Patents

Literature

79results about How to "Good extreme pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound lithium base grease composite and preparation method thereof

ActiveCN101838580AGood colloidal stabilityGood mechanical stabilityAdditivesLithiumMechanical stability

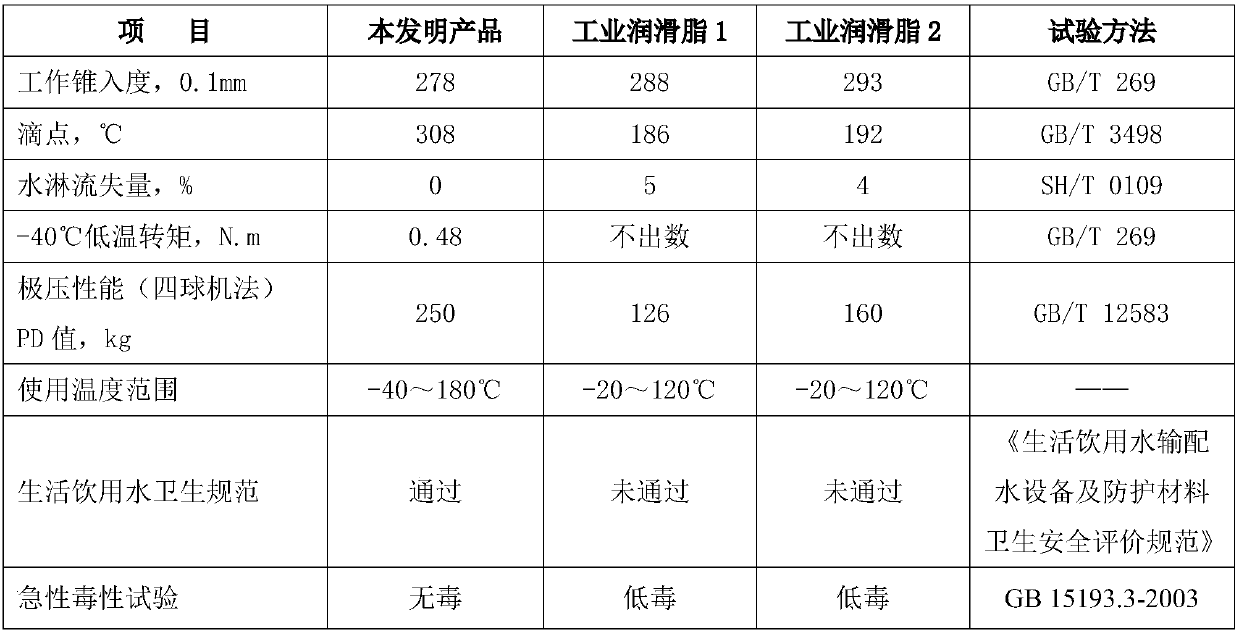

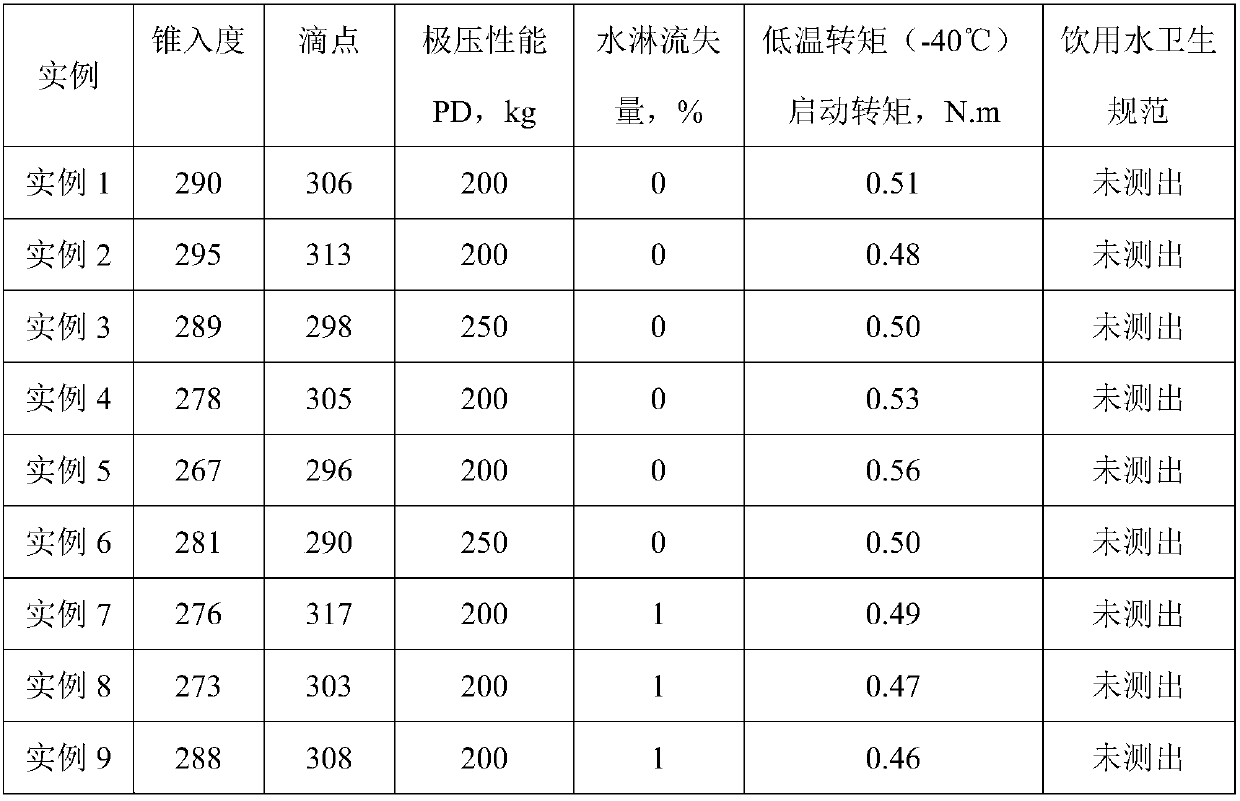

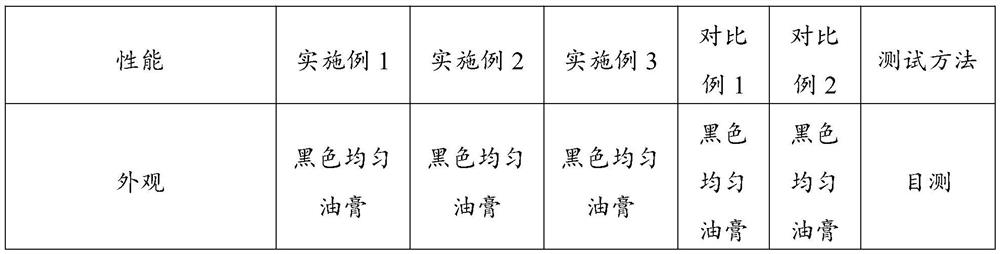

The invention discloses a compound lithium base grease composite, which comprises the following materials in percentage by weight: 70-89% of grease base oil, 10-25% of densifier, 0.02-2% of additive, and 0.01-5% of bismuth oxide. In the compound lithium base grease composite, micron-level bismuth oxide powder is added as an extreme-pressure additive, and the prepared compound lithium base grease composite has good colloidal stability and mechanical stability, and better high temperature performance and extreme pressure resisting performance.

Owner:SUN YAT SEN UNIV

Heavy-duty antiemulsifying oil film bearing oil

InactiveCN1346874AGuaranteed normal operationImprove the lubrication effectAdditivesWire rodDemulsifier

A heavy-duty antiemulsifying oil film type bearing oil for high-speed wire rolling mill contains demulsifier, antiwear agent, antifoaming agent, alkylnaphthalene, antioxidant and mineral oil. Its advantages are excellent antiemulsifying, antiwear, anti-extreme-pressure, anticorrosion, antirust, antifoaming and antioxidizing performance, and better viscosity-temp characteristic.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Full-synthetic gear/bearing oil for four seasons and preparation method thereof

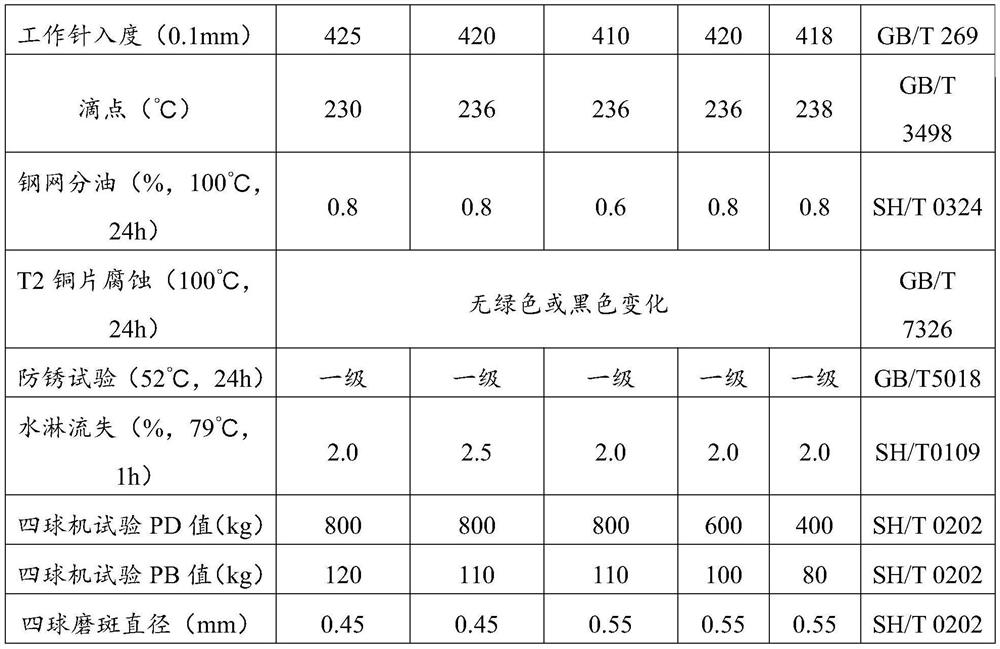

ActiveCN101531947ASignificant positive effectWide temperature rangeBase-materialsViscosity gradeOil additive

The invention discloses full-synthetic gear / bearing oil for four seasons and a preparation method thereof. The full-synthetic gear / bearing oil for four seasons is prepared by blending synthetic oil taken as base oil and an additive; the selected base oil is one of ester oil, synthetic hydrocarbon-type oil and a mixture of the ester oil and the synthetic hydrocarbon-type oil; the selected additive is a high-performance complexing agent, which is one of gear oil compound additive, wind turbine oil additive, industrial lubricant friction modifier, general gear oil complexing agent and multifunction gear oil additive; and the blending ratio of the base oil to the additive is 1.0 to 5.0 weight percent of the high-performance complexing agent and the balance of the base oil. According to viscosity grades of the gear oil, the synthetic oil with one or more compositions is added to a blending kettle with a stirrer in required proportion, is stirred for 0.5 to 1.5 hours at a temperature of between 30 and 60 DEG C, and is blended into the base oil of the gear oil; and the base oil is added with the high-performance complexing agent in a certain proportion and stirred for 1 to 3 hours at a temperature of between 30 and 60 DEG C to form the gear lubricant of the invention.

