Patents

Literature

37results about How to "Improve flowback capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for acidification to dispel block

The present invention discloses an acidizing plugging removal method which comprises steps of: injecting liquid gas as energy increased slug into target layer before traditional acidification process, the liquid gas is liquid nitrogen or liquid carbon dioxide, the injection rate is 1-1.5 stere each meter oil layer, optimal selection is 1.2 stere, the injection speed is 100-250L / min, optimal selection is 200L / min. The method of present invention can relieve zone blocking, improve yield of oil well, successful rate of plugging removal is above 98%, the average base increase production of single well is above 1.5ton / day.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Energy enhancing steering acid liquid system

InactiveCN102443386AIncrease flow resistanceRelieve pressureDrilling compositionAutomatic steeringEngineering

The invention discloses an energy enhancing steering acid liquid system, which comprises 615 parts of hydrochloric acid, 10 to 20 parts of corrosion inhibitors, 30 to 50 parts of steering agents, 10 to 20 parts of foam boosters and 10 to 20 parts of iron ion stabilizing agents. The system has the advantages that liquid has better automatic steering low-seepage storage layers, the goals of uniformly distributing acid and reforming the storage layers with poor storage seepage conditions are reached, simultaneously, the static liquid post pressure of liquid in a well tube is also reduced, and the liquid return and discharge capability after the construction is improved.

Owner:CNPC CHUANQING DRILLING ENG DOWNHOLE OPERATION

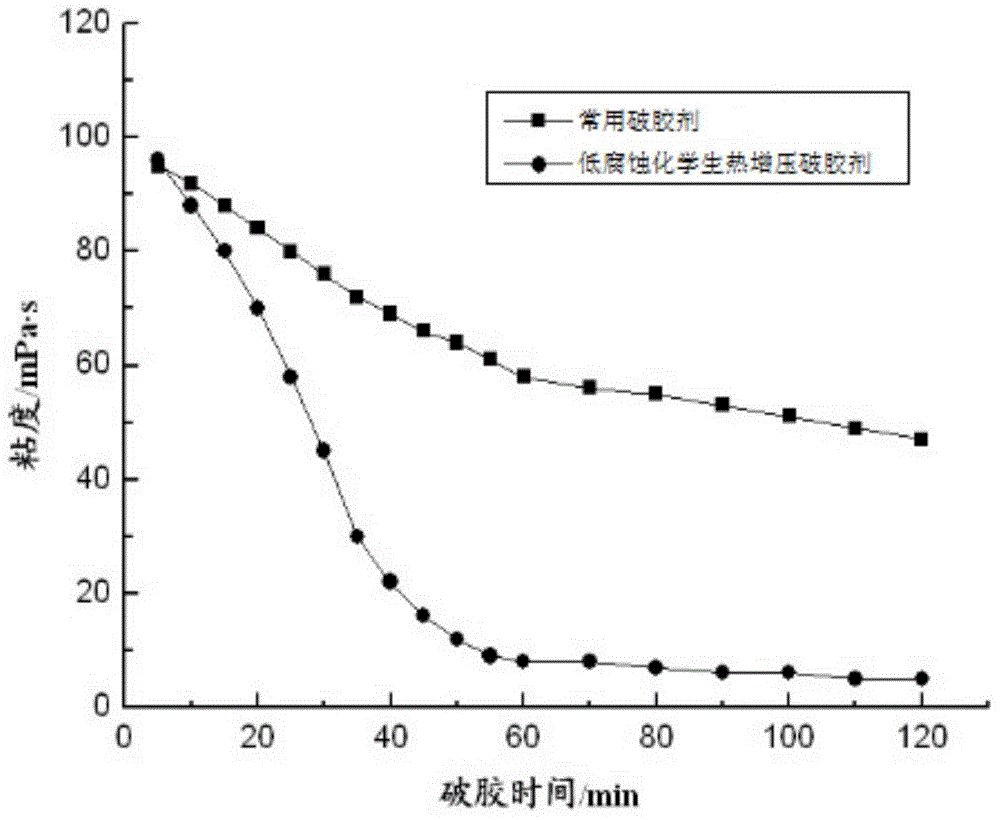

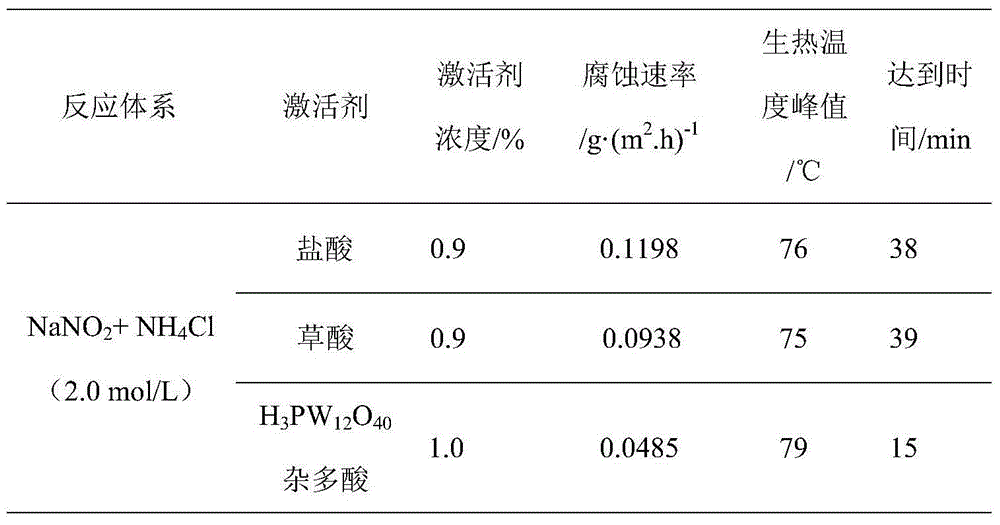

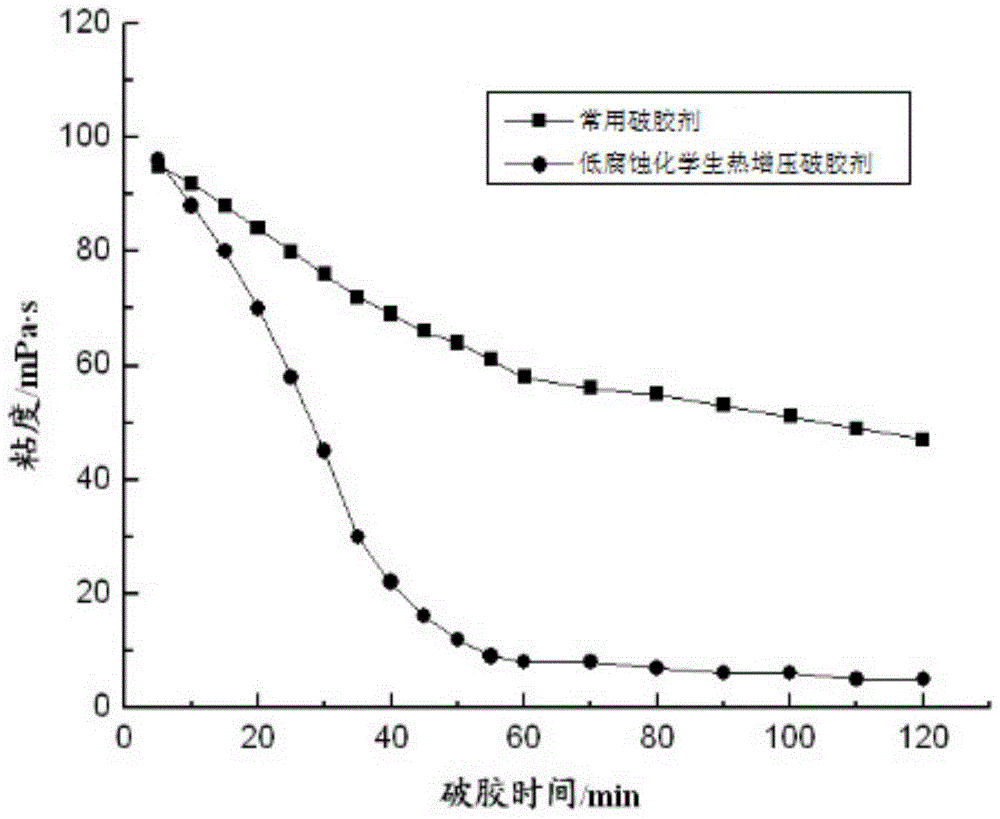

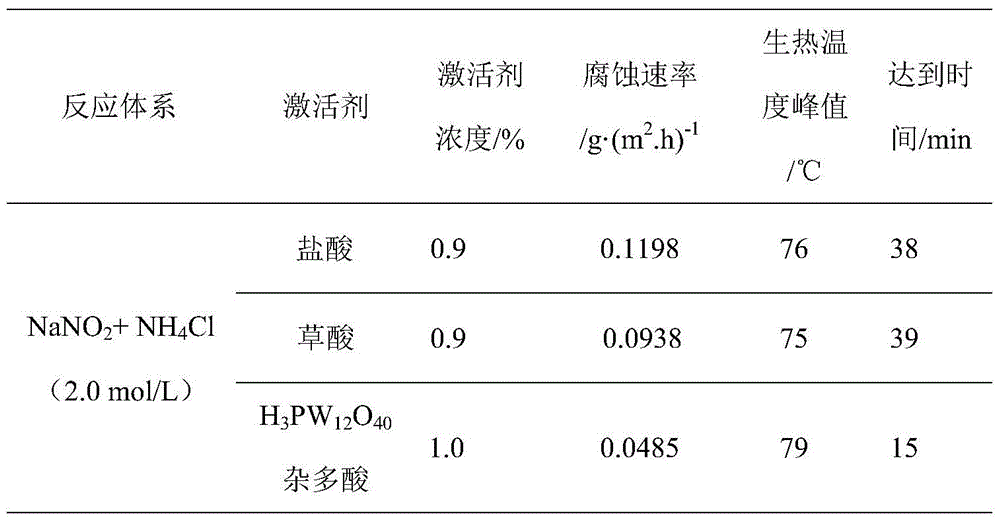

Low-corrosion chemical themogenic pressurizing gel breaker and preparation method thereof

The invention discloses a low-corrosion chemical themogenic pressurizing gel breaker which comprises an agent A solution, an agent B solution and an activator solution. The invention further discloses a preparation method of the gel breaker. The preparation method comprises the following step: uniformly mixing the agent A solution, the agent B solution and the activator solution in volume ratio of 1.0 to (1.0-1.3) to (1.0-1.2). The formation temperature is improved by the heat generated by virtue of gel breaker reaction, and the gel breaker is activated, so that a fracturing fluid is thoroughly broken. Gas generated by the gel breaking has the effect of increasing the formation pressure, so that the fracturing flowback capacity is improved. In addition, by using H3PW12O40 heteropolyacid as the activator of a system, on the basis of not affecting the acid strength, the corrosivity of the system is reduced, and the destructiveness on a soil environment in the fracturing process is effectively reduced.

