Patents

Literature

677results about How to "Excellent anti-rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

ActiveUS20120031528A1Improve crash performanceHigh yield stressHot-dipping/immersion processesFurnace typesUltimate tensile strengthImpurity

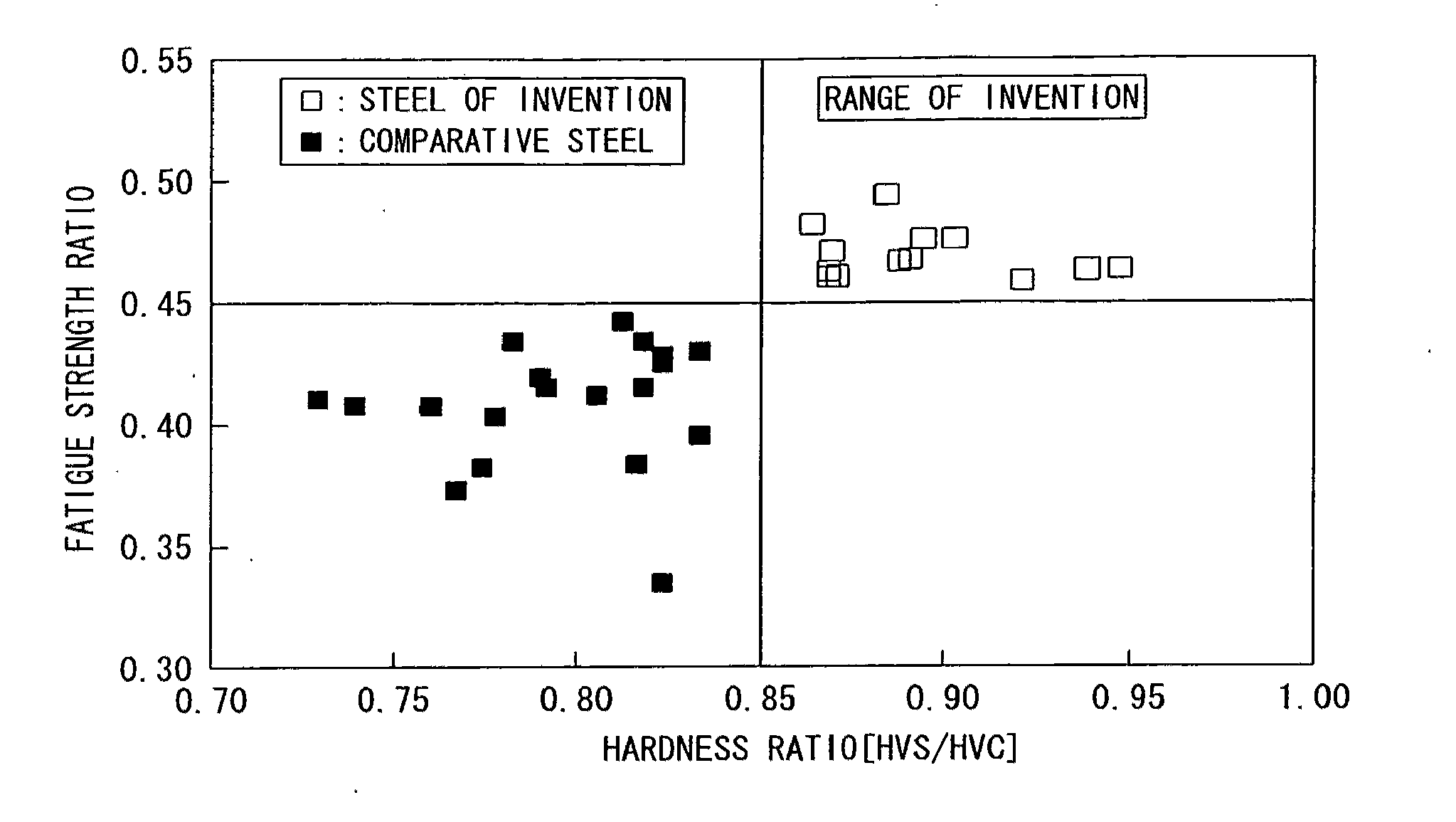

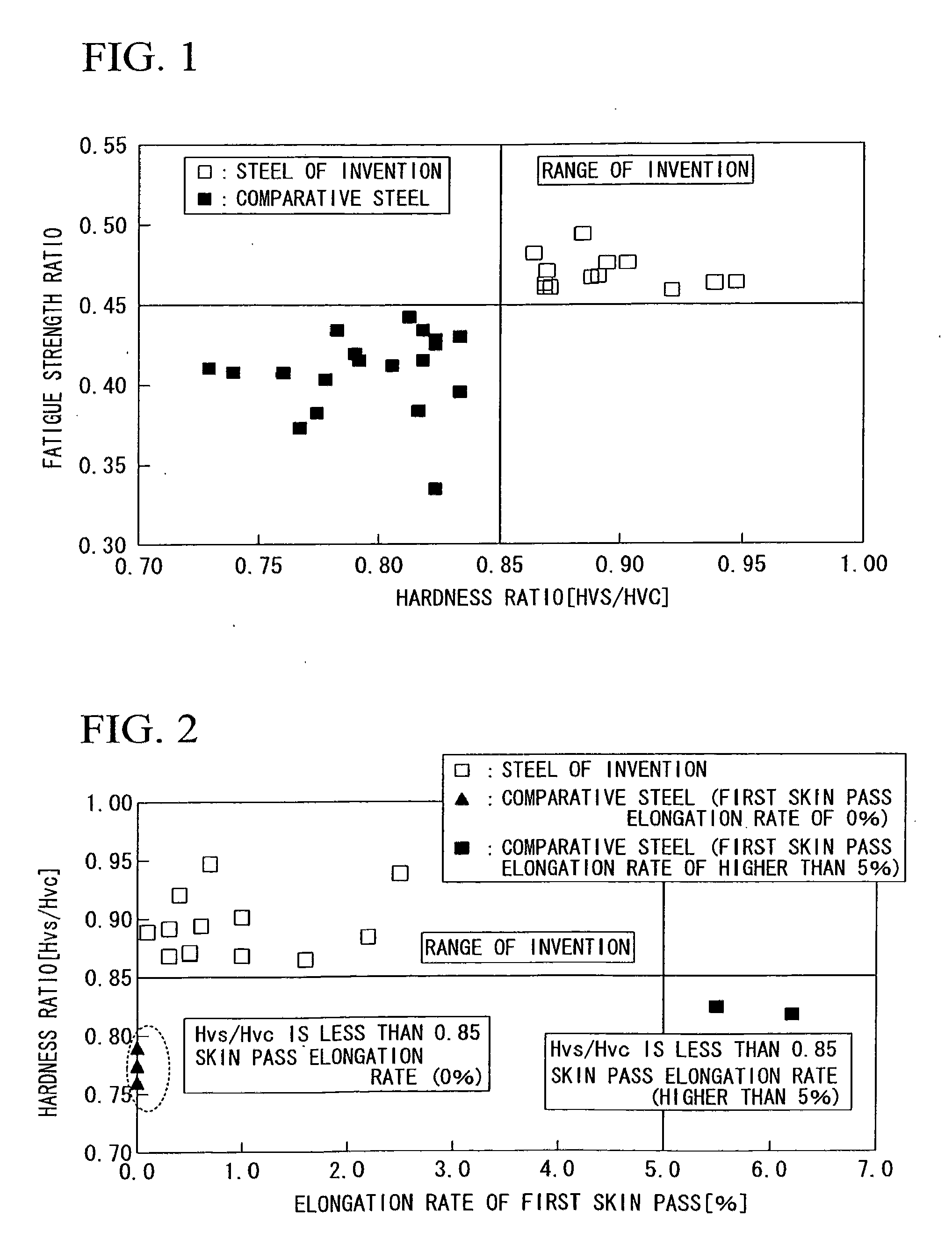

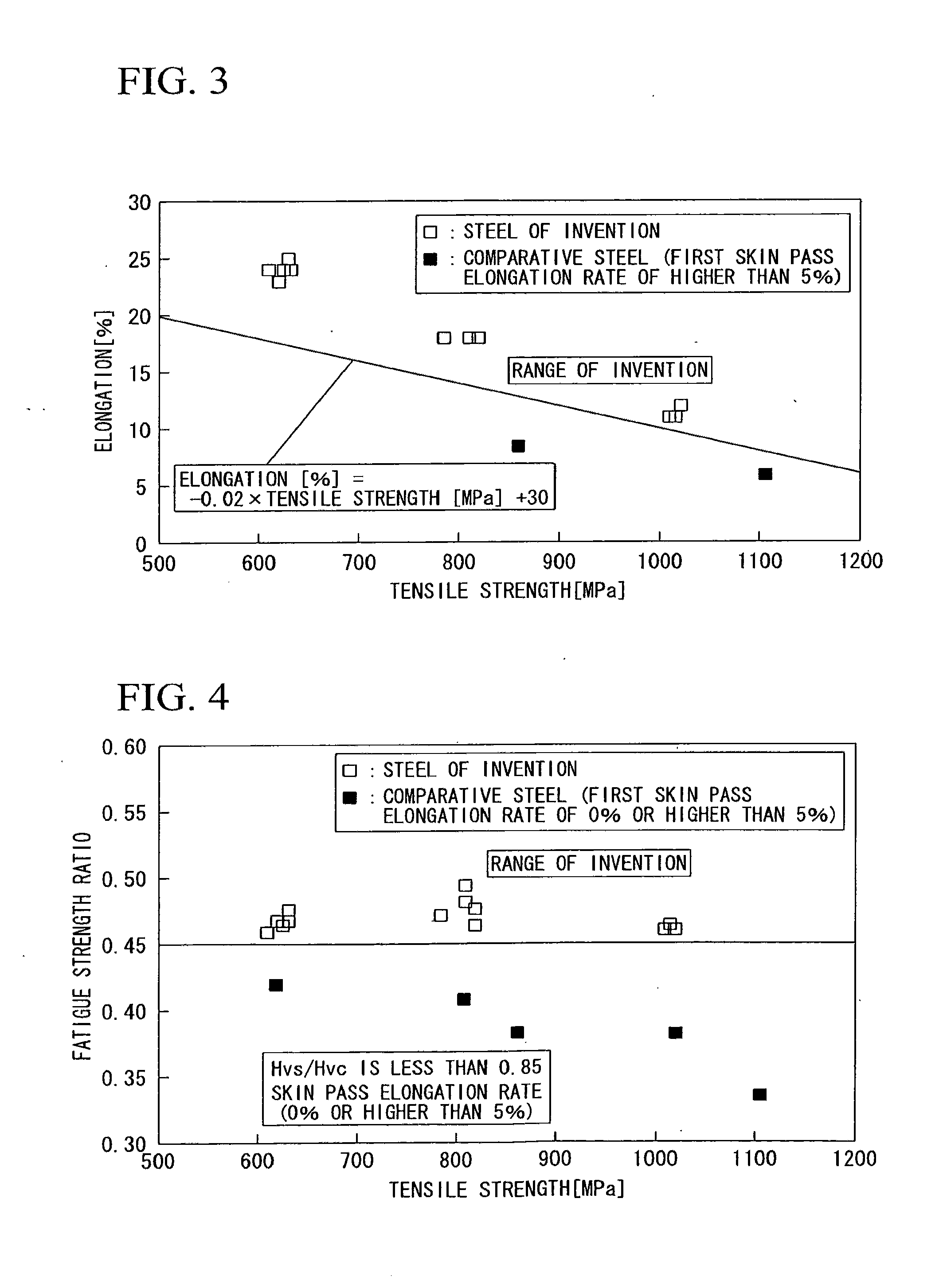

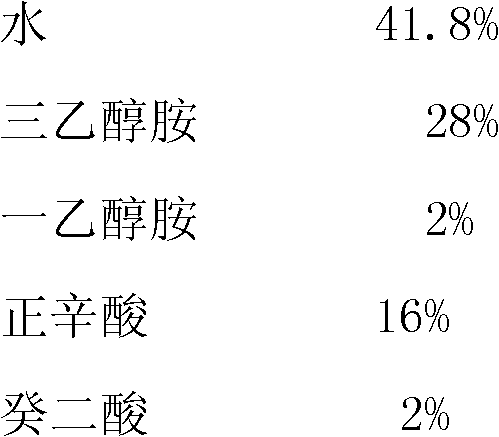

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

Environment-friendly water-based cleaning agent

The invention discloses an environment-friendly water-based cleaning agent which is characterized by comprising the following components in percentage by weight: 15-60% of antirust agent, 5-20% of surfactant, 0.1-0.5% of nonferrous metal corrosion inhibitor, 0-0.5% of bactericide and the balance of water. The environment-friendly water-based cleaning agent disclosed by the invention has the beneficial effects of no toxicity or phosphorus, excellent antirust performance, favorable inter-process antirust effect, wide application range, suitability for cleaning various metals including black metal, aluminum alloy and copper alloy, no corrosion to nonferrous metal, excellent cleaning capability for oil stain with higher viscosity, long service cycle and effective range, simplicity and practicability in use and maintenance, multiple functions for efficiently removing oil, preventing rusting and the like, no harm to body health and no adverse effect on the environment.

