Patents

Literature

107 results about "Caramelization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

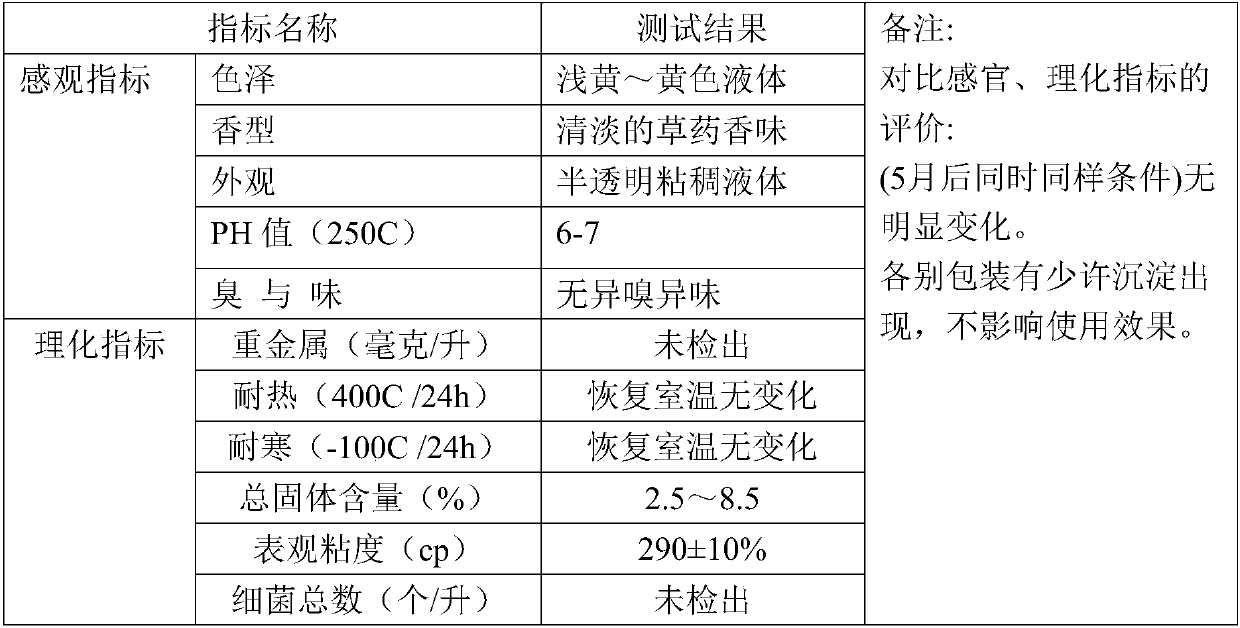

Caramelization is the browning of sugar, a process used extensively in cooking for the resulting sweet nutty flavor and brown colour. The brown colours are produced by three groups of polymers: caramelans (C₂₄H₃₆O₁₈), caramelens (C₃₆H₅₀O₂₅), and caramelins (C₁₂₅H₁₈₈O₈₀). As the process occurs, volatile chemicals such as diacetyl are released, producing the characteristic caramel flavor.

Pizza crust and process and apparatus for making same

InactiveUS6629493B1Speed up the processEasy to adjustAir-treating devicesBakery productsStarch gelatinizationMoisture absorption

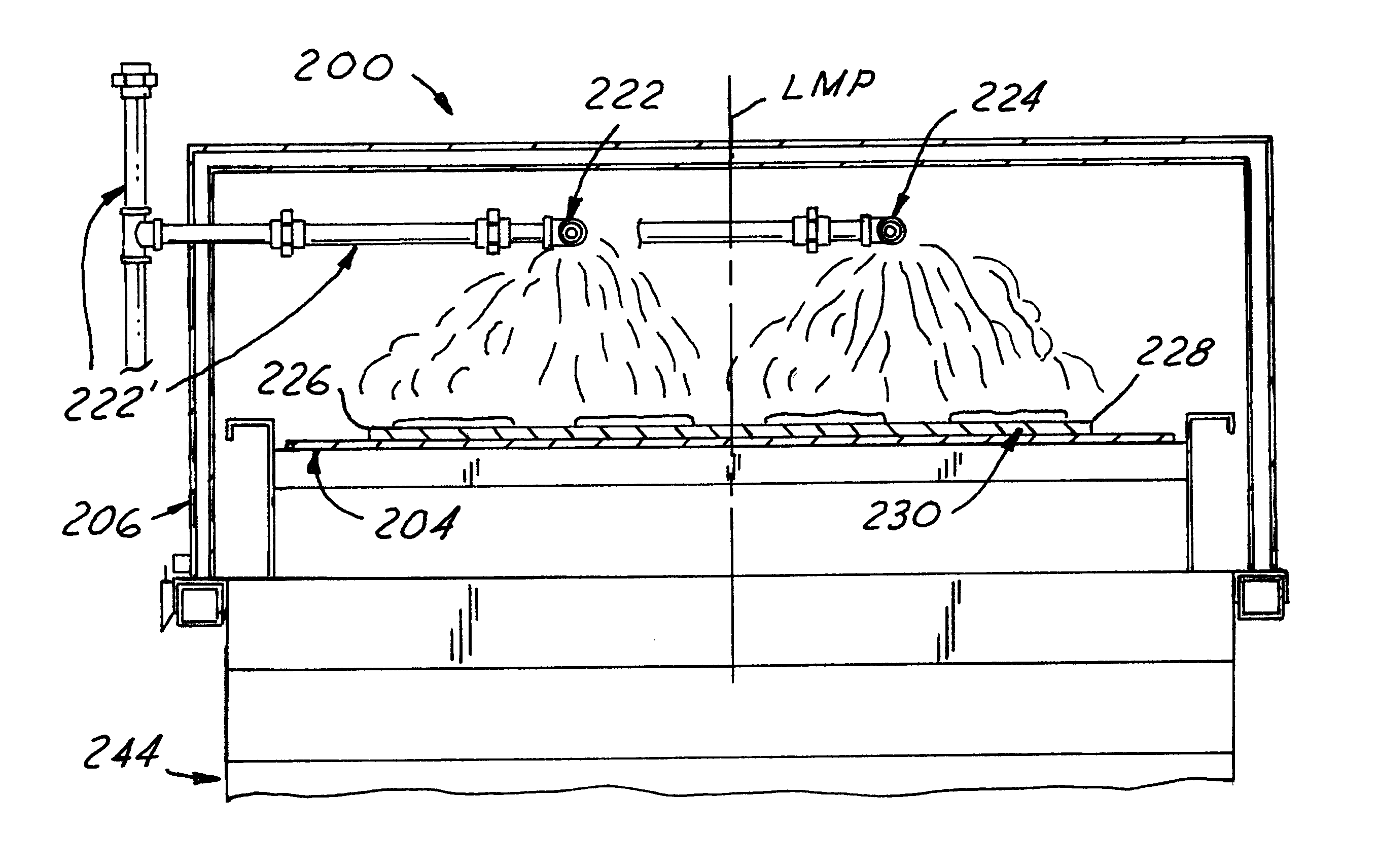

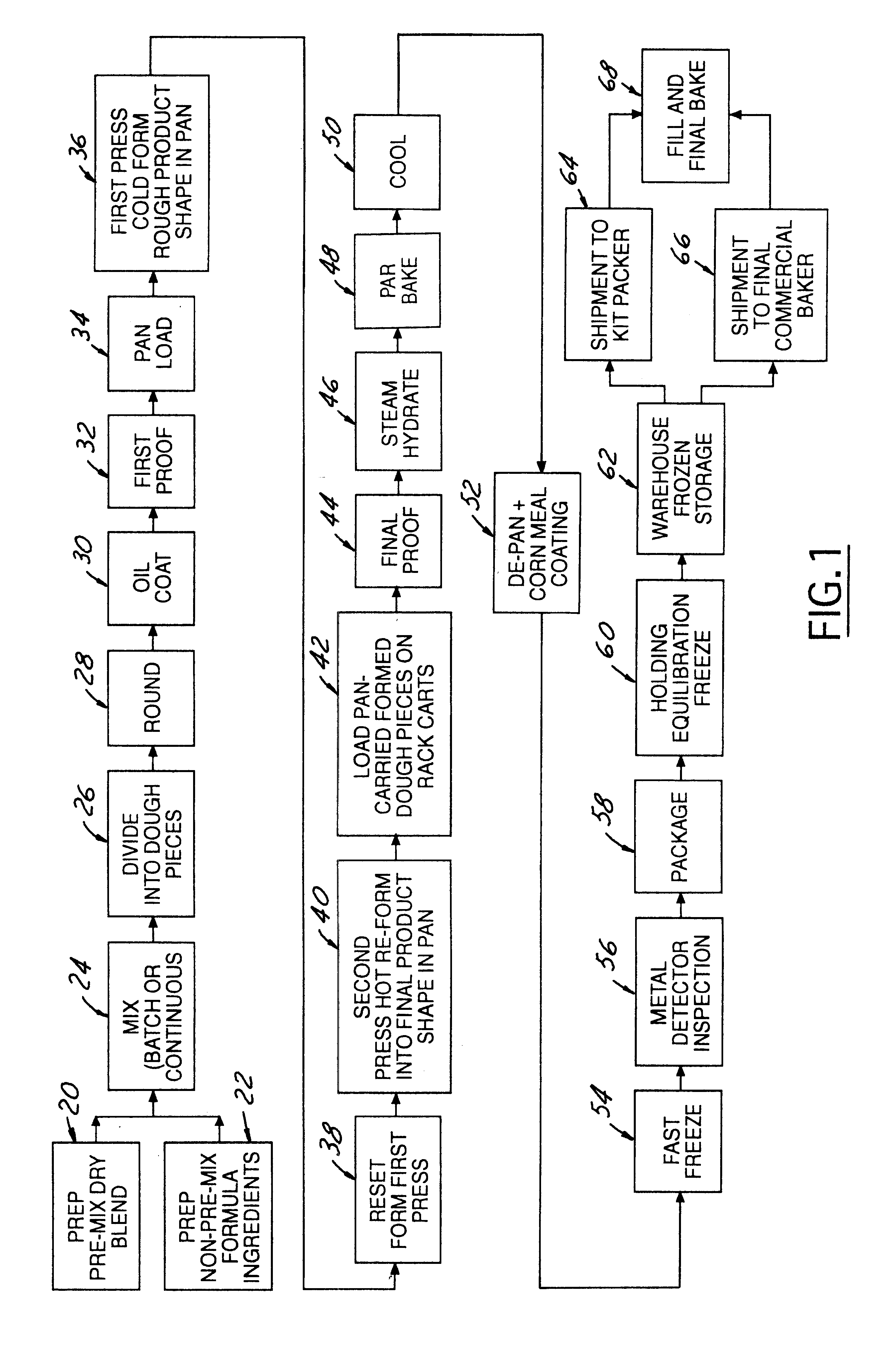

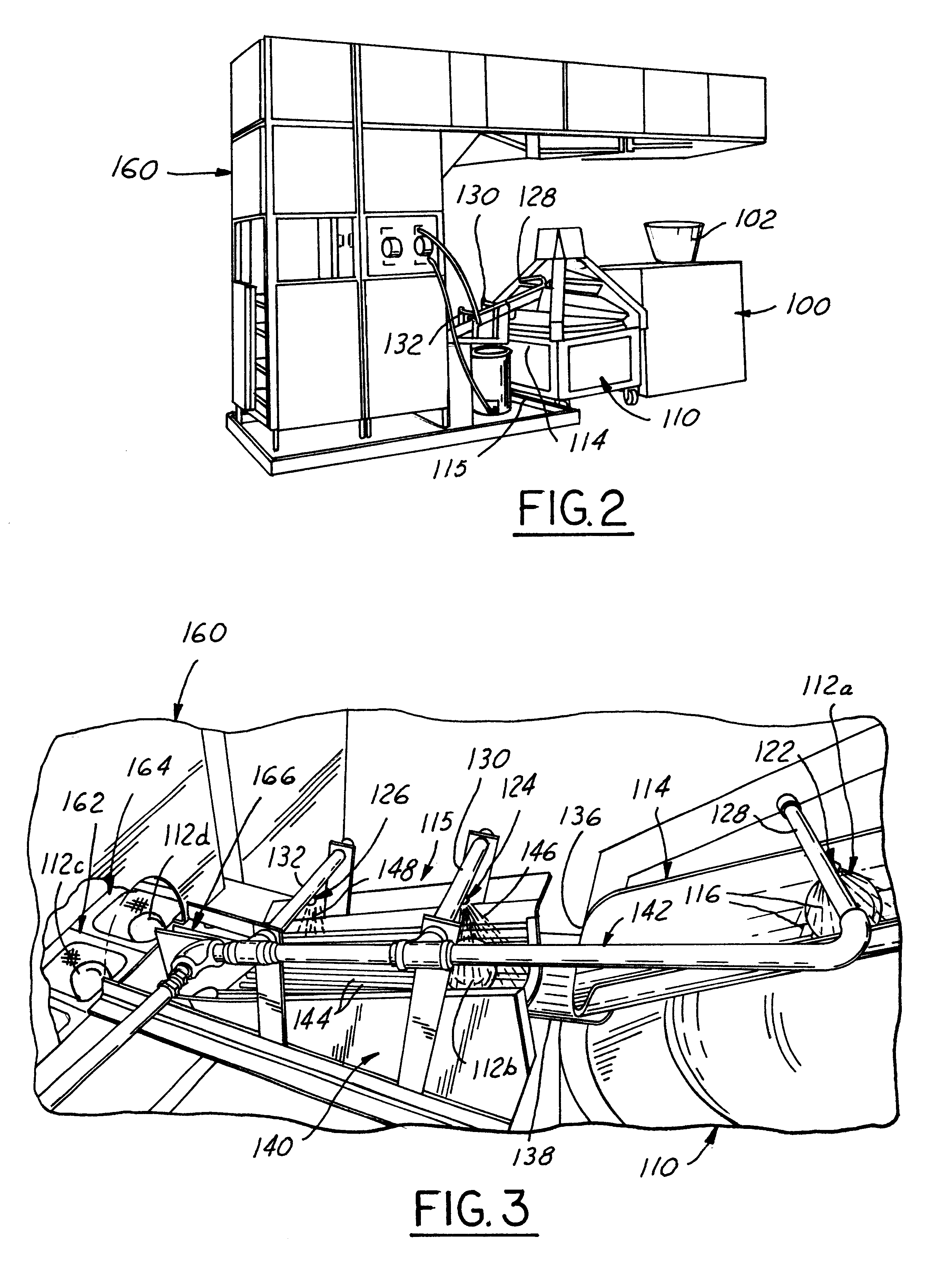

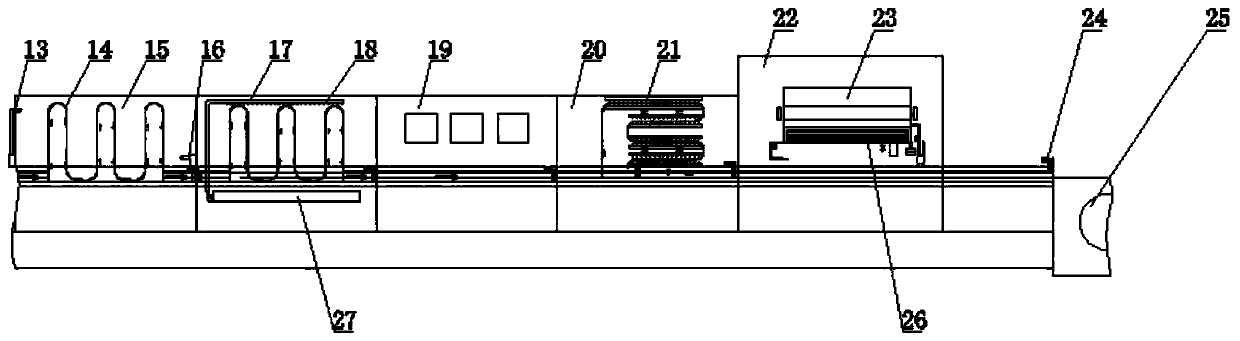

Apparatus for preparing parbaked food products, such as pizza crust shells, and dough formulation used therein, and the product produced thereby and / or therefrom. The apparatus operates on a starting material dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed in the apparatus. The prepared dough piece is then steam hydrated in the apparatus under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition of the apparatus is adjusted as selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough until the starch gelatinization is complete, and for thereby discontinuing the parbaking before substantial caramelization of the sugar in the crust takes place.