Owner:精锐化学(上海)有限公司

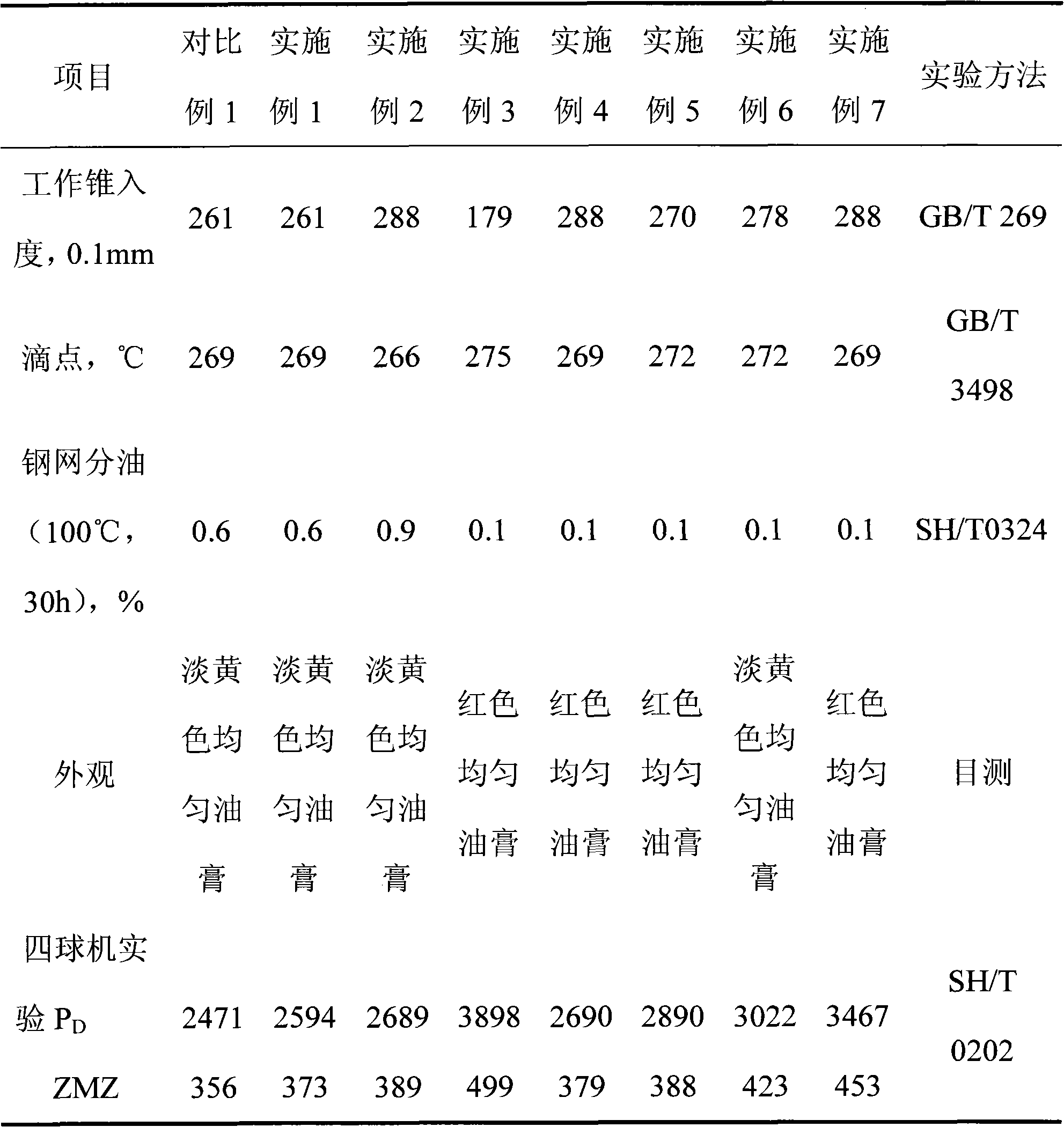

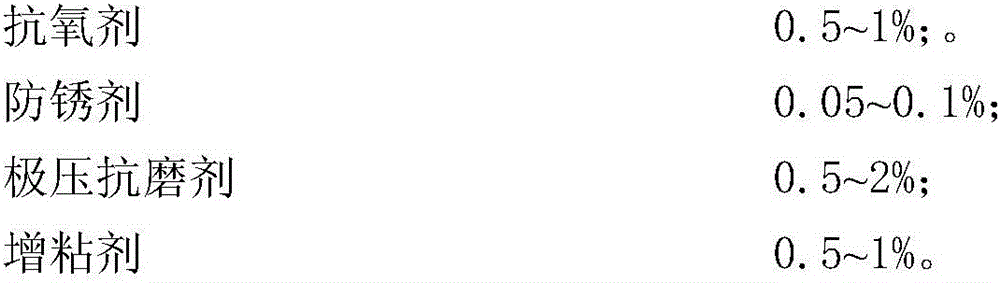

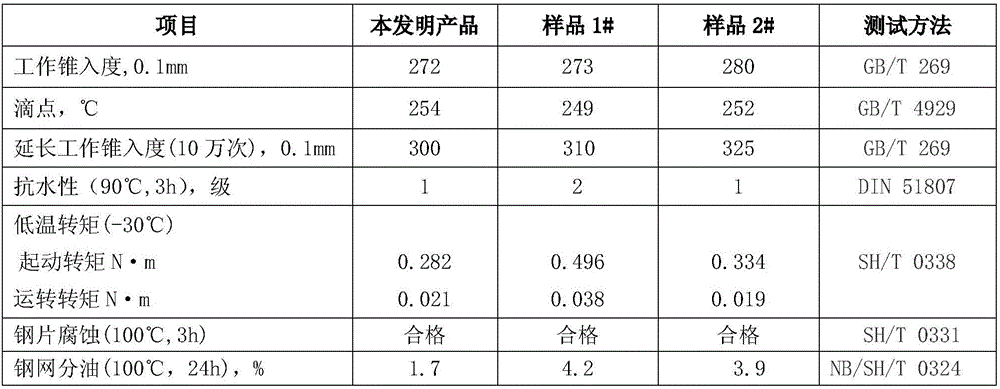

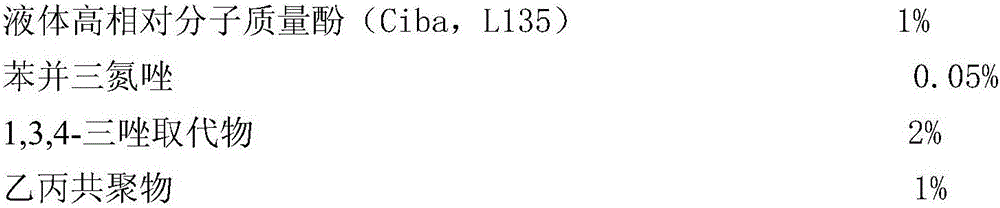

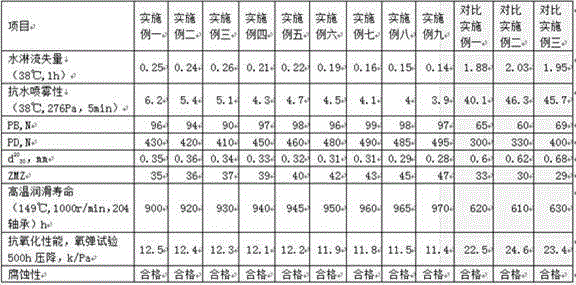

Turbine worm lubricating grease composition and preparation method thereof

InactiveCN106497659AImprove water resistanceImprove antioxidant capacityAdditivesLithium hydroxideEvaporation

The invention relates to a turbine worm lubricating grease composition and a preparation method. The turbine worm lubricating grease composition is prepared from 85-90% of base oil, 10-15% of thickener, 0.5-1% of antioxidant, 0.05-0.1% of antirust agent, 0.5-2% of extreme-pressure abrasion-resisting agent and 0.5-1% of tackifier. The thickener is generated through reaction of fatty acid and an alkaline water solution, wherein the fatty acid is a mixture of 12-hydroxy stearic acid and sebacic acid, and alkali is the mixture of lithium hydroxide and calcium hydroxide. The lubricating grease is of a unique mixed thickener type, so that the water-resistant and shearing properties of the lubricating grease are remarkable, and the usage requirement for the 30-70 DEG C wide temperature range of a turbine worm accessory itself can be well met. The colloid stability, water resistance and oxidation resistance of the lubricating grease are effectively improved, meanwhile the lubricating grease composition has the advantages of being low in oil separation rate, small in evaporation loss, high in shear stability, good in high and low temperature performance and corrosion protection effect and the like, and the usage temperature range of the lubricating grease is 30-150 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation of extreme pressure anti-wearing additive and energy-saving environmental-friendly engine oil containing same

ActiveCN106085549AImprove carrying capacityGood extreme pressure resistanceAdditivesTetrafluoroborateAntioxidant

The invention belongs to the field of engine lubricants, and relates to preparation of an extreme pressure anti-wearing additive and energy-saving environmental-friendly engine oil containing same. Preparation of the extreme pressure anti-wearing additive comprises the following steps: dissolving lanthanum bromide into distilled water, stirring till a clear and transparent liquid, dropping an ethanol solution containing polymeric ionic liquid modified graphene and sodium carbonate drop by drop under violent stirring, then the solution can be white and muddy immediately, implementing constant-temperature reaction, after reaction is completed, leaving to stand and precipitate, filtering, washing the precipitate for multiple times with distilled water, further washing for multiple times with absolute ethyl alcohol, finally washing for multiple times with a potassium tetrafluoroborate solution, implementing particle exchange, drying so as to obtain a sample, and grinding for later use. The energy-saving environmental-friendly engine oil containing the extreme pressure anti-wearing additive comprises basic oil, an anti-wearing agent, the extreme pressure anti-wearing additive, a high-temperature antioxidant, a clearing agent, a dispersing agent, a viscosity index improver, and the like. The engine oil designed from the extreme pressure anti-wearing additive is relatively good in bearing capability and extreme pressure anti-wearing property, and is relatively good in environmental-friendliness.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

