Titanium alloy rolling lubricating liquid based on core-shell structure SiO2 (at) Graphene quantum dots and preparation method thereof

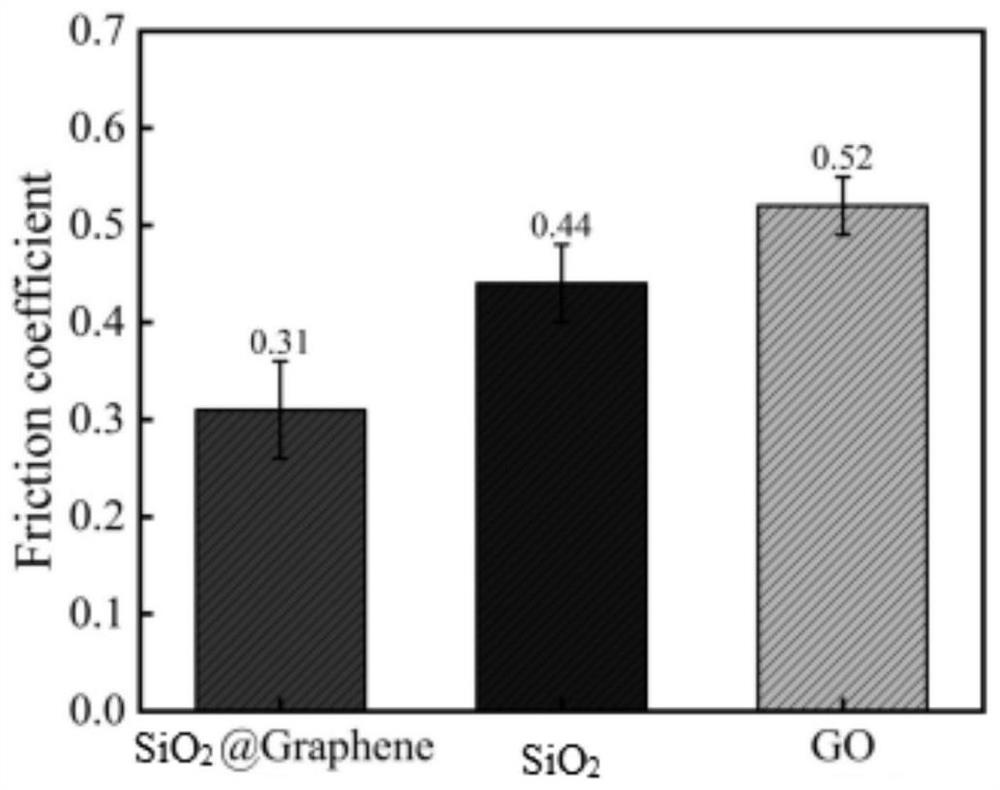

A technology of core-shell structure and quantum dots, which is applied in the field of mechanical processing lubrication, can solve the problems of decreased anti-wear performance, etc., and achieve the effects of good extreme pressure resistance, excellent performance, and low friction coefficient at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

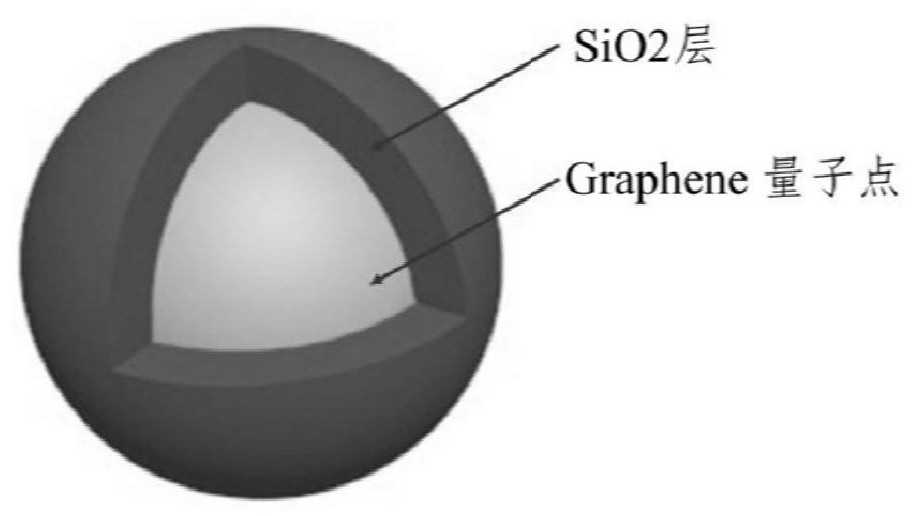

[0024] SiO of the present invention 2 A method for preparing @Graphene core-shell structure quantum dots, including the following steps:

[0025] 1) Graphene oxide is mixed with polymethylpyrrolidone and ball milled for 35-45h, the product obtained by ball milling is centrifuged at 2000-3000rpm for 20-40min, the supernatant is taken and centrifuged at 10000-12000rpm for 20-40min, and the centrifuged precipitate Washing with deionized water for 3-5 times to obtain an aqueous solution of graphene oxide quantum dots;

[0026] 2) Dissolve ethyl orthosilicate in ethanol, add the graphene oxide quantum dot aqueous solution after stirring for 2-4 hours, obtain the reaction solution after stirring for 8-12 hours, heat and evaporate to dryness in a crucible to obtain a crude product, the crude product The product was washed with deionized water and ethanol for 5-8 times and then dried to obtain SiO with a core-shell structure. 2 @Graphene quantum dot powder.

