800 MPa-grade low-yield-ratio structural steel plate and production method thereof

A low-yield ratio, structural steel plate technology, applied in the field of steel materials, low-carbon high-strength steel materials, can solve the problems of high additive content, unfavorable welding performance, increased production costs, etc., and achieve the effect of excellent low-temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

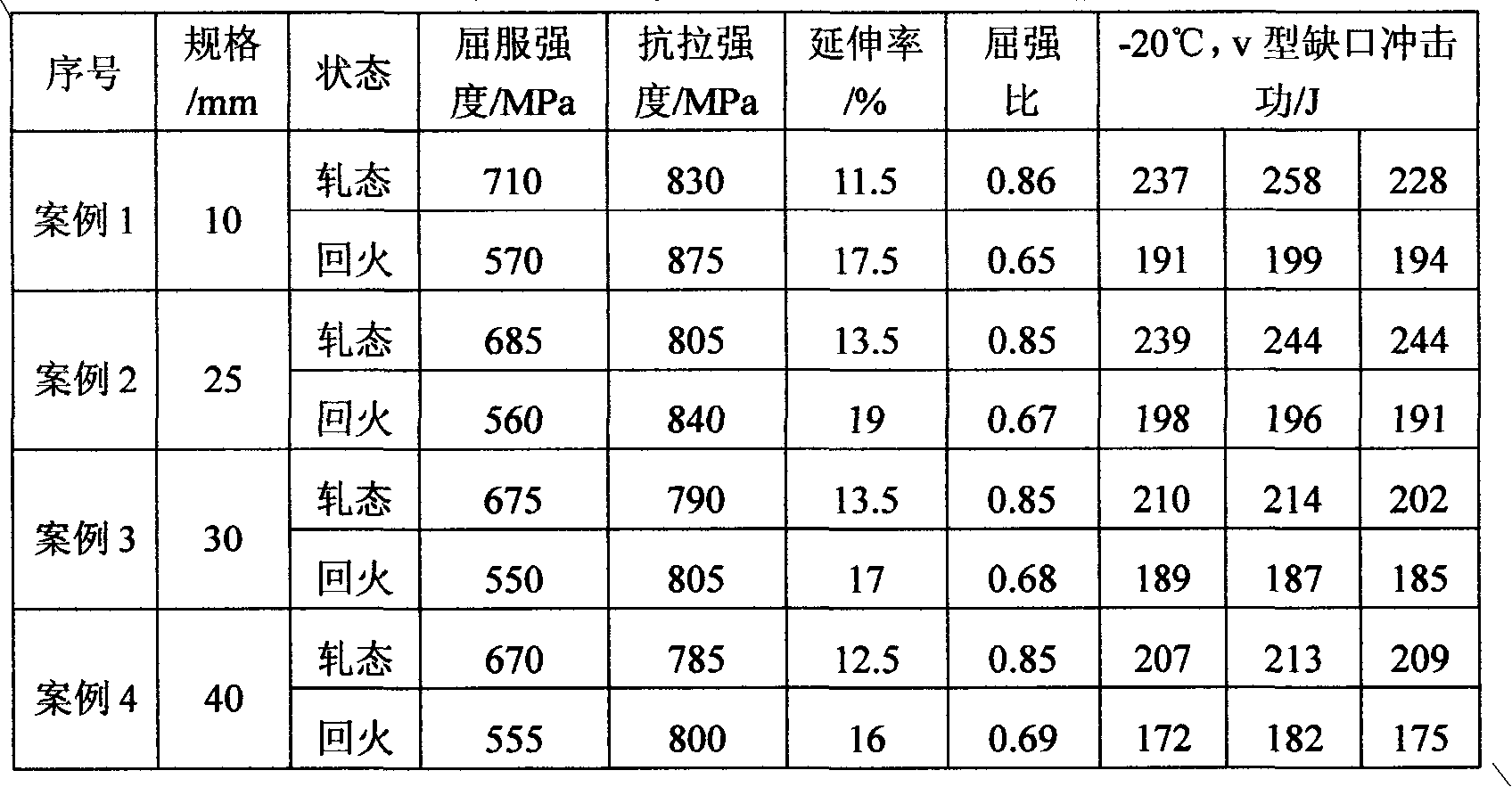

Examples

Embodiment Construction

[0029] specific implementation

[0030] The following specific cases illustrate the technical solution of the present invention, but the protection scope of the present invention is not limited thereto:

[0031] Case 1:

[0032] The smelting composition of the billet is shown in Table 1 below:

[0033] Table 1 Billet components used in Case 1, wt%

[0034] C%

Si%

Mn%

P%

S%

Ni%

Cr%

Cu%

Nb%

Mo%

Ti%

B%

Pcm%

0.06

0.27

1.60

0.009

0.003

0.26

0.26

0.42

0.056

0.22

0.014

0.0013

0.22

[0035] Billet heating temperature: 1182°C;

[0036] Rolling start temperature in initial rolling stage: 1090°C;

[0037] The second stage rolling temperature: 850℃; final rolling temperature: 820℃; final cooling temperature: 605℃; cooling speed 20K / s

[0038] Tempering temperature: 720°C, holding time: 10min

[0039] The mechanical properties of rolling and temperi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com