Patents

Literature

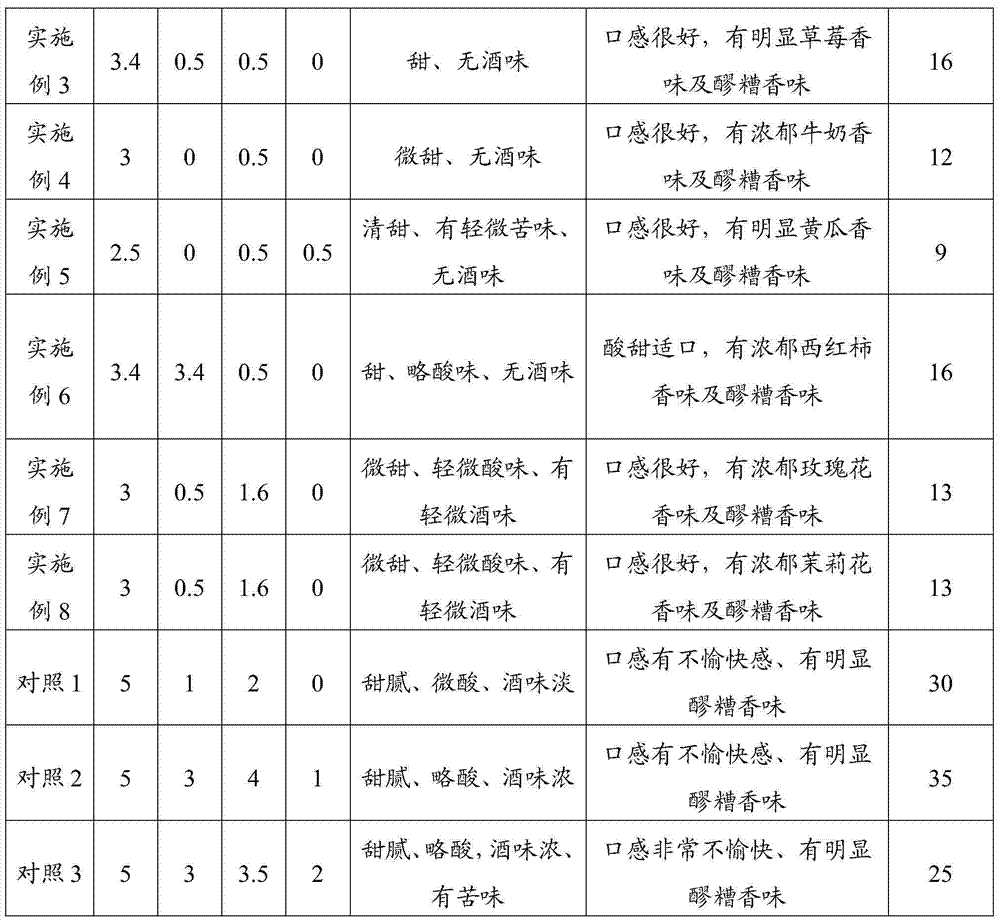

215results about How to "Lower sugar content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for supplementing the diet

InactiveUS20190313682A1Lower sugar contentIncrease in blood sugarAcidic food ingredientsFood ingredient as flavour affecting agentMedicineKetogenic diet

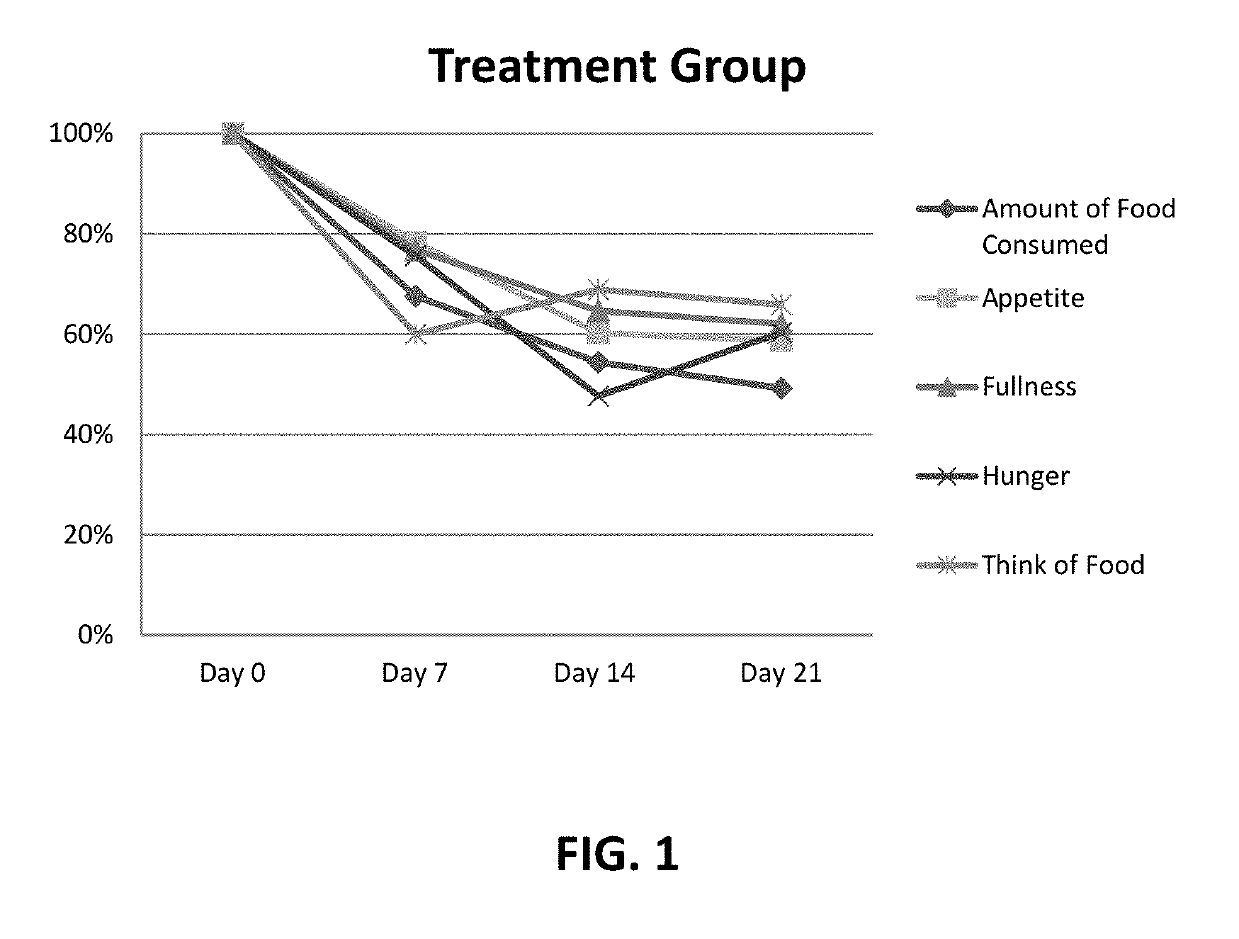

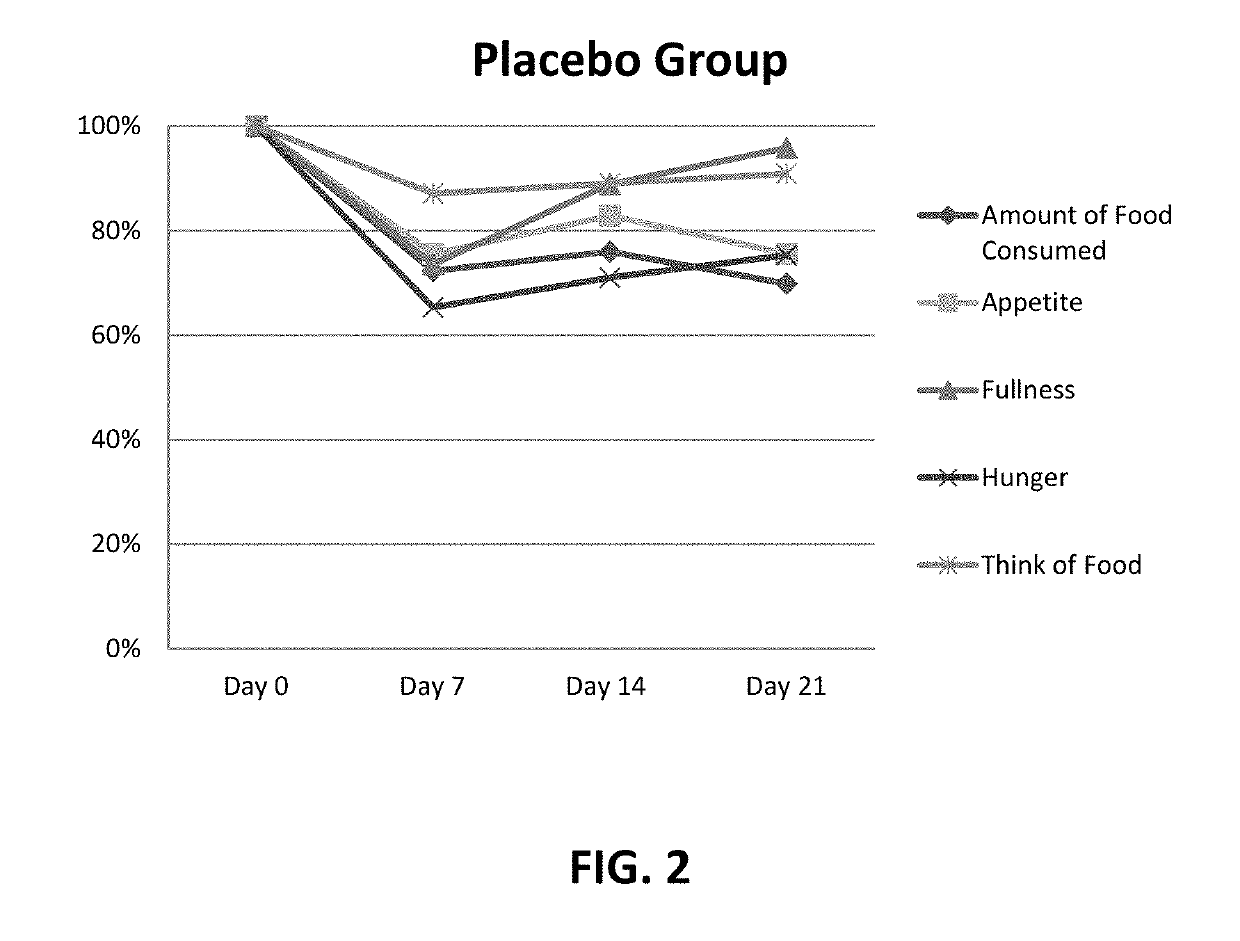

Various aspects and embodiments disclosed herein relate generally to compositions that can be used to increase physical and mental energy, reduce the sensation of hunger. At least some of the composition disclosed herein can be used to obviate or moderate some of the discomfort which may be associated with initiating or maintaining reduced calorie and / or ketogenic diets.

