Patents

Literature

323 results about "Caramel color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caramel color or caramel coloring is a water-soluble food coloring. It is made by heat treatment of carbohydrates, in general in the presence of acids, alkalis, or salts, in a process called caramelization. It is more fully oxidized than caramel candy, and has an odor of burnt sugar and a somewhat bitter taste. Its color ranges from pale yellow to amber to dark brown.

Diet cola beverages

InactiveUS20080226800A1Low potencyTotal calories lowFood ingredient as flavour affecting agentLow calorieSuccinic acid

Diet cola beverage and other beverage products and methods for making the same are disclosed. The diet cola beverages comprise water, at least one natural, potent, non-nutritive sweetener, at least one natural, low potency, low calorie sweetener, an acidulant comprising at least one of lactic, citric, tartaric, malic, fumaric, cinnamic, maleic, adipic, glutaric, and succinic acids, a caramel colorant, and cola flavor.

Owner:CONCENTRATE MFG OF IRELAND

Pure natural sweet-sour plum juice and its preparing method

ActiveCN101584488AOvercome the defects that are not originalGuaranteed stabilityFood preparationSmoked PlumThirst

The invention discloses a pure natural sweet-sour plum juice belonging to the food beverage range and its preparing method. The pure natural sweet-sour plum juice, having the original taste and flavour and no essence, no burned sugar pigment, no additive agent such as citric acid, malic acid and the like, is prepared from the extract of the raw materials such as smoked plum, haw thorn, extractum glycyrrhizae liquidum, citrus reticulata blanco and the like by the meticulous preparation. The stability of the pure natural sweet-sour plum juice beverage in the shelf life is guaranteed by the thermal sterilizing, the pure natural sweet-sour plum juice beverage has the health-care function of reducing fever, relieving summer-heat and quenching thirst.

Owner:北京燕京饮料有限公司

Process for producing caramel pigment

InactiveCN101693903AEliminate the extraction processImprove stabilityNatural dyesFermentationAlpha-amylaseHigh pressure

The invention discloses a process for producing caramel pigment, comprising the following procedures of a) gelatinization procedure, b) liquefaction and saccharification procedure, c) hydrolysis procedure and d) ammonification procedure, wherein the b) liquefaction and saccharification procedure comprises the following steps: adding alpha-amylase and saccharifying enzyme to the gelatinized purple sweet potato with the pH of 4.5-6.0 and the temperature of 70-95 DEG C, and reacting for 30-60min, wherein the weight proportion of the purple sweet potato, the alpha-amylase and saccharifying enzyme is 1:0.01-0.04:0.01-0.04. Compared with the prior art, in the invention, the purple sweet potato is taken as the raw material, therefore the extraction procedure of starch is saved and the process flow is simplified; furthermore, the purple sweet potato contains natural pigment and has good acid resistance, salt resistance and good stability; the caramel pigment produced by taking the sweet potato as the raw material has high color ratio and good stability, generates no pollutants during the hydrolysis process, shortens the production period and saves the cost; and the caramel pigment prepared by utilizing the sugar solution through a high-pressure ammonia method has good color ratio and good product quality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

