Patents

Literature

147 results about "Phase point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

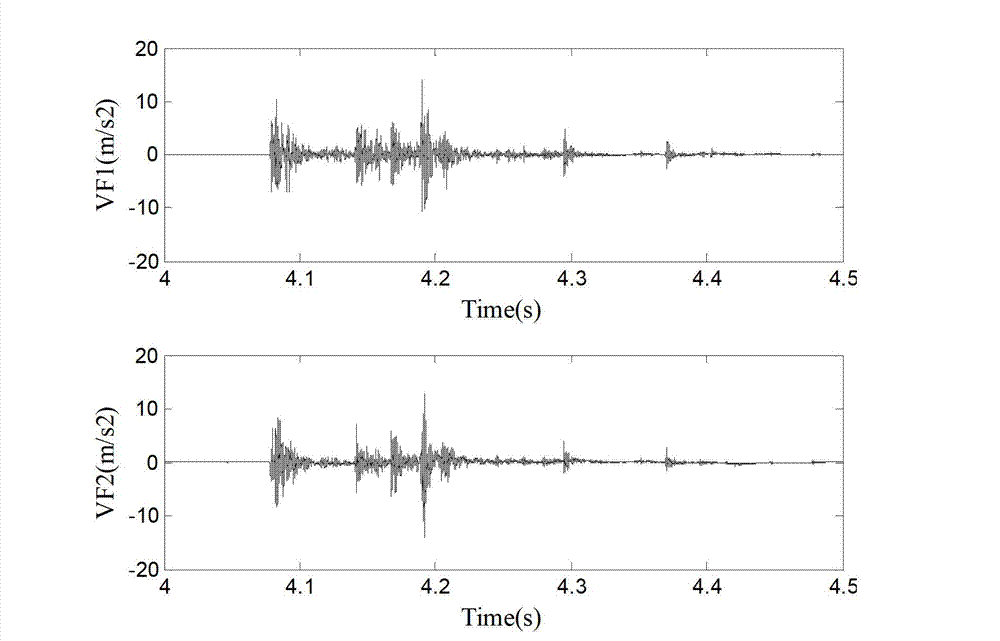

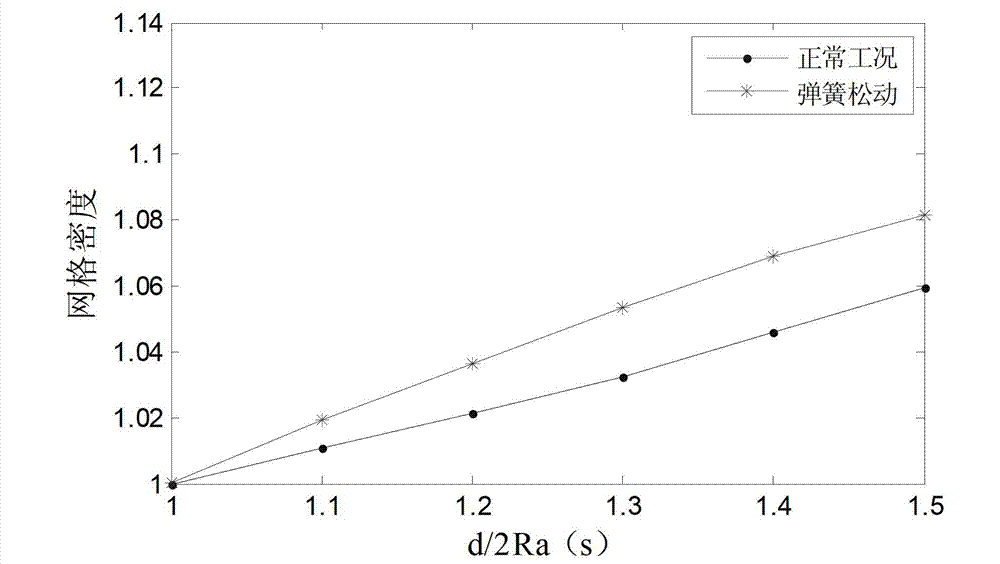

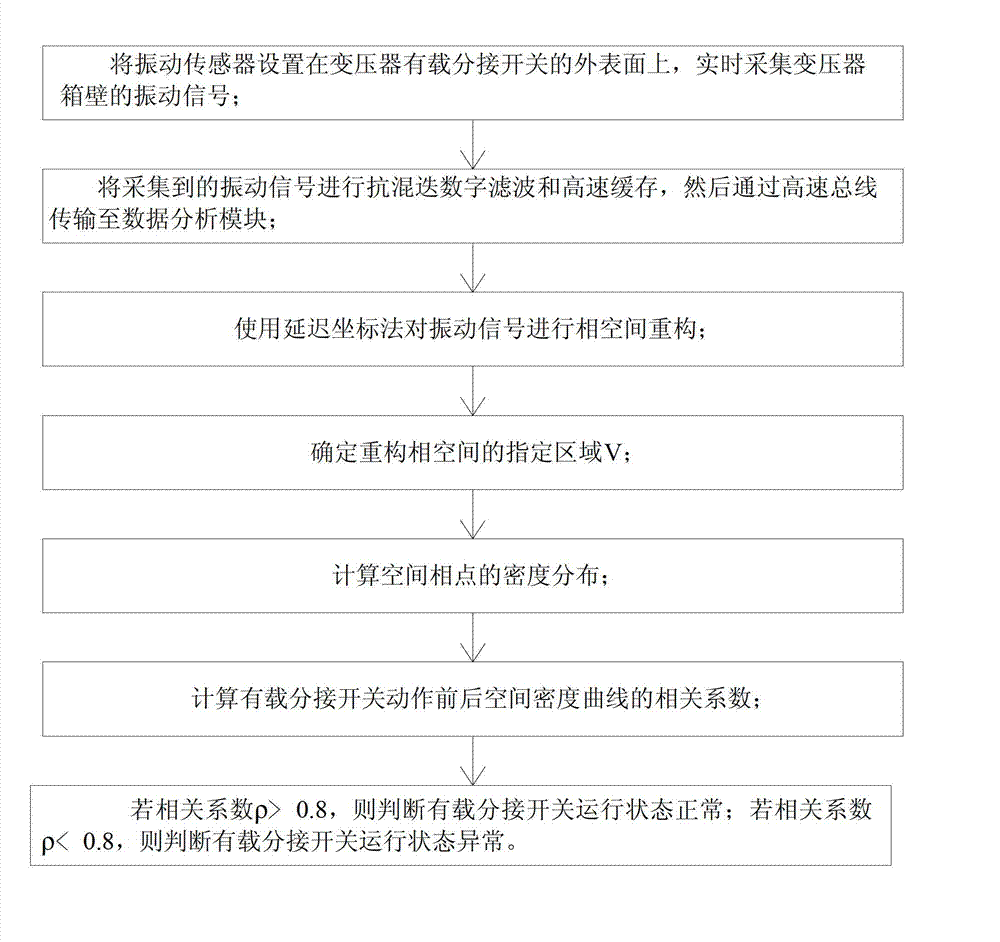

Method for carrying out online monitoring on operating state of transformer OLTC (on-load tap-changer)

ActiveCN103048036ADetect abnormalities in timeReduce failure rateVibration measurement in solidsMachine part testingDensity curveCorrelation coefficient

The invention relates to a method for carrying out online monitoring on an operating state of a transformer OLTC (on-load tap-changer) and belongs to the field of signal monitoring. The method comprises the following steps of: acquiring a mechanical vibrating signal of a box wall of a transformer in real time; carrying out phase space reconstruction on the vibrating signal x(t) by using a delay coordinate method; determining a designated area V of a reconstructed phase space; calculating density distribution of space phase points; calculating a correlation coefficient rho of a space density curve before and after the OLTC actuates; if the correlation coefficient rho is more than 0.8, judging that the operating state of the OLTC is normal; and if the correlation coefficient rho is less than 0.8, judging that the operating state of the OLTC is abnormal. By carrying out real-time monitoring on the vibrating signal in the actuating process of the OLTC, efficient and accurate judgment on the working state of the transformer OLTC can be implemented. The method can be widely used for the field of online monitoring and fault diagnosis of various transformer OLTCs.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

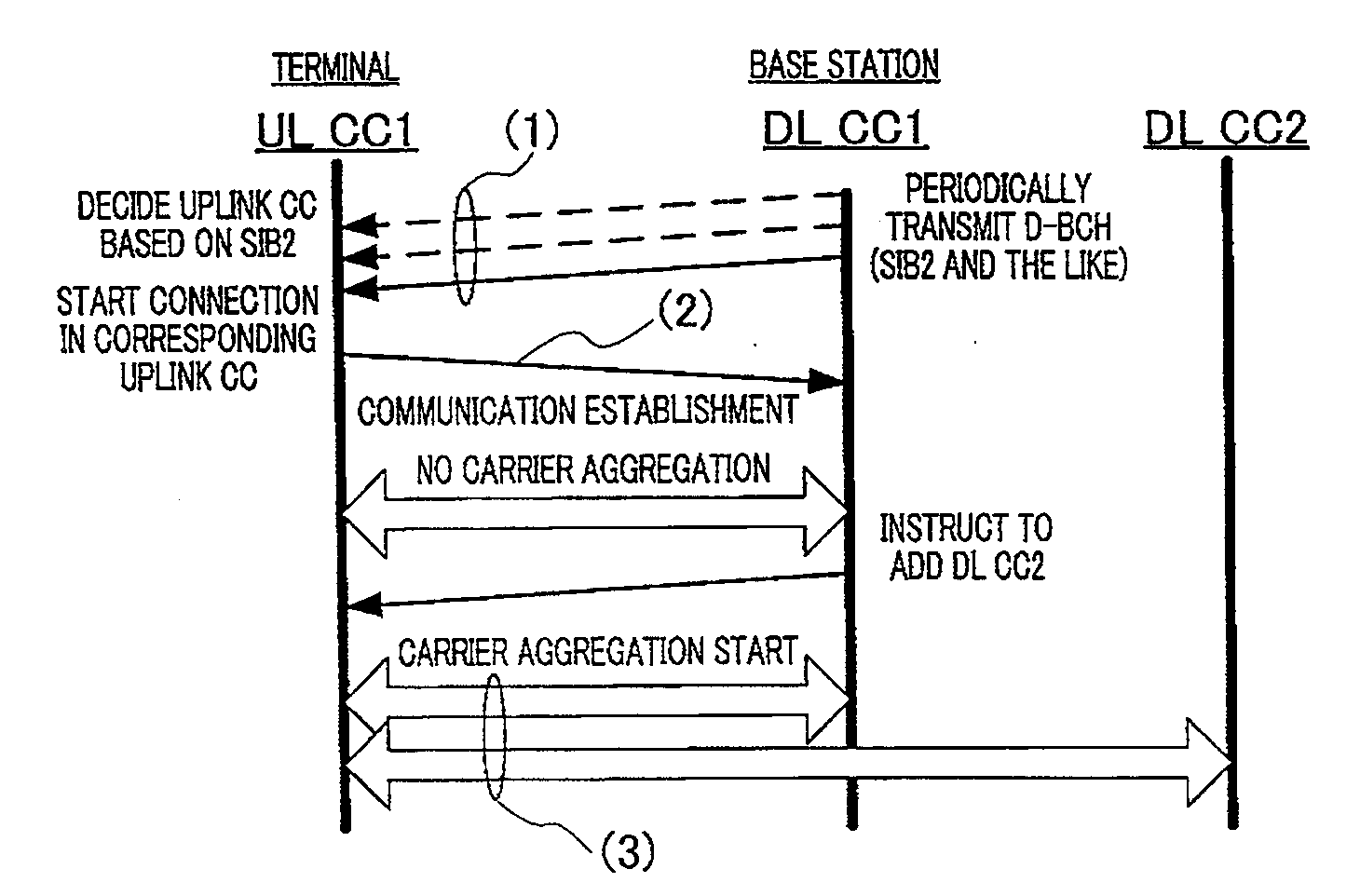

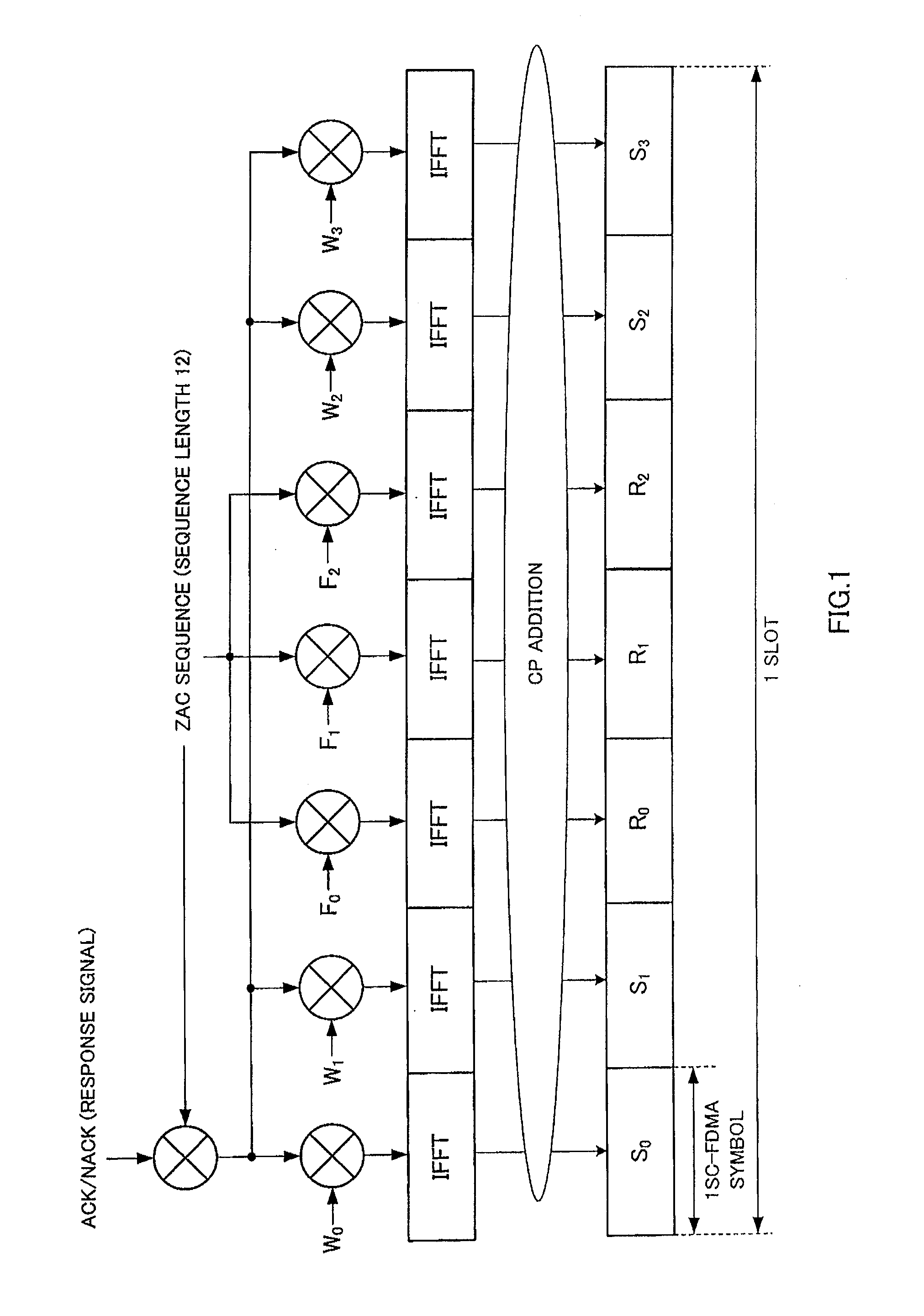

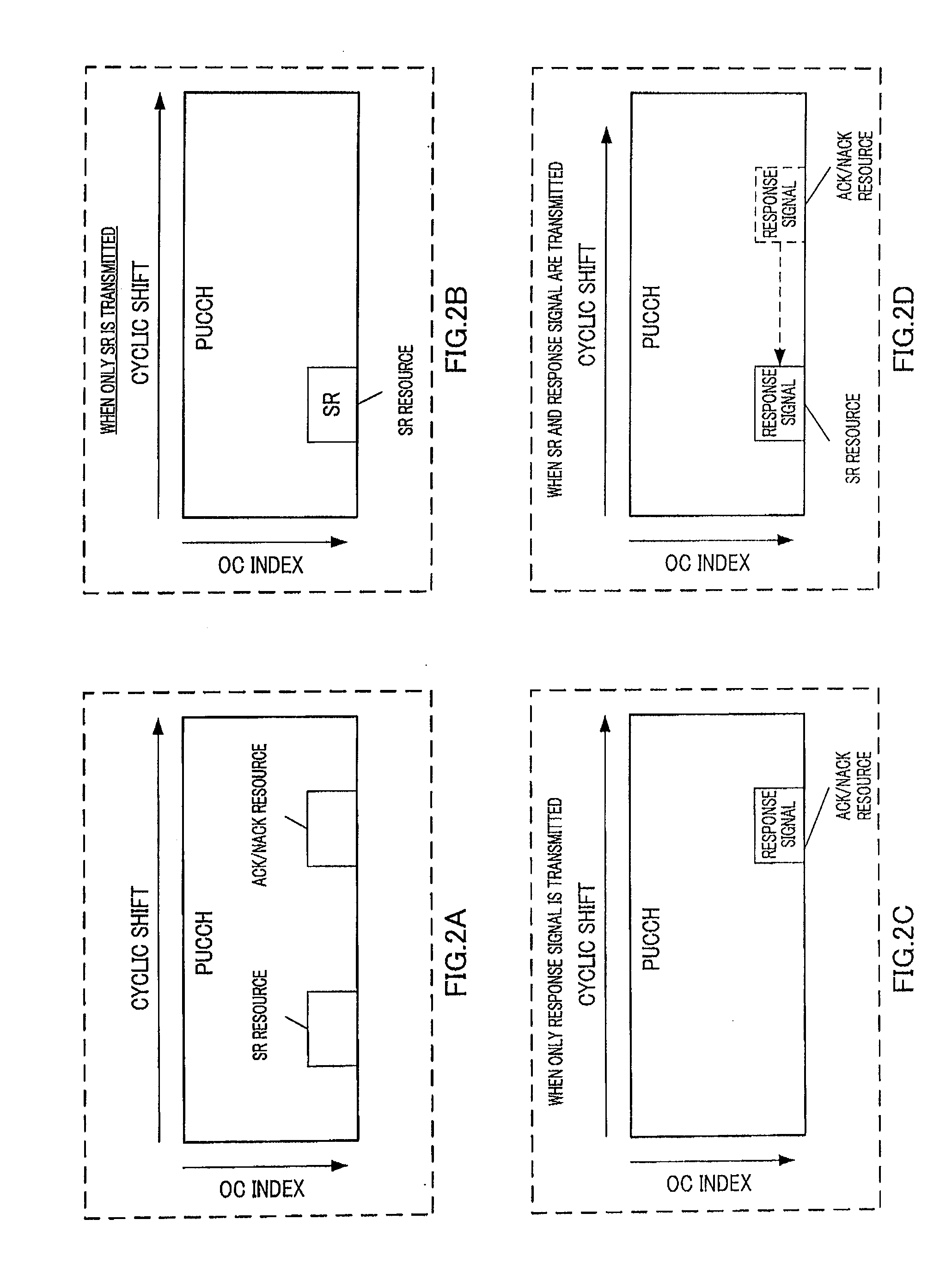

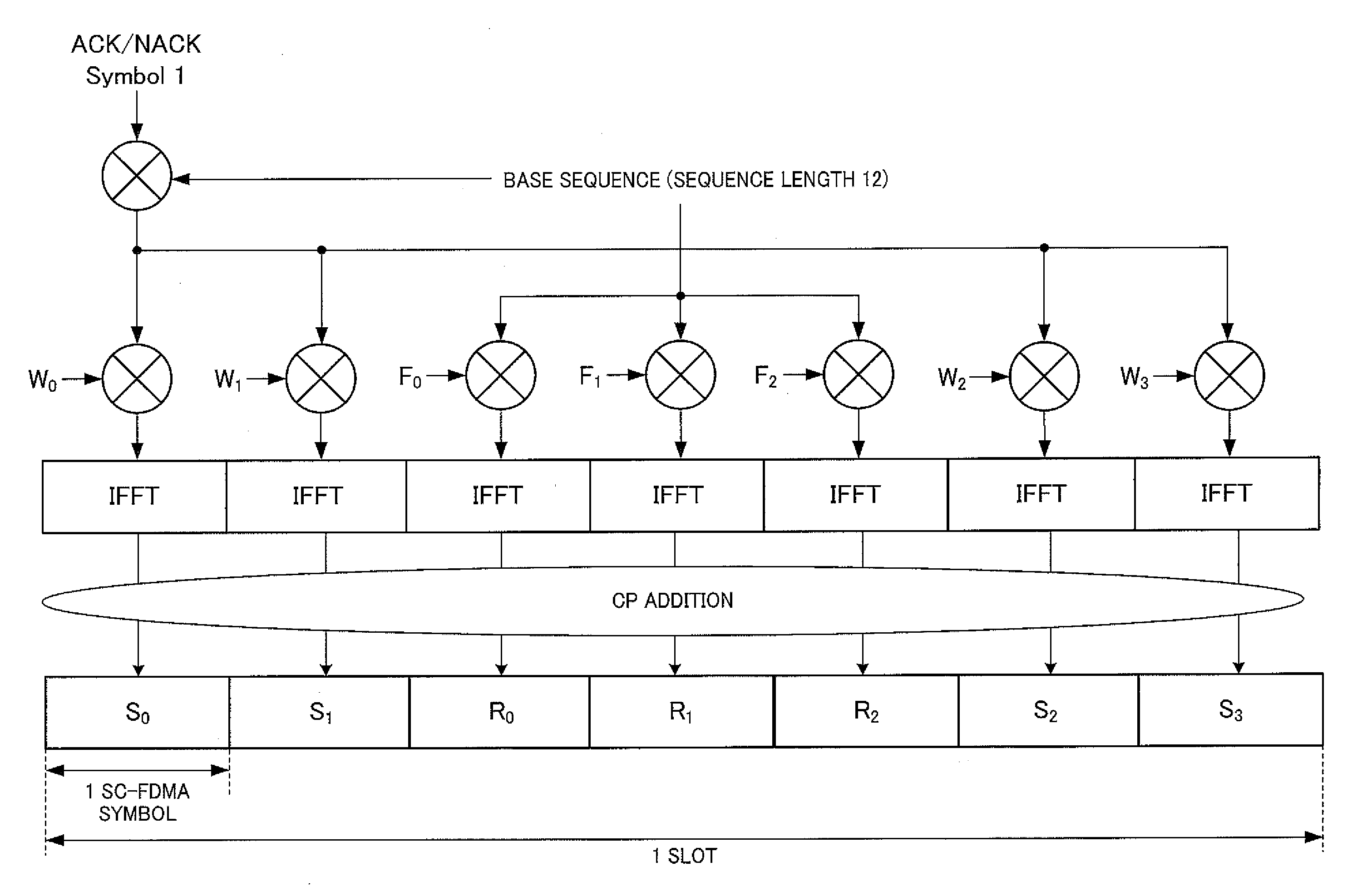

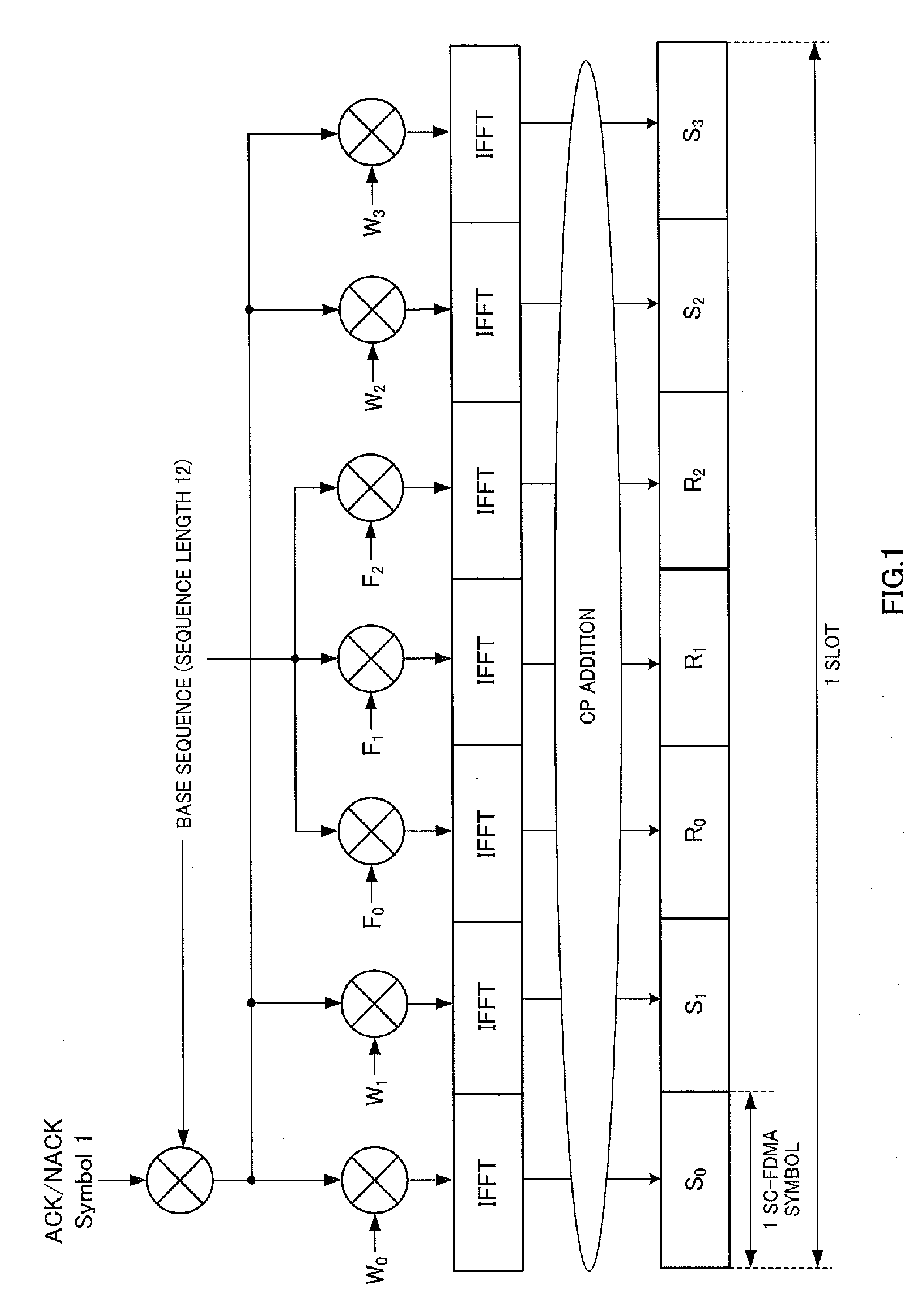

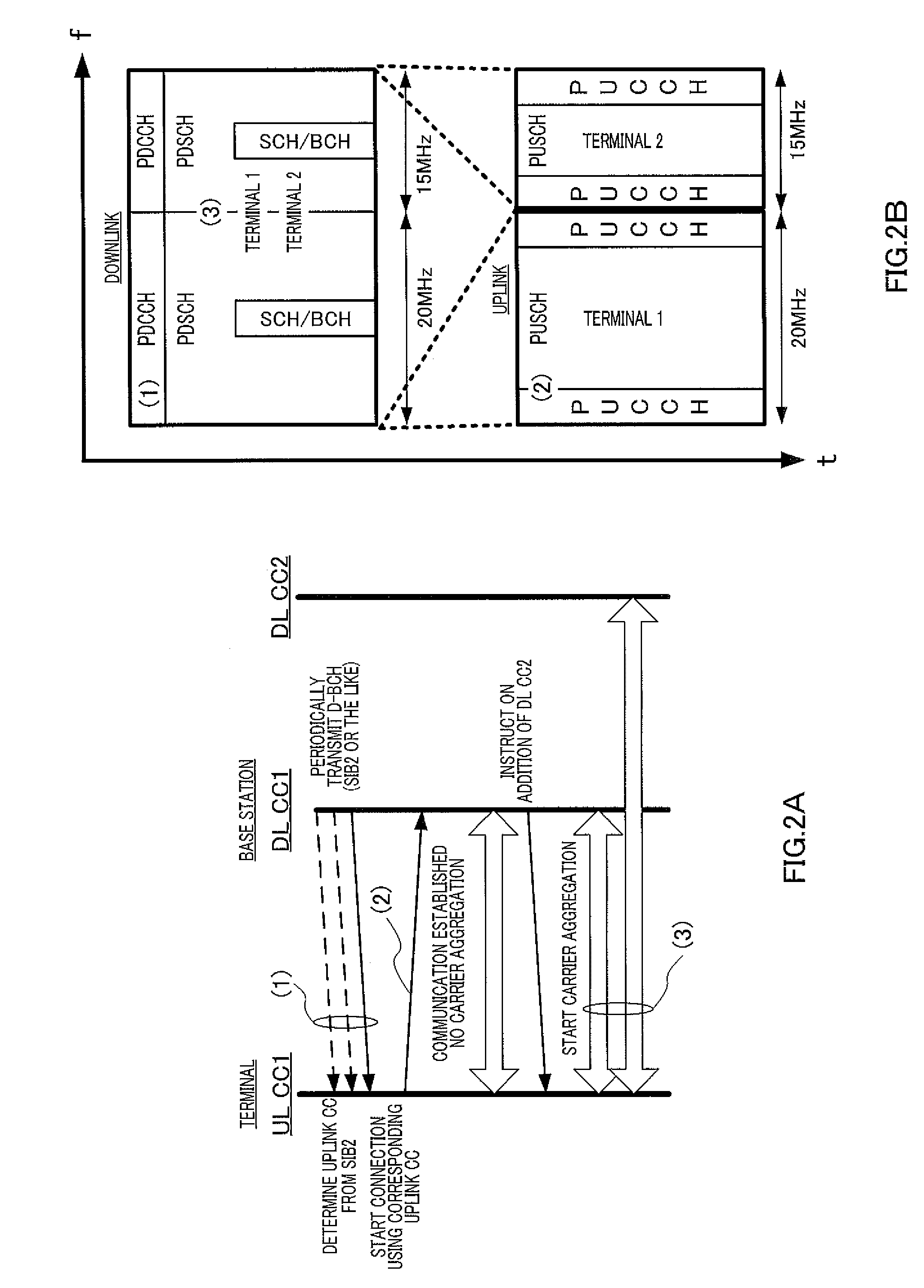

Terminal device and retransmission control method

ActiveUS20120182858A1Suppressing increase in overhead of uplinkIncrease overheadError prevention/detection by using return channelFrequency-division multiplex detailsControl signalTerminal equipment

Provided are a terminal device and a retransmission control method that make it possible to minimize increases in overhead in an uplink control channel (PUCCH), even if channel selection is used as the method to transmit response signals during carrier-aggregation communication using a plurality of downlink unit bands. On the basis of the generation status of uplink data and error-detection results obtained by a CRC unit (211), a control unit (208) in the provided terminal (200) uses response signal transmission rules to control the transmission of response signals or uplink control signals that indicate the generation of uplink data. If an uplink control signal and a response signal are generated simultaneously within the same transmission time unit, the control unit (208) changes the resources allocated to the response signal and / or the phase point of the response signal in accordance with the number and position of ACKs within the error-detection result pattern.