Owner:METABOLIC RECOVERY SYST LLC

Brown lactic acid bacteria drink and preparation method thereof

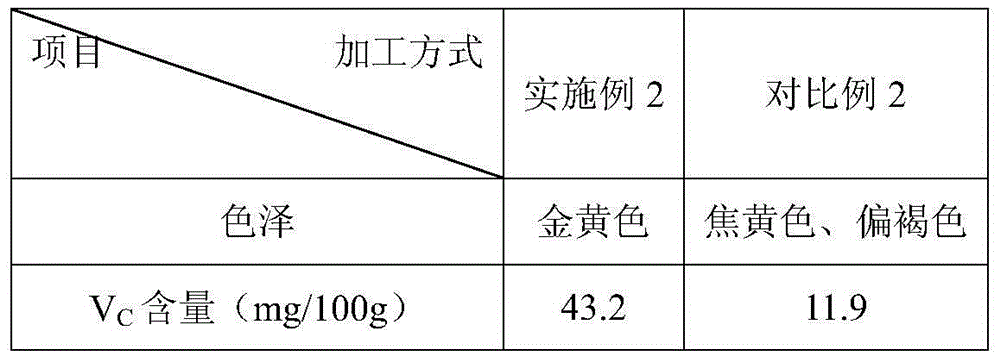

ActiveCN104186651ALower sugar contentImprove textureMilk preparationMaillard reactionLactic acid bacterium

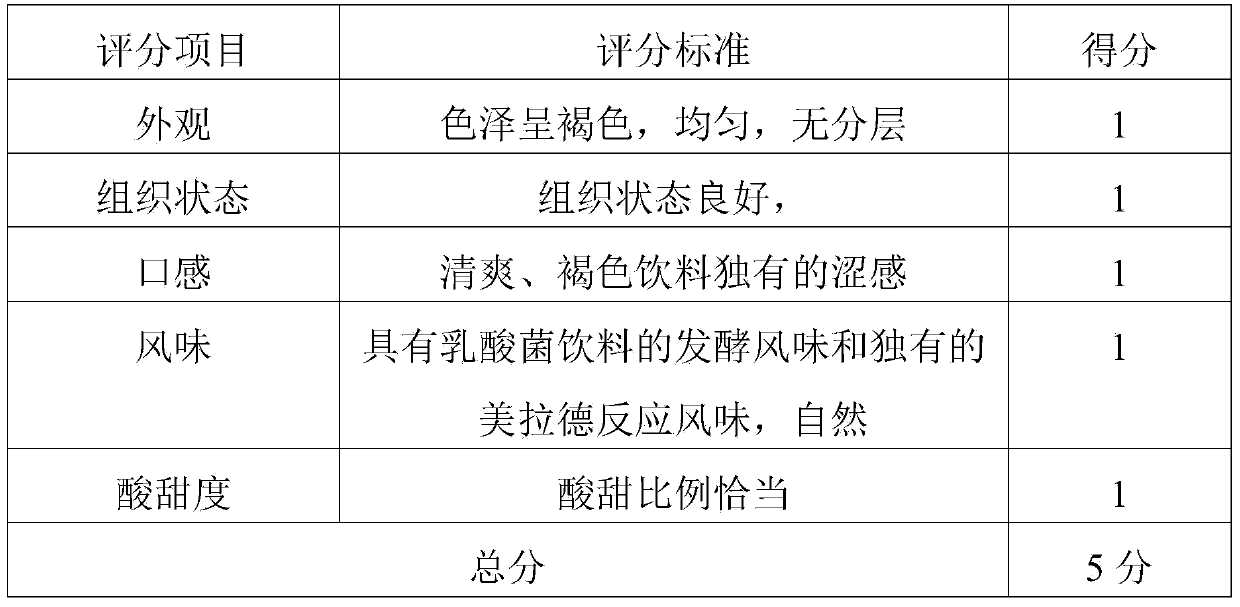

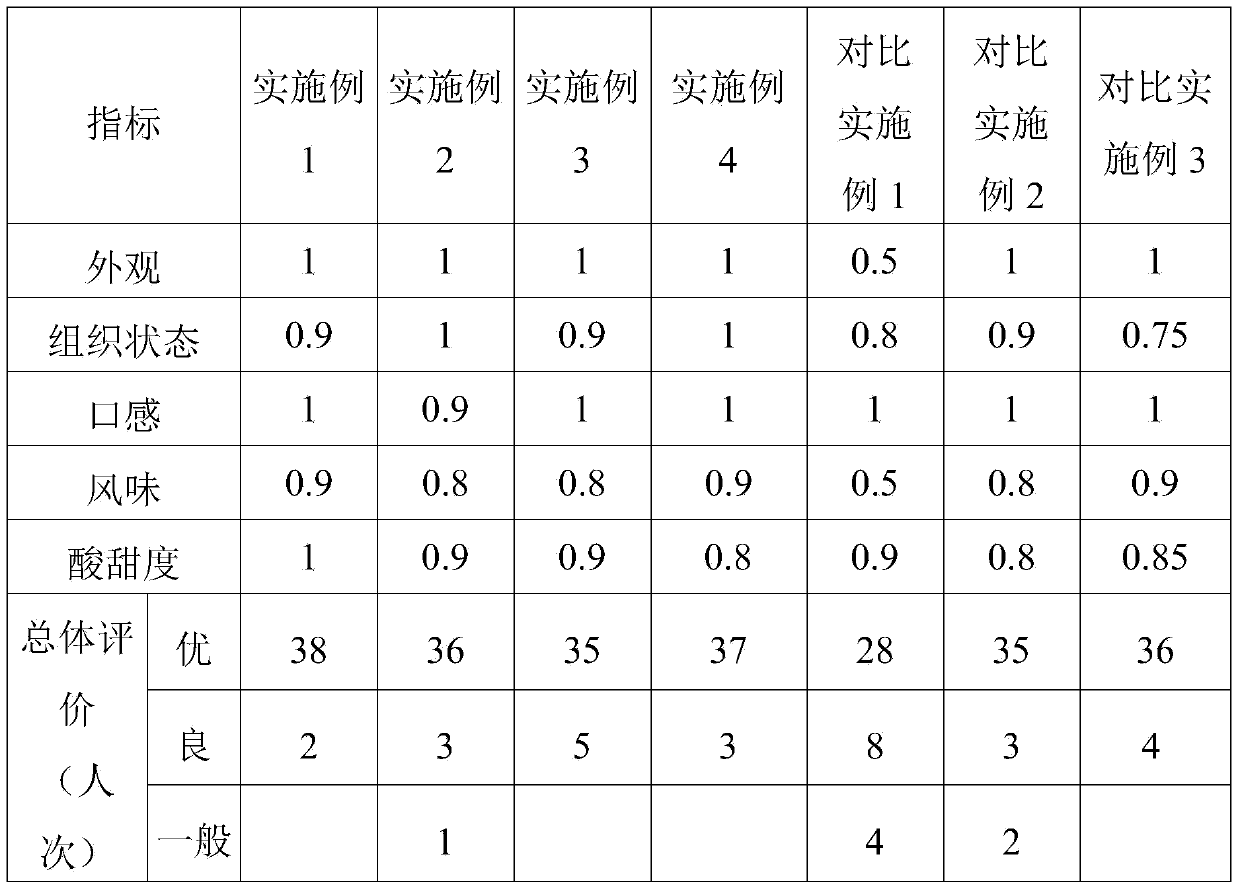

The invention discloses a brown lactic acid bacteria drink and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing a raw material A to obtain a mixed liquid A and standing the mixed liquid A for 1-10h under the temperature condition of 4-40 DEG C to obtain a sizing agent A, wherein the raw material A comprises 8%-16% of milk powder, 0.02%-0.2% of lactase and water; (2) carrying out maillard reaction on the sizing agent A, cooling, uniformly mixing with a lactic acid bacteria starter, fermenting, turning over matters in a vat, homogenizing and cooling to obtain a fermented milk-based material; and (3) mixing an uniformly mixed additive B and the fermented milk-based material in the step (2) to obtain a mixed liquid B, adjusting the acidity and homogenizing so as to obtain the drink, wherein the additive B comprises an emulgator, a stabilizer and water. The preparation method is simple, the fermentation time is shortened, reducing sugar or pigment is not additionally added, and the prepared brown lactic acid bacteria drink is low in sugar content, and has good stability in shelf life.

Owner:BRIGHT DAIRY & FOOD

Preparation method and fermented glutinous rice prepared by method

InactiveCN103695243AObvious fermented glutinous rice aromaAvoid lostAlcoholic beverage preparationFermentationChemistry

The invention relates to the technical field of foods, and in particular relates to a preparation method and fermented glutinous rice prepared by the method. The method comprises the following steps: soaking 1 part by mass of sticky rice in water for 4 to 24 hours; draining off water from the sticky rice; steaming the sticky rice for 10 to 30 minutes so as to obtain steamed sticky rice; flushing the steamed sticky rice with pure water until the sticky rice is cooled to reach 30 DEG C to 35 DEG C; draining off water; mixing the sticky rice with 0.004 part by mass of sweet wine cube; performing first fermentation at 30 DEG C to 34 DEG C for 20 to 50 hours; adding a liquid; performing second fermentation at 30 DEG C to 34 DEG C for 5 to 20 hours; and refrigerating at 0 DEG C to 10 DEG C for 1 to 48 hours, thereby obtaining the fermented glutinous rice. According to the method, the fermented glutinous rice is fresh and sweet, so that the palatability of the fermented glutinous rice is enhanced; a cooking or blending process required by a traditional fermented glutinous rice product before the product is eaten is avoided, so that the loss of nutrition is avoided.

Owner:郑明星

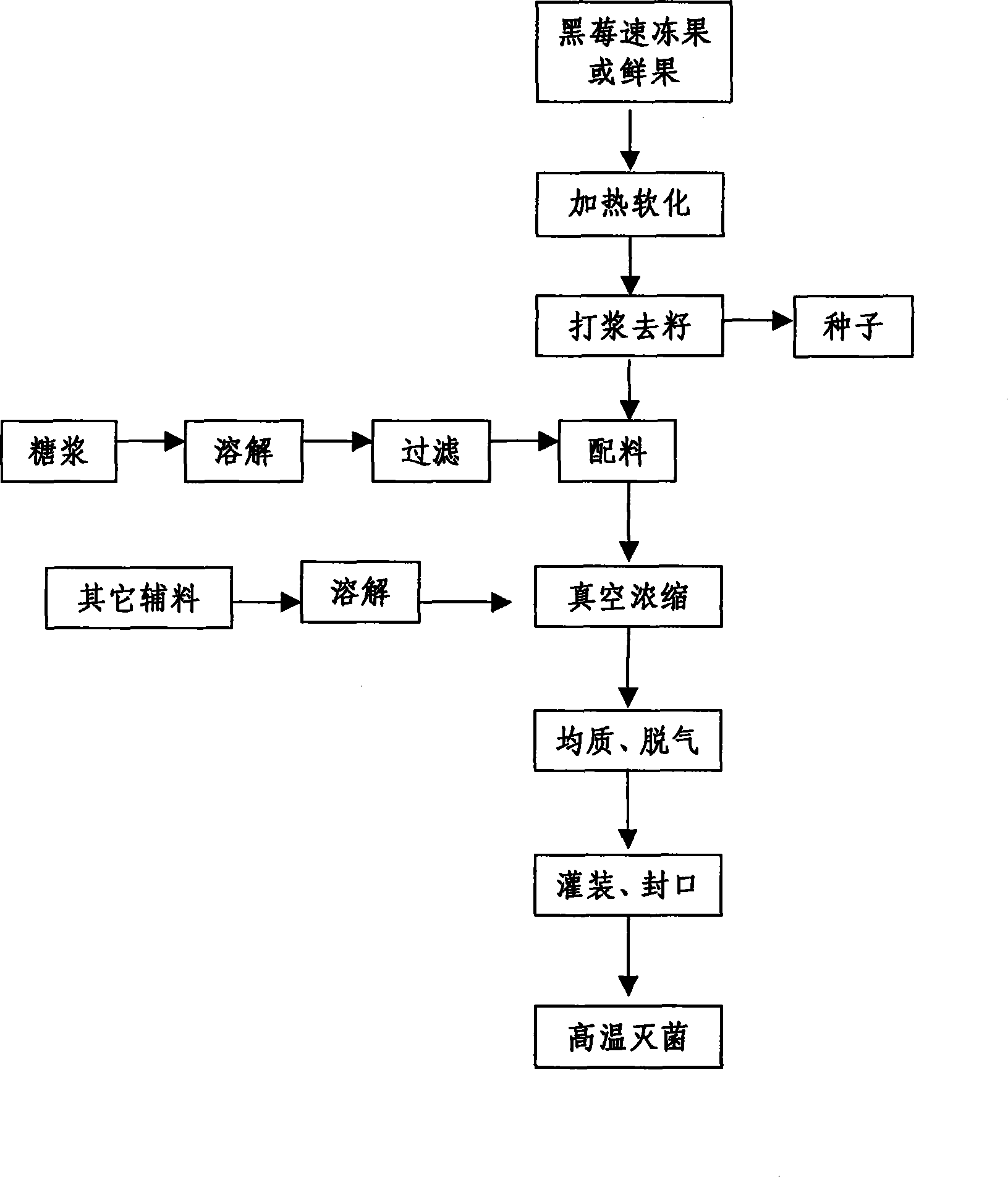

Method for processing blackberry fruit pulp with low sugar

The invention relates to a making method of low-sugar blackberry jam in the jam process technological field, which is characterized by the following: choosing flash-freezing or fresh blackberry with good color and flavor and high sugar acidity as raw material; choosing natural food additives; using modern process technique and unique dispense prescriptions; making the blackberry jam with low sugar content, beautiful in color and sour-sweet taste; having more dense scent of raspberry with stable quality. The invention has the merits of (1) the dispense prescriptions is formed through researching over many years and fits the needs of food with low sugar and high pulp content and mellowing taste for modern people, and (2) the invention utilizes the methods of vacuum concentration, homogeneity and degassing to reserve nutrient in high limit and retains the natural flavor of the blackberry and stability of the product.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Composite bamboo shoot fermenting agent and preparation method of fermented bamboo shoots