Owner:M & M HLDG

High temperature countercurrent solvent extraction of herb or spice solids

InactiveUS6013304AShorten the counting processBacterial Count ReductionSolid waste disposalFood preparationAntioxidantFine particulate

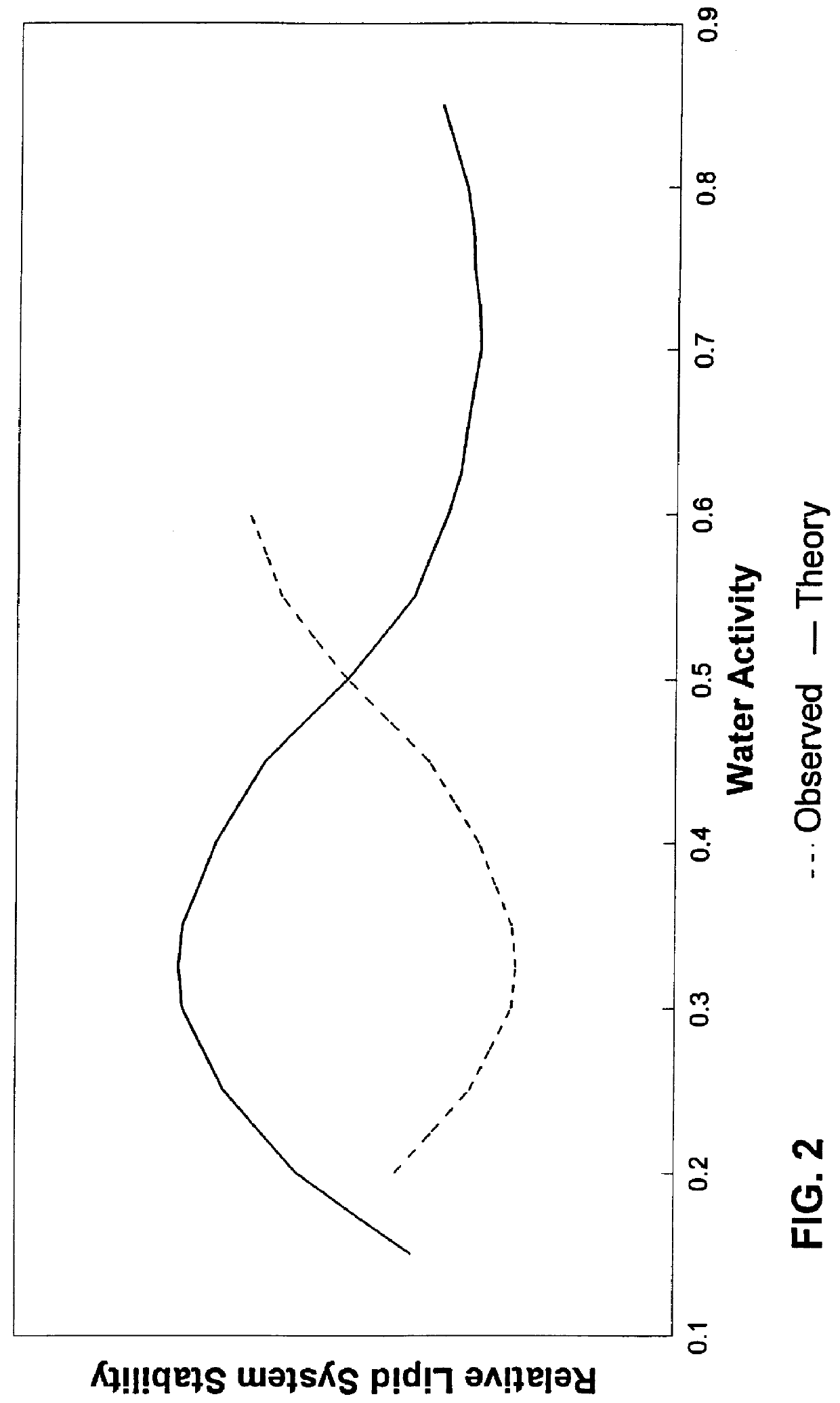

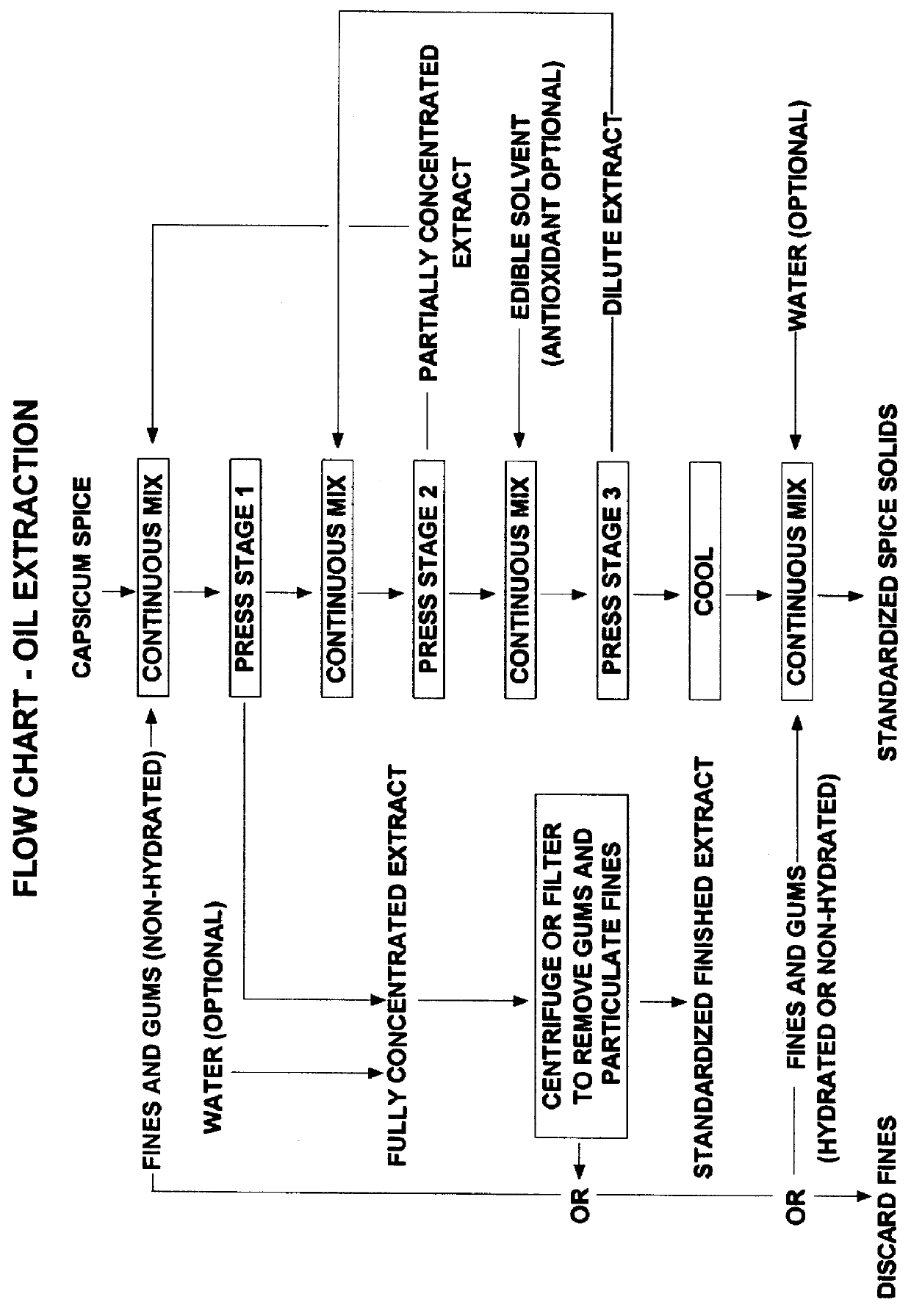

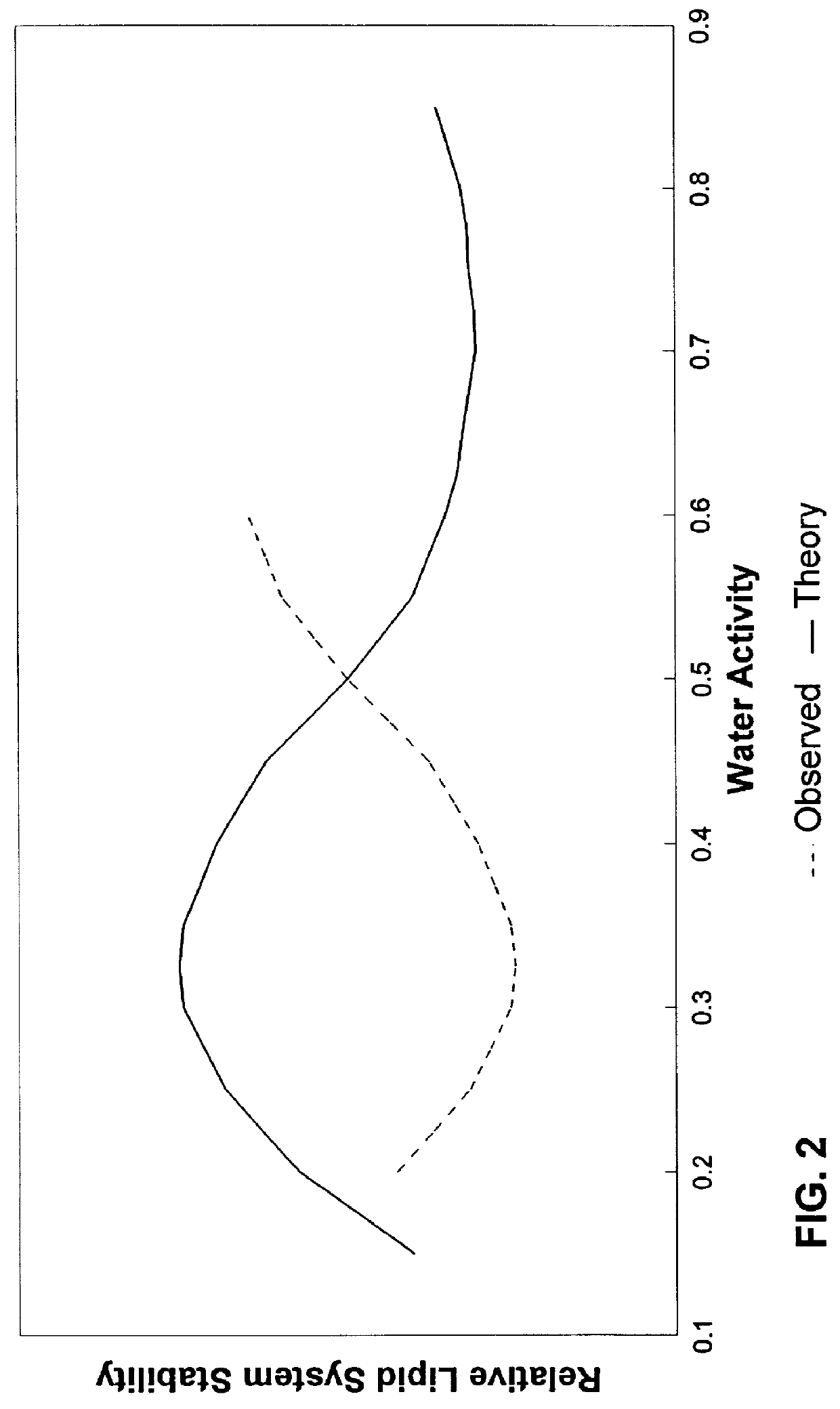

Principal components of spice and herb plant solids are simultaneously extracted and concentrated with an edible solvent in a series of mixing and high temperature and pressure mechanical pressing steps using edible solvent and a countercurrent extraction procedure. The extract may be hydrated and then centrifuged to remove fine particulate solids and gums. A solution having several times the concentration of pigments and other flavor and aroma and / or antioxidant components of the starting raw material is obtained. The residual press solids may be cooled and hydrated following the last pressing operation. The residual press solids and extract have significantly reduced bacterial counts as a result of the temperatures, high pressure, and high shear utilized, as well as the low moisture levels employed, thus producing not only a food grade extract but also a food grade residual solid having low bacterial counts and predictable, standardized levels of the principal components of interest. The tissue of the residual spice or herb plant solid is ruptured in the process so as to provide quick release of the components thereof when utilized in a food or beverage, this greatly increasing its use effectiveness. The degree of browning or caramelization of the residual press solids is controlled, and the resistance to oxidative deterioration of both the extract and the residual solid is improved, by control of the temperature employed. Additionally, edible antioxidants can be included in the solvent to enhance the stability of both the extract and the residual solid.

Owner:KALAMAZOO HLDG INC

Process for preparing a noncrystallizable polyol syrup

The invention relates to a process for preparing a noncrystallizable polyol syrup stable to heat and to alkaline medium, using a step of hydrogenation of a sugar syrup and a step of caramelization of the hydrogenated sugar syrup, wherein the hydrogenated and caramelized sugar syrup is subjected to purification on ion-exchange resins, the said purification comprising at least one passage over a strong cationic resin at a temperature of less than 50° C., the said temperature being chosen according to the level of reducing sugars desired in the noncrystallizable polyol syrup. It also relates to the use of the polyol syrup obtained for the preparation of toothpastes.