Owner:YANAN UNIV

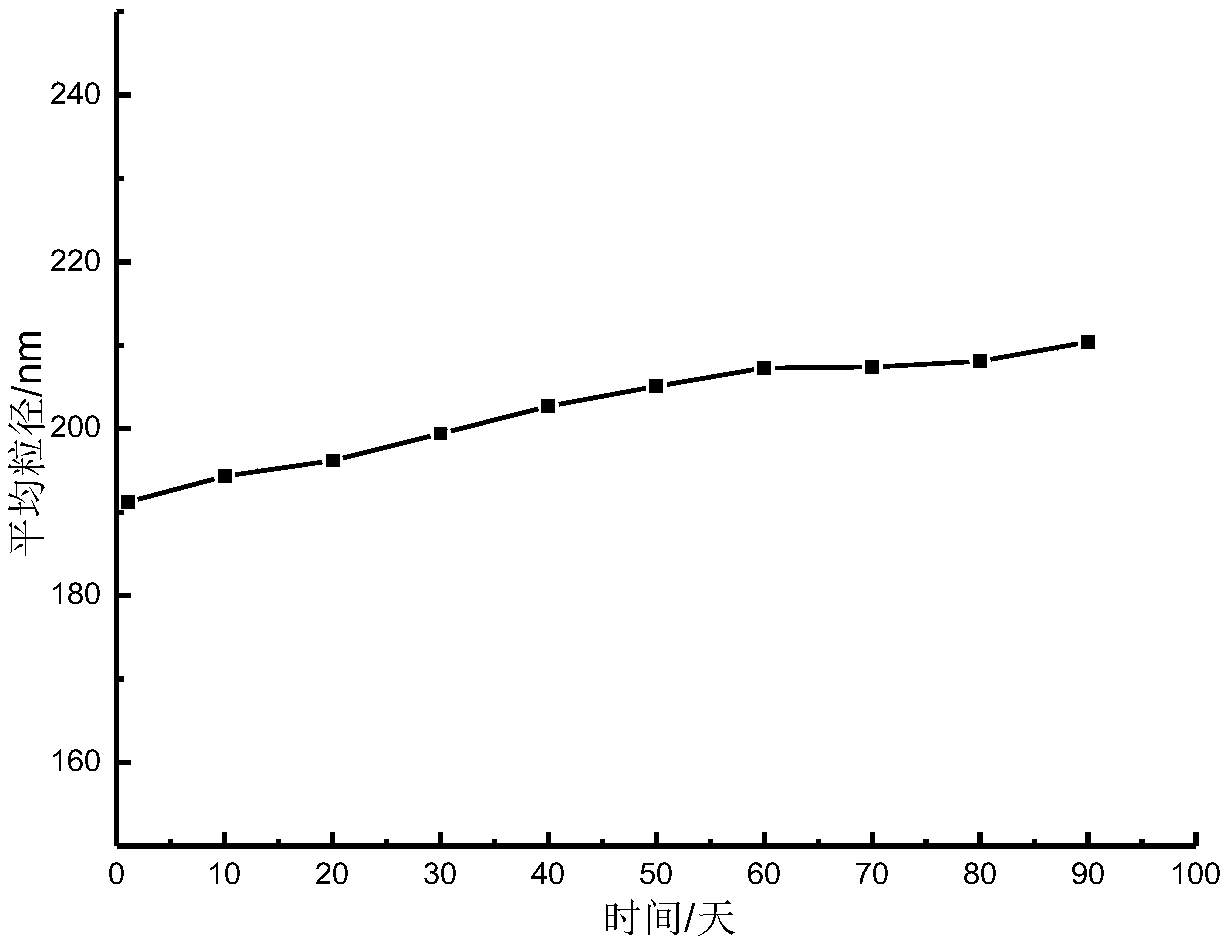

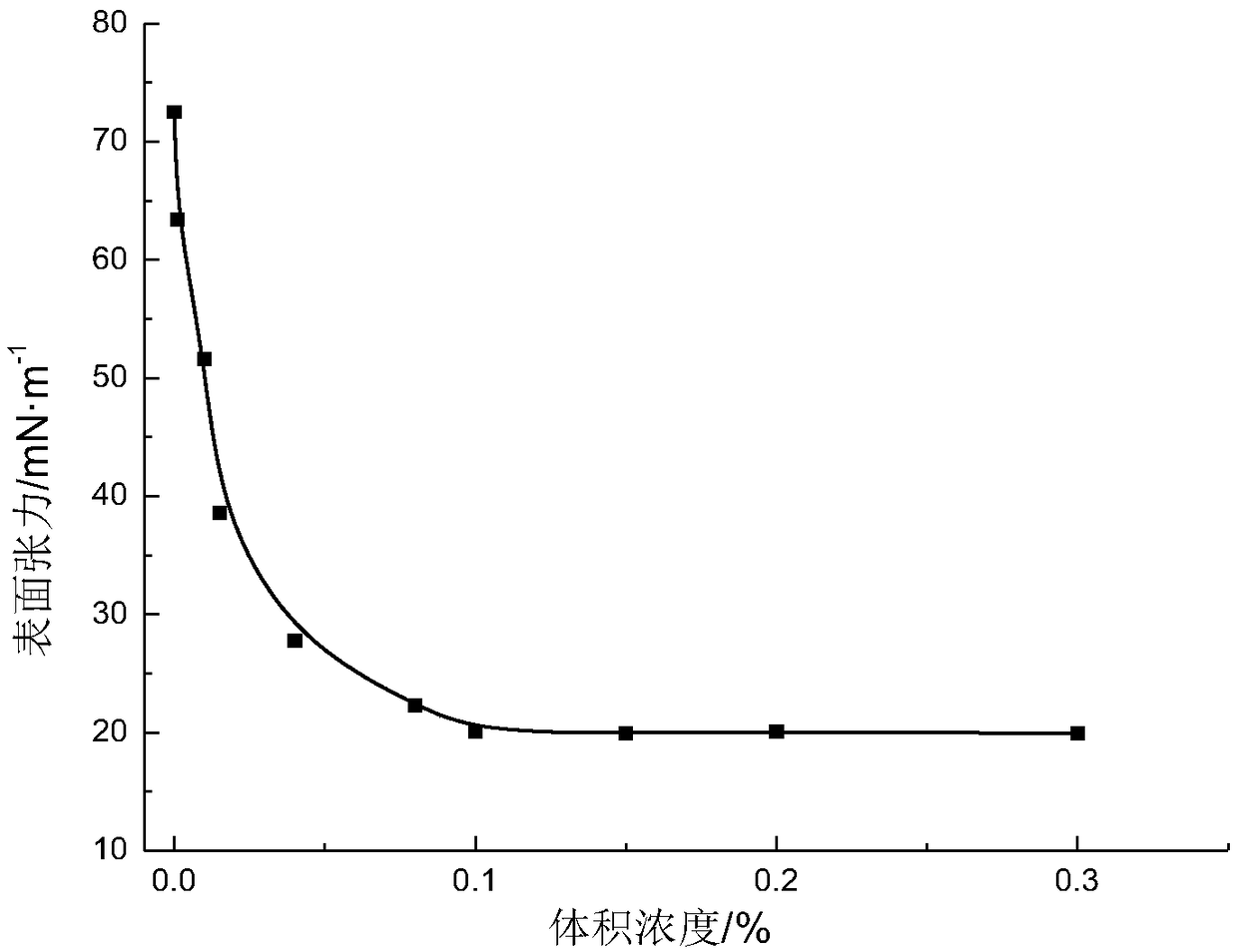

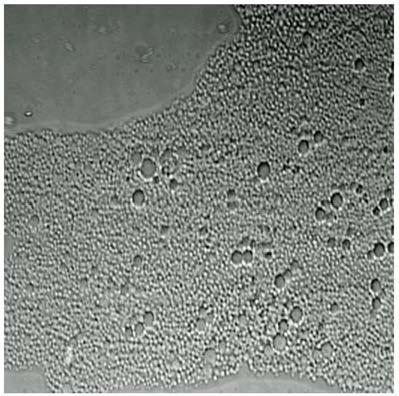

Nanometer emulsion discharge aiding agent for irregular gas reservoir fracturing and preparation method thereof

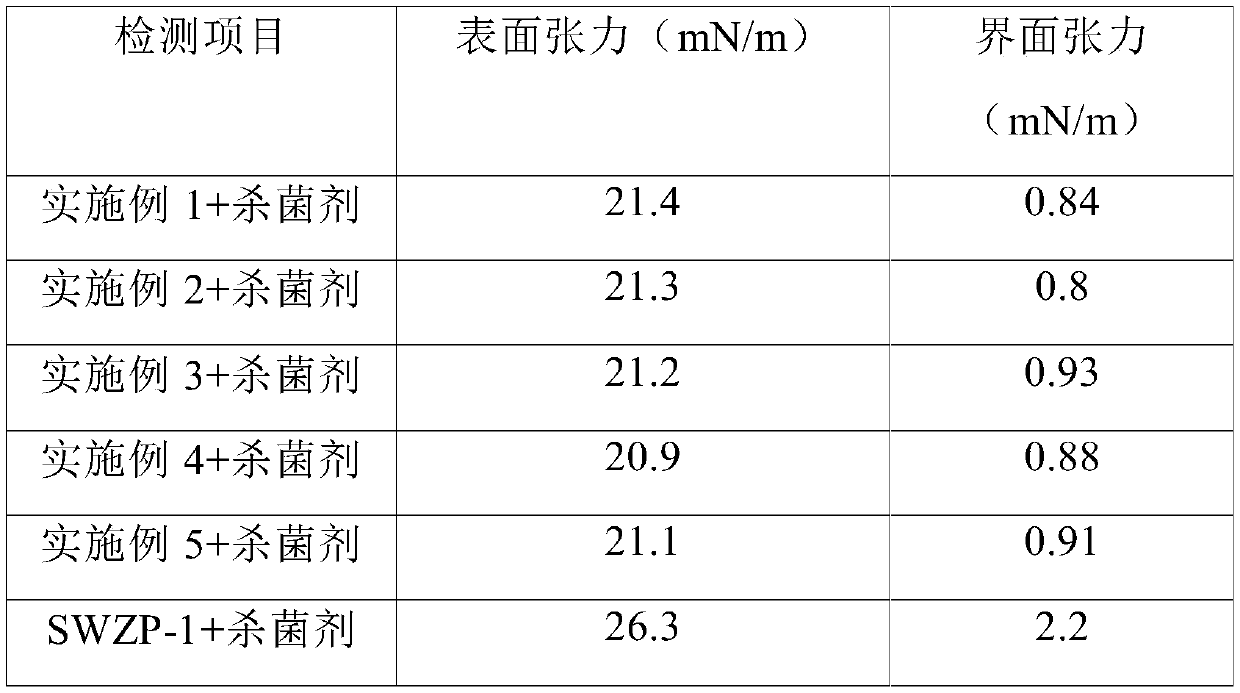

The invention relates to the technical field of oil gas field mining, in particular to a nanometer emulsion discharge aiding agent for irregular gas reservoir fracturing and a preparation method thereof. The nanometer emulsion discharge aiding agent is prepared from the following ingredients in parts by mass: 10 to 30 percent of nonpolar oil phases, 10 to 15 percent of main surfactants, 10 to 15 percent of cosurfactants and the balance of inorganic salt water solution; the nonpolar oil phases are alkane with the carbon chain length being 7 to 10; the alkane is cycloalkane and alkane; the mainsurfactants are quaternary ammonium salt gemini surfactants and tween; the cosurfactants are one or several kinds of materials from ethanol, propanol, isopropanol, normal butanol or n-amyl alcohol; the inorganic salt is soluble metal halide. The discharge aiding agent can reduce the surface tension of the solution to 20.1 mN / m; the rock surface wetting performance is changed, so that the contact angle between water and rock surface exceeds 90 degrees; the capillary force effect can be obviously weakened; the flowback effect of the irregular gas reservoir fracturing liquid is greatly improved.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

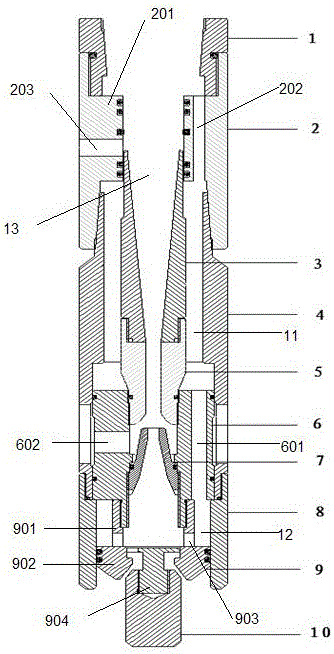

Concentric double-tube sand removal well-washing machine

The invention provides a concentric double-tube sand removal well-washing machine. The concentric double-tube sand removal well-washing machine comprises an upper joint, a backwashing bridge joint, a diffusion tube, a working cylinder, a choke, a jet flow bridge joint, a nozzle, a lower joint, a supporting seat and a supporting valve; backwashing is implemented by the concentric double-tube sand removal well-washing machine; during well washing, a flowing channel of the well-washing machine is small, an impacting force on a well bottom is strong, a concentric double-tube inner tube is small in diameter, flowing speed of well-washing liquid is high, and sand carrying capability of the well-washing liquid is also high; and moreover, when the sand removal well-washing machine reaches to the well bottom, a well-washing channel can be closed, high negative pressure can be generated through high-speed water flow of the nozzle, and flowback capability is improved.

