Lubricating anticorrosive oil and use thereof

A technology of lubricating anti-rust and anti-rust agent, applied in the field of lubricating anti-rust oil, which can solve the problems of only focusing on anti-rust performance, poor adhesion performance of anti-rust products, and failure to take into account the extreme pressure performance of oil products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

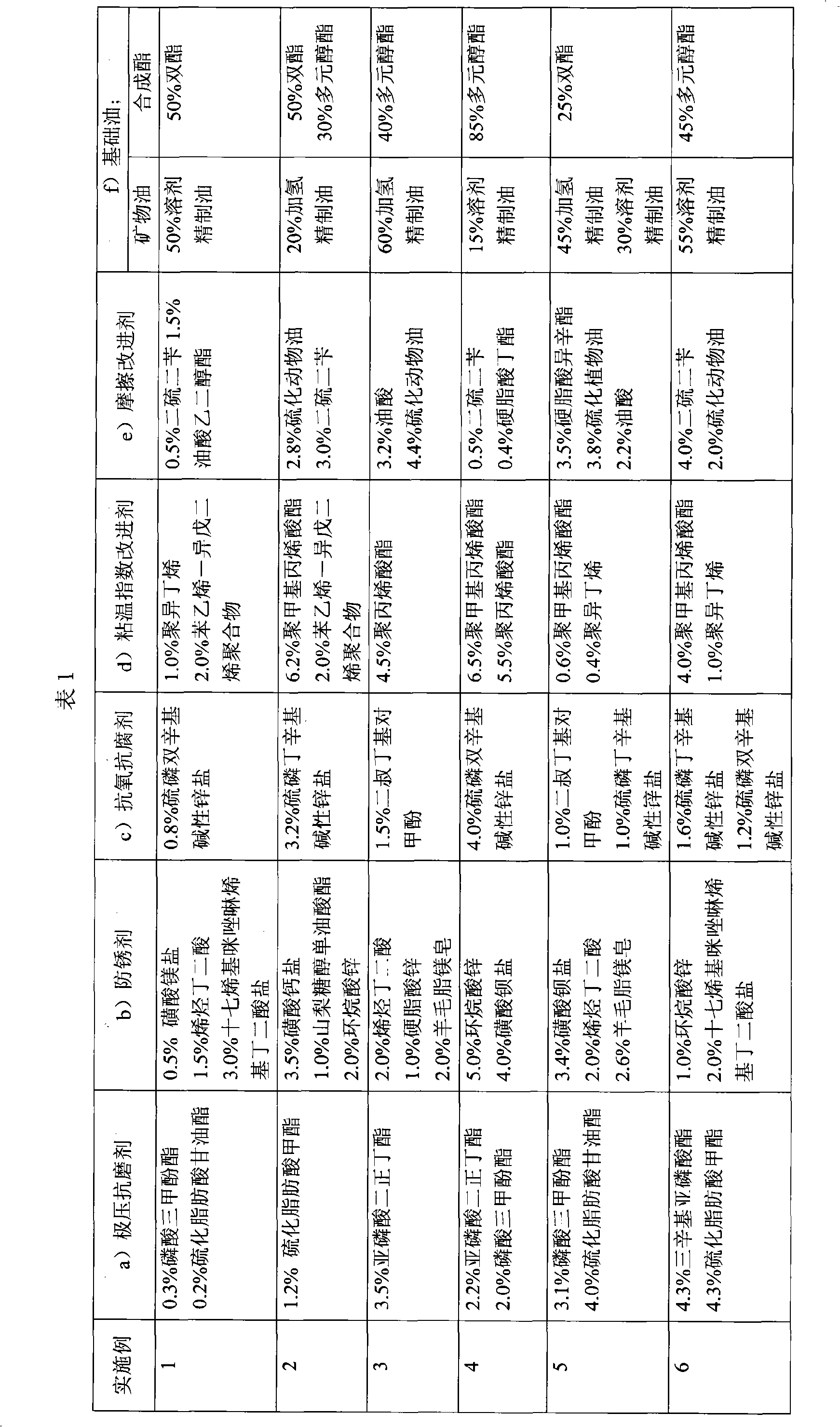

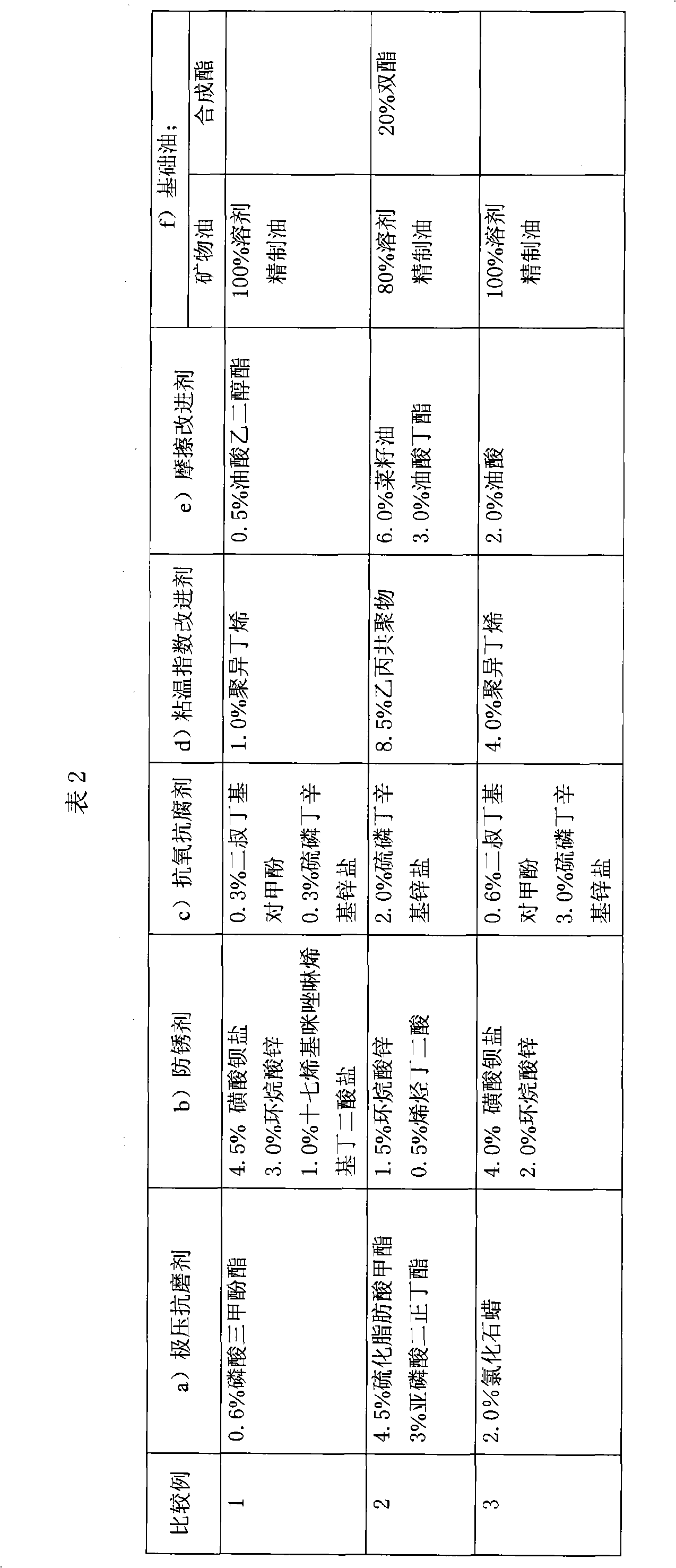

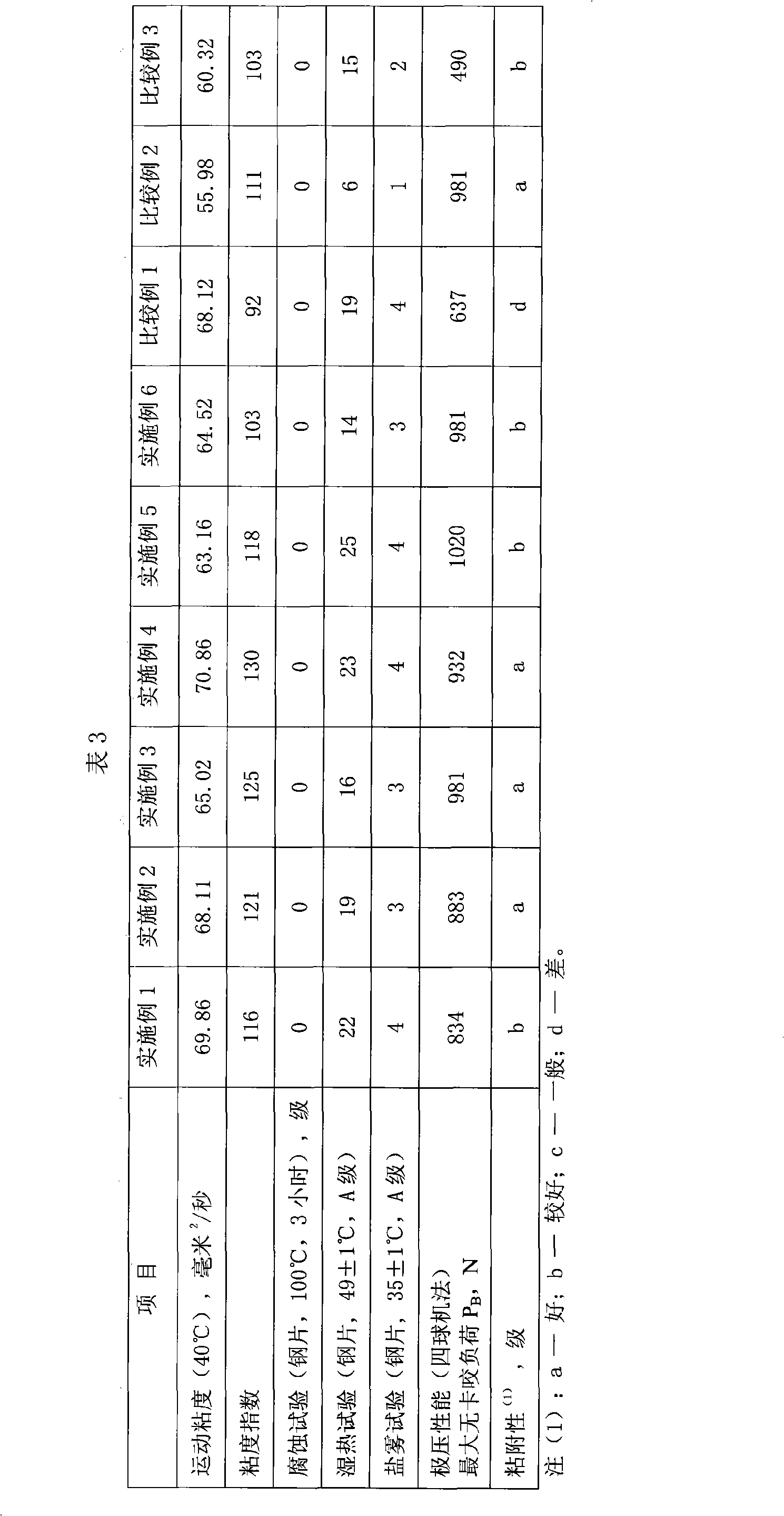

[0026] Pump the correctly measured base oil into the blending tank, heat and stir evenly, when the temperature of the oil product rises to 75°C, add viscosity-temperature index