Owner:ROQUETTE FRERES SA

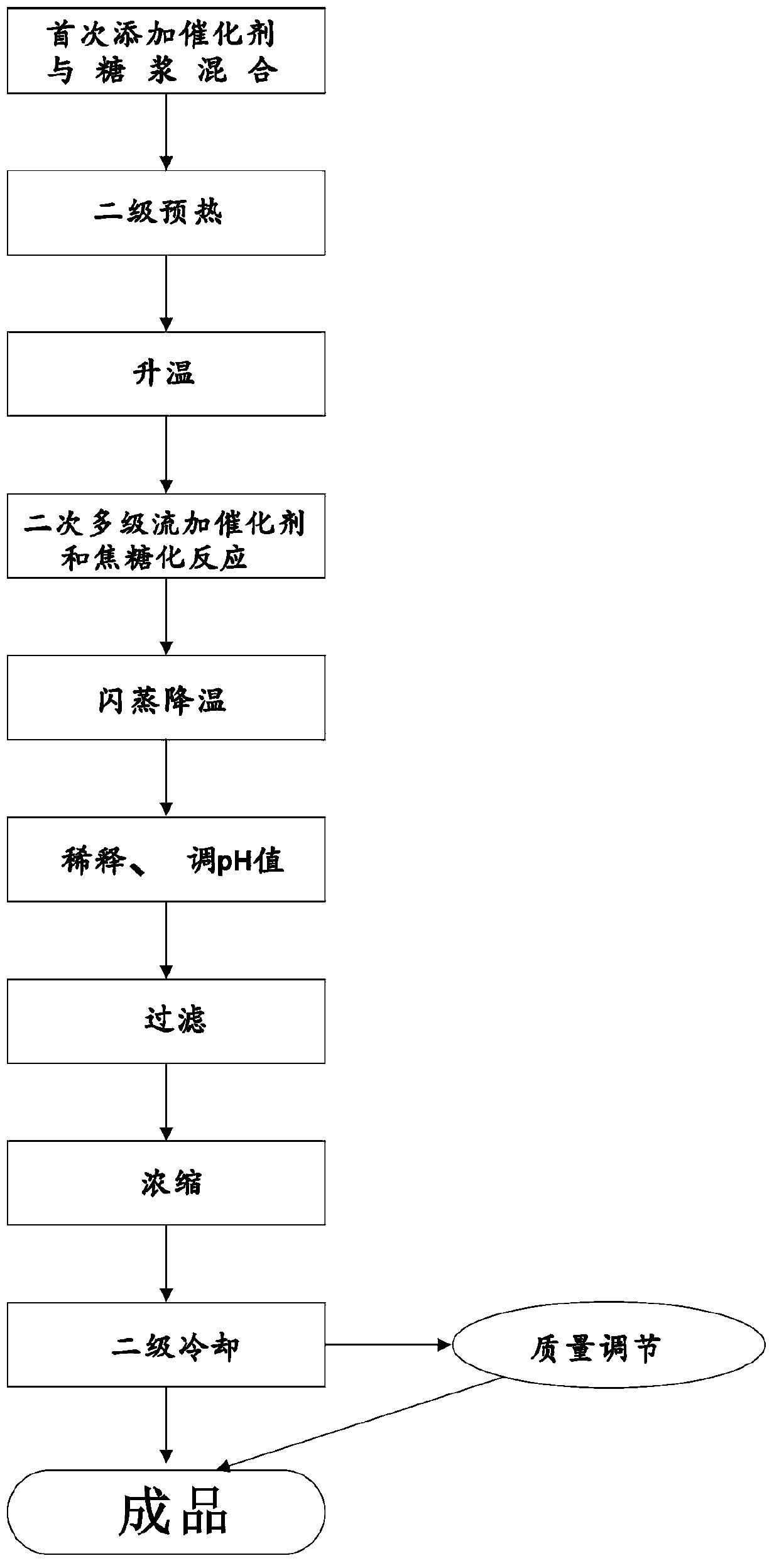

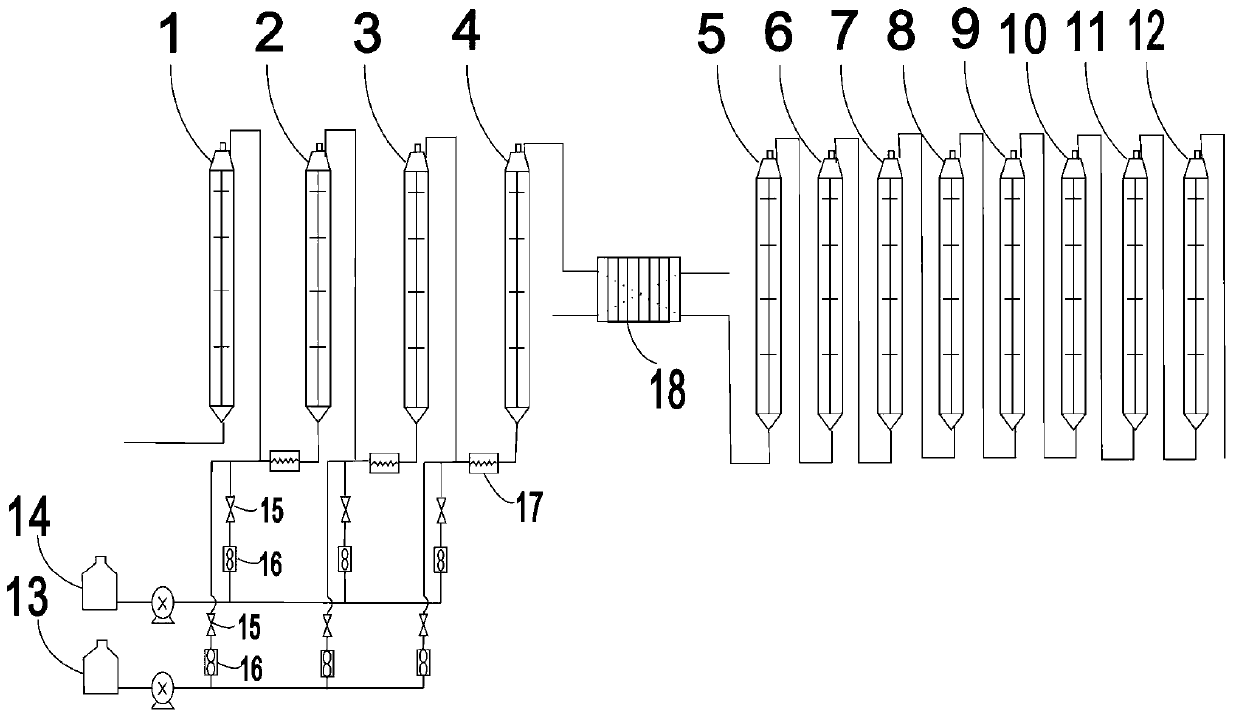

Process for continuous preparation of caramel pigment by ammonium sulfite method

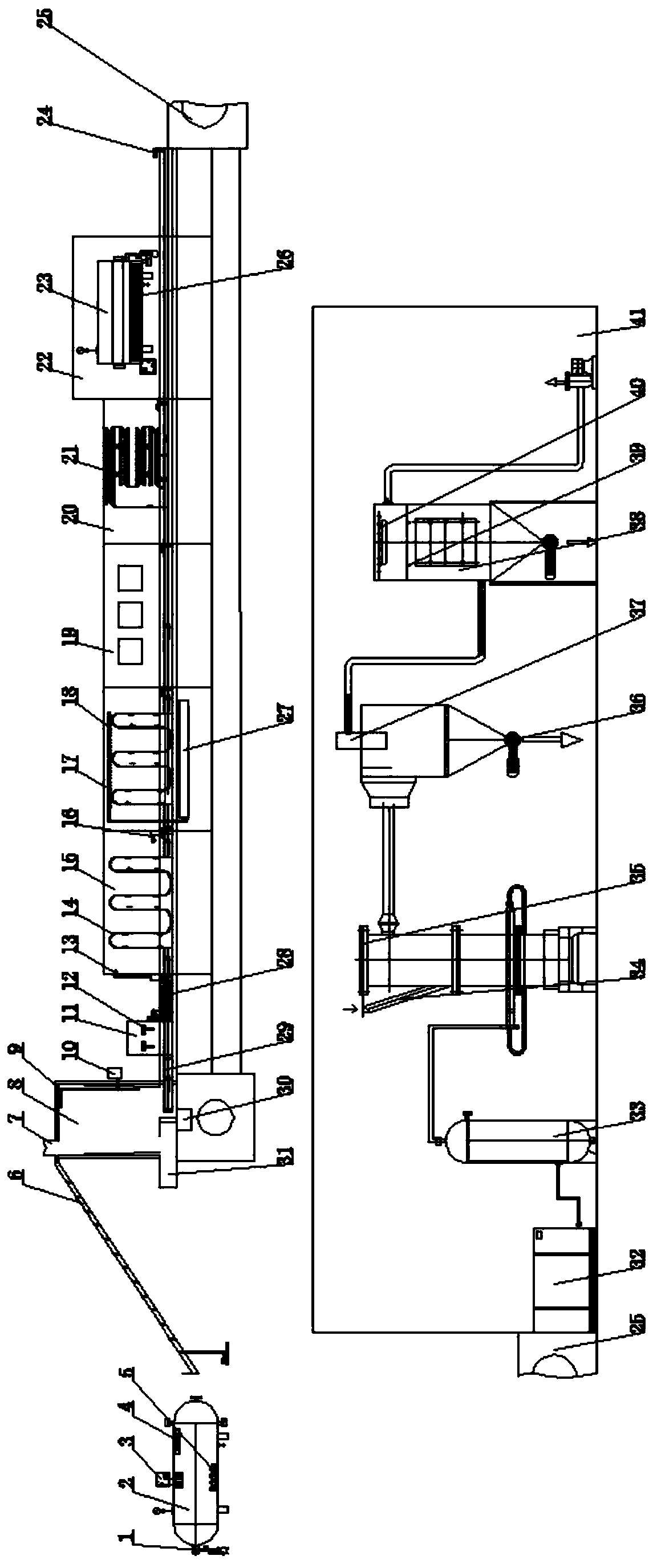

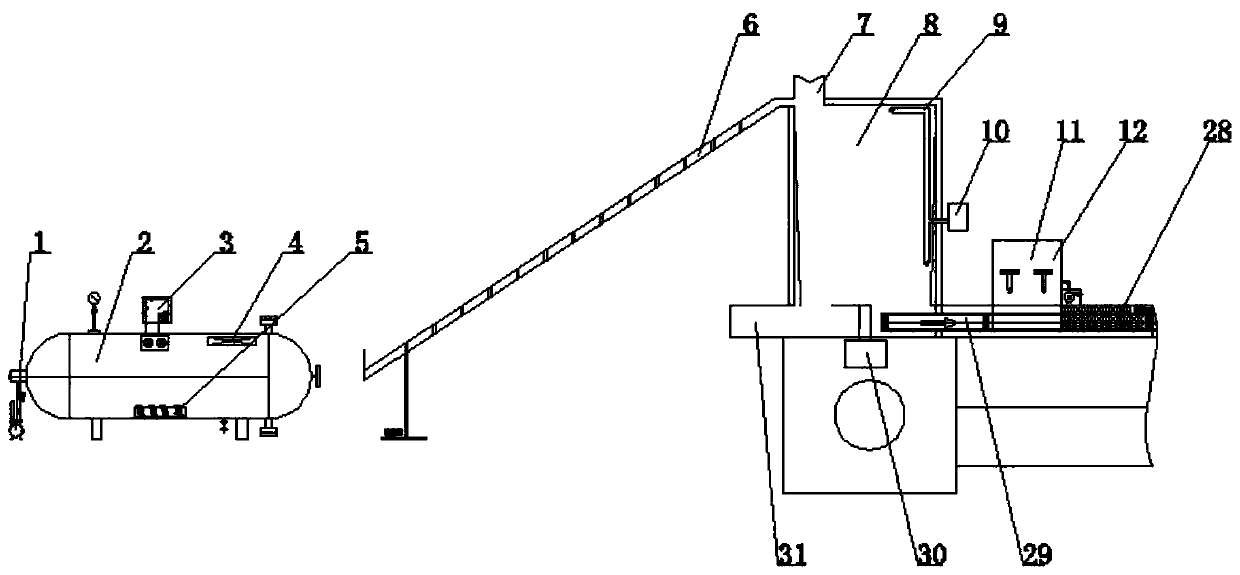

The invention discloses a process for continuous preparation of caramel pigment by an ammonium sulfite method, which comprises the following steps of: (1) adding a catalyst for the first time, and mixing with syrup; (2) performing two-stage pre-heating; (3) increasing temperature; (4) performing secondary multi-stage catalyst feeding and caramelization; (5) flashing and reducing temperature; (6) diluting and regulating pH value; (7) filtering; (8) condensing; (9) performing two-stage cooling, and (10) quality regulating which can be further comprised. The process for continuous preparation of the caramel pigment by the ammonium sulfite method disclosed by the invention can realize continuous and sealed preparation of the caramel pigment by the ammonium sulfite method, improve production efficiency and output, improve safety of the product and reduce the energy consumption; the produced caramel pigment is stable in quality, and is capable of simultaneously meeting high color index and high red index, being ideal caramel pigment in many fields, particularly in soy sauce.

Owner:GUANGZHOU SHUANGQIAO

Method for preparing caramel pigment

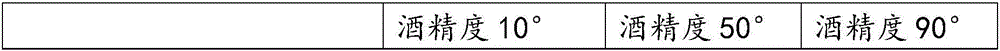

InactiveCN1594442ASufficient sourceReach the color ratioNatural dyesFood preparationFood additiveSucrose

The invention discloses a method for preparing caramel pigment mainly used as the liquor color mixing agent and food additive, the preparation process comprises the steps of disintegrating, filtering, concentration. The method can not only meet the color ratio and stability requirement for the cane sugar production, but also preserve the eighteen amino acids and part of the trace elements in the zein.

