Patents

Literature

638results about How to "Facilitate the realization of industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin adhesive modified by unsaturated polyimide and preparation method thereof

InactiveCN102181251AModerate viscosityGood workmanshipEpoxynovolac adhesivesMicroelectronicsChemistry

The invention relates to an epoxy resin adhesive modified by unsaturated polyimide and a preparation method thereof. A formula of the adhesive contains 80-85% of epoxy resin, 8-10% of unsaturated polyimide resin and 7-10% of curing agent in percentage by mass. By using the invention, the strength of the adhesive is effectively increased, the tensile shear strength at room temperature reaches up to 17.3 MPa and the brittleness of condensate is reduced; the epoxy resin adhesive provided by the invention is of very high practical value to the development of the adhesive industry, is favorable for realizing industrial production and has the advantages of simple preparation process and low cost. Broad application prospects are obtained in the fields of electronics, microelectronics, flexible copper clad laminates, flexible printed circuit boards, hard copper clad laminates, motors, aerospace and the like.

Owner:DONGHUA UNIV +1

Method for preparing aromatic polybenzimidazole resin film

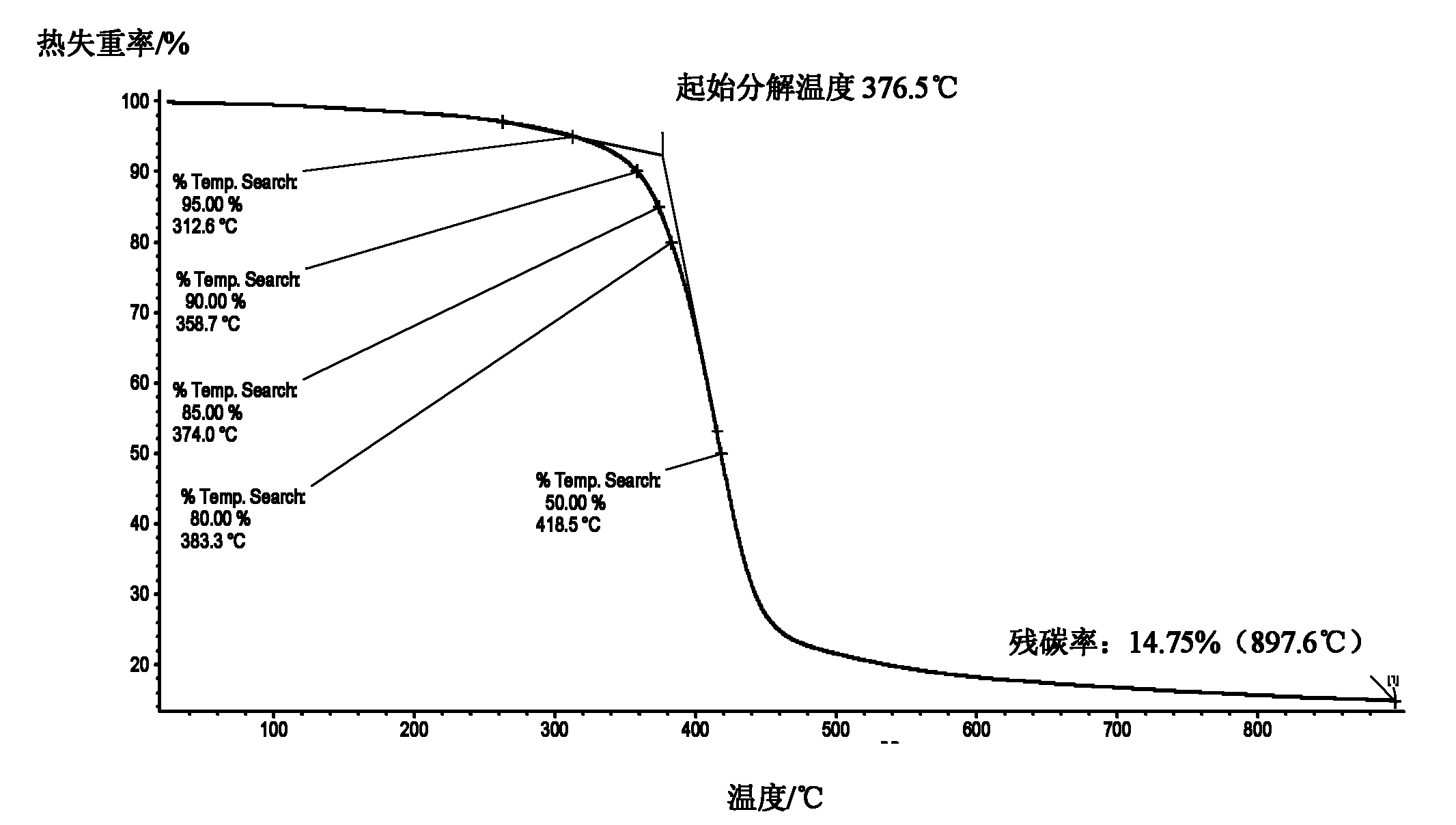

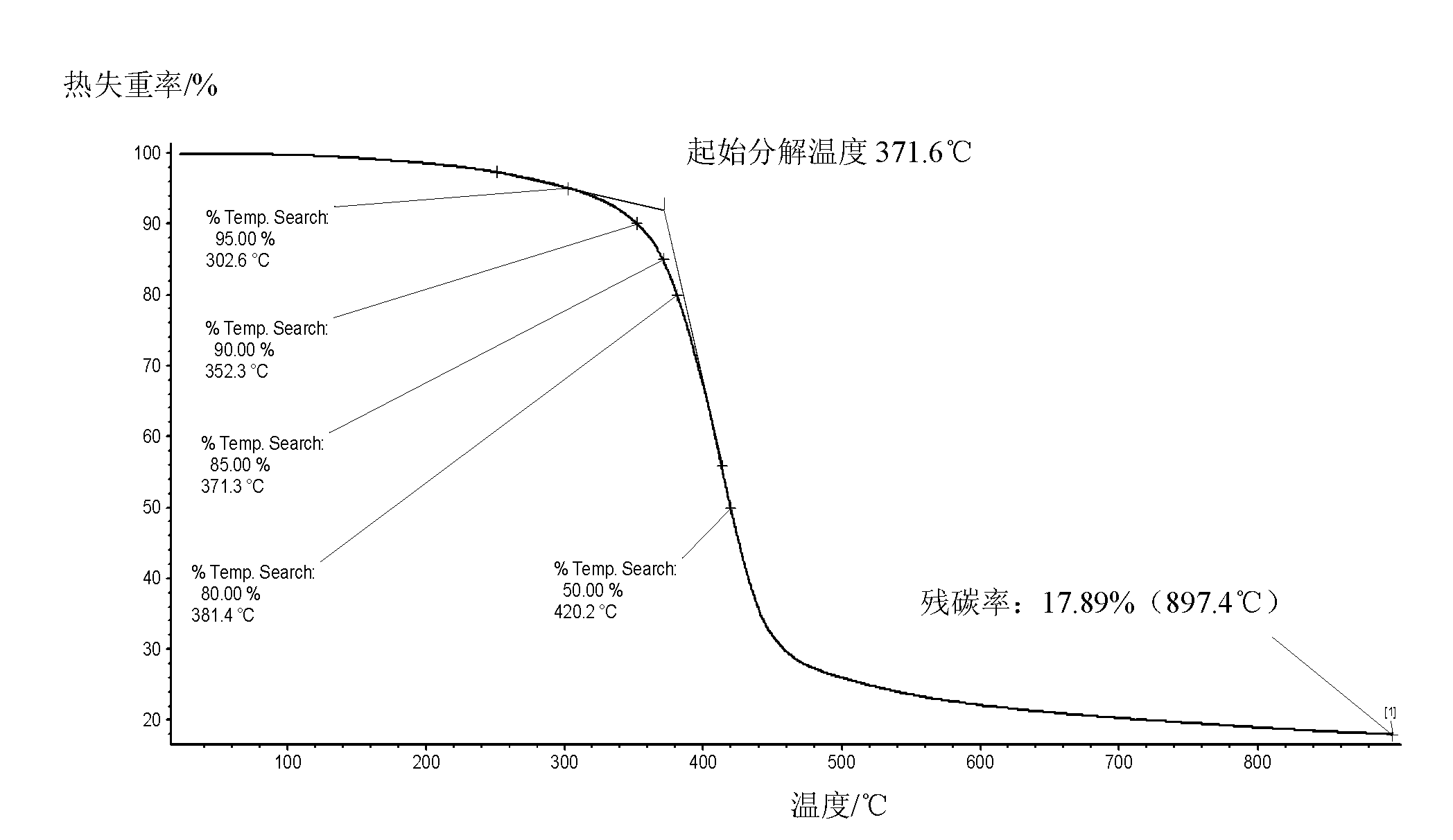

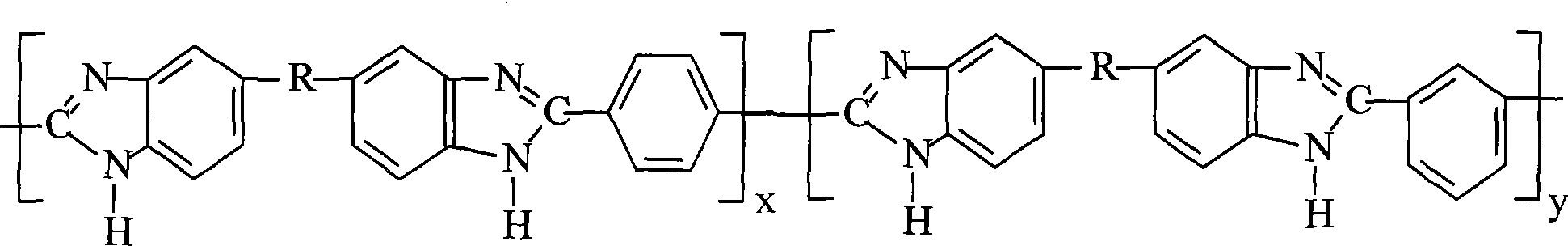

InactiveCN101456964AHigh molecular weightImprove thermal stabilitySemi-permeable membranesCell component detailsSolubilityNitrogen gas

The invention relates to a preparation method for aromatic series polybenzimidazole resin film, comprising: (1) under function of polyphosphoric acid / phosphorus pentoxide system, condensation polymerization reaction is carried out to aromatic series amine and aromatic series dicarboxylic acids mixed according to mol ratio of 1:1 in nitrogen atmosphere; (2) after cooling, polymer is poured into water and broken down into powder in a resin pulper and washed over and over again by distilled water and soaked for 48 hours in NaHCO3 solution and washed till pH value shows neutral and drawn and filtered for drying in vacuum; (3) the polymer dried is dissolved in even solution prepared by organic solvent with mass percent of 5 percent, and then is dried at temperature of 130 DEG C for 12 hours, and is soaked in hot water for boiling and striping, and is dried in vacuum at temperature of 100 DEG C for 5 hours and then is obtained. The polybenzimidazole prepared by the invention has the advantages of big molecule weight, stable thermal stability, fine solubility and film forming performance, etc. The preparation has simple technology, low cost, convenient operation and can be finished in common equipments through preparation procedure.

Owner:DONGHUA UNIV

A kind of high temperature resistant modified epoxy resin adhesive and preparation method thereof

InactiveCN102260480AModerate viscosityGood workmanshipCarboxyl rubber adhesivesEpoxy resin adhesivesMicroelectronicsChemistry

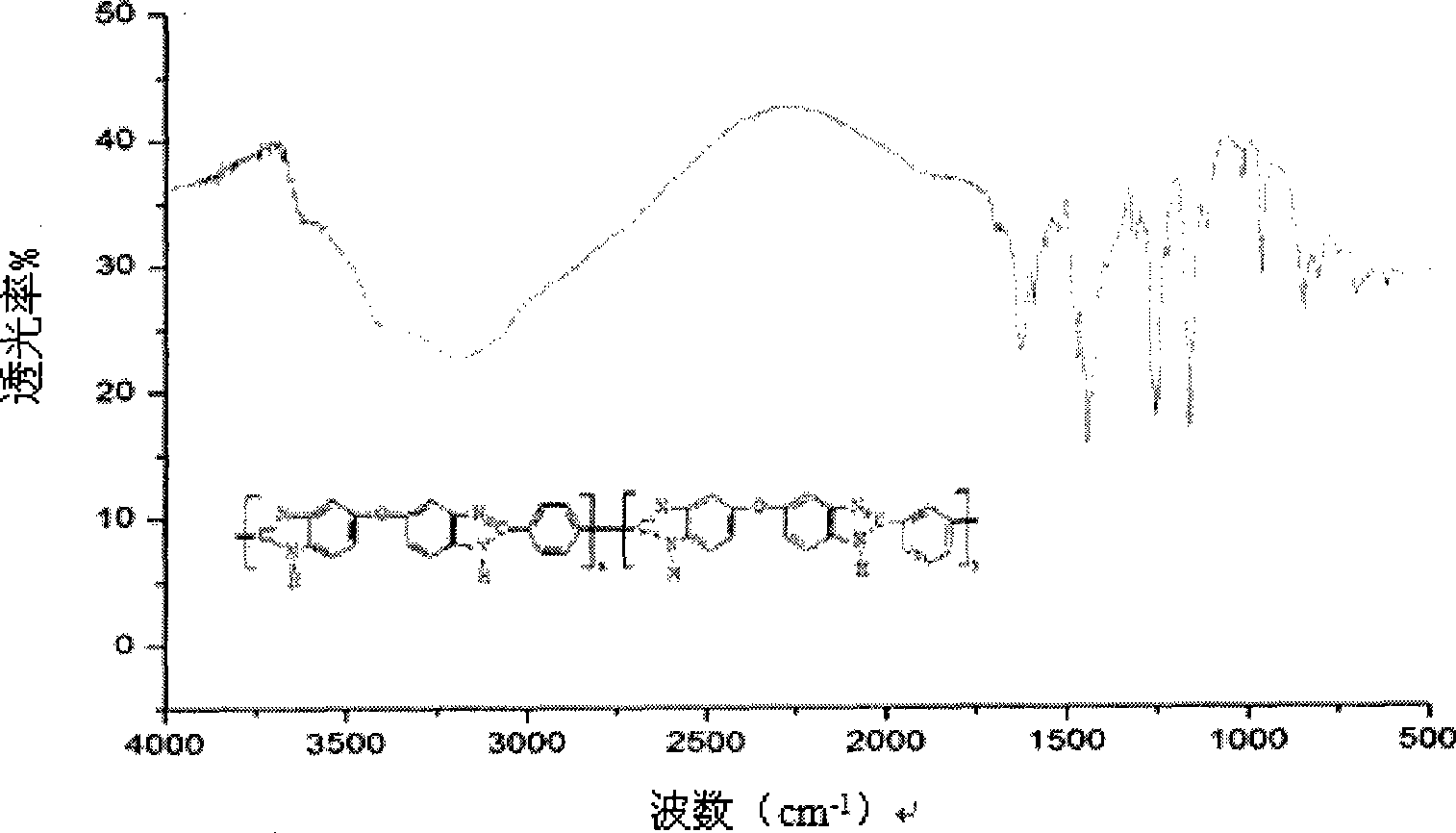

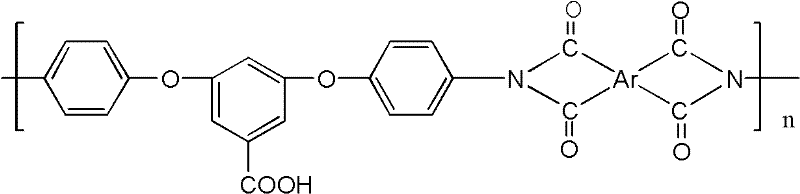

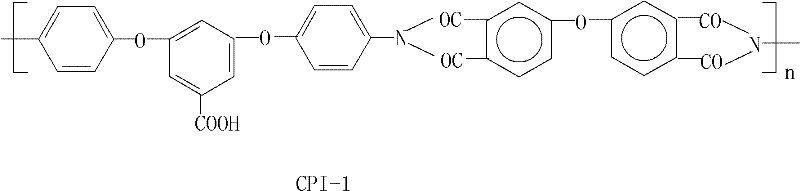

The invention relates to a high-temperature-resistant modified epoxy resin adhesive and a preparation method thereof. The high-temperature-resistant modified epoxy resin adhesive comprises the following formula components by weight percent: 55%-58% of epoxy resin, 1%-6% of carboxyl-containing polyimide powder, 3.8%-4% of curing agent, 28.7%-30.5% of diluent and 6.3%-6.8% of terminal carboxyl nitrile rubber. The formula components are mixed evenly to obtain the adhesive. According to the preparation method, carboxyl-containing polyimide is added in an epoxy resin substrate, thereby effectivelyimproving the strength of the adhesive and reducing the brittleness of the cured material of the adhesive; the preparation method has the advantages of simple process and low cost, and is convenient for operation; and the preparation method has a high practicable value for the development of the adhesive industry and has a wide application prospect in multiple fields, such as electronics, microelectronics and the like.

