Aluminum alloy welding wire surface scraping method and device

A technology of aluminum alloy welding wire and welding wire, applied in welding equipment, metal processing equipment, welding medium, etc., can solve problems such as spattering, insufficient surface finish, welding wire smoke, etc., achieve good surface finish, prevent black spots and splashes, and equipment The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

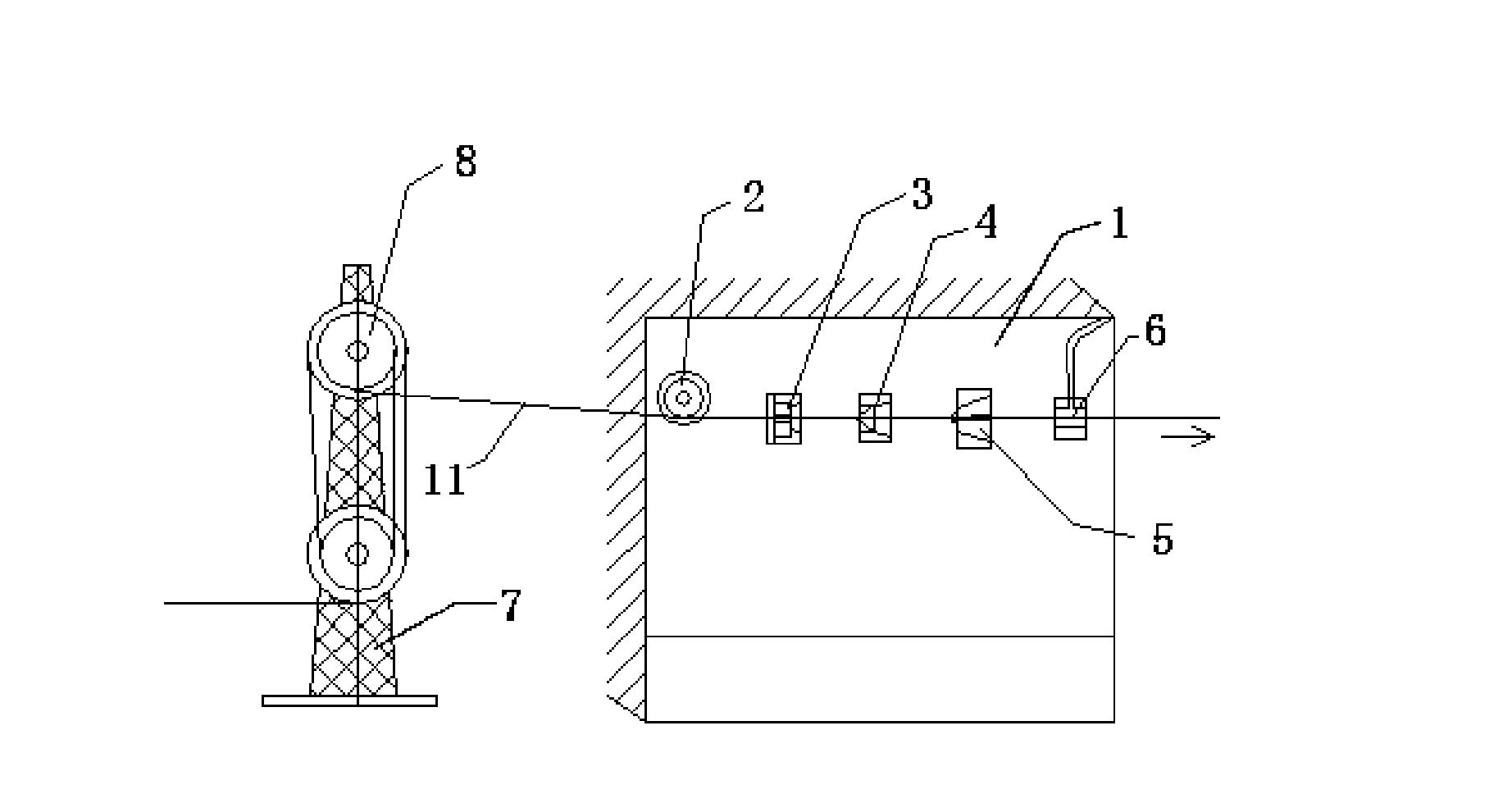

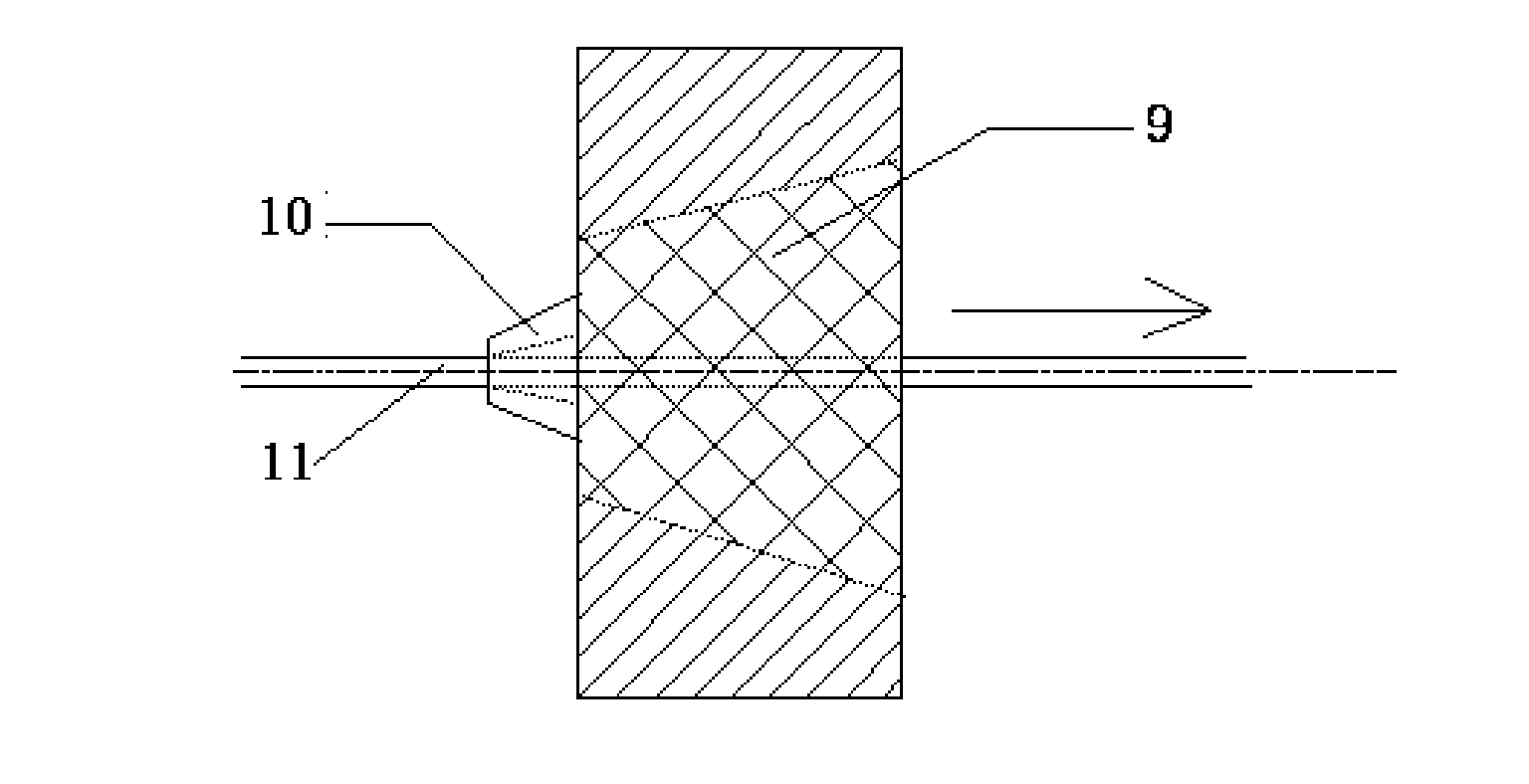

[0027] Embodiment 1: A kind of aluminum alloy welding wire surface scraping equipment of this example is used for preparing the aluminum alloy welding wire of ¢0.8, such as figure 1 , there is a frame 1, and the interior of the frame 1 is connected with a positioning wheel 2, a wiping die 3, a rough scraping die 4, a fine scraping die 5, and a cooling device 6 in sequence. The distance between the positioning wheel and the wiping die is 200mm, the distance between the wiping die and the rough scraping die is 120mm, and the distance between the rough scraping die and the fine scraping die is 120mm. The positioning wheel can locate the welding wire 11, the wiping die can wipe off the oil stain on the surface of the welding wire and the fine metal dust left by the wire drawing, the rough scraping die can rough scrape the welding wire 11, and the fine scraping die can finely scrape the welding wire. Such as figure 2, the rough scraping mold 4 includes a rough scraping mold cover...

Embodiment 2

