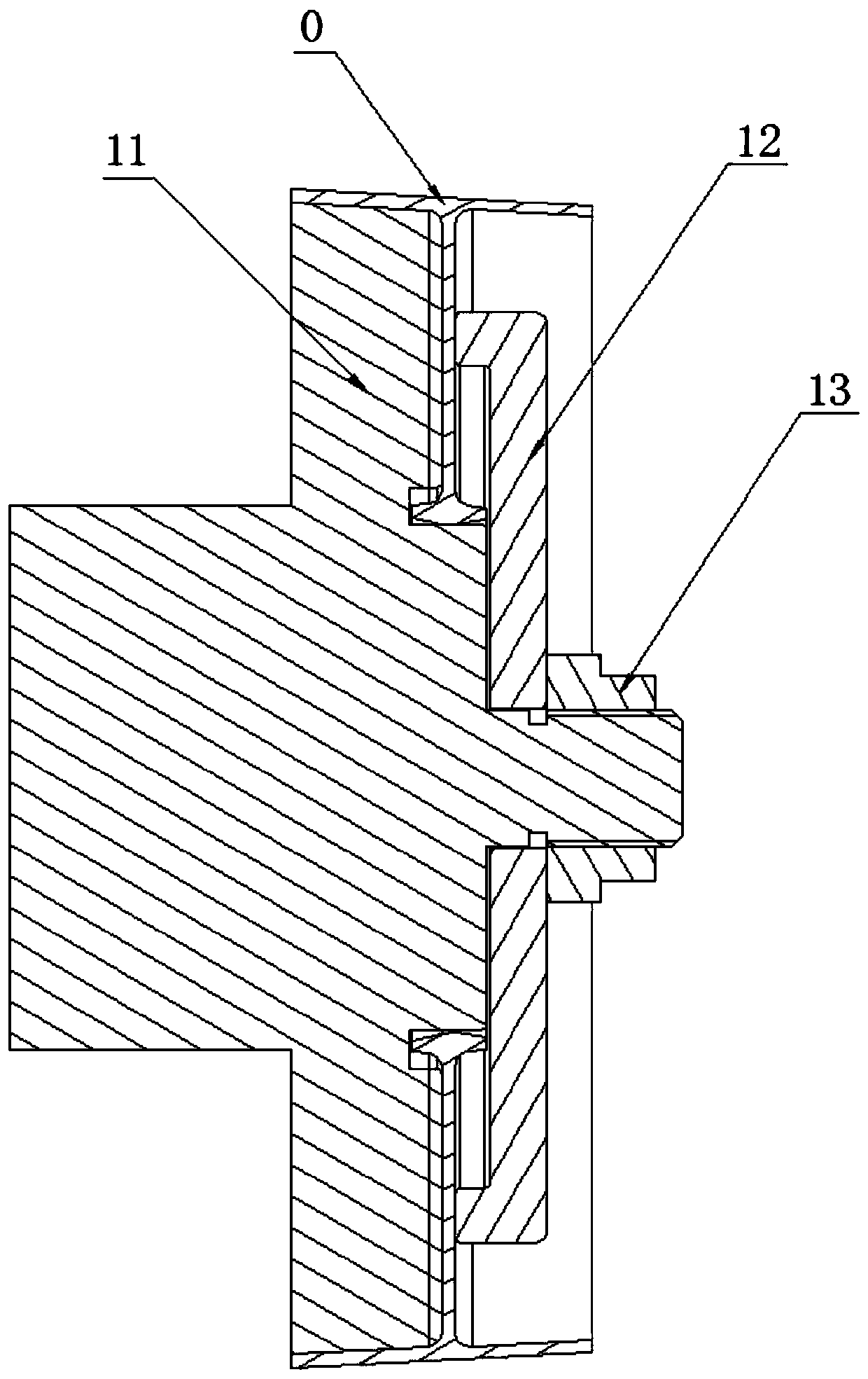

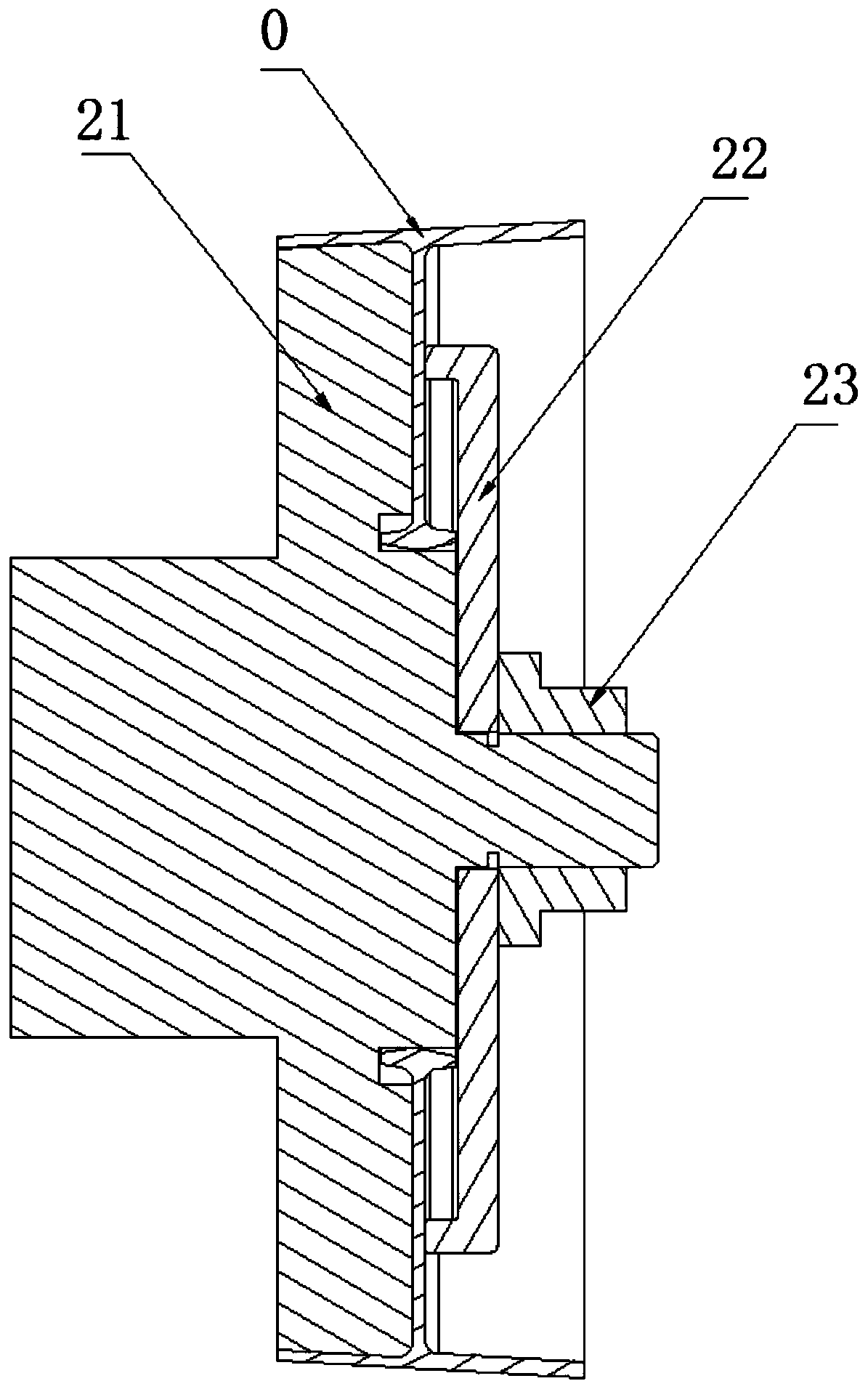

Method for machining aluminum alloy large-diameter thin-wall rotation part

ActiveCN110340378AGood consistencyGood surface finishTurning machinesLarge apertureSurface smoothness

The invention discloses a method for machining an aluminum alloy large-diameter thin-wall rotation part. The method comprises the steps that an external circle of a workpiece is clamped, and inner holes and the external circle of the workpiece are roughly machined; the inner hole in one end of the workpiece and the inner hole in the other end of the workpiece are roughly turned; the external circle of the workpiece is clamped, an inner cavity in the large-aperture end of a conical hole of the workpiece and a root circular bead are subjected to semi-finish turning, middle connecting ribs and through holes of the workpiece are subjected to finish turning, and the aperture and angle of the conical hole are detected through a sample plate after semi-finish turning is carried out; truing aroundis carried out to clamp the external circle of the workpiece, the clamping depth exceeds the middle connecting rib, and the middle connecting rib at the small-aperture end of the conical hole of theworkpiece is subjected to finish turning; the large-aperture end of the conical hole of the workpiece is positioned through a first positioning tool, the appearance of the taper of the outer ring of the workpiece is subjected to finish turning, and an inner cavity in the small-aperture end of the conical hole of the workpiece and a root circular bead are subjected to finish turning at the same time; and the inner cavity in the large-aperture end of the conical hole is subjected to finish turning again until the wall thickness meets the design requirement. The part machined through the method is high in consistency, good in surface smoothness and very high in product precision.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