Owner:LOCKS LUBE SHANGHAI

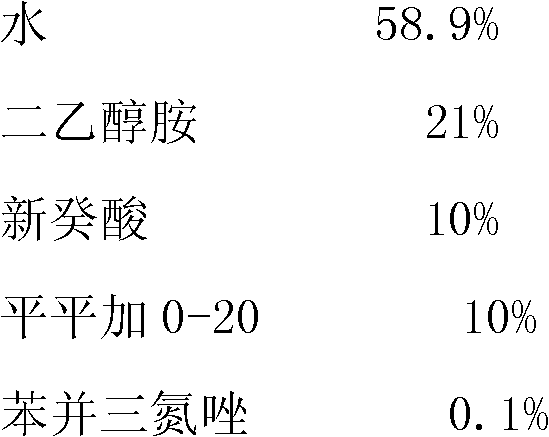

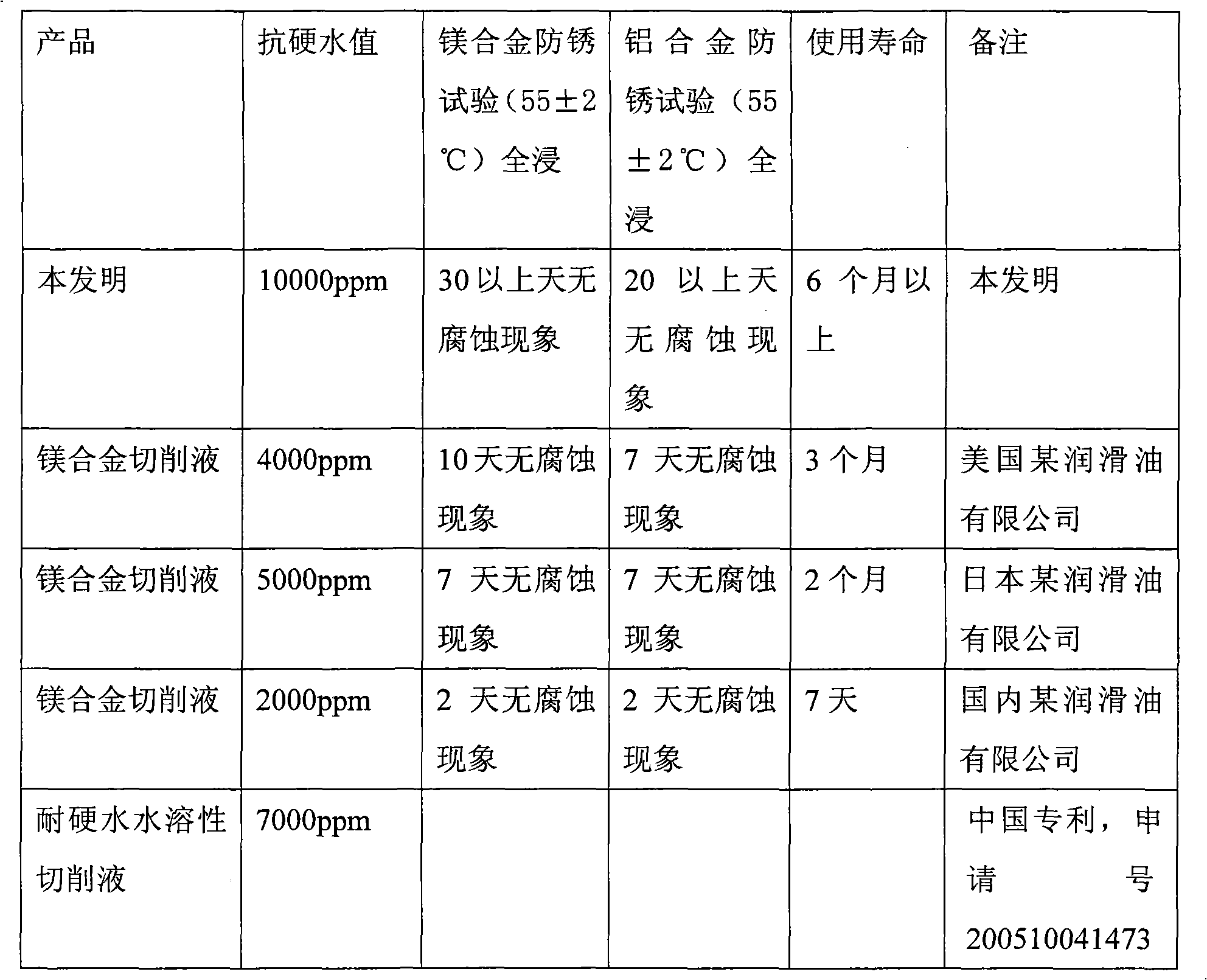

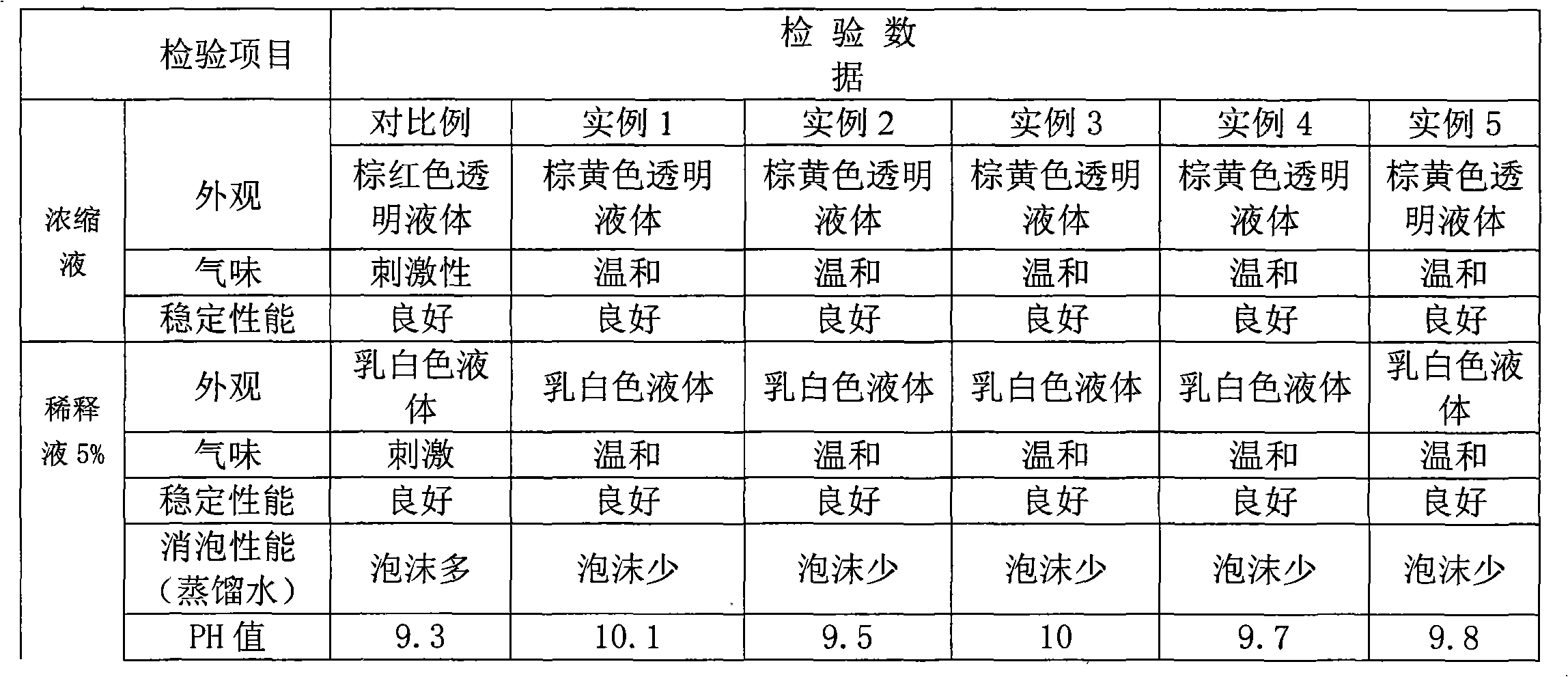

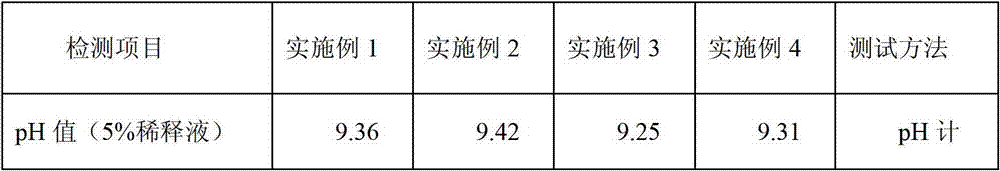

Magnesium alloy cutting liquid

ActiveCN101870909AImprove rust resistanceInhibition of hydrogen evolutionAdditivesColor changesCast iron

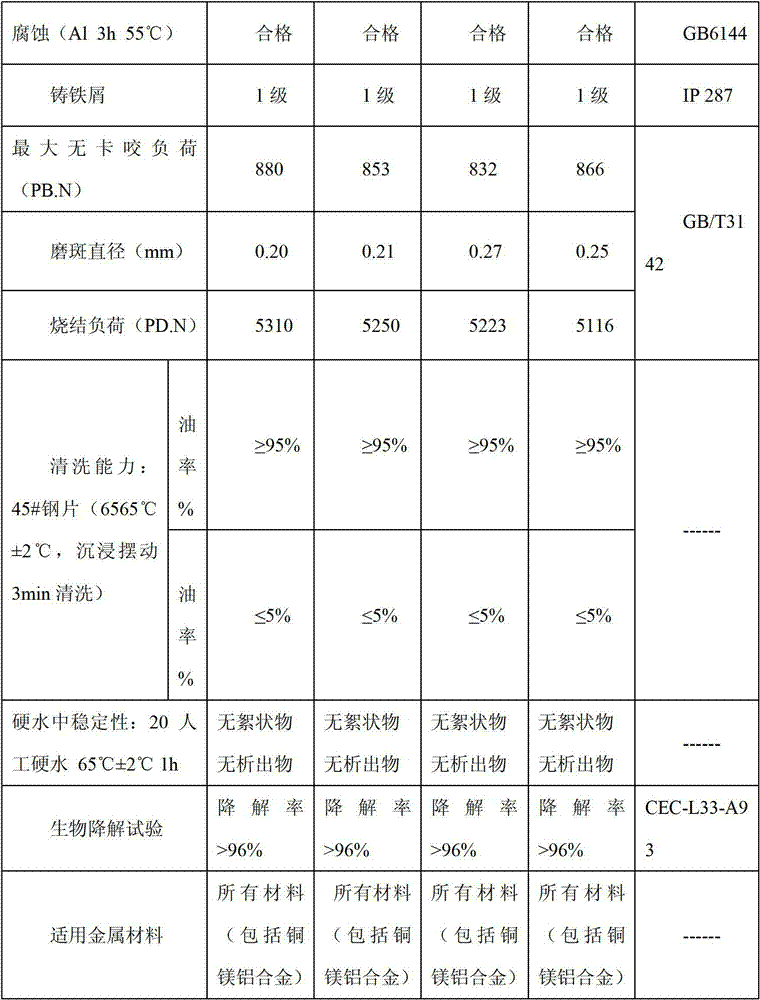

The invention relates to metal cutting liquid, in particular to magnesium alloy cutting liquid, which comprises basic oil, nonionic surfactants, anionic surfactants, antirust agents, lubricating agents, coupling agents, corrosion inhibitors and bactericide raw materials. The unique recipe in the invention has the advantages that magnesium alloy can no generate color change corrosion phenomena after being continuously soaked for more than 30 days at 55 DEG C in 5 percent diluent, the hydrogen release phenomenon of the magnesium alloy in water can be effectively inhabited, in addition, the hardwater resistance of the product is as high as 10000 ppm, and in addition, the work liquid can be used for more than half a year. At the same time, the invention has excellent performance such as rust prevention, lubrication, cooling and the like. In addition, the cutting liquid can be used for processing the magnesium alloy, and can also be used for processing metals such as aluminium alloy, cast iron, stainless steel and the like.

Owner:东莞太平洋博高润滑油有限公司

Composite lithium base lubricant and its preparing method

ActiveCN1616612AGood mechanical stabilityGood colloidal stabilityBase-materialsLithium soapLithium hydroxide

The composite lithium-base lubricating grease consists of the following components: high alkality calcium sulfonate with calcium carbonate existing in calcite crystal and dispersed colloid particle form in 20-60 wt%; thickener comprising composite lithium soap in 3-15 wt%; and lubricating base oil in the rest amount. The preparation process of the lubricating grease includes mixing and heating Newtonian fluid high alkality calcium sulfonate, converting agent and base oil until thickening; adding C12-C24 fatty acid and auxiliary acid and producing saponification with lithium hydroxide aqua; heating to dewater and cooling to form grease. The composite lithium-base lubricating grease of the present invention has excellent mechanical stability, colloid stability, water resistance, rust resistance and high temperature use performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

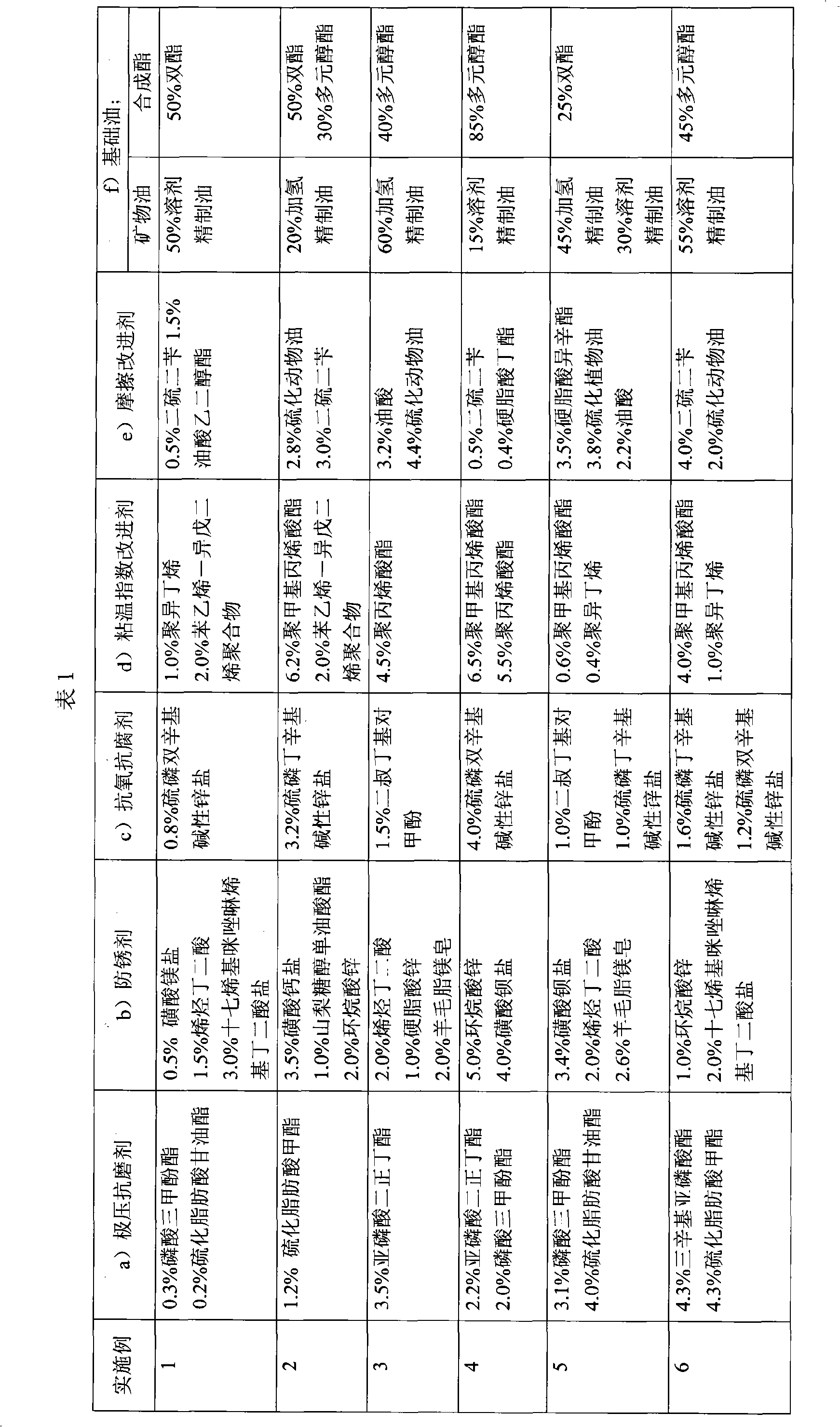

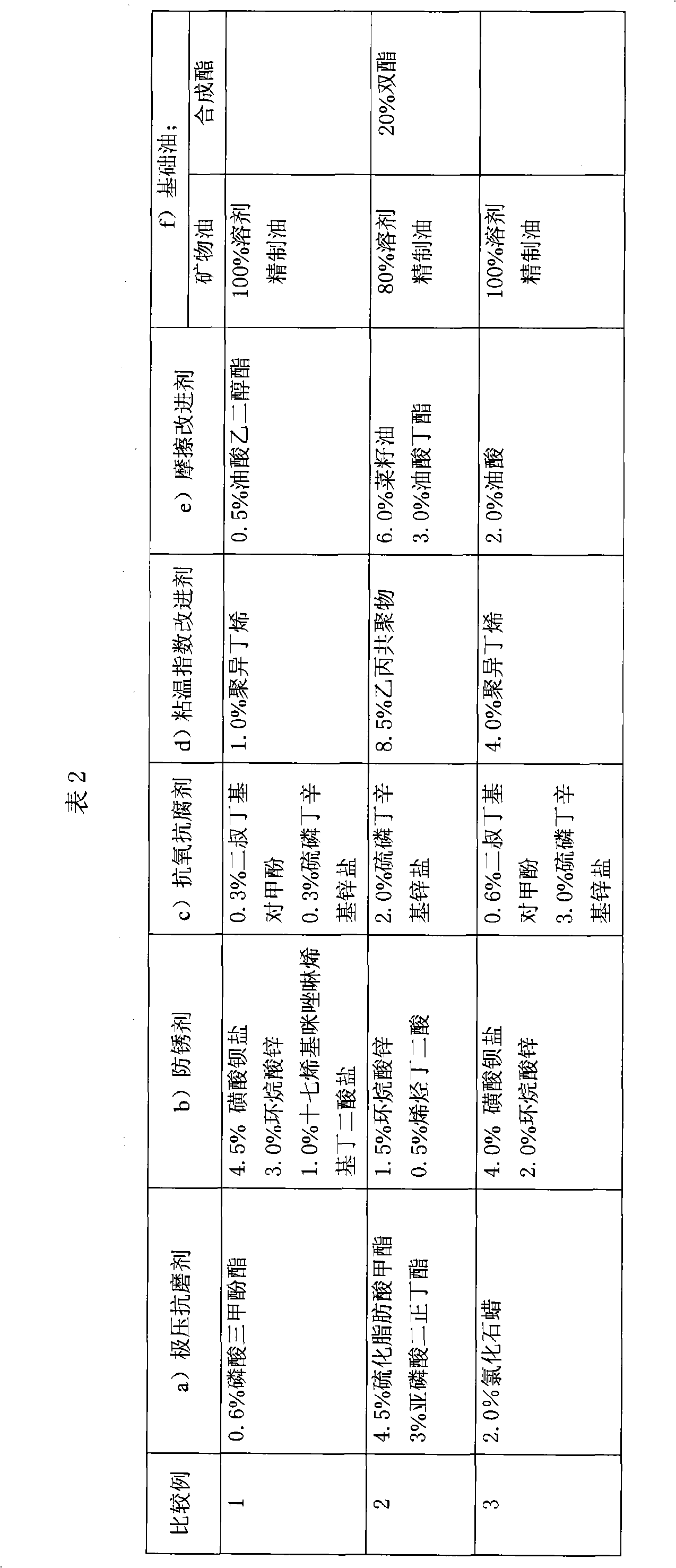

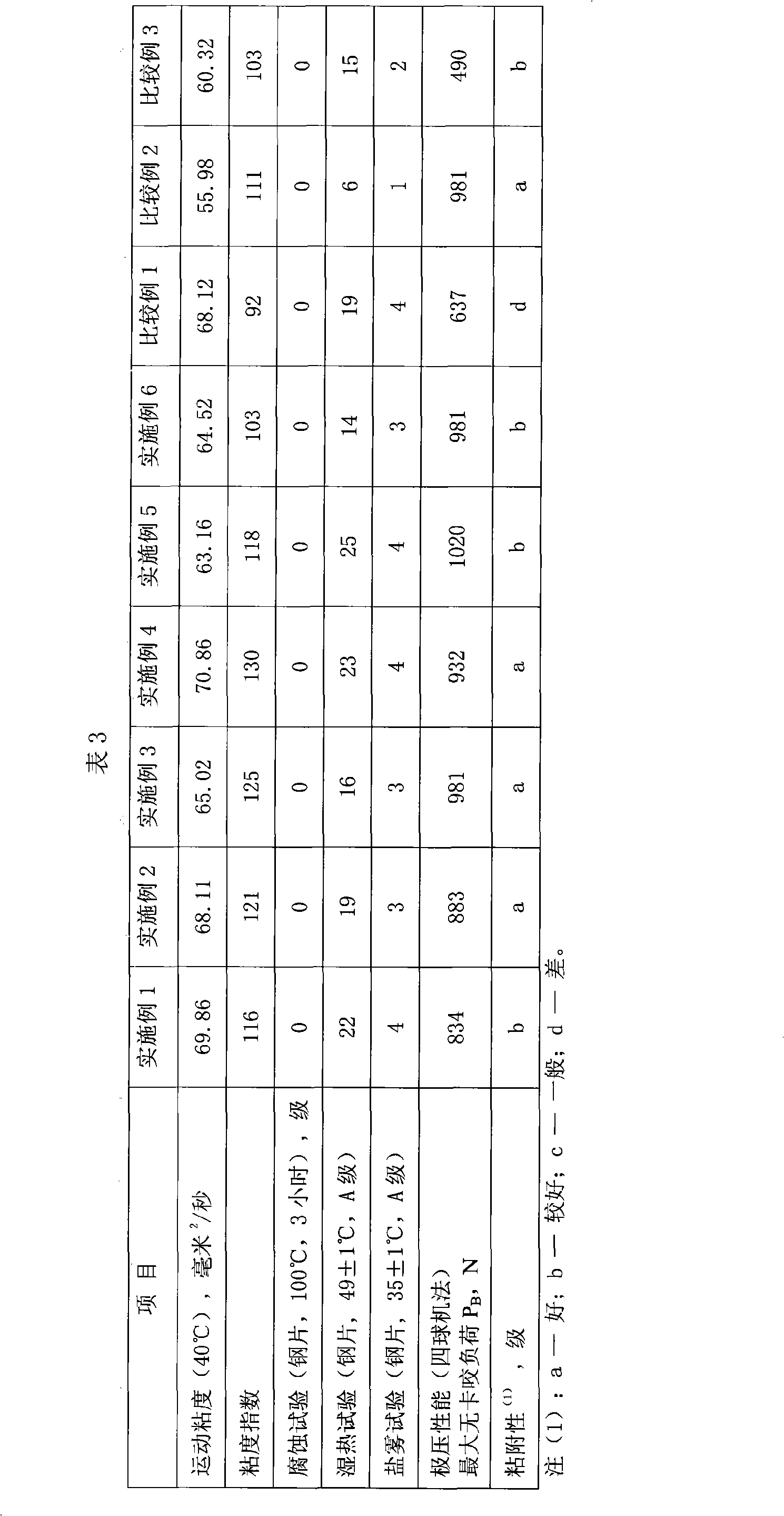

Lubricating anticorrosive oil and use thereof

ActiveCN101328445AExcellent anti-rustImprove the lubrication effectAdditivesPetroleum productOxidation resistant

The invention relates to lubricating rust preventive oil and application thereof, mainly aiming to solve the problems of the prior art that: a rustproof product has poor adhering property; and the prior art only lays stress on rustproof property and does not attach equal importance to the extreme pressure property, oxidation resistance and permeability of a petroleum product. The lubricating rust preventive oil solves the problems better through adopting the following technical proposal that: the compositions in percentage by weight of the lubricating rust preventive oil are: (a) 0.1 to 10 percent of extreme pressure antiwear agent, (b) 0.5 to 15 percent of rustproof agent, (c) 0.5 to 5 percent of oxidation and corrosion inhibitor, (d) 0.1 to 15 percent of viscidity temperature index improver, (e) 0.1 to 12 percent of friction improver and (f) the balance being base oil. The lubricating rust preventive oil can be used in fields such as harbor machinery, excavator, travelling crane, cargo winch and commercial elevator cable.