Owner:DONGHUA UNIV +1

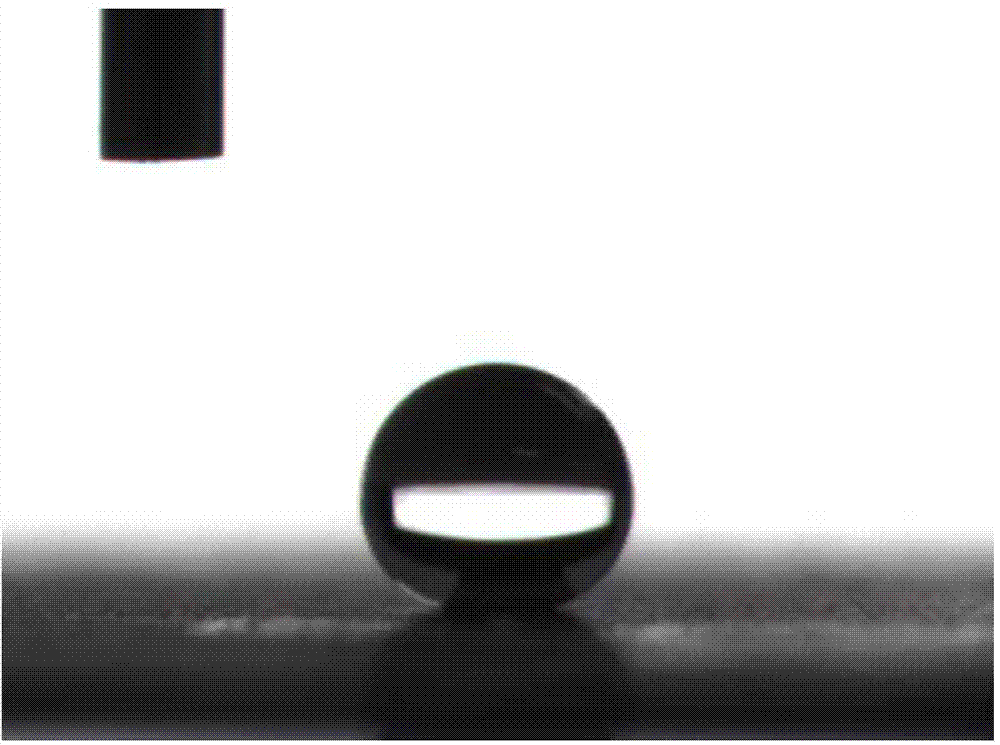

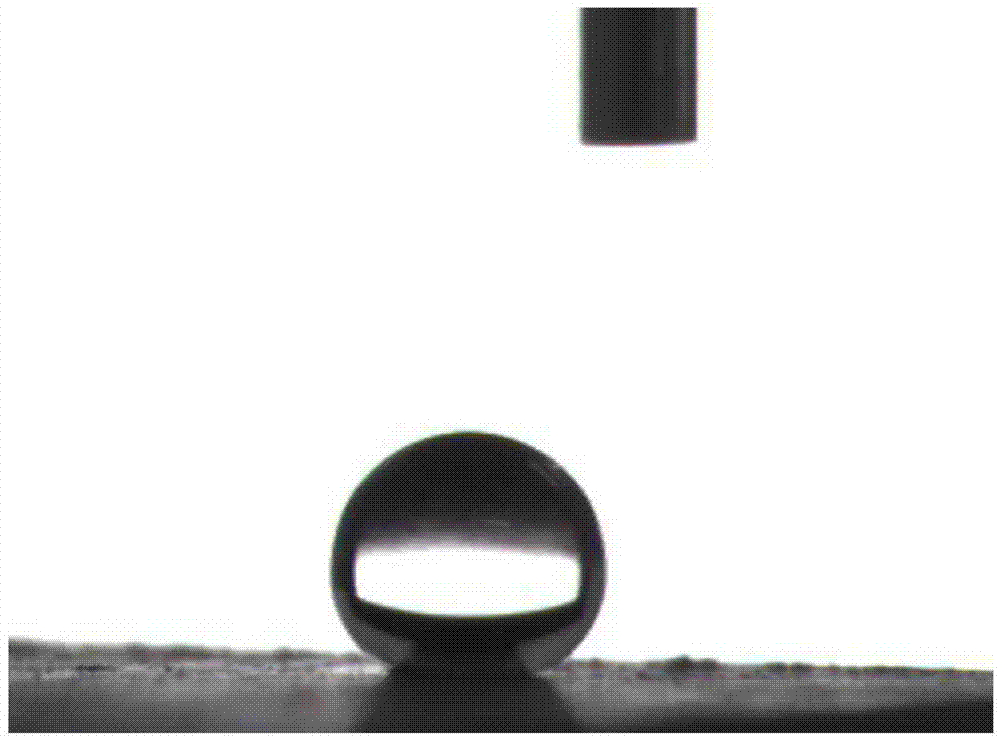

Super-hydrophobic and oleophobic composite coating and preparation method thereof

InactiveCN104745045AImprove hydrophobicity and oleophobicityHydrophobic and oleophobicPretreated surfacesEpoxy resin coatingsGas phaseSolvent

The invention discloses a super-hydrophobic and oleophobic composite coating which comprises a super-hydrophobic and oleophobic primer coat layer and a super-hydrophobic and oleophobic finishing coat layer. The coating is characterized in that the super-hydrophobic and oleophobic finishing coat layer is located on the super-hydrophobic and oleophobic primer coat layer; the super-hydrophobic and oleophobic primer coat layer is coated by a super-hydrophobic and oleophobic primer coat which is a composition containing epoxy resin, an auxiliary A, extinction powder and a solvent; the super-hydrophobic and oleophobic finishing coat layer is coated by a super-hydrophobic and oleophobic finishing coat which is a composition containing fumed silica, an auxiliary B, an auxiliary C, a mixed solution A and a mixed solution B. Compared with the prior art, the super-hydrophobic and oleophobic composite coating disclosed by the invention not only has a super-hydrophobic performance, but also can resist greasy dirt and has a super-oleophobic performance as well as good wear resistance and stability; the preparation process is simple, and realization of industrialized production is facilitated.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

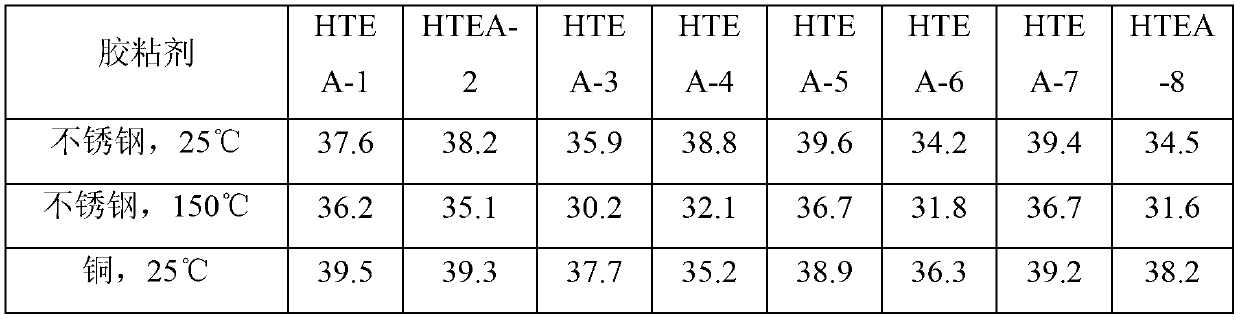

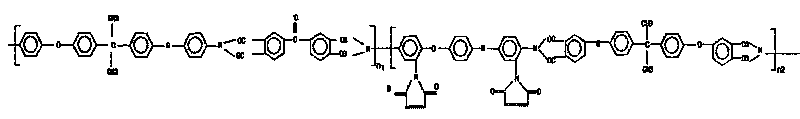

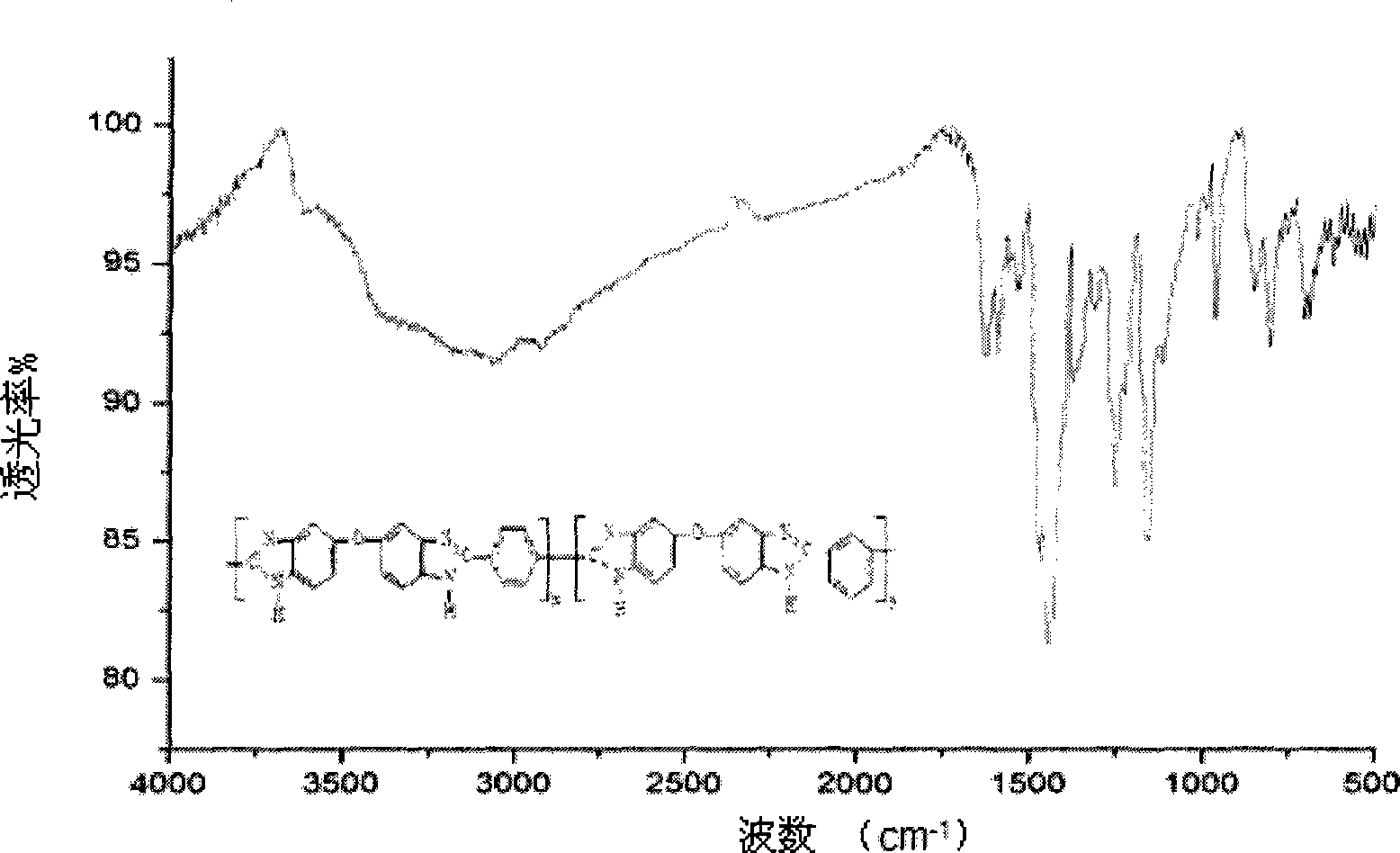

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

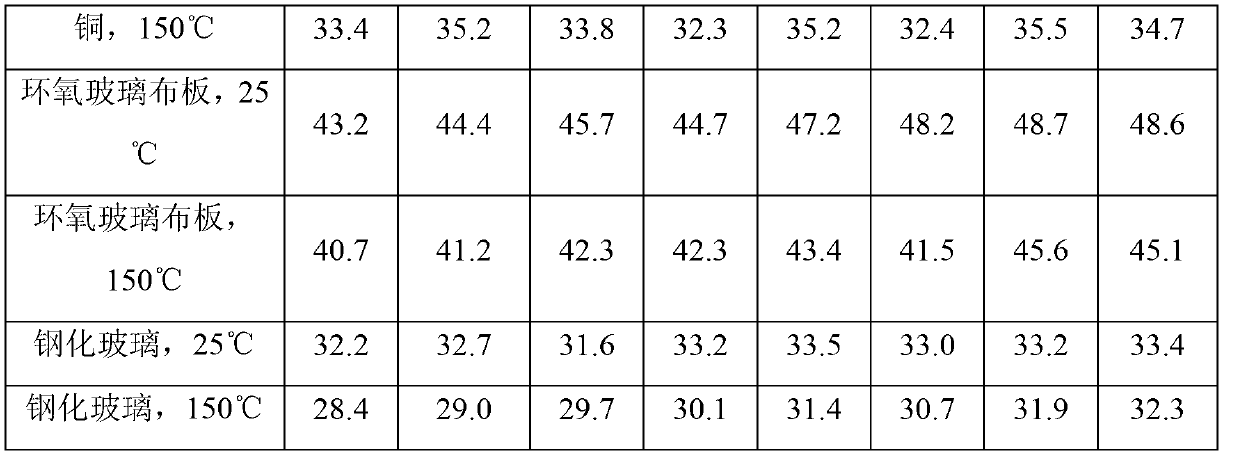

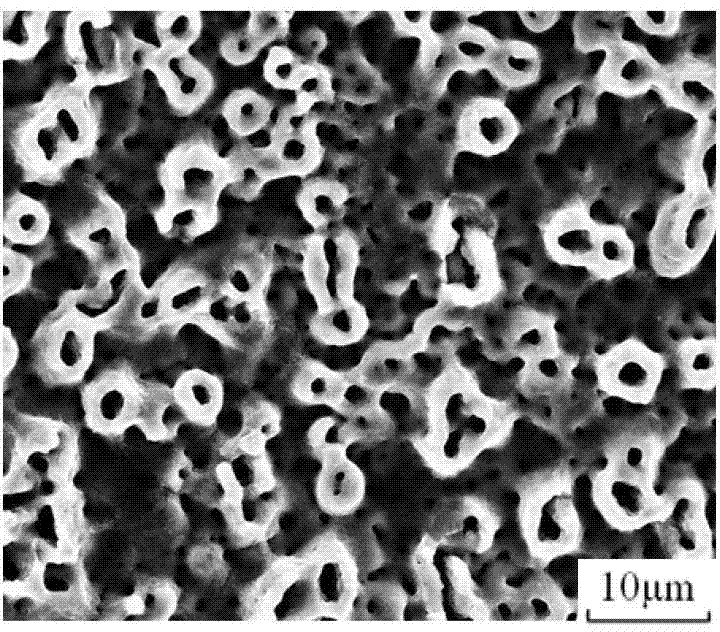

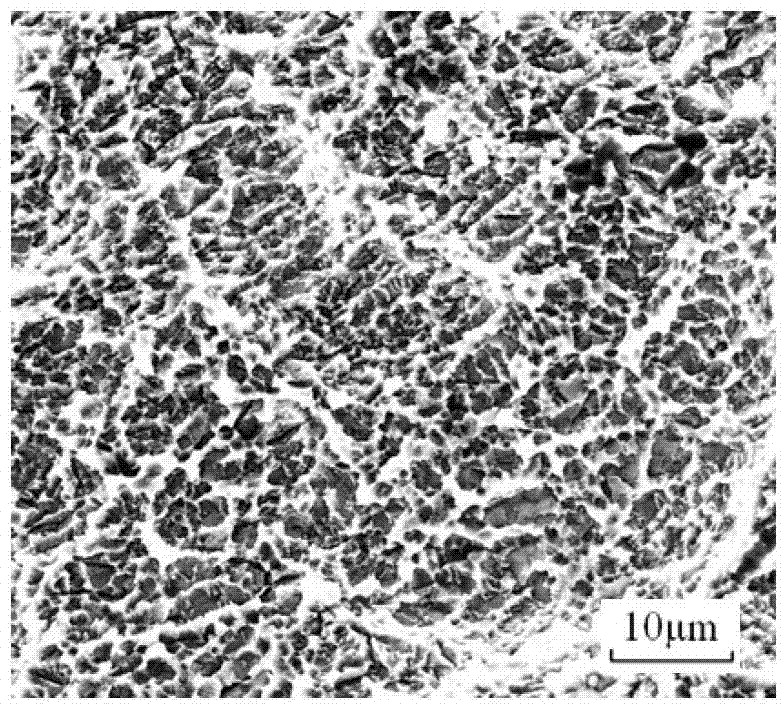

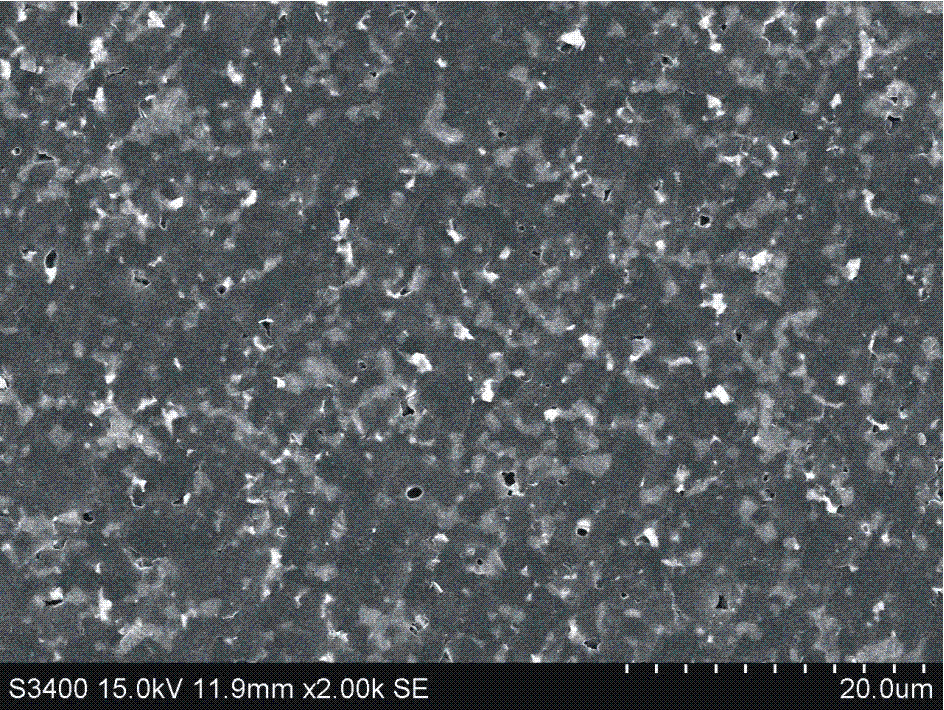

Method for preparing multistage micron structure on titanium implant surface

ActiveCN102921037ARich morphologyImprove the production operating environmentProsthesisTitanium implantImplant surface

The invention discloses a method for preparing a multistage micron structure on a titanium implant surface and relates to a titanium implant. The method includes polishing the titanium implant surface, performing oil removing treatment, and cleaning; subjecting the titanium implant which is subjected to the oil treatment and cleaning to acid dipping treatment in a mixed solution containing a nitric acid, a hydrofluoric acid and hydrogen peroxide; subjecting the titanium implant surface to sand blasting treatment; cleaning the titanium implant which is subjected to the sand blasting treatment; subjecting the cleaned titanium implant to acid etching post-treatment in an acid etching solution; and subjecting the titanium implant to heat treatment and cooling the titanium implant to the normal temperature to obtain the titanium implant with the surface in the multistage micron structure. According to the method for preparing the multistage micron structure on the titanium implant surface, the contact area between the titanium implant and bone tissues is increased, osteoblast ingrowth is facilitated, and thereby the forming of bone closure is facilitated; processing devices are easy to obtain, the operation process is simple, the environmental pollution is small, and the industrialization is easy to achieve; and the appearance is abundant, and the hydrophilic performance is excellent.