Owner:PETROCHINA CO LTD

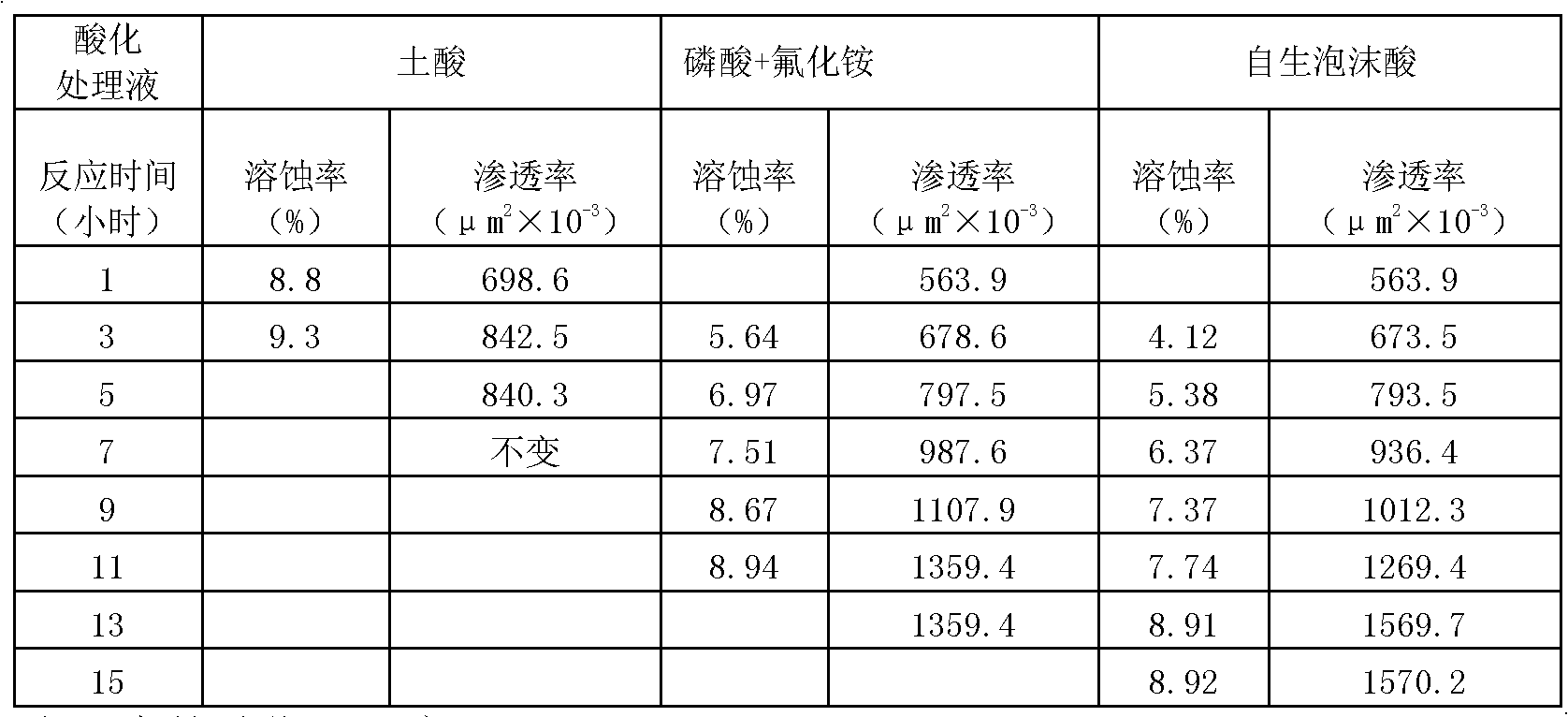

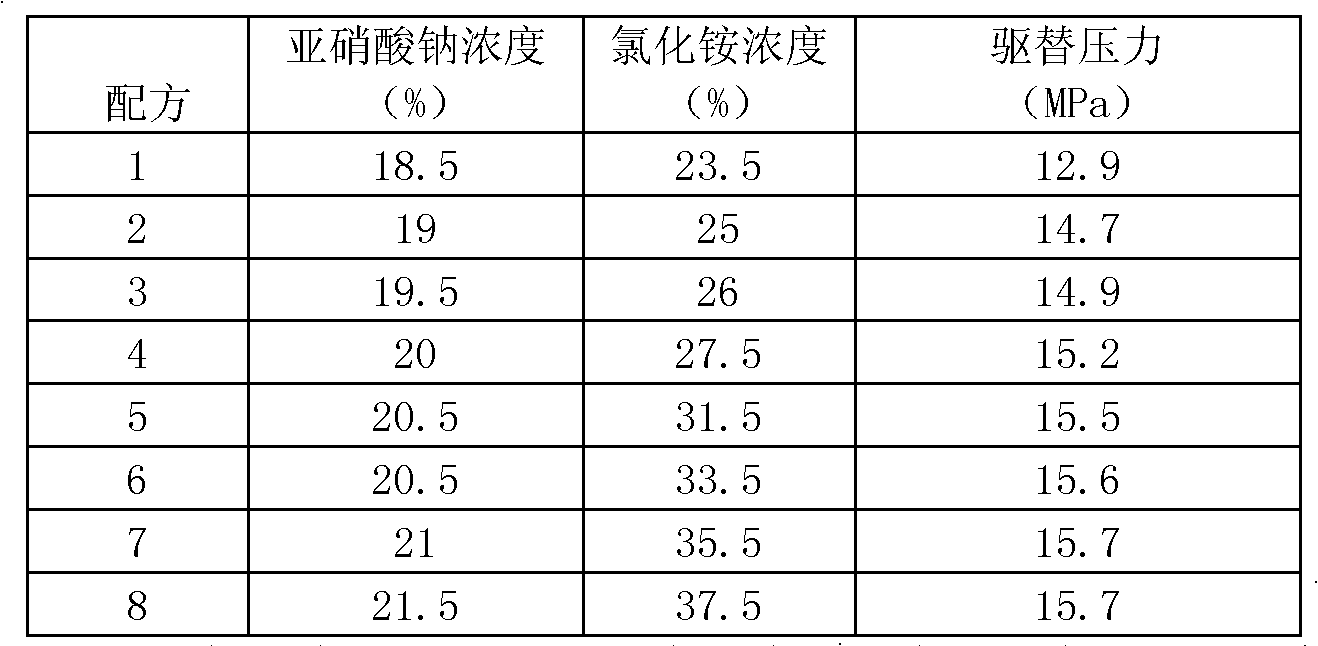

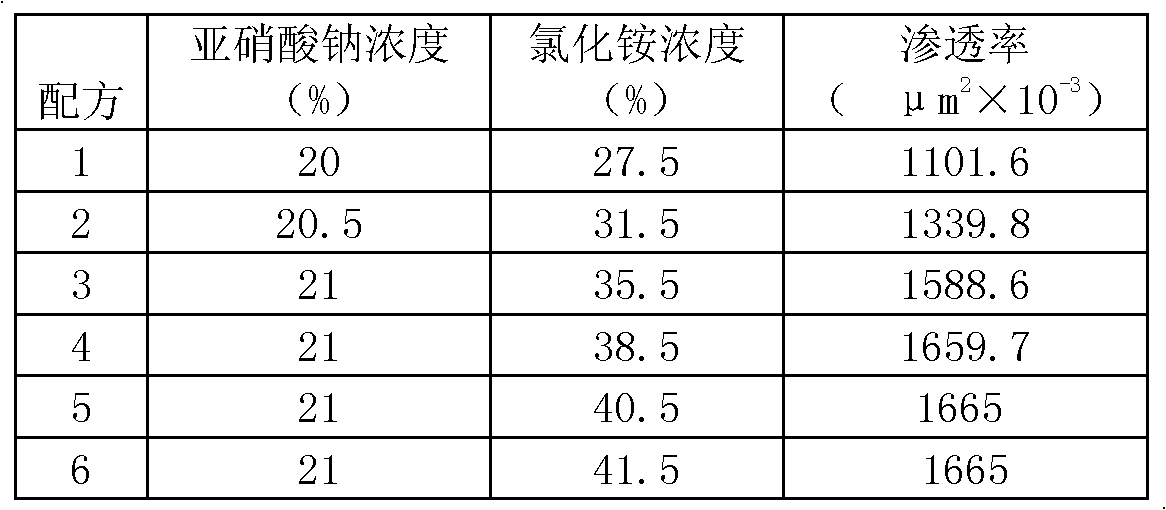

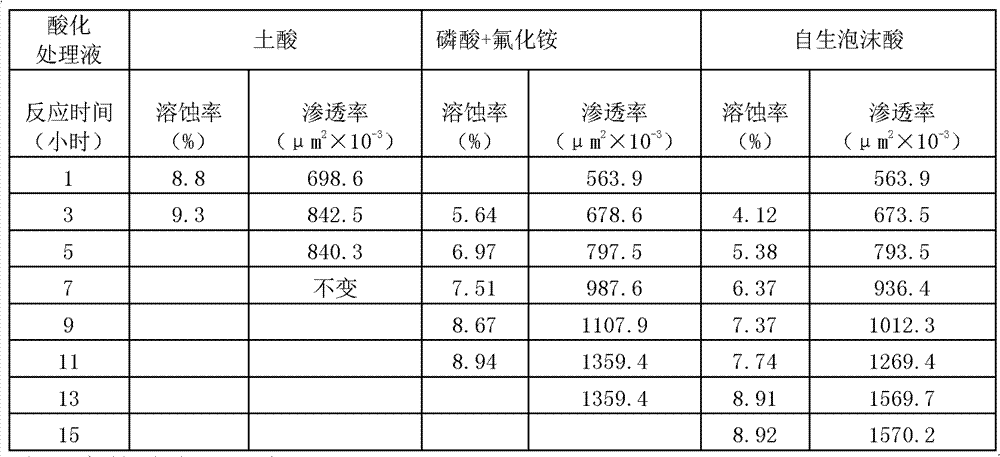

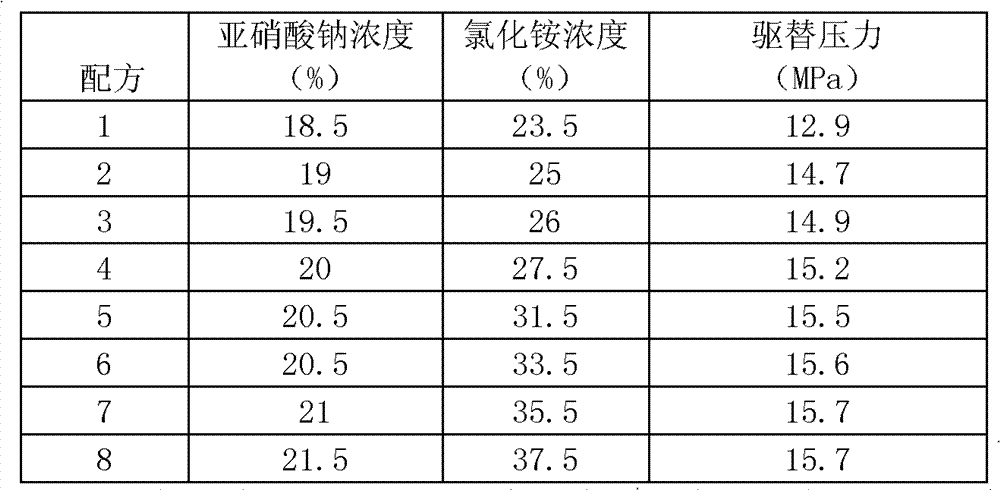

Method for deep treatment of oil layer through self-generation foam acidification

ActiveCN102536166AImprove flowback capacityIncrease viscosityCleaning apparatusInsulationHydrofluoric acidMicroparticle

