Patents

Literature

512results about How to "Improve anti-friction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

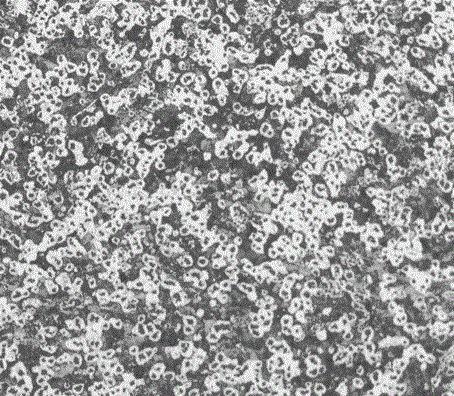

Carbon nanotube reinforced aluminum based composite material and its vacuum hot pressing prepn. method

InactiveCN1834280AImprove wear resistanceImprove anti-friction performanceDistilled waterCarbon nanotube

This invention discloses a method for preparing carbon nanotube-reinforced aluminum-based composite by vacuum hot pressing. The composite, comprising carbon nanotubes 0.1-5 wt.% and aluminum alloy powders 95-99.9 wt.%, is prepared by: (1) immersing carbon nanotubes in mixed acids, and adding surfactant; (2) dispersing; (3) filtrating, and washing carbon nanotubes with distilled water to neutrality; (4) performing two-step ball milling; (5) vacuum drying; (6) hot pressing in vacuum; and (7) hot extruding to obtain carbon nanotube-reinforced aluminum-based composite. This invention improves the capacity of aluminum alloy matrix in resisting abrasion, reducing friction, self-lubricating, surface wettability and mechanical properties.

Owner:HARBIN INST OF TECH

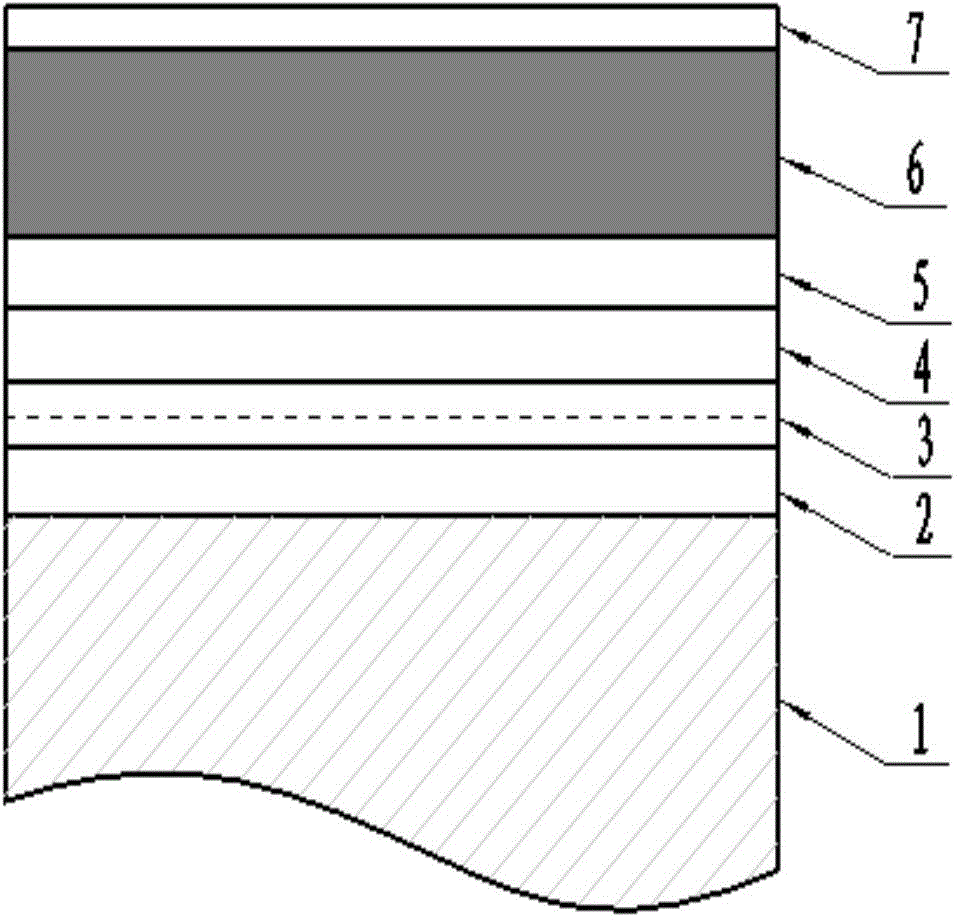

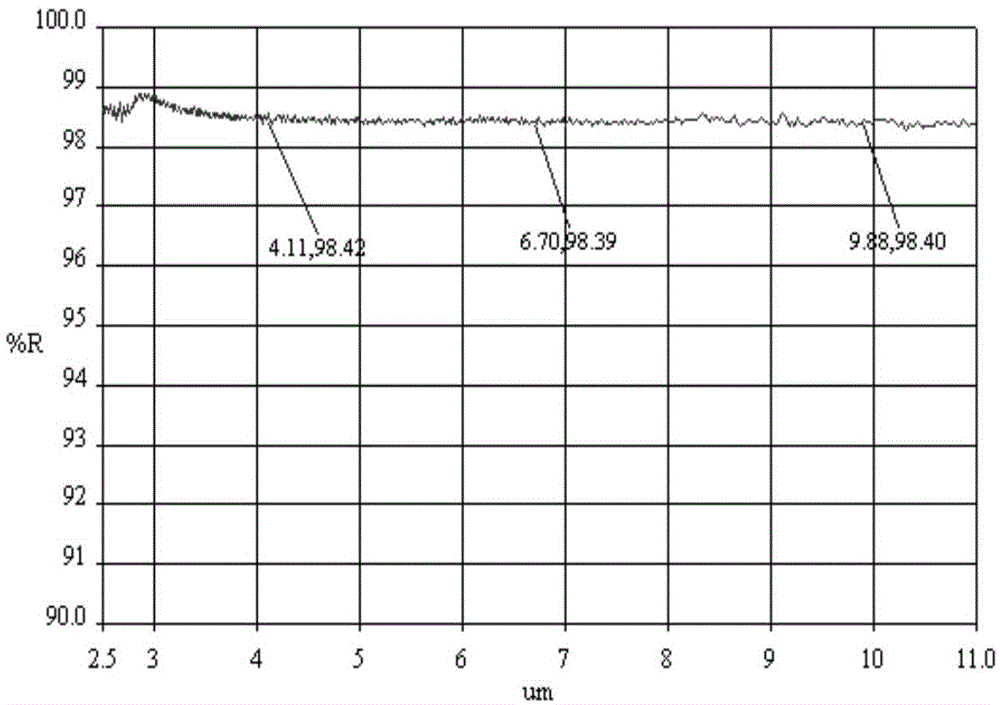

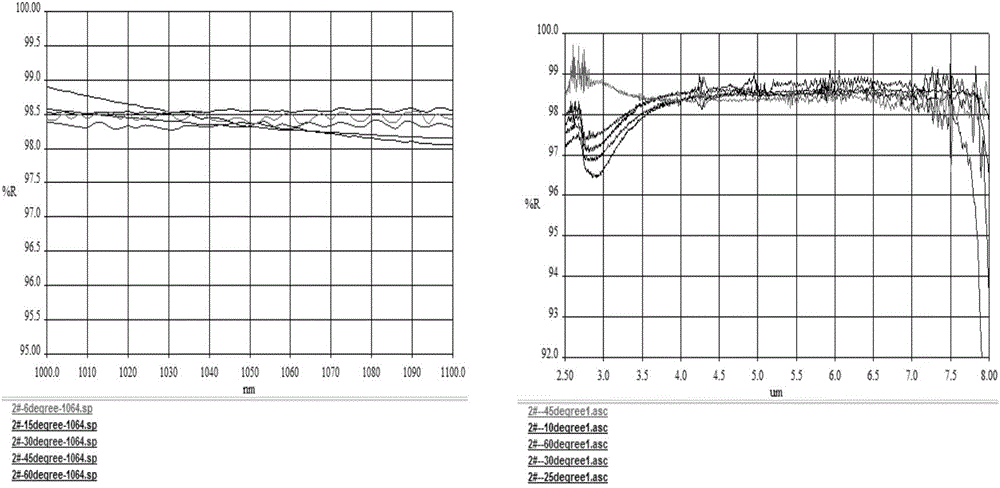

Infrared metal reflecting film with high adhesive force and manufacturing method thereof

ActiveCN104090312AGood physical occlusionImprove adhesionVacuum evaporation coatingSputtering coatingAdhesiveWear resistant

The invention provides an infrared metal reflecting film with high adhesive force and a manufacturing method thereof, wherein the infrared metal reflecting film with high adhesive force is plated on substrates of optical components such as glass, metal and silicon crystals. The infrared metal reflecting film with high adhesive force comprises a substrate, and is characterized in that a first transition layer, a holding-on bonding layer, a metal layer, a stress matching layer, a dielectric enhancement protecting layer and a hard wear-resistant layer are sequentially arranged on the substrate in an evaporation mode. The infrared metal reflecting film has the advantages of being good in film adhesive force, high in reflectivity, resistant to wear and high in environmental suitability, has a high laser damage resistance threshold value level, and can be widely applied to military and civilian photoelectron technical fields such as infrared lasers, refraction-reflection type optical systems and laser / infrared universal photoelectric equipment.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

Alloy steel for braking discs

ActiveCN101519754AImprove mechanical propertiesImprove thermal fatigue resistanceFriction liningNiobiumManganese

The invention relates to alloy steel for braking discs. Chemical compositions of the alloy steel comprise in percentage by weight: 0.21 to 0.26 percent of carbon, 0.8 to 1.0 percent of silicon, 0.5 to 1.0 percent of manganese, 1.2 to 1.55 percent of chromium, 1.95 to 1.99 percent of nickel, 0.34 to 0.41 percent of molybdenum, 0.1 to 0.2 percent of vanadium, 0.05 to 0.06 percent of niobium, less than 0.01 percent of tungsten, less than 0.02 percent of titanium, less than 0.02 percent of aluminum, 0.05 to 0.09 percent of copper, 0.02 to 0.03 percent of zirconium, and the balance of Fe and unavoidable impurities. The alloy steel provided by the invention is steel for casting, has higher mechanical strength and thermal fatigue resistance, also has better thermal cracking resistance, stable friction property and good thermal conductivity at the same time, and is particularly suitable for producing the braking discs used for rail transit vehicles such as city rail transit vehicles, railway locomotive vehicles, motor vehicles, high-speed trains, and the like.