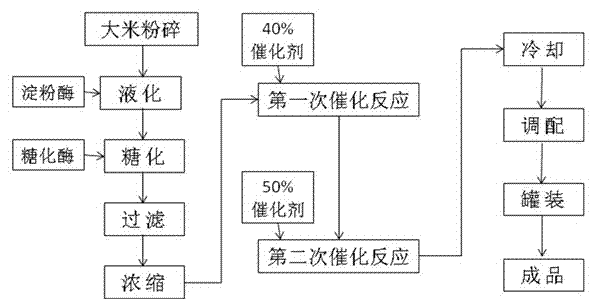

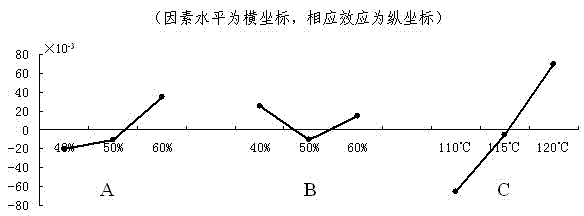

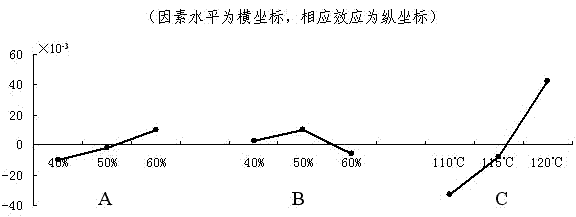

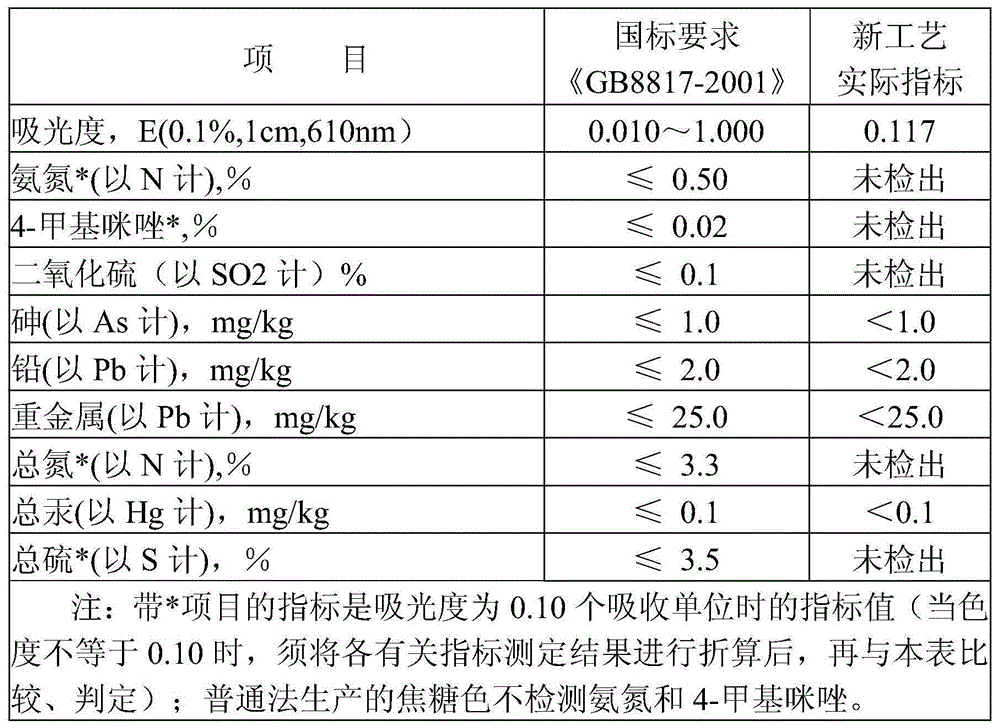

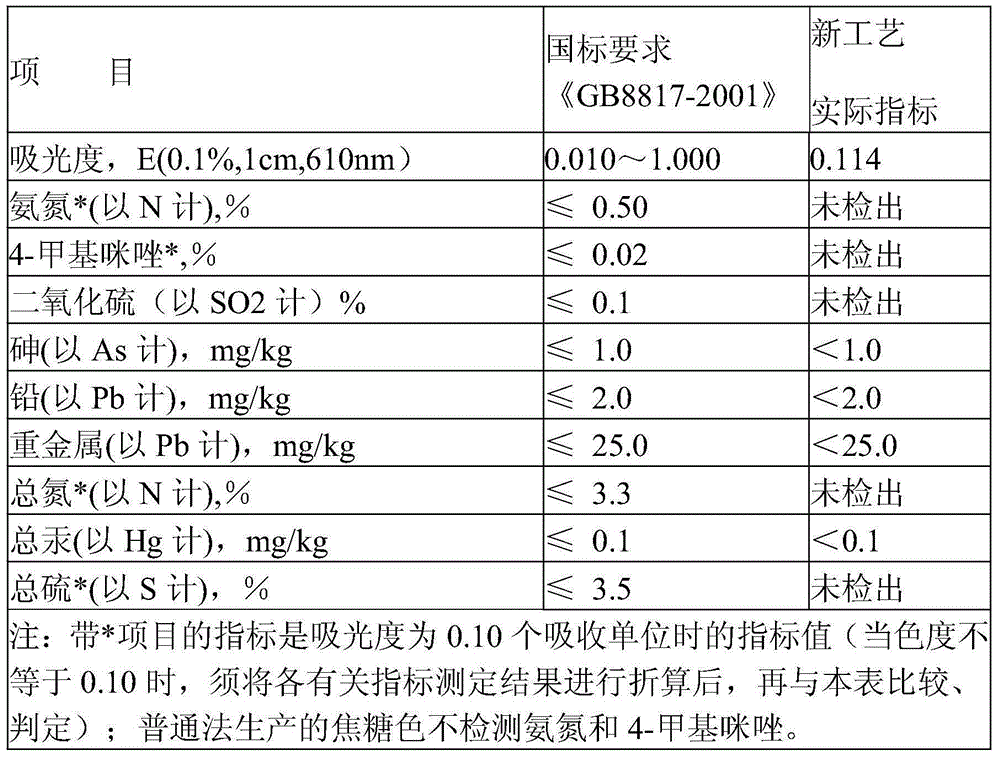

Method for producing high-safety caramel color through twice catalytic reaction

ActiveCN102643862AReduce unit consumptionReduce the temperatureNatural dyesFermentationReaction temperatureDry basis