InactiveCN101999450AAppropriate proportionLow alcoholFruits/vegetable preservation using acidsFlavorAlcohol

The invention discloses a composite bamboo shoot fermenting agent and a preparation method of fermented bamboo shoots. The composite bamboo shoot fermenting agent contains monascus vinasse and liqueur koji. The preparation method of the fermented bamboo shoots comprises the following steps of: firstly, blanching bamboo shoots; and then, fermenting the bamboo shoots under the action of the composite bamboo shoot fermenting agent. Under the action of the composite bamboo shoot fermenting agent, aromatic substances, pigments, and the like in the vinasse are infiltrated in the bamboo shoot tissues. The prepared vinasse-processed bamboo shoots have the characteristics of unique fragrance and flavor, mellow and pleasant taste, elegant flavor, attractive color and rich nutrition. The preparation method can effectively prevent fresh bamboo shoots from aging, lessen the loss of nutrient contents, preserve the nutrient contents of the bamboo shoots and ensure the quality and the grade of the bamboo shoots. The fermented bamboo shoots prepared by using the method disclosed by the invention have appropriate proportions of liquor, sugar and acid, and have the advantages of low alcohol and sugar contents, stable resistance to acid and alkali, strong heat resistance and light resistance, stable resistance to oxidoreduction and favorable practical values and application prospects.

Owner:健盛食品股份有限公司

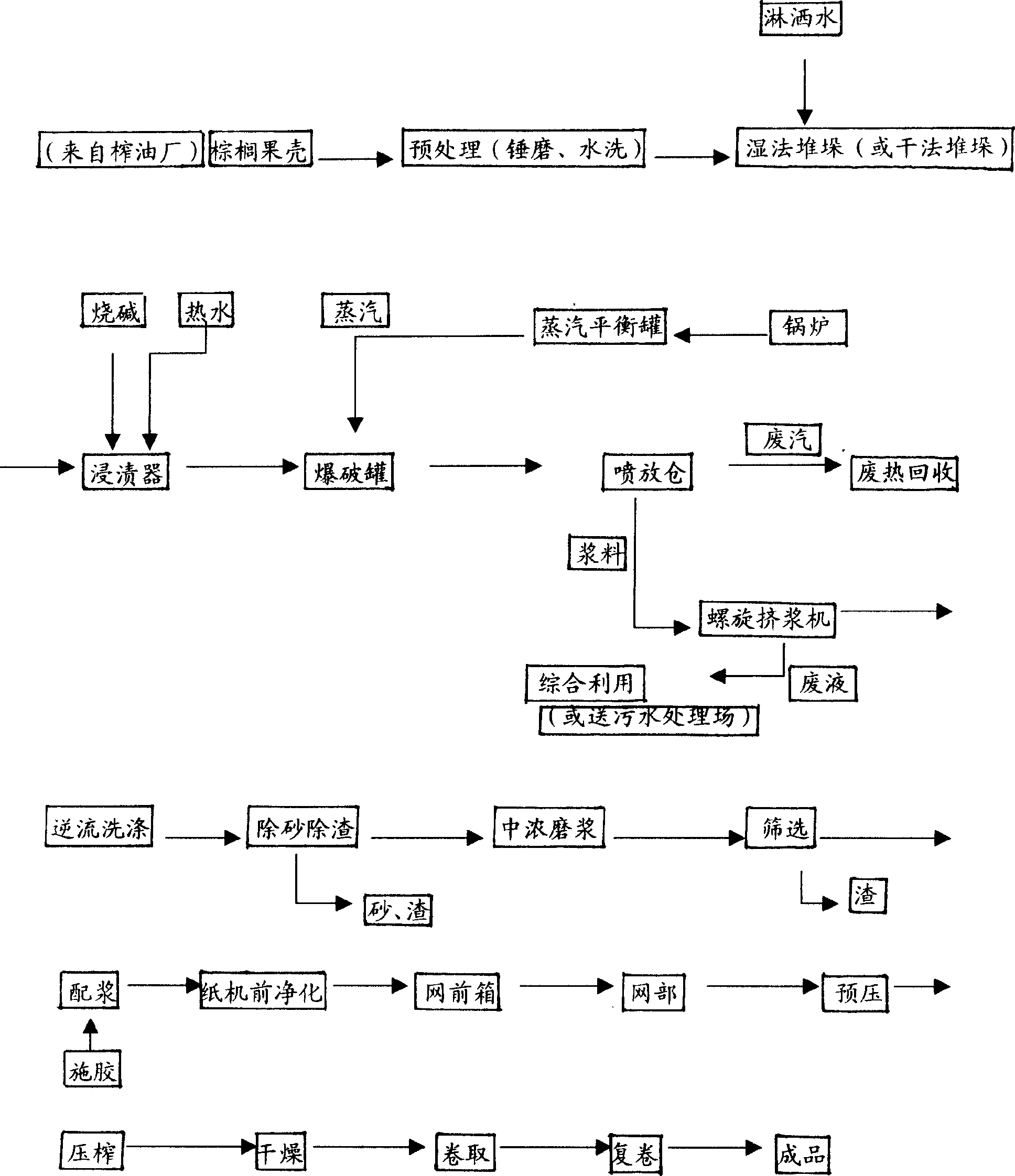

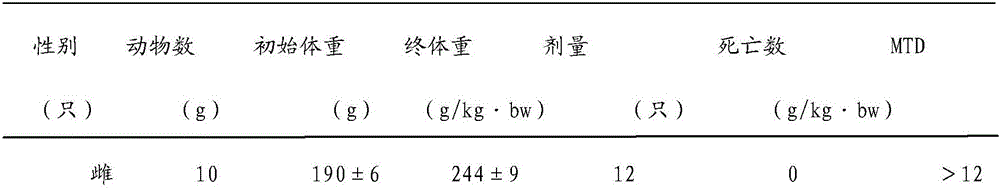

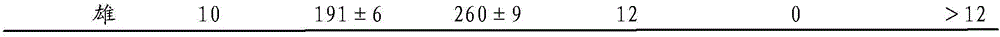

Method for producing packing paper board by explosion pulp of oil palm fruit shell

InactiveCN1702235AHigh yieldLow costPaper/cardboardPulping with inorganic basesOil palmBiological tissue

This invention relates to a method for making the packing board through the blasting pulp, which belongs to the slurrying papermaking field. The method comprises the following steps: a) hammering, washing and stackable preprocessing the palm husk; b) adding caustic soda and adjuvant to immerse; c) setting the material in the blasting tin to steam, then discharging the slurry to the spreading chamber; d) extracting devil liquor of the slurry by the shoving mill, the devil liquor can be multi-purpose used or sent to sewage disposal place; e) backflushing pulp, purifying, grinding, seasoning, the blasting pulp single or with the waste pulp, sulfate wood pulp to make the packing board. The invention based on the biological tissue of the palm husk, through blasting to prepare pulp with low pollution, while the paper pulp has good intensity property especially high collar pressure intensity.

Owner:ZHEJIANG SAIER INVESTMENT

Process of producing fermented fresh date dry white liquor

InactiveCN101020880ARetain nutrientsFull of nutritionAlcoholic beverage preparationAlcohol contentWhite liquor

The present invention relates to wine, is especially process of producing fermented fresh date dry white liquor, and belongs to the field of food and drink producing technology. The process of producing fermented fresh date dry white liquor includes the steps of sorting material, washing, crushing, adding yeast, fermentation, storing, ageing at 20 deg.c for 5-12 months, clarifying with glue, filtering, freezing, stabilizing, sterilizing, filling and bottling. The production process without heat treatment has well maintenance of the nutritious components in the materials. The white liquor has low alcohol content, low sugar content, high vitamin C content, good taste, rich nutrients and health functions.

Owner:三门峡华天生物科技有限公司

Brewing of honey vinegar and nutritious healthy vinegar and method for making vinegar drink

InactiveCN1763169AEnhance detoxification functionPromote absorptionVinegar preparationFood scienceBenzoic acidAdditive ingredient

The present invention is brewing process of honey vinegar and nutritious health honey vinegar and the blending process of vinegar beverage. Honey vinegar is prepared through mixing honey and water, heating to disinfect, adding yeast to ferment, adding acetic acid seed to acidify and ferment, separating to obtain vinegar, adding salt via stirring and filtering, sealed anaerobic maintenance, and filtering. The honey vinegar beverage is prepared through mixing the honey vinegar, honey, benzoic acid solution and bacteria-free pure water and filtering the mixture. The nutritious health honey vinegar is prepared through mixing and steaming glutinous rice, soybean residue and wheat bran, mixing with cooked date and red rice, fermentation, mixing with pure water, squeezing and filtering, clarifying to obtain fermented nutritious liquid, mixing with the honey vinegar and filtering. The beverages of the present invention have good tastes, rich nutrients and multiple health functions.

Owner:伊犁百信草原蜂业有限责任公司

Plant protein peptide powder and preparing method thereof

InactiveCN105725217AMeets requirementsCompatibility scienceLipidic food ingredientsFood ingredient functionsEconomic benefitsPlant Sources

The invention discloses a plant protein peptide powder, which is a green, safe and healthy plant protein peptide powder, preferably protein powder derived from natural plants such as soybean protein isolate, pea protein, soybean peptide, wheat oligopeptide, and Peptide powder is the main raw material, which is more suitable for long-term use of existing sub-healthy people and middle-aged and elderly people. The preparation method of the plant protein peptide powder is also disclosed, the preparation is simple and the plant protein peptide powder can be mass-produced. The production process of the invention is simple, only needs to be sieved and mixed for packaging, has low production cost, high economic benefit, high product stability, is not easy to agglomerate, and is suitable for large-scale production.

