Patents

Literature

224 results about "Color ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

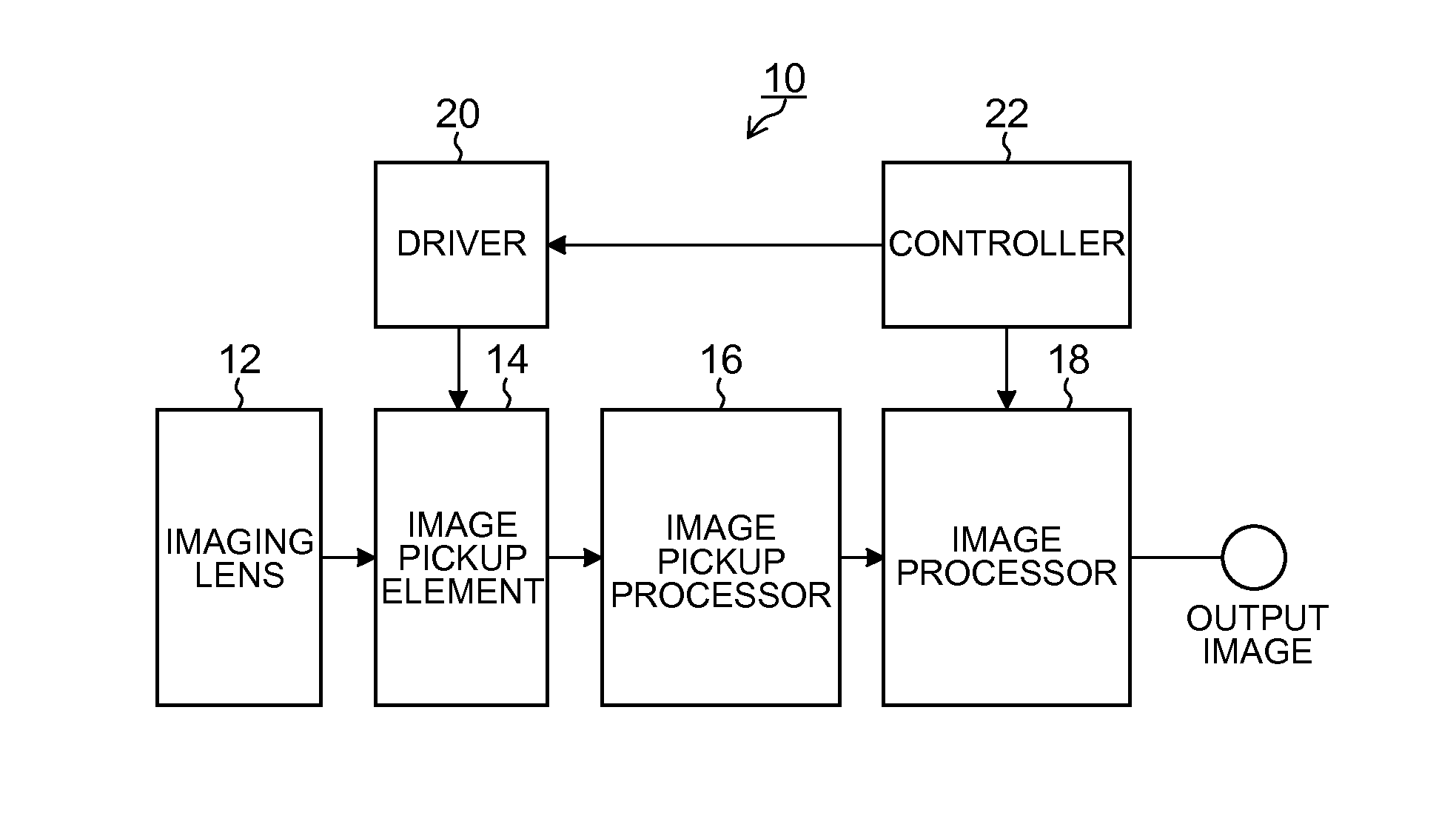

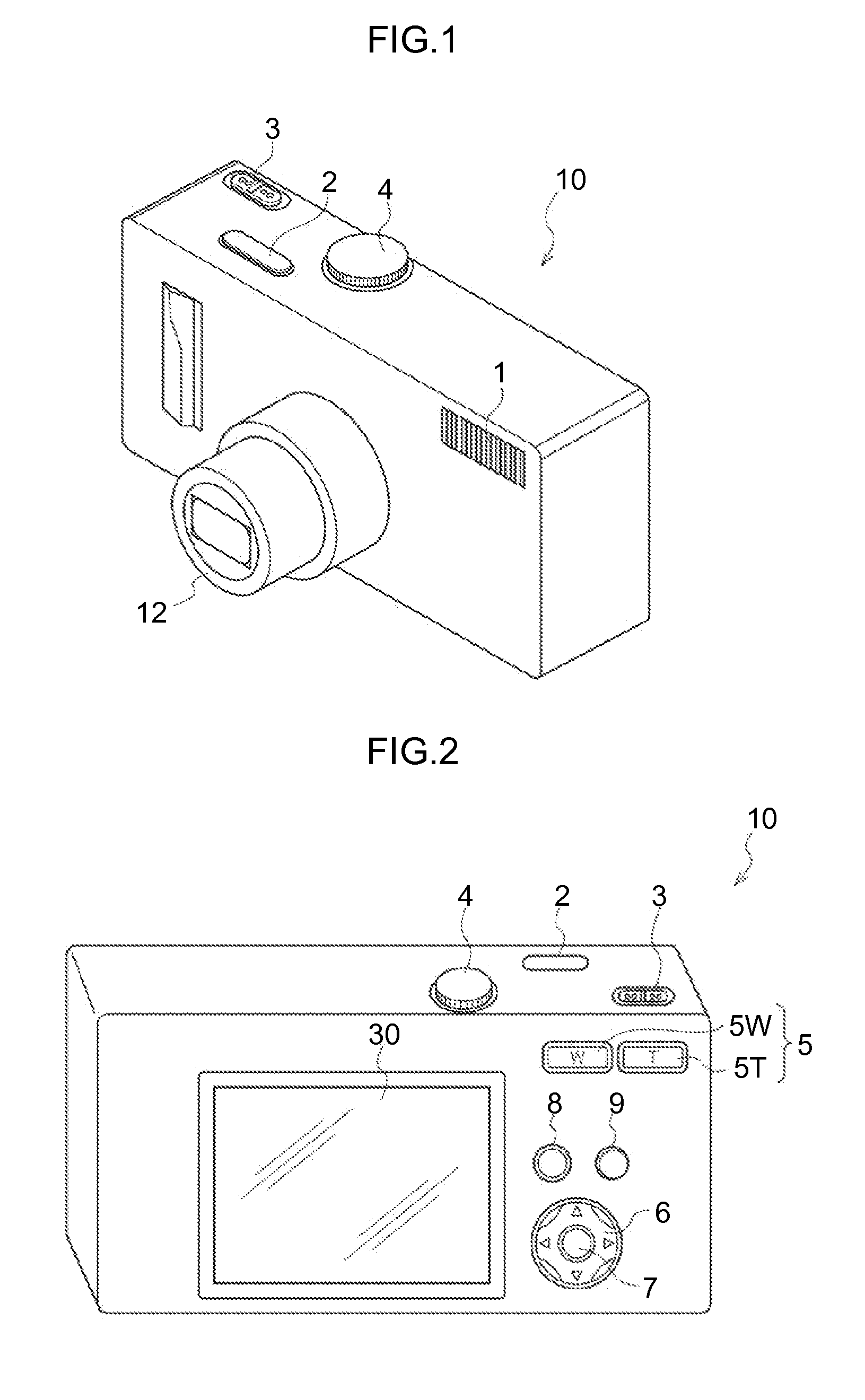

Color imaging apparatus

ActiveUS20120293695A1Accurate estimateSuppress generationTelevision system detailsTelevision system scanning detailsColor imageAverage filter

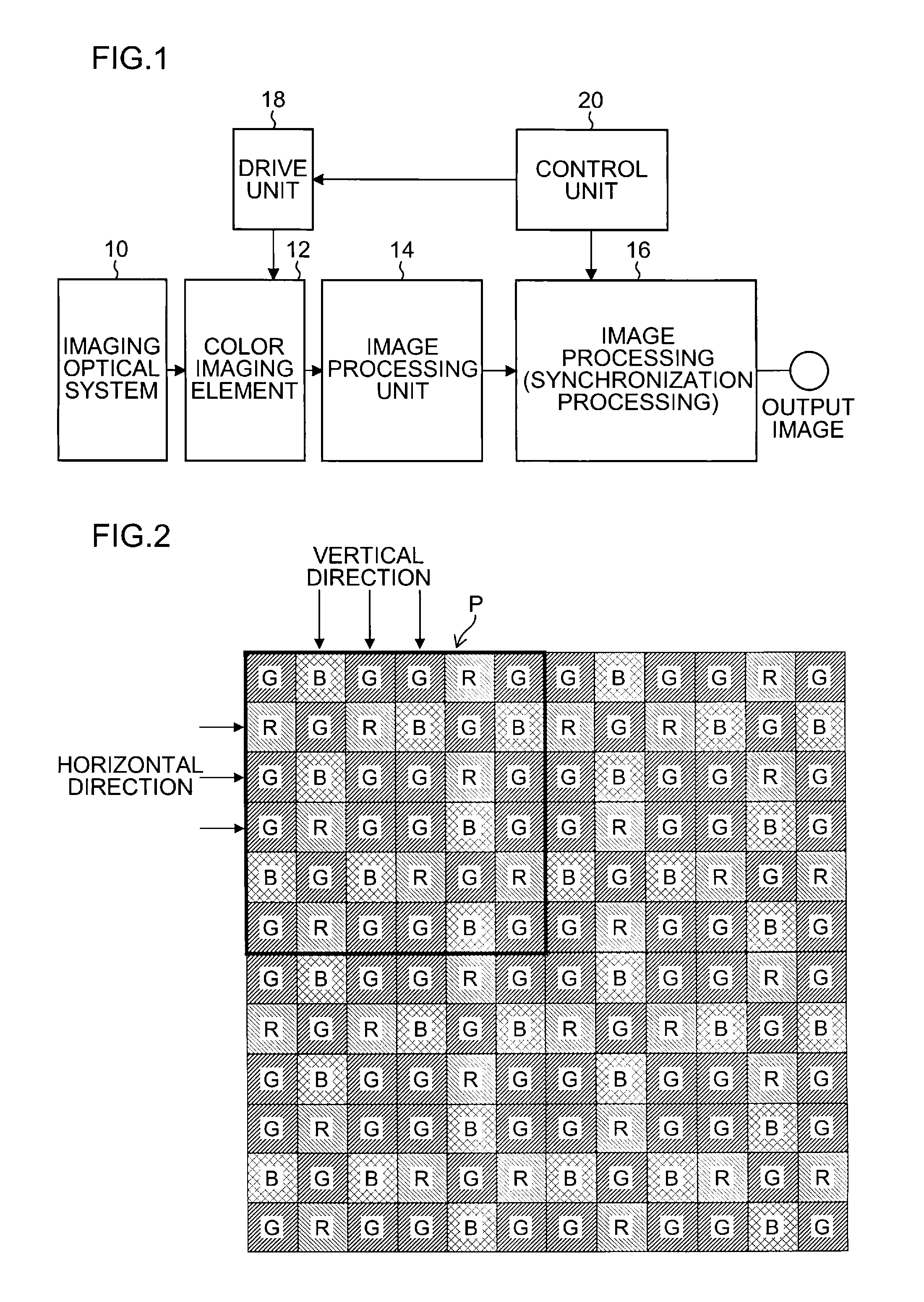

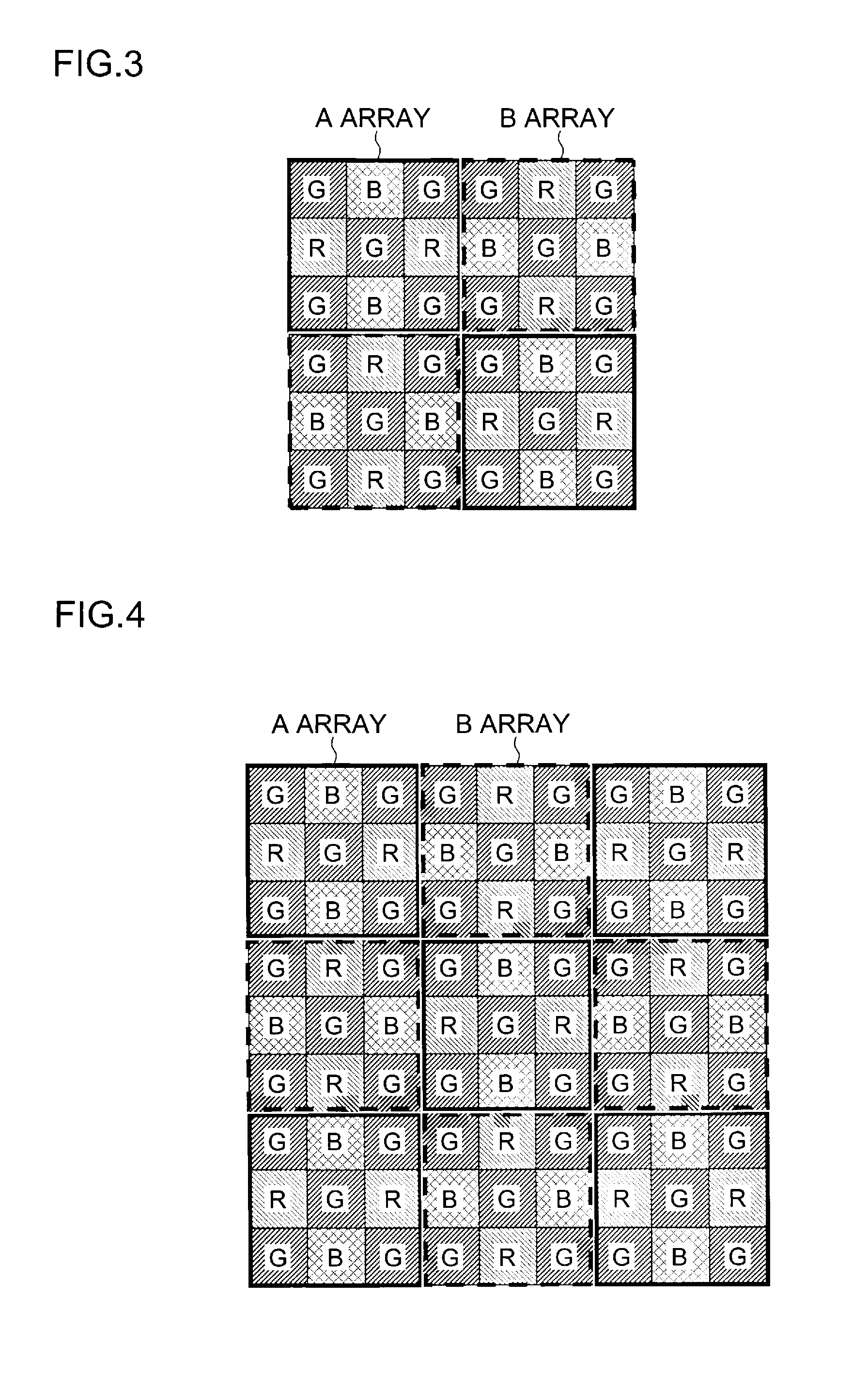

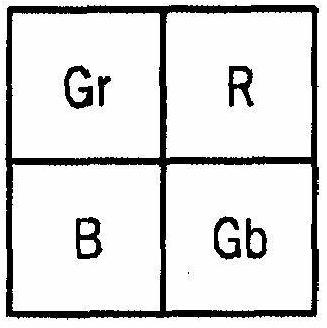

A color imaging apparatus comprising: a single-plate color imaging element including color filters arranged on pixels arranged in horizontal and vertical directions where all colors are arranged in each line in the directions; weighted average filters with filter coefficients set in a local area extracted from a mosaic image acquired from the color imaging element corresponding to the weighted average filters so that proportions of sums of the filter coefficients of each color in the lines in the horizontal and vertical directions are equal; a weighted average calculation unit that calculates weighted average values of each color; a demosaicking processing unit that calculates a pixel value of another color at a pixel position of a target pixel of demosaicking processing and that interpolates a pixel value of the target pixel based on a color ratio or a color difference of the calculated weighted average values to calculate the pixel value.

Owner:FUJIFILM CORP

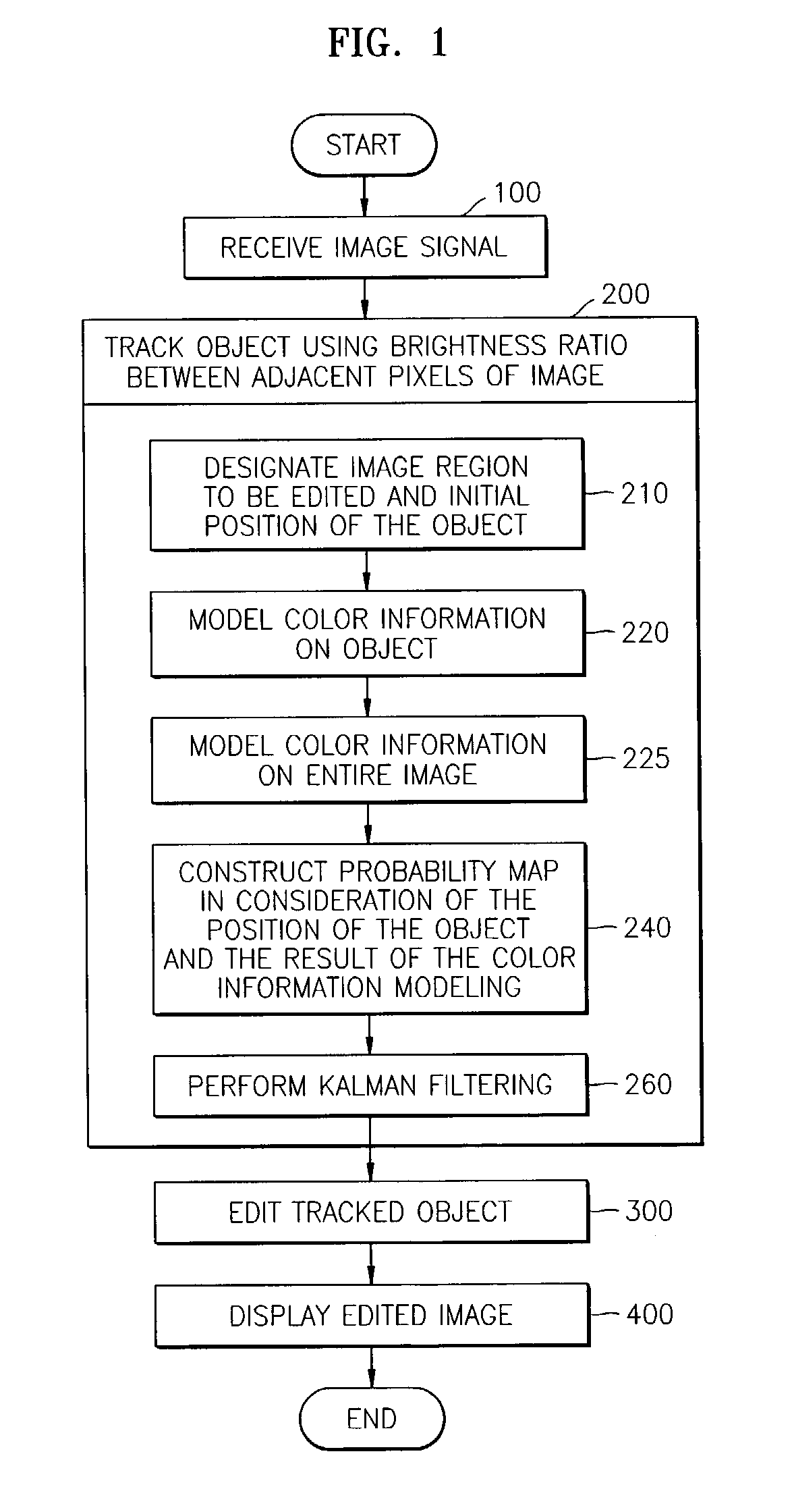

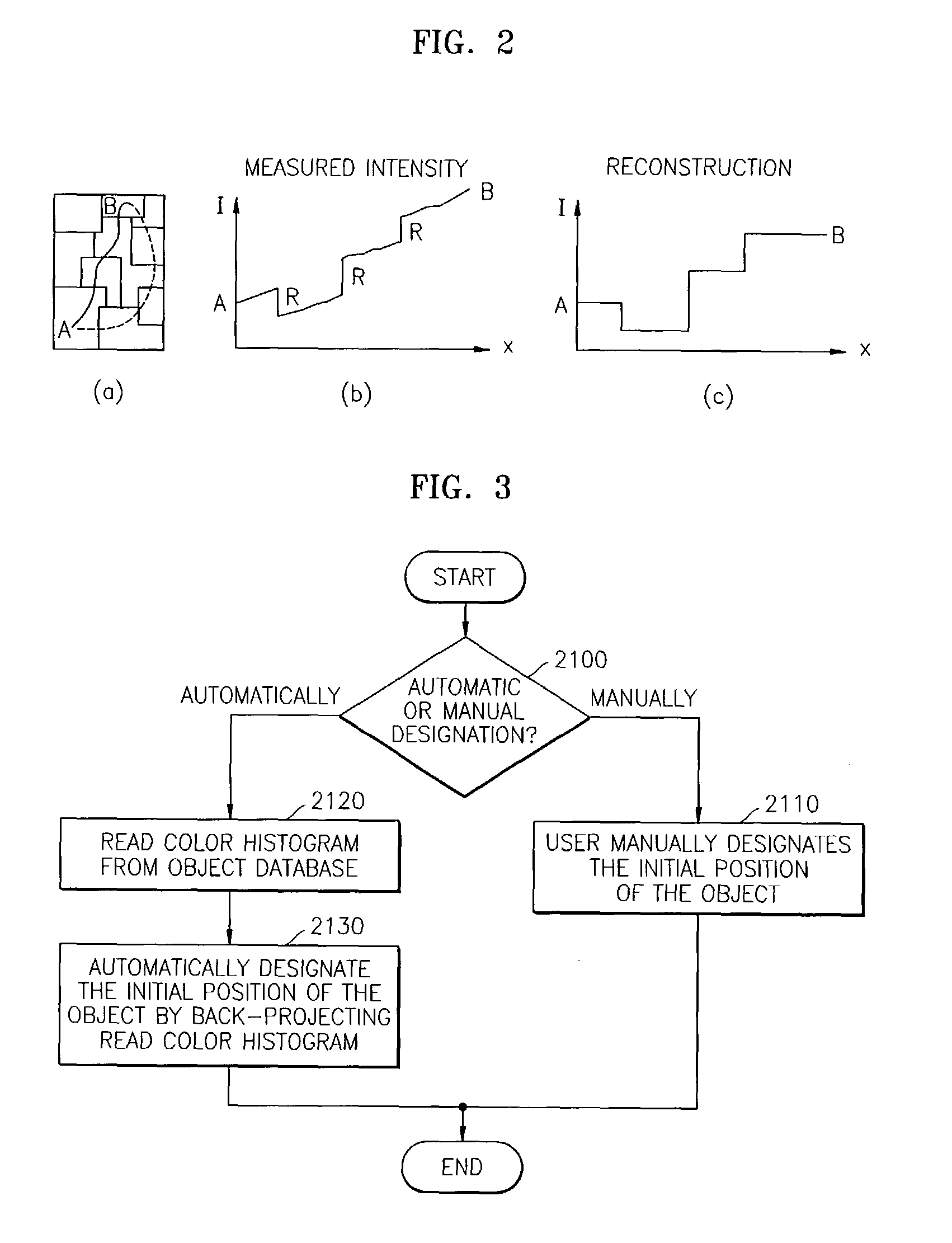

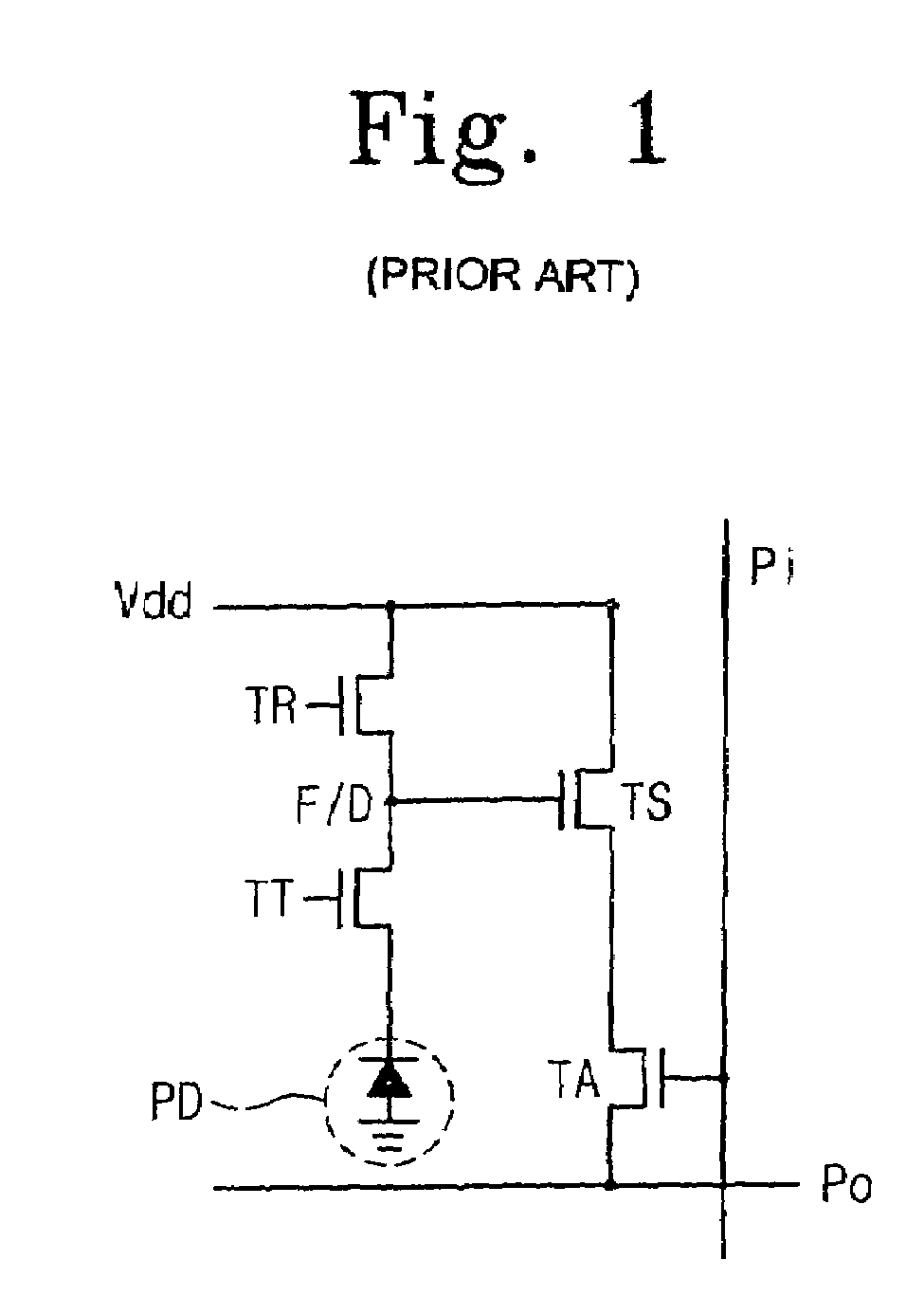

Illumination-invariant object tracking method and image editing system using the same

ActiveUS7171023B2Reliably region of imageImage analysisColor signal processing circuitsIlluminanceComputer science

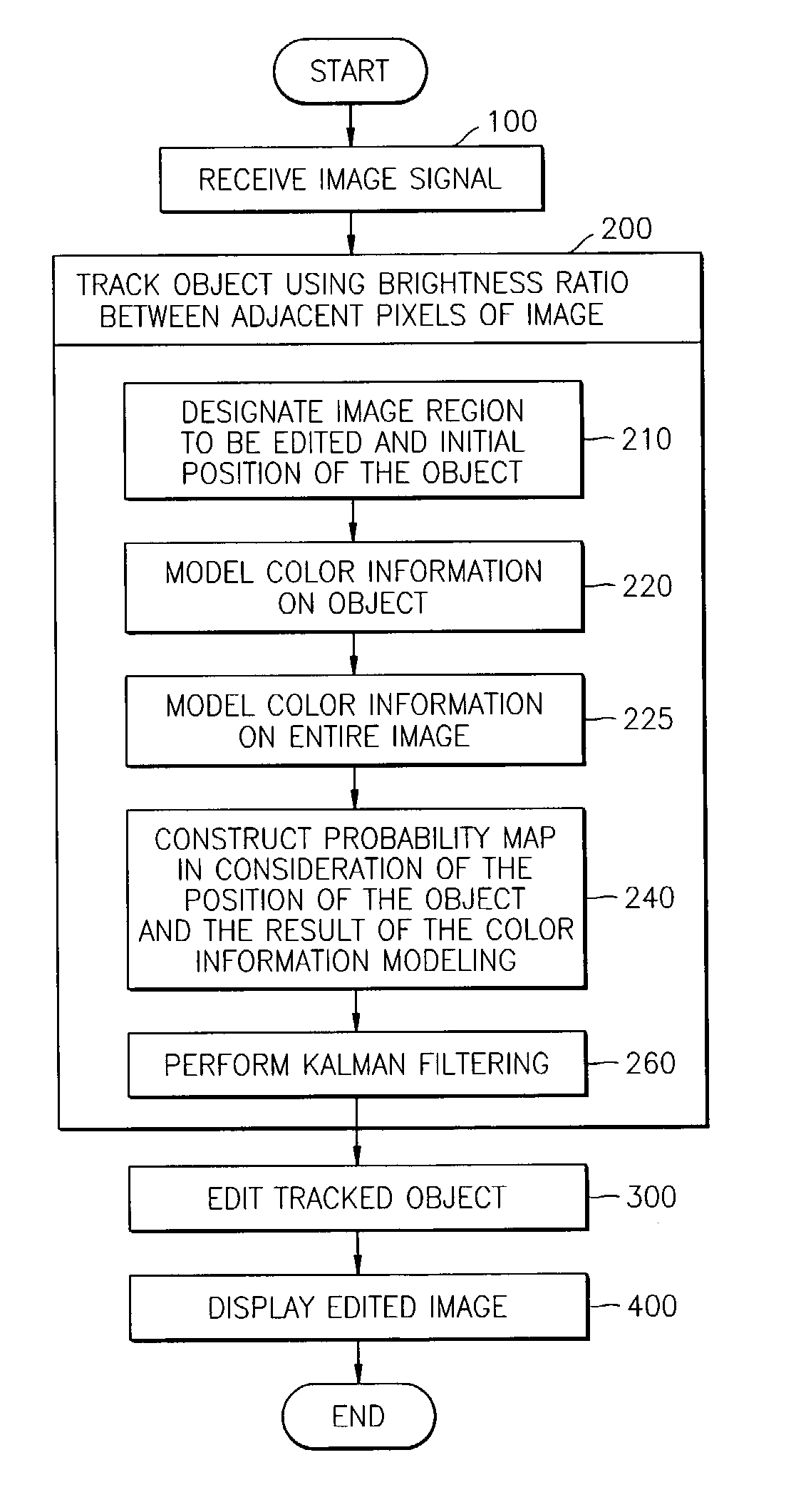

An illumination-invariant object tracking method and an image editing system using the same are provided. The illumination-invariant object tracking method involves: designating an initial position of an object of interest to be tracked in an image; constructing a probability map for object tracking in consideration of a color ratio of adjacent pixels in the image; and performing Kalman filtering based on the initial position of the object and the probability map. The image editing system based on the illumination-invariant object tracking method includes: a data input unit which receives an image to be edited; an object tracking unit which tracks a target object in consideration of a color ratio of adjacent pixels in the image; an image editing unit which edits and outputs an edited image in a predetermined region of the image, in response to information on the position, size, and boundary of the tracked target object.