Nickel chrome wire

InactiveCN107841740AGood antioxidantGood surface finishMetallic material coating processesIonChemistry

The invention discloses a nickel chrome wire which is passivated. The passivating treatment comprises the following steps: (1) feeding 1 to 2 weight parts of alkyl polyoxyethylene oxide, 0.7 weight part of disodium hydrogen phosphate, 3.2 weight parts of tannic acid, 1.1 weight parts of sodium persulfate and 0.8 weight part of lauryl trimethyl ammonium chloride into 25 weight parts of deionized water in sequence for uniform stirring; (2) then feeding 1.3 weight parts of benzotriazole, 4.2 weight parts of polyacrylic acid, 1.3 weight parts of isomerous tridecanol polyoxyethylene ether phosphate, 0.3 weight part of zinc dihydrogen phosphate and 0.7 weight part of zinc dialkyl dithiophosphate in sequence, continuously stirring the components till the components are fully and uniformly mixed,thus preparing a passivating treatment solution; and (3) putting the nickel chrome wire into the passivating treatment solution for passivating treatment at treatment temperature of 50 DEG C for 30 s,taking out the nickel chrome wire, cleaning the nickel chrome wire with pure water, and drying the nickel chrome wire. The nickel chrome wire disclosed by the invention is high in performance after being subjected to the passivating treatment, and is high in surface smoothness.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

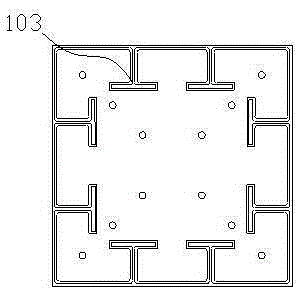

Environment-friendly and energy-saving plastic shell cement quadrel

InactiveCN105256685AImprove toughness and strengthGood surface finishSingle unit pavingsSidewalk pavingsEngineeringSurface smoothness

The invention discloses an environment-friendly and energy-saving plastic shell cement quadrel, which comprises plastic shells, the plastic shells are filled up with cement, the plastic shells are seamlessly connected with one another, reinforcing rib plates are arranged in the plastic shell, the reinforcing rib plate is arranged in the form of a T, eight reinforcing rib plates are arranged, and are evenly distributed on the four sides of the plastic shell, the surface of the plastic shell is provided with an anti-slip pattern, the anti-slip pattern is composed of a plurality of small rectangles, more than one drain hole is arranged, and the drain holes have the same size, and are evenly distributed on the plastic shell. The appearance of the environment-friendly and energy-saving plastic shell cement quadrel does not have apparent cracks, the number of air holes is less as well, and the environment-friendly and energy-saving plastic shell cement quadrel has the advantages of high toughness and strength, good surface smoothness and long service life.

Owner:李春奎

Static var generator for electrical equipment

InactiveCN106349791AExcellent abrasion resistanceGood surface finishFireproof paintsAnti-corrosive paintsIonChemistry

The invention discloses static var generator for electrical equipment. The static var generator comprises a metal shell, and the metal shell is subjected to film mulching processing. The film mulching processing comprises the following steps: (1) sequentially pouring 1-2 parts by weight of inositol hexaphosphate, 2.6 parts by weight of itaconic acid, 1.8 parts by weight of sodium pyrophosphate and 0.8 part by weight of fatty alcohol-polyoxyethylene ether into 50 parts by weight of deionized water to uniformly stir; (2) then sequentially pouring 8.9 parts by weight of diethylene glycol, 10.9 parts by weight of methyl methacrylate, 1.2 parts by weight of secondary alkyl sodium sulfonate and 0.8 part by weight of calcium gluconate, and continuously stirring to be fully and uniformly mixed to prepare film mulching processing liquid; and (3) placing the metal shell in the film mulching processing liquid to steep, taking out and drying. With the adoption of the static var generator used for the electrical equipment, the surface of the metal shell is covered with a protective film, the performance is good, and the surface smoothness is good.

