Method for preparing caramel colorant by using multistage membrane separation

A caramel pigment and membrane separation technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as non-removal, achieve low turbidity, increase product yield, and solve unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

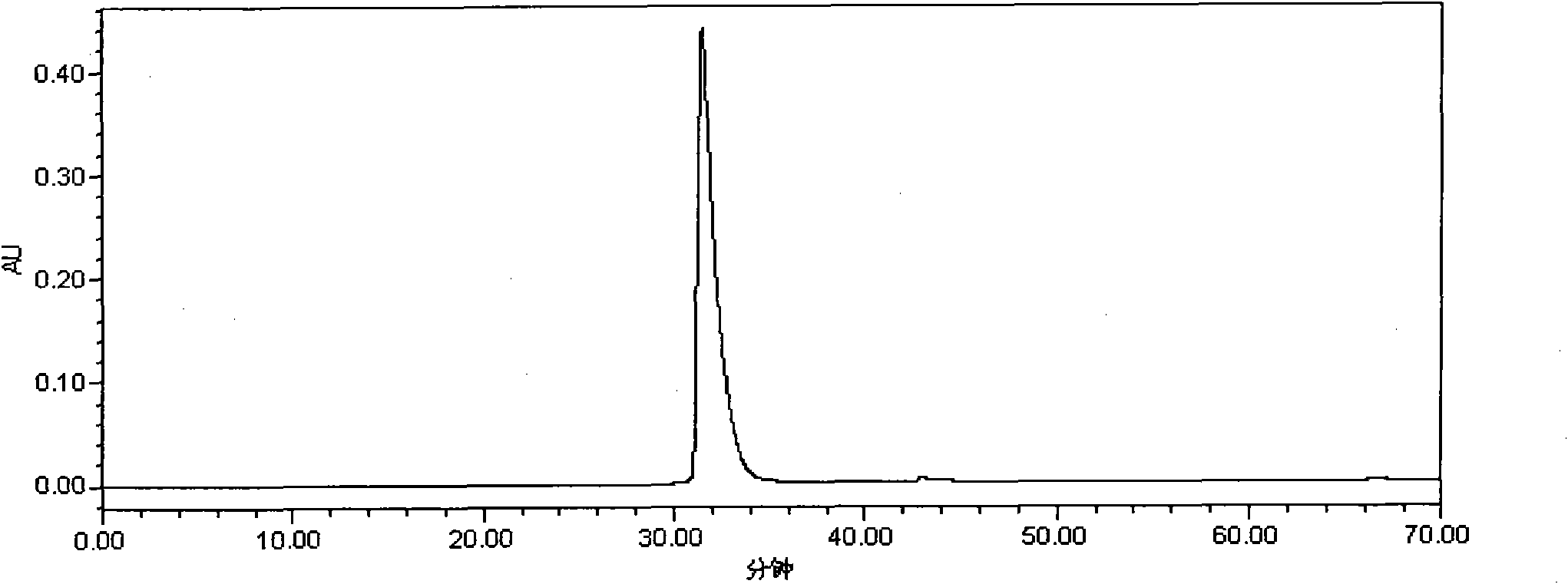

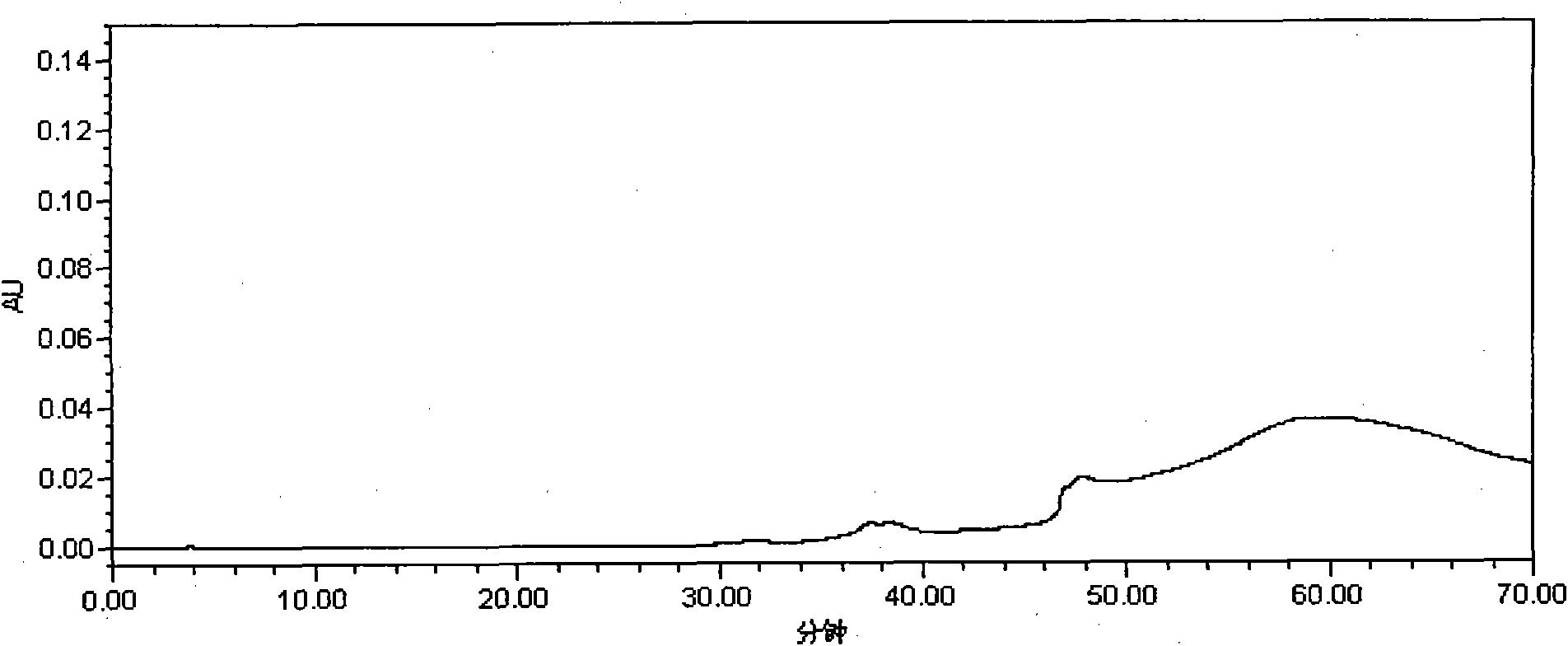

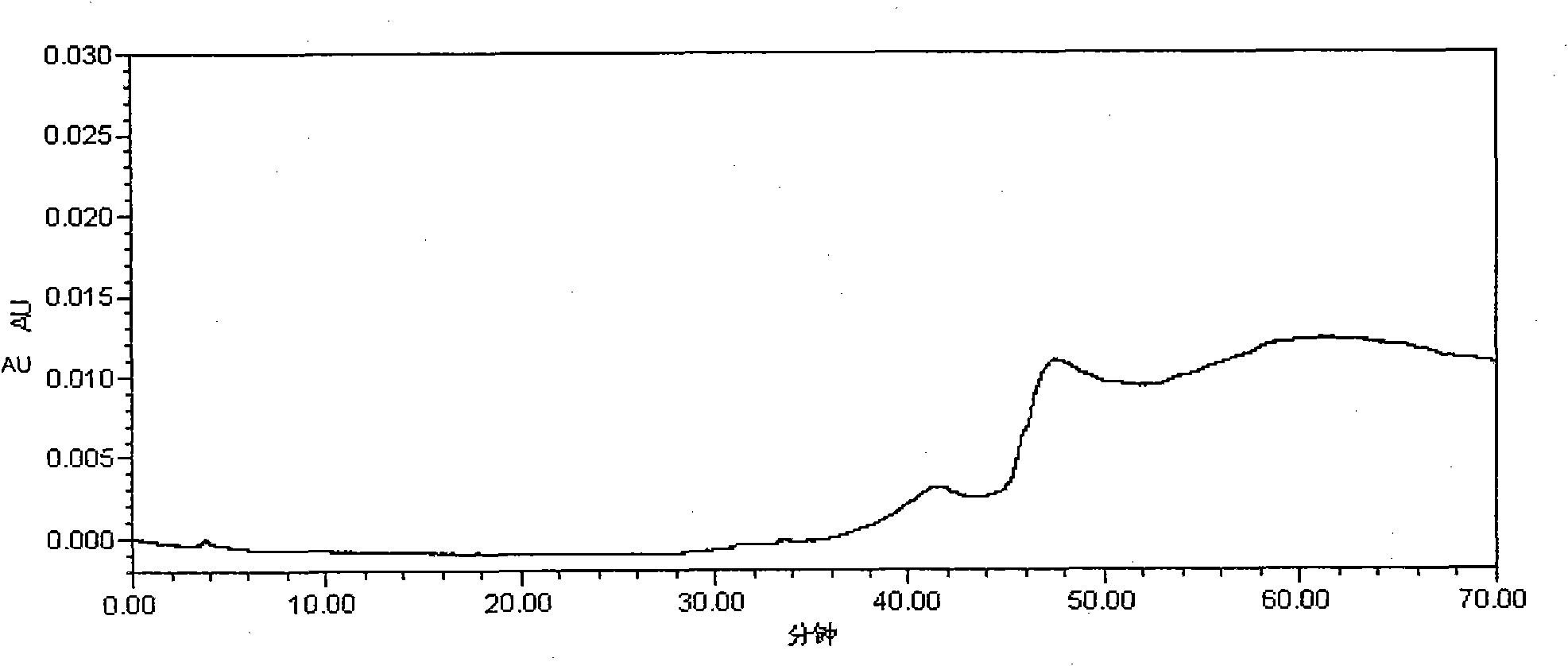

[0037] Take 9 kg of maltose, mix it with 15 L of pure water to prepare a maltose solution, add glycine to the maltose solution in an amount of 10.0% of the mass of the maltose, and obtain a mixed reaction solution. Put the mixed solution in a high-pressure reaction kettle, seal it, heat the material, and simultaneously turn on the magnetic stirring device, set the reaction temperature to 130° C., and hold the temperature for 80 minutes. After the reaction is completed, the obtained liquid material is cooled and subjected to membrane separation. The membrane separation steps are as follows: firstly separate the reaction solution through membrane A, collect the intercepted component and filtrate al, and homogenize the