Owner:兰州金陵石化有限责任公司

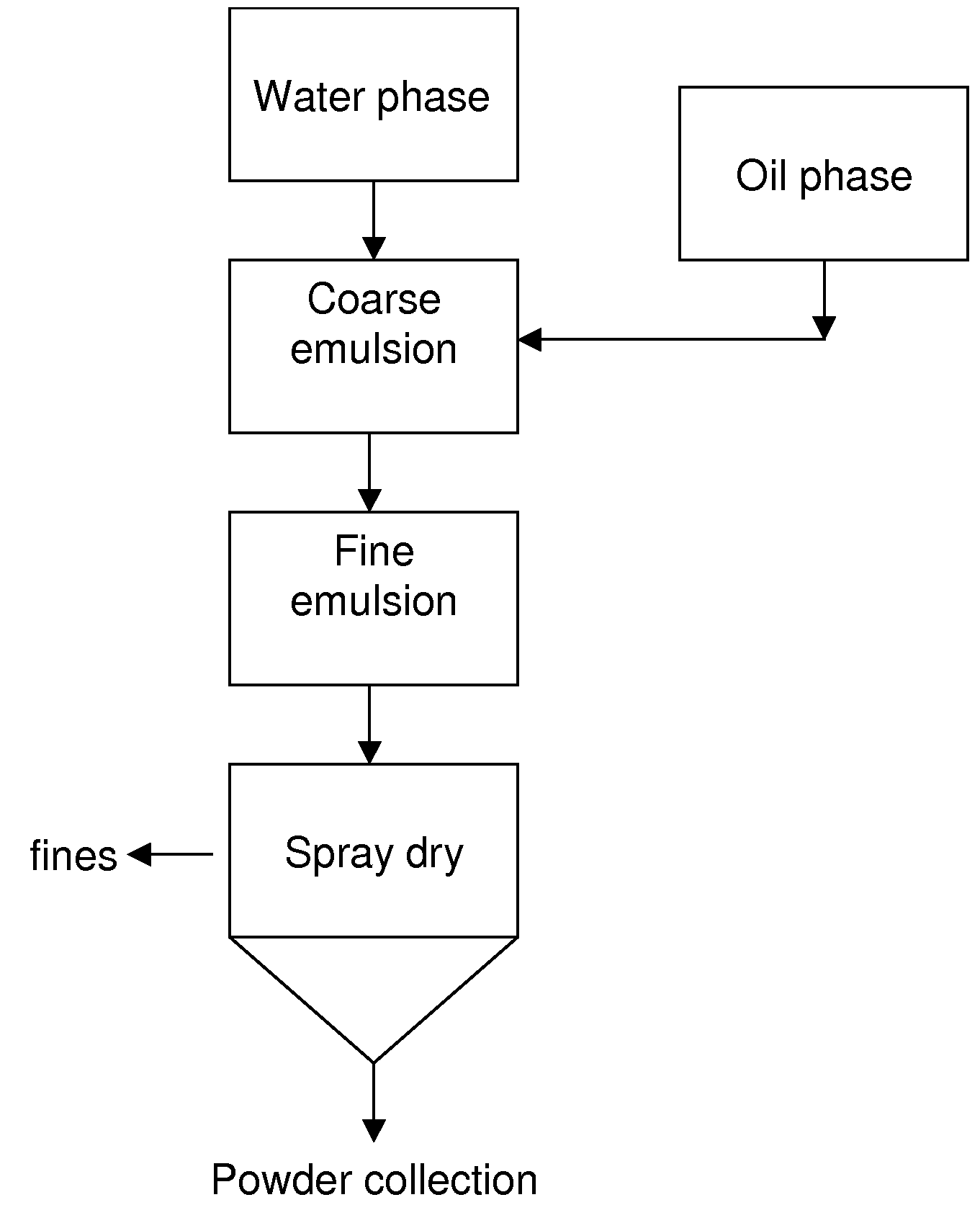

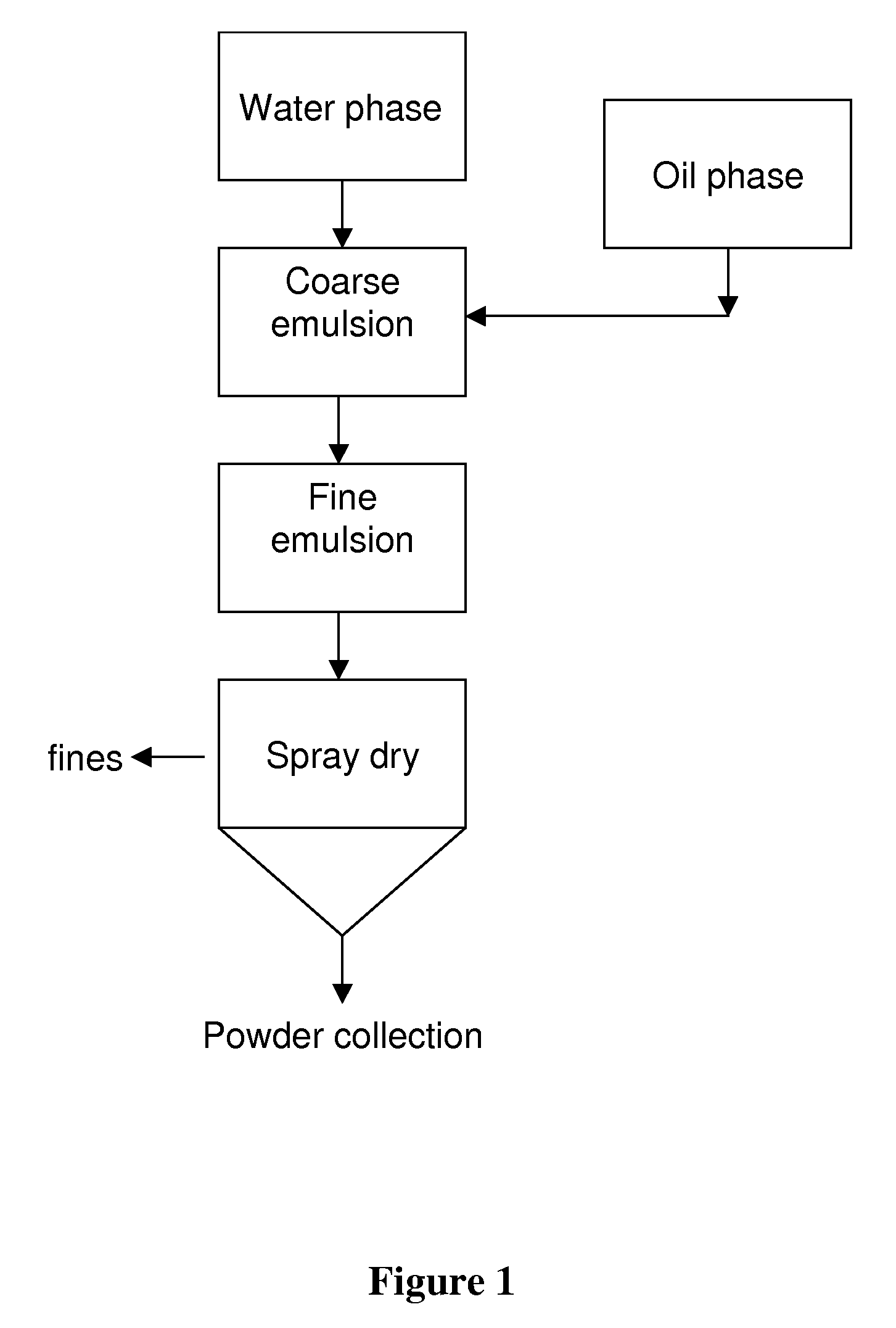

Microencapsulating compositions, methods of making, methods of using and products thereof

Products comprising core materials, such as polyunsaturated fatty acids, encapsulated by an encapsulant formed from hydrolyzed protein having a degree of protein hydrolysis of between about 1% and about 15%, and from caramelization products, are disclosed. Methods of making the same and of making the encapsulant are also provided.

Owner:DSM IP ASSETS BV

Low moisture, low water activity caramel, caramel composite products and process for preparation

InactiveUS20060286212A1Extension of timeDesirable textureConfectionerySweetmeatsPolyolAdditive ingredient

New caramel compositions suitable for use with crisp bases such as cookies and crackers are provided. The new caramel compositions are able be packaged over long periods of storage in direct contact with a crisp base comprised of a cookie or cracker without adversely affecting the texture of either the crisp base or the caramel. They comprise a cooked mixture prepared from: liquid triglyceride, monosaccharide, disaccharide, polyol, milk solids, and emulsifier. The caramel exhibits an Aw of less than 0.42. Processing entails: mixing ingredients comprising liquid triglyceride, monosaccharide, disaccharide, polyol, milk solids, and emulsifier in a heating vessel; heating the ingredients to form a uniform heated mixture while scraping the vessel during heating to prevent scorching; and increasing the heat to boil the ingredients to a temperature and for a time to achieve caramelization.

Owner:KRAFT FOODS INC

Common-process production technique of caramel color with color ratio of at least 30000EBC

ActiveCN105086503APromote caramelization reactionImprove solubilityProductsReagentsChemical oxygen demandEvaporation

The invention relates to a common-process production technique of caramel color with the color ratio of at least 30000EBC, which comprises the following steps: metering and concentrating a raw material, regulating the pH value to 7.0-11.0, adding sodium polyphosphate and propyl gallate as catalysts, carrying out pressurized reaction, terminating the reaction when the color ratio is satisfactory, cooling, filtering, blending, metering and filling. The caramelization reaction is performed by adding the catalysts under increased pressure under alkaline conditions, thereby lowering the activation energy of the reaction system; and thus, the reaction can be performed more easily, and can obtain the high-color-ratio product more easily. No material condensation water is discharged, thereby preventing evaporation heat dissipation and lowering the reaction energy consumption. Since no condensation water is discharged, no peculiar smell or COD (chemical oxygen demand) pollution is generated in the reaction process.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Low-temperature baking cake and manufacturing method thereof

InactiveCN105053136APromote hydrationRetain moreDough treatmentBakery productsBiotechnologyHealthy diet

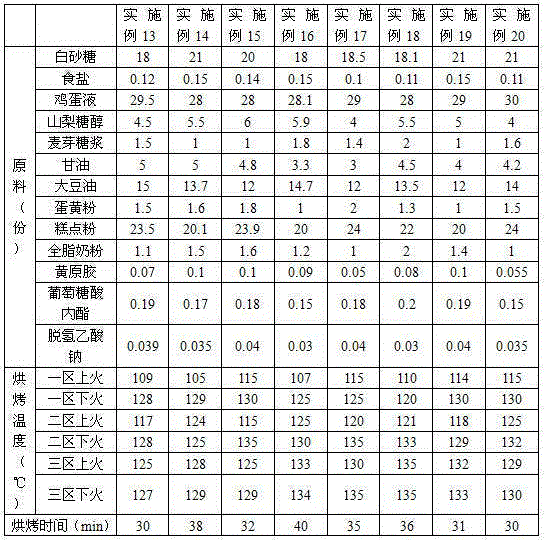

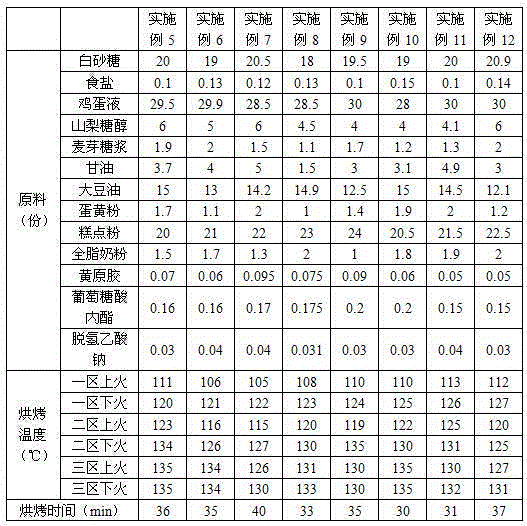

The present invention discloses a low-temperature baking cake which is prepared from the flowing raw materials in parts by weight: 18-21 parts of white granulated sugar, 0.1-0.15 part of edible salt, 28-30 parts of egg liquid, 4-6 parts of sorbitol, 1-2 parts of malt syrup, 3-5 parts of glycerin, 12-15 parts of soybean oil, 1-2 parts of egg yolk powder, 20-24 parts of pastry flour, 1-2 parts of whole milk powder, 0.05-0.1 part xanthan gum, and 0.18-0.24 part of preservatives. The cakes are manufactured by using a creative baking process which employs a baking temperature of 105-135 DEG C and a baking time of more than 30 minutes. The manufactured cakes have a higher moistening degree, and have superiority in melting properties in mouth and post moisturizing ability compared with the high-temperature baking cakes. And also because the cakes are baked at low temperatures for a long-time, relatively more nutrients of the cakes are retained, and also some unhealthy caramelized products induced by high temperatures are not easily produced. The low-temperature baking cakes are good products which fit to the current healthy diet.

Owner:MAIFENG FOOD CHINA CO LTD

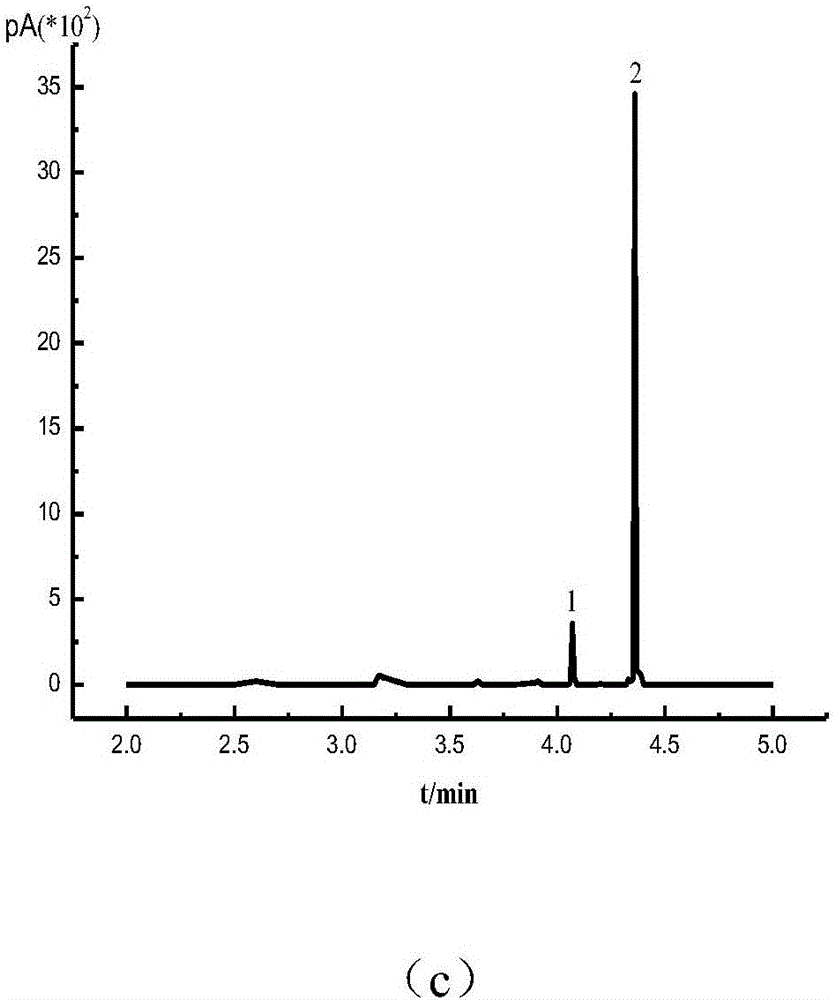

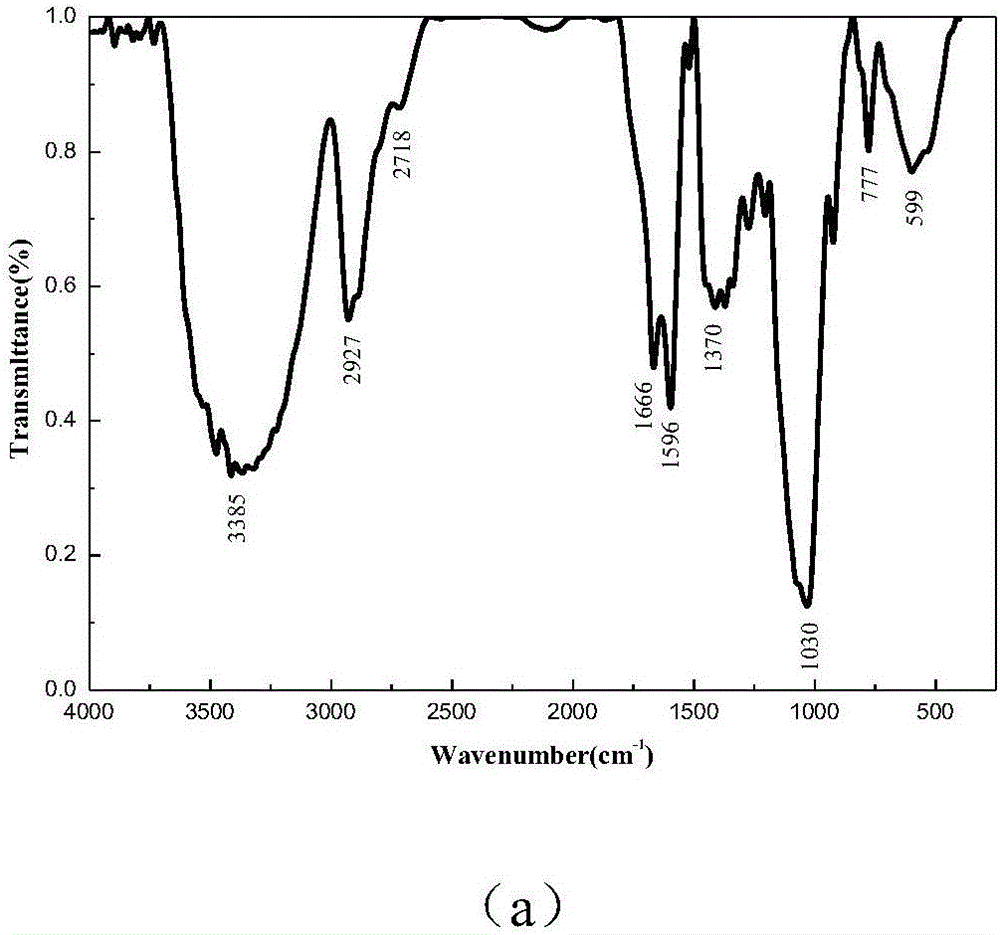

Device and method for preparing tobacco source basic cigarette flavor material for novel tobacco products

The invention discloses a device and a method for preparing a tobacco source basic cigarette flavor material for novel tobacco products. The technical scheme includes: subjecting tobacco materials to Maillard reaction and caramelization at 60-180 DEG C, collecting products of Maillard reaction and caramelization, performing carbonization and pyrolysis at 180-365 DEG C, collecting carbonized products, and finally extracting the tobacco materials after carbonization and pyrolysis to obtain extracts. More than one or two of the three products can be combined to obtain the tobacco source basic cigarette flavor material for the novel tobacco products. The device and the method for preparing the tobacco source basic cigarette flavor material for the novel tobacco products have the advantages of simple process and equipment, evident utilization effects and high tobacco material utilization value and are efficient, economical and safe, thereby being extensive in application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

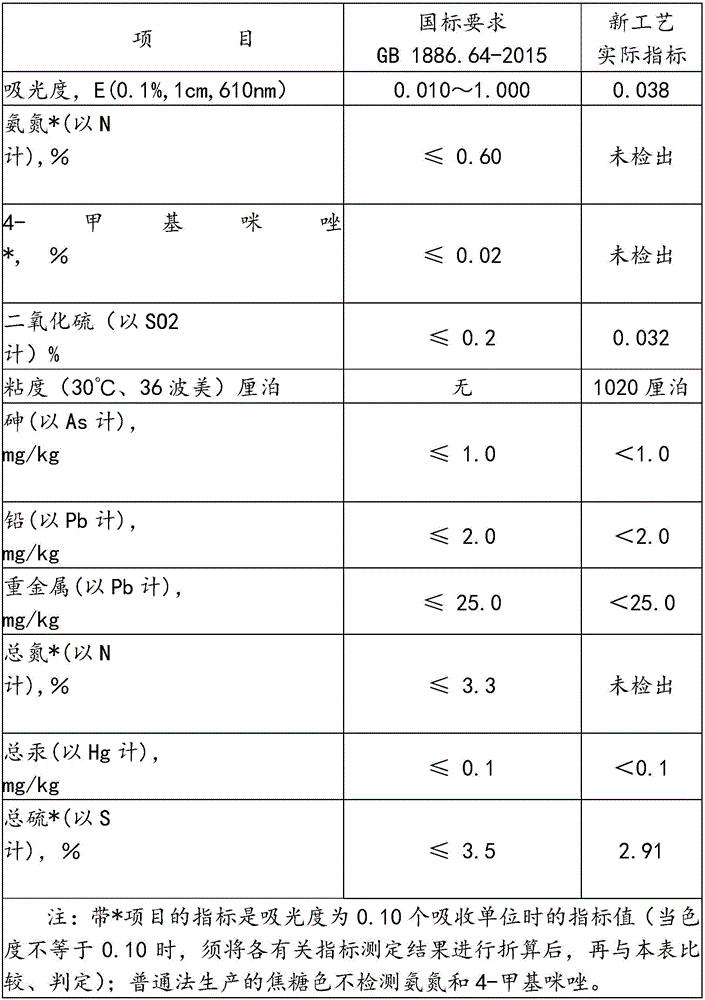

Preparation method of caramel pigment without 4-methylimidazole

ActiveCN104861736AImprove salt toleranceImprove acid resistanceNatural dyesIsoelectric point4-Methylimidazole