Owner:CHINA PETROLEUM & CHEM CORP

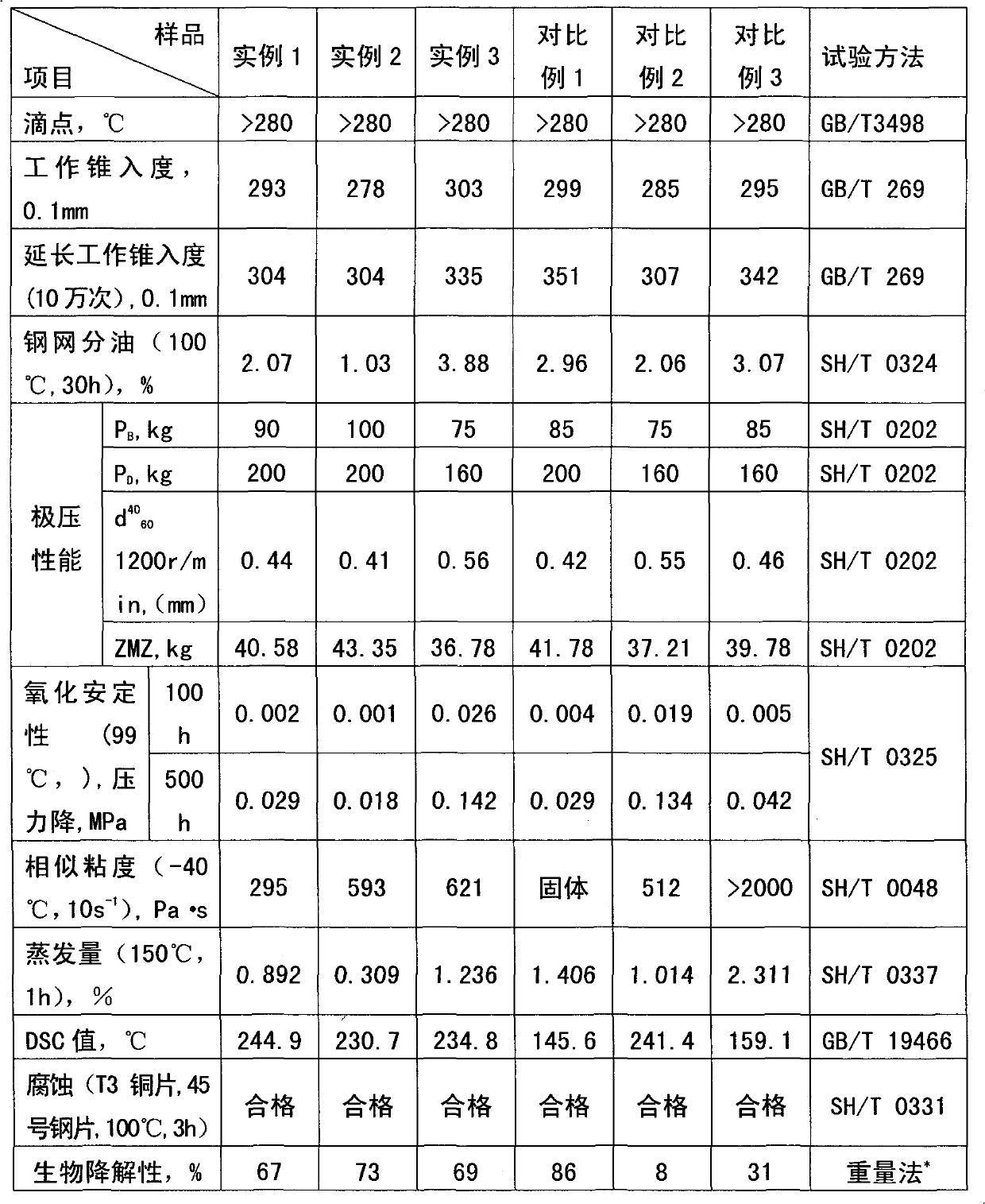

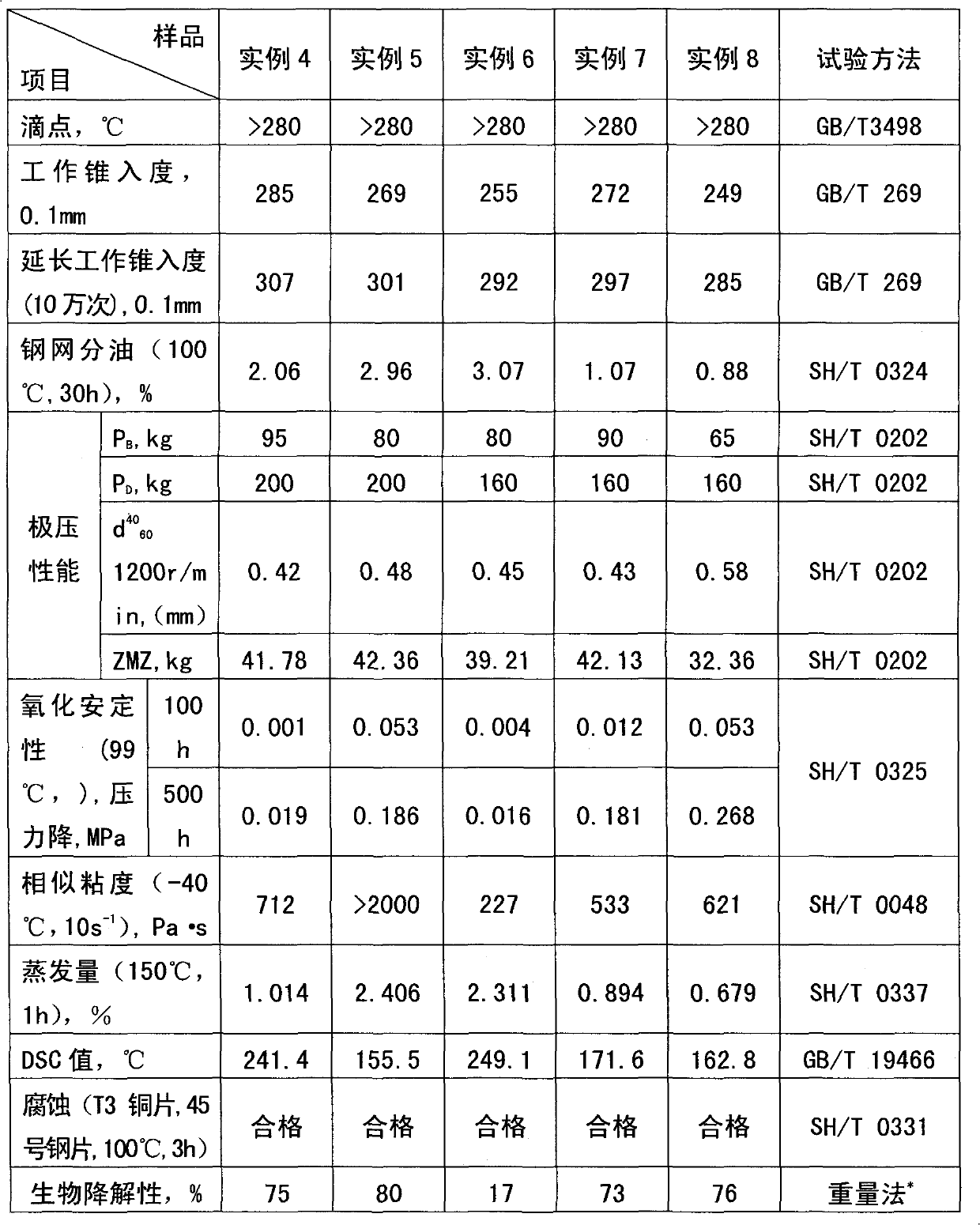

Environmental protection type lubricating grease composition and method for preparing same

ActiveCN102199471AWide high and low temperature adaptabilityGood biodegradabilityLubricant compositionChemistryAntioxidant

The invention provides an environmental protection type lubricating grease composition. The composition comprises basic grease and an additive, wherein the basic grease comprises the following ingredients in percentage by weight: 60 to 95 percent of basic oil and 5 to 40 percent of composite lithium soap thickener; and the additive comprises the following ingredients based on the 100 weight percent of the basic oil: 0.05 to 2 percent of antioxidant, 0.5 to 10 percent of extreme pressure anti-wear agent and 0.1 to 2 percent of anti-rusting agent. The environmental protection type lubricating grease composition has high high-low temperature adaptability, high biodegradability, excellent an anti-oxidation, shear resistance and extreme pressure wear resistance and high anti-rusting property and corrosion inhibition, and is suitable to be used as the lubricating grease for bearings of electromotors of rail locomotives.