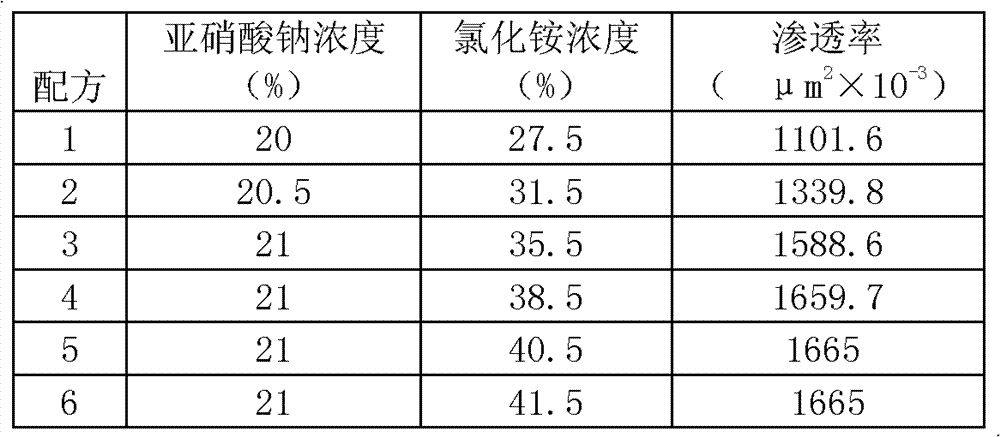

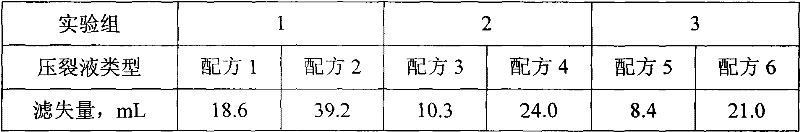

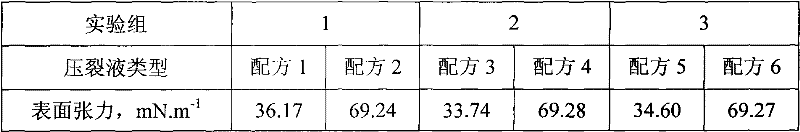

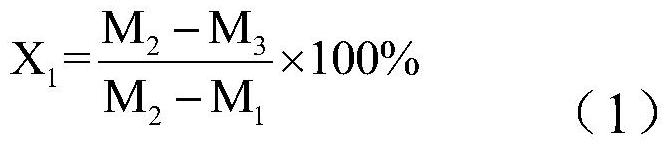

The invention belongs to the technical field of deep treatment of an oil layer, and particularly relates to a method for deep treatment of an oil layer through self-generation foam acidification. The method comprises the following step of injecting a sodium nitrite solution, a sealing liquid and an ammonium chloride solution into an oil well mineshaft in sequence after an oil well is subjected to a self-generation foam acidification treatment of self-generation hydrofluoric acid solution. According to the method disclosed by the invention, residual reacted acid which is regularly acidified is utilized for reacting with the sodium nitrite solution and the ammonium chloride solution to generate foams in a short time. Bu utilizing the characteristics of high viscosity and strong carrying capability of the foams, the flow-back capability of the reacted acid is increased, particles and secondary precipitation generated by acidification are taken out of the mineshaft, and heat can be simultaneously generated to remove organic block in stratum and increase the measure effect. Meanwhile, the use of dedicated equipment is omitted.

Owner:PETROCHINA CO LTD

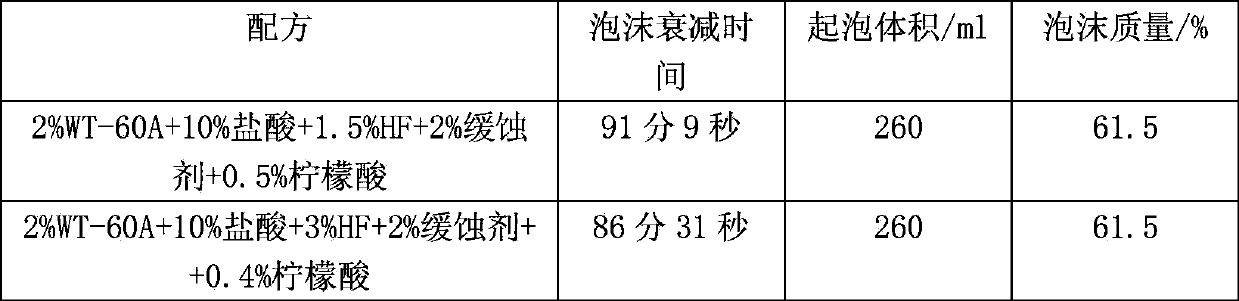

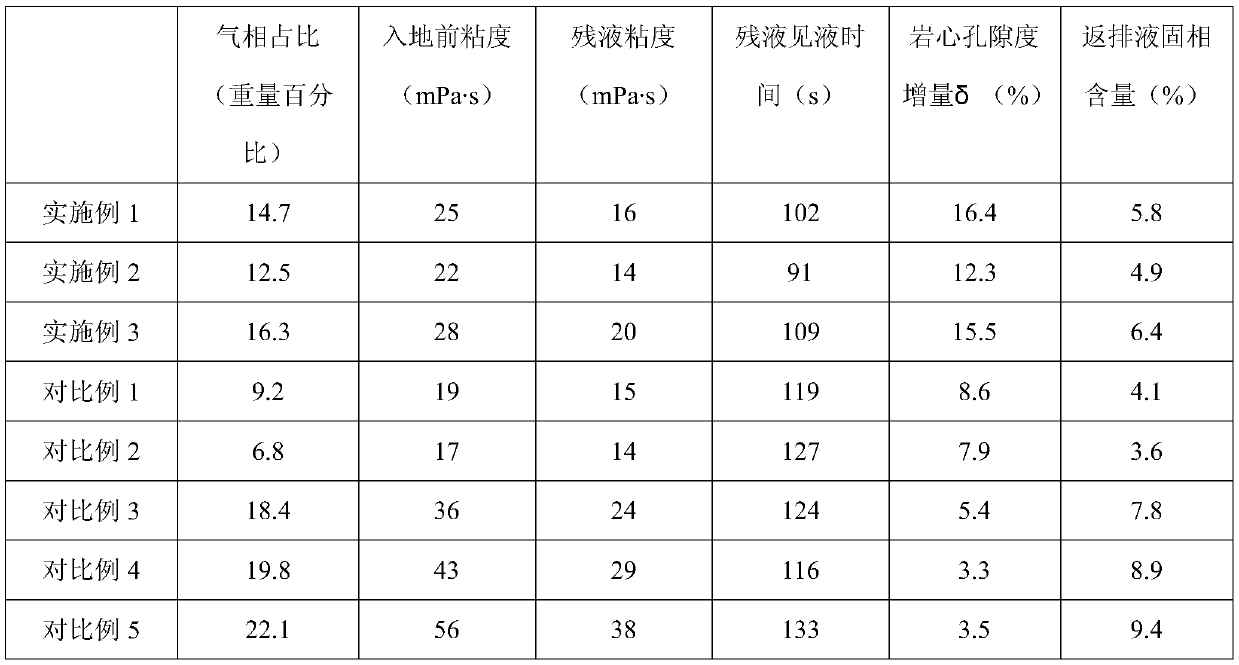

Turning foamed acid for heterogeneous reservoir acidification

InactiveCN103865515AImprove acidification effectAvoid secondary pollutionDrilling compositionCross-linkHydrofluoric acid

The invention relates to a turning foamed acid for heterogeneous reservoir acidification. The turning foamed acid comprises, by volume, a nitrogen gas phase, 10% of hydrochloric acid, 1.5-3% of hydrofluoric acid, 2WT-60A, 2% of a corrosion inhibitor and 0.5% of citric acid. The 2WT-60A is cocoalkanoylamido propyl betaine or dodecyl dimethyl betaine. After the turning foamed acid is stirred at a stirring rate of 1000r / min for 1min, a foam half-life period is about 91min and form mass is 61.5% of the original mass. The turning foamed acid has the characteristic of self-tackifying, is free of a cross-linking agent and a gel breaker, controls a self-turning function based on a pH value, and has good diffluence performances, good retardance and high flowback performances.

Owner:PETROCHINA CO LTD

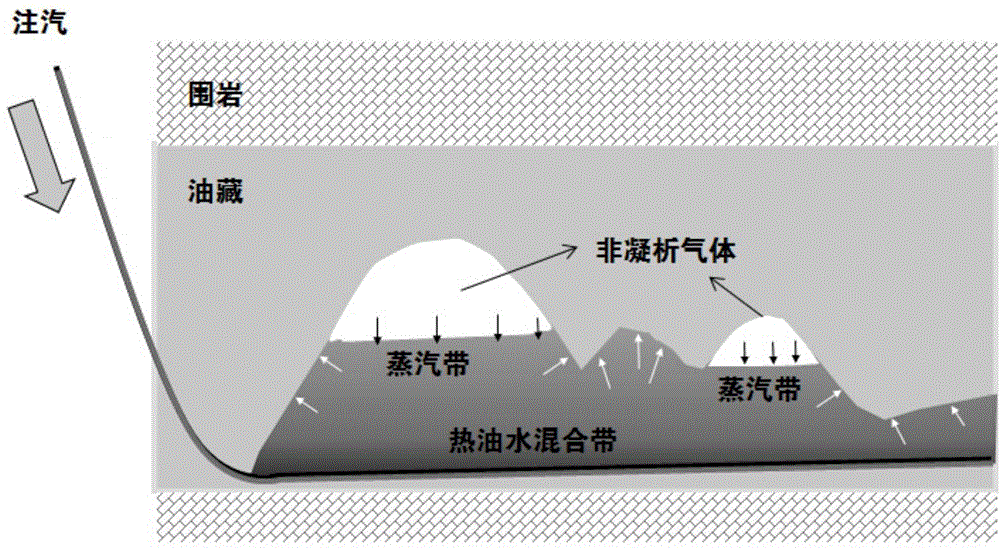

Method for multi-medium steam huff-puff oil recovery in old area of heavy oil reservoir

InactiveCN109113700AIncrease throughput utilization radiusIncrease throughput cycleFluid removalFoaming agentWater vapor

The invention provides a method for multi-medium steam huff-puff oil recovery in an old area of heavy oil reservoir. The method comprises the steps that the heavy oil reservoir with the lower pressure, low yield and low efficiency at the later stage of steam huff-puff is selected, and an implementation well is determined; water vapor is stopped to be injected into the oil reservoir at the later stage of steam huff-puff, and a urea foam solution is injected into the implementation well; then the water vapor continues to be injected for steam huff-puff; and after soaking, the well is opened forproduction and oil recovery, wherein on the basis that the weight percentage of the urea foam solution is 100%, the urea foam solution comprises, by weight, 30-35% of urea, 1-5% of foaming agents andthe balance water. According to the method, formation energy can be supplemented, the steam huff-puff producing radius and the swept volume are increased, and the flowback ability of a fluid is improved; the steam huff-puff period can be prolonged, the longitudinal producing degree is increased, and the steam huff-puff development effect is improved; and under the condition that the periodically injected steam volume is not changed, the periodic oil yield and the oil vapor ratio are increased by 40% or above.