Owner:BEIJING ZONGHENG ELECTROMECHANICAL TECH DEV

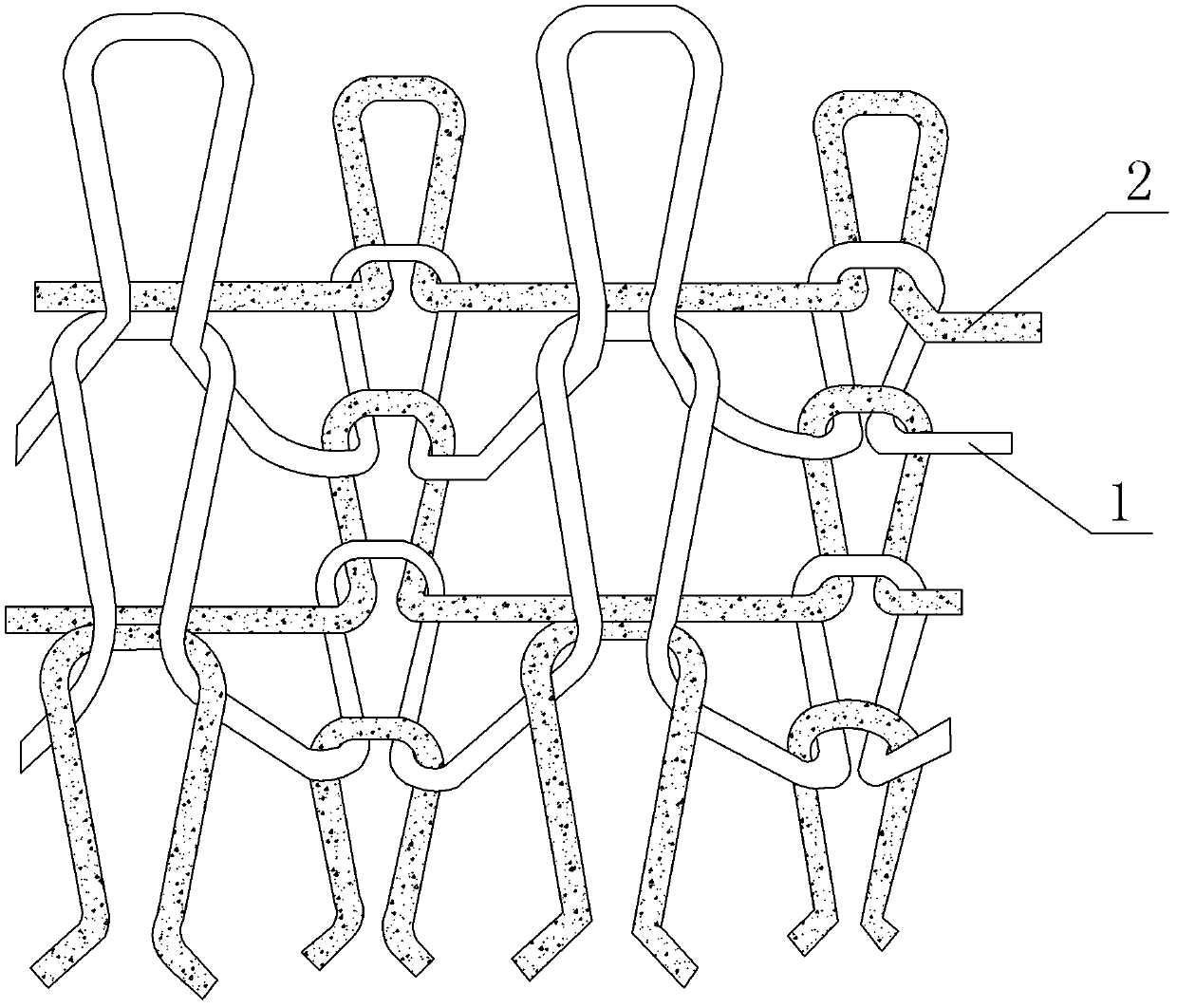

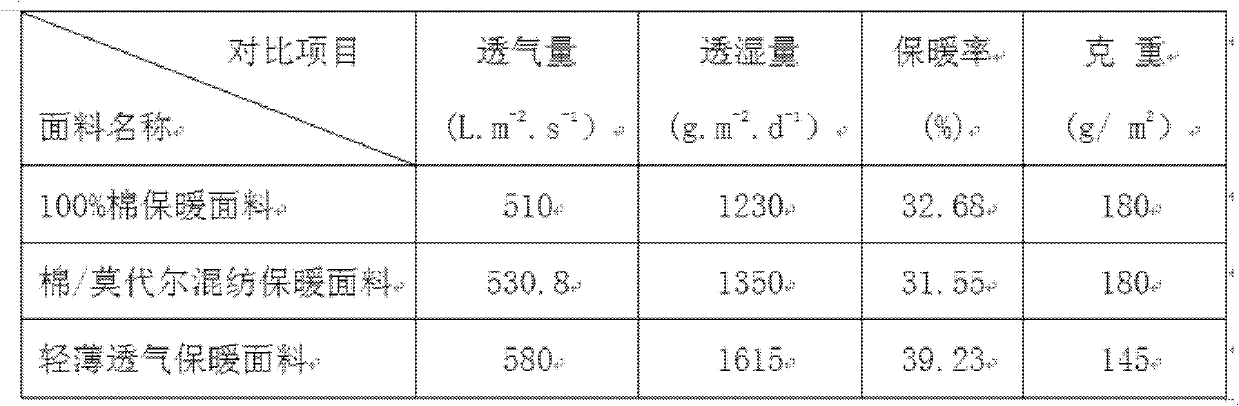

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

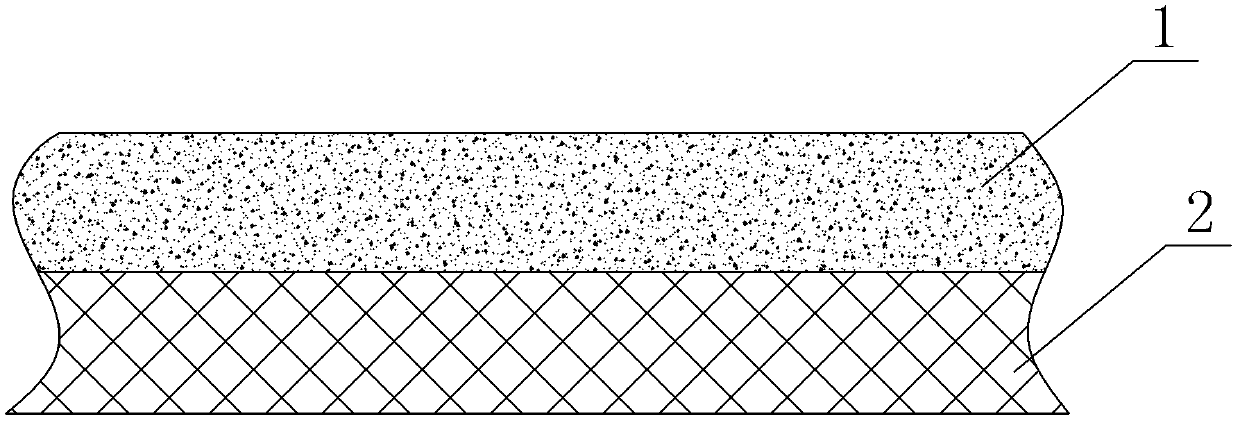

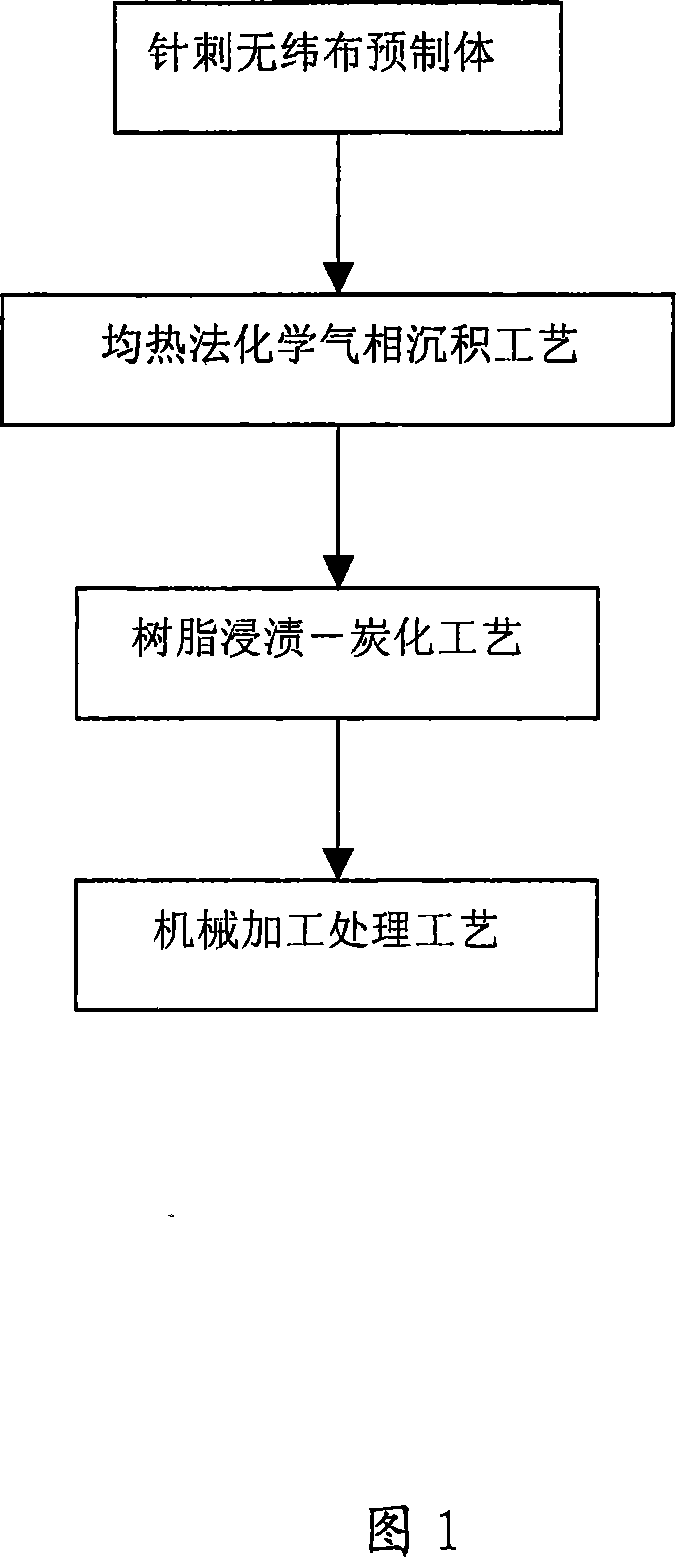

Method for manufacturing charcoal / charcoal pantograph pan in use for electric locomotive

ActiveCN101049803AHigh strengthImprove anti-friction performanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialGas phaseEngineering

A carbon / carbon slide block of current collector for electric locomotive is prepared through providing prefabricated body made of punched non-weft fabric with tridirectional structure, depositing pyrolytic carbon by CVD, compacting by resin dipping-charring process several times, and machining.

Owner:XIAN CHAOMA SCI TECH

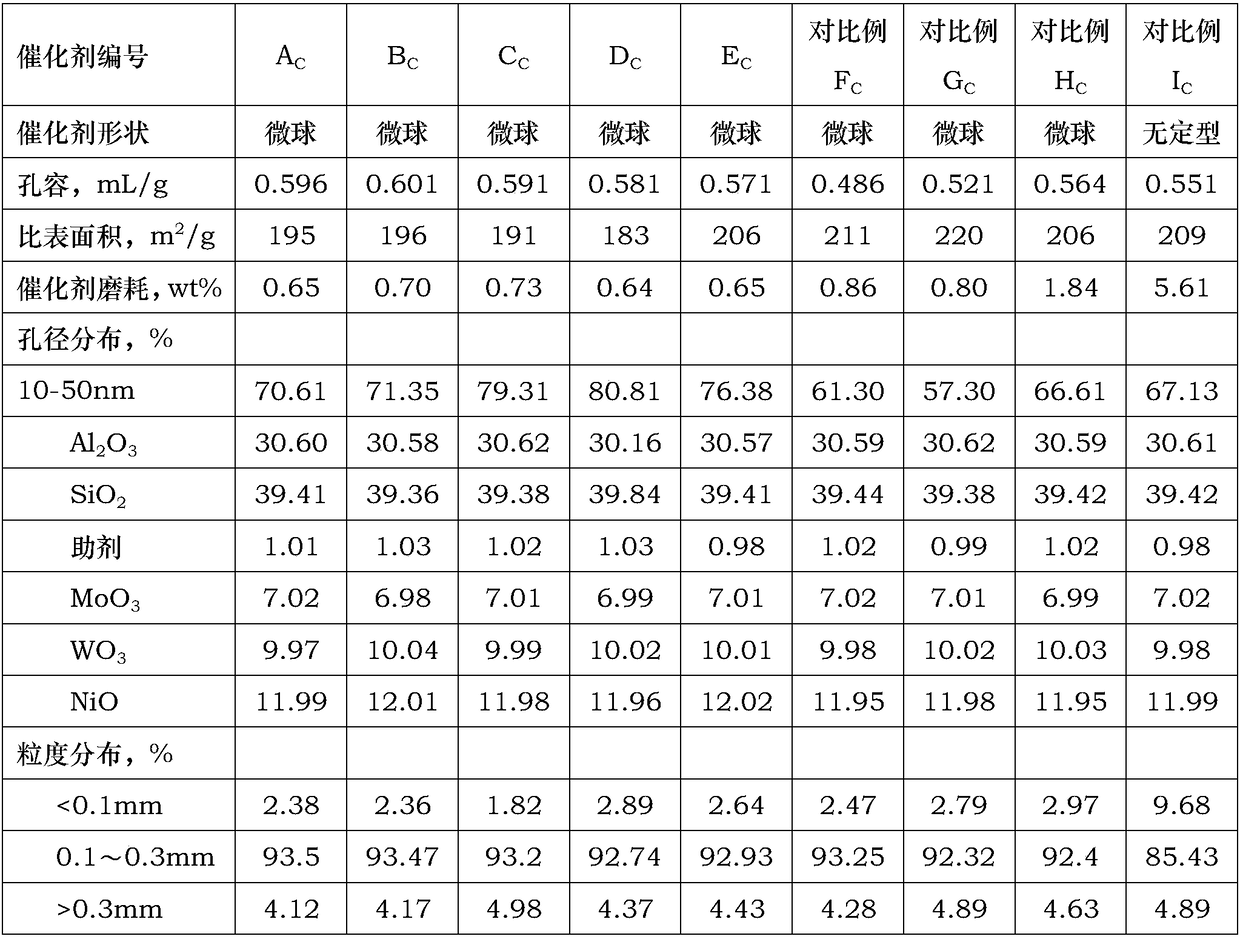

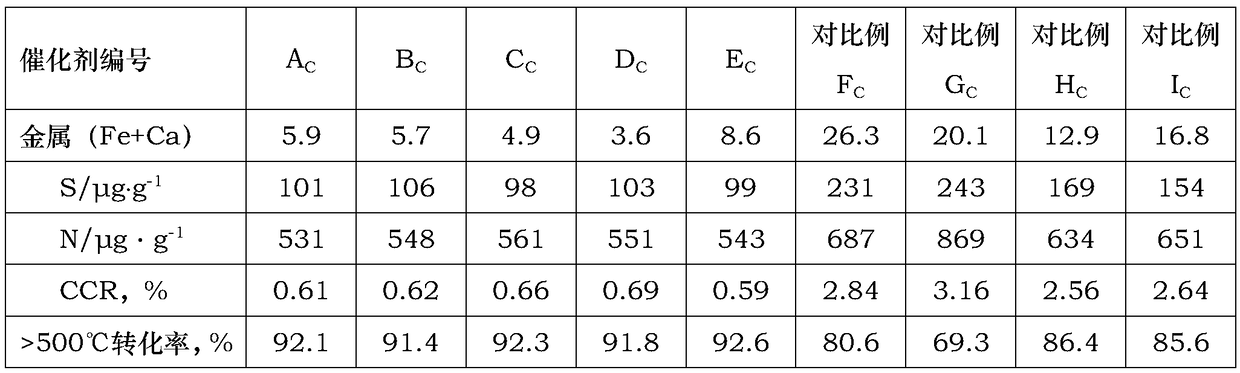

Boiling bed coal tar hydrotreating-hydrocracking composite catalyst and preparation method thereof