Owner:苏州菲斯特电力科技有限公司

Fruit and vegetable cleaning agent

InactiveCN111363634AGood surface finishGood protectionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBiotechnologyOrganic acid

The invention relates to the technical field of cleaning agents, and concretely relates to a fruit and vegetable cleaning agent. The cleaning agent is prepared from, by weight, 1-5 parts of an organicacid, 1-2 parts of a chelating agent, 3-8 parts of a surfactant, 0.5-2 parts of a corrosion inhibitor, 30-40 parts of an inorganic base, and the balance of water. The cleaning agent provided by the invention not only has very strong cleaning and degreasing performance on the surfaces of fruits and vegetables, but also has relatively good surface protection performance, is non-corrosive, has a good cleaning effect, and has very strong practical value.

Owner:山东海天生物化工有限公司

Golf ball

InactiveUS7059977B2Good surface finishHigh surface finishGolf ballsSolid ballsEthylene acrylic acidMixture formation

In a golf ball comprising a core and a cover of one or more layers, the cover or its layer is formed primarily of a mixture comprising a blend of (a) an ionomer resin in the form of an alkali metal-neutralized ethylene-acrylic acid copolymer and (b) an olefin-unsaturated carboxylic acid copolymer or an olefin-unsaturated carboxylic acid-unsaturated carboxylate copolymer, and (c) a thermoplastic elastomer. The golf ball exhibits good surface finish and has improved rebound, feel and durability.

Owner:BRIDGESTONE SPORTS

Preparation method of metal filament with high porosity

InactiveCN106345838AGood surface finishHigh tear strengthFurnace typesMetallic material coating processesSodium carbonateMetal filament

The invention discloses a preparation method of a metal filament with high porosity. The preparation method comprises a first step of selecting a raw metal wire as a raw material; a second step of delivering the raw metal wire to a rough wire drawing machine to draw; a third step of immersing the metal wire in the sodium carbonate solution and then draining off; a fourth step of delivering the dried metal filament to a first annealing furnace to anneal; a fifth step of delivering the metal wire after the first annealing to the wire drawing machine to draw; a sixth step of immersing the metal filament in the sodium carbonate solution and then draining off for the second time; a seventh step of delivering the dried metal wire to a second annealing furnace to anneal; an eighth step of delivering the metal wire after the second annealing to a tiny wire drawing machine to draw; a ninth step of delivering the metal wire after the tiny wire drawing to a third annealing furnace to anneal, and then obtaining the metal filament. Diameter of the metal filament can reach 0.025 mm, the surface smoothness is good, the tear strength is high, and flexibility is good; moreover, the percentage elongation can reach 30%-40%; meanwhile, the porosity is more than 50%, aperture is less than 50Mum, and open hole rate is 90% above.

Owner:桥运精密部件(苏州)有限公司

High-resistance electrothermal alloy

InactiveCN107794521AGood antioxidantGood surface finishMetallic material coating processesIonBenzene

The invention discloses high-resistance electrothermal alloy which is subjected to passivation treatment. Passivation treatment comprises the following steps that (1) 1-2 parts by weight of organic amine alkali, 1.5 parts by weight of barium metaborate, 1.1 parts by weight of boric anhydride, 0.7 part by weight of sodium bromite and 1.6 parts by weight of ethylene glycol monostearate are sequentially put into 25 parts by weight of deionized water and uniformly stirred; (2) 1.2 parts by weight of dioscorea cirrhosa lour residue extractive, 0.8 part by weight of sodium hexametaphosphate, 1.2 parts by weight of sec-alkyl sodium sulfate, 2.3 parts by weight of carbamide and 1.7 parts by weight of benzotriazole are added into the mixture obtained in the step (1), and stirring continues till theadded components are uniformly mixed, and passivation treating fluid is obtained; and (3) the high-resistance electrothermal alloy is put in the passivation treating fluid to be subjected to passivation treatment at the temperature of 50 DEG C for 30 s, and then the high-resistance electrothermal alloy is taken out, cleaned with pure water and dried. The high-resistance electrothermal alloy is good in performance and surface smoothness after being subjected to passivation treatment.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