Owner:CHINA PETROLEUM & CHEM CORP +1

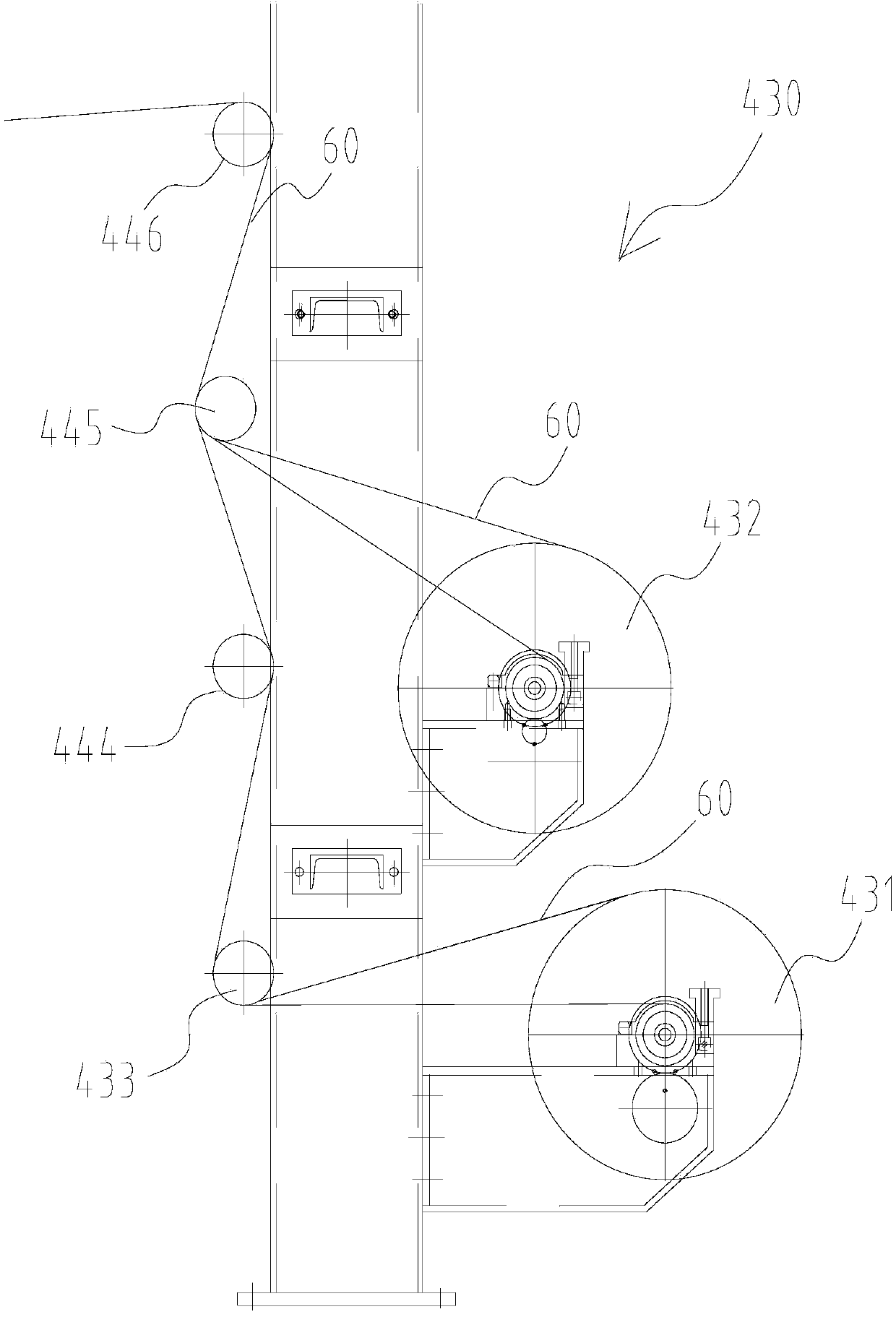

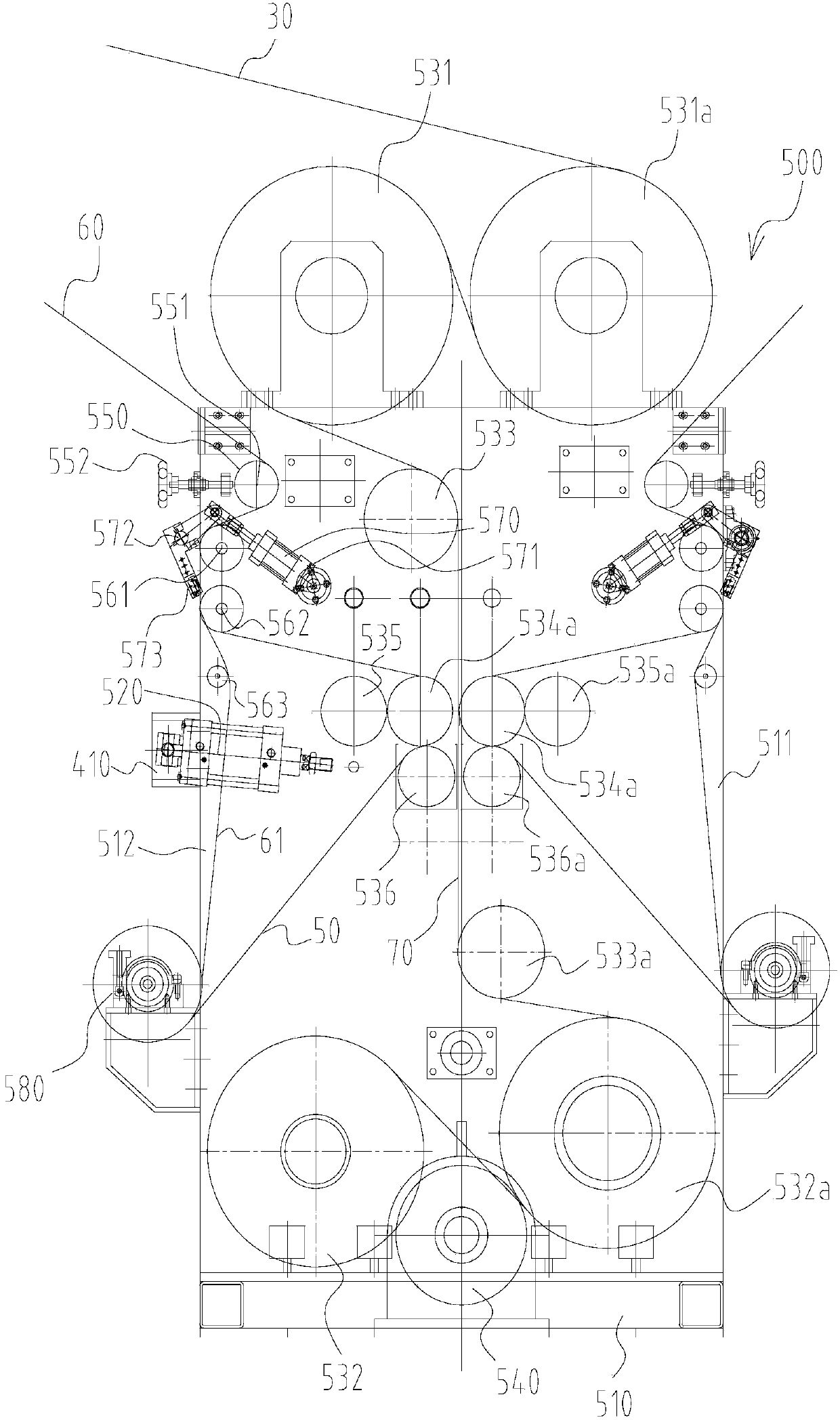

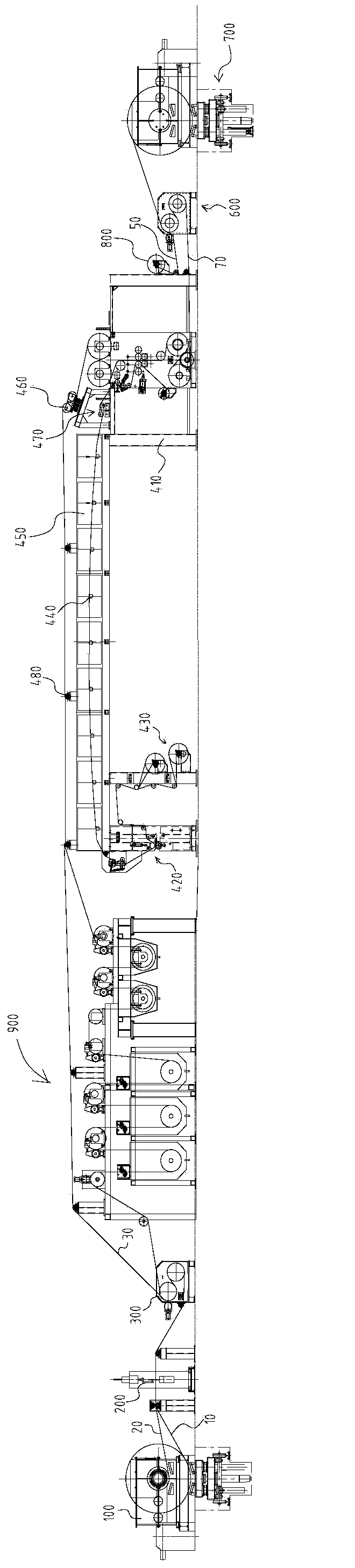

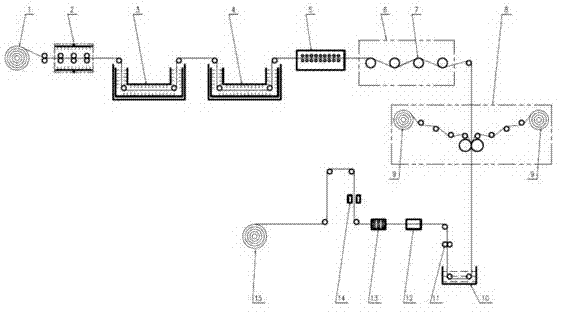

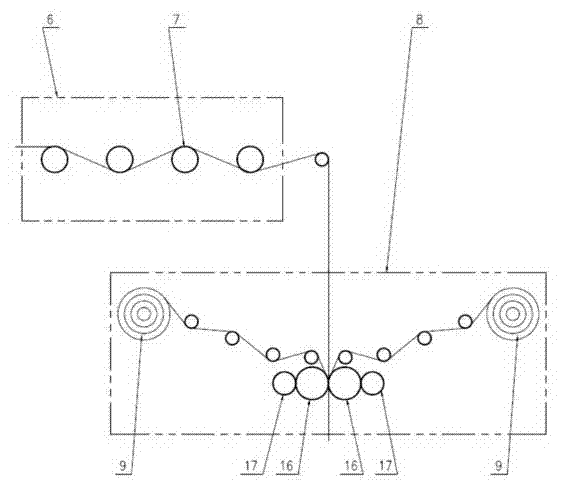

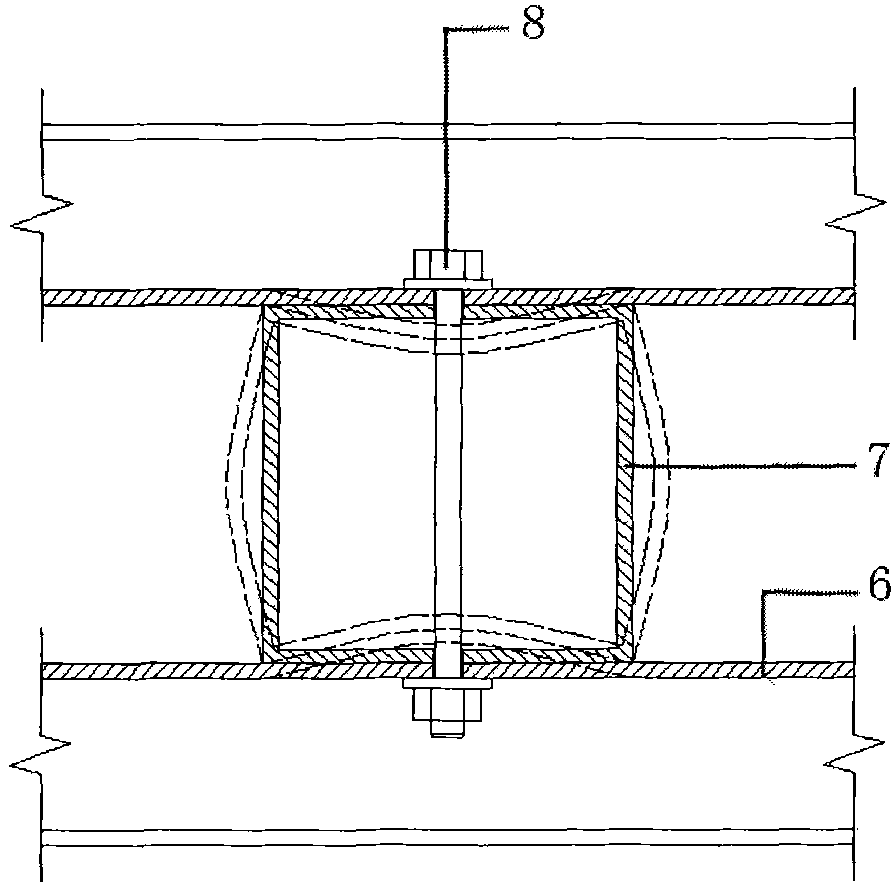

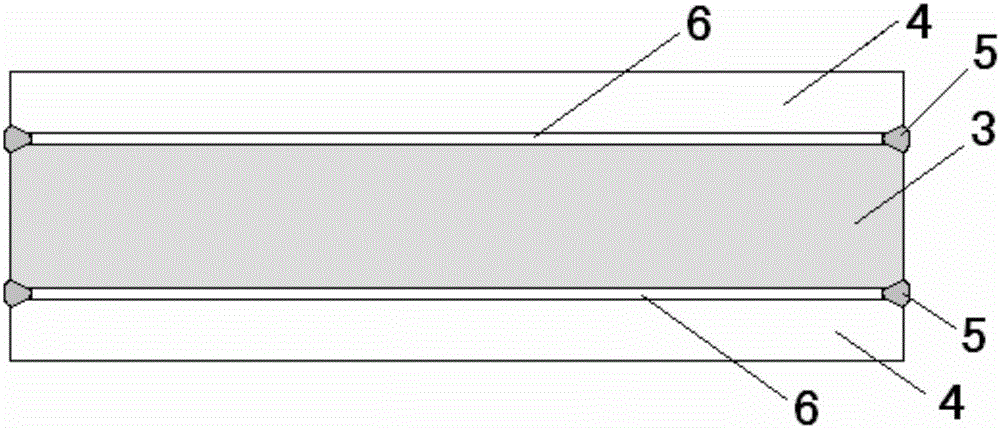

Multi-functional laminated iron production line

ActiveCN103640315AExcellent anti-rustImprove the decorative effectLamination ancillary operationsLaminationWinding machineProduction line

The invention discloses a multi-functional laminated iron production line. The multi-functional laminated steel production line comprises a cold rolled base plate unwinding device, a seam welder, two S turning roller sets, a first or / and second thin film release device, an iron sheet laminating device and a laminated iron winding machine, which are sequentially arranged in a conveying direction of metal base plates; the metal base plate from the seam welder enters the iron sheet laminating device after being tensioned and rectified, and a first thin film or / and second thin film is / are fed into an iron sheet laminating machine after rectification, so that the iron sheet laminating machine covers one surface or two surfaces of the metal base plate with the first thin film or / and the second thin film to form single-sided or double-sided laminated iron, the single-sided or double-sided laminated iron is fed into the other S turning roller set by the iron sheet laminating machine to be tensioned, and the tensioned single-sided laminated iron is wound by the laminated iron winding machine. The multi-functional laminated iron production line can produce both low-temperature bonded laminated iron and high-temperate melted laminated iron, is advanced iron laminating equipment capable of realizing efficient and continuous production, and can be well adaptive to the change of market requirement.

Owner:SUZHOU DONGHONGRUI PACKAGE TECH

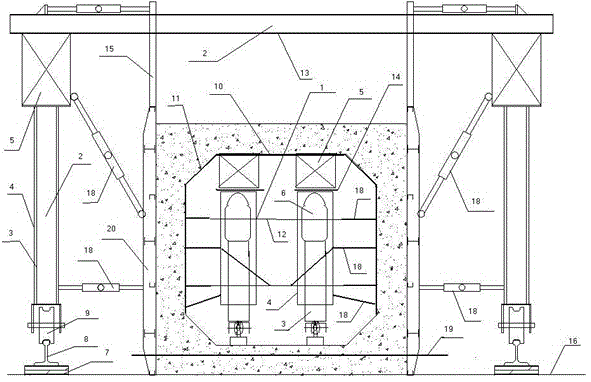

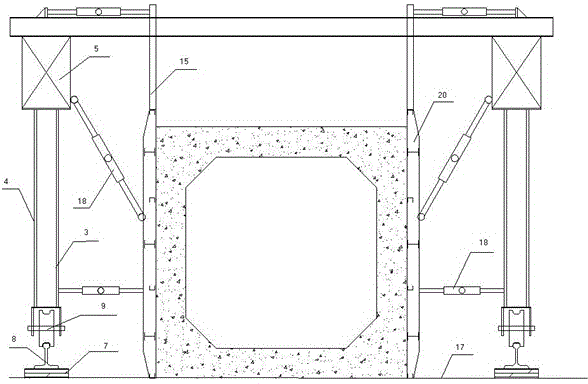

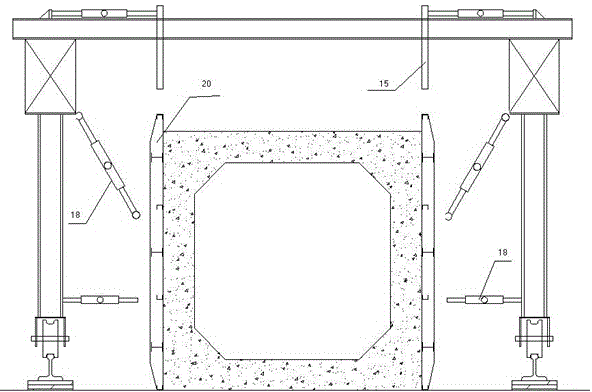

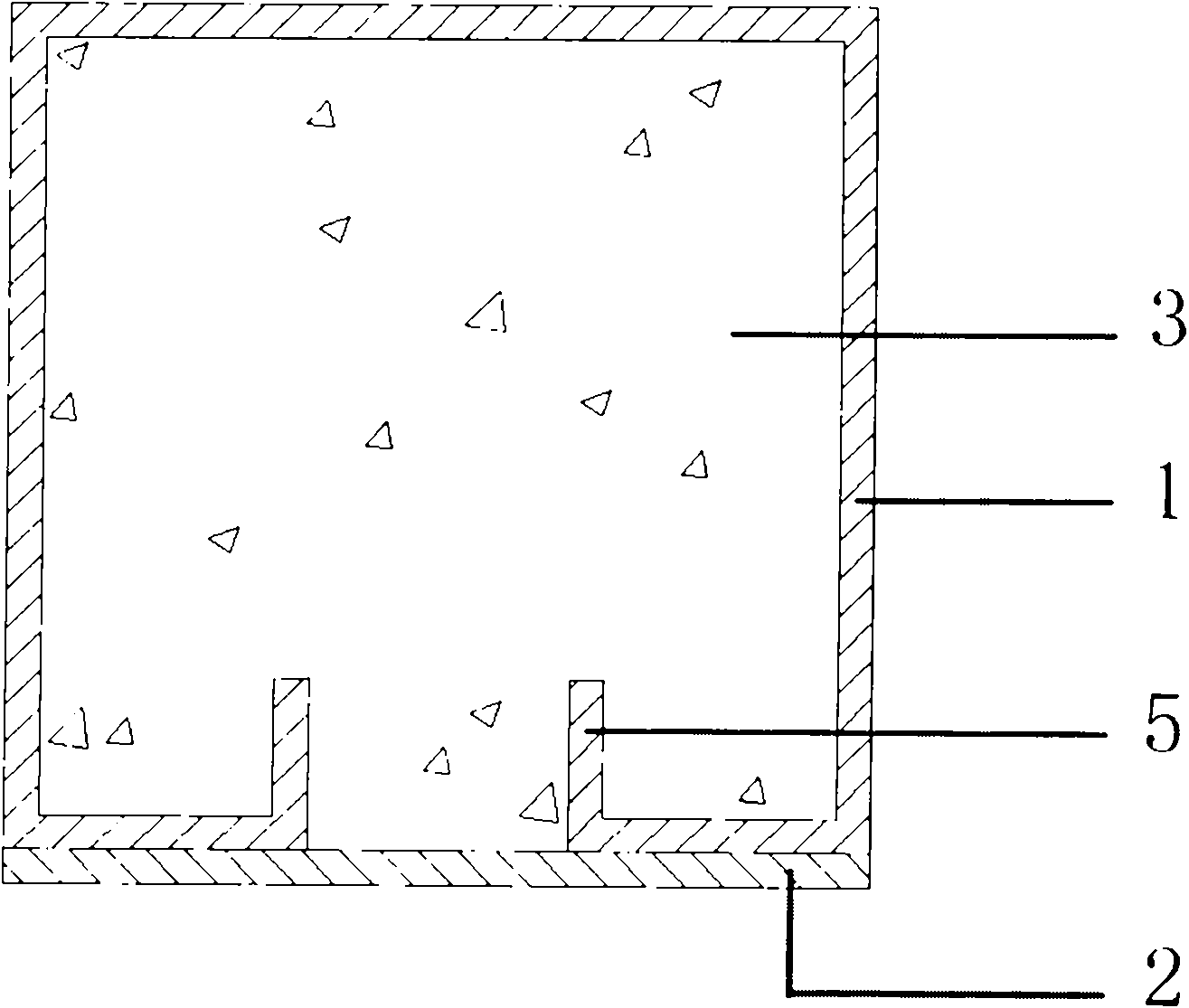

Modularization steel die trolley and construction process thereof

ActiveCN104895584AExcellent anti-rustEasy to remove formworkUnderground chambersTunnel liningSupporting systemEngineering

The invention provides a modularization steel die trolley and a construction process thereof. The trolley comprises an inner die trolley and an outer die trolley. The inner die trolley is of a semi-closed steel structure and comprises a support elevating system and a walking system. The outer die trolley also comprises the same support elevating system and the same walking system. The inner die trolley also comprises a support template. The outer die trolley also comprises a support system, an outer support template and a lead screw. According to the invention, one set of special outer die trolley door frame can be used with multiple sets of common template assemblies.

Owner:金中天建设集团有限公司

Multi-station cold heading oil and preparation method thereof

InactiveCN104403738AExtended service lifeGood extreme pressure and anti-wear propertiesLubricant compositionVegetable oilFoaming agent

The invention relates to an oil product of a petroleum chemical product, and especially relates to multi-station cold heading oil and a preparation method thereof. According to the method, a deep refining mineral oil is taken as a base oil, an extreme pressure additive, an anti-rust agent, an oiliness additive, an anti-foaming agent, and animal and vegetable oil are added by blending, the cold heading oil comprises the following components by weight: 75% of base oil, 6% of extreme pressure additive, 3.7% of anti-rust agent, 8% of oiliness additive, 2.3% of anti-foaming agent and 5% of animal and vegetable oil. The cold heading oil is suitable for a cold heading machine, and has the advantages of good extreme pressure abrasion resistance, good antirust performance and anti-foaming performance, so that the usage life of the cold heading machine can be increased.

Owner:NINGBO BAORUN PETROCHEM

Super-high extreme pressure type micro-emulsification cutting fluid and preparation method thereof

ActiveCN102766510AHigh extreme pressureExcellent anti-rustLubricant compositionPhenyl EthersChlorinated paraffins

The invention relates to a metal processing cutting fluid and specifically relates to a super-high extreme pressure type micro-emulsification cutting fluid and a preparation method thereof. According to the super-high extreme pressure type micro-emulsification cutting fluid, 5# white oil is used as basic oil and is easy to emulsify; emulsification lubricating agents comprise tall oil, oleic diethanolamide, polyoxyethylene(10)nonyl phenyl ether, isononanoicacid, synthetic petroleum sodium sulfonate and zinc naphthenate, and the emulsifying capacity is stronger when the emulsification lubricating agents are matched for using; and more chlorine containing extreme-pressure agent chlorinated paraffin S52 and sulfur containing extreme-pressure agents TPS32 can be emulsified into the basic oil to obtain the super-high extreme pressure type micro-emulsification cutting fluid. According to the super-high extreme pressure type micro-emulsification cutting fluid, emulsification particles are small, and the cutting fluid is stable; simultaneously, a synthetic ester of a fatty acid methyl ester which serves as a lubrication reinforcing agent is added, extreme pressure lubrication requirements of medium-high temperature processing are met, and the super-high extreme pressure type micro-emulsification cutting fluid is suitable for mechanical processing with wider ranges of processing temperatures; and triazine amino-acid esters are used for reinforcing rust protection so that the rust-protecting effects can reach to the best.