Owner:SAMSUNG ELECTRONICS CO LTD

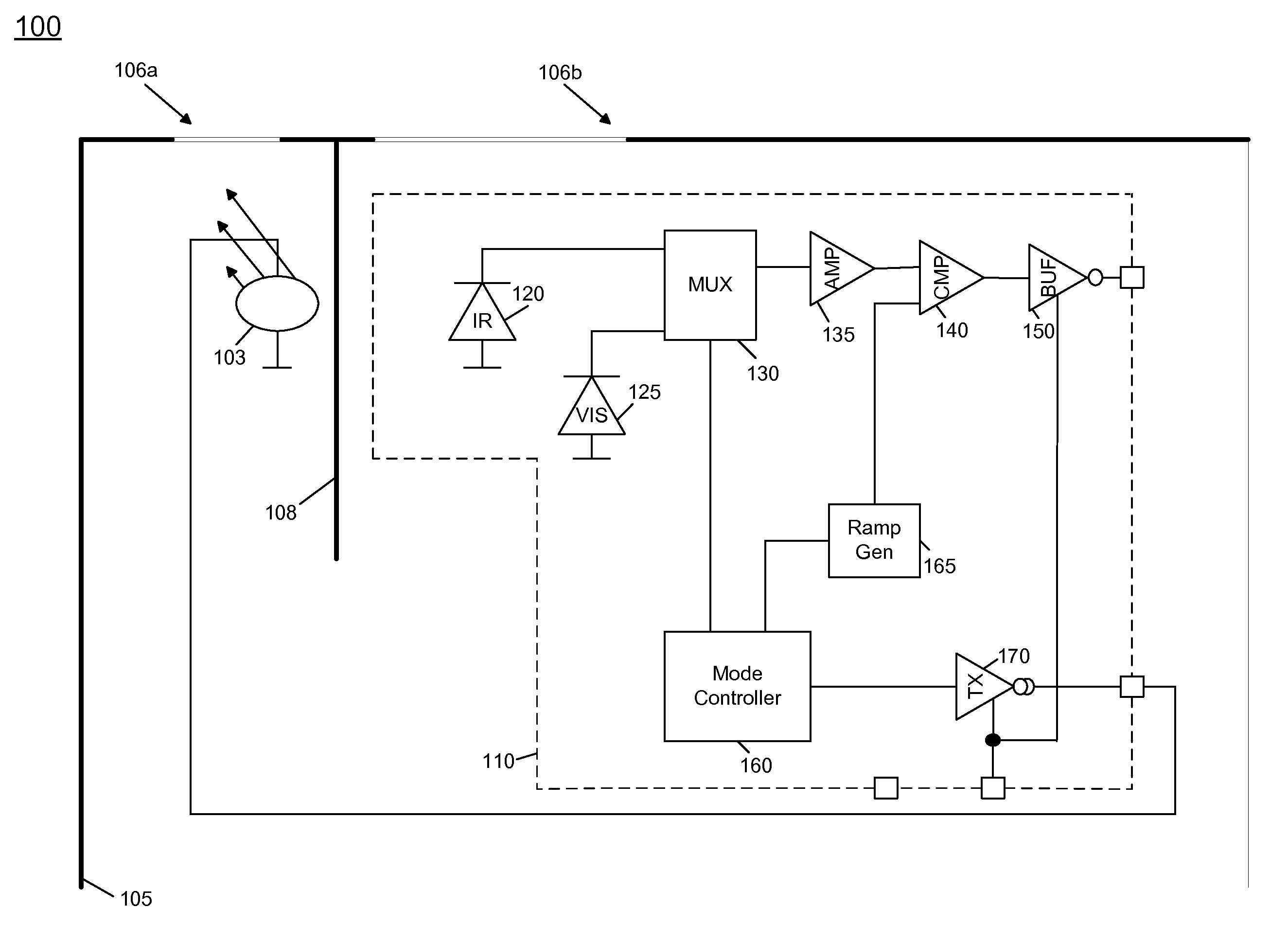

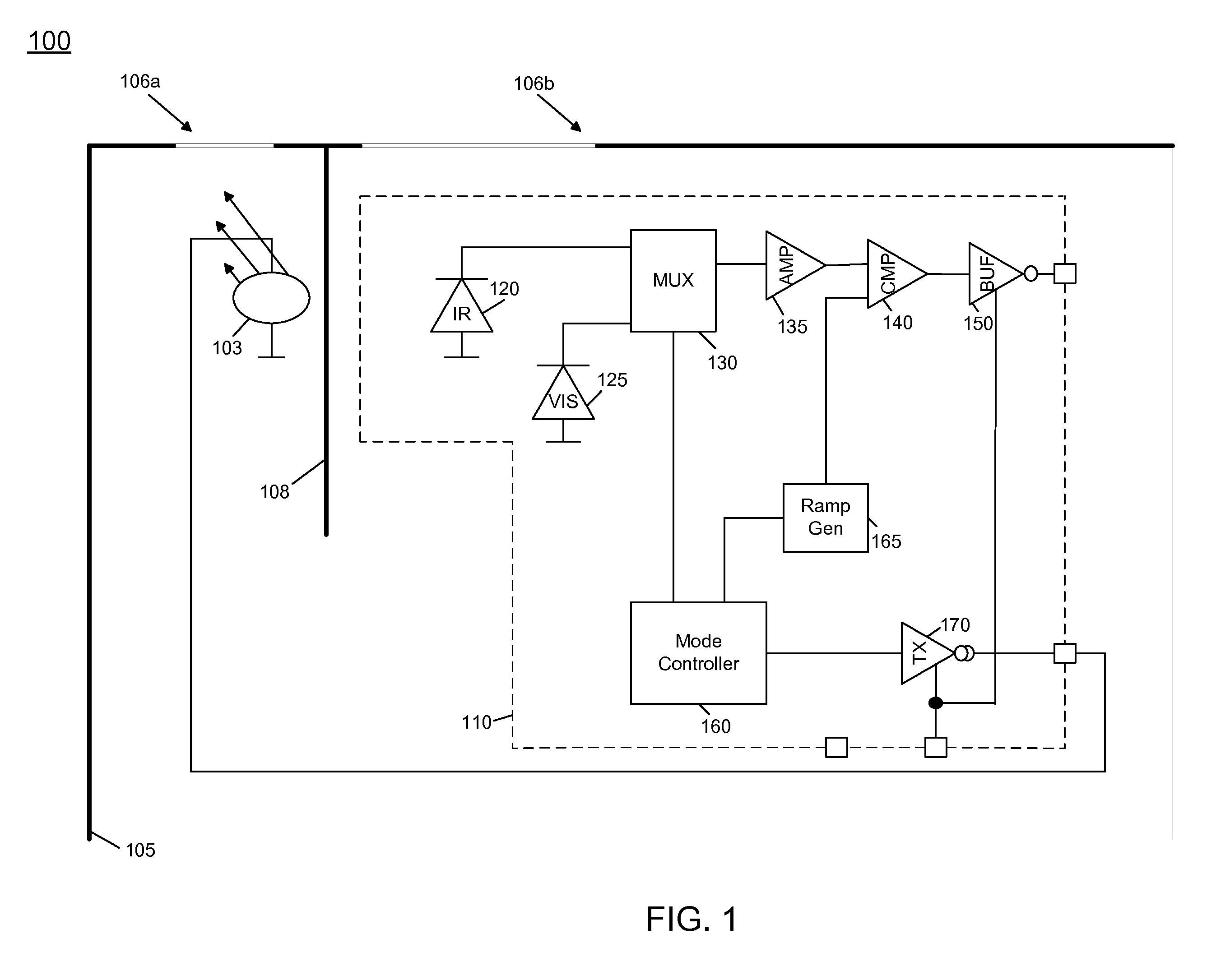

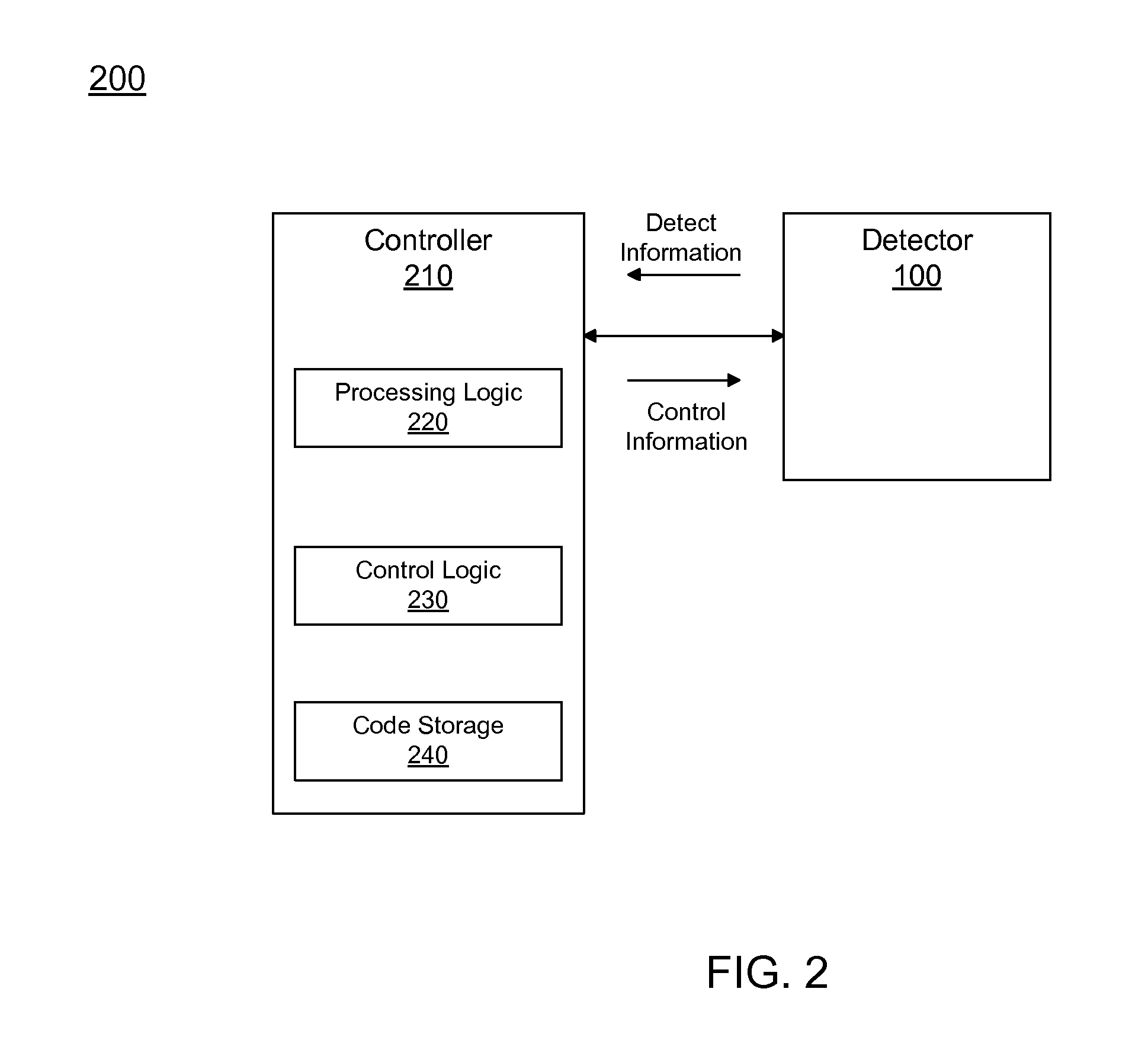

Identifying ambient light type and illuminance compensation using a plurality of photodetectors

InactiveUS20120001841A1Photometry using reference valueRadiation pyrometryPhotovoltaic detectorsIlluminance

A method for determining an ambient light type is described. The method includes receiving measurement information from multiple photodetectors configured for different light spectra, calculating a color ratio using the measurement information, obtaining a correction value using the color ratio, applying the correction value to at least one of the first and second measurement information to obtain a photopic illuminance value, and determining an ambient light type using the photopic illumination value and the color ratio.

Owner:SILICON LAB INC

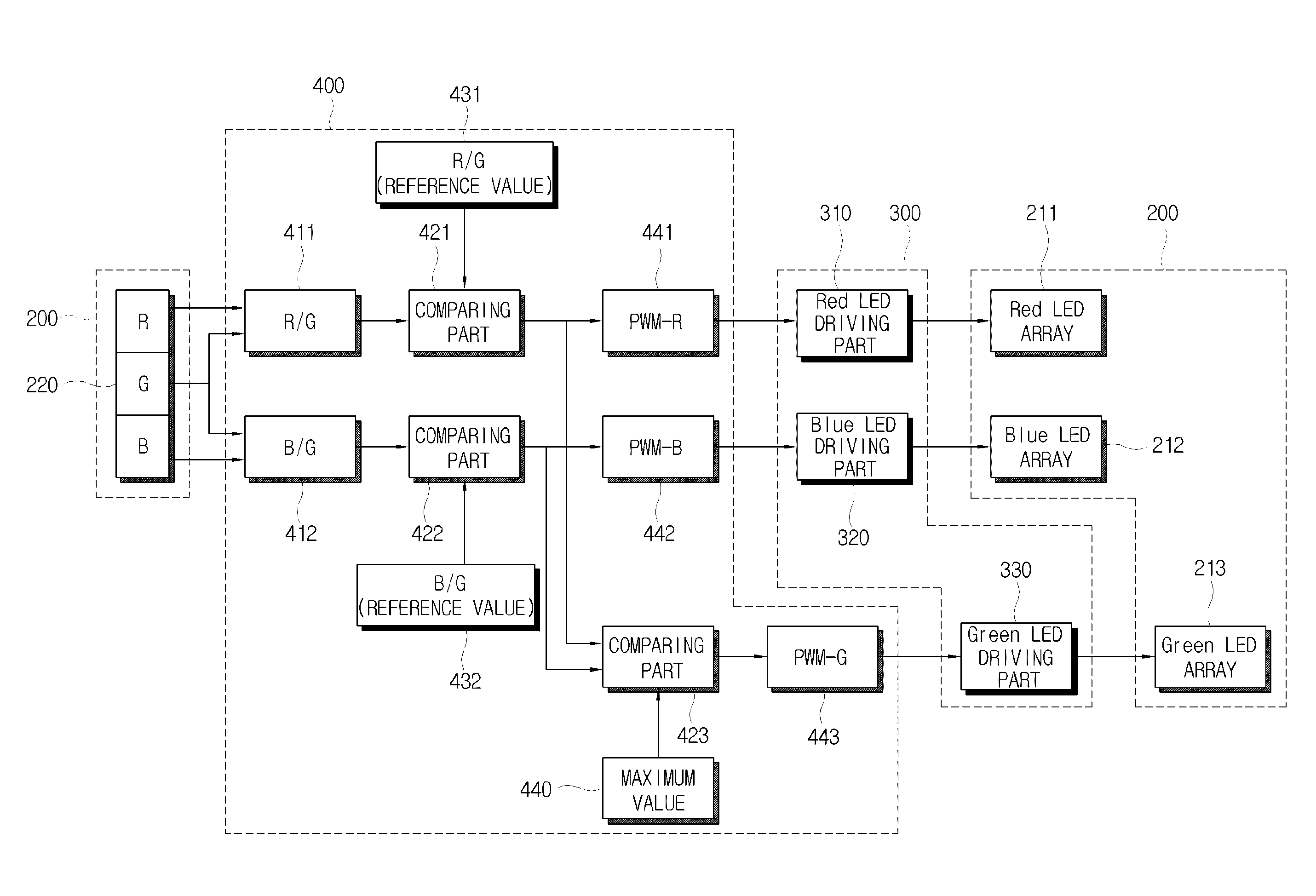

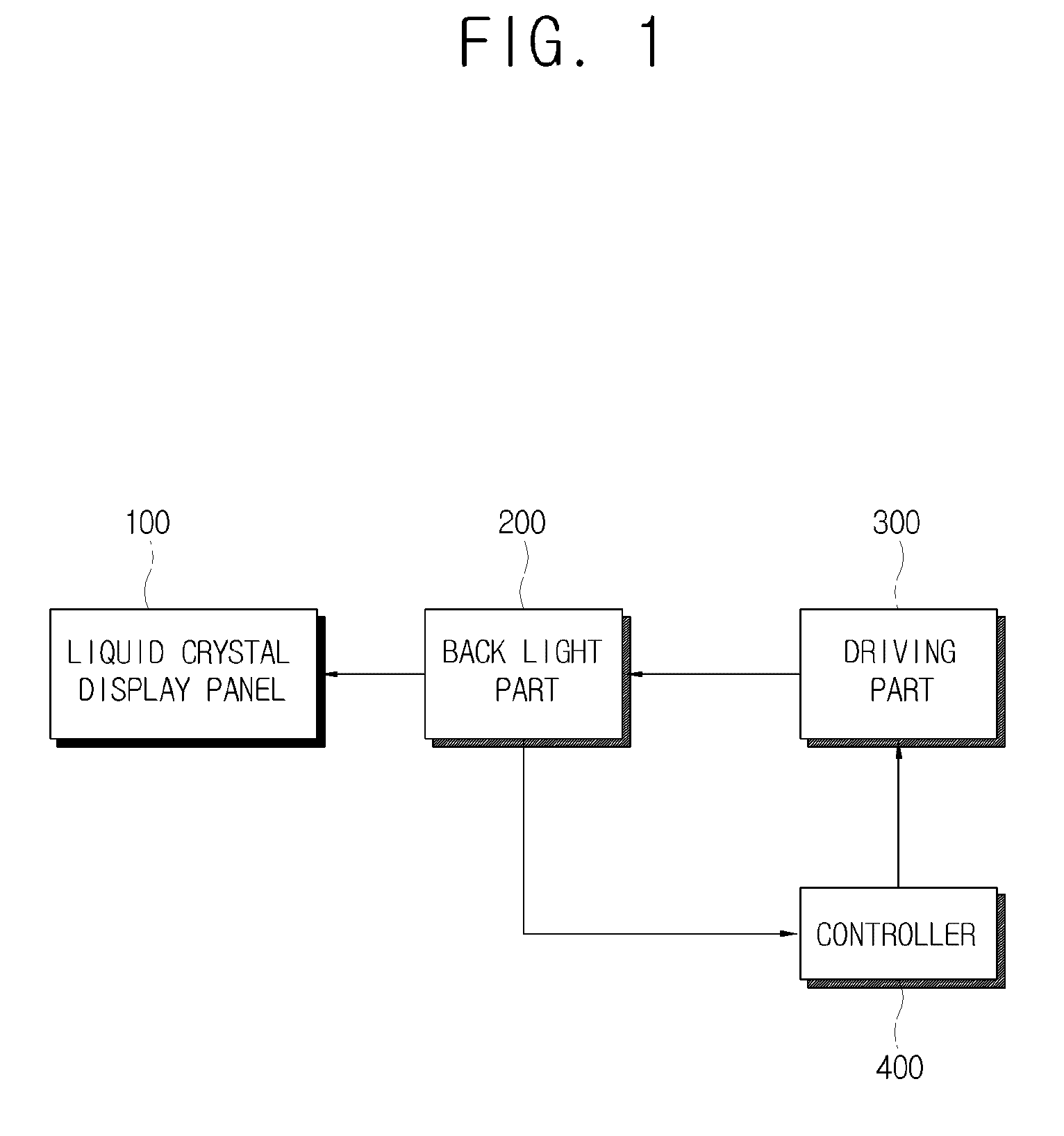

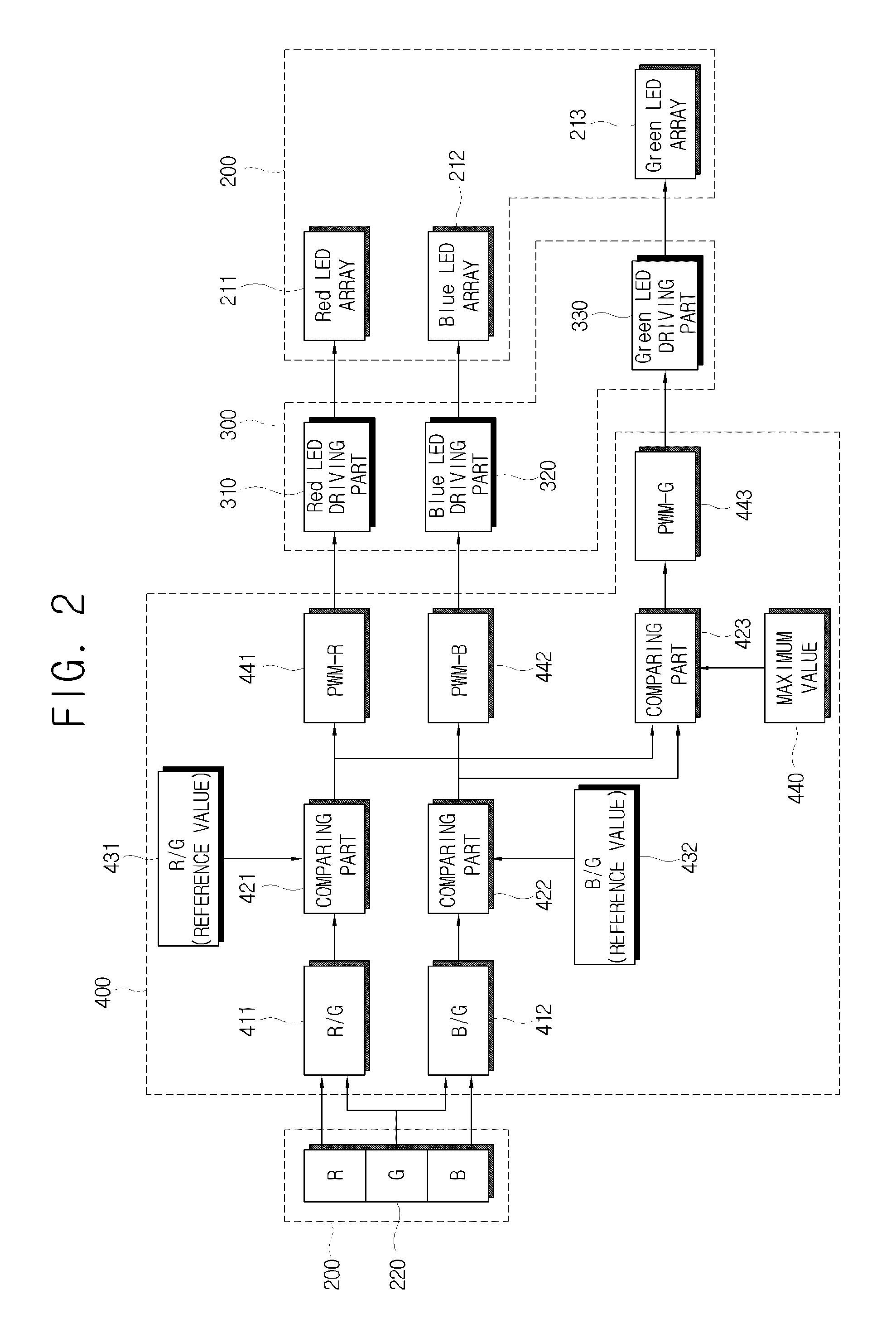

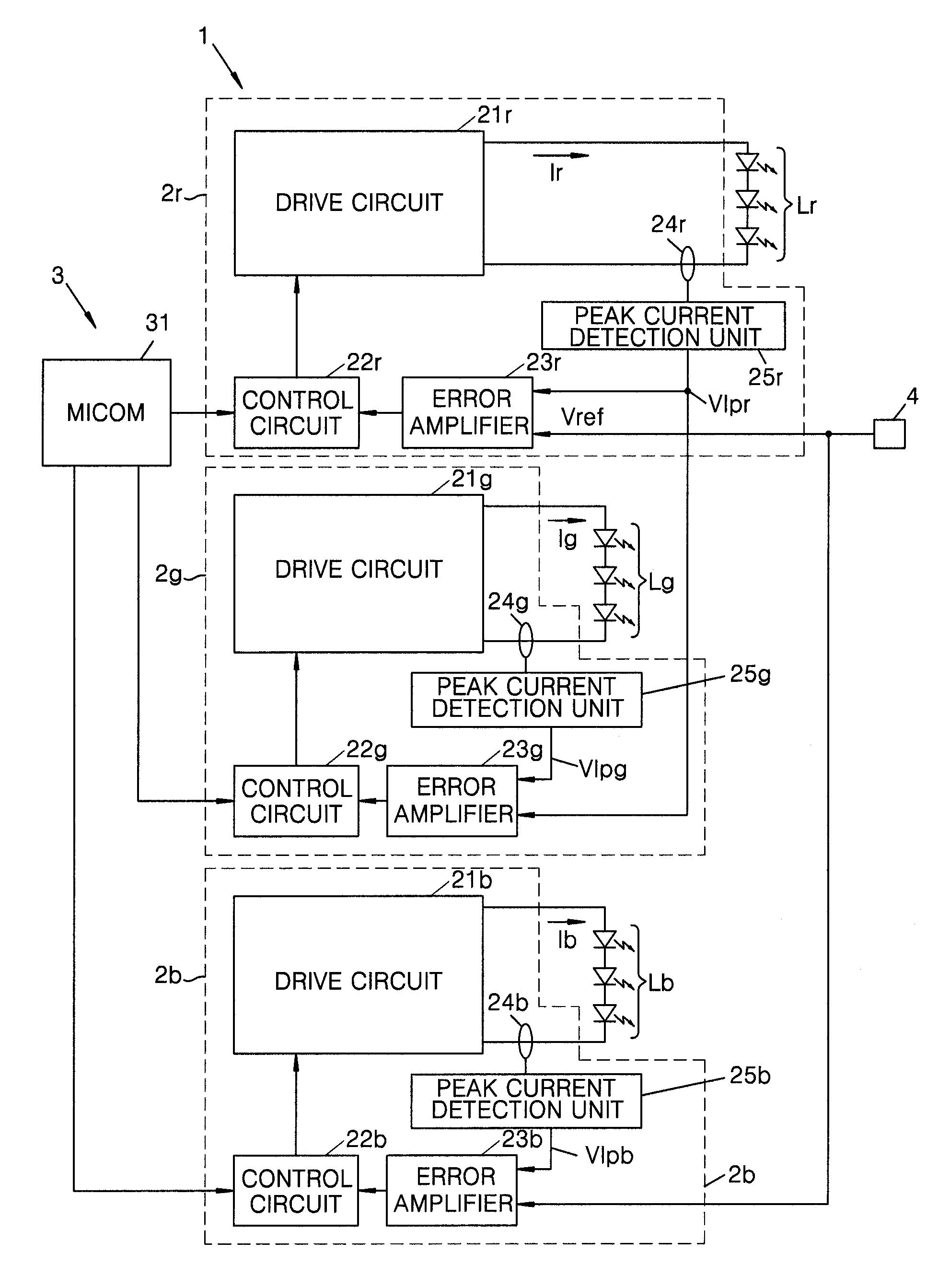

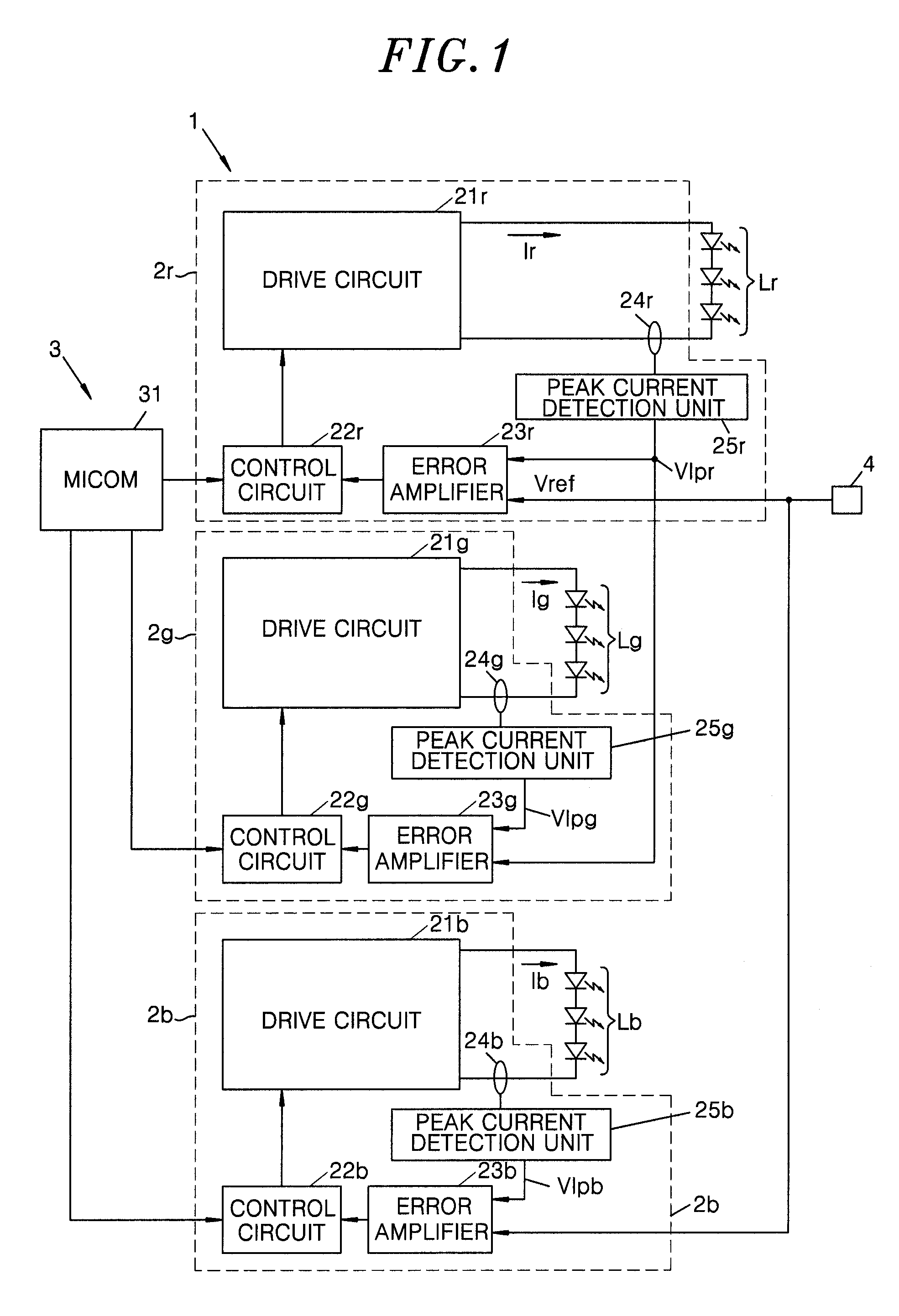

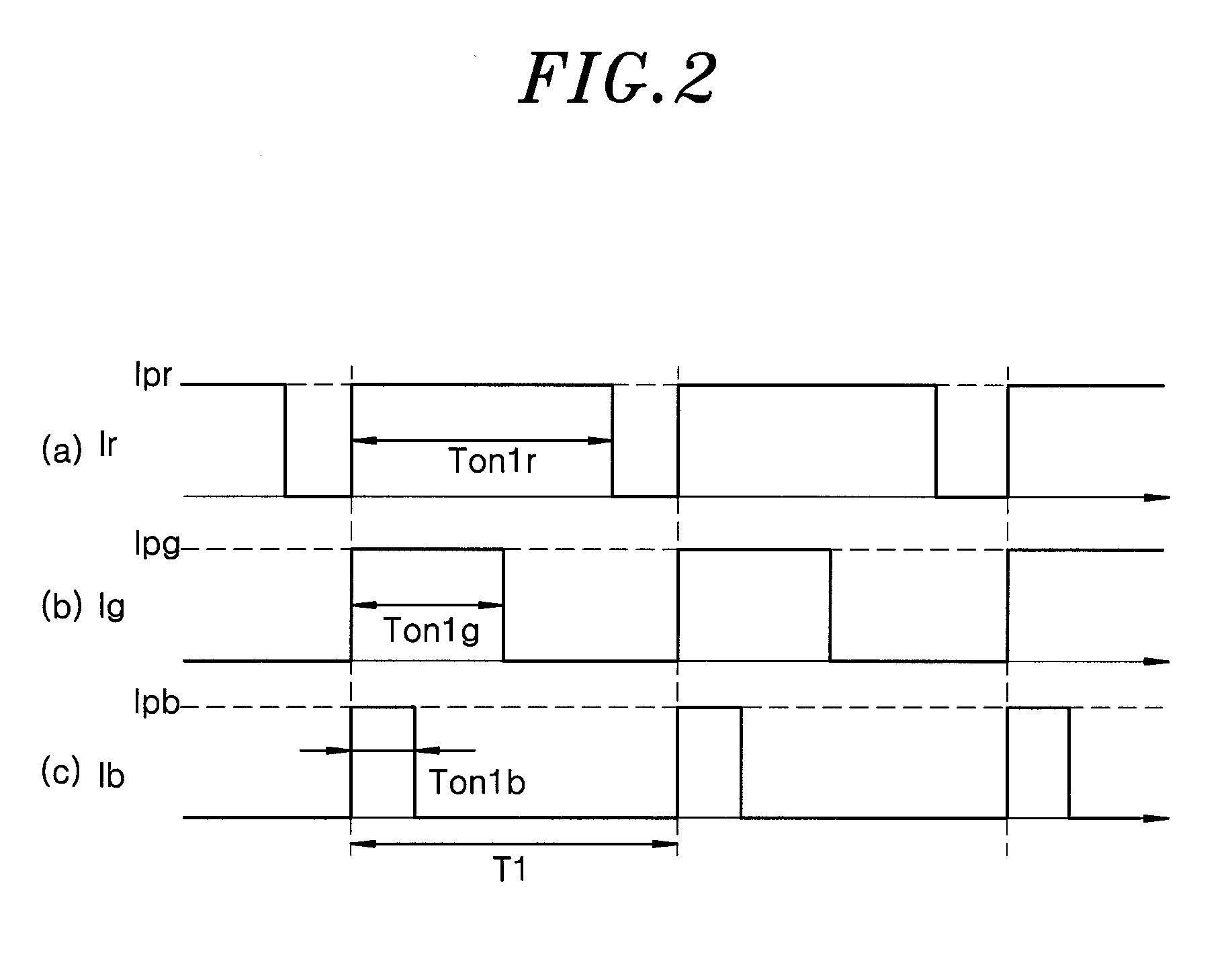

Back light apparatus and control method thereof

InactiveUS8044918B2Increase brightnessColor signal processing circuitsStatic indicating devicesLiquid-crystal displayEngineering

A back light apparatus includes a back light part which emits light to a liquid crystal display panel, and includes a plurality of LEDs respectively corresponding to a plurality of colors, a detecting part which detects the light emitted from the plurality of the LEDs, a driving part which drives the LEDs to emit, and a controller which controls the driving part to make color ratios substantially equal to a reference value if the reference value is not equal to the color ratio between at least two colors among the plurality of colors of the light detected in the detecting part.