Owner:PETROCHINA CO LTD

High-temperature microemulsion cleanup additive used for fracturing, and preparation method thereof

ActiveCN106244131AImprove surface activityHigh discharge rateDrilling compositionMass ratioFracturing fluid

The invention provides a high-temperature microemulsion cleanup additive used for fracturing, and a preparation method thereof. The preparation method comprises the following steps: 1, adding 10-20 parts by mass of water into a reactor, adding 40-60 parts by mass of a cosurfactant to water, and stirring the cosurfactant and water at room temperature until the cosurfactant is completely dissolved; and 2, sequentially adding 20-40 parts by mass of a gemini surfactant and 3-4 parts by mass of a nonionic surfactant into the reactor, supplementing water to the reactor until the mass part number of a mixture obtained in the reactor is 100, and uniformly stirring the mixture at room temperature to obtain the high-temperature microemulsion cleanup additive. The high-temperature microemulsion cleanup additive is directly added to a fracturing fluid or an acidifying liquid according to a mass ratio of 0.1-0.3:100 when used.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam huff and puff exploitation method

InactiveCN104389569AIncrease injection volumeImprove flowback capacityFluid removalProduct gasHydrocarbon

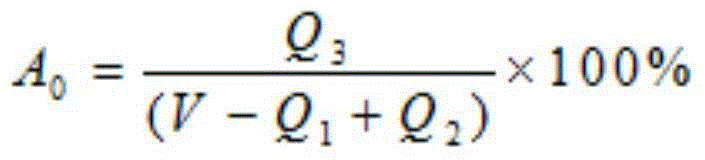

The invention provides a steam huff and puff exploitation method. The method comprises the following steps: selecting a well network of a closed horizontal well as an injection and exploitation well network; injecting non-condensed non-hydrocarbon gas into the injection and exploitation well network, wherein the injection amount is calculated according to the following formula: Q=AV / T, wherein Q is a ground injection amount of the non-condensed non-hydrocarbon gas, the unit of Q is m<3>, V is a ground layer voidage volume, the unit of V is m<3>, A is 9669, T is a ground layer temperature, and the unit of T is K; continuously injecting high-temperature steam into the injection and exploitation well network; carrying out a huff and puff production process, and carrying out sleeve gas monitoring in the production process; when the content of injected gas is raised to 70%-100%, closing a well for 6-12 hours; after a gas-liquid interface is recovered, opening the well to produce. The steam huff and puff exploitation method provided by the invention can be used for steam huff and puff exploitation of heavy oil reservoirs, and the steam huff and puff exploitation effect of the heavy oil reservoirs can be effectively improved.

Owner:PETROCHINA CO LTD

Modifier for preventing bittern scaling

The invention discloses a modifier for preventing bittern scaling. The modifier comprises the following ingredients (by weight): 10-20 parts of 2-phosphonobutane-1,2,4-tetrasodium trihydroxy, 5-10 parts of sodium polyacrylate, 2-3 parts of coco fatty acid diethanol amide, 0.2-0.5 part of polyether modified silicone and the rest of water. The modifier has a good effect of preventing scaling and has strong flowback performance. By the use of the modifier, construction is simple, and workload is not increased, and cost is saved.

Owner:PETROCHINA CO LTD

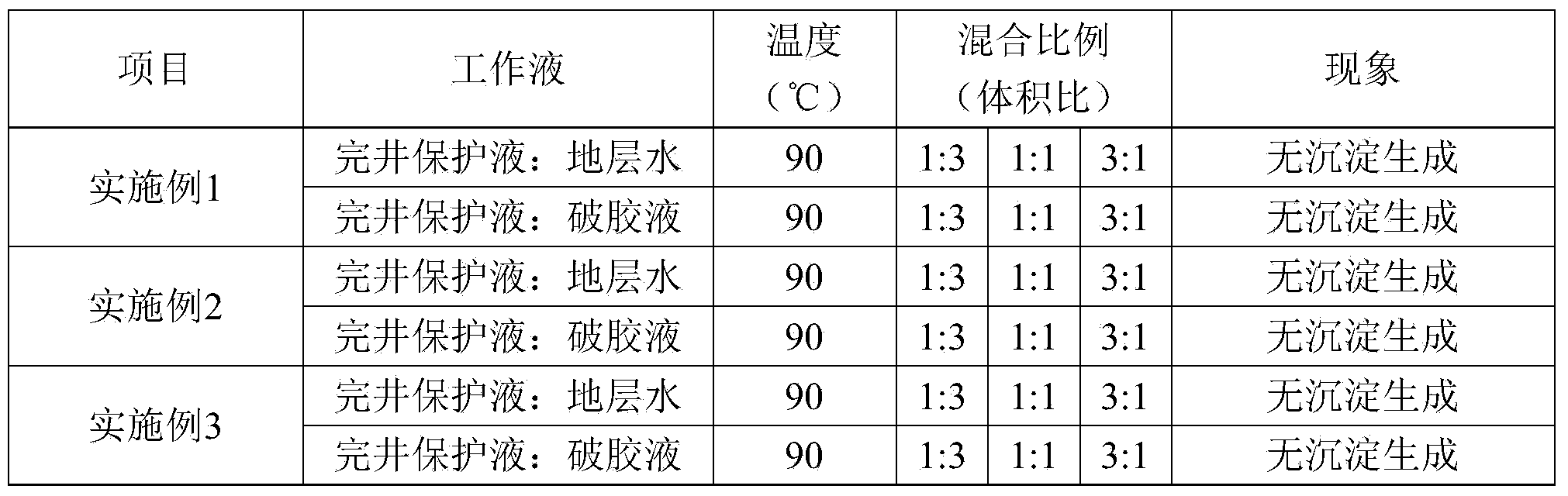

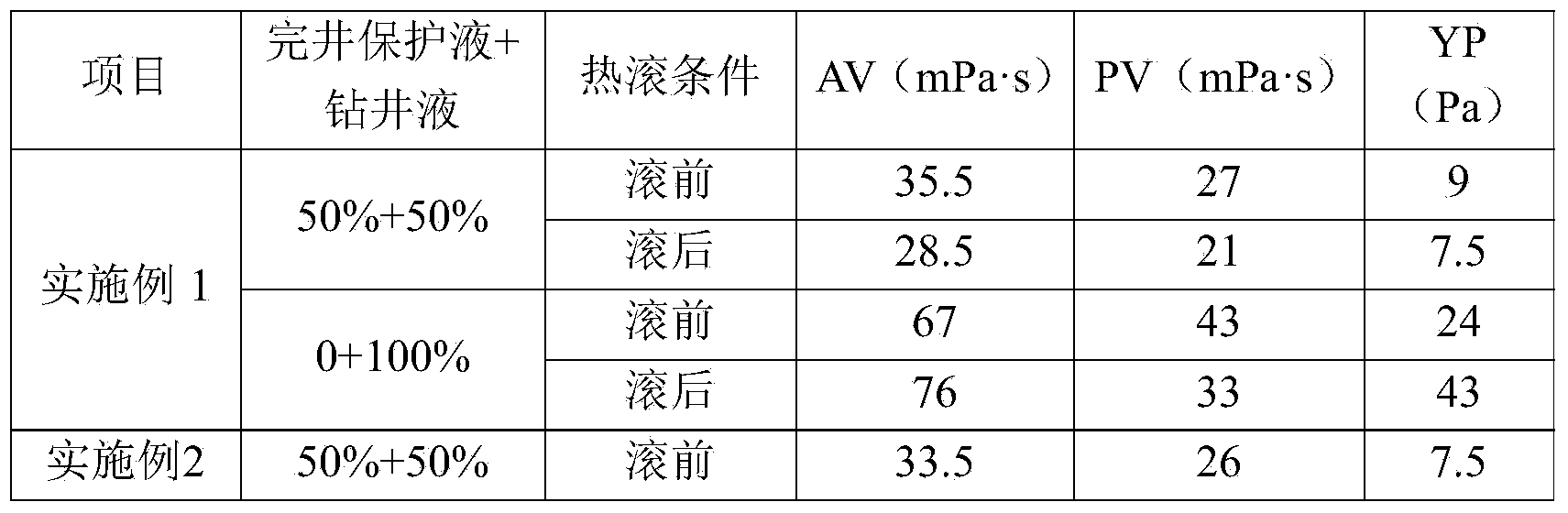

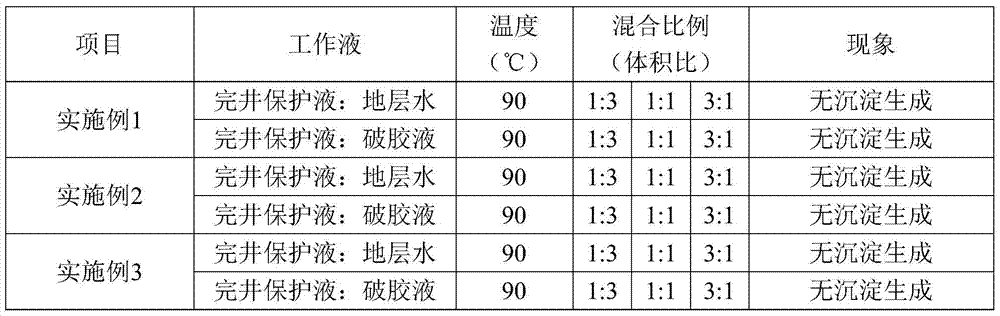

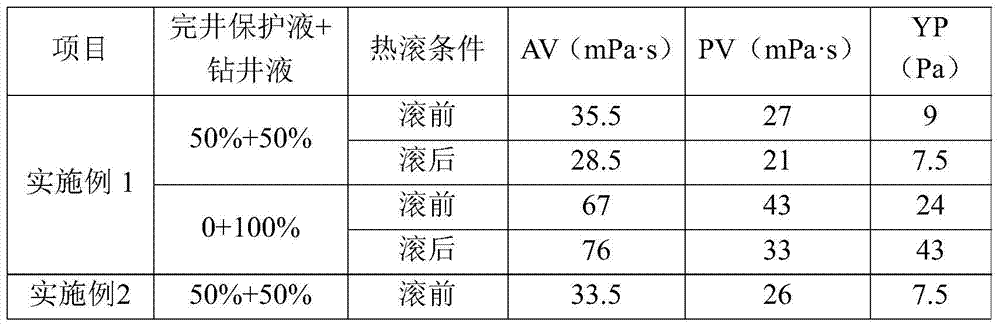

Solid-free slurry-replacing well completion protective fluid and preparation method thereof

The invention discloses a solid-free slurry-replacing well completion protective fluid and a preparation method thereof, which belongs to the technical field of exploitation of oil and gas fields. The completion protective fluid comprises, by weight, 100 parts of a formate-based liquid, 0.2 to 0.4 part of a thickening agent, 1 to 3 parts of a high temperature high temperature, 0.2 to 3 parts of a clay stabilizing agent and 0.2 to 1 part of a waterproof locking agent. The completion protective fluid has the following advantages: (1) the completion protective fluid has no solid phase, so solid phase settlement does not exist; (2) the completion protective fluid has good rheological properties and a low shearing force value; (3) the completion protective fluid has an excellent hydrocarbon reservoir protection function; (4) the completion protective fluid has good high temperature resistance and salt resistance stability, and a system has good displacement and carrying capability under reservoir temperature; (5) the completion protective fluid is safe, nontoxic, easily degradable and compatible with the environment; (6) the completion protective fluid has good compatibility with a drilling fluid and a fracturing fluid, and the rheological properties of the completion protective fluid are not influenced after mixing; (7) the completion protective fluid has little corrosivity and greatly reduces corrosivity of a saline solution to downhole tools; and (8) the completion protective fluid has great specific gravity and no solid phase and is applicable to areas with abnormal high temperature and high-pressure area.

Owner:CHINA PETROLEUM & CHEM CORP +1

High strength ultralight ceramsite propping agent, and preparation method and applications thereof

ActiveCN110804432AImprove thermal efficiencyWell formedFluid removalDrilling compositionManganeseMullite

The invention discloses a high strength ultralight ceramsite propping agent, which is composed of bauxite, sodium silicate, silica micro powder, nano silica, and manganese ore powder according to a mass ratio of 55-70: 5-10: 10-20: 0-10: 5-10. The apparent density is 1.00-1.75 g / cm3, the bearing strength is greater than 80 MPa, and the phase component comprises a corundum phase, a mullite phase, and a glass phase. The shortages of the prior art can be overcome. The construction technical demands of water fracturing or water-free fracturing of middle-deep layer shale gas (oil) can be effectively satisfied. The operation cost of fracturing is effectively reduced.

Owner:NORTH CHINA INST OF AEROSPACE ENG +1

Modifying agent for preventing calcium halide scaling

ActiveCN105419761AStrong anti-scaling performanceReduce dosageDrilling compositionDocusate SodiumDioctyl Sulfosuccinic Acid

The invention discloses a modifying agent for preventing calcium halide scaling. The modifying agent is prepared from, by mass, 15-25 parts of amino trimethylene phosphonic acid, 4-8 parts of docusate sodium, 2-3 parts of cetyltrimethylammonium chloride, 0.1-0.3 part of tributyl phosphate and the balance water. The modifying agent has the advantages of being high in scaling resistance, small in use amount, easy to construct, not capable of increasing operation workloads, high in flow-back capacity, capable of saving cost, and the like.