ActiveCN108686702ALarge hole volumeLarger than surfaceMolecular sieve catalystsHeterogenous catalyst chemical elementsMicrosphereSilicon oxide

The invention relates to a boiling bed coal tar hydrotreating-hydrocracking composite catalyst and a preparation method thereof. The boiling bed coal tar hydrotreating-hydrocracking composite catalystis prepared from the following components in percentage by mass: MoO3, WO3, NiO, aluminum oxide, silicon oxide molecular sieve and assistant. An acidized silicon-containing raw material and alkali gas react with each other, and the reaction product is cured to generate microsphere gel which has higher scale-accommodating capability and proper cracking performance. Active metal nickel, the assistant and a carrier raw material are prepared into slurry, the NiO is highly dispersed on the catalyst carrier, and nickel aluminum spinel is formed by a small amount of nickel and aluminum, so that thewater resistance and friction resistance of the catalyst are enhanced. Spray drying is performed, so that the grain distribution is concentrated, and high mechanical strength and abrasion resistance are achieved. A curing agent is added into the slurry, and the channel of the catalyst is enlarged in the escaping process of ammonia gas released in a drying process, so that the channel distributionis concentrated, and larger pore volume, larger specific surface area and higher abrasion resistance are achieved. The boiling bed coal tar hydrotreating-hydrocracking composite catalyst has higher hydrogenation activity, proper cracking activity and higher stability. The preparation method is simple and is low in cost.

Owner:一重集团大连工程建设有限公司

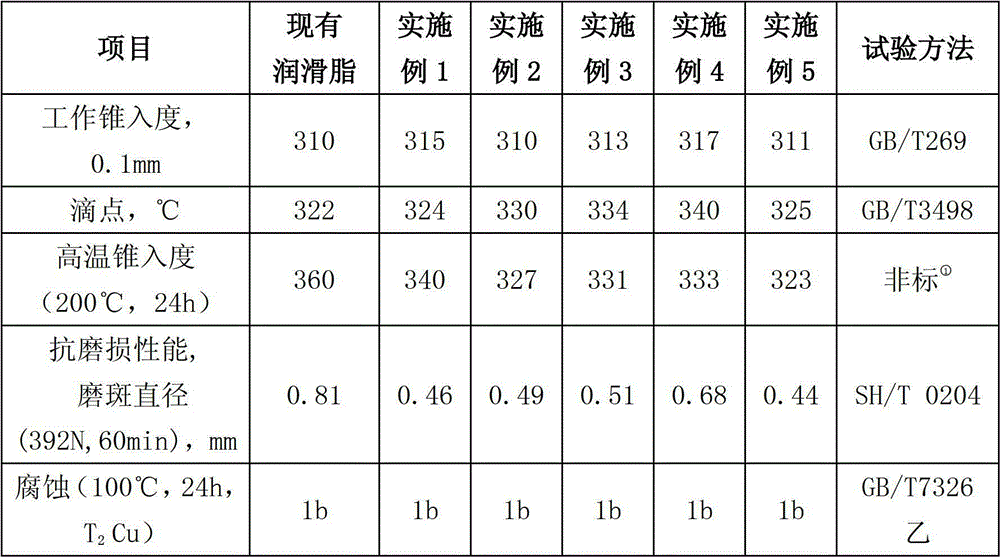

Lubricating grease containing carbon nanotubes and preparation method of lubricating grease

InactiveCN102911774AImprove anti-friction performanceImprove high temperature colloidal stabilityLubricant compositionCarbon nanotubePropylene carbonate

The invention relates to lubricating grease containing carbon nanotubes and a preparation method of the lubricating grease. The lubricating grease comprises bentonite as a thickening agent, refined mineral oil or synthetic oil as base oil, padding of carbon nanotube, and a polarity disperse assisting agent. The preparation method includes the steps of adding the carbon nanotubes treated in all base oil, adding organic bentonite for pre-dispersing, adding propylene carbonate as the polarity disperse assisting agent until a black uniform paste-structured lubricating grease is formed in a reactor, and finally obtaining the lubricating grease product. Compared with conventional bentonite lubricating grease, abrasion resistance performance of the lubricating grease containing carbon nanotubes is remarkably improved, and stability performance of high-temperature rubber bodies of the bentonite lubricating grease can be improved. A new application field is developed in nano lubricating materials for the carbon nanotube.

Owner:CHINA PETROLEUM & CHEM CORP

Energy enhancing steering acid liquid system

InactiveCN102443386AIncrease flow resistanceRelieve pressureDrilling compositionAutomatic steeringEngineering

The invention discloses an energy enhancing steering acid liquid system, which comprises 615 parts of hydrochloric acid, 10 to 20 parts of corrosion inhibitors, 30 to 50 parts of steering agents, 10 to 20 parts of foam boosters and 10 to 20 parts of iron ion stabilizing agents. The system has the advantages that liquid has better automatic steering low-seepage storage layers, the goals of uniformly distributing acid and reforming the storage layers with poor storage seepage conditions are reached, simultaneously, the static liquid post pressure of liquid in a well tube is also reduced, and the liquid return and discharge capability after the construction is improved.

Owner:CNPC CHUANQING DRILLING ENG DOWNHOLE OPERATION

Wear-resistant, noise-reduction and heat-insulation epoxy resin emulsified asphalt mortar coating

The invention relates to the technical field of engineering construction and maintenance, in particular to an epoxy resin emulsified asphalt mortar coating which can be widely applied to the fields of surface water prevention, crack pouring, leakage mending, bonding, thermal insulation, freeze prevention, heat insulation, noise reduction and the like of highways, bridges and buildings, and is prepared by the following procedures: using double-component emulsified asphalt (containing 30-70 percent of solid asphalt) containing 10-60 percent of modified epoxy resin as the bonding and film forming material of the coating, adding 3-15 percent of hollow glass beads, adding 5-30 percent of aqueous epoxy resin curing agent and blending the mixture uniformly, and then adding ore sand or high-strength quartz sand (with particle size of 3-80 meshes) accounting for 100-200 percent of the total amount of the mixture into the improved epoxy resin emulsified asphalt mortar coating. The epoxy resin emulsified asphalt mortar coating has the advantages that the viscosity is low and the permeability is good; the ductility and the flexibility as well as the fatigue resistant strength of a condensate are great; and a coating formed after curing does not dissolve or stick the tire; the compression resistance, the water leakage prevention capability and the wear resistance of the road surface are improved, the friction coefficient of the road surface is increased, and the capabilities of noise reduction, heat insulation and frost crack prevention of the road surface are enhanced.

Owner:东莞市东物合成材料有限公司 +2

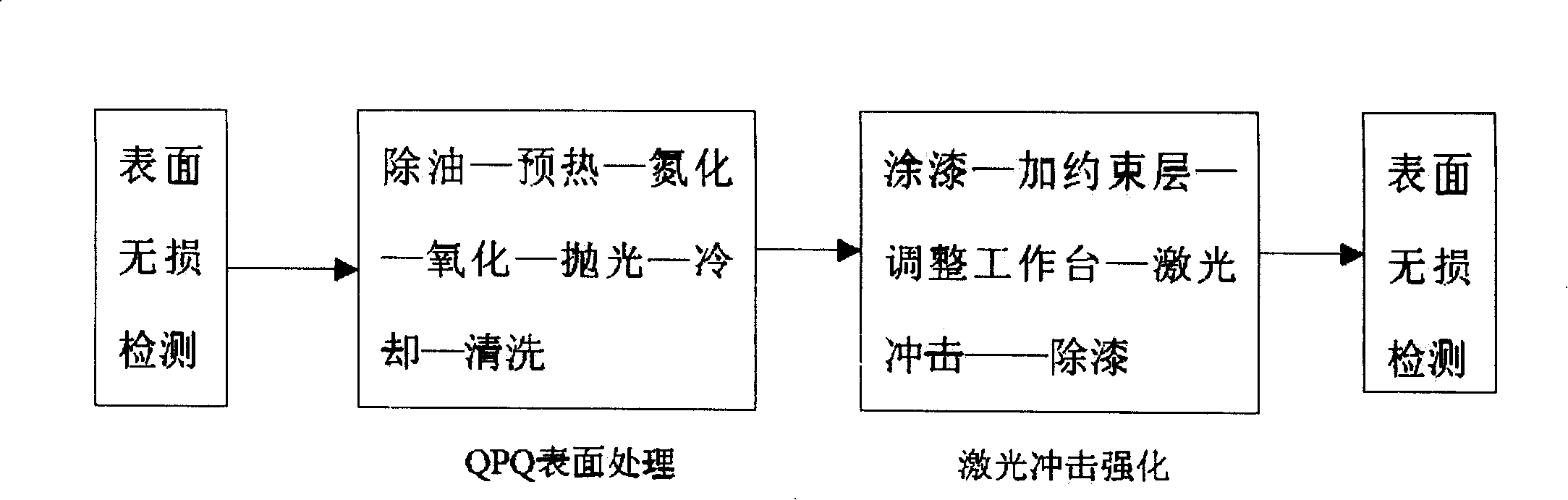

Composite treating method for prolonging life of grating machine key components

ActiveCN101225456APrecise positioningSave resourcesSolid state diffusion coatingHeat treatment process controlStress concentrationMolten salt

The invention relates to a complex processing method for prolonging the service lift of chain grate key parts, belonging to mechanical manufacturing and material processing and application technical field, which comprises: firstly, surface nondestructive testing is carried out on the key parts of the chain grate of process; molten salt complex processing are carried out in parts of the surface according to the surface drawbacks tested by surface nondestructive testing; before the laser shocks, the workpiece surface is coated with black coating layer and use water as protective layer, and the laser shock processes the area which is easy to fatigue and fracture and has concentrated stress. The molten iron pretreatment spray-feeding device before iron-making blast furnace has the advantages of simple shortcut, high efficiency, low maintenance cost, short processing time (30 minutes to 5 hours), and the continuous operation can be realized, thus, high efficiency of production is ensured.