Owner:SUN PATENT TRUST

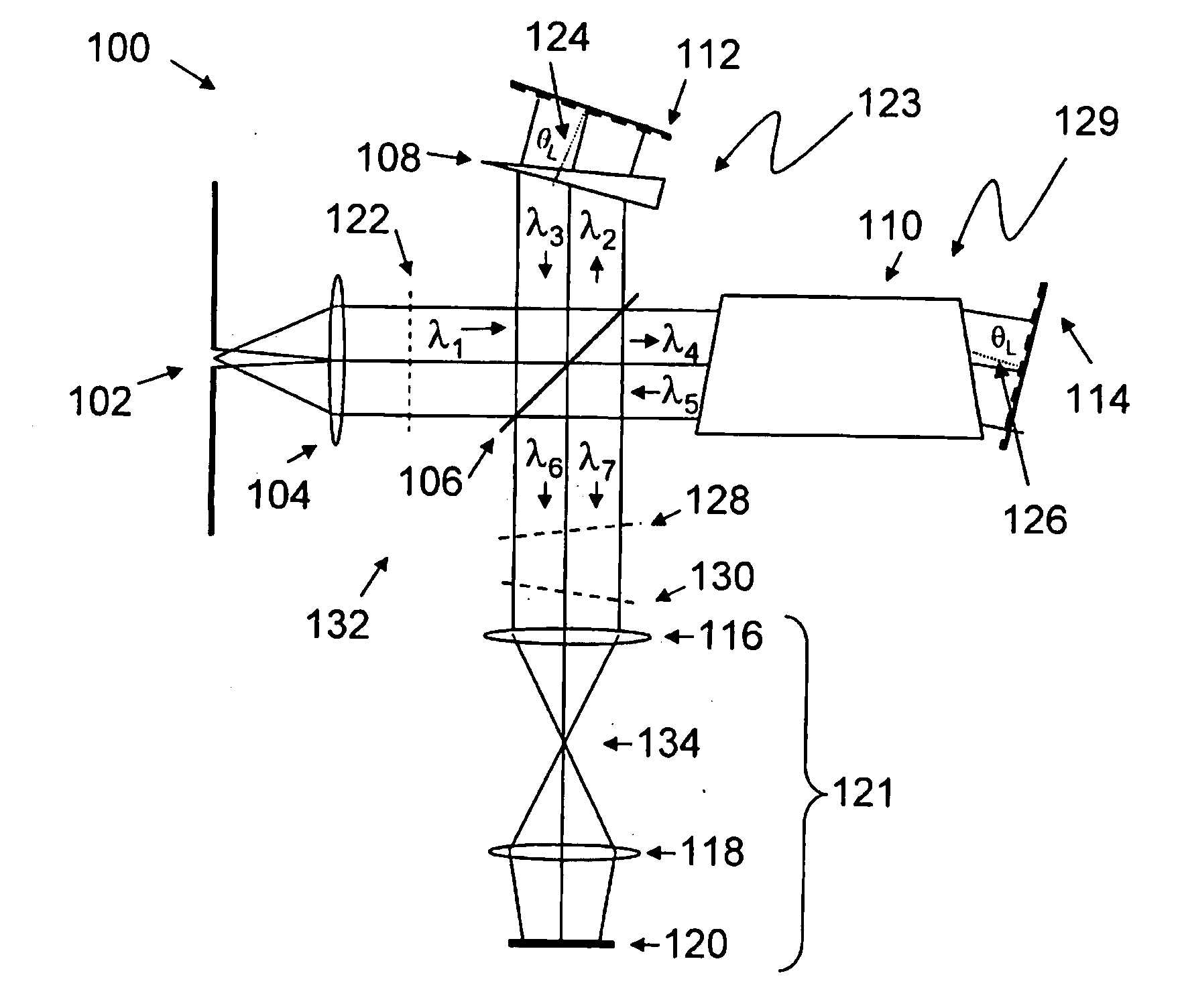

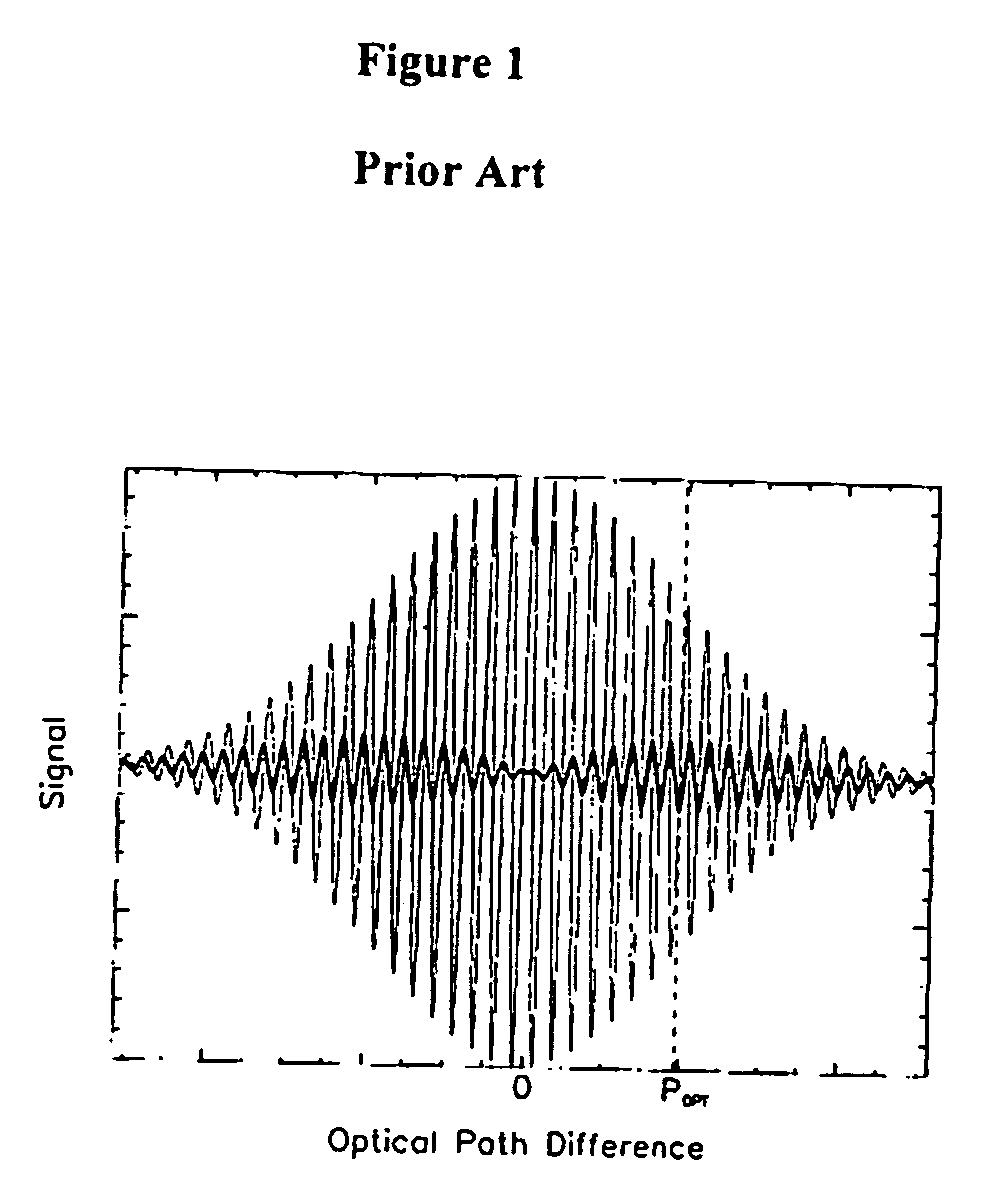

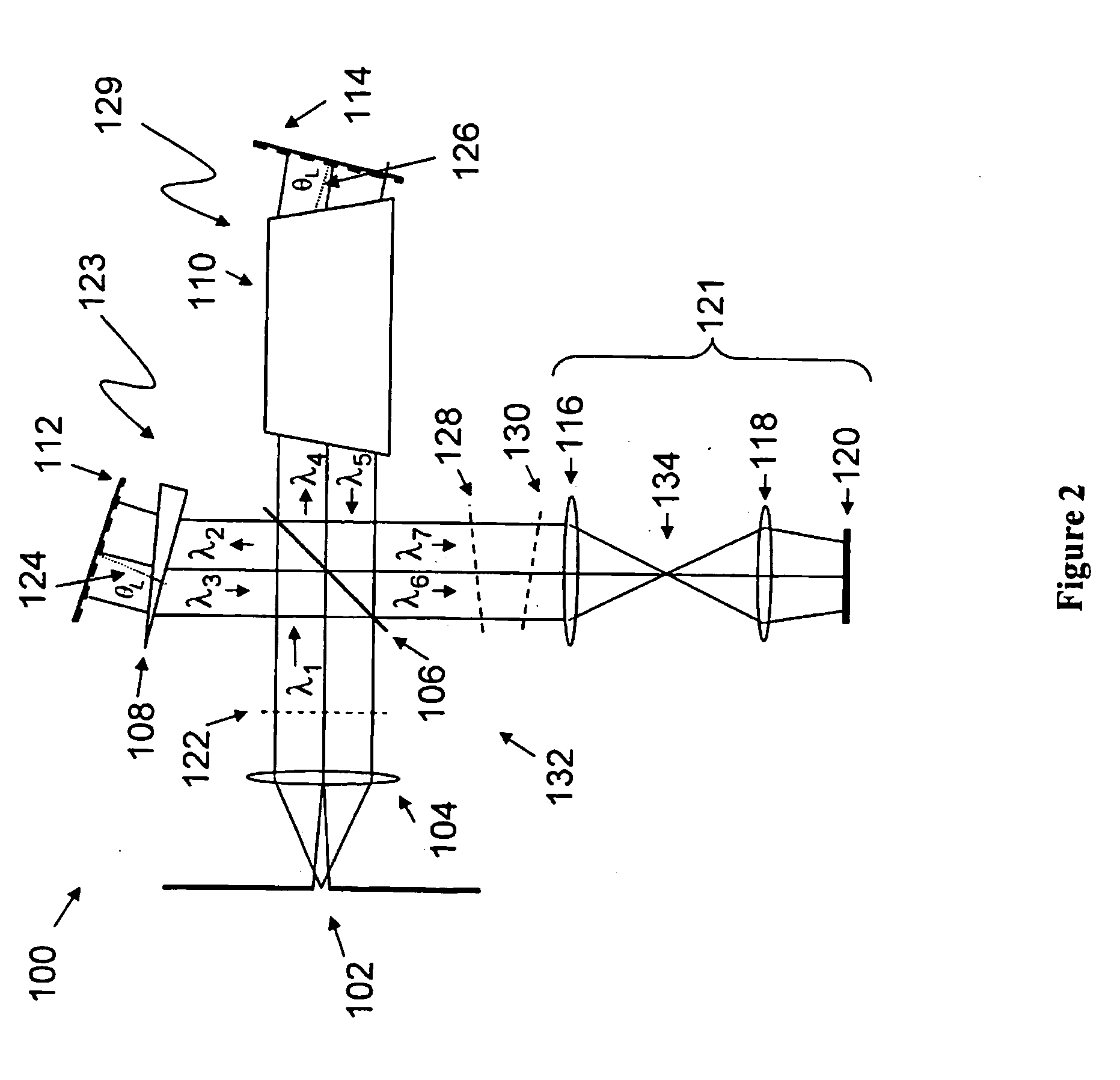

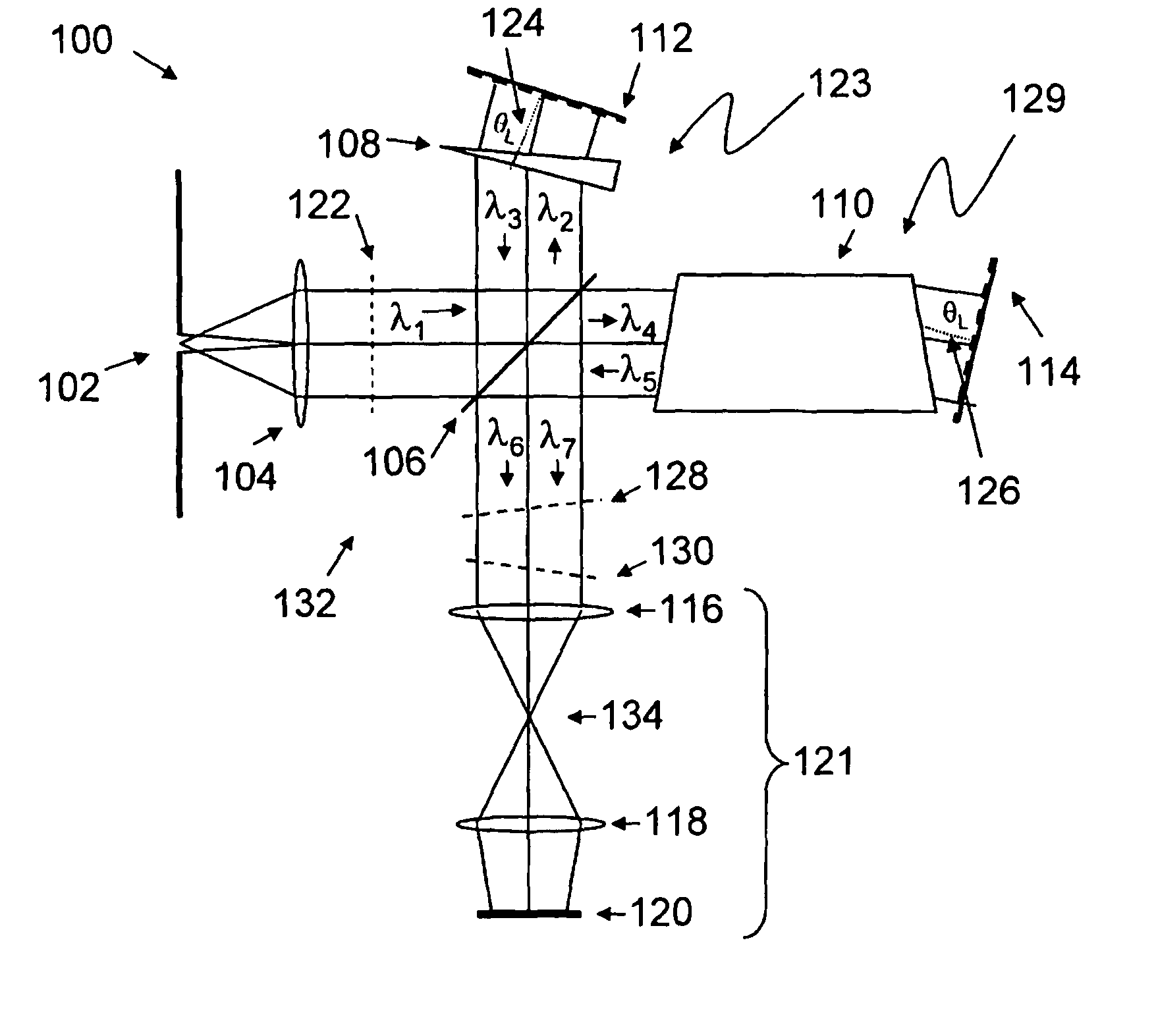

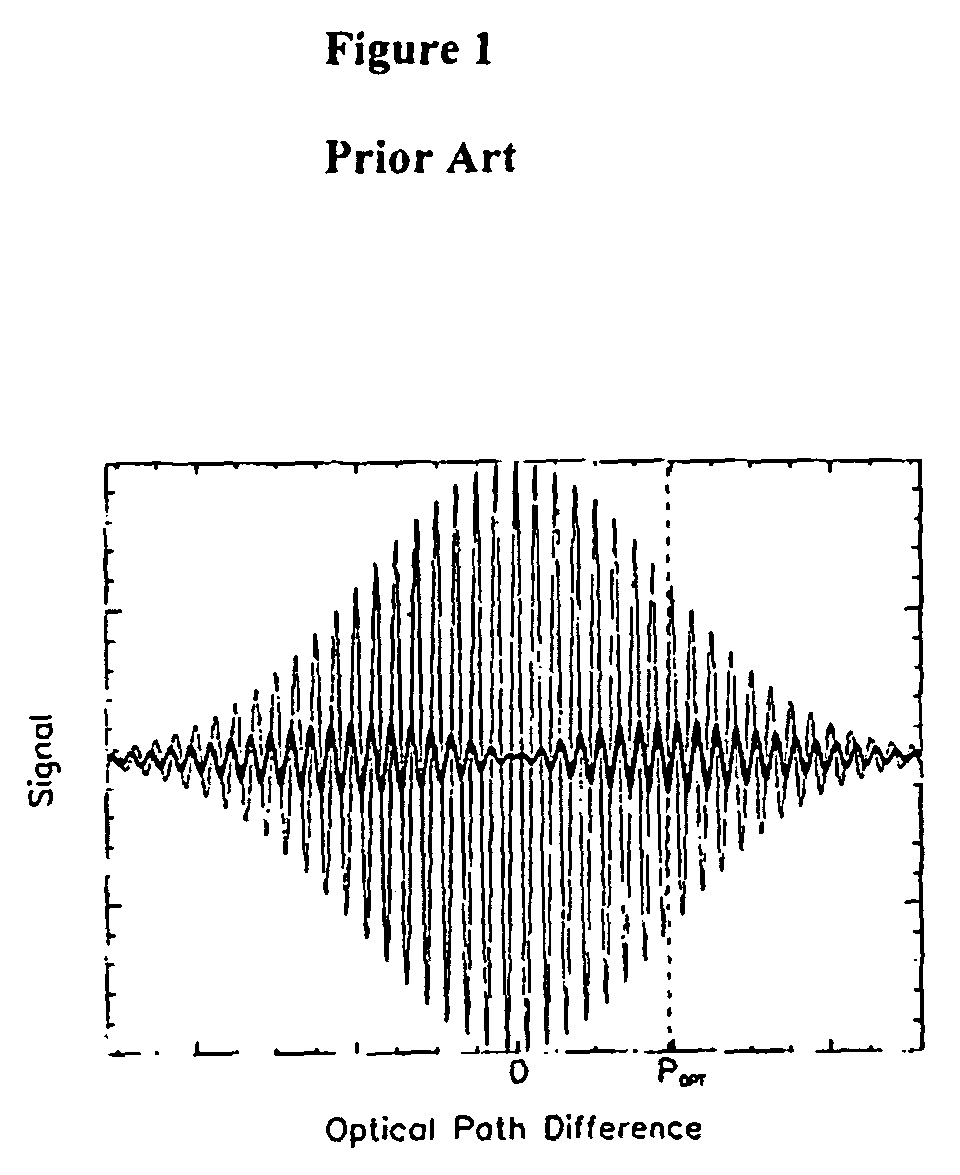

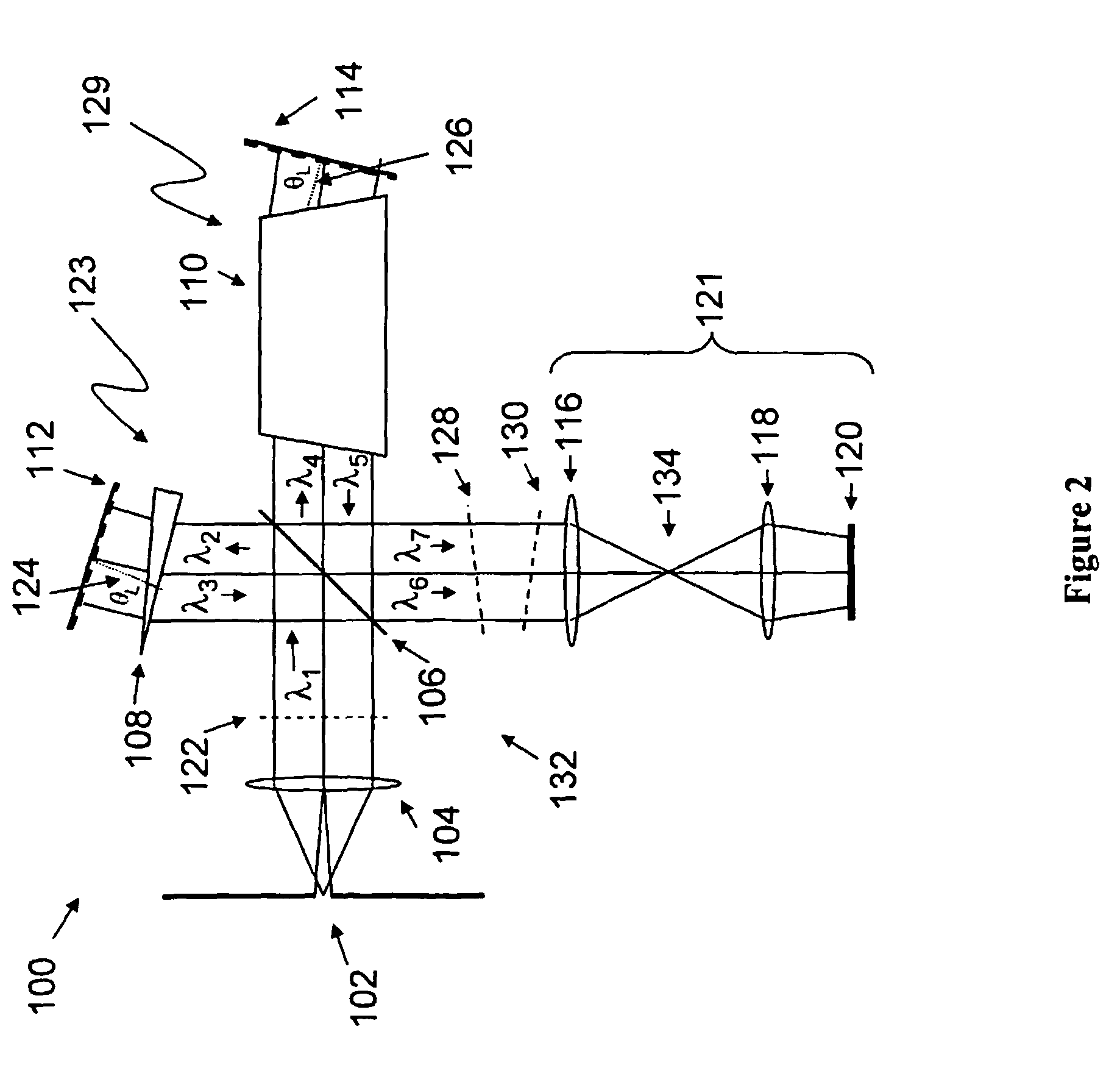

Doppler asymmetric spatial heterodyne spectroscopy

ActiveUS20090051899A1Improve the ability to solveSmall sensitivityRadiation pyrometryInterferometric spectrometryWavefrontGrating

A Doppler Asymmetric Spatial Heterodyne (DASH) spectrometer includes an input aperture for receiving an input light; a collimating lens for collimating the input light into a collimated light; offset establishing means, including at least one grating, for i) receiving and splitting the collimated light into a first light wavefront in a first optical path and into a second light wavefront in a second optical path, ii) establishing an offset in a light wavefront path distance between the first and second optical path light wavefronts, and iii) diffracting and recombining the first and second optical path light wavefronts into an interference wavefront to form an interference image that includes a plurality of phase points of a heterodyned interferogram measured simultaneously over the path distance offset; and an output optics section comprising a detector for receiving the interference image and outputting an interference image pattern.

Owner:UNITED STATES OF AMERICA

Doppler asymmetric spatial heterodyne spectroscopy

ActiveUS7773229B2Improve the ability to solveSmall sensitivityRadiation pyrometryInterferometric spectrometryGratingWavefront

A Doppler Asymmetric Spatial Heterodyne (DASH) spectrometer includes an input aperture for receiving an input light; a collimating lens for collimating the input light into a collimated light; offset establishing means, including at least one grating, for i) receiving and splitting the collimated light into a first light wavefront in a first optical path and into a second light wavefront in a second optical path, ii) establishing an offset in a light wavefront path distance between the first and second optical path light wavefronts, and iii) diffracting and recombining the first and second optical path light wavefronts into an interference wavefront to form an interference image that includes a plurality of phase points of a heterodyned interferogram measured simultaneously over the path distance offset; and an output optics section comprising a detector for receiving the interference image and outputting an interference image pattern.

