Method for preparing alpha phase and beta phase silicon nitride powder by improved direct nitriding method

A technology of phase silicon nitride powder and nitriding method, which is applied in the field of preparation of silicon nitride products, can solve the problems of high powder production cost, influence powder performance, complicated preparation process, etc., to save gas consumption and improve penetration. The effect of pressure, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

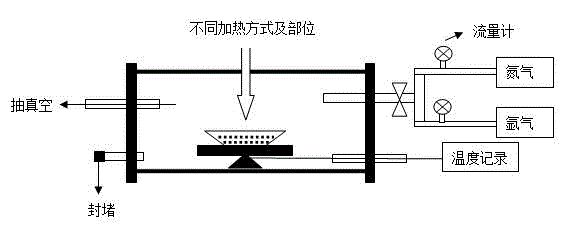

[0024] The present invention adopts the traditional commonly used such as figure 1 The experimental device used an improved direct nitriding method to prepare α-phase and β-phase silicon nitride powders, followed by the following steps:

[0025] (1) After crushing the metal silicon block, ball mill and sieve to control the particle size of silicon powder to ≤500μm;

[0026] (2) Loosely pack metal silicon powder into a rectangular corundum crucible, put the crucible and the powder into a tube-type test furnace, and evacuate to (1.0~2.0)×10 -2 Pa, filled with protective gas argon, the pressure is 0.1~0.15MPa;

[0027] (3) Turn on the power and heat at a rate of 3°C / min. After the temperature rises to 1500°C, vacuumize to (1.0~2.0)×10 -2 Pa, adjust the volume ratio of nitrogen and argon to 1:1 through gas flow meters (1) and (2), open the valve, mix evenly and fill into the furnace chamber, the total pressure is about 0.1MPa, and the reaction time is 6h.

[0028] (4) Turn off...

Embodiment 2

[0030] The present invention adopts the traditional commonly used such as figure 1 The experimental device used an improved direct nitriding method to prepare α-phase and β-phase silicon nitride powders, followed by the following steps:

[0031] (1) Ball mill and sieve metal silicon powder to control the particle size of silicon powder to ≤150μm;

[0032](2) Loosely pack the silicon powder into a rectangular corundum crucible, put the crucible and the powder into the tubular test furnace, and evacuate to (1.0~2.0)×10 -2 Pa, filled with protective gas argon, the pressure is 0.1~0.15MPa;

[0033] (3) Turn on the power and heat at a rate of 3°C / min. After the temperature rises to 1400°C, vacuumize to (1.0~2.0)×10 -2 Pa, adjust the volume ratio of nitrogen and argon to 1:2 through gas flow meters (1) and (2), open the valve, mix evenly and fill into the furnace chamber, the total pressure is about 0.1MPa, and the reaction time is 5h.

[0034] (4) Turn off the power, cool down ...

Embodiment 3

[0036] The present invention adopts the traditional commonly used such as figure 1 The experimental device used an improved direct nitriding method to prepare α-phase and β-phase silicon nitride powders, followed by the following steps:

[0037] (1) Ball mill and sieve metal silicon powder to control the particle size of silicon powder to ≤74μm;

[0038] (2) Loosely pack metal silicon powder into a rectangular corundum crucible, put the crucible and the powder into a tube-type test furnace, and evacuate to (1.0~2.0)×10 -2 Pa, filled with protective gas argon, the pressure is 0.1~0.15MPa;

[0039] (3) Turn on the power supply and heat at a heating rate of 3°C / min. After the temperature rises to 1300°C, vacuumize to (1.0~2.0)×10 -2 Pa, adjust the volume ratio of nitrogen and argon to 1:3 through gas flow meters (1) and (2), open the valve, mix evenly and fill into the furnace chamber, the total pressure is about 0.1MPa, and the reaction time is 4h.

[0040] (4) Turn off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com