Owner:江苏宏大特种钢机械厂有限公司

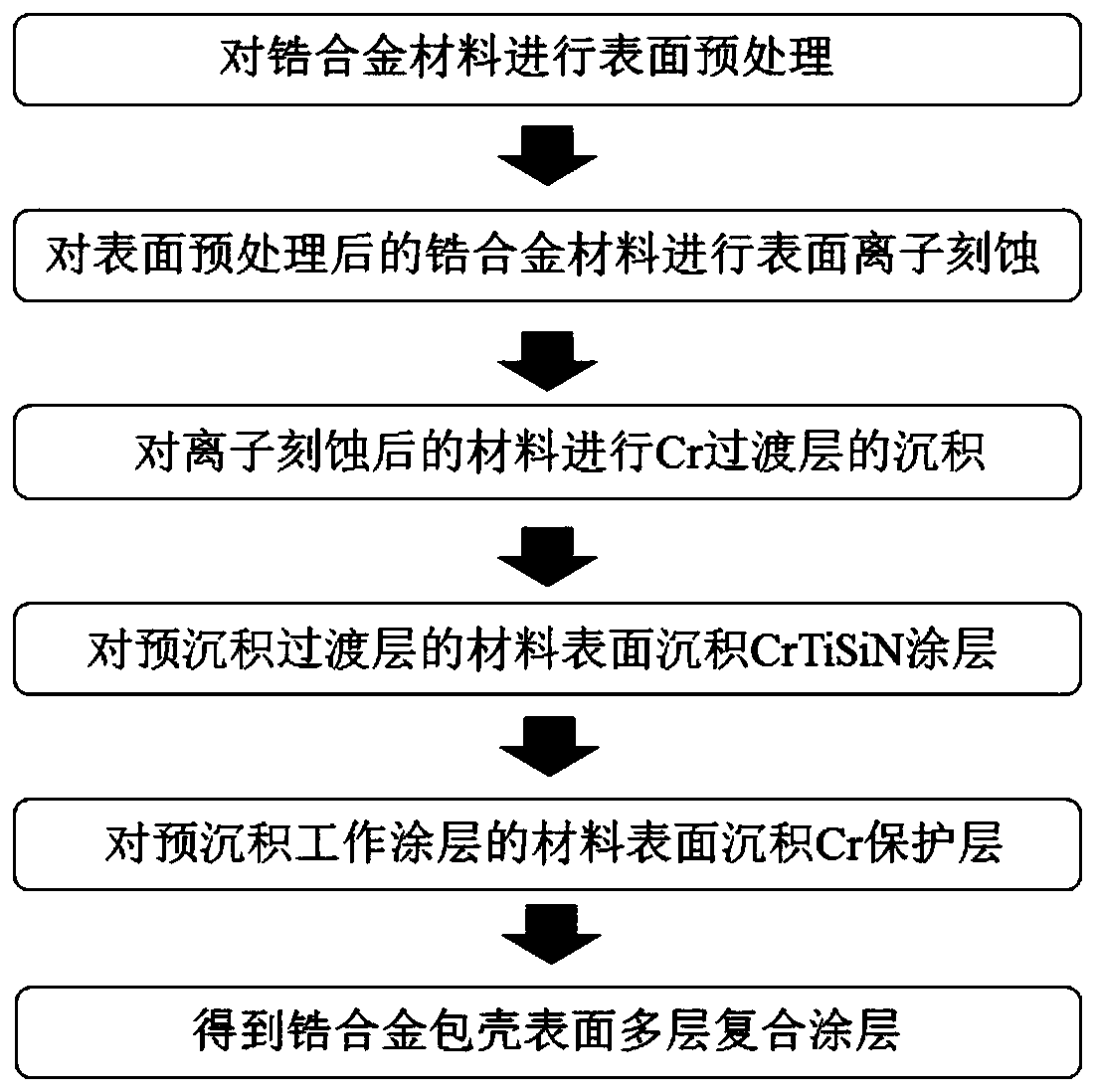

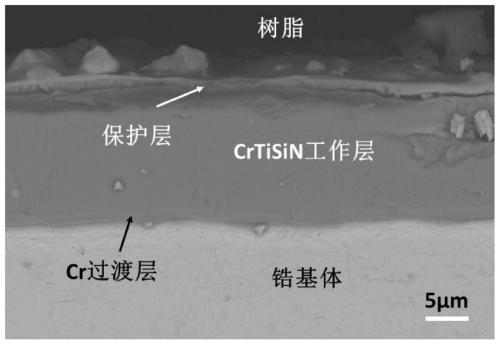

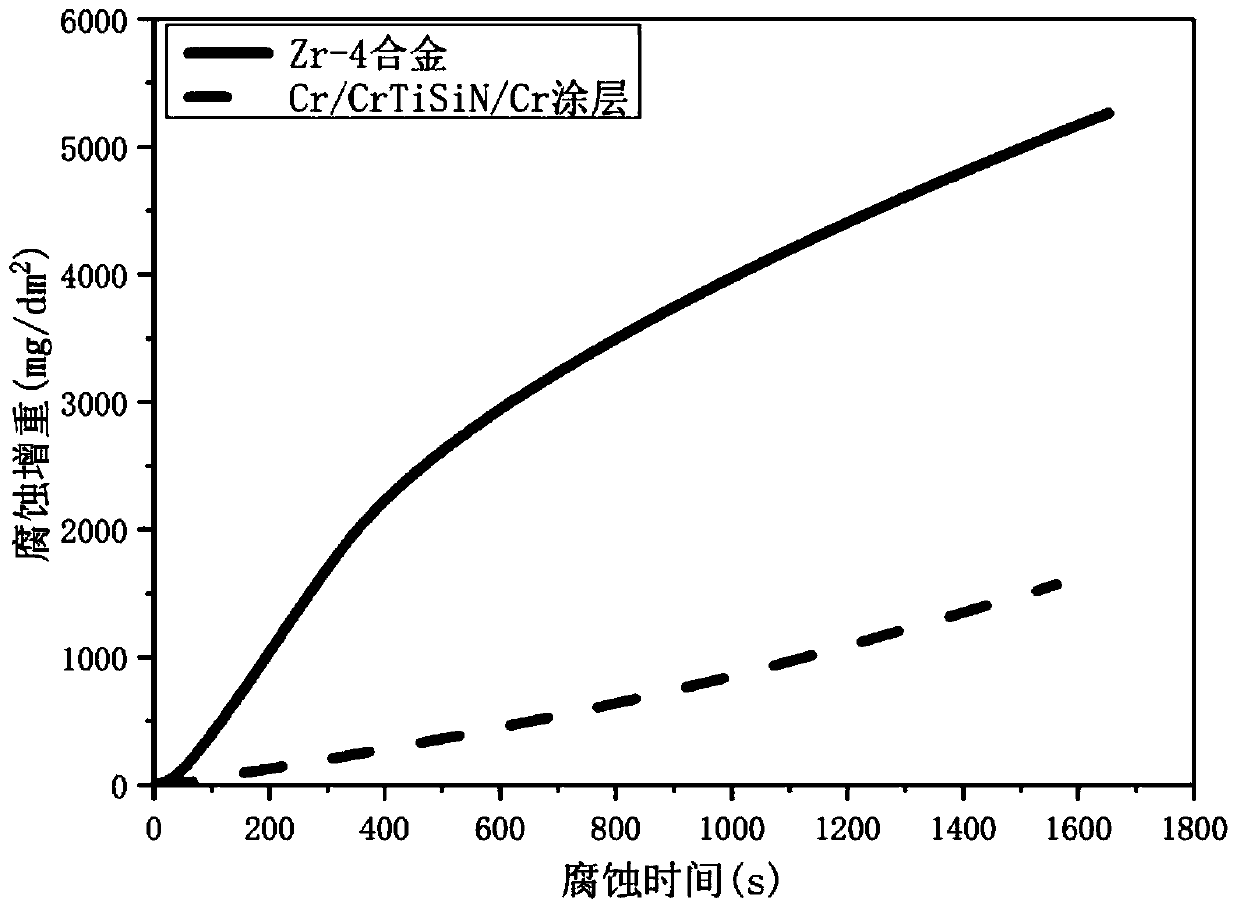

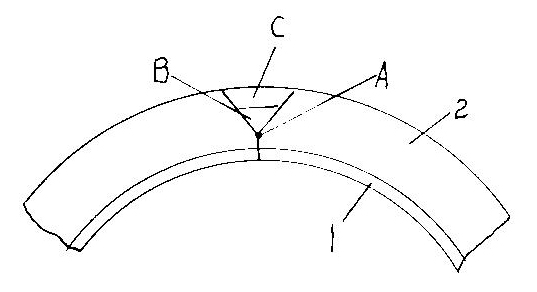

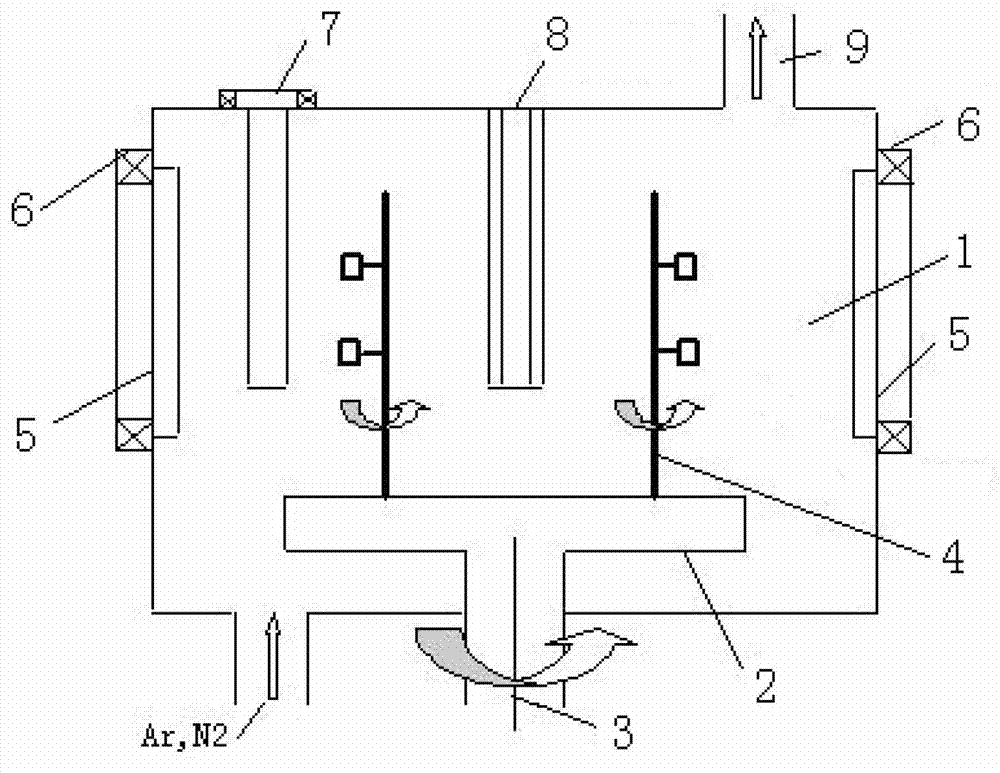

Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

ActiveCN111172503AImprove economyUniform thicknessVacuum evaporation coatingSputtering coatingFrettingNitrogen gas

The invention discloses a multilayer composite coating of a zirconium alloy cladding surface, and a preparation method thereof. According to the method, a multi-arc ion plating technology is adopted,and zirconium alloy materials are used as a base; high purity nitrogen is used as reaction gas, and high purity argon is used as protective gas; the vacuum degree, arc current, temperature, depositiontime, gas flow and other parameters of a vacuum chamber are regulated; and a three-layer composite coating, using Cr as a transition layer, a CrTiSiN as a working coating and Cr as a protective coating, are formed on the surface of the zirconium alloy materials through deposition. The coating is uniform and compact, and the binding force between the coating and the zirconium alloy base is strong;the cladding integrity is ensured, and generation of hydrogen is inhibited; and hydrogen explosion is avoided. The coating is extremely high in hardness, and the friction resistance of zirconium alloy can be improved effectively; the a cladding pipe is prevented from being failed due to fretting wear, and the safety and accident tolerance of a reactor are improved.

Owner:XI AN JIAOTONG UNIV

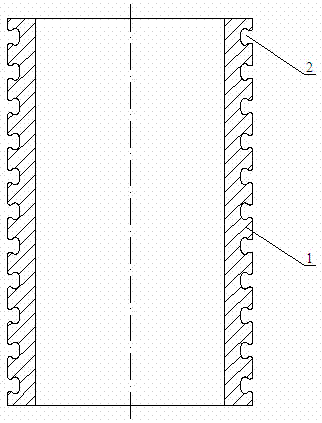

Process method of seamless sintering bimetallic lining

The invention discloses a process method of a seamless sintering bimetallic lining, mainly comprising the following steps: 1 performing contamination and oxidation layer removing treatment on the surface of a steel plate; 2 preparing copper alloy powder; 3 sintering; 4 performing precision rolling on the sintered bimetallic material, pressing the material into a round shape, and carrying out welding forming, wherein the process comprises rolling, crimping, mouth milling, groove welding and shape reforming; 5 performing the de-stressing and shaping through heat treatment; and 6 manufacturing the seamless sintering bimetallic lining through the rough machining and finish machining. The seamless sintering bimetallic lining has the following technical advantages: 1 the hardness of the copper alloy layer of the bimetallic lining is higher, and the friction coefficient is reduced, thereby greatly enhancing the combination properties and the service life of the lining; 2 the seamless sintering bimetallic lining has no shape limitation in the manufacture process; 3 the seamless sintering bimetallic lining has no size limitation, and is suitable for being used in various loads and severe environment; and 4 the method of the invention has the significant characteristic of seamless sintering, thereby solving the problem that the seam exists in the process of sintering the bimetallic material, greatly enhancing the accuracy, the stability and the bearing capacity of the lining.