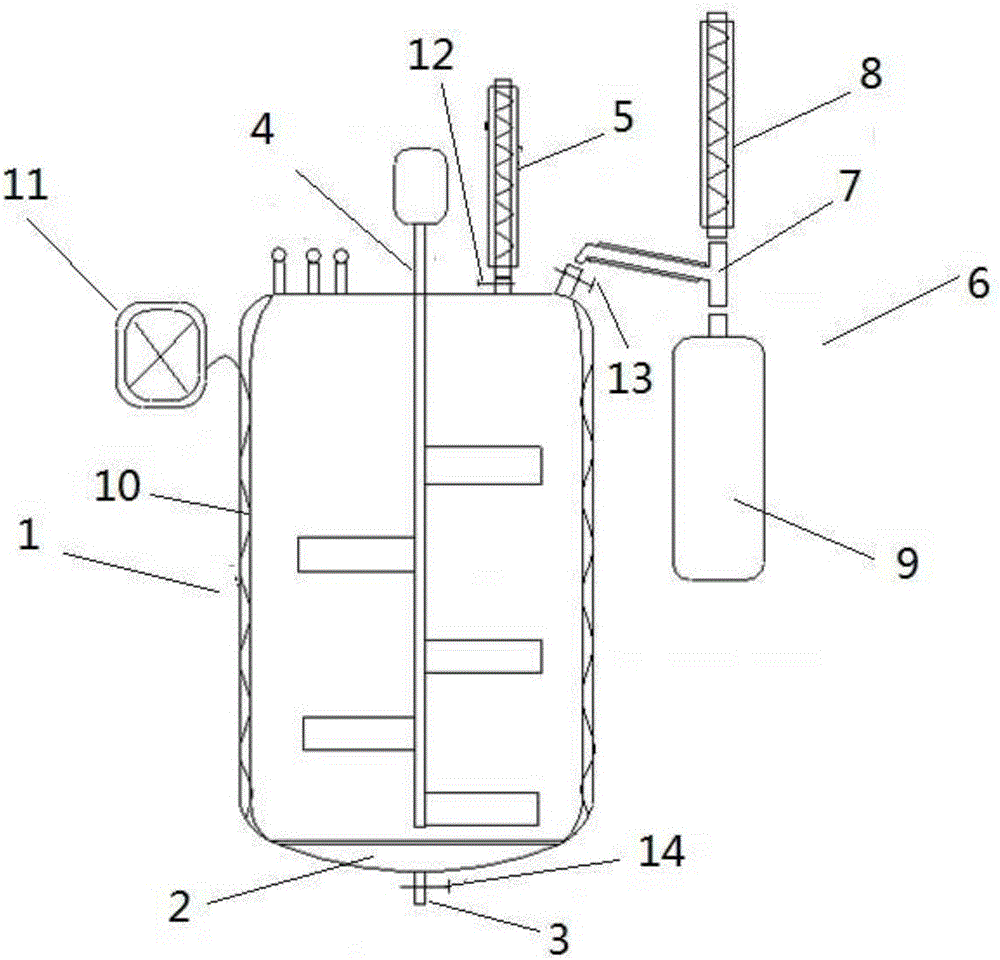

The invention discloses a preparation method of a caramel pigment without 4-methylimidazole. The preparation method comprises the following steps of: 1) sugar-melting, to be specific, adding a sugar source to a reaction kettle with a condensing and draining device while mixing, turning on a heating device for heating, melting the sugar source after the temperature of the reaction kettle rises above the melting point of the sugar source; 2) draining, to be specific, turning on condensing water, collecting cooling water, and controlling the volume of the cooling water to 5%-8% of the volume of the sugar source; 3) caramelization reaction, to be specific, after draining is finished, changing a condenser pipe into a cooling water return pipe, and keeping at 150 DEG C to 170 DEG C for 1 h-2 h; 4) diluting (neutralizing), to be specific, before the caramelization reaction is finished, adding an alkaline solution to the reaction system slowly to adjust the pH value of the system to be close to the isoelectric point of the caramel pigment, and mixing slowly and continuously until complete reaction is finished; 5) obtaining the product, to be specific, obtaining liquid caramel pigment without 4-methylimidazole after the reaction. The preparation method of the caramel pigment without 4-methylimidazole is economical, practical, safe and high in quality, industrial production is realized, and quality of the caramel pigment is controlled.

Owner:SHAANXI UNIV OF SCI & TECH

Powdery caramel pigment and manufacturing method thereof

InactiveCN101705007ASimple process routeEasy to operateNatural dyesFood preparationCooking & bakingManufacturing technology

The invention relates to a powdery caramel pigment and a manufacturing method thereof, belonging to the technical field of natural pigment manufacture. The powdery caramel pigment is manufactured by using barley as raw material, soaking and germinating the barley under certain conditions, and then conducting heat preservation, baking, cooling and crushing. The method does not need the processes of crushing the raw material, adding enzyme for liquefaction, saccharifying or acidolysis, and does not add amino-compound additionally. The powdery caramel pigment uses reducing sugar and free amino in malt to conduct Maillard reaction and using little molecular saccharides to conduct caramelization under a high temperature so as to produce present-color materials and fragrant substances. The powdery caramel pigment has the advantages of simple technique route, convenient operation, high edible safety of products and the like. The solid product is easily packaged, stored and transported.

Owner:YANCHENG INST OF TECH

A process of preparing a liquid flavouring by utilization of a clam enzymolysis product

ActiveCN104824595AIncrease umamiImprove stabilityFood preparationMonosodium glutamateSodium cyclamate

The invention relates to a process of preparing a liquid flavouring by utilization of a clam enzymolysis product. The process includes a step of temporarily culturing fresh and live clams to completely remove sand from the clams, and heating with steams until shells of the clams are open; a step of taking clam flesh, adding water, mincing, adding aquatic product protease, performing enzymolysis, adding flavourzyme, performing enzymolysis, and adding yeast powder to remove fishy smell; a step of subjecting the enzymolysis liquid the fishy smell of which is removed to enzyme deactivation, centrifuging to obtain liquid supernatant, and keeping the liquid supernatant for further use; a step of subjecting white sugar to caramelization at a high temperature, adding the enzymolysis liquid, modified starch, protein hydrolysate, salt, soy sauce and water, boiling and then stewing; a step of adding xanthan gum and stewing; and a step of adding monosodium glutamate, yeast extract, I+G, sodium cyclamate, citric acid and potassium sorbate after heating is stopped, fully mixing, and bottling when the mixture is still hot to obtain the liquid flavouring. The process utilizes the rich clam resource to develop the novel flavouring with high nutrition value and good flavour for the flavouring market, promotes comprehensive utilization of the clam resource, meets demands of the market, and is simple in operation and low in production cost. Products of the process have high economic value.

Owner:辽宁邦盈商贸电子商务有限公司 +1

Burnt reaction type milk essence and preparation method thereof

The invention discloses burnt reaction type milk essence and a preparation method of the burnt reaction type milk essence. The burnt reaction type milk essence is acquired by the following materials in parts by weight through a caramelization reaction and a Maillard reaction: 30 parts of concentrated coconut, 15 parts of nestle condensed milk, 5 parts of New Zealand whole milk powder, 20 parts of maltose, 1 part of xylose, 0.6 part of aspartic acid, 0.2 part of glutamic acid, 0.6 part of proline and 37.9 parts of propylene glycol. The acquired essence is burnt-brown in colour, provided with pure and thick burnt toffee incense, and soft and full in burnt coconut toffee style. The acquired essence is provided with thick and unique burnt coconut toffee style, and can be applied in preparing a plurality of types of burnt milk essences.

Owner:TIANNING FLAVOR JIANGSU

Caustic sulfite process caramel color production technology

The invention discloses a caustic sulfite process caramel color production technology. Carbohydrates are taken as raw materials, sulfite and acid are added in batches under the pressurization condition, or sulfite and alkaline generate a caramelization reaction to prepare a caramel color. According to the technology, the method that the catalysts (sulfite and acid, or sulfite and alkaline) are added in batches under the pressurization condition is adopted for the first time in caramel industry, therefore, the dosage of the catalysts is decreased, the inhibition effect of too much sulfite on browning is overcome, the oxidation reaction degree is effectively controlled, excessive catalysis of the product is prevented, and the product quality is improved.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Extraction method for improving oil yield of tea seed

The invention relates to an extraction method for improving the oil yield of tea seeds. The tea seeds are subjected to the treatment of screening, winnowing, impurity removal and shelling; and the material is dried at a temperature between 70 and 75 DEG C so that the water content of the material reaches between 3 and 4 percent; and 5 percent of bran coat is added into the material and is extracted. The method can overcome the disadvantages that tea seeds are vulnerable to adhesion and agglomeration, so as to form hard lumps and produce caramelization due to high content of tea saponine, and can increase oil yield by 3 to 4 percentage points.

Owner:浙江泰谷农业科技有限公司

Floral coffee and production method thereof

The invention relates to floral coffee and a production method thereof. The production method of the floral coffee comprises the steps of firstly selecting beans; then baking the beans; cooling to a normal temperature; nourishing the beans; grinding coffee beans into powder; baking flower petals independently; drying the baked flower petals to a caramelization state; cooling; grinding into powder; and mixing the flower petal powder with the coffee bean powder. The floral coffee overcomes the disadvantages that conventional coffee is too bitter, has a single function and is not suitable for habits of Chinese consumers.

Owner:陈慈

Real fruit drink concentrate and process of preparing the same

InactiveUS20160235107A1Improve fluencyExtended shelf lifeFruits/vegetable preservation by heatingFood preparationWater bathsFlavor

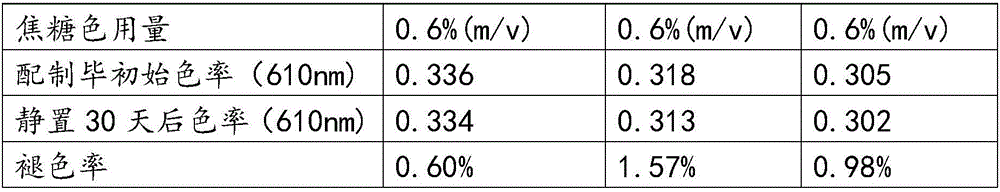

The embodiments herein relate to a composition of real fruit drink concentrate, a method of making the real fruit drink concentrate and a method of making hot as well as cold real fruit drinks. The real fruit drink concentrate comprises a plurality of fruits, spices, herbs, flowers, lemon juice, sugar and water. The method of preparing a real fruit drink concentrate comprises preparing a mixture. The mixture is prepared by mixing fresh or frozen fruit pieces, spices, sugar, lemon juice and a quantity sufficient water in a container. The mixture is cooked in a pre-heated oven at 420° F. till the caramelization of fruits and sugar occurs. A boiling water is added to the mixture and cooked again. The total cooking time is 45 minutes and the boiling water is added after atleast ⅔rd of the total cooking time. The mixture is canned. The canning is done by using a boiling water bath for 5-10 minutes. The mixture is stored in sealed jars in a cool dark place.

Owner:HRDINOVA ERIKA +1

Method for reducing tar of cigarette products

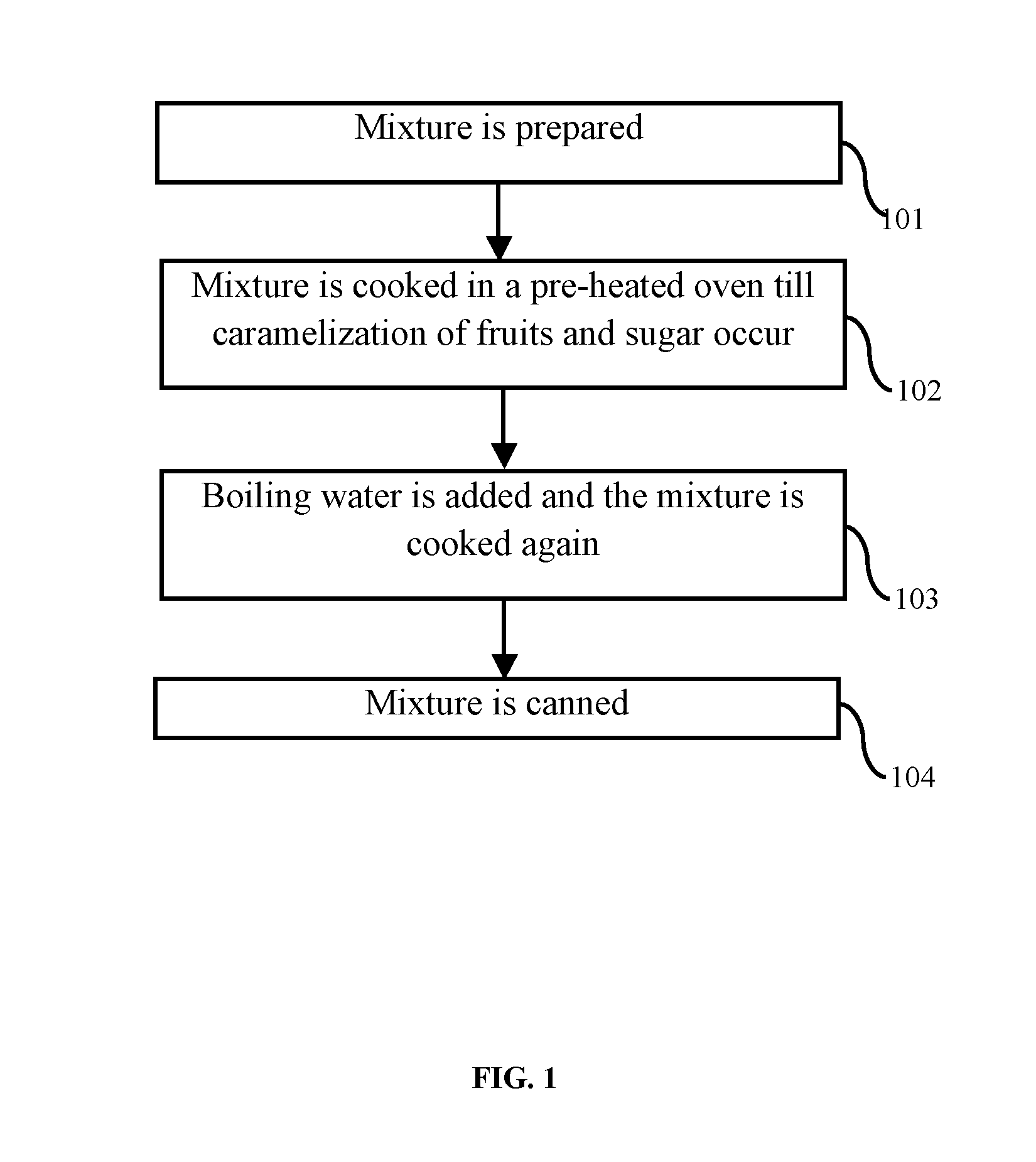

InactiveCN103202527ALower nicotine levelsIncrease potassium to chlorine ratioTobacco preparationToxicologyNicotine

The invention discloses a method for reducing tar of cigarette products. The method includes the steps: firstly, slicing flue-cured tobacco laminas, absorbing moisture, regaining the moisture, loosening the flue-cured tobacco laminas, regaining the moisture, blowing atomized water into the flue-cured tobacco laminas, baking the flue-cured tobacco laminas and blowing atomized water into the flue-cured tobacco laminas again; secondly, shredding the flue-cured tobacco laminas, and then drying, perfuming and rolling shreds. After tobacco leaves are repeatedly baked and regain the moisture, substances in blades and liquid can be promoted in browning reaction and sugar caramelization while unpleasant odor of the tobacco leaves is removed, so that flavoring substances are generated, inherent fragrance of the tobacco leaves diffuses, the content of chemical components of flue-cured tobaccos is changed, the nicotine content of the flue-cured tobaccos is reduced, the potassium-chlorine ratio of the flue-cured tobaccos is increased, combustibility of the flue-cured tobaccos is improved, and the tar release amount of the flue-cured tobaccos can be reduced. Compared with an existing process, the method has the advantage that indexes such as reducing sugar, nicotine, chlorine, potassium and total nitrogen are consistently changed. The combustibility of the tobacco leaves is enhanced, so that the tar release amount of cigarettes can be controlled. The tar yield of the cigarettes is reduced, the nicotine and carbon monoxide are reduced to varying degrees, and harm of the cigarettes to a human body can be remarkably decreased.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Application of L-arabinose to coloring agent of fried minced fillet product

ActiveCN103948016AGood colorUniform colorFood ingredient functionsFood preparationBiotechnologyGolden syrup

The invention relates to the technical field of a food coloring agent, and in particular relates to an application of L-arabinose to a coloring agent of a fried minced fillet product. The application comprises the following steps: feeding the coloring agent containing the L-arabinose into oil with the weight being equal to that of the coloring agent; preheating the mixture and frying into the caramel color; feeding 5-10 times of water to prepare golden syrup; and putting the minced fillet product into the syrup to enable the surface of the product is evenly stained with the syrup, and frying. A caramelization reaction is carried out, and the colored syrup exists on the coating of the surface of the minced fillet product, so that the minced fillet product has attractive golden yellow color after being fried; the coloring agent not only is good in coloring effect and even in coloring, but also has small possibility of generating carcinogenic substances such as acrylamide due to low temperature, short time and rapid coloring in the frying process.