The invention relates to a method for producing high-safety caramel color through twice catalytic reaction. The method comprises the following steps of: a, rice pulverization; b, spraying liquefaction; c, diastatic enzyme addition into liquefied rice for saccharification; d, filtering; e, concentration; f, primary catalytic reaction: through being metered by the mass percentage content of dry basis, catalysts accounting for 40 percent of the catalyst consumption are adopted and added in the primary catalytic reaction, then, through the pressurization and temperature rise reaction, the reaction pressure is controlled to a value being smaller than or equal to 0.1 MPa, the temperature is smaller than or equal to 110 DEG C, and the primary catalytic reaction is stopped when the reaction is carried out to reach 60 percent of the total required color rate; g, secondary catalytic reaction: the secondary catalytic reaction is stopped when the reaction is carried out to reach the required color rate; h, cooling; and i, finished product blending. Through the twice catalytic reaction, the reaction temperature and the reaction pressure are reduced, the reaction conditions are milder, the single consumption of steam is reduced, the reaction process and the control are easier and more stable, each ton of products can save 100kg of steam, and the method is favorable for improving the market competitiveness of products.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Common-process production technique of caramel color with color ratio of at least 30000EBC

ActiveCN105086503APromote caramelization reactionImprove solubilityProductsReagentsChemical oxygen demandEvaporation

The invention relates to a common-process production technique of caramel color with the color ratio of at least 30000EBC, which comprises the following steps: metering and concentrating a raw material, regulating the pH value to 7.0-11.0, adding sodium polyphosphate and propyl gallate as catalysts, carrying out pressurized reaction, terminating the reaction when the color ratio is satisfactory, cooling, filtering, blending, metering and filling. The caramelization reaction is performed by adding the catalysts under increased pressure under alkaline conditions, thereby lowering the activation energy of the reaction system; and thus, the reaction can be performed more easily, and can obtain the high-color-ratio product more easily. No material condensation water is discharged, thereby preventing evaporation heat dissipation and lowering the reaction energy consumption. Since no condensation water is discharged, no peculiar smell or COD (chemical oxygen demand) pollution is generated in the reaction process.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Roasted egg food with shell and preparation method thereof

ActiveCN102972801AMake up for the defect that the color is too singleUnique flavorFood preparationViscosityMarket potential

The invention provides roasted egg food with a shell and a preparation method thereof. The preparation method of the roasted egg food with the shell comprises the six steps of selecting eggs, cooking, flavoring, coloring, roasting and refrigerating. The roasted egg food with the shell has the advantages of having a smooth and bright appearance with a caramel color and slight viscosity, being delicious in taste and unique in flavor, making up the defect that the color of the egg product is excessively single, and enriching the variety of the domestic egg products and is a novel egg highly processed product with great market potential. The preparation method provided by the invention has the advantages of being wide in source of raw materials, simple in processing steps, mild in manufacturing conditions and suitable for large-scale application in the food industrial circle.

Owner:BEIJING HELEE BIO ENERGY TECH

Method for simultaneously preparing caramel pigment and aromatiser for edible safety beverage

ActiveCN101619173AShort manufacturing timeSave energyNatural dyesFood preparationOrganic solventAlcohol

The invention relates to a method for simultaneously preparing caramel pigment and an aromatiser for edible safety beverage. The reaction conditions of high-pressure low-heat distillation integration are as follows: (1) reaction pressure: 1MPa to 20MPa; (2) total time of reaction: 10 minutes to 80 minutes; (3) reactant temperature: 30 DEG C to 100 DEG C, carrying out distillation while carrying out high-pressure low-heat reaction; the steps and the conditions of the distillation are as follows: (1) the temperature of the distillation is the temperature of high-pressure low-heat reaction; (2) collecting the distilled aromatiser in a collecting device which is filled with an extracting agent and connected with the tail end of a heat exchanger after being condensed by the heat exchanger; and(3) the extracting agent is an eatable level ester organic solvent and an alcohol organic solvent the boiling point of which is higher than the separated component by 5 DEG C to 80 DEG C. The caramelpigment product is obtained in a reaction kettle. The method has the advantages of having no pollution, simple technique and low processing temperature, being capable of improving edible safety, being capable of preparing the caramel pigment and the aromatiser simultaneously and the like.

Owner:SOUTH CHINA UNIV OF TECH

Hearth-care vinegar and preparation method thereof

The invention discloses a hearth-care vinegar and a preparation method thereof, each 1000 ml of hearth-care vinegar contains the following components: brewed vinegar, dates, wolfberry, lily, orange peel, longan, fruit juice concentrate, white sugar, fructose syrup, honey, ginger extract, potassium sorbate, and caramel color. The preparation method comprises: adding water to dates, wolfberry, lily, orange peel and longan, extracting and cooling, filtering and obtaining the filter liquid; dissolving honey, potassium sorbate and caramel color into water, obtaining a mixed solution; then mixing the filter liquid, the mixed solution with the brewed vinegar, fruit juice concentrate, white sugar and fructose syrup, then adding ginger extract, adding water to determine the volume; sterilizing the material after determining the volume, then potting. The hearth-care vinegar of the invention has not only good taste and convenient ingestion, and it also has the hearth-care functions of dates, lily, wolfberry, orange peel, longan and honey; the preparation method of the hearth-care vinegar of the invention is simple and easy to operate.