Owner:SAMSUNG ELECTRONICS CO LTD

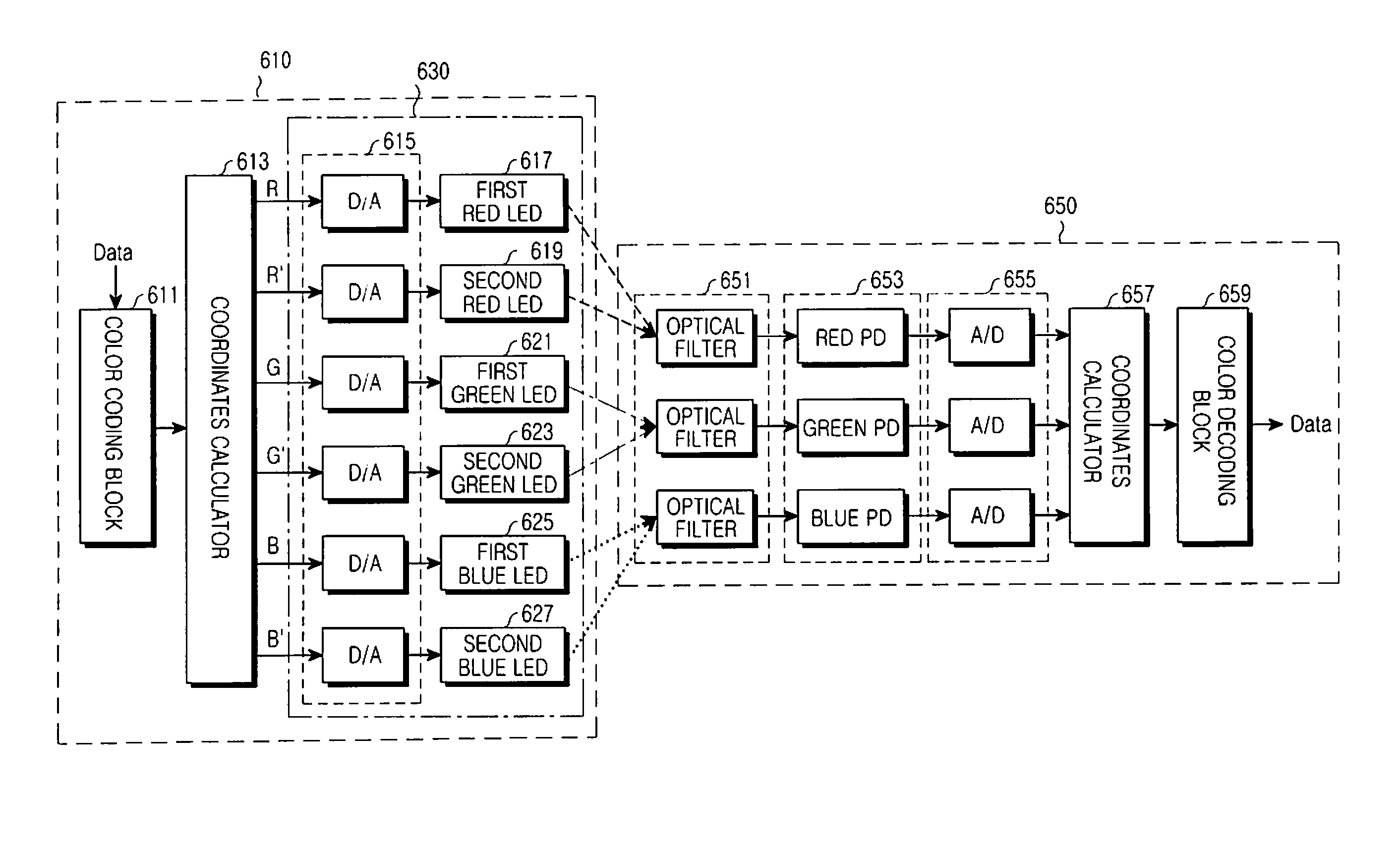

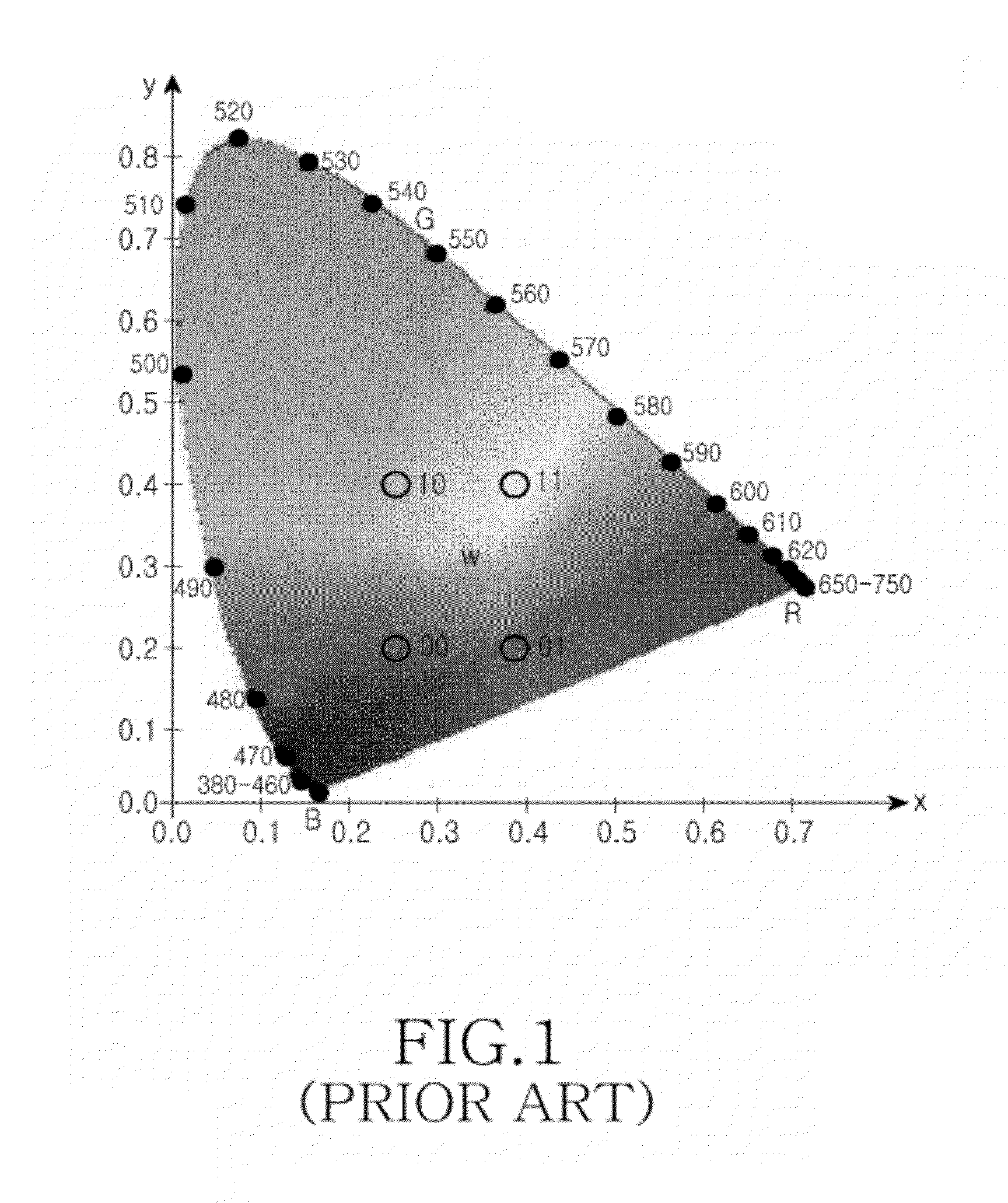

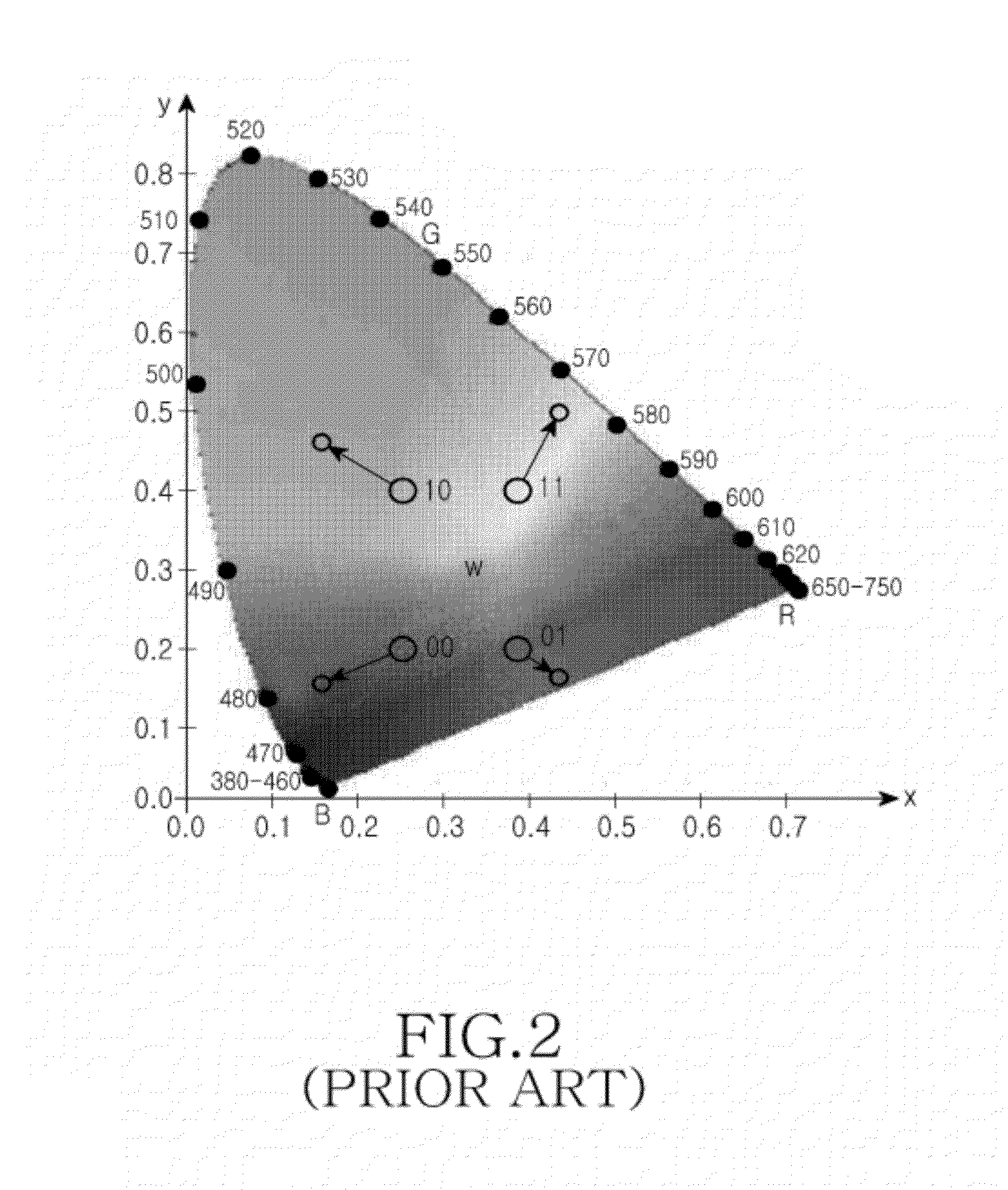

Apparatus and method for transmitting and receiving an information symbol in a visible light communication system for color code modulation

ActiveUS8195054B2Close-range type systemsElectromagnetic transmittersPulse-code modulationVisible light communication

A visible light communication system and method for transmitting and receiving an information symbol in a visible light communication system for a Color Code Modulation (CCM) scheme using a chromaticity diagram. The method includes determining a first coordinates value corresponding to an information symbol to be transmitted on the chromaticity diagram; determining a first color ratio corresponding to the first coordinates value; determining a second coordinates value corresponding to a compensation symbol for compensating for the first color ratio into a color white and determining a second color ratio corresponding to the second coordinates value; and emitting a visible ray corresponding to each of the first color ratio and second color ratio. The first and second coordinates values are located on a line on the chromaticity diagram.

Owner:SAMSUNG ELECTRONICS CO LTD

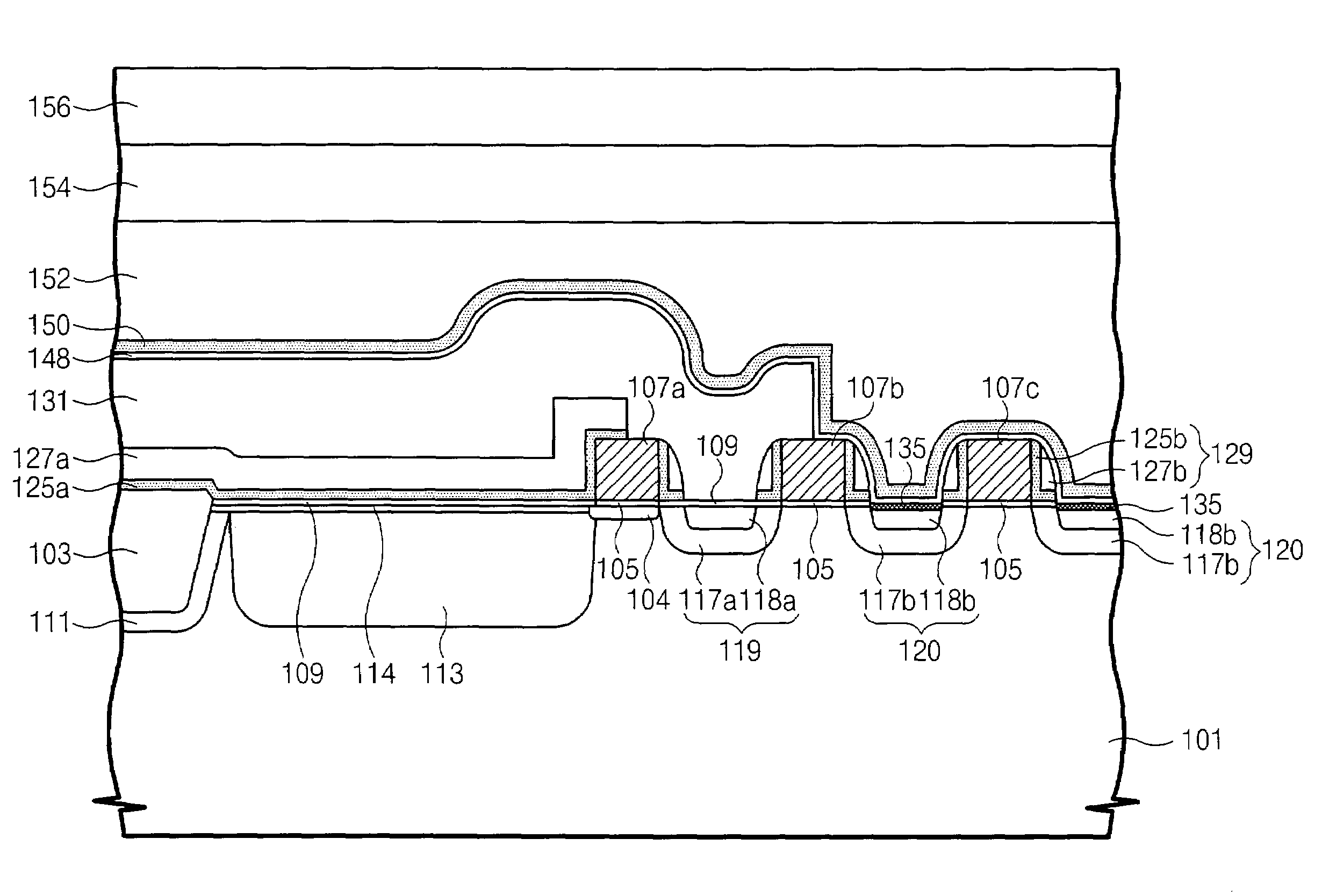

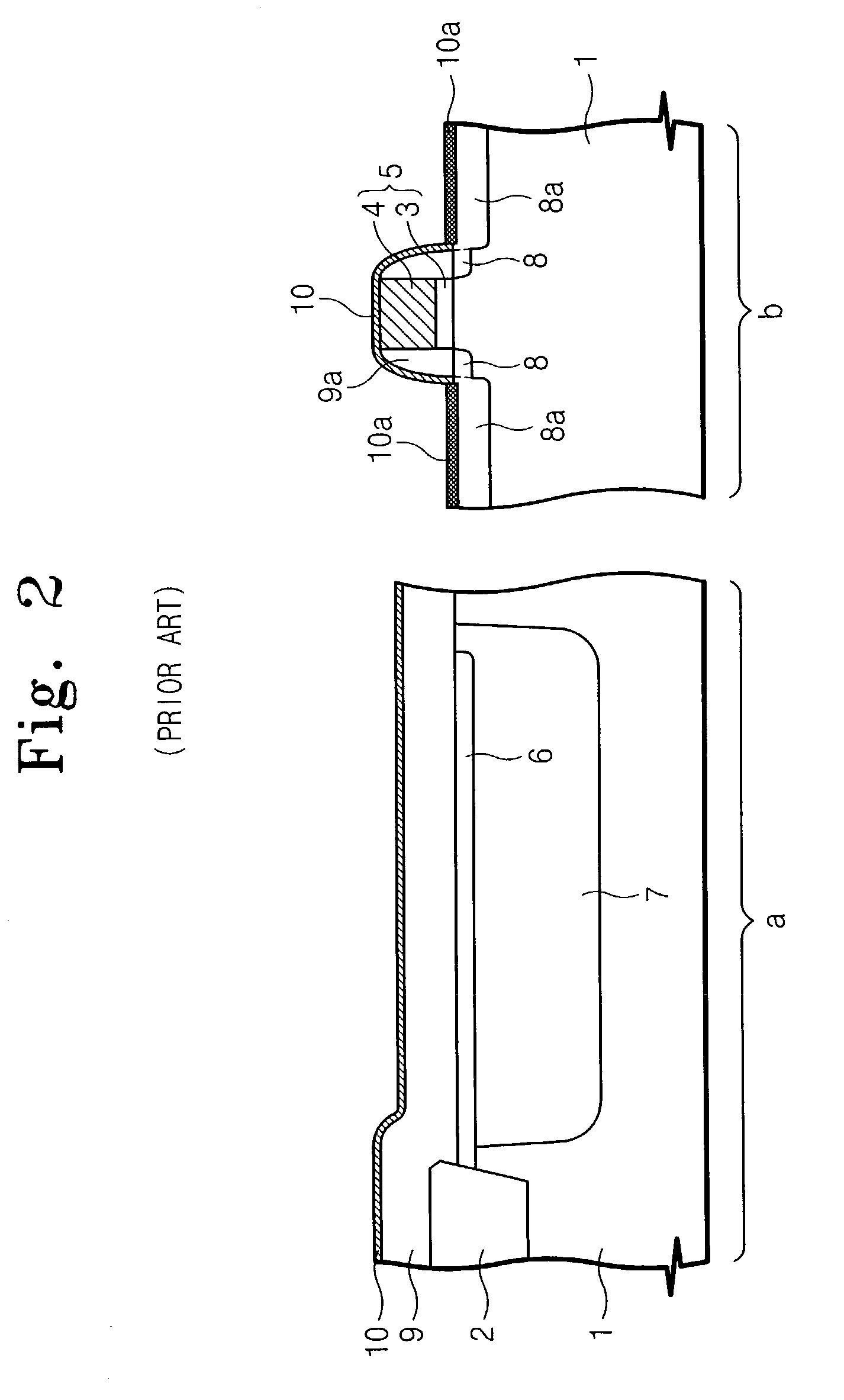

Image sensor and method of fabricating the same

InactiveUS7005689B2Reduce dark defectGood colorTransistorSolid-state devicesControl layerSilicon oxide

Image sensors and methods of fabricating the same are provided. The image sensor includes a blocking pattern disposed on photodiodes. The blocking pattern is formed of insulation material having a metal diffusion coefficient which is lower than a silicon oxide diffusion coefficient. Therefore, dark defects of the image sensor are reduced. In addition, the image sensor includes a color-ratio control layer. The color ratio control layer controls color ratios between the sensitivities to blue, green and red. As a result, color distinction of the picture that is embodied by the image sensor can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

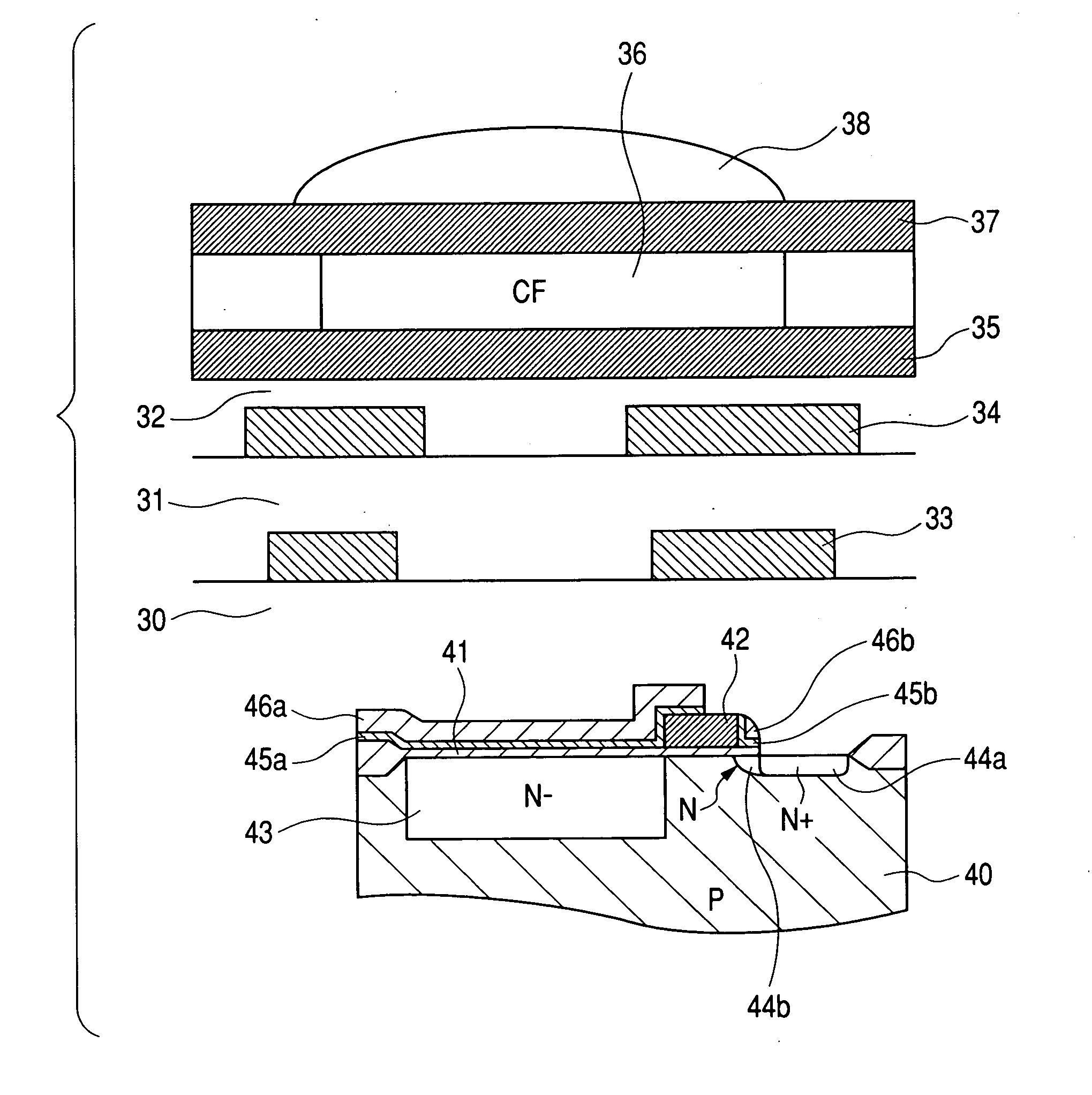

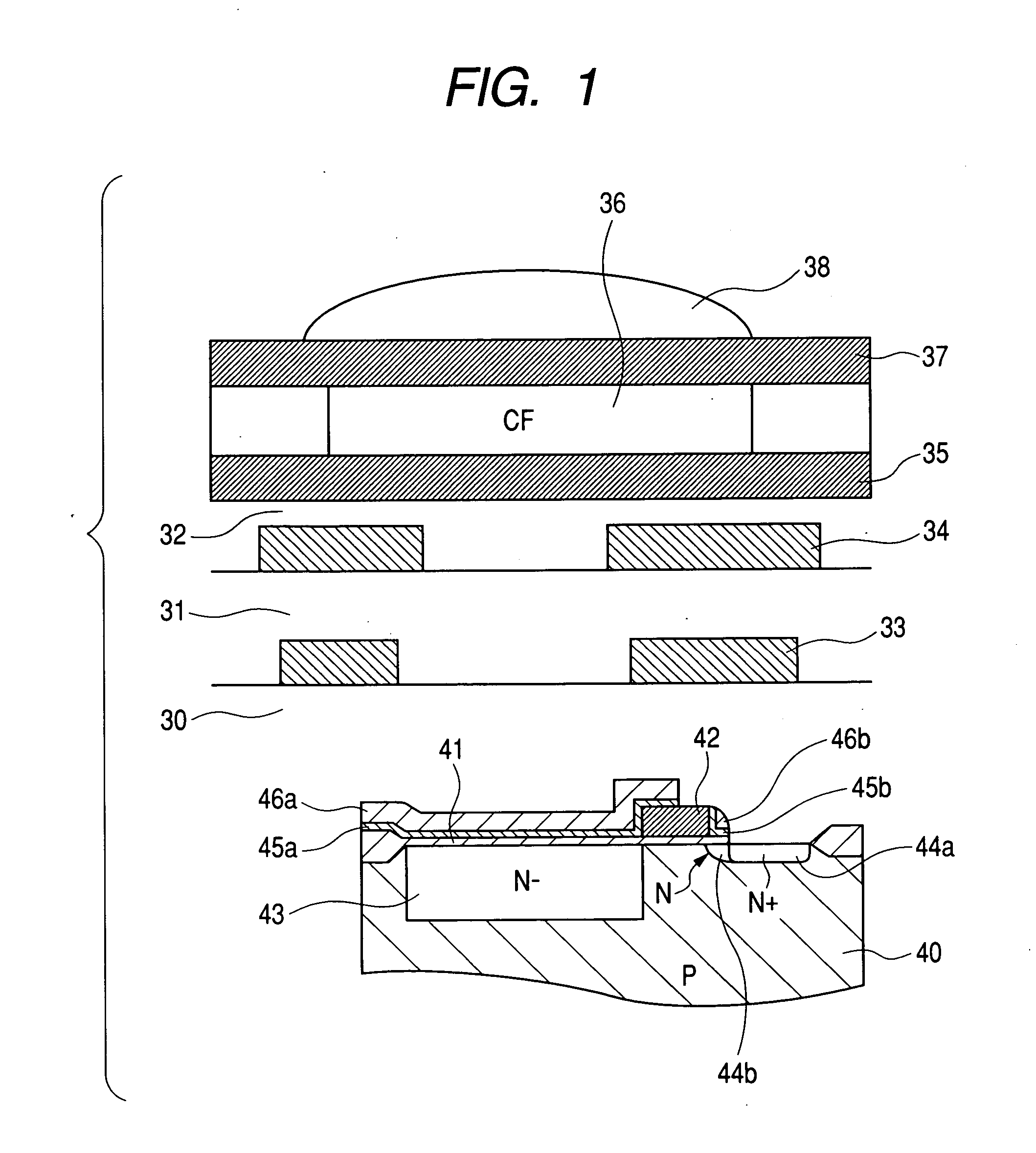

Photoelectric conversion apparatus and image pickup system using photoelectric conversion apparatus

InactiveUS20050110002A1High color reproductionTelevision system detailsRadiation pyrometrySpectral transmittanceEngineering

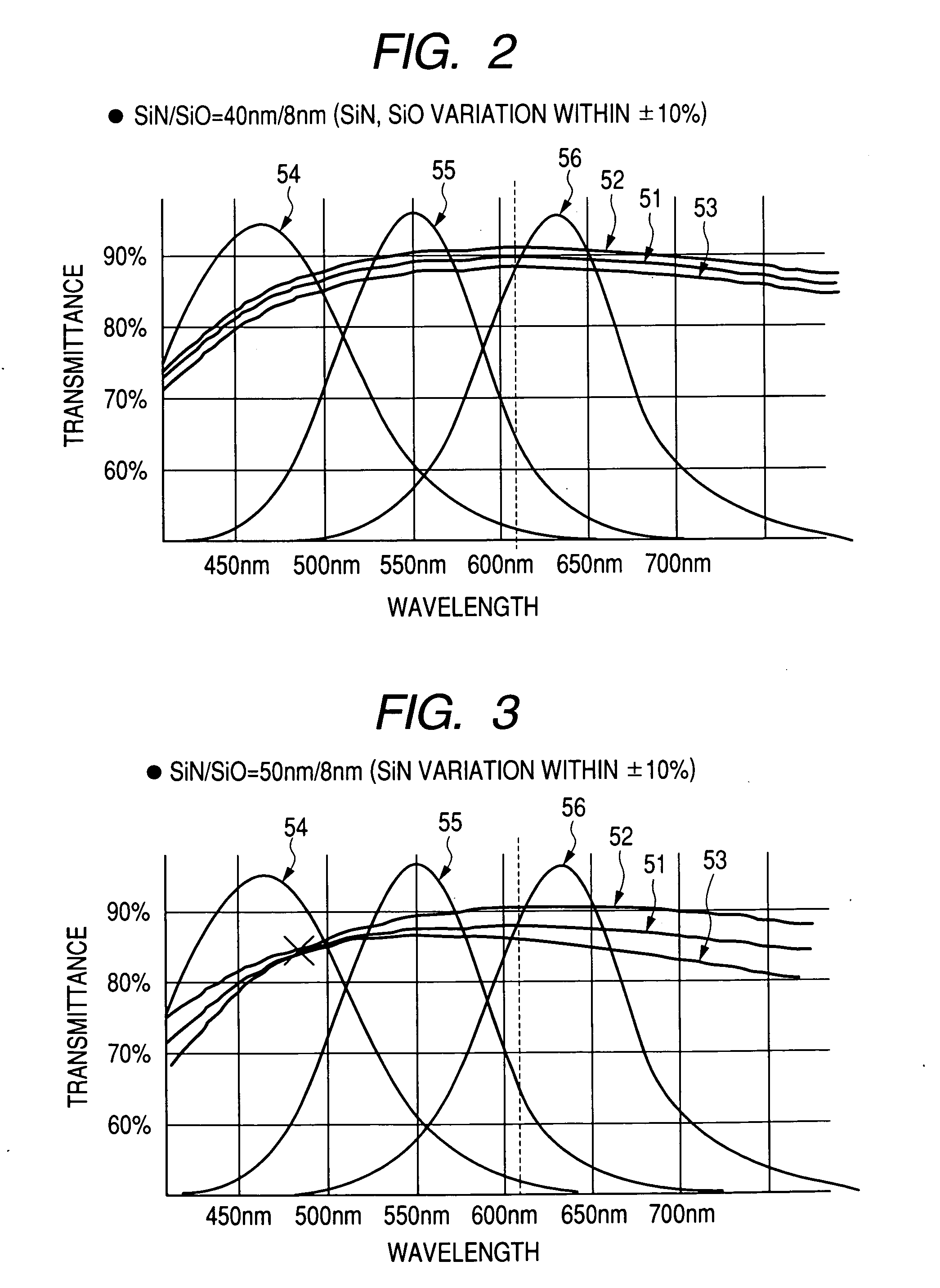

It is a main object of the present invention to suppress the differences of color ratios of B / G and R / G when the film thicknesses of antireflective films and insulation films vary at a processing process. The present invention is a photoelectric conversion apparatus including a plurality of light receiving portions arranged on a semiconductor substrate, antireflective films formed on the light receiving portions with insulation films put between them, and color filter layers of a plurality of colors formed on the antireflective films, wherein film thicknesses of the insulation films and / or the antireflective films are changed such that changing directions of spectral transmittances at peak wavelengths of color filters on sides of the shortest wavelengths and at peak wavelengths of color filters on sides of the longest wavelengths after transmission of infrared cutting filters may be the same before and after changes.