Owner:SHENGQUAN HEALTANG CO LTD

High temperature countercurrent solvent extraction of capsicum solids

InactiveUS6074687AImproved color stabilitySolid waste disposalFood shapingAntioxidantFine particulate

Owner:KALAMAZOO HLDG INC

Yacon fruit flake and whole powder multielement joint processing production system

PendingCN109832585AWith cavitation effectWith mechanical shear effectFruits/vegetable preservation by irradiation/electric treatmentFood shapingFreeze-dryingCyclonic separation

The invention belongs to the technical field of agricultural product processing devices, relates to a pulverizing device, and in particular relates to a yacon fruit flake and whole powder multielementjoint processing production system. A pretreatment unit, a peeling and slicing unit, an anti-browning unit, an anti-caking treatment unit and a high-speed nitrogen flow pulverizing unit are mounted sequentially from the upstream side to the downstream side of the working procedure, wherein the pretreatment unit comprises an airtight decompression tank; an ultrasonic generation device and a magnetic field generation device are arranged in the airtight decompression tank; the peeling unit comprises a centrifugal peeling device and a slicing device; the centrifugal peeling device and the slicingdevice are sequentially mounted; the anti-browning unit comprises an anti-browning induction treatment device, an anti-metal ion induction treatment device and an anti-caramelization browning treatment device; the anti-caking treatment unit comprises a microwave drying device, an anti-caking polarity remover spray device and a freeze drying device; the high-speed nitrogen flow pulverizing unit comprises a nitrogen generating device, a nitrogen tank, a nitrogen pulverizer and a cyclone separator; and the cyclone separator is provided with a multi-stage discharge port.