[0035] Embodiment 2: A kind of equipment for scraping the surface of aluminum alloy welding wire in this example is used to prepare aluminum alloy welding wire of ¢0.9mm. The rough scraping die 4 includes a rough scraping die head 10, which has a bell mouth capable of scraping welding wire 11 in the rough scraping die head, and the diameter of the small mouth of the bell mouth is ¢0.915mm. The fine-scraping die includes a fine-scraping die head, and a bell mouth that can scrape welding wire is opened inside the fine-scraping die head. All the other are with embodiment 1.

[0036] A method of scraping the surface of an aluminum alloy welding wire in this example is used to prepare an aluminum alloy welding wire of ¢0.9mm, and the steps are as follows:

[0037] a. Pass the ¢0.92mm welding wire through the pay-off device, and then enter the positioning wheel of the scraping equipment for positioning;

[0038] b. Feed the positioned welding wire into the wiping mold for mechanic...

Embodiment 3

[0043] Embodiment 3: A kind of equipment for scraping the surface of aluminum alloy welding wire in this example is used to prepare aluminum alloy welding wire of ¢1.0mm. The rough scraping die 4 includes a rough scraping die head 10, which has a bell mouth capable of scraping welding wire 11 in the rough scraping die head, and the diameter of the small mouth of the bell mouth is ¢1.025mm. The fine scraping die includes a fine scraping die head, which has a bell mouth that can scrape welding wire. The diameter of the small mouth of the bell mouth is ¢1.0mm of the diameter of the unscraped welding wire. All the other are with embodiment 1.

[0044] A method of scraping the surface of an aluminum alloy welding wire in this example is used to prepare an aluminum alloy welding wire of ¢1.0mm, and the steps are as follows:

[0045] a. Pass the ¢1.03mm welding wire through the pay-off device, and then enter the positioning wheel of the scraping equipment for positioning;

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com