Owner:温州宝罗润滑材料有限公司

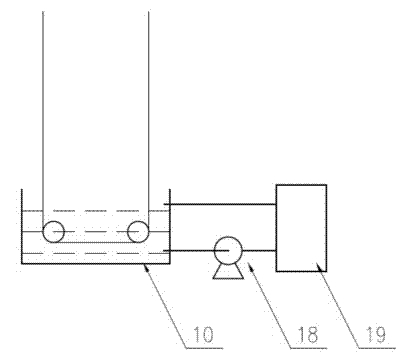

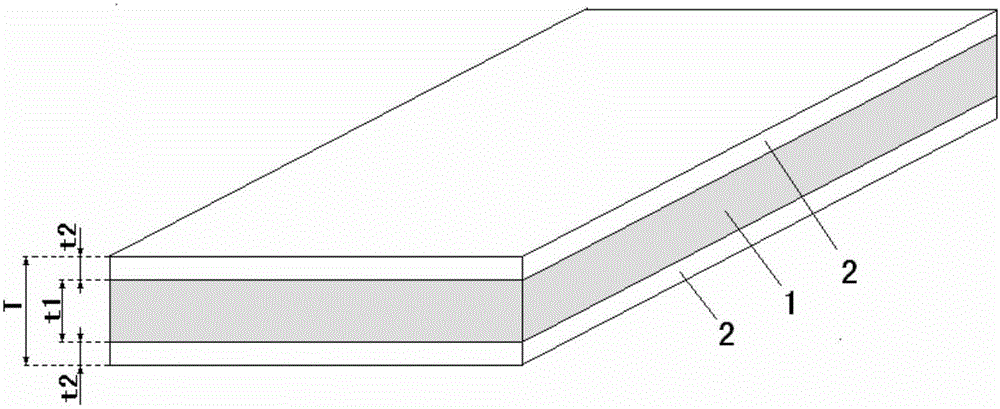

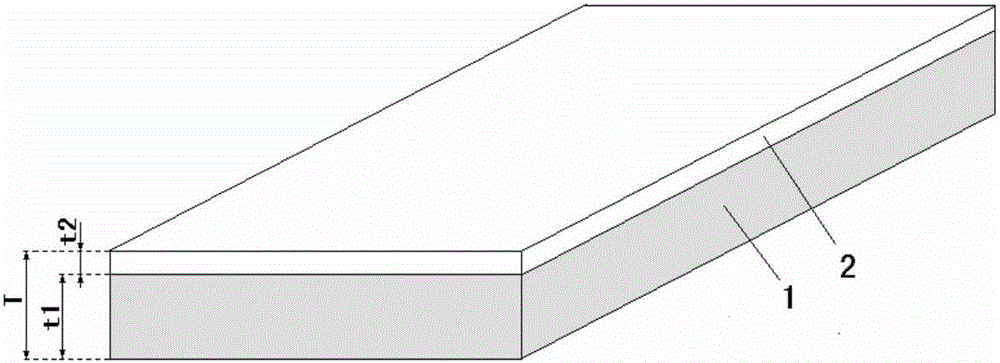

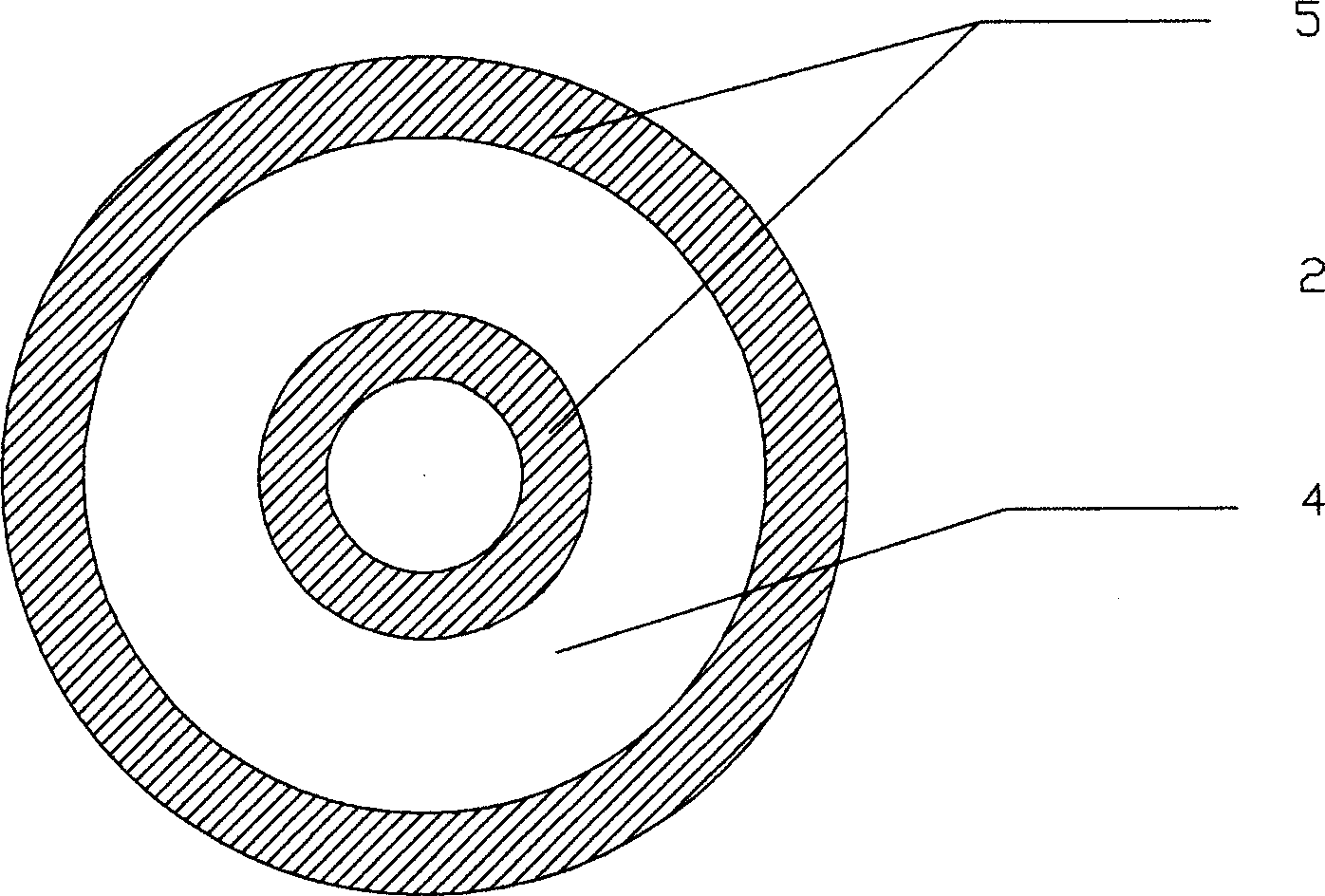

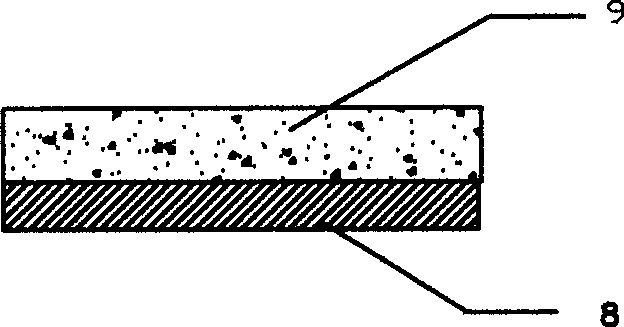

Technology and device for processing film-coated iron

ActiveCN102431269ALess surface pinholesHigh tensile strengthLamination ancillary operationsLaminationSteel platesSheet steel

The invention provides a technology for processing film-coated iron. The technology for processing film-coated iron comprises the following steps that a cold-rolled thin collared steel plate (chrome-coated iron) subjected to surface chrome coating treatment is unreeled by an unreeling machine, then is cleaned up, is dried and is put into a preheating device for preheating; and the preheated steel plate is treated by a film pressing device so that the preheated steel plate and a plastic film are compounded by heating. The invention also provides a device for processing film-coated iron. The technology and the device for processing film-coated iron have the advantages that high efficiency, environmentally friendly and low-cost steel plate surface coating is realized; a production process is environmentally friendly; a product has good impact resistance and corrosion resistance; toxic low-molecular residues are not produced; and the technology and the device accord with a modern industrial large-scale production idea of low carbon and environmental protection.

Owner:上海联净复合材料技术有限公司

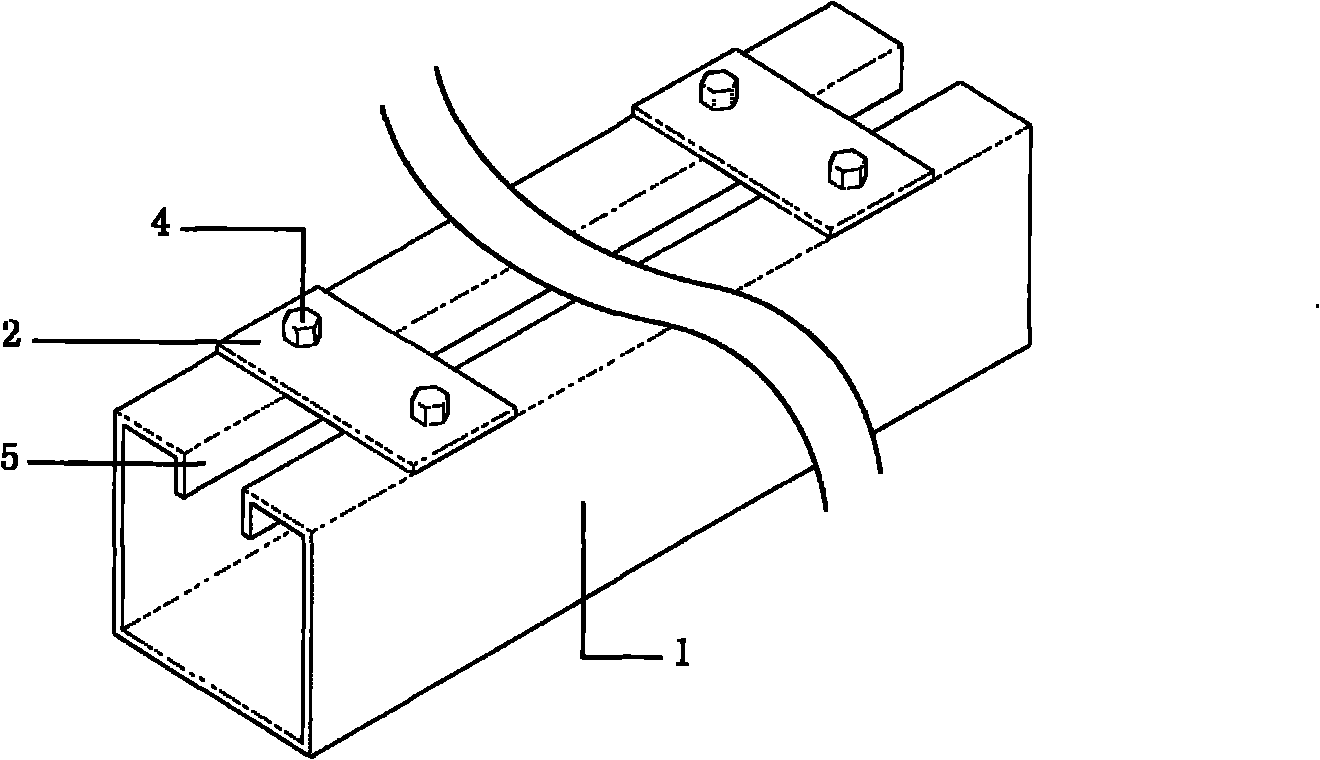

Square light steel member with reinforcement parts

The invention relates to a square light steel member with reinforcement parts, which comprises a main structure and the reinforcement parts, wherein the main structure is a square steel tube which is integrally formed by a steel plate with a certain thickness, an opening is arranged at one side of the square steel tube, the two side edges of the opening are respectively provided with bending edges, and the reinforcement parts are fixedly connected with the side of the main structure provided with the opening, and are arranged at certain intervals. The square light steel member with the reinforcement parts provided by the invention has the advantages of strong compressive resistance and deformation resistance, relative low manufacturing cost, good corrosion resistance, easiness in processing, convenience in being connected and constructed with other components and the like.

Owner:谢英俊

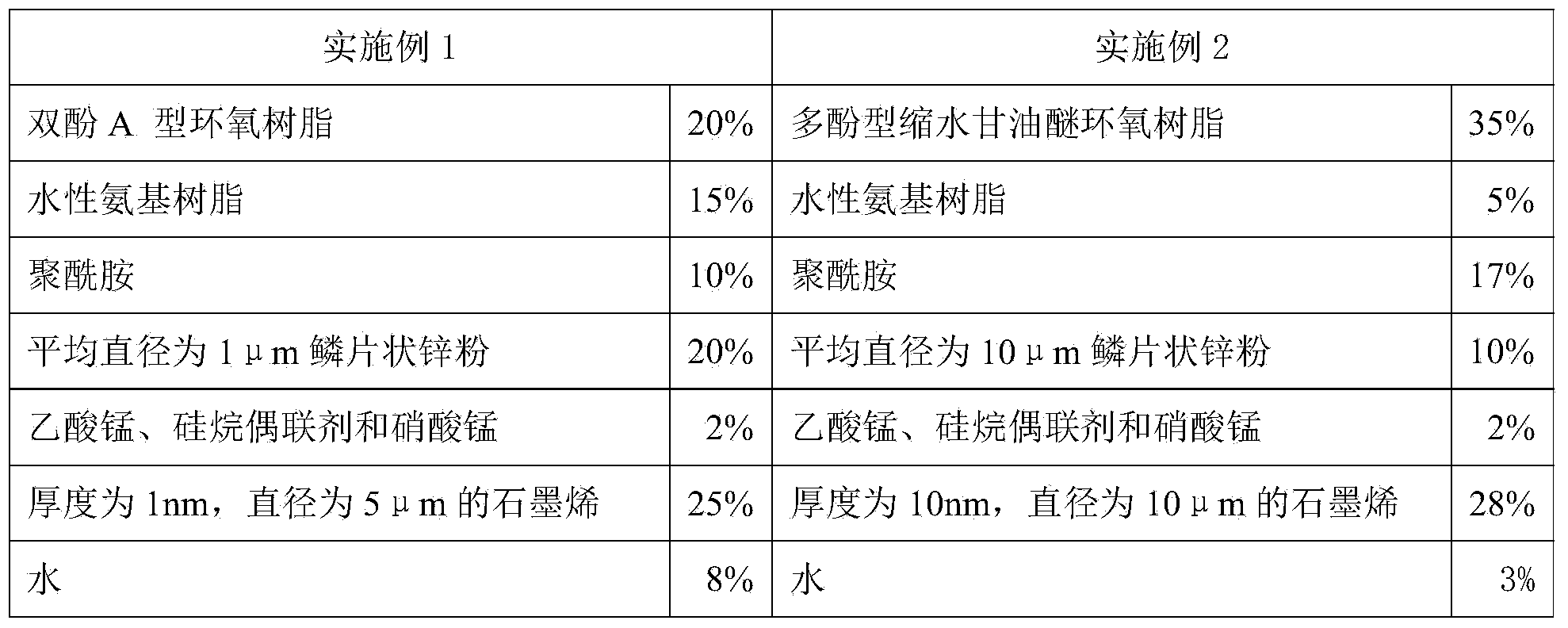

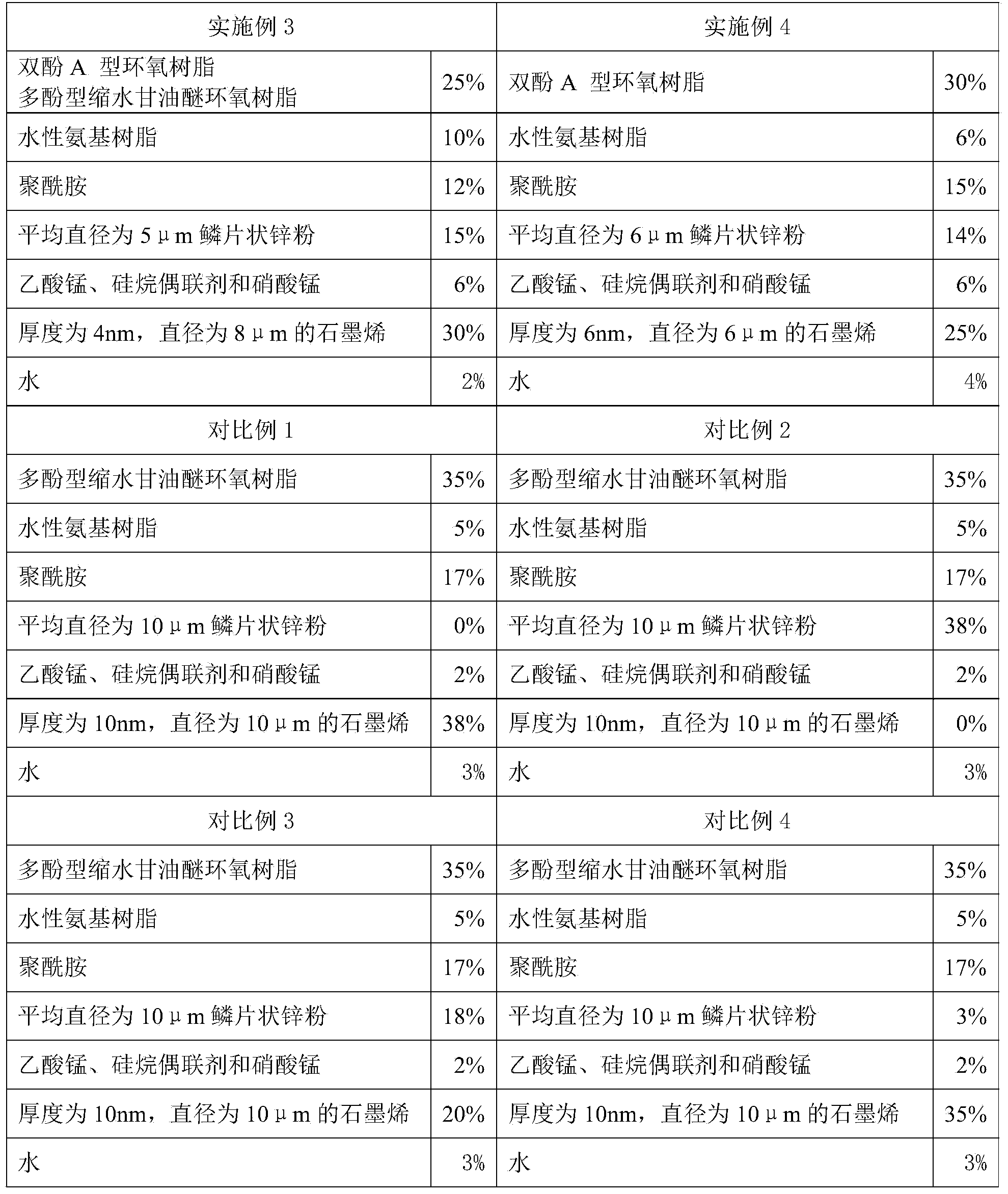

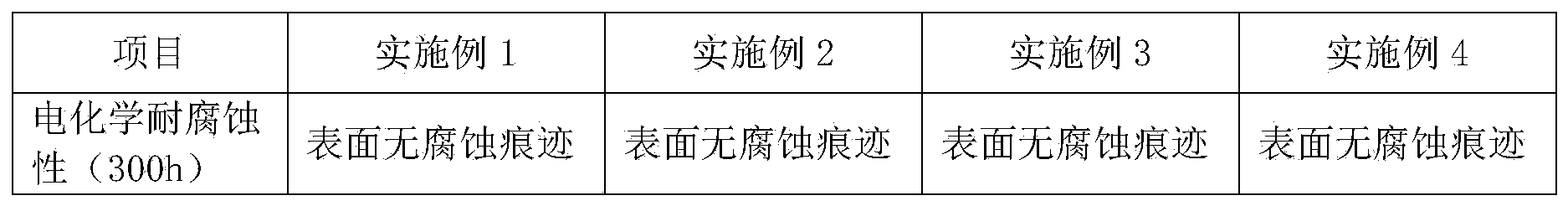

High-corrosion-resistance metal anti-corrosive paint and preparation method thereof

InactiveCN104371500AExcellent anti-rustReduce corrosionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention relates to the technical field of corrosion prevention of metals, and particularly relates to a high-corrosion-resistance metal anti-corrosive paint. The paint consists of the following components in percentage by mass: 20-35 percent of epoxy resin, 5-15 percent of water-based amino resin, 10-17 percent of polyamide, 10-20 percent of zinc powder, 2-6 percent of a film forming agent, 25-30 percent of graphene and the balance of water. The high-corrosion-resistance metal anti-corrosive paint disclosed by the invention has a good rustproof effect on metals by strictly controlling the amount of used zinc and grapheme, and can be used for slowing down metal corrosion, lowering the cost and also forming a uniform passivation layer and a uniform corrosion inhibition layer on the surface of a metal so that an overall coating is subjected to synchronous corrosion inhibition, and the anti-corrosive paint for a boat is endowed with excellent waterproofness, alkali resistance, artificial weathering aging resistance and corrosion resistance. The adopted paint system is a water-based paint system which has an excellent anti-corrosive effect in seawater, so the application range of the paint is effectively widened.