intercepted component through a colloid mill, the homogenization pressure is 10 bar, and the temperature of the homogenized material is 50°C; after homogenization The components are then separated by membrane A. Membrane A is a flat membrane with a molecular weigh...

Embodiment 2

[0040] Take 16kg of sucrose, mix it with 20L of pure water to prepare a solution, add glutamic acid in the sucrose solution, the dosage is 2.0% of the sucrose mass, to obtain a mixed reaction solution. The mixed solution was placed in a collector type constant temperature heating magnetic stirrer for heating in an oil bath, the reaction temperature was set at 140° C., and the holding time was 70 minutes. After the reaction is completed, the obtained liquid material is cooled and subjected to membrane separation. Membrane separation conditions are as follows: Separation of membrane A is performed first, the intercepted component and filtrate a1 are collected, and the intercepted component is homogenized by an ultra-high pressure micro-fluidizer with a homogenization pressure of 5000 bar; the temperature of the homogenized material is 25°C. The homogenized components are then separated by membrane A. Membrane A is a flat membrane with a molecular weight cut-off of 4,400,000 Da ...

Embodiment 3

[0043] Take 10kg of glucose, mix it with 10L of pure water to prepare a glucose solution, add ammonium sulfite to the sugar solution, and the dosage is 6.0% of the glucose mass to obtain a mixed reaction solution. The mixed solution was placed in a high-pressure reactor, sealed, and heated for reaction. The reaction temperature was set at 150° C., and the holding time was 60 minutes. After the reaction is completed, the liquid material is cooled and subjected to membrane separation. Membrane separation steps are as follows: Separation of membrane A is carried out first, the intercepted component and filtrate a1 are collected, and the intercepted component is homogenized by an ultra-high pressure micro-fluidizer, with a homogenization pressure of 2500 bar; the temperature of the homogenized material is 80°C; after homogenization The components are then separated by membrane A. Membrane A is a flat membrane with a molecular weight cut-off of 4400000Da produced by Shanghai Xinya ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com