Owner:CANON KK

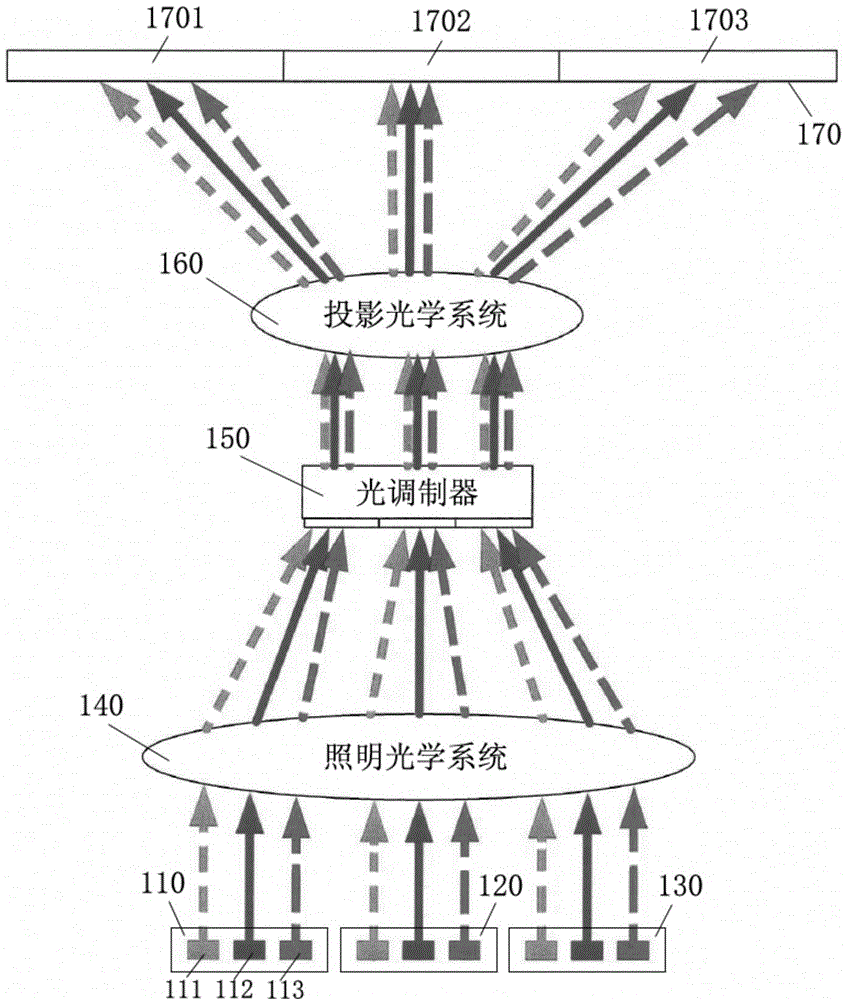

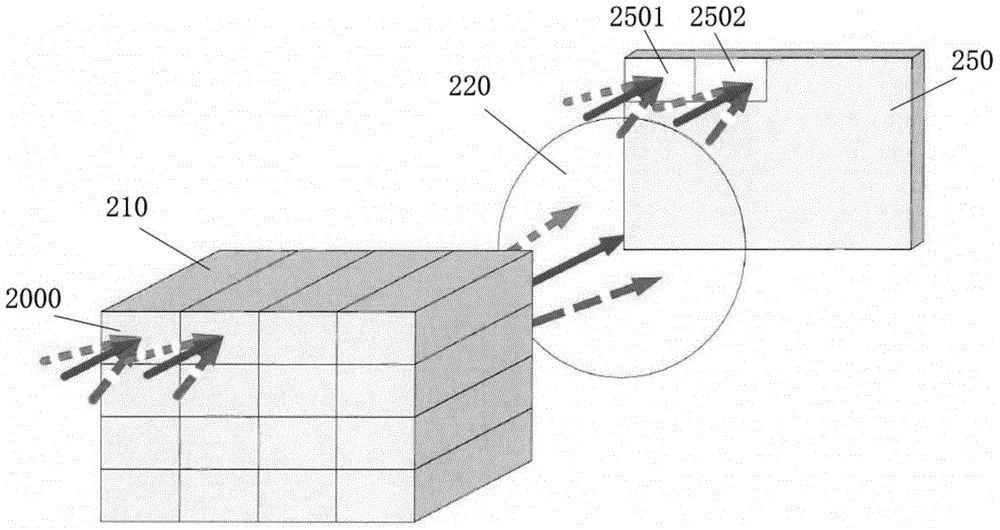

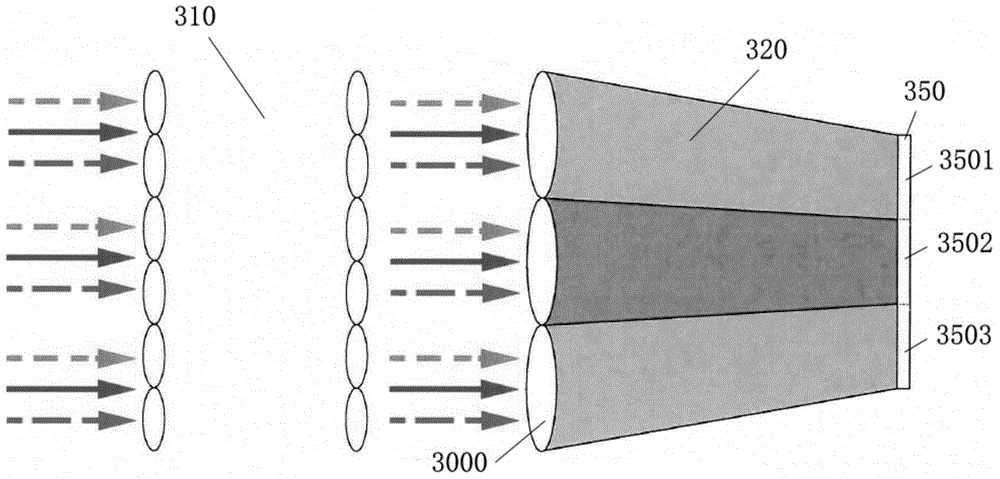

Projection system

The invention provides a projection system, which comprises at least two light-emitting surface groups, a light modulator, an illuminating optical system and a light source controller, wherein each light-emitting surface group comprises a plurality of light-emitting surfaces of emitting different colors; the illuminating optical system is arranged between the at least two light-emitting surface groups and the light modulator; the illuminating optical system comprises at least two light paths which correspond to the at least two light-emitting surface groups respectively; light emitted from each light-emitting surface group evenly irradiates a specific input region of the light modulator through the corresponding light path; and the light source controller adjusts the illuminating brightness and / or color ratio on the corresponding input region of the light modulator by individually controlling at least one of the light-emitting surface groups.

Owner:OSRAM GMBH

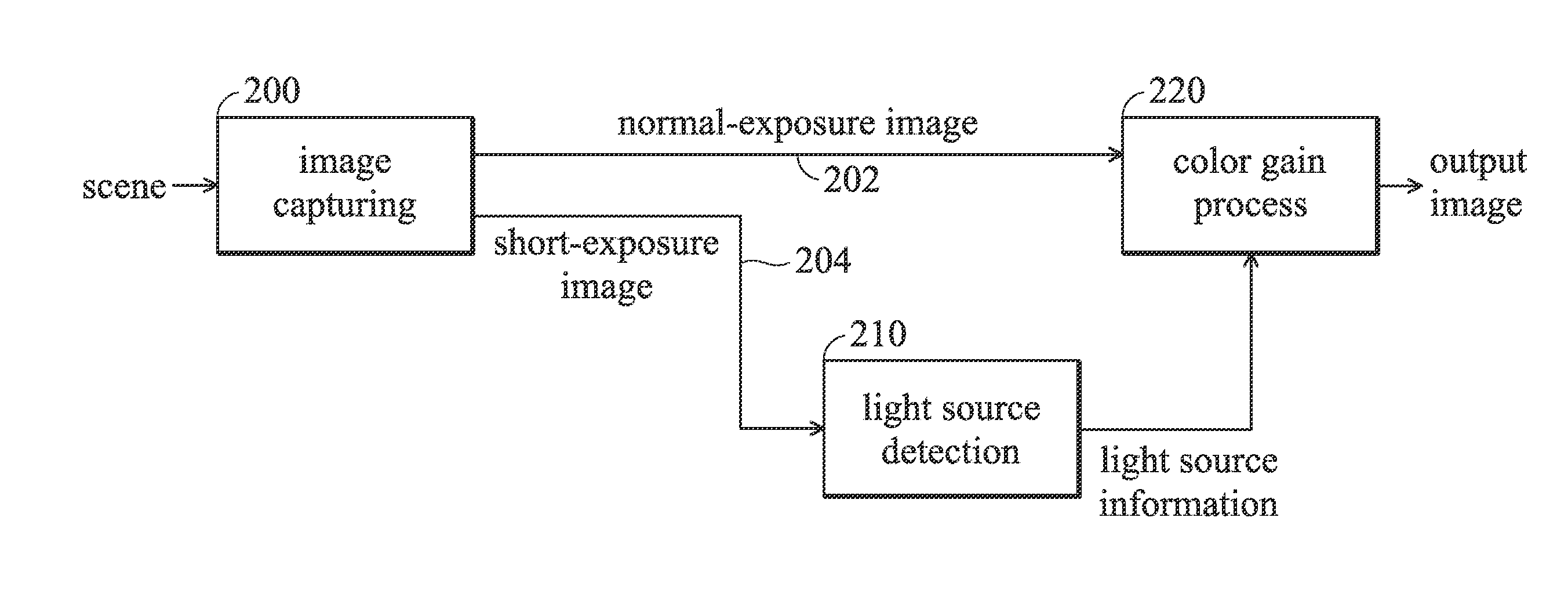

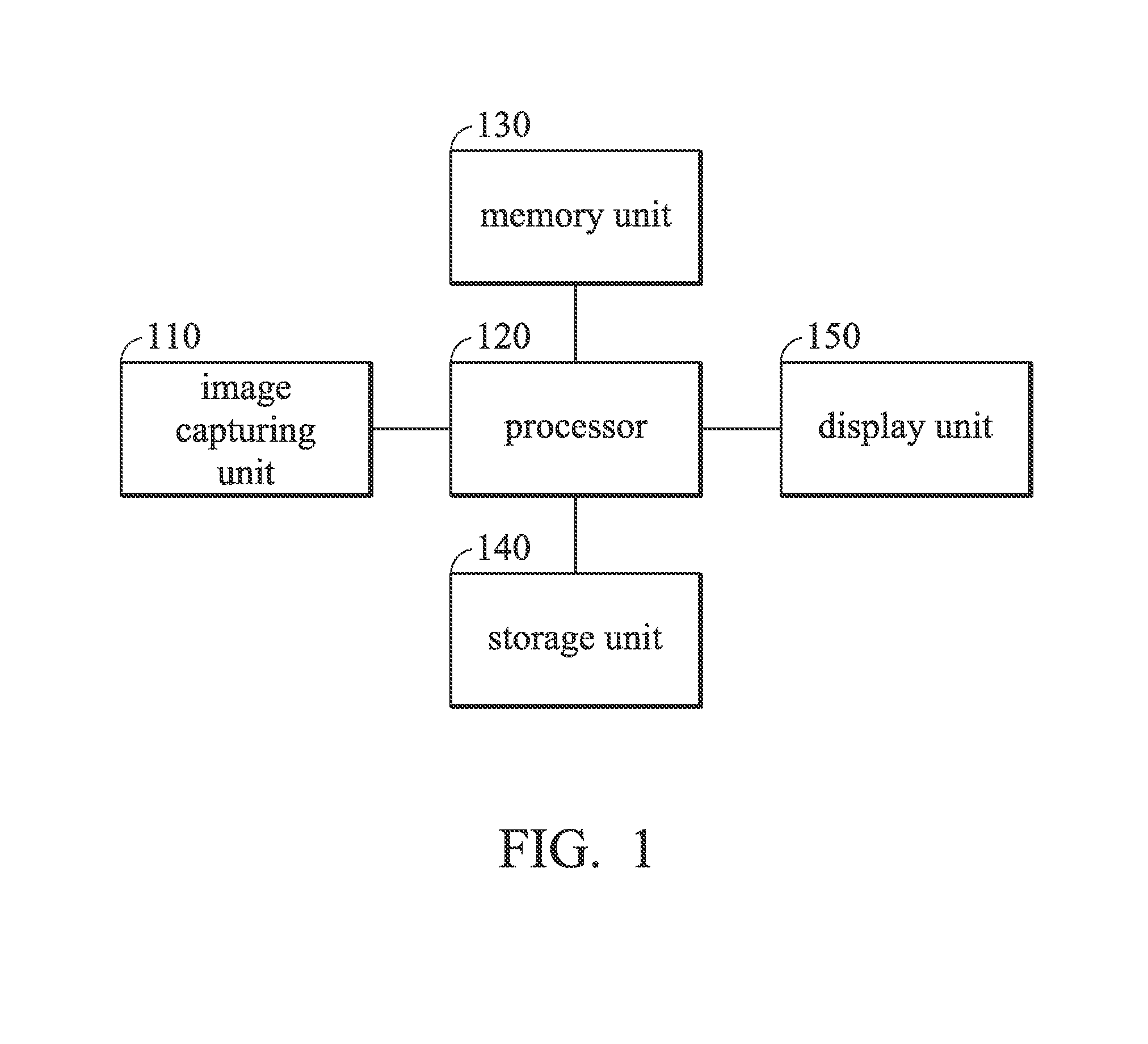

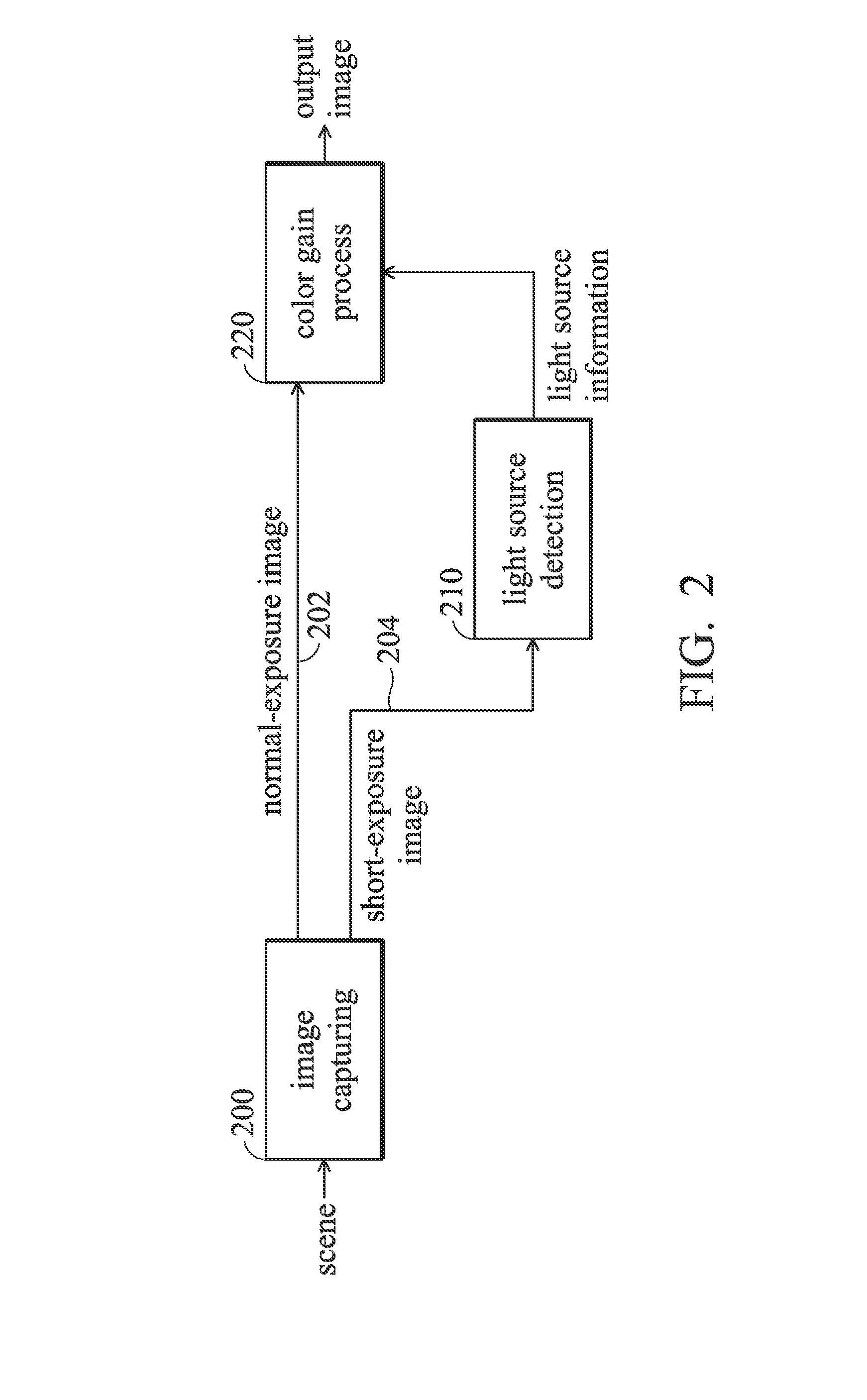

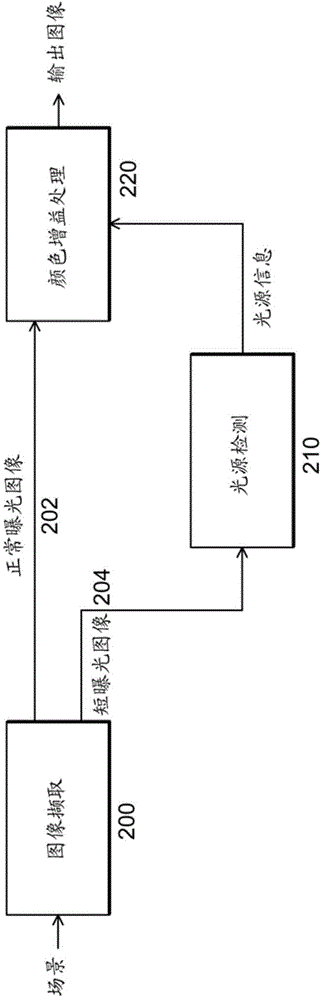

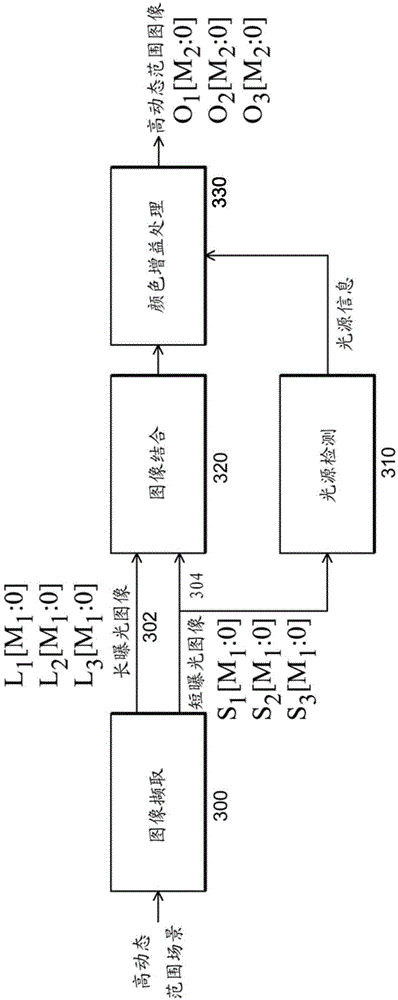

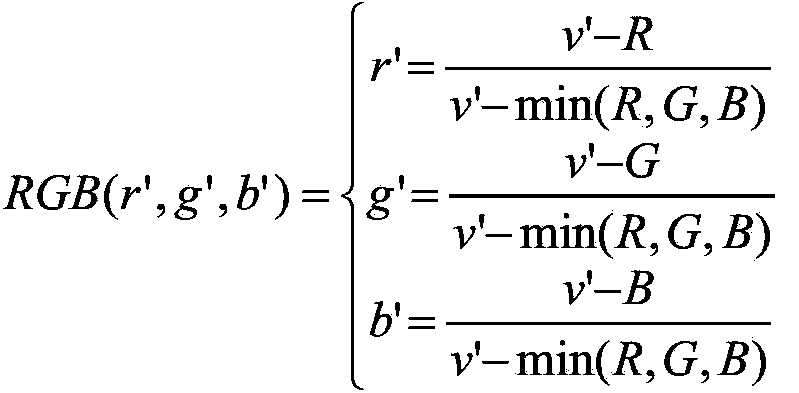

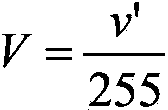

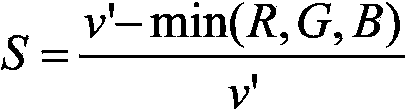

White balance method in multi-exposure imaging system

ActiveUS20160105656A1Television system detailsColor signal processing circuitsExposure valueExposure

A white-balance method for use in a multi-exposure imaging system having an image capturing unit is provided. The method includes the steps of: utilizing the image capturing unit to simultaneously capture a first image and a second image of a scene with a first exposure value and a second exposure value, respectively, wherein the second exposure value is smaller than the first exposure value, and the first exposure value and the second exposure value have individual exposure time and exposure gain; performing light source detection on the second image to obtain light source information and a corresponding light source color ratio of the scene; and performing a color gain process on the first image according to the light source color ratio to generate an output image.

Owner:QUANTA COMPUTER INC

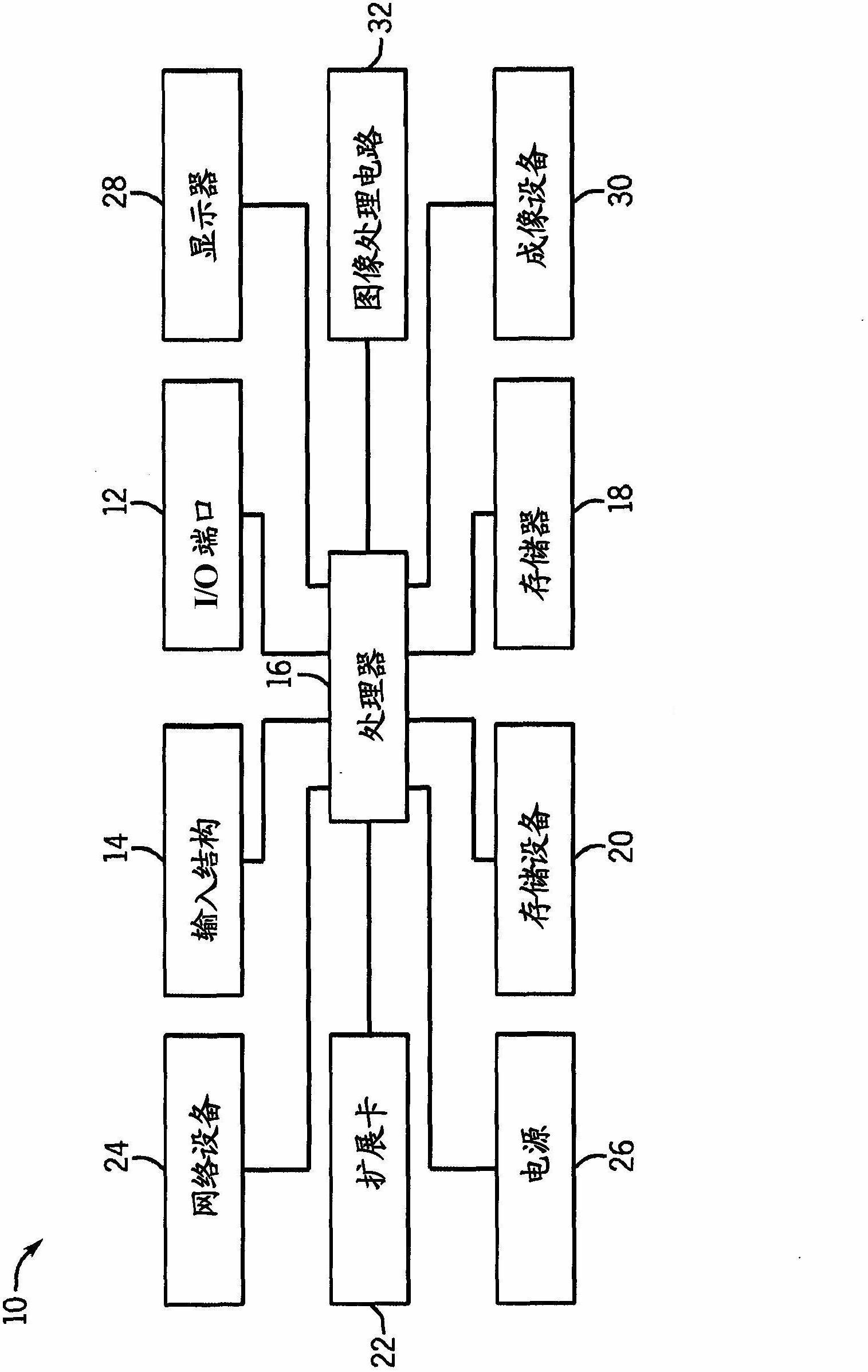

System and method for demosaicing image data using weighted gradients

InactiveCN102640499AGeometric image transformationPicture signal generatorsAdaptive filterColor filter array

Various techniques are provided herein for the demosaicing of images acquired and processed by an imaging system. The imaging system includes an image signal processor 32 and image sensors 30 utilizing color filter arrays (CFA) for acquiring red, green, and blue color data using one pixel array. In one embodiment, the CFA may include a Bayer pattern. During image signal processing, demosaicing may be applied to interpolate missing color samples from the raw image pattern. In one embodiment, interpolation for the green color channel may include employing edge-adaptive filters with weighted gradients of horizontal and vertical filtered values. The red and blue color channels may be interpolated using color difference samples with co-located interpolated values of the green color channel. In another embodiment, interpolation of the red and blue color channels may be performed using color ratios (e.g., versus color difference data).