[0027] In the step 1, ...

Embodiment 1

[0039] 1) Mix 0.5g graphite powder with 3ml phosphoric acid (H 3 PO 4 ) and 30ml concentrated sulfuric acid (H 2 SO 4 )mix. The mixture was cooled to 0 °C in an ice bath and stirred for 15 min. Subsequently, 2 g of potassium permanganate (KMnO 4 ) was slowly poured into the above solution, and continued stirring at 0° C. for 15 min. After that, the temperature of the system was raised to 65 °C, and stirring was continued for 15 h. Then add 20ml of 30% hydrogen peroxide (H 2 o 2 ) hydrogen peroxide was added to the above mixture, and washed with 5% hydrochloric acid (HCl) solution and excess water until the filtrate pH=6.5. Finally, the product was centrifuged to obtain graphene oxide (GO).

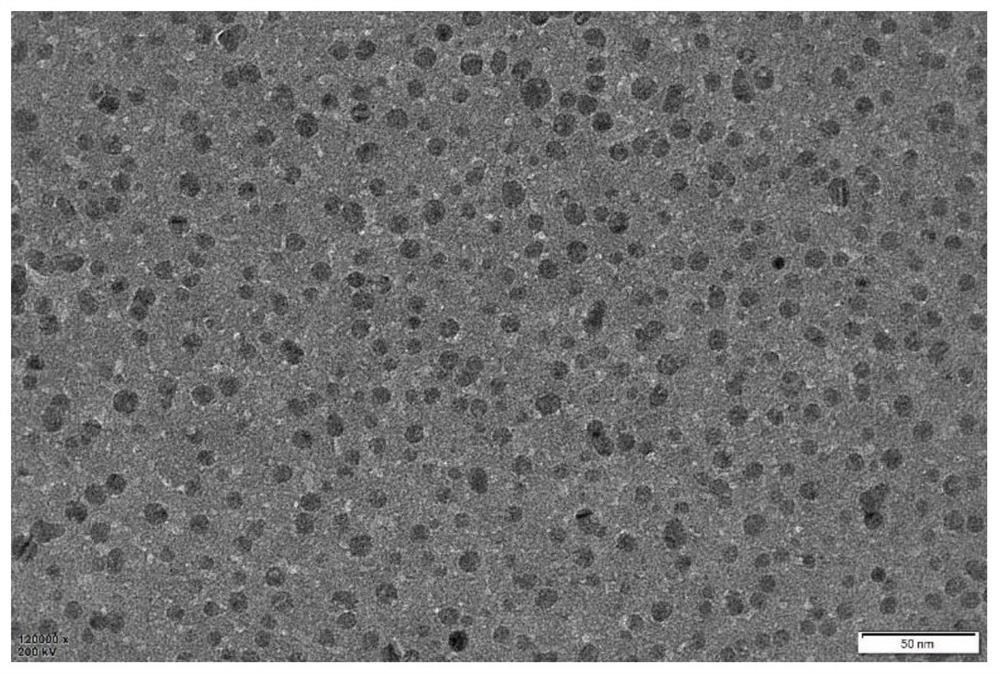

[0040] 2) Add graphene oxide and polymethylpyrrolidone (NMP) into a hard steel ball mill jar at a mass ratio of 10:1, take it out after ball milling for 35 hours, first centrifuge the product at 2000rpm for 20 minutes and extract the supernatant, then The supernatant was centrifu...

Embodiment 2

[0043] 1) Mix 0.8g graphite powder with 4ml phosphoric acid (H 3 PO 4 ) and 40ml concentrated sulfuric acid (H 2 SO 4 )mix. The mixture was cooled to 0 °C in an ice bath and stirred for 25 min. Subsequently, 2.5 g of potassium permanganate (KMnO 4 ) was slowly poured into the above solution, and continued stirring at 0° C. for 25 min. Afterwards, the temperature of the system was raised to 70 °C, and the stirring was continued for 20 h. Then add 25ml of 30% hydrogen peroxide (H 2 o 2 ) hydrogen peroxide was added to the above mixture, and washed with 5% hydrochloric acid (HCl) solution and excess water until the filtrate was almost neutral. Finally, the product was centrifuged and graphene oxide (GO) was obtained.

[0044] 2) Add graphene oxide and polymethylpyrrolidone (NMP) into a hard steel ball mill tank at a mass ratio of 7:1, take it out after ball milling for 40 hours, first centrifuge the product at 3000rpm for 30 minutes and extract the supernatant, then The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com