Patents

Literature

2132 results about "Lower yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lower yield point corresponds to the min load that is required to maintain yield. Normally we use the lower yield point to determine the yield strength of the material being tested, cause the upper yield is momentary.

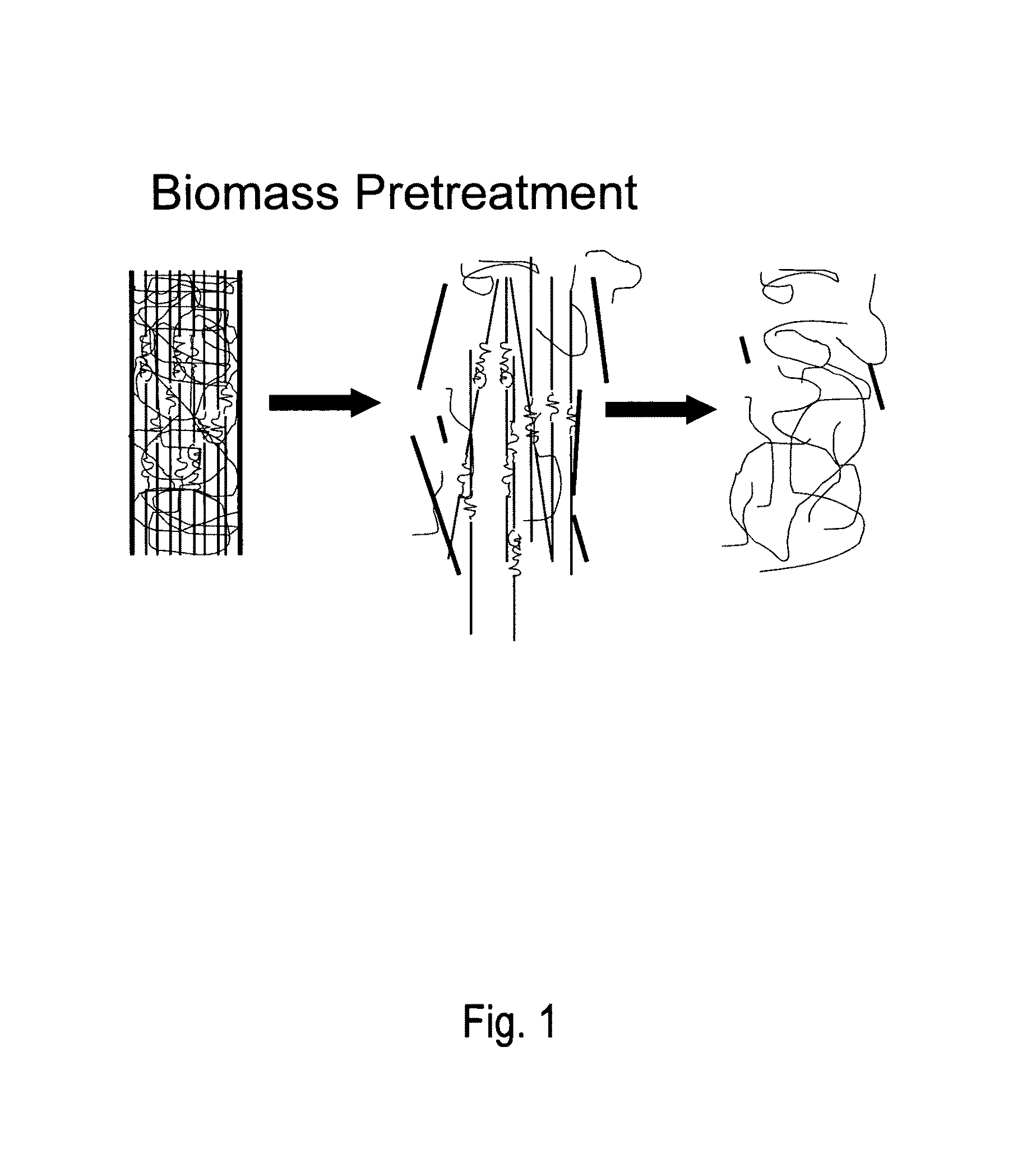

Biomass pretreatment

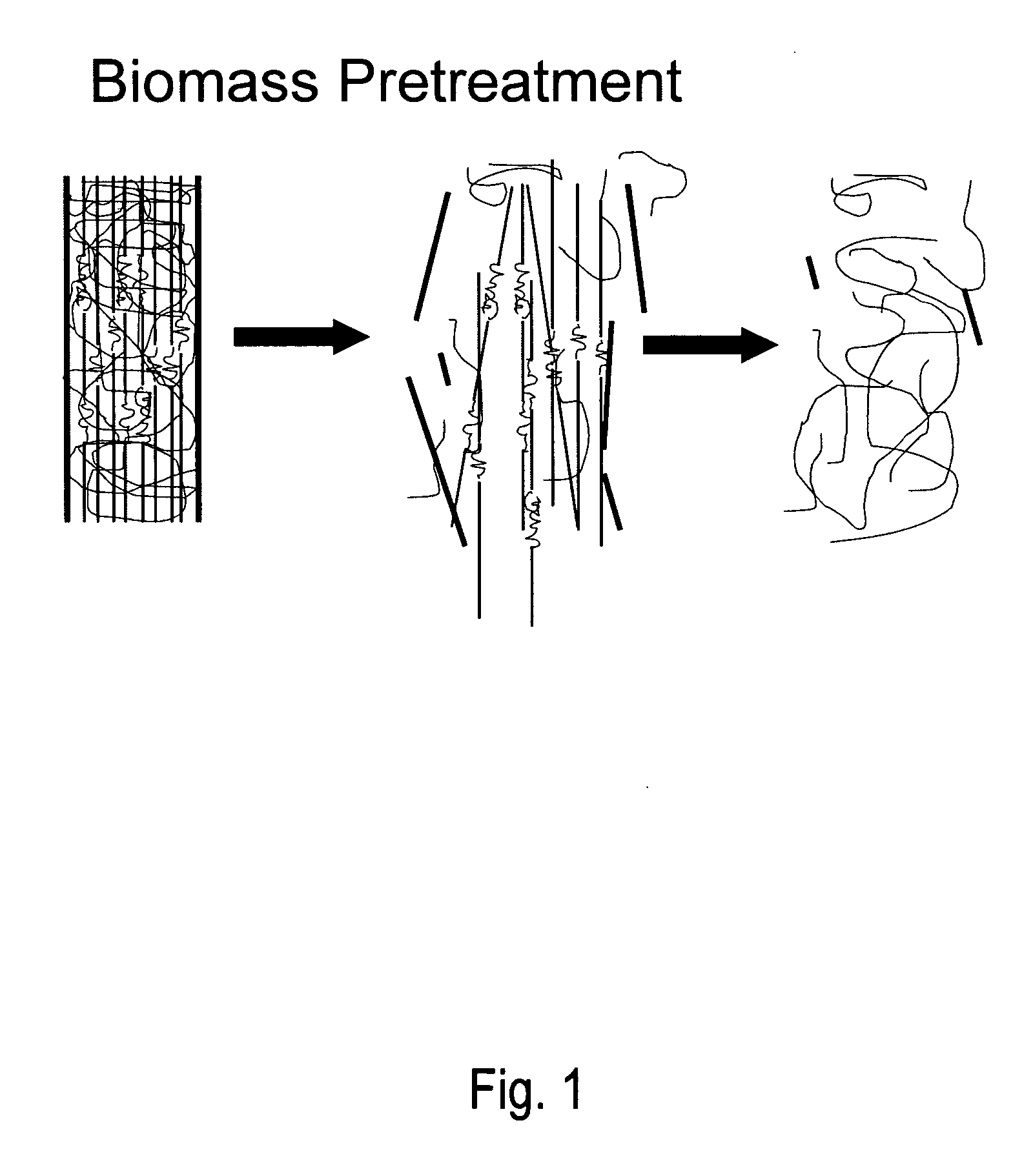

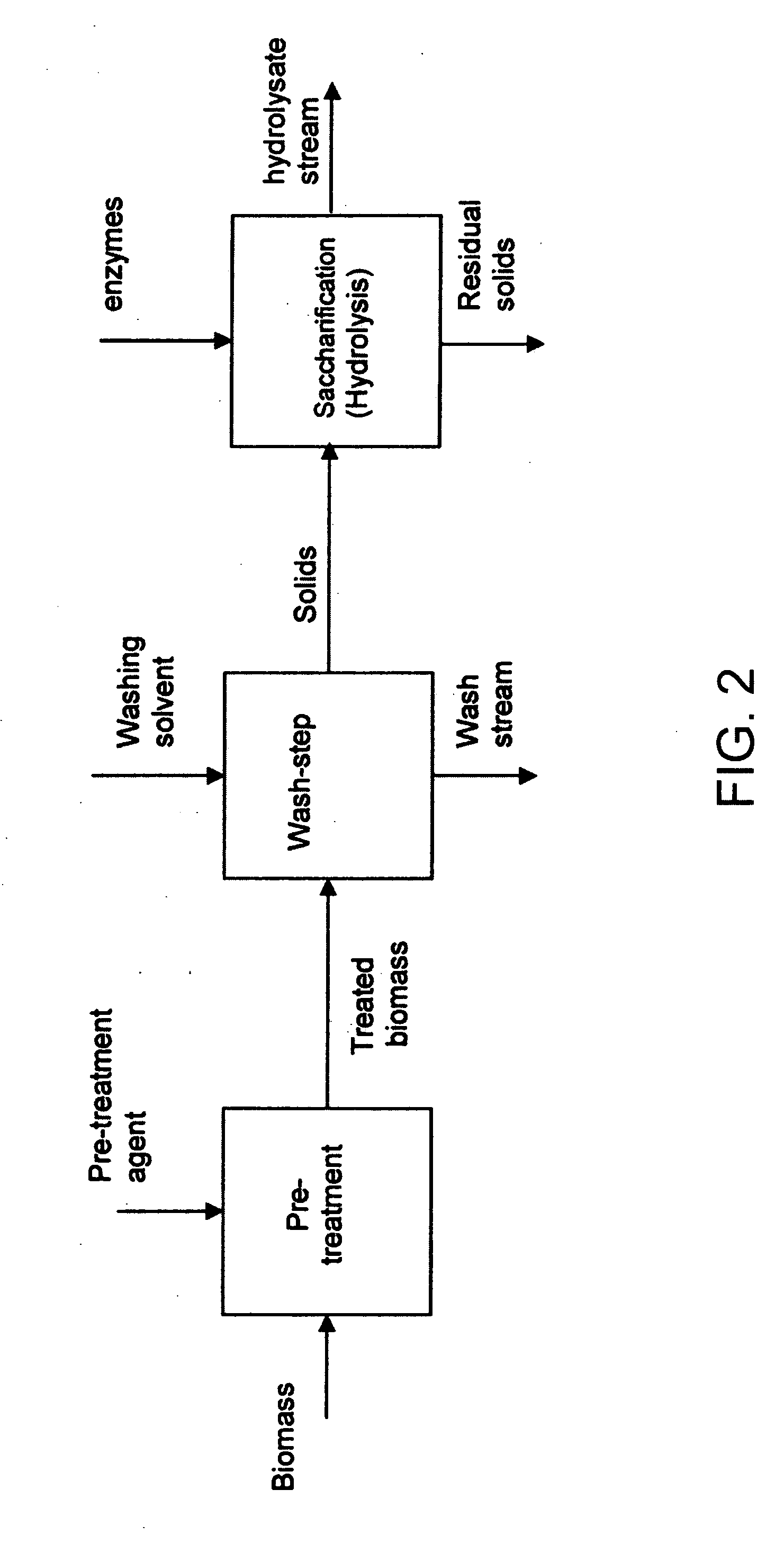

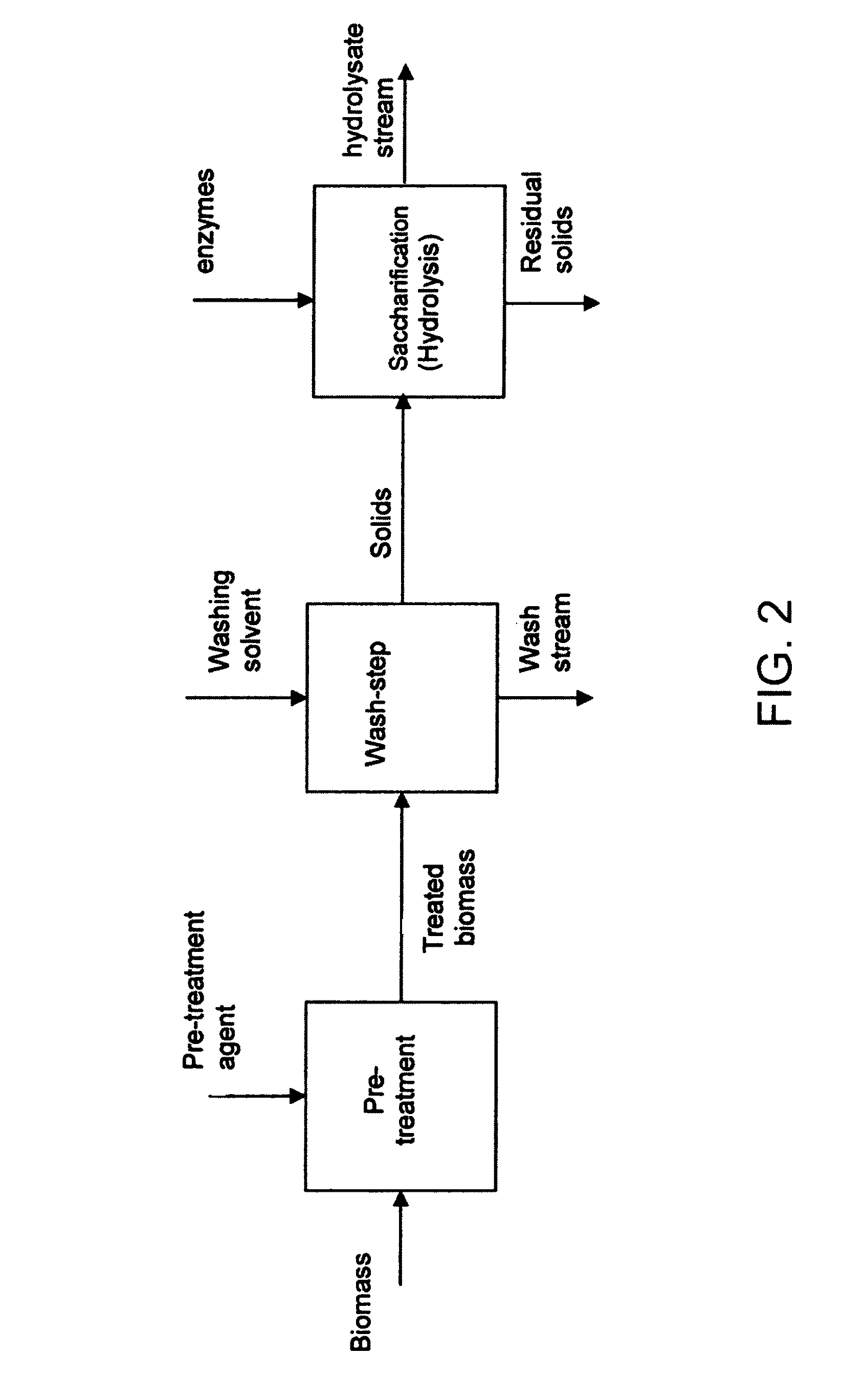

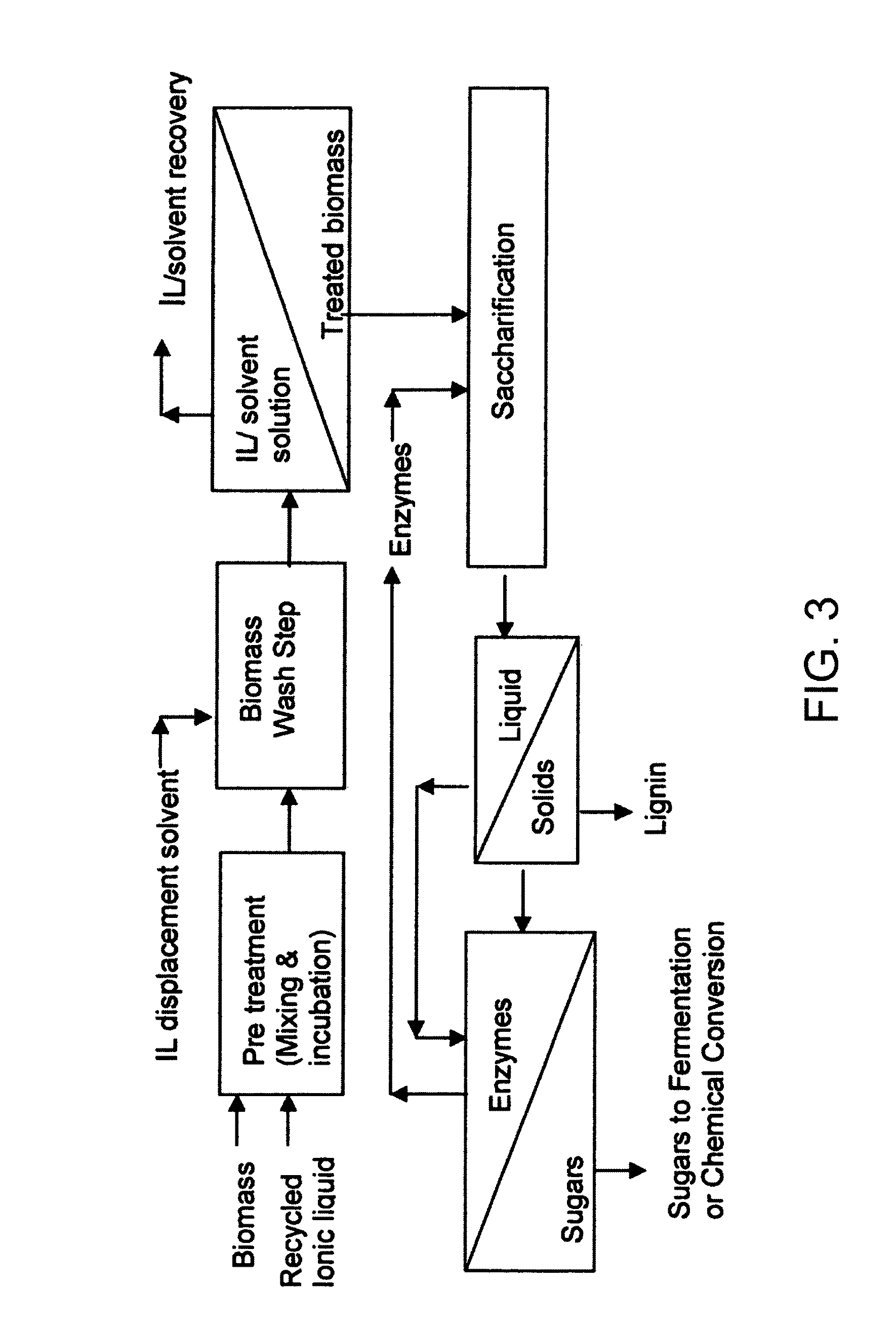

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

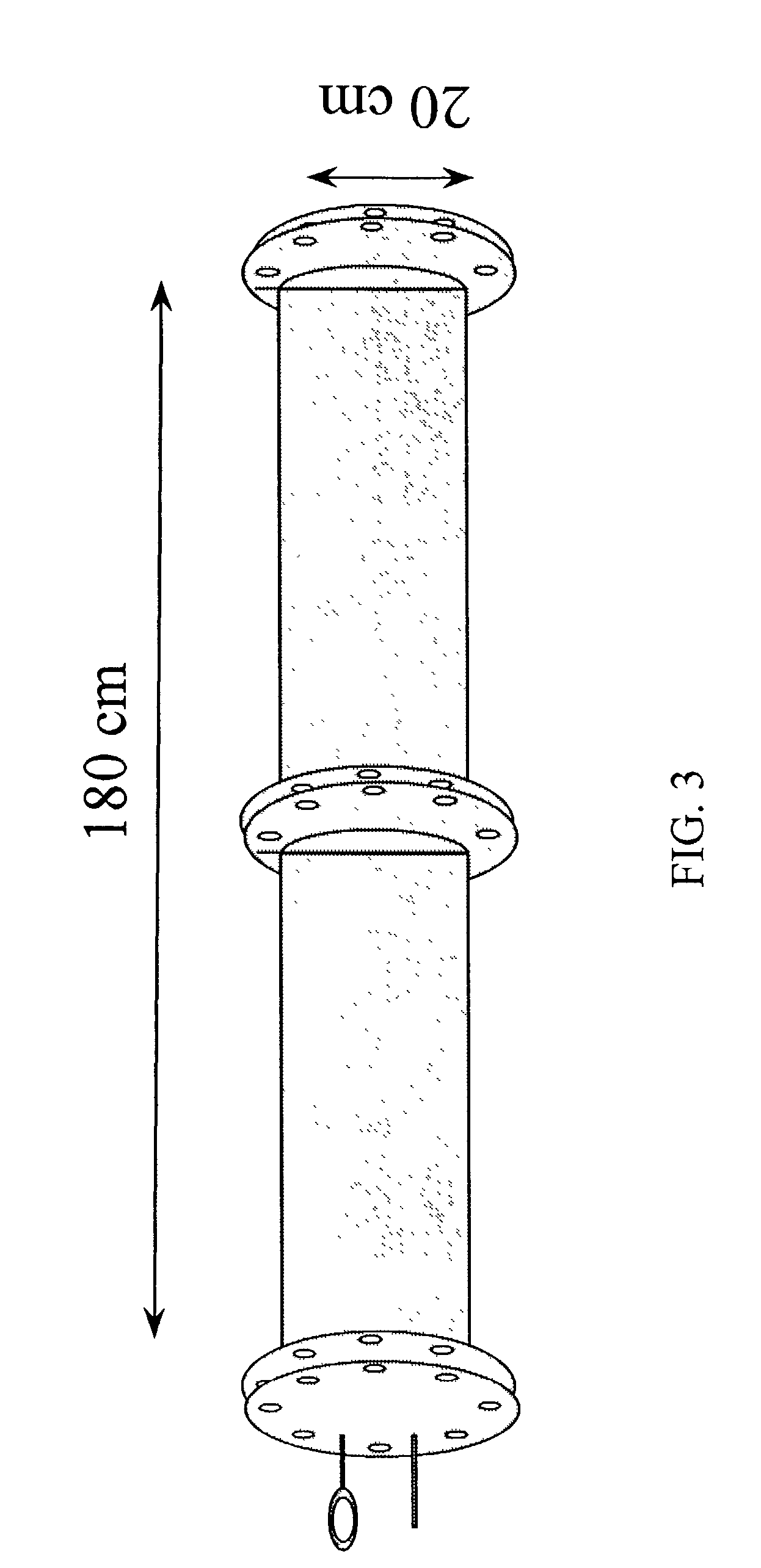

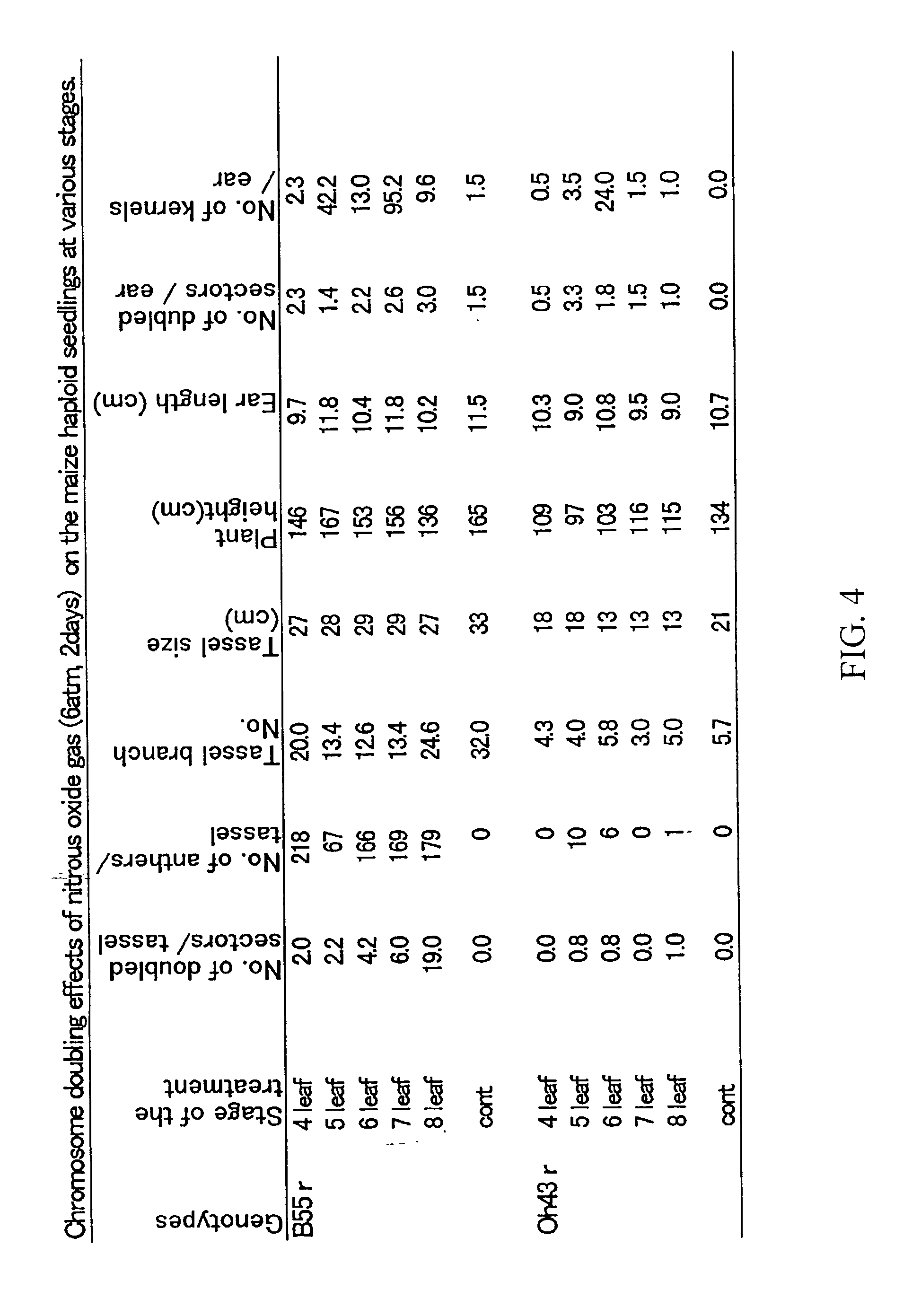

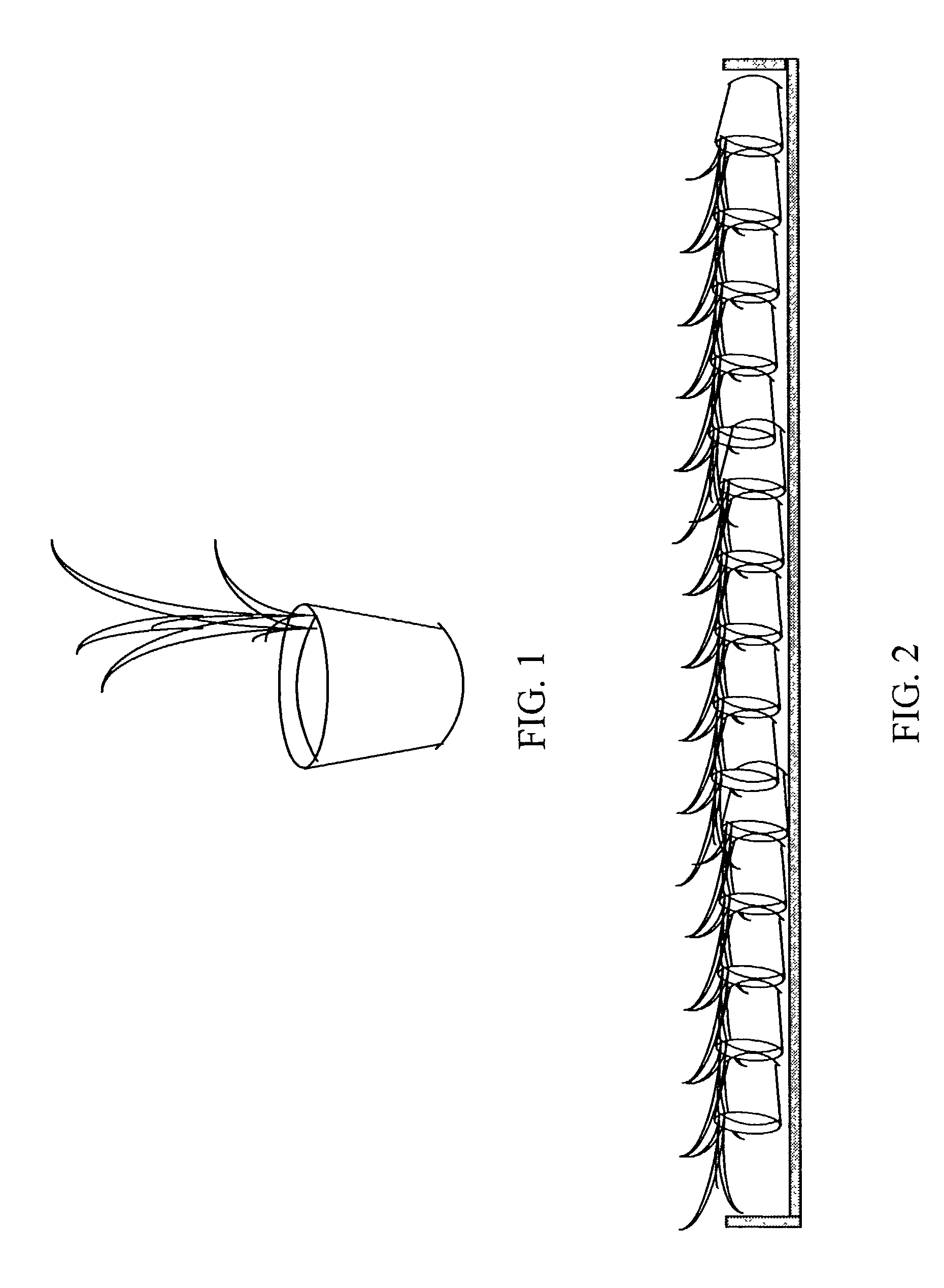

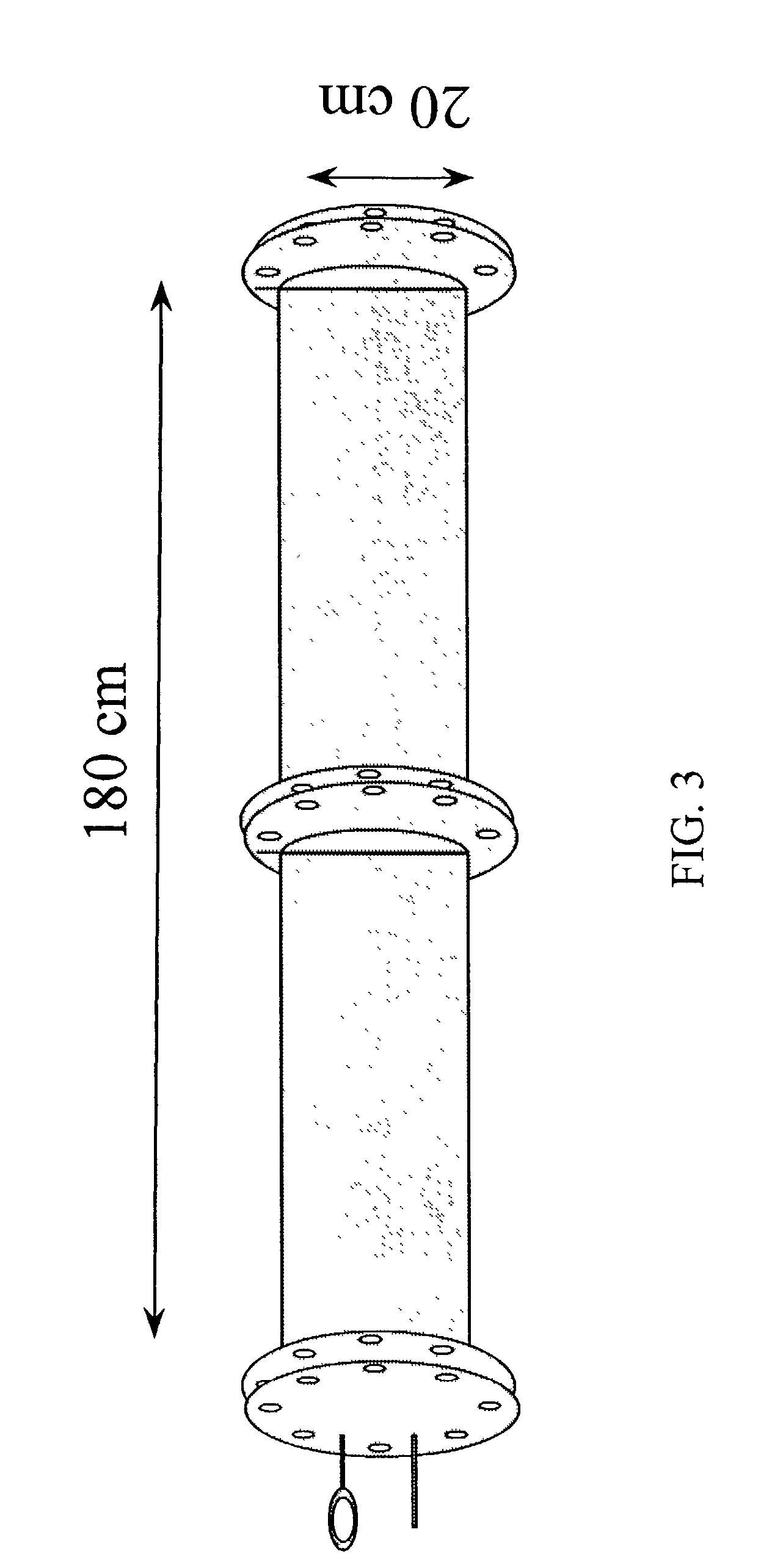

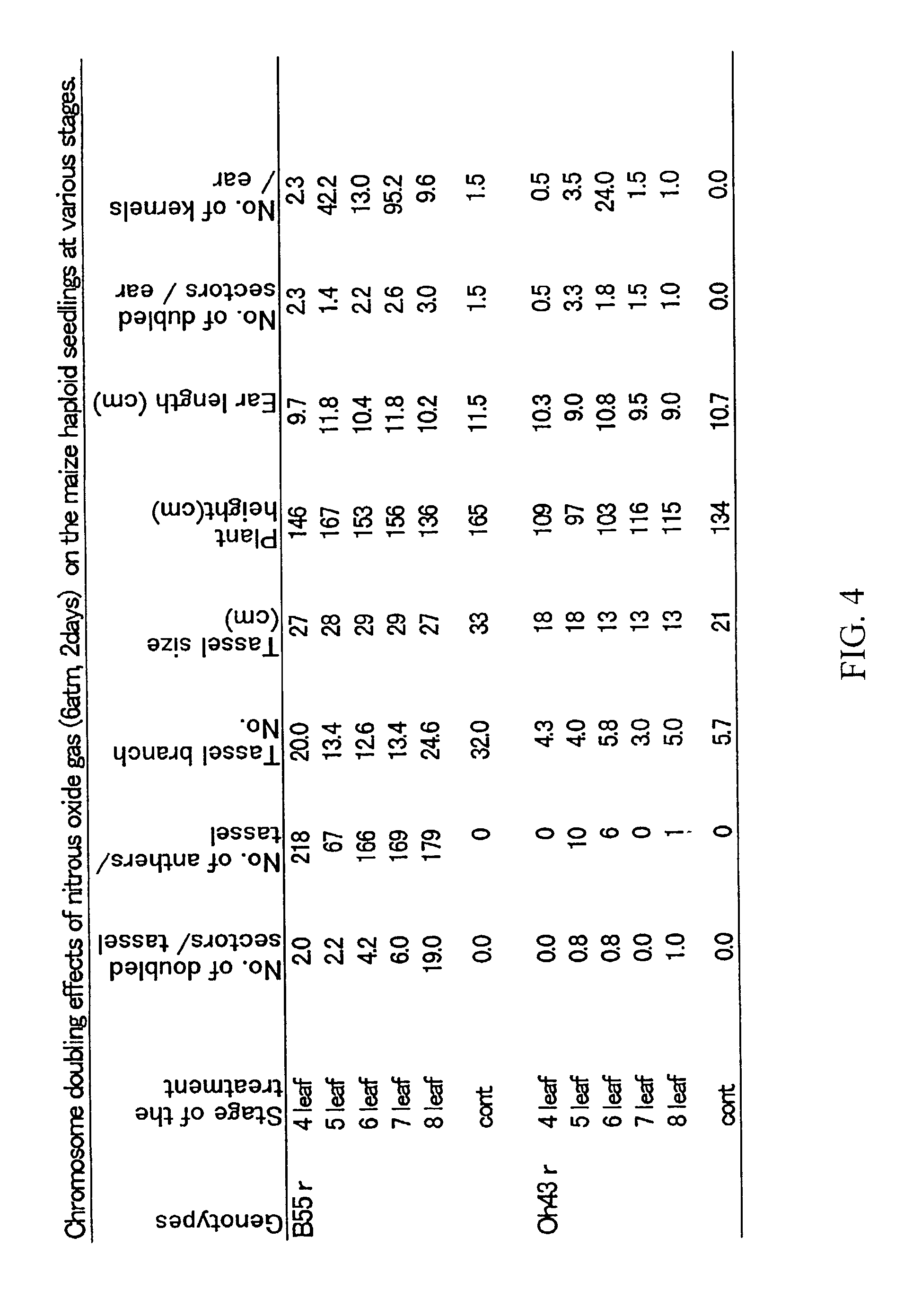

Chromosome doubling method

The invention provides methods for chromosome doubling in plants. The technique overcomes the low yields of doubled progeny associated with the use of prior techniques for doubling chromosomes in plants such as grasses. The technique can be used in large scale applications and has been demonstrated to be highly effective in maize. Following treatment in accordance with the invention, plants remain amenable to self fertilization, thereby allowing the efficient isolation of doubled progeny plants.