Owner:百齿泰(厦门)医疗科技有限公司

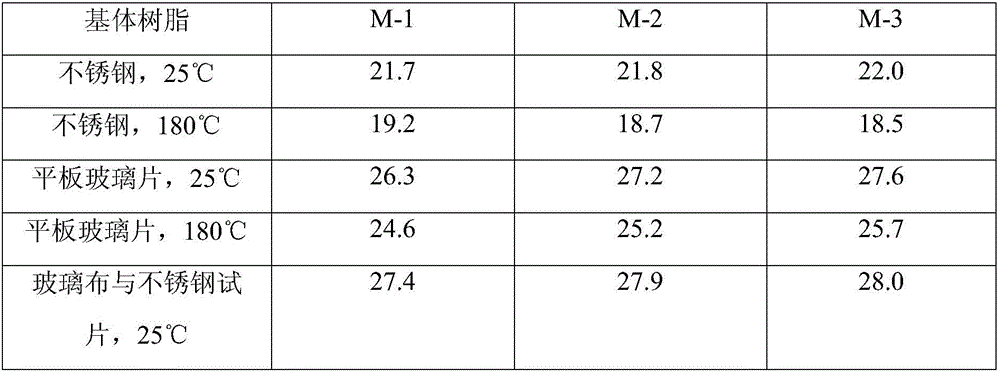

YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and preparation method thereof

The invention relates to a YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and a preparation method thereof. The matrix resin is composed of YASI, an epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; and (2) adding the YASI and epoxy resin into a reaction kettle, stirring and mixing to react, adding the imide oligomer, continuing stirring to react, adding the 3-aminopropyl trialkoxysilane, stirring to react, adding the curing agent, and uniformly stirring and mixing. The resin can be widely used for bonding metals (such as steel, copper, aluminum and the like) and substrates (ceramic, glass, resin-base composite materials and the like), and preparing glass fibers, aramid fibers and carbon-fiber-reinforced polymer composite materials, and thus, has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

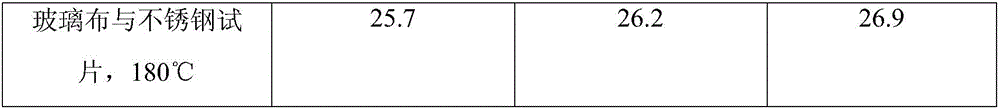

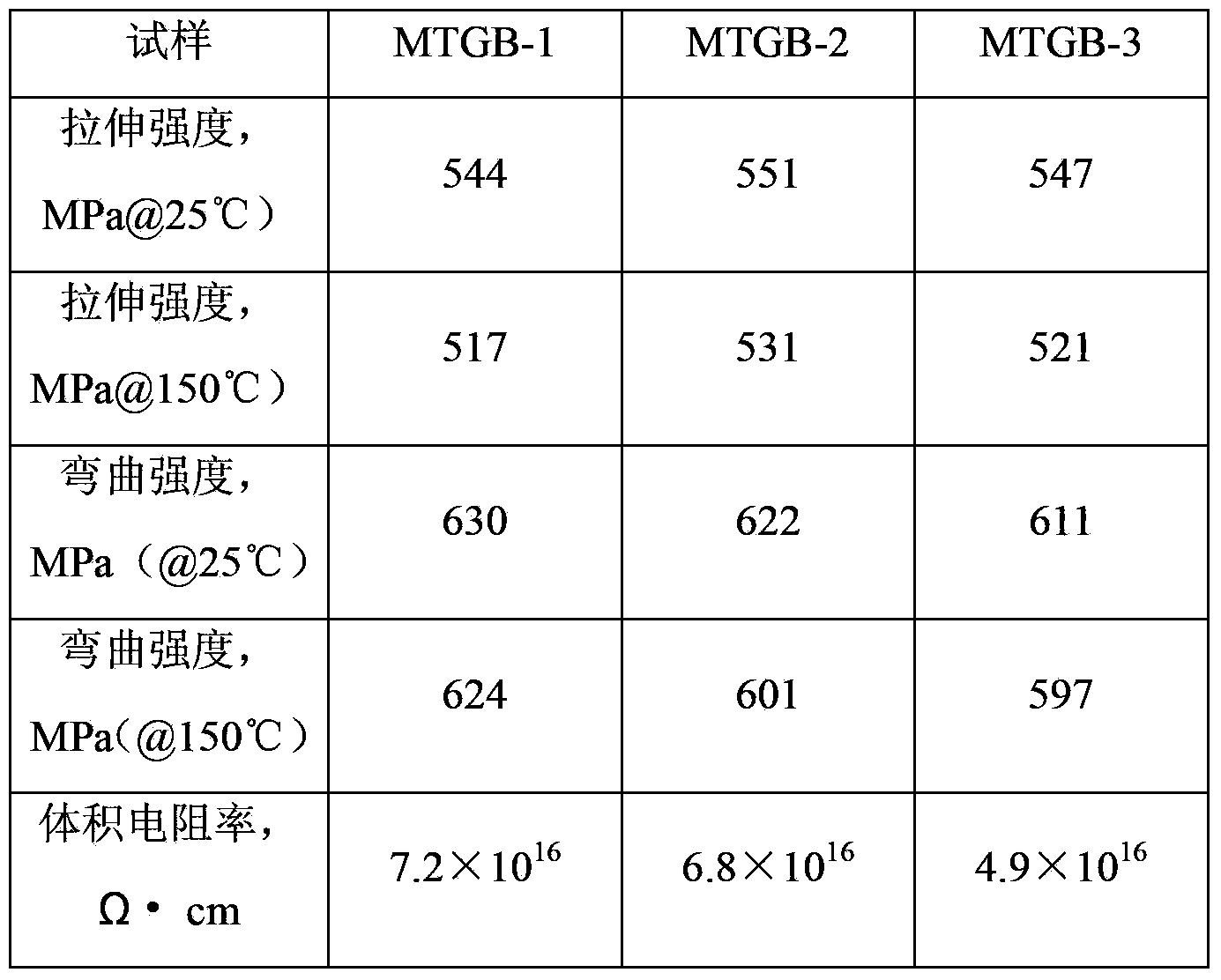

High-toughness high-heat-conduction epoxy-imine resin system and preparation method and application thereof

The invention relates to a high-toughness high-heat-conduction epoxy-imine resin system and a preparation method and application thereof. The high-toughness high-heat-conduction epoxy-imine resin system comprises epoxy resin, carboxyl-containing polyimide resin solution, firming agent, filler and organic solvent in a weight ratio of 100:100-200:30-50:30-50:150-250. The preparation method includes sequentially adding the epoxy resin, the carboxyl-containing polyimide resin solution, the firming agent, the filler and the organic solvent into a mixer, and mixing well to obtain the high-toughness high-heat-conduction epoxy-imine resin system. The high-toughness high-heat-conduction epoxy-imine resin system is applicable to preparation of glass cloth reinforced composite material. The high-toughness high-heat-conduction epoxy-imine resin system is moderate in viscosity and fine in usability. The preparation process is simple and convenient to operate. The glass cloth enhanced composite is high in impact resistance, fine in heat conductivity, high in heat resistance, and fine in electrical insulation.

Owner:DONGHUA UNIV +1

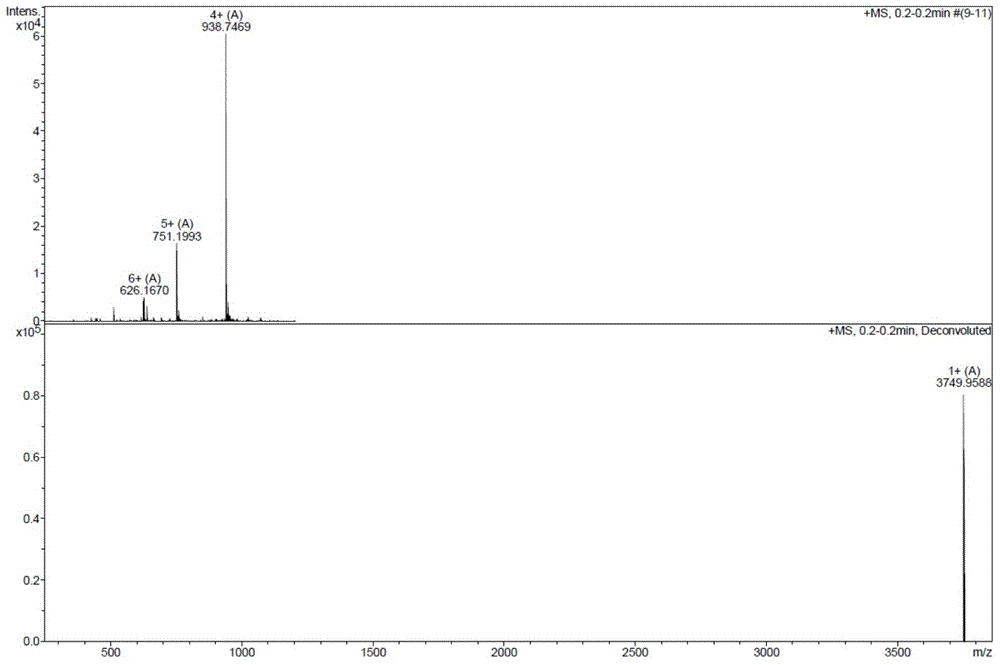

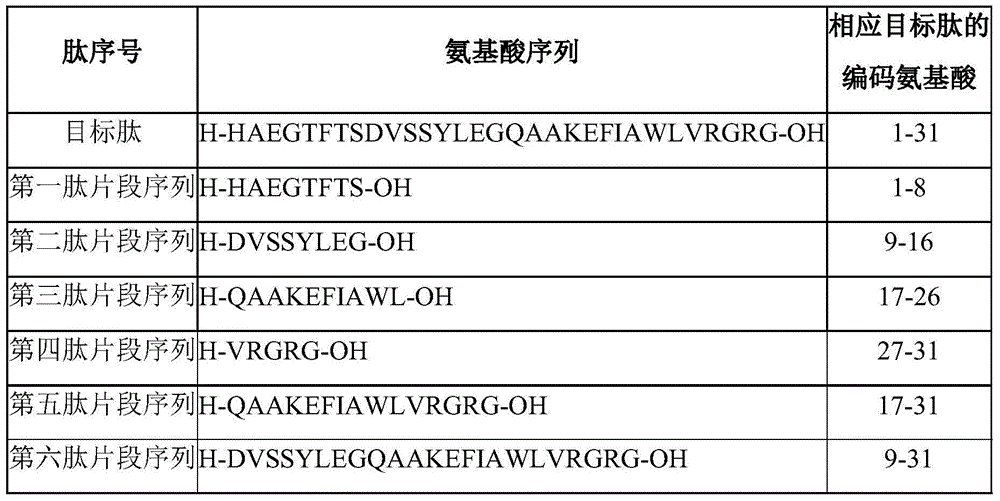

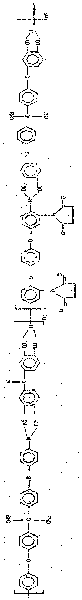

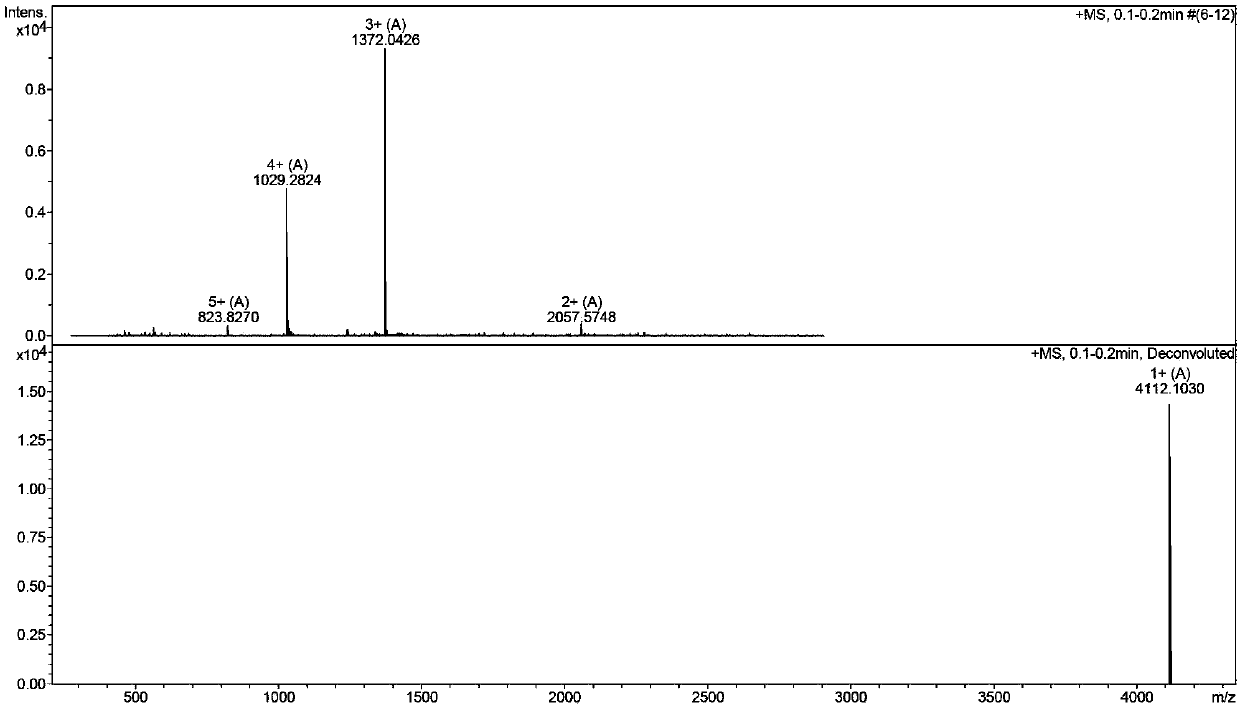

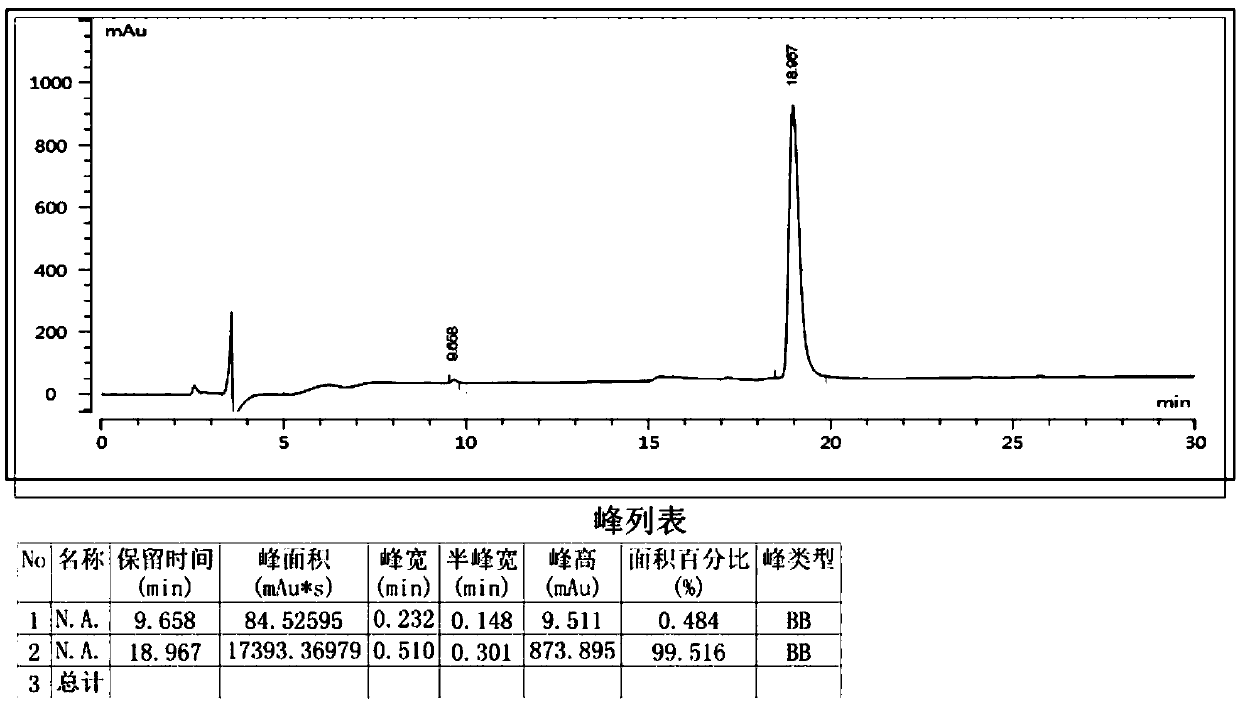

Method for preparing liraglutide by convergent synthesis

ActiveCN104650219AHigh purityHigh yieldPeptide preparation methodsBulk chemical productionSide chainPeptide fragment