improver, friction modifier, and rust inhibitor in sequence, keep stirring at 65°C for 2.5 hours, When the oil temperature is cooled to 50°C, add antioxidant and anti-corrosion agent, extreme pressure and anti-wear agent in turn, and stir at constant temperature for 2 hours. Wherein each component and its weight percentage are shown in Table 1, and product performance is shown in Table 3.

Embodiment 7

[0030] The lubricating antirust oil of [embodiment 4] is evenly brushed on the steel wire rope, and the oil has good extreme pressure and antiwear properties, antirust and anticorrosion, permeability and adhesion, and the lubricating antirust oil can be used for a period of time. After the actual application, there is no flow down from the wire rope, and there is no phenomenon of hardening, cracking and falling off. At the same time, the wire rope coated with lubricating anti-rust oil has not been rusted within 6 months. The product performance is as follows:

[0031] Kinematic viscosity (40℃), mm 2 / sec 70.86

[0032] Viscosity index 130

[0033] Corrosion test (steel sheet, 100°C, 3 hours), level 0

[0034] Damp heat test (steel sheet, 49±1℃, grade A) 23

[0035] Salt spray test (steel sheet, 35±1℃, grade A) 4

[0036] Extreme pressure performance (four-ball machine method) maximum non-jamming load P B , N 932

[0037] Adhesion (1) , class a

[0038] Note (1): a-goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com