Owner:UNIVERSITY OF MISSOURI

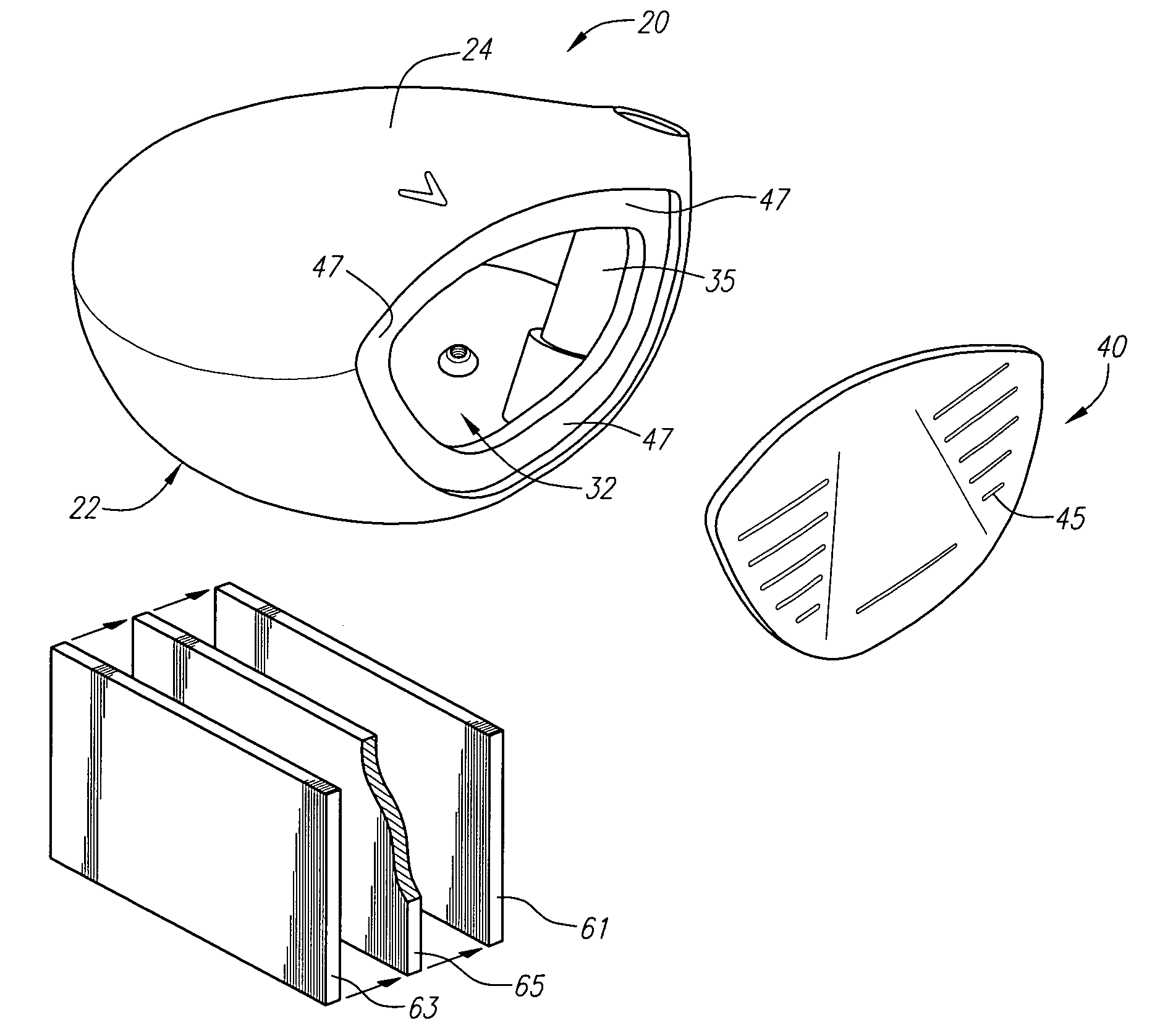

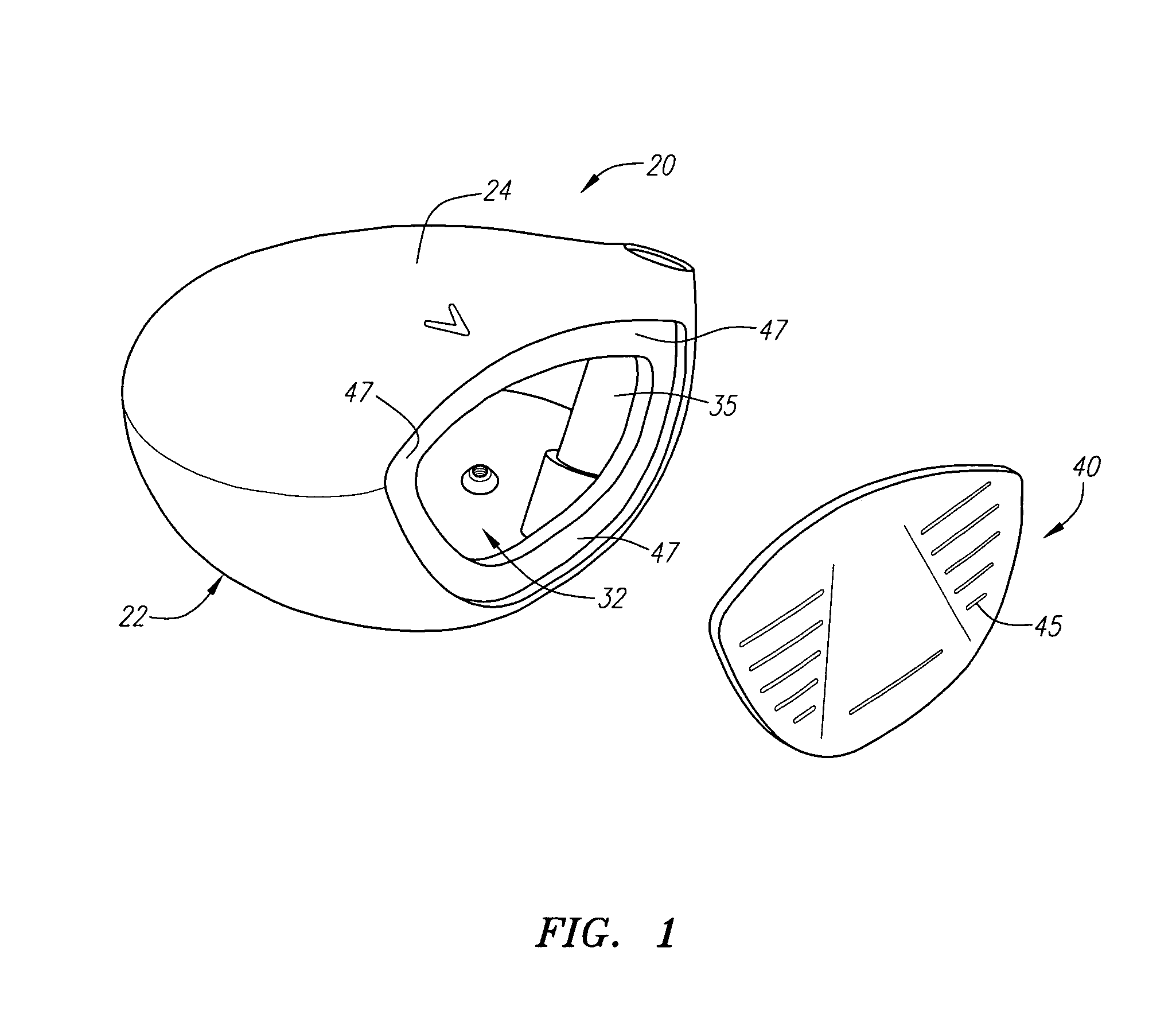

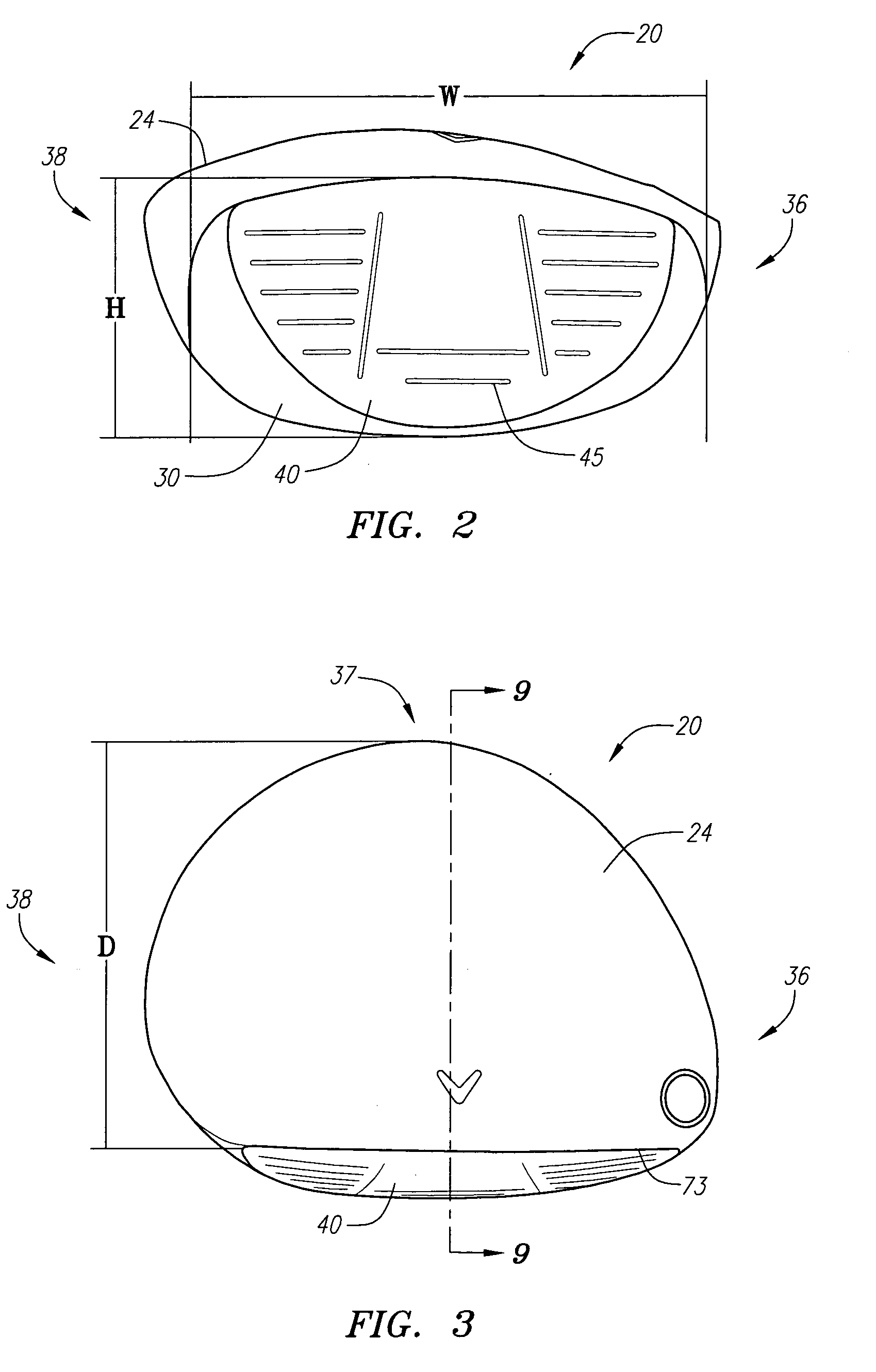

Golf club head with a face insert

InactiveUS6986715B2Improve performanceLaminate strength is lowGolf clubsRacket sportsBonding processEngineering

A golf club head (20) having a body (22) with a front wall (30) with an opening (32) and a striking plate insert (40) is disclosed herein. The striking plate insert (40) preferably includes an outer layer (61) and an inner layer (65) that are joined together by an explosion bonding process. The inner layer (65) is preferably composed of a material that has a lower yield strength than that of the outer layer (61). The explosion bonding process results in the striking plate insert having an increased yield strength relative to the yield strengths of the individual layers. The golf club head (20) preferably has a moment of inertia, Izz, about the Z axis through the center of gravity of the golf club head ranging from 2700 g-cm2 to 4000 g-cm2.