The invention discloses a method for preparing liraglutide by convergent synthesis. The method comprises the steps of performing solid phase synthesis to obtain four side chain protected peptide fragment sequences, gradually coupling the peptide fragments in a solution system to obtain an all-protected liraglutide straight chain polypeptide, removing the side chain protection of the 20th Lys, performing modification to form all-protected liraglutide, then cracking to remove protecting groups to obtain a crude liraglutide peptide, purifying and exchanging salt to obtain liraglutide; wherein in the four peptide fragment sequences, the first peptide fragment sequence is 1st to 8th amino acids in the liraglutide sequence, the second peptide fragment sequence is 9th to 16th amino acids in the liraglutide sequence, the third peptide fragment sequence is 17th to 26th amino acids in the liraglutide sequence, and the fourth peptide fragment sequence is 27th to 31st amino acids in the liraglutide sequence. By adopting the method, the yield is improved, and the synthesis cost is greatly reduced; and the method is favorable for large-scale and industrialized production.

Owner:LANZHOU UNIVERSITY

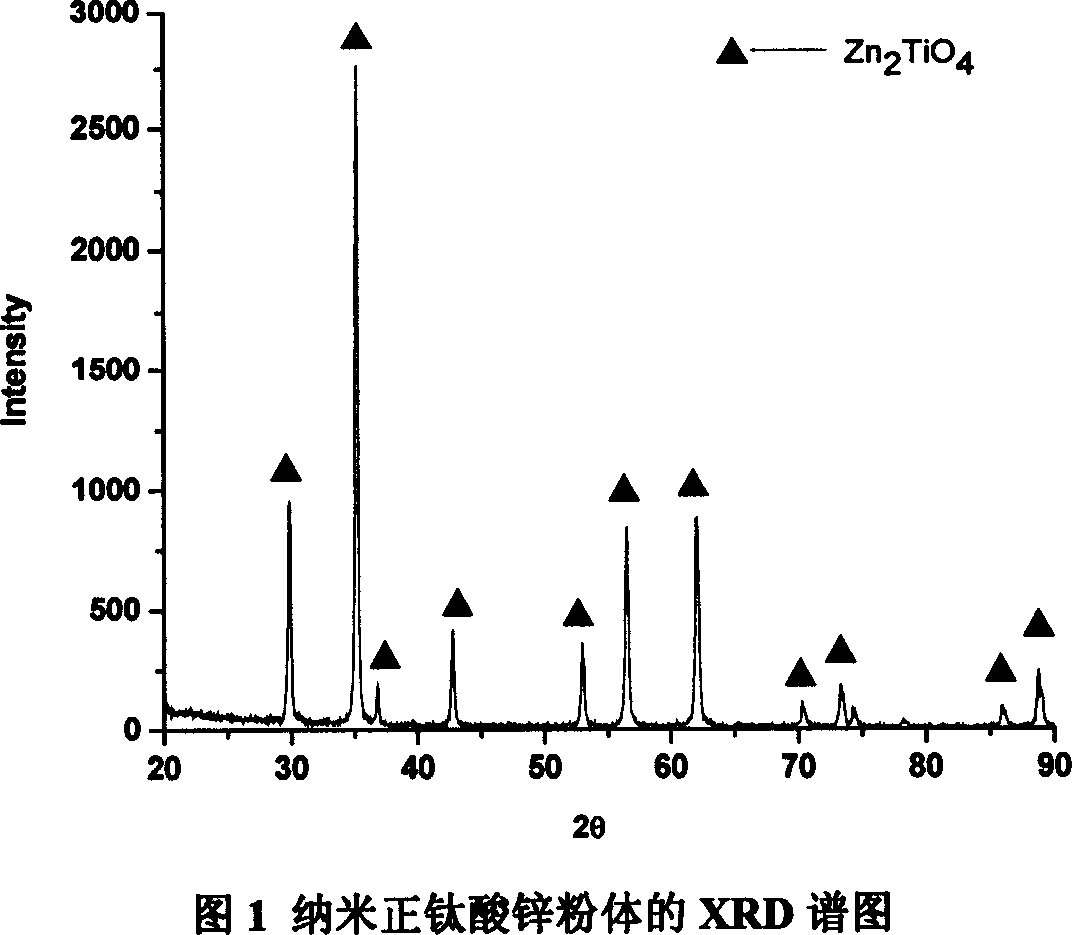

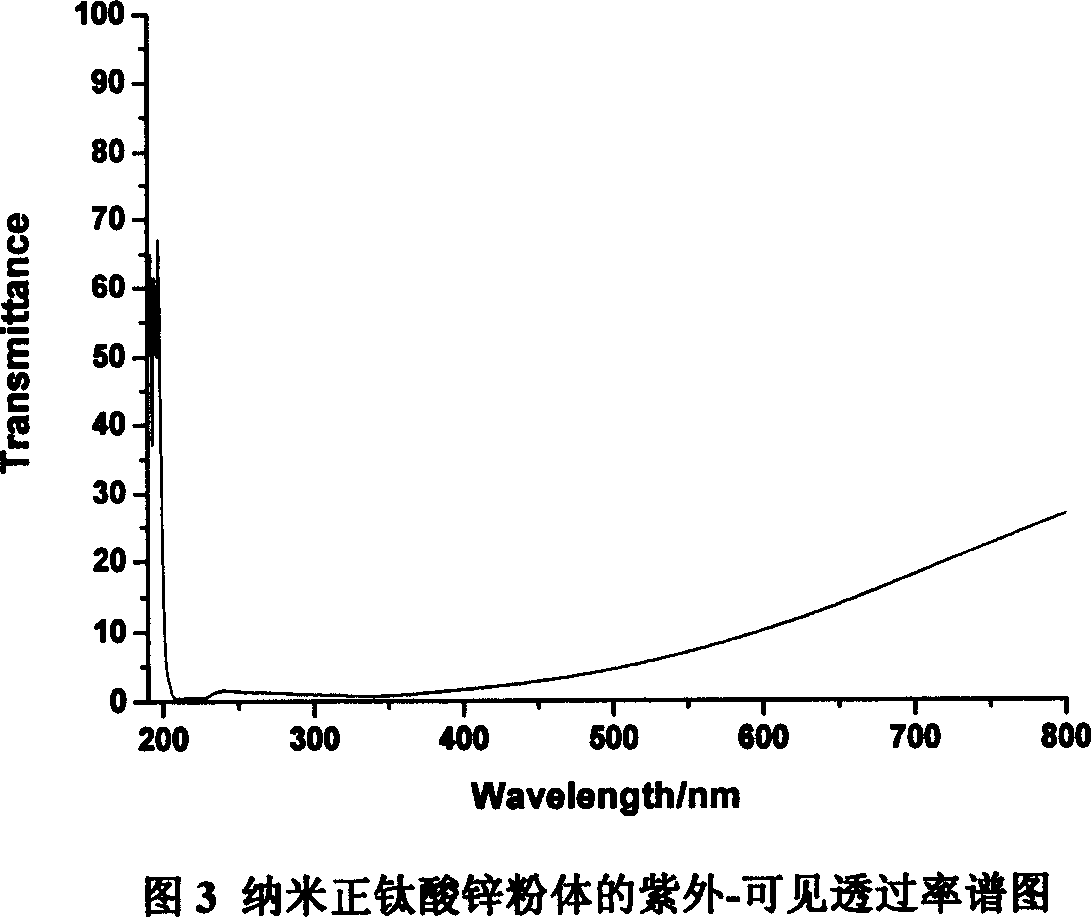

UV-shielding nano normal zinc titanate powder and process for preparing same

InactiveCN1884095AImprove shielding effectLow costCosmetic preparationsToilet preparationsSal ammoniacSulfate

The invention discloses a new ultraviolet nanometer screening titanate zinc powder and preparing method; which is characterized by the following: adopting industrial metatitanate, zinc sulfate as raw material to prepare TiOSO4 solution; blending TiOSO4 and ZnSO4; adding surface activist PEG400; utilizing ammonia as sedimenting agent to adjust system pH value to generate priority sedimentation; filtering; washing; drying; grinding; sintering to obtain Zn2TiO4 powder. The invention provides pure Zn2TiO4 analyzed by XRD phase with 70 nm for TEM observing grain size, which screens ultraviolet effectively by over 95 percent.

Owner:SICHUAN UNIV

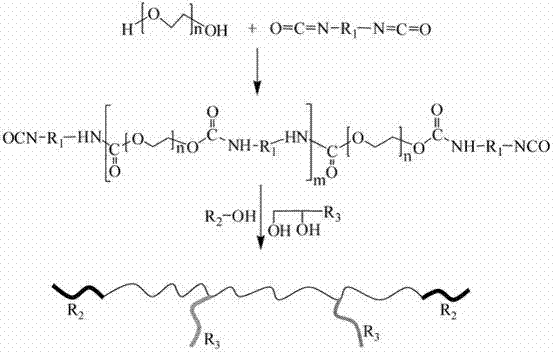

Preparation method of linear water-based polyurethane thickener containing hydrophobic side bases

InactiveCN102898612ASimple preparation stepsReaction conditions are easy to controlPolyurea/polyurethane coatingsEndcappingPolymer science

The invention relates to a linear water-based polyurethane thickener containing hydrophobic side bases and a preparation method of the linear water-based polyurethane thickener. The preparation method is characterized in that 40 weight percent to 60 weight percent of dibasic alcohol polymers, 10 weight percent to 30 weight percent of diisocyanate and 0 weight percent to 5 weight percent of catalysts are mixed, under the condition of N2 gas existence and the temperature being 50 DEG C to 100 DEG C, the stirring is carried out for 1 to 6 hours, then, 10 weight percent to 30 weight percent of end-capping agents are added, under the condition of the temperature being 50 DEG C to 100 DEG C, the stirring is carried out for 1 to 6 hours, polyurethane prepolymers are prepared, then, 5 weight percent to 20 weight percent of chain extenders are added into the prepared polyurethane prepolymers, the stirring is carried out for 1 to 6 hours under the condition of the temperature being 50 DEG C to 100 DEG C, and the linear water-based polyurethane thickener containing hydrophobic side bases is prepared. The linear water-based polyurethane thickener and the preparation method have the characteristics that no solvent exists, the toxicity is low, the environment is protected, the preparation process is simple, and the like. The prepared linear water-based polyurethane thickener containing hydrophobic side bases is applicable to the thickening of water-based paint, and the obvious thickening effect is realized.

Owner:LISHUI UNIV

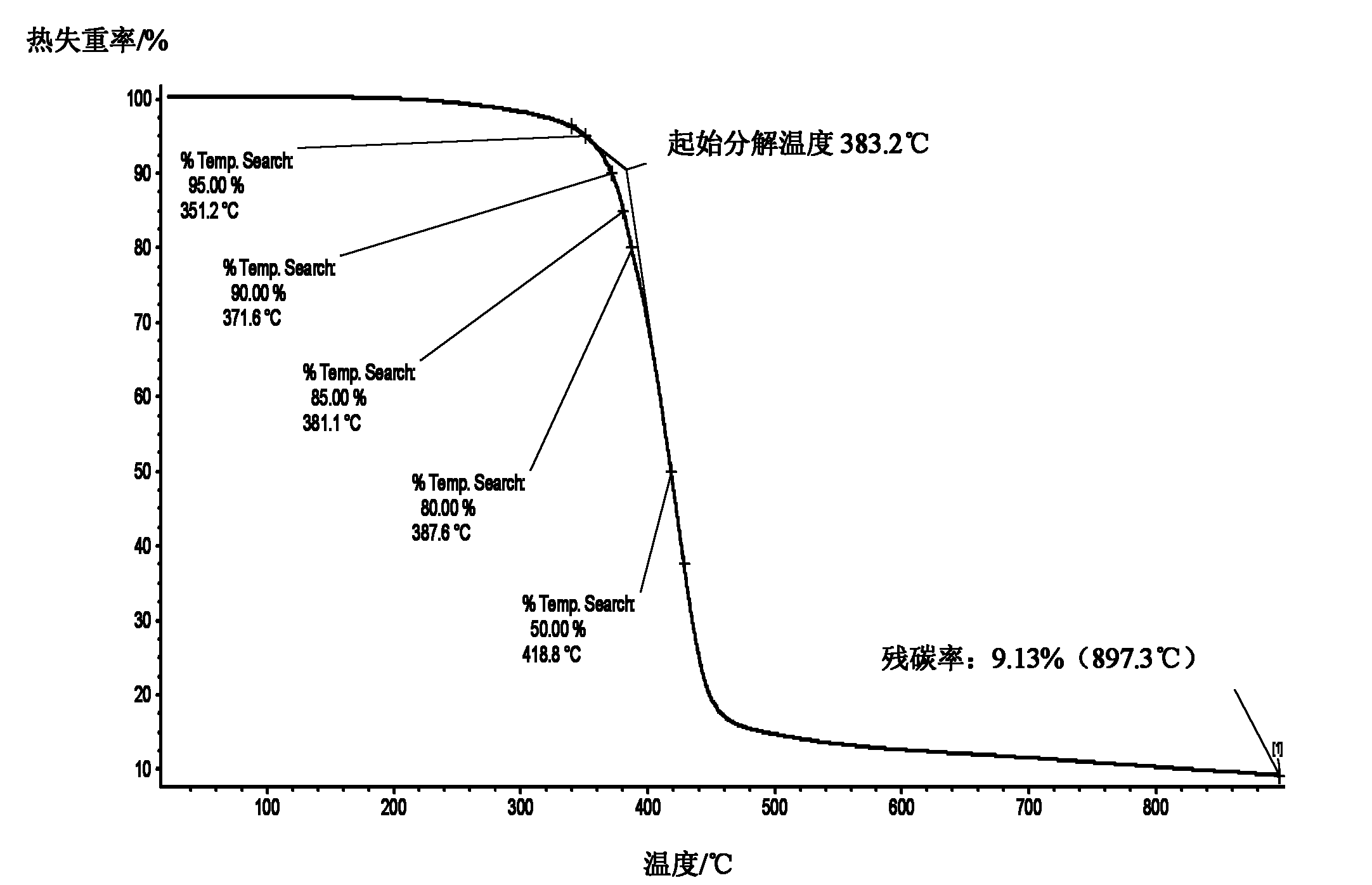

High-temperature resistant copper foil glue and preparation and application thereof

InactiveCN101717613AGood viscosity controllabilityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOrganic solventPolyetherimide

The invention relates to high-temperature resistant copper foil glue containing the following components: 5-15wt percent of trifluoromethyl-contained maleimide resin, 10-30wt percent of polyfunctional ethoxyline resin, 10-40wt percent of bisphenol A epoxy resin, 5-15wt percent of ethylene-contained polyetherimide, 5-10wt percent of curing agent and 25-45wt percent of organic solvent; the preparation comprises the following steps of: adding the trifluoromethyl-contained maleimide resin and the ethylene-contained polyetherimide to the mixture of the polyfunctional ethoxyline resin and the bisphenol A epoxy resin, stirring while heating for reacting, and then cooling to 30-50 DEG C; adding the organic solvent and the curing agent; evenly stirring to obtain the high-temperature resistant copper foil glue the homogeneous phase of which is transparent and clear. The high-temperature resistant copper foil glue has Tonset temperature reaching up to 415 DEG C and excellent comprehensive performance, can be applied to the high-tech fields of electronics and microelectronics, automobiles, electrical machines, aerospace and the like; moreover, the invention has simple preparation process, low cost, convenient operation and available reaction raw materials, thereby being beneficial to realizing industrial production.