Owner:JIANGSU HENGSHUN VINEGAR IND

Gargle for relieving pain for oral inflammation disease

InactiveCN101559077ANot pollutedGuaranteed chemical stabilityInorganic boron active ingredientsHydroxy compound active ingredientsDiseaseSodium bicarbonate

The invention belongs to the technical field of medicine, in particular to a drug composition of gargle which contains sodium dichlorophenolate and can relieve pain and be anti-inflammatory for the oral inflammation disease; wherein the drug composition comprises the following components by percentage: 0.10 to 30 percent of sodium dichlorophenolate hydroxypropyl-Beta-cyclodextrin inclusion (equal to 0.065 to 0.20 percent of concentration of sodium dichlorophenolate), 0.01 to 0.10 percent of lidocaine hydrochloride, 0.10 to 5.0 percent of borax, 0.1 to 2.0 percent of boric acid, 0.1 to 10 percent of glycerin, 0.10 to 5.0 percent of sodium bicarbonate, 0.001 to 0.10 percent of vitamin B12, 0.02 to 1.0 percent of tromethamine, 0.01 to 5.0 percent of sucralose, 0.10 to 5.0 percent of peppermint essence and 0.01 to 1.0 percent of sodium benzoate; a proper amount of pharmaceutical caramel color and water for injection is added till to reach the needed weight / volume concentration. All the above components are weighted by weight / volume percentage; the aqueous solution of the composition has the pH value of 6.5 to 9.0. The composition has little thrill to oral mucosa, stable storage for long time and good biological tolerance and has fast and long-lasting curative effect for relieving pain and being anti-inflammatory to the oral inflammation disease.

Owner:官培龙 +1

Ginger cola health drink and preparation technology thereof

The invention relates to a ginger cola health drink and a preparation technology thereof. The invention is characterized by using old ginger, cocoa beans, amino acid, fruit sugar, glucose, citric acid, brown sugar, a low-calorie sweetening agent and edible phosphoric acid as raw materials to prepare the ginger cola health drink which integrates the nutrition and the drug effects of the cocoa beans and the ginger, has suitable taste, is popular to the public and contains no cola essence or caramel pigment.

Owner:重庆姜可乐饮料股份有限公司

Powdery caramel pigment and manufacturing method thereof

InactiveCN101705007ASimple process routeEasy to operateNatural dyesFood preparationCooking & bakingManufacturing technology

The invention relates to a powdery caramel pigment and a manufacturing method thereof, belonging to the technical field of natural pigment manufacture. The powdery caramel pigment is manufactured by using barley as raw material, soaking and germinating the barley under certain conditions, and then conducting heat preservation, baking, cooling and crushing. The method does not need the processes of crushing the raw material, adding enzyme for liquefaction, saccharifying or acidolysis, and does not add amino-compound additionally. The powdery caramel pigment uses reducing sugar and free amino in malt to conduct Maillard reaction and using little molecular saccharides to conduct caramelization under a high temperature so as to produce present-color materials and fragrant substances. The powdery caramel pigment has the advantages of simple technique route, convenient operation, high edible safety of products and the like. The solid product is easily packaged, stored and transported.