Owner:UNITED STATES OF AMERICA

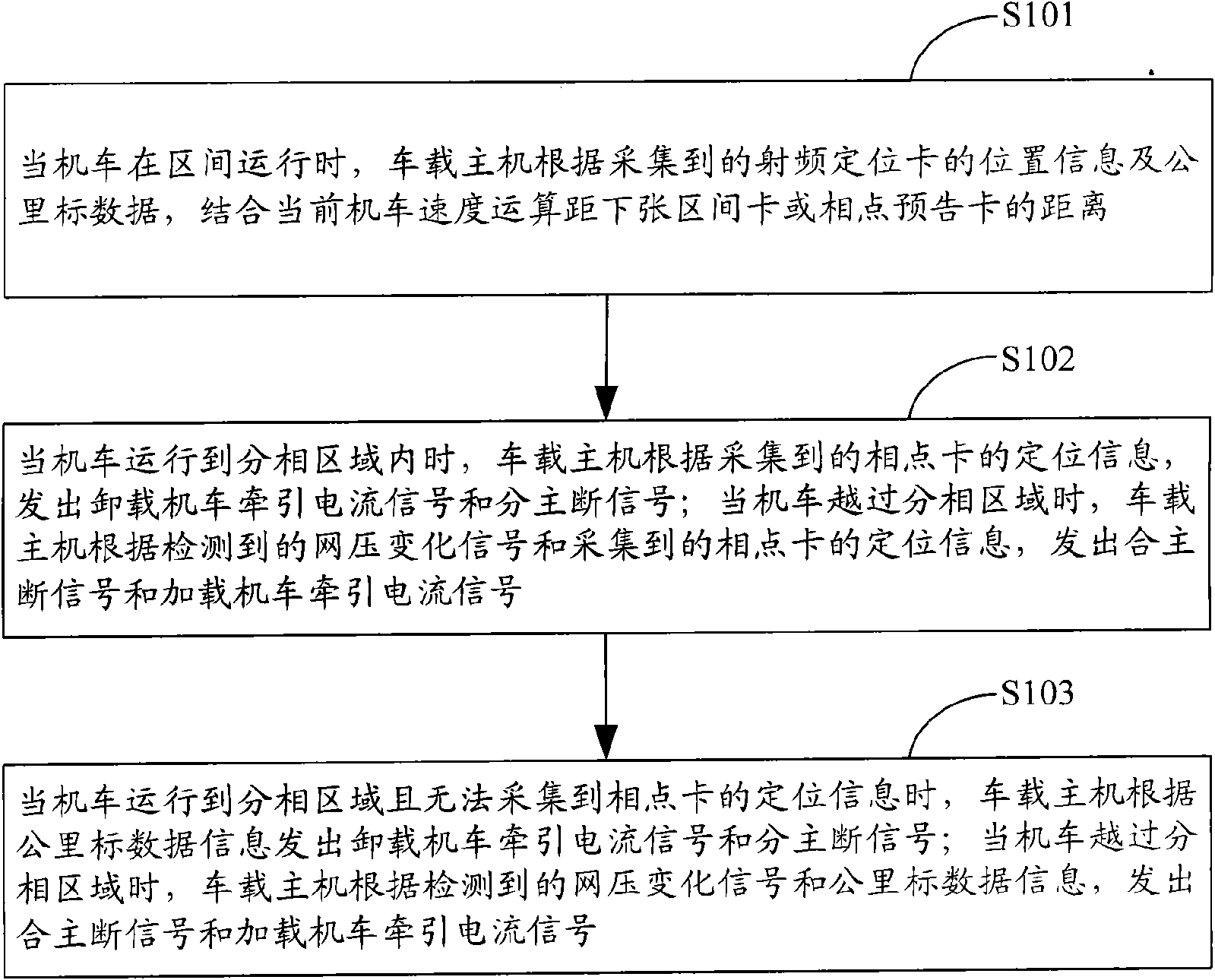

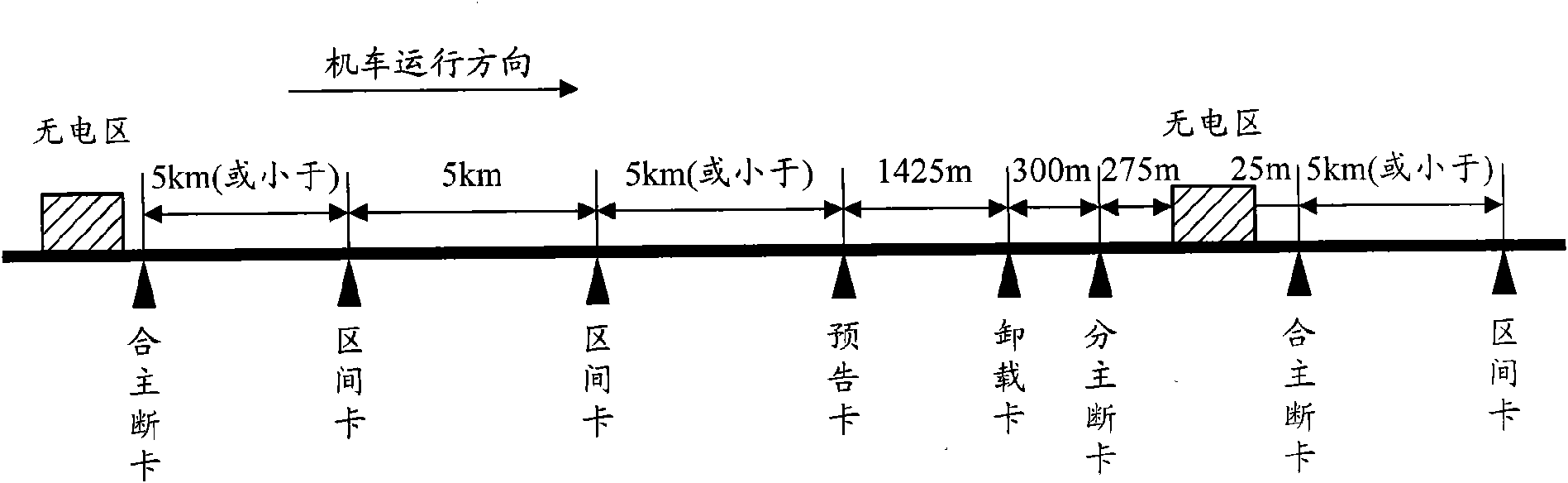

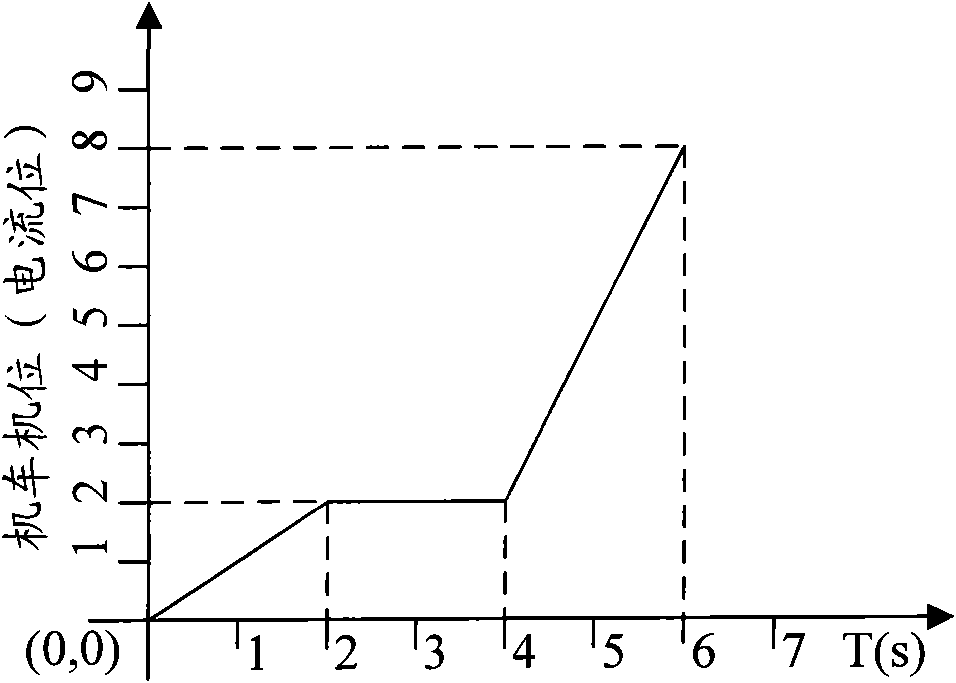

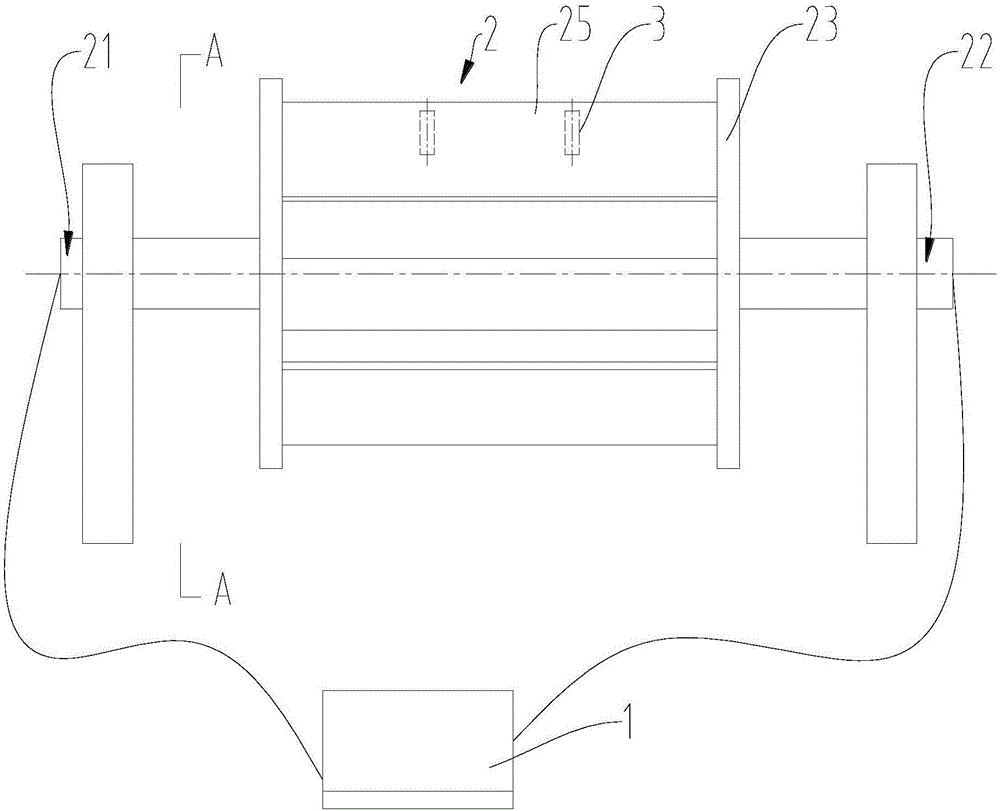

Automatic neutral section passover control method of electric locomotive, device thereof, and electric locomotive

InactiveCN101559732AReduce speed lossEnsure safetyPower supply linesElectric locomotivesEngineeringPhase point

The invention is applicable to the railway electric locomotive field, and provides an automatic neural section passover control method of an electric locomotive, a device thereof, and the electric locomotive. An RF locator card is arranged on an overhead contact, an RFID location reader is arranged on a roof and used for identifying the RF locator card, a vehicle host computer calculates and calibrates distance between the locomotive and a front section card or a phase point prediction card according to location information of the RF locator card collected by the RFID location reader on the top and kilometer post data read by the vehicle host computer from a TAX box as well as current speed of the locomotive, and performs on / off blockout control with the location information of the RF locator card as main means and the kilometer post data as supplementary means in a neural section passover area so as to ensure optimal blockout position from calculation output and reduce speed loss, meanwhile, the dual locating technology also ensures safety and reliability of the automatic neural section passover of the electric locomotive, avoid missed neural neutral section detection, and provide convenient installation and maintenance.

Owner:SHENZHEN FTRD IND

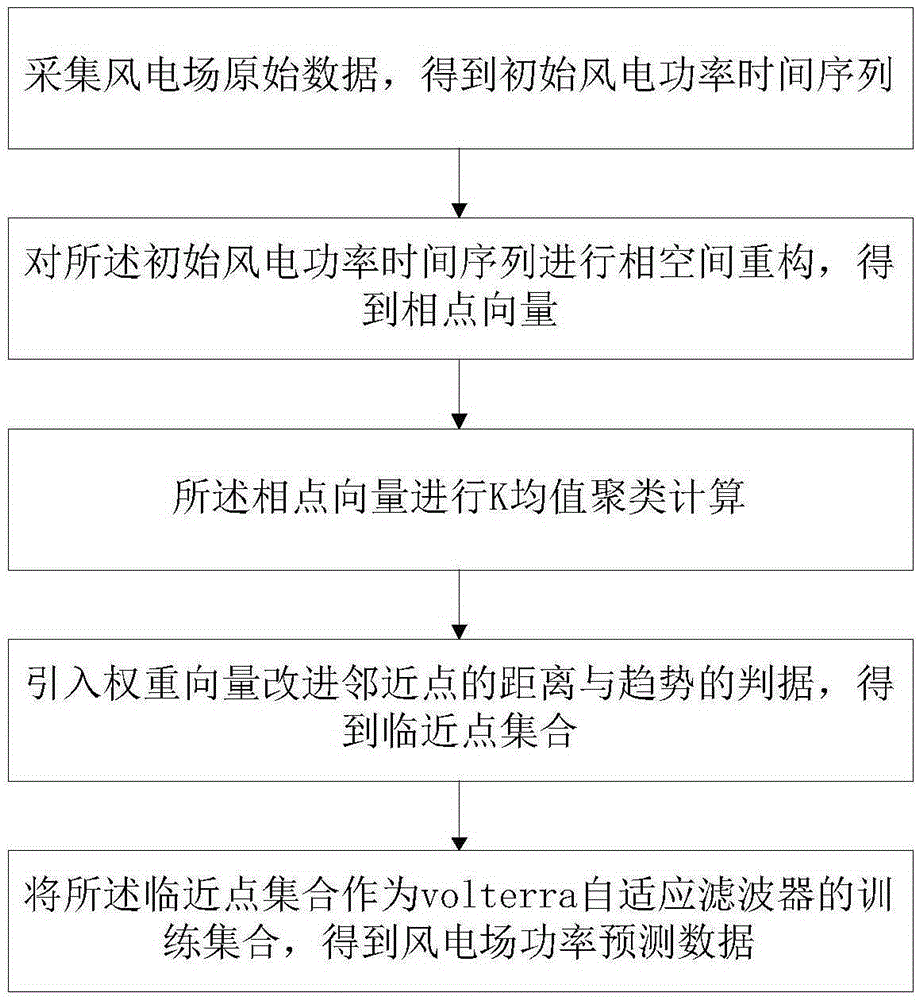

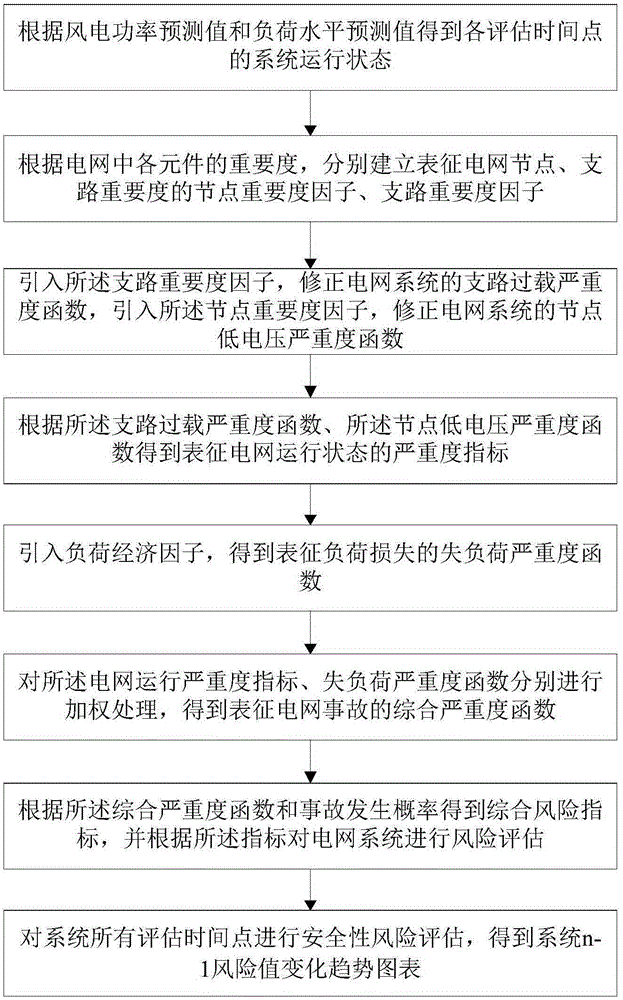

Risk prediction evaluation method for wind power grid integration

InactiveCN105354643AElimination of different effects in timeElimination of different effectsForecastingElectricityPeaking power plant

The invention discloses a risk prediction evaluation method for wind power grid integration, comprising the following steps of: collecting original data of a wind power plant to obtain an initial wind power time sequence; performing phase space reconstruction on the initial wind power time sequence to obtain a phase point vector; performing K mean clustering computation on the phase point vector; introducing a weight vector to improve criterion for distance and trend of proximal points, and thereby obtaining a proximal point set; using the proximal point set as a training set of volterra self-adaptive filter to obtain wind power plant power prediction data. The risk prediction evaluation method for wind power grid integration provided by the invention eliminates the technical defect in the prior art which ignores different influence of the time sequence of own different coordinate components of the phase point on the prediction point and is prone to introducing false proximal points, effectively avoids the false proximal points, chooses the proximal point with distance and evolutionary trend both similar to the prediction point, and is thereby improved in computation accuracy and speed.

Owner:STATE GRID SICHUAN ECONOMIC RES INST +1

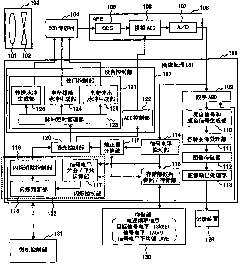

Imaging equipment

InactiveCN102196184AAvoid flickeringTelevision system detailsColor television detailsImaging equipmentPhase point

The present invention provides an imaging equipment. In an aperture fiation type imaging equipment, the problem is that: an image flicker is generated by a fluorescent lamp lighted in dependence on a commercial AC supply and a LED lighting, it is imposible to fix a shutter at the shutter speed at which the image flicker does not occur. Because each image in the imaging equipment for monitoring is very important information, it is necessary to still obtain the image in which a residual image or flicker is not present relative to to a moving imaging target even though the shutter speed is set at high speed. When a decision is made that the flicker is present, the timings of applying a discharging pulse and a charge readout pulse respectively are varied depending on a field in order to implement shutter speed control in a CCD sensor, so that the imaging equipment can be exposed to a portion of light falling into the same phase thereof within a luminescence period of the lighting during each field. After the start of the control, the phase point treatment is immediately performed, so that the timing of the exposure if the imaging equipment in the lighting period of lighting is set to ensure the part with maximum exposure amount to be exposed. Even though a light source emits light while being repeatedly lit and extinguished in a certain period, the exposure without flicker is performed.

Owner:HITACHI LTD

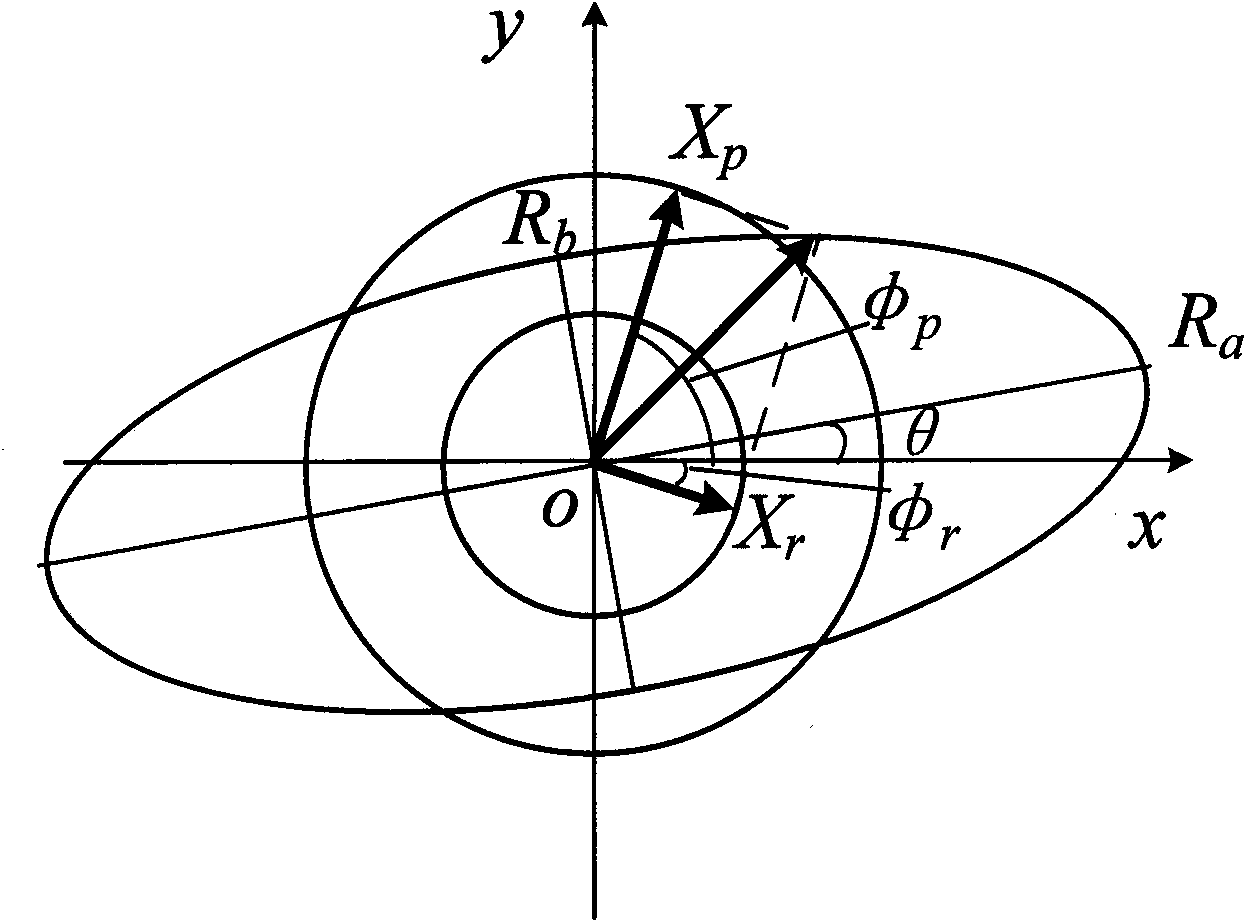

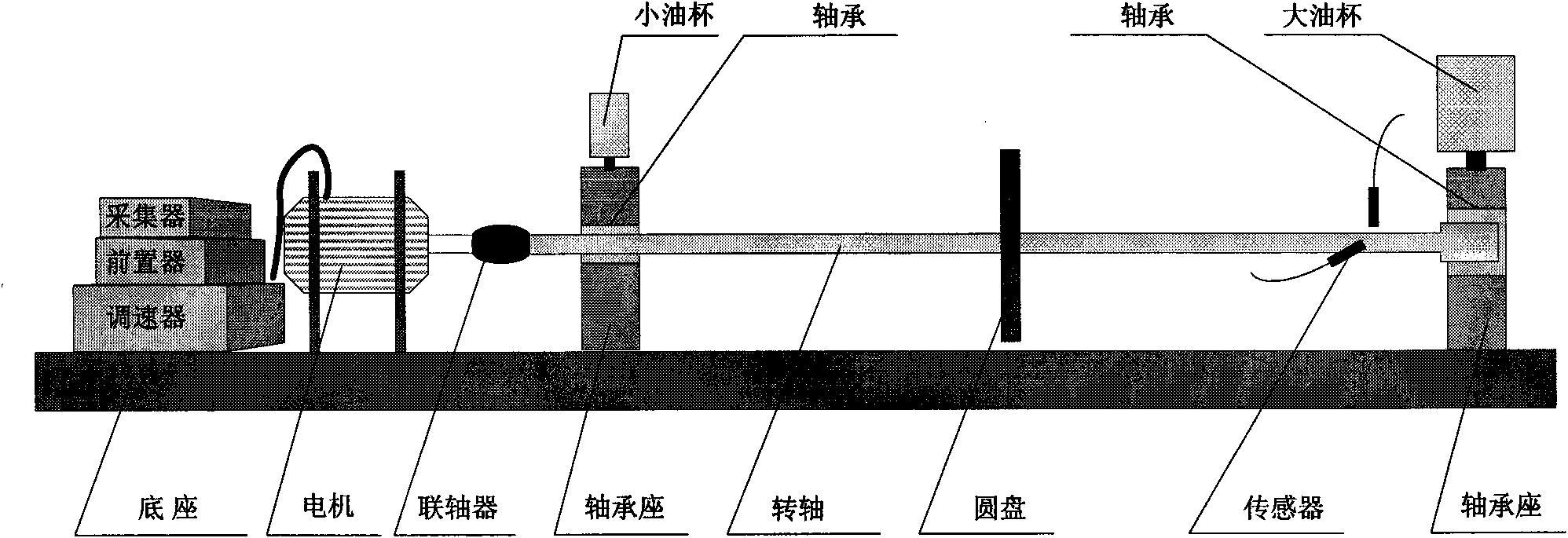

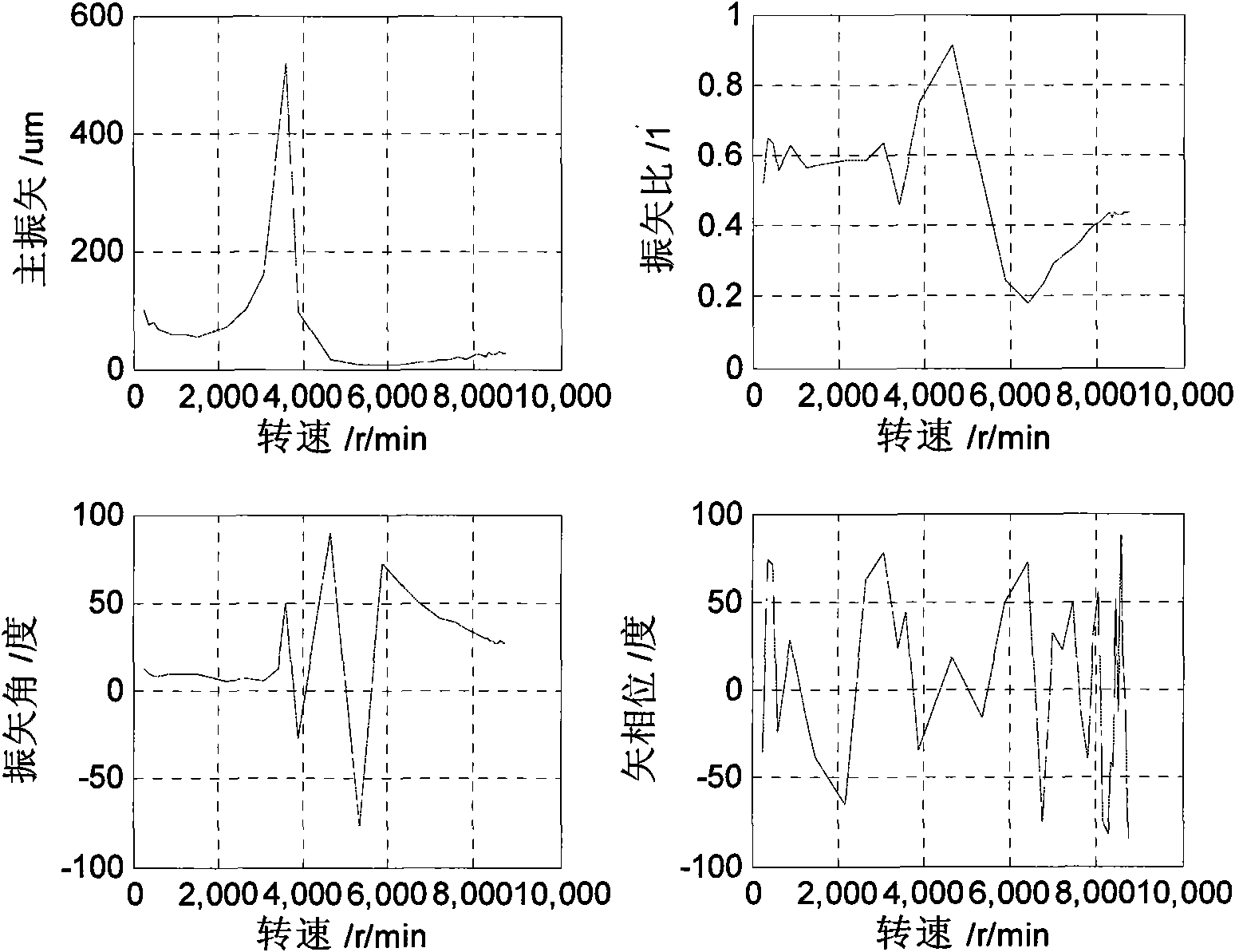

Analytical method of rotor transient signal

ActiveCN101561312AEasy to identifyMake up for limitationsMachine part testingSubsonic/sonic/ultrasonic wave measurementUltimate tensile strengthPhase point

The invention discloses an analytical method of a rotor transient signal, which comprises the following steps: 1) two orthogonal current vortex displacement sensors are arranged on a rotor section to collect a vibration signal of a rotor relative to a bearing support, the direction of the sensor from X to Y is consistent with the rotation direction of the rotor, and an equal rotary speed signal is adopted for collection and a key phase signal is used for simultaneous complete alternation sampling; 2) signals collected are processed with anti-alias filtering, low-pass filtering and the like to remove unnecessary interference noise signals; 3) the computation of main vibration vector, vibration vector ratio, vibration vector angle and vector phase is conducted, complex FFT conversion is adopted and one-time FFT computation is utilized to obtain such characteristic parameters; 4) a relational graph of each parameter relative to rotation speed or other variables is drawn; and 5) a main vibration vector graph is used for expressing the vibration strength change of measuring points under a single frequency, a vibration vector ratio graph is used for expressing the ovality change of the single frequency vortex track of measuring points, a vibration vector angle graph is used for expressing the change of maximum vibrating direction, and a vector phase graph is used for expressing the change of a vibration vector and a reference phase point.

Owner:郑州恩普特科技股份有限公司

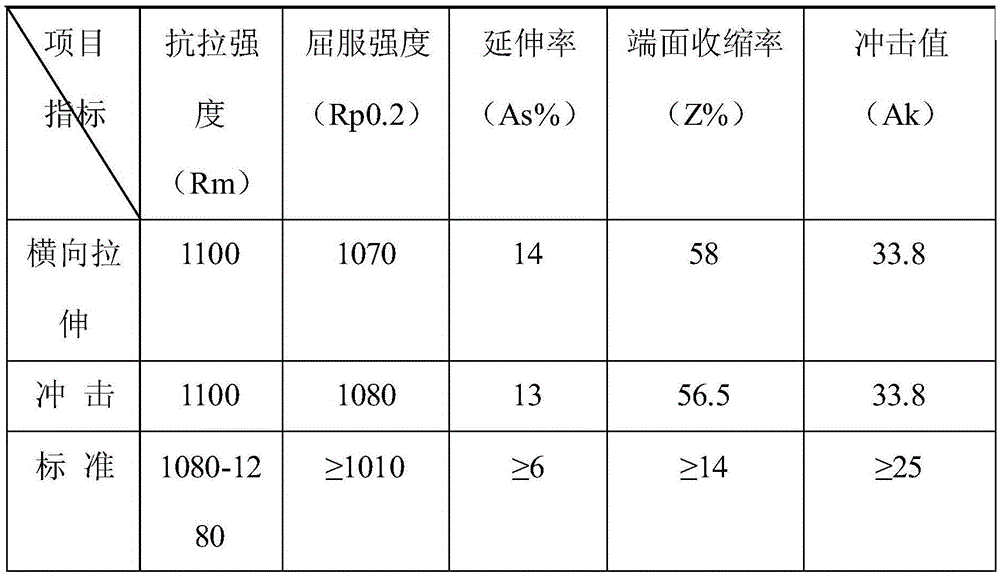

Forging method for improving TC18 titanium alloy structure property

ActiveCN105483586AImprove organizational reliabilityMetal-working apparatusBeta phaseMaterials processing

The invention relates to a forging method for improving the TC18 titanium alloy structure property, and belongs to the field of material processing. A microscopic structure of a TC18 titanium alloy is sensitive in temperature influence, during two-phase-zone forging, the microscopic structure is composed of conversion structures of a primary alpha phase and a beta phase, along with rising of the forging temperature, the content of the primary alpha phase is decreased, the size is increased, and the equiaxial degree is increased. During quasi beta forging above a phase change point, if the heat preservation time and the deformation amount are appropriately controlled, an even basket-weave microstructure can be obtained, even though the room-temperature plasticity of the structure is worse than an equiaxial structure, the strength is high, and the high-temperature behavior, the breaking tenacity and the fatigue property are better than those of the equiaxial structure; but above the phase point, a Widmannstatten structure can be obtained if the heat preservation time is too long; and compared with the equiaxial structure, the room temperature strength and high temperature strength of the Widmannstatten structure are improved, the stretching plasticity is reduced, and the room temperature impact is reduced. By means of the forging method, the structure reliability of a TC18 titanium alloy component is improved while the high strength, the high plasticity and the high breaking tenacity are obtained.