Owner:TOPGOLF CALLAWAY BRANDS CORP

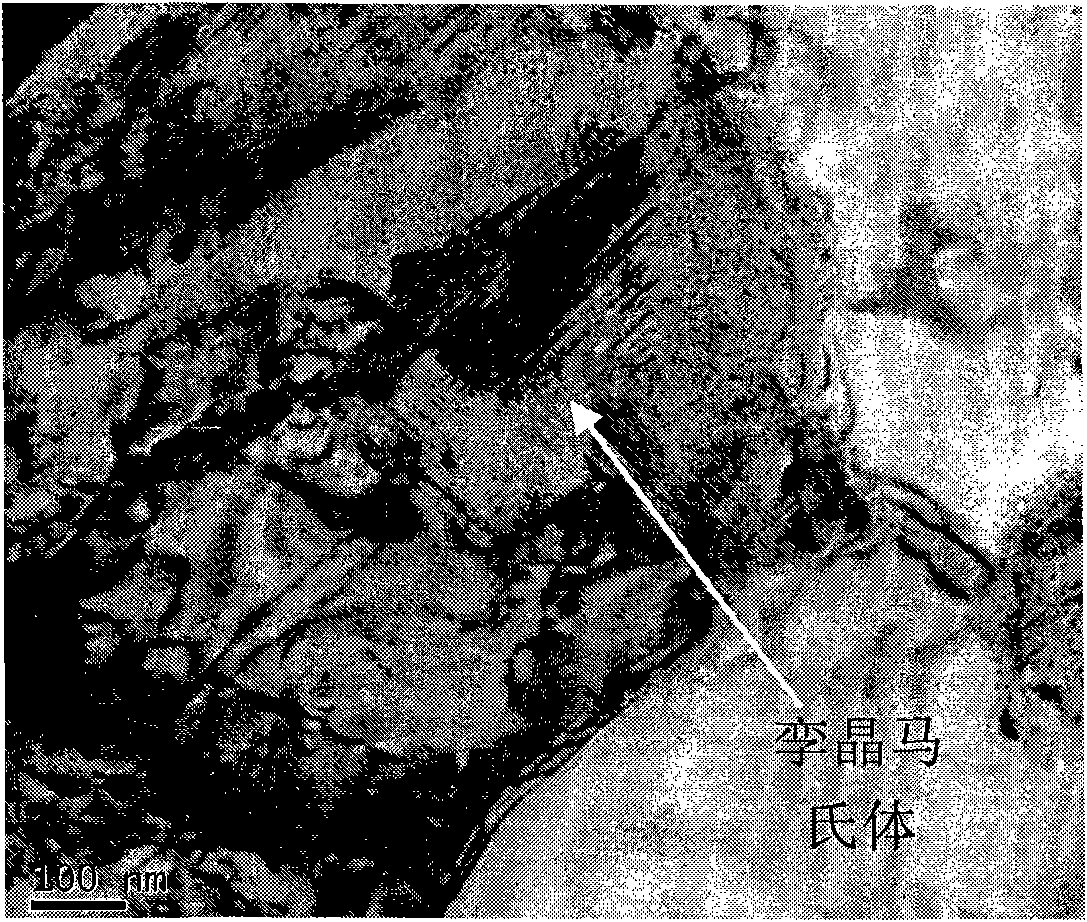

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

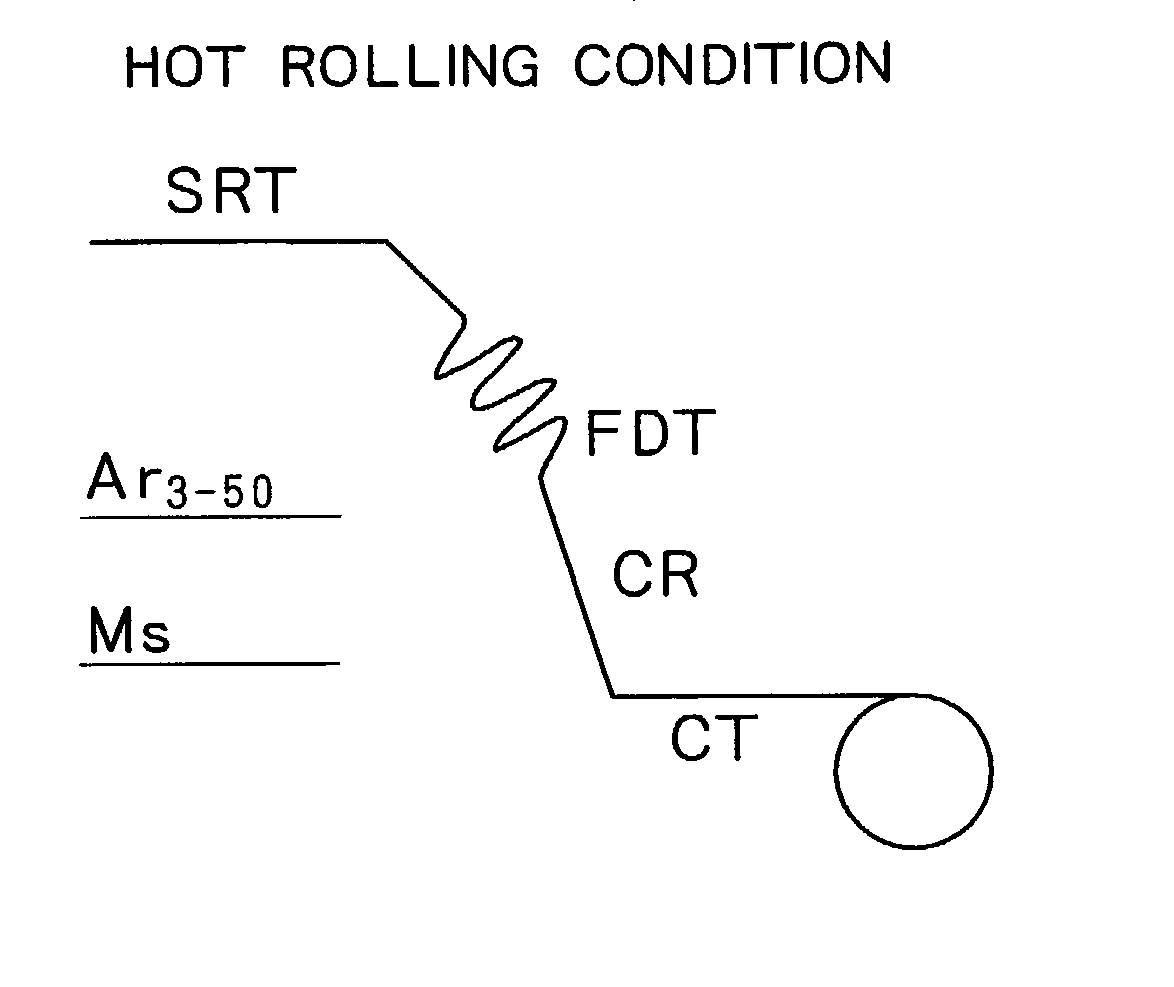

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

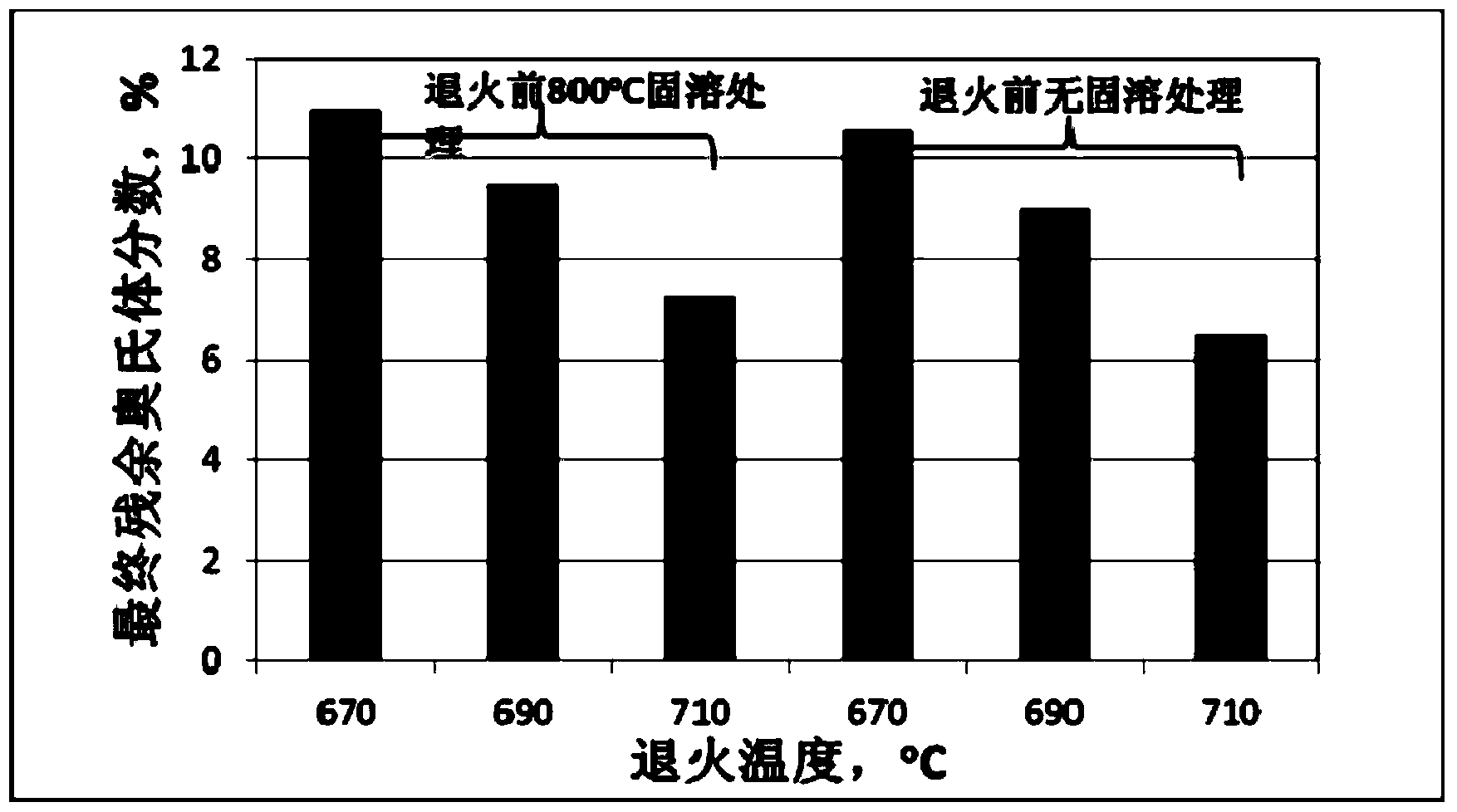

Low-yield strength anti-ageing continuous annealing cold-roll steel sheet and production method thereof

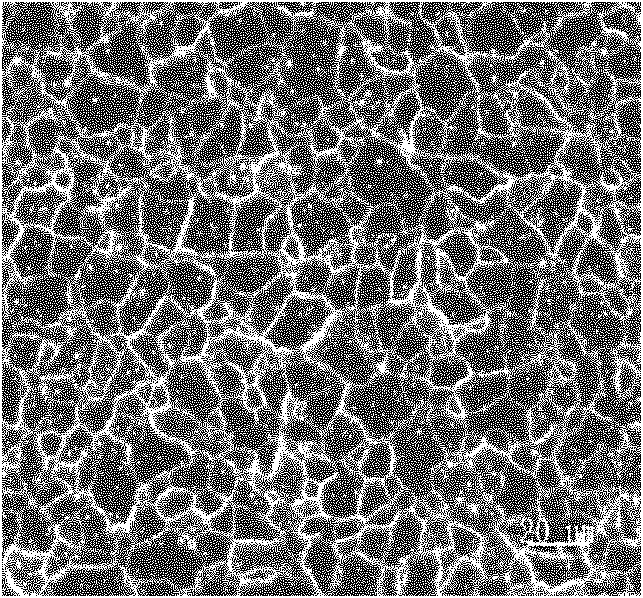

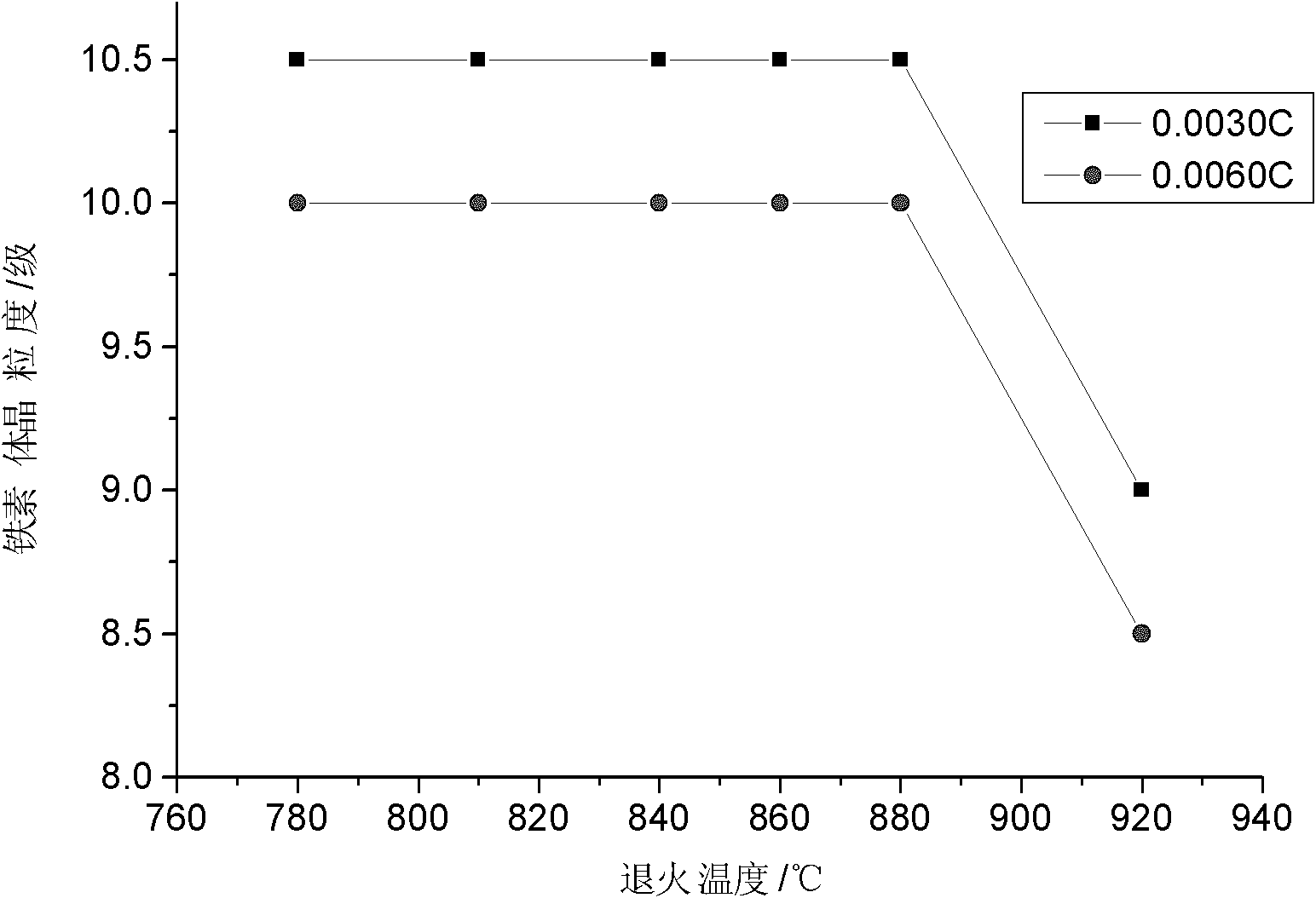

InactiveCN101956133ARefine and stabilize crystal sizeLower yield strengthSheet steelContinuous annealing

The invention belongs to the field of roll steel, in particular to a low-yield strength anti-ageing continuous annealing cold-roll steel sheet and a production method thereof, which solves the technical problem that stable-performance low-yield strength anti-ageing cold-roll steel sheets are difficult to be produced on a machine set with worse equipment level. The technical scheme of the invention is characterized by providing the low-yield strength anti-ageing cold-roll steel sheet and the production method thereof. The method of the invention can be implemented on the machine set with worse equipment level; and by adopting the method of the invention, the stable-performance low-yield strength anti-ageing cold-roll steel sheet can be produced, and the technical problem existing in the field of roll steel for a long term can be overcome.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method for reliving FCC dead catalyst

ActiveCN101219396AIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

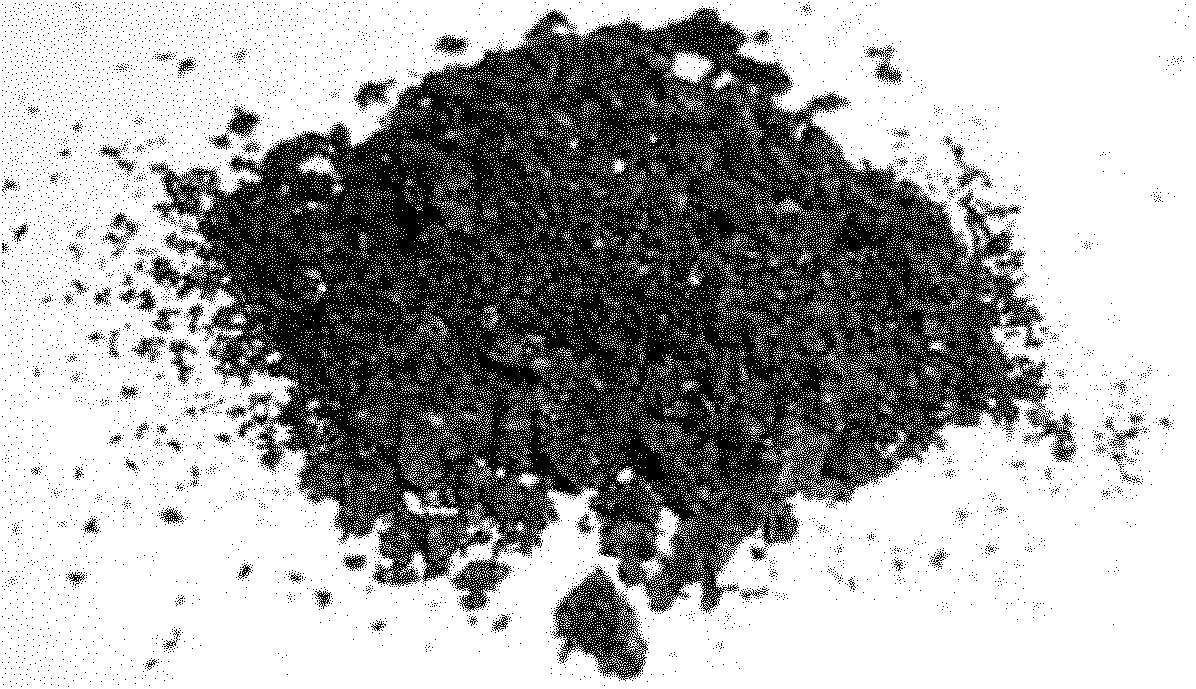

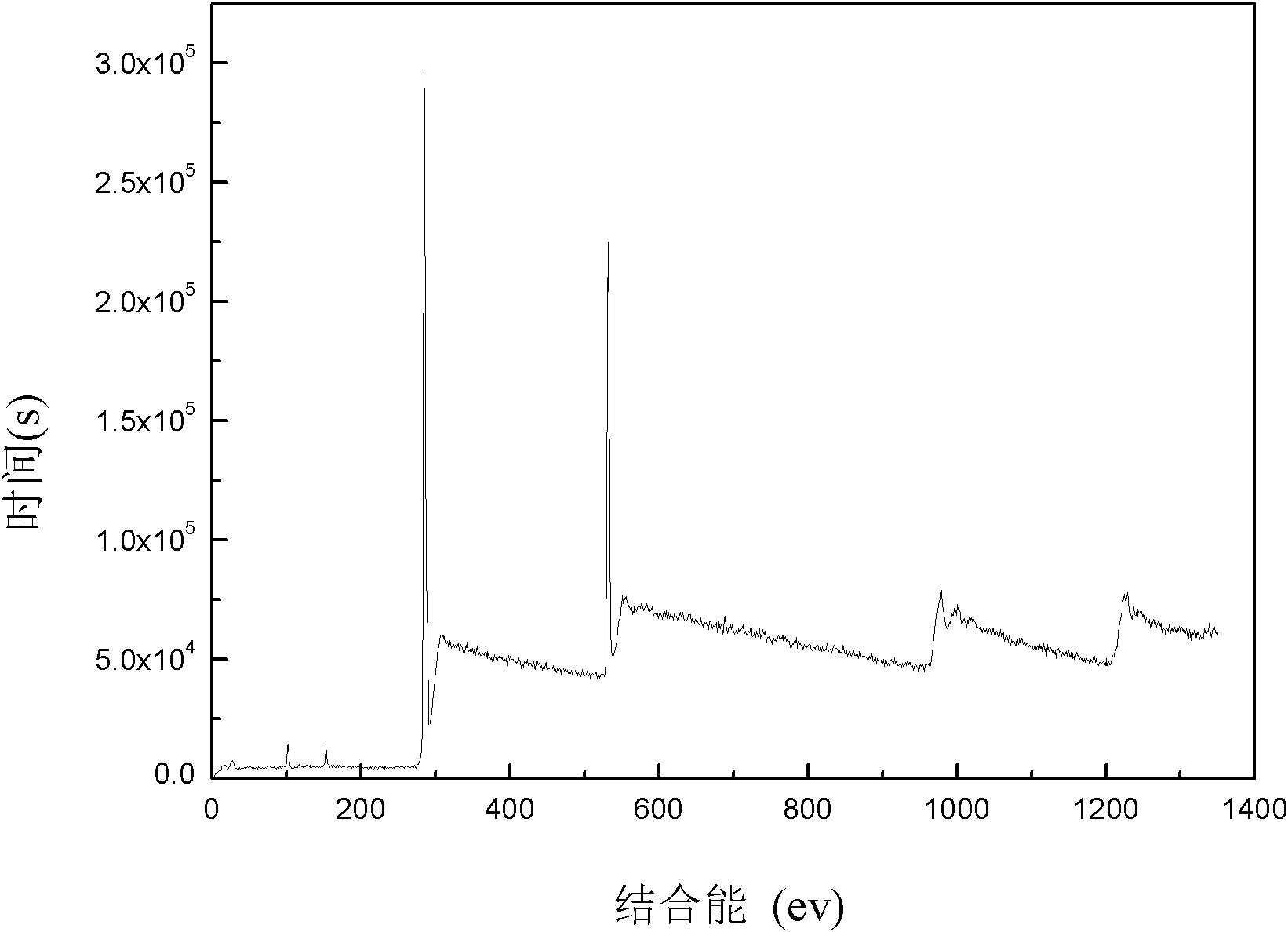

Method for preparing graphene powder

InactiveCN101966988AGood dispersionIncrease the amount of dissolutionBulk chemical productionCentrifugationReaction temperature

The invention discloses a method for preparing graphene powder, which belongs to the field of graphene preparation and aims to solve the technical problems of low efficiency, low yield and environmental protection in the conventional graphene preparation methods. The method of the invention comprises the following steps of: 1, preparing graphite oxide; 2, stripping the graphite oxide; 3, performing purification, namely, performing centrifugation treatment and collecting upper-layer solution; and 4, controlling the reaction temperature to be above the supercritical temperature of a solvent in the step 2 to perform reaction for 1 to 24 hours under the conditions of the protection of an inert gas and the pressure of 20 to 100 MPa, naturally cooling or quenching with water a reaction kettle, and slowly exhausting the gas from the kettle to obtain the graphene powder. The graphene powder prepared by the method is goose feather-like black fluffy powder. The method of the invention has the advantages of the high efficiency of 100 percent, high yield and less environmental pollution.