Owner:DONGHUA UNIV

Preparation method for non-halogen smoke suppressing fire-retardant polyester fiber non-woven fabric

The invention relates to a preparation method for non-halogen smoke suppressing fire-retardant polyester fiber non-woven fabric, which comprises the following steps: mixing ammonium dibasic phosphate and phosphorus pentoxide according to the molar ratio of 1:0.9-1.2; adding a catalyst, stirring the mixture, heating the mixture and raising the temperature; introducing liquid ammonia, and carrying out vacuum discharging; adding polyatomic alcohol, bimaleimide and melamine, and mixing the mixture evenly to obtain a non-halogen smoke suppressing fire retardant for non-woven fabric; adding deionized water, sanding the mixture, adding an emulsion of an adhesive into the mixture, mixing the mixture to obtain grout of the fire retardant; and roller coating the grout on polyester fiber non-woven fabric, and padding and baking the coated polyester fiber non-woven fabric to obtain the non-halogen smoke suppressing fire-retardant polyester fiber non-woven fabric. The preparation process has simplicity, low cost, convenient operation, convenient source of reaction raw materials, few three wastes and environment friendliness, can complete the preparation process in universal equipment, and is favorable for realizing industrialized production; and the horizontal burning rate of the fire retardant is 10 to 20 mm / min, completely reaches and even exceeds the standard value, and the fire retardant has obvious retardant effect and good application prospect.

Owner:XUSEN NON HALOGEN SMOKE SUPPRESSING FIRE RESTARDANTS

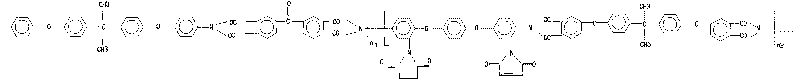

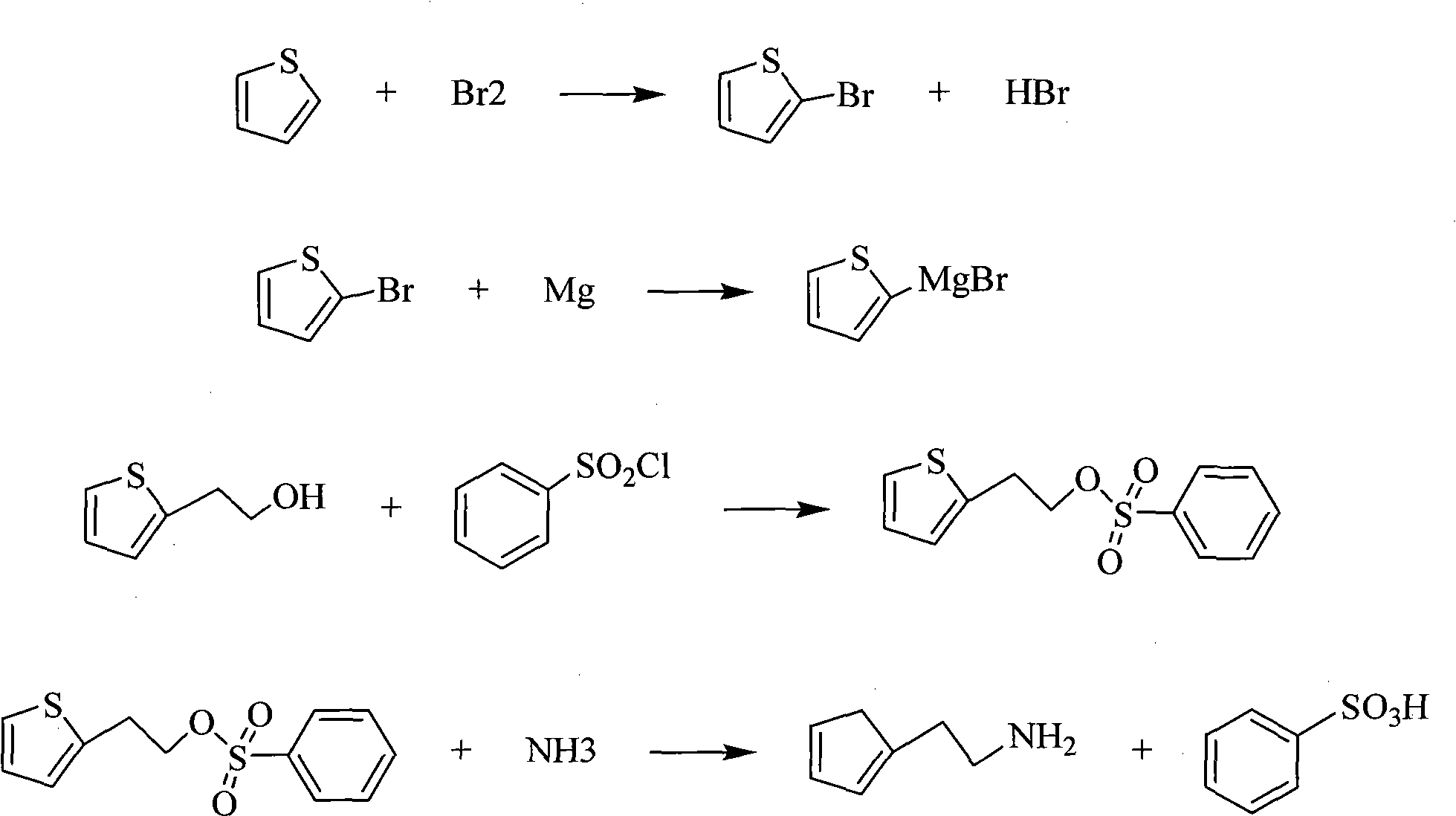

Method for synthesizing 2-thiophene ethylamine

ActiveCN101885720AReduce manufacturing costMild reaction conditionsOrganic chemistryTerthiopheneEthylene oxide

The invention relates to a method for synthesizing 2-thiophene ethylamine, which is characterized in that thiophene is taken as a raw material, intermediate 2-thiophene ethanol is firstly prepared, and then the 2-thiophene ethylamine is obtained through pressurization and ammonolysis. The method mainly comprises the following steps: bromizing thiofuran at low temperature to obtain 2-bromo thiophene; carrying out Grignard reaction on the 2-bromo thiophene and magnesiumchips and reacting with ethylene oxide to generate the 2-thiophene ethanol; and preparing 2-thiophene ethylamine from the 2-thiophene ethanol through the two steps of esterification and ammonolysis. The invention takes cheap and easily obtained thiophene as the raw material which is subjected to the fives reactions of bromination, Grignard, addition, esterification and ammonolysis, greatly reduces the production cost, has mild reaction condition, simple process and small pollution, facilities the realization of the industrialized production, does not use the reducing agent and avoids the utilization of expensive or toxic materials.

Owner:LIANYUNGANG DIPU CHEM

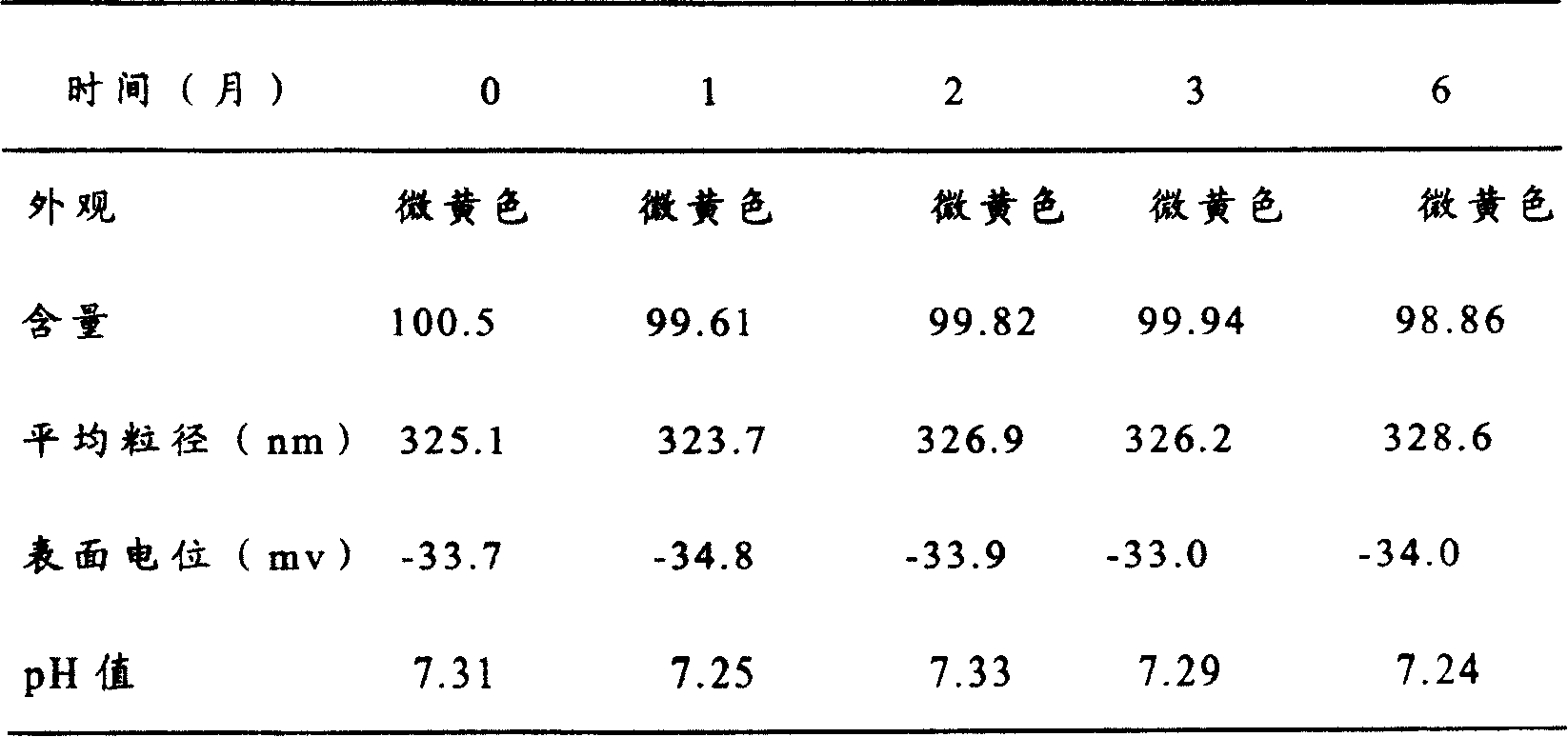

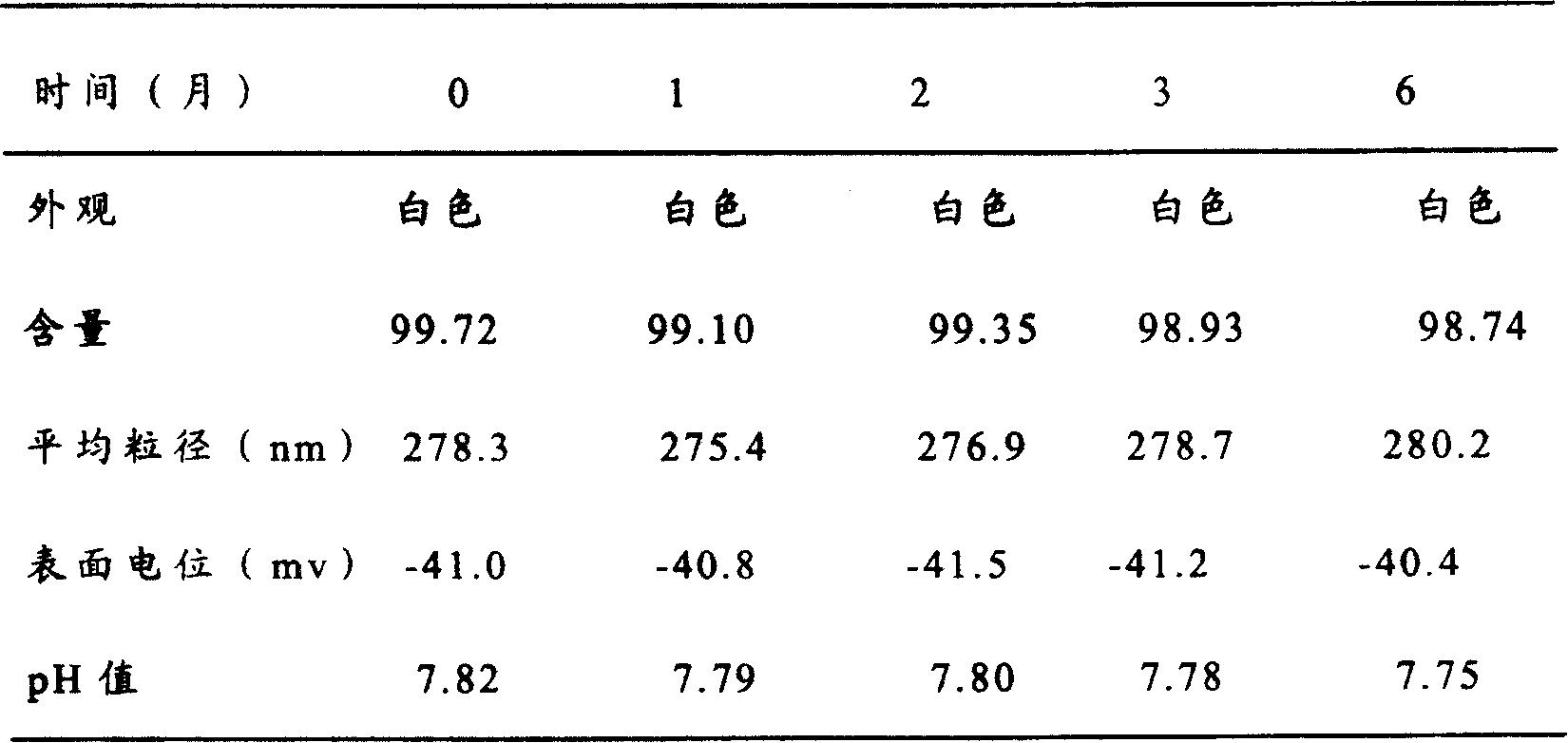

Oryzanol composition and its preparation method

ActiveCN100386082CStrong solubilizing abilityQuick effectPowder deliveryOrganic active ingredientsFreeze-dryingSURFACTANT BLEND

Owner:SHANDONG BESTCOMM PHARMA CO LTD

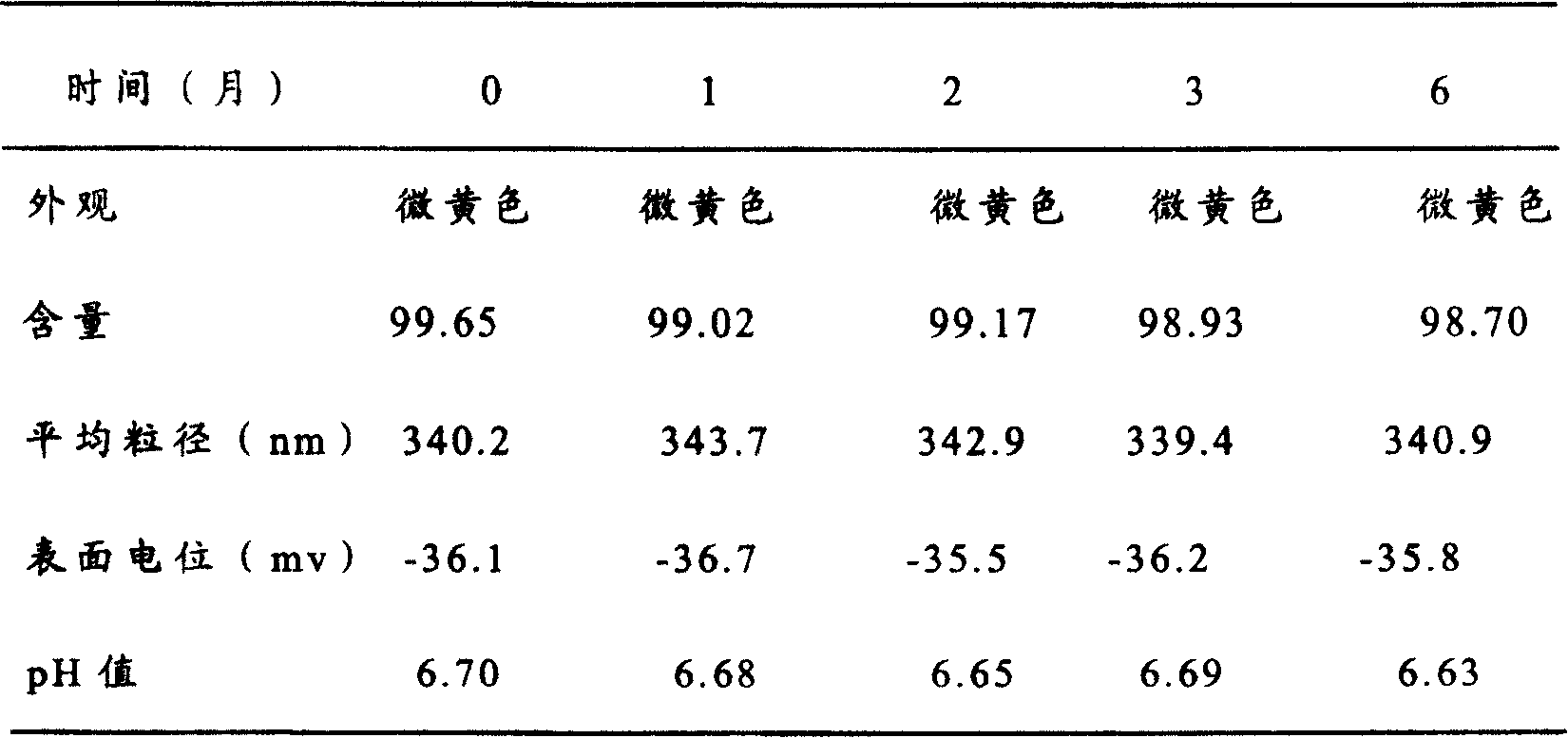

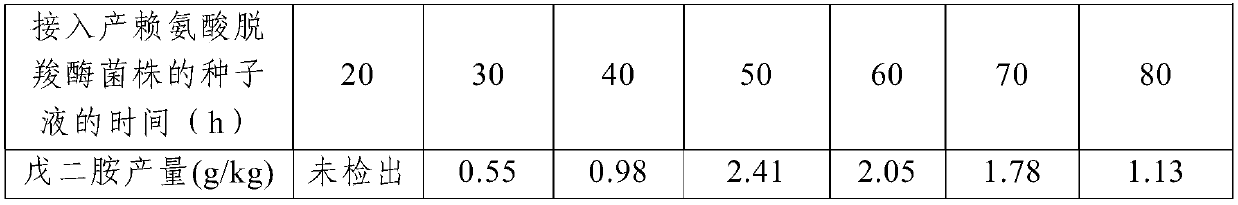

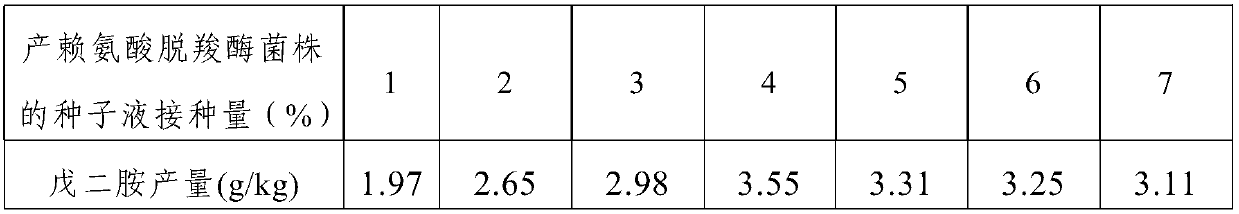

Preparation process of 1,5-pentamethylene diamine

PendingCN109536542AFacilitate the realization of industrial productionReduce toxic effectsMicroorganism based processesFermentationMicroorganismLysine fermentation