Owner:SHAANXI HONGYUAN AVIATION FORGING

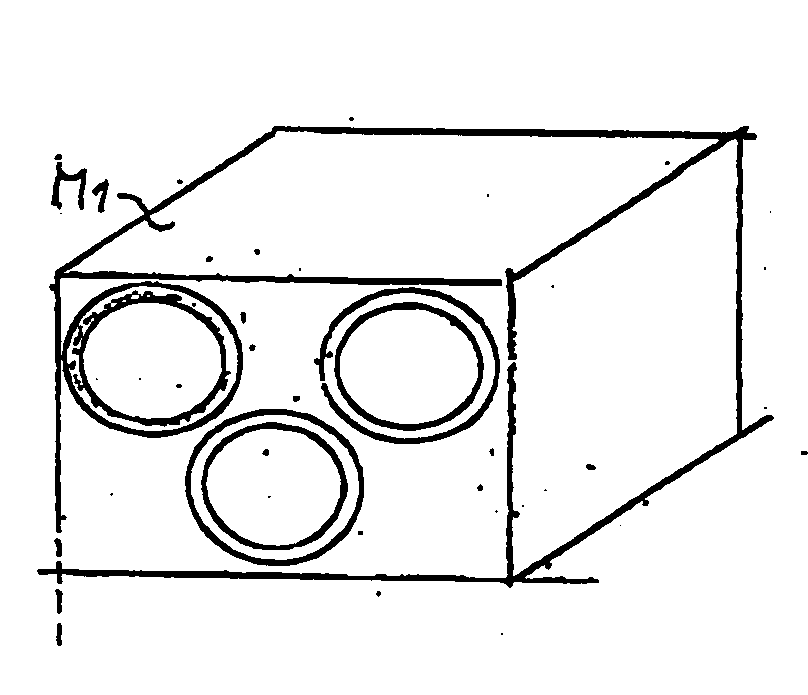

Method for Diagnosis of Functional Lung Illnesses

ActiveUS20080269592A1Fast and inexpensive and radiation-free and good spatially-resolved detectionThe effect is accurateComputerised tomographsRespiratory organ evaluationDiseaseTissue density

In a method for diagnosing functional lung illnesses, image exposures of the lungs are obtained at various phase points in time of the respiration of a subject, such as at maximum inhalation and maximum expiration, and the image exposures are segmented and at least two of the image exposures are compared on a segment-by-segment basis to identify a change in tissue density between the compared segments, as an indicator of lung functioning.

Owner:SIEMENS HEALTHCARE GMBH

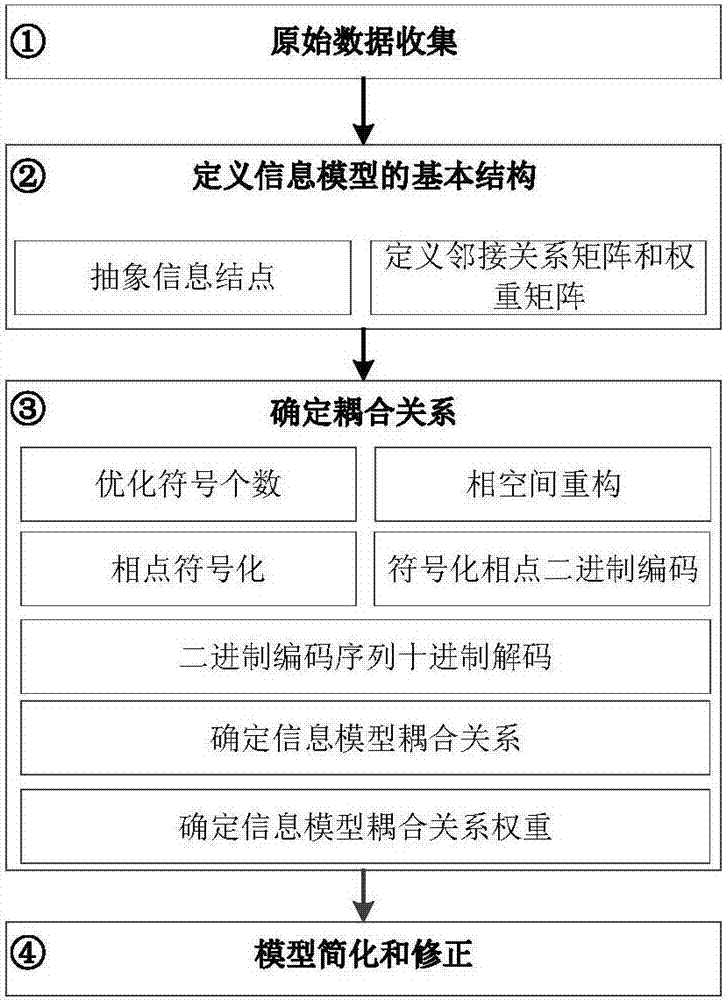

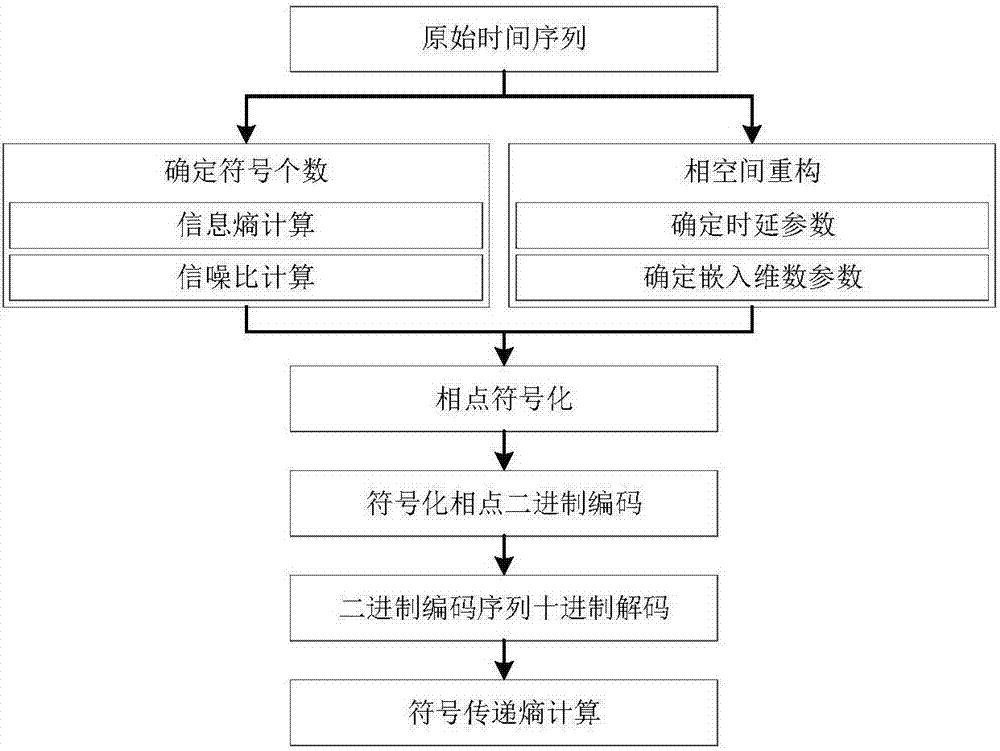

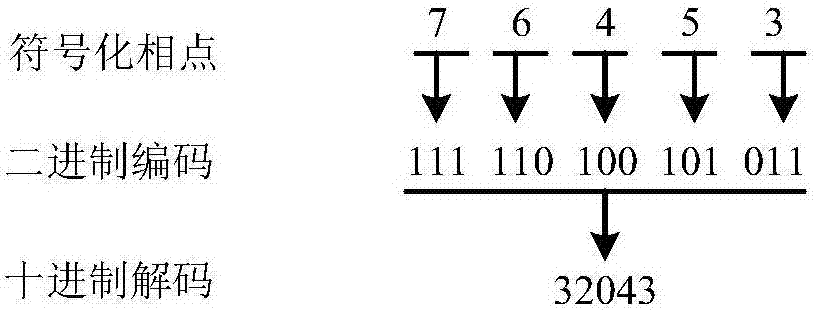

Data-driven information modeling method for complex electromechanical system in process industry

InactiveCN107292061AOptimize the symbolization processAchieve integrationDesign optimisation/simulationSpecial data processing applicationsCouplingProcess industry

The invention discloses a data-driven information modeling method for a complex electromechanical system in the process industry. The data-driven information modeling method for the complex electromechanical system in the process industry is employed. The overall modeling process does not need prior knowledge of physical topology. In the modeling process, an information flow relationship is taken as a reference for analyses of coupling relations among different functional components of the system. By taking the anti-noise property and information loss into full consideration, a symbolization process of the system for monitoring time sequences is optimized. By binary coding and decimal decoding of symbolized phase points, the integration between the symbolization process with automated analyses and calculations is achieved. Therefore, the difficulty in building an information model of the complex electromechanical system in the process industry based on monitored data under the noise condition is resolved.

Owner:XI AN JIAOTONG UNIV

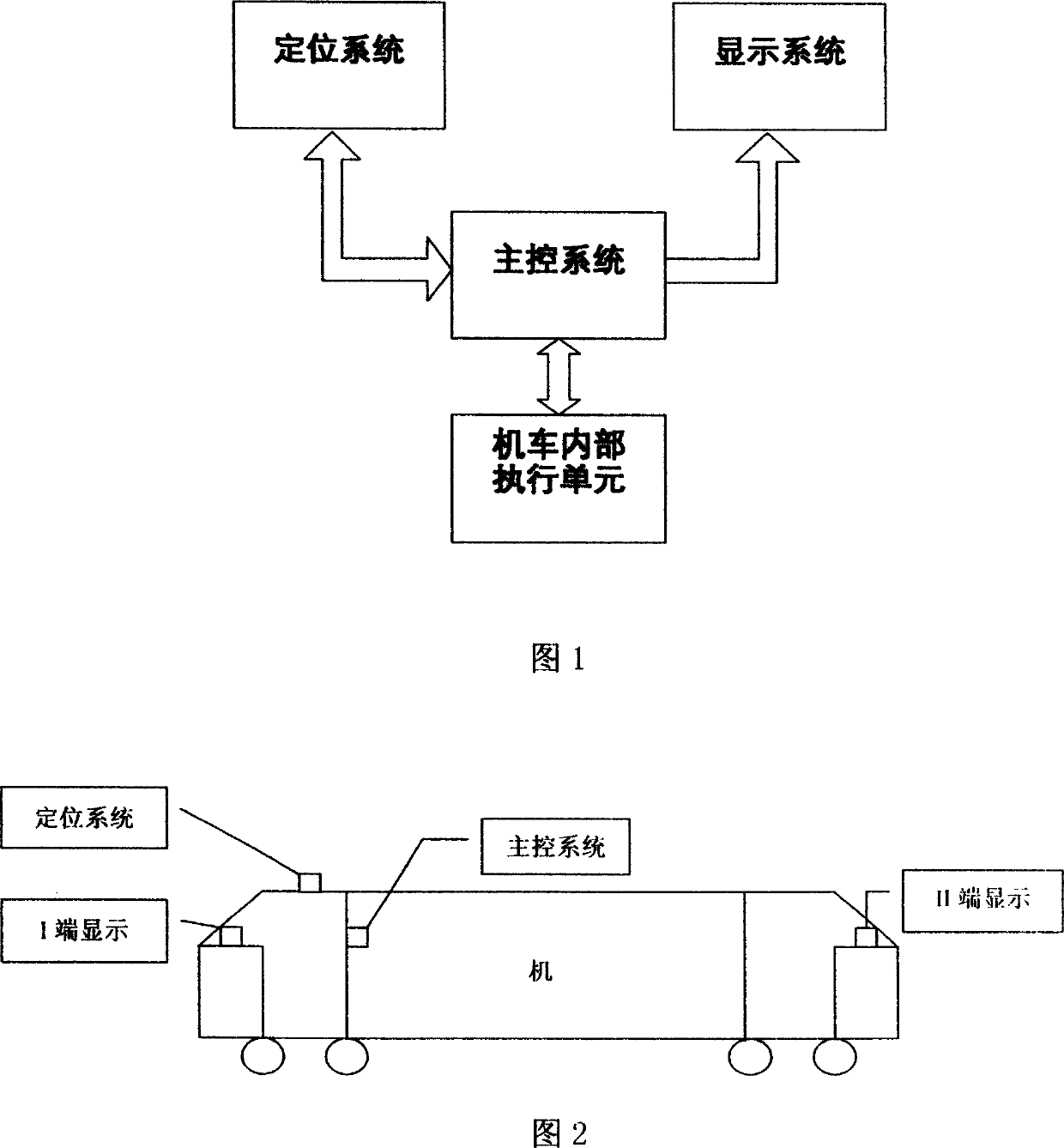

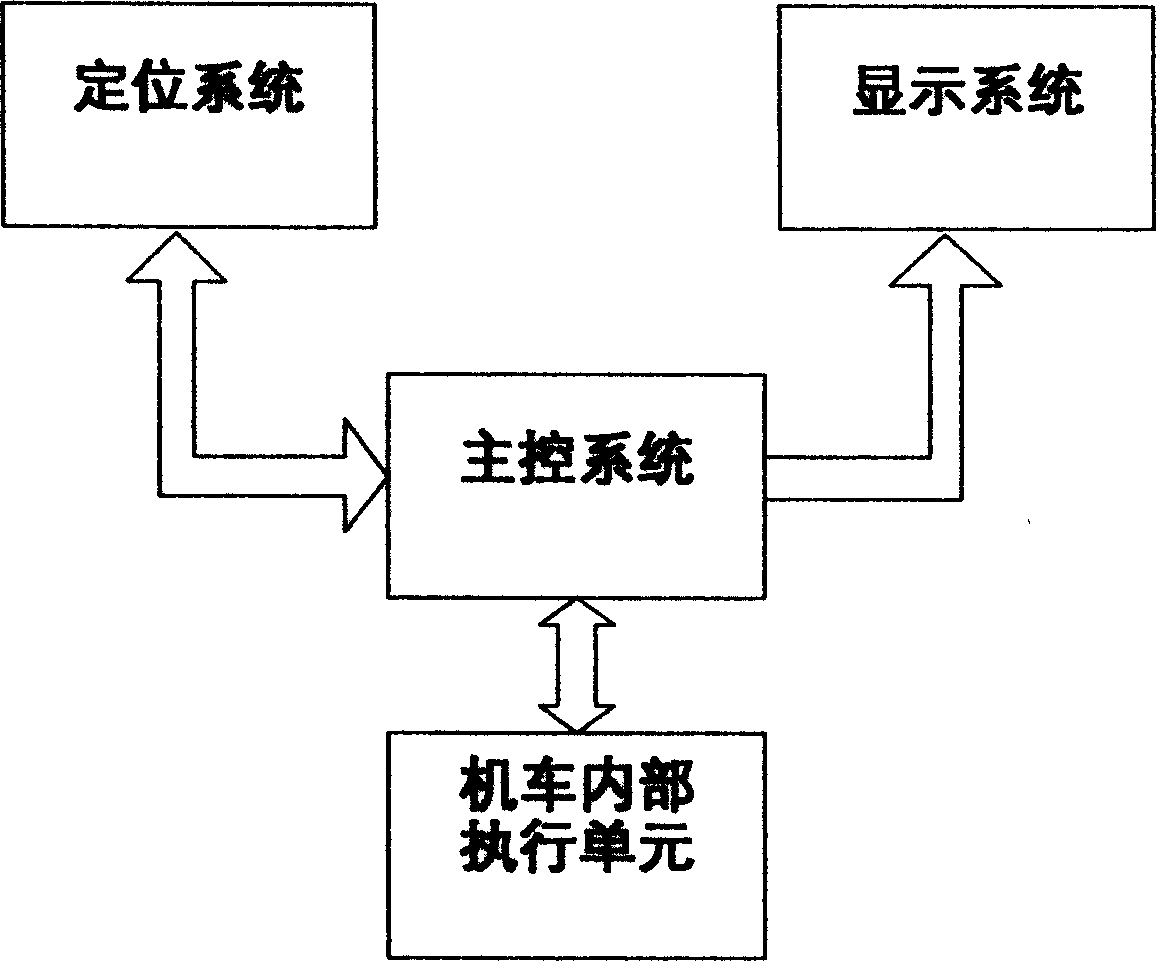

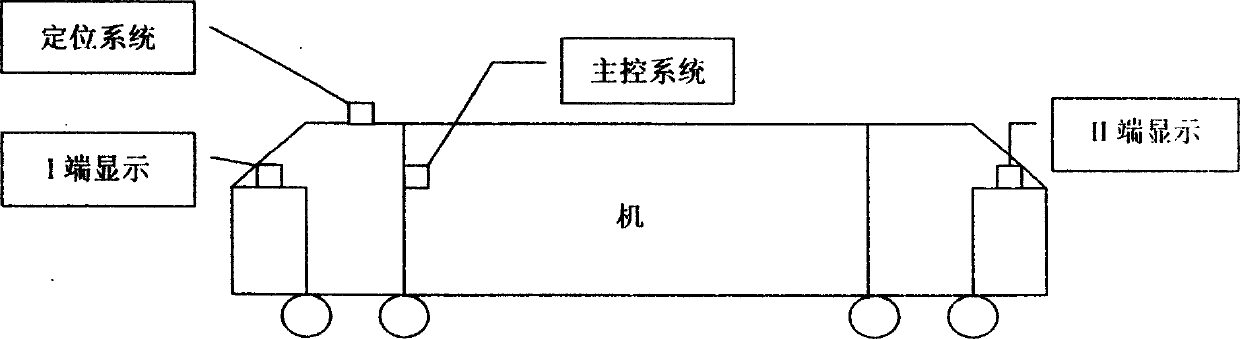

Vehicle-carrying automatically passing neutral section system of electric locomotive

InactiveCN1569509ASafe automatic over-phaseAccurate judgmentElectric vehicle charging technologyPower current collectorsMicrocontrollerEngineering

The invention discloses car carrying over split phase system, providing a system for car and vehicle passes the split phase stably and safely which not only can judge the position at front of the split phase point, but also can control the velocity of decreased current and upgraded current. The invention includes localizing system, primary control system, displaying system, primary controller procedure and localizing system procedure. The localizing system is made up of radio frequency identification system (RFID) and GPS localizing system. The localizing system procedure includes radio frequency identification system procedure and GPS localizing system procedure. The localizing system and the displaying system are connected to the primary control system through cables. The radio frequency identification system is made up of identifier and radio frequency card. The primary system includes a power, primary controller and external signal circuit, the external signal circuit is connected to the primary controller. The displaying system includes digital code tube, LED display, primary microchip and peripheral hardware circuit.

Owner:深圳市三英特高科技有限公司

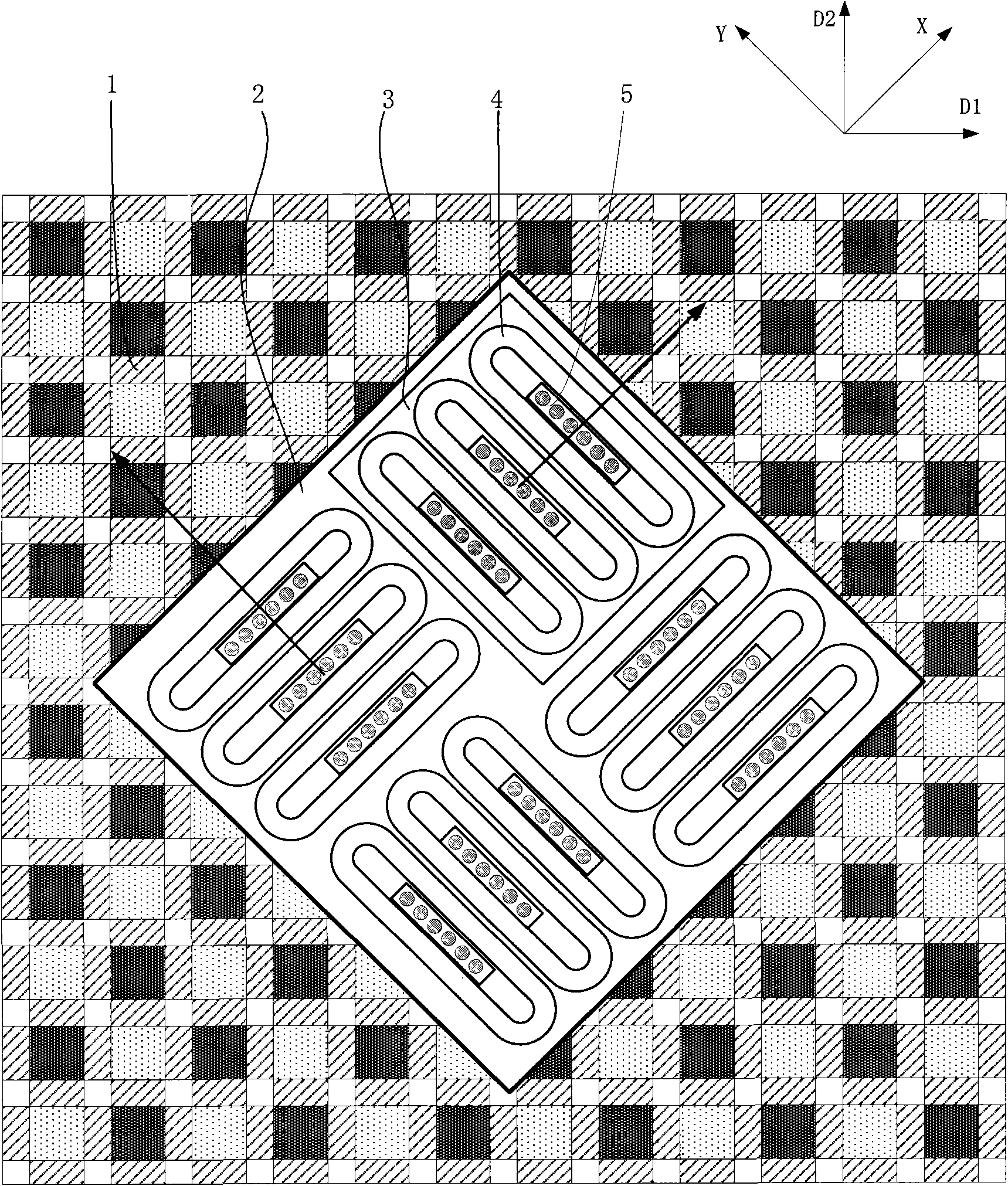

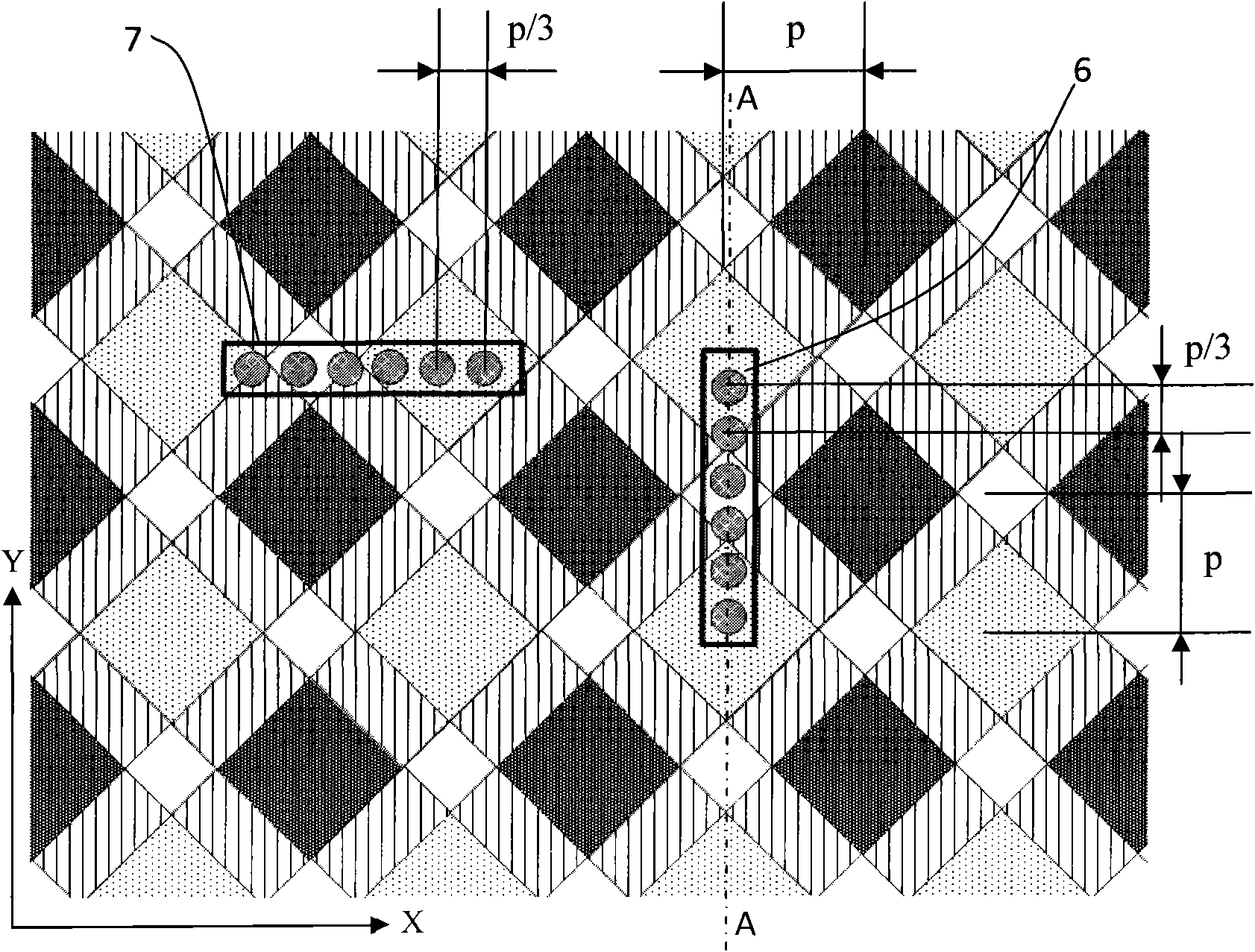

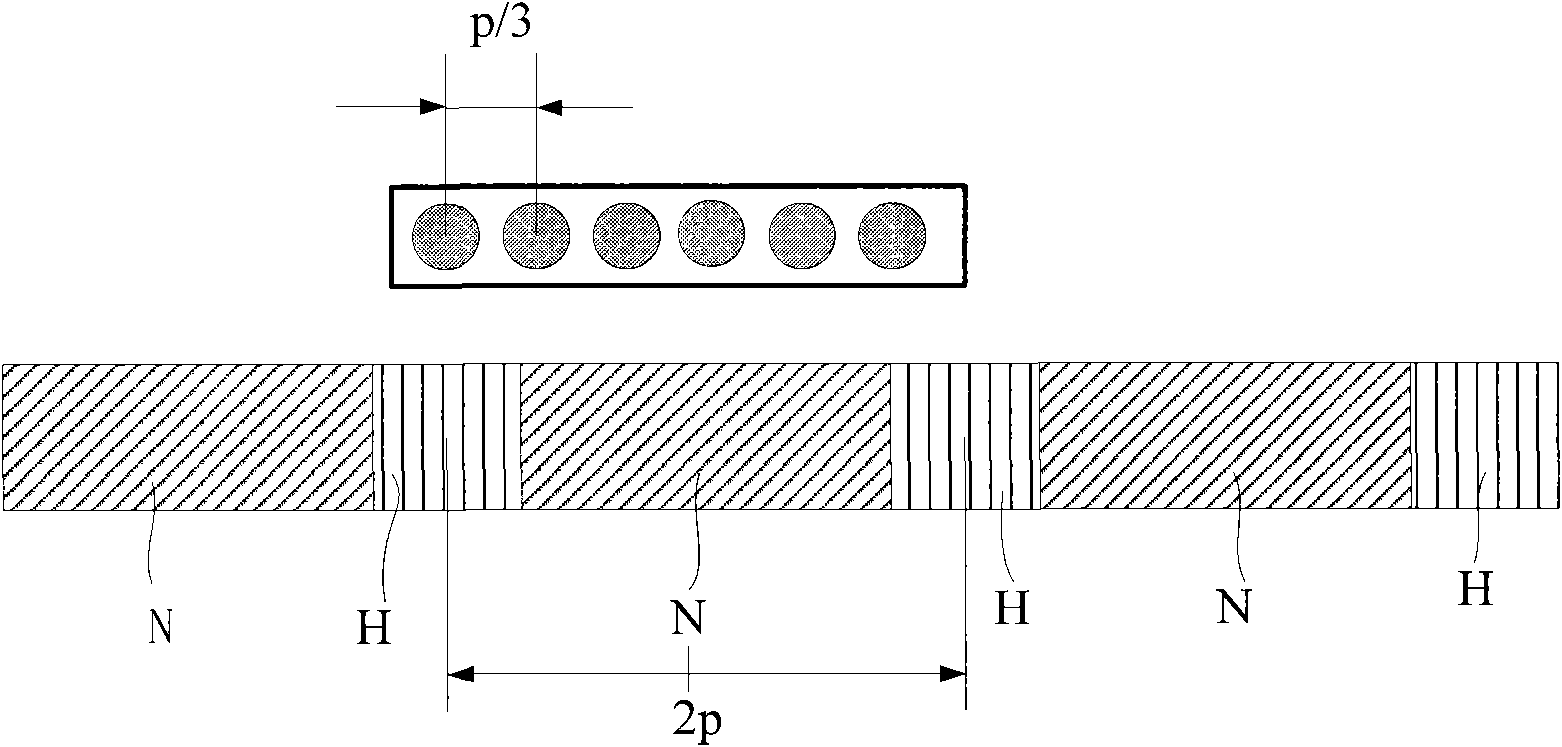

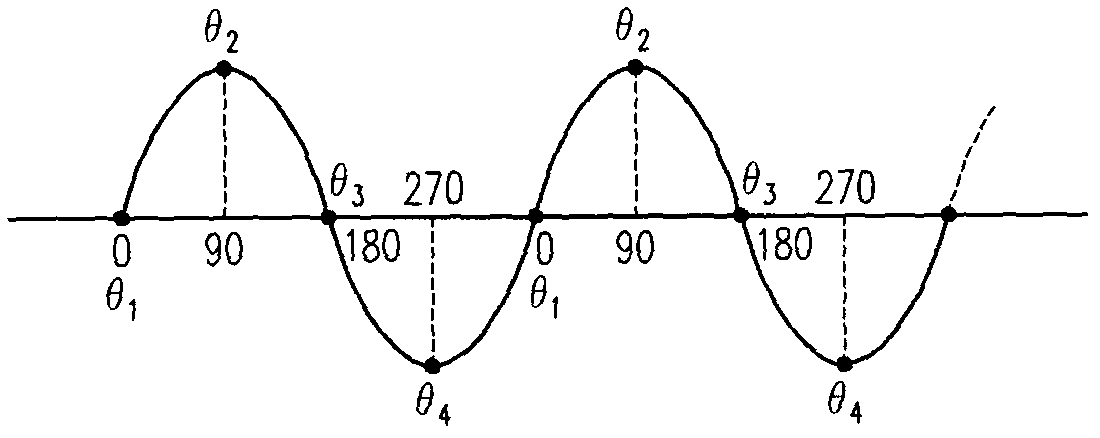

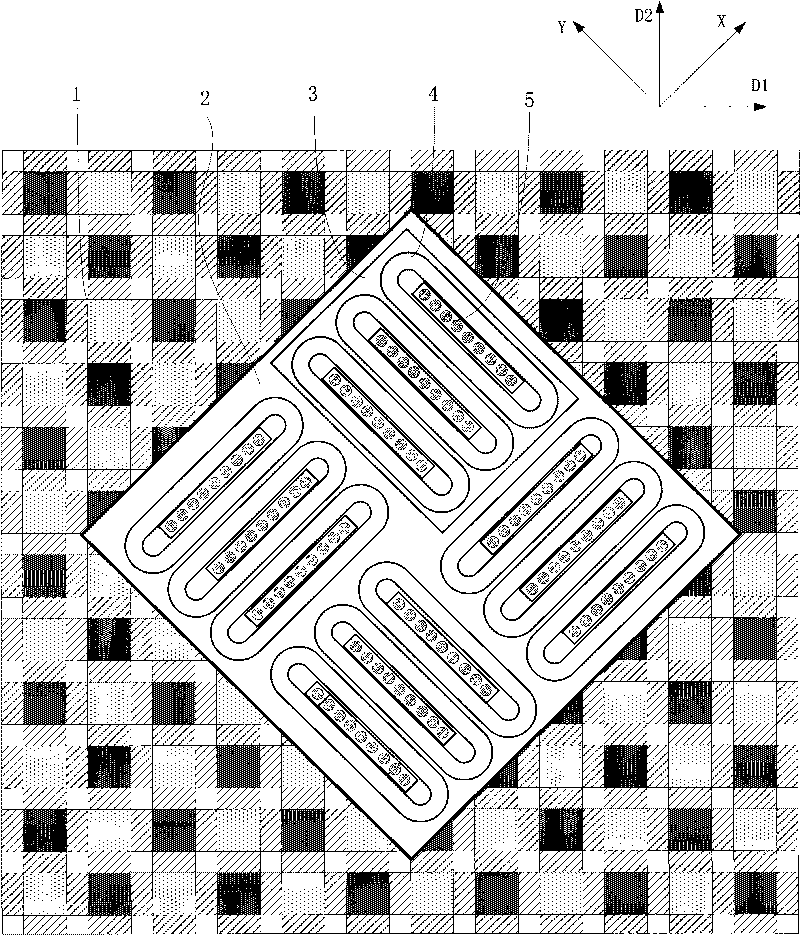

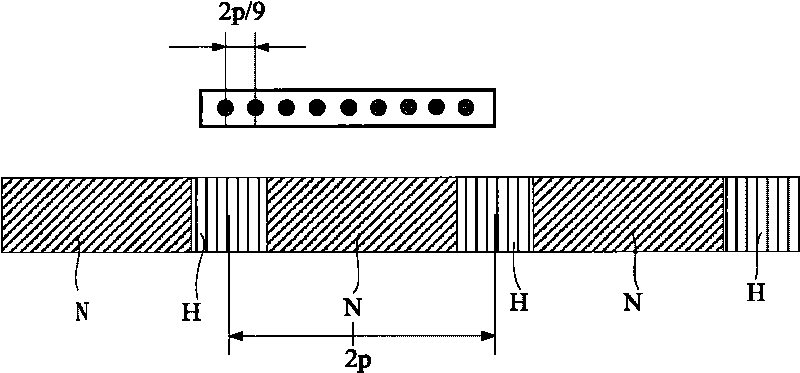

Phase searching detection method for permanent-magnet planar motor by adopting linear Hall array