Owner:HARBIN INST OF TECH

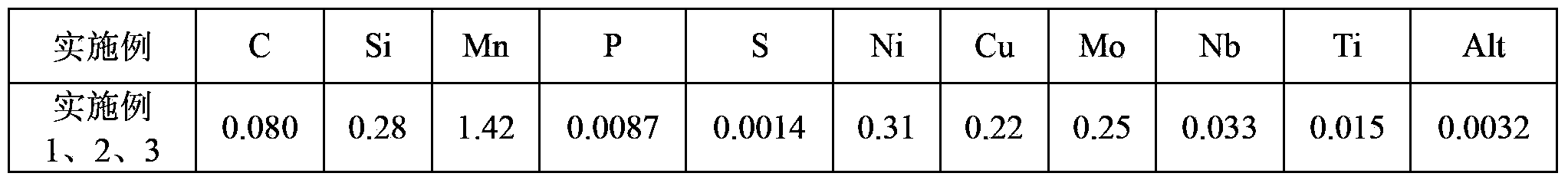

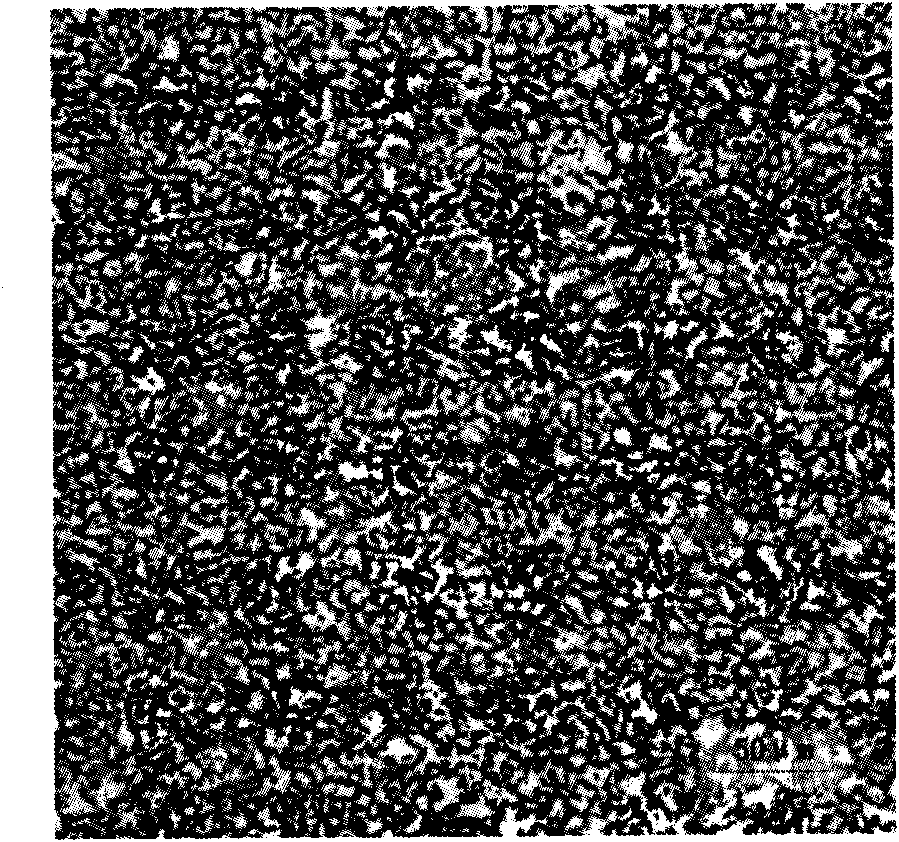

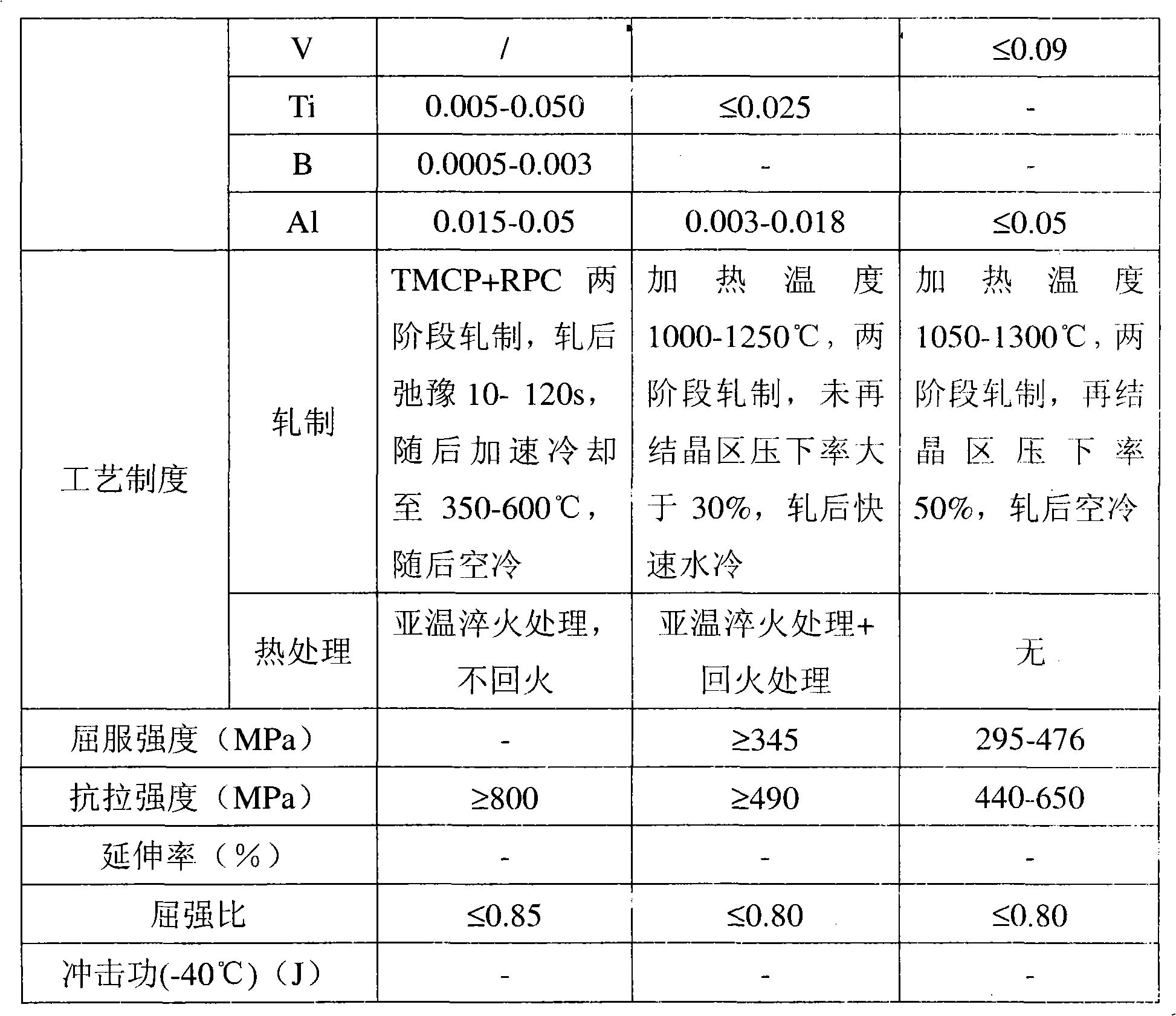

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

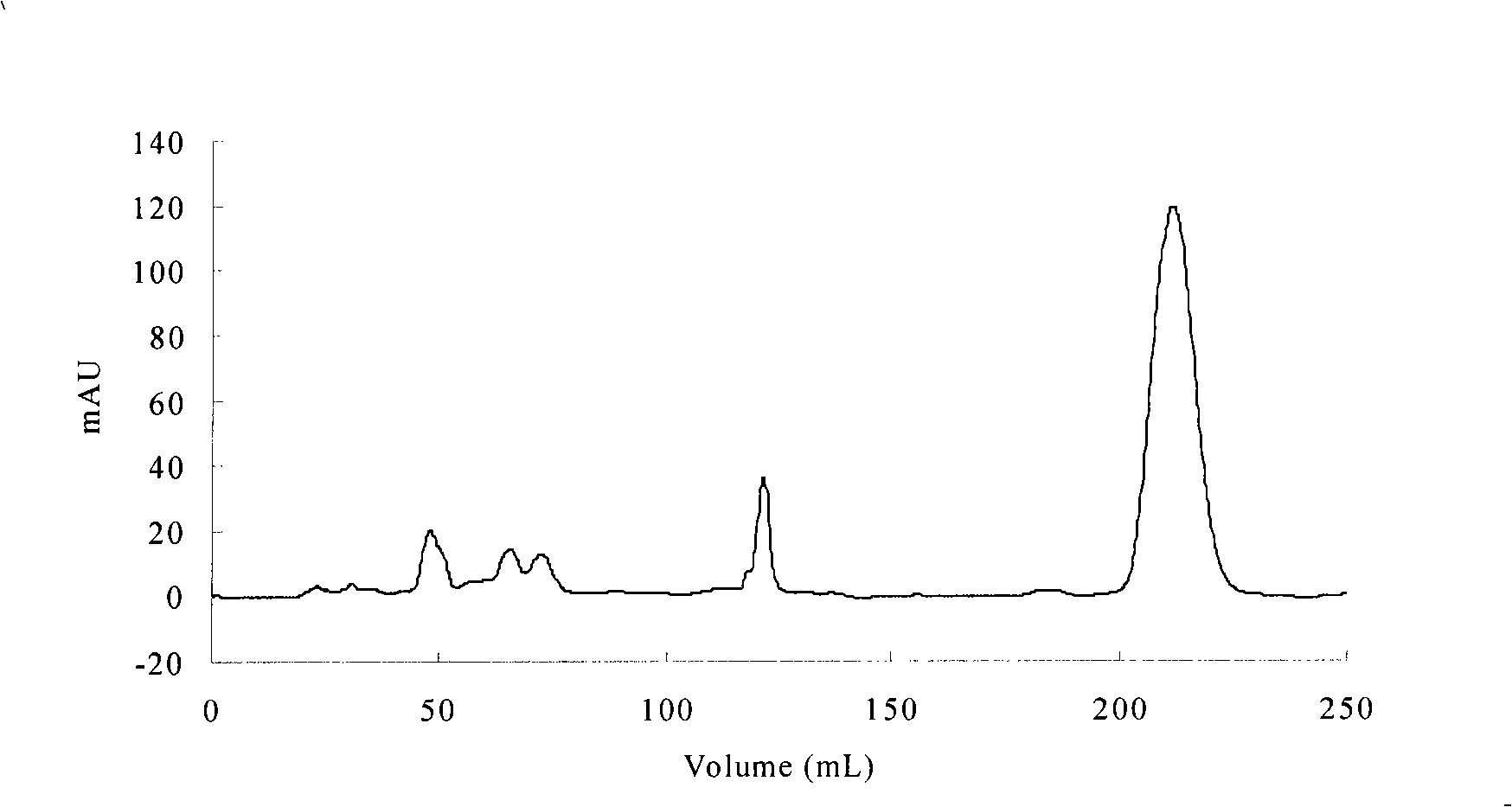

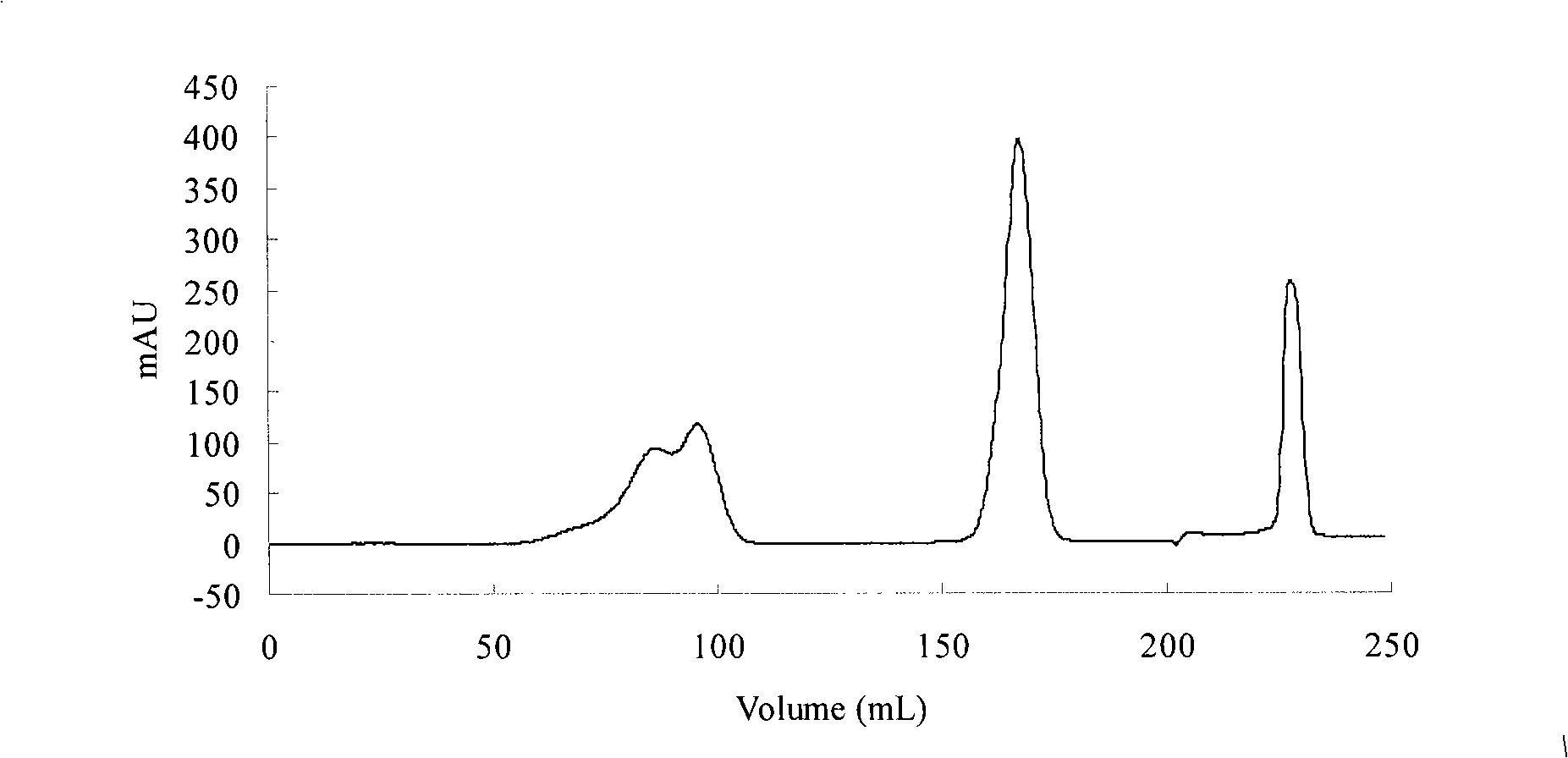

Method for separating and purifying sea-mussel mucin by using mixing adsorption chromatography

ActiveCN101348520AOvercoming the problem of low yieldHigh yieldPeptide preparation methodsAnimals/human peptidesHigh concentrationChromatographic separation

The invention relates to a method for separating and purifying mussel mucin by using a mixed adsorption chromatography. Mussel mucin contains a group of L-3,4- -Dihydroxyphenylalanine (L-DOPA), a phenohydroxyl group thereof can act as the supplier for hydrogen bond, the benzene ring thereof can generate a hydrophobic effect, and the lysine thereof with strong positive charges is capable of forming a static bond. On the basis of the properties of mussel mucin, a mixed adsorption chromatography (i.e. the adsorption chromatography based on three principles of adsorption with hydrogen bond, adsorption with hydrophobic effect, and static adsorption) is adopted to overcome the problem of low yielding rate of mussel mucin in the prior art for separating and purifying mussel mucin. An strong acid extraction is adopted to eliminate small-molecular compounds from a desalting column, an argar medium with high concentration and high cross-linking degree to separate and purify mussel mucin, and an acetic acid-urea- polyacrylamide gel electrophoresis is used to differentiate mussel mucin through specific chromogenesis with nitro blue tetrazolium. Three principles adopted with one separation medium to separate mussel mucin achieve high selectivity, simplify the purification technology, and decrease production cost.

Owner:JIANGYIN USUN BIOCHEMICAL TECH CO LTD

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

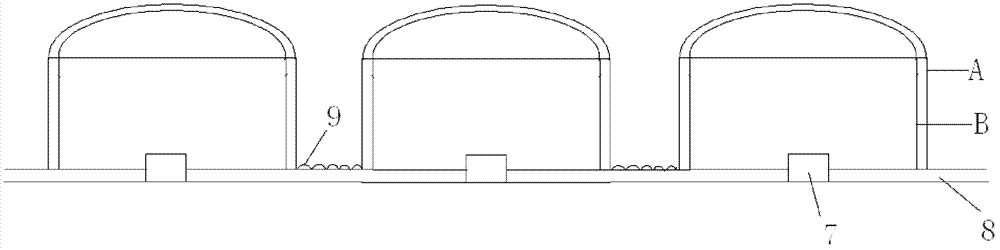

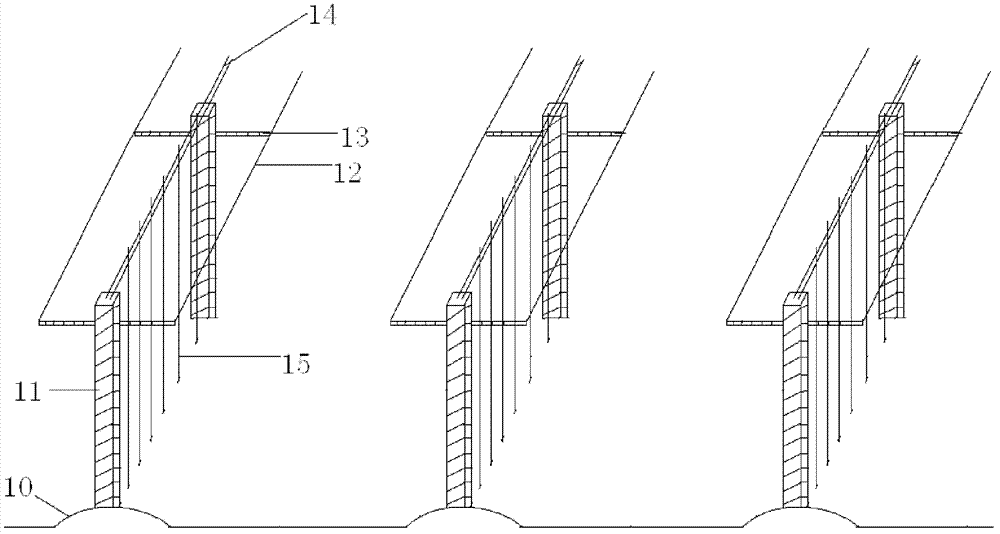

Greenhouse cultivation method and greenhouse structure for promoting high quality and high yield of dragon fruit

ActiveCN102948305AOvercome costsOvercoming pollutionClimate change adaptationGreenhouse cultivationGreenhouse cultivationPollination

The invention discloses a greenhouse cultivation method for promoting high quality and high yield of the dragon fruit. The method includes steps of construction of greenhouse heat-preserving facility, soil preparation and bed making, frame erecting and modeling, planting, water and fertilizer management, shaping and trimming, artificial pollination, blossom and fruit thinning, pest control and the like. In addition, the invention further discloses a greenhouse structure and a dragon fruit frame building structure. The greenhouse cultivation method and the greenhouse structure for promoting high quality and high yield of the dragon fruit solves problems of high cost, low yield, poor quality and the like in conventional greenhouse cultivation technologies of the dragon fruit, cultivation of the dragon fruit is simplified, production cost is lowered, and the dragon fruit yielded is high in yield, is truly green and healthful fruit and has nutrient value obviously higher than that of the dragon fruit cultivated by conventional methods.

Owner:上海合庆火龙果科技开发有限公司

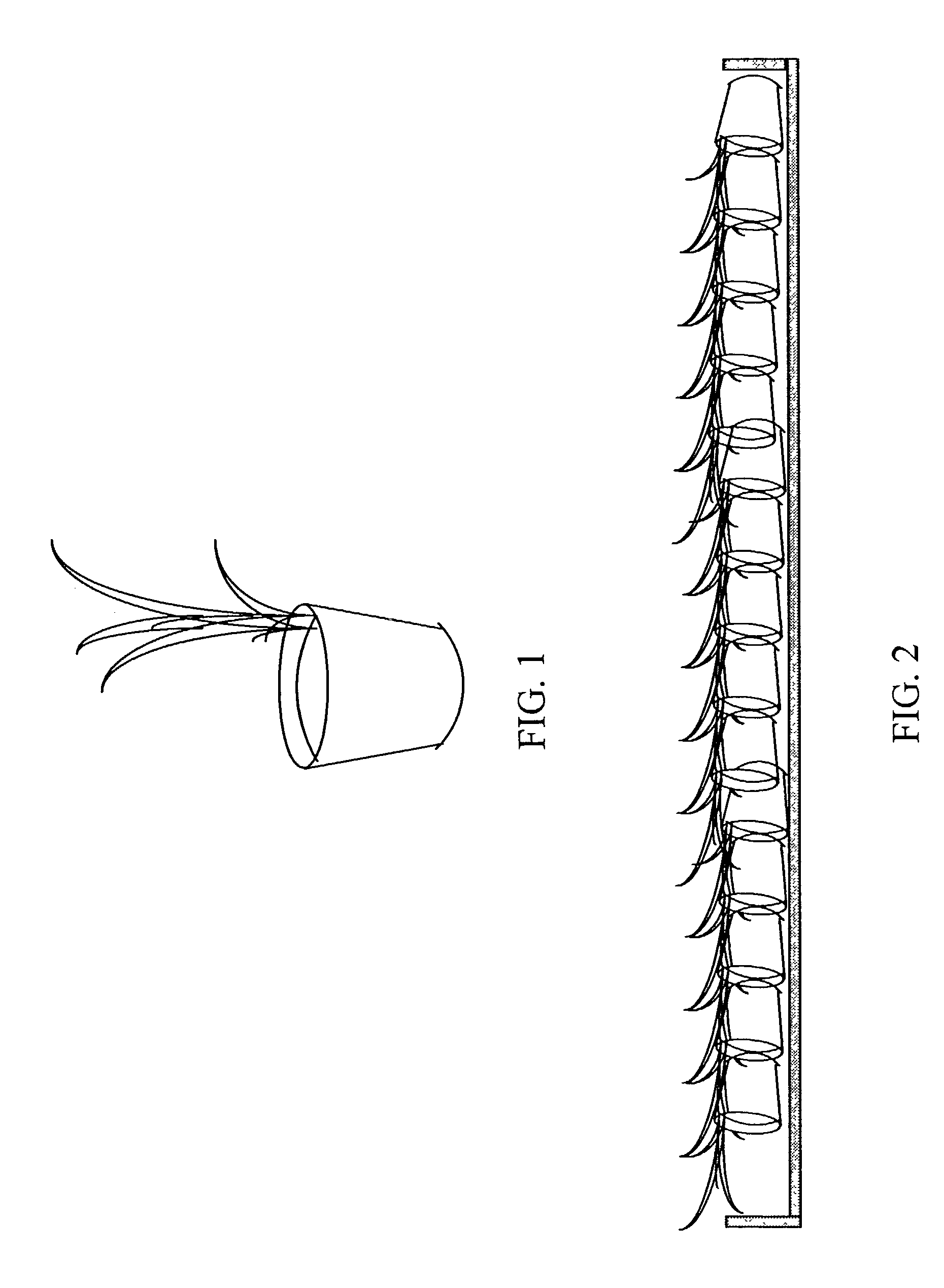

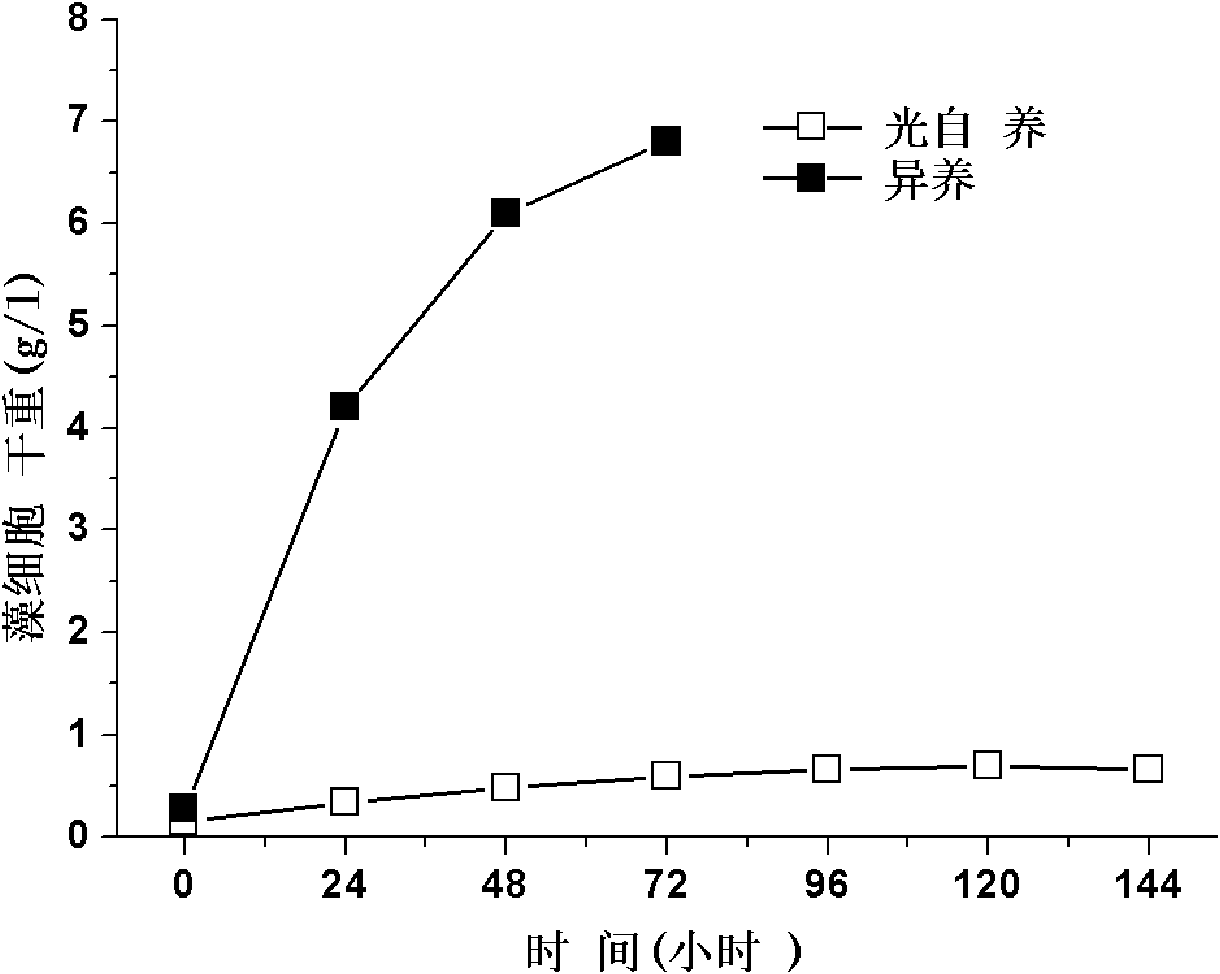

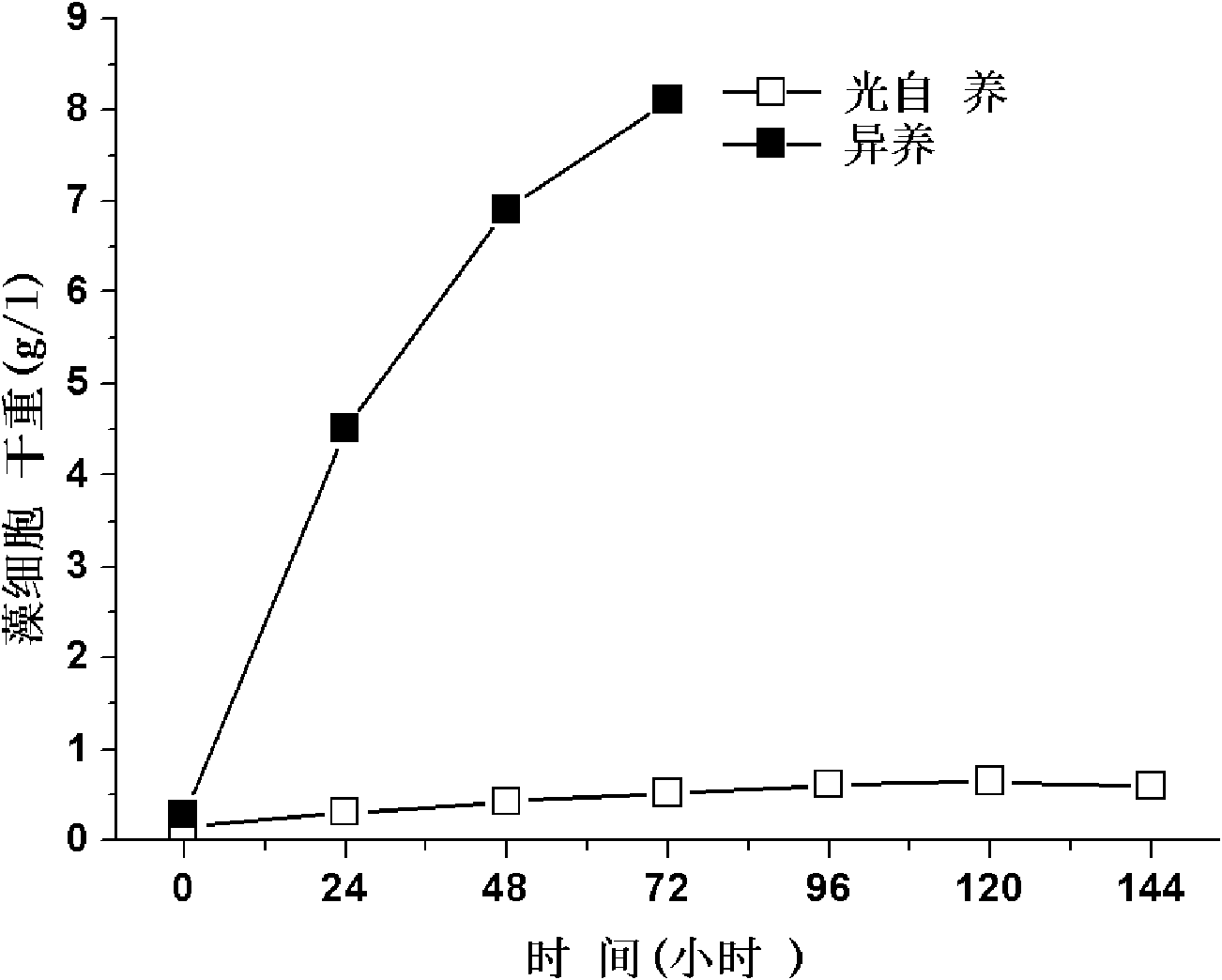

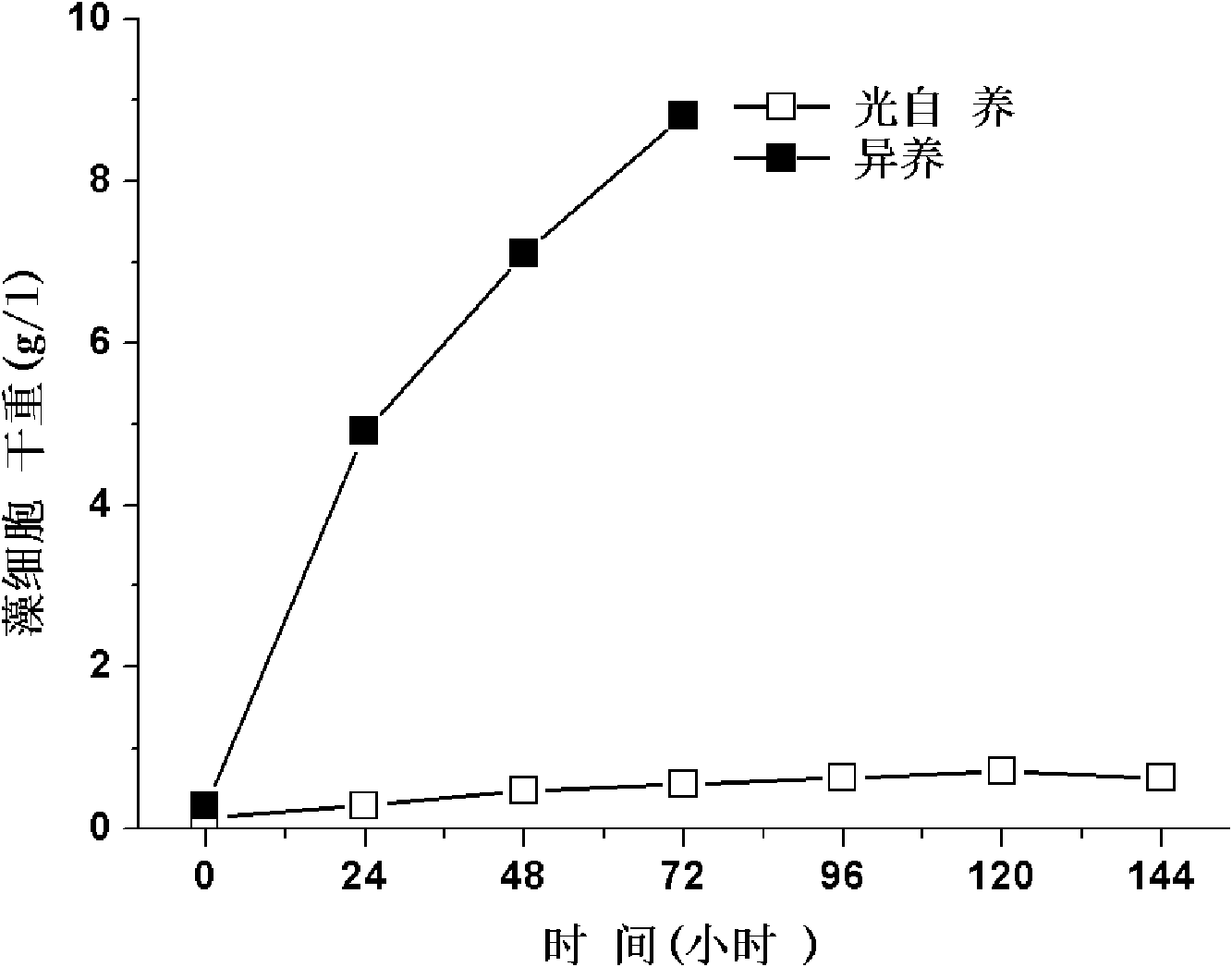

High-yield microalgae cultivating method

ActiveCN102154110AIncrease the culture rateReduce the number of devicesUnicellular algaeMicroorganism based processesCell growthAlgae