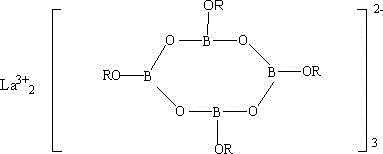

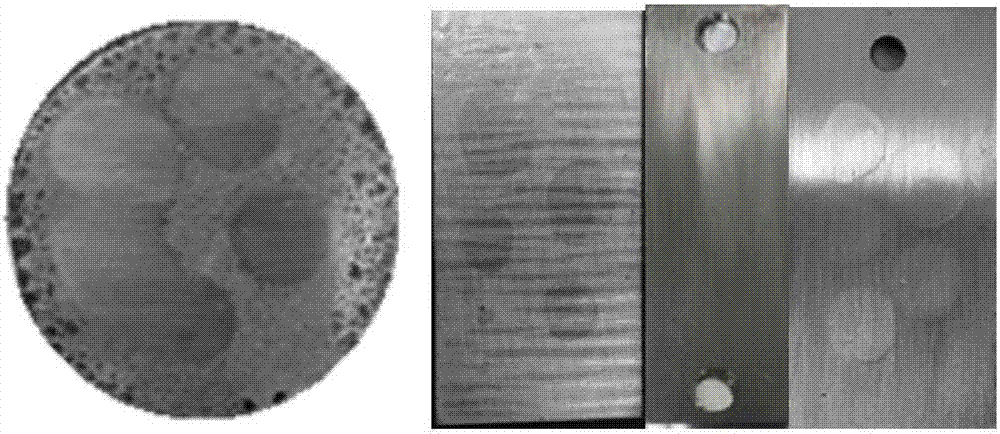

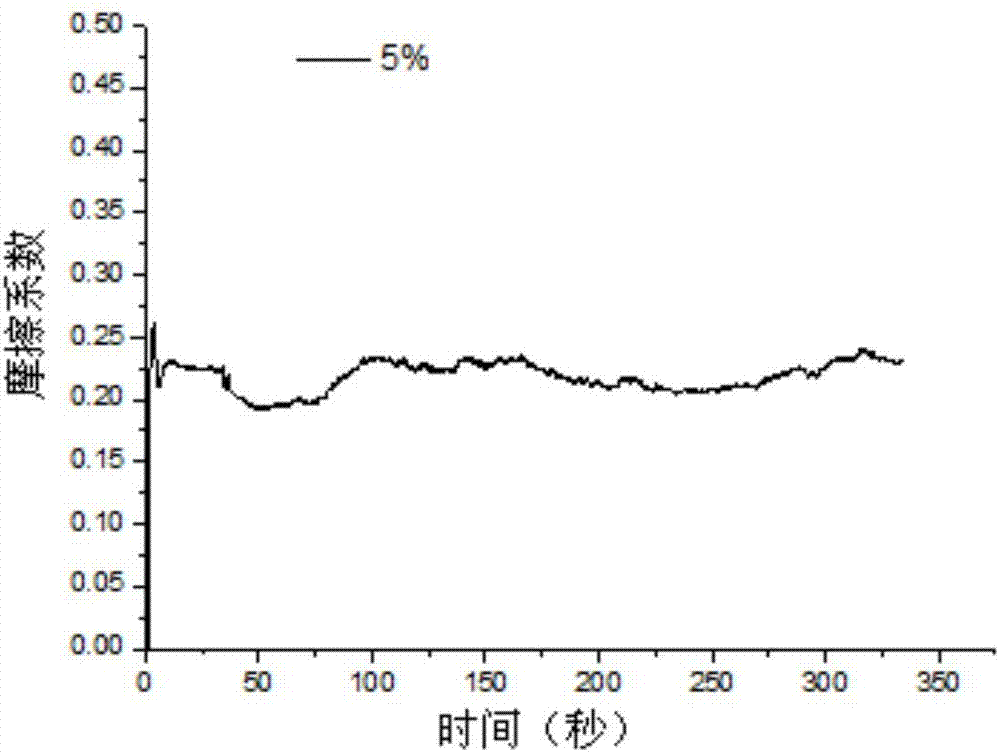

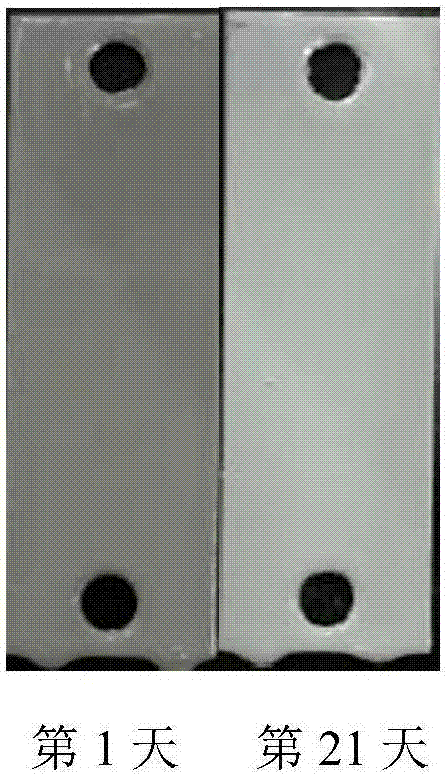

Preparation of extreme pressure anti-wear agent and vehicle gear oil containing extreme pressure anti-wear agent

InactiveCN106046037AImprove carrying capacityGood extreme pressure resistanceGroup 3/13 element organic compoundsAdditivesRare-earth elementDistillation

The invention belongs to the field of vehicle gear lubricant, and relates to preparation of an extreme pressure anti-wear agent and vehicle gear oil containing the extreme pressure anti-wear agent. The preparation of the extreme pressure anti-wear agent comprises steps as follows: a certain amount of borax is added to a lanthanum nitrate solution and subjected to a reaction for a few hours; then a certain amount of n-butyl alcohol is added to a reaction liquid and subjected to esterification for a few hours; after the reaction, an appropriate amount of lauryl alcohol modified graphene oxide is added and subjected to transesterification, impurities of a reaction product are removed through distillation, and the extreme pressure anti-wear agent is obtained. The vehicle gear oil containing the extreme pressure anti-wear agent comprises components as follows: base oil, the extreme pressure anti-wear agent, ammonium thiophosphate, sulfurized isobutylene, a clearing agent, a dispersing agent, a pour point depressant and a deforming agent. According to the preparation of the extreme pressure anti-wear agent and the vehicle gear oil containing the extreme pressure anti-wear agent, the friction coefficient of the surface of a friction pair is reduced, a rare earth element and a boron element are diffused from the friction surface to a substrate in a friction process so as to form a permeable layer, the wear resistance of a material surface is improved, an extreme pressure anti-wear effect is realized, and properties of good wear resistance, rust resistance, corrosion resistance and the like are achieved.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Metallic nano-particle surface amendment

The invention relates to a metal nanometer particle surface conditioner as well as the preparation method and the application, belonging to the technical field of nanometer additives of lubricating oil. The invention is characterized in that the metal nanometer particle surface conditioner is prepared according to the mass percentage as follows: 5 to 80% at least one metal nanometer fine particle of copper, zinc, nickel or tin with the particle size of less than 30 nanometers; 20 to 90 % nanometer macromolecular composite material (B) formed by the copolymer of hydrocarbon, ester or sulfonate surfactants and iron-bas ion with the average particle size of less than 25 nanometers; 0.001 to 10 % mixture (C) comprises antioxidant, anticorrosive agent and friction modifier. Compared with the prior art, the metal nanometer particle surface conditioner has the advantages of simple process, convenient preparation, and good stability, dispersion, extreme pressure resistance performance and self-repairing function.

Owner:郑州东申石化科技有限公司 +1

Ultra-low foam total synthesis water-based lubricating fluid

InactiveCN107034003AImprove antibacterial propertiesImprove rust resistanceLubricant compositionWater basedFoaming agent

The invention discloses water-based lubricating fluid. The water-based lubricating fluid comprises water-soluble lubrication base liquid, an antirust agent, an anti-grinding agent, a coupler, an anti-foaming agent, a bactericide, a pH value conditioning agent and water. The water-based lubricating fluid has good anti-foaming property and anti-rust property, and excellent lubricity, paint adaptability and anti-extreme pressure performance.

Owner:TSINGHUA UNIV

Synthetic type cutting fluid containing nanoparticle molybdenum sulfide and preparation method thereof

InactiveCN108865388AImprove the lubrication effectImprove wear resistanceLubricant compositionSodium acetateFoaming agent

The invention discloses synthetic type cutting fluid containing nanoparticle molybdenum sulfide and a preparation method thereof. The synthetic type cutting fluid disclosed by the invention is prepared from the following components in percentage by mass: 5 to 12 percent of an antirust agent, 0.3 to 0.4 percent of a de-foaming agent, 2 to 15 percent of a lubricant, 0.4 to 2 percent of an anticorrosion and bactericidal agent, 34 to 50 percent of a surfactant, 0.2 to 0.6 percent of methylbenzotriazole and the balance of water; the total weight is 100 percent; the lubricant is a dispersion solution of nano molybdenum sulfide, and is prepared from the following components in percentage by mass: 4.5 to 5.5 weight percent of the nano molybdenum sulfide, 1.2 to 1.6 weight percent of alkyl sulfanilamide sodium acetate, 1.8 to 2.2 weight percent of glycerin polyethenoxy ether and the balance of water. The synthetic type cutting fluid disclosed by the invention has good lubricating property, antirust property, extreme pressure property and cooling property.

Owner:SHANGHAI INST OF TECH

Food grade bearing grease for hydraulic engineering as well as preparation method and application thereof

InactiveCN107686763AMeet health and safety regulationsMeet lubrication needsLubricant compositionOperating temperature rangeHydraulic engineering

The invention provides food grade bearing grease for hydraulic engineering as well as a preparation method and application thereof. The grease composition comprises food grade base oil, a thickening agent and an additive composition. The grease composition comprises the following components in percentage in weight: 84-94% of base oil, 6-16% of the thickening agent, 0.5-10% of an additional antirust agent and 0.1-10% of an additional anti-wear reagent at extreme pressure. The thickening agent is composed of reactants of C16-C20 long-chain fatty acids, aromatic acid and organic aluminum and meets the food grade requirement. The molar ratio of the three raw materials is 1 to 1-1.7 to 1-1.3. The organic aluminum comprises aluminum isopropoxide or triisopropanol trioxide. The bearing grease disclosed by the invention is excellent in anti-wear and extreme pressure property, and the service life of the bearing is prolonged; the water resistance is excellent, the high / low-temperature performance is excellent, and the operating temperature ranges from 40 DEG C below zero to 80 DEG C. The bearing grease disclosed by the invention can meet the lubricating requirements of hydraulic engineeringbearings, and the safety and hygiene requirements in the drinking water industry are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

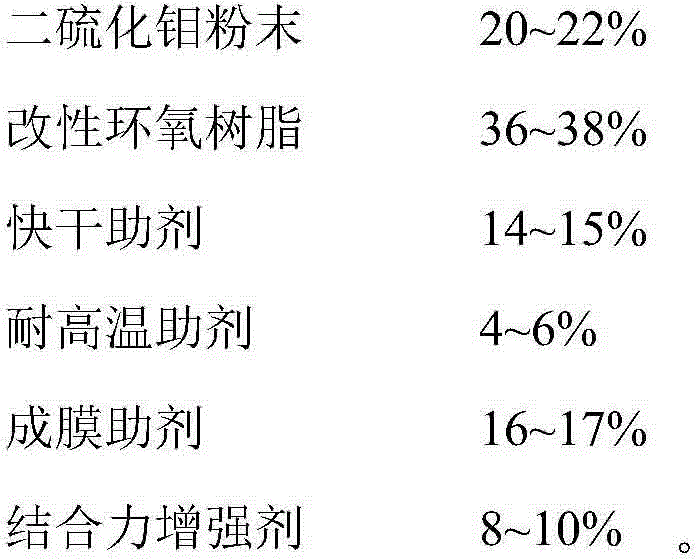

Molybdenum disulfide lubricating spray and preparation method thereof

ActiveCN105886074AEasy to useEasy to carryEpoxy resin coatingsLubricant compositionEpoxyWear resistance

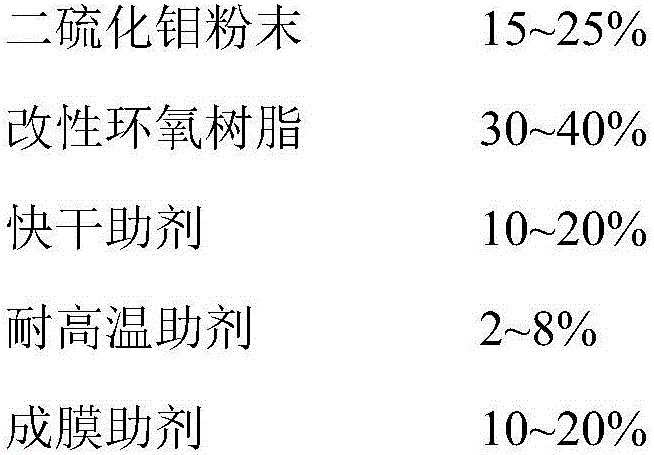

The invention discloses a molybdenum disulfide lubricating spray. The molybdenum disulfide lubricating spray comprises components in percentage by weight as follows: 15%-25% of molybdenum disulfide powder, 30%-40% of modified epoxy resin, 10%-20% of a quick-drying auxiliary, 2%-8% of a high-temperature-resistant auxiliary, 10%-20% of a coalescing agent and 5%-15% of a binding force enhancer. The molybdenum disulfide lubricating spray is simple and convenient to use, has good quick-drying capacity and temperature tolerance, can be applied to the ultrahigh temperature environment and the ultralow temperature environment and has good lubricating property, abrasion performance and extreme pressure resistance, and the temperature tolerance range is 180-450 DEG C.

