Common-process production technique of caramel color with color ratio of at least 30000EBC

A common method coke and production process technology, applied in the field of common method caramel color production technology, can solve the problems of difficult product color rate, slow caramelization reaction speed, and increased addition ratio, so as to reduce activation energy and facilitate reaction , the effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

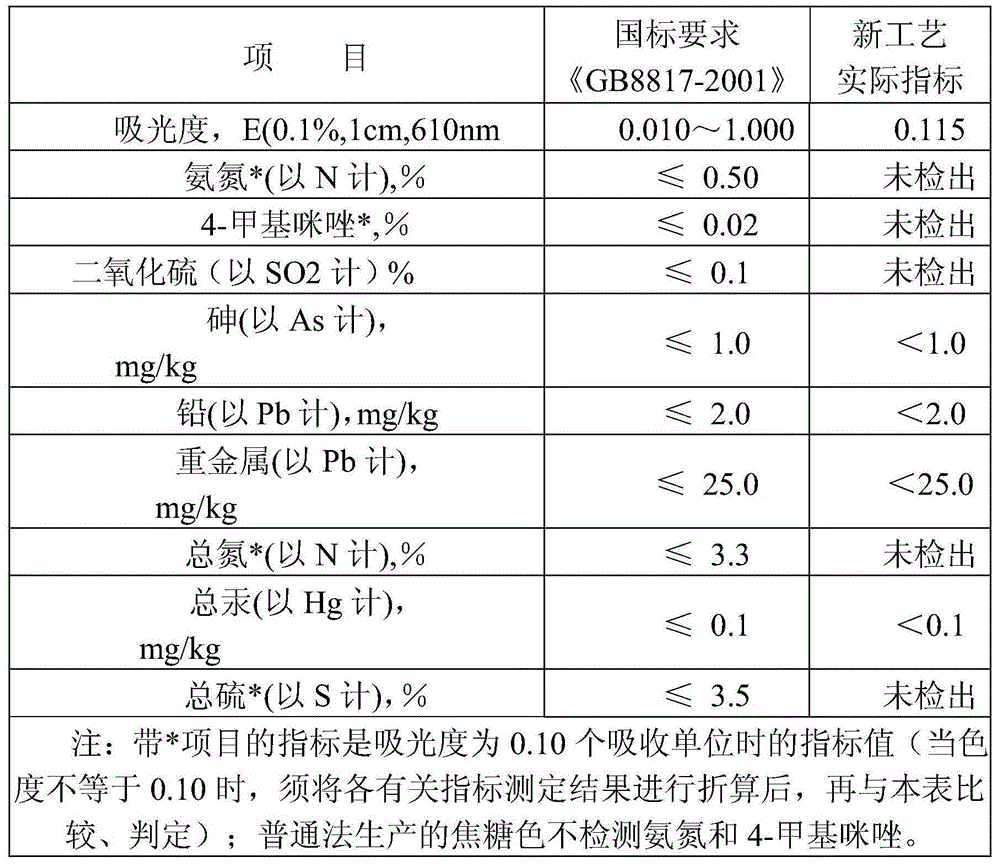

Embodiment 1

[0029] Production of 36Be, 30000EBC common method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are the measurement indicators of caramel color)

[0030] (1) Raw material metering concentration: 6000kg DE value 99%, the glucose syrup that dry basis is 71% is metered into the reaction tank, and the raw material dry basis is concentrated to 80% by raising the temperature in the reaction tank; DE value refers to reducing sugar (calculated by glucose ) accounted for the mass percentage of dry matter;

[0031] (2) Adjust the pH value: add the concentrated glucose syrup to sodium hydroxide to adjust the pH to 11.0;

[0032] (3) Add catalyst: Add 12.78kg (3‰ of glucose syrup dry basis) propyl gallate and 34.08kg (8‰ of glucose syrup dry basis) sodium polyphosphate to the raw material that has adjusted the pH value, and stir thoroughly mix;

[0033] (4) Pressurized reaction: pressurize the raw mate...