Owner:APPLE INC

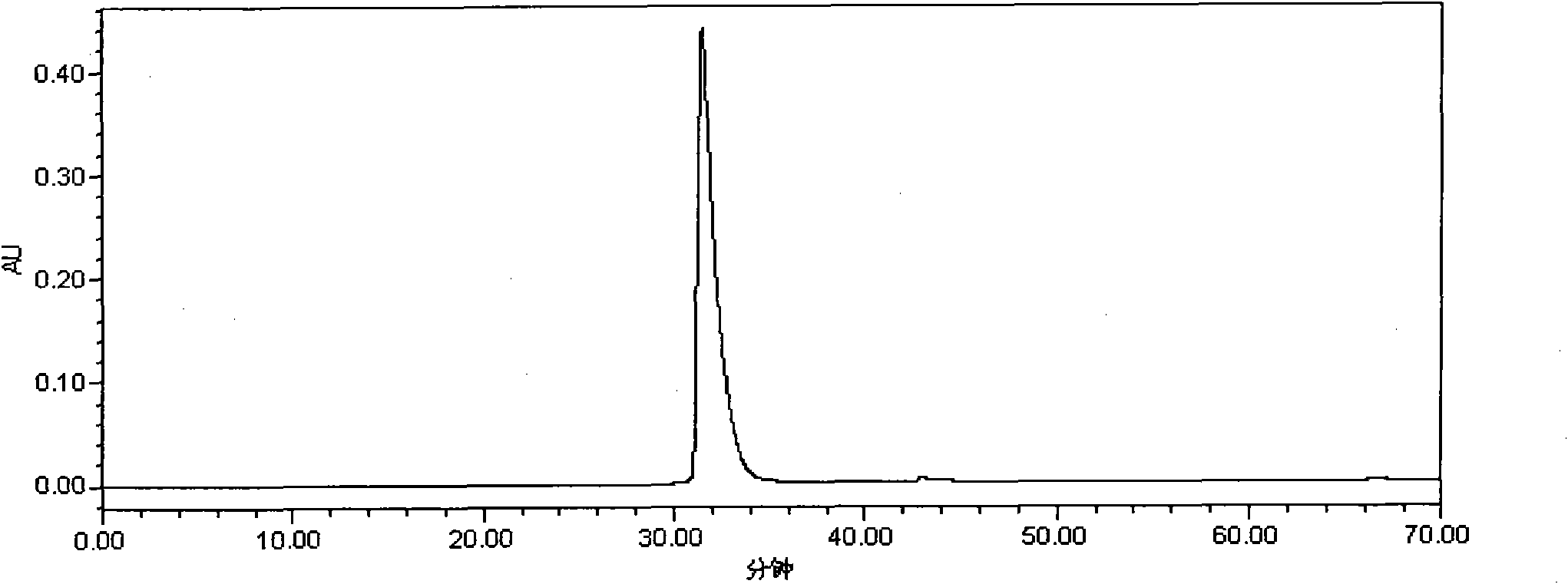

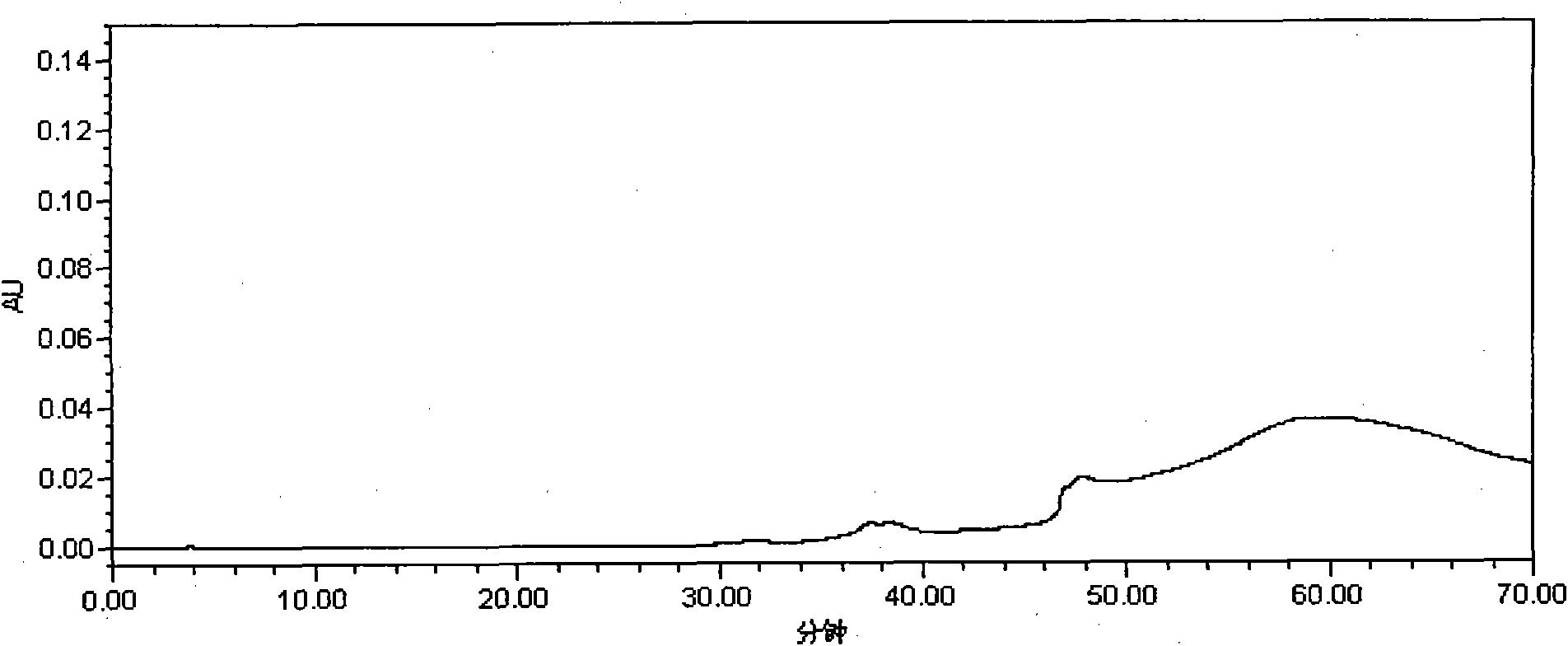

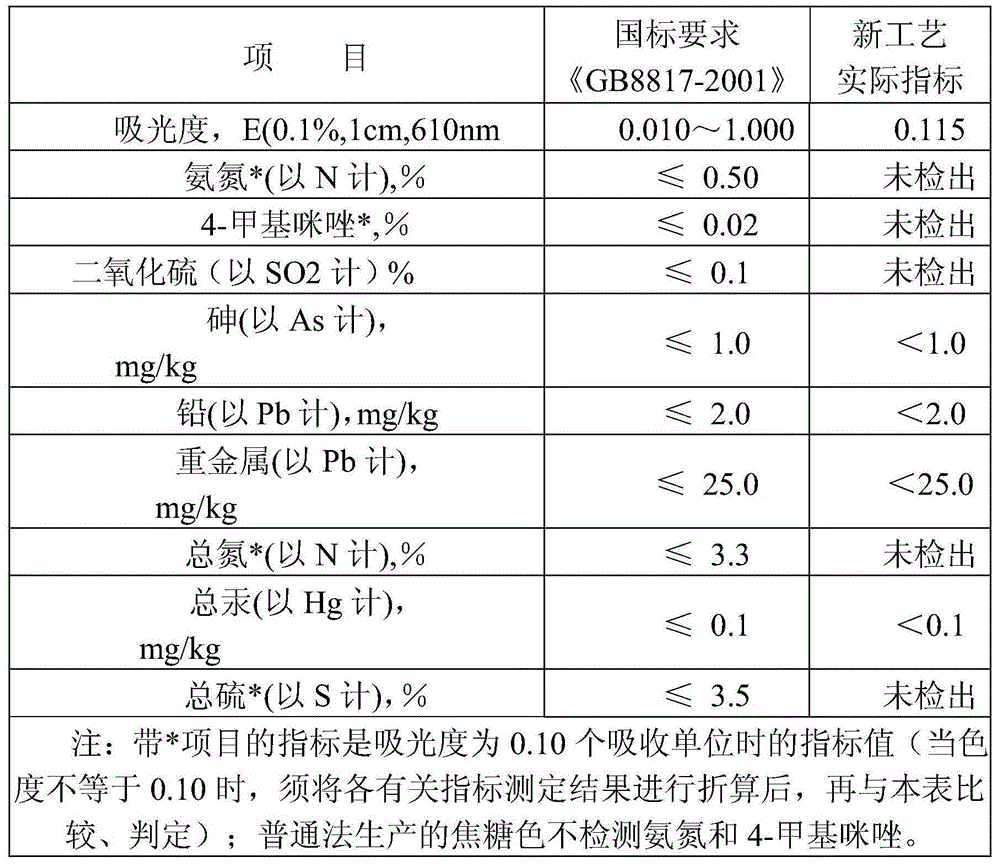

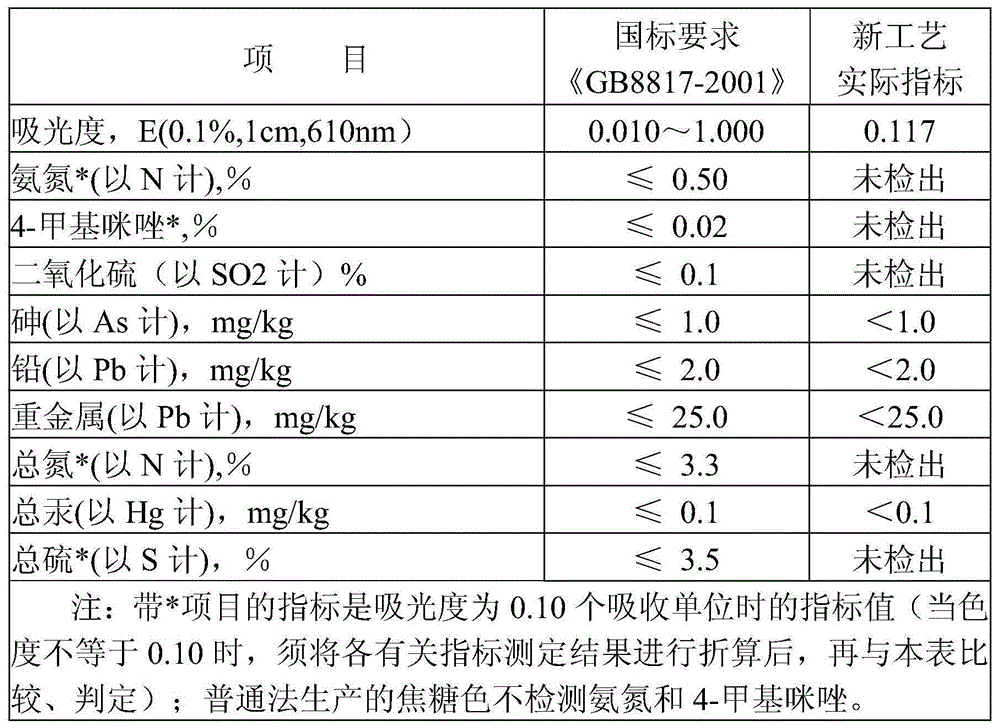

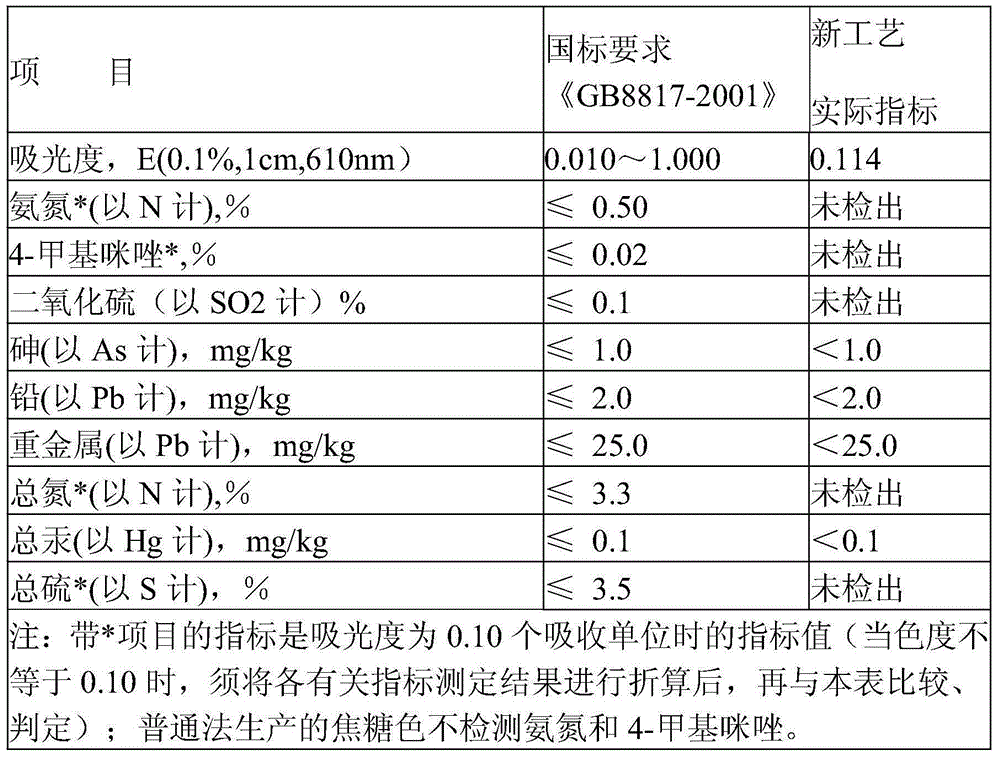

Method for preparing caramel colorant by using multistage membrane separation

The invention discloses a method for preparing a caramel colorant by using multistage membrane separation. The method comprises the following steps of: mixing sugar sources and amino acid or ammonium salt, heating the mixture in solution or suspension state to the temperature of between 110 and 150 DEG C, and holding the temperature; passing an obtained reaction liquid through a membrane A under the pressure of between 0 and 5 bar and at the temperature of between 4 and 60 DEG C, and collecting an entrapped component and filtrate; homogenizing the entrapped component by using a colloid mill, an ultra-high pressure microfluidizer or an ultra-high pressure homogenizer, passing the homogenized component through the membrane A again for filtration, and collecting a filtered component; merging the filtrate, passing the filtrate through one or more of membranes B, C and D step by step under the pressure of between 0 and 5 bar and at the temperature of between 4 and 60 DEG C, and collecting an entrapped component and a filtered component; and concentrating or drying the entrapped component to prepare a caramel colorant product. Through the selection of multistage membranes, the aim of preparing the caramel colorant which meets the requirements of different color ratios, red indexes and yellow indexes, and improves food quality and safety is fulfilled.

Owner:上海爱普食品工业有限公司

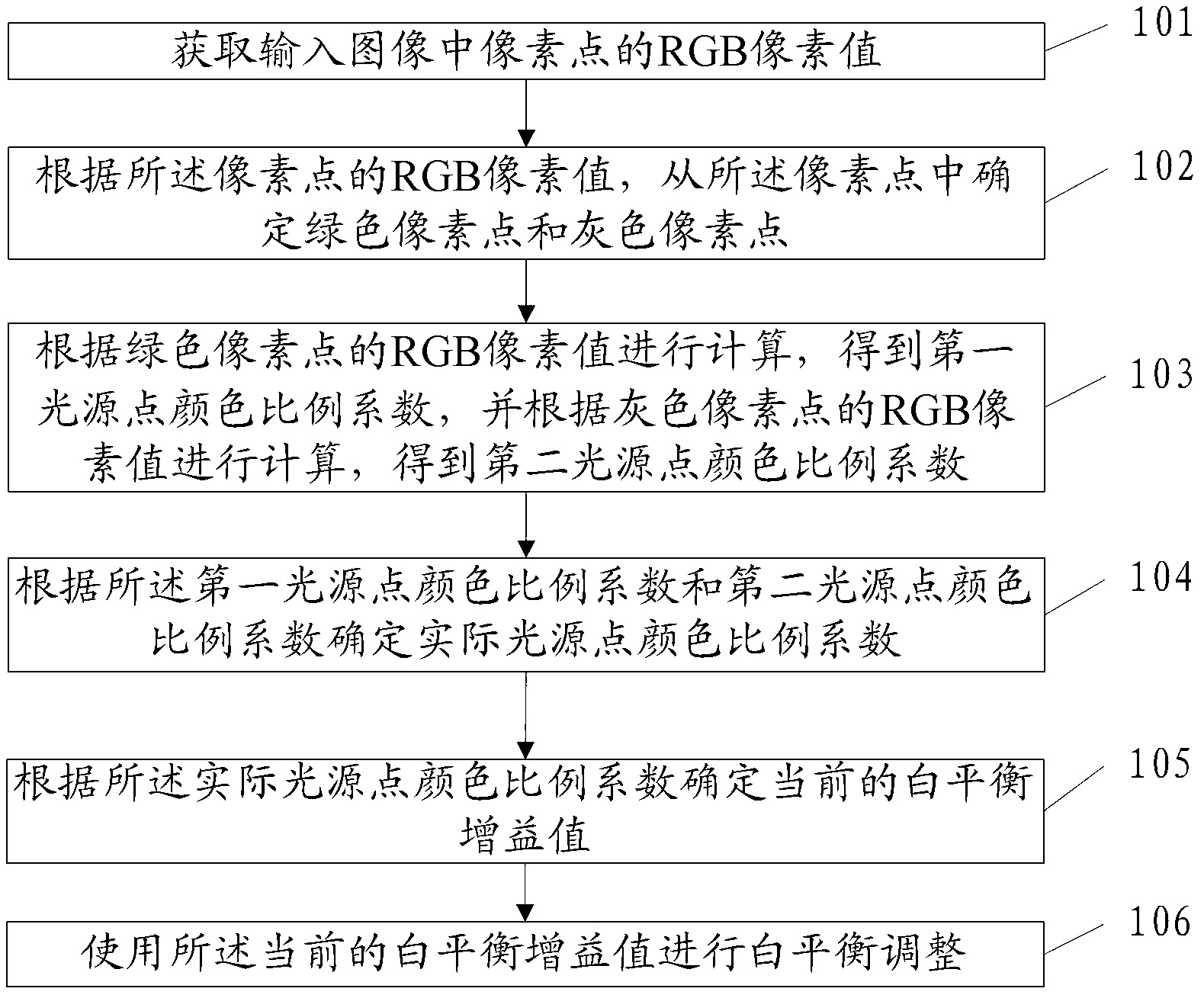

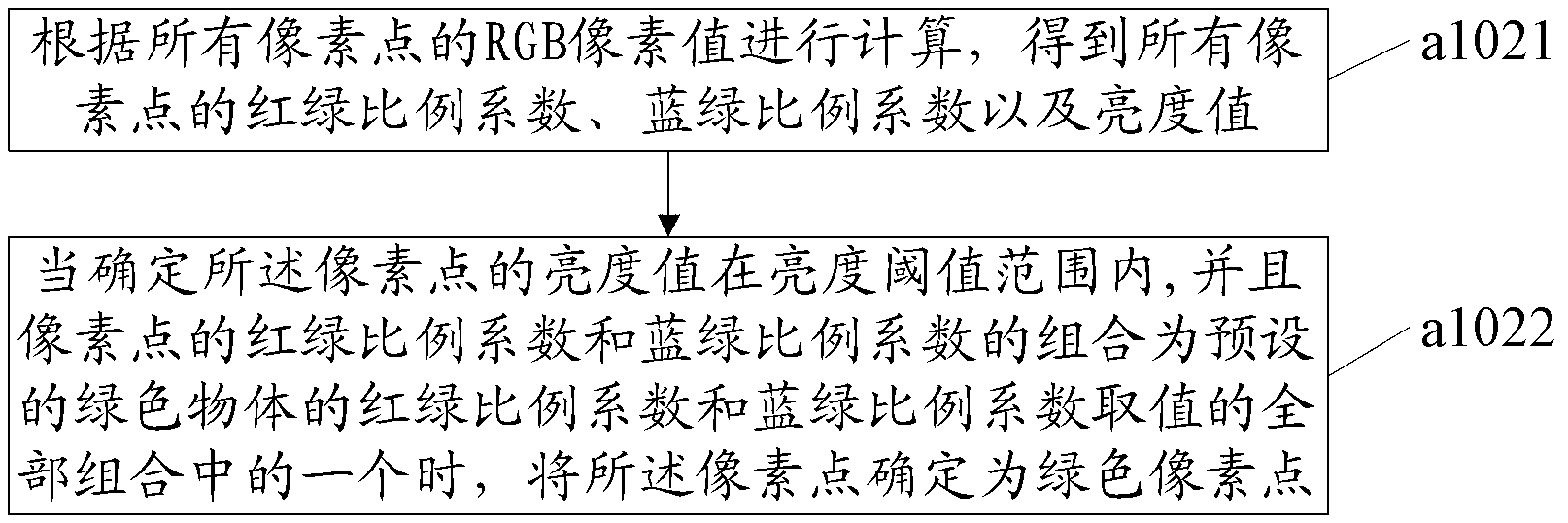

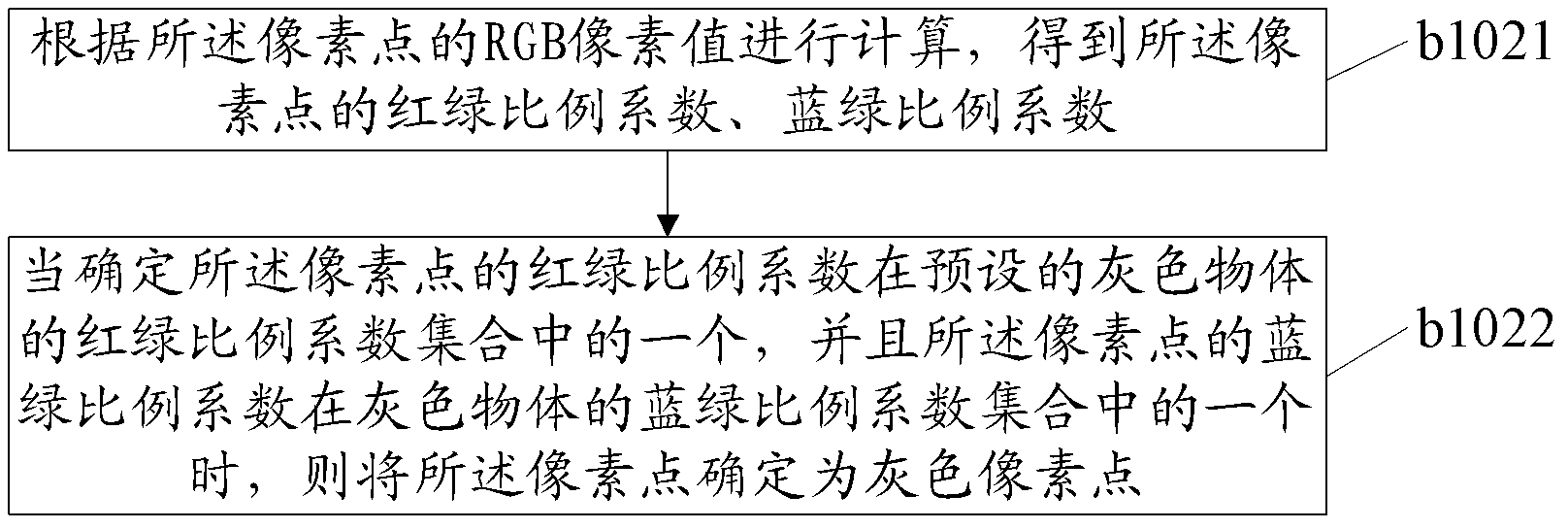

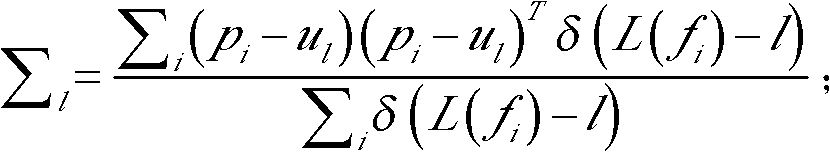

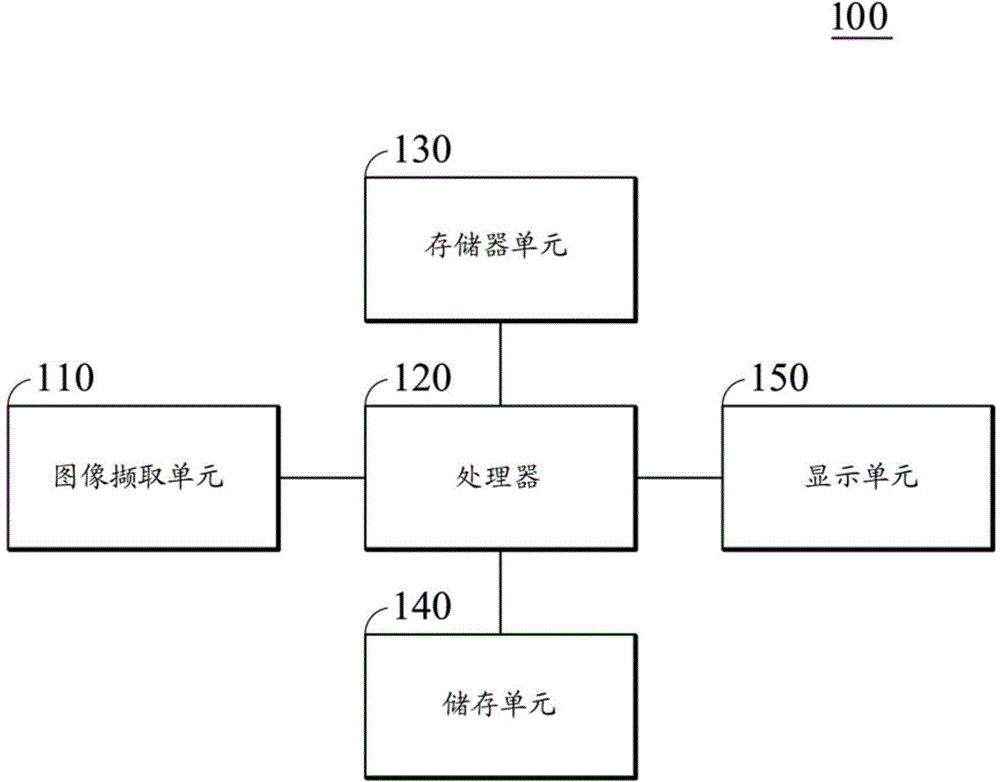

White balance adjusting method and device

ActiveCN103227928AWhite balance autoAccurate gain valueColor signal processing circuitsImaging processingColor ratio

The invention relates to the field of image processing, and discloses a white balance adjusting method and device. The method includes the following steps: obtaining the corresponding RGB pixel values through distinguishing green pixels and grey pixels; confirming impossible light source points as per the RGB pixel values respectively corresponding to the green pixels and the grey pixels; then performing comprehensive judgment as per the impossible light source points to confirm the accurate actual color-ratio factor of the light source points; then calculating the white balance gain value as per the accurate actual color-ratio factor of the light source points; and finally performing the white balance adjustment.

Owner:HUAWEI TECH CO LTD

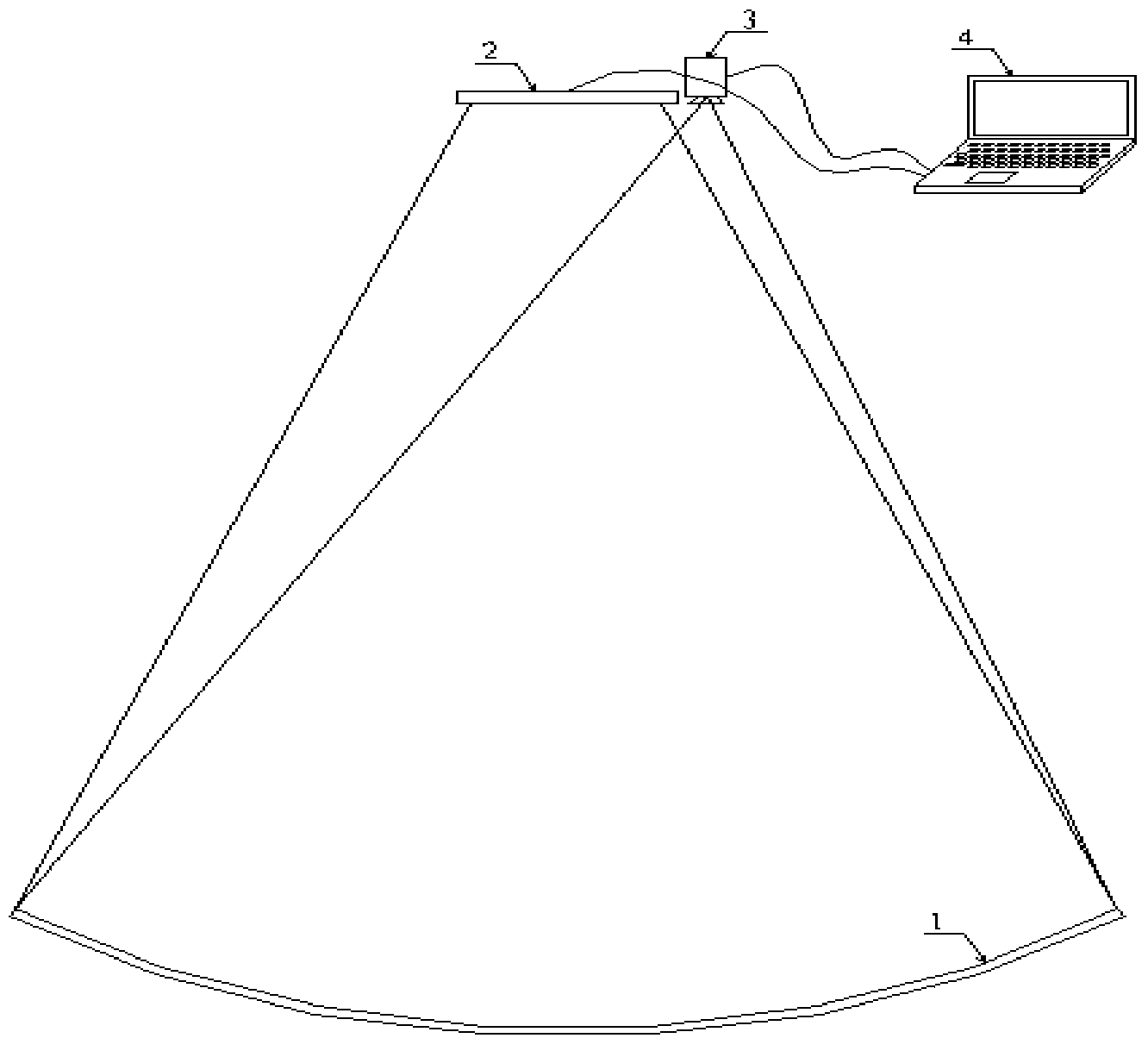

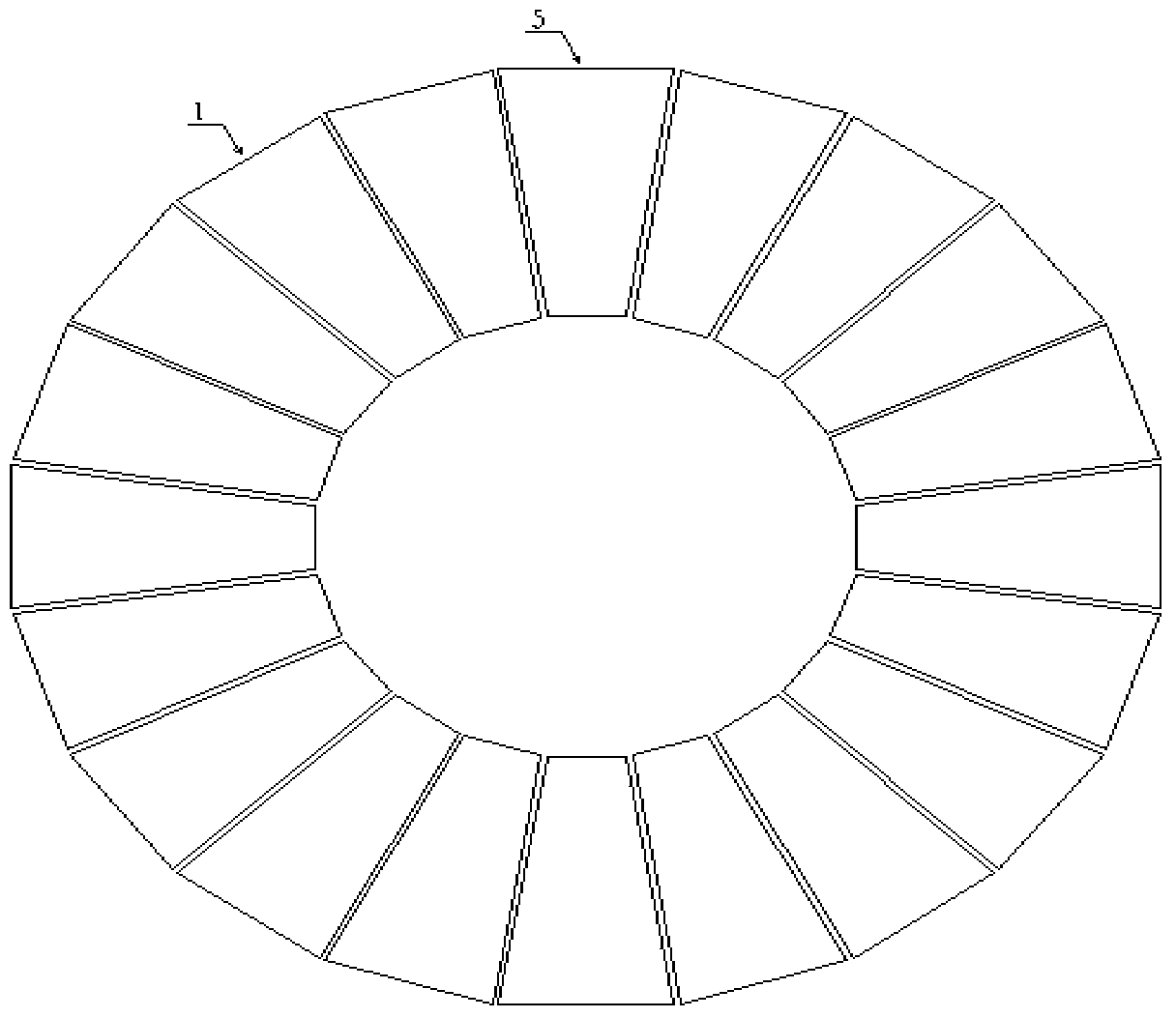

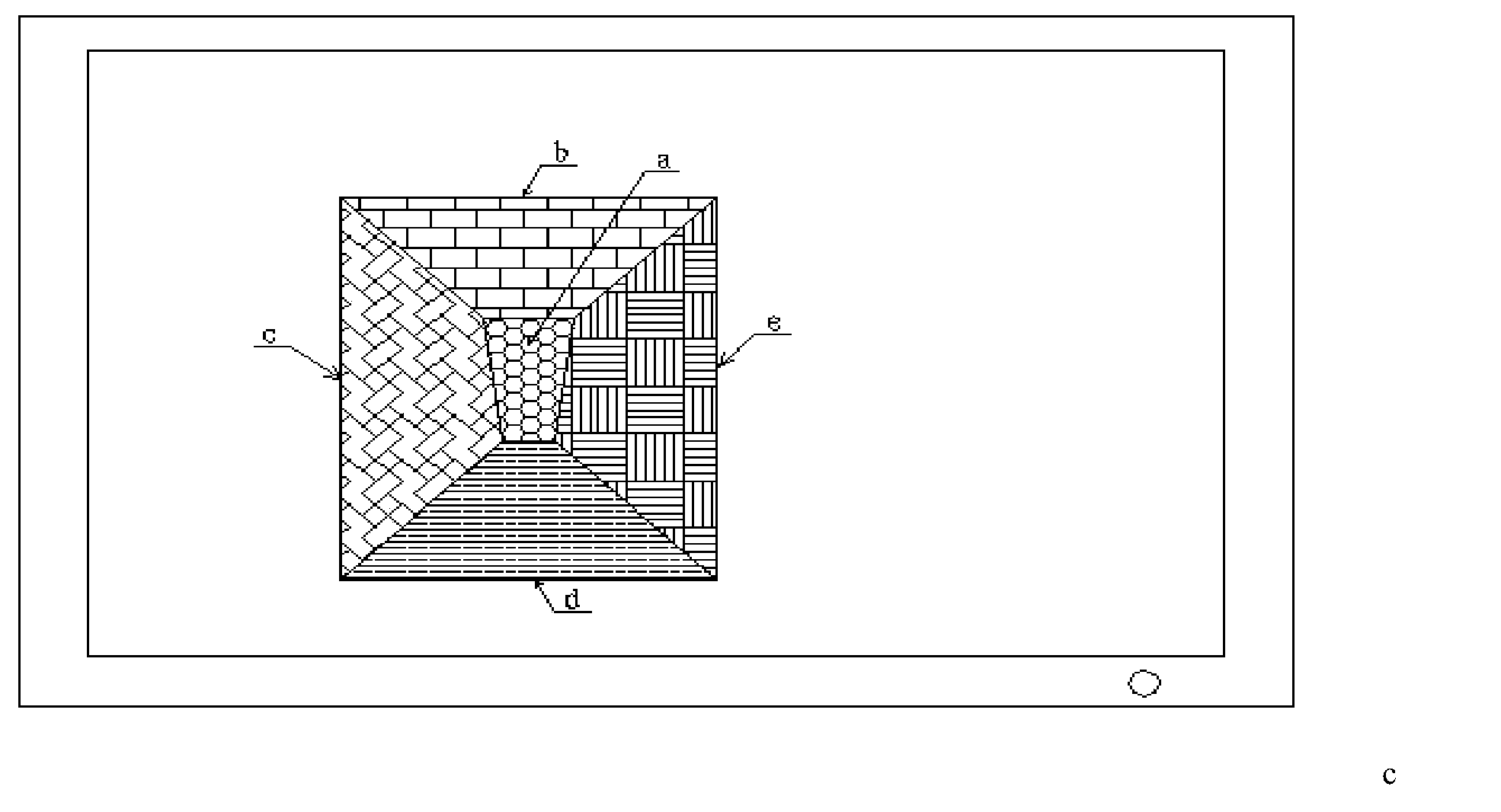

Automatic focusing system used for regulating solar condensing lens and focusing method thereof

