A kind of preparation method of intumescent flame retardant of phosphorus, nitrogen and carbon trinity

An intumescent flame retardant and trinity technology, which is applied in the field of intumescent flame retardants with phosphorus, nitrogen and carbon trinity, can solve the problems of high reactivity of phosphorus oxychloride, high viscosity of esterification products, difficult operation, etc., and save raw materials. , Good compatibility and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

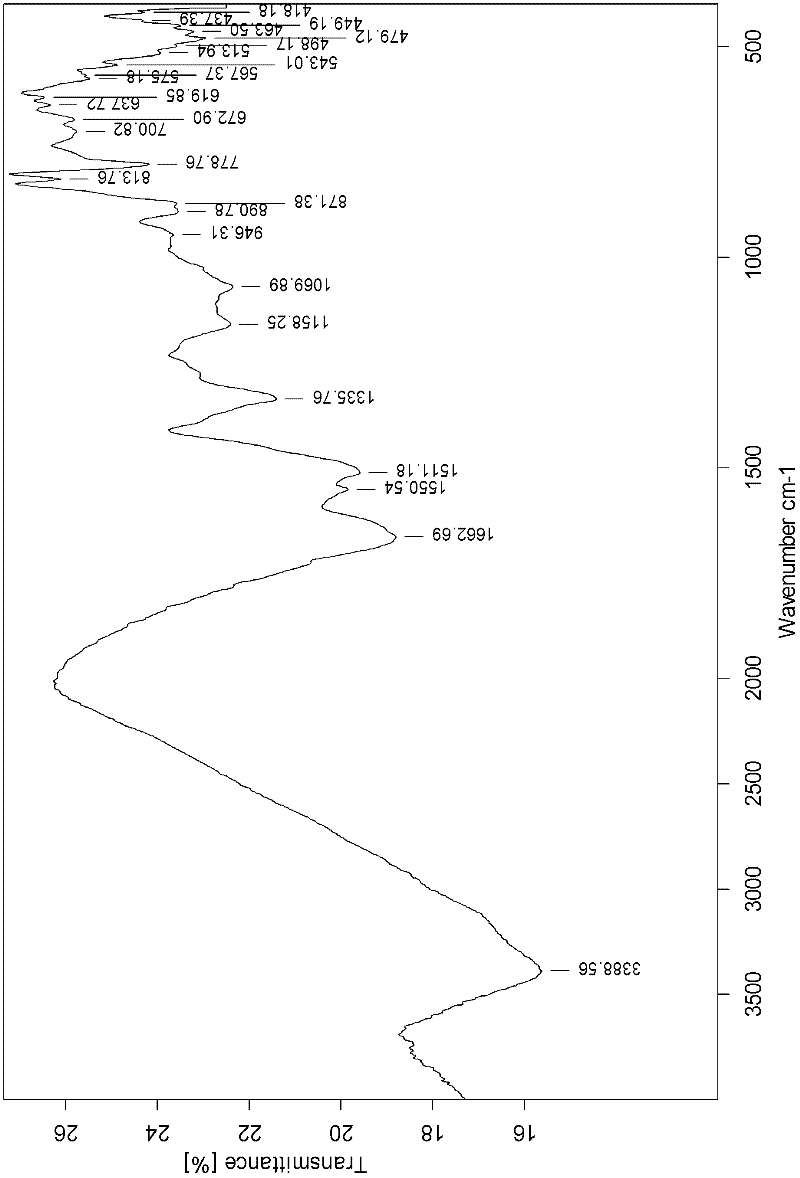

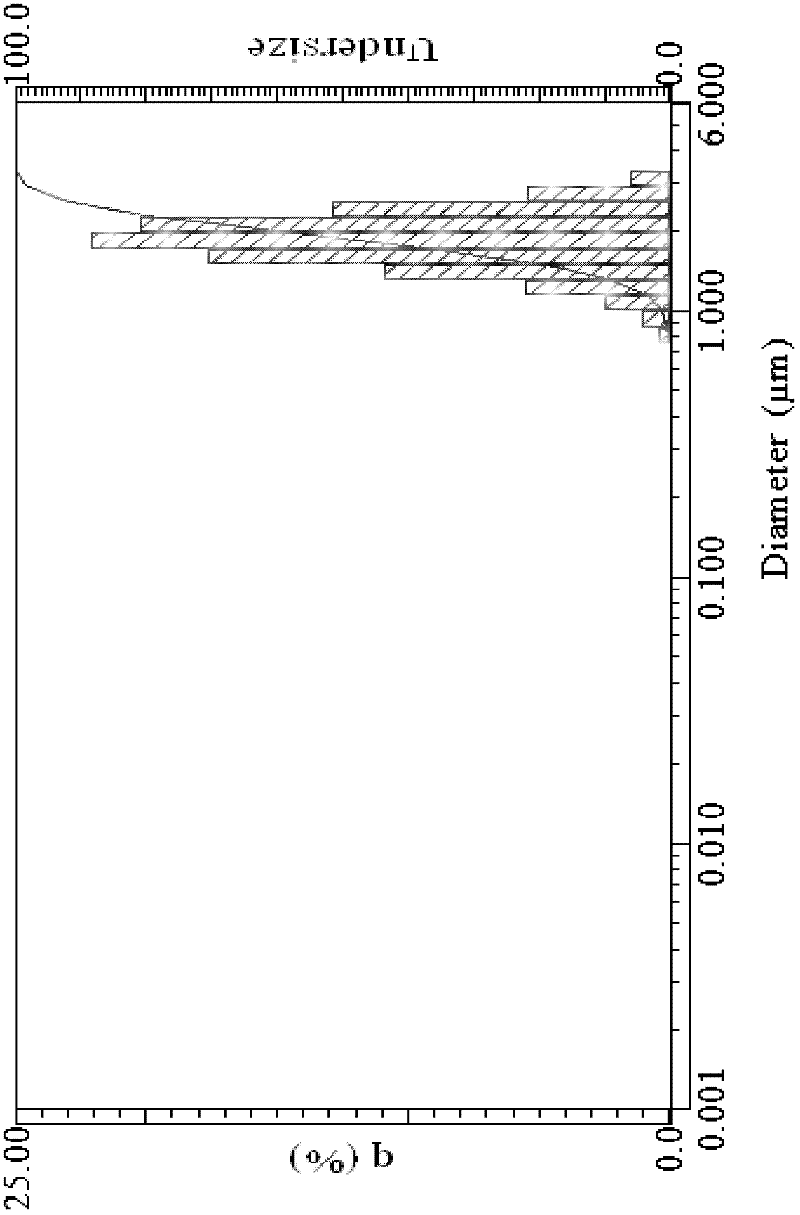

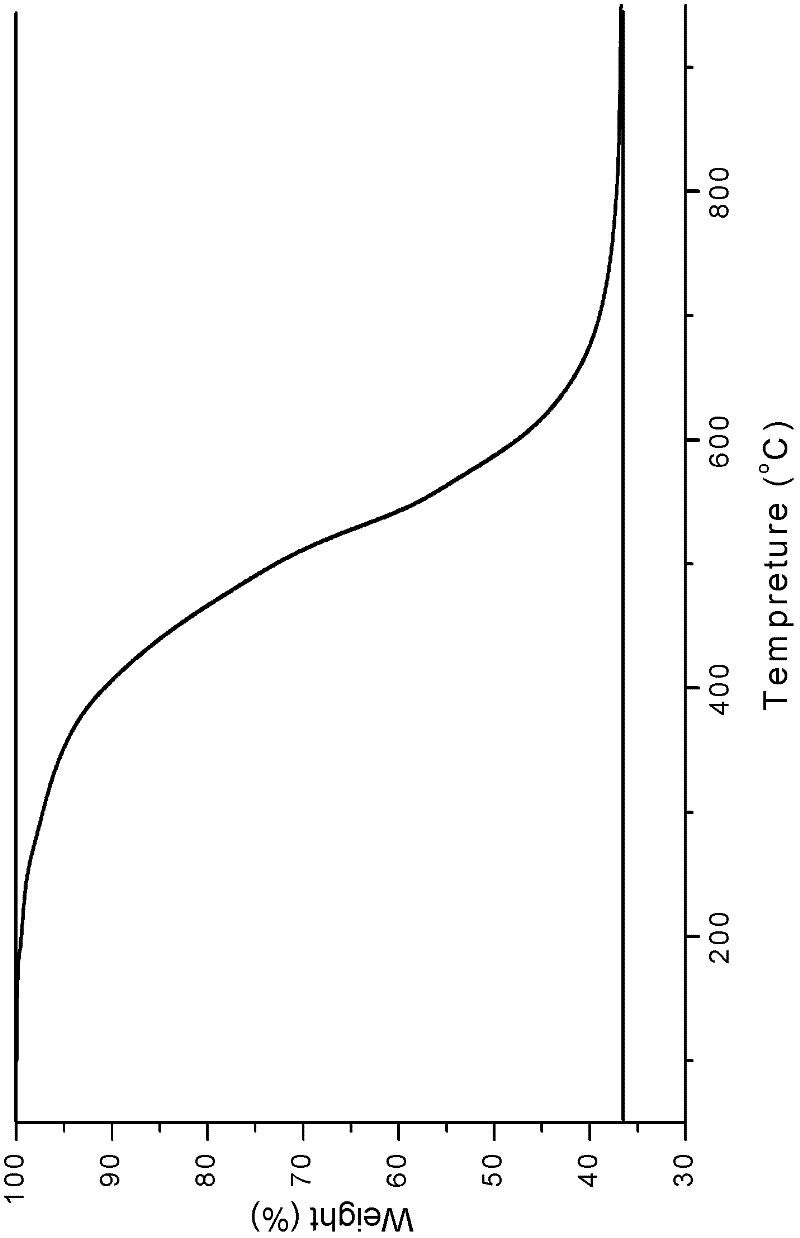

Embodiment 1

[0037]Disperse 30g of hexamethylolmelamine in 50mL of chlorobenzene, slowly add 45g of phosphorus oxychloride dropwise at 60°C for esterification, and obtain an esterified product dispersed in chlorobenzene. 