Owner:ZHANGJIAGANG FREE TRADE ZONE GUANXIANG TRADE

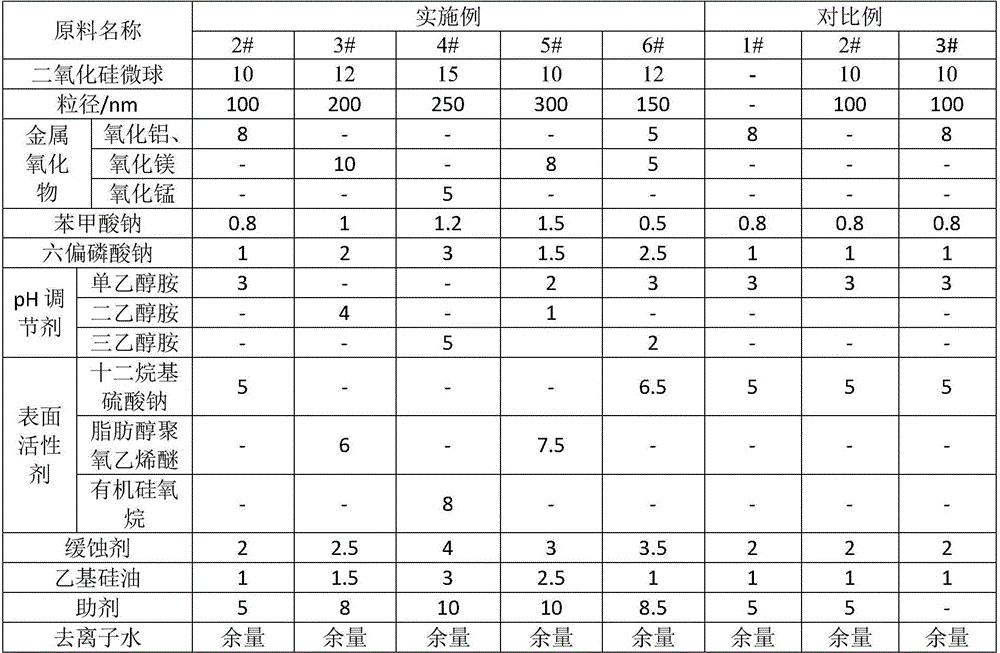

Polishing solution for stainless steel surface machining

InactiveCN106318220AModerate hardnessImprove stress resistancePolishing compositions with abrasivesSurface-active agentsSilicon dioxide

The invention belongs to the technical field of materials, and particularly relates to a polishing solution for stainless steel surface machining. The polishing solution is prepared from, by weight, 10-15 parts of modified silicon dioxide pellets, 5-10 parts of metallic oxide, 0.5-1.5 parts of sodium benzoate, 1-3 parts of sodium hexametaphosphate, 3-5 parts of a pH conditioning agent, 5-8 parts of a surface active agent, 2-4 parts of a corrosion inhibitor, 1-3 parts of ethyl silicon oil, 5-10 parts of auxiliaries and the balance deionized water. The prepared polishing solution is easy to prepare, low in cost, good in polishing effect and high in polishing precision and polishing efficiency, and has the advantages of removing oil stain, resisting rust, being easy to clean and non-toxic, doing no harm to human bodies or environment and being suitable for large-scale production.

Owner:JIANGSU JINYANG STAINLESS PROD

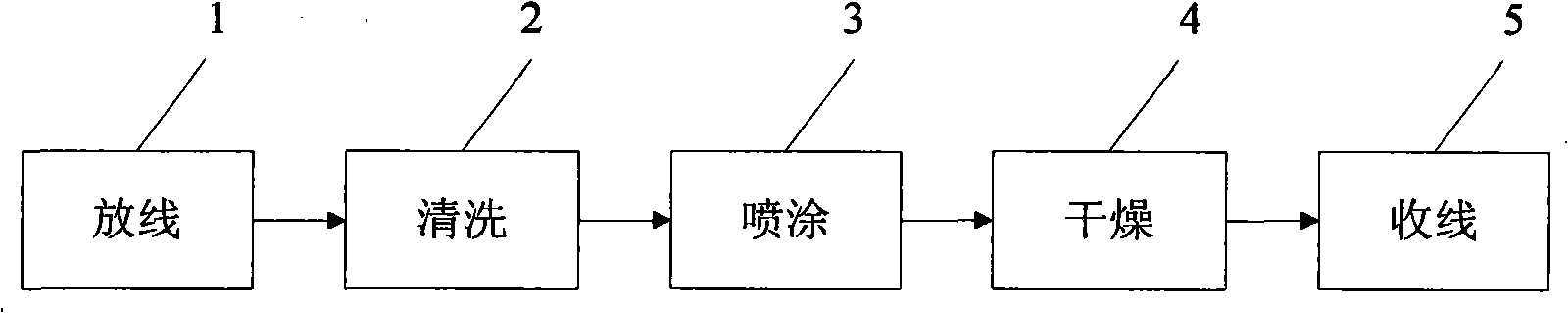

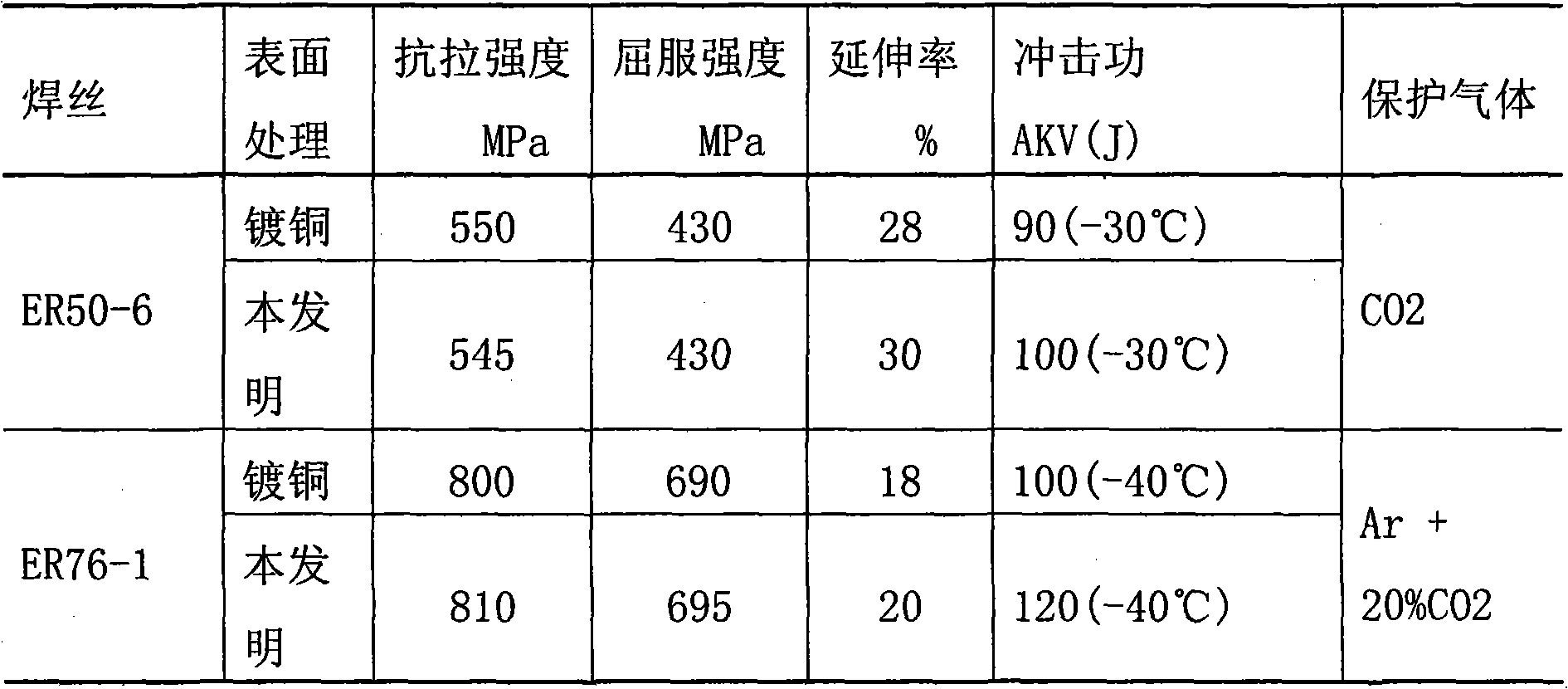

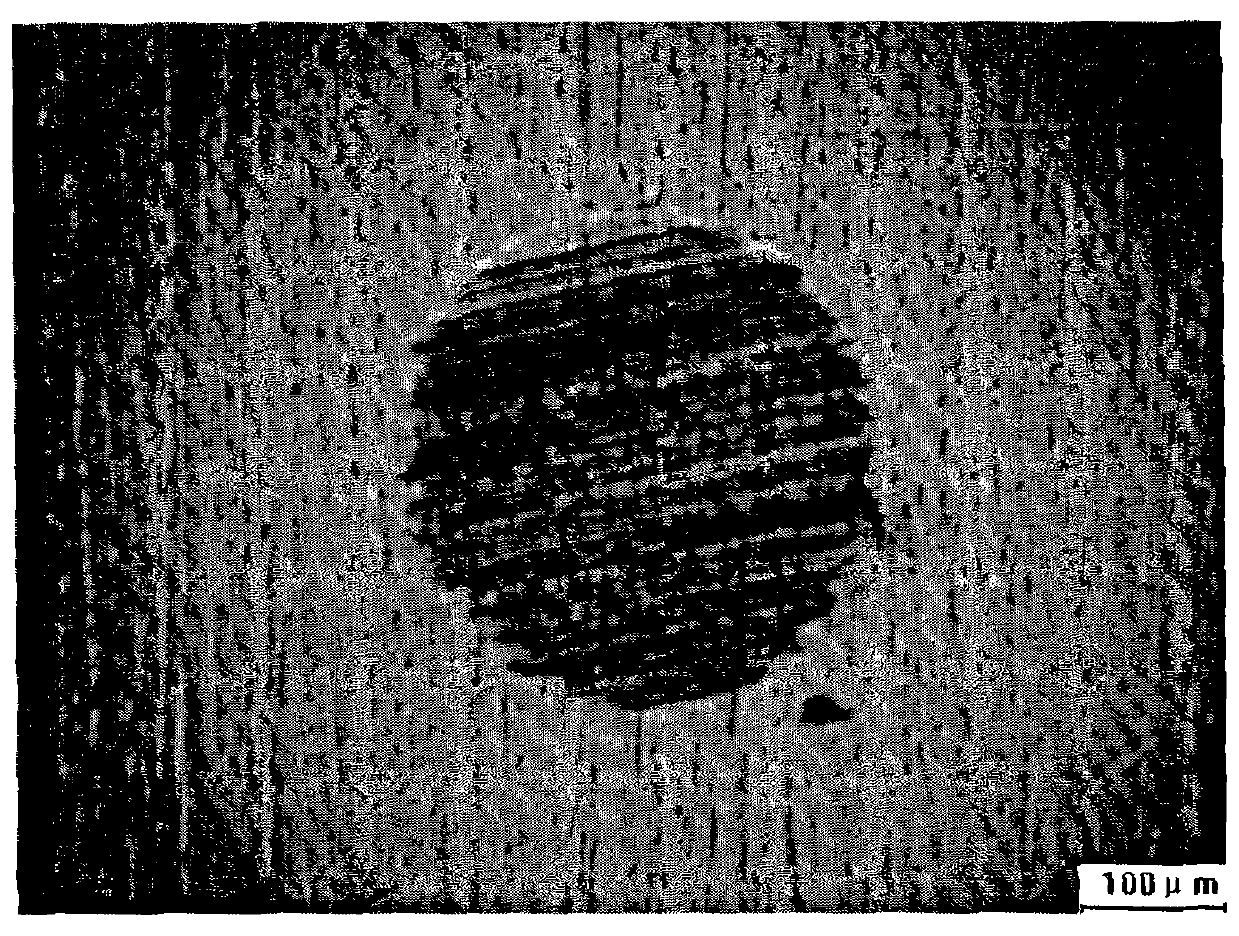

Gas protecting welding wire with nano-coating

ActiveCN101407004AArc stabilizationExcellent anti-rustWelding/cutting media/materialsSoldering mediaArc stabilityCopper plating

The invention relates to the welding field, in particular to a gas protection welding wire with nano coating. The gas protection welding wire with nano coating is characterized in that the surface of the welding wire is provided with a coating, and the coating comprises the following components in weight percentage: 0.05 to 0.18 percent of potassium tetraborate, 0.15 to 0.80 percent of calcium stearate, and the balance of titanium dioxide; and the thickness of the coating is between 100 and 300nm. Due to the adoption of the technical proposal, the defects that the weld spatter of the copper coated welding wire is big, the surface of the welding is easy for pitting corrosion, the copper element which is transitional to the welding seam possibly lowers the performance of the welding seam, and the content of the poisonous substance copper element is high are completely overcome, so that with the technical proposal of the invention, the gas protection welding wire which has the advantages of arc stability, small weld spatter, good rust proof performance, easy wire feed and good toughness of the welding seam.

Owner:上海斯米克焊材有限公司

Compound calcium sulfonate base lubricating grease and preparation method thereof

The invention discloses compound calcium sulfonate base lubricating grease and a preparation method thereof. The key points of the technical scheme of the invention lie in that the compound calcium sulfonate base lubricating grease is prepared by adding calcium sulfonate in an inorganic substance and an organic substance compound calcium soap and thickening base oil, and an arylamine antioxidant is added in a thickening procedure. The high-performance compound calcium sulfonate base lubricating grease is prepared and acquired in a certain raw material ratio and operation condition. By using the compound calcium sulfonate base lubricating grease and the preparation method, the cost of a user is reduced; a product has favorable water resistance, lubricating property and high temperature resistance, cannot be emulsified and degreased, and is not easy to run off; the service life of mechanical equipment is prolonged; the maintenance time of the equipment is decreased; the production efficiency of the equipment is improved; a raw material formula is reasonable; the cost is low; the emission of three wastes does not exist in a production procedure; the compound calcium sulfonate base lubricating grease and the preparation method are environment-friendly while an industrial requirement is met; and the preparation method is a green production process.

Owner:XINXIANG HENGXING TECH CO LTD

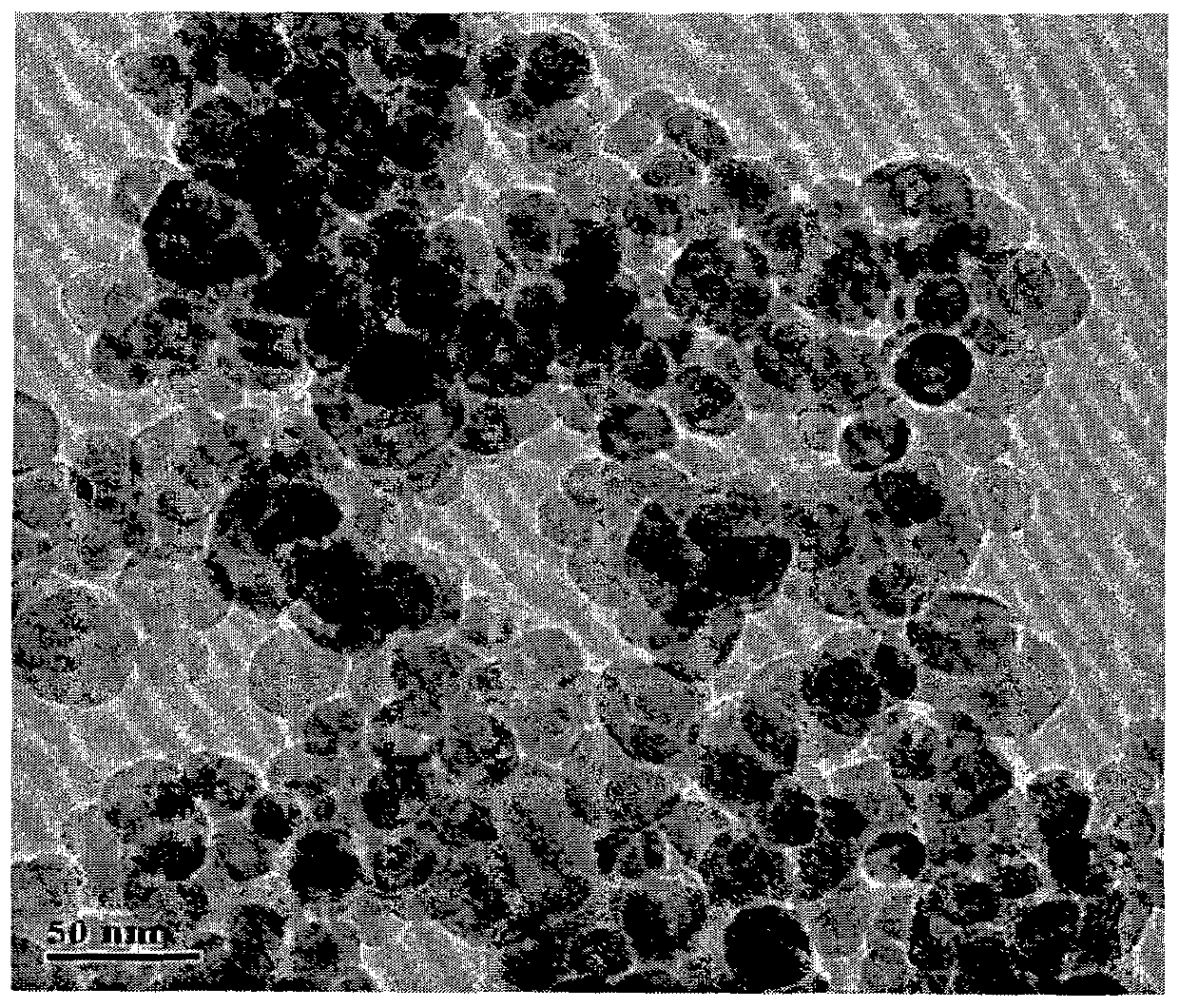

Preparation method of water dispersible nano copper cooling lubricant for cold rolling

InactiveCN101948712AReduce coefficient of frictionSoluble in waterAdditivesChemical reactionMetallurgy

The invention discloses a preparation method of a water dispersible nano copper cooling lubricant for cold rolling. In the lubricant, oleate is used as a surfactant, divalent copper salt is used as a copper element, and hydrazine hydrate is used as a reducing agent. Nano copper is selected as a main raw material of the lubricant, and meanwhile, certain dispersant and surfactant are added to prepare the water dispersible nano copper cooling lubricant applicable to a cold rolling process. The invention aims at improving the lubricity of cold rolling, a friction surface can be primed and repaired to a certain extent through products of a friction chemical reaction, and thus, rolled steel has self repairing action.

