Energy enhancing steering acid liquid system

A system and acid technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of oil and gas reservoir depletion, water lock damage, poor effect on deep stimulation, etc., achieve good friction reduction performance, improve Flowback capability, easy pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

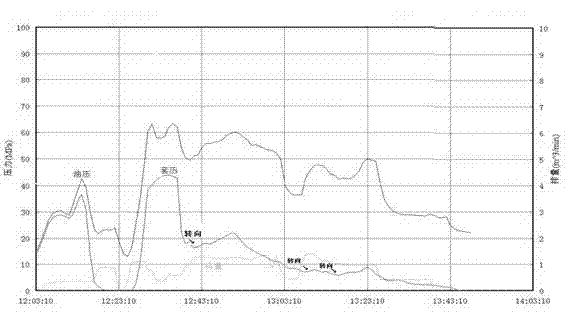

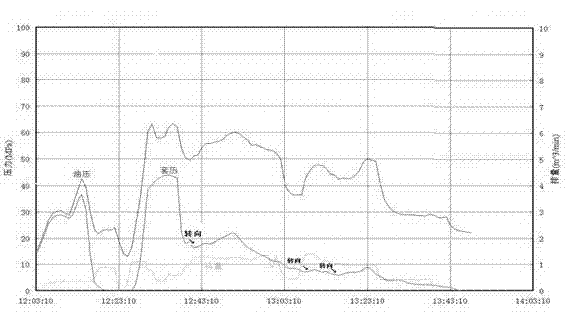

Image

Examples

Embodiment 1

[0021] An energy-enhancing diverting acid solution system, comprising: 615 parts of hydrochloric acid, 10 parts of a corrosion inhibitor, 30 parts of a diverting agent, 10 parts of a foam booster, and 10 parts of an iron ion stabilizer.

[0022] The acid viscosity of the energized steering acid liquid system is 15mPa·s~25 mPa·s, and the resistance reduction rate is 40%~50%; when the acid concentration is reacted from 20% to 8%~10%, the viscosity increase value is ≥ 80mPa·s; when the pressure coefficient is 0.41-0.7 and the foam quality is 15%-73%, the residual liquid flowback rate after acidification is >80%.

[0023] The corrosion inhibitor is a compound of Schiff's base, Pingpingjia, propynyl alcohol, and isopropanol, and the composite ratio is 40% of Schiff's base by mass percentage; Pingpingjia 5%; Proynyl alcohol 20%; Isopropanol 35%, no chemical reaction occurs between the complexes.

[0024] The diverting agent is docosyl dimethyl betaine.

[0025] The foam booster is...

Embodiment 2

[0028] An energized steering acid system to prepare 1m 3 Acid solution as an example, including: 615 parts of hydrochloric acid, 20 parts of corrosion inhibitor, 50 parts of steering agent, 20 parts of foam booster, and 20 parts of iron ion stabilizer.

[0029] The acid viscosity of the energized steering acid liquid system is 15mPa·s~25 mPa·s, and the resistance reduction rate is 40%~50%; when the acid concentration is reacted from 20% to 8%~10%, the viscosity increase value is ≥ 80mPa·s; when the pressure coefficient is 0.41-0.7 and the foam quality is 15%-73%, the residual liquid flowback rate after acidification is >80%.

Embodiment 3

[0031] An energized steering acid system to prepare 1m 3 Take acid liquid as an example, including: 615 parts of hydrochloric acid, 15 parts of corrosion inhibitor, 40 parts of steering agent, 15 parts of foam booster, and 17 parts of iron ion stabilizer.

[0032] The acid viscosity of the energized steering acid liquid system is 15mPa·s~25 mPa·s, and the resistance reduction rate is 40%~50%; when the acid concentration is reacted from 20% to 8%~10%, the viscosity increase value is ≥ 80mPa·s; when the pressure coefficient is 0.41-0.7 and the foam quality is 15%-73%, the residual liquid flowback rate after acidification is >80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com