InactiveCN104062743AHigh measurement accuracyHigh precisionSolar heating energySolar heat devicesColor imageComputer science

The invention discloses an automatic focusing system used for regulating a solar condensing lens and a focusing method of the automatic focusing system. The automatic focusing system comprises image display equipment, image collection equipment and image data processing equipment, wherein the image collection equipment is used for collecting data of images reflected by reflectors; the image display equipment is used for displaying display images which are controlled to be output by the image data processing equipment; the image data processing equipment is used for controlling the image display equipment to output the display images corresponding to region areas of the reflectors of a condensing system in a one-to-one mode, the display image of the region area of any one reflector and display images of region areas on the peripheries of the reflectors are different color images, and the image collection equipment is controlled to perform analysis and processing and output corresponding focusing data after collecting the corresponding images. According to the automatic focusing system, the inclination angle is judged by observing the image colors of the reflectors, the color ratios of discs are calculated and are compared with a pre-stored empirical data base, regulating efficiency is improved substantially, and the regulating time is shortened.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

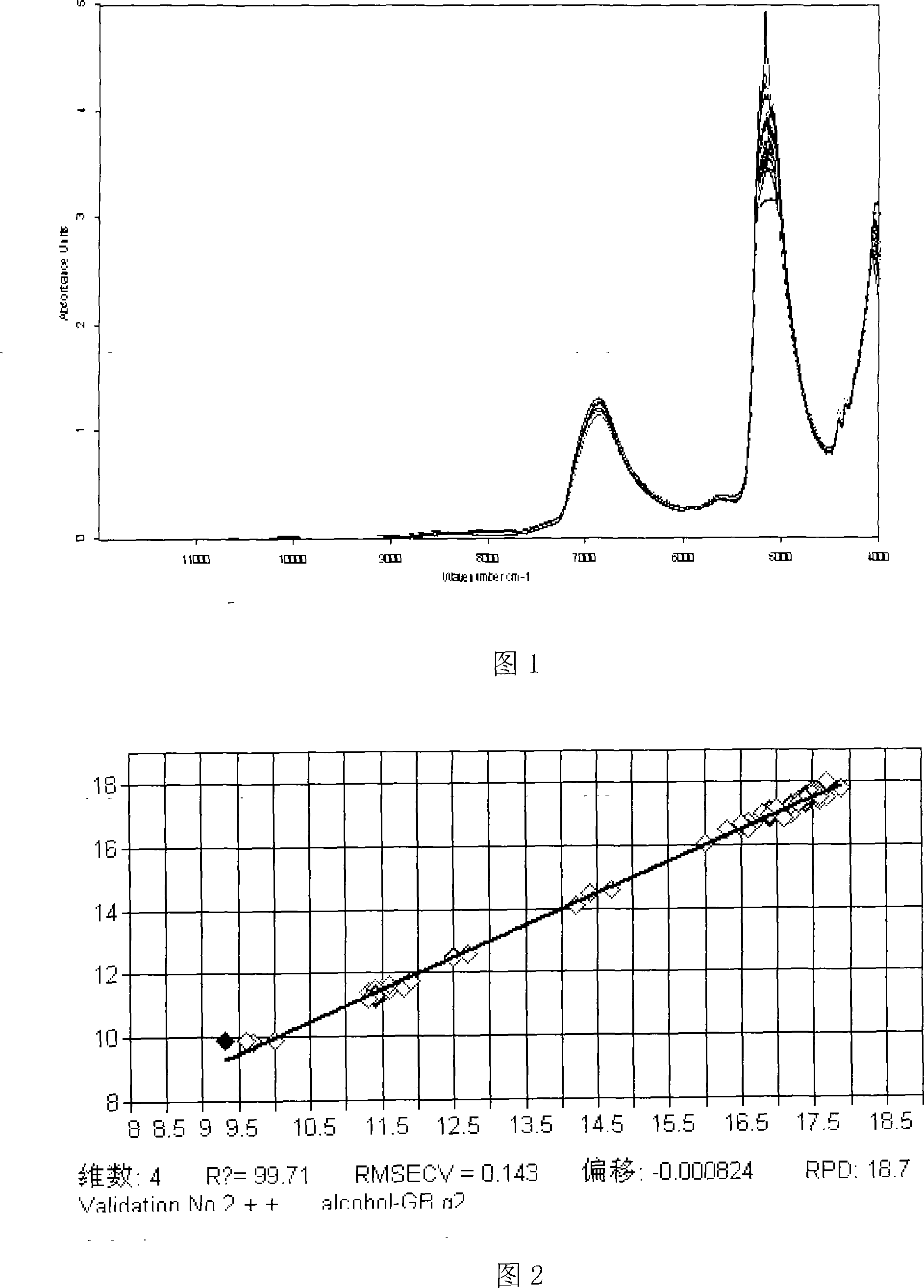

Method for quickly detecting yellow wine quality index

InactiveCN101216419AEasy to operateFast testColor/spectral properties measurementsComplex mathematical operationsFourier transform on finite groupsBiology

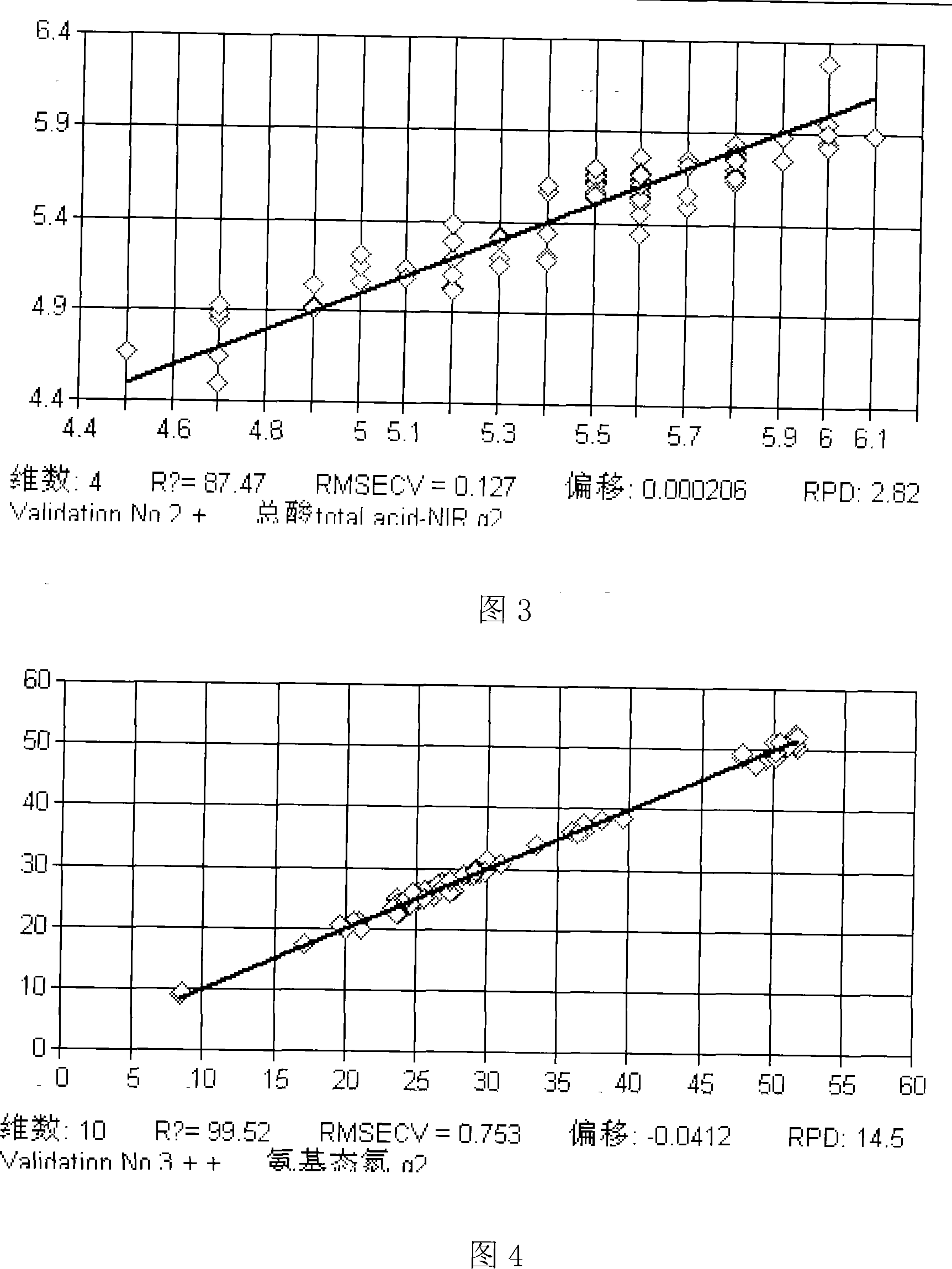

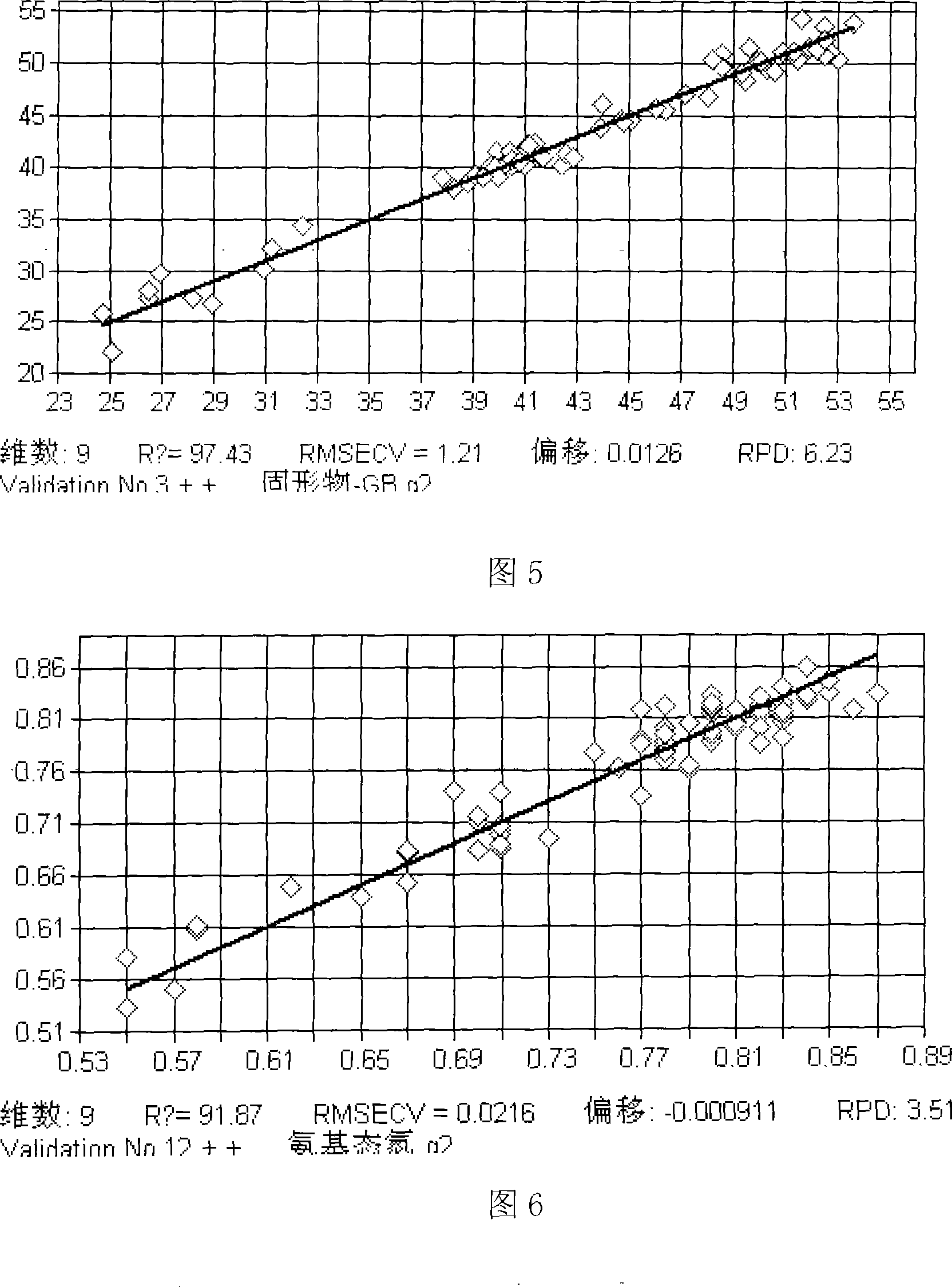

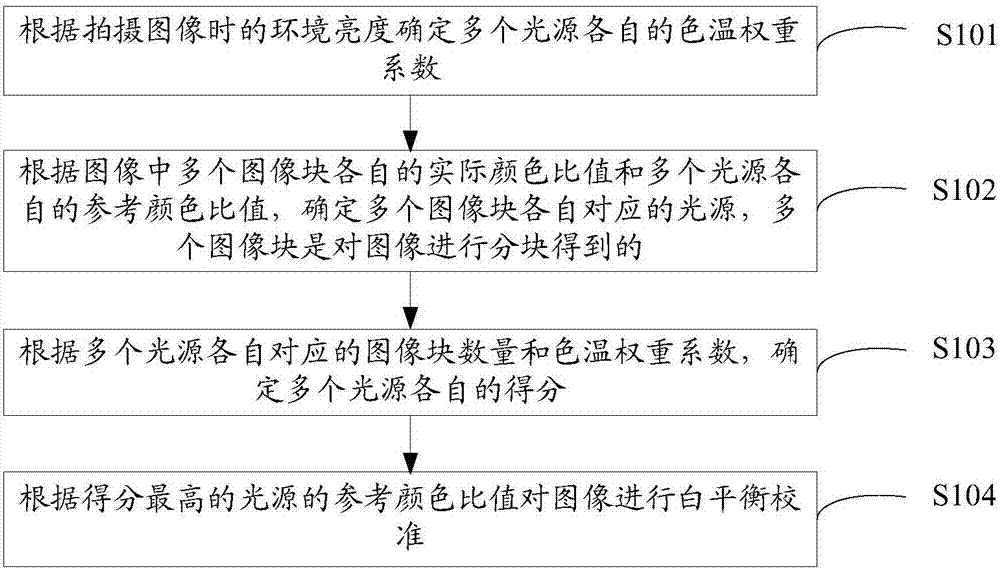

The invention relates to a detection method of quality index of yellow rice wine, in particular to a method for rapidly detecting quality index of yellow rice wine, which has simple operation, improved detection speed and greatly improved time efficiency and production efficiency. The method comprises the following steps of: (1) scanning a yellow rice wine sample to be detected by Fourier transform near infrared spectrometer and a liquid fiber probe to obtain the spectrum of the yellow rice wine sample; and (2) sending the spectrum of the yellow rice wine sample obtained in step (1) to a quantitative spectrum analysis software package, and calculating the contents of quality indexes of the yellow rice wine sample by using a pre-constructed quality index model of the yellow rice wine, wherein the quality indexes comprise one or more of alcohol degree, total acid, total sugar, ammonia nitrogen, non-sugar solids, volatile ester and color ratio. The invention has the advantages of simple operation, improved detection speed, no pollution in the detection process and nondestructive detection, and can be further used for production line to achieve online detection and control.

Owner:陈郁

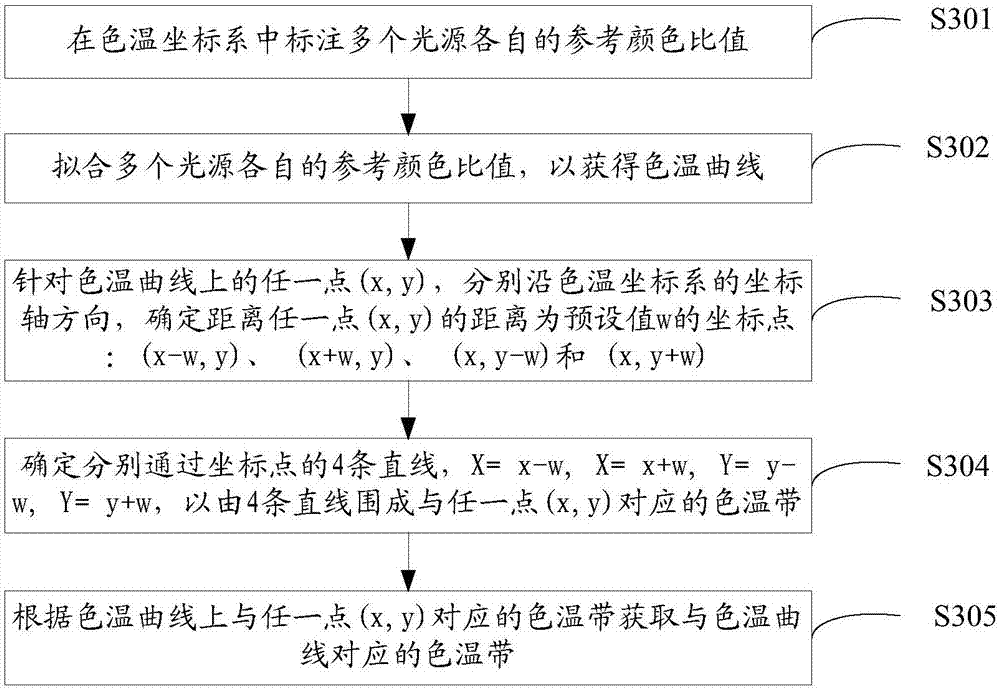

White balance calibration method and electronic equipment

InactiveCN107483908AImprove image qualityColor signal processing circuitsPicture signal generatorsWeight coefficientImaging quality

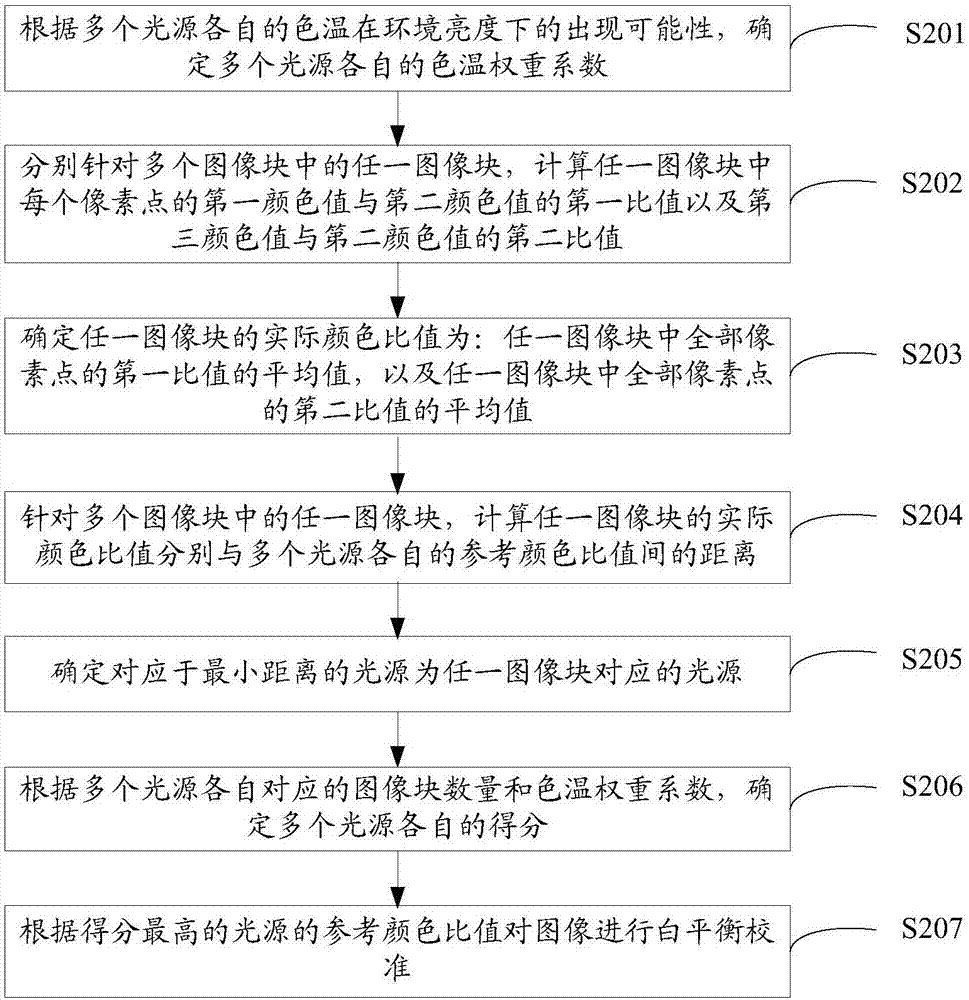

The embodiment of the invention provides a white balance calibration method and electronic equipment. The method comprises the following steps: determining color temperature weight coefficients of multiple light sources according to the ambient brightness during image shooting; performing blocking processing for an image, calculating the actual color ratio of each image block after being subjected to blocking processing, and determining which light source each image block should correspond to according to the actual color ratio of the image blocks and the reference color ratio of each light source; separately determining the own scores of multiple light sources according to the number of the image blocks and the color temperature weight coefficient corresponding to each light source, and determining that the color temperature of the shooting environment is closer to the color temperature of the light source when the score is higher; and calibrating the color of each pixel point in the image according to the reference color ratio of the light source with the maximum score to achieve white balance calibration of the image. By adopting the scheme provided by the invention, the light source corresponding to the image shooting process can be accurately determined according to the brightness, and even if a large area of monochrome appears in the image, the phenomenon of wrongly determining the light source cannot occur, and thus the image quality can be improved.

Owner:GEER TECH CO LTD

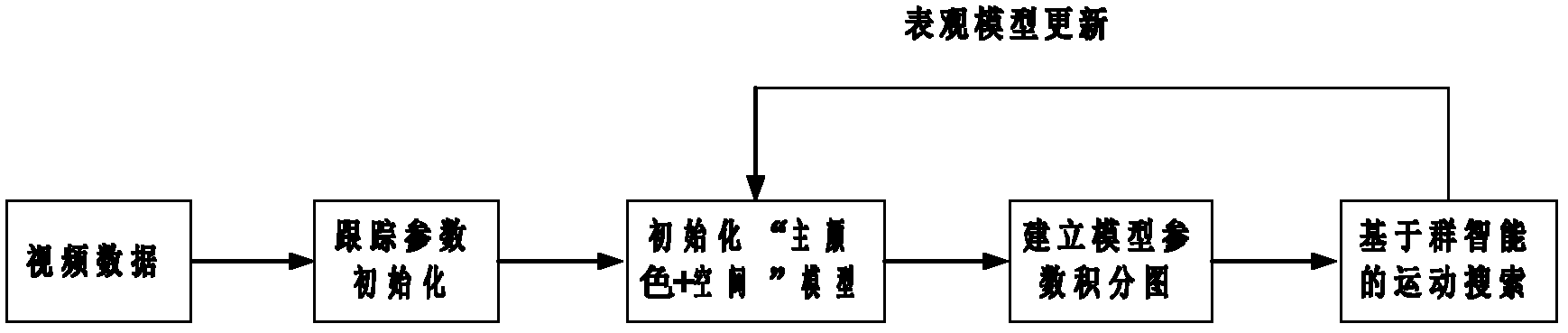

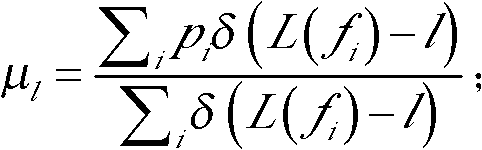

Target tracking method oriented to video with low frame rate

InactiveCN102663775ASmall amount of calculationRetain fitnessImage analysisDistribution characteristicComputer science

The invention discloses a target tracking method oriented to a video with a low frame rate. The method comprises the following steps: (1), representing a target region by a method integrating a dominant color and a space distribution characteristic thereof; (2), employing a cross color ratio-based matching criterion to carry out similarity matching on a candidate region and the target region; (3), employing a parameter integrogram-based fitness function to characterizing a matching degree of a sample particle and a target template; and (4), utilizing an annealing particle swarm optimization framework with simulation of biological swarm intelligence to search abrupt motions caused by a video with a low frame rate. According to the invention, the effective target tracking method is realized; and moreover, experimental results show that the provided method, compared with other classical low frame rate tracking methods, has good effectiveness and robustness.

Owner:WENZHOU UNIVERSITY

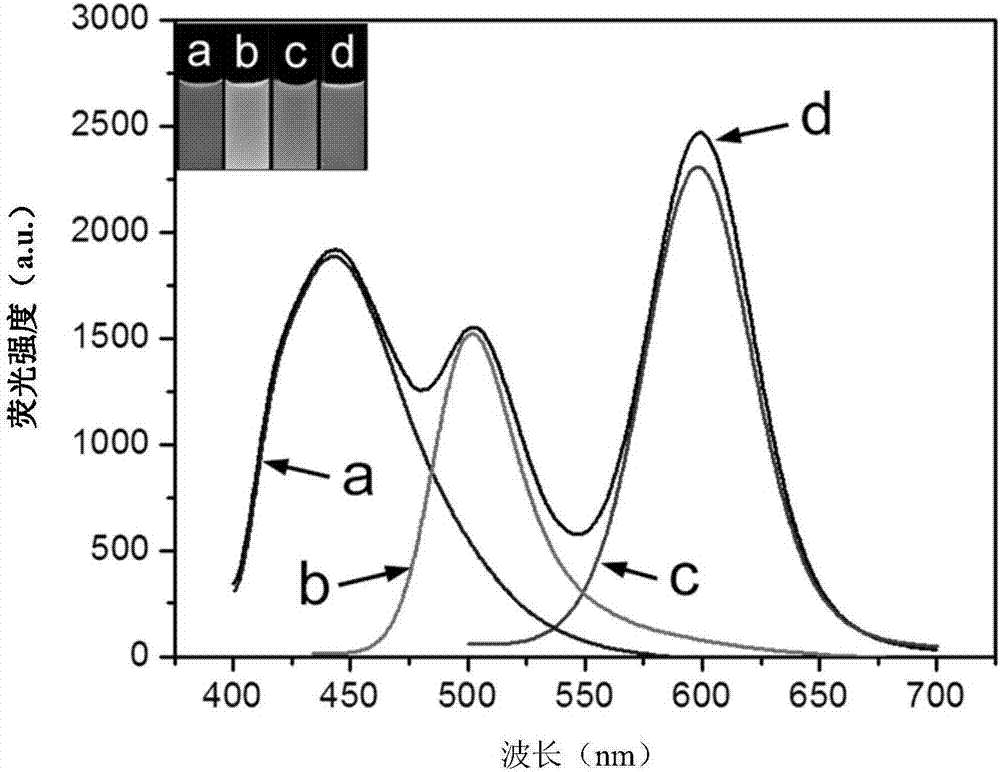

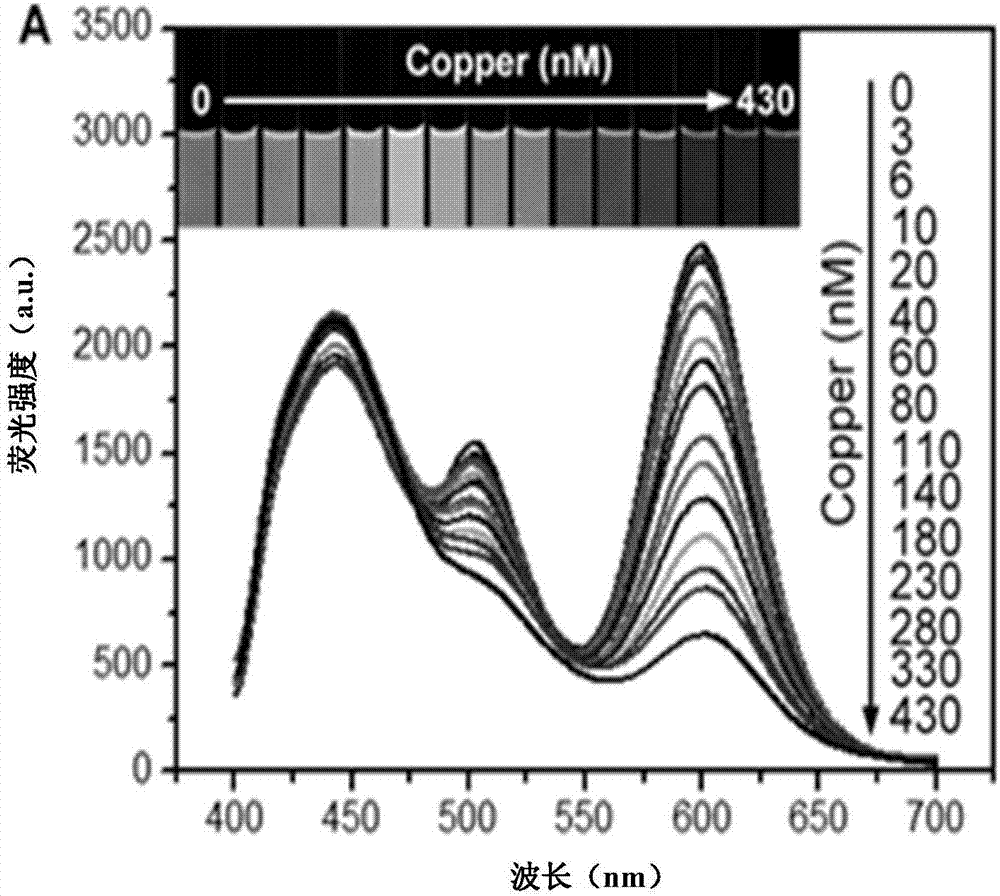

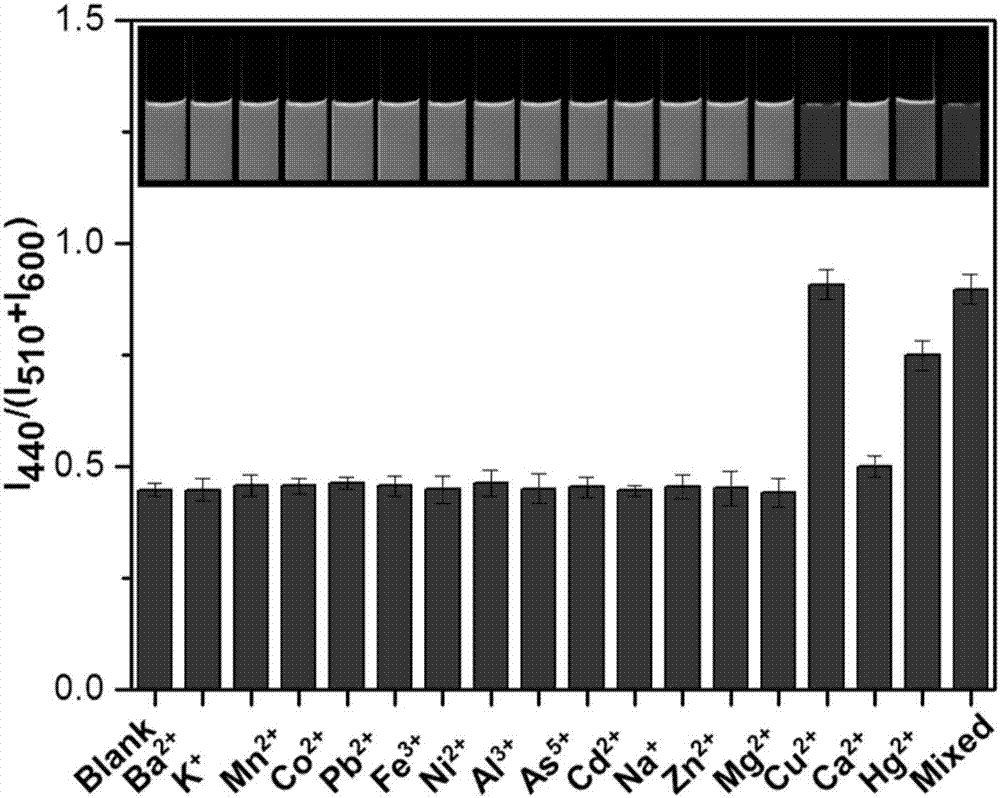

Fluorescent wide chroma test paper for visually detecting copper ions as well as preparation method and application of test paper

ActiveCN107345910AAvoid interferenceWide range of discolorationFluorescence/phosphorescenceFluorescenceColor changes

The invention discloses fluorescent wide chroma test paper for visually detecting copper ions as well as a preparation method and application of the test paper. The preparation method comprises the following steps: by taking a three-color ratio fluorescence probe as ink and taking filter paper as a solid-phase carrier through an inkjet printer, uniformly printing, thereby obtaining the test paper capable of visually detecting the copper ions, wherein the three-color ratio fluorescence probe refers to blue carbon dots, green quantum dots and red quantum dots, and the quantum dots are all modified by 3-mercaptopropionic acid. The three-color ratio fluorescence test paper is constructed to be used for visually detecting the copper ions by utilizing double-quenching principle first, the prepared detection test paper has the advantage that the color change range is wide compared with the conventional double-ratio fluorescence test paper, and along with addition of the detection object, test paper colors can be obviously identified by naked eyes from light scarlet, light flesh color, deep orange, grass green, dark olive green, slate blue, royalblue to cyanic color (Figure 4).