The present invention relates to a preparation process of 1,5-pentamethylene diamine. According to the method, a seed liquid containing lysine decarboxylase strains is introduced during lysine fermentation, and mixed fermentation is carried out. The method is suitable for industrial production of 1,5-pentamethylene diamine, minimizes toxicity of pentamethylene diamine to microorganisms to avoid adverse effects on fermentation, makes the subsequent process more simplified, and has certain commercial value.

Owner:CATHAY R&D CENT CO LTD +1

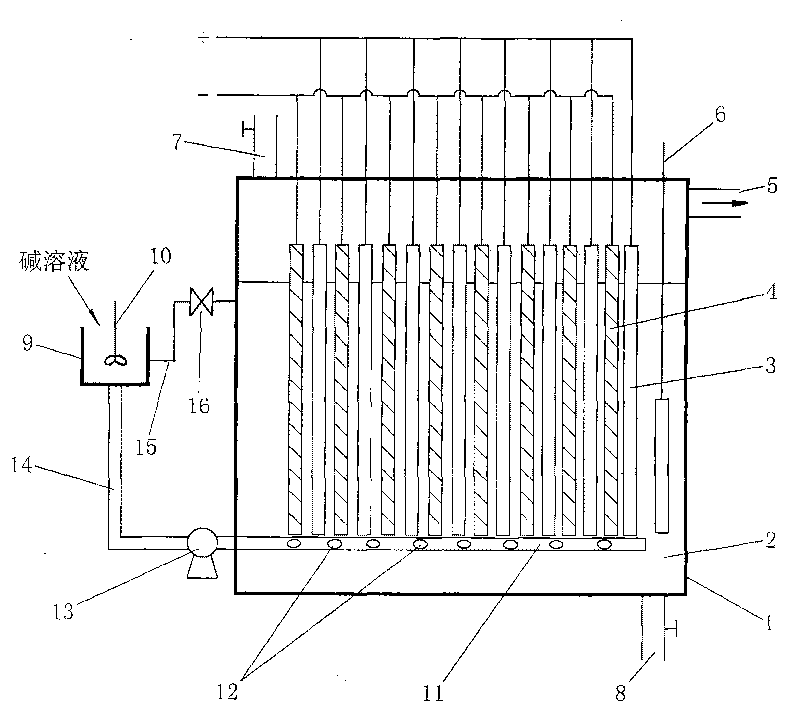

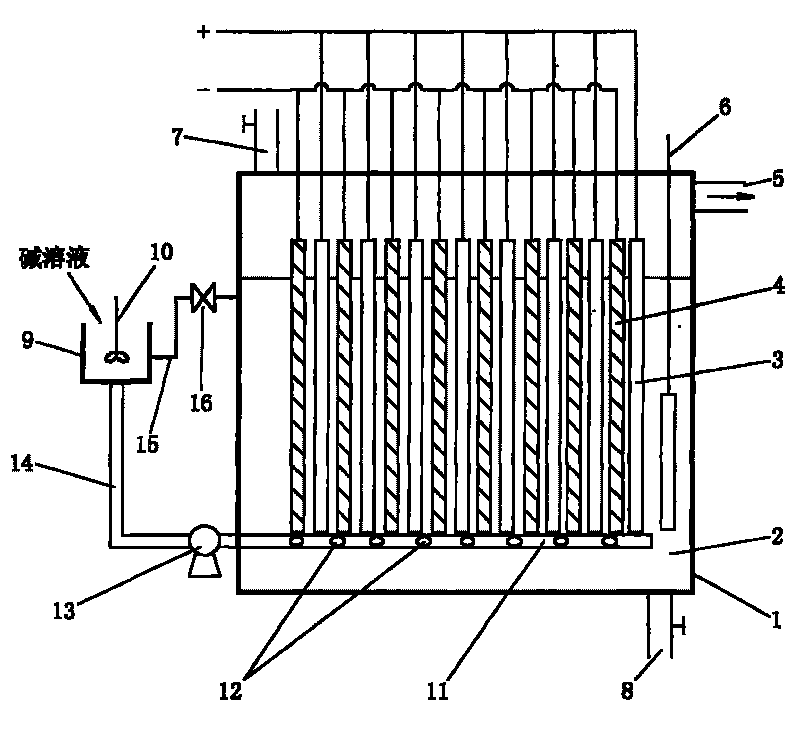

Method for treating nickel-containing electroplating wastewater and recovering nickel by electrolysis

InactiveCN101717135AReduce the side reaction of hydrogen electrolysis on the cathode plateStrong acidWater contaminantsWaste water treatment from metallurgical processGraphite electrodeTitanium

The invention discloses a method for treating nickel-containing electroplating wastewater and recovering nickel by electrolysis. The method has the characteristics of simple process, no secondary pollution, high removal rate and recyclable deposited metallic nickel. The nickel-containing electroplating wastewater is subjected to electrolysis treatment by an electrolysis treatment nickel-containing electroplating wastewater device, which comprises an electrolytic bath and an electrolyte stirring apparatus, wherein the anode adopts a titanium-based platinum electrode; the cathode adopts a nickel electrode or a graphite electrode; and a pH meter is arranged in the electrolytic bath. The method for treating the nickel-containing electroplating wastewater by electrolysis comprises the following steps: before the electrolysis treatment, putting the nickel-containing electroplating wastewater serving as an electrolyte into the electrolytic bath, and adding alkali solution into the electrolyte to adjust the pH value of the electroplating wastewater; and adding the aqueous alkali into the electrolyte during the electroplating to adjust the pH value of the electrolyte to between 6.0 to 9.0, and recycling the nickel precipitated from a negative plate by measuring the charge accumulation amount of the electrolyte.

Owner:ZHEJIANG NORMAL UNIVERSITY

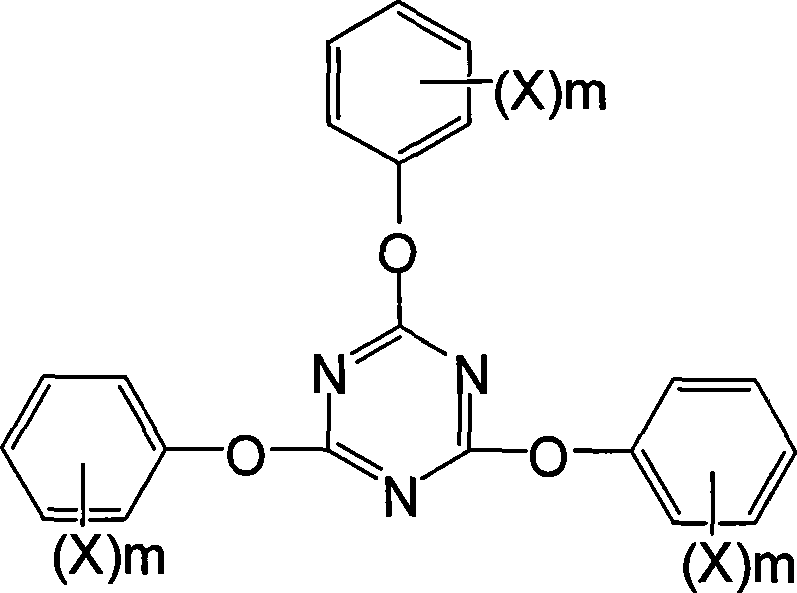

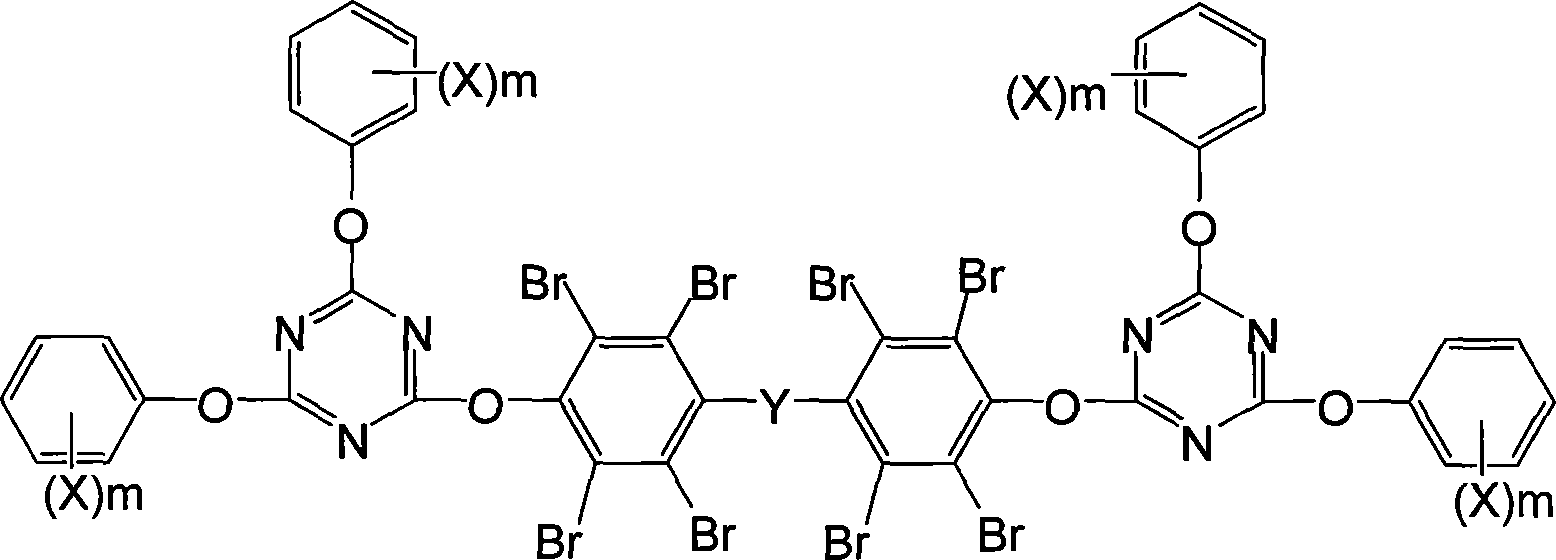

Method for preparing polybromophenoxy-substituted striazine fire-retardant compound

ActiveCN101070475AAvoid the problems of high reaction temperature and high energy consumptionAvoid complex operationsOrganic chemistryRadical substitutionBenzene

The invention relates to the more monobromo-benzene oxygen radical substitutions even triazine flame retardance compound's preparation method. Its characteristic is: The reactant three will gather the chlorine cyanogens, the multi-bromophenols, shift the catalyst according to 1:2.5-3.1:0.01-0.1 a mole of allocated proportion to take the quantity, with the right amount organic solvent one and joins to a reactor, stir and cool it to 10 degree C below; Take the 5%-30% sodium hydroxide peroxide solution which mole of quantity sodium hydroxide compounds the weight percentage concentration with the multi-bromophenols, add by drops in the reactor stated, and maintain the system temperature not to surpass 10 degree C when adding by drops in the process; After the installment, heat the reaction material to 30-60 degree C ,and respond 1h-5h again; Then distillate to clean the resolve, cool, filtrate, the solid which the filtration obtains after the washing, drying is the system results in the product. This invention uses a method of 'a pot synthesis', the operation is simple, the pollution is reduced, the resolve may recycle repeatedly, the cost is small, and it is suitable for the industrialization production.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

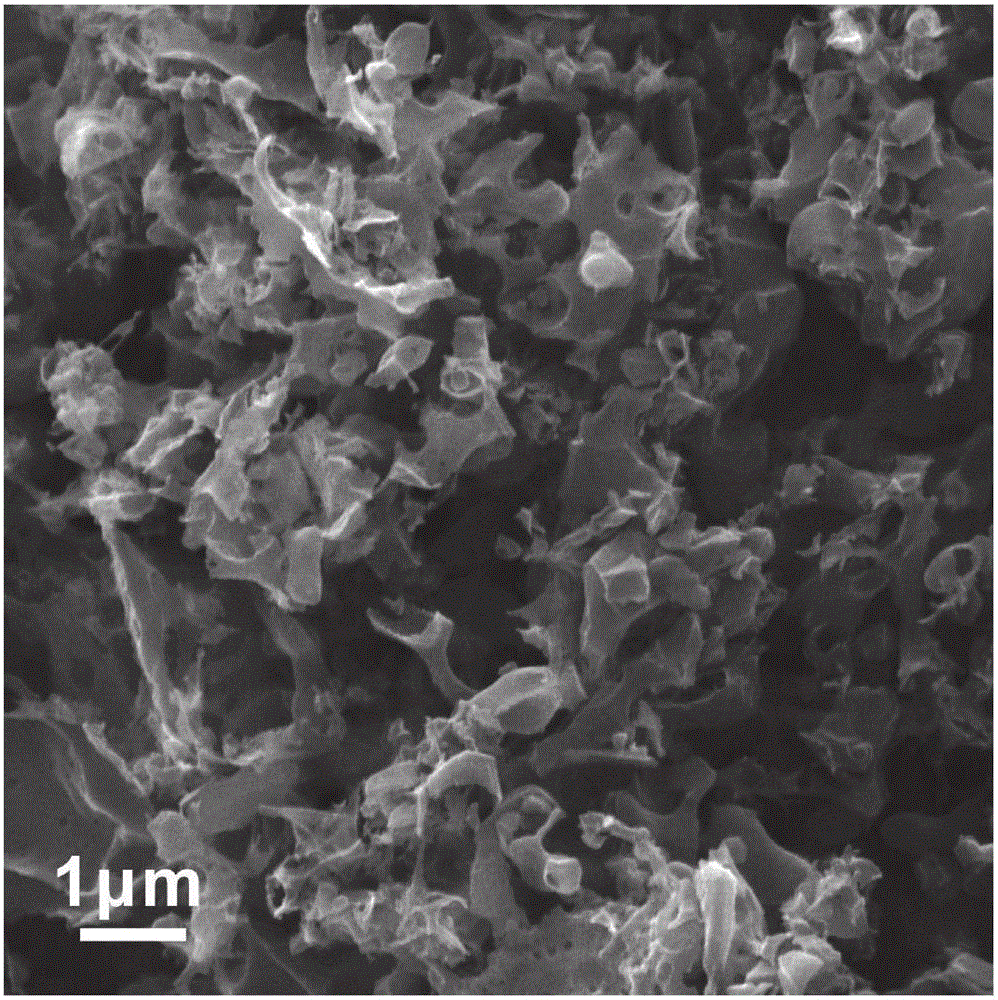

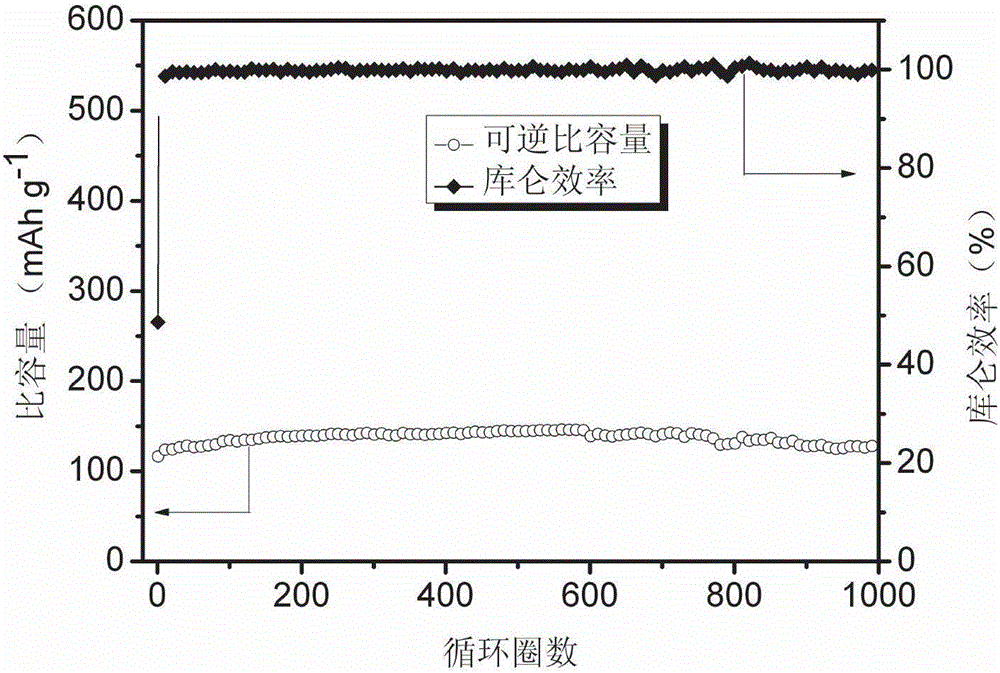

Hetero atom-doped three dimensional porous carbon material, preparation method and application thereof