A phase searching detection method for a permanent-magnet planar motor by adopting a linear Hall array is characterized in that each coil corresponds to a Hall array and the Hall array is placed perpendicular to the horizontal output direction of each driving unit of the coil; linear Hall sensors in the Hall array are distributed in equal space in the even-multiple polar distance, are placed parallel with a permanent magnet array and are used for measuring the magnetic flux density component perpendicular to the movement direction of the planar motor; and the output signal of the Hall array is generated by adding all the signals of the linear Hall sensors in the Hall array. The output signal is basically changeless when the Hall array moves perpendicular to the horizontal thrust direction of the corresponding coil, and the signal carries out positive-negative alternation in the horizontal thrust direction of the corresponding coil and changes close to the sinusoidal waveform. The position relations between the coils and the permanent magnet array when the current in the coils of the driving units is zero (phase-change point) are determined. The phase searching detection of the permanent-magnet planar motor in two dimensions becomes superposition of two one-dimensional phase searching detection, thus realizing planar phase searching detection.

Owner:TSINGHUA UNIV +1

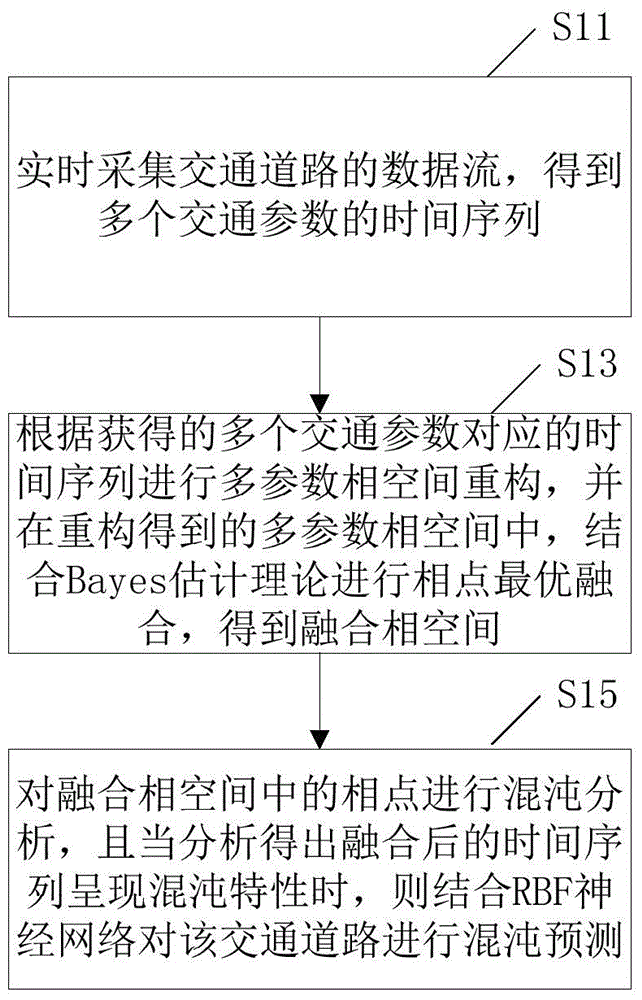

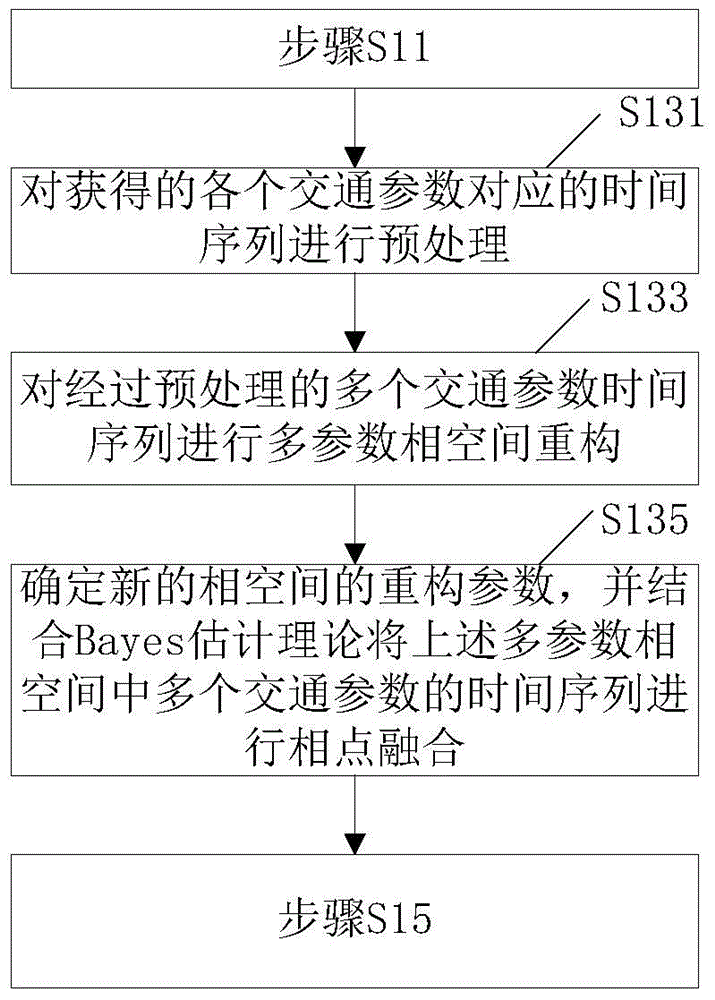

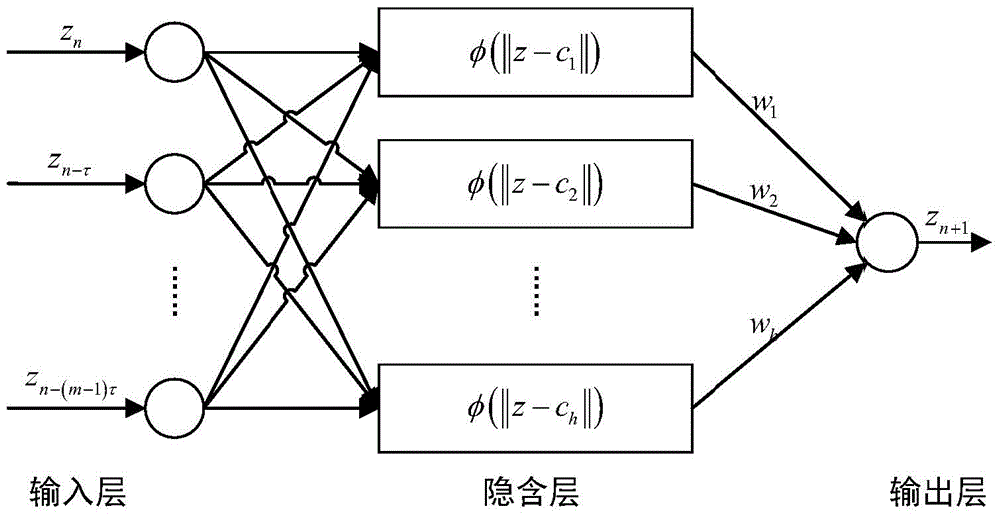

Traffic state prediction method based on chaos theory and device thereof

InactiveCN104978857AEasy to calculateHigh precisionDetection of traffic movementNeural architecturesChaos theoryData stream

The invention discloses a traffic state prediction method based on the chaos theory and a device thereof. The traffic state prediction method comprises the steps that data stream of traffic roads are acquired so that time sequences of multiple traffic parameters are obtained; multi-parameter phase space reconstruction is performed according to the time sequences of the traffic parameters and multi-parameter phase space is obtained, and optimal fusion of phase points is performed through combination of the Bayes estimation theory in the multi-parameter phase space so that fused phase space corresponding to the multiple traffic parameters is obtained; chaos analysis is performed on the time sequences in the fused phase space, and chaos prediction is performed on the traffic roads through combination of an RBF neural network when the time sequences of the fused phase space present chaos characteristics through analysis. Compared with a conventional single-parameter time sequence prediction method, a better prediction effect can be acquired by the traffic state prediction method so that predictability and precision of the traffic state prediction method are relatively high.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

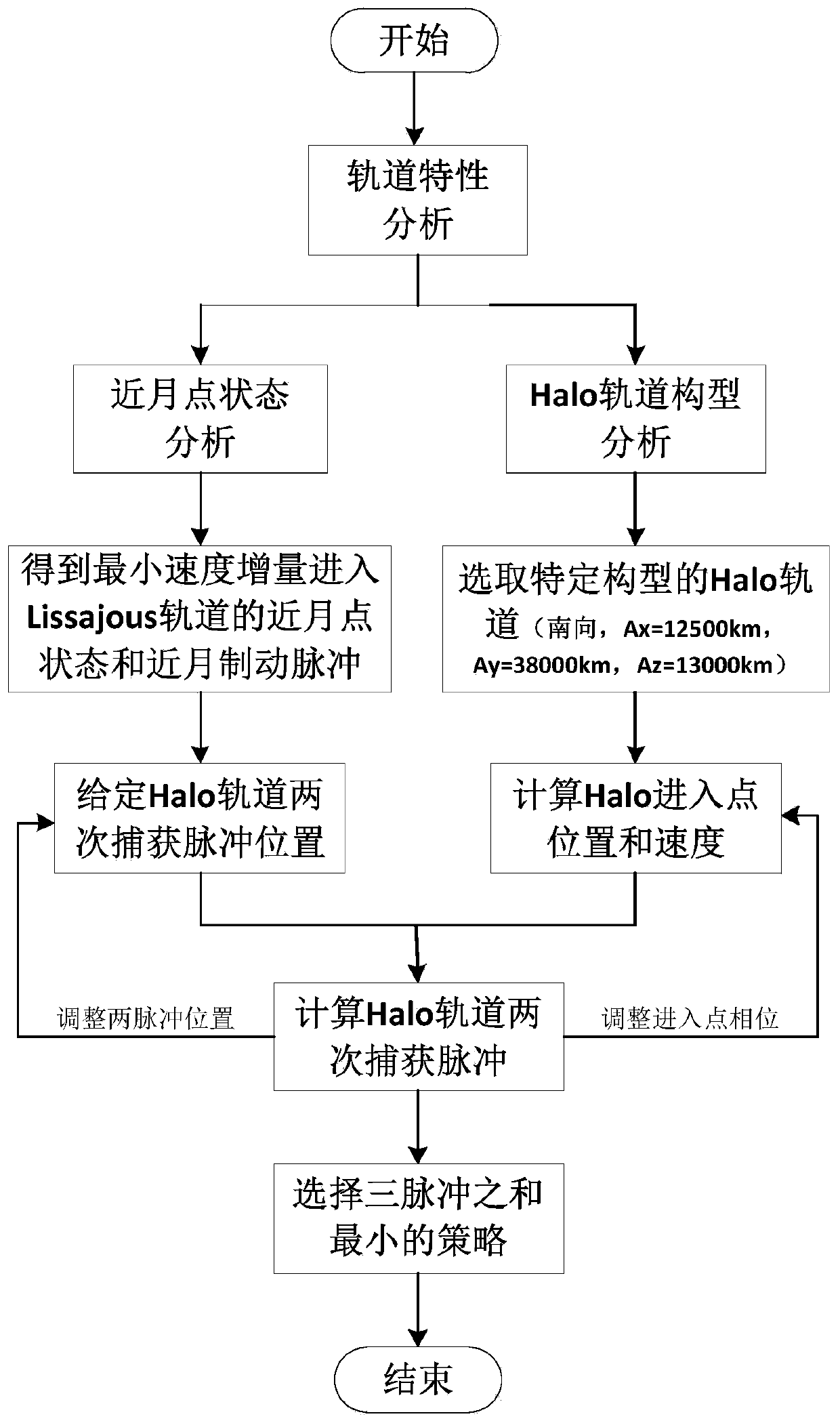

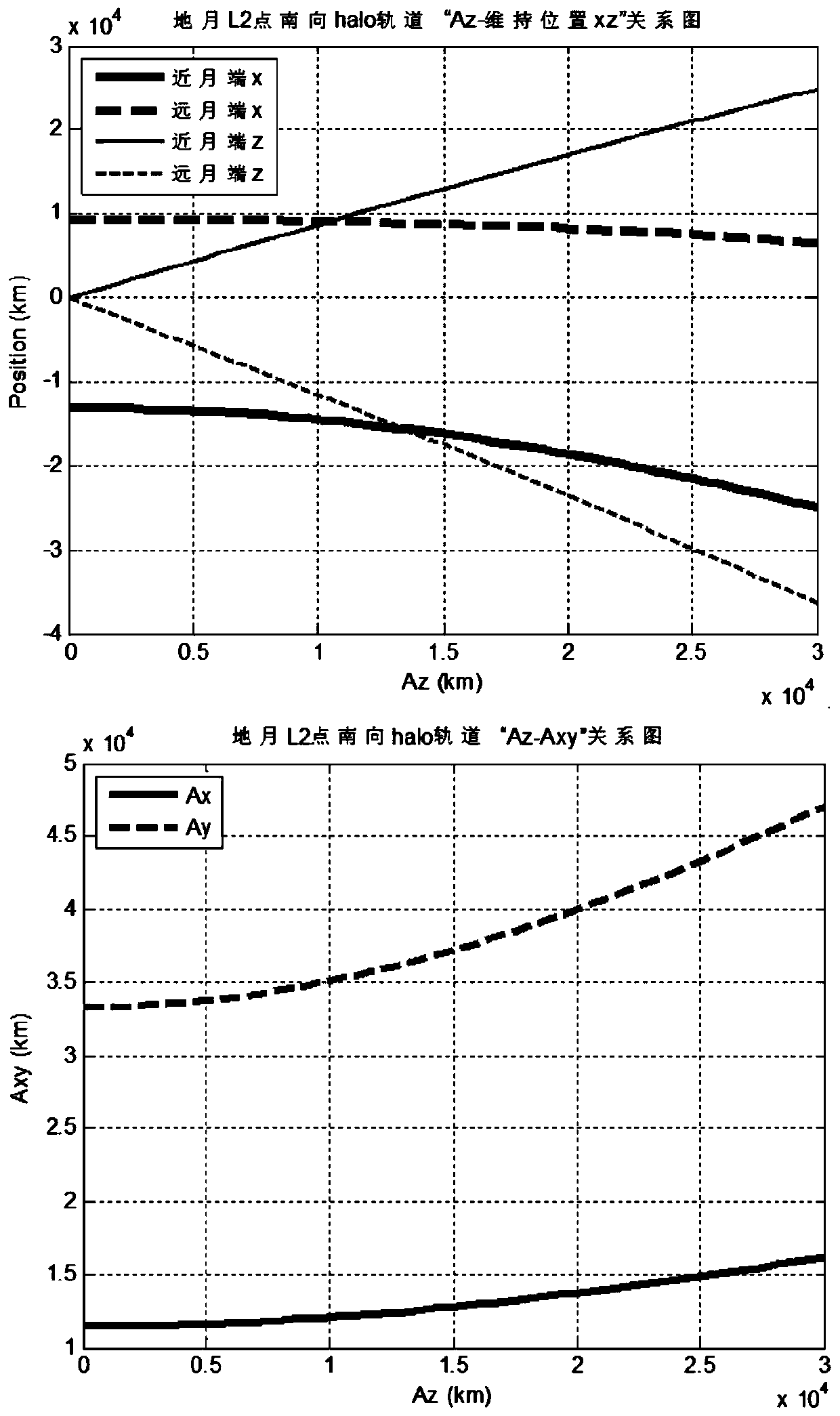

Capturing method of three-pulse earth-moon L2 point Halo orbit

ActiveCN110077626ASave speed incrementMeet the measurement and control conditionsCosmonautic vehiclesSpacecraft guiding apparatusEntry pointComputer vision

The invention provides a capturing method of a three-pulse earth-moon L2 point Halo orbit. The capturing method comprises the specific processes: firstly, the perilune pulse entering an earth-moon L2point Lissajous orbit is calculated according to characteristics of the orbit; then positions of two-time pulse capturing and the Halo entry point positions are given, the first-time captured pulse ofthe Halo orbit is solved by a method for correcting the initial state through a state transition matrix, and the second-time captured pulse is obtained by subtracting the speed of the orbit when operating to the second-time capturing position from the speed needed by the Halo orbit on the second-time capturing position; and finally, according to the engineering constraint, the positions of two-time pulse capturing are adjusted, two times of pulsed quantities needed by entering of the Halo orbit from different phase points are calculated, and a strategy with the minimum sum of the pulses of three times is selected. The strategy optimizes a Halo orbit capturing strategy through the three pulses, the multi-constraint demand in engineering is met, the speed increment is decreased, and the application range is wide.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

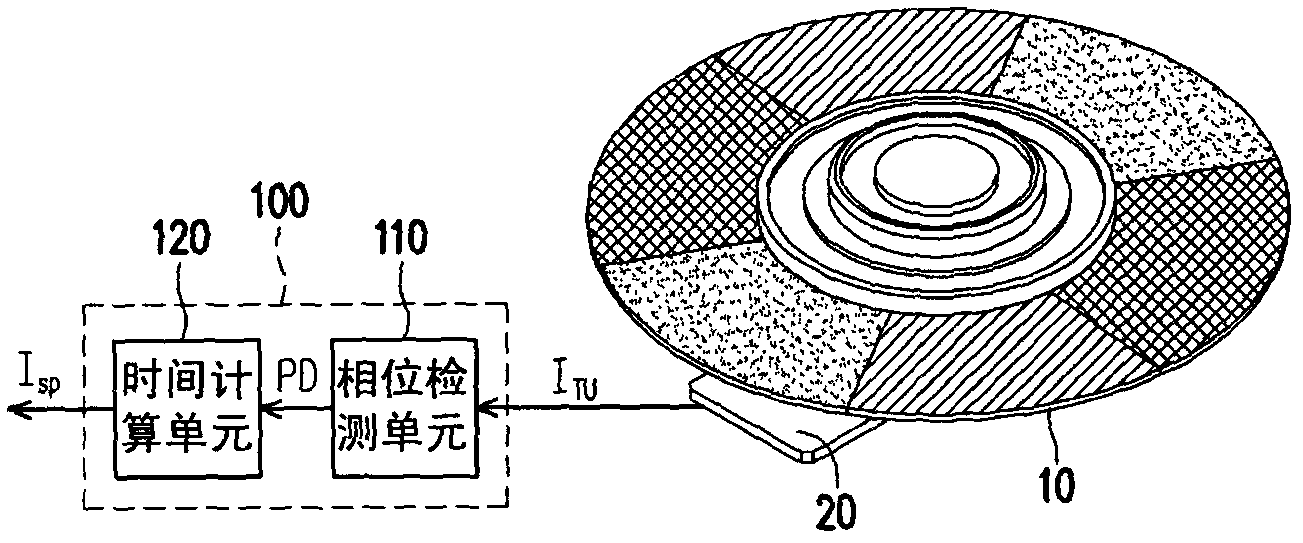

Speed detection device and speed detection method

InactiveCN102809664AAccurate speedAccurate measurementDevices using electric/magnetic meansElectricityPhase point

A rotation speed detecting device is provided. The rotation speed detecting device is electrically connected to a motor of a color wheel, and includes a phase detecting unit and a time calculating unit. The phase detecting unit is suitable for detecting a reference phase point of a rotation information outputted by the motor, and outputting a phase signal according to the reference phase point. The time calculating unit is electrically connected to the phase detecting unit, and calculates a speed information of the motor according to the phase signal. In this way, the rotation speed of the motor of the color wheel is correctly measured.

Owner:CORETRONIC

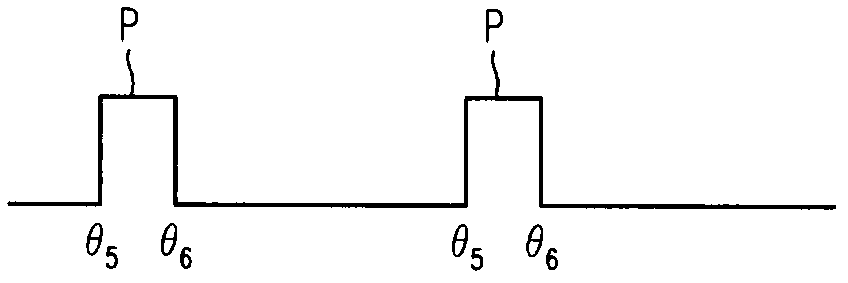

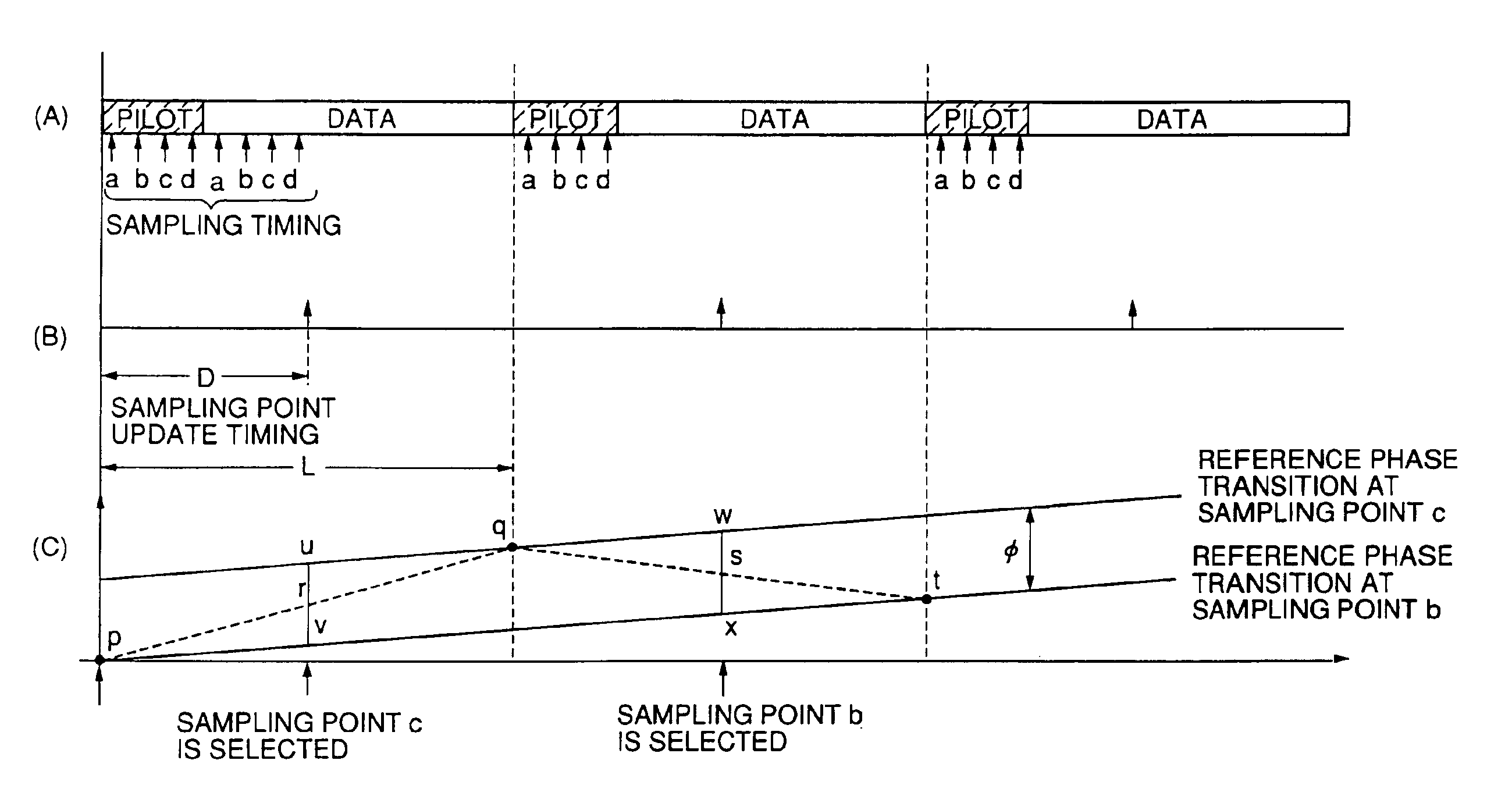

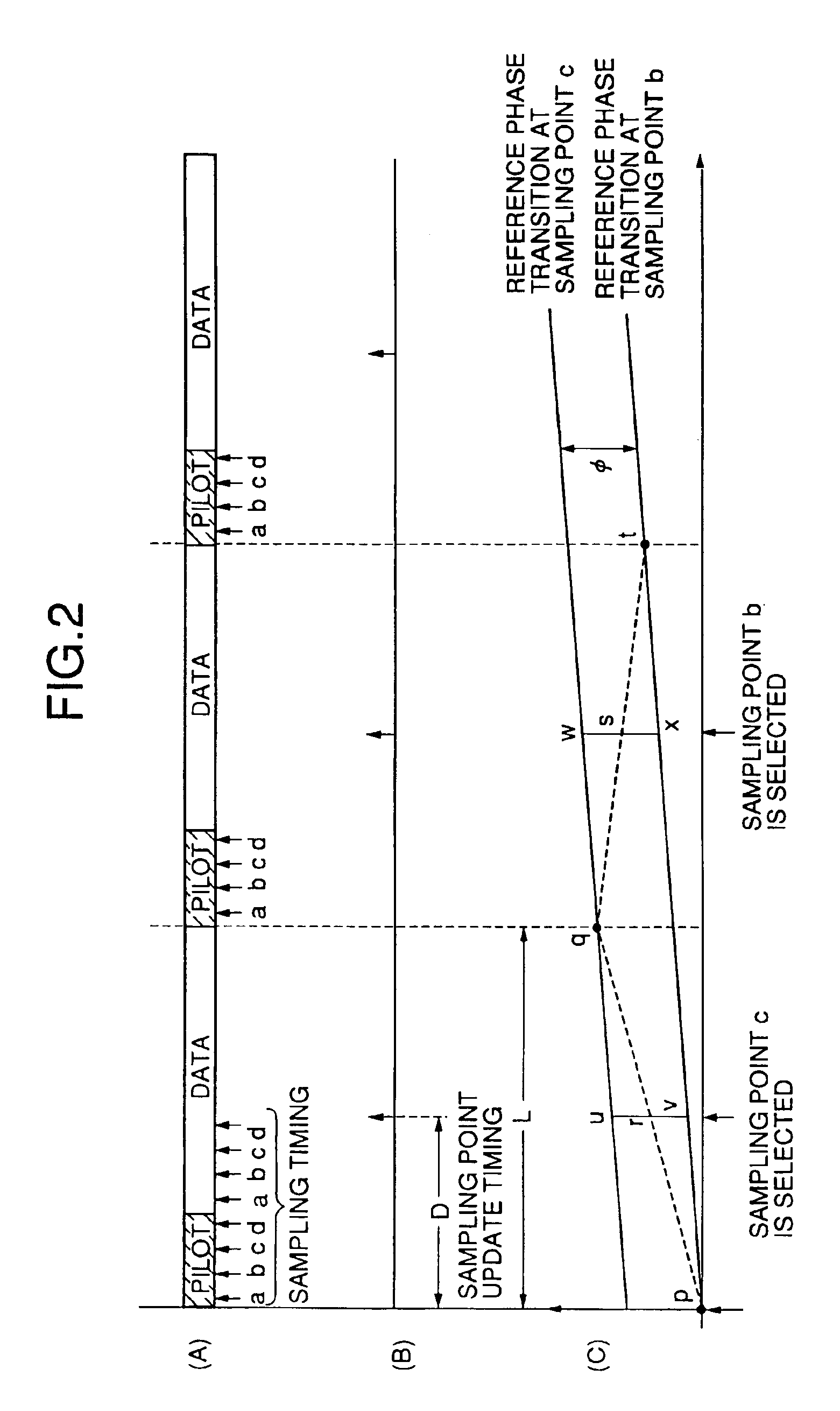

Interpolation synchronous detection method and radio communication system

InactiveUS6912259B1Minimizes transfer function errorImprove accuracyError preventionTransmission control/equalisingCommunications systemSynchronous detection

In an interpolation synchronous detection method in a radio communication system in which a pilot symbol whose phase point is known is periodically inserted in an information signal to allow interpolation synchronous detection on a receiving side, synchronous detection of the information between the pilot symbols is performed by linearly interpolating a transfer function estimated from the pilot symbols respectively located before and after the information signal, and a reception sampling point timing used for the synchronous detection is updated at the middle point between the pilot symbols respectively located before and after the information signal. A radio communication system is also disclosed.