Owner:PETROCHINA CO LTD

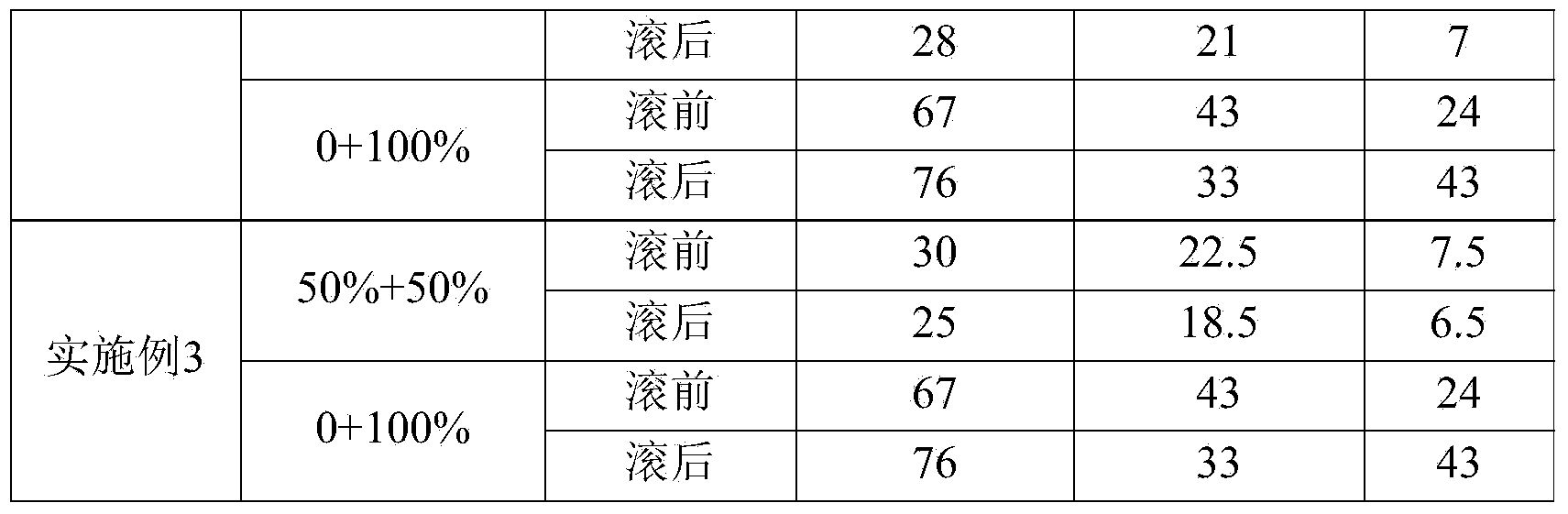

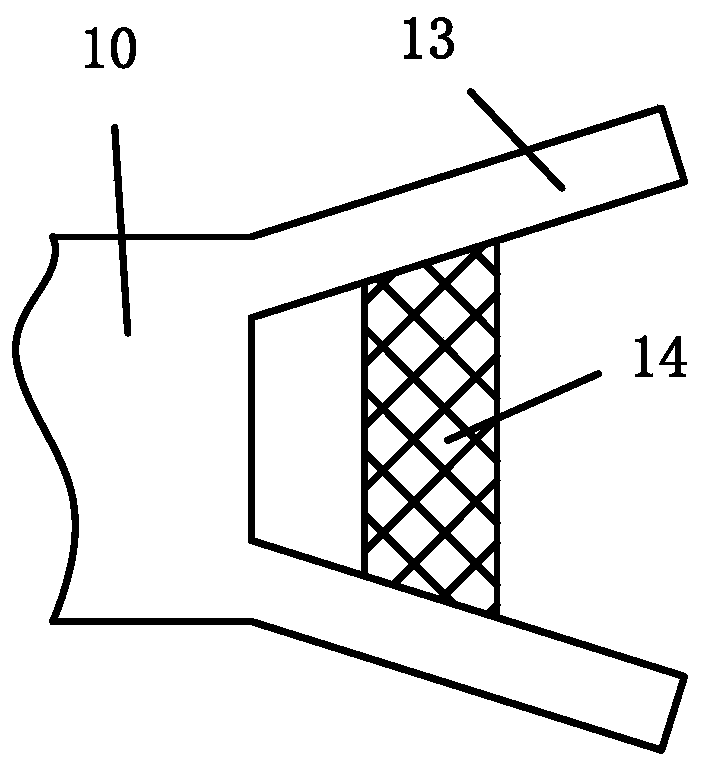

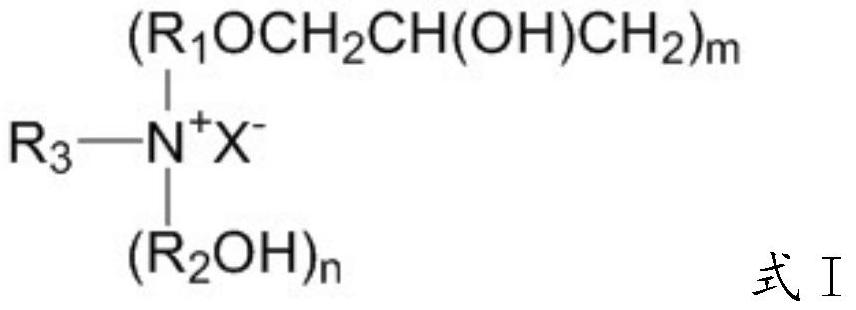

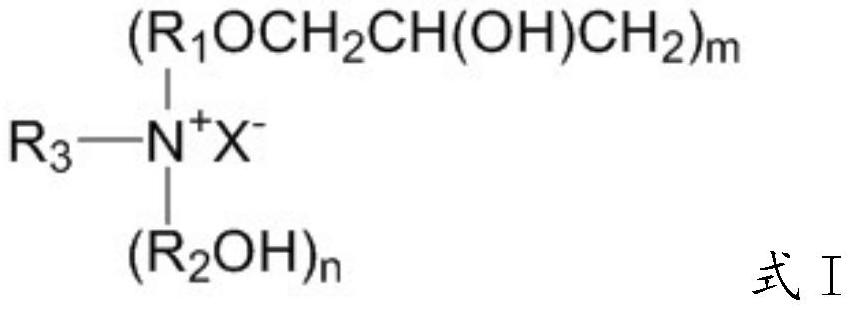

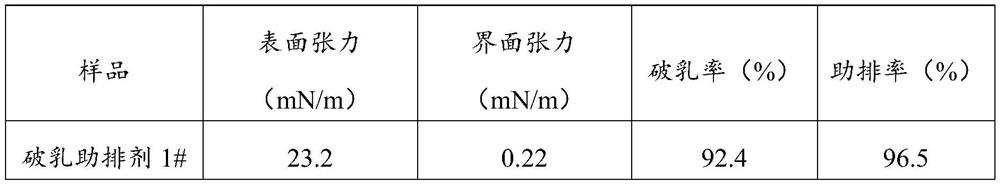

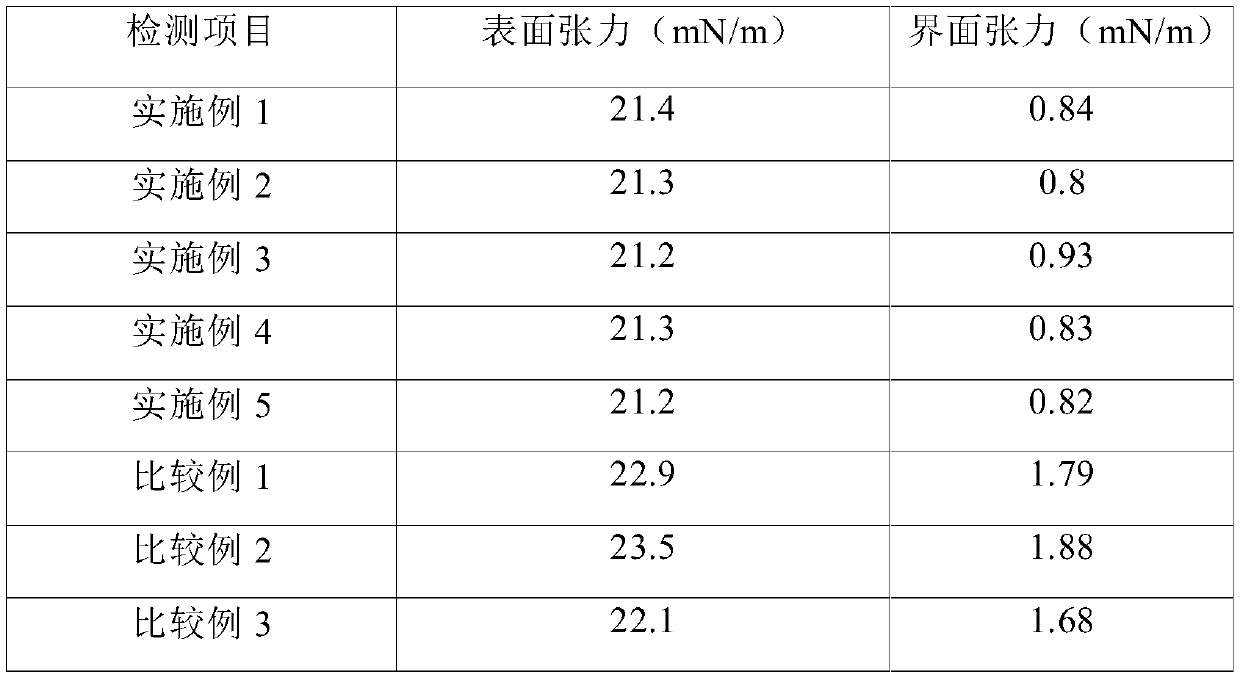

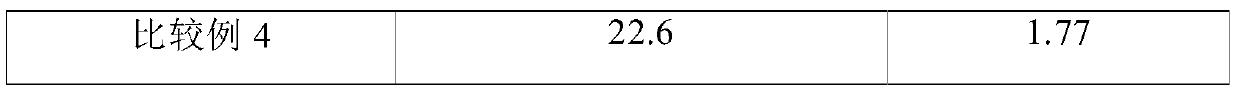

Demulsification cleanup additive for fracturing and preparation method thereof

ActiveCN112480899AReduce capillary resistanceImprove flowback rateOrganic compound preparationEther preparation from oxiranesProcess engineeringAlkanolamine

The invention discloses a demulsification cleanup additive for fracturing and a preparation method thereof. The demulsification cleanup additive comprises the following components in parts by weight:1-30 parts of alkanolamine compounds, 1-30 parts of fatty acid polyoxyethylene ether sulfonate, 1-20 parts of alkyl glycoside and 1-15 parts of low-molecular alcohol. The alkanolamine compound is selected from at least one of compounds with a structural formula as shown in a formula I which is described in the specification. The alkanolamine compound not only has demulsifying and cleanup assistingeffects, but also can effectively fuse and enhance the fatty acid polyoxyethylene ether sulfonate, alkyl glycoside and low-molecular alcohol, so that the demulsifying cleanup additive has lower surface tension and interfacial tension and higher demulsifying rate and cleanup assisting rate, the demulsifying cleanup additive is used for fracturing treatment of oil field reservoirs, capillary resistance and resistance generated by emulsion blockage can be effectively reduced, the flowback rate of waste liquid after fracturing is effectively increased, and the fracturing treatment effect is improved.