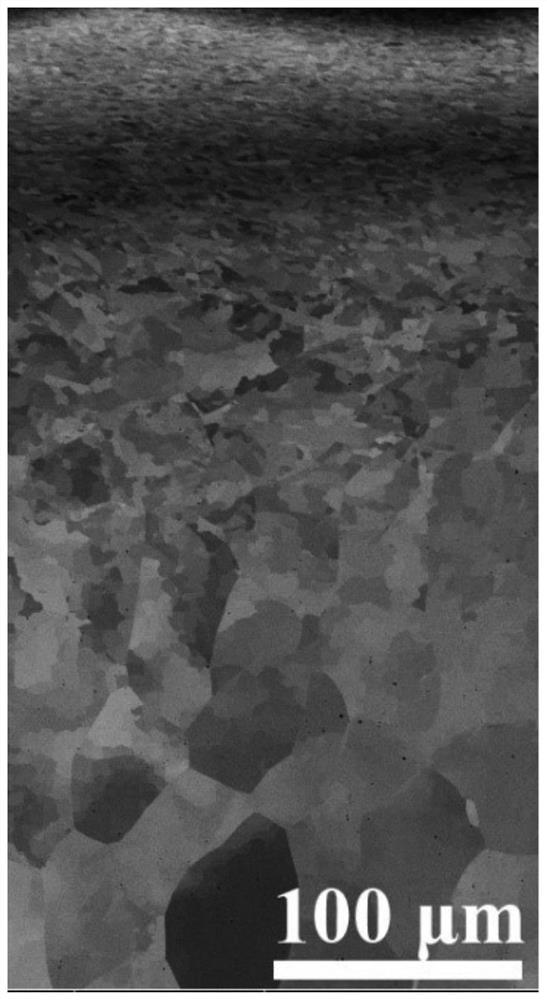

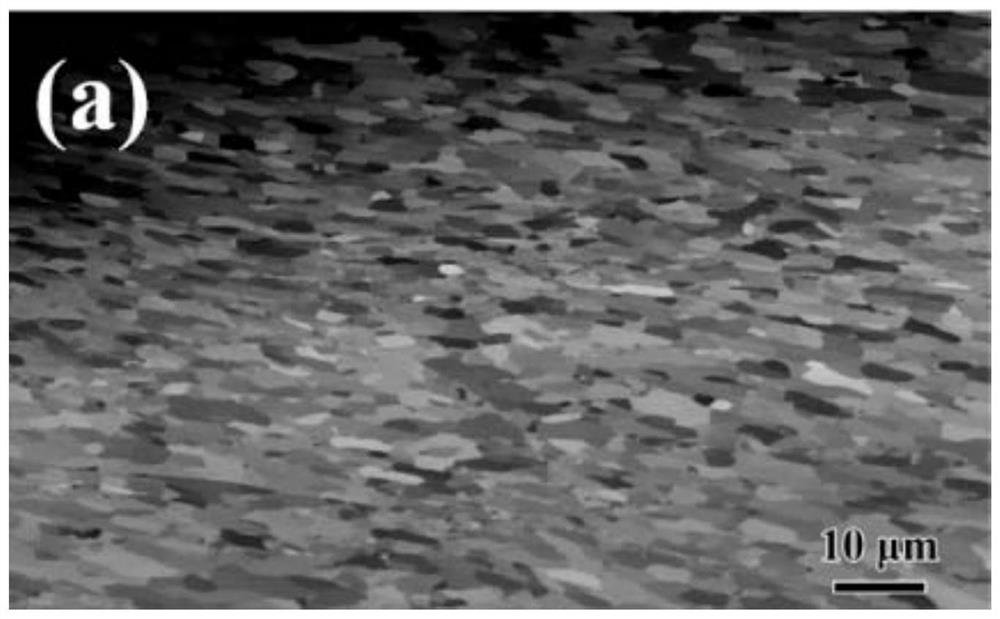

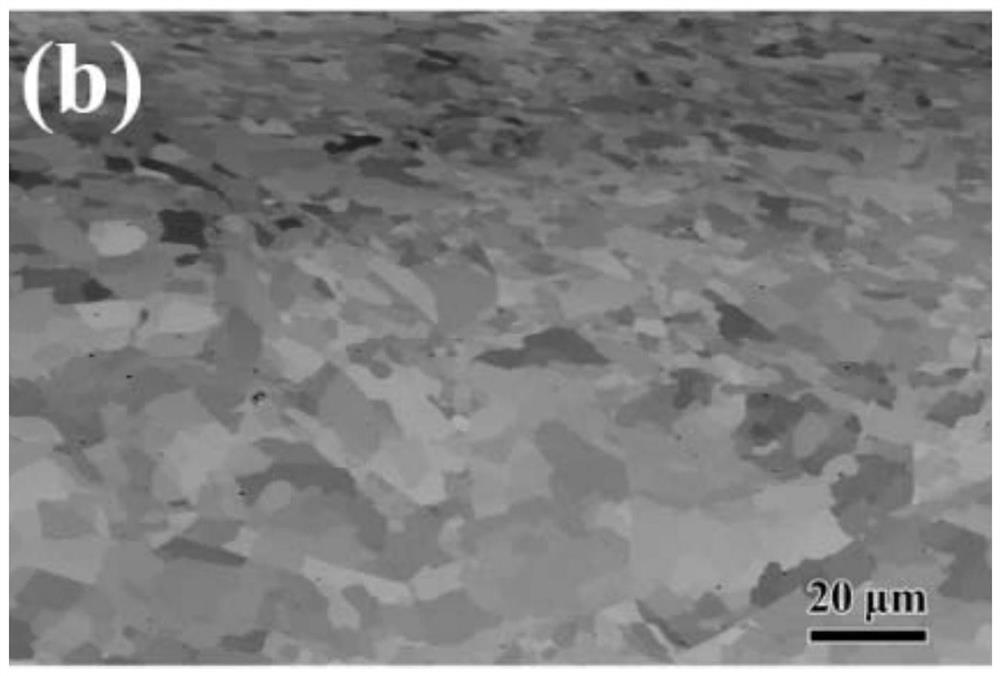

Tungsten-based alloy with grain size having gradient effect and preparation method of tungsten-based alloy

The invention discloses a tungsten-based alloy with a grain size gradient effect and a preparation method of the tungsten-based alloy, and belongs to the field of alloy material preparation. The product is of a body-centered cubic structure, the grain size has a gradient effect, the depth range related to the gradient effect is 100-500 microns, the grain morphology from surface layer ultra-fine grains to internal coarse grains of the material is formed, and the characteristic structure that the grain size is uniformly and gradually transited to 50 microns from 0.5 microns is formed. The hardness value of the product is gradually transited to 3.5-4.5 GPa of the matrix from 4.5-6.5 GPa of the surface layer, the excellent wear resistance of the product is guaranteed, the interior of the product has certain toughness, the strength and plasticity during use are effectively considered, uneven strain caused by local plastic deformation is coordinated, and wear is inhibited. The invention further discloses a preparation method of the product, through special thermal deformation treatment, a grinding process and annealing treatment, the product has good processability, and meanwhile, no crack is generated.

Owner:GUANGDONG UNIV OF TECH

Novel decoration board with acrylic sheet layer on surface

InactiveCN109304912AGood surface finishGood anti-corrosion performanceDomestic upholsterySynthetic resin layered productsEnvironmental resistanceThin sheet