Owner:LENOVO INNOVATIONS LTD HONG KONG

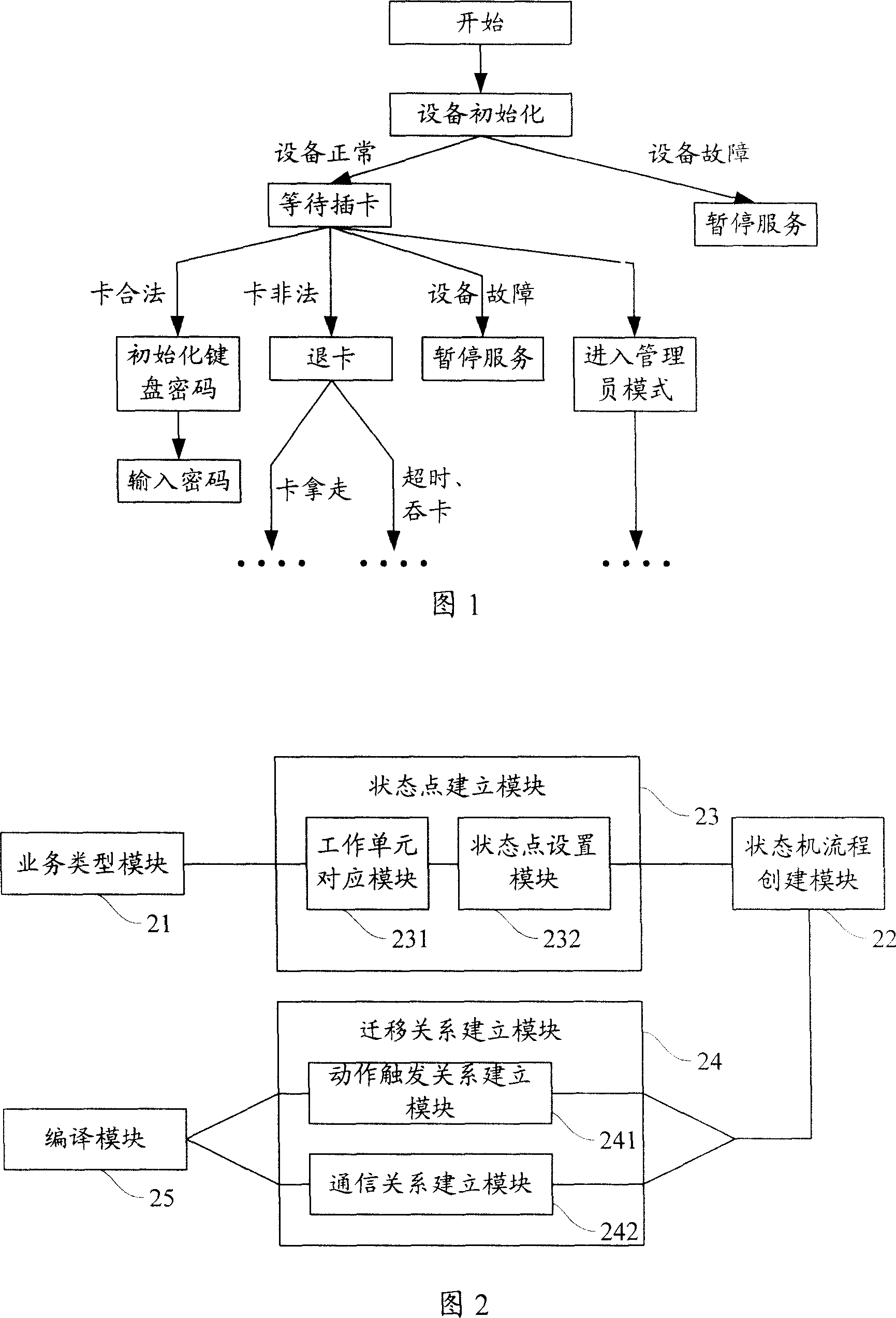

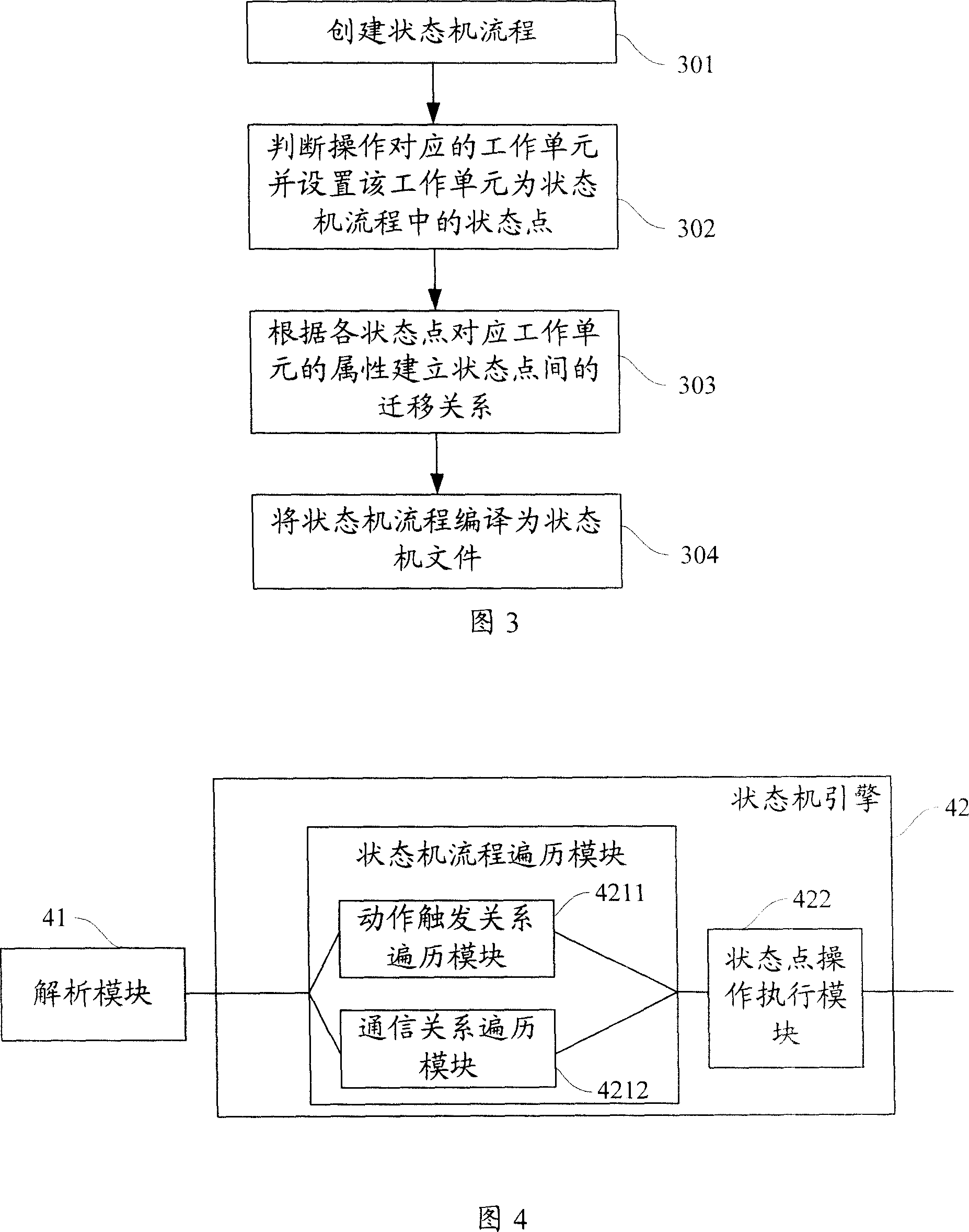

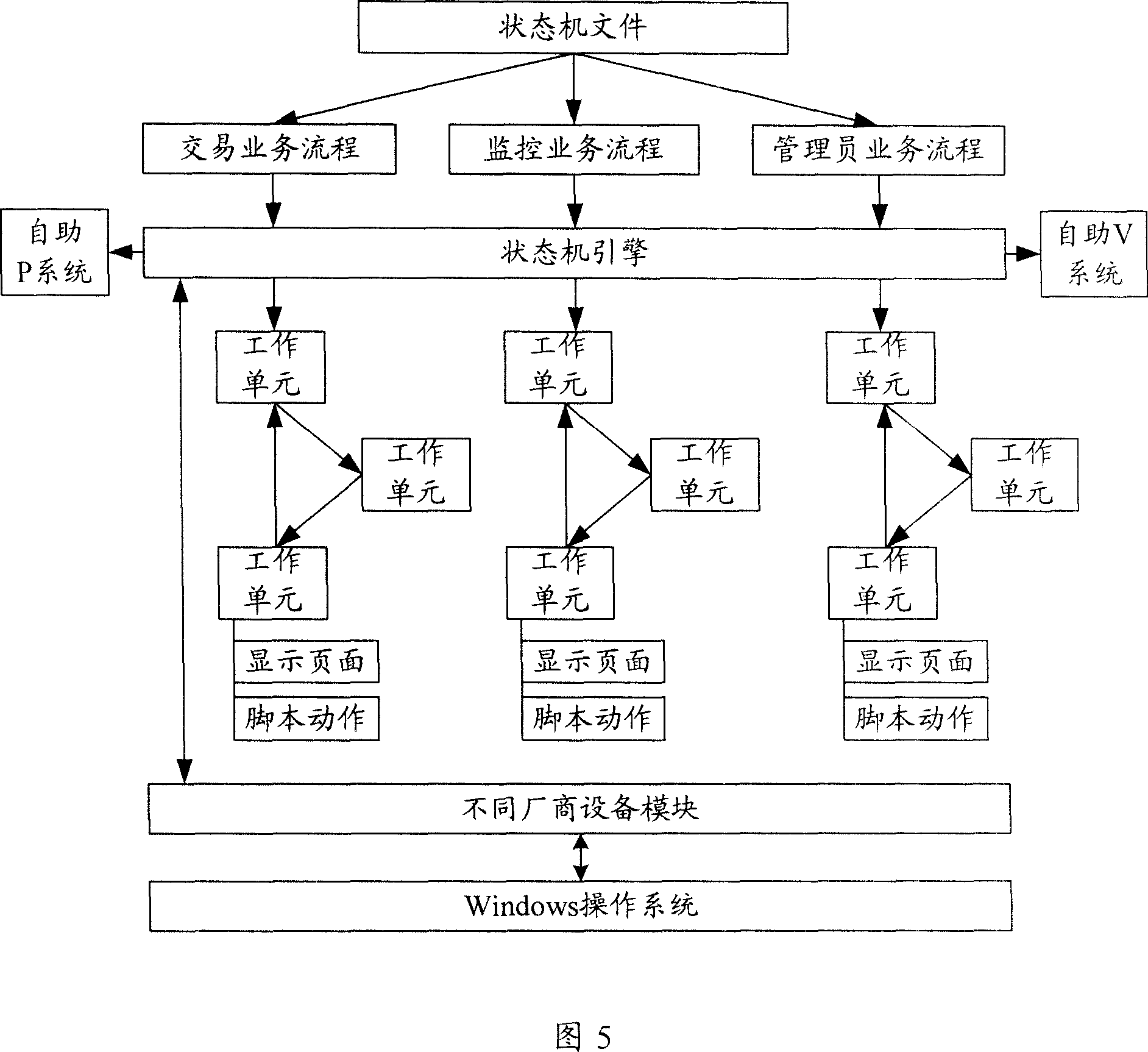

Developing platform of application software, generating method and operation platform and operation method

ActiveCN1987781AEasy to upgradeComplete banking machinesSpecific program execution arrangementsCode moduleComputer module

This invention provides a development platform of the application software, and it includes business kind module which is used to store at least one business and containing working element of group; phase fellow module which is used to found and store at least one phase fellow; phase point founding module which is used to judge the corresponding working element of the operation and sets the working element the phase point of the phase fellow; migrating relation founding module which is used to found the migrating relation between the phase point according to the working element property of all phase point in the phase fellow; coding module which is used to code the phase fellow to phase profile. This invention also provides the formation method of application software, running platform and running method. By this invention, self equipment can execute many business fellows which are independent, and the adjusting and updating can be done to the corresponding module, the updating is convenient and the other module and business can not be affected.

Owner:CHINA CONSTRUCTION BANK

Interactive type four-dimensional dummy endoscopy method and apparatus

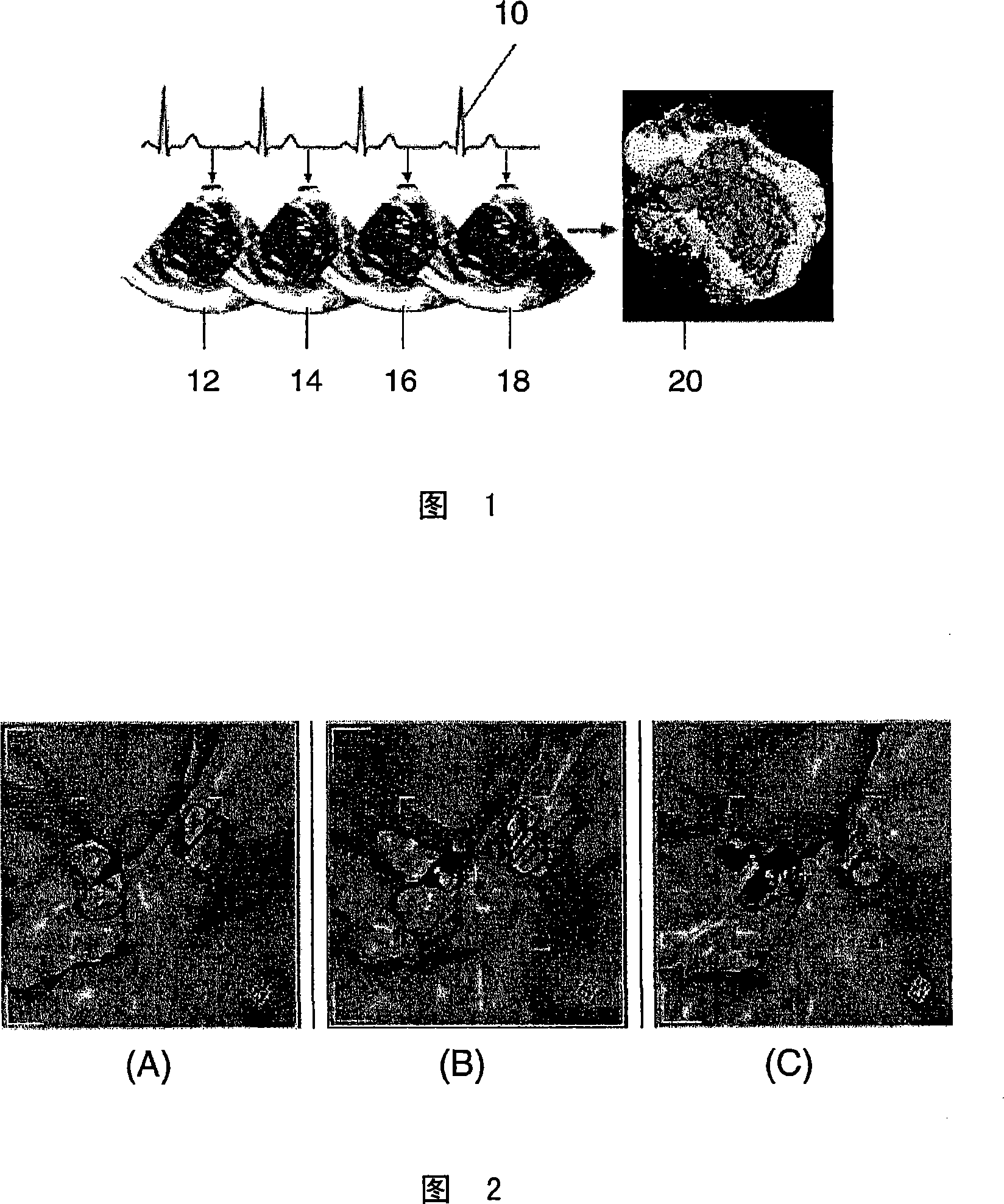

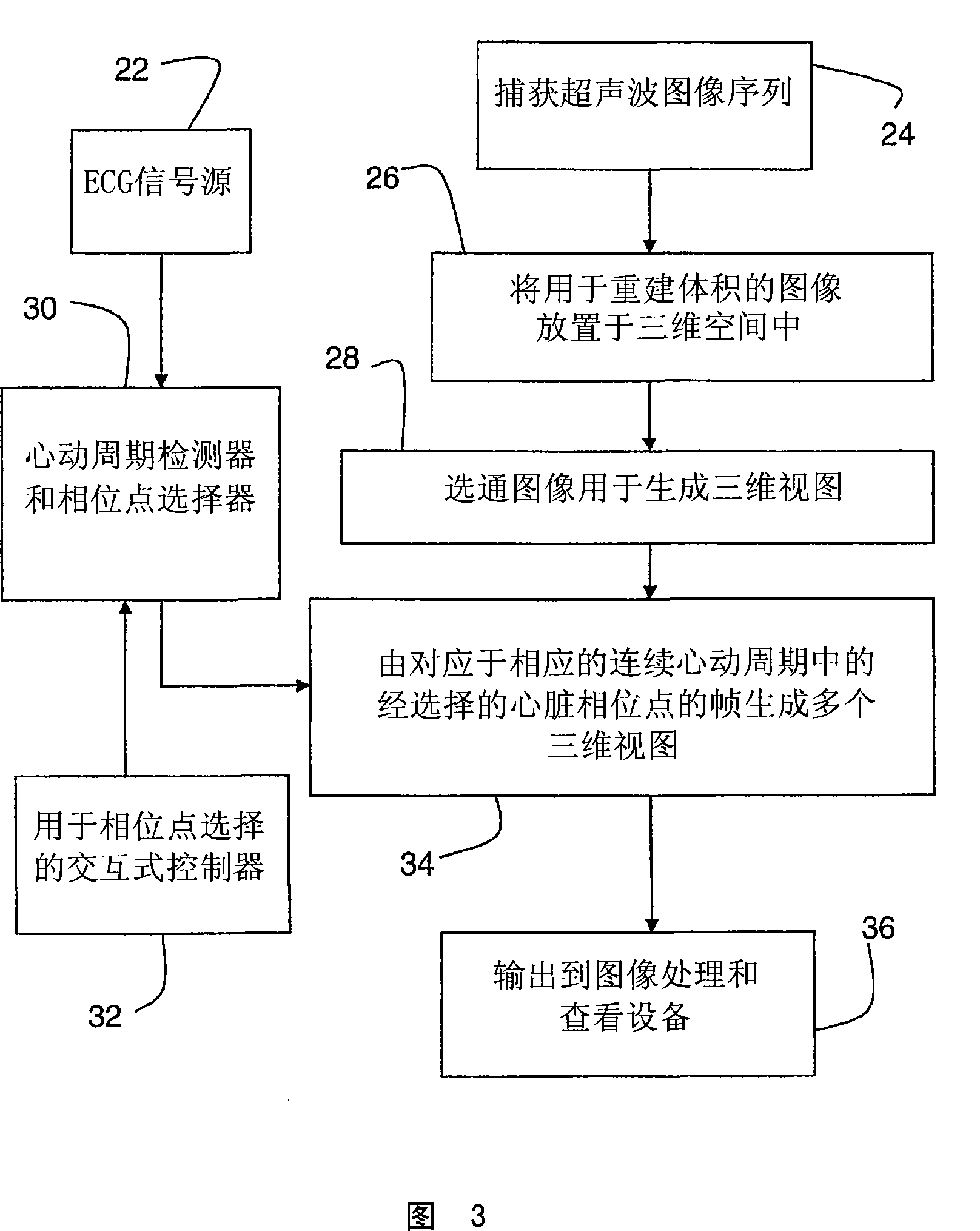

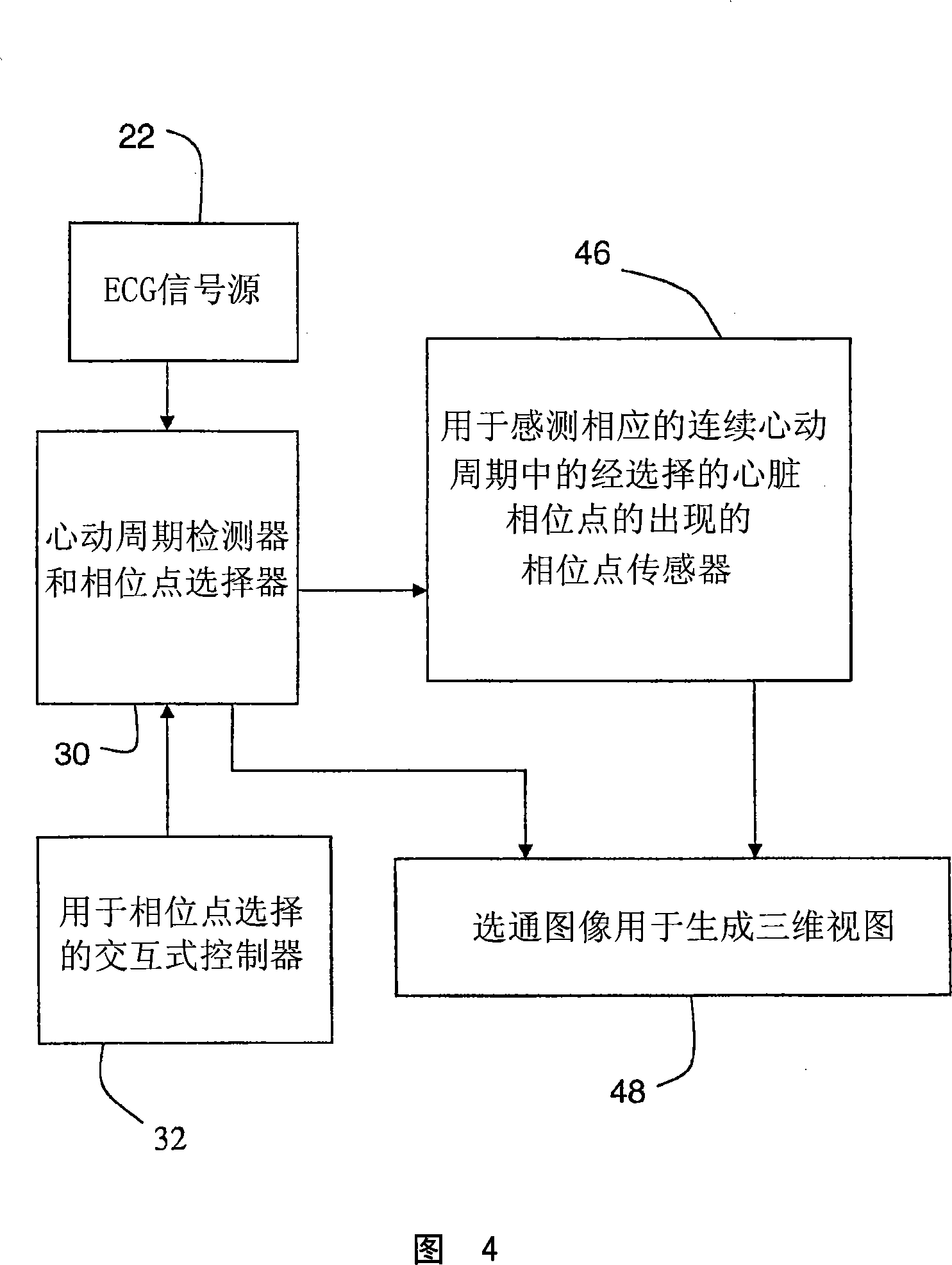

ActiveCN101190124ARich visual informationUltrasonic/sonic/infrasonic diagnosticsImage enhancementFlexible endoscopeCardiac cycle

A method for performing four-dimensional virtual endoscopy, includes capturing a heart image sequence of a patient by an imaging equipment and a electrocardiagram signal displaying a cardiac cycle of the heart. The electrocardiagram signal is used to select images to derive the corresponding three-dimensional view successively in the corresponding cardiac cycle with the corresponding heart image in the common and selected phase point of each corresponding cardiac cycle.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Terminal apparatus and response signal transmitting method

This invention is related to a terminal apparatus that can normally transmit an upstream response signal. A response signal generating unit (212); generates response signals on the basis of a setting rule in which pattern candidates of success or failure in the reception of downstream allocation control information and downstream data are associated with the phase points of response signals and further in which the phase point of one response signal associated with an arbitrary pattern of success or failure in the reception during the second communication has been set to be identical with the phase points of two response signals associated with pattern candidates for which the pattern of success or failure in the reception at PCC during the first communication is identical with the arbitrary pattern and for which all of the receptions of downstream allocation control information have been failed at SCC.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