Owner:陈友贵

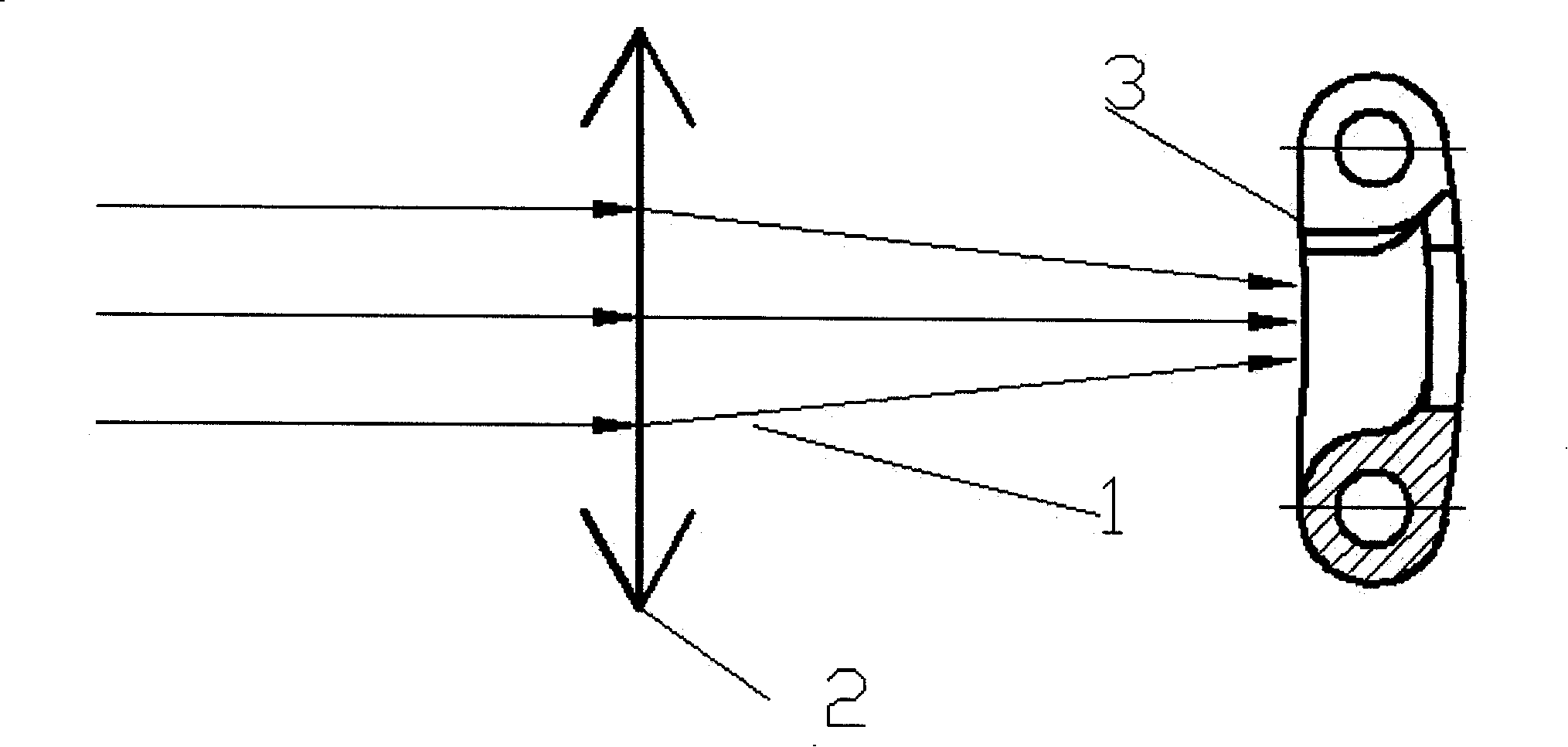

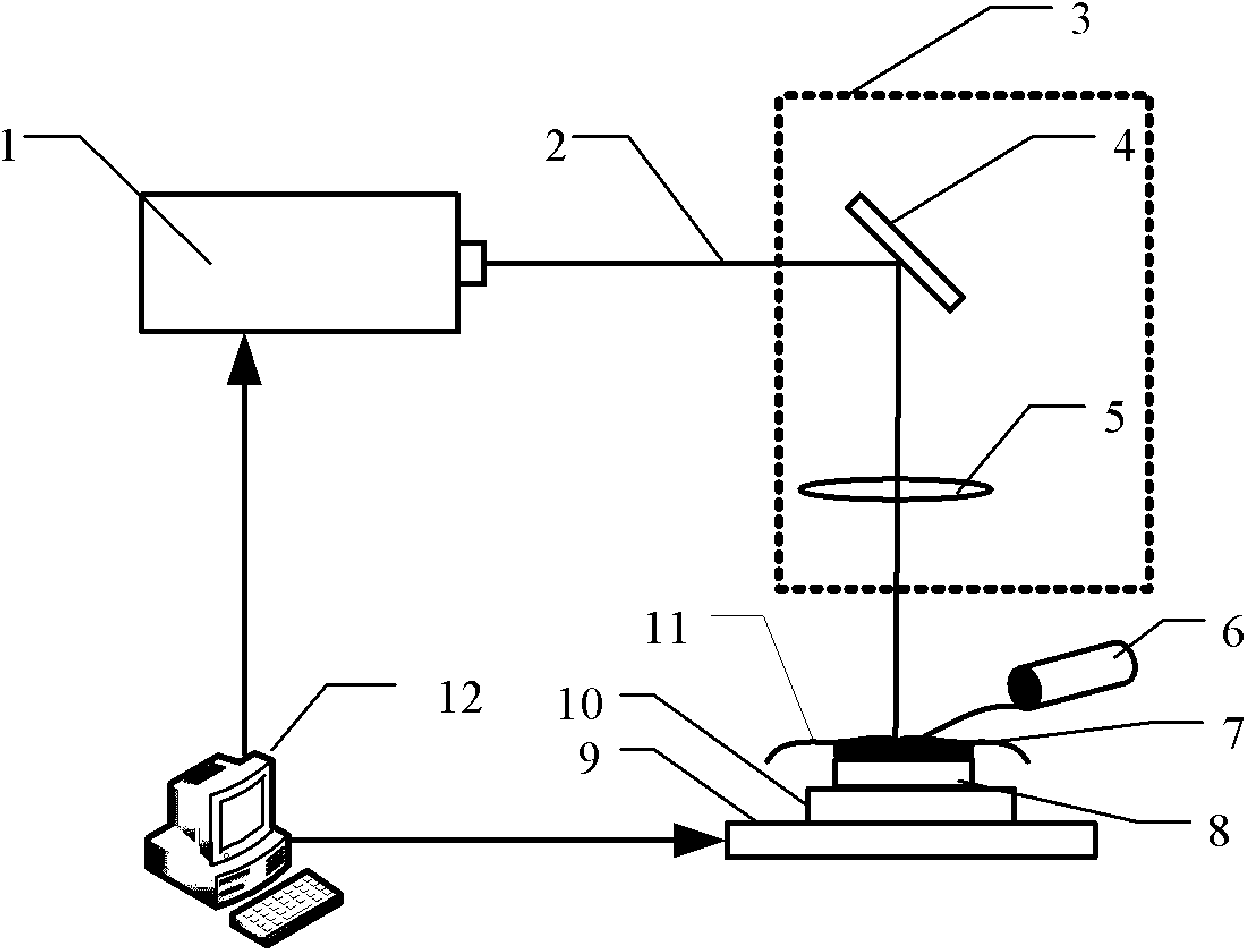

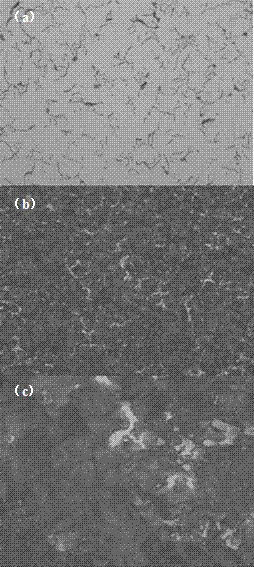

Micro-pit array-processing method based on laser impact effect

InactiveCN101653802AImprove wear resistanceAvoid the influence of laser honing melting and ablationLaser beam welding apparatusLaser processingHigh energy

The invention relates to a micro-pit array-processing method based on laser impact effect, belonging to the technical field of laser processing. The method comprises the following steps: attaching anabsorption layer on the surface of a working piece to be processed; mounting the working piece on a worktable; applying a restraint layer on the absorption layer; and starting a laser to output a beamto impact the working piece so as to generate a plurality of impact points on the surface of the working piece to be processed and realize the laser impact processing of a micro-pit array. The methodadopts the high-energy short-pulse laser to act on an energy source and has simple, reliable and easily automated technological method and strong controllability of a technological process. Comparedwith a traditional laser-boning process, the technological method does not thermally influence the surface of the working piece, generates residential stress on the surface of the working piece, ensures and improves the abrasion-resistant performance of the working piece and is especially suitable for processing a micro-pit array on a friction secondary surface.