ActiveCN106115654ASimple manufacturing methodConditions are easy to controlCell electrodesPorous carbonCarbon quantum dots

The invention discloses a hetero atom-doped three dimensional porous carbon material preparation method. According to the invention, carbon quantum dot, an alkali metal hydroxide and a hetero atom source are mixed, a mixture is put under inert gas atmosphere for being calcined, and the calcined product is subjected to neutralization, solid-liquid separation, and drying in order to obtain the hetero atom-doped three dimensional porous carbon material. The hetero atom source is selected from at least one of a boron compound, a sulfur compound, a nitrogen compound, and a phosphor compound. In addition, the invention also provides the three-dimensional porous carbon material, and an application of the three dimensional porous carbon material as an electrode material in preparation of an energy storage device. The preparation method has the advantages of easy and rapid operation, high efficiency and high yield, controllable condition, and low cost, and is in favor of industrial production; and the produced three-dimensional porous carbon material as the electrode material of the energy storage device, and has the excellent performances of high capacity, high power and long service life.

Owner:CENT SOUTH UNIV

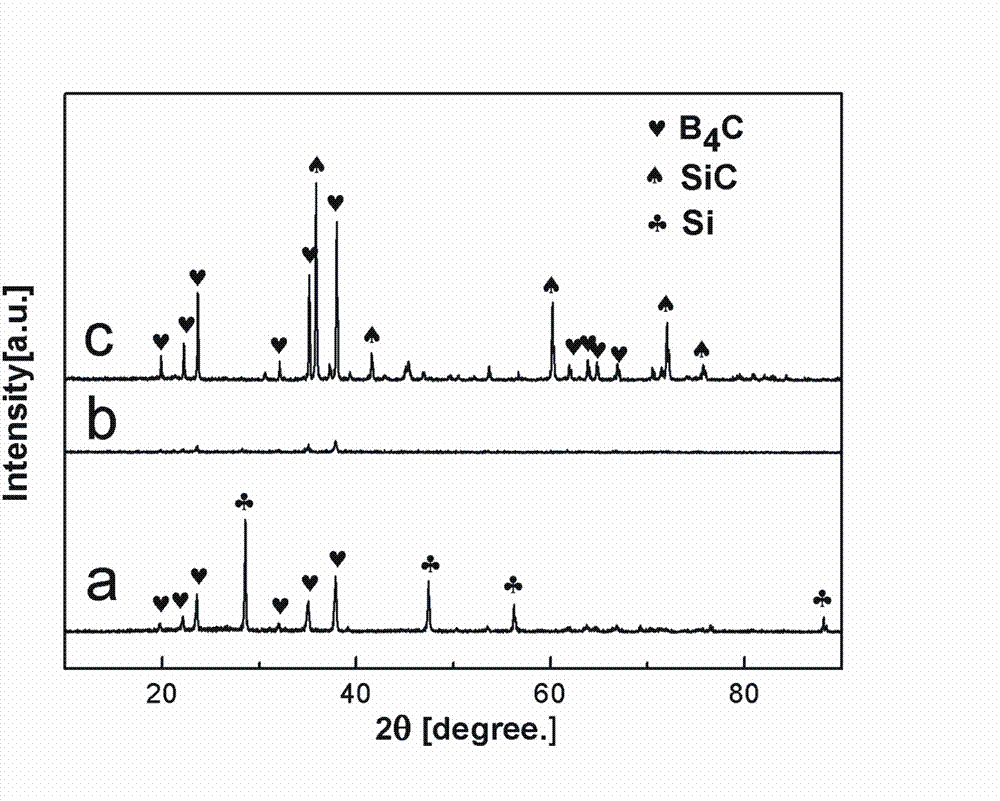

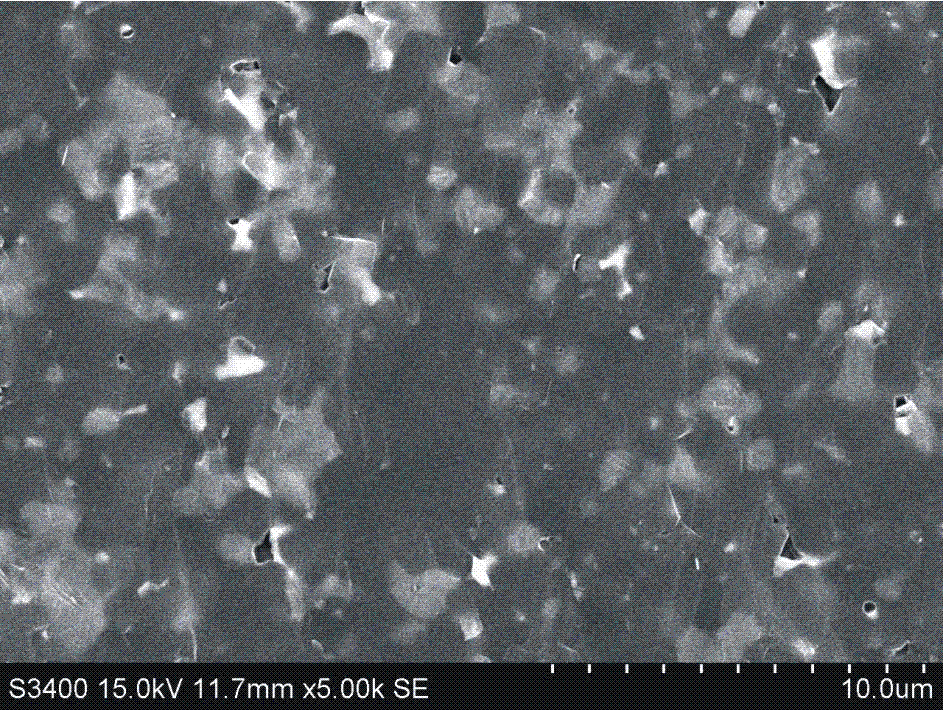

Boron carbide silicon carbide composite ceramic and preparation method thereof

The invention relates to a method for preparing boron carbide silicon carbide composite ceramic and belongs to the technical field of ceramic materials. The boron carbide silicon carbide composite ceramic is prepared by mechanically alloying three-element mixed powder of boron carbide, carbon powder and silicon powder and sintering by a reaction hot-pressing technology, wherein the three-element mixed powder comprises 50 to 90 weight percent of boron carbide powder, 15 to 3 weight percent of carbon powder and 35 to 7 weight percent of silicon powder; and the molar ratio of the carbon powder to the silicon powder is 0.8 to 1.2. The high-compactness boron carbide silicon carbide composite ceramic can be obtained at low temperature without adding a liquid phase sintering aid. Silicon carbide which is obtained through in-situ synthesis in the sintering process of carbon and silicon has high purity and the crystal grains are small and dispersed uniformly, so the mechanical property of the ceramic is improved. The boron carbide silicon carbide composite ceramic prepared by the method has high compactness, high hardness and high high-temperautre mechanical property and can serve as an anti-impact and wear-resistant part of precise structure engineering.

Owner:WUHAN UNIV OF TECH

Large plastometric set method for producing ultra-fine crystal material

InactiveCN101294238AOvercome deficienciesExtended service lifeProcess efficiency improvementEqual channel angular extrusionUltra fine

The invention provides a severe plastic deformation method for manufacturing ultra-fine grain material, which comprises an equal-channel angular extrusion step. The method is characterized in that the severe plastic deformation method has the following processing steps, namely the preparation of raw material, homogenizing annealing, compression extrusion deformation, equal-channel angular extrusion deformation, repeated upsetting-extrusion deformation, and annealing treatment. The shapes and sizes of the material before and after the extrusion deformation are the same so as to realize the multi-pass accumulated deformation; combining the other technologies, the disadvantages during the manufacture process of the ultra-fine grain material are effectively avoided because of absorbing the advantages of a equal-channel angular extrusion method, thereby realizing that the uniform ultra-fine grain microstructure material can be obtained after less-pass upsetting-extrusion deformation; therefore, the uniform and stable ultra-fine grain bulk material is obtained, in addition, the productivity effect is increased obviously, the service life of an extrusion die is prolonged, the manufacturing cost is lowered, and the severe plastic deformation method is favorable for realizing large-scale industrial production at the same time.

Owner:KUNMING UNIV OF SCI & TECH

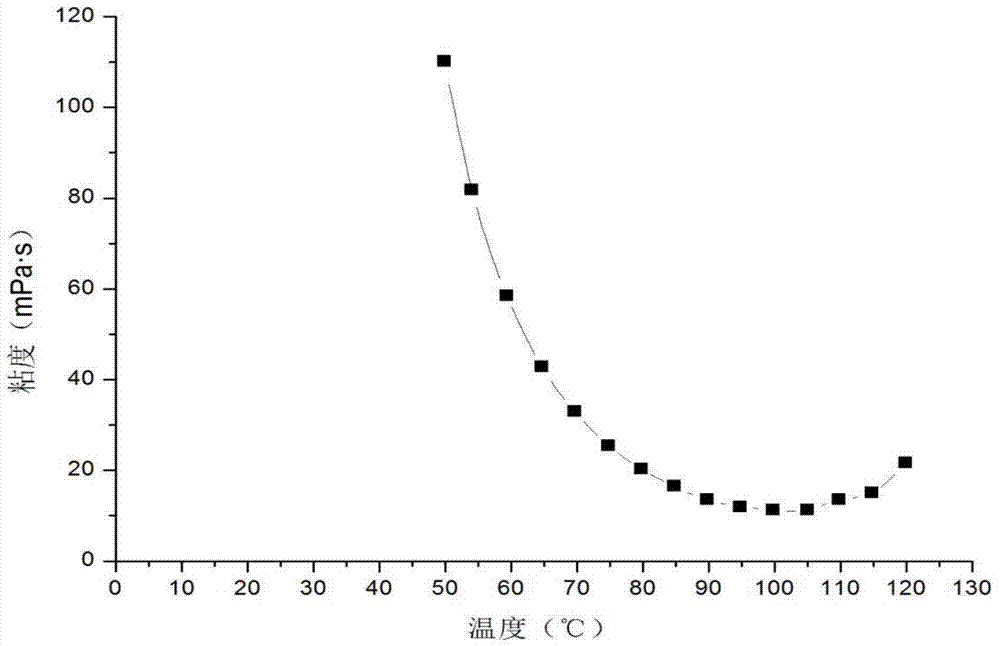

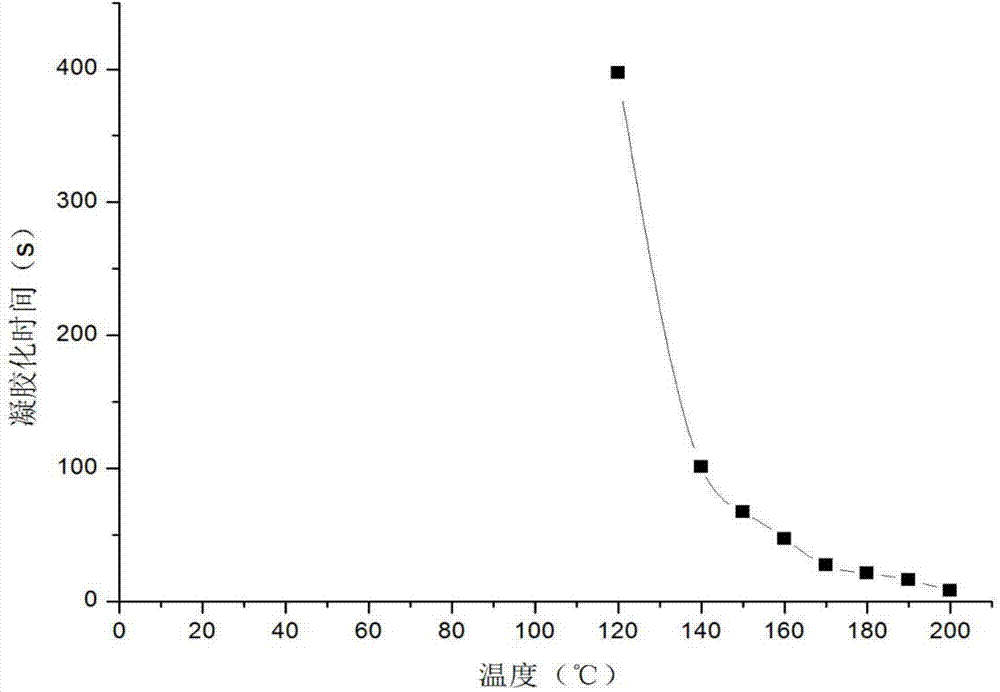

Pultrusion resin for high temperature-resistant carbon fiber-reinforced cable core and preparation method of pultrusion resin

The invention relates to pultrusion resin for a high temperature-resistant carbon fiber-reinforced cable core and a preparation method of the pultrusion resin. The resin comprises hydroxyl-containing and carboxyl-containing active polyimide resin (HCPI), polyfunctional epoxy resin, SR22000 organic silicon resin, thermoplastic bisphenol A phenolic resin, maleic anhydride, an active diluent, a curing agent and an accelerator. The preparation method comprises the following steps: putting polyfunctional epoxy resin, hydroxyl-containing and carboxyl-containing active polyimide resin, SR22000 organic silicon resin, thermoplastic bisphenol A phenolic resin and maleic anhydride into a reaction kettle, performing stirring reaction, adding the active diluent, performing the stirring reaction, then adding the curing agent and the accelerator, and uniformly stirring. The pultrusion resin provided by the invention has the advantages of convenient raw material sources, no solvent, environment friendliness, simple operation process and excellent comprehensive performance, is very suitable for a pultrusion process, is very suitable for manufacturing a high temperature-resistant carbon fiber-reinforced cable core composite material with excellent comprehensive performance by pultrusion, and has broad application prospects.

Owner:DONGHUA UNIV +1

Process for extracting alpha-crocin from fructus gardeniae

The invention relates to a process for extracting alpha-crocin from fructus gardeniae, which comprises the following steps of degreasing, aqueous extraction, tannin removal, resin adsorption, recrystallization and the like, and particularly comprises a method of degreasing by a No.4 solvent, tannin removal by polyamide resin and the recrystallization of hot water and propylene glycol. The production process has the characteristics of simplicity, convenience and low cost.

Owner:NANJING ZELANG AGRI DEV

Method for preparing semaglutide by fragment condensation

ActiveCN109627317AHigh purityHigh yieldPeptide preparation methodsBulk chemical productionImpuritySolid-phase synthesis

The invention relates to a method for preparing soematoglutide. A solid-liquid phase-binding fragment condensation scheme is adopted and includes conducting solid phase synthesis to obtain side chainprotecting peptide, conducting liquid phase fragment condensation to obtain fully protected semaglutide, then conducting cleavage to obtain crude semaglutide and conducting purification salt exchangeto obtain the semaglutide. A pseudoproline strategy is adopted to reduce by-products caused by racemization. Acccording to the method, impurities are reduced, the yield is improved, the synthesis timeis reduced, the waste liquid discharge is reduced, the synthesis cost is greatly reduced, and the method is very beneficial to industrial production.

Owner:LANZHOU UNIVERSITY

Method for preparing nonane diacid catalyzed by solid acid

InactiveCN101077856AEasy to separateFacilitate the realization of industrial productionMolecular sieve catalystsOrganic compound preparationTemperature controlMixed fatty acid

The solid acid catalyzed process of preparing azelaic aid includes the following steps: mixing unsaturated fatty acid or mixed fatty acid produced through hydrolyzing animal and vegetable oil, solid acid catalyst and ammonium hexadecyl trimethyl chloride; stirring, heating to 50-70 deg.c, introducing gas mixture containing 2-10 wt% ozone in the flow rate of 500 ml / min, stepped adding 20-40 wt% concentration hydrogen peroxide solution at temperature controlled below 70 deg.c; heating to 95-110 deg.c for reaction for 5-12 hr; and separating the resultant liquid mixture and purifying to obtain pure azelaic aid. The used solid acid catalyst may be separated from other materials for reuse, and the process has facile materials and environment friendship, and is suitable for industrial production.