Owner:NANJING MEDICAL UNIV

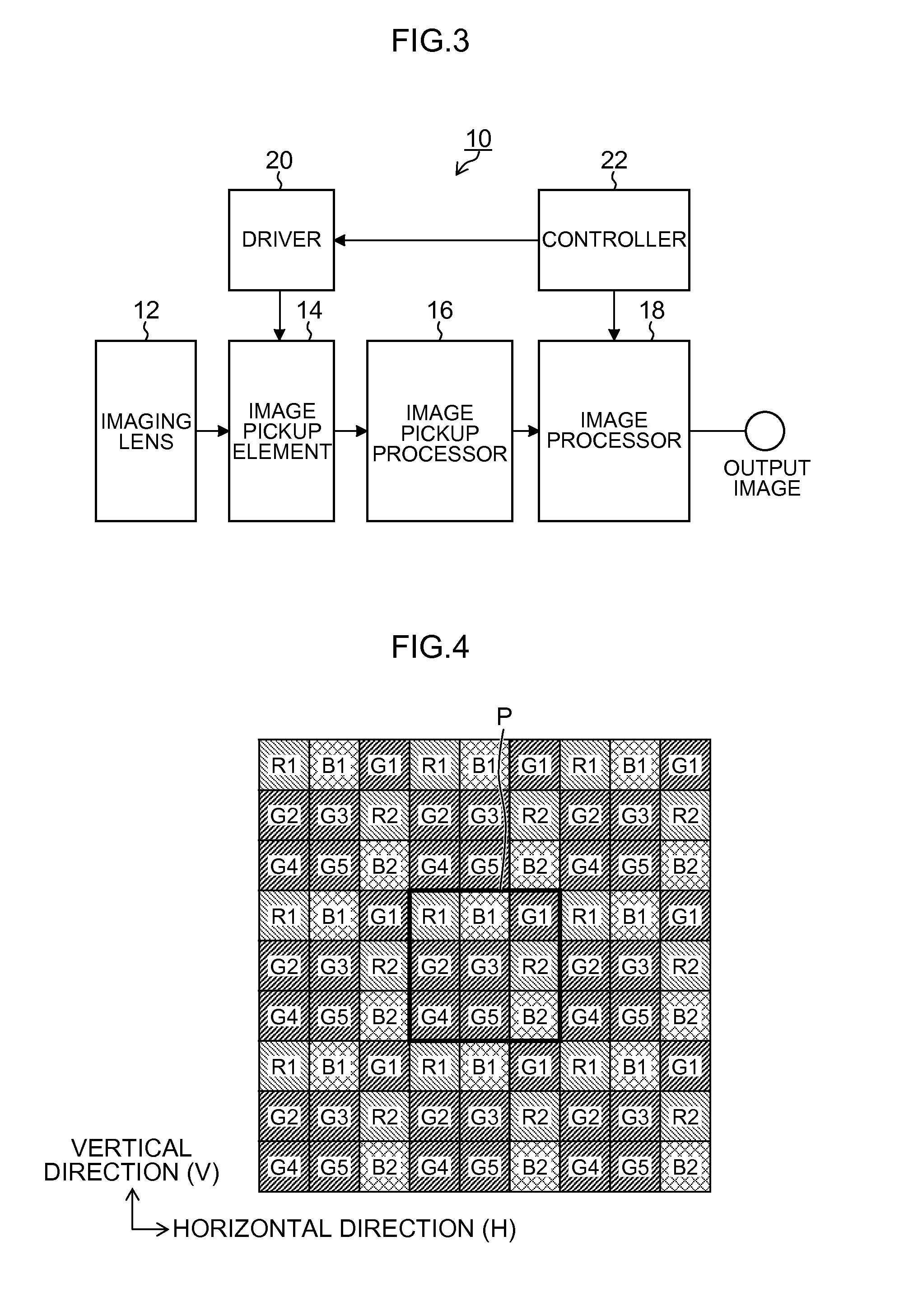

Image processing apparatus, method, recording medium and image pickup apparatus

ActiveUS20150172615A1Accurate calculationReduce generationImage analysisColor signal processing circuitsPattern recognitionImaging processing

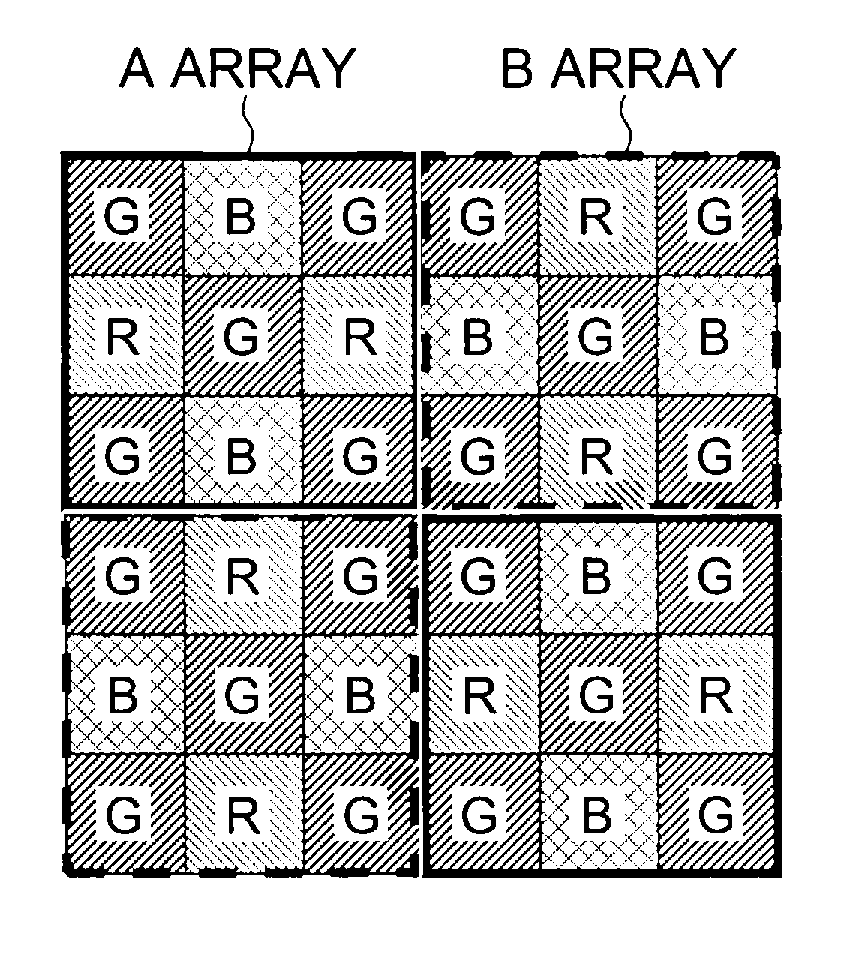

Calculation of GR and GB color ratios in a local area uses a weighted average filter having weighting coefficients where the ratio of total sums of weighting coefficients for G and R pixels is 1:1, and weighted average filter having weighting coefficients where the ratio of total sum of weighting coefficients for G and B pixels is 1:1, respectively, on pixel lines in a horizontal direction and a vertical direction in a kernel. R and B pixel values are then calculated by interpolating the pixel value of a pixel to be processed with the G pixel value at the pixel position to be subjected to a demosaic process and the color ratio.

Owner:FUJIFILM CORP

Method for preparing caramel pigment

InactiveCN1594442ASufficient sourceReach the color ratioNatural dyesFood preparationFood additiveSucrose

The invention discloses a method for preparing caramel pigment mainly used as the liquor color mixing agent and food additive, the preparation process comprises the steps of disintegrating, filtering, concentration. The method can not only meet the color ratio and stability requirement for the cane sugar production, but also preserve the eighteen amino acids and part of the trace elements in the zein.

Owner:兰州金陵石化有限责任公司

Process for producing caramel pigment

InactiveCN101693903AEliminate the extraction processImprove stabilityNatural dyesFermentationAlpha-amylaseHigh pressure

The invention discloses a process for producing caramel pigment, comprising the following procedures of a) gelatinization procedure, b) liquefaction and saccharification procedure, c) hydrolysis procedure and d) ammonification procedure, wherein the b) liquefaction and saccharification procedure comprises the following steps: adding alpha-amylase and saccharifying enzyme to the gelatinized purple sweet potato with the pH of 4.5-6.0 and the temperature of 70-95 DEG C, and reacting for 30-60min, wherein the weight proportion of the purple sweet potato, the alpha-amylase and saccharifying enzyme is 1:0.01-0.04:0.01-0.04. Compared with the prior art, in the invention, the purple sweet potato is taken as the raw material, therefore the extraction procedure of starch is saved and the process flow is simplified; furthermore, the purple sweet potato contains natural pigment and has good acid resistance, salt resistance and good stability; the caramel pigment produced by taking the sweet potato as the raw material has high color ratio and good stability, generates no pollutants during the hydrolysis process, shortens the production period and saves the cost; and the caramel pigment prepared by utilizing the sugar solution through a high-pressure ammonia method has good color ratio and good product quality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

White balance method in multi-exposure imaging system

ActiveCN105635593ATelevision system detailsColor signal processing circuitsExposure valueColor ratio

A white-balance method for use in a multi-exposure imaging system having an image capturing unit is provided. The method includes the steps of: utilizing the image capturing unit to simultaneously capture a first image and a second image of a scene with a first exposure value and a second exposure value, respectively, wherein the second exposure value is smaller than the first exposure value, and the first exposure value and the second exposure value have individual exposure time and exposure gain; performing light source detection on the second image to obtain light source information and a corresponding light source color ratio of the scene; and performing a color gain process on the first image according to the light source color ratio to generate an output image.

Owner:QUANTA COMPUTER INC

Fabric image color feature extraction method

ActiveCN104281849AGray quantization works fineImprove accuracyCharacter and pattern recognitionSpecial data processing applicationsFeature extractionGray level

The invention relates to a fabric image color feature extraction method. According to the method, a color space quantification improvement method based on an essential color clustering method is provided during image color quantification grading, so that gray level quantification is better conducted on the color of each pixel in an image; meanwhile, the essential color histogram of the image and the color ratio information of each essential color are extracted with the essential color weight histogram, so that the accuracy of fabric image retrieval is improved and a fabric image meeting requirements of users is retrieved efficiently.

Owner:广州盖特软件有限公司

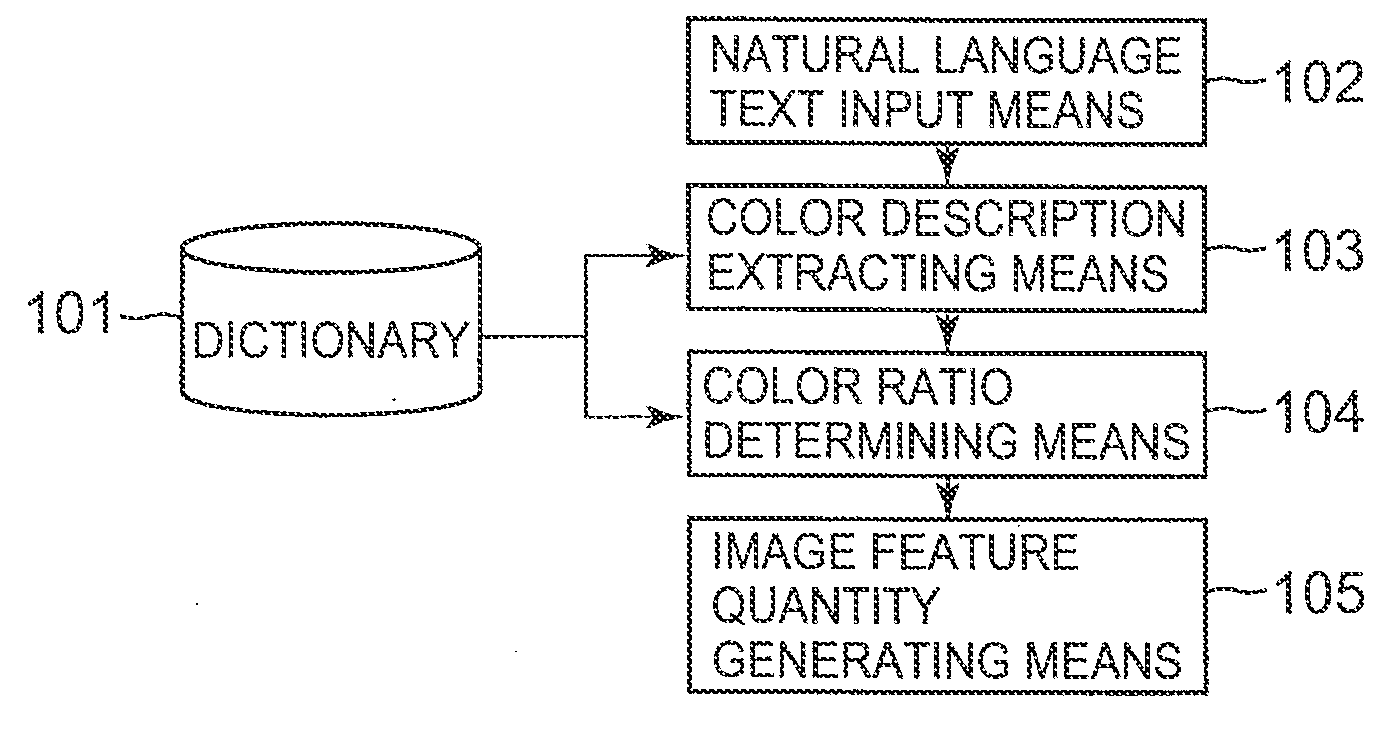

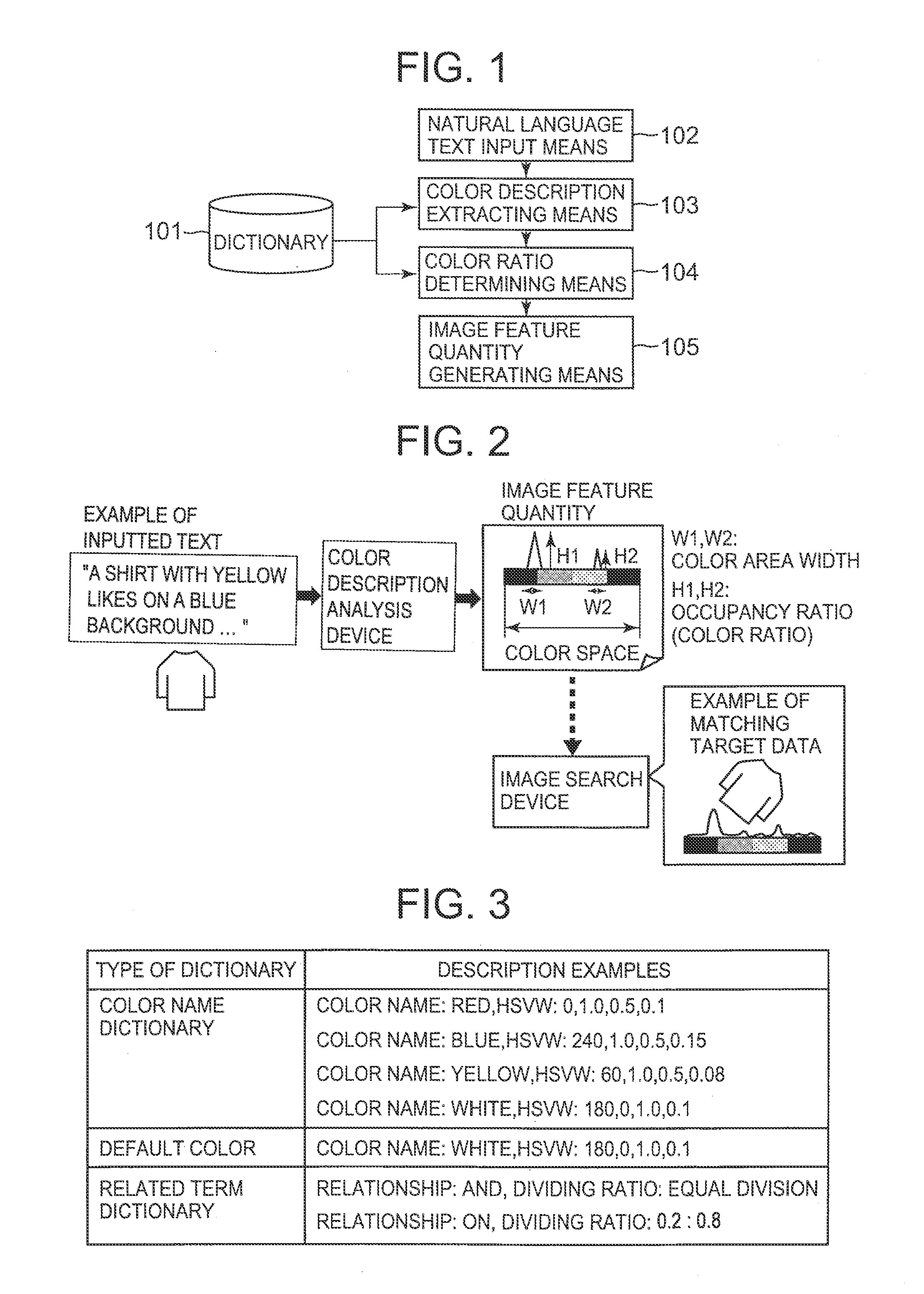

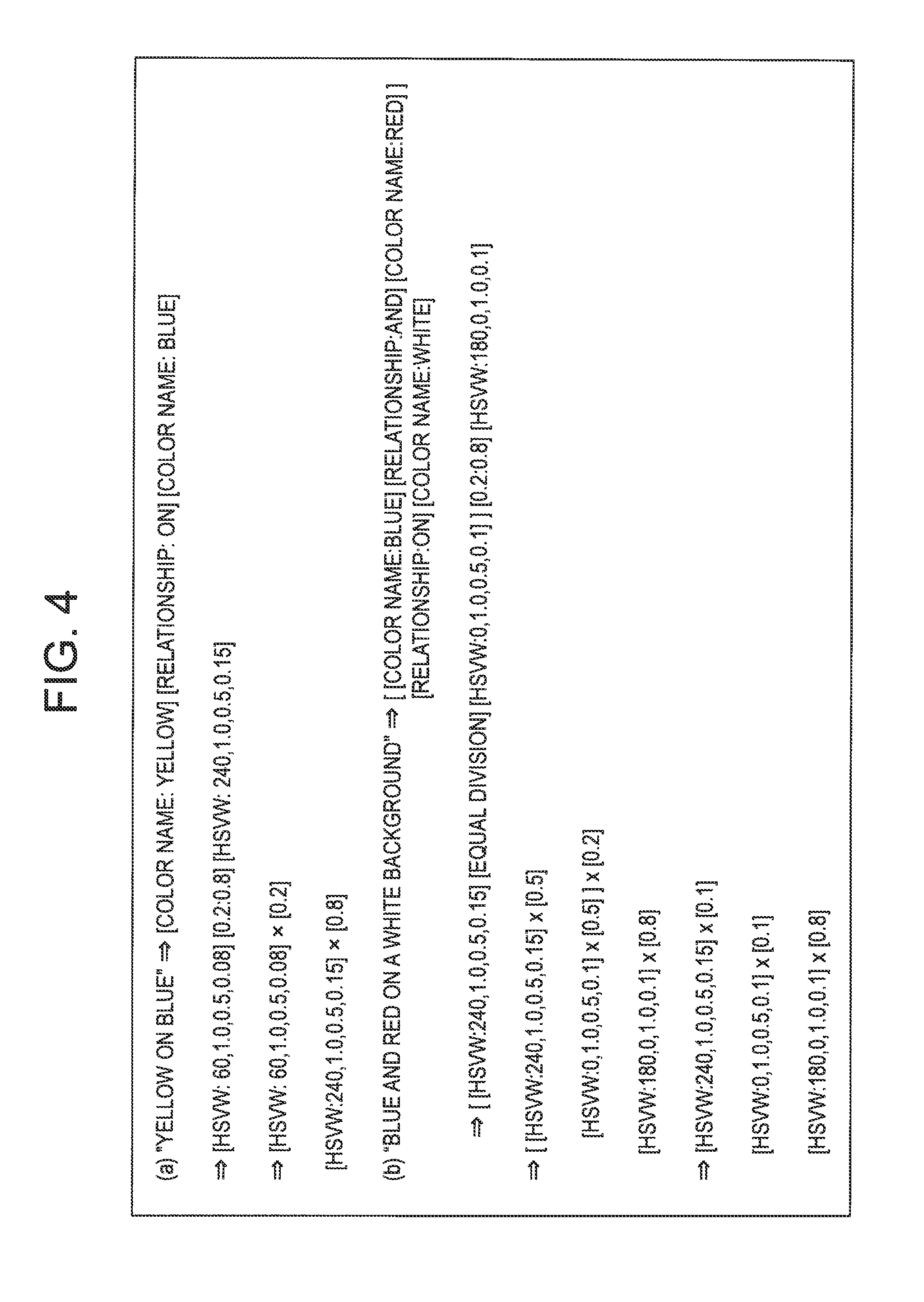

Color description analysis device, color description analysis method, and color description analysis program

ActiveUS20120195499A1Improve accuracyCharacter and pattern recognitionMetadata still image retrievalComputer graphics (images)Algorithm

The present invention provides a color description analysis device which converts a natural language description as a description regarding colors expressed in a natural language into data representing distribution of values in a prescribed color space, comprising color ratio determining means which determines the ratio of each area occupied by each color included in the natural language description in the whole area of an image as the object of the natural language description by use of words and phrases indicating relationship between colors and included in the natural language description.

Owner:NEC CORP

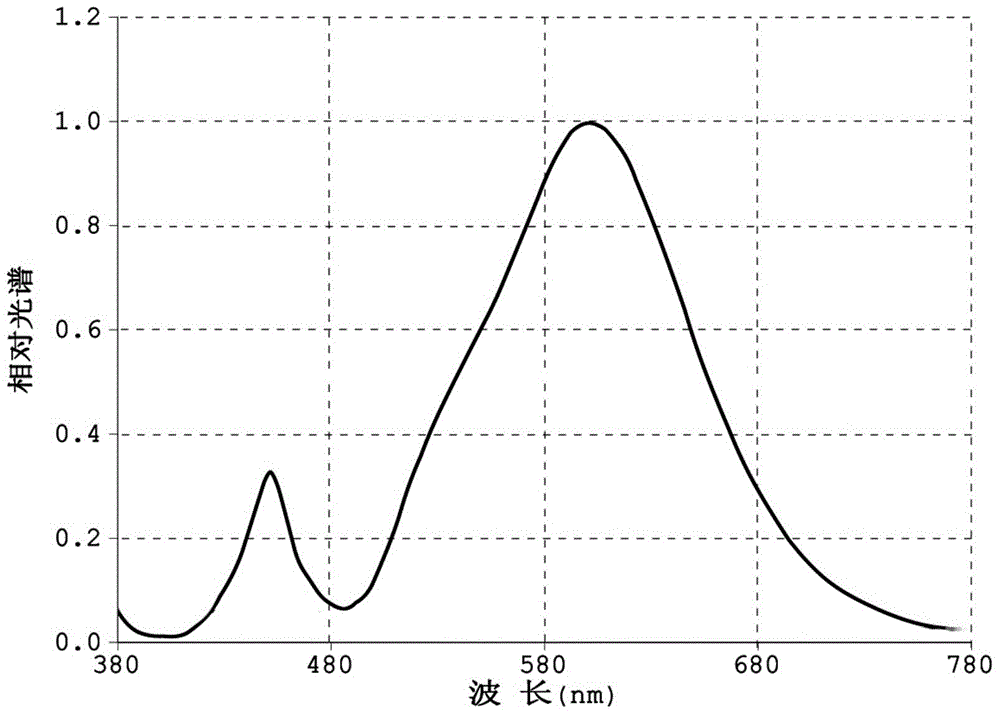

Special LED illumination method and system for laying hen and breeding chicken scale breeding

ActiveCN105028239ANo hidden danger of pollutionImprove photoelectric conversion efficiencyPoint-like light sourceElectric circuit arrangementsTimerBiology

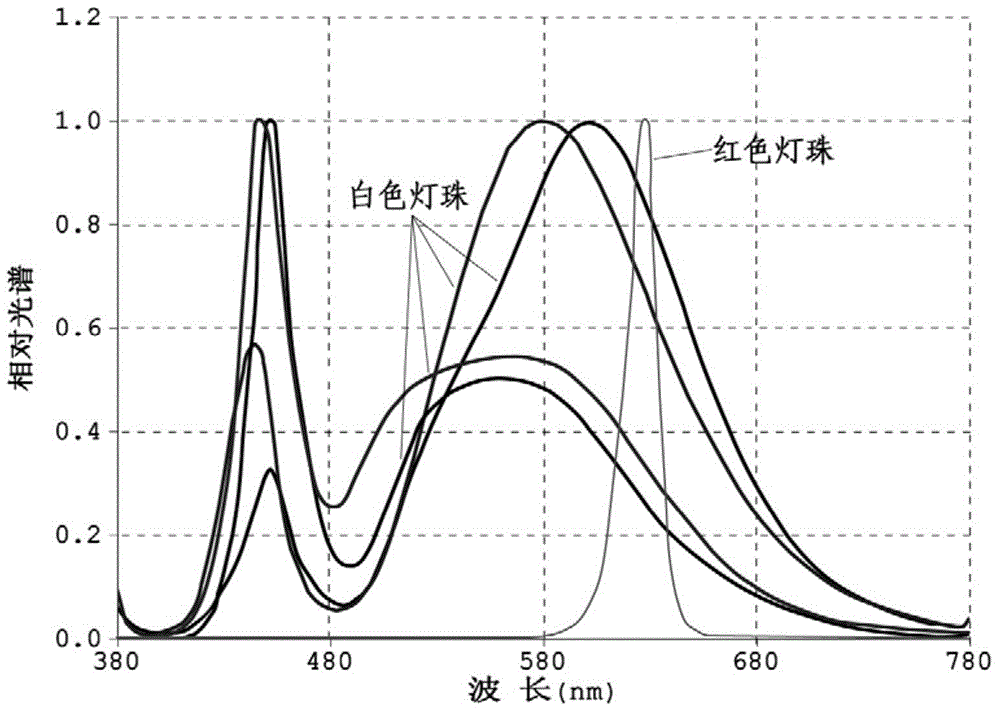

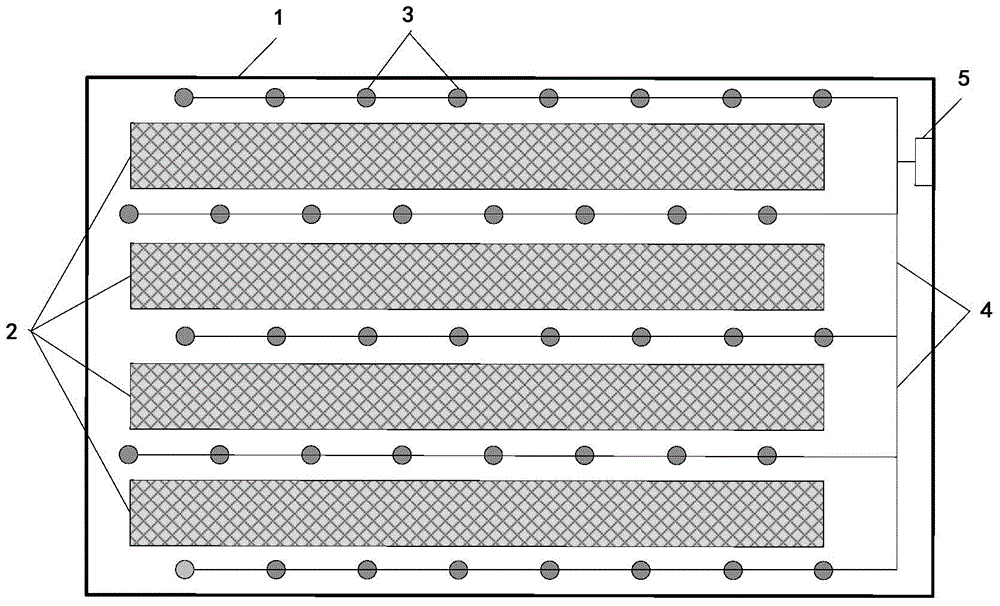

The invention discloses a special LED illumination method and system for laying hen and breeding chicken scale breeding. LED lamps A or LED lamps B are mounted in an enclosed chicken house or a half-open chicken house. The average light intensity of the light reaching the chickens breeding plane and emitted by the LED lamps A or LED lamps B is 5-80 Lux, wherein the average light intensity is adjusted through an LED dimming controller or through the replacement of LED lamps of different power. The lighting time is controlled through a manner that a manual switch, a relay switch or an automatic timer is connected to a power supply. The dominant wavelength of each LED lamp A is 584.0 nm, the color temperature of each LED lamp A is 2700K QUOTE plus or minus 10%, the color ratio of R is larger than 20%, and the color ratio of B is less than 1.5%. Each LED lamp B is composed of white beads and red beads which are uniformly arranged in a cross manner with the ratio being 1:5-5:1. The method and system are mainly applied to laying hen and breeding chicken scale breeding in laying hen or breeding chicken houses, can improve the laying rate, can increase the egg yield, can reduce the poultry cannibalism, and can enhance the physical health of laying hens or breeding chickens.

Owner:HANGZHOU LANGTUO BIOTECH

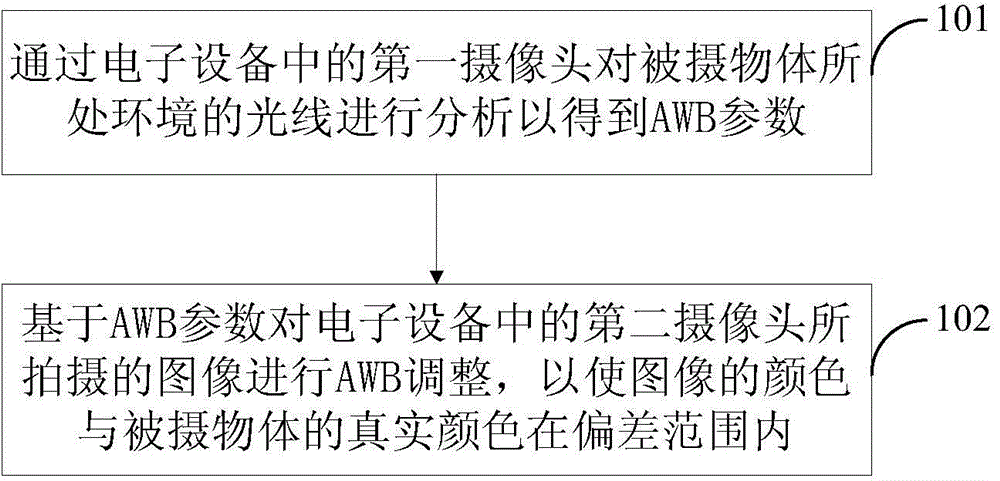

Image processing method and electronic equipment

InactiveCN105657392ALower color requirementsReduce biasColor signal processing circuitsImaging processingGray level

The invention provides an image processing method and electronic equipment. Light in an environment, where a photographed object is, is analyzed through a first camera in the electronic equipment, such that an automatic white balance parameter is obtained; based on the automatic white balance parameter, automatic white balance adjustment of an image photographed by a second camera in the electronic equipment is carried out, such that the deviation between the colour of the image and the real colour of the photographed object is in a deviation range; when the environment, where the photographed object is, does not comprise white or gray-level colour that the proportion of R, B to G is 1:1:1, the deviation between the colour of the image and the real colour of the photographed object is still in a deviation range; and thus, the deviation between the colour of the photographed image and the real colour of the photographed object is reduced while the colour requirement of the environment, where the photographed object is, is reduced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Common-process production technique of caramel color with color ratio of at least 30000EBC

ActiveCN105086503APromote caramelization reactionImprove solubilityProductsReagentsChemical oxygen demandEvaporation

The invention relates to a common-process production technique of caramel color with the color ratio of at least 30000EBC, which comprises the following steps: metering and concentrating a raw material, regulating the pH value to 7.0-11.0, adding sodium polyphosphate and propyl gallate as catalysts, carrying out pressurized reaction, terminating the reaction when the color ratio is satisfactory, cooling, filtering, blending, metering and filling. The caramelization reaction is performed by adding the catalysts under increased pressure under alkaline conditions, thereby lowering the activation energy of the reaction system; and thus, the reaction can be performed more easily, and can obtain the high-color-ratio product more easily. No material condensation water is discharged, thereby preventing evaporation heat dissipation and lowering the reaction energy consumption. Since no condensation water is discharged, no peculiar smell or COD (chemical oxygen demand) pollution is generated in the reaction process.