Owner:YANCHENG INST OF TECH

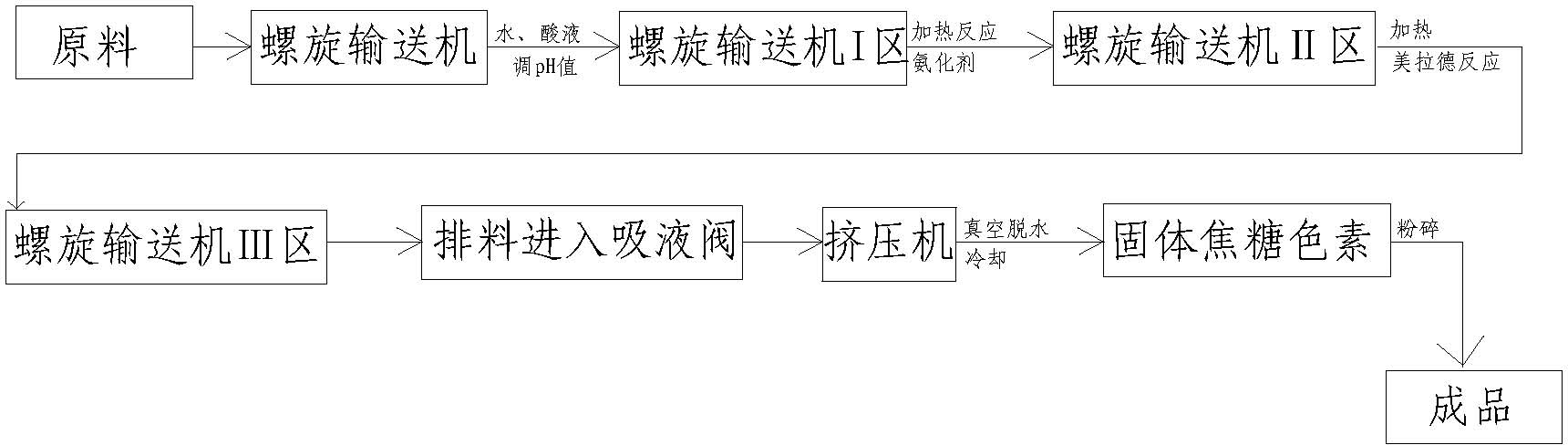

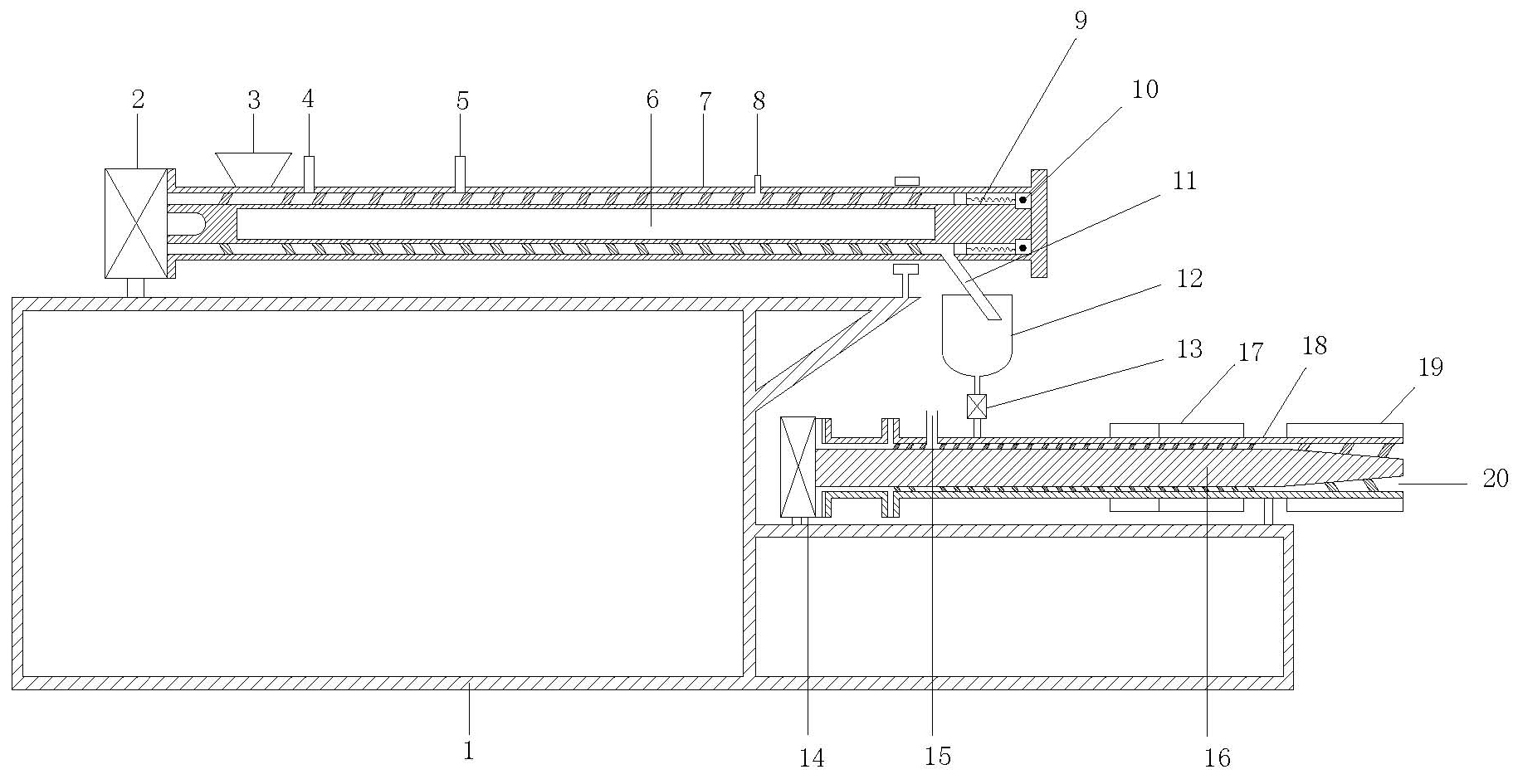

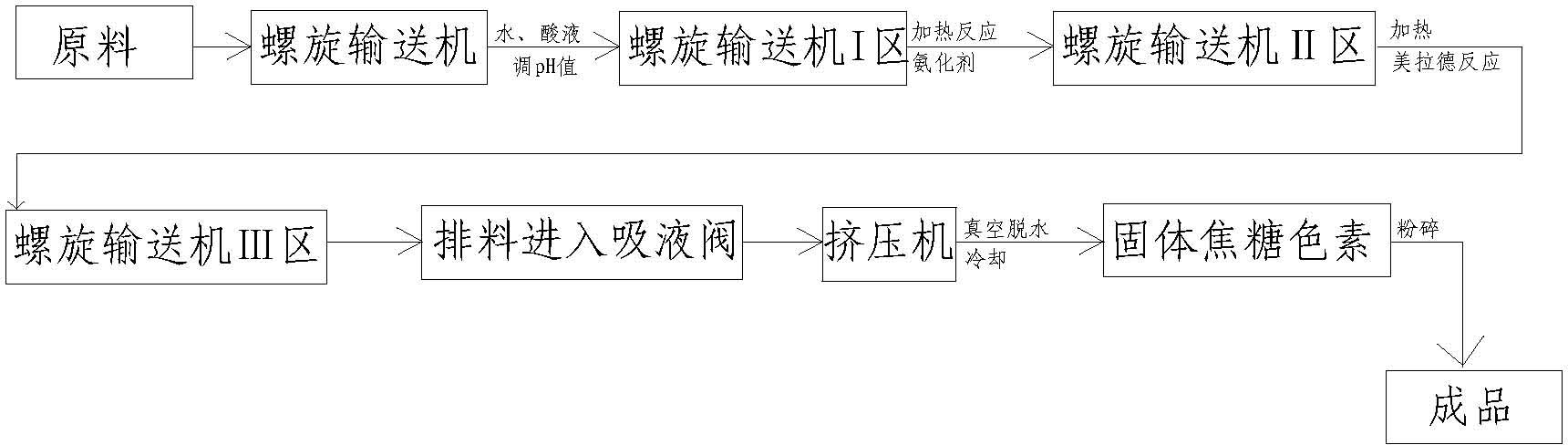

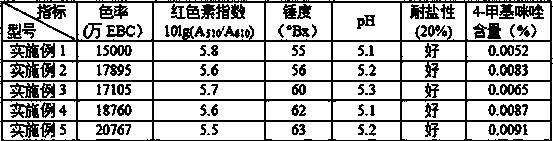

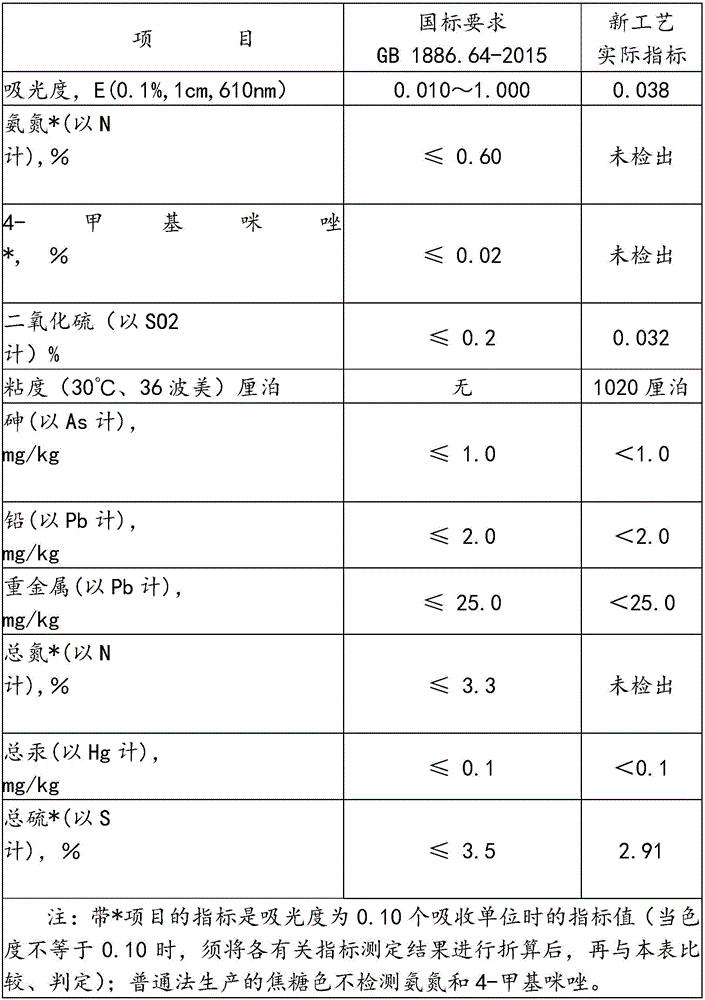

Method for producing powder caramel color through combination of spiral conveyer and extruder

The invention relates to a method for producing powder caramel color through the combination of a spiral conveyer and an extruder, which can effectively solve the problems that the operation is easy, the product quality is poor and the production efficiency is low. The method is characterized by comprising the following steps of: firstly mounting the spiral conveyer and the extruder to form a conveyance and extrusion integrated production device, conveying a raw material of glucose or cane sugar into the spiral conveyer, mixing the raw material with water and acid liquid, regulating the pH value of the raw material, enabling the raw material to enter an area I of the spiral conveyer, heating a saccharification reaction to form an acidolysis sugar liquid, feeding the acidolysis sugar liquid into an area II of the spiral conveyer, injecting an amino compound to carry out a Maillard reaction to form the liquid high-temperature caramel color, heating the mixture by an area III of the spiral conveyer, feeding the mixture into the extruder, carrying out vacuum air-liquid separation on the mixture, cooling down by a coolant to obtain a solid, and crushing the solid to obtain finished-product caramel color. The method for producing the powder caramel color through the combination of the spiral conveyer and the extruder has the advantages of simpleness and easiness for operation, integration of conveyance and extrusion, good product quality and high production efficiency, and is an innovation on the production of the caramel color.