Owner:在邦润滑材料(上海)有限公司

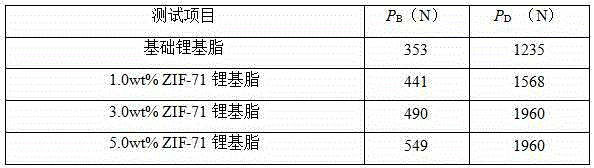

Lubricating grease and preparation method thereof

The invention discloses lubricating grease and a preparation method thereof, and belongs to the technical field of lubricating grease and preparation thereof. The lubricating grease consists of the following raw materials: 95-99 parts of basic lubricating grease and 1-5 parts of additives. The additives are ZIF-71 materials with RHO topological structures. The preparation method of the lubricating grease is simple, convenient and practical, and the performance of the lubricating grease is stable. By the lubricating grease, surfaces of friction pairs can be prevented from being in contact with each other directly, friction is reduced, and the extreme pressure resistance of the lubricating grease is improved.

Owner:TAIYUAN UNIV OF TECH

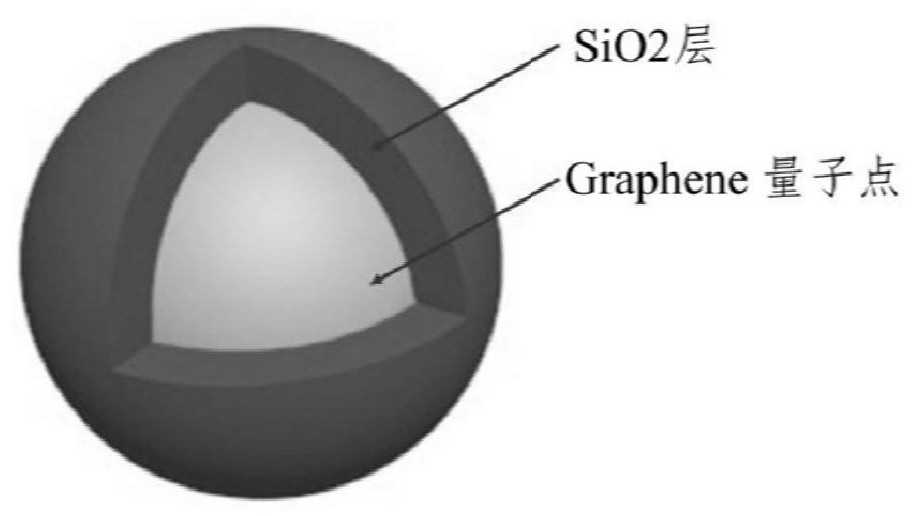

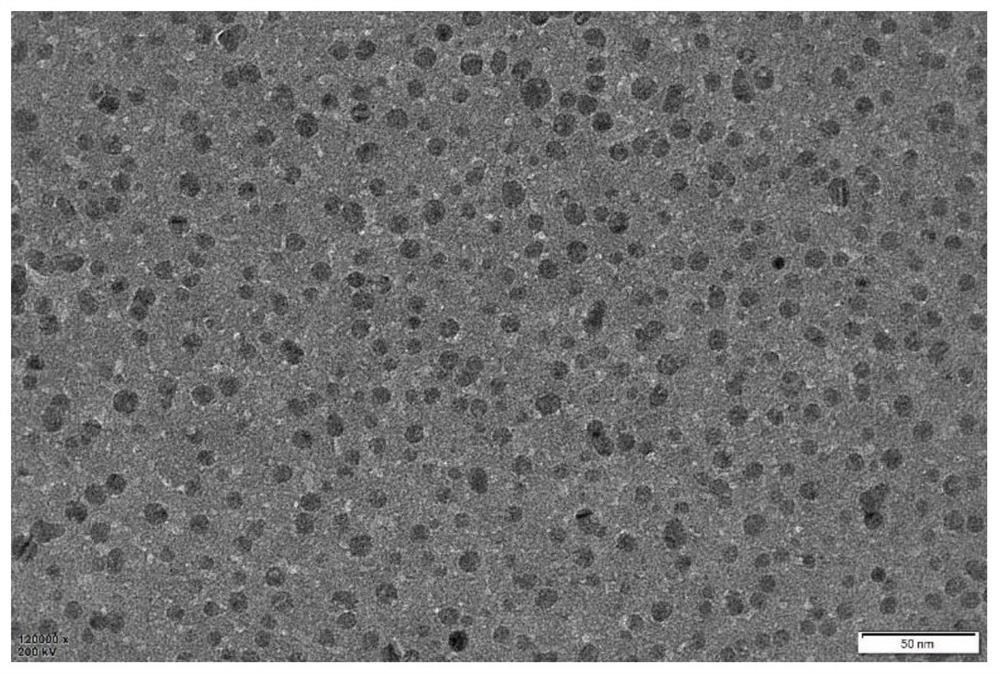

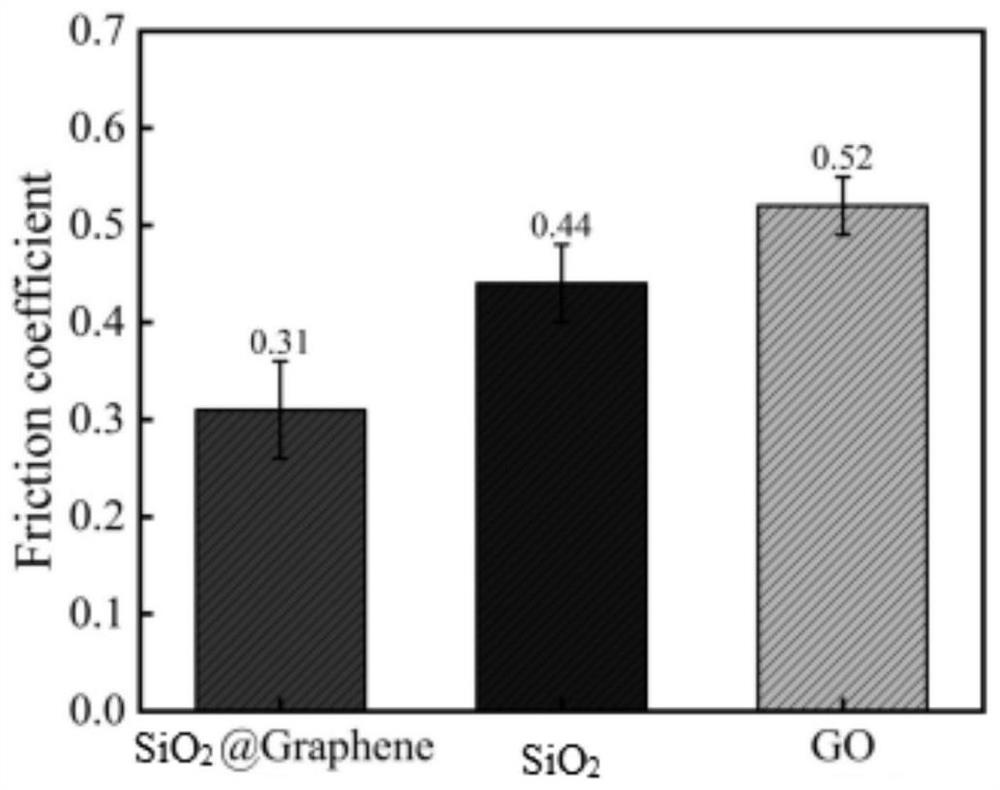

Titanium alloy rolling lubricating liquid based on core-shell structure SiO2 (at) Graphene quantum dots and preparation method thereof

ActiveCN112920876ALow coefficient of friction at high temperatureGood extreme pressure resistanceAdditivesActive agentGraphite

The invention discloses a titanium alloy rolling lubricating liquid based on core-shell structure SiO2 (at) Graphene quantum dots and a preparation method thereof The titanium alloy rolling lubricating liquid is specifically prepared from the following components in parts by weight: 1.5 to 2.5 parts of base oil, 1.5 to 2.5 parts of SiO2 and Graphene quantum dot powder, 90 to 96 parts of deionized water, 0.3 to 0.7 part of a surfactant, 0.8 to 1.2 parts of a dispersing agent, 0.8 to 1.2 parts of a sulfur-containing additive, 0.5 to 1.4 parts of an antioxidant and 0.5 to 1.4 parts of an auxiliary agent. The preparation method of the titanium alloy rolling lubricating liquid comprises the following steps: mixing and stirring SiO2 (at) Graphene quantum dot powder, base oil and deionized water, carrying out ultrasonic treatment, adding the dispersing agent, the sulfur-containing additive, the antioxidant and the auxiliary agent, and adjusting the pH value to alkalescence, thereby obtaining the titanium alloy rolling lubricating liquid. The SiO2 (at) Graphen core-shell structure particles are prepared by a hydrothermal method, take graphene as a core and nano silicon dioxide as a film-coated shell, and have the characteristics of high temperature resistance, lower friction coefficient and better extreme pressure resistance. The prepared rolling lubricating liquid has the advantages of being excellent in performance, lasting in efficiency and the like, and can be suitable for the field of cold rolling machining of titanium alloy ultra-thin plates.

Owner:KUNMING IRON & STEEL HLDG CO LTD +2

Lubricating grease

The present invention relates to a lubricating grease, which comprises base oil, 12-hydroxystearic acid, lithium hydroxide, potassium hydroxide, petroleum calcium sulfonate, rosin, vegetable oil, (NH4)xMoS2, a first solid additive, a second solid additive, a first composite modifier comprising trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene, a second composite modifier comprising diphenylamine, 2,6-di-tert-butyl and benzotriazole, and a third composite modifier comprising sulfurized cottonseed oil T404, bis(2-mercapto-4-n-propylamino-1,3,5-triazine)thioether and bis(2-mercapto-4-cyclopentylamino-1, 3,5-triazine)thioether. The lubricating grease of the present invention has advantages of good sealing performance, strong corrosion resistance, excellent anti-wear performance, and excellent anti-extreme pressure performance.