Owner:GUANGZHOU SAIJIAN BIO TECH

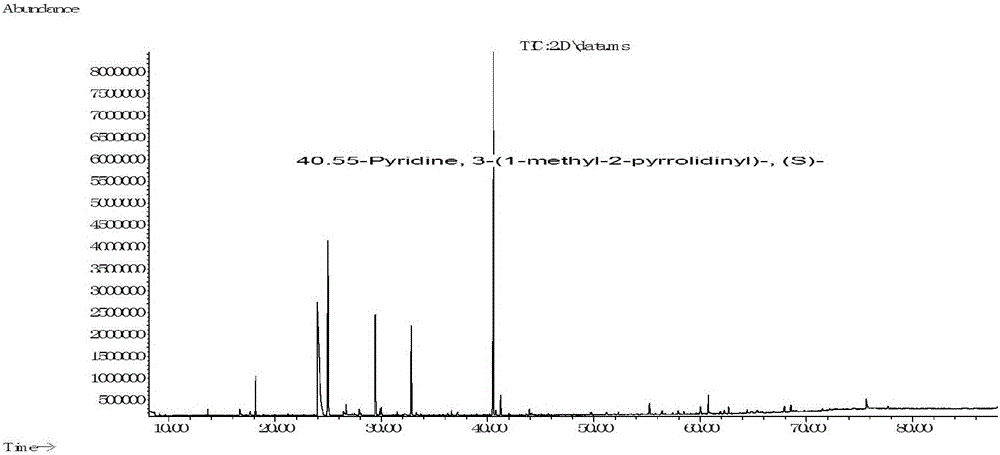

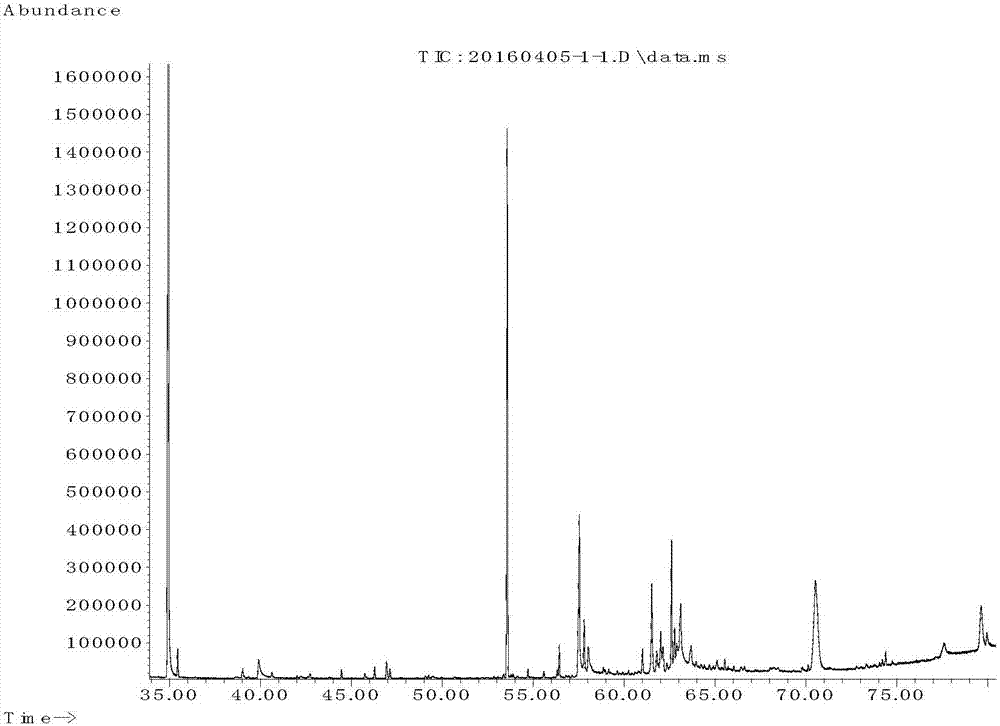

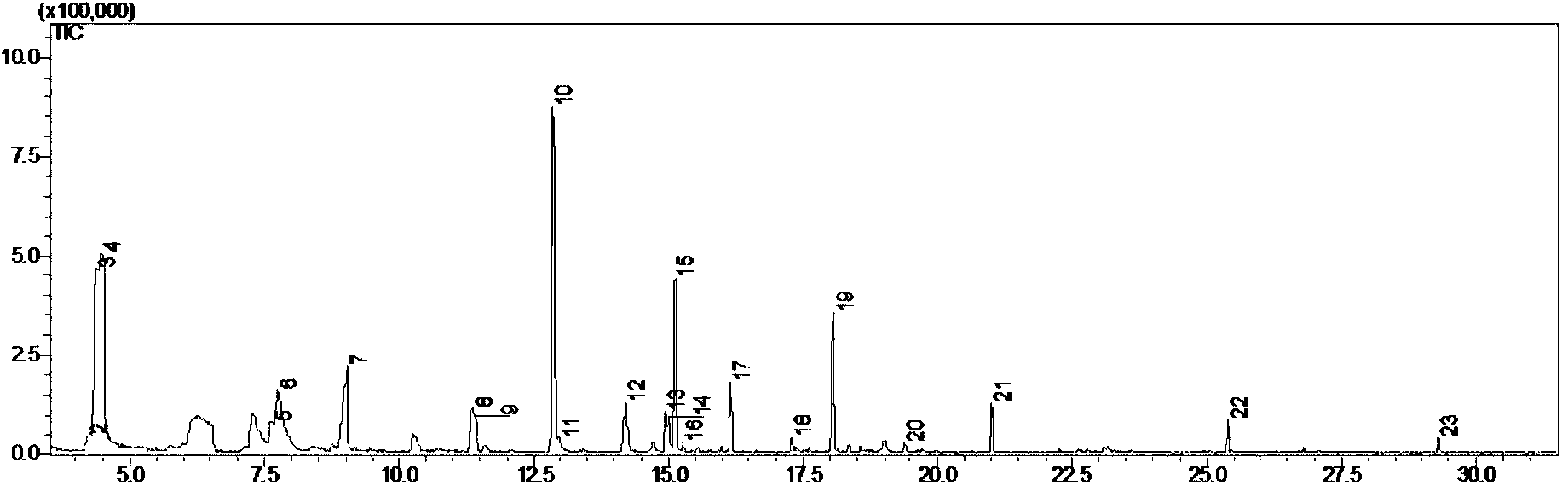

Preparation method of tobacco-sourced basic cigarette-smell raw material

InactiveCN105852199ARealistic traditional cigarette smoking experienceImprove aroma qualityTobacco treatmentTobacco productDry distillation

The invention discloses a preparation method of tobacco-derived basic smoke flavor raw material. The technical scheme of the invention is to carry out dry distillation and pyrolysis of tobacco raw materials in a closed system at 180-365° C.; and then extract aroma substances from the tobacco raw materials after dry distillation and pyrolysis. The extracted product and its further refined product are the tobacco-derived basic smoke flavor raw materials. This raw material is applied to new tobacco products, which not only has the natural aroma of tobacco, but also can significantly increase the aroma characteristics of new tobacco products, such as smoky aroma, burnt aroma, and roasted aroma, making it closer to traditional cigarettes. The raw material can also be applied to traditional cigarettes. The invention has the advantages of simple process, economical safety, obvious application effect and broad application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

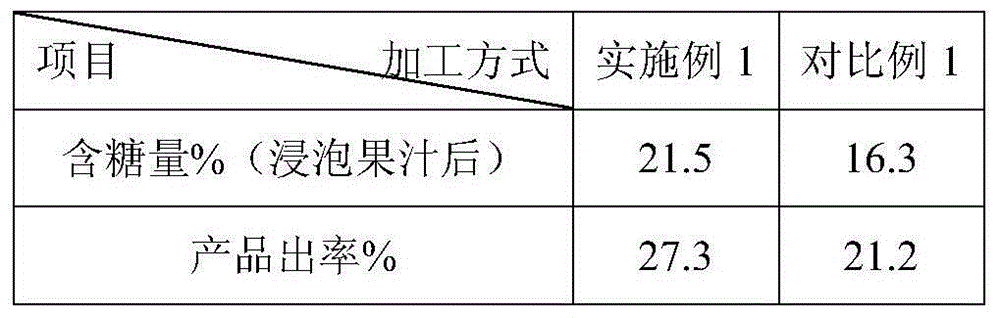

Method for producing low-sugar and low-heat value golden thread preserved date

ActiveCN101297686ALower sugar contentIncrease osmotic pressureConfectionerySweetmeatsReducing sugarFlavor

The invention relates to a manufacturing method for golden thread preserved dates with low carbohydrate and lower calorific value, which comprises the steps of the screening, the cleaning, the filum dividing, the scalding and bleaching, the saccharifying and soakage, the baking and the reshaping of Chinese date fruit and the packaging of finished products; and is characterized in that: ethroglucin is used for replacing part of saccharose in the saccharifying or soakage process for manufacturing the Chinese date fruit. Being determined by tests, the sugar content of the golden thread preserved dates produced by the method of the invention is reduced from 70 percent or so which is originally processed by adopting the traditional technology to 20 to 30 percent, and the original flavor and sweet taste of the golden thread preserved dates are not affected; furthermore, as the permeation pressure of the ethroglucin is high, sugar-permeating time is greatly reduced, process is simplified and cost is reduced; in addition, the ethroglucin does not have the Maillard reaction of reducing sugar, therefore, in the process of saccharigying, the color change of the Chinese dates is small, and the products have light color and luster and better condition.