Owner:BEIHANG UNIV

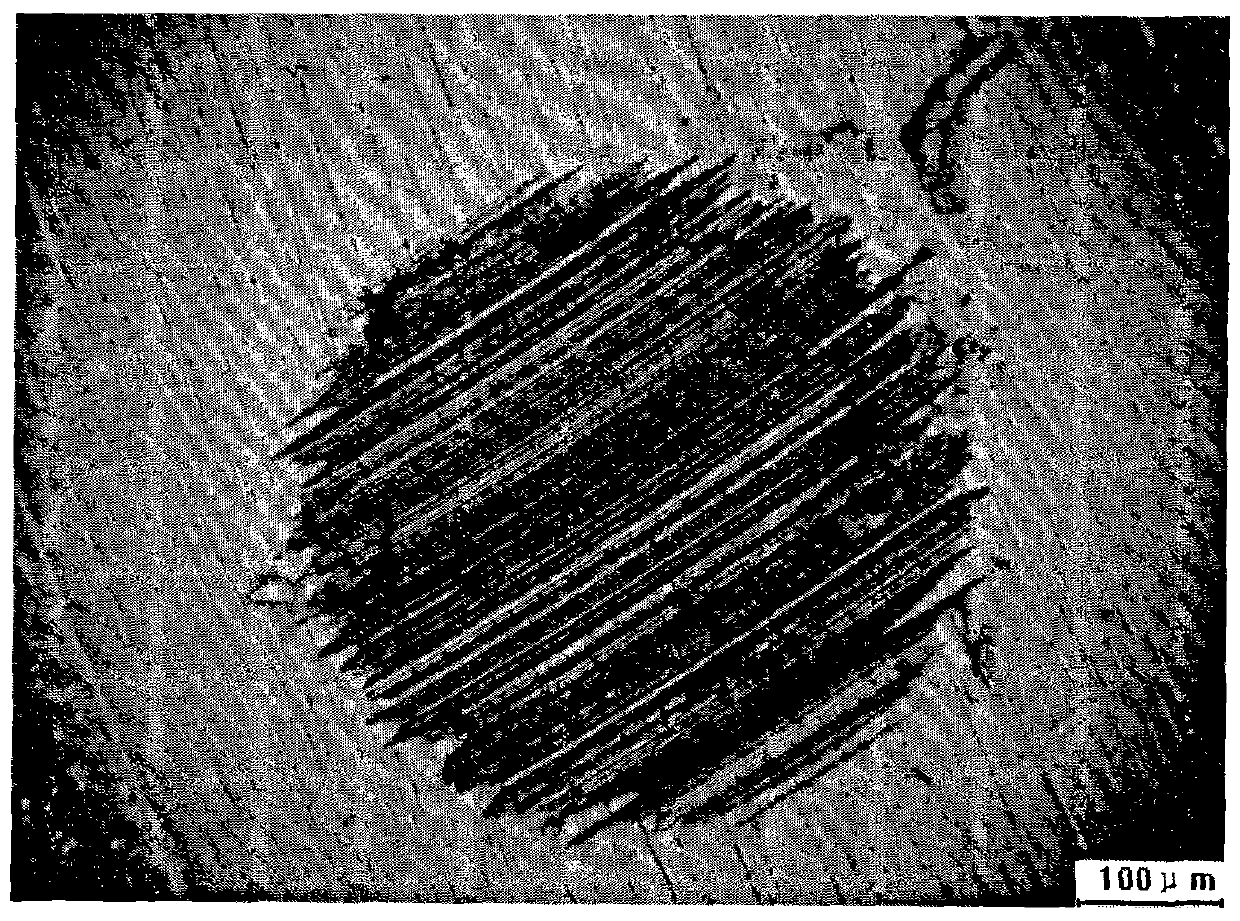

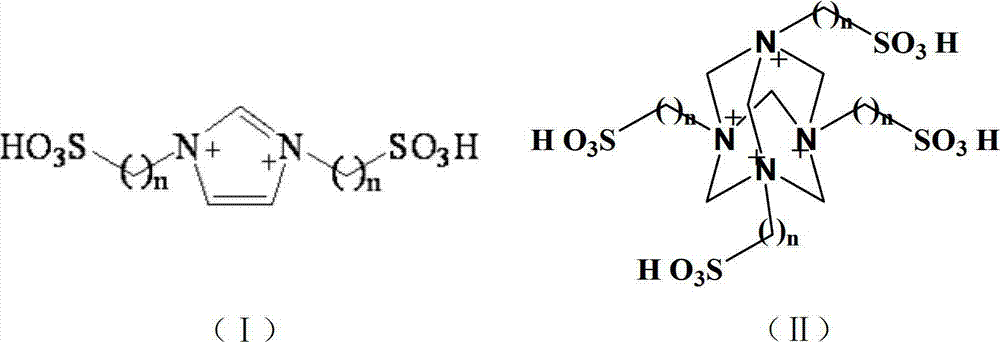

Aqueous environment-friendly cutting fluid synergized by functional ionic liquid and method for preparing same

ActiveCN102732365AMild reaction conditionsEasy separation and handlingLubricant compositionIonCorrosion inhibitor

The invention discloses an aqueous environment-friendly cutting fluid synergized by a functional ionic liquid and a method for preparing the same. The method comprises the following steps: stirring and mixing a synthetic ester, a vegetable oil and an antiseptic uniformly under normal pressure and temperature to obtain a mixture A; stirring and mixing a PH stabilizer, an antirust agent and water at 30-80 DEG C for 10 minutes to 1 hour to obtain a mixture B; stirring and mixing an emulsifier and an ionic liquid extreme-pressure agent under normal pressure and temperature to obtain a mixture C; adding the mixture A, the mixture B and the mixture C into a reactor, adding a copper corrosion inhibitor and an aluminum corrosion inhibitor, and stirring and mixing at 30-80 DEG C for 10 minutes to 1 hour to obtain the product. The extreme-pressure agent has excellent abrasion resistance and can be subjected to chemical reaction with the metal surface to produce a passivation film so as to protect the metal surface. In addition, the ionic liquid compound comprises a variety of anions and cations so that the system has the advantages of special bactericidal performance, lubricating performance, cooling performance and chemical stability which are not owned by the common antiseptic.

Owner:广州市联诺化工科技有限公司

Ship corrosion preventing method

InactiveCN104525458ALower surface free energyReduce coefficient of frictionPretreated surfacesAnti-corrosive paintsSand blastingPre treatment

The invention discloses a ship corrosion preventing method. The ship corrosion preventing method comprises the following steps of steel plate surface pre-treatment, base material sanding treatment, weld joint and other structure defect repair sand blasting, priming paint coating, strengthening paint spraying, finishing paint spraying and follow-up maintenance. According to the ship corrosion preventing method, steel plate surface pre-treatment is performed before coating, an epoxy anticorrosive coating is sprayed on the position with high rust-proof requirement, and whole spraying is performed after spraying; during whole spraying, corrosion resistant polyurethane serves as film forming matter, a coating for a framework formed by sheet metal flakes does not contain precious metal and toxic components and is a novel environment-friendly coating, flakes are formed and distributed on the material surface, multiple layers of flakes are horizontally arranged in an overlapped mode, a path for a corrosive medium to permeate into a base material is prolonged, and the corrosion preventing performance of the coating is improved. The ship corrosion preventing method is short in technological process, and produced ships have excellent rust, corrosion and fouling preventing performance.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

Nano coating of functional polymer and preparation method thereof

The invention discloses a nano coating of functional polymer and a preparation method thereof. The nano coating comprises silicon dioxide polymer nano particle which contains part of organic group and is obtained by reaction of reactive materials and a solvent thereof. The reactive materials comprise organic siloxane material, inorganic base, water and organic solvent. The preparation method comprises the following steps of: mixing the organic siloxane material and the base, adding water diluted with the organic solvent in the mixture and leads the mixture thereof to generate hydrolytic polymerization reaction so as to obtain the nano coating. The nano coating is evenly dispersed transparent collosol prepared by a collosol-congealing method has extremely strong adhesive effect towards base material; and the nano coating endows the surface of the base material with the functions of wear resistance, scratch resistance, corrosion resistance, easy cleaning, rust resistance and adherence resistance.

Owner:吕文生

Special corrosion-resistant high-temperature-resistant paint for chemical equipment

InactiveCN104946091AIncrease viscosityIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsEpoxyFiber

The invention discloses a special corrosion-resistant high-temperature-resistant paint for chemical equipment, which is prepared from a novolac epoxy resin, an acrylic resin, a boron modified organic silicon resin, a polytetrafluoroethylene resin, vapor-phase silicon dioxide, kaolin, polypropylene staple fiber, modified floating bead, alumina powder, graphite, iron oxide red, expanded perlite, polyvinylidene fluoride, ethanol, n-butanol, water, melamine, an amino resin, a film-forming assistant, a dispersing agent, a defoaming agent, a thickener, a wetting agent and a silane coupling agent. The special corrosion-resistant high-temperature-resistant for chemical equipment has the advantages of favorable corrosion resistance, favorable high temperature resistance and high adhesive force. When being used in chemical equipment, the paint can not easily shed and has long service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Cloth cart

InactiveCN105331240AExcellent abrasion resistanceImprove corrosion resistanceAnti-corrosive paintsWorking fluidPhenol

The invention discloses a cloth cart. The cloth cart comprises a metal rotating shaft subjected to surface treatment. The surface treatment process includes the following steps that firstly, by mass, 1-2 parts of mercaptobenzothiazole, 0.9 part of nickel nitrate, 1.4 parts of 1-Hydroxyethylidene-1,1-diphosphonicacid, 2.3 parts of polyvinylpyrrolidone, 1.8 parts of dipyrazolone, 2.3 parts of 2,6-di-t-butyl-alpha-dimethylamino hydroquinone and 1.6 parts of tetramethyl ammonium bromide are added into 12 parts of deionized water and evenly stirred and mixed, and surface treatment working fluid is obtained; secondly, the surface treatment working fluid is heated to 53 DEG C; thirdly, the metal rotating shaft is put into the surface treatment working fluid to be steeped for 32 min, taken out and then dried. Due to the fact that the metal rotating shaft of the cloth cart is subjected to surface treatment, good rub resistance, corrosion resistance, rust resistance, heat resistance, cold resistance and weather resistance are achieved.

Owner:CHANGSHU NUO XIN DA MACHINERY EQUIP CO LTD

Waterborne diamond wire silicon wafer cutting liquid

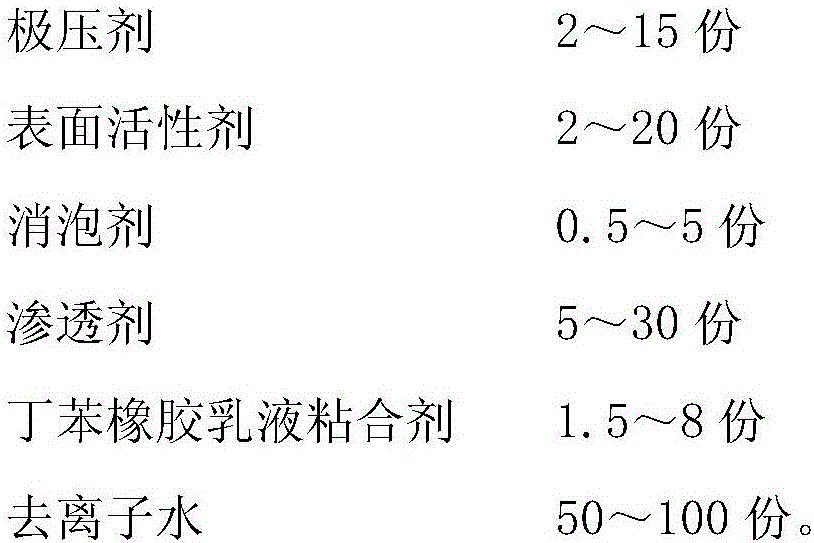

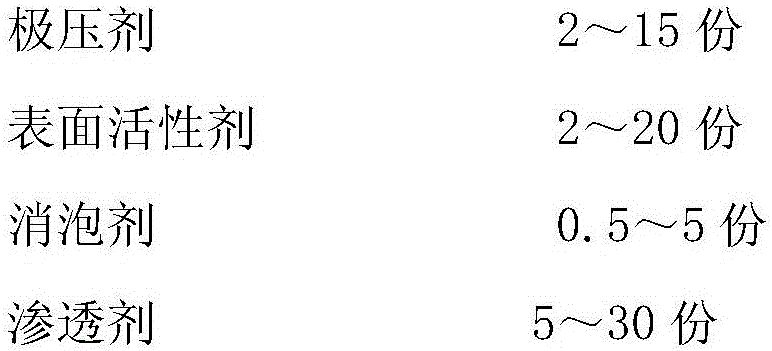

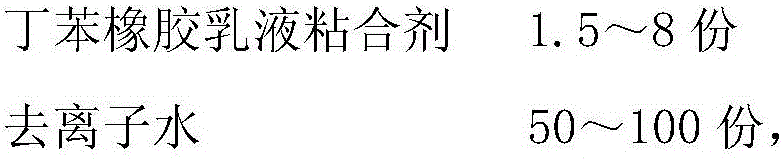

ActiveCN105695076AImprove the lubrication effectImprove cooling effectLubricant compositionSURFACTANT BLENDButadiene-styrene rubber

The invention belongs to the technical field of silicon crystal cutting, and particularly relates to waterborne diamond wire silicon wafer cutting liquid. The waterborne diamond wire silicon wafer cutting liquid is prepared from an extreme pressure agent, surfactant, a defoaming agent, a penetrating agent, butadiene styrene rubber latex binding agent and deionized water. The waterborne diamond wire silicon wafer cutting liquid obtained through the formula has excellent lubricating, cooling, anticorrosive, rust-proof and extreme-pressure-resisting functions, on the basis, a preparing method is simple in technology, low in cost, low in requirement for equipment and suitable for industrial production, and conditions are easy to control.

Owner:CHANGZHOU GREATOP NEW MATERIAL CO LTD

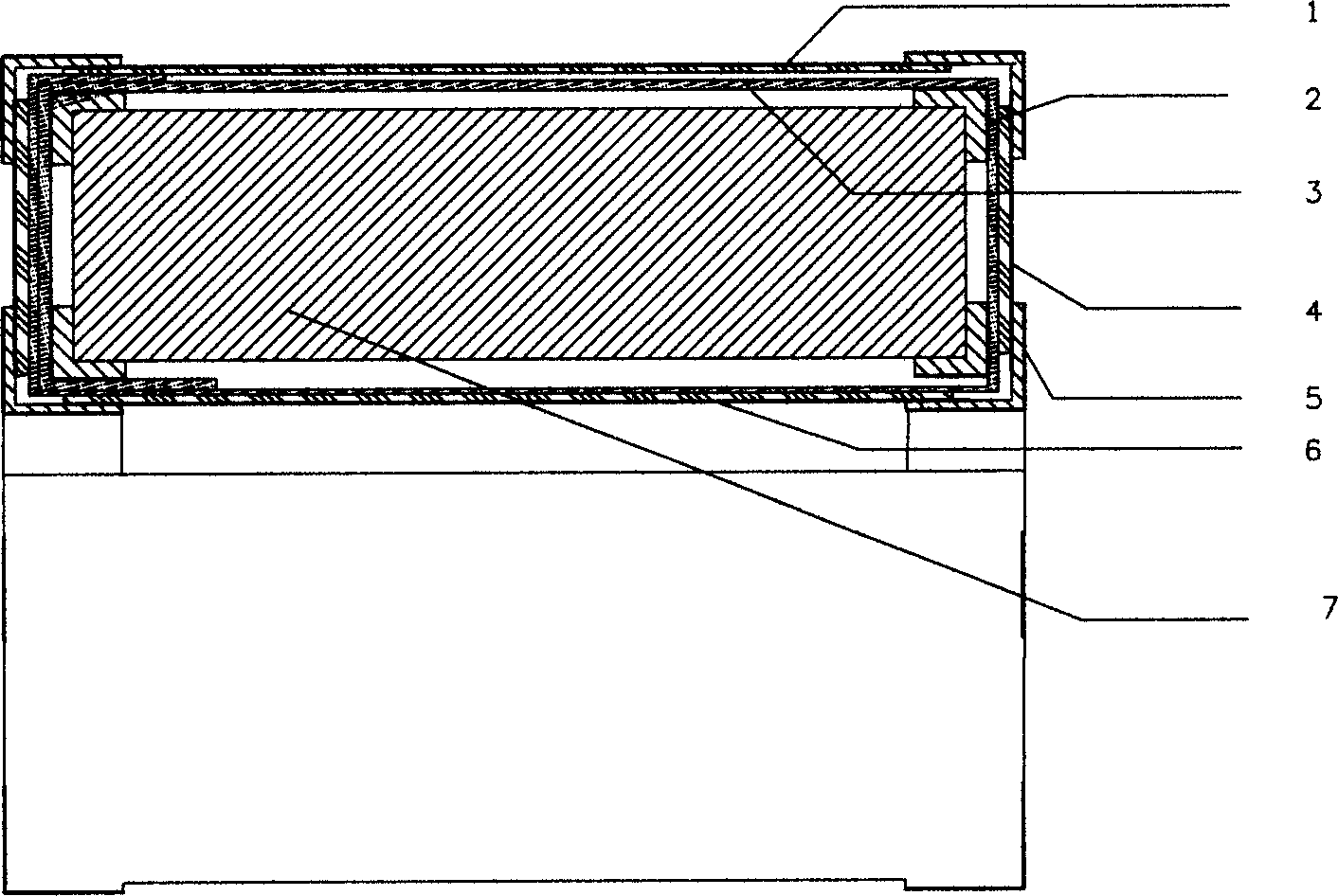

9Ni steel and stainless steel composite steel plate for LNG storage tank and movable vessel and manufacturing method of composite steel plate

ActiveCN105690910AExcellent anti-rustImprove mechanical propertiesMetal layered productsSheet steelSS - Stainless steel

The invention relates to a 9Ni steel and stainless steel composite steel plate for an LNG storage tank and a movable vessel and a manufacturing method of the composite steel plate. The composite steel plate comprises a substrate and multiple layers which cover at least one surface of the substrate, the substrate is made of 9Ni steel, and the multiple layers are made of Austenite stainless steel. The composite steel plate is obtained through blank surface treatment, seaming, heating, cooling, rolling and a heat treatment technology, the shear strength of a compound interface is larger than or equal to 210 MPa, -196 DEG C lower-temperature Charpy impact energy is larger than or equal to 100 J, the tensile strength ranges from 680 MPa to 820 MPa, the yield strength is larger than or equal to 50 MPa, the elongation is larger than or equal to 18%, and the remanence strength is smaller than or equal to 30 gauss.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation of extreme pressure anti-wearing additive and energy-saving environmental-friendly engine oil containing same

ActiveCN106085549AImprove carrying capacityGood extreme pressure resistanceAdditivesTetrafluoroborateAntioxidant

The invention belongs to the field of engine lubricants, and relates to preparation of an extreme pressure anti-wearing additive and energy-saving environmental-friendly engine oil containing same. Preparation of the extreme pressure anti-wearing additive comprises the following steps: dissolving lanthanum bromide into distilled water, stirring till a clear and transparent liquid, dropping an ethanol solution containing polymeric ionic liquid modified graphene and sodium carbonate drop by drop under violent stirring, then the solution can be white and muddy immediately, implementing constant-temperature reaction, after reaction is completed, leaving to stand and precipitate, filtering, washing the precipitate for multiple times with distilled water, further washing for multiple times with absolute ethyl alcohol, finally washing for multiple times with a potassium tetrafluoroborate solution, implementing particle exchange, drying so as to obtain a sample, and grinding for later use. The energy-saving environmental-friendly engine oil containing the extreme pressure anti-wearing additive comprises basic oil, an anti-wearing agent, the extreme pressure anti-wearing additive, a high-temperature antioxidant, a clearing agent, a dispersing agent, a viscosity index improver, and the like. The engine oil designed from the extreme pressure anti-wearing additive is relatively good in bearing capability and extreme pressure anti-wearing property, and is relatively good in environmental-friendliness.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Packaging material for roll material and its packaging method

InactiveCN1380229AExcellent anti-rustImprove waterproof performancePaper article packagingFlexible coversFiberEngineering

The present invention relates to a packaging material for coiled material and its packaging method. It uses industrial composite packaging film, protection plate, end protection plate and metal protective corner as packaging material, and is characterized by that the industrial packaging film is formed from three layers of water-proofing layer, reinforcing layer and rust-proofing layer through the process of co-extrusion, its protection plate and end protection plate adopt the composite fibre packaging plate with water-proofing property. Said invention also provides the use method of these packaging material, and its packaging effect is good and solves the problem of resisting rust for coiled material.