Owner:蔡家俊

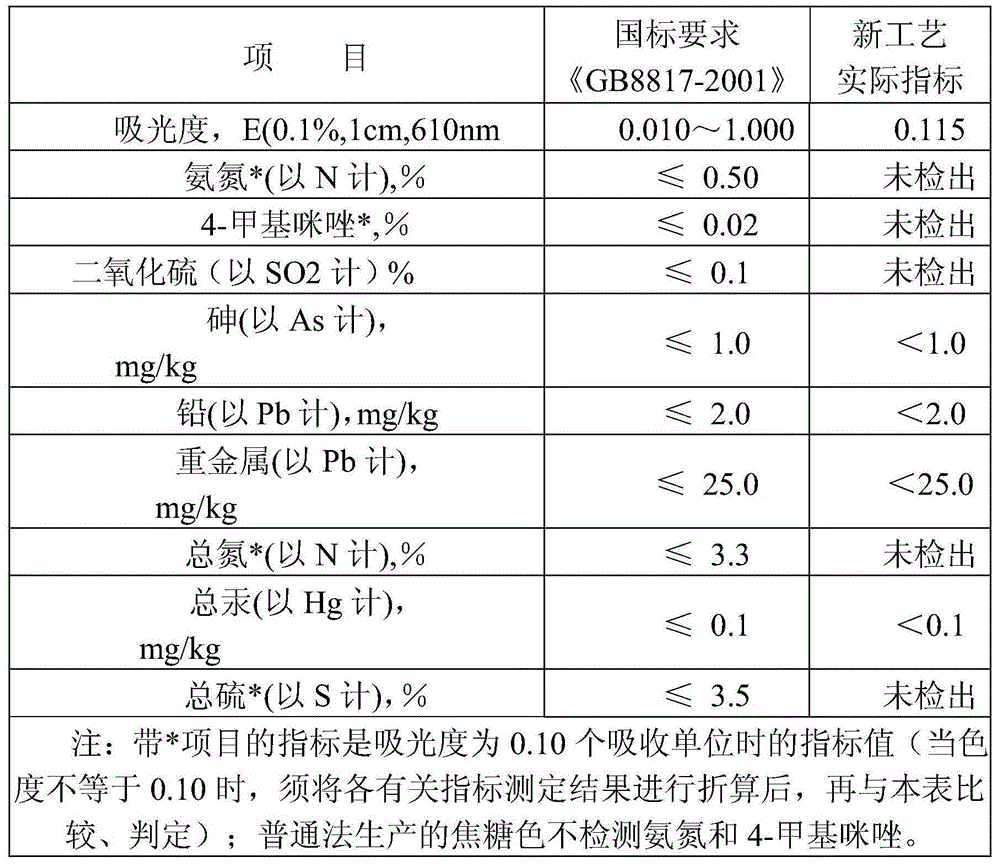

Preparation process of low 4-methylimidazole caramel pigment

The invention discloses a preparation process of low 4-methylimidazole caramel pigment, wherein an ammonium carbonate catalyst is added step by step, the reaction temperature and reaction time are controlled strictly, a caramel reaction is carried out stage by stage, the prepared caramel pigment has a bright red color (the haematochrome index is higher than 5.5), the 4-methylimidazole content is low (smaller than 100 ppm), and all the physical and chemical indexes reach the GB8817-2001 national standard.

Owner:广州华糖食品有限公司 +1

Method of preparing sodium gluconate from xylose crystallization mother liquor

InactiveCN101586129AReduce manufacturing costMild conditionsCarboxylic acid salt preparationFermentationLiquid wasteIon exchange

The invention discloses a method of preparing sodium gluconate from xylose crystallization mother liquor, relates to prepartion method of sodium gluconate. The invention uses indurtrial sewage of xylose crystallization mother liquor, through steps of dilution and nanofiltration, enzyme oxidation, anion exchange, washing concentrating and drying to obtain completed products. The invention uses indurtrial sewage of xylose crystallization mother liquor to produce product sodium gluconate with a purity of 96 to 98% and byproduct such as caramel color, waste is made as treaure, and waste source are made of full use, production cost is reduced; simple method, simple device, no waste residue is discharged in production process, clean production and target of energy saving and discharge reducing are implemented, and then production cost is reduced further. Products according to the invention can be used in industry of foods, chemistry, medicine, and light industry, and particularly suitable for using as nutritional supplements, curing agent and buffers for food industry.

Owner:CHONGQING UNIV

Vegetable dried mushroom and its making method

The vegetable dried beef consists of Xianggu mushroom stem 50 wt%, water 19wt% and seasoning 31 wt%. The seasoning consists of soy sauce 48.4 wt%, sugar 6.5wt%, table salt 12.9wt%, cassia bark 3.2wt%, aniseed 3.2wt%, fennel 3.2wt%, spice powder 6.5wt%, caramel color 12.9wt% and dried scallop essence 3.2wt%. The making process includes finishing and soaking Xianggu mushroom stem, pre-cooking, cooking after adding seasoning, stoving and packing. The vegetable dried beef has look and taste similar to that of dried beef.