Owner:BINZHOU SANYUAN BIOLOGICAL TECH

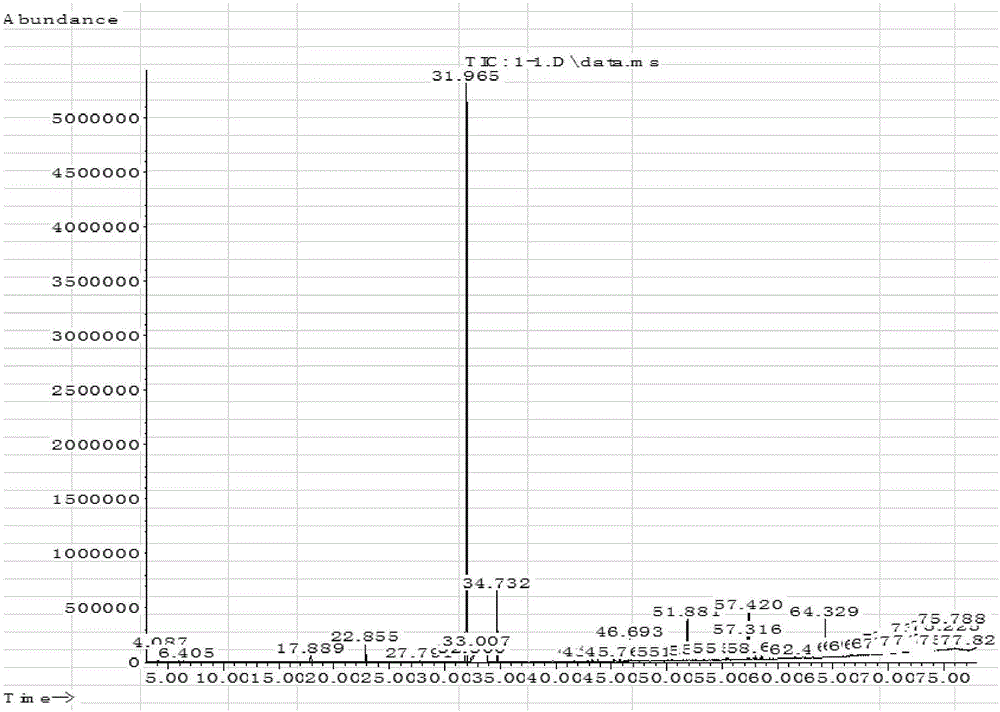

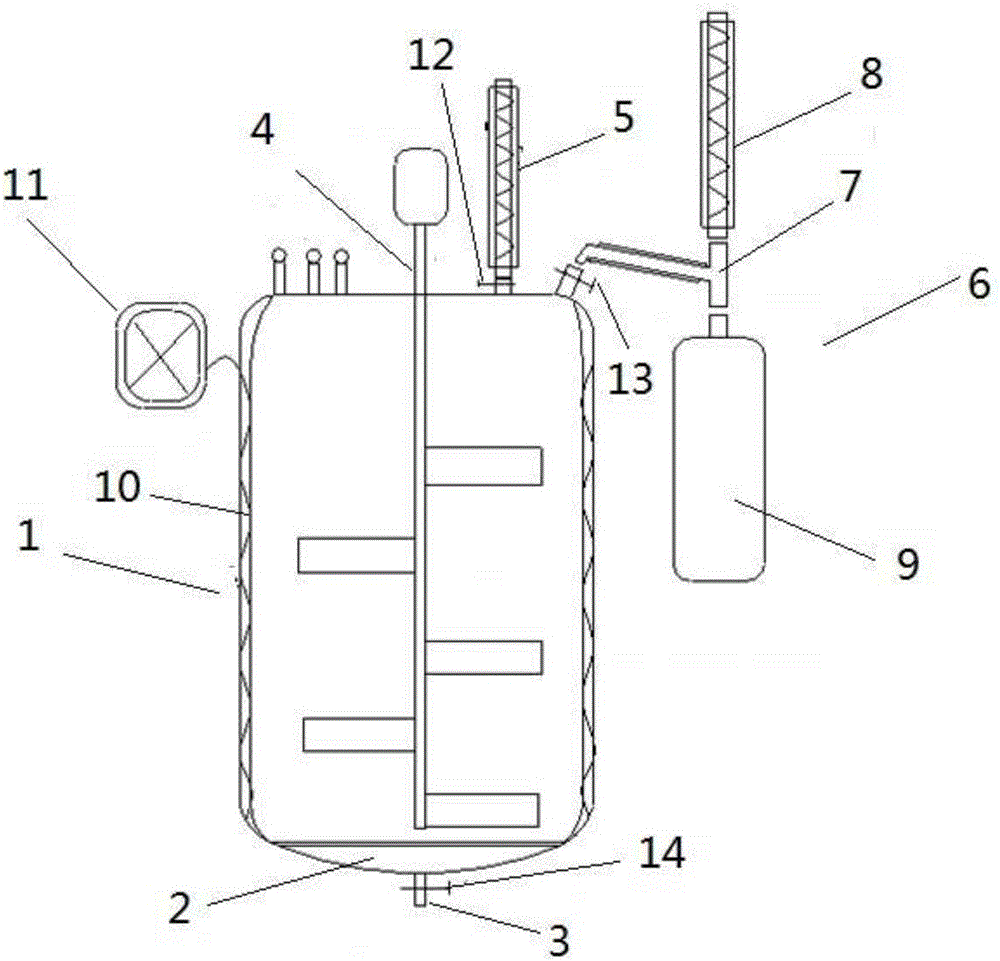

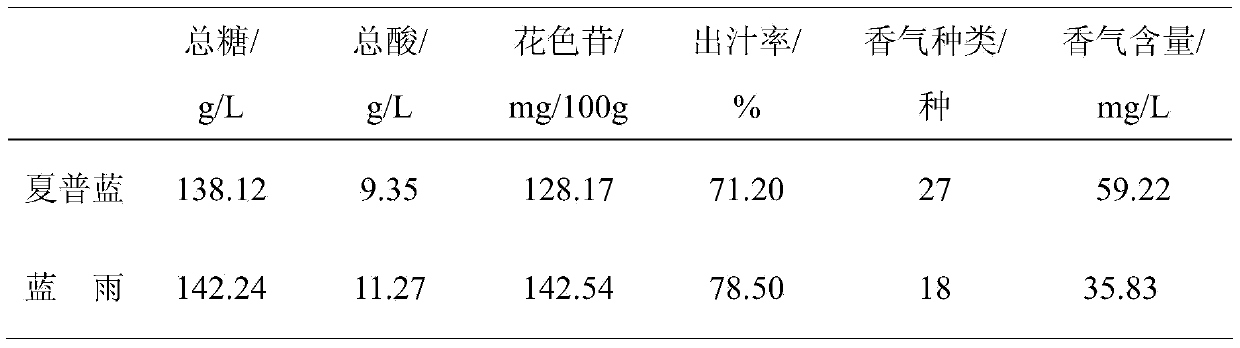

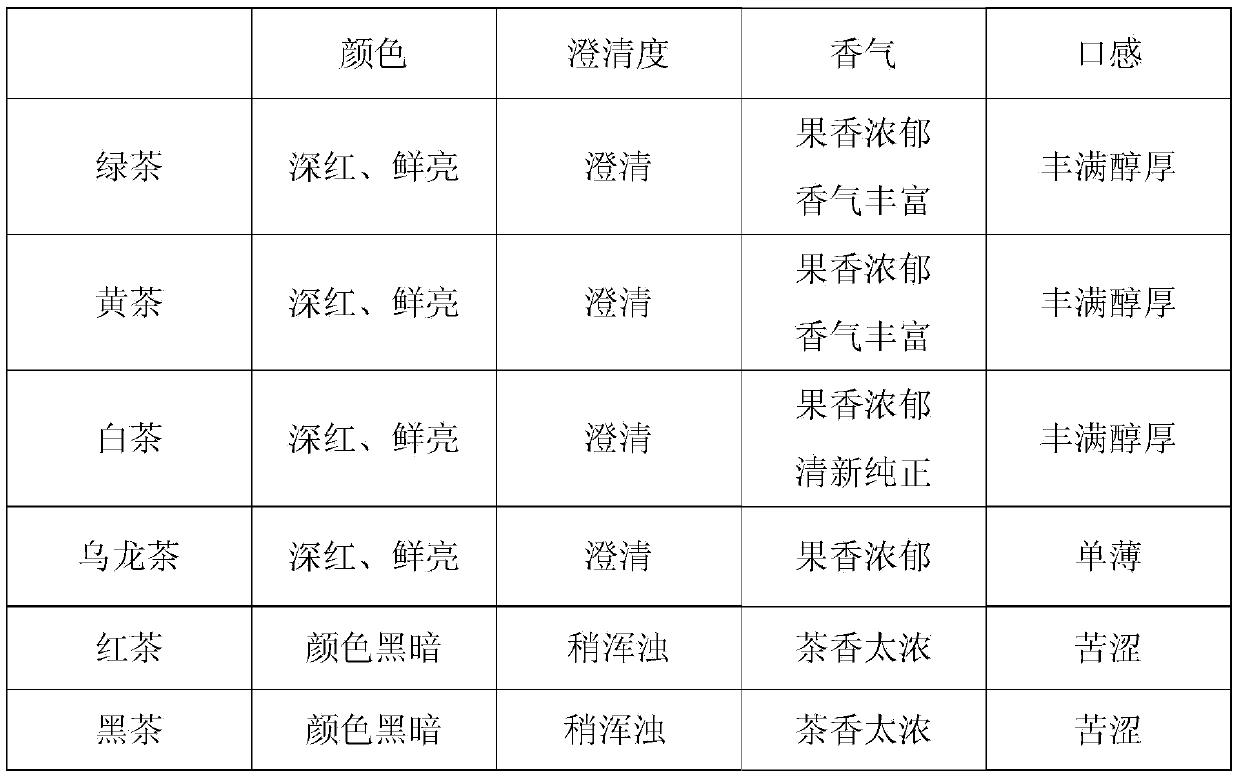

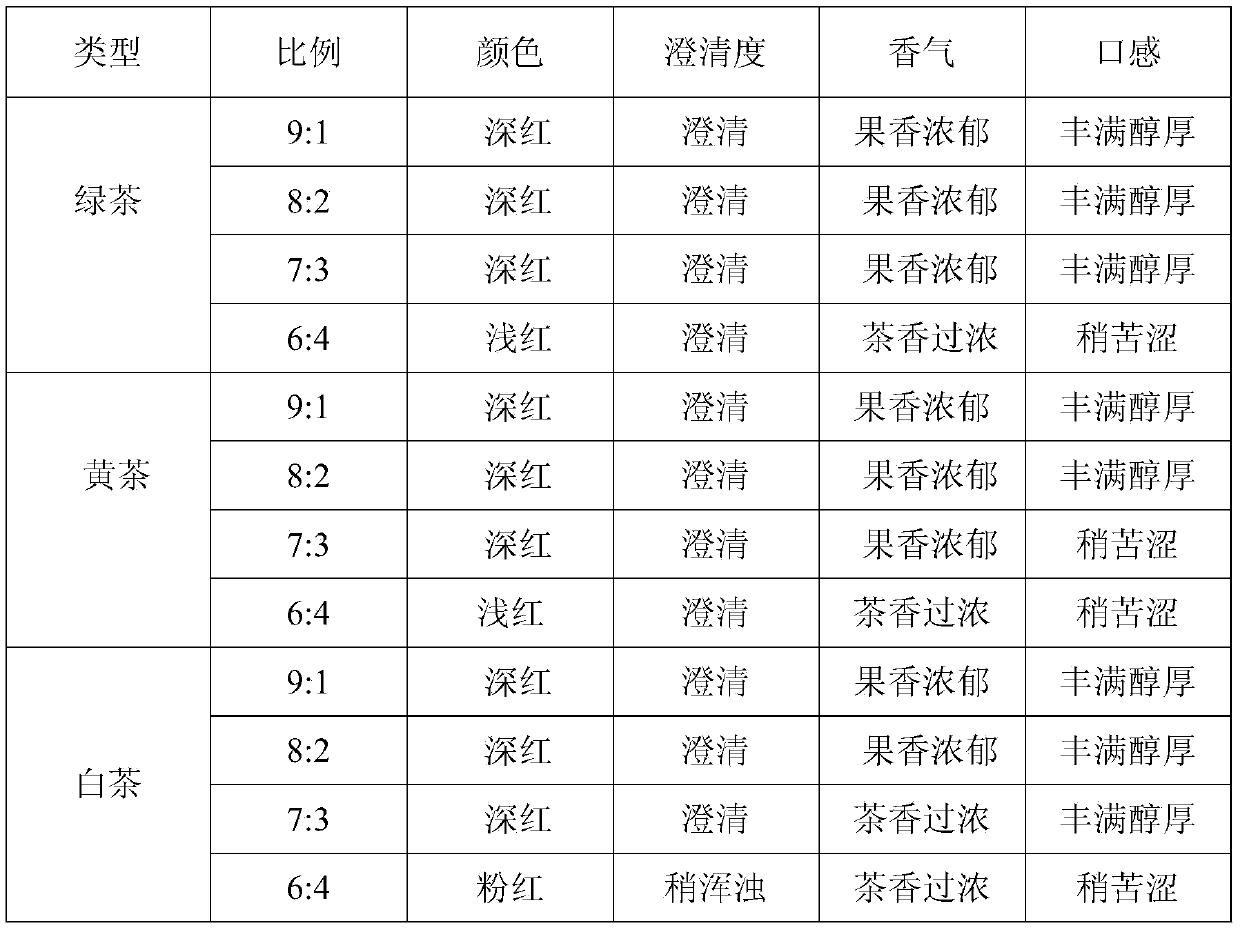

Brewing method of lower-alcohol blueberry health-care wine

ActiveCN105368631ADeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesFruit wineStable state

The invention discloses a brewing method of lower-alcohol blueberry health-care wine. The method comprises the steps of blueberry selection and processing, tea preprocessing, raw material blending, ethanol fermentation, ageing, clarification stabilizing processing and the like. The method uses an optimized blue rain variety of blueberries as raw materials, and meanwhile tea leaching liquid, prebiotics and soluble dietary fibers are added; the lower-alcohol blueberry wine is obtained through raw pulp steeping, high-temperature enzymolysis, high-temperature start, mixed-bacteria synergy and low-temperature long-time fermentation; low-temperature ageing is assisted by microwaves to accelerate wine body mature, and the quality of the fruit wine is improved; a wine body is higher in clarity and is kept in a stable state for a long period of time through clarification stabilizing processing; the taste of the wine is improved and meanwhile a health-care function is increased for the wine by adding a functional sweetener. By the adoption of the process, the high-quality lower-alcohol blueberry wine having good color, fragrance and taste and integrating nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

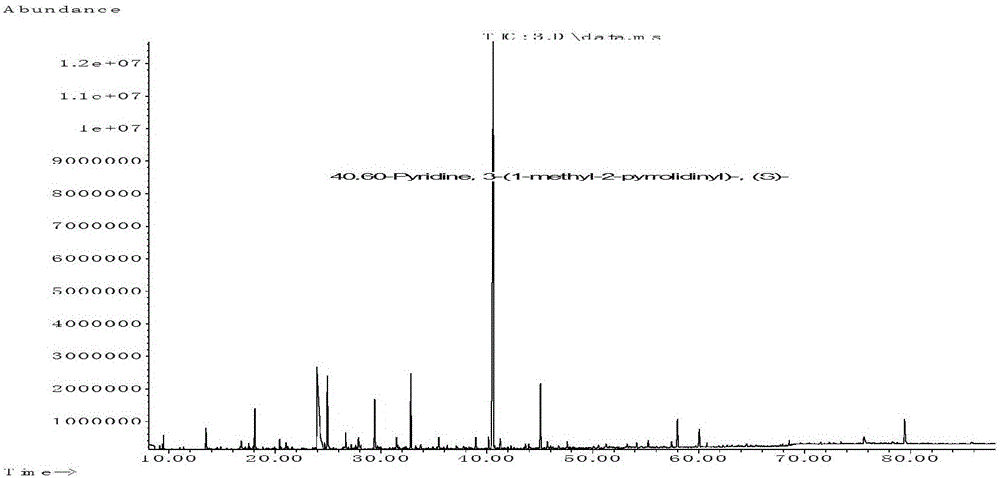

Device and method for preparing tobacco source basic cigarette flavor material for novel tobacco products