Owner:鞍山市煜辉包装材料有限公司

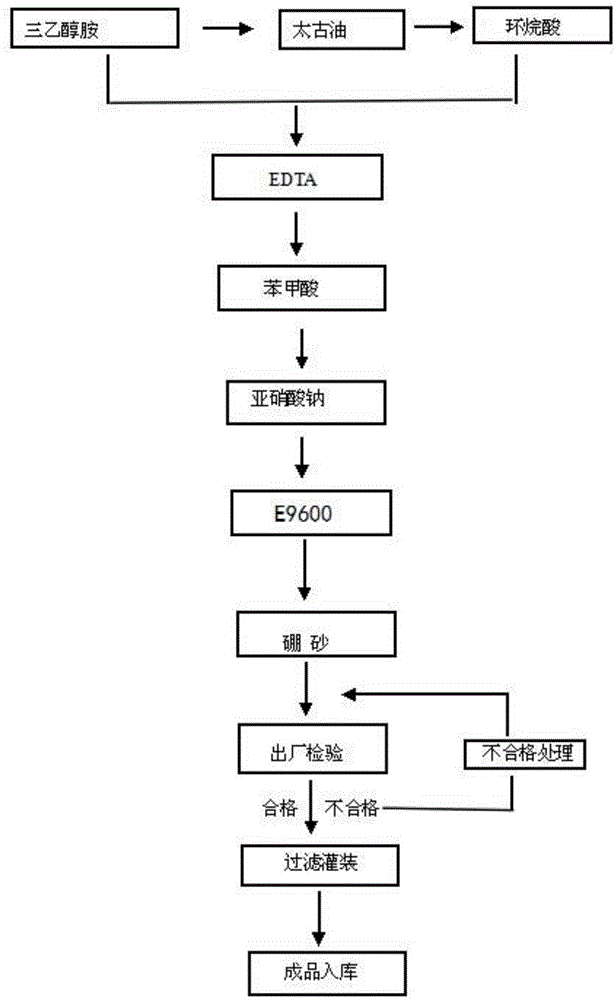

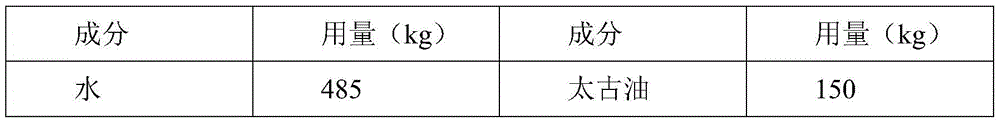

Environment-friendly emulsified oil for hydraulic support and preparation method of environment-friendly emulsified oil

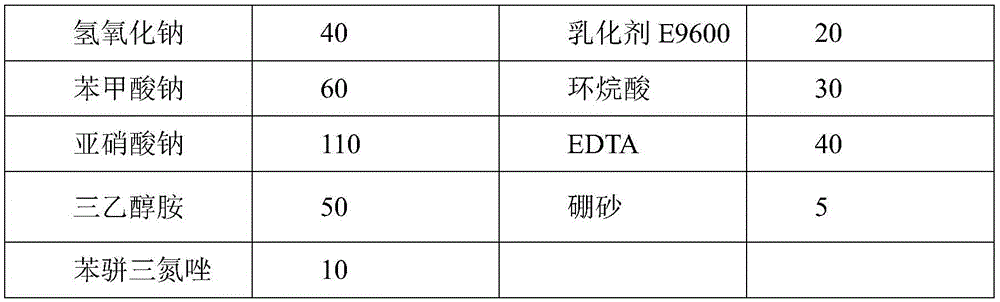

ActiveCN105462673ASolve the short service lifeReduce wearLubricant compositionOrganosolvSodium nitrite

The invention discloses environment-friendly emulsified oil for a hydraulic support and a preparation method of the environment-friendly emulsified oil. The emulsified oil is prepared from the following raw materials in percentage by mass: 15.0 to 25.0 percent of Turkey red oil, 2 to 4 percent of sodium hydroxide, 2 to 5 percent of emulsifier E9600, 3 to 6 percent of sodium benzoate, 3 to 6 percent of naphthenic acid, 9 to 11 percent of sodium nitrite, 4 to 6 percent of EDTA, 5 to 7 percent of triethanolamine, 0.5 to 2.0 percent of borax, 0.1 to 1 percent of benzotriazole and the balance of water. According to the emulsified oil and the preparation method thereof, provided by the invention, the defects that the production technology process is complex, the materials are various and the odor is great in the prior art can be overcome, and the production cost is reduced; in the formula of the emulsified oil, the plant Turkey red oil is adopted, the quality of the emulsified oil is improved due to the selection of the raw materials, the using amount of organic solvents in the whole formula is reduced and the demand of environment protection is met.

Owner:ZIZHOU XINRUN BIOTECH CO LTD

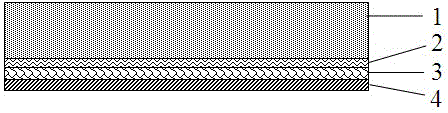

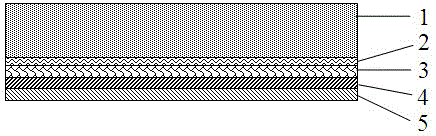

Metal wire drawing-imitating decoration film

InactiveCN104416993AImprove adhesion fastnessEasy to useSynthetic resin layered productsSpecial ornamental structuresPrinting inkSteel plates

The invention provides a metal wire drawing-imitating decoration film which comprises a PET base film, a primer layer, a metal wire drawing-imitating pattern layer, and a printing ink layer; the primer layer is printed on the surface of the PET base film; the metal wire drawing-imitating pattern layer is printed on the surface of the primer layer; and the printing ink layer is printed on the surface of the metal wire drawing-imitating pattern layer. The decoration film of the invention is few in production procedures, low in manufacturing cost, and distinct in the metal wire drawing-imitating pattern, has different glossiness effects such as matt, common, highlight, and the like, has high combining strength with various sheet materials, has good aging resistance and long service life, is widely used in surface decoration of color steel plates, integrated furred ceilings, bureau doors, cabinets, and industrial products, and has very good anti-rust, protective, decorative, and beatifying effect on decorated color plates.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

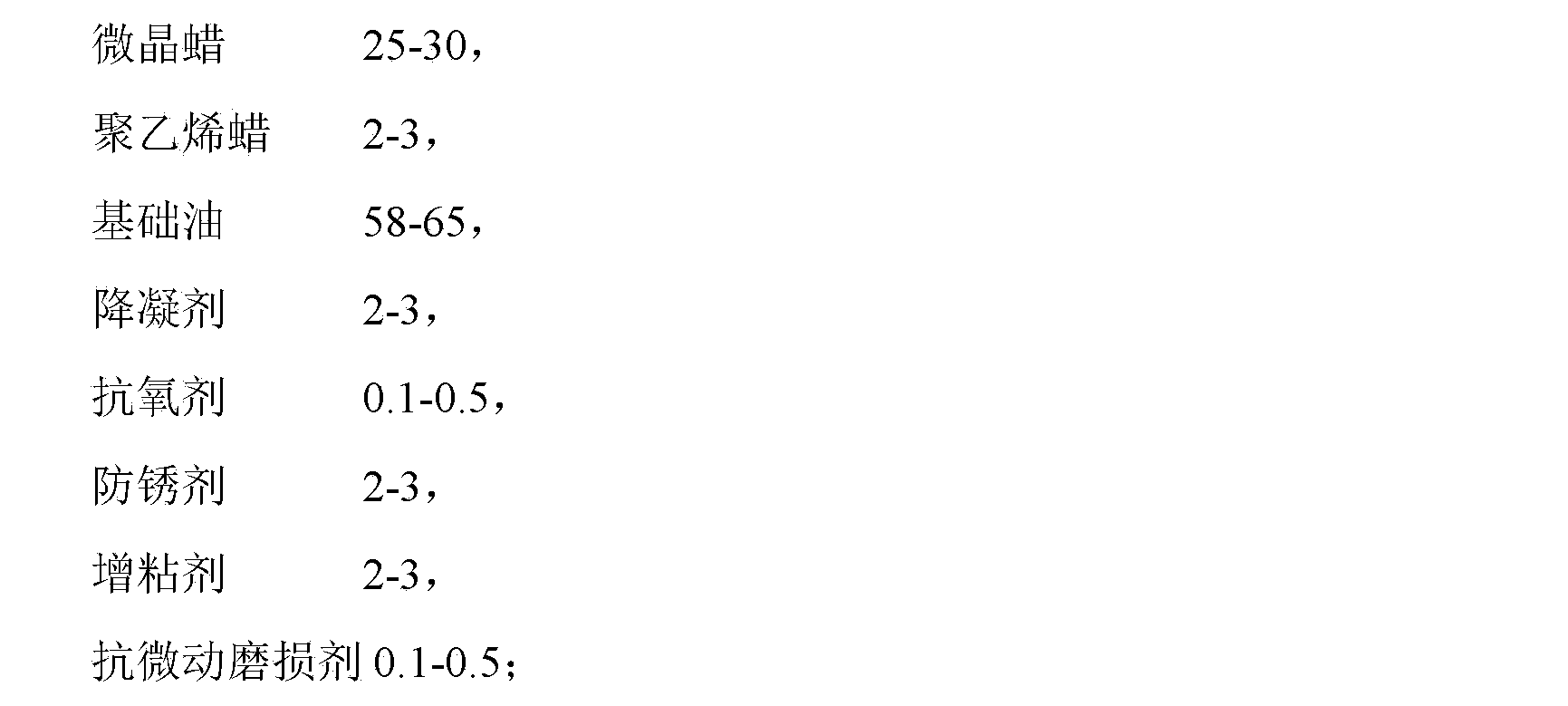

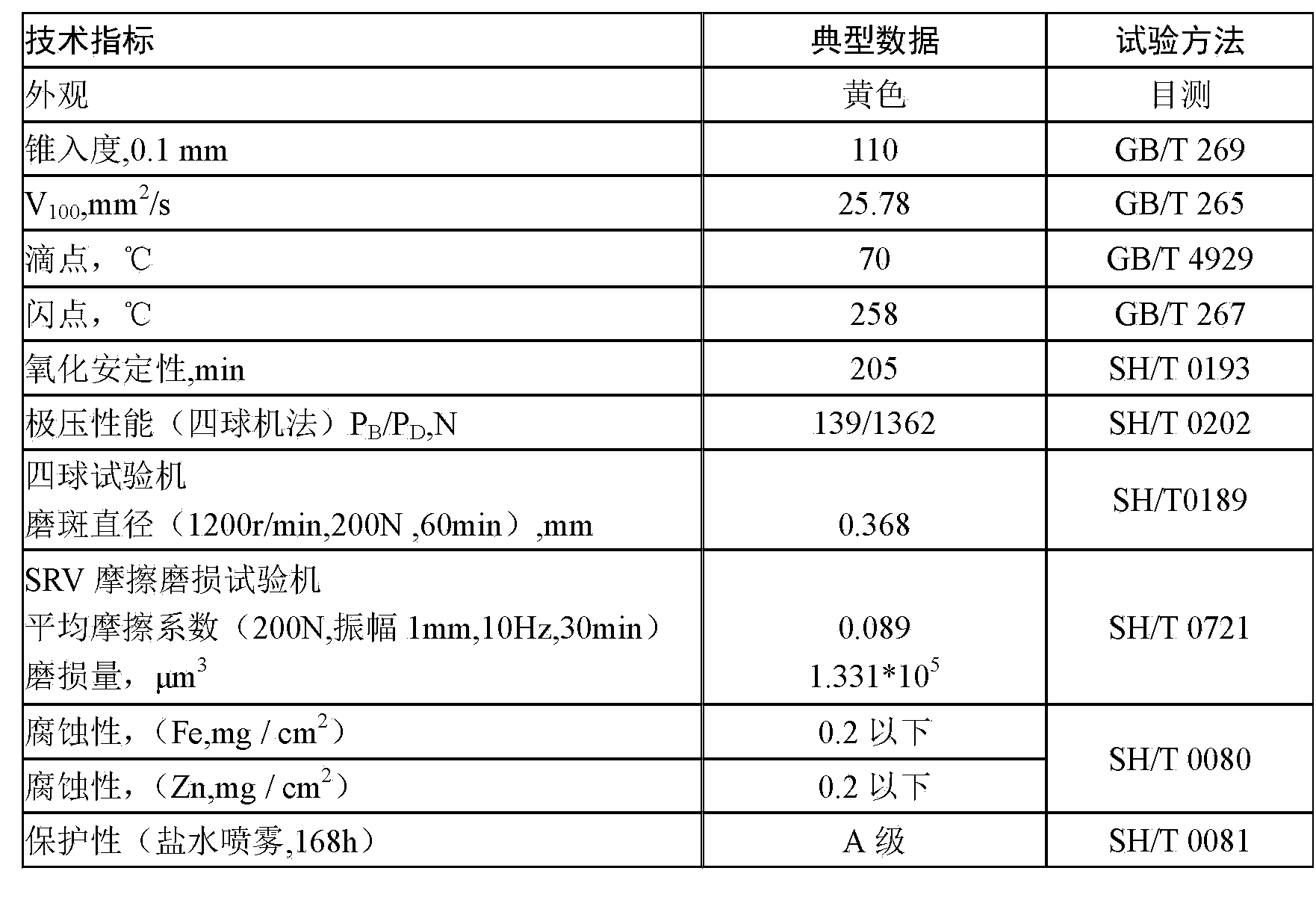

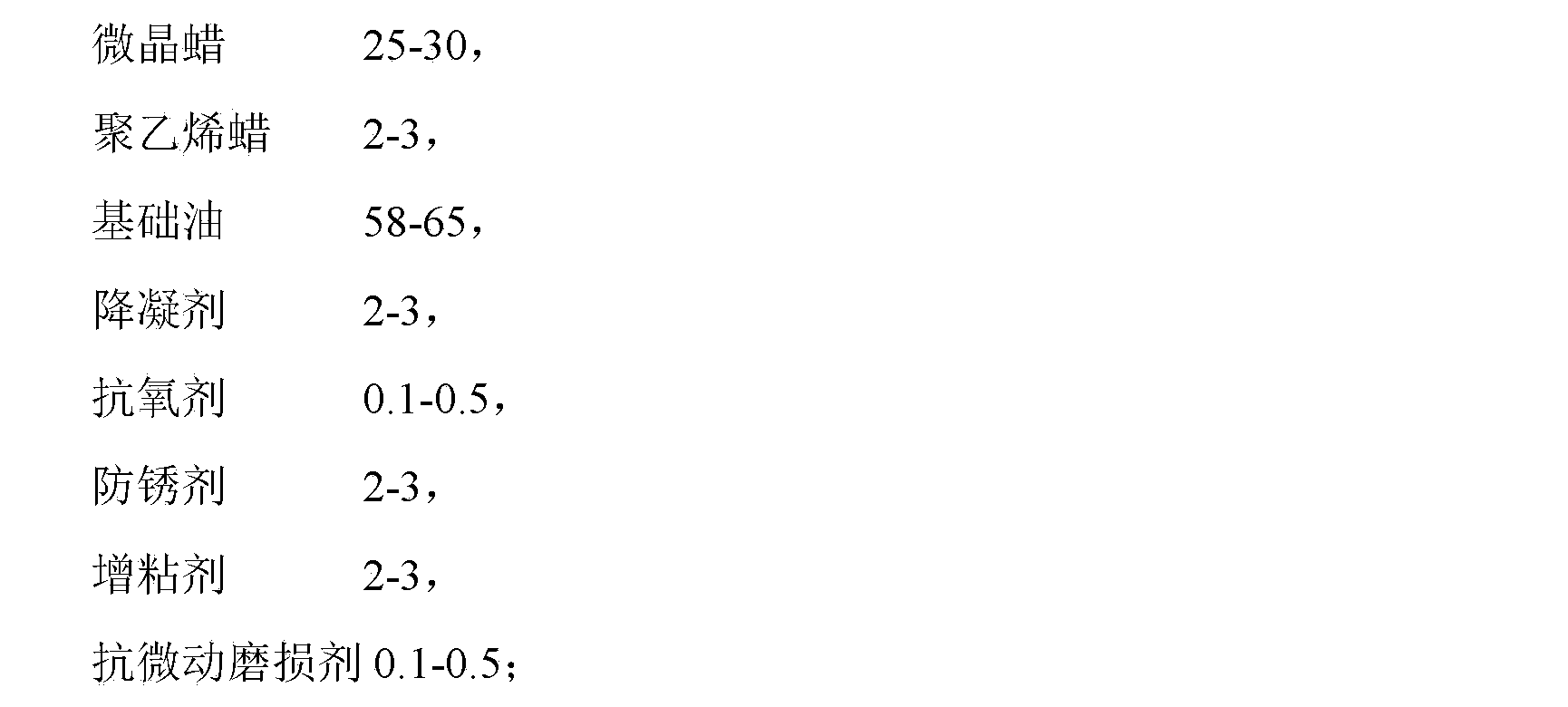

Elevator steel wire rope lubricating grease and preparation method thereof

ActiveCN103436329AExtended service lifeReduce coefficient of frictionLubricant compositionMicrocrystalline waxButylated hydroxytoluene

The invention relates to elevator steel wire rope lubricating grease and a preparation method thereof. The lubricating grease comprises the following components in parts by weight: 25-30 parts of microcrystalline wax, 2-3 parts of polyethylene wax, 58-65 parts of base oil, 2-3 parts of pour point depressant, namely poly-alpha olefin, 0.1-0.5 parts of antioxygen, namely butylated hydroxytoluene, 2-3 parts of antirust agent, namely barium sulfonate, 2-3 parts of tackifier, namely polyisobutylene, and 0.1-0.5 parts of fretting wear resistant agent, namely sulfur-phosphorous type ashless antiwear agent. The lubricating grease has the advantages that a using temperature range is wider; the carrying capacity is higher; and the oxidation stability, the rust resistance, the fretting wear resistance and the like are good.

Owner:辽宁海华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com