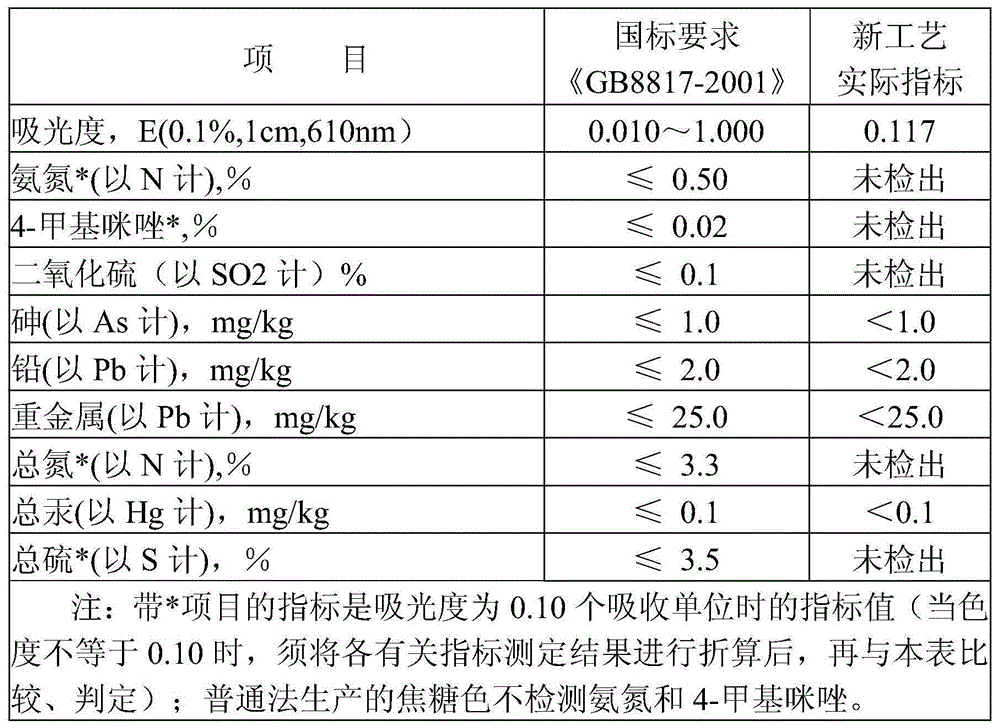

Embodiment 2

[0041] Production of 36Be, 30000EBC common method caramel color

[0042] (1) Raw material metering and concentration: 6000kg of glucose syrup with a DE value of 98% and a dry basis of 74% is metered into the reaction tank, and the temperature is raised in the reaction tank to concentrate the raw material dry basis to 84%;

[0043] (2) Adjusting the pH value: Adding the concentrated glucose syrup to sodium hydroxide and sodium bicarbonate to adjust the pH to 10.0;

[0044] (3) Catalyst addition: Add 4.44kg (1‰ of glucose syrup dry basis) propyl gallate and 22.20kg (5‰ of glucose syrup dry basis) sodium polyphosphate to the raw materials that have adjusted the pH value, and stir thoroughly mix;

[0045] (4) Pressurized reaction: pressurize the raw materials that have been added with the catalyst in the reaction tank, control the temperature at 135°C during the pressurization process, and the pressure in the tank at 0.4Mp, take samples every 30 minutes to detect the color rate, ...

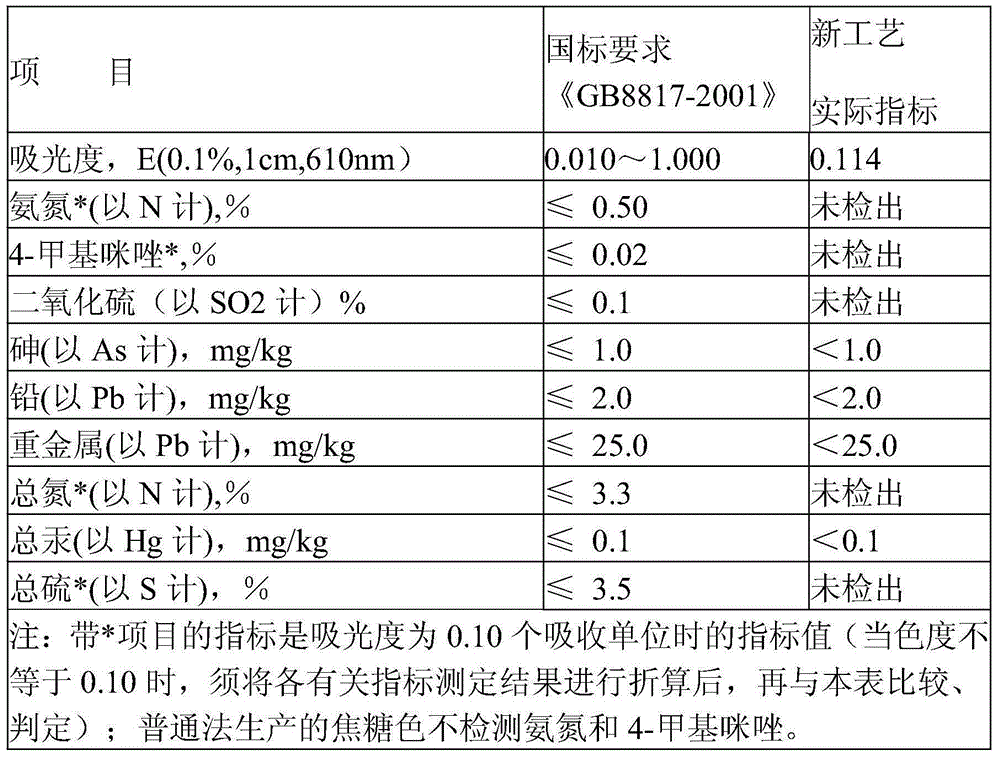

Embodiment 3

[0053] Production of 36Be, 30000EBC common method caramel color

[0054] (1) Raw material metering and concentration: 6000kg of glucose syrup with a DE value of 98% and a dry basis of 73% is metered into the reaction tank, and the temperature is raised in the reaction tank to concentrate the raw material dry basis to 83%;

[0055] (2) adjust the pH value: add the concentrated glucose syrup to sodium carbonate to adjust the pH to 7.0;

[0056] (3) Catalyst addition: Add 21.9kg (5‰ of glucose syrup dry basis) propyl gallate and 43.8kg (10‰ of glucose syrup dry basis) sodium polyphosphate to the raw materials that have adjusted the pH value, and stir thoroughly mix;

[0057] (4) Pressurized reaction: pressurize the raw materials that have been added with the catalyst in the reaction tank, control the temperature at 115°C during the pressurization process, and the pressure in the tank at 0.18Mp, take samples every 30 minutes to detect the color rate, when using a spectrophotomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com