Owner:HANGZHOU DADI OCEAN ENVIRONMENT PROTECTION

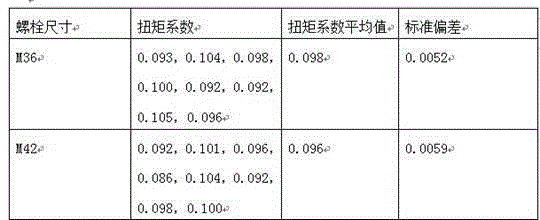

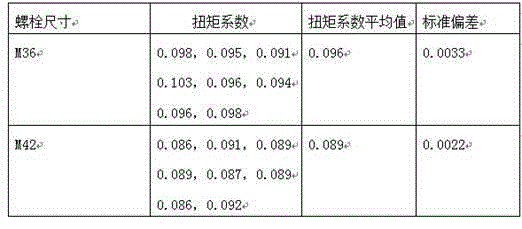

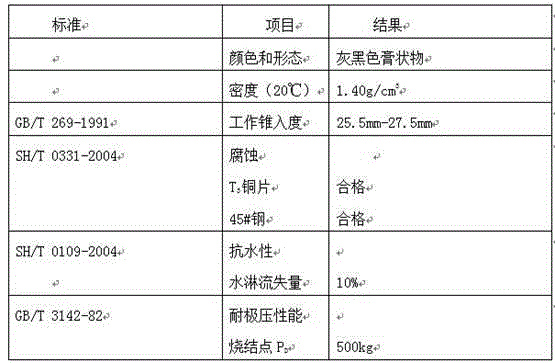

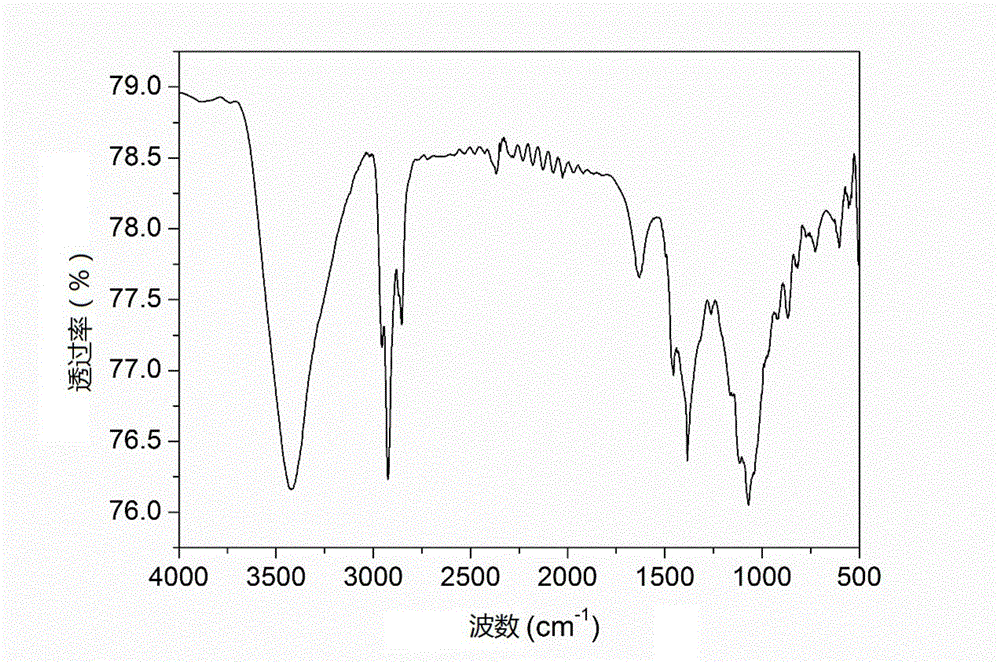

Wind power bolt lubricant resistant to extreme pressure and water shower and convenient for low-temperature brushing

ActiveCN104371810AGood extreme pressure resistancePlay a protective effectLubricant compositionTorque coefficientNaphthalanic oil

The invention discloses a wind power bolt lubricant resistant to extreme pressure and water shower and convenient for low-temperature brushing. The wind power bolt lubricant is composed of, by weight, 8-20 parts of paraffin oil, 40-70 parts of naphthenic oil, 0.5-2 parts of castor oil, 5-35 parts of graphite, 20-40 parts of molybdenum disulfide, 0.5-6 parts of lubricating synergy additive, 0.5-2 parts of calcium oxide and 5-10 parts of organic bentonite. The wind power bolt lubricant is high in extreme pressure resistance and stable in torque coefficient; a large-size and high-strength wind power bolt is enabled to have low and stable torque coefficient through the wind power bolt lubricant, so that the large-size and high-strength wind power bolt is free of seizing and crawling in the process of assembly; the wind power bolt lubricant can be brushed conveniently even at low temperature of minus 15 DEG C, has good anti-water-shower effect and plays certain role in corrosion prevention and protection of the bolt.

Owner:TONSAN ADHESIVES INC

Hydroxyalkylated heterocycle boric acid ester and preparation method and purpose thereof

ActiveCN103601748AImprove extreme pressure and anti-wear performanceImprove PB valueGroup 3/13 element organic compoundsAdditivesCompound aAlcohol

The invention relates to hydroxyalkylated heterocycle boric acid ester and preparation method and purpose thereof; the structural formula of the additive is shown in the formula (I) or (II); the invention also relates to a preparation method of the hydroxyalkylated heterocycle boric acid ester lubrication additive, which comprises the following steps: 1. with organic solvent and catalyst, a heterocyclic compound and a alkyl epoxide are reacted, and a compound A is generated; 2. with organic solvent and catalyst, compound B and compound A or heterocycle-containing alcohol are reacted; the invention also relates to the purpose of hydroxyalkylated heterocycle boric acid ester.

Owner:SHANGHAI JIAO TONG UNIV

Novel extreme pressure-resistant cutting fluid

A disclosed novel extreme pressure-resistant cutting fluid is prepared from the following raw materials in parts by weight: 15-20 parts of glycerin, 5-15 parts of friction improver DAN-ZY-1, 3-7 parts of diethanolamine phosphate ester, 2-6 parts of maleic anhydride, 3-6 parts of sodium nitrite and 4-9 parts of methyl silicone oil. Compared with conventional lubricating oil, the novel extreme pressure-resistant cutting fluid has thixotropy, can be transformed from a paste into a liquid when conveyed to a to-be processed pipe fitting by an air powered pump or being stirred, is easy to convey and use, and helps to save the usage amount; the novel extreme pressure-resistant cutting fluid has extremely excellent permeability and is easy to clean; the novel extreme pressure-resistant cutting fluid has extremely good lubricity, heat-transfer cooling performance, stability, rheological property and extreme pressure resistance; and the novel extreme pressure-resistant cutting fluid helps to furthest reduce tapping cutting temperature and cutting force, improve tapping efficiency and precision, reduce workpiece roughness, improve surface quality and prolong screw tap service life.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Wearing-resistant vehicle lubricating oil and preparation method thereof

InactiveCN108485764AGood extreme pressure resistanceGood wear resistanceLubricant compositionParaffin waxLubrication

The invention discloses wearing-resistant vehicle lubricating oil which comprises the following raw materials in parts by weight: 20-30 parts of polybutylene synthetic oil, 15-30 parts of corn oil, 8-15 parts of nano diamonds, 1-3 parts of poly-boron amine, 7-11 parts of oxymolybdenum dialkydithiophosphate, 2-6 parts of sodium citrate, 4-9 parts of polyimide, 6-12 parts of modified bentonite, 8-13parts of liquid paraffin, 9-15 parts of pentaerythritol, 5-14 parts of an antioxidant and 3-7 parts of an anti-corrosion anti-rusting agent. The wearing-resistant vehicle lubricating oil is scientific and reasonable in formula, a product made of the lubricating oil is excellent in extreme pressure resistance, high in bearing capability, high in wearing resistance and in addition high in low-temperature flowability, and excellent long-lasting lubrication properties can be achieved.

Owner:合肥市闵葵电力工程有限公司

Special industrial lubricant for cement mixer and reduction box, and method for preparing special industrial lubricant

The invention discloses a special industrial lubricant for a cement mixer and a reduction box, and a method for preparing the special industrial lubricant. The special industrial lubricant is prepared from raw materials according to weight by part as follows: 5-20 parts of drainage oil, 5-20 parts of dioctadecyl dimethyl ammonium modified bentonite, 60-90 parts of 100# machine oil and 0.5-2 partsof sodium hydroxide. The method provided by the invention comprises the following steps: removing solid impurities from the drainage oil at first; after removing moisture through heating, mixing the drainage oil with a base oil and organic modified bentonite; taking a small quantity of alkali as a catalyst, and forming excellent-performance special industrial lubricant at a certain temperature through a certain period of time. The special industrial lubricant provided by the invention is convenient for filling if being applied to the cement mixer, and capable of quickly reaching a frictional surface, and has excellent anti-rust and anti-friction properties. If the special industrial lubricant is applied to the reduction box, the toothed surface of the reduction box can have good adhesion force and excellent anti-friction and anti-extreme-pressure performances; and the special industrial lubricant is capable of well solving the usage problem of the drainage oil and provides a good way for solving the problem of reusing the drainage oil for meals.