The invention discloses a novel decoration board with an acrylic sheet layer on the surface. The novel decoration board comprises a substrate board layer, a reactive PU (Polyurethane) hot-melt adhesive layer, a PVC (Polyvinyl Chloride) layer and an acrylic sheet layer. An acrylic sheet adopted has high plane smoothness, is bright as a mirror, and can be adjusted at any time in patterns according to the demands of customers. The decoration board has high strength, and is insusceptible to deformation. The decoration board can be applied to indoor decoration, indoor furniture, cabinets and the like instead of ordinary decoration boards, and the application range of the acrylic decoration board is enlarged greatly. Meanwhile, the need of secondary decoration of the existing ordinary artificialboard is omitted, so that the pollution caused by secondary decoration is avoided, and health and environment protection are facilitated.

Owner:严晓凤

Traffic sign

InactiveCN106283002AExcellent anti-rustGood surface finishMetallic material coating processesIonChemistry

The invention discloses a traffic sign of which a metal plate main body is subjected to passivating treatment. The passivating treatment comprises the following steps: 1) sequentially adding 1-2 parts by weight of phosphate, 4.1 parts by weight of phosphorus tungsten heteropoly acid, 5.1 parts by weight of fluorozirconic acid, 0.9 part by weight of sodium benzoate and 1.3 parts by weight of hydrogen peroxide into 30 parts by weight of deionized water, and stirring uniformly; 2) sequentially adding 3.6 parts by weight of hexyl decanol, 1.6 parts by weight of alkyltrimethylammonium methylsulfate, 1.8 parts by weight of 1-hydroxybenztriazole, 2.5 parts by weight of alkylphenol polyoxyethylene and 4.1 parts by weight of dipropanediol, continuing stirring and sufficiently mixing uniformly to obtain a passivating treatment solution; and 3) putting the metal plate main body in the passivating treatment solution, carrying out passivating treatment at 37 DEG C for 43 seconds, taking out, cleaning with pure water, and drying. The metal plate main body of the traffic sign is subjected to passivating treatment, so the traffic sign has favorable properties and favorable surface smoothness.