Owner:DESHI ENERGY TECH GRP CO LTD +1

Cleanup additive for fracturing fluid and preparation method

ActiveCN111518536AQuality improvementImprove flowback capacityDrilling compositionActive agentFracturing fluid

The invention provides a cleanup additive for fracturing fluid. The cleanup additive is mainly prepared from the following raw materials in parts by mass: 10-30 parts of an amide type nonionic surfactant, 30-60 parts of a polyoxyethylene type nonionic surfactant, 20-40 parts of an emulsifier, 60-80 parts of a fluorocarbon surfactant, 30-50 parts of a low molecular alcohol and 20-40 parts of a heavy metal trapping agent. According to the cleanup additive for the fracturing fluid, on one hand, the surface tension and the interfacial tension are small, the performance is stable, and the flowbackeffect of the fracturing fluid can be improved; on the other hand, the compatibility with other additives is good, under the condition that other additives are added, the influence on the surface tension and the interfacial tension is small, the manufacturing method is simple, and the cost is low.

Owner:XINJIANG DELAND

Gel breaker with high-efficiency positioning double-effect and preparation method thereof

InactiveCN104927831AGood slow releaseImprove sand carrying capacityDrilling compositionAcetic acidMass ratio

The invention discloses a gel breaker with high-efficiency positioning double-effect. The gel breaker is formed by mixing a mixture A and a mixture B according to a mass ratio of 1:1.5, the mixture A is composed of organic iron, fluxing agent and esters, the organic iron accounts for 1% of total mass of the mixture A, the esters account for 50-70% of the total mass of the mixture A, the rest is the fluxing agent, the organic iron is ferrocene, and the fluxing agent is petroleum ether; the mixture B is hydrogen peroxide, and the mixture B accounts for 50-60% of total mass of the gel breaker. The invention further discloses a preparation method of the gel breaker. Fracturing liquid after gel breaking by the gel breaker is low in molecular weight and little in residue, secondary damage to a bottom layer is reduced, and adding amount of the gel breaker is small, so that construction cost is saved; a unique gel breaking mode has higher oxidation and degrading capability, so that the gel breaking process is easy to control, and damage to a formation is reduced to greatest extent.

Owner:SHAANXI UNIV OF SCI & TECH

Composite acid liquid system for weak heterogeneous reservoir acidification and preparation method of composite acid liquid system

InactiveCN110699061AImprove the effect of increasing productionIncrease profitDrilling compositionFoaming agentEnvironmental engineering

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

Method for deep treatment of oil layer through self-generation foam acidification

ActiveCN102536166BImprove flowback capacityIncrease viscosityCleaning apparatusInsulationHydrofluoric acidMicroparticle

The invention belongs to the technical field of deep treatment of an oil layer, and particularly relates to a method for deep treatment of an oil layer through self-generation foam acidification. The method comprises the following step of injecting a sodium nitrite solution, a sealing liquid and an ammonium chloride solution into an oil well mineshaft in sequence after an oil well is subjected to a self-generation foam acidification treatment of self-generation hydrofluoric acid solution. According to the method disclosed by the invention, residual reacted acid which is regularly acidified is utilized for reacting with the sodium nitrite solution and the ammonium chloride solution to generate foams in a short time. Bu utilizing the characteristics of high viscosity and strong carrying capability of the foams, the flow-back capability of the reacted acid is increased, particles and secondary precipitation generated by acidification are taken out of the mineshaft, and heat can be simultaneously generated to remove organic block in stratum and increase the measure effect. Meanwhile, the use of dedicated equipment is omitted.

Owner:PETROCHINA CO LTD

A Modifier for Preventing Calcium Halogen Scaling

ActiveCN105419761BStrong anti-scaling performanceReduce dosageDrilling compositionDioctyl Sulfosuccinic AcidTributyl phosphate

The invention discloses a modifying agent for preventing calcium halide scaling. The modifying agent is prepared from, by mass, 15-25 parts of amino trimethylene phosphonic acid, 4-8 parts of docusate sodium, 2-3 parts of cetyltrimethylammonium chloride, 0.1-0.3 part of tributyl phosphate and the balance water. The modifying agent has the advantages of being high in scaling resistance, small in use amount, easy to construct, not capable of increasing operation workloads, high in flow-back capacity, capable of saving cost, and the like.

Owner:PETROCHINA CO LTD

Method for improving performance of fracturing fluid

ActiveCN103087702BImprove stabilityReduce the effects of stressDrilling compositionTetramethylammonium hydroxideCompound organic

The invention relates to the technical field of oil formation hydraulic fracturing and in particular relates to a method for improving performance of a fracturing fluid. The method provided by the invention comprises the steps of adding a compound organic base into a base solution of the fracturing fluid and mixing to be uniform until pH value of the mixed liquor to be 10-12, wherein the compound organic base comprises the following components in percentage by weight: 8-12% of sodium hydroxide, 0.4-0.6% of triethanolamine, 0.15-0.25% of tetramethylammonium hydroxide and the balance of water. By adopting the method provided by the invention, after the compound organic base is added, usage amount of guanidine gum during preparation of the cracking fluid can be reduced, and residue content is low, a friction coefficient is low and flowback rate is high, so that comprehensive performance of the cracking fluid is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formulated fracturing fluid of micro emulsion gel

The invention provides a formulated fracturing fluid of micro emulsion gel and a proportion thereof, the formulated fracturing fluid of micro emulsion gel comprises the following components by weight percent: 3.8 to 16.7 percent of micro emulsion system, 0.1 to 0.5 percent of polymer, 0.25 to 1.20 percent of cross linking agent, 0.05 to 0.60 percent of gel breaker, 0.05 to 0.10 percent of heat stabilizer and 80.90 to 95.75 percent of water, wherein the micro emulsion system consists of kerosene, compound surfactant, low-molecule alcohol and water, and the polymer is guar gum. By utilizing thesynergistic effect of the micro emulsion and gel, the formulated fracturing fluid of micro emulsion gel is characterized by low content of polymer, high viscosity, low filtration, low content of polymer residual in solution after gel breaking, micro emulsion status of the system after gel breaking, lower surface tension, good suspending power and the like, can greatly reduce flow-back pressure and damage to reservoir, and improve the fracture flow capacity and crude output.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Offshore oilfield anti-emulsification workover fluid as well as preparation method and use method thereof

PendingCN114854386AReduce surface tensionReduce interfacial tensionDrilling compositionWater useWater source

The invention relates to an anti-emulsification workover fluid for an offshore oilfield as well as a preparation method and a use method of the anti-emulsification workover fluid. The anti-emulsification workover fluid for the offshore oilfield comprises the following components in percentage by mass: 0.5-1.5% of a drainage-aiding cleaning agent, 0.1-0.5% of a demulsifying agent and the balance of water, the water is selected from production sewage and / or water source well water; adding water into a stirring tank, heating to 50 DEG C or above, adding other raw materials, and uniformly stirring; and controlling the in-well temperature of the anti-emulsification workover fluid for the offshore oilfield to be higher than 50 DEG C. The technical problem to be solved is how to provide the anti-emulsification workover fluid for the offshore oilfield, reduce the damage of the anti-emulsification workover fluid to a reservoir, improve the recovery effect of the oil well yield after well repair and reduce the treatment capacity of oil-water separation of a workover flow-back fluid on an offshore platform, so that the anti-emulsification workover fluid is more practical.

Owner:CNOOC TIANJIN BRANCH

A low-corrosion chemical heat-generating pressurized gel breaker and preparation method thereof

The invention discloses a low-corrosion chemical themogenic pressurizing gel breaker which comprises an agent A solution, an agent B solution and an activator solution. The invention further discloses a preparation method of the gel breaker. The preparation method comprises the following step: uniformly mixing the agent A solution, the agent B solution and the activator solution in volume ratio of 1.0 to (1.0-1.3) to (1.0-1.2). The formation temperature is improved by the heat generated by virtue of gel breaker reaction, and the gel breaker is activated, so that a fracturing fluid is thoroughly broken. Gas generated by the gel breaking has the effect of increasing the formation pressure, so that the fracturing flowback capacity is improved. In addition, by using H3PW12O40 heteropolyacid as the activator of a system, on the basis of not affecting the acid strength, the corrosivity of the system is reduced, and the destructiveness on a soil environment in the fracturing process is effectively reduced.