Owner:东昊石油集团有限公司

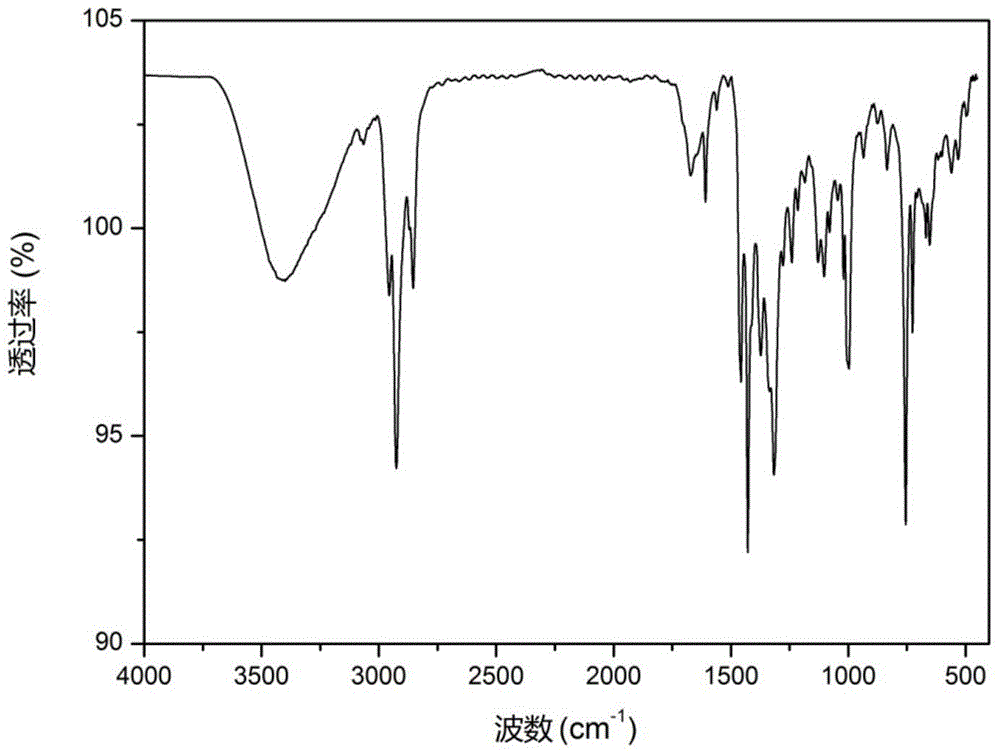

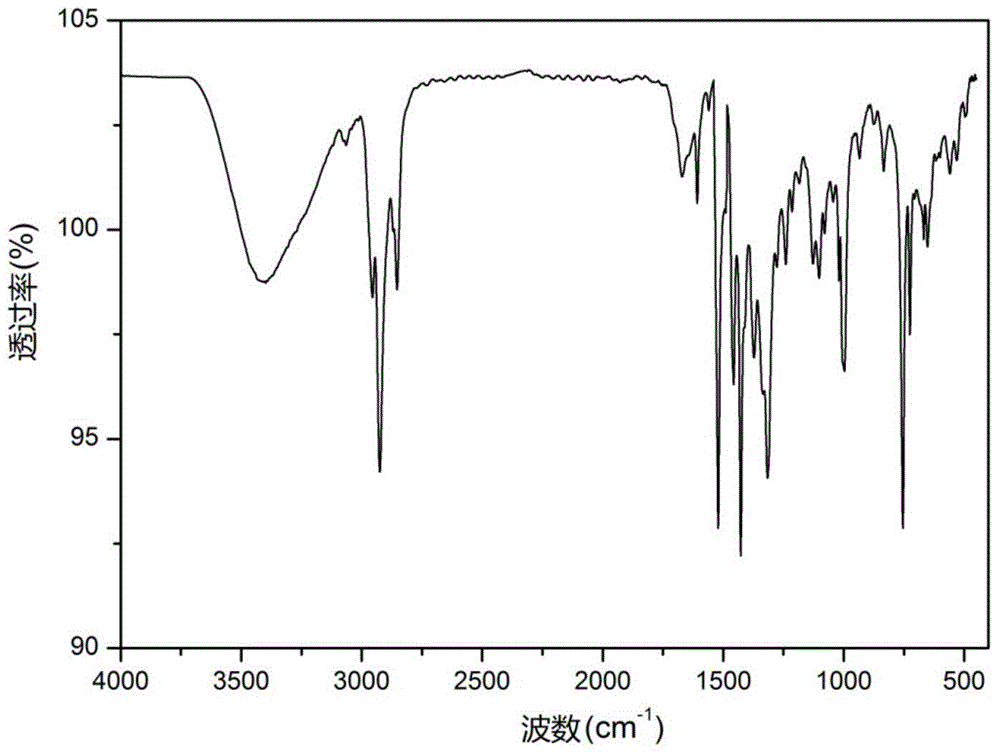

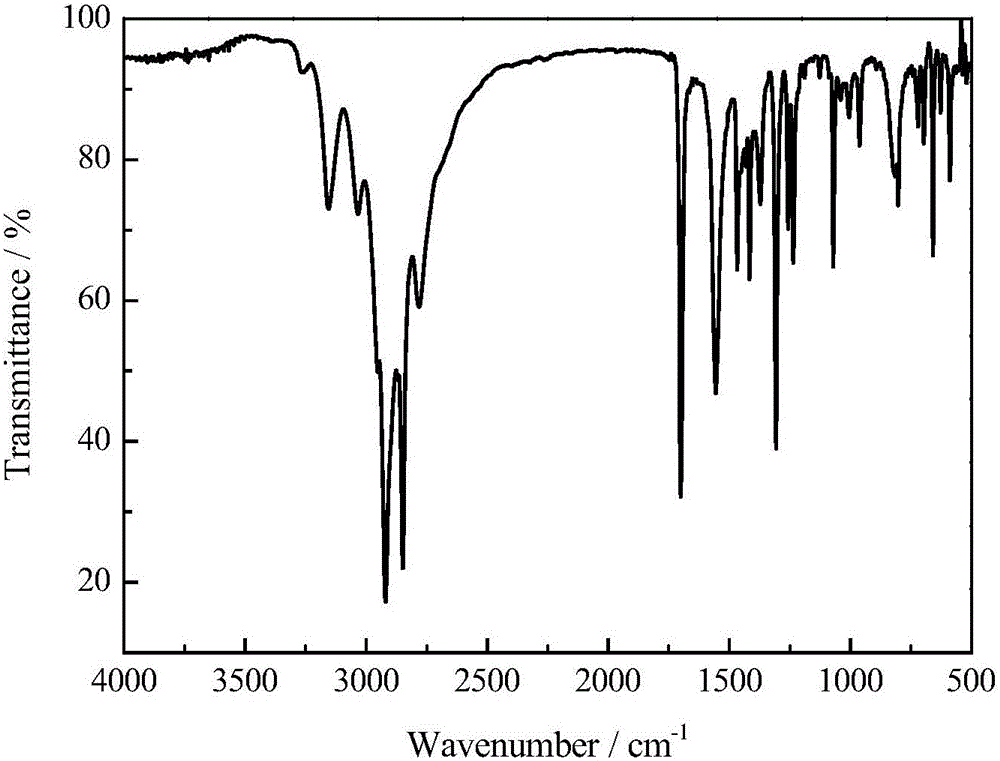

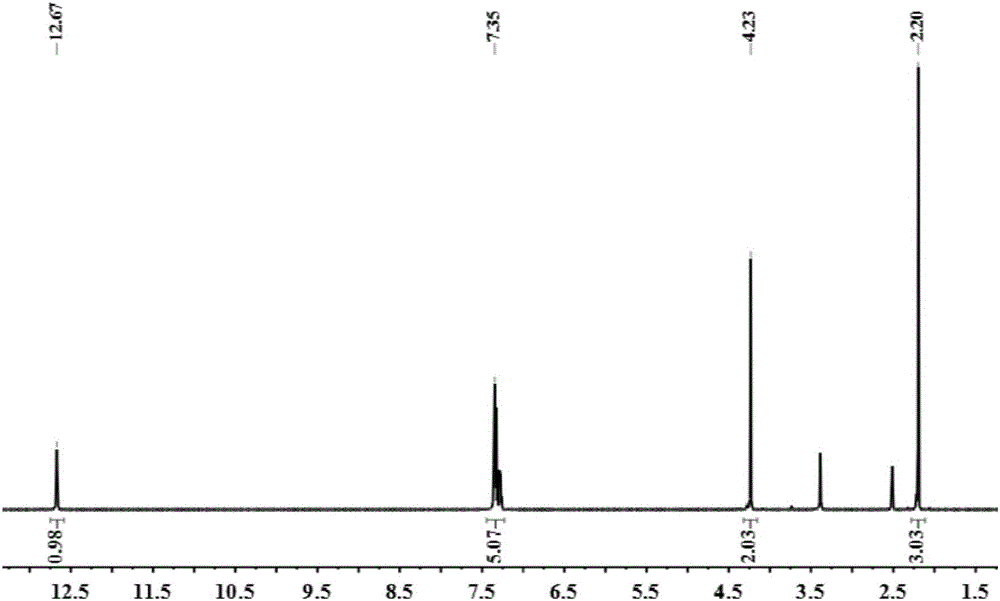

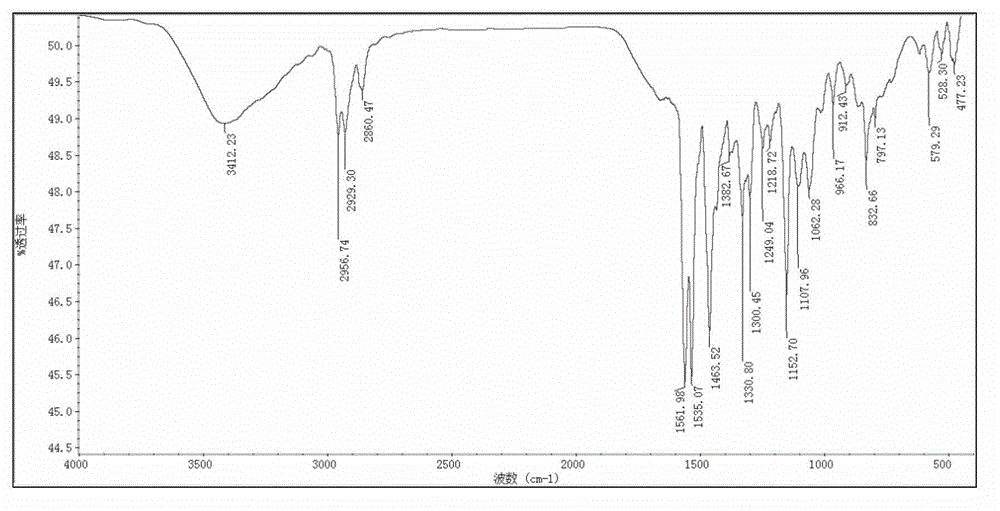

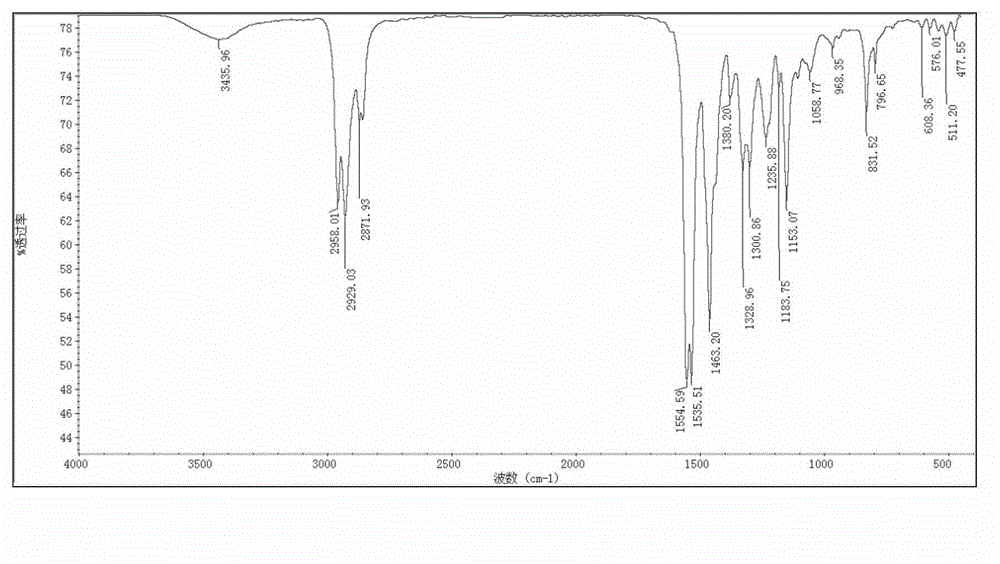

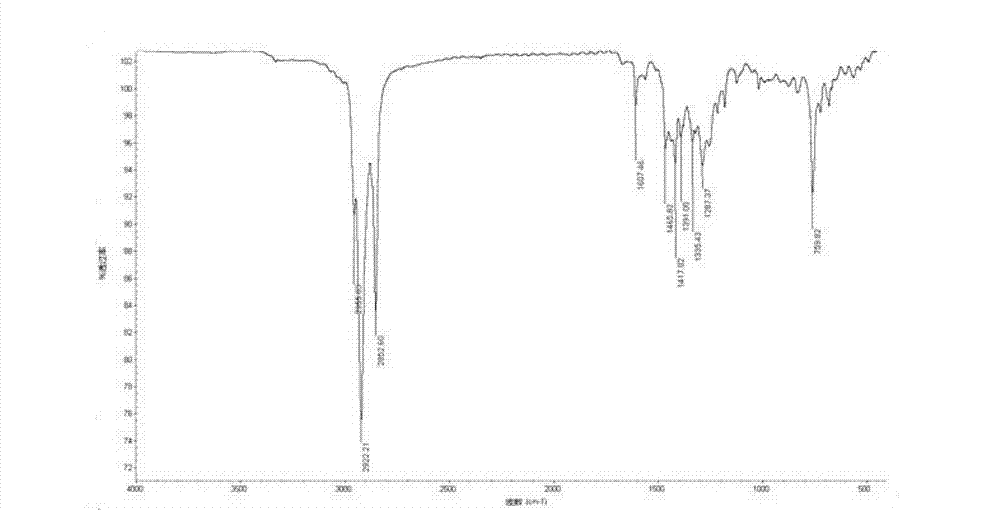

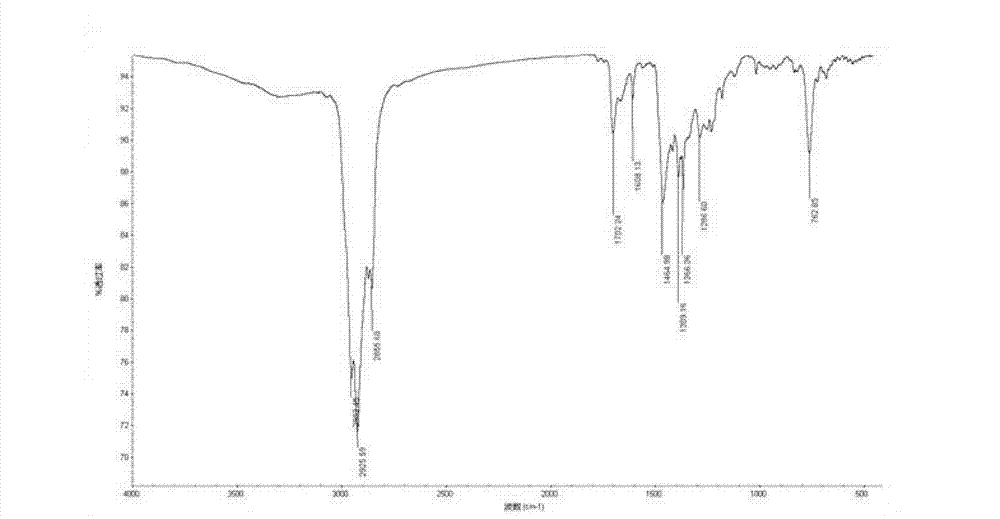

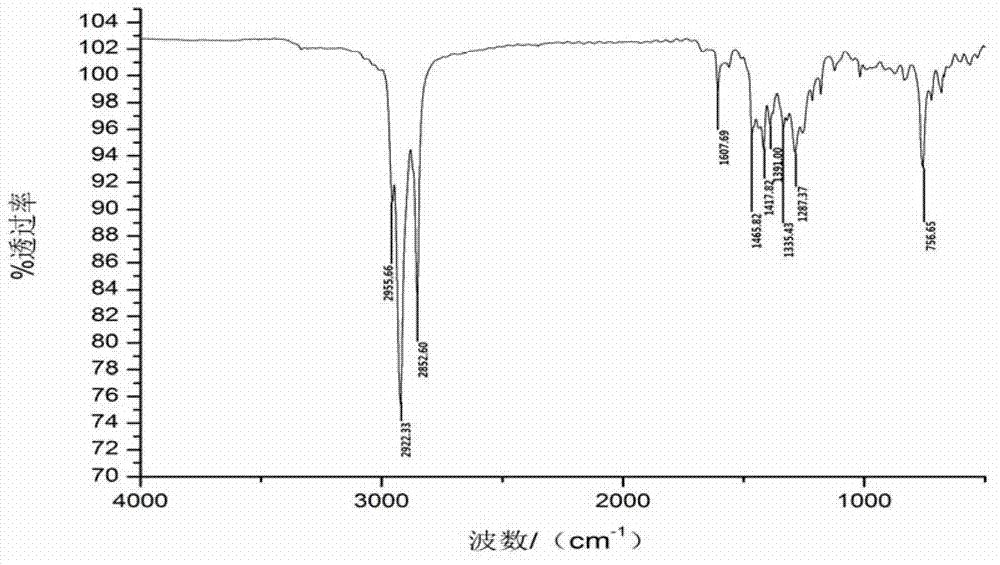

1,3,4-thiadiazole derivatives, preparing method thereof and applications of the derivatives

InactiveCN105837529AHigh yieldImprove responseOrganic chemistryAdditivesNMR - Nuclear magnetic resonanceOil additive

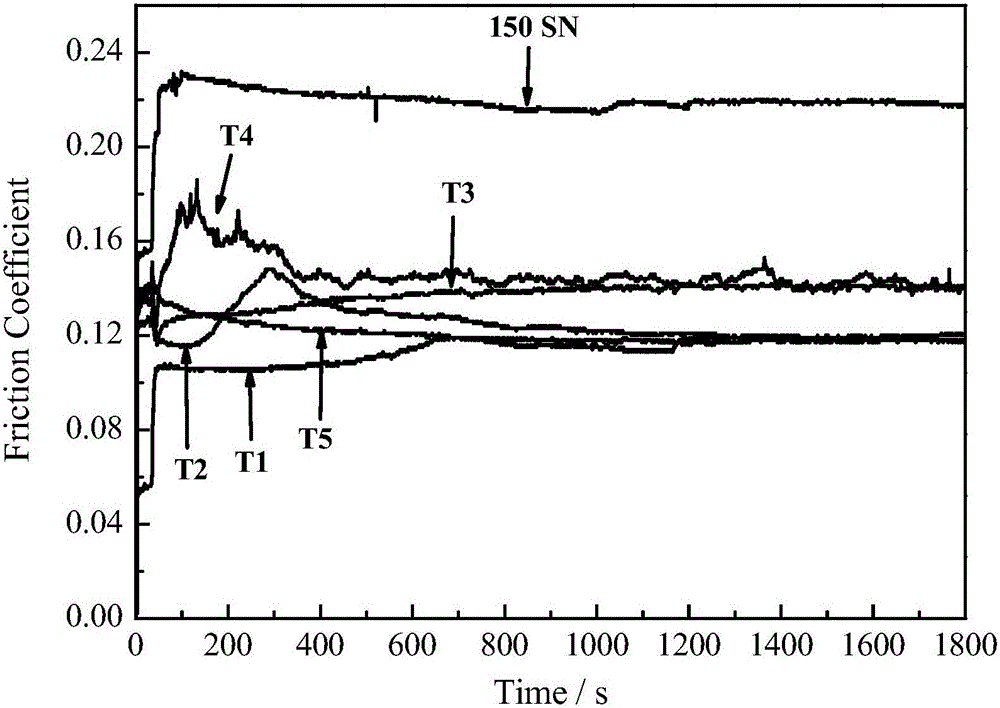

The invention provides 1,3,4-thiadiazole derivatives, a preparing method thereof and applications of the derivatives. Structures of the derivatives are characterized through infrared spectroscopy and nuclear magnetic resonance. Antifriction and extreme-pressure resisting properties of the derivatives as 150 SN base oil additives are evaluated in an SRV testing machine. Results show that the synthesized compounds have a good lubricating property, can effectively improve antifriction and extreme-pressure resisting properties of lubricating oil, and are lubricating oil additives with good properties. The compounds are synthesized by adopting 5-amino-2-mercapto-1,3,4-thiadiazole as a raw material. A reaction process is simple and easy to implement. The product yield is high. The production cost can meet requirements on industrial production. In addition, the 1,3,4-thiadiazole compounds have good antifriction and extreme-pressure resisting properties when being adopted as lubricating additives, and can be used as antifriction and extreme-pressure resisting additives for lubricating oil.

Owner:DALIAN UNIV OF TECH

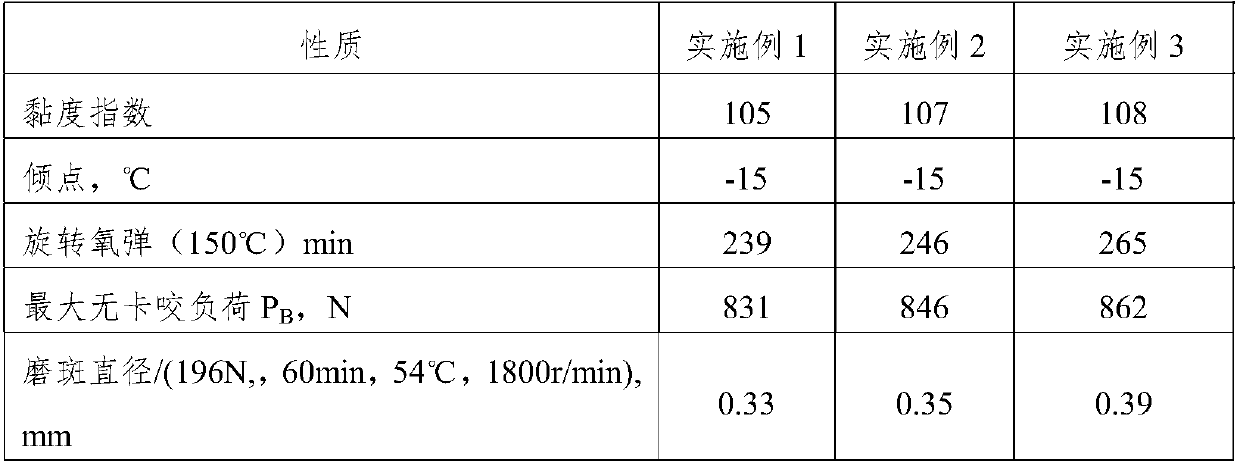

Composite calcium sulfonate based lubricating grease for open gear as well as preparation method and application thereof

ActiveCN111961518AImprove mechanical propertiesImprove impact resistanceLubricant compositionVulcanizationMaterials science

The invention provides a composite calcium sulfonate based lubricating grease for an open gear as well as a preparation method and application thereof, and belongs to the technical field of lubricating grease preparation. The provided composite calcium sulfonate based lubricating grease comprises the following components in percentage by mass: 67-72% of base oil, 11-15% of a composite calcium sulfonate thickening agent, 4.5-6.0% of an extreme pressure anti-wear additive, 1.5-3% of ethylene-propylene rubber, 