The invention relates to a high-yield microalgae cultivating method. The method comprises a step of carrying out heterotrophic cultivation on microalgae algae species and a step of carrying out photoautotrophic cultivation by using algae cells obtained by heterotrophic cultivation as seeds. For the microalgae capable of growing heterotrophically, due to the adoption of the method, the advantage that the algae cells grow rapidly in the heterotrophic phase of the microalgae can be sufficiently played, not only a great amount of algae species can be provided in time for large scale photoautotrophic cultivation of the microalgae, but also the photoautotrophic growth of the microalgae and a forming rate of target products (such as oil, proteins and the like) can be quickened. An important technical means is provided for solving the problems of long algae specie spreading cultivation period, low cell growing speed and low yield of the target products in the large scale photoautotrophic cultivation process of the microalgae.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Chromosome doubling method

Owner:UNIVERSITY OF MISSOURI

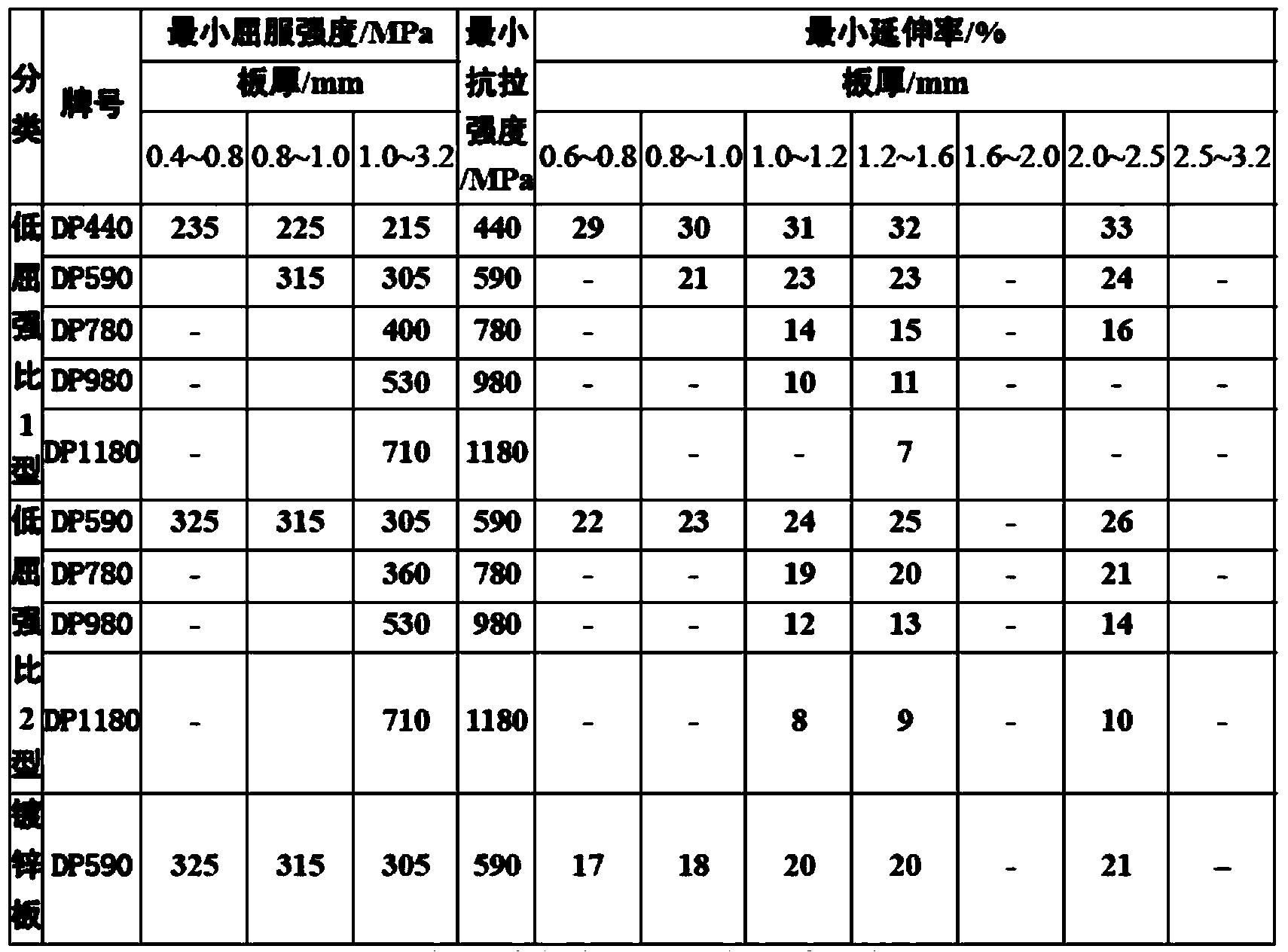

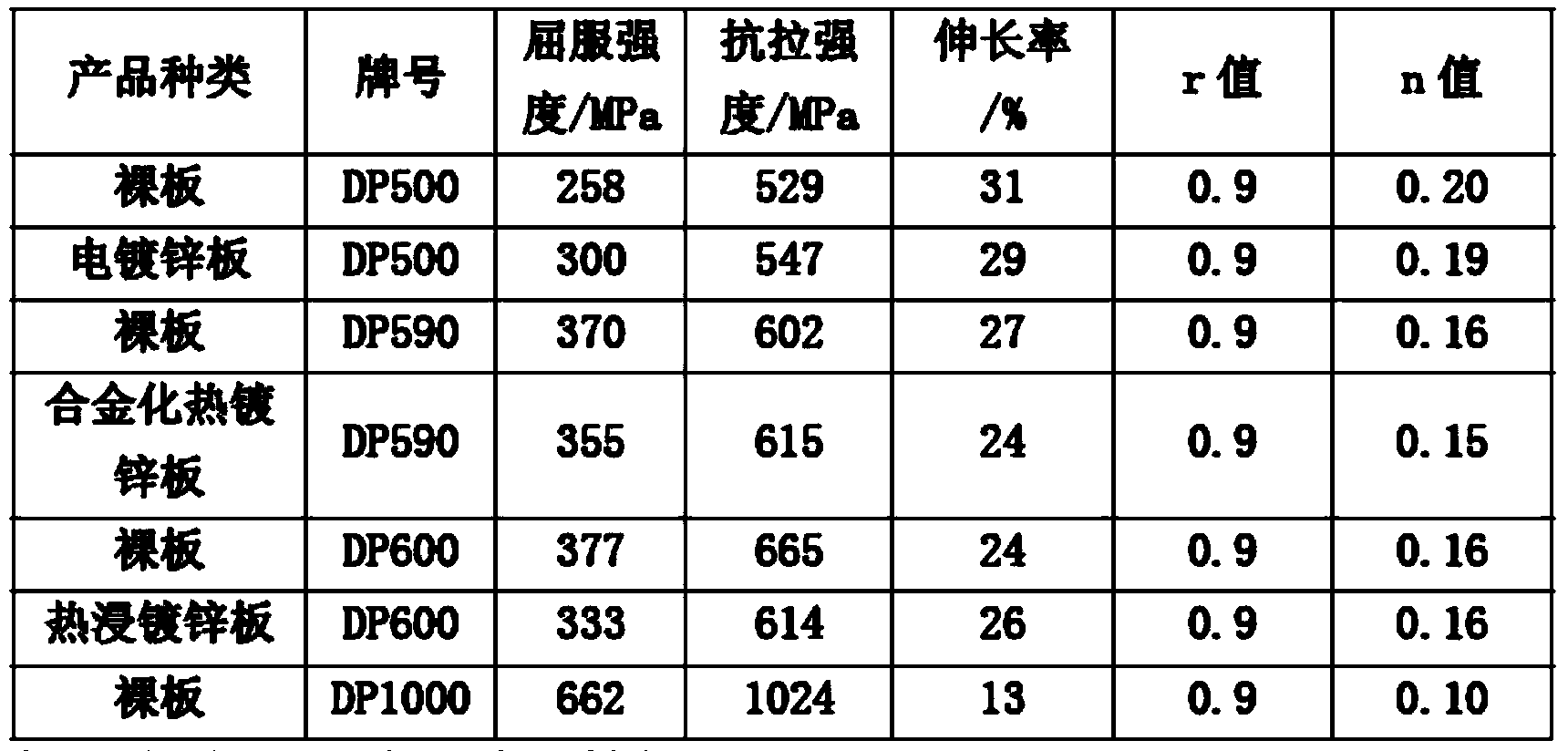

Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

The invention discloses a two-phase automobile steel plate with low yield-strength ratio and high strength and a production method of the two-phase automobile steel plate, belonging to the technical field of steel for automobiles. The two-phase automobile steel plate comprises the following chemical components: 0.1-0.40wt% of C, 3.0-8.0wt% of Mn, less than or equal to 0.020wt% of P and less than or equal to 0.02wt% of S; on the basis, the two-phase automobile steel plate can be additionally provided with one or more of the following elements: 0.1-3.0wt% of Ni, 0.2-3.0wt% of Cr, 0.1-0.8wt% of Mo, 0.3-2.3wt% of Si, 0.5-2.0wt% of Cu, 0.0005-0.005wt% of B, 0.02-0.10wt% of Nb, 0.002-0.25wt% of [N], 0.05-0.25wt% of Ti, 0.02-0.25wt% of V, 0.015-0.060wt% of Al, 0.002-0.005wt% of RE (Rare Earth) and 0.005-0.03wt% of Ca. The two-phase automobile steel plate has the advantages that the two-phase automobile steel plate with low yield strength, high tension strength and favorable elongation can be produced through annealing within short time; the performance indexes of the two-phase automobile steel plate are as follows: two-phase steel with the tension strength of 980MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 22%, and two-phase steel with the tension strength of 1180MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 17%.

Owner:CENT IRON & STEEL RES INST

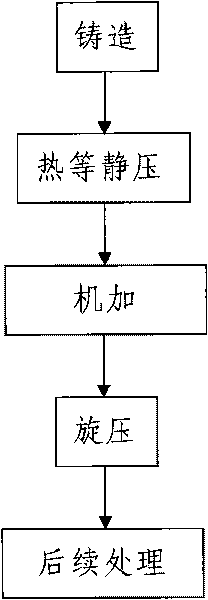

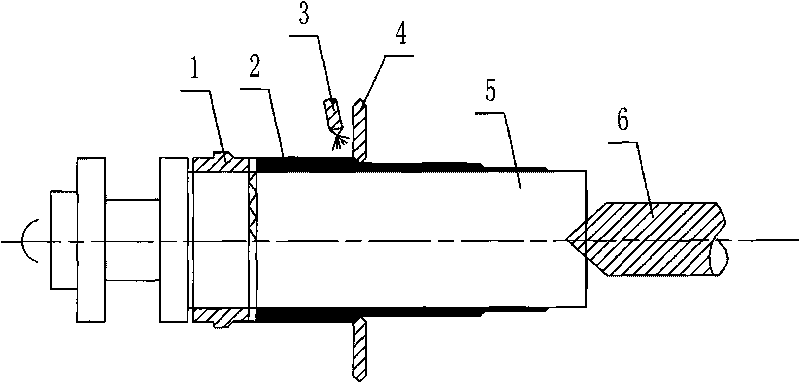

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

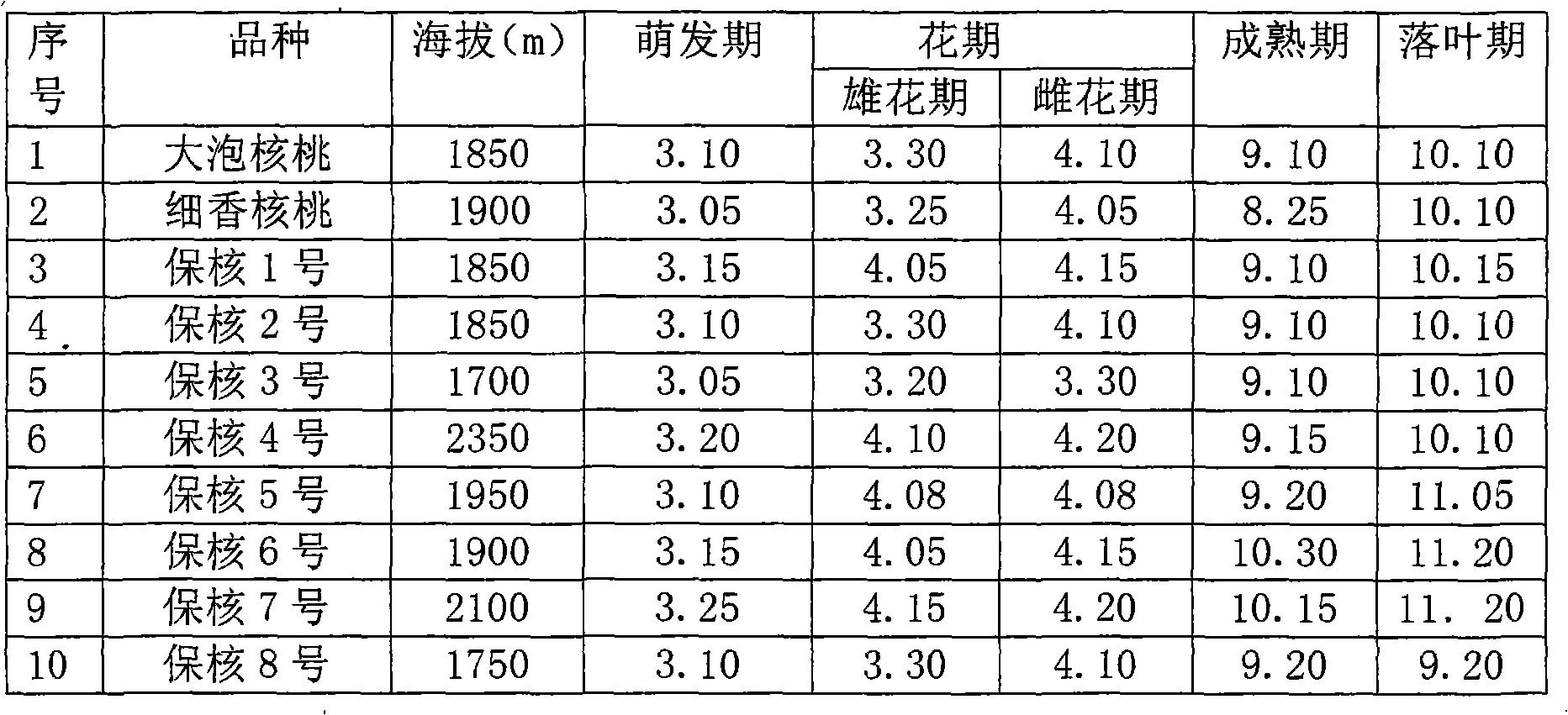

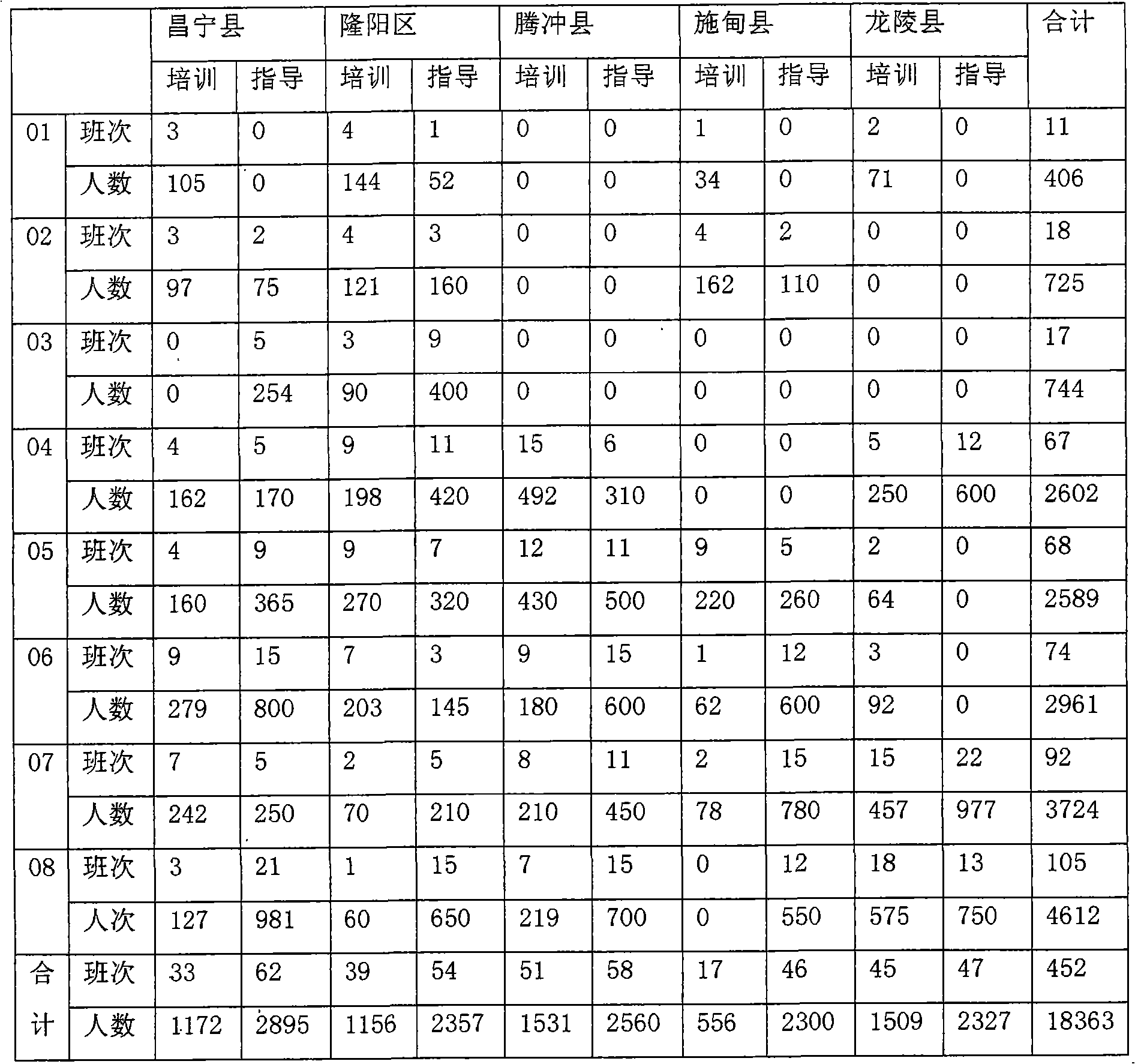

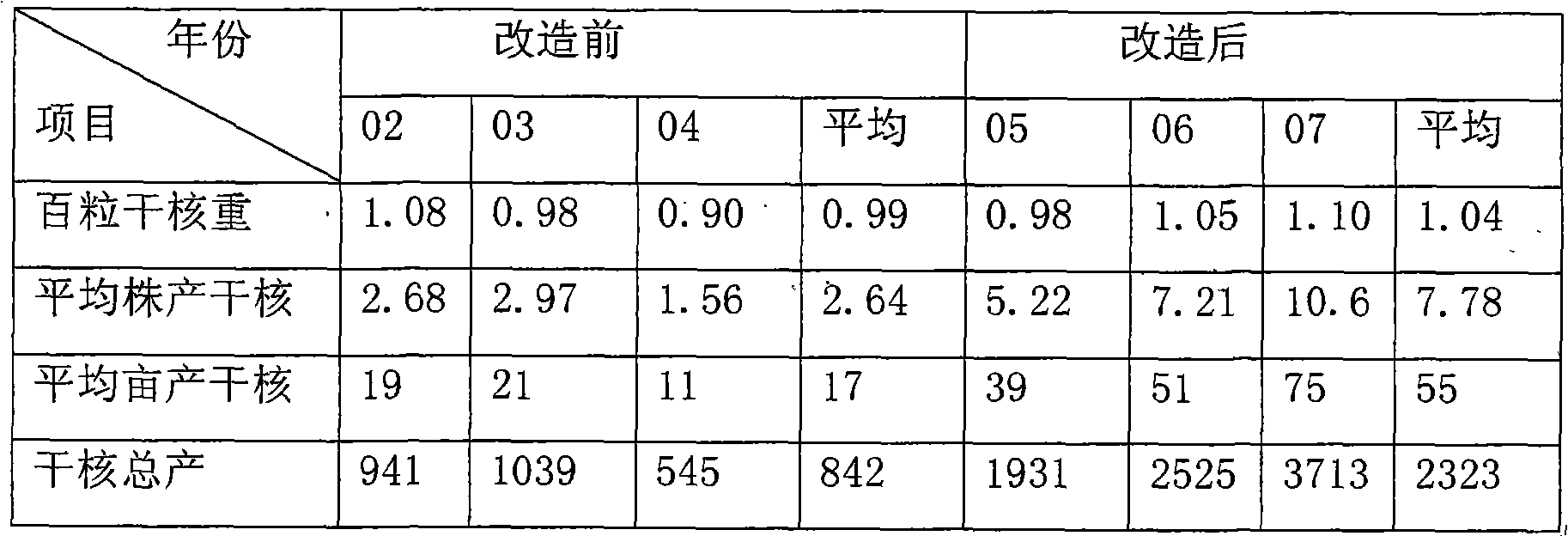

Seed selection method for improved variety of walnut and high-yield cultivation method thereof

The invention discloses a seed selection method for the improved variety of a walnut and a high-yield cultivation method thereof, comprising the steps of: selecting 8 walnut local improved varieties which are suitable for cultivating at different areas, namely, protecting the first-the eighth walnuts; adopting ten measures, namely, selecting a good area (siting control technology), building a large pond (preliminary soil preparation technology), fertilizing a picul of stable manure (base fertilizer fertilizing technology and soil improving technology), planting a improved variety strong seedlings (improved variety strong seedlings technology), irrigating a picul of root-fixing water (root-fixing water technology), covering a mulching film (water-retaining technology), a set of scientific fertilizer management method (fertilizing technology), a set of cultivation fostering management technology (soil management technology), a set of normative shaping trimming technology (tree body management technology), and a set of systemic pest preventive measure (soil management technology); and promoting the yield of young tress, updating old trees and improving low-yield tress.

