Method for multi-medium steam huff-puff oil recovery in old area of heavy oil reservoir

A heavy oil reservoir and multi-media technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low oil-steam ratio, rising development cost, high energy consumption, etc., and achieve oil production and The effect of increasing the oil-steam ratio, improving fluid flowback capacity, and increasing the degree of vertical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

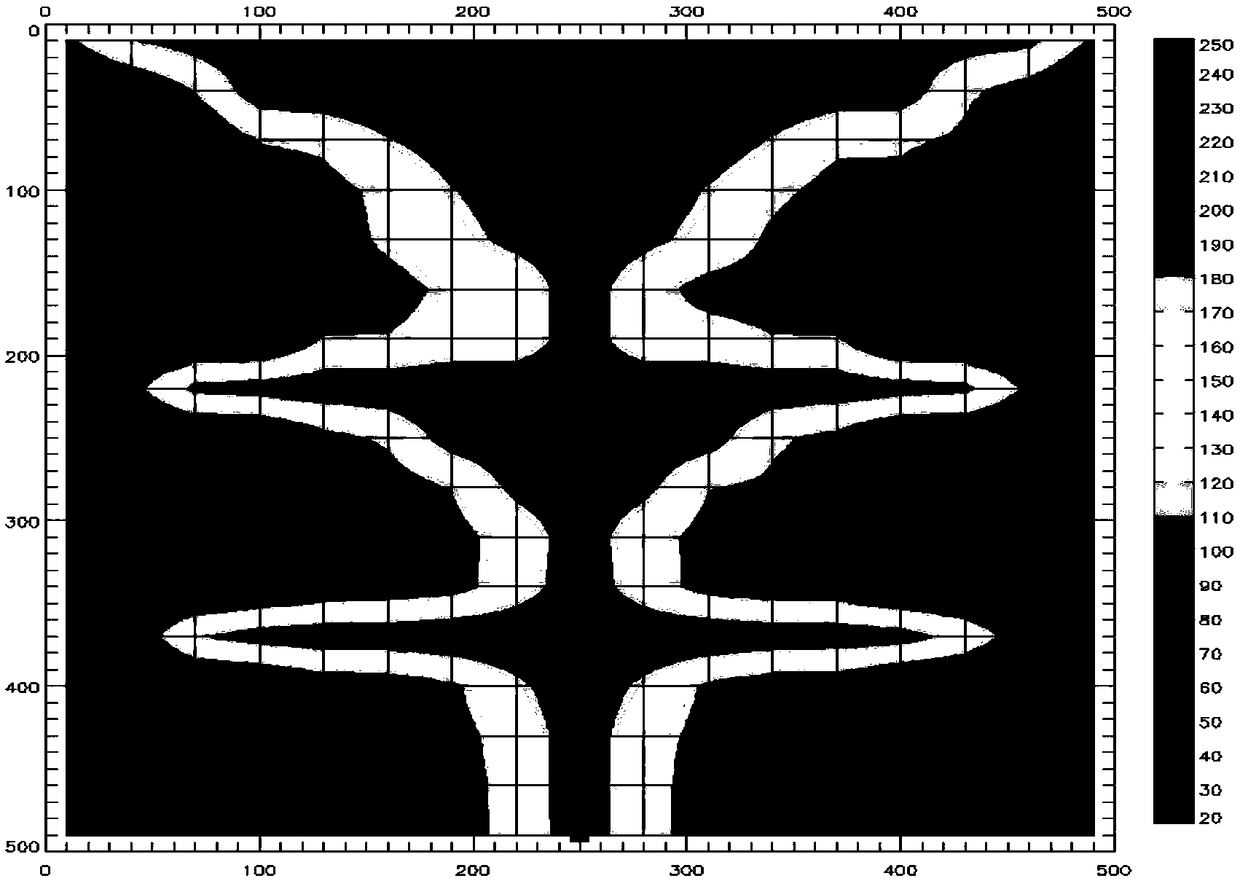

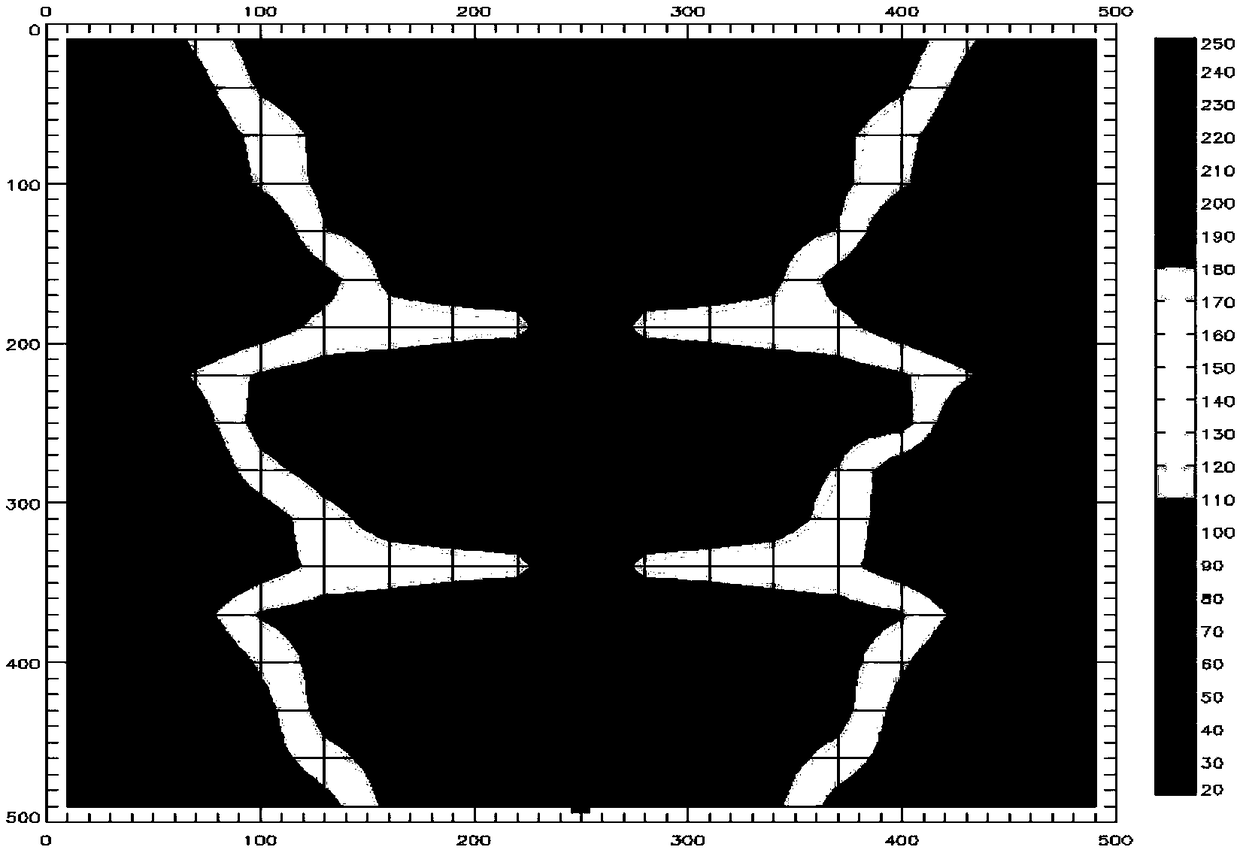

Image

Examples

Embodiment 1

[0050] This implementation is aimed at multi-medium steam huff and puff production in a certain block of Henan Province. The general situation of the reservoir is as follows:

[0051]The oil reservoir is buried shallowly, and the reservoir is loosely cemented, between 200-900m. The oil layer is thin and has serious heterogeneity. The thickness of a single layer is generally between 1-4m, the thickness of a combination of layers is generally between 3-10m, the permeability is 200-4000md, and the average permeability is 1050md. Crude oil has high viscosity and poor fluidity. The viscosity of degassed crude oil at 50°C is between 10000-16000mPa·s, and the recovery degree is 15.78%. The distribution of oil layers is scattered, and the efficiency of thermal recovery is relatively low. Most of the blocks can only be combined into a set of development strata, and the pure total thickness ratio of the development strata is 0.2-0.8, generally only about 0.5.

[0052] According to t...

Embodiment 2

[0067] This implementation is aimed at multi-medium steam huff and puff production for a reservoir in a well area in Xinjiang. The overview of the reservoir is:

[0068] The average throughput production is 10.6 cycles, and it has entered the middle and late stages of throughput. The comprehensive water cut is over 90%, the average effective thickness is 10.2m, the average porosity is 24.3%, the average permeability is 324mD, the average crude oil viscosity at 50°C in the reservoir is 20077mPa·s, and the oil-gas ratio Already lower than 0.08, the degree of recovery is 10.7%. The average daily oil production is less than 1.5t, and measures to improve the development effect are urgently needed.

[0069] The reservoir parameters of the horizontal well section are that the average thickness of the third section oil layer is 10.5m, the average porosity of the oil layer is 29.9%, and the average horizontal permeability is 1605mD, which belongs to the high porosity and high permeabil...

Embodiment 3

[0079] This implementation is aimed at the multi-media steam huff and puff exploitation of a certain block in Xinjiang. The overview of the reservoir is as follows:

[0080] Reservoir thickness is 0-34.1m, with an average of 8.1m; oil layer analysis porosity changes between 16.0%-34.08%, average 21.5%; oil layer analysis horizontal permeability changes from 20mD-2314mD, average 318mD. Crude oil density of gram group is 0.8963-0.962g / cm 3 , with an average of 0.9198g / cm 3 ; At 50°C, the viscosity of ground degassed oil is 225-8854mPa·s, with an average of 2423mPa.s; the viscosity-temperature response is sensitive, and the viscosity of crude oil decreases by 50%-70% when the temperature increases by 10°C. The depth of the middle part of the reservoir is 242m, the original reservoir pressure is 2.52MPa, and the pressure coefficient is 1.04. It is a structural and lithological shallow ordinary heavy oil reservoir. Steam stimulation began in 2005. Up to now, the cumulative oil-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com