0.4-0.5% of diphenylamine and 10-12% of graphite, and the sum of the mass percentages of the components is 100%, wherein the extreme pressure anti-wear additive comprises vulcanized olefin and petroleum calcium sulfonate; the composite calcium sulfonate is prepared from the following raw materials through a phase inversion reaction: high-base-number petroleum calcium sulfonate, isopropanol, calcium carbonate, glacial acetic acid and dodecyl benzene sulfonic acid. The provided composite calcium sulfonate based lubricating grease for an open gear has an excellent extreme pressure property and temperature resistance.

Owner:上海果石实业(集团)有限公司

Special cold ring rolling oil composition for bearing processing

ActiveCN109666530AImprove anti-friction performanceGood extreme pressure resistanceLubricant compositionChemical compositionBase oil

The invention provides a special cold ring rolling oil composition for bearing processing, wherein the special cold ring rolling oil composition comprises, by weight, 0.1-10% of an anti-oxidation anti-corrosion agent, 0.01-1.0% of an anti-rust agent, 5.0-50% of an extreme pressure anti-wear agent, and the balance of mineral base oil, and further comprises an antifoaming agent accounting for 0.001-0.1% of the total mass of the previous components. According to the present invention, the special cold ring rolling oil composition has advantages of good extreme pressure abrasion resistance, good oxidation resistance and good cooling property, and can be used for the lubrication of cold ring rolling equipment for producing bearing rings.

Owner:CHINA PETROLEUM & CHEM CORP

Polyaniline cutting fluid

ActiveCN103194306AExcellent anti-rustImprove mildew resistanceLubricant compositionEngineeringPolyacrylamide

The invention provides polyaniline cutting fluid, belongs to the technical field of metal machining, and solves the problems of poor lubricating property and extreme pressure resistance of the existing polyaniline cutting fluid. The polyaniline cutting fluid comprises the following components by weight percent of 5-15 parts of water-soluble polyaniline, 10-15 parts of polyacrylamide, 2-4 parts of polyether polyol, 10-15 parts of triethanolamine, 5-10 parts of dibutyl phosphate, 5-10 parts of boric acid, 5-10 parts of silicone emulsion, and the balance of water. The polyaniline cutting fluid disclosed by the invention has good lubricating property and extreme pressure resistance besides good corrosion resistance and mildew-proof performance; and the maximal anti-bite load value is greater than 70kg.