Owner:保山市林业和草原技术推广站 +1

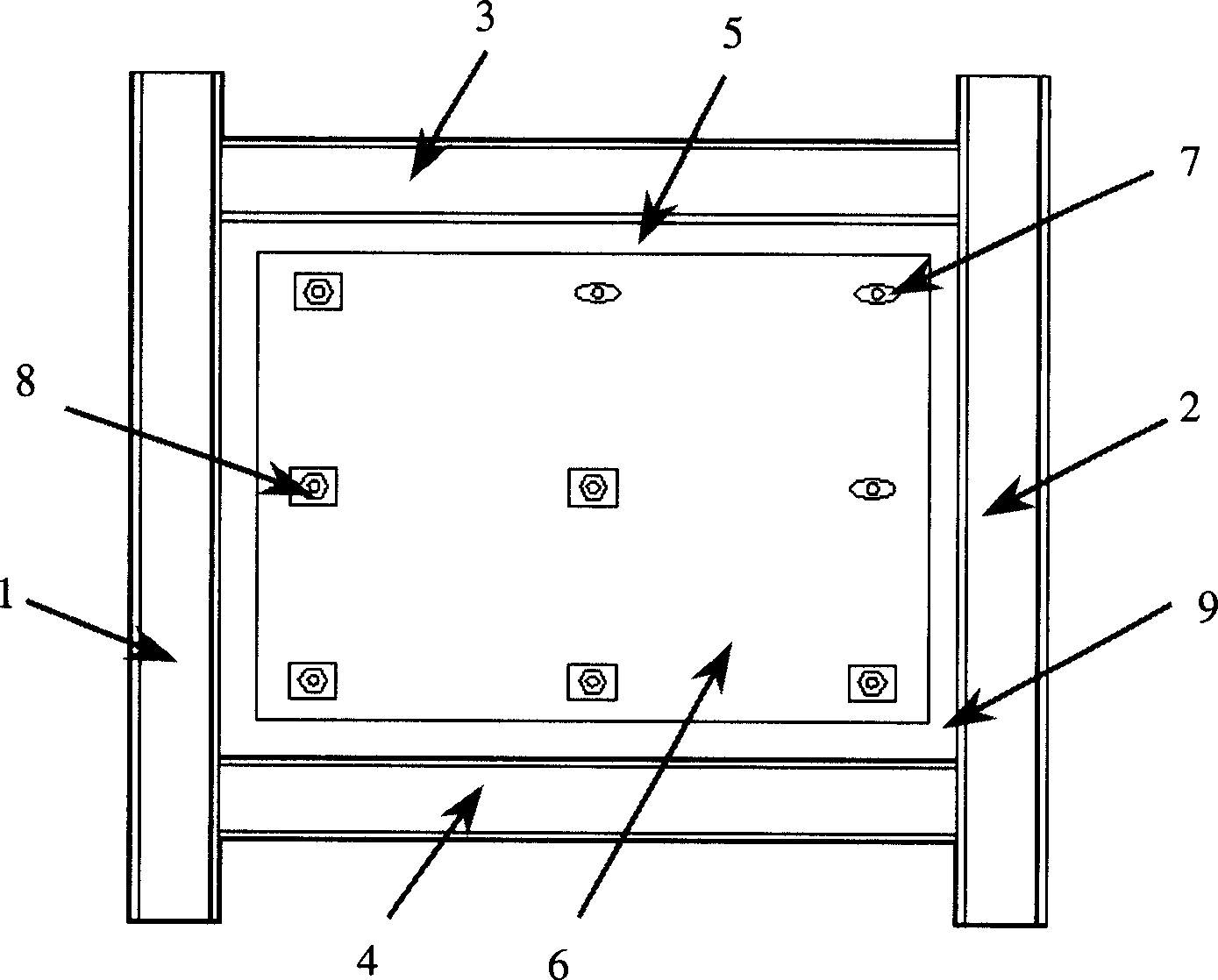

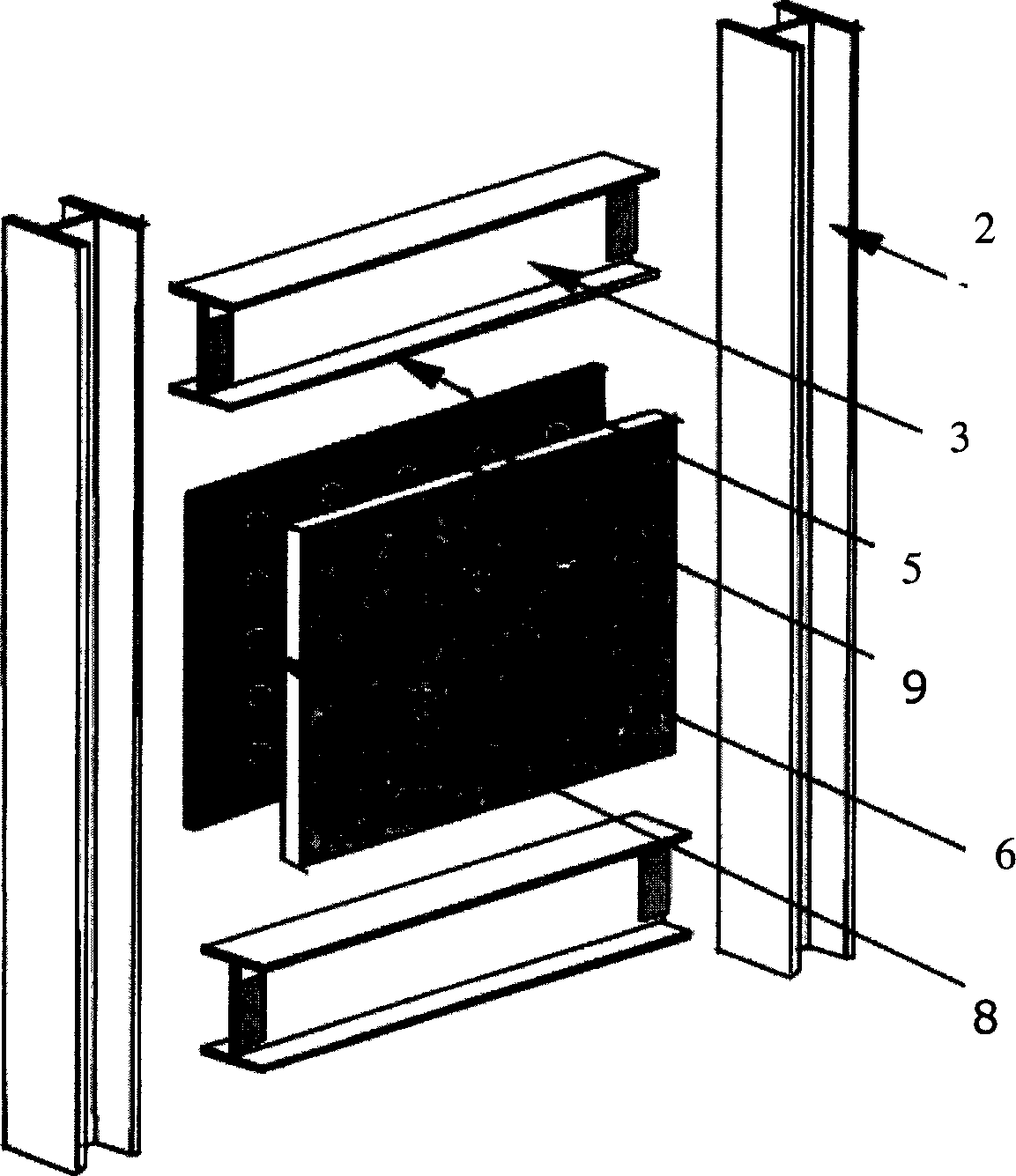

Buckling and energy consumption preventing steel plate shear wall

The invention involves a kind of data organization project area of technology to guard against the flexure to consume energy the steel plate shearing force wall. Its characteristic causes to state the shearing force wall to inlay the steel plate and two sides periphery concrete lap by in is composed; In states inlays the steel plate to use the low yield point high ductility steel products or the high strength high ductility steel products; States the periphery concrete lap to use the common concrete slab; States the edge component is composed by the marginal beam and the edge column; In states inlays the steel plate with to state between the concrete lap through to penetrate three blocks the bolts or the pre-stressed bold fastening, in states on the concrete lap to open the ellipse hole in order to the bolt passed through also has the enough slipping space; In states the concrete lap to open the hole site with to bury the trough section to give strengthens. And is strengthening the channel steel the corresponding position to open oval hole. The invention provides guards against the flexure steel plate shearing force wall is the high-rise construction structure or other structures a kind of new anti- lateral force components, it has the earthquake resistance performance well, the ductility is high, consumes energy stagnates winds full and so on the characteristic, is a kind of superior earthquake resistance consumes energy the component.

Owner:TSINGHUA UNIV

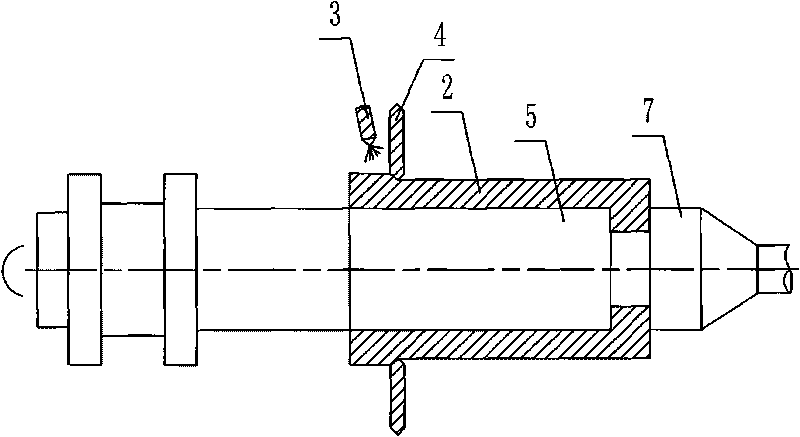

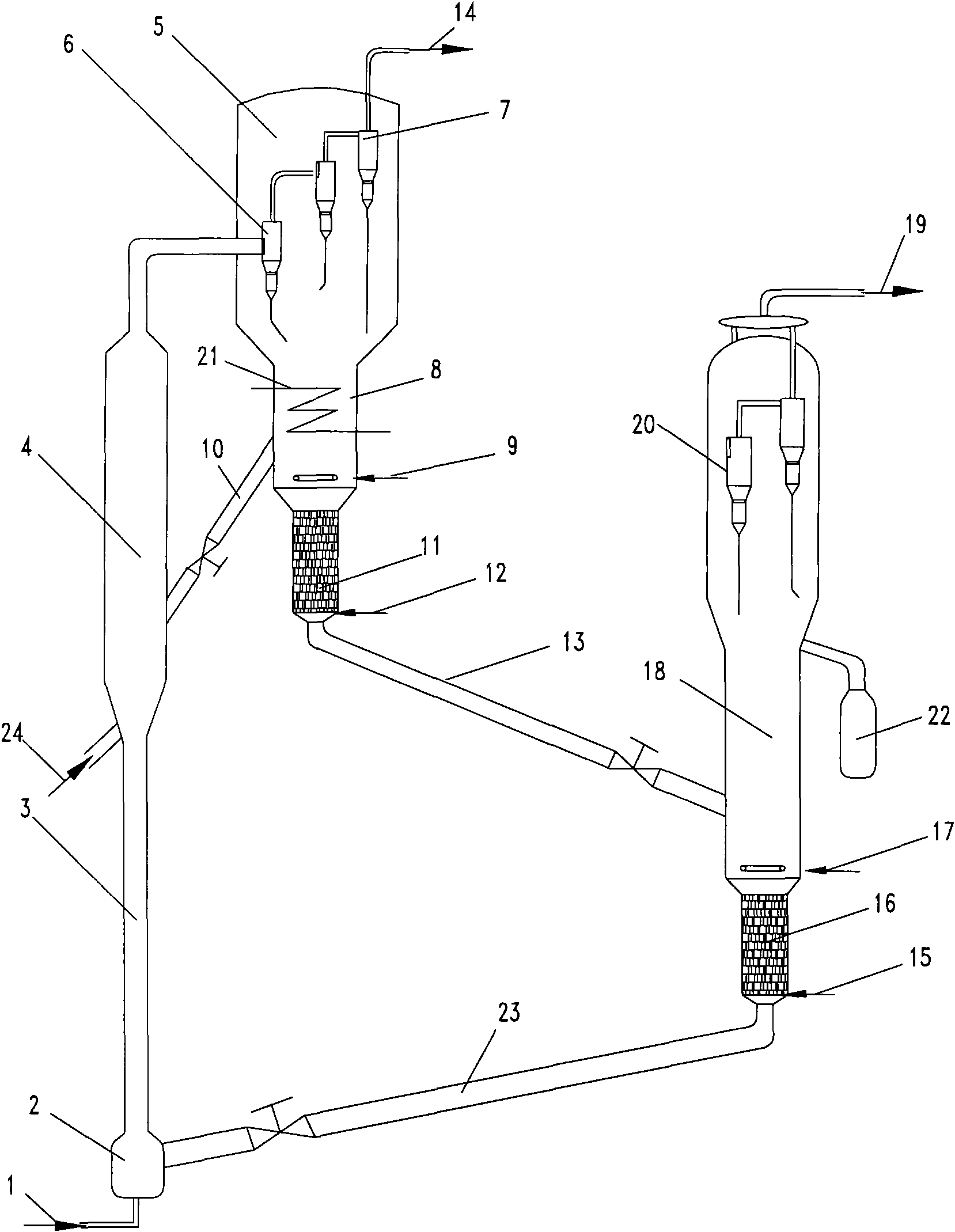

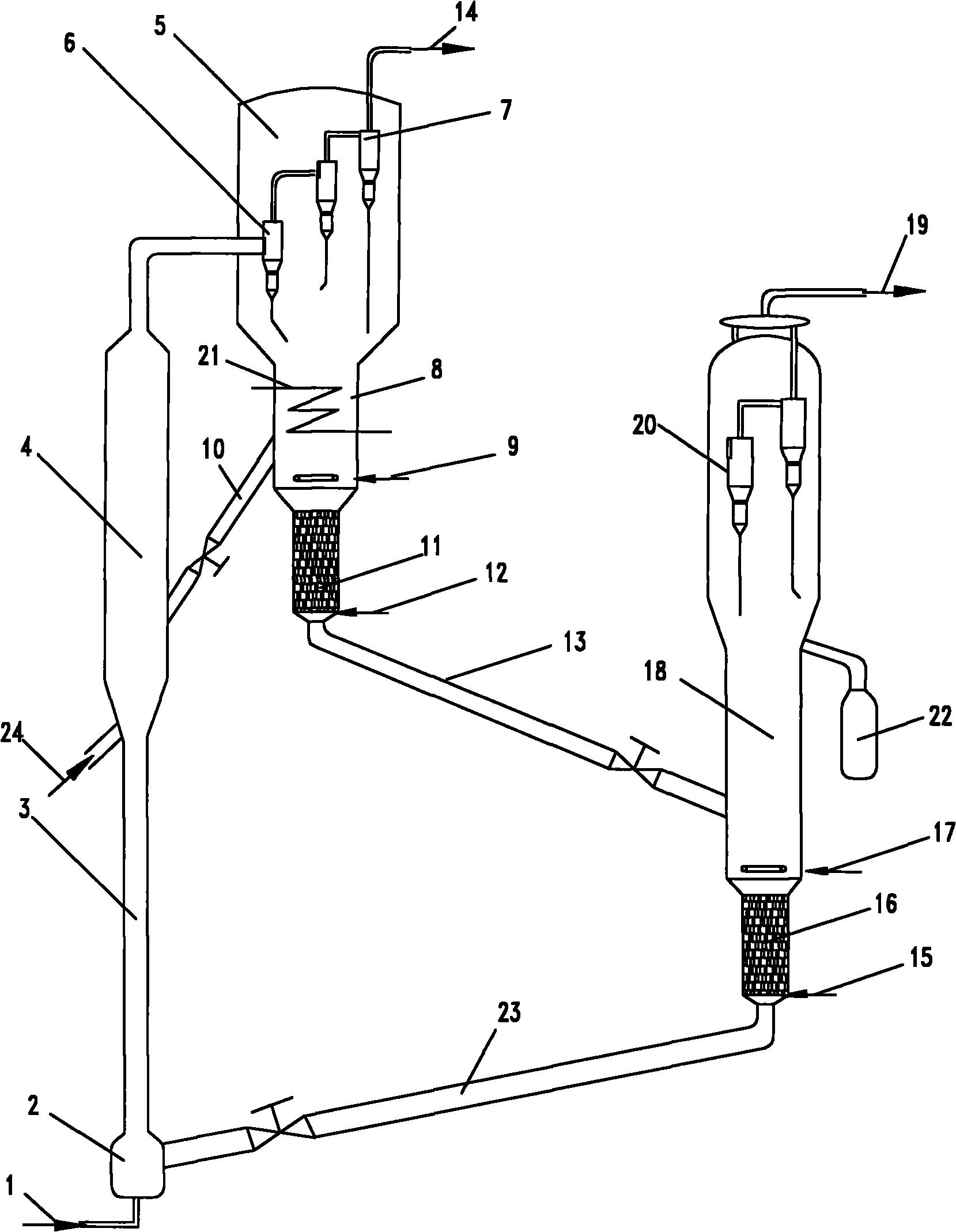

Reaction device for co-producing low-carbon olefin and p-xylene

The invention relates to a reaction device for co-producing low-carbon olefin and p-xylene, which is used for mainly solving the problem of lower yield of low-carbon olefin and p-xylene in the prior art. The problem is well solved by adopting the technical scheme as follows: the reaction device disclosed by the invention mainly comprises a first reaction zone 3, a second reaction zone 4, a third reaction zone 8, a gas-solid separation zone 5 and a regeneration zone 18 of a regenerator; the top of the first reaction zone 3 is connected with the second reaction zone 4; the outlet of the second reaction zone 4 is connected with the gas-solid separation zone 5; a product outlet 14 is arranged on the top of the gas-solid separation zone 5; the bottom of the gas-solid separation zone 5 is connected with the third reaction zone 8; the bottom of the third reaction zone 8 is connected with a stripping zone 11; the bottom of the stripping zone 11 is connected with the regeneration zone 18 of the regenerator through a spent catalyst inclined pipe 13; the bottom of the regeneration zone 18 of the regenerator is connected with a degassing zone 16; and the bottom of the degassing zone 16 is connected with the first reaction zone 3 through a regeneration catalyst inclined pipe 23. The reaction device for co-producing the low-carbon olefin and the p-xylene disclosed by the invention can be used in industrial production of the low-carbon olefin and the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Forest cultivation method of morchella crassipes

The invention relates to the technical field of organisms, and particularly relates to a forest cultivation method of morchella crassipes. The forest cultivation method is a cultivation method for producing the morchella crassipes by a free forest land. The cultivation method comprises the following steps of: selecting a forest land suitable for growth of the morchella crassipes as the forest land to be cultivated; preparing the forest land to be cultivated before sowing; spreading solid cultivated species of the morchella crassipes on the prepared forest land to be cultivated; and carrying out forest land management until harvesting the morchella crassipes after sowing. A method for cultivating the morchella crassipes under the forest, expanding the cultivation range of the morchella crassipes, and improving the yield and the quality of the morchella crassipes is provided by the invention; the problem of low yield of the natural morchella crassipes is solved fundamentally; a foundation is provided for large-scale production of the morchella crassipes; and the forest cultivation method has significant economic and ecological benefits and wide application prospect.