The invention discloses a device and a method for preparing a tobacco source basic cigarette flavor material for novel tobacco products. The technical scheme includes: subjecting tobacco materials to Maillard reaction and caramelization at 60-180 DEG C, collecting products of Maillard reaction and caramelization, performing carbonization and pyrolysis at 180-365 DEG C, collecting carbonized products, and finally extracting the tobacco materials after carbonization and pyrolysis to obtain extracts. More than one or two of the three products can be combined to obtain the tobacco source basic cigarette flavor material for the novel tobacco products. The device and the method for preparing the tobacco source basic cigarette flavor material for the novel tobacco products have the advantages of simple process and equipment, evident utilization effects and high tobacco material utilization value and are efficient, economical and safe, thereby being extensive in application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Sugar-free grain yoghurt

The invention relates to sugar-free grain yoghurt and a preparation method of the sugar-free grain yoghurt. Dairy products are matched with stabilizing agents, non-sugar sweeteners, sugar alcohol and hippophae rhamnoides powder to be subjected to strain fermentation and grain particle addition for obtaining the sugar-free grain yoghurt, wherein the stabilizing agents are selected from combinationof pectin, gelatin, modified starch, sodium chloride and sodium pyrophosphate. The yoghurt provided by the invention solves the problems that in the prior art, hippophae rhamnoides are rich in vitamin C (Vc), the acidity is strong, and the flavor is special, so the casein crystallization is caused, the tissue state of the yoghurt is changed, and the flavor of the yoghurt is influenced. In addition, the yoghurt realizes various health care and nutrition effects of grains, various kinds of probiotics and the hippophae rhamnoides and belongs to good yoghurt meal replacing food. The yoghurt provided by the invention is suitable for being drunk by customers who cannot take sugar, and in addition, the deserved sweetness of the yoghurt is maintained.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Sugar-free yoghourt

The invention relates to sugar-free yoghourt and a preparation method thereof. The sugar-free yoghourt is prepared by fermenting a dairy product, a non-carbohydrate sweetening agent, sugar alcohol, a stabilizing agent and sea backthern powder through strains, wherein the stabilizing agent is selected from a combination of pectin, gelatin, modified starch, sodium chloride and sodium pyrophosphate.The yoghourt disclosed by the invention not only solves the problem of influence on the yoghourt flavor caused by casein crystallization and yoghourt tissue state change due to Vc enrichment, strong acidity and special flavor of the sea backthern in the prior art, but also has various healthcare and nutrition actions of multiple probiotics and sea backthern. The yoghourt disclosed by the invention is suitable for being drunk by consumers incapable of absorbing the sugar, and the due sweetness of the yoghourt is kept.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Reduced sugar sweet roll

InactiveUS20060172053A1High expectationLow and no sugar contentBaking mixturesBakery productsBiotechnologyPolydextrose

A low or no sugar sweet roll product or intermediate is provided wherein at least a portion of the sweetness of the sweet roll product is provided by a non-nutritive sweet flavorant provided in combination with at least one sugar alcohol having a molecular weight less than about 350. Additionally, specific formulations of non-nutritive sweet flavorant with defined sugar alcohols and / or polydextrose are provided when the non-nutritive sweet flavorant and sugar alcohol is in the filling component or the icing component of the sweet roll product or intermediate.

Owner:GENERAL MILLS MARKETING INC

Manufacturing method for scorch-aroma selenium-rich purple hybrid glutinous rice wine

InactiveCN104611168ALower sugar contentHigh alcohol contentAlcoholic beverage preparationRoom temperatureFermentation

A related manufacturing method for scorch-aroma selenium-rich purple hybrid glutinous rice wine comprises the following steps: selecting selenium-rich purple hybrid glutinous rice and common glutinous rice as raw materials according to the weight ratio of 3:1-3.5:1, airing the raw materials for 1 h-3 h and roasting; immersing the roasted raw materials for 3 h-5 h; boiling the immersed raw materials for 20 min-40 min; cooling the cooked raw materials to 30 DEG C-32 DEG C and draining water; weighting a wine starter accounting for 0.8%-1.0% by weight of the raw materials, grinding the wine starter and uniformly spreading into the drained raw materials, uniformly stirring, putting into a container and nesting; putting the container in an environment with the temperature of 30 DEG C-32 DEG C, performing saccharification fermentation for 48 h-50 h, so as to form a mixture of rice wine and wine lees; transferring the mixture subjected to saccharification fermentation to a room-temperature environment, standing for 24 h, and performing after-ripening fermentation; putting the mixture subjected to later-aging fermentation into a wine basket, squeezing at a pressure of 900 Pa-1000 Pa so as to separate rice wine and wine lees, precipitating squeezed-out rice wine for 8 h-10 h, and then putting in a wine jar and sealing.

Owner:XIHUA UNIV

Blueberry jam and preparation method thereof

The invention discloses a blueberry jam and a preparation method thereof. The blueberry jam is characterized by comprising the following raw materials in percentage by weight: 69.65 to 79.82 percent of blueberry pulp, 20 to 30 percent of white granulated sugar, 0.03 percent of sodium citrate, 0.05 to 0.1 percent of malic acid, and 1 to 0.18 percent of acid resisting sodium carboxymethylcellulose, wherein the preparation process comprises the following steps: selecting and cleaning fresh blueberry to pulp so as to separate blueberry pulp; mixing blueberry pulp with the ingredients mentioned according to proportion; carrying out vacuum concentration to materials for 10 to 20 minutes to obtain soluble solid with the temperature of 30 to 35 degrees; and quickly increasing the temperature to 85 to 90 DEG C, then sealing after a jam jar is filled with the materials, placing the jam jar horizontally and keeping the temperature for 20 to 30 seconds, and cooling in time to obtain the product. The blueberry jam has the advantages that the specific form, real feeling and tastes of the natural blueberry are kept, the sugar degree is low, the coating performance is better, nutritional ingredients are rich, the taste is unique and the cost is low.

Owner:宁波市圆蓝食品科技有限公司

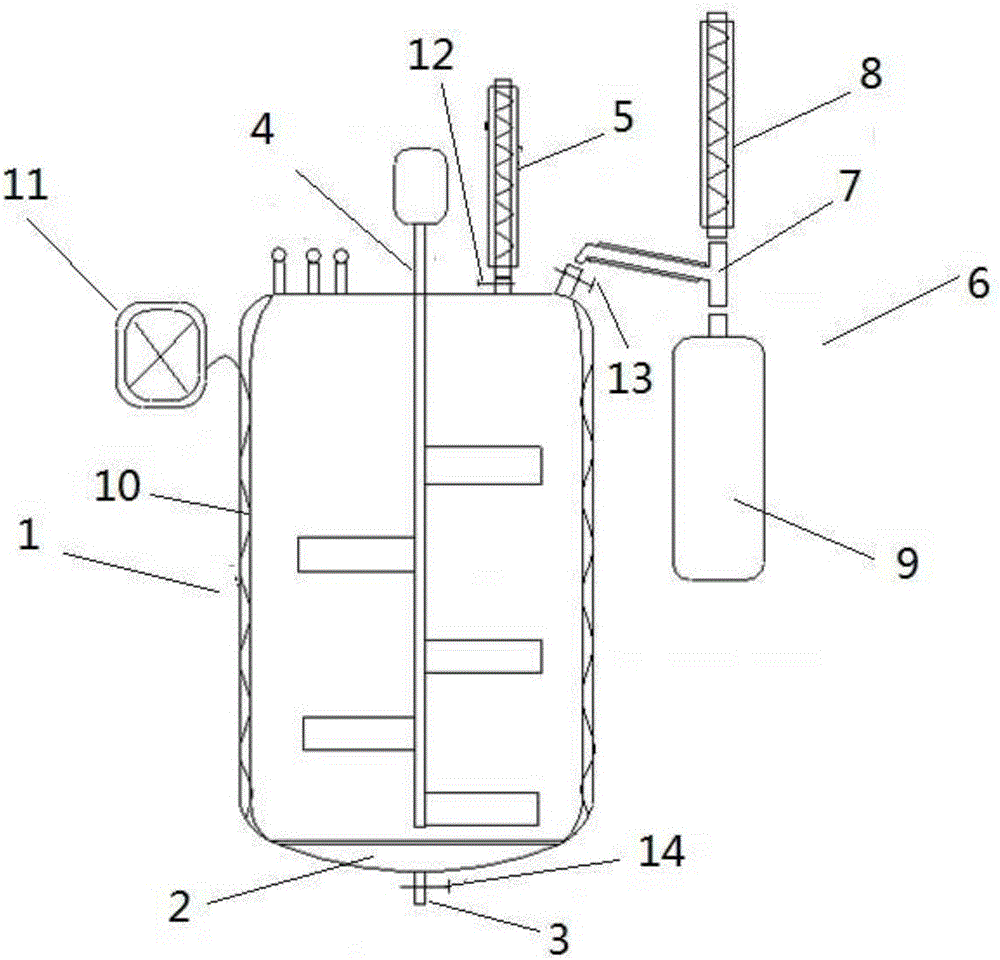

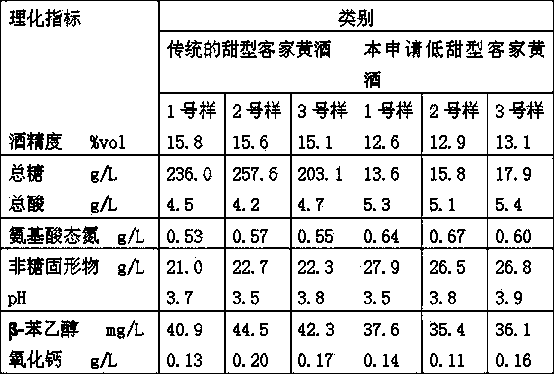

Low-sweetness Hakka rice wine brewing method

ActiveCN104194990AReduce manufacturing costCatering to healthy drinking habitsAlcoholic beverage preparationYeastSweetness

The invention discloses a low-sweetness Hakka rice wine brewing method which comprises the following steps: (1) soaking rice; (2) washing the rice; (3) steaming the rice; (4) sprinkling water to the steamed rice; (5) mixing the steamed rice with yeast powder; (6) conducting diastatic fermentation; (7) conducting after-fermentation to mature the wine and increase the aroma; (8) squeezing and clarifying; (9) heating the wine for sterilization; and (10) ageing the wine. The rice wine brewed according to the technical scheme provided by the invention and the rice wine brewed in a Hakka area are both sweet rice wine; the Hakka rice wine brewed by the method is of low sweetness; and the low-sweetness Hakka rice wine keeps the style of the traditional Hakka rice wine, has a mellow and pleasant aroma, tastes soft and refreshing, reduces the production cost and caters to the healthy drinking habits of modern people.

Owner:广东三友酿酒股份有限公司

Making process for kirschwasser

InactiveCN103468465AGuaranteed qualityAchieve sterile hygieneAlcoholic beverage preparationYeastTrace element

The invention relates to a making process for kirschwasser. The process includes the steps of: 1) subjecting cherries to peduncle removing, washing, drying, disinfection and crushing; 2) letting cherry juice and peels contact, adding a distiller's yeast according to a proportion to make them ferment together; 3) in the fermentation process, making the pigment and aroma in the peels dissolved in wine; 4) after the fermentation, carrying out peel pomace separation to separate the original wine from the peel pomace and wine sediment, and then performing cylinder pouring to make the wine liquid clear and transparent; 5) fermenting the separated original wine; 6) ageing the separated original wine liquid; 7) carrying out clarification and gelatin charging at the end of ageing to make a gel net generated in the wine liquid, and filtering out the peels; 8) performing freezing treatment after the clarification treatment; 9) conducting heat treatment after the freezing treatment; 10) performing deployment after the heat treatment to deploy various trace elements of the kirschwasser; 11) then removing sediment and floating matters to make the wine liquid clear and stable; and 12) canning the filtered wine juice by a stainless steel canning machine, performing packaging by an aseptic packaging machine, and conducting sealing by a cork stopper.