Owner:QIANHE CONDIMENT & FOOD CO LTD

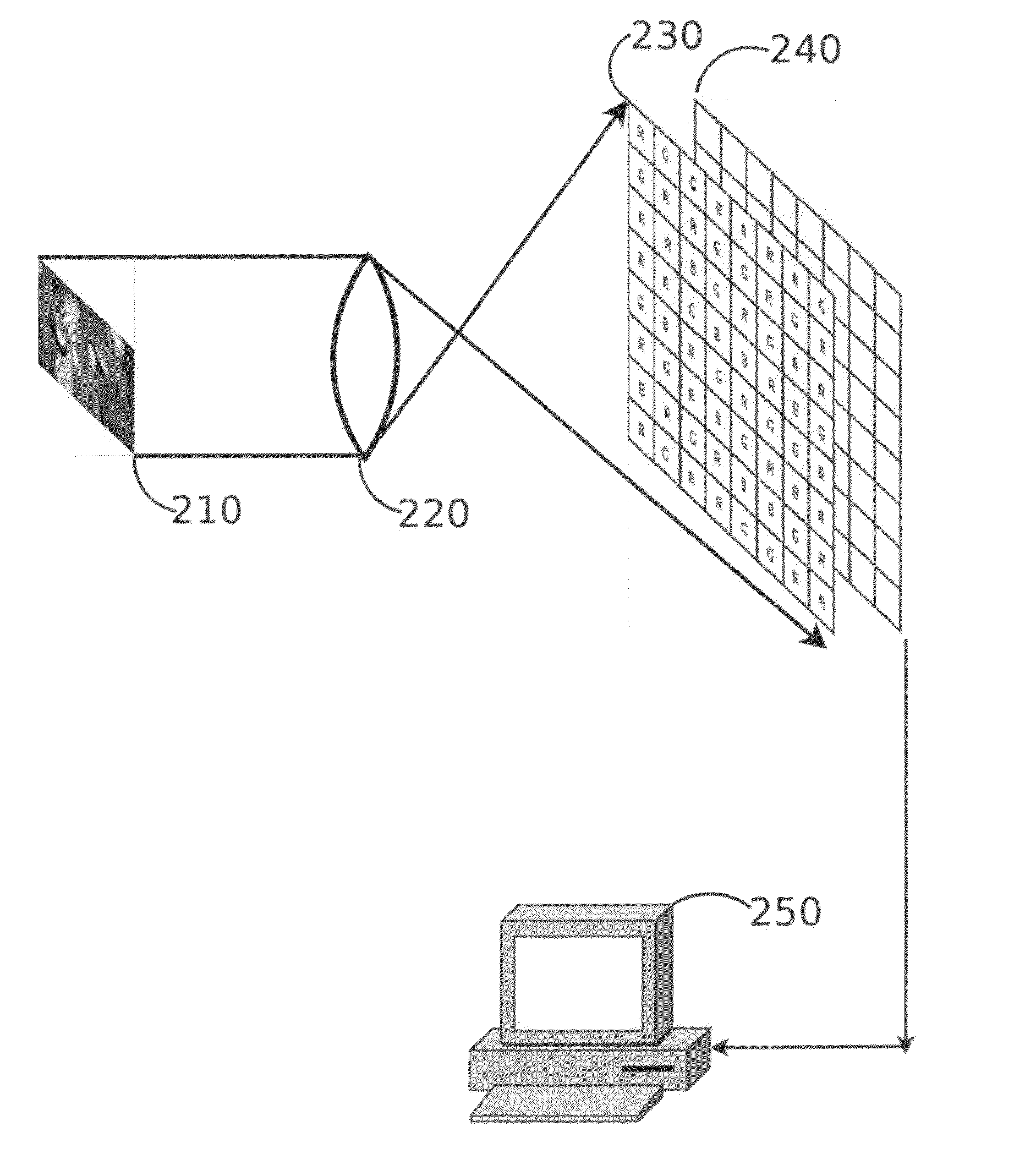

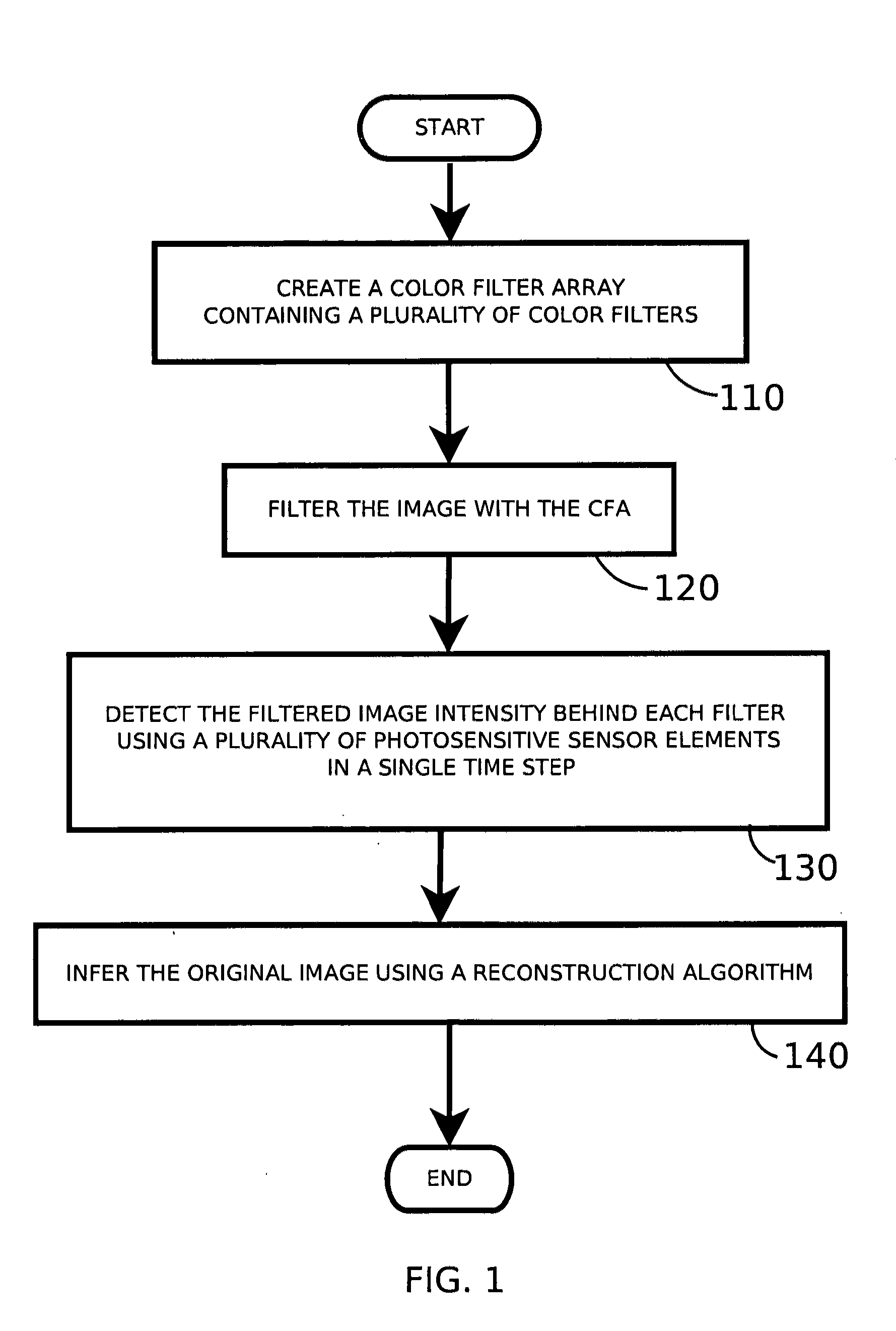

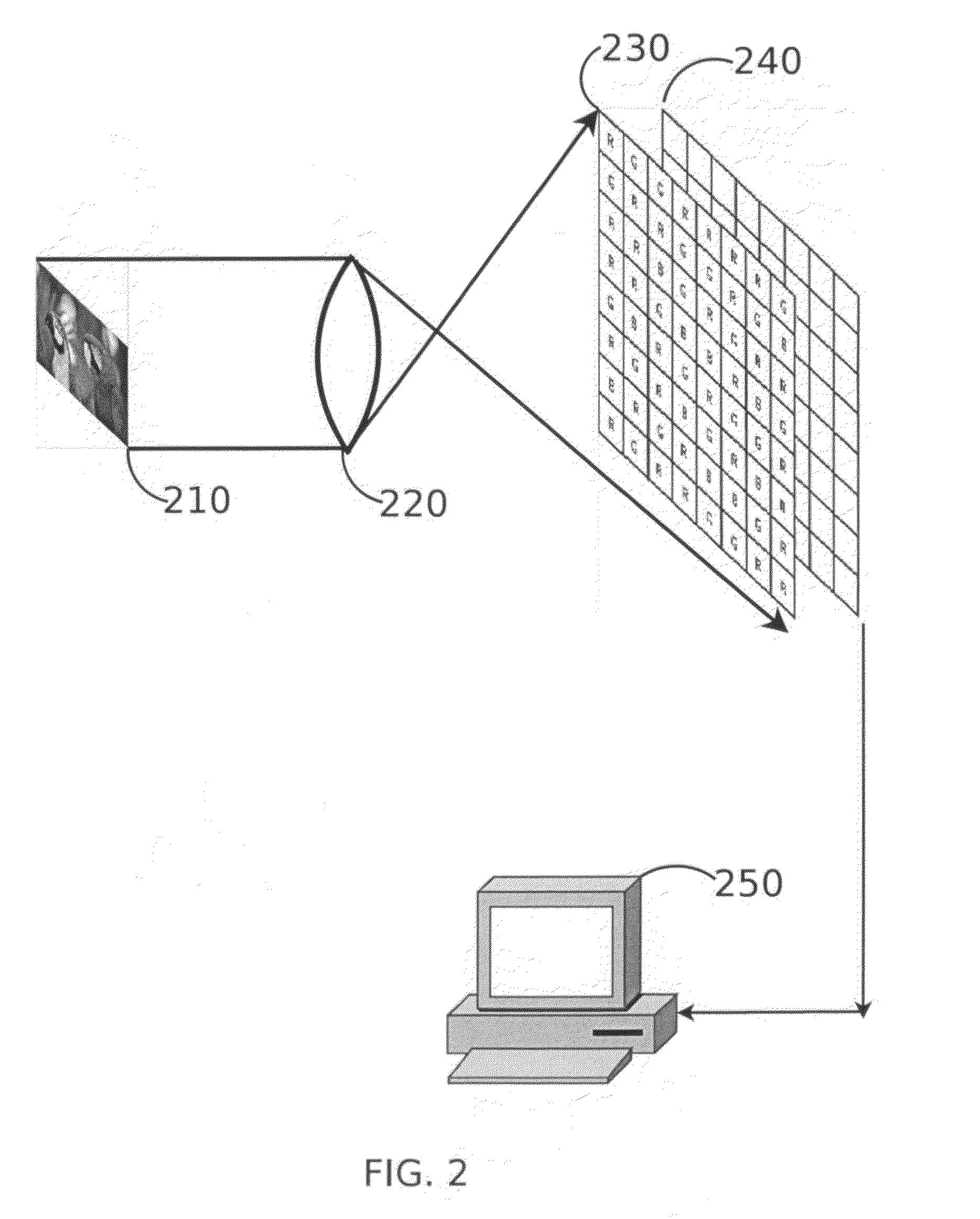

Method and system for robust and flexible extraction of image information using color filter arrays

InactiveUS20120075493A1Reduce noise imagingNoise in imaged image can be reducedTelevision system detailsGeometric image transformationColor imageFrequency spectrum

Methods and systems for robust and flexible extraction of image information using color filter arrays. Methods are provided comprising receiving a sample set of data generated by transforming and sampling an optical property of an original color image in a spatial basis, wherein the transformation effected is substantially local in the spatial basis and has partially overlapping spectra. A generalized inverse of the transform augmented with regularization constraints is applied to the sample set of data to infer original image data. According to one approach the generalized inverse does not use variational minimization or assume constant color ratios. According to an alternative approach regularization can take the form of predetermined spectral constraints applied to the sample set of data to infer the original image data. According to another alternative approach regularization can promote spectral sparsity. Methods are also provided for creating an optical color filter array, for sampling an image, for reducing noise in an image, and for computing a sparse representation of an image signal. Systems for carrying out these and other methods are also provided.

Owner:SINGH TRIPURARI +1

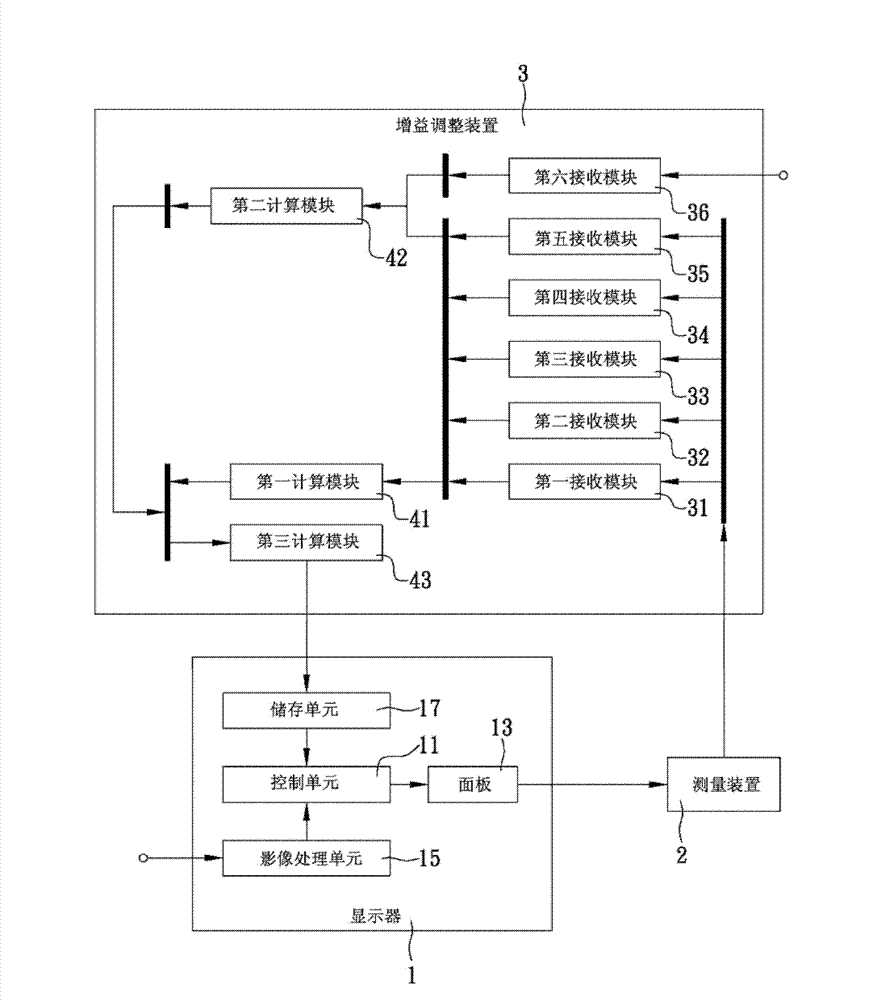

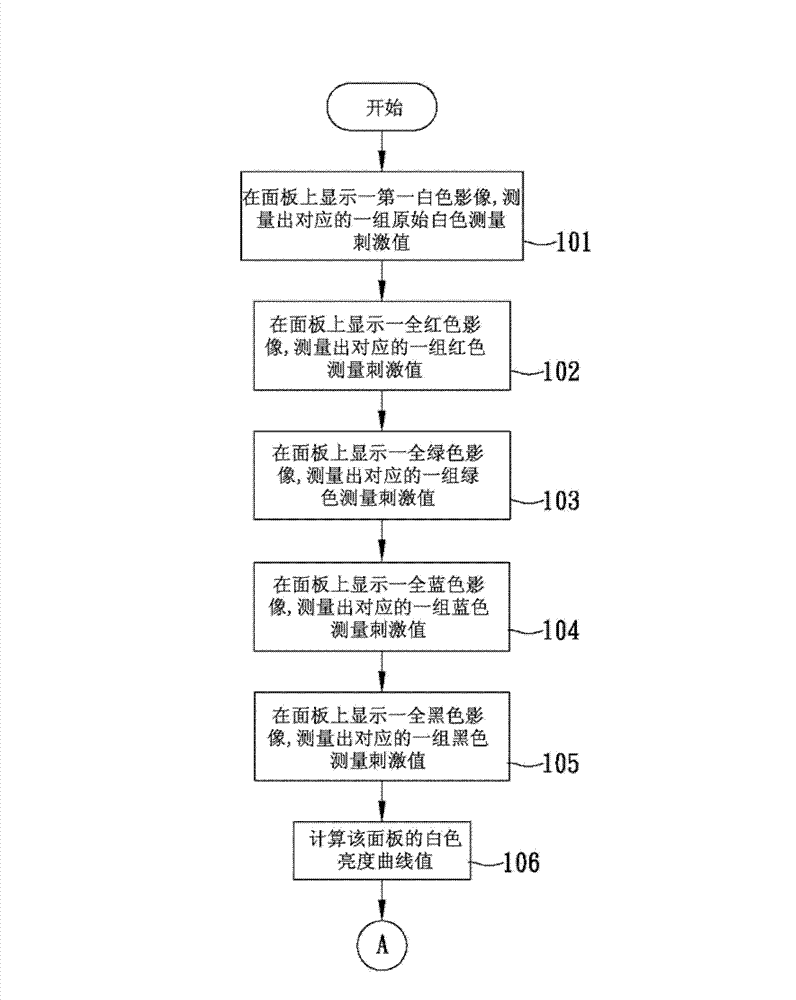

Method for improving four color white balance adjustment and calibration precision through white color luminance parameters

InactiveCN103366710AImprove tuning issuesReduce mistakesCathode-ray tube indicatorsColor imageOptical property

The invention discloses a method for improving four color white balance adjustment and calibration precision through white color luminance parameters. The method for improving four color white balance adjustment and calibration precision through white color luminance parameters is characterized in that a gray scale white balance yield value is calculated by importing white color luminance parameters of a display device panel according to display device panel original three primary colors and white color optical properties, and therefore gray scale white balance adjustment and calibration precision can be improved. A first white color image, an entirely red color image, an entirely green color image and an entirely blue color image that have a set gray scale value are orderly displayed on the panel; stimulation values of the images are measured, stimulation values which are obtained when an entirely black image is displayed on the panel are subtracted, and therefore corresponding corrected stimulation values can be acquired; a white color luminance curve value of the display device panel is measured; a first color ratio for mixing the red color, green color and blue color image corrected stimulation values into the first white color image and a second color ratio for mixing the red color, green color and blue color image corrected stimulation values into an ideal white color image are calculated according a color mixing law; red color, green color and blue color adjustment and correction yield values are calculated through utilization of the color mixing ratios and the white color luminance curve value and then are set in a display device.

Owner:MARKETECH INT

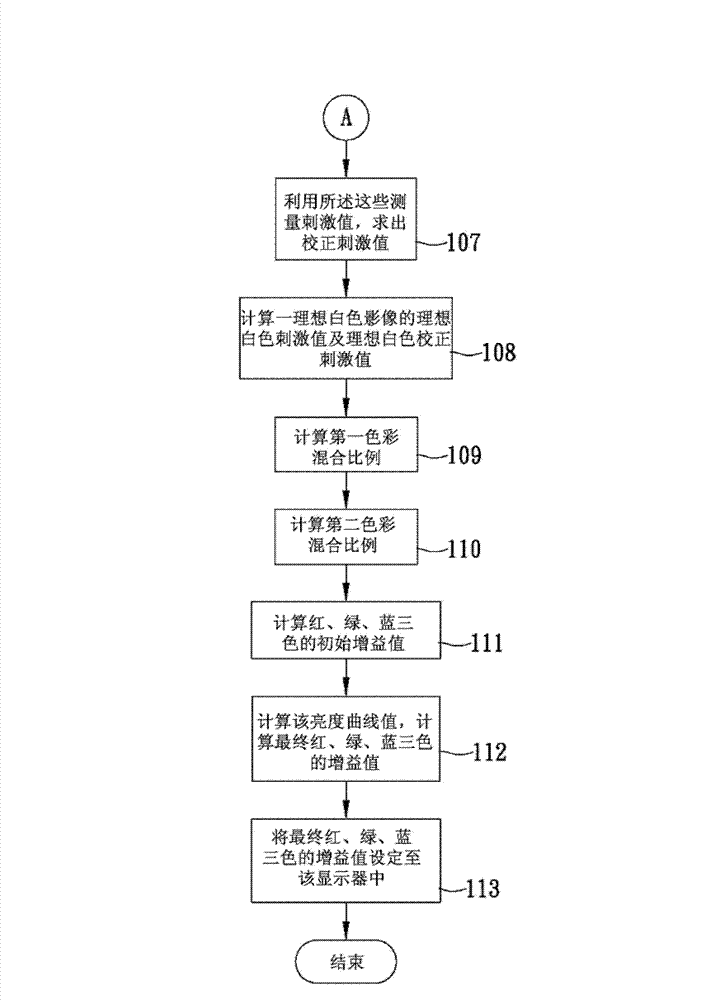

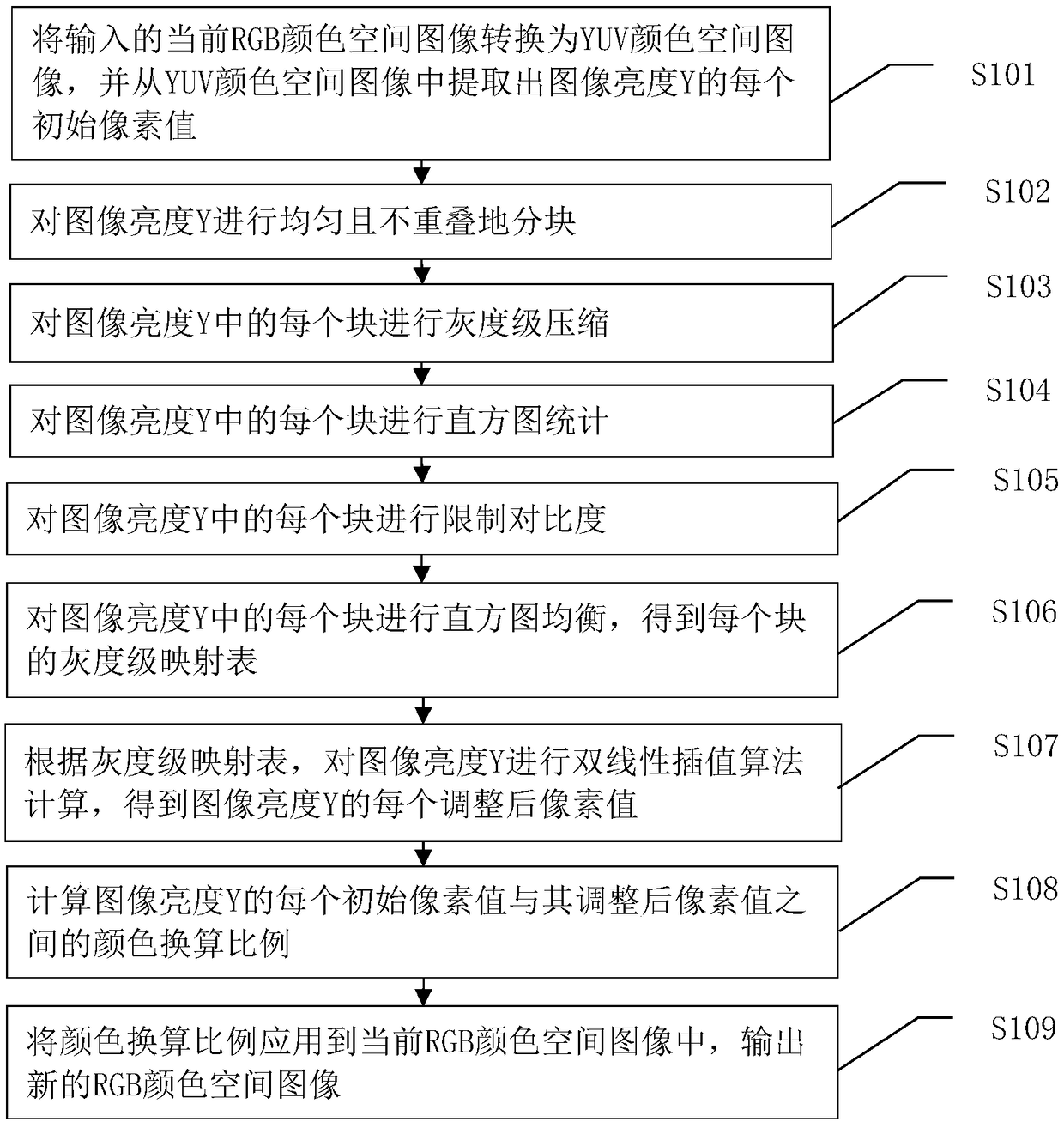

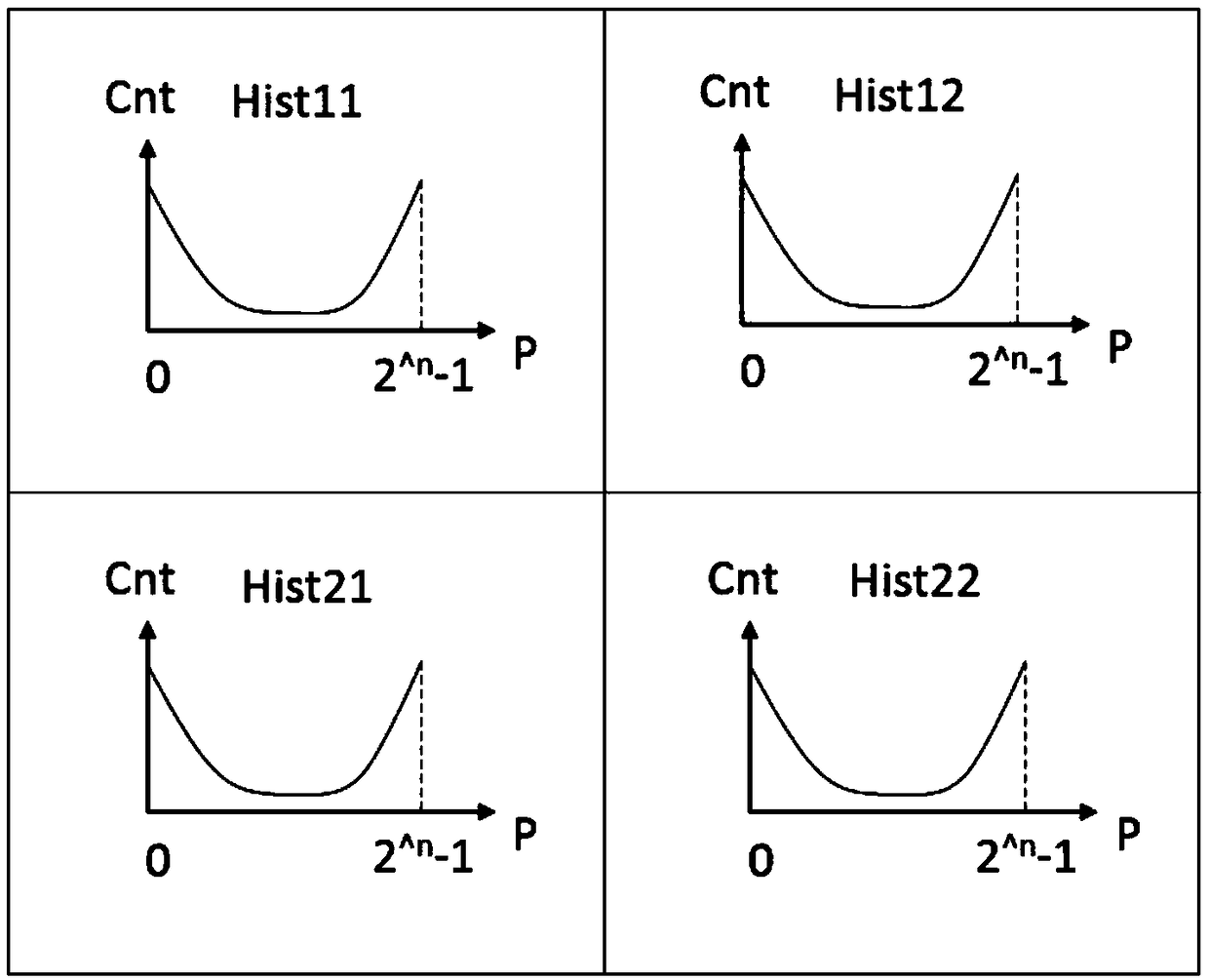

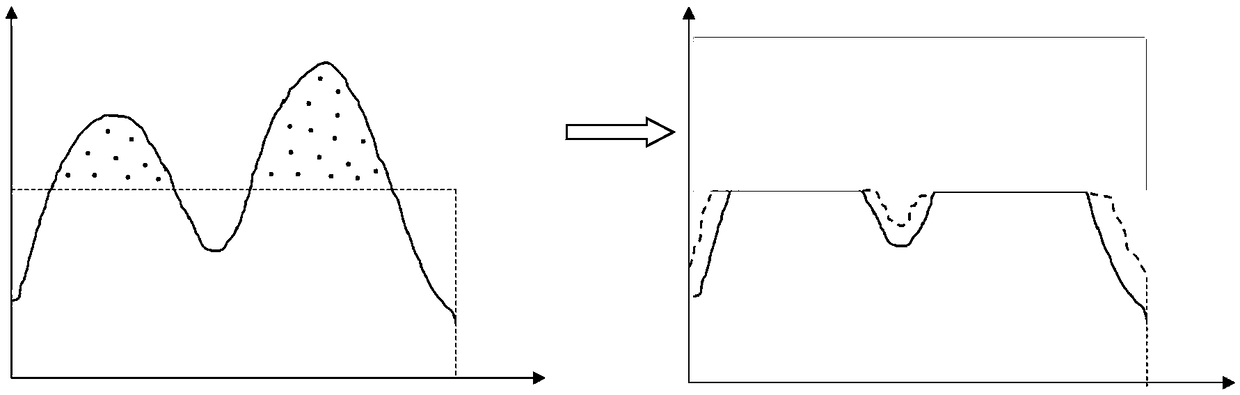

CLHAE image enhancement method based on gray level compression

InactiveCN108846812AEasy to handleImprove processing efficiencyImage enhancementImage analysisGray levelHistogram equalization

The invention discloses a CLHAE image enhancement method based on gray level compression. The method comprises: converting a current RGB color space image into a YUV color space image, and extractingeach initial pixel value of image brightness Y; performing uniform and non-overlapping partitioning, gray level compression, histogram statistics, contrast limitation, and histogram equalization on the image brightness Y, to obtain a gray level mapping table of each block; performing bilinear interpolation algorithm calculation on the image brightness Y, to obtain each adjusted pixel value of theimage brightness Y; calculating a color conversion ratio between each initial pixel value of the image brightness Y and the adjusted pixel value, and applying to the current RGB color space image, tooutput a new RGB color space image. The method can improve processing efficiency, expand a dynamic range of an image and enhance contrast of the image on the basis of keeping the color ratio of an original image, thereby realizing fast and efficient image enhancement effect.

Owner:CHENGDU LIGHT COLLECTOR TECH

Lighting device and illumination apparatus including same

InactiveUS20120326631A1Reduce biasHigh color reproductionElectrical apparatusElectroluminescent light sourcesLight equipmentBlack body

A lighting device includes lighting control units respectively provided for controlling lighting of solid state light emitting element groups irradiating light of different chromaticities and a color ratio setting unit for setting a target output ratio of the solid state light emitting element groups. In an xy chromaticity diagram of an XYZ color system, a straight line connecting chromaticity coordinates of lights irradiated by a first and a second solid state light emitting element group intersects a black body locus. Further, the lighting control units include a first and a second lighting control unit for controlling lighting of the first and the second solid state light emitting element group, and the first and the second control unit perform a feedback control such that an output ratio of the second to the first solid state light emitting element group becomes equal to the target output ratio thereof.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com