Owner:常熟市古里镇白茆新兴网印标牌厂

Metal casting mold release agent

The invention discloses a metal casting mold release agent. The release agent comprises, by weight, 15-26 parts of acrylic acid, 9-22 parts of ammonium persulfate, 8-30 parts of mercaptopropionic acid, 12-28 parts of methoxy polyethylene glycol methacrylate, 10-16 parts of glycerinum, 22-35 parts of fatty alcohol-polyoxyethylene ether, 7-12 parts of petroleum sulfonic acid, 2-4 parts of oxidized polyethlene wax and 12-25 parts of ethyl alcohol. The agent has the beneficial effects that sectional materials after mold release are good in surface smoothness.

Owner:TAICANG XIAOXIAO PRECISION MOLD CO LTD

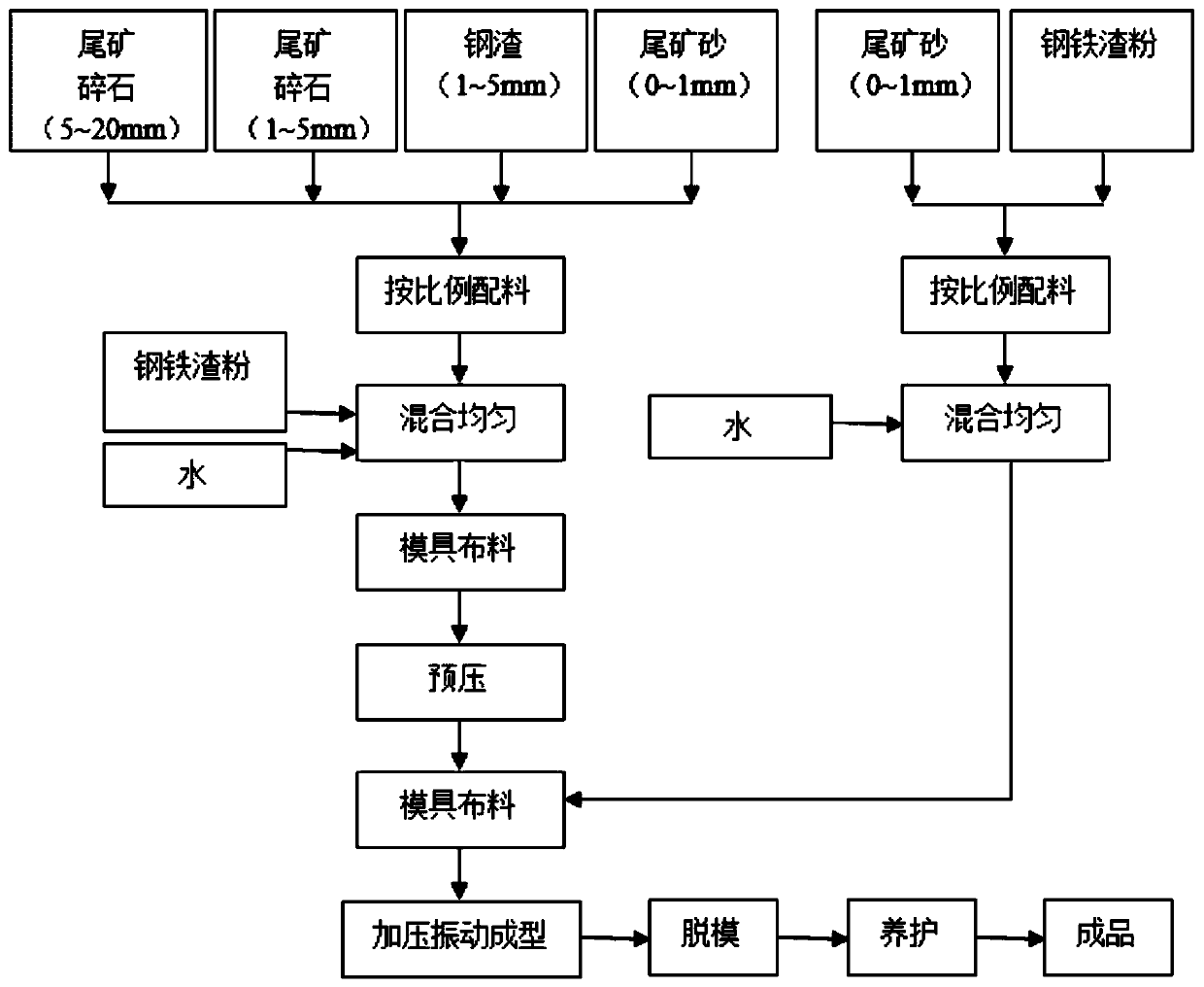

Preparation method of all-solid-waste ecological slope protection brick

ActiveCN110818370AGood surface finishImprove waterproof performanceCoastlines protectionCeramic shaping apparatusMaterials preparationBrick