Owner:SHANGHAI JIAO TONG UNIV

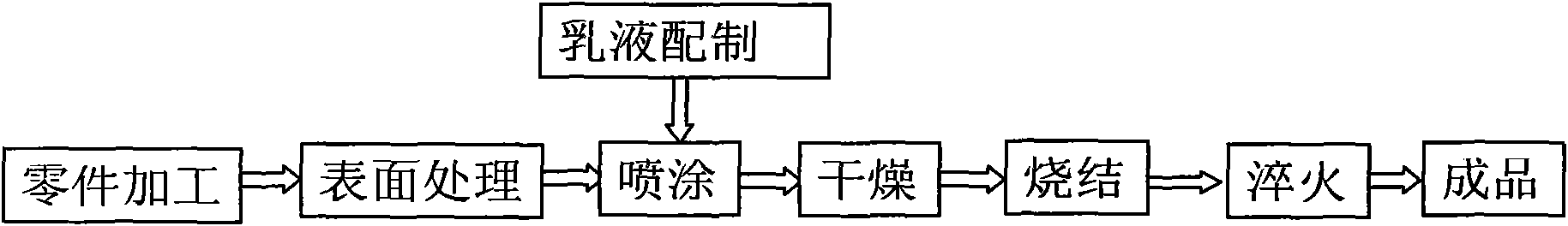

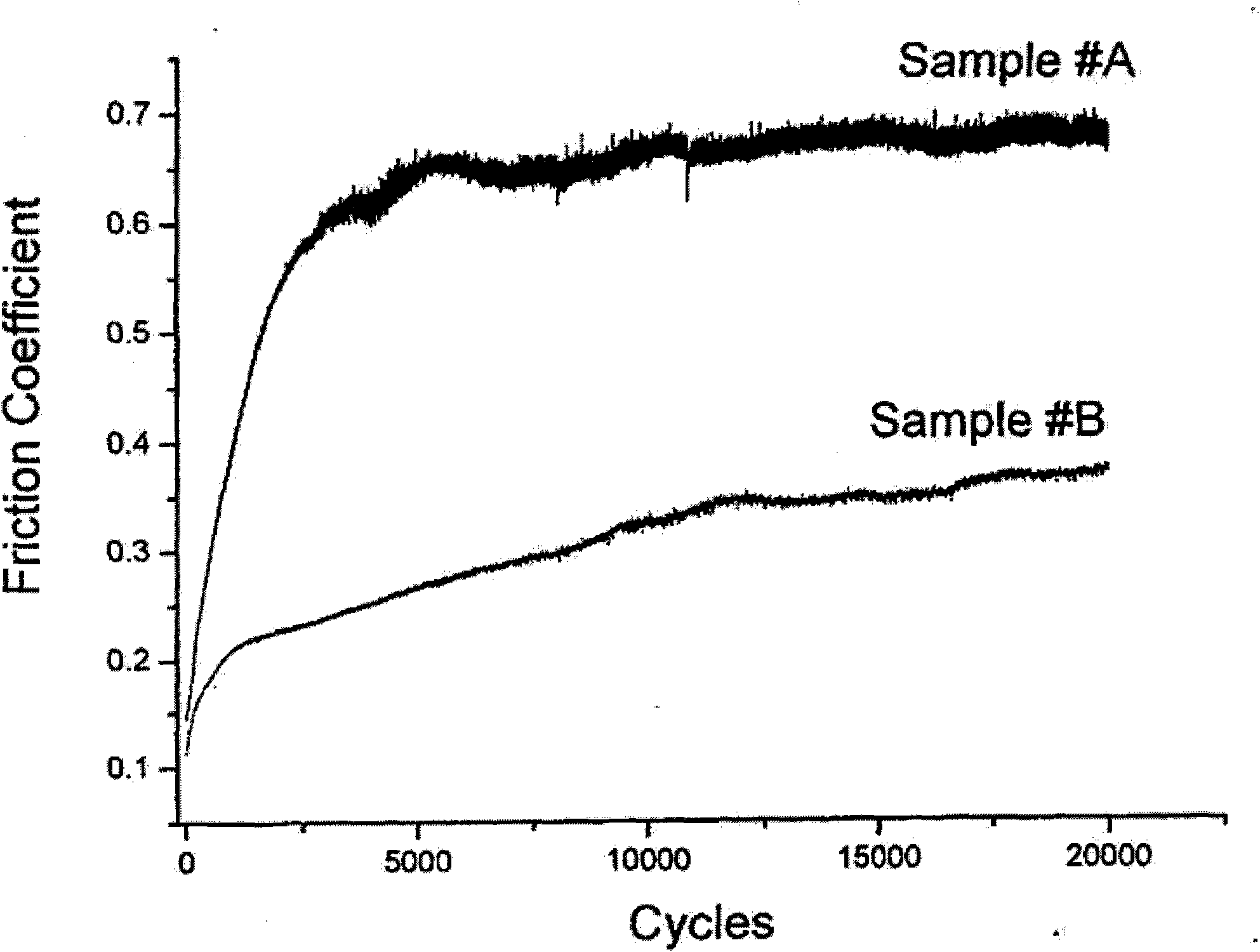

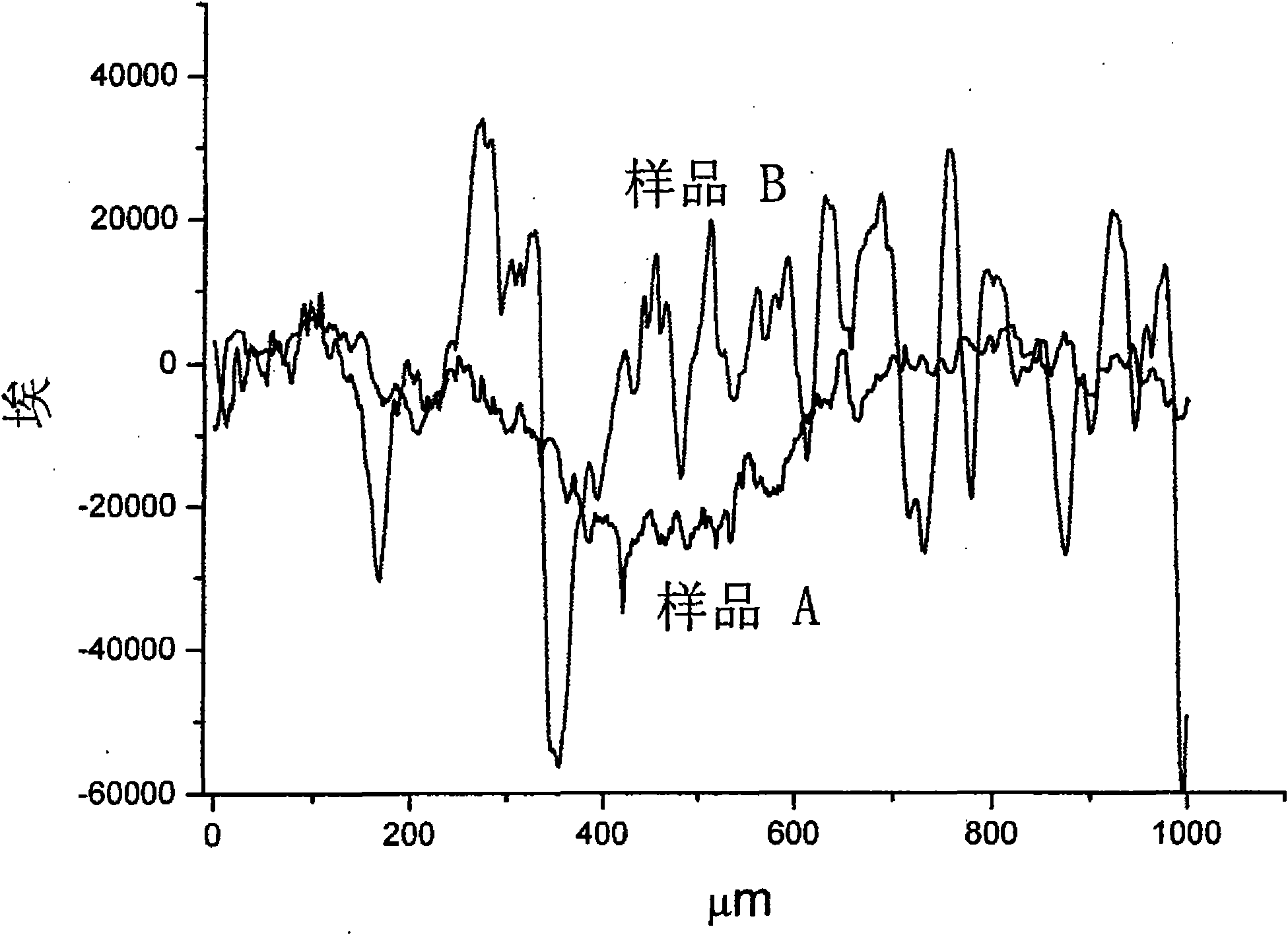

Abrasion-resistant and friction-reducing emulsion and preparation method for spraying same on surface of soft metal

InactiveCN101831222AExtended service lifeReasonable thicknessPretreated surfacesSpecial surfacesPhosphoric acidAlloy

The invention discloses abrasion-resistant and friction-reducing emulsion. The abrasion-resistant and friction-reducing emulsion comprises 50 to 69 parts of polytetrafluoroethylene emulsion, 2.0 to 5.9 parts of chromium oxide, 2.5 to 5.4 parts of phosphoric acid, 0.2 to 0.4 part of lauryl sodium sulfate, 0.5 to 3.0 parts of abrasion-resistant additive and 20 to 40 parts of distilled water. The invention also relates to a preparation method for spraying the abrasion-resistant and friction-reducing emulsion on the surface of a soft metal. The method comprises the following steps of: preparing the abrasion-resistant and friction-reducing emulsion with the components; treating the surface of soft metal matrix; spraying the emulsion on the surface of the soft metal; drying the soft metal; sintering the soft metal; and quenching the soft metal. When the abrasion-resistant and friction-reducing emulsion of the technical scheme of the invention is coated on the surface of the soft metal, the friction coefficient can be reduced by 20 percent, and the abrasion amount ratio of the soft metal to the basis material is less than or equal to 0.5. The abrasion-resistant and friction-reducing emulsion can be widely used for surface treatment of the soft metal such as copper, aluminum and alloy thereof and the like at a friction and abrasion part of a gear pump side plate, a bearing bush, a bearing block hole, a cylinder barrel and the like, and has novel structure and originality.

Owner:LUZHOU GUOBANG MACHINERY

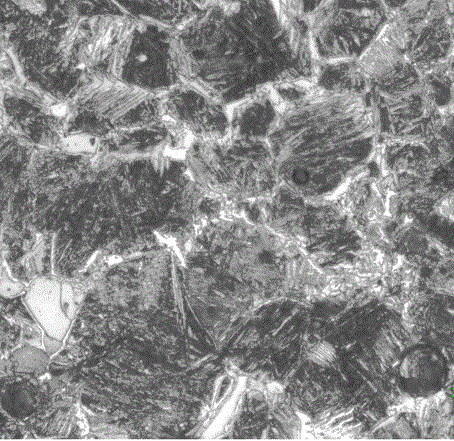

Spiral groove cast-in type air cylinder sleeve and preparation method thereof

The invention belongs to the technical field of air cylinder sleeves, and particularly relates to an energy-saving light spiral groove cast-in type air cylinder sleeve and a preparation method thereof. The air cylinder sleeve is prepared from, by weight percentage, 2.8%-3.5% of carbon, 1.2%-2.1% of silicon, 0.2%-0.5% of phosphorus, 0.06%-0.12% of sulfur, 0.3%-0.7% of manganese, 0.3%-0.7% of copper, 0.2%-0.5% of chromium, 0.1%-0.4% of molybdenum, 0.1%-0.2% of tin, larger than 0 and smaller than or equal to 0.05% of vanadium and the balance iron. According to the air cylinder sleeve, through smelting, casting and machining, graphite on the wear surface of the material of the air cylinder sleeve is evenly distributed in a flaky shape, fine lamellar pearlite bodies are the main of the base body structure of the friction surface, the hardness ranges from 94 HRB to 104 HRB, and tensile strength is larger than or equal to 360 MPa. After casting, the bonding strength of the air cylinder sleeve and a cylinder body is high and is 40 MPa or more.

Owner:ZYNP GRP

Lead acid start accumulator separator and preparing method

The lead-acid actuating storage battery separator overcomes the problems of large bore and low strength in common 10G separator, which comprises following material as weight share: 100 ultrathin glass-fiber wool of 1.0~1.4ªm diameter, 10~15 polyester fiber of 6~9ªm diameter, 0.2~0.3 wet strength agent, 6~7 precipitation latex, and 0.3~0.4 cationic polyacrylamide. This production holds traditional advantages, reduces maximal bore diameter 30~50%, and improves almost 1 time of tensile strength, 80% dry breaking strength and 65% corrosion breaking strength.

Owner:风帆股份有限公司玻璃纤维制品分公司

High-density polyethylene double-wall corrugated tube

InactiveCN103554601AGood tensile strengthGood mechanical properties and anti-friction propertiesFlexible pipesRigid pipesEthyl phosphateKetone

The invention discloses a high-density polyethylene double-wall corrugated tube. The high-density polyethylene double-wall corrugated tube is characterized by comprising the following raw materials in parts by weight: 80 to 86 parts of high-density polyethylene, 2 to 3 parts of polycarbonate, 2 to 3 parts of tetradecanedioic acid, 1 to 2 parts of tartaric acid, 1 to 2 parts of octyl-isothiazolin-ketone, 0.5 to 1 part of tetramethylthiourea, 1 to 2 parts of N-ethyl-p / m-toluene sulfonamide, 4 to 5 parts of fluorite powder, 1 to 2 parts of monopotassium phosphate, 2 to 4 parts of poly-4-methyl-1-amylene, and 7 to 10 parts of composite filler. The corrugated tube disclosed by the invention has high tensile strength, high elongation at break and high notch impact strength, and also has high mechanical properties and anti-friction properties.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

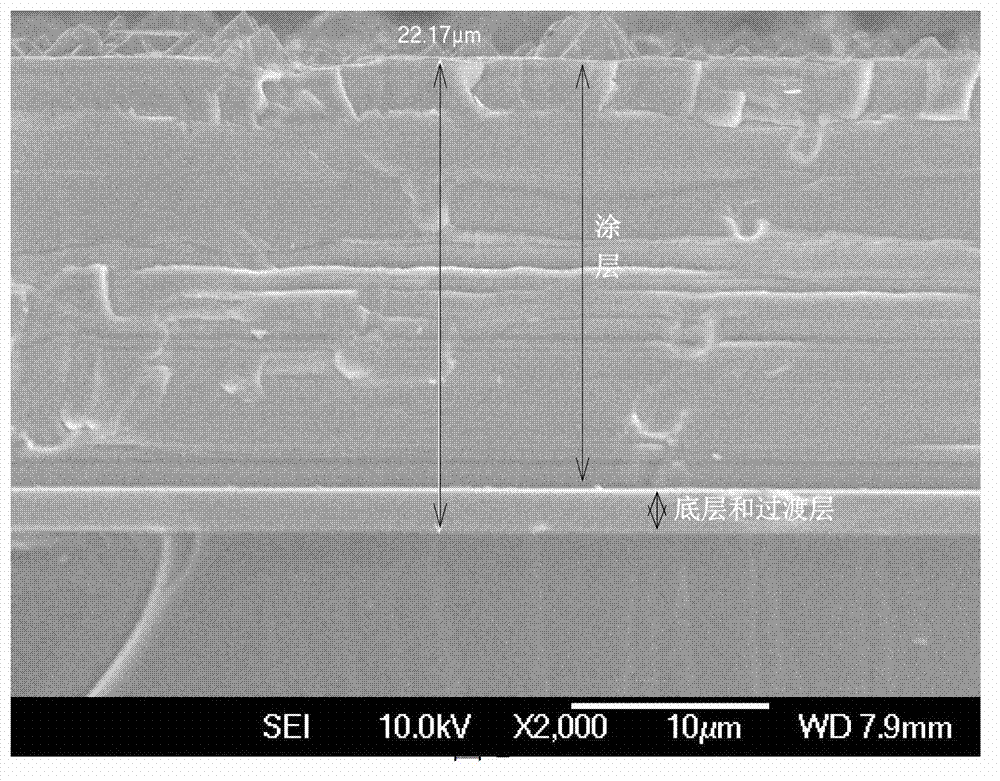

Super-thick super-hard coating and preparation method thereof

InactiveCN102756514AIncreasing the thicknessImprove bindingVacuum evaporation coatingSputtering coatingIonizationAs element

The invention provides a super-thick super-hard coating and a preparation method thereof. The super-thick super-hard coating comprises a Ti bottom layer deposited on the surface of a basal body, a TiN transitional layer prepared on the Ti bottom layer, and a TiAlSiCN coating prepared on the TiN transitional layer; and the thickness of the super-thick super-hard coating is larger than or equal to 20 microns. During preparation, a columnar electric arc Ti target serves as a Ti source; a planar magnetron sputtering Si target, a planar magnetron sputtering Al target and a planar magnetron sputtering target serve as sources of Si, Al and C correspondingly; Ar serves as an ionization gas; and N2 serves as a reaction gas. According to the invention, the binding force of the basal body to a TiAlSiCN coating as well as the thickness of the TiAlSiCN coating prepared on the basal body is remarkably improved; and as elements such as Si, C and Al are added into the TiN coating, the TiAlSiCN coating with five elements is obtained, and the hardness, the abrasion resistance, the anti-friction quality, the high-temperature oxidization resistance and the corrosion resistance of the coating are further improved.

Owner:XI AN JIAOTONG UNIV

Ferrotitanium-based oily antifriction material

The invention discloses a ferrotitanium-based oily antifriction material. The ferrotitanium-based oily antifriction material comprises, by weight, 1.5%-5% of titanium hydride powder, 84.5%-97.1% of reduced iron powder, 1%-5% of copper powder, 0.2%-2.0% of graphite powder, 0.1%-1.5% of ferrophosphorus powder and 0.1%-2% of zinc stearate, and is made through the steps of powder mixing, pressing, sintering, oil-impregnated treatment and the like. Compared with the prior art, by adding the titanium hydride powder into the material, on one hand, the open porosity of the material is improved, more lubricating oil can be stored inside the material, a dynamic pressure oil film formed on the surface of a friction pair can be separated out favorably, and the function of supplementing lubrication is achieved; on the other hand, elementary substance titanium produced by decomposing titanium hydride is reacted with graphite to generate titanium carbide hard particles, so the wear-resisting property of the material is improved. The tribological property of the ferrum-based powder metallurgy material is obviously improved due to the addition of the titanium hydride, and the ferrotitanium-based oily antifriction material has the advantages of being low in cost and wide in application range.