Owner:SHANGHAI UNIV

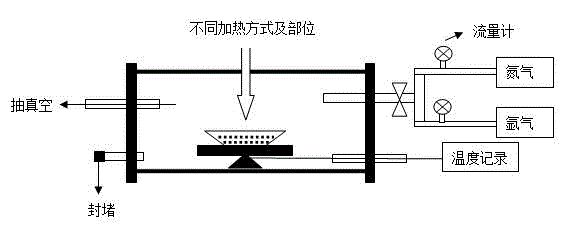

Method for preparing alpha phase and beta phase silicon nitride powder by improved direct nitriding method

InactiveCN103332662AIncrease osmotic pressurePromote nitridingNitrogen compoundsSilica fumeChemistry

The invention relates to a method for preparing alpha phase and beta phase silicon nitride powder by improved direct nitriding method. The method is mainly an improvement based on the existing direct nitriding method; metallic silicon powder and nitrogen react in a completely sealed reaction device; reaction gas is mixed gas of the nitrogen and inert gas (such as argon); and the inert gas has two functions of serving as shielding gas to prevent the silicon powder from oxidation and performing supercharging to raise seepage pressure of the nitrogen to promote nitriding of metallic silicon during reaction. The reaction speed of the metallic silicon and the nitrogen is controlled by adjusting the proportion of the nitrogen in the mixed gas to control the temperature in a reaction vessel, and a silicon nitride product with an objective constituent phase (an alpha phase and a beta phase) can be obtained finally. The method is simple in operation process, reduces energy and raw material consumption, does not require an additional diluent, a catalyst and the like, greatly saves production cost, and facilitates realizing industrial production.

Owner:SHANGHAI UNIV

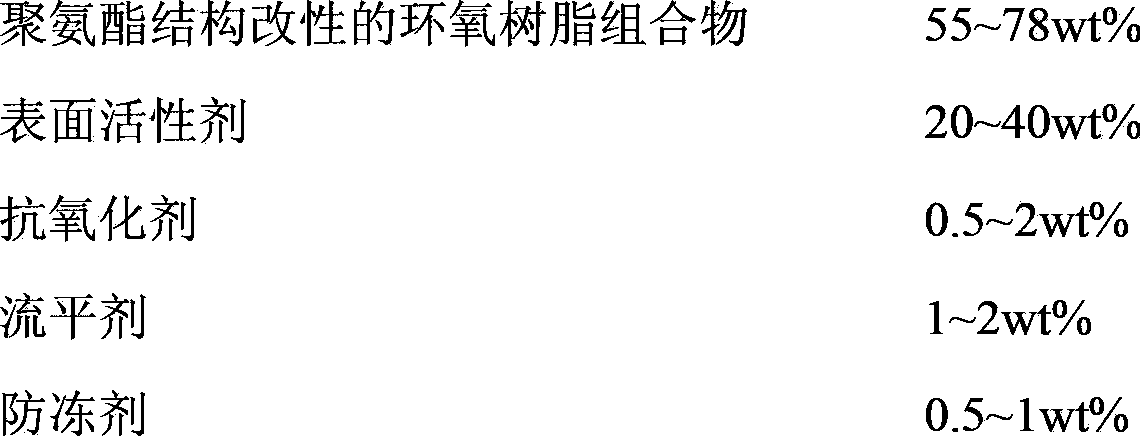

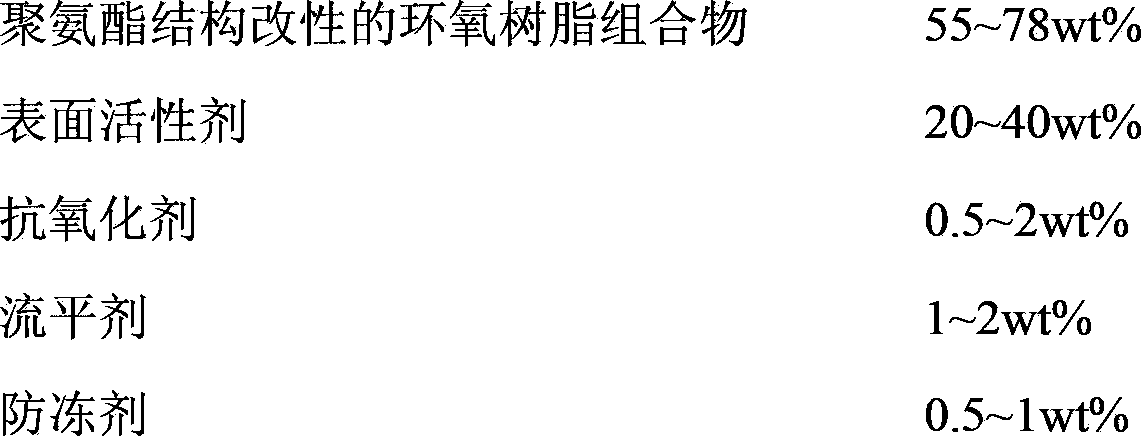

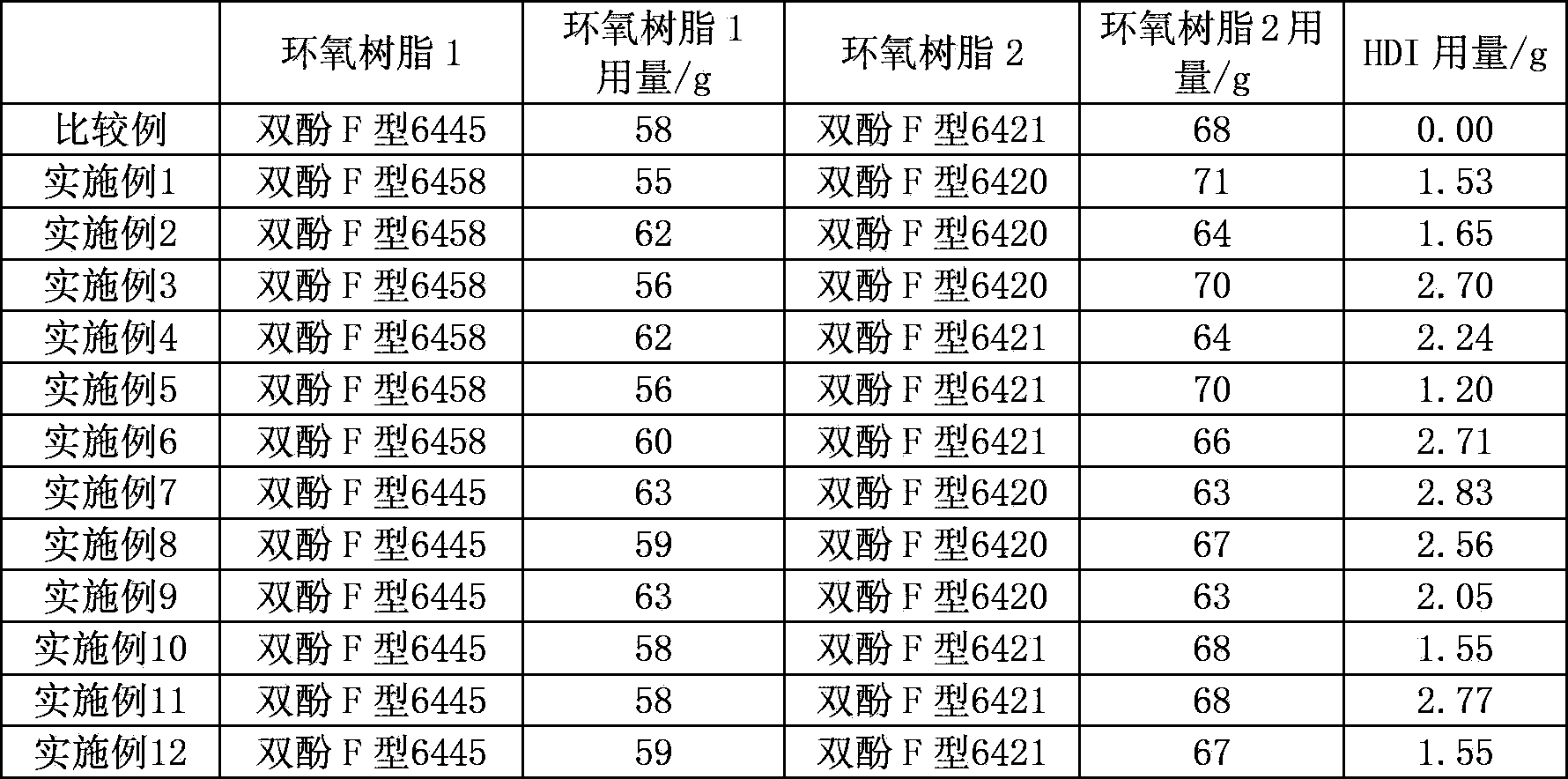

Epoxy-based carbon fiber sizing agent emulsion, its preparation method and its application

The invention relates to an epoxy-based carbon fiber sizing agent emulsion, which comprises the following components: 55-78wt% of polyurethane structure-modified epoxy resin composition, 20-30wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. A preparation method comprises the following steps: pumping a bisphenol F epoxy resin reactant under vacuum, dehydrating until no bubbles can be generated, adding an isocyanate reactant to prepare an epoxy resin composition; mixing and homogenizing the surfactant and the anti-oxidant in a reaction vessel according to the above material fraction; and then gradually adding deionized water, a levelling agent and an antifreezing agent to prepare the sizing agent emulsion. The carbon fiber from the epoxy-based carbon fiber sizing agent emulsion has good convergence, wear resistance and toughness, the sizing agent resin has good chemical stability, and is in favor of long-term storage and quality guaranteeing of sizing carbon fiber; the preparation method has the advantages of simple technology and easy operation, the reaction raw material has the advantages of convenient source and low cost, and the epoxy-based carbon fiber sizing agent emulsion is in favor of realization of industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

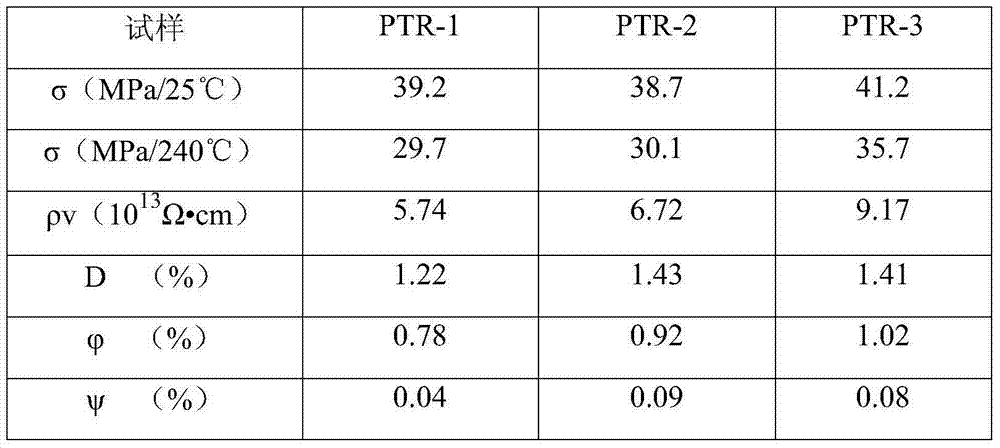

TGBAPOPP type matrix resin used for preparing advanced composite and preparation method of TGBAPOPP type matrix resin

The invention relates to TGBAPOPP type matrix resin used for preparing an advanced composite and a preparation method of the TGBAPOPP type matrix resin. The TGBAPOPP type matrix resin comprises N, N, N', N'-quadriglycidyl-2, 2-double[4-(4-amidogenphenoxy) phenyl]dimethylmethane, o-cresol-formaldehyde epoxy resin, 2, 2-double[4-(4-maleimidephenoxy) phenyl]dimethylmethane, N-isopropyl-N'-phenyl ursol, 2, 2, 4-trimethyl-1, 2-di-hydrogenationquinoline, curing agent and organic curing agent, wherein the mass ratio of all the components is 100: (50-100): (10-30): (2-5): (2-5): (60-100) : (500-900). The TGBAPOPP type matrix resin, disclosed by the invention, has excellent overall performance and excellent wettability to glass fiber, carbon fiber, basalt fiber and aramid fiber, can be used for preparing advanced composites with excellent overall performance, and has a broad application prospect.

Owner:DONGHUA UNIV +1

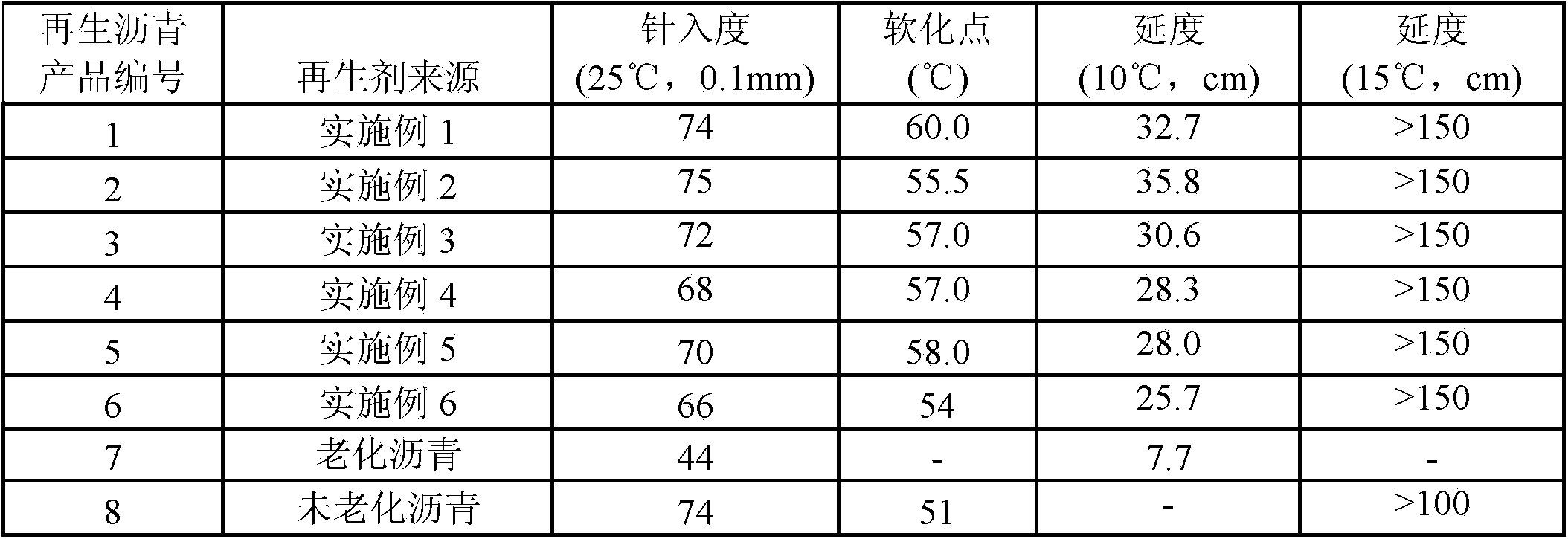

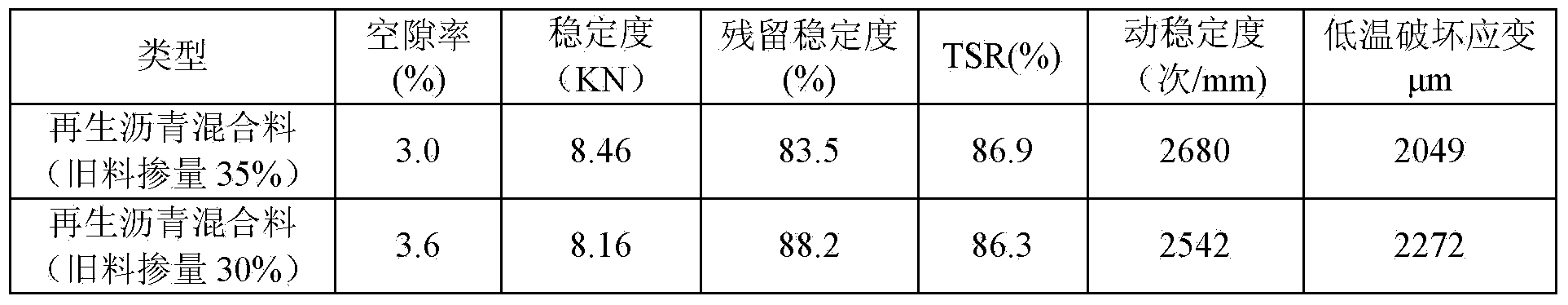

Waste and old road asphalt regenerating agent and preparation method thereof

ActiveCN103436038AImprove performanceImprove anti-agingBuilding insulationsThermoplastic elastomerEngineering

A waste and old road asphalt regenerating agent comprises the components in parts by weight: 20 to 45 parts of petroleum asphalt; 40 to 50 parts of aromatics-rich oil; 5 to 10 parts of biomass pyrolysis oil; 8 to 15 parts of rosin; and 2 to 5 parts of a thermoplastic elastomer. The invention also discloses a preparation method of the waste and old road asphalt regenerating agent.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)