The invention discloses a preparation method of an all-solid-waste ecological slope protection brick, belonging to the field of solid waste resource utilization. The method comprises the following four steps: blank preparation, surface material preparation, brick preparation, and maintenance forming. The slope protection brick meeting use requirements is successfully prepared by completely adopting metallurgical solid waste resources according to reasonable proportions and process parameters obtained through layered pressing, vibration pressure forming and multiple tests; and preparation costis extremely low, and the metallurgical solid waste resources are recycled.

Owner:MAANSHAN IRON & STEEL CO LTD

Warehousing shelf for supermarkets

InactiveCN106349787AGood heat resistanceGood surface finishFireproof paintsAnti-corrosive paintsRackingIon

The invention discloses a warehousing shelf for supermarkets, comprising a metal shelf body; the metal shelf body is subjected to laminating treatment; the laminating treatment includes the steps of 1) adding 1-2 parts by weight of tri(2-ethylhexyl)acetocitrate, 1.5 parts by weight of sorbitol, 1.9 parts by weight of Upsilon-methacryloxypropyltrimethoxysilane and 0.9 part by weight of dimethyldistearylammonium chloride sequentially into 43 parts by weight of deionized water, and stirring well; 2) adding 8.9 parts by weight of ethanol, 9.7 parts by weight of dipropylene glycol, 2.2 parts by weight of fatty alcohol polyoxyethylene ether and 3.8 parts by weight of dibutyl succinate, and continuing to stir until full mixing to obtain a laminating liquid; 3) soaking the metal shelf body in the laminating liquid, removing, and drying. The metal shelf body of the warehousing shelf for supermarkets has the surface coated with a protective film, the good properties are provided, and the surface is highly glossy.

Owner:常熟市古里镇淼泉大光金属制品厂

Treble block for hoisting machinery

InactiveCN106317983AExcellent anti-rustGood surface finishFireproof paintsAnti-corrosive paintsIonChemistry

The invention discloses a treble block for hoisting machinery. The treble block comprises a metal axle, which is treated by coating. The coating comprises the steps of 1) adding 1-2 parts of N- phenyl- 2- naphthylamine (by weight), 2.2 parts of itaconic acid (by weight), 1.8 parts of hydroxypropyl cellulose (by weight), 0.7 parts of sodium alkylary sulfonate (by weight) in 45 parts of deionized water (by weight) in sequence and mixing even; 2) Adding 4.1 parts of methyl acrylate (by weight), 9.8 parts of coplymer terpolymer of acrylic resin and polyurethane (by weight), 1.3 parts of alkyl sodium sulfonate (by weight), 0.5 parts of sodium molybdate (by weight) and mixing even to obtain the coating solution; 3) Soaking the metal axle in the coating solution, getting out and letting it dry. The treble block for hoisting machinery has a coating on the surface, with good performance and surface smoothness.

Owner:CHANGSHU SHUANGLING MARINE EQUIP CO LTD

Composition for metal surface treatment and environment-friendly treatment method thereof

InactiveCN105779993AGood processing effectGood surface finishMetallic material coating processesIonActive agent

The invention provides a composition for metal surface treatment and an environment-friendly treatment method thereof. The composition for metal surface treatment is characterized by comprising the following components in percentage by weight: 4-10 parts of silicate, 3-9 parts of Bi ions, 2-5 parts of chitosan, 1-2 parts of active agents, 3-5 parts of antioxidants, 3-7 parts of lubricants, 2-5 parts of coalescing agents, 5-12 parts of ethanol and the balance of water. The composition for metal surface treatment, provided by the invention, enables the surface treatment to become cleaner. The degreasing treatment is firstly performed to remove grease on a metal surface, so that the smoothness of next operation is guaranteed, and the treatment effect is better. Such operations as passivation and protective film spraying are performed after soaking of the composition; and a protective film is formed on the metal surface again after treatment, so that the surface smoothness of metal can be preferably kept, the interior of the metal can be preferably isolated from the exterior, the metal is prevented from being corroded, and the service life of the metal is prolonged.

Owner:TIANJIN ZHONGDING ALUMINUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com