Owner:王战乐

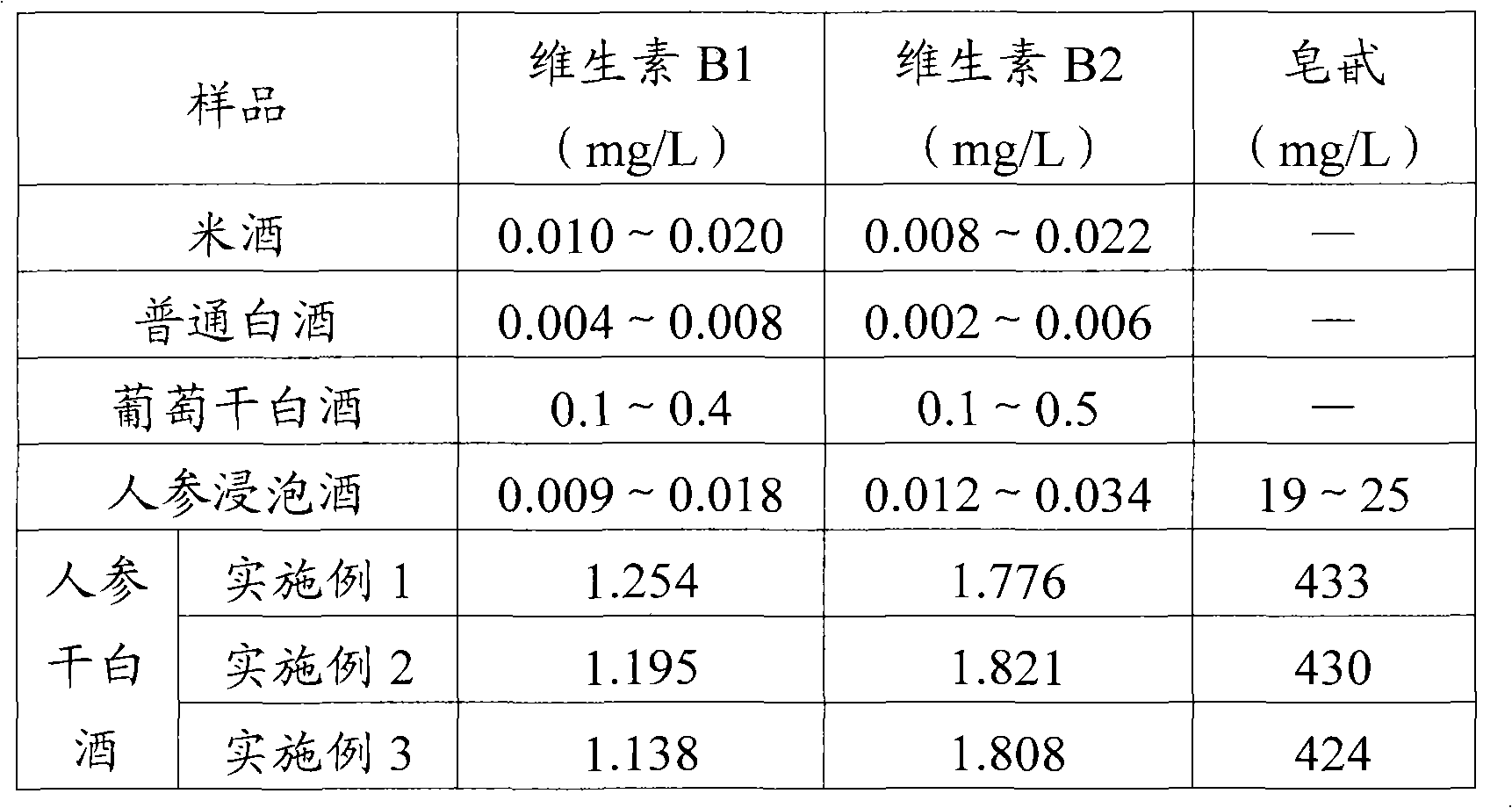

Ginseng dry white wine and processing technique thereof

ActiveCN101875890APromote absorptionFit for drinkingMicroorganism based processesAlcoholic beverage preparationTrace elementNatural substance

The invention provides a ginseng dry white wine. The wine comprises ginseng, honey, sugar and water in the weight ratio of 2-5 to 1-3 to 7-12 to 45-65. The processing technique comprises the following steps of: screening and cleaning the ginseng; pulping the ginseng; adding the honey and the sugar into the pulp; controlling the temperature to perform fermentation; and checking, filtering, secondarily fermenting, preparing, finely filtering and sterilizing the mixture. The processed ginseng dry white wine maintains the characteristics of natural substances and nutritive constituents, makes full use of the various nutritional functions of the ginseng and the honey, contains the saponin, amino acid, vitamin and trace element in the ginseng and the nutritive constituents in the honey which are fully dissolved into the wine and combines various beneficial bacteria produced in the fermentation so as to be easily absorbed by a human body, has a sugar degree less than that of ginseng pickled wine, and is suitable for various people to drink.

Owner:丁政然

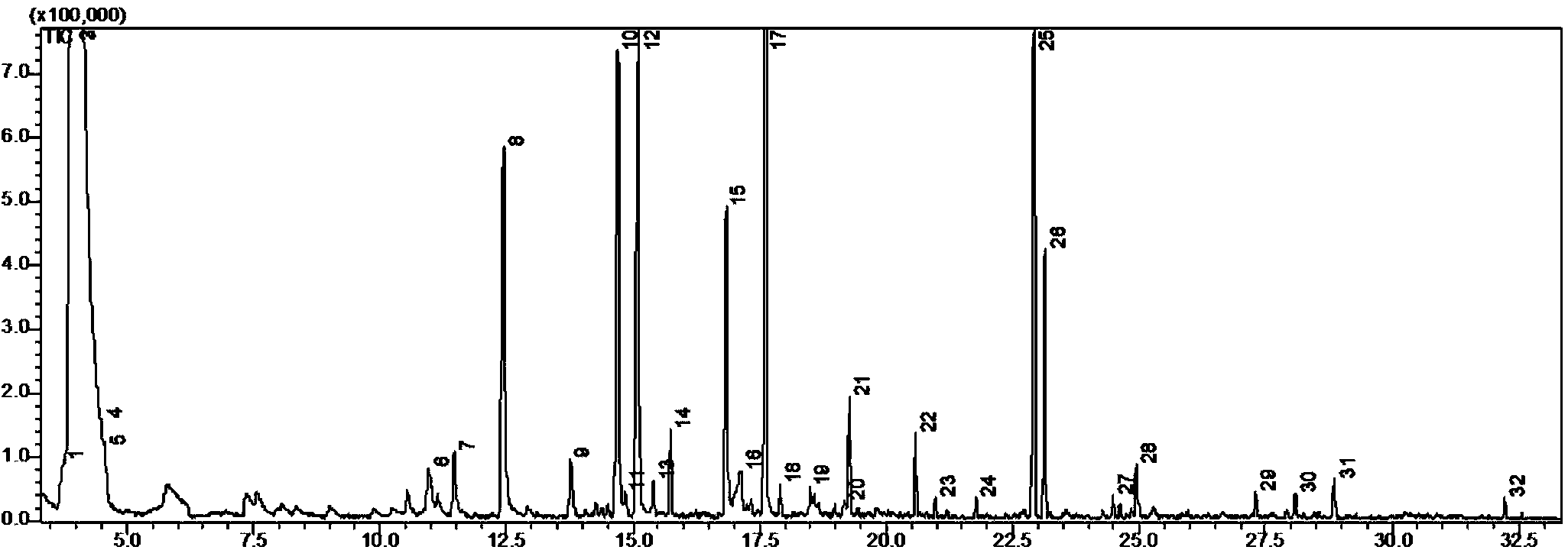

Preparation method of tobacco-sourced basic cigarette-smell raw material

InactiveCN105852200AStrong smoky aromaRealistic traditional cigarette smoking experienceTobacco treatmentTobacco productDry distillation

The invention discloses a preparation method of tobacco-derived basic smoke flavor raw material. The technical solution of the present invention is to carry out dry distillation and pyrolysis of tobacco raw materials; cool and collect the material produced by dry distillation and pyrolysis to obtain dry distillation pyrolysis liquid; extract the tobacco residue after dry distillation and pyrolysis to obtain extract; dry distillation pyrolysis liquid and extraction The tobacco-derived basic smoke taste raw material can be obtained after mixing the substances in any proportion. The raw material is applied to new tobacco products directly or after further processing, which can significantly increase / enhance the aroma characteristics of smoke, burnt, and roasted aroma of new tobacco products, making it closer to traditional cigarettes. The raw material can also be used for flavoring traditional cigarettes. The invention has the advantages of simple process, economic safety, obvious and unique use effect, and broad application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Processing method of dried yellow kiwi fruit

ActiveCN104305039APreserve nutrientsLess nutrient lossFruit and vegetables preservationFood ingredient functionsKiwi fruitNitrogen

The invention discloses a processing method of a dried yellow kiwi fruit. The processing method comprises steps of peeling off and slicing a raw material, cleaning kiwi pulp through normal temperature processing water added with 0.1% of V, placing the sliced kiwi in a plate after protecting color and cleaning, and quick-freezing the sliced kiwi; soaking the quick-frozen sliced kiwi in 25-30% of deacidified and decolorized apple juice for about 20-24h, wherein ratio of the sliced kiwi to sugar liquid is (1: 2)-(1: 3); placing the soaked sliced kiwi in the plate and drying in a vacuum environment with a vacuum degree less than or equal to -0.09Mpa at 50-60 DEG C until water content is 16-18%; and cooling the dried sliced kiwi to normal temperature, immediately filling nitrogen or deoxidizing and packaging the sliced kiwi in an aluminum foil bag. The processing method disclosed by the invention has the beneficial effects that the processed dried yellow kiwi fruit meets characteristics of a finished product which is nutritive and healthy, natural in raw and auxiliary materials, and green in processing technology, and is applicable to processing of other dried fruits.