Owner:HEFEI UNIV OF TECH

High-damping and high-performance alloy cylinder sleeve and preparation technology thereof

ActiveCN105821294AHigh damping characteristicsReduce vibrationCylinder headsCylindersCavitationAlloy coating

The invention discloses a high-damping and high-performance alloy cylinder sleeve and a preparation technology thereof. The high-damping and high-performance alloy cylinder sleeve comprises a cylinder sleeve body and a zinc-aluminum high-damping alloy coating sprayed to the outer wall of a cylinder sleeve body. The thickness of the zinc-aluminum alloy coating is 0.3-1 mm. The cylinder sleeve body comprises, by weight, 3.2-3.5% of C, 2.8-3.3% of Si, 0-0.02% of P, 0-0.01% of S, 3.0-4.0% of Cu, 1.5-2.0% of Mn, 0.4-0.6% of Ni, 0.04-0.08% of Mg, 0.02-0.05% of Ce, and the balance Fe. The nodular cast iron cylinder sleeve obtained through the formula and preparation technology has high damping characteristics, vibration and noise of the engine cylinder sleeve can be effectively reduced, and a wearing surface on the inner wall of the cylinder sleeve has good wear resistance and anti-attrition performance, and the outer wall of the cylinder sleeves has the advantages of being high in strength, good in plasticity, good in corrosion resistance and anti-cavitation ability, short in run-in period with pistons and the like.

Owner:ZYNP GRP

Overlaying process of drilling tool for petroleum extraction

InactiveCN102343471AIncrease depth of fusionGuaranteed service lifeArc welding apparatusAutomatic controlTungsten

The invention provides an overlaying process of a drilling tool for petroleum extraction. Primarily, an overlaying region of the drilling tool is electrically welded by an automatic control carbon dioxide welding machine by using a carbon steel welding wire; pure tungsten powder which is preheated to 200 DEG C is sprayed to an electrical welding position by a powder spraying mechanism during the electrical welding to perform facing; and finally, a tungsten carbide-containing thickening wear-resistant belt is formed by performing facing at the overlaying region of the drilling tool. By adopting the overlaying process of the drilling tool for petroleum extraction, the forming of a weld joint and the fusion depth of a welding wire and a parent metal are effectively increased, and the hardness of a welding layer is improved; and thus, the wear resistance of the drilling tool and the anti-friction quality of the drilling tool to a bushing are improved, and the service life of the drilling tool is prolonged by more than two times.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING +1

Aluminum-based material and preparation method thereof

InactiveCN109706350AHigh hardnessImprove wear resistanceFoundry mouldsMetallic material coating processesWear resistantAlloy substrate

The invention discloses an aluminum-based material. Aluminum nitride, zirconium oxide and tantalum oxide particles are uniformly distributed in an aluminum alloy substrate, MoS2, Al2O3 and SiC are distributed on part of a surface layer of the aluminum alloy substrate, the hardness of aluminum nitride, zirconium oxide and tantalum oxide is high, the hardness and wear-resisting performance of the substrate are significantly improved, and fluorinated graphite powder can improve the anti-friction property. The surface of the substrate is coated with a Mn-Cr coating in a fusion mode to effectivelyimprove the wear-resisting performance and corrosion resistance of the alloy surface. The dispersion strengthening of strengthening phases of Si, Cu, Cr, Ni, Hf, Fe, Ag, Ca, Li, Ba and other elementsin the alloy improves the mechanical properties of the material. A preparation method enables mixed powder to be located in the center of a master alloy solution during casting through a method by adhering the mixed powder to a pure aluminum metal wire, the rapid diffusion and homogenization of micro powder particles is facilitated, the production efficiency is improved, wear-resistant materials are locally added by friction stir machining, and the material utilization ratio is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Method for preparing rare earth modified graphene ceramic composite film on glass substrate

InactiveCN102718500AImprove mechanical propertiesImprove tribological propertiesCeramic layered productsGlass/slag layered productsFriction reductionCeramic composite

The invention relates to a method for preparing a rare earth modified graphene ceramic composite film on a glass substrate. The method includes: (1) subjecting the surface of the glass substrate to hydroxylation pretreatment to obtain a treated glass substrate; (2) preparing rare earth sol solution and placing graphene into the obtained rare earth sol solution for treatment for 4-10h to obtain rare earth modified graphene sol; (3) immersing the treated glass substrate into the rare earth modified graphene sol, standing, upwardly lifting the glass substrate out of the sol, and drying; and (4) preserving the glass substrate obtained at the step (3) at 80-120 DEG C for 30-90min, heating to 600-800 DEG C, preserving heat for 1-5h and naturally cooling to the room temperature. The method is simple in preparation process, low in cost, free of environment pollution and fine in film forming. The composite ceramic film prepared by the method is uniform and compact and has excellent characteristics of friction reduction and abrasion resistance.

Owner:DONGHUA UNIV

Lubricating oil composition

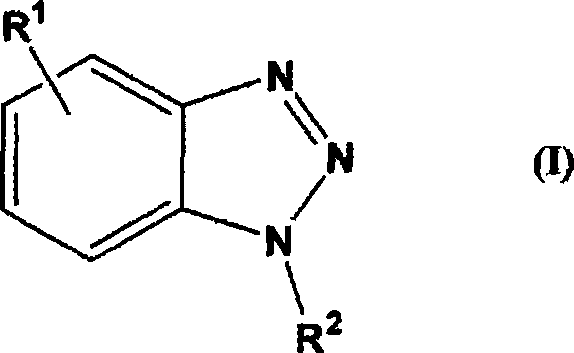

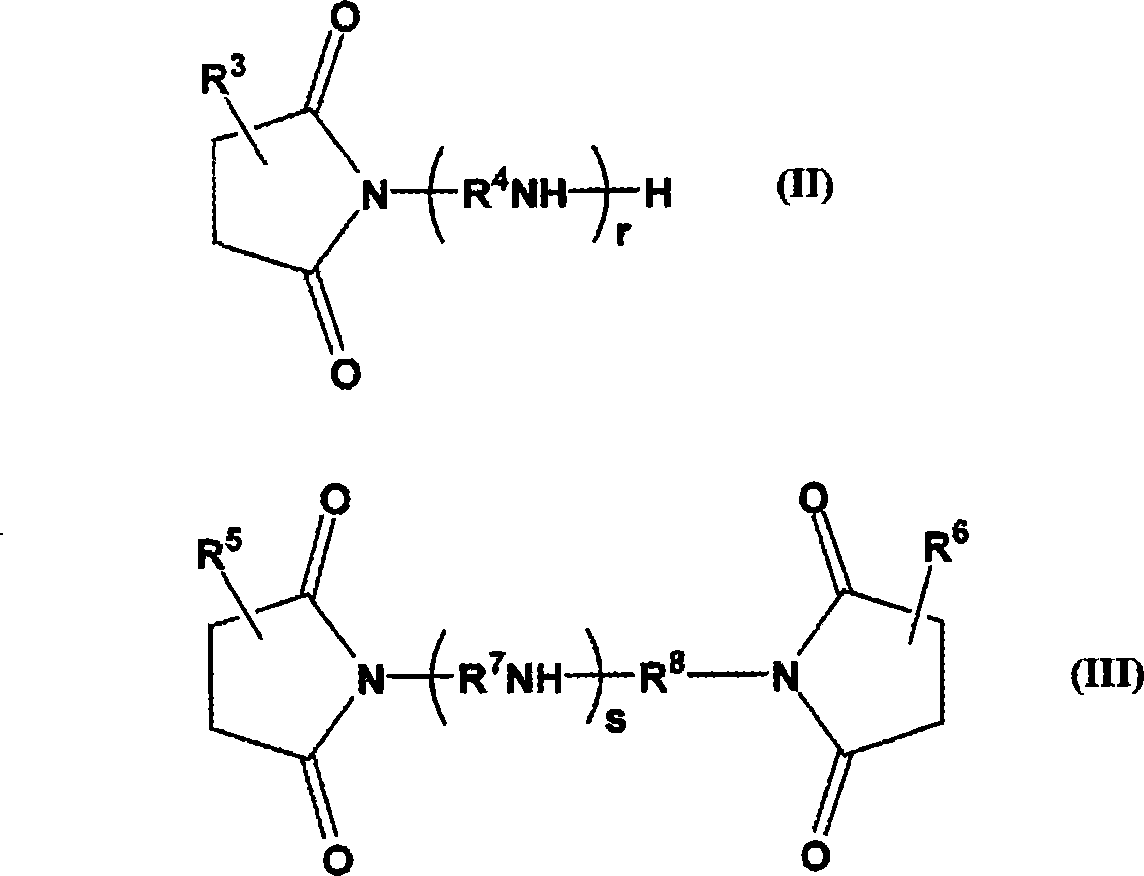

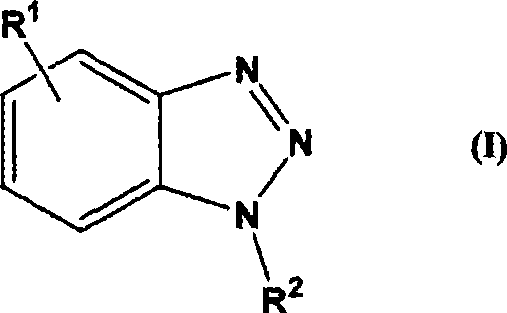

ActiveCN101522873AImprove anti-friction performanceImprove oxidation stabilityAdditivesBase-materialsInternal combustion engineFatty acid

The present invention provides a lubricating oil composition comprising a base oil for a lubricating oil, (A) a fatty acid partial ester compound, 0.5 to 1.5 % by mass of (B) (b1) an aliphatic amine compound and / or (b2) an acid amide compound, 0.01 to 0.1 % by mass of (C) a specific benzotriazole derivative and a specific amount of (D) a specific succinimide compound. It is a lubricating oil composition of an environmental regulation compliant type which is used for internal combustion engines such as gasoline engines, diesel engines, engines using dimethyl ether for fuel, gas engines and thelike, which does not contain Mo base friction reducing agents and is reduced in ash, phosphorus and sulfur and in which a friction reducing effect, an oxidation stability and a corrosion inhibiting effect are enhanced.

Owner:IDEMITSU KOSAN CO LTD

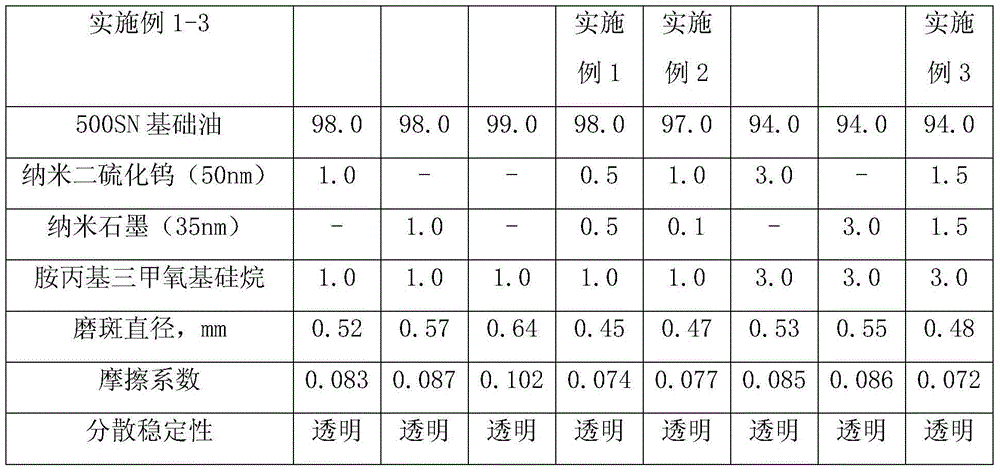

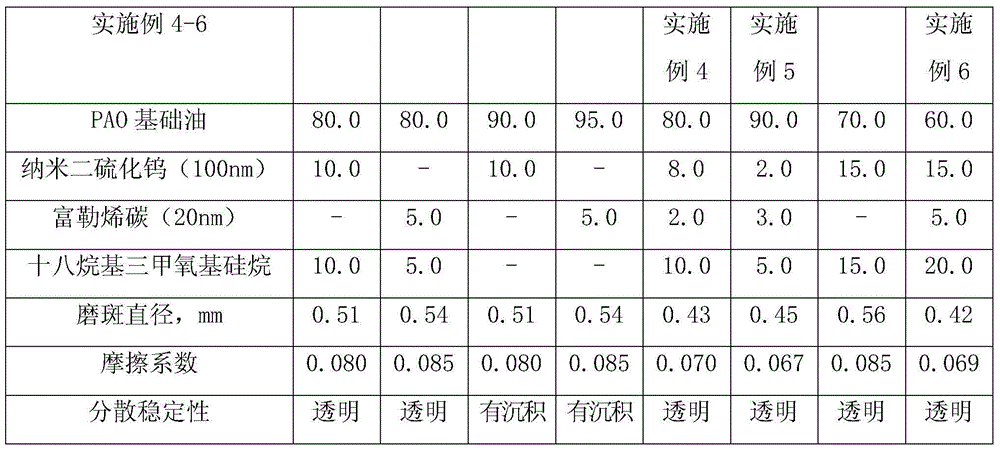

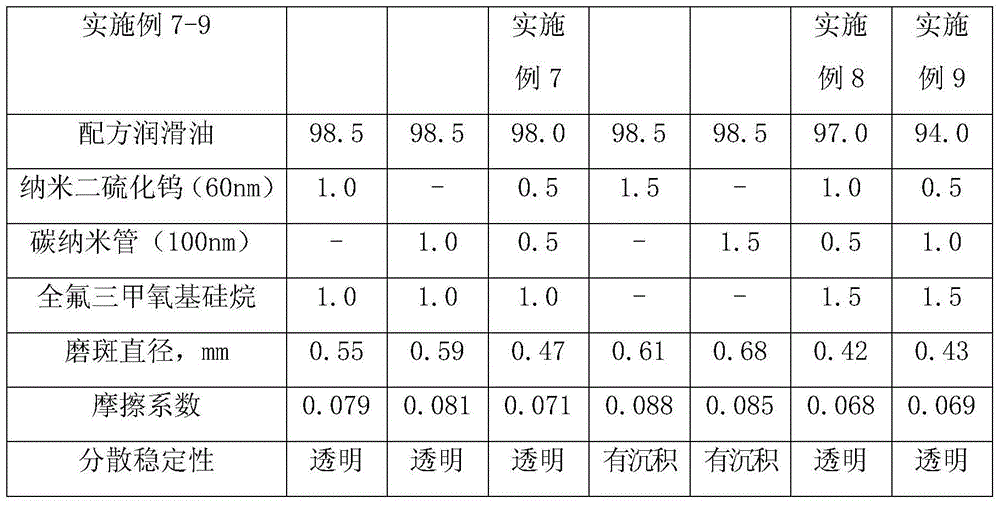

Antifriction and antiwear lubricant oil additive containing nano tungsten disulfide

InactiveCN104560307AImprove dispersion stabilityImprove anti-wear and anti-friction performanceAdditivesDispersion stabilityOil additive

The invention discloses an antifriction and antiwear lubricant oil additive containing nano tungsten disulfide, and belongs to the technical field of lubricant oil. The lubricant oil additive comprises the following components in percentage by weight: 0.5-15% of nano tungsten disulfide, 0.1-5% of a carbon nano additive, 1-20% of a surface modifier and 60-98.4% of basic lubricant oil. The lubricant oil additive disclosed by the invention can remarkably improve antifriction and antiwear performances of the basic lubricant oil, has relatively good dispersion stability in the basic lubricant oil, can be widely applied to lubricant grease of various vehicles and large-sized mechanical equipment, and can contain an extreme-pressure antiwear agent, an antioxidant, a purification dispersant, a corrosion inhibitor and the like.