Owner:上海大山农业发展有限公司

Health care buckwheat-black rice soy sauce and its production process

InactiveCN1436489ADelicate tasteFlavor harmonyFood preparationPolygonum fagopyrumAdditive ingredient

The health care buckwheat-black rice soy sauce is produced with soybean, buckwheat, black rice and bran as material. During brewing, the function factors contained in buckwheat and black rice enter the soy sauce. The produced soy sauce contains rich flavone matter rutin, trace elements Ca, Fe, Zn, Mn, Se, etc., vitamin B and vitamin E, and thus has the functions of softening blood vessels, lowering blood fat, nourishing Yin, nourishing blood, etc. The soy sauce has no caramel and other pigment added and less harmful components to influence flavor and quality. The present invention combines advanced biotechnology and traditional low-salt solid fermentation process and makes soy sauce more fragrant and delicious. The said process has high material utilization, high soy sauce yield and high soy sauce quality.

Owner:SICHUAN UNIV

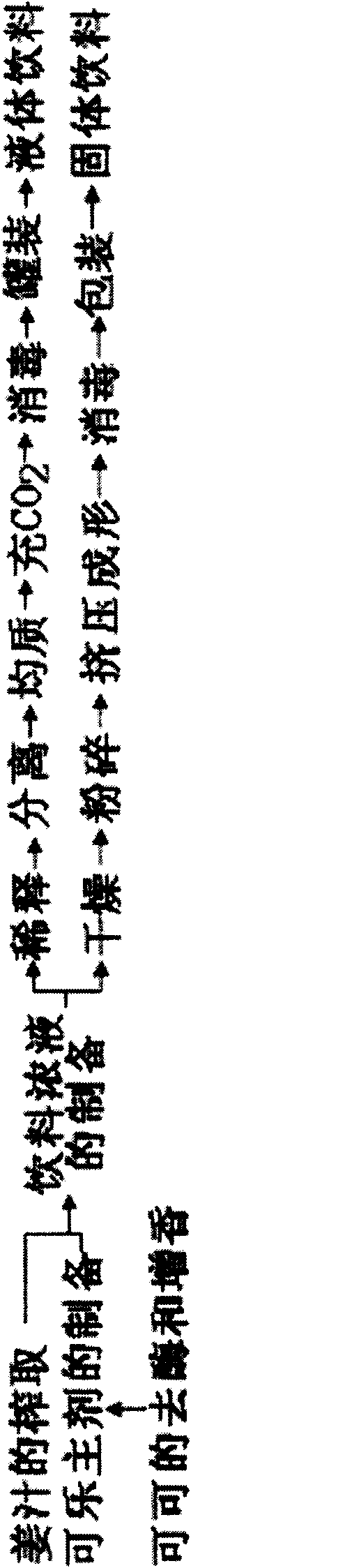

Acid inflatable cool-tea drink and preparation method thereof

The invention discloses an acid inflatable cool-tea drink and a preparation method thereof. The cool-tea drinks is prepared by the following raw materials in permillage by weight: 80-100 white granulated sugar, 5-8 liquorice, 2-4 wild chrysanthemum 4-6 dried hawthorn piece, 4-6 dried orange peel, 1.8-2.3 acidity agent, 0.8-1.2 acidity modifier, 0.4-0.6 cool tea essence, 0.5-0.1 caramel colorant, 1.5-5 CO2 gas, and the balance water. The preparation method comprises the following steps: extracting the liquorice, the wild chrysanthemum, the dried hawthorn piece and the dried orange peel, filtering to obtain extract; mixing the white granulated sugar, the acidity agent, the acidity modifier and the extract; adjusting flavor and color; homogenizing, sterilizing and filling CO2 gas; and fillingand sealing to obtain the acid inflatable cool-tea drink. The invention has the advantages of unique taste, stable quality, explicit effect, safe and convenience, has the effects of clearing away summer heat, invigorating stomach, promoting digestion, promoting metabolism of human bodies and enhancing physical strength, and can adapt to the requirements of crowd in different places and at different ages, has good taste and is a good product for drinking in four seasons.

Owner:广州市凯虹香精香料有限公司

Caustic sulfite process caramel color production technology

The invention discloses a caustic sulfite process caramel color production technology. Carbohydrates are taken as raw materials, sulfite and acid are added in batches under the pressurization condition, or sulfite and alkaline generate a caramelization reaction to prepare a caramel color. According to the technology, the method that the catalysts (sulfite and acid, or sulfite and alkaline) are added in batches under the pressurization condition is adopted for the first time in caramel industry, therefore, the dosage of the catalysts is decreased, the inhibition effect of too much sulfite on browning is overcome, the oxidation reaction degree is effectively controlled, excessive catalysis of the product is prevented, and the product quality is improved.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Removal of reaction byproducts and impurities from caramel color and a shelf