Owner:SDIC ZHONGLU FRUIT JUICE

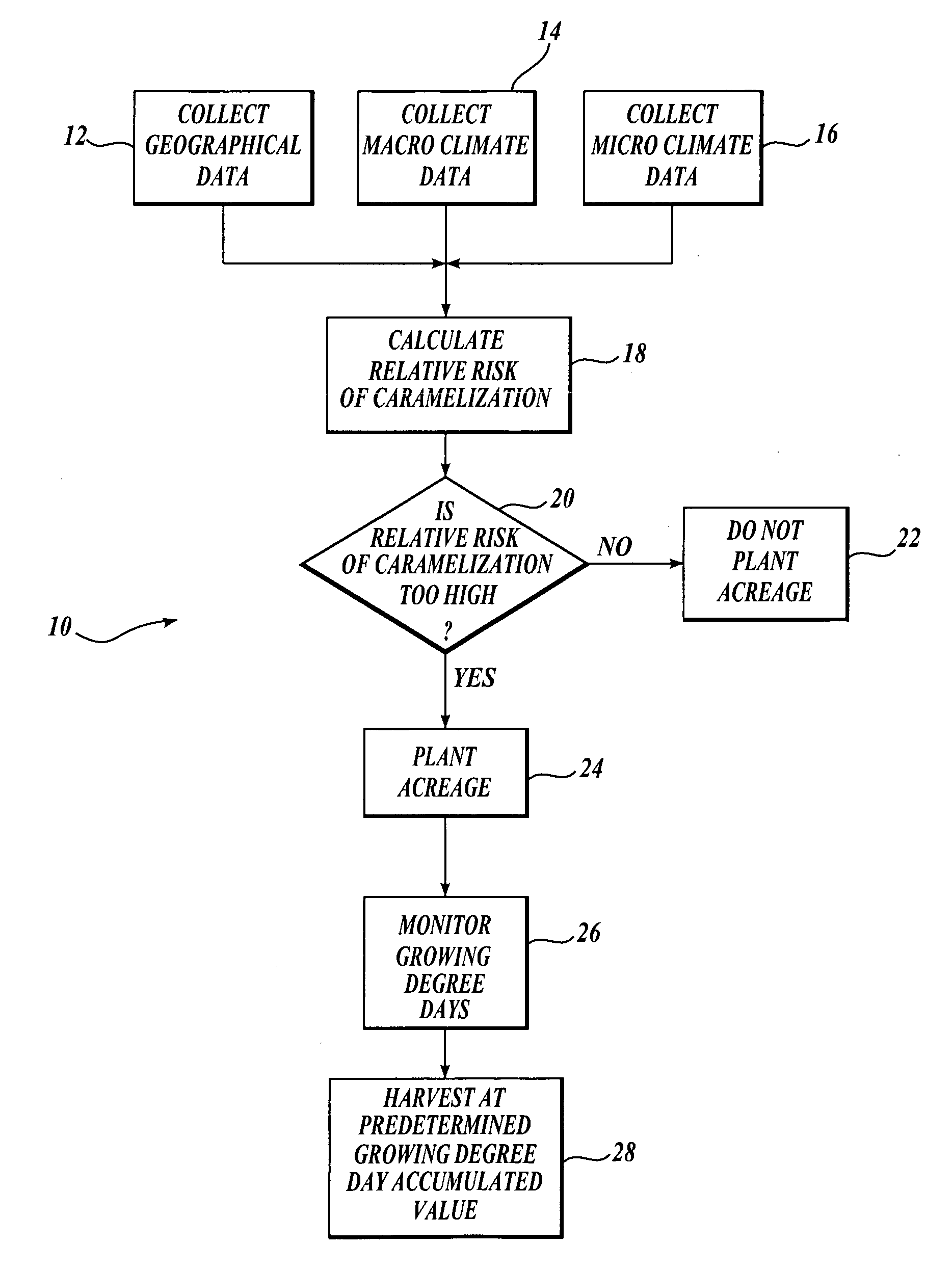

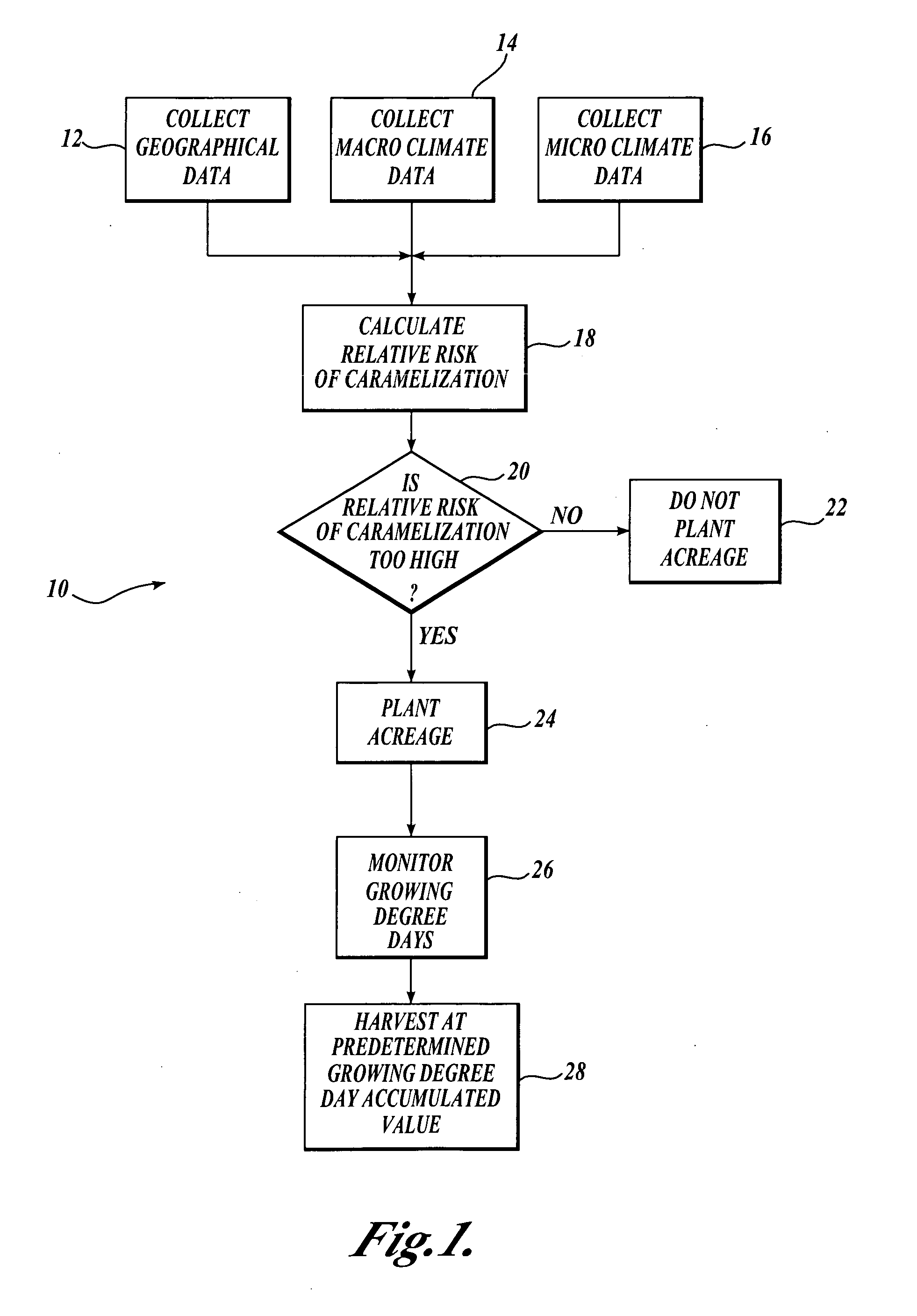

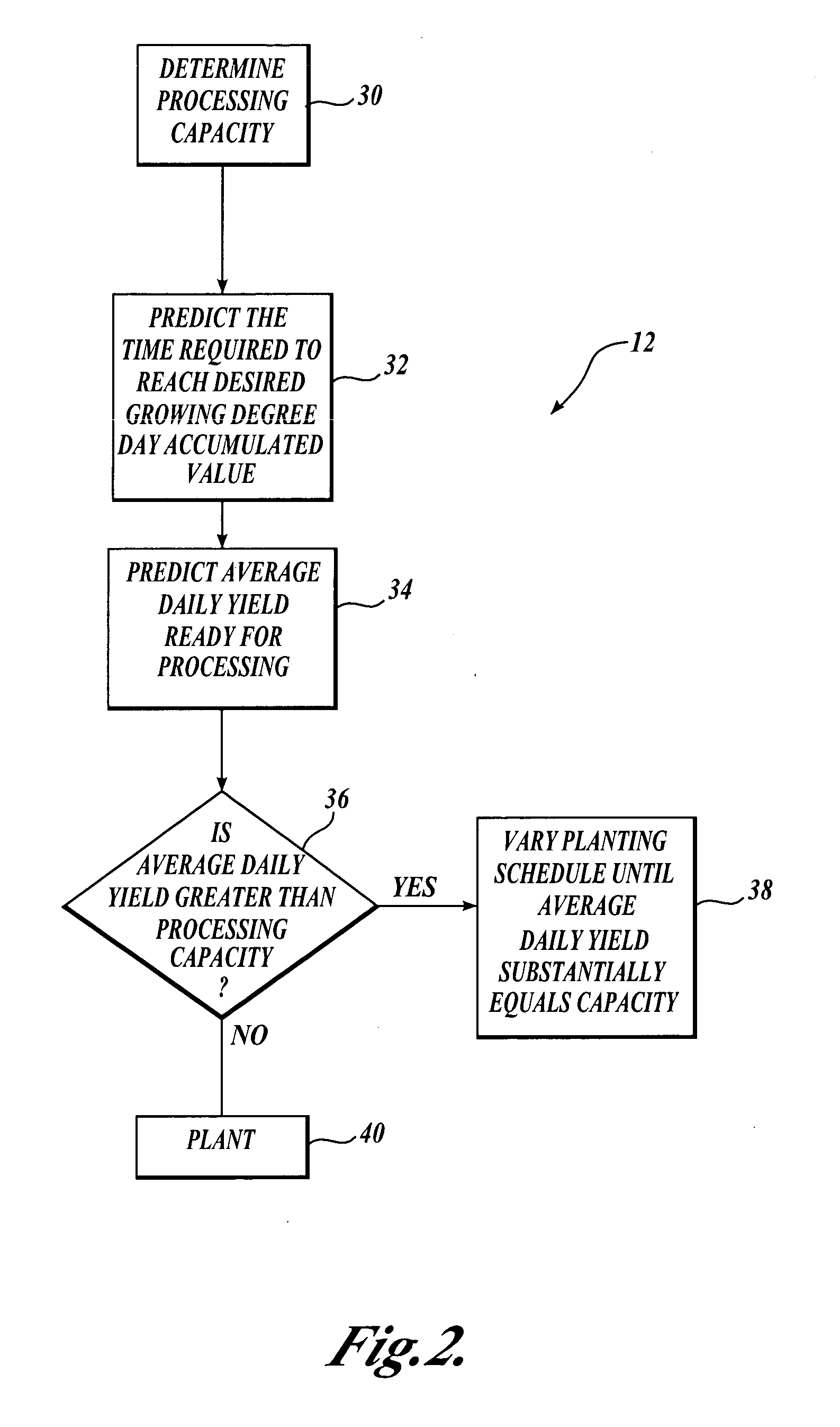

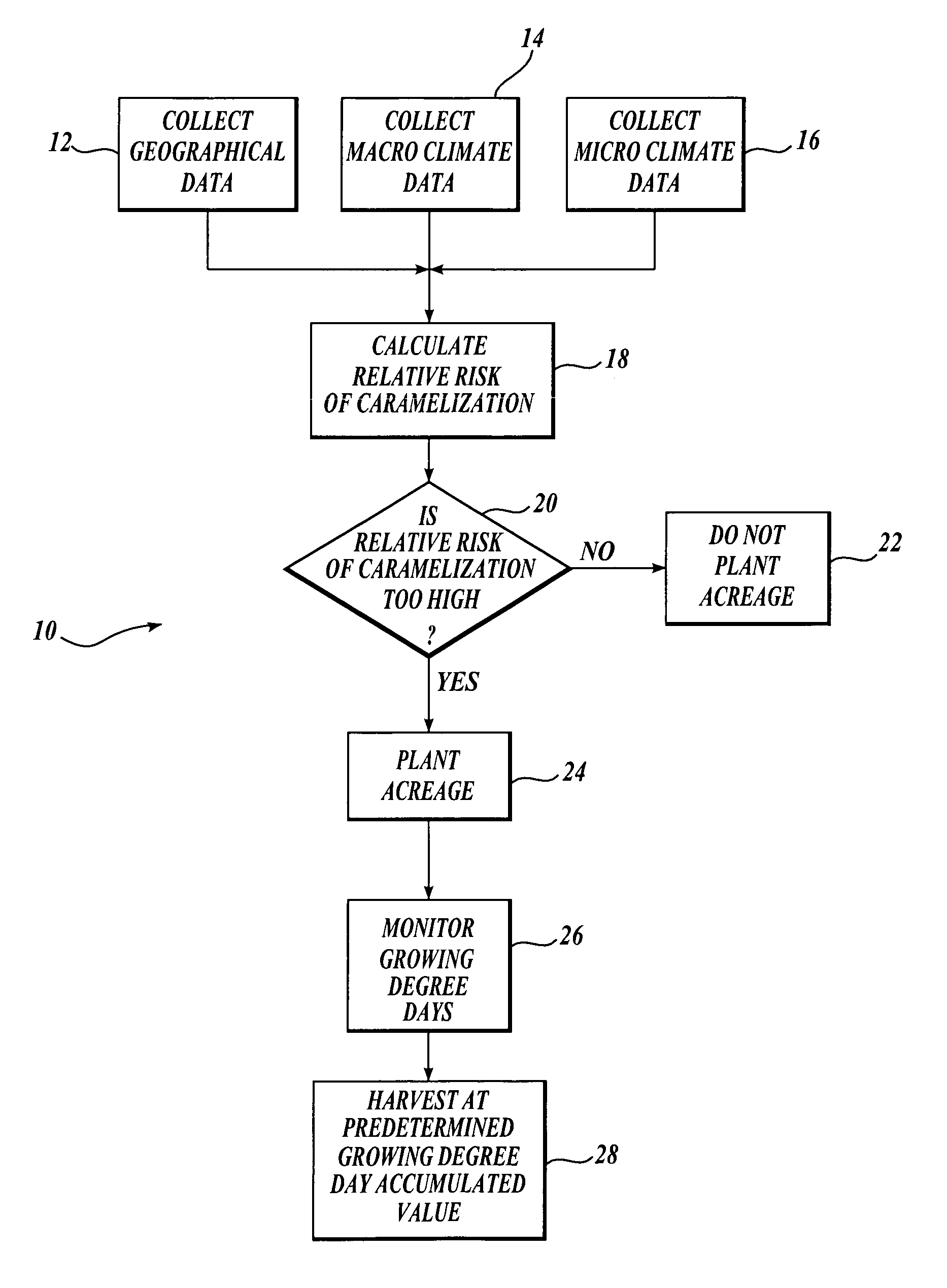

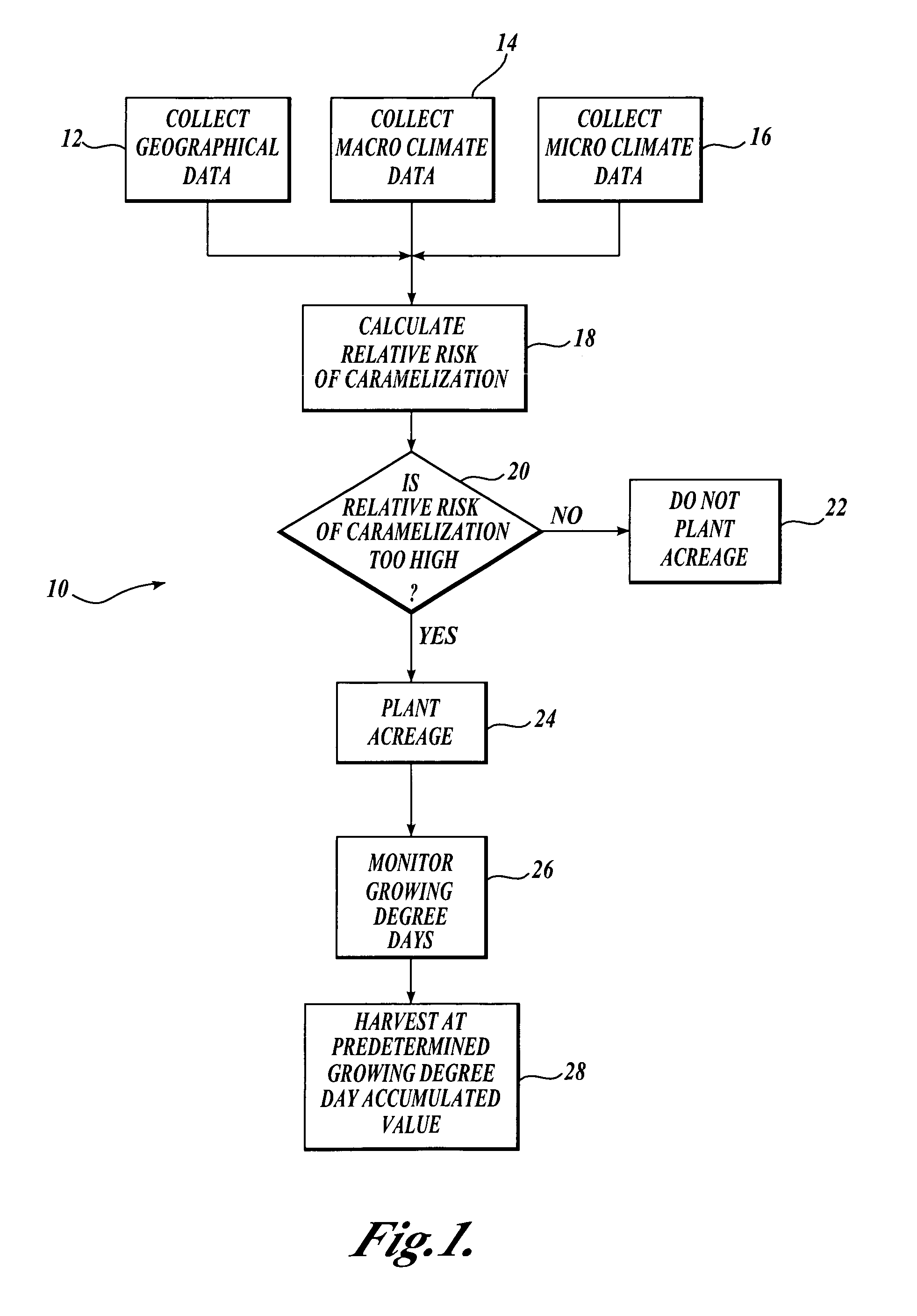

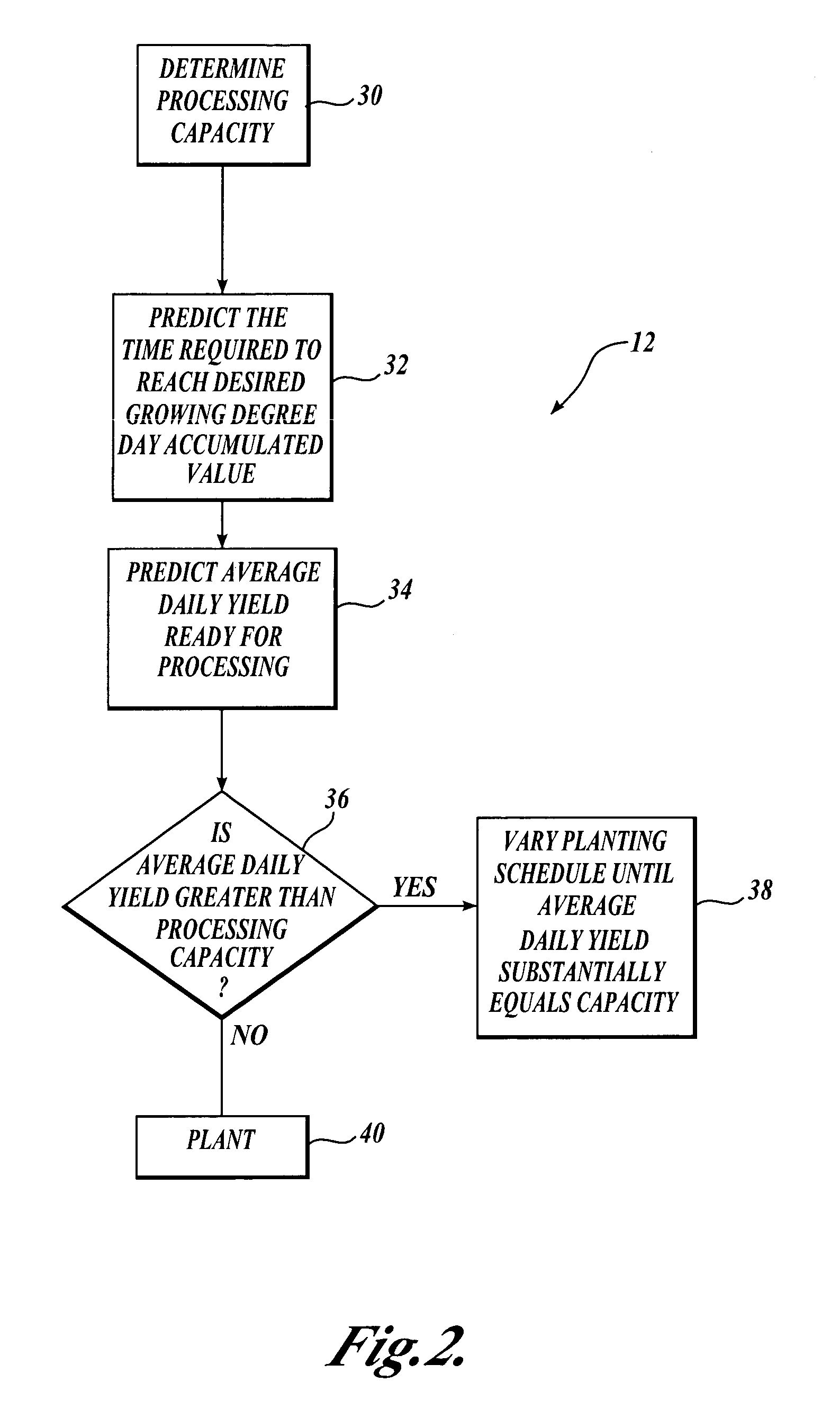

Agronomic method for commercial production of the green Cicer bean

An agronomic system is disclosed for the commercial production of green Cicer beans wherein a relative risk of caramelization is determined based on geographical data, macro climate data, and micro climate data for a given locale. Relative risk of caramelization helps select acreage to be planted. Additionally, an agronomic system and method for cultivation and commercial production of the green Cicer bean is described herein for preferred row spacing and variety selections that are usable for the commercial production of the green Cicer bean. Prior to the present invention there were no agronomic methods or systems adapted for commercial production of the green Cicer bean. The agronomic systems and methods disclosed herein also help to adjust planting times based on growing degree day calculations for given parcels wherein harvesting of the green Cicer bean is in rhythm with processing plant capacity.

Owner:TD MOSER FARMS L L C

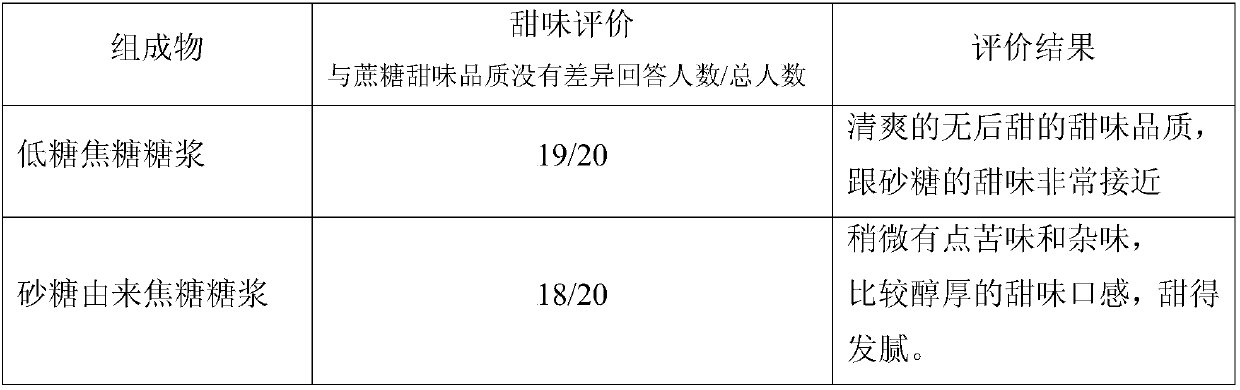

Low-sugar caramel flavor composition containing mogroside as well as preparation method and application

InactiveCN108618083AImprove sweetness qualityIncrease the sense of thicknessBakery productsDietary fiberAlcohol sugars

The application relates to a low-sugar caramel flavor composition containing mogroside as well as a preparation method and application. The caramel flavor composition contains a fructus momordicae extract which contains the mogrosides and one or more of water-soluble dietary fibers and sugar alcohol, wherein the weight proportion of the fructus momordicae extract in the composition is 0.1 to 95 percent and the composition is a caramelized composition. The caramel flavor composition disclosed by the invention has the advantages of good sweetness quality and low sugar properties and can be usedas a sweetener, a flavoring agent or a flavor enhancer in foods, medicines, health care products or cosmetics.

Owner:嘉兴纳诺生物工程有限公司

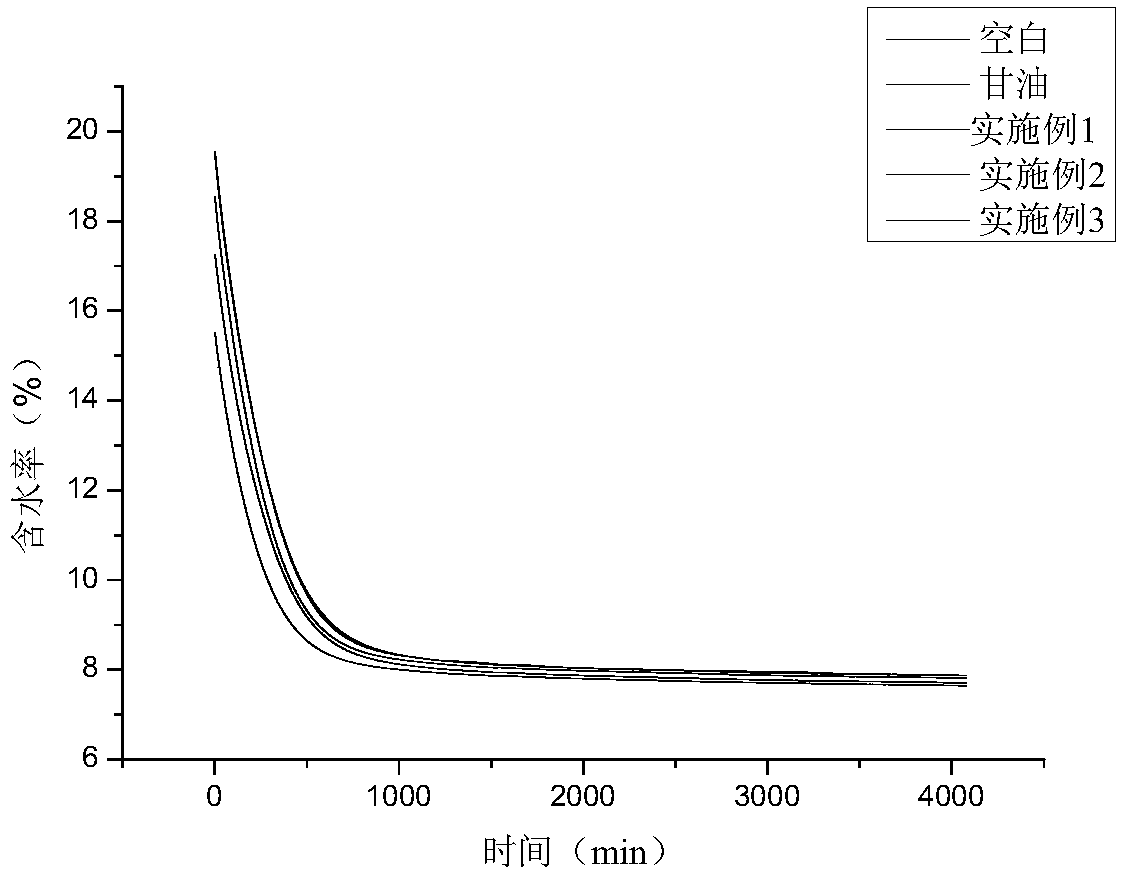

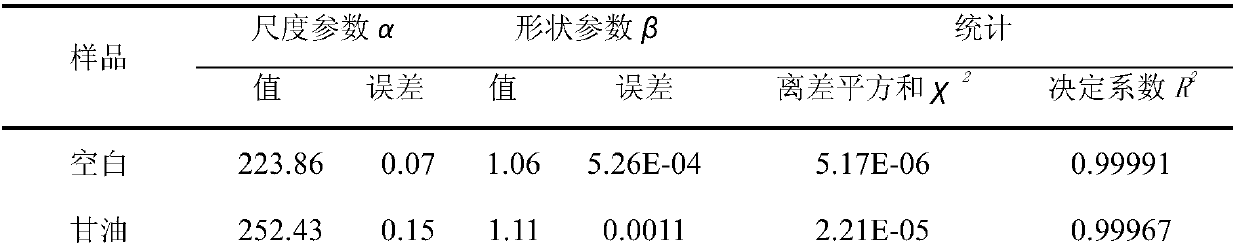

Composite additive for improving physical moisture retention property of reconstituted tobacco

ActiveCN108013498ASimple structureNo bad breathTobacco preparationTobacco treatmentPolyethylene glycolBalance water

The invention discloses a composite additive for improving the physical moisture retention property of reconstituted tobacco. The composite additive comprises, by mass, 5-10% of polyethylene glycol, 2-4% of propylene glycol, 1-3% of tobacco extracts, 1-3% of caramelization reaction product, 1-3% of maillard product and the balance water. The composite additive is a water-soluble component, polyhydric alcohols, such as polyethylene glycol and propylene glycol, in the composite additive and moisture in the reconstituted tobacco can form a stable hydrogen bond, the molecular potential energy is reduced, and the stability of the moisture in the reconstituted tobacco is improved. The caramelization reaction product can be complexed with the reconstituted tobacco to form a stable structure by utilizing the charge effect of the caramelization reaction product. The composite additive is good in uniformity and stability, reconstituted tobacco coating liquid can be prevented from going bad, badsmell cannot be generated in the burning process, the defect that the moisture of the reconstituted tobacco is greatly influenced by the humidity of the outside environment is overcome, and the physical moisture retention property of the reconstituted tobacco is improved.