100 mL of water was added to the above organic solution, and stirred at room temperature for 2 hours. After the stirring was stopped, the organic phase and the aqueous phase were separated, and the hydrolyzate was dissolved in the aqueous phase. Add 40 g of melamine to the aqueous solution of the hydrolyzate, react in a water bath at 70° C. for 60 minutes, and a white precipitate is formed. The pH was adjusted to 7 with liquid caustic soda, cooled and placed, then dehydrated and dried to obtain the final product.

Embodiment 2

[0039] Disperse 55g of phosphorus pentachloride in 80ml of carbon tetrachloride, and slowly add 30g of hexamethylolmelamine at 80°C for esterification to obtain an esterified product dispersed in carbon tetrachloride. 120ml of water was added to the above organic solution, and stirred at room temperature for 2 hours. After the stirring was stopped, the obtained hydrolyzate was dissolved in the water phase, the organic phase and the water phase were separated, and carbon tetrachloride was recovered. Finally, 35 g of melamine was added to the aqueous solution of the hydrolyzate, reacted in a water bath at 90°C for 90 minutes, adjusted to pH 5 with soda ash, washed with water after cooling, dehydrated and dried to obtain the final product.

Embodiment 3

[0041] Disperse 30kg of hexamethylolmelamine in 50L of chlorobenzene in a reaction kettle, slowly add 45kg of phosphorus oxychloride dropwise at 60°C to undergo esterification reaction, and obtain an esterified product dispersed in chlorobenzene. 100 L of water was added to the above organic solution, and stirred at room temperature for 2 hours. After the stirring was stopped, the organic phase and the aqueous phase were separated, and the hydrolyzate was dissolved in the aqueous phase. Add 40 kg of melamine to the hydrolyzate aqueous solution, stir at 70° C. for 60 minutes, and a white precipitate is formed. The pH was adjusted to 6 with ammonia water, left to cool, and then centrifuged and dried to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com