Owner:CHANGCHUN UNIV OF TECH

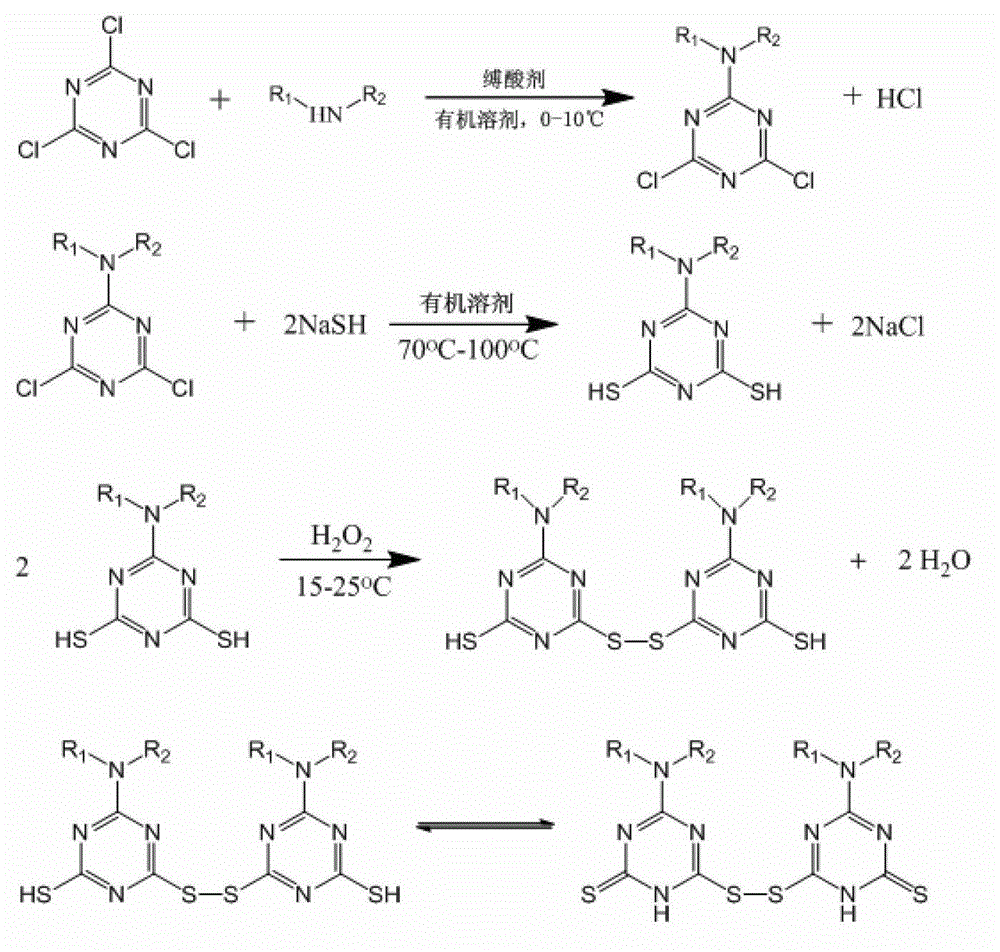

Coupled dimercaptotriazine derivative, and preparation method and use thereof

ActiveCN103145634AImprove wear resistanceGood extreme pressure resistanceOrganic chemistryAdditivesFood additiveLithium

The invention discloses a coupled dimercaptotriazine derivative, and a preparation method and a use thereof. 2,4,6-trichloro-1,3,5-triazine, amine and sodium bisulfide are adopted as raw materials and undergo substitution and coupling reactions to obtain the coupled dimercaptotriazine derivative. The coupled dimercaptotriazine derivative can be used through the combination with other lubricating greases and lubricating oil additives as an extreme-pressure anti-wear agent, and can also be individually used as a lubricating oil or a lubricating grease additive to make a lubricant have very good wear and extreme pressure resistances; the derivative in lithium-based grease can improve the PB value by 40-100% and reduce the wear scar diameter by 35-50%; and the derivative in rapeseed oil can improve the PB value by 45-65% and reduce the wear scar diameter by 25-45%.

Owner:SHANGHAI JIAO TONG UNIV

High-hydrolysis stability organic ammonium borate extreme-pressure antiwear additive and preparation method thereof

ActiveCN103113959AImprove extreme pressure and anti-wear performanceHybrid empty orbital stabilizationGroup 3/13 element organic compoundsAdditivesBromineOil additive

The invention provides a high-hydrolysis stability organic ammonium borate extreme-pressure antiwear additive and a preparation method of the additive. The structural formula of the additive is shown as in formula (I). The invention further relates to a preparation method of the additive; and according to the preparation method, the additive is prepared from alkylbenzene, bromine, tributyl borate and alkylamine. The additive prepared by the preparation method disclosed by the invention can be independently added into lubricating oil to obtain a lubrication system with good antiwear performance and extreme pressure resistance, so that PB value of the lubricating oil is increased by 30%-110% and the wear scar diameter is reduced by 30%-50%. The additive prepared by the preparation method disclosed by the invention can be further compounded with other lubricating oil additives for use so as to achieve a synergistic interaction effect. The additive prepared by the preparation method disclosed by the invention has good antiwear performance and extreme pressure resistance, as well as excellent corrosion resistance, anti-oxidation performance and the like, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Multi-effect lubricating oil additive

InactiveCN104403725AGood extreme pressure resistanceExtended use timeAdditivesButanedioic acidPolyvinyl alcohol

The invention relates to a multi-effect lubricating oil additive, which is prepared from the following raw materials by weight: 6-10 parts of triethanolamine, 5-9 parts of ditert-butyl paracresol, 5-7 parts of sodium dodecyl benzene sulfonate, 3-6 parts of polyvinyl alcohol, 4-8 parts of nanometer silica, 3-6 parts of succinate, 1-5 parts of oleic acid, 4-10 parts of methyl acrylate, 5-10 parts of polyisobutylene succinimide, 3-6 parts of isopropanol, 1-4 parts of ethylene, 6-8 parts of zinc butyl octyl dithiophosphate, and 3-7 parts of molybdenum dibutyl dithiocarbamate. The multi-effect lubricating oil additive has the following beneficial effects that: the extreme pressure resistance of the lubricating oil can be improved, the good cleaning property and the good chemical stability are provided, and the service life of the lubricating oil can be prolonged.

Owner:QINGDAO TOPLINK INFORMATION TECH

Lubricating composition for grinding roller bearing of vertical mill and tug wheel bearing of rotary kiln

InactiveCN109880676AWide viscosity rangeMeet viscosity grade requirementsLubricant compositionEngineeringWear resistance

The invention belongs to the technical field of lubricating compositions characterized by using mixtures of high molecular and non-high-molecular compounds as additives, and specifically relates to alubricating composition for a grinding roller bearing of a vertical mill and a tug wheel bearing of a rotary kiln. The lubricating composition is prepared from the following ingredients: synthetic oil, a bearing oil composite additive, an antirust agent, a metal deactivator and an anti-friction agent. The lubricating composition has excellent wear resistance, emulsification resistance and foam resistance.

Owner:重庆化工职业学院

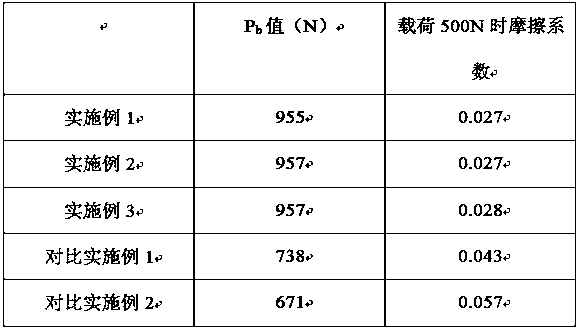

Anti-wear anti-friction gear lubricating oil and preparation method thereof

ActiveCN108949302AGood anti-extreme pressure effectImprove anti-friction performanceAdditivesOxidation resistantFriction effect

The invention discloses anti-wear anti-friction gear lubricating oil and a preparation method thereof. The prepared anti-wear anti-friction gear lubricating oil has high maximum anti-seize duty valueand excellent extreme pressure resistance, the friction coefficient at the load of 500N is low, and the antifriction performance is improved. After nano-zirconia is subjected to synergistic treatmentwith phosphate by utilizing petroleum sodium sulfonate, the dispersion performance is greatly improved, the nano-zirconia is difficult to aggregate and can be stably dispersed in the lubricating oil,and the anti-wear anti-friction effect is improved; and by modifying the nano-zirconia by utilizing manganese dioxide, the wear resistance and extreme pressure resistance of the nano-zirconia are improved, the compatibility of the nano-zirconia and the lubricating agent substrate is further promoted, and the anti-wear anti-friction, anticorrosive and antioxidant effects of the lubricating agent are improved.

Owner:四川瑞荣科技有限公司

Marine propeller lubricating grease and preparation method thereof

InactiveCN106635348AImprove corrosion resistanceGood extreme pressure resistanceLubricant compositionLithiumEmulsion

The invention discloses marine propeller lubricating grease and a preparation method thereof, and belongs to the technical field of special lubricating grease. The technical scheme mainly includes that the marine propeller lubricating grease is prepared from, by weight, 55-80 parts of base oil, 13-38 parts of thickening agents, 3-5 parts of additives and 1-2 parts of fillers. The lubricating grease is prepared from high-quality national standard base oil and lithium-calcium mixed soap, the national standard base oil has excellent corrosion resistance and extreme pressure resistance, namely good emulsion resistance, so that the lubricating grease has low-temperature torque lubricating property and long service life, and the mixed soap can ensure good hydrophobic property and wide temperature use range of the lubricating grease, so that the lubricating grease is particularly suitable for underwater propellers.

Owner:XINXIANG HENGXING TECH CO LTD

Wollastonite-based high-temperature resisting lubricant and preparation method and application thereof

The invention discloses a wollastonite-based high-temperature resisting lubricant and a preparation method and application thereof. Taking water as a solvent, the wollastonite-based high-temperature resisting lubricant is prepared from the following components in parts by weight: 10-40 parts of wollastonite powder, 1-5 parts of glass fiber, 1-10 parts of sodium polyphosphate, 1-3 parts of polyethylene glycol and 0.1-1 part of a thickening agent. The preparation method of the wollastonite-based high-temperature resisting lubricant comprises the following steps: step one, the water and the polyethylene glycol are added into a reaction kettle, and then stirring is conducted for 5-10 min; step two, the wollastonite powder, the glass fiber, the sodium polyphosphate, a dispersant and an antifoaming agent are added into the reaction kettle in sequence, and then stirring continues being conducted for 60-90 min; and step three, a preservative and the thickening agent are added into the reactionkettle, then stirring is conducted for 60-90 min, and thus the wollastonite-based high-temperature resisting lubricant is obtained. The wollastonite-based high-temperature resisting lubricant has theadvantages of health, environmental protection and good stability, has extremely excellent lubrication performance under the high temperature condition, and is suitable for being used for hot-rolledseamless steel pipes.

Owner:HUNAN JINHUA SCI & TECH GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com