Owner:中国人民解放军空军勤务学院

Copper-coating compound powder and method for making the same

ActiveCN101130838AImprove anti-friction performanceHigh temperature strengthLiquid/solution decomposition chemical coatingBase-materialsCopper coatingCopper plating

The present invention discloses a composite powder covered with copper and its preparation method. The composite powder covered with copper is made up by using copperplating superfine powder to completely and uniformly cover lubricating phase or abrasion-resistant phase or lubricating phase and abrasion-resistant phase mixed powder. The above-mentioned lubricating phase powder is MoS2 and WS2, and the described abrasion-resistant phase powder is Al203 and SiC.

Owner:CENT SOUTH UNIV +1

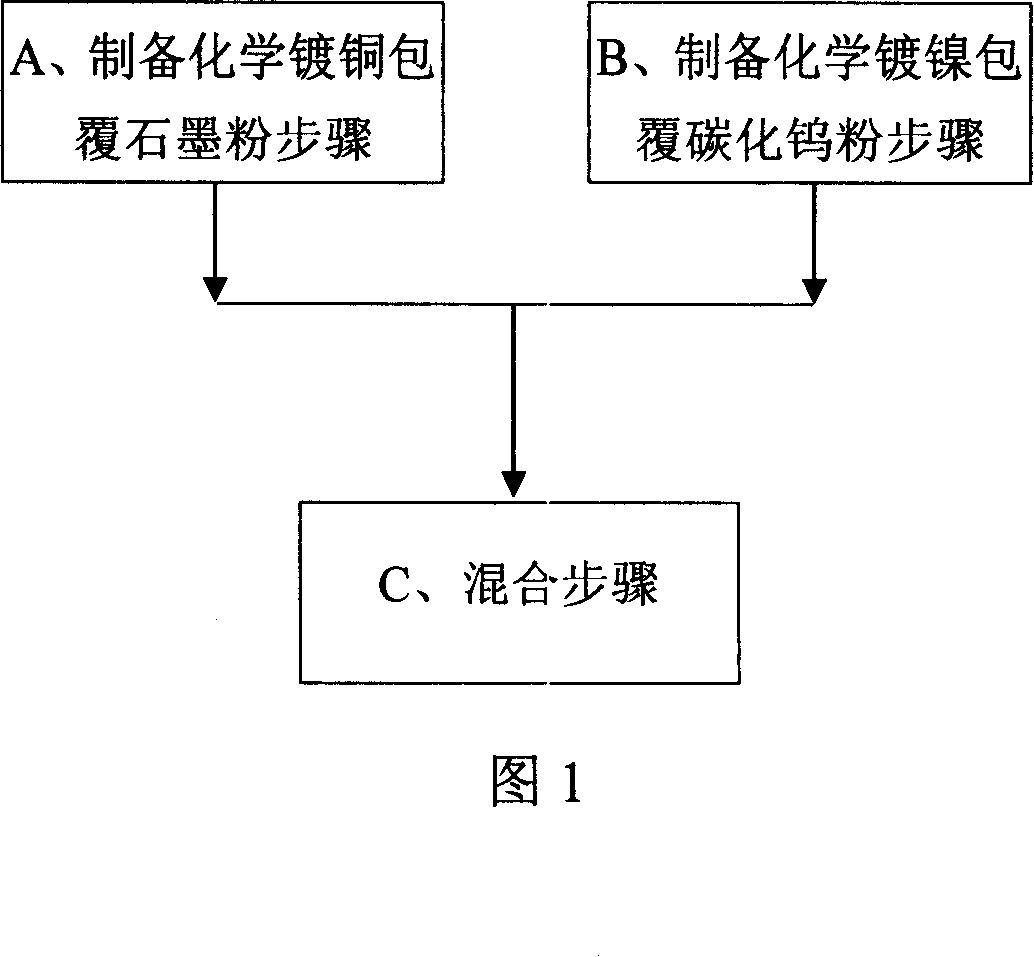

Copper-radicle antifriction compound powder and method of producing the same

ActiveCN101152669AImprove anti-friction performanceHigh temperature strengthCoatingsCopper platingGraphite

The invention discloses copper-based antifriction compound powder, which comprises copper powder, chemical copper plating coating graphite powder and chemical nickel plating coating tungsten carbide powder. The copper-based antifriction compound powder is made of main raw material and assisting raw material, the main raw material is copper and weight portion is 75 to 95 portion; assisting raw material comprises graphite, tungsten carbide and nickel and the weight portion of each component is as follows; 4 to 19 portion of graphite, 0.5 to 5 portion of tungsten carbide and 0.5 to 5 portion of nickel. The invention also provides a manufacturing method for copper-based antifriction compound powder which comprises: A. the step of preparing chemical copper plating coating graphite powder; B. the step of chemical nickel plating coating tungsten carbide powder; C. the step of mixing. The copper-based antifriction compound powder provided by the invention contains antifriction phase and strengthening phase and greatly improves performance and product service life of copper-based antifriction compound material made of copper-based antifriction compound powder; the manufacturing method provided by the invention has simple process and low cost and is suitable for conventional production.

Owner:惠州市新宏泰科技有限公司

Process for obtaining high-wear-resistant friction-reducing composite function nano-coating

InactiveCN1435514AImprove the lubrication effectImprove anti-friction performanceElectrolytic coatingsChemical platingWear resistant

An antiwear and friction-reducing nano-class plated layer is characterized by that its nickel plating liquid for electroplating or chemical plating contains the slurry prepared from nanoparticles of alpha-Al2O3 or SiC, which are uniformly dispersed in the plating liquid by stirring with compressed air. The resultant plated layer has features of high hardness and toughness, and high antiwear and friction-reducing function.

Owner:重庆阿波罗机电技术有限公司

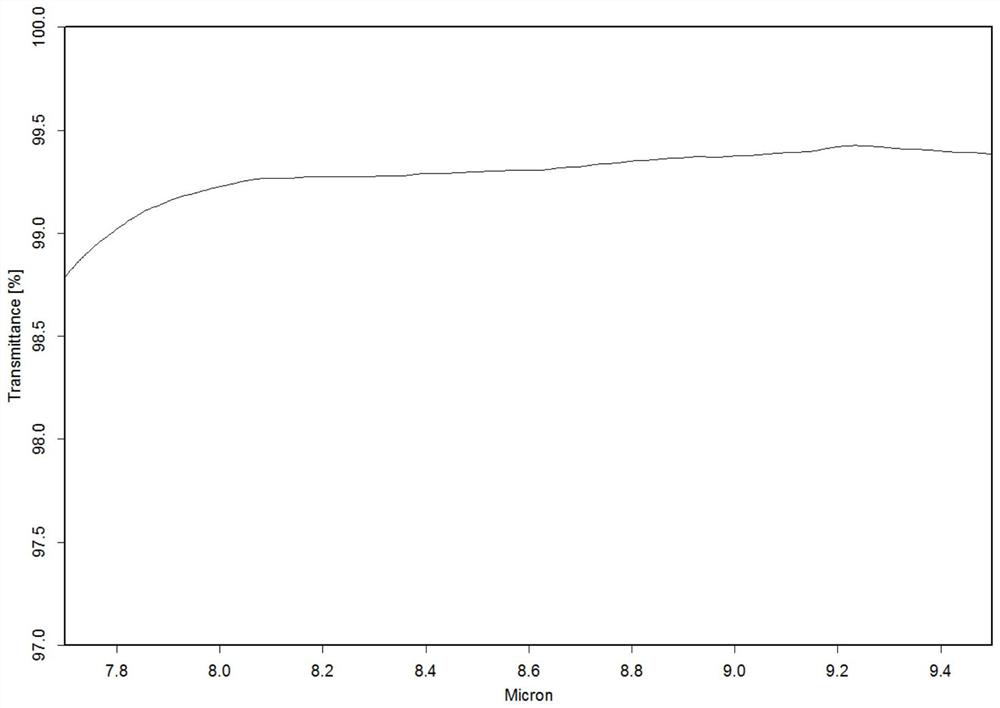

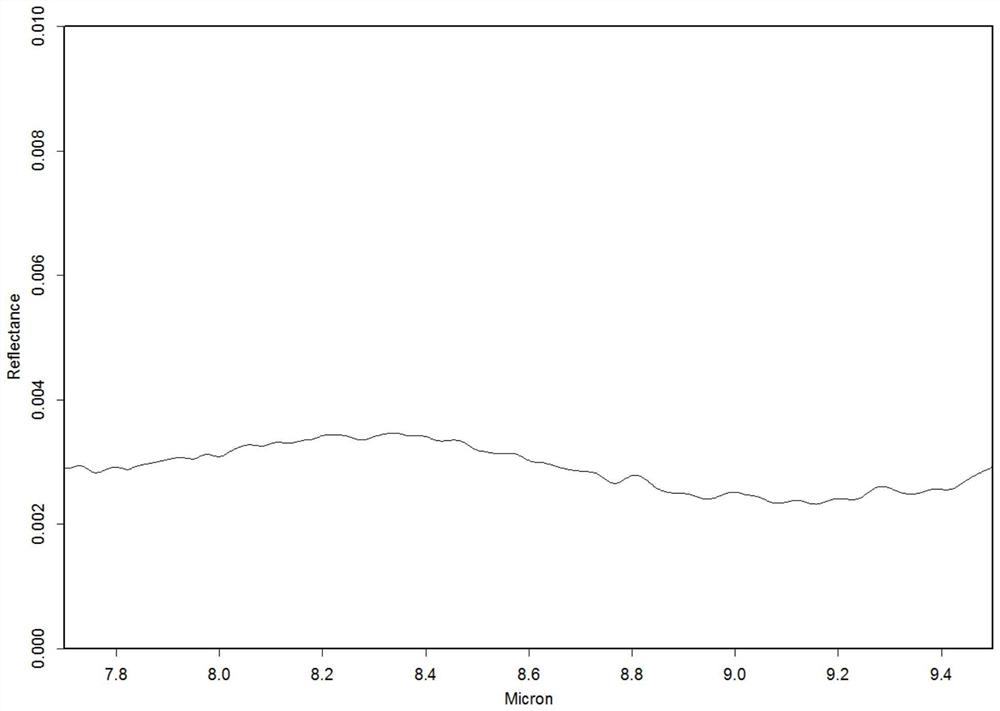

ZnSe substrate 7.7-9.5micrometer waveband high-durability antireflection film and preparation method

InactiveCN112505803AImprove transmittanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOptical instrumentWave band

The invention relates to the technical field of infrared coating, in particular to a ZnSe substrate 7.7-9.5micrometer waveband high-durability antireflection film and a preparation method. The ZnSe substrate 7.7-9.5micrometer waveband high-durability antireflection film is a film layer structure arranged on the surface of a base layer and contacted with air, and is composed of a ZnSe layer, a Ge layer, a ZnSe layer, a Ge layer, a ZnSe layer, a YbF3 layer and a ZnS layer that are stacked and connected sequentially. The ZnSe substrate 7.7-9.5micrometer waveband high-durability antireflection film disclosed by the invention is used for solving the technical problems that in the prior art, a ZnSe material substrate 7.7-9.5micrometer waveband antireflection film is poor in optical performance,poor in salt solution soaking resistance and friction resistance and incapable of well meeting the use requirements of a novel optical instrument.

Owner:YUNNAN KIRO CH PHOTONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com