Owner:WOLIN QINGDAO FOOD CO LTD

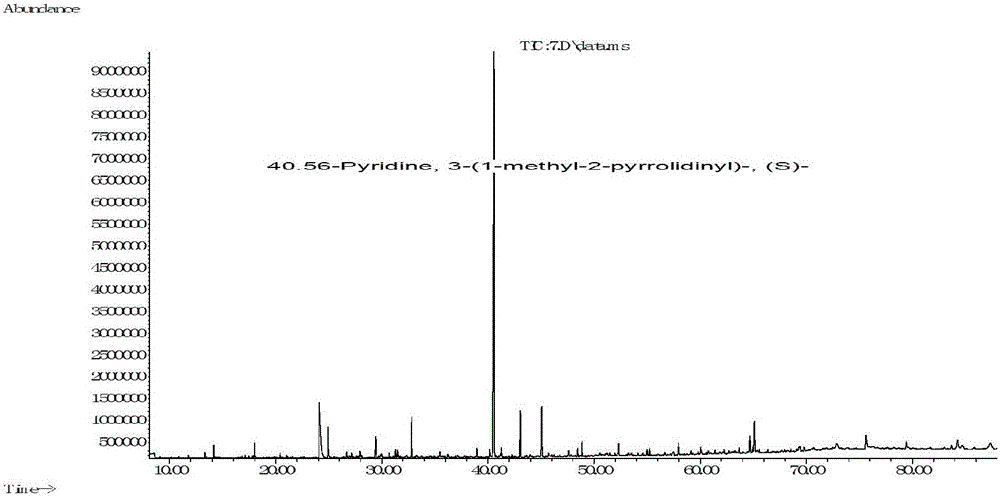

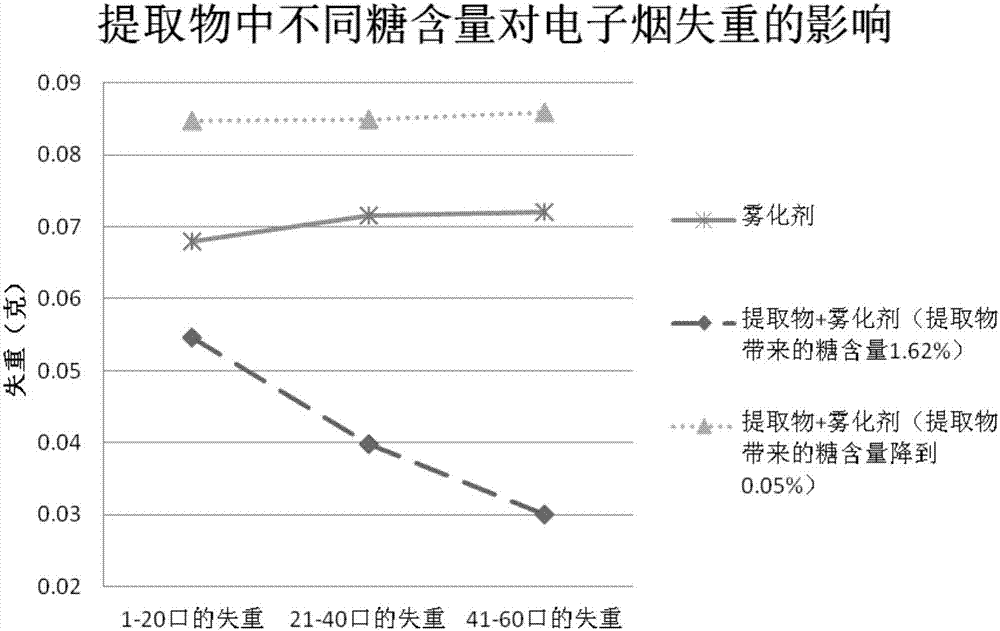

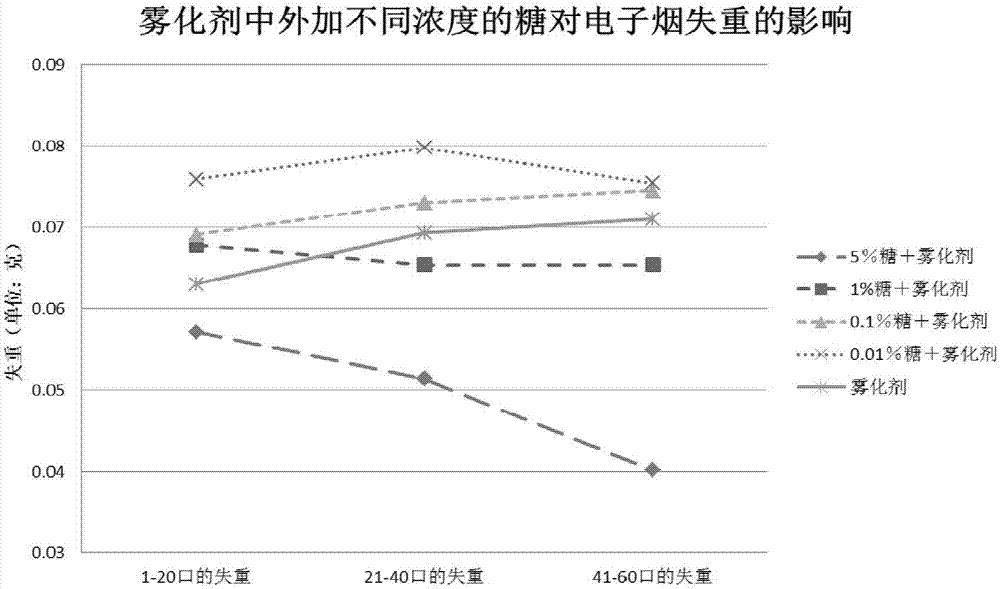

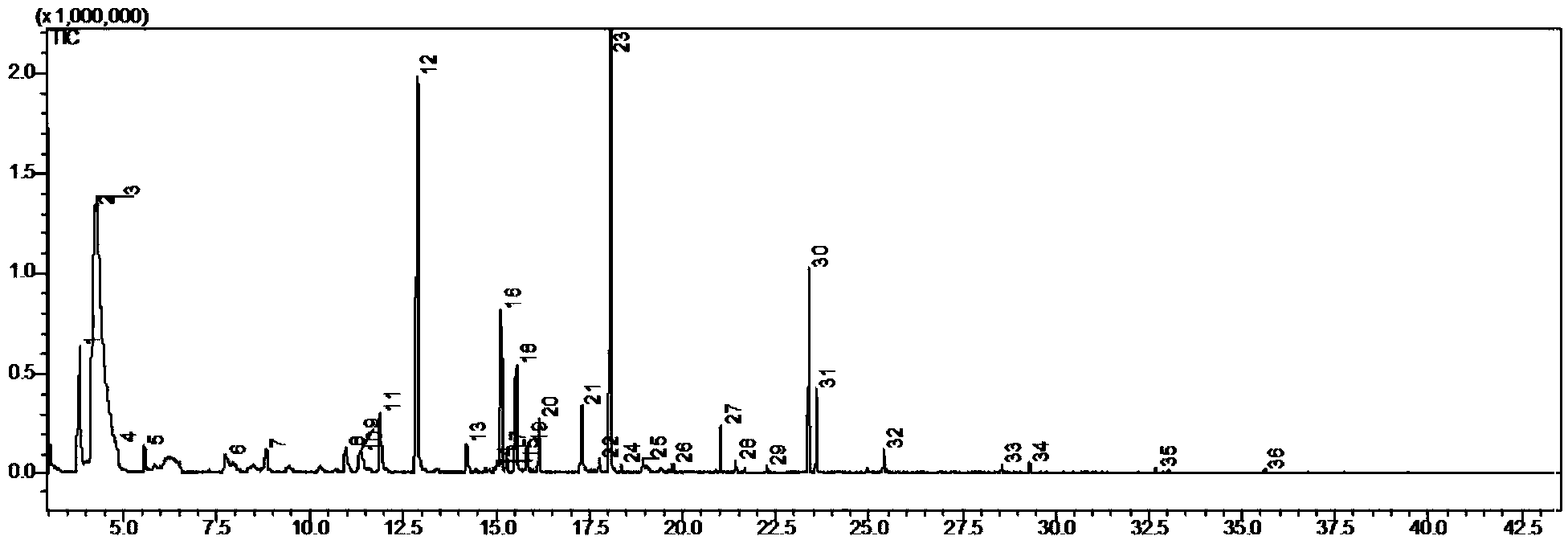

Method for extracting basic smoke smell raw material of tobacco source for electronic cigarettes

InactiveCN107319637AAtomization ability was not significantly affectedFilling was not significantly affectedTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention discloses a method for extracting basic smoke smell raw material of tobacco source for electronic cigarettes. The raw material can solve the problems that the suction frequency, the amount of smoke and the state of the smoke of electronic cigarettes are affected since the traditional tobacco extract is used in electronic cigarettes. The method is specific by reducing sugar content in the tobacco juice of cigarettes with tobacco extract to 1% and below and removing insoluble substances in the tobacco juice. The extracting method comprises following steps: (1) extracting as many aroma compounds as possible from tobacco raw material by wet extrusion or solvent immersion to obtain the initial product of tobacco source basic smoke smell raw material; (2) extraction or dissolution of the obtained initial product of tobacco source basic smoke smell raw material using a solvent (system) that is (almost) insoluble for sugar but as soluble as possible for flavor substances; the extraction or solution is concentrated and then dissolved in another solvent ( system ) to remove the insoluble matter to obtain the tobacco source basic smoke smell raw material for the electronic cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Method for producing orange sparkling wine

The invention discloses a method for producing orange sparkling wine. The method comprises the following steps: controlling the orange fruit maturity; performing scald peeling, peeling, pulping and juicing; clarifying; and performing first fermentation and secondary fermentation. The processing shortcoming of high acid content of the orange fruit can be avoided, the special fragrance and the mouth feel of the orange fruit can be kept, the nutrient value can be stored, and simultaneously the problems of the bitter feeling of the orange wine and the poor stability of the orange sweet fruit wine can be well solved, and the harmful flavor substances can be reduced. No chemical substance such as artificial color, spice or preservative is added in the production process and the wine is completely fermented by pure juice. The orange sparkling wine produced by the method provided by the invention is in orange yellow color, thoroughly clear, tiny and lasting in bubbles, intense in fruit flavor, fresh and cool in mouth feel and prominent in orange characteristic feature.

Owner:四川华橙酒业有限公司

Bitter bamboo shoot juice drink and preparation method thereof

InactiveCN104187930AWith fresh fragranceWith fermented sour aromaNatural extract food ingredientsFlavorAdditive ingredient

The invention discloses a bitter bamboo shoot juice drink and a preparation method thereof and relates to the field of processing of bamboo shoot drinks. The bitter bamboo shoot juice drink disclosed by the invention comprises 30-35% of bitter bamboo shoot juice, 5-7% of white granulated sugar, 0-0.5% of ascorbic acid, 0-0.05% of acid-resistant carboxymethylcellulose sodium and the balance being water according to a formula. The invention aims at providing the bitter bamboo shoot juice drink and the preparation method thereof. The method comprises the process steps of cutting, blanching, enzymolysis, pasteurization, fermentation and the like. The bitter bamboo shoot juice drink can effectively save nutritional ingredients in bitter bamboo shoots, increase the fermented flavor by inoculated lactobacillus for fermentation and effectively cover the bitter taste of the bitter bamboo shoots.

Owner:SICHUAN AGRI UNIV

Preparation method for tobacco source raw material with basic cigarette smell

InactiveCN105686070AAffect the number of suction portsAffect the atomization effectTobacco treatmentTobacco productDry distillation

The invention discloses a preparation method for a tobacco source raw material with a basic cigarette smell. According to the technical scheme, the preparation method comprises the steps of extracting a tobacco raw material to obtain extract; performing dry distillation and pyrolysis on tobacco residues after extraction to obtain a dry distillation and pyrolysis solution; and combining the extract with the dry distillation and pyrolysis solution in any ratio (the usage amount of the extract is less than 100%) to obtain the tobacco source raw material with the basic cigarette smell. The tobacco source raw material with the basic cigarette smell is applied to a novel tobacco product, and not only has good tobacco aroma but also can remarkably improve the aromatic characteristics of the smoky aroma, scorch aroma, baking aroma and the like of the novel tobacco product to enable the novel tobacco product to be closer to a conventional cigarette. Meanwhile, the raw material also can be applied to the conventional cigarette. The preparation method is simple in process, economic and safe, thereby having wide application prospects; and the raw material has a good use effect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Application of pericarp powder of citrus plants as filler in food processing

InactiveCN103637034AEasy to prepareReduce viscosityDough treatmentFood processingFood industryCitrus plant

The invention relates to the field of foods, and particularly relates to a novel application of pericarp prepared powder of citrus plants as filler in food processing. The pericarp prepared powder of citrus plants can be used as food filler in food industry or can be further used as a meal substituent for processing and application. The pericarp prepared powder of citrus plants provided by the invention is simple in preparation method, and the pericarp of waste materials of citrus plants are comprehensively utilized, so that the environment is protected and the cost is lowered. By using the pericarp prepared powder (such as shaddock peel powder, flavedo powder and orange peel powder) of citrus plants to prepare various foods, the medical effect of the pericarp of citrus plants is maintained. The powder has the functions of tonifying stomach, moistening lug, supplementing blood, cleaning intestines, relaxing the bowels and the like, and the viscosity of blood can be reduced to reduce thrombogenesis, so that the powder is a health-care food which provides the added value of products and the competitiveness of the products.

Owner:重庆市柚神酒业有限责任公司

Brewing method of low-alcohol-content dry blueberry wine

InactiveCN103484290AIncrease anthocyanin contentPleasant aromaAlcoholic beverage preparationMicroorganism based processesAlcohol contentSugar

The invention discloses a brewing method of low-alcohol-content dry blueberry wine. According to the method, microzyme is inoculated to the blueberry fruit used as the raw material in a full fruit crushing or peel trimming contact mode to obtain the blueberry wine with pleasant aroma and high anthocyanin content, in which the alcohol content is 6-8% and the sugar content is less than 4 g / L. The blueberry wine has the advantages of simple preparation technique, low alcohol content, low sugar content, high anthocyanin content and pleasant aroma; and the method can easily implement industrial production, is low in production cost and has favorable generalization performance.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Wine of rice fermented with red yeast, and producing technique

InactiveCN101050410AMellow and elegant tasteGood health effectAlcoholic beverage preparationYeastProbiotic

This invention relates to a process for producing red koji wine that has good enterogastric healthcare function. The red koji wine contains 50-350 g / L of oligoisomaltose, which can decompose enterogastric fats together with ethanol, and can protect probiotics. The red koji wine has a good taste after added with oligoisomaltose.

Owner:王顺寿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com