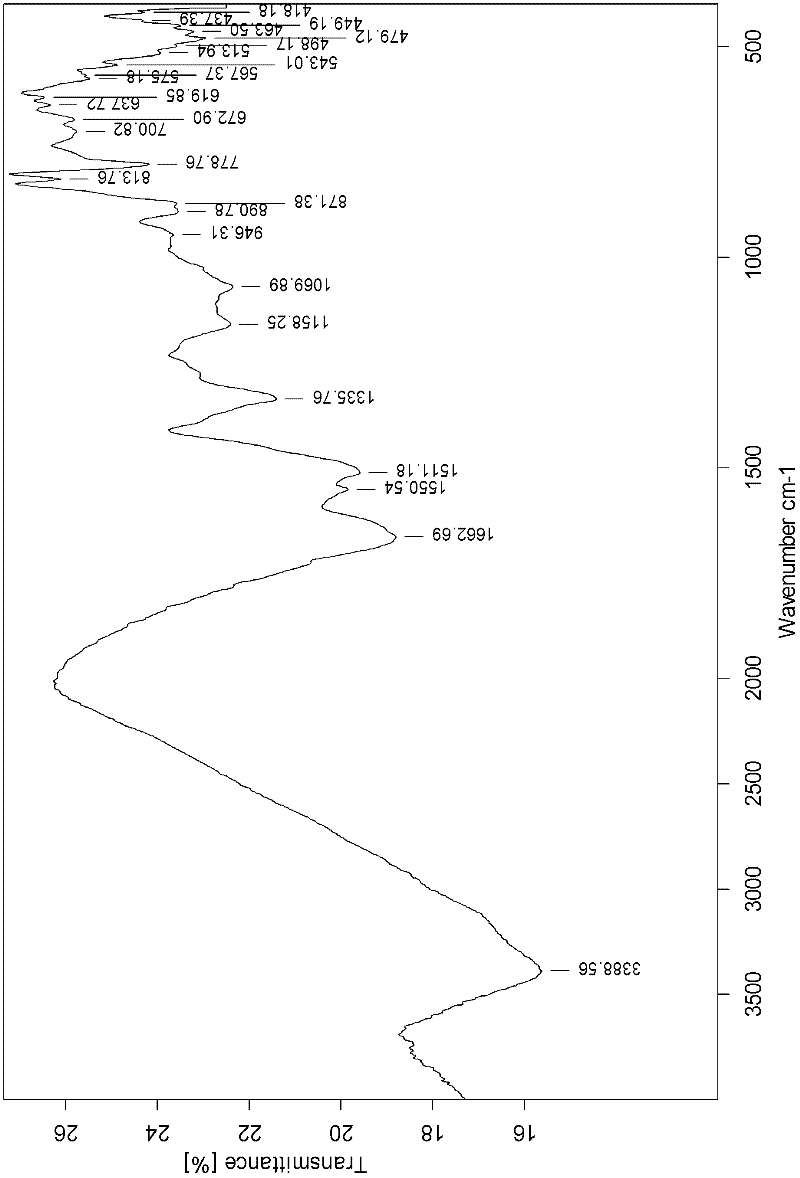

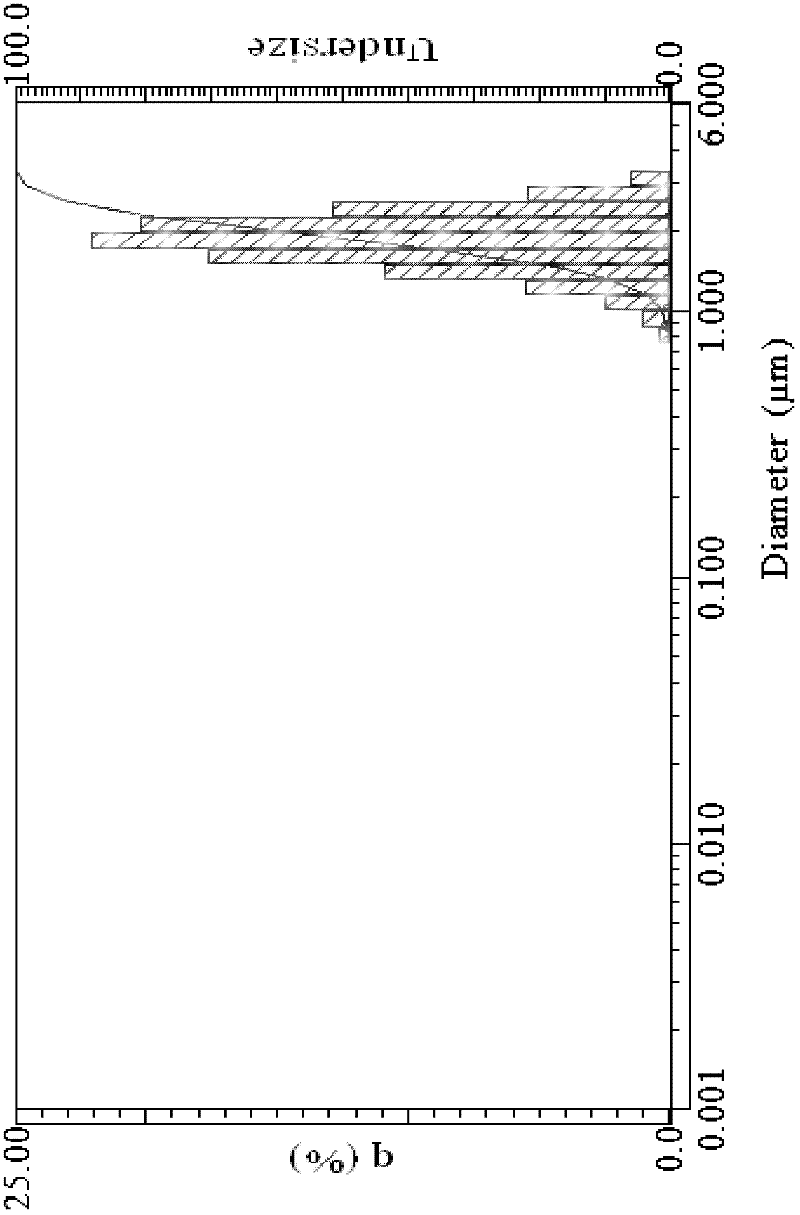

A kind of preparation method of intumescent flame retardant of phosphorus, nitrogen and carbon trinity

InactiveCN102286027AHigh reactivityLow viscosityGroup 5/15 element organic compoundsOrganic solventPhosphorus halide

The invention provides a new method for preparing a phosphorus-nitrogen-carbon trinity intumescent flame retardant with hexamethylolmelamine, melamine and phosphorus halide as the main raw materials and an inert organic solvent as the reaction medium. The reaction of methylol melamine and phosphorus halide in an inert organic solvent to obtain an esterification product; then adding water to the esterification product for hydrolysis, after the organic phase and the aqueous phase are separated, the organic phase is separated to obtain a hydrolyzate solution; the hydrolyzate Melamine is added to the solution to form a salt, and a white precipitate is produced to obtain hexamethylol melamine phosphate melamine salt. The compound molecule contains three elements of phosphorus, nitrogen and carbon, that is, an intumescent flame retardant of the trinity of phosphorus, nitrogen and carbon. Since an inert organic solvent is used as the reaction medium, the preparation method is convenient to operate and is conducive to realizing industrial production. Excellent combustion performance.

Owner:HUAZHONG UNIV OF SCI & TECH +1

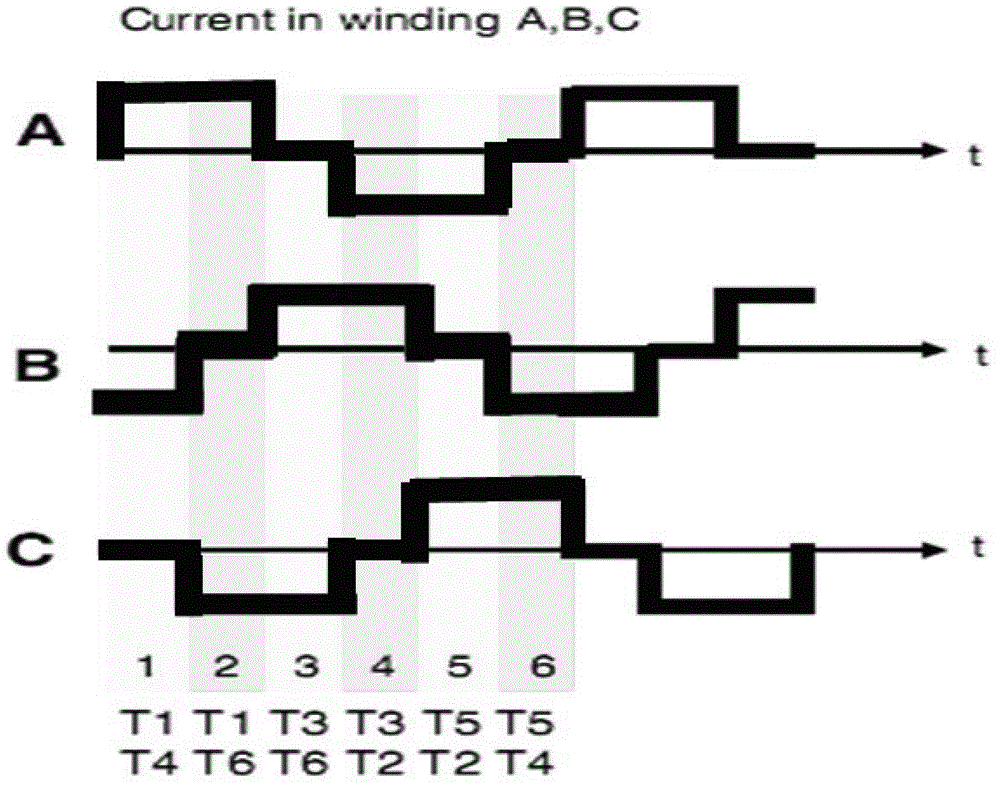

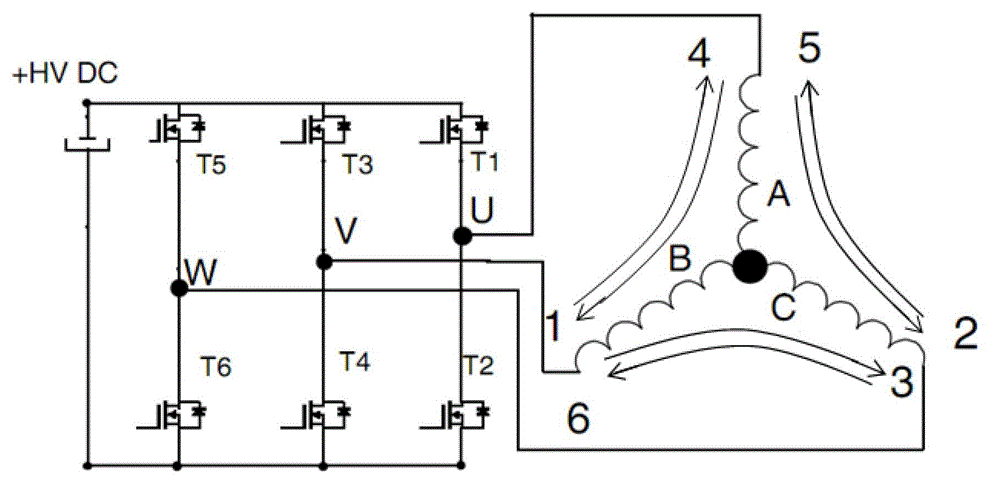

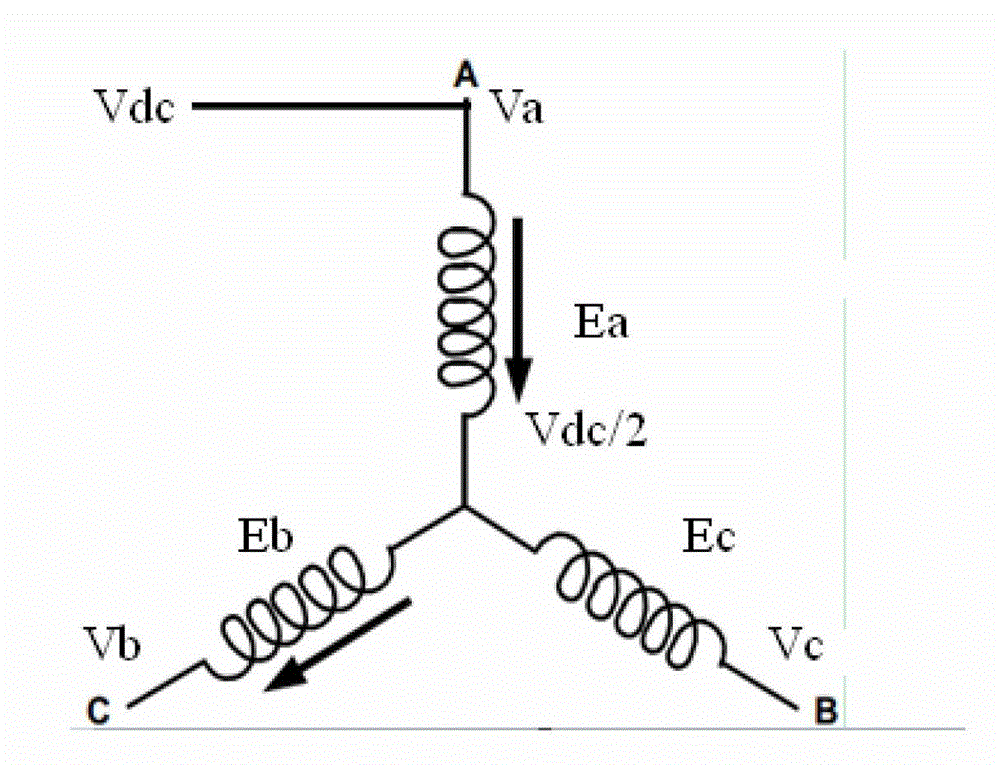

Brushless direct current motor counter electromotive force phase point detecting method

InactiveCN103187911AImprove safety and reliabilityLow costElectronic commutatorsEngineeringElectromotive force

The invention discloses a brushless direct current motor counter electromotive force phase point detecting method. The method comprises the following steps of: connecting three stator windings of a motor onto a control power supply to apply a voltage to the three stator windings of the motor to ensure that one winding is connected to the positive electrode of the control power supply after the reversing is carried out every time; connecting a second winding to the negative electrode of the control power supply; ensuring that a third winding is in a power-losing state; detecting voltages Va, Vb and Vc at the grounding ends of the three stator windings to ensure that the counter electromotive force E is equal to (Va+Vb+Vc)-3Vd<c / 2>; judging a zero crossing point of the counter electromotive force of a brushless direct current motor according to the change of the positive electrode and the negative electrode of the counter electromotive force; and delaying an electric angle of 30 degrees from the zero crossing point of the counter electromotive force of the brushless direct current motor to obtain a phase change point. The brushless direct current motor counter electromotive force phase point detecting method has the advantages of low cost and high detection reliability, an external comparator is not needed, and the safety reliability of operation of the motor is improved.

Owner:ANHUI ZHONGJIA ZHIRUI TECH

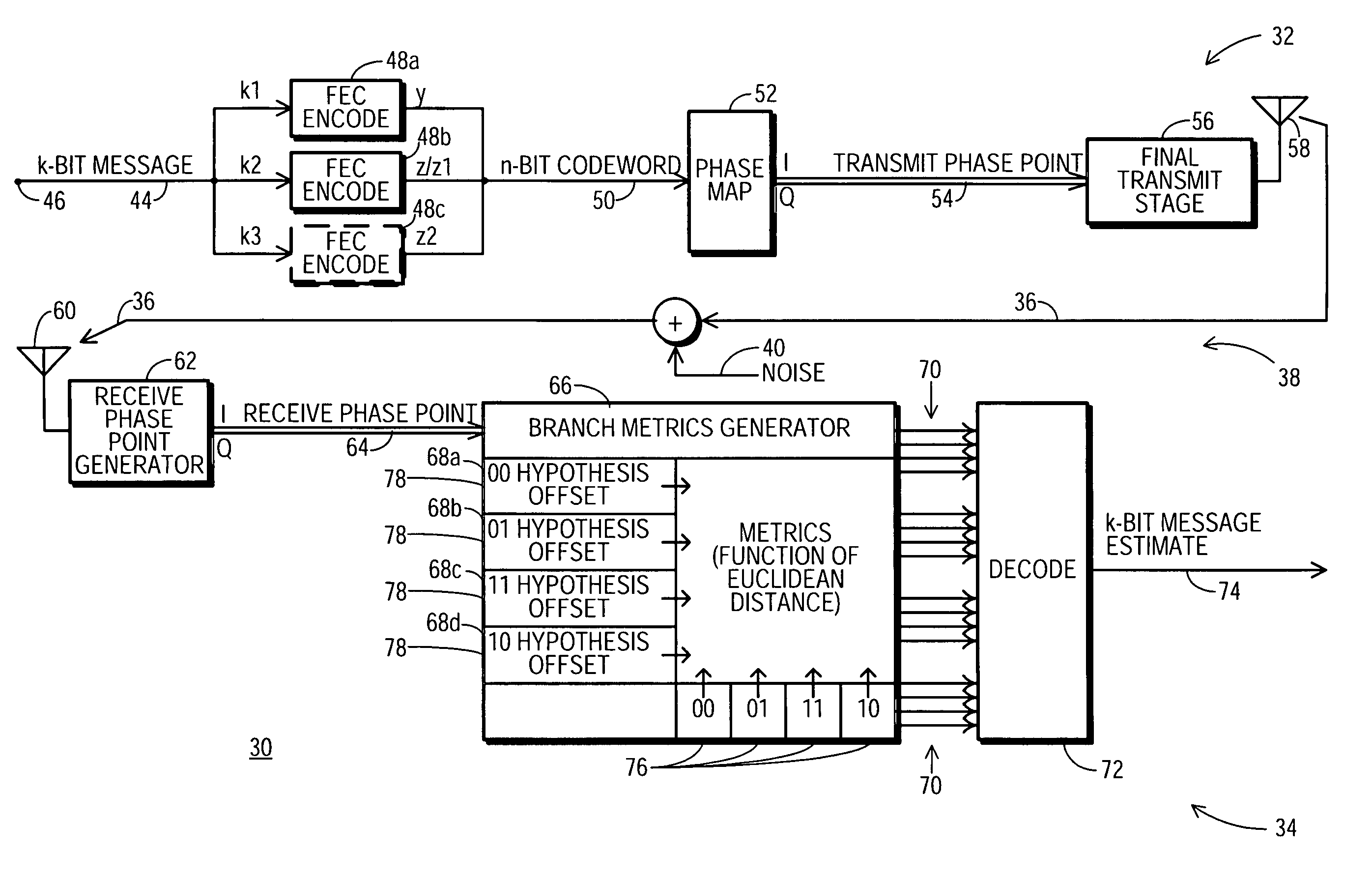

Communication method and apparatus

ActiveUS8098773B1Easy to optimizeSimple methodAmplitude-modulated carrier systemsAmplitude demodulationCommunications systemForward error correction

A communication system (30) includes a transmitter (32) which generates transmit phase points (54) defined to be the vector sum of two or more QPSK signals (76, 78). Forward error correction encoding (48) is performed independently for the QPSK signals. In a receiver (34) alternate hypotheses are formed about the potential values that might have been transmitted for at least one of the QPSK signals, and offset phase points (68) are defined for each hypothesis. Each offset phase point has the effect of cancelling at least one of the two or more QPSK signals from the combined communication signal (36). Branch metrics (70) are responsive to Euclidean distances between all offset phase points (68) and all noise-free phase points that correspond to the QPSK signal about which no hypotheses are formed. A decoder (72) is configured to accept and reject the hypotheses in addition to counteracting noise.

Owner:PIESINGER GREGORY H

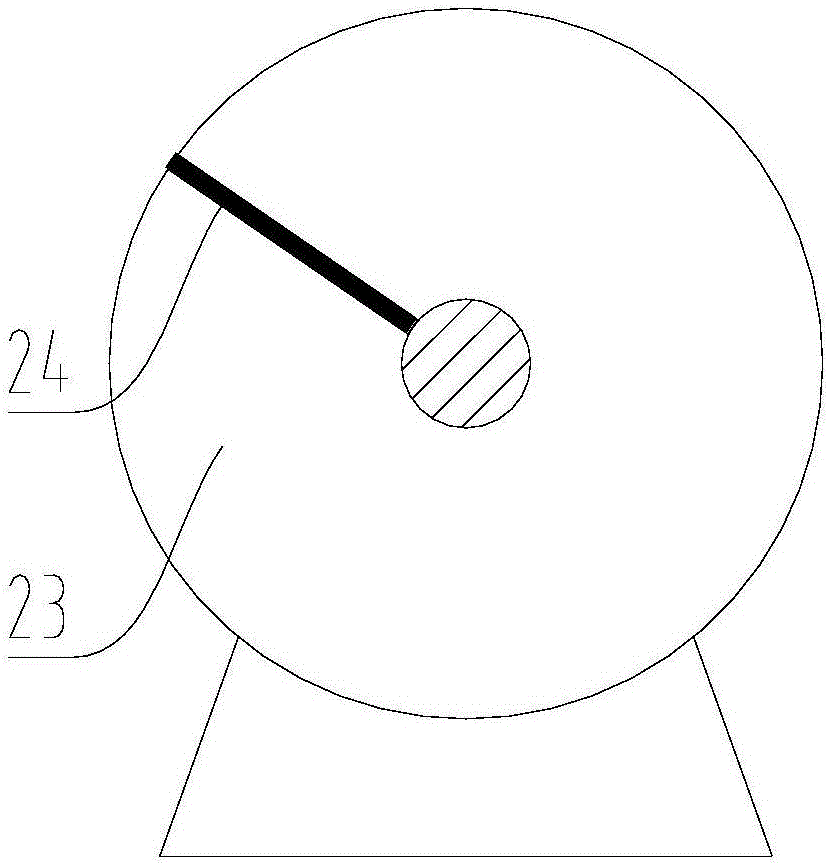

Online dynamic balance correction method of large-size draught fan impeller

InactiveCN106353035AReduce disassembly processExcellent vibration standardStatic/dynamic balance measurementImpellerVibration amplitude

The invention discloses an online dynamic balance correction method of a large-size draught fan impeller, belonging to the field of equipment overhauling, and aiming at reducing impeller assembling and disassembling procedures and shortening an overhauling period. The online dynamic balance correction method comprises the following steps: A, connecting one end of a vibration detection balancing apparatus with a driving end of the draught fan impeller on line and connecting the other end of the vibration detection balancing apparatus with a driven end of the draught fan impeller; marking a vibration starting phase point on a wheel disc of the impeller; B, starting the vibration detection balancing apparatus and detecting an original vibration amplitude and an original phase of a bearing bush at the driving end of the draught fan impeller; C, calculating balance counter weight needing to be added and a phase of the added balance counter weight; and D, adding the balance counter weight to the back surface of the impeller. According to the online dynamic balance correction method of the large-size draught fan impeller, after the balance counter weight and the mounting position of the balance counter weight are measured in a large-size draught fan installation site by utilizing the vibration detection balancing apparatus, the balance counter weight is mounted on the impeller and the draught fan impeller does not need to be assembled and disassembled, so that the impeller assembling and disassembling procedures are reduced and the overhauling period is shortened.

Owner:PANGANG GRP ENG TECH

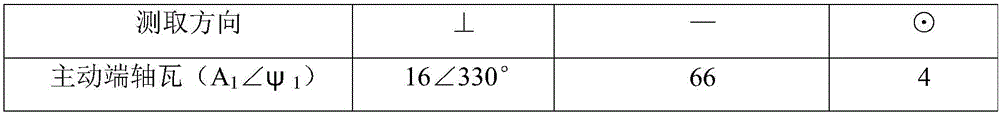

Aortic valve semi-automatic segmentation method based on CTA dynamic image

ActiveCN110570424ASolving Consistency IssuesAccurately reflectImage enhancementImage analysisAutomatic segmentationFeature extraction

The invention discloses an aortic valve semi-automatic segmentation method based on a CTA dynamic image, and the method comprises the steps: obtaining CT angiography image data under electrocardio gating, carrying out the division of 20 time phases, and carrying out the following steps for an image of each time phase point: step A, segmenting Valsalva sinus according to the upper and lower boundaries of the root of an aorta; and step B, segmenting the aortic valve from the Valsalva sinus. According to the method, the feature extraction range in the CTA image is expanded, so that more completeanatomical details are presented, and the working efficiency and safety during an operation are further improved.

Owner:ARMY MEDICAL UNIV

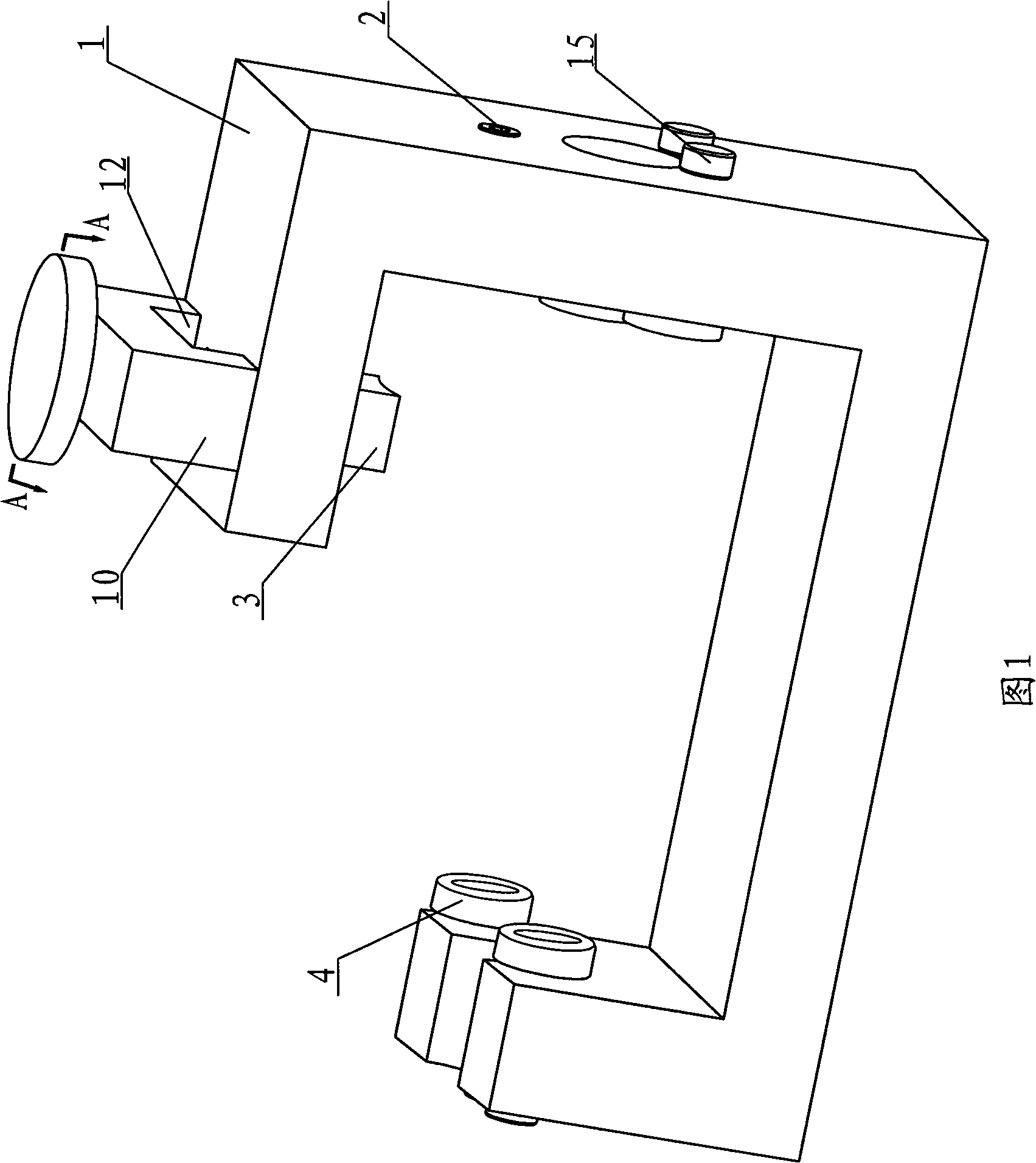

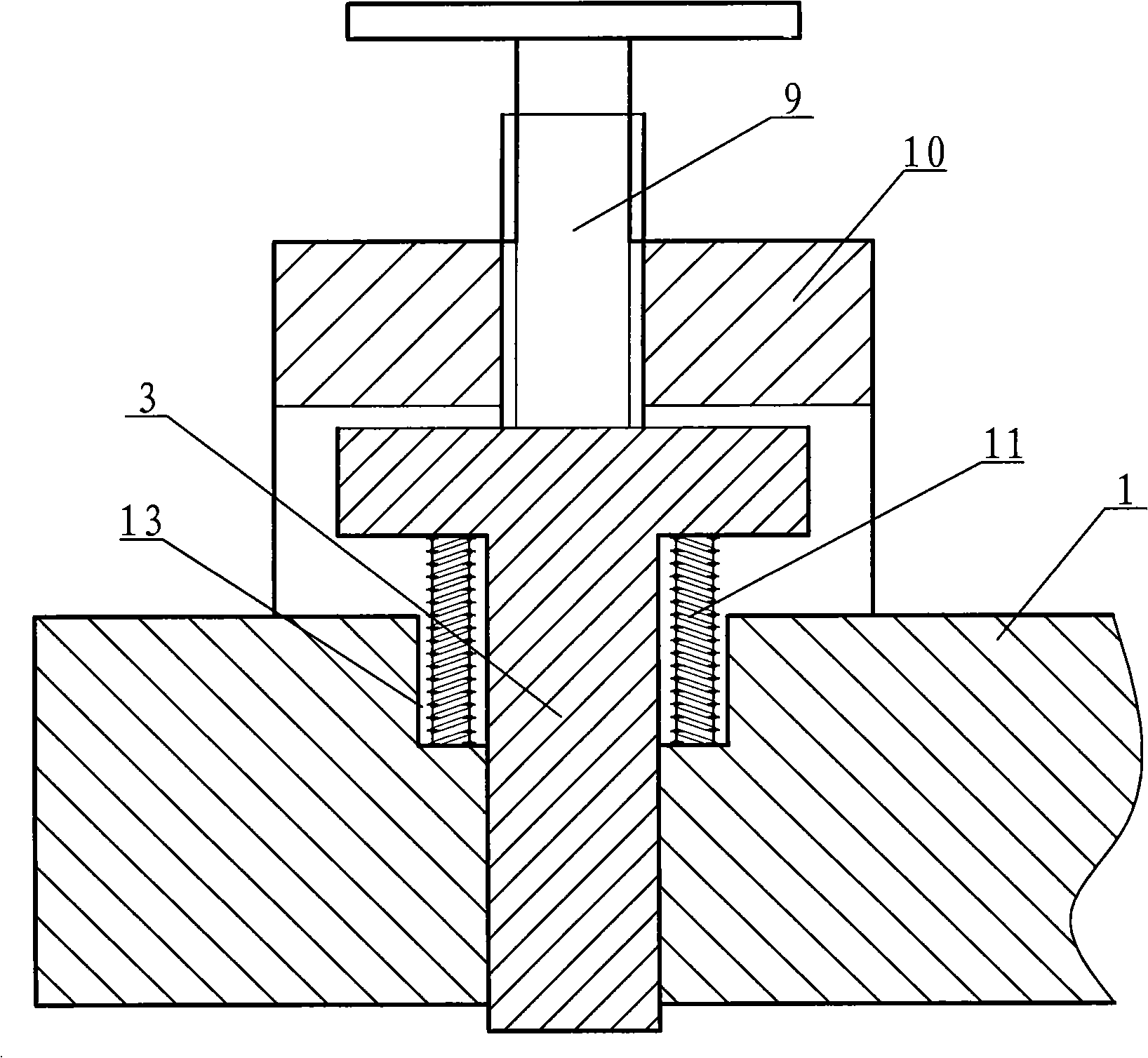

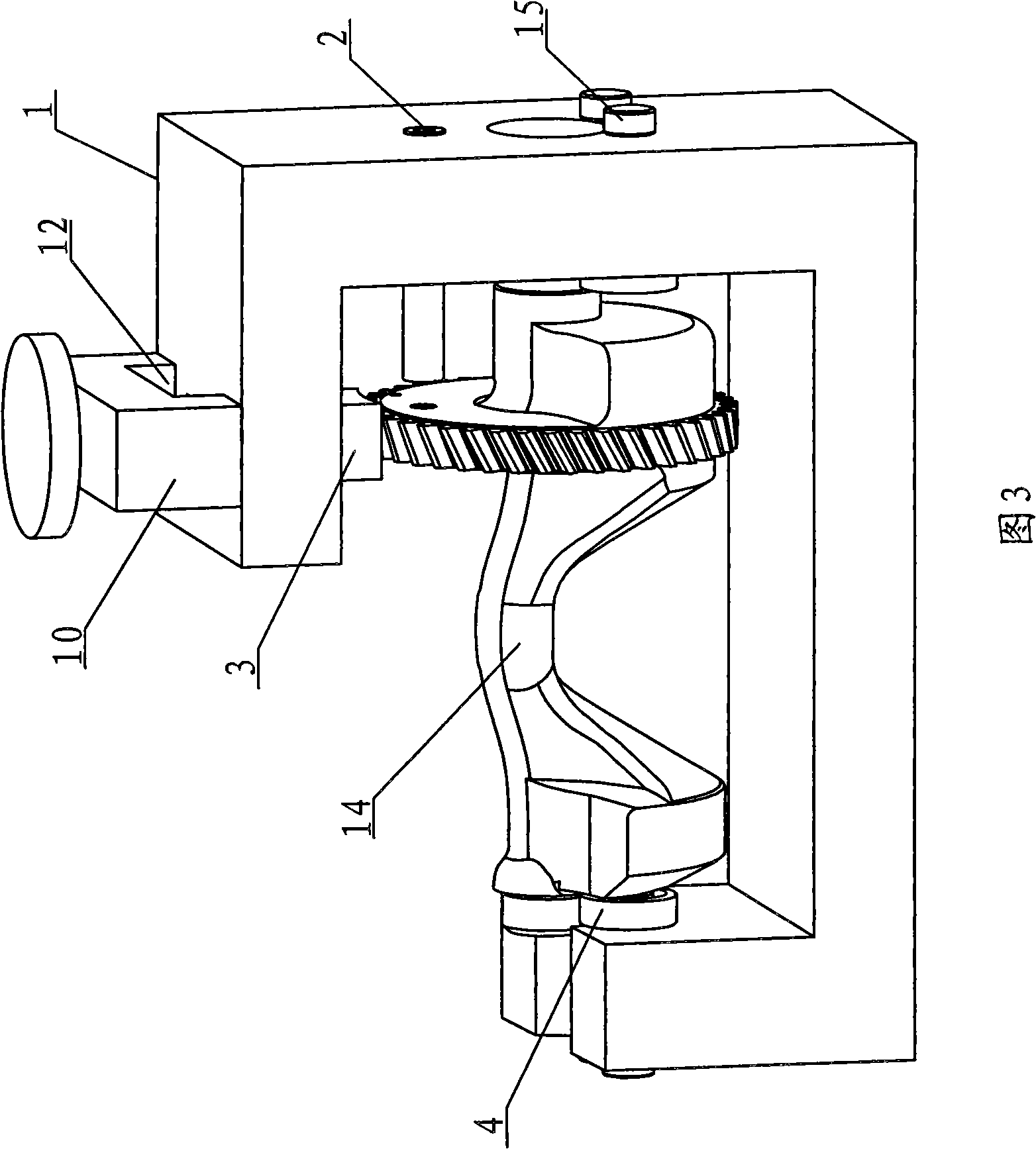

Positioning method for trunnion shaft assembly phase point

InactiveCN101314204AReduce vibrationStatic/dynamic balance measurementMetal working apparatusVertical planeEngineering