Owner:CHONGQING ACADEMY OF FORESTRY SCI

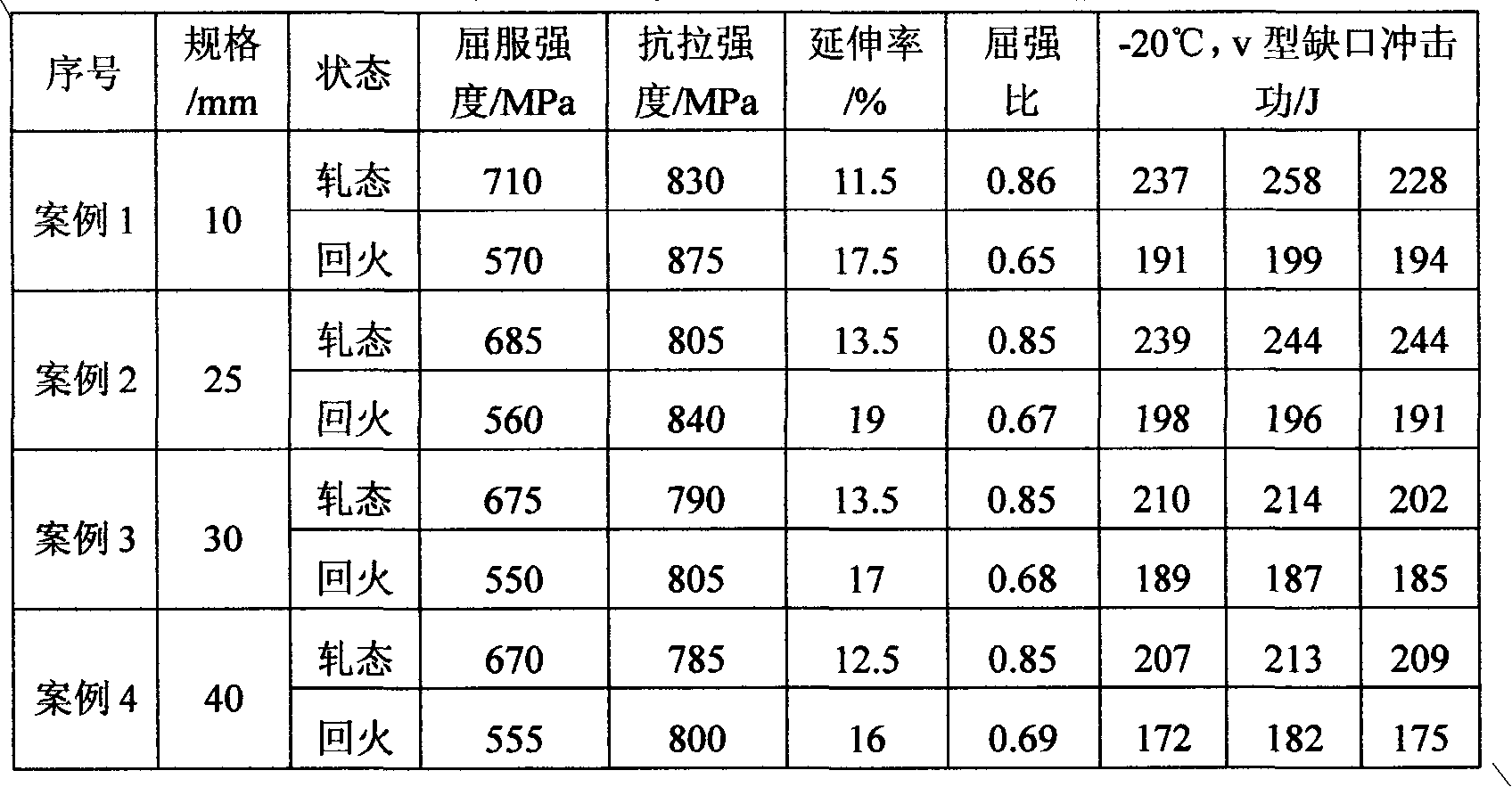

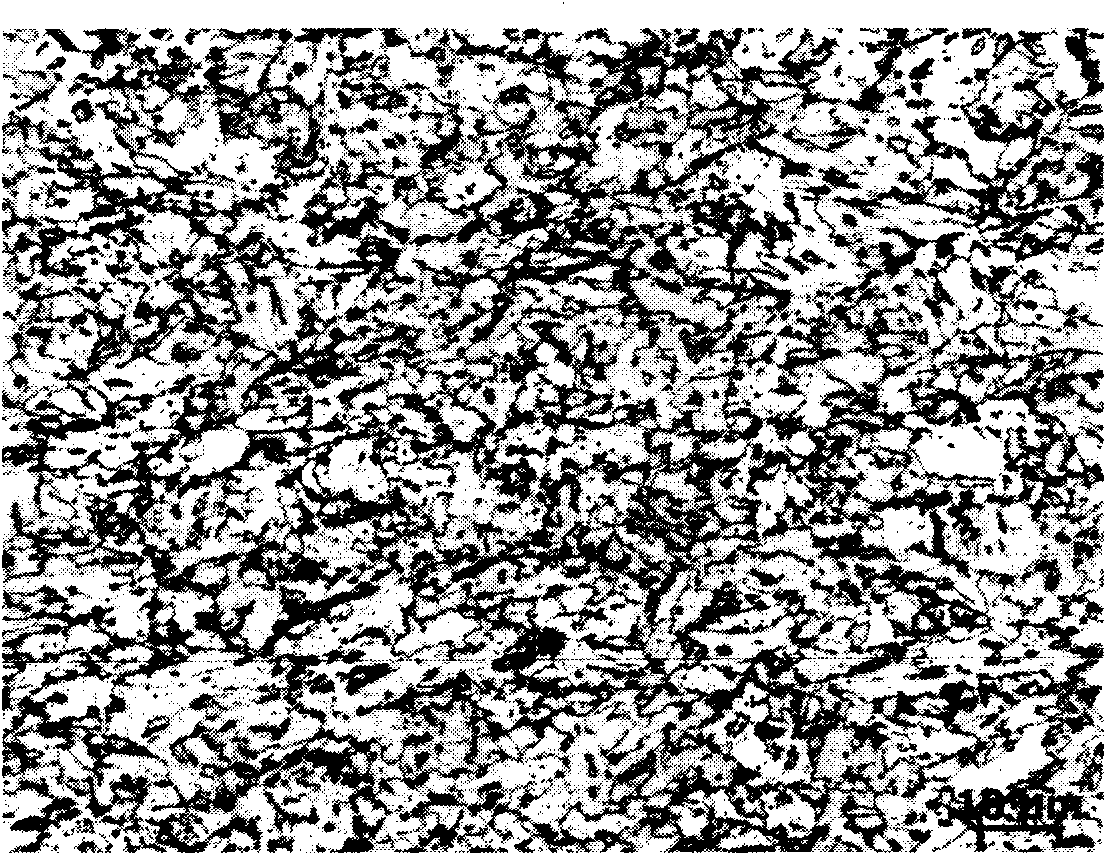

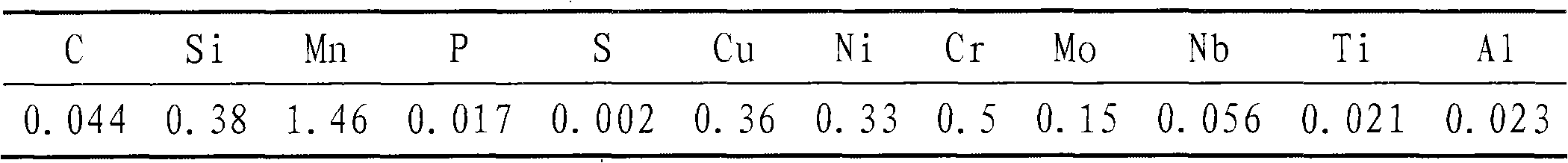

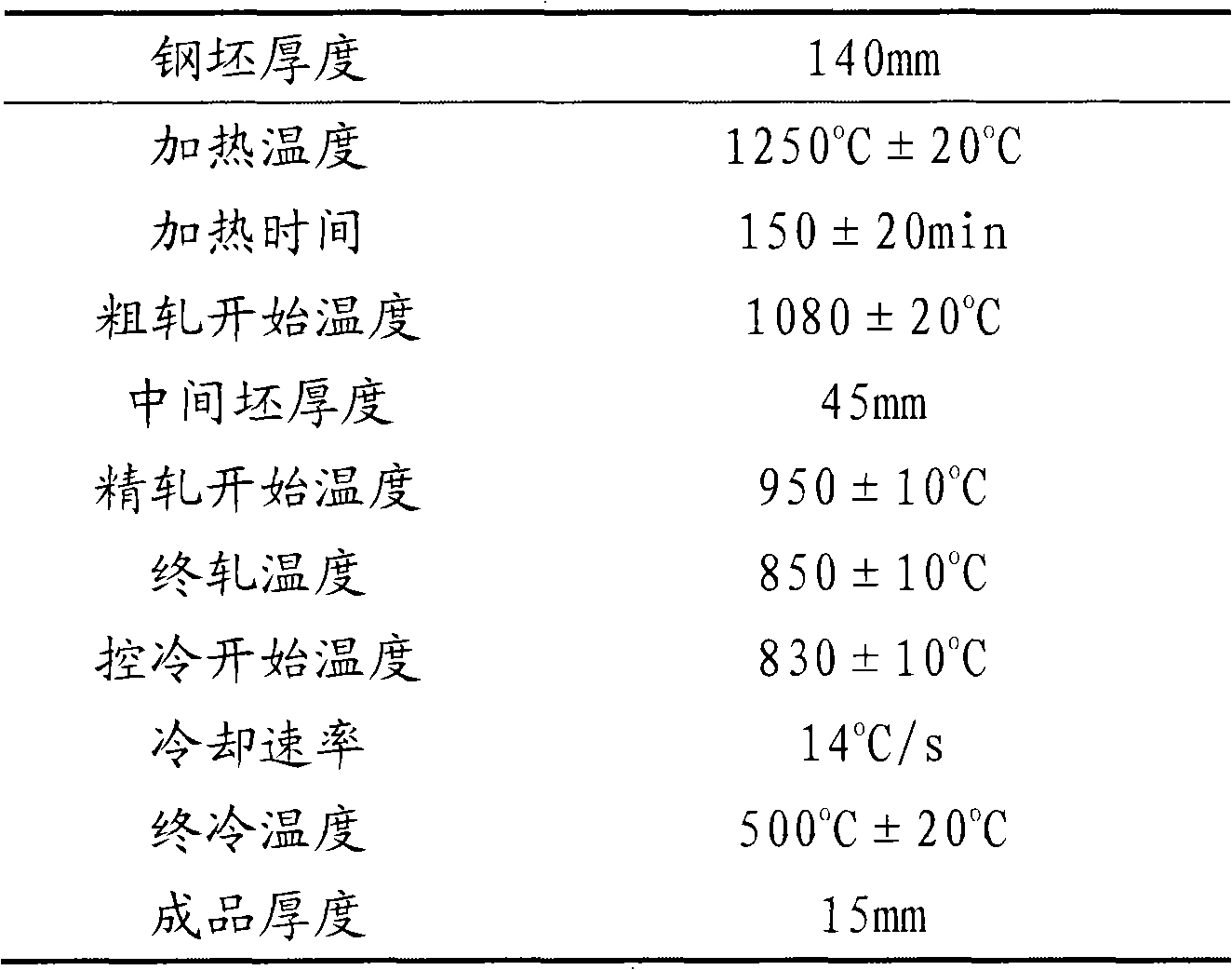

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

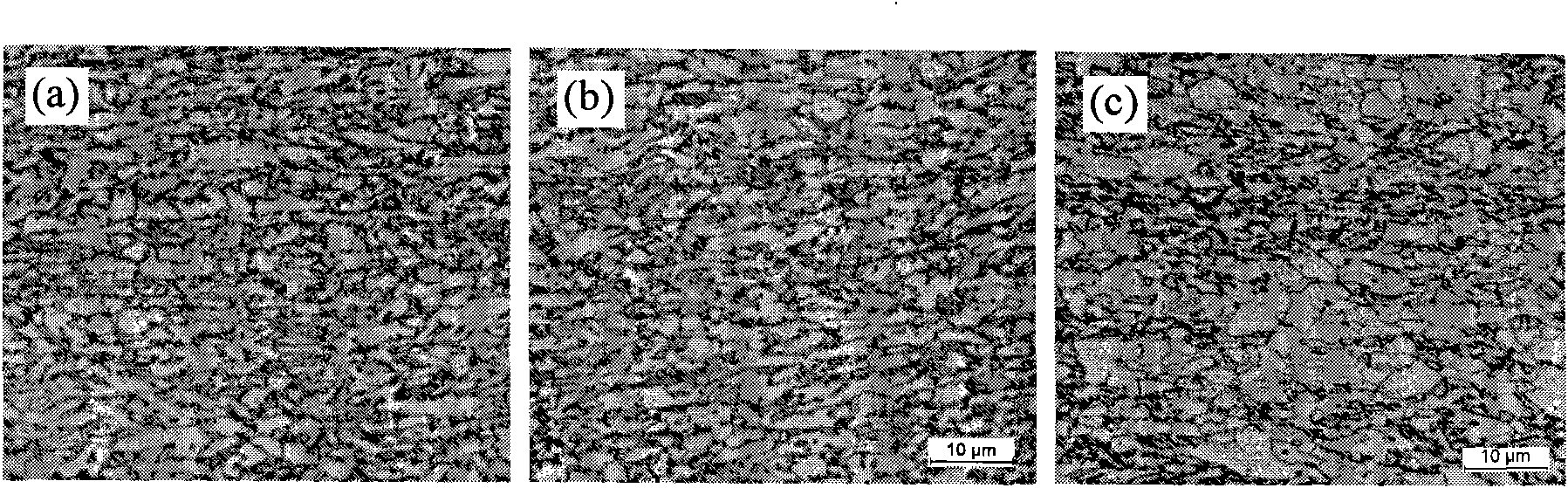

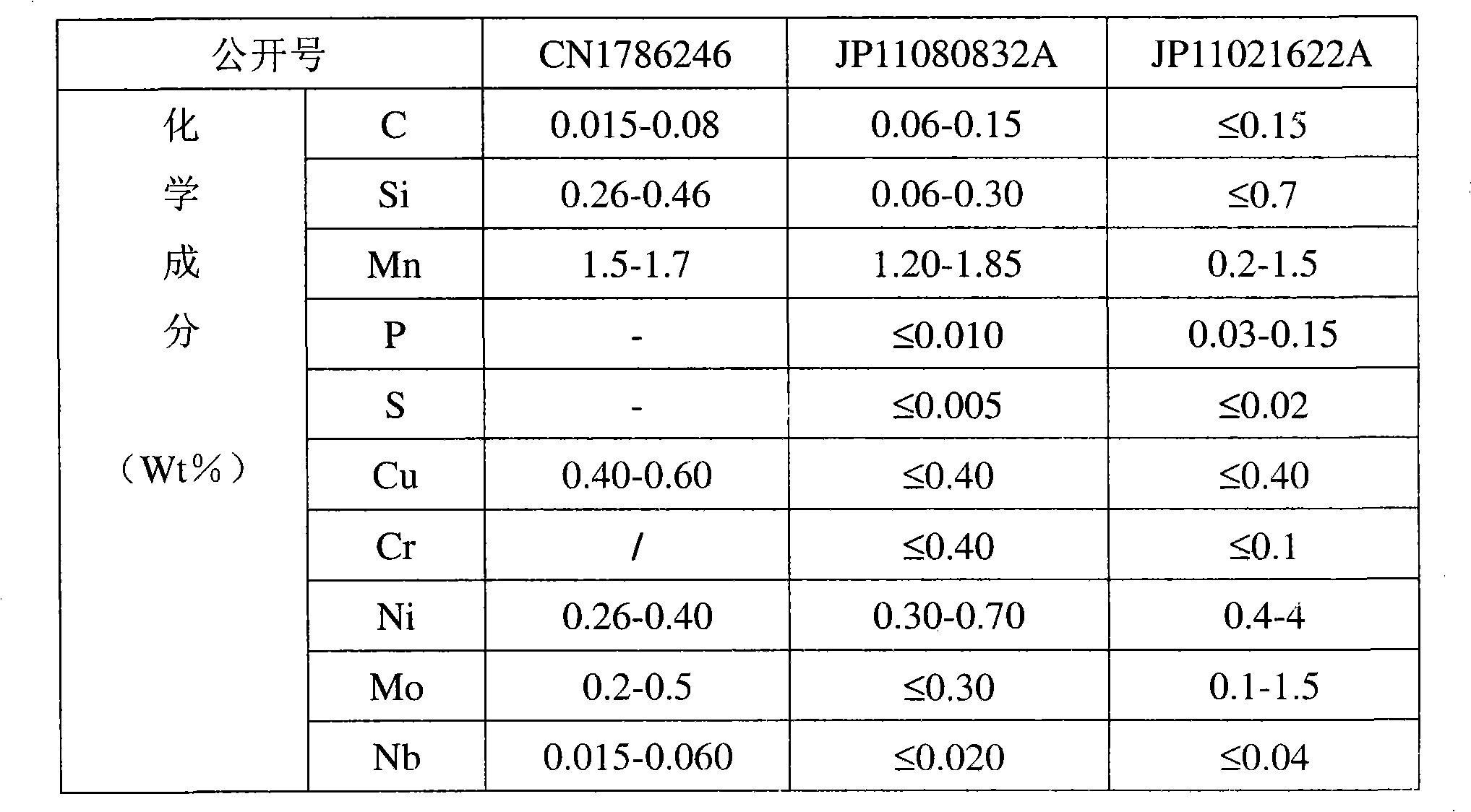

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

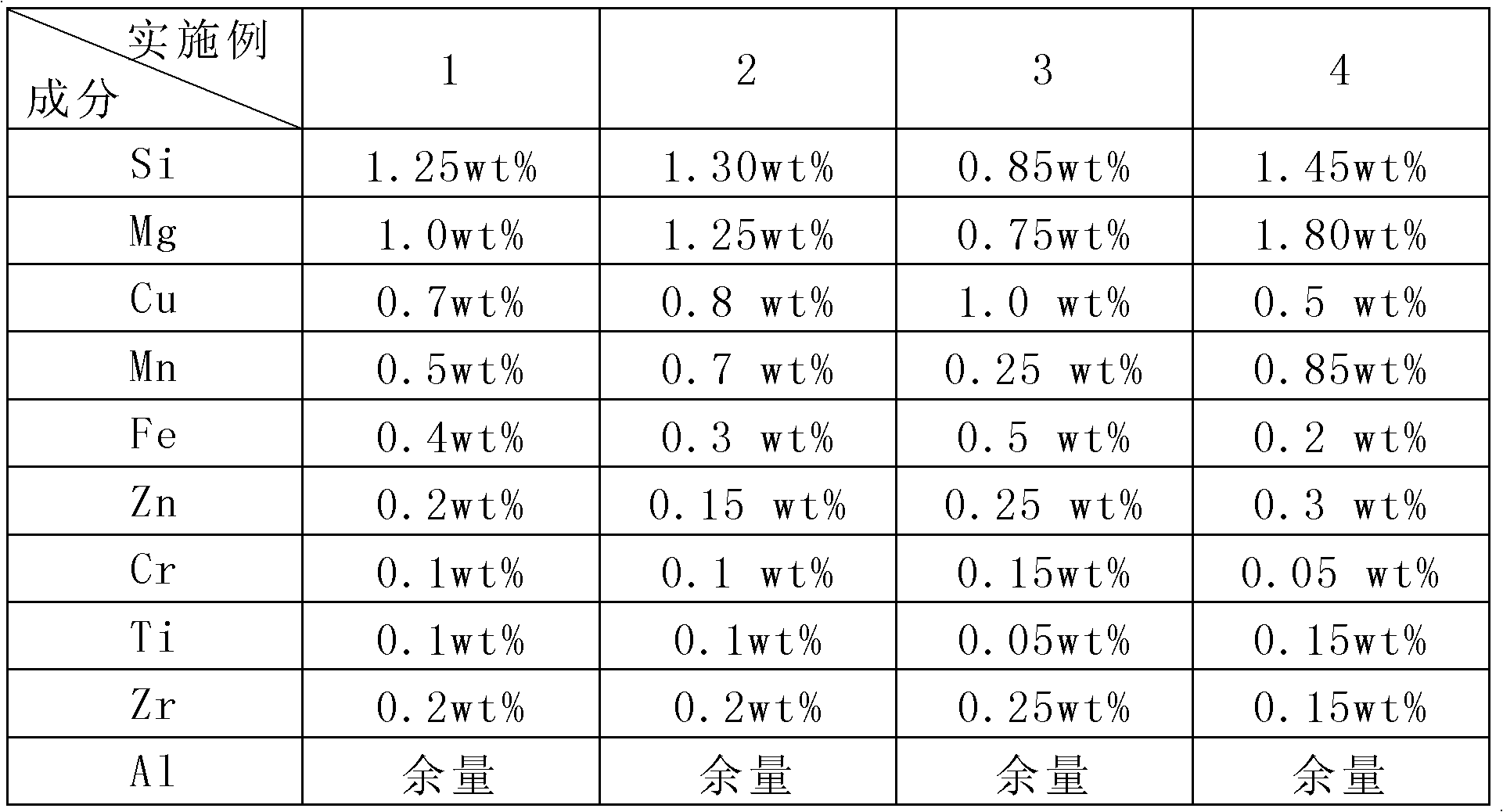

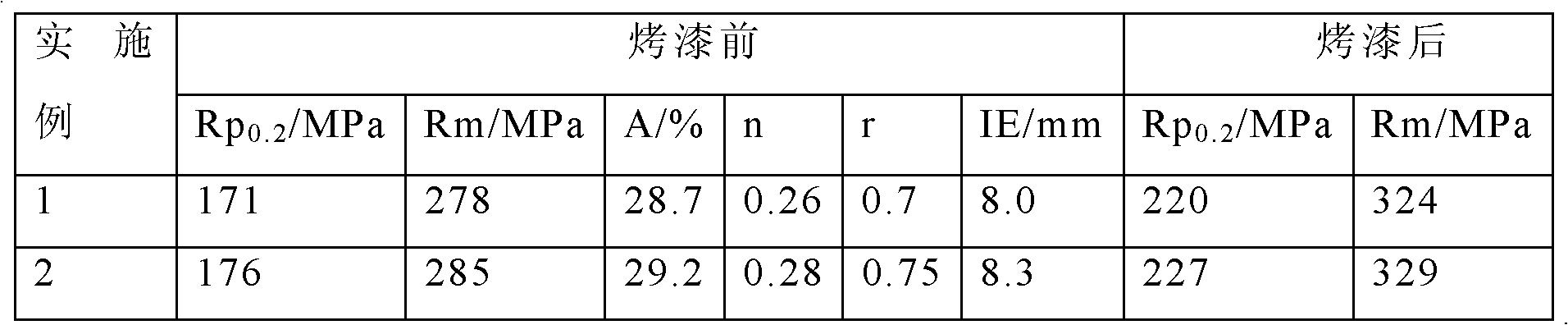

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

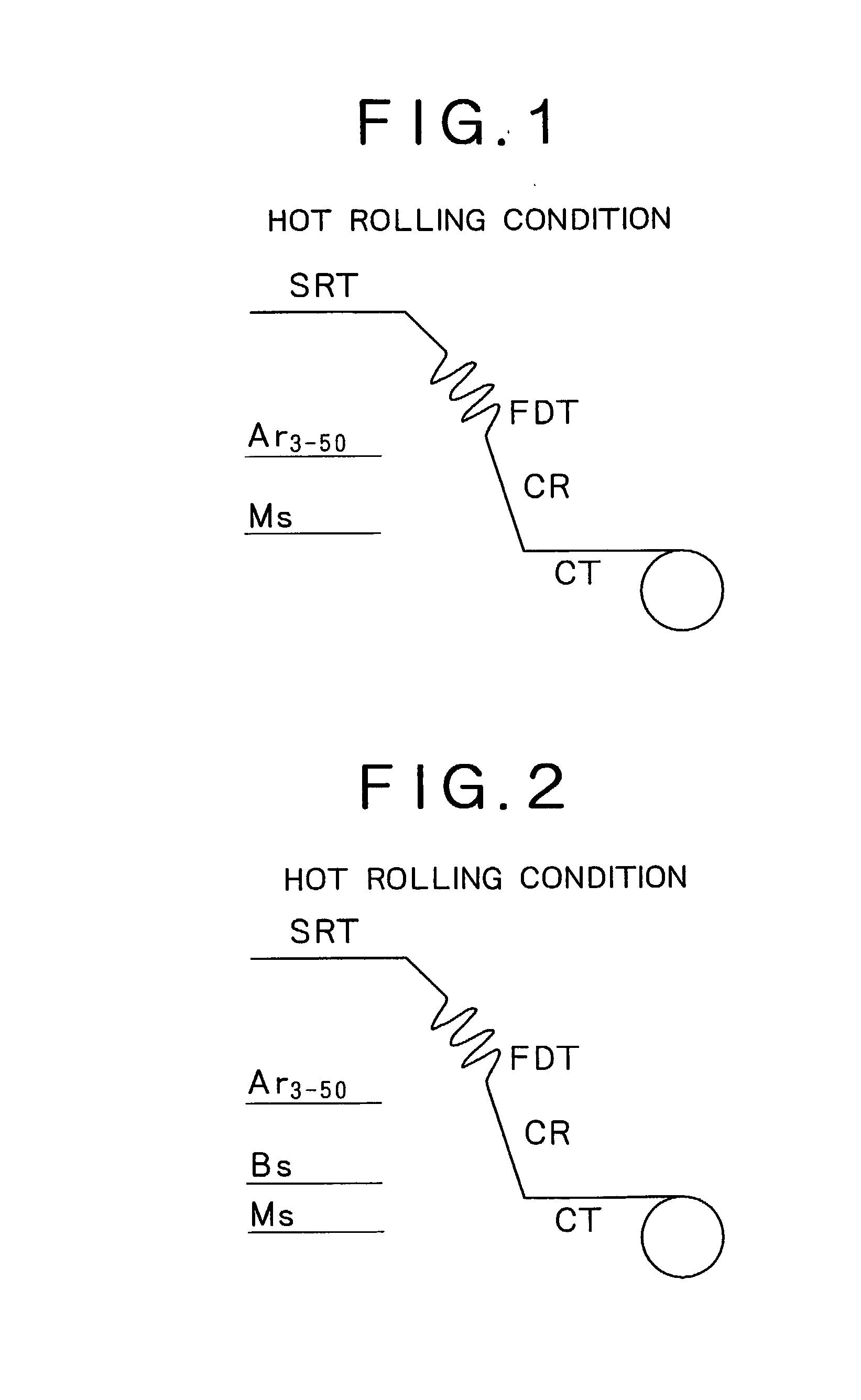

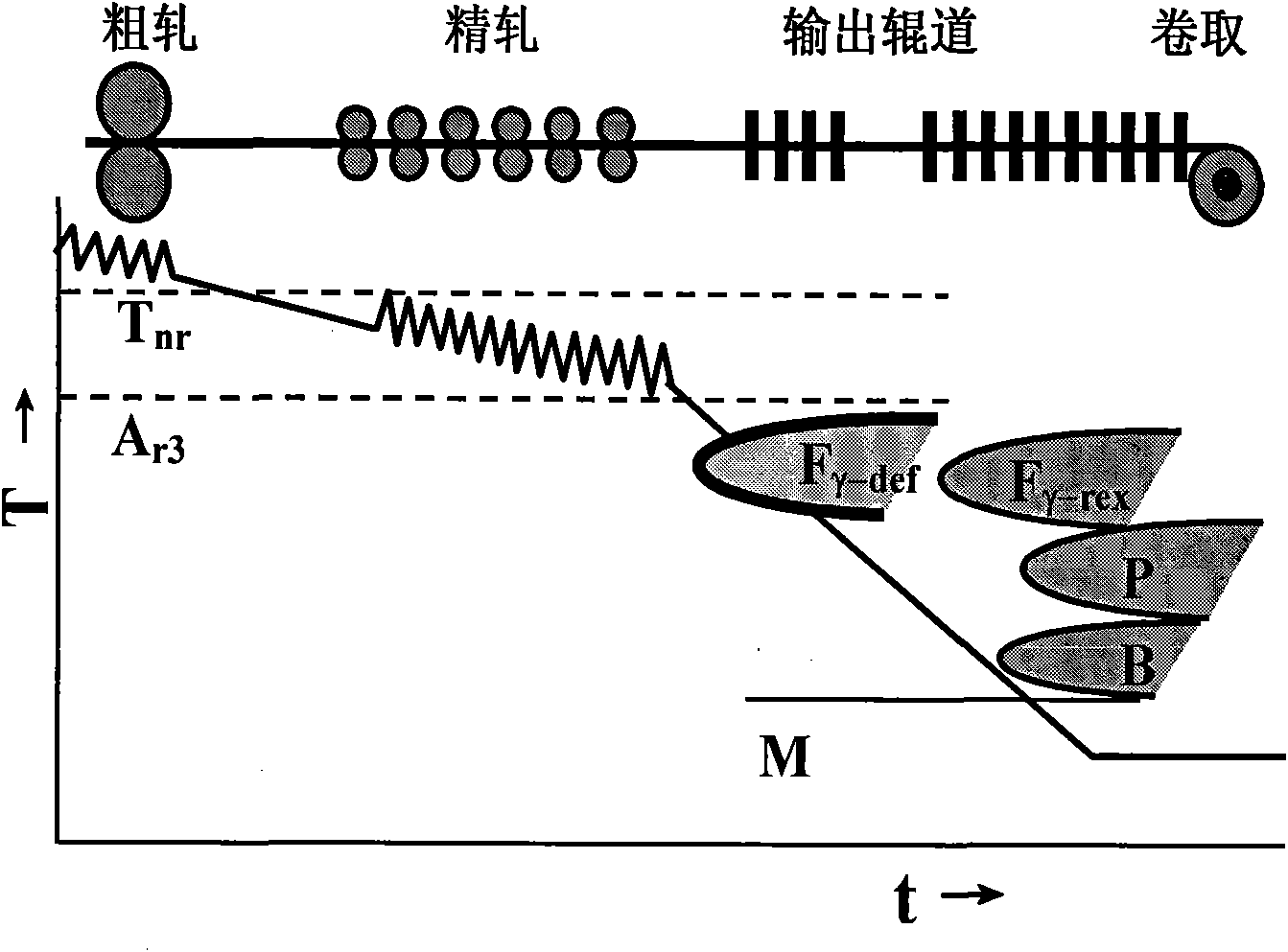

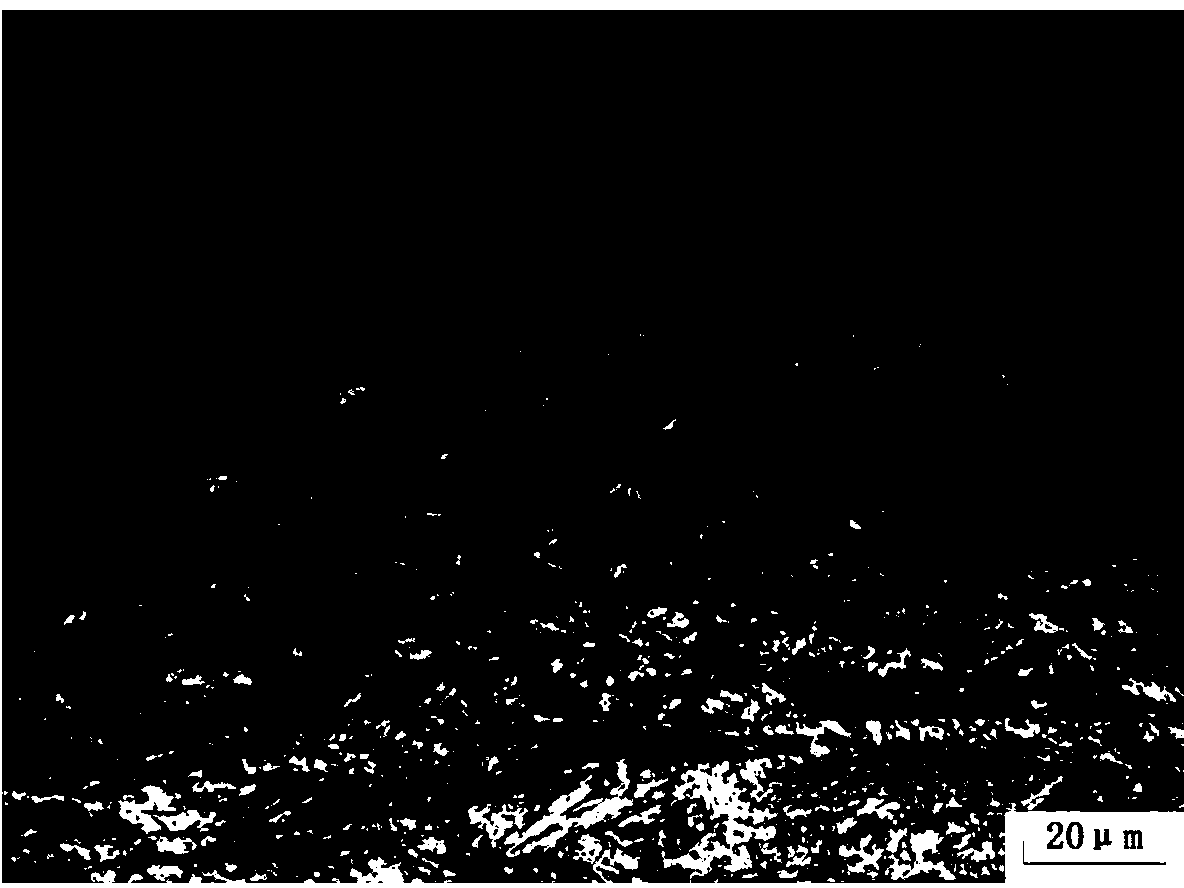

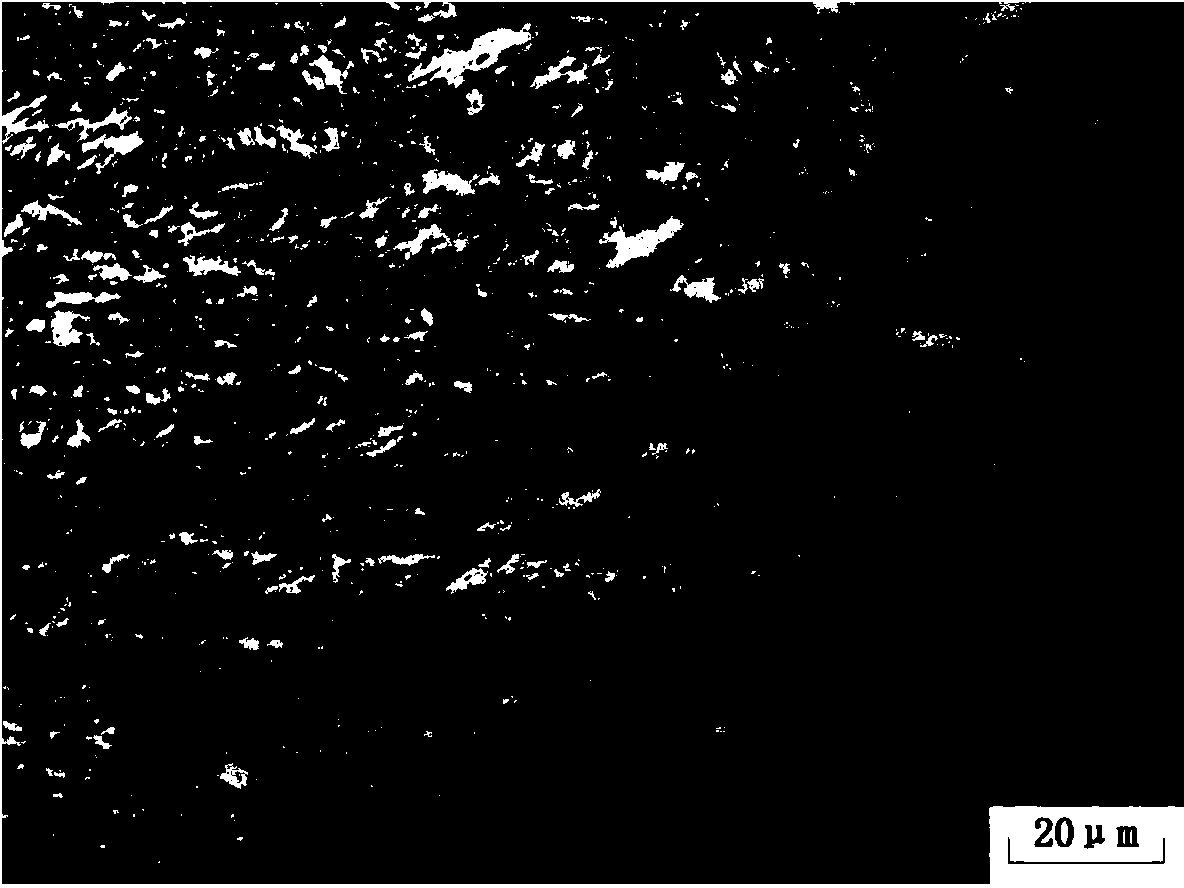

Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

The invention relates to ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and a manufacturing method of a plate thereof, belonging to the technical field of steel rolling, and the dual-phase steel comprises the following chemical components by weight percentage: 0.06-0.16% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, 0.02-0.06% of Al, 0.01-0.08% of Nb, 0-0.03% of Ti, not more than 0.1 of P, not more than 0.05 of S and the balance of Fe. The manufacturing method of the dual-phase steel comprises the following steps: 1) heating, heating a plate blank with the thickness of not less than 60mm to 1100-1250 DEG C, and keeping the temperature for 1-4h; 2) rolling and adopting the two-stage controlled rolling, wherein the reduction rate in a recrystallization zone is larger than 60%, the reduction rate in a non-recrystallization zone is larger than 70%, the initial rolling temperature of the recrystallization zone is 1100-1150 DEG C, the initial rolling temperature of the non-recrystallization zone is 880-940 DEG C, and the final rolling temperature is 770-860 DEG C; and 3) cooling, and adopting the continuous cooling after final rolling, wherein the cooling rate is 30-40 DEG C / s, the coiling temperature is lower than 350 DEG C, and the thickness of a finished product is 2-10mm. The manufacturing method can obtain the high-performance steel plate with high strength, low yield-strength ratio and good extension property, and the steel plate can be suitable for forming processing of high-strength automobiles, other industrial mechanical parts and the like.