Owner:YANAN UNIV

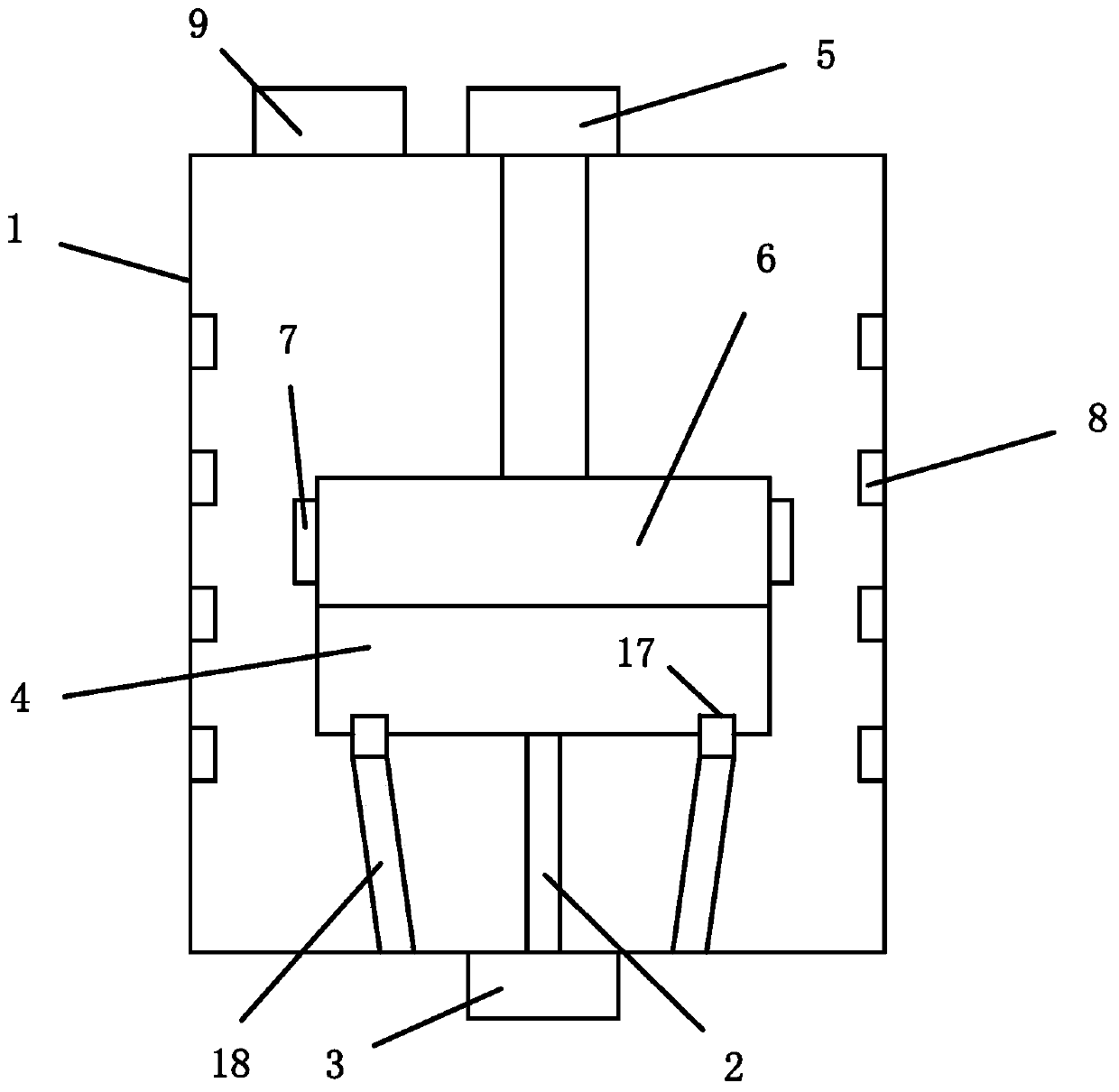

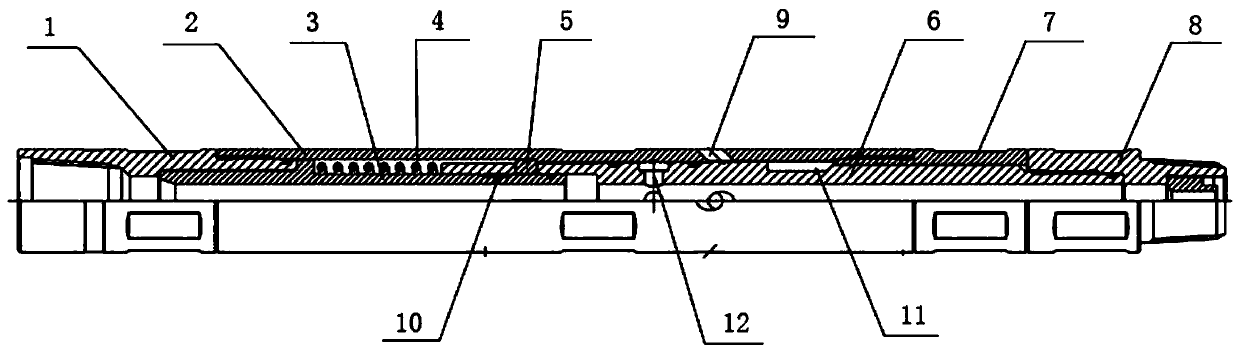

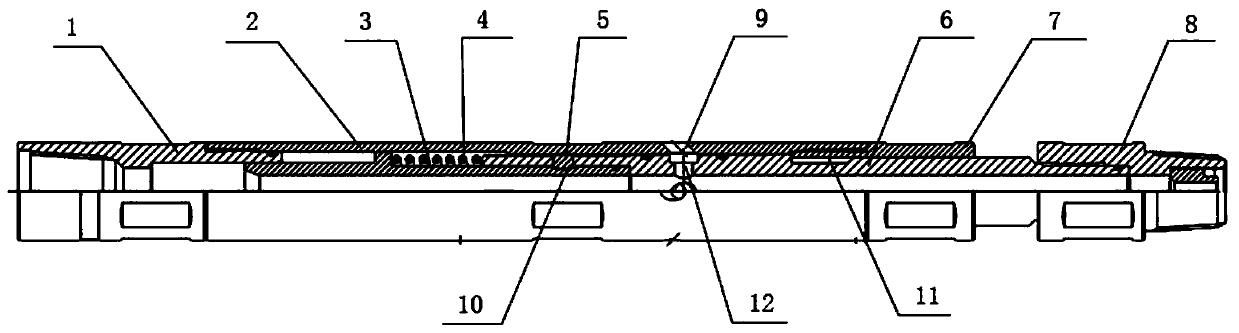

Hydraulic multi-time switching circulating valve

PendingCN111472704AImprove flowback capacityIncrease flushing capacityFlushingReciprocating motionEngineering

The invention discloses a hydraulic multi-time switching circulating valve. A channel is arranged on a shell, the left end of the shell is in threaded connection with a first connector, the right endof the shell is in threaded connection with a second connector, the outer surface of the right end of a first mandrel is in contact with the inner surface of the left end of a second mandrel, the first mandrel and the second mandrel are arranged inside the shell together, the outer surface of the left end of the first mandrel is in contact with the inner surface of the first connector, the outer surface of a first shoulder is in contact with the inner surface of the shell, the right end of the first shoulder and the shell form an annular space, a compression spring is arranged in the annular space, the right end of the second mandrel is in threaded connection with a third connector, a clamping block is matched with a first limiting groove to realize the reciprocating motion of the second mandrel in the shell, a second limiting groove is matched with the second connector to realize the staggering and coincidence of the channel and a hole, a nozzle is arranged in the third connector, andthe nozzle is in threaded connection with the third connector. The hydraulic multi-time switching circulating valve has the beneficial effects that the flushing displacement is greatly increased, thebackflow capacity of debris is improved, the risk of encountering resistance is reduced, and meanwhile the operation efficiency is improved.

Owner:JEREH ENERGY SERVICES

High performance cleanup additive for oil and gas well and method for making same

InactiveCN1313562CImprove flowback speedReduce surface tensionFluid removalDrilling compositionAlcoholSurface-active agents

The invention relates to a high performance cleanup additive for oil and gas well and method for making which comprises the steps of, heating host crystal anion (25%-35%) and non-ionic surface active agent (35%-45%) to 50-90 deg. C for mixing and reaction 3h, dissolving the anionic surface active agent with alcohols and charging into host agent, stirring, mixing uniformly and charging other auxiliary agent (5-10%), stirring again and mixing homogeneously.

Owner:梁利平

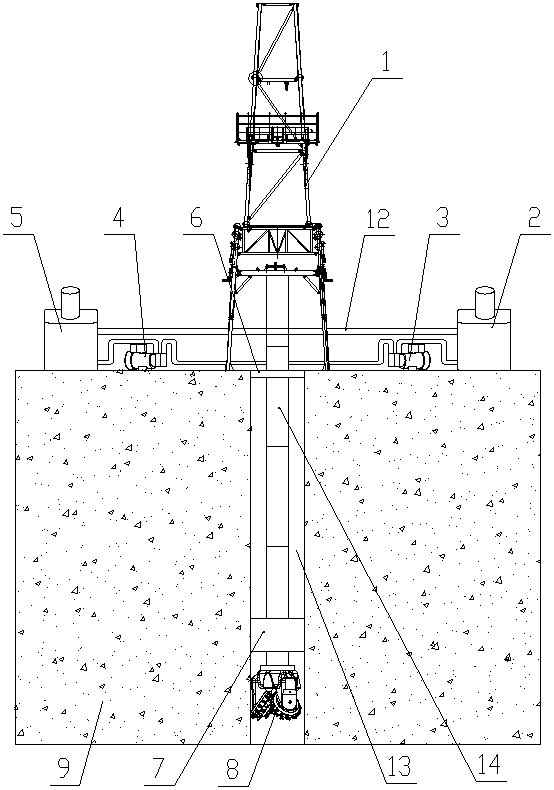

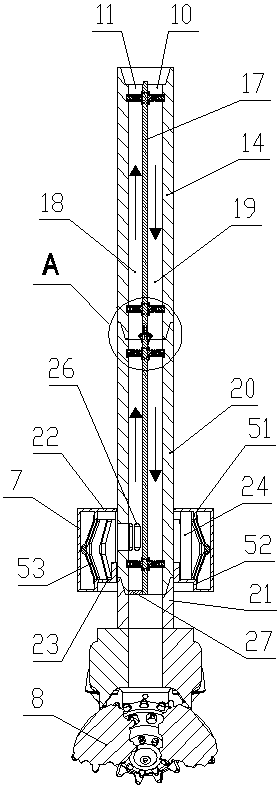

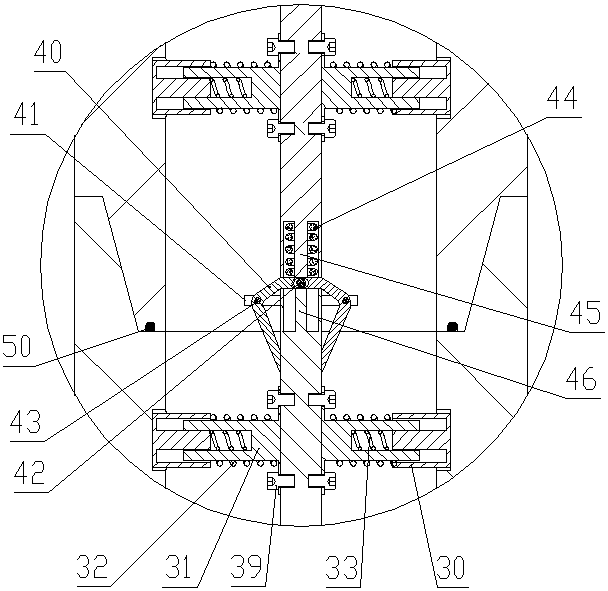

Oil drilling system with drilling fluid in and out

The invention provides a petroleum drilling system for inside-input and inside-output type drilling fluid. The petroleum drilling system comprises a drilling derrick, a drilling fluid inlet tank, a drilling fluid pressurization pump, a drilling fluid recovery pump, a drilling fluid recovery tank, a wellhead blowout preventer, a drill rod assembly, a stratum sealing drum and a drill bit, wherein the drill rod assembly comprises a plurality of drill rod units which are sequentially connected; a drill rod clapboard is arranged inside each drill rod unit; the front and rear side edges of each drill rod clapboard are in sealed contact with the inner wall of each drill rod unit; each drill rod clapboard is fixed in each drill rod unit through a clapboard fixing assembly; the drill rod clapboardsarranged in different drill rod units are connected through clapboard connecting assemblies; and the interior of the drill rod assembly is divided into a left drilling fluid output channel and a right drilling fluid input channel by the drill rod clapboards. The petroleum drilling system provided by the invention has the advantages that under the action of the drilling fluid recovery pump and thedrilling fluid pressurization pump, the input and output of the drilling fluid can be completed inside the drill rod assembly so as to avoid massive loss of the drilling fluid, and simultaneously, the drilling fluid is circularly utilized so as to lower the drilling cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of solid-phase replacement mud completion protection fluid and preparation method thereof

ActiveCN104109510BThe formula is scientific and reasonableAvoid formation damageDrilling compositionFormateFracturing fluid

The invention discloses a solid-free slurry-replacing well completion protective fluid and a preparation method thereof, which belongs to the technical field of exploitation of oil and gas fields. The completion protective fluid comprises, by weight, 100 parts of a formate-based liquid, 0.2 to 0.4 part of a thickening agent, 1 to 3 parts of a high temperature high temperature, 0.2 to 3 parts of a clay stabilizing agent and 0.2 to 1 part of a waterproof locking agent. The completion protective fluid has the following advantages: (1) the completion protective fluid has no solid phase, so solid phase settlement does not exist; (2) the completion protective fluid has good rheological properties and a low shearing force value; (3) the completion protective fluid has an excellent hydrocarbon reservoir protection function; (4) the completion protective fluid has good high temperature resistance and salt resistance stability, and a system has good displacement and carrying capability under reservoir temperature; (5) the completion protective fluid is safe, nontoxic, easily degradable and compatible with the environment; (6) the completion protective fluid has good compatibility with a drilling fluid and a fracturing fluid, and the rheological properties of the completion protective fluid are not influenced after mixing; (7) the completion protective fluid has little corrosivity and greatly reduces corrosivity of a saline solution to downhole tools; and (8) the completion protective fluid has great specific gravity and no solid phase and is applicable to areas with abnormal high temperature and high-pressure area.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high-temperature microemulsion drainage aid for fracturing and preparation method thereof

ActiveCN106244131BImprove surface activityImprove liquidityDrilling compositionEmulsionFracturing fluid

The invention provides a high-temperature microemulsion cleanup additive used for fracturing, and a preparation method thereof. The preparation method comprises the following steps: 1, adding 10-20 parts by mass of water into a reactor, adding 40-60 parts by mass of a cosurfactant to water, and stirring the cosurfactant and water at room temperature until the cosurfactant is completely dissolved; and 2, sequentially adding 20-40 parts by mass of a gemini surfactant and 3-4 parts by mass of a nonionic surfactant into the reactor, supplementing water to the reactor until the mass part number of a mixture obtained in the reactor is 100, and uniformly stirring the mixture at room temperature to obtain the high-temperature microemulsion cleanup additive. The high-temperature microemulsion cleanup additive is directly added to a fracturing fluid or an acidifying liquid according to a mass ratio of 0.1-0.3:100 when used.

Owner:CHINA PETROLEUM & CHEM CORP +1

Foaming flowback agent for oil field fracturing and application thereof

The invention relates to the technical field of chemical additives for oilfield fracturing and acidification, in particular to a foaming flowback agent for oilfield fracturing and its application. The foaming flowback agent is composed of A agent and B agent, and the A agent It includes sodium nitrite and fast penetrating agent T, and the B agent includes ammonium chloride, persulfate and surfactant; the foaming flowback agent can be used for deblocking and flowback of oil wells with water content not exceeding 50%. The foaming flowback agent can not only reduce the formation of fracturing fluid filter cake, but also remove wax, colloid, and asphaltenes, increase flowback capacity, stabilize formation clay, reduce oil-water surface interfacial tension, and improve fracturing performance. Effect.

Owner:山东滨州昱诚化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com