Owner:CHINA TOBACCO GUANGXI IND

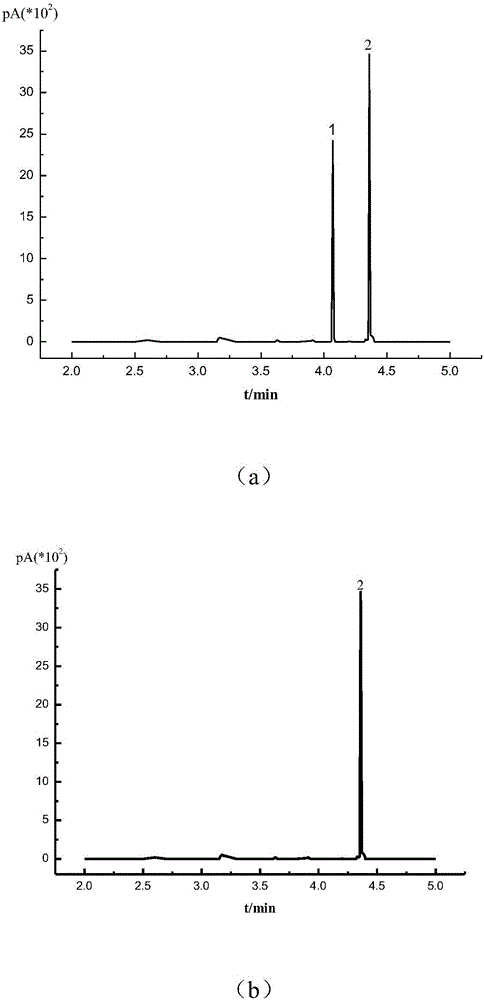

Preparation method of caramel pigment

InactiveCN106590024AOvercome the disadvantages of low color rate and high cost of useLow red pigment indexNatural dyesFood ingredient functionsFood additiveSalt resistance

The invention provides a preparation method of caramel pigment, and belongs to the field of foodstuff additive technology. The method comprises the following steps: (1) a caramelization reaction primary phase, white sugar is added into a reactor, heating is carried out with continuous stirring to 190-200 DEG C, insulation is carried out and condensate liquid is collected at the same time, and till the temperature of the reaction system reaches 175-185 DEG C; (2) alkali is added for neutralizing, formation of caramel pigment is promoted, a Na2CO3 solution is added dropwisely into the reaction system with stirring, the temperature of the reaction system is reduced to 110-120 DEG C, and the reaction is carried out for 3-4 hours at the temperature with continuous stirring; 3) water is added for dilution, in order to prepare the product, purified water is added dropwisely into the reaction system with stirring, after uniform mixing, heating is continuous, the temperature of the system is 110-115 DEG C, a reaction is carried out with stirring for 0.5-1 hour, and the caramel pigment whose color yield percentage is 30000 or above and haematochrome index is 6.2 is obtained. The method has the advantages of simple operation, low reaction temperature, saved energy consumption, the pH value of the prepared caramel pigment is 5.1-5.5, and salt resistance and acid resistance accord with national standard of the caramel pigment.

Owner:SHAANXI UNIV OF SCI & TECH

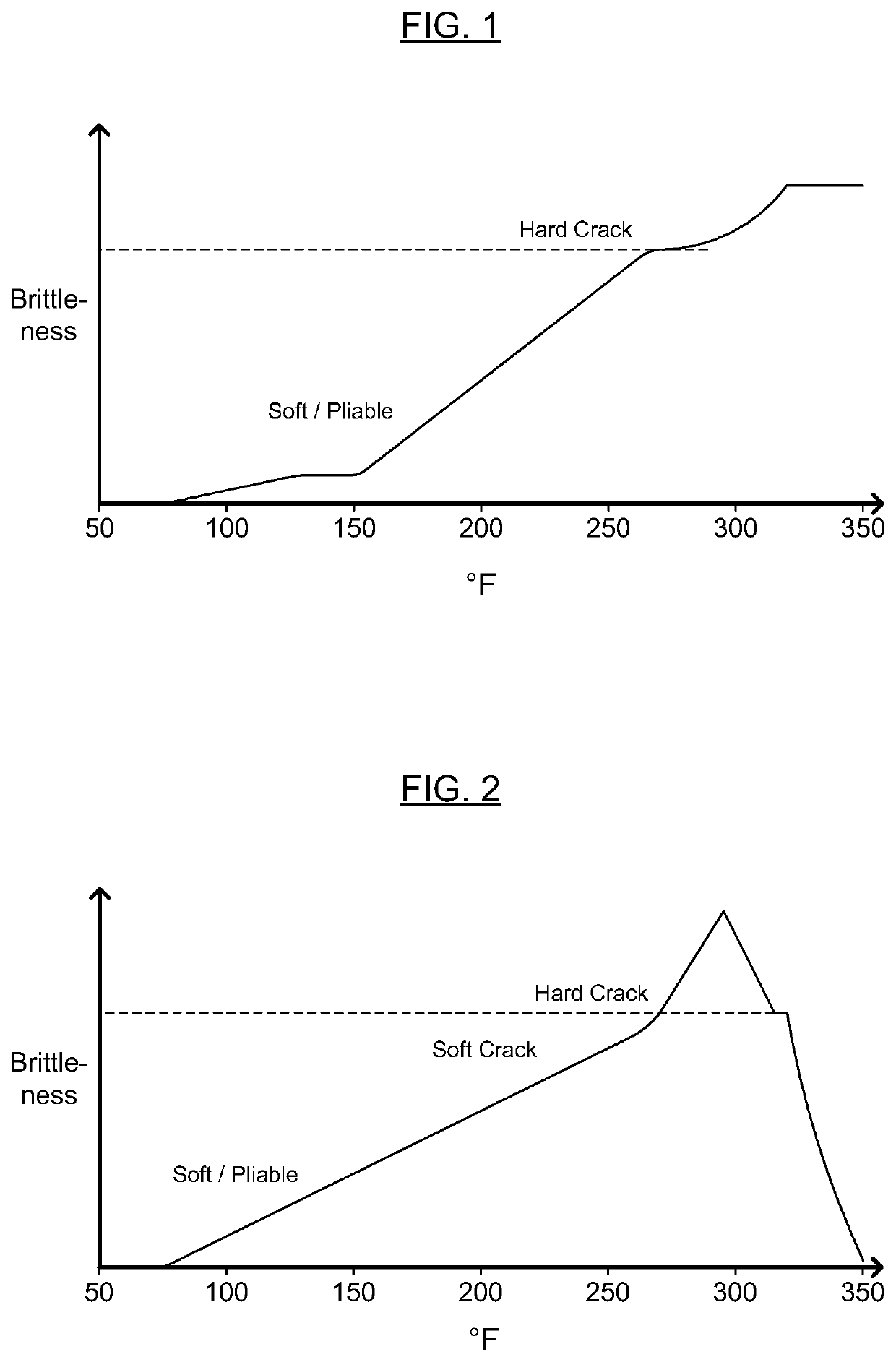

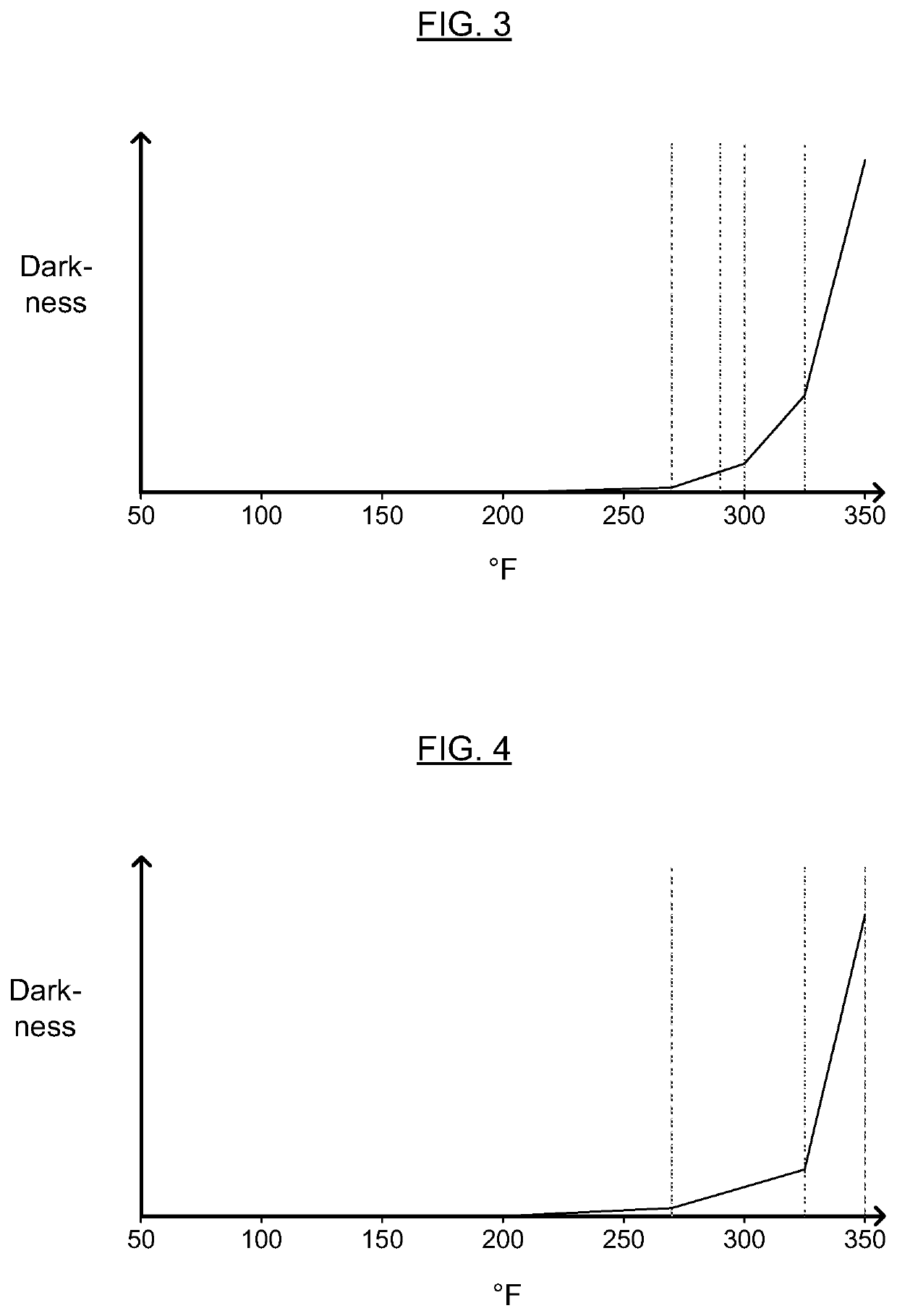

Food Composition and Methods of Making and Using the Same

A method for preparing a caramelized product, a kit for a caramelizable composition, a food product comprising a caramelized composition, and a caramelized sauce are disclosed. The caramelized product may be a caramel, a brittle, or a syrup. The method includes mixing a sugar alcohol and / or a non-metabolizable sugar and a dietary fiber to form a mixture, and heating the mixture at a temperature and for a length of time sufficient to caramelize the mixture. The kit includes a container and a sugar alcohol / non-metabolizable sugar and a dietary fiber in the container. The sugar alcohol / non-metabolizable sugar and the dietary fiber are present in a ratio by weight or by volume such that a mixture thereof, when heated to a temperature of from 270° F. to 350° F. for a sufficient length of time, is caramelized.

Owner:WAROUJ VAROUJ KACHICHIAN INC

Caramel aroma spice as well as preparation method and application method thereof

InactiveCN111254014AOvercome the disadvantage of lack of aromaObvious burnt sweetnessTobacco preparationEssential-oils/perfumesBiotechnologyAmmonia-process caramel

The invention provides a caramel aroma spice, a preparation method and an application method. Sugar and water are subjected to an ammonia-free caramelization reaction under a high temperature condition (140-200 DEG C), and a caramel sweet flavor spice is prepared. The caramel spice can improve the caramel aroma of tobaccos or tobacco products when applied to cigarettes, and has the effects of enriching tobacco aroma, coordinating smoke and reducing smoke irritation. The caramel spice can also be used for inapplicable tobacco leaves, cut tobacco stems and expanded cut tobaccos, can improve thearoma quality of tobacco products, and can also be used for coloring as a natural pigment. Besides, by changing the solvent of the caramelization reaction system, a caramel spice suitable for a glycerol-propylene glycol system or a popping bead oil system can be prepared, and the caramel spice can be applied to electronic cigarettes, heating-not-burn cigarettes and popping beads for cigarettes, and can endow novel tobacco products with natural and harmonious tobacco aroma and improve the tobacco characteristics of the products.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Anti-browning fruit-vegetable preservative and preparation method thereof

InactiveCN108029750ASignificant effectInhibition formationFruit and vegetables preservationAlcoholic food ingredientsSucroseGrape seed

The invention relates to the field of food preservation, and discloses an anti-browning fruit-vegetable preservative and a preparation method thereof. The preservative is prepared from the following raw materials of a composite chitosan solution and Chinese herbal medicine extract, wherein the mass percentage ratio of the composite chitosan solution to the Chinese herbal medicine extract is (6-22%):(78-94%). Composite chitosan comprises chitosan, water-soluble oligochitosan and chitosan hydrochlorides. The Chinese herbal extract comprises rosemaries, wheat bran, grape seeds, ginkgo fruits, cysteine, sucrose ester, ascorbic acid, citric acid, glycol and glycerin. With reasonable organic compatibility, the preservative can perform effective protection from browning reaction, generated brownpigment or melanin, Maillard reaction and caramelization effect caused by enzymatic browning and non-enzymatic browning, and plays the efficacy of fruit-vegetable browning resistance and fresh keeping.

Owner:丹东市红升包装材料有限公司

Agronomic method for commercial production of the green Cicer bean

An agronomic system is disclosed for the commercial production of green Cicer beans wherein a relative risk of caramelization is determined based on geographical data, macro climate data, and micro climate data for a given locale. Relative risk of caramelization helps select acreage to be planted. Additionally, an agronomic system and method for cultivation and commercial production of the green Cicer bean is described herein for preferred row spacing and variety selections that are usable for the commercial production of the green Cicer bean. Prior to the present invention there were no agronomic methods or systems adapted for commercial production of the green Cicer bean. The agronomic systems and methods disclosed herein also help to adjust planting times based on growing degree day calculations for given parcels wherein harvesting of the green Cicer bean is in rhythm with processing plant capacity.

Owner:TD MOSER FARMS L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com