Owner:NORTHEASTERN UNIV

Ultra-strength, high toughness and low yield ratio steel and steel plate and manufacturing method thereof

The invention provides ultra-strength, high toughness and low yield ratio steel, which comprises the following chemical components: 0.05 to 0.12 weight percent of C, 0.15 to 0.50 weight percent of Si,1.0 to 1.5 weight percent of Mn, less than or equal to 0.025 weight percent of P, less than or equal to 0.015 weight percent of S, 0.20 to 0.50 weight percent of Cu, less than or equal to 0.25 weightpercent of Ni, 0.015 to 0.05 weight percent of Nb, 0.015 to 0.045 weight percent of V, 0.010 to 0.050 weight percent of Ti, less than or equal to 0.55 weight percent of Cr, less than or equal to 0.30weight percent of Mo, 0.015 to 0.05 weight percent of Al and the balance of Fe and inevitable impurities. The invention also provides a steel plate manufactured by using the ultra-strength, high toughness and low yield ratio steel and a manufacturing method thereof. The steel plate has excellent mechanical property, has a yield strength of more than or equal to 460 Pa and a yield ratio of less than or equal to 0.80. Moreover, the steel plate has good low-temperature impact toughness and weldability, and is suitable for high steel-structure buildings and other large-scale steel structure fields with low yield ratio requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

Biomass pretreatment

ActiveUS8030030B2Improvement in yield and rateImprove efficiencyHydrolasesBiofuelsPretreatment methodReaction rate

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

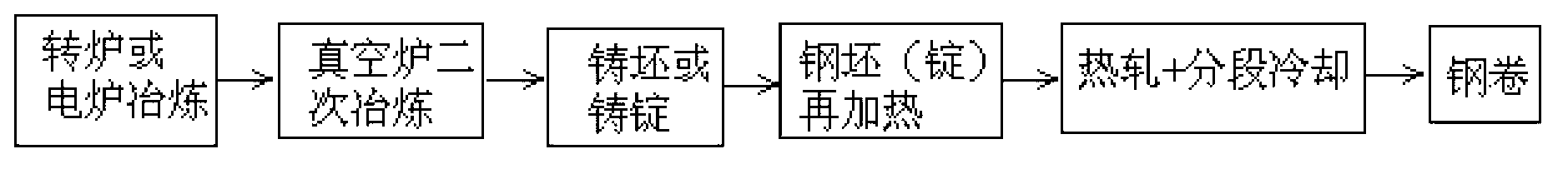

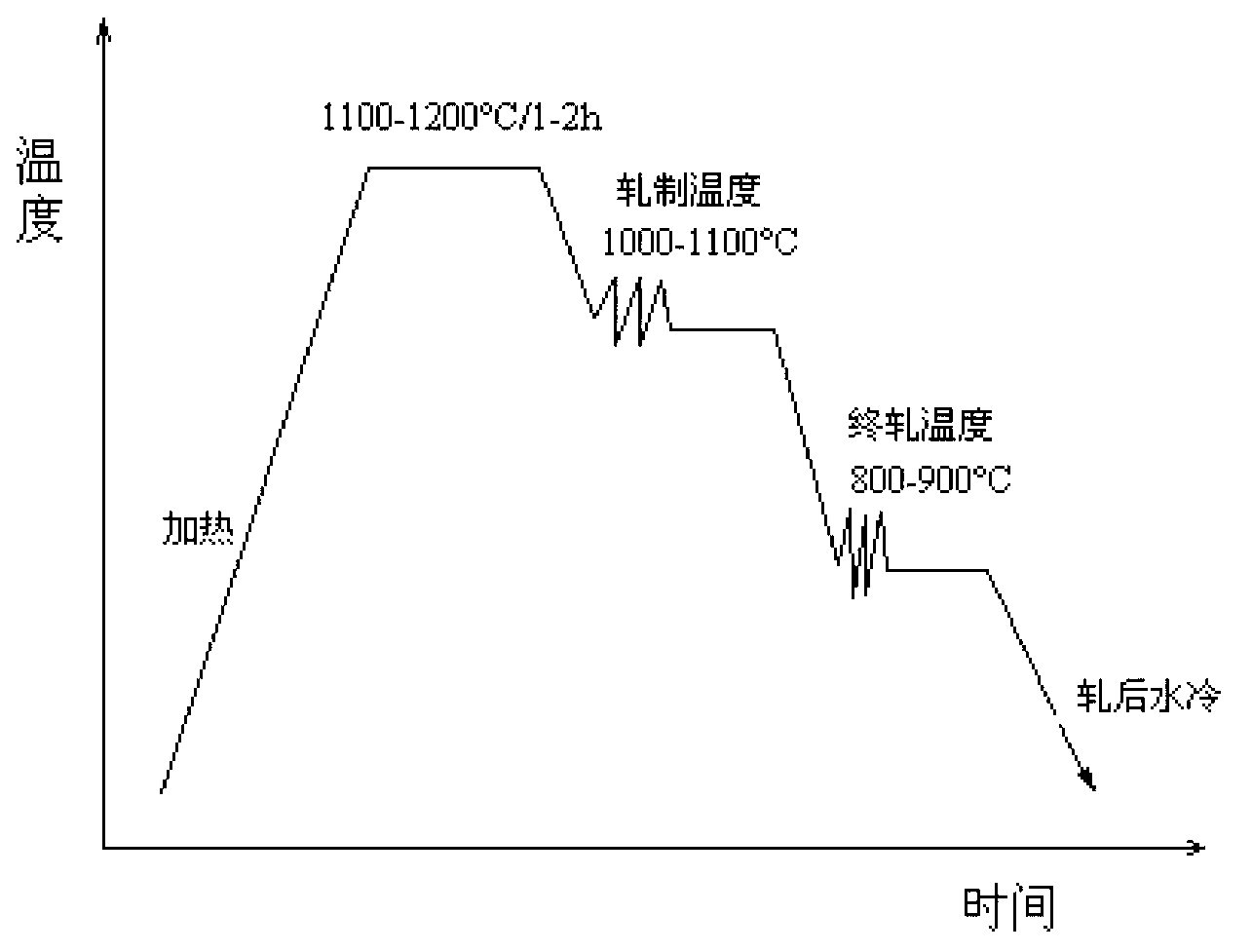

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

The invention relates to low-yield-ratio high-strength hot-rolled Q&P steel and a manufacturing method thereof. The steel comprises the chemical components of 0.20-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.02-0.08% of Al, no more than 0.006% of N, 0.005-0.015% of Ti, and balance of Fe and unavoidable impurities. According to the invention, through low-cost component design, on a basis of common C-Mn steel, Si content is increased such that cementite precipitation is inhibited, and austenite grains are micronized through micro-Ti treatment. Also, with a combination of hot continuous rolling process and sectioned cooling process, a structure comprising proeutectoid ferrite, martensite, and residual austenite is obtained. The yield strength is lower than 700MPa, a tensile strength is higher than 1000MPa, a yield ratio is 0.50-0.60, and alloy cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

690MPa-yield-strength low-yield-tensile-ratio antiseismic steel and manufacturing method thereof

InactiveCN103710622AMeet the mechanical performance requirementsChemical compositionMechanical property

The invention relates to a 690MPa-yield-strength low-yield-tensile-ratio antiseismic steel and a manufacturing method thereof, belonging to the technical field of architectural structural steel. The antiseismic steel comprises the following chemical components: 0.05-0.13wt.% of C, 0.00-0.50wt.% of Si, 1.50-2.50wt.% of Mn, less than 0.012wt.% of P, less than 0.006wt.% of S, 0.15-0.50wt.% of Mo, 0.02-0.12wt.% of Nb, 0.00-0.15wt% of V, 0.01-0.025wt.% of Ti, 0.0010-0.0030wt.% of B, 0.01-0.06wt.% of Al and the balance of Fe and inevitable impurities. On such basis, one or more of the following alloy elements are added: 0.00-0.80wt% of Cu, 0.00-0.50wt% of Cr and 0.00-1.00wt% of Ni. The total addition amount of the alloy elements in the steel is not greater than 5%. A heavy and medium plate mill is utilized to perform controlled rolling and controlled cooling to obtain the fine-grain bainite-martensite structure; and two-phase region secondary isothermal heat treatment is combined to obtain a certain amount of metastable austenite / microalloy precipitate enhanced substrate; the antiseismic steel satisfies the requirements for mechanical properties of 690MPa-yield-strength architectural antiseismic design code, can be used in an antiseismic structure, and can also be used in the field of engineering machinery.

Owner:CENT IRON & STEEL RES INST

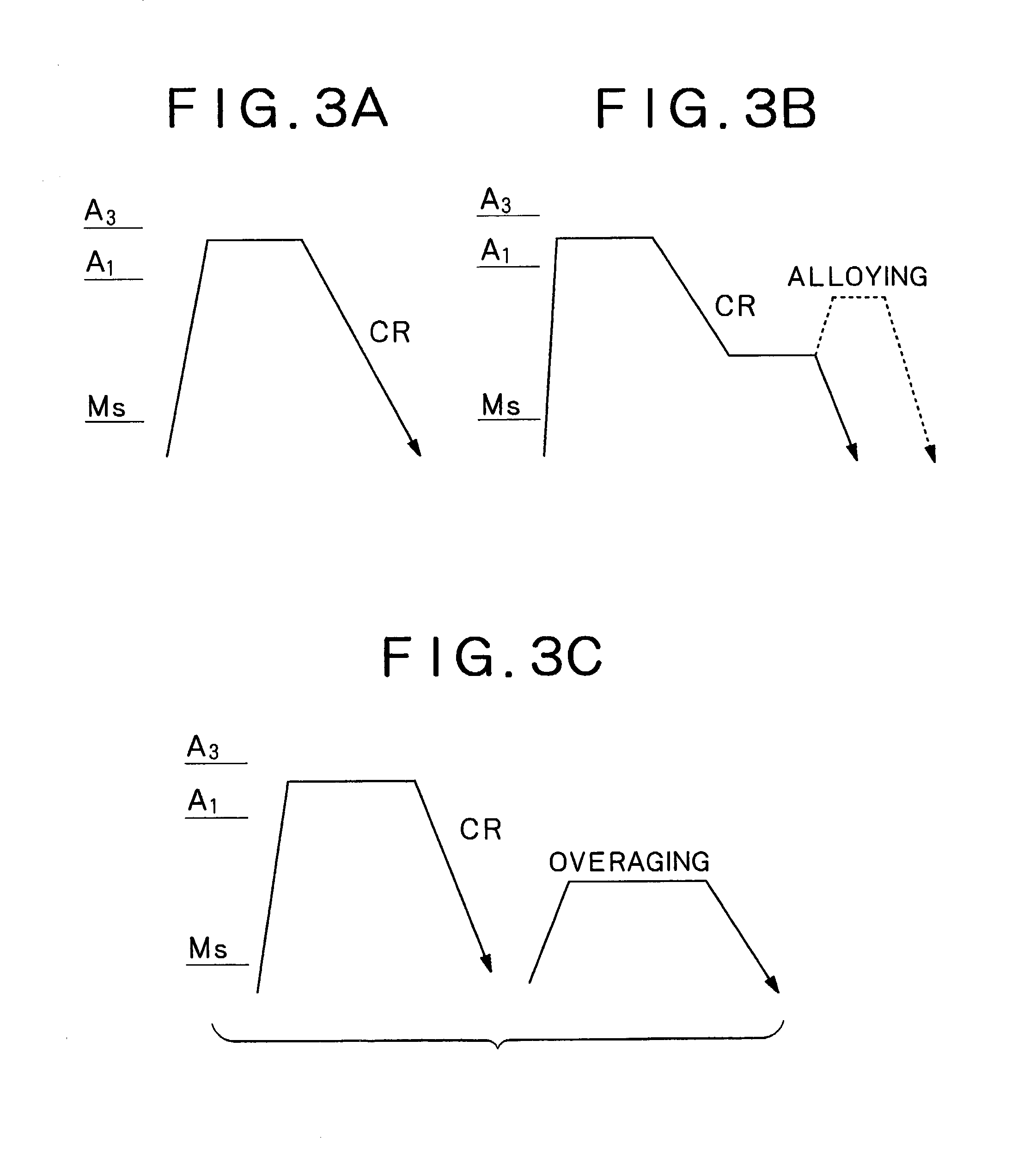

High strength and low yield ratio cold rolled steel sheet and method of manufacturing the same

ActiveUS20050161134A1High strengthLow yield ratioSolid state diffusion coatingFurnace typesHigh intensityUltimate tensile strength

To provide a high strength and low yield ratio cold rolled steel sheet having high elongation property and high flange drawing property, or a plated steel sheet made by plating the same. The high strength and low yield ratio cold rolled steel sheet or the plated steel sheet made by plating the same has such a constitution as 0.10 to 0.25% of C, 1.0 to 2.0% of Si and 1.5 to 3.0% of Mn, are contained in terms of weight percentage, while other elements are controlled such as Al within 0.2%, P within 0.15% and S within 0.02%, with residual austenite occupying at least 5%, bainitic ferrite occupying at least 60% (preferably 80% or more), and polygonal ferrite within 20% (containing 0%), so that a tensile strength is 980 MPa or higher, while an elongation (El in %), a flange drawing property (λ in %), a tensile strength (TS in MPa) and a yield strength (YP in MPa) satisfy the following inequality (1): [(El×λ×TS) / YP]≧645.

Owner:KOBE STEEL LTD

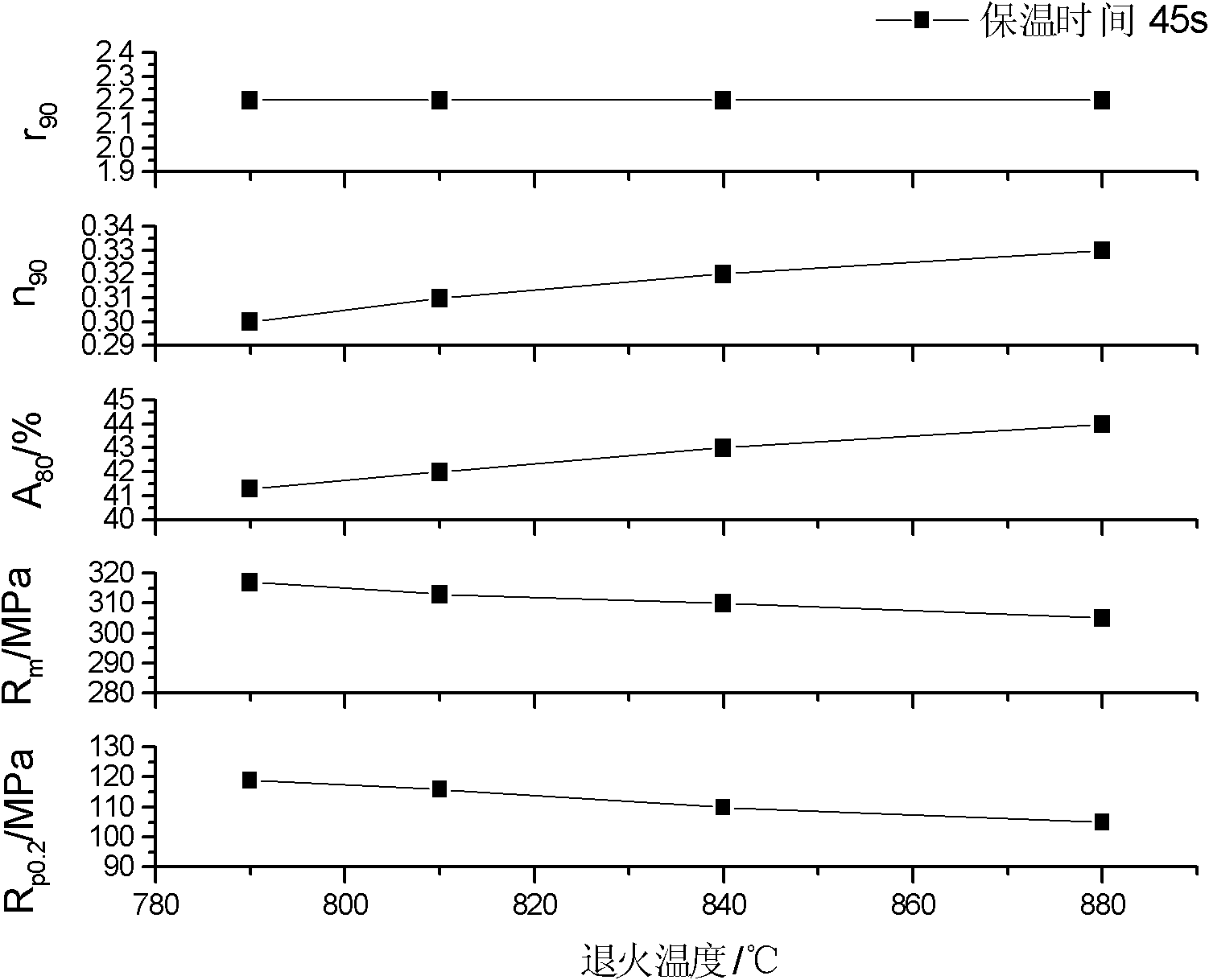

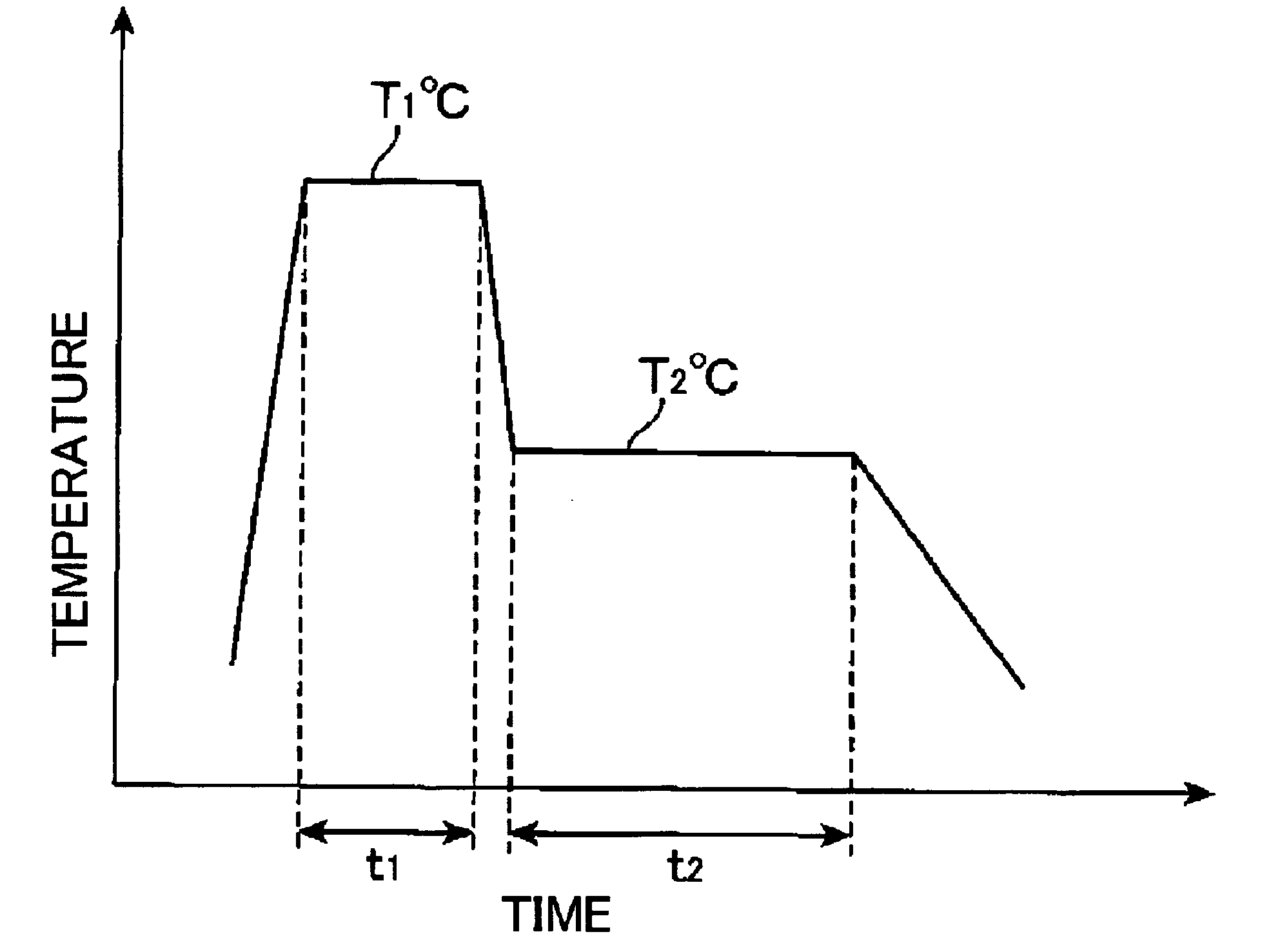

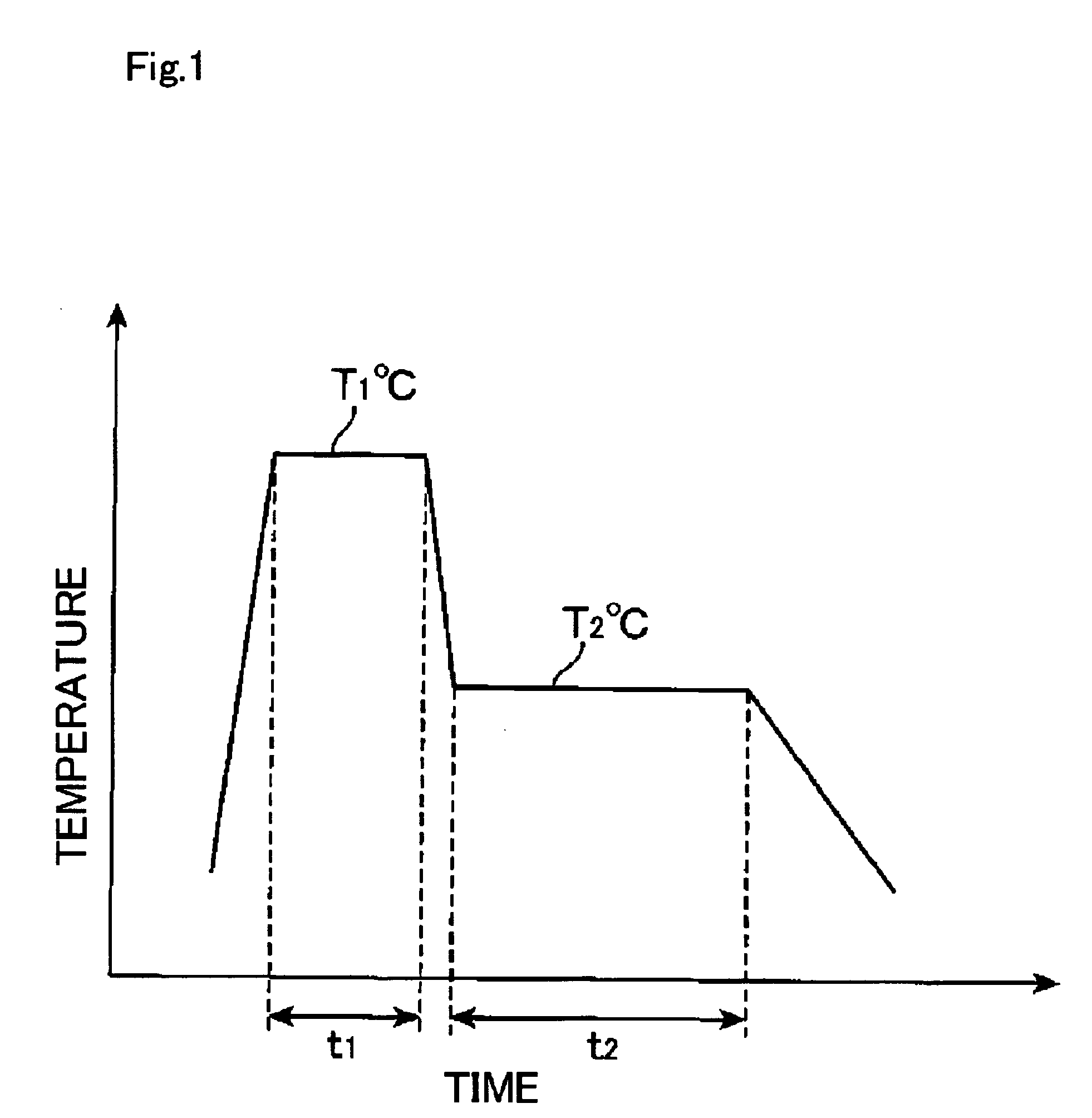

Continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles

The invention relates to a continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles, belonging to the field of metallic materials processing. The chemical composition of the steel plate is as follows by mass percentage: 0.02-0.04% of C, 0.2-0.35% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.02-0.06% of Als, 0.0020-0.0050%of N, and the rest being Fe. The hot rolling parameter is as follows: heating temperature at 1250+ / -30 DEG C; finishing temperature at 930+ / -20 DEG C; coiling temperature at 730+ / -20 DEG C; cold rolling reduction ratio being controlled at 75-85%; soaking time for 50-100s; annealing temperature at 780+ / -20 DEG C; outlet temperature of the slow-cooling section at 675+ / -20 DEG C; outlet temperature of the rapid-cooling section at 400+ / -20 DEG C; overaging temperature at 350+ / -20 DEG C; and level elongate ratio being 0.9+ / -0.3%. The generated steel plate has the advantages of low yield strength, high tensile strength, fine formability, high product quality and considerable economic benefit.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com