The invention relates to a method for positioning an assembly phase point of a balancing shaft. The method is characterized by comprising the following steps that: two ends of the balancing shaft are supported on special tool equipment in a laying mode in order that an axial lead of the balancing shaft is horizontal; a balance weight of the balancing shaft is positioned in a free overhanging state; when the balancing shaft is in static balancing, the balancing shaft is fixed; a process hole is processed on the upper part of the balance weight on the end face of a fluted disc of the balancing shaft in order that the process hole is positioned in a vertical plane which passes through the center of gravity of the balance weight; with an axial centre as a centre and the process hole as a benchmark, a marker is marked on a set angle position of the fluted disc end face of the balancing shaft in the clockwise direction or counterclockwise direction; and the marker is the assembly phase point of the balancing shaft. The assembly phase point of the balancing shaft determined by the method is not influenced by the foundry process, manufacturing error and uneven materials. The vibration of an engine after the balancing shaft is assembled is obviously reduced.

Owner:CHONGQING JUCHENG MACHINERY

Phase hunting detection method for permanent magnet planar motor adopting switch Hall array

ActiveCN101750548AEasy to handleImprove anti-interference abilityPhase sequence/synchronism indicationHorizontal forceElectric machine

The invention relates to a phase hunting detection method for a permanent magnet planar motor adopting a switch Hall array. The method is characterized in that: a Hall array consists of M (M is an odd number and more than or equal to 3) switch Hall sensors, wherein the Hall array is vertical to the horizontal force direction of a driving unit where the coil is positioned; the switch Hall sensors in the Hall array are arranged at equal intervals which is an even number times the pole pitch, are parallel to a permanent magnet array and used for measuring the component of the magnetic flux density in the direction vertical to the movement direction of the planar motor. All the switch Hall sensor signals in the Hall array are added up and then an judgment is made to determine whether the sum is greater than M / 2 so as to acquire an output signal 0 or 1; the output signal is kept unchanged when the Hall array moves in the direction vertical to the horizontal thrust direction of the corresponding coil; the output signals 0 and 1 are alternated when the Hall array moves in the horizontal thrust direction of the corresponding coil; and the current zero-crossing point (phase shifting point) in the driving coil is determined. The method changes the phase hunting detection of the permanent magnet planar motor in two dimension into superposition of two one-dimensional phase hunting detections to realize the planar phase hunting detection.

Owner:TSINGHUA UNIV

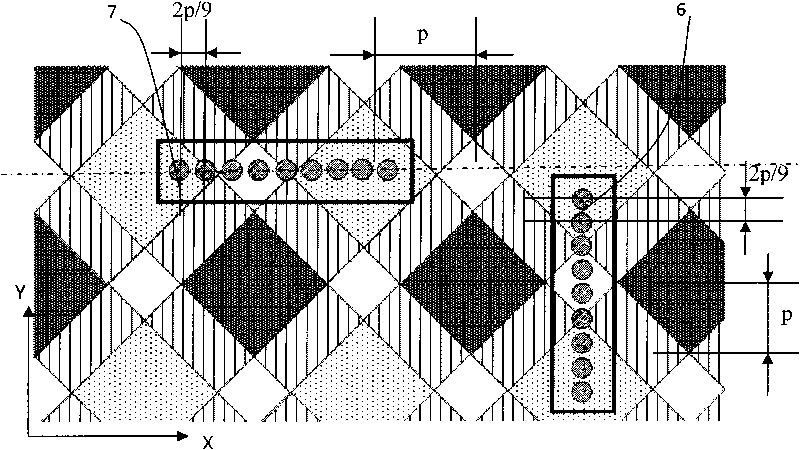

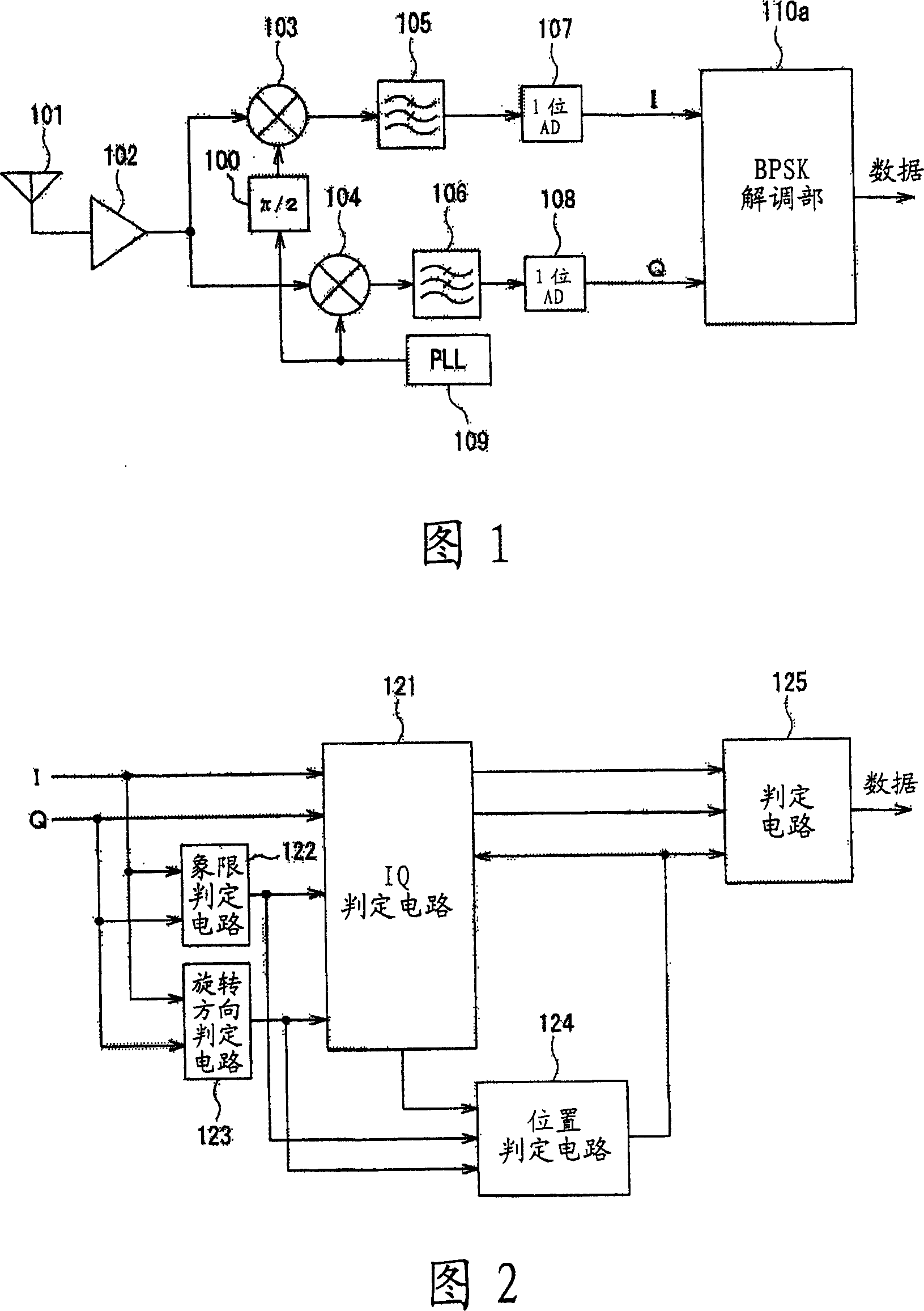

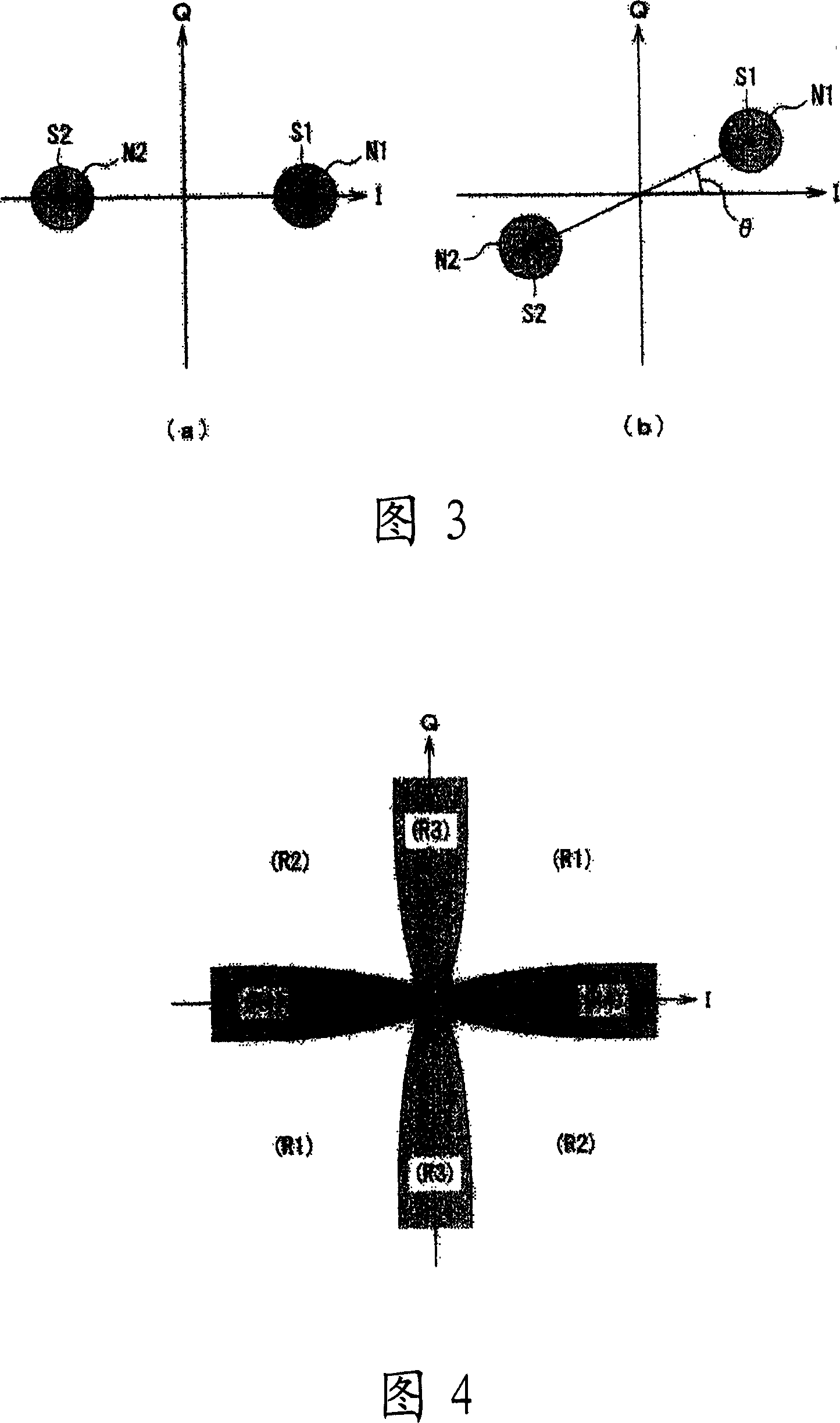

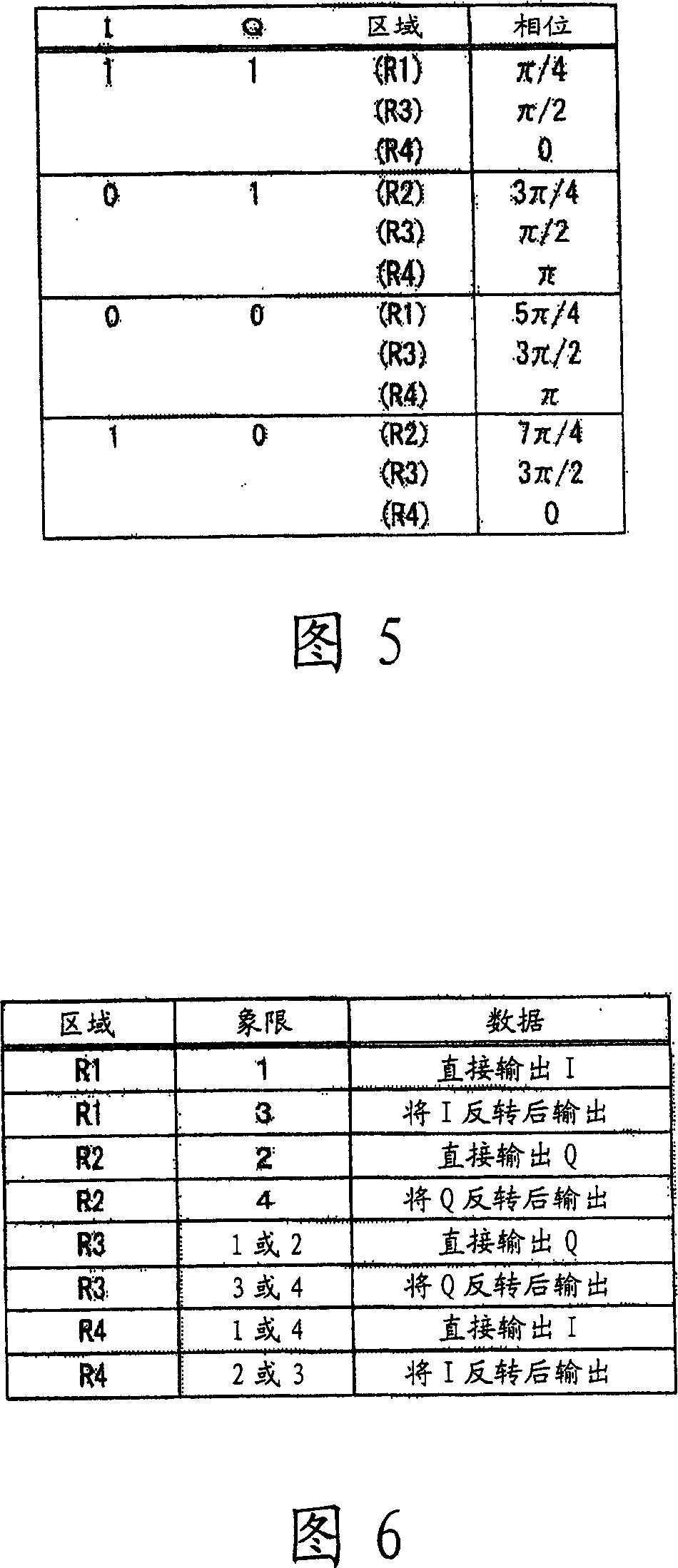

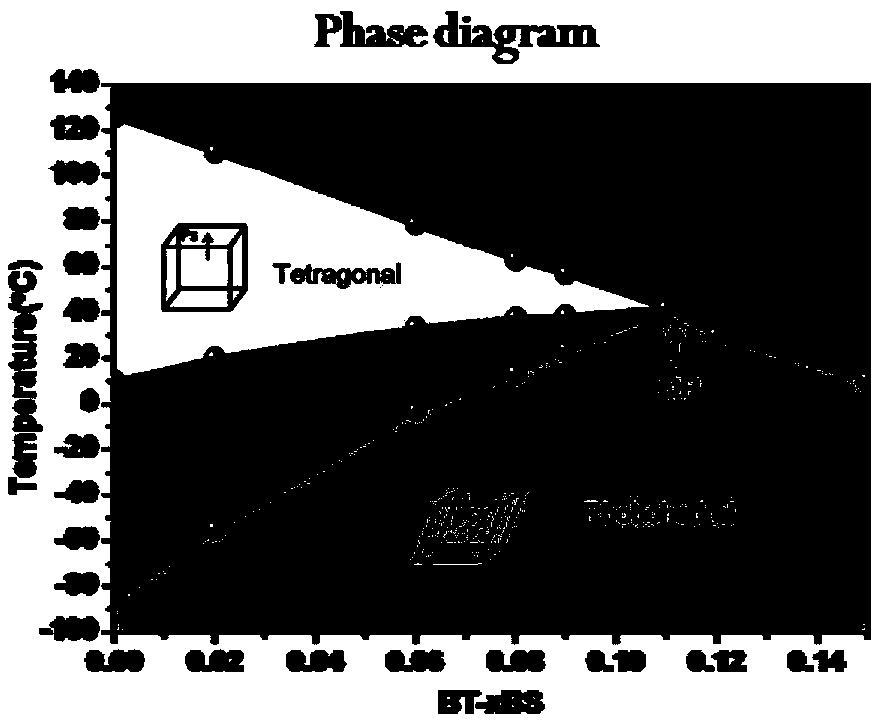

PSK receiver, PSK demodulating circuit, communication apparatus, and PSK receiving method

The invention provides a PSK receiver and a receiving method thereof, a PSK demodulating circuit and a communication apparatus, which can restrain the increase of the circuit scale and perform demodulation on phase modulated signals. As a solving means, an in-phase component (I) and an quadrature component (Q) contained in a reveived signal are converted to a 1-bit digital signal by 1-bit A / D converters (107, 108) respectively, when a phase point distance I-axes determined by the in-phase component (I) and the quadrature component (Q) is used as a predetermined region, a BPSK demodulator (110a) demoluates the received signal only according to the in-phase component (I), and when a phase point distance Q-axes determined by the in-phase component (I) and the quadrature component (Q) is used as a predetermined region, the BPSK demodulator (110a) demoluates the received signal only according to the quadrature component (Q).

Owner:SEIKO EPSON CORP

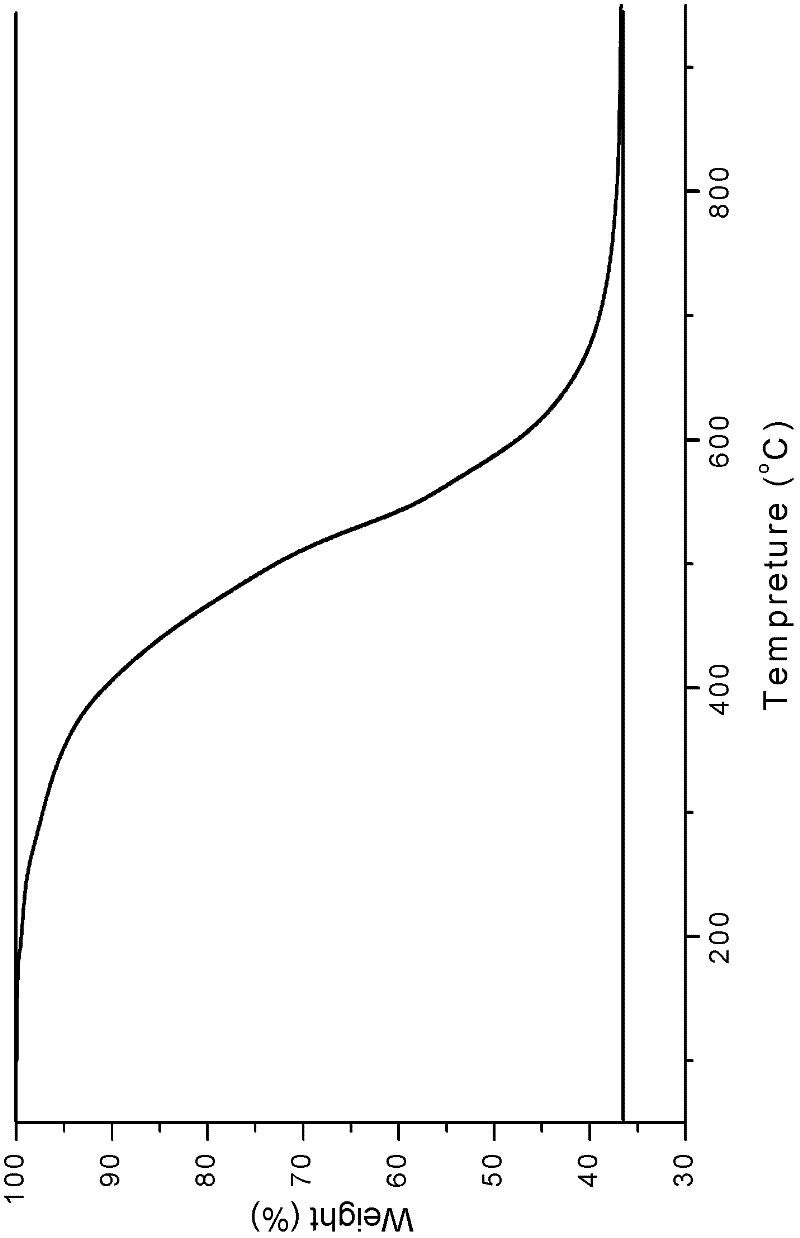

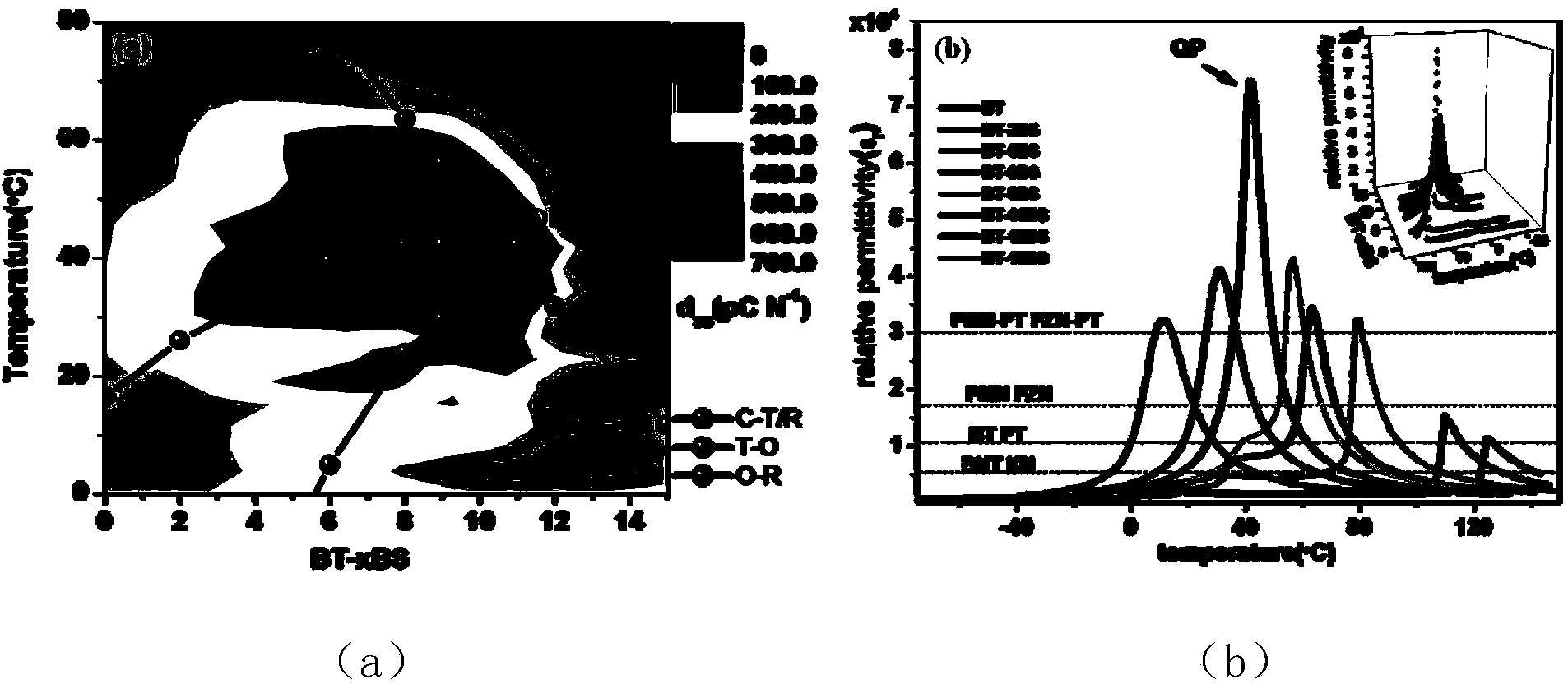

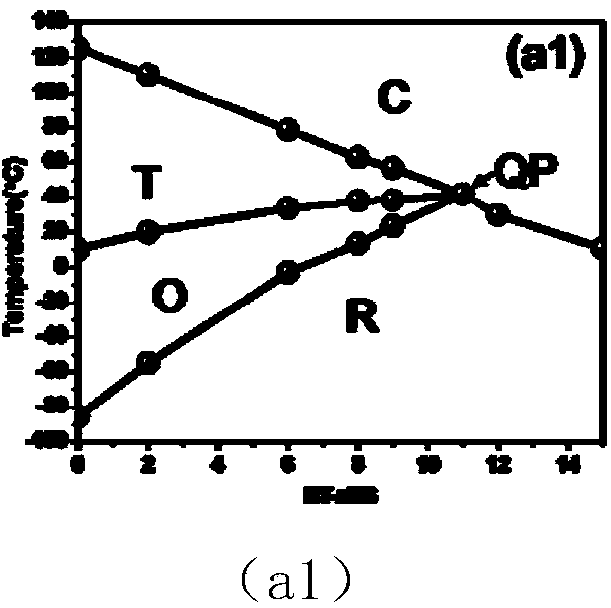

High performance leadless piezoelectric ceramics and preparation technology

The invention relates to high performance leadless piezoelectric ceramics and its preparation technology, the preparation technology comprises the following steps: burdening titanium dioxide, barium carbonate and stannic oxide according to stoichiometric ratio of 0.89: 1: 0.11, ball milling, pre-burning, performing secondary ball milling, granulation granulating and molding, covering by a crucible finally, putting in a sintering furnace, heating to the temperature of 500 DEG C by a speed of 2 DEG C / min, insulating for 2 hours and dumping, then heating to the temperature of 1400 DEG C at the speed of 4 DEG C / min and insulating for 4 hours, and then cooling in furnace to the room temperature to obtain the required leadless piezoelectric ceramics. The leadless piezoceramic material has high dielectric and piezoelectric performance at quasi four-phase point, the relative dielectric constant of the material can reach 75000 which is 6-7 times of the dielectric constant of pure barium titanate at the Curie temperature, the piezoelectric coefficient d33 can reach 697pC / N which is 5 times of the room temperature piezoelectric coefficient of the pure barium titanate, and the data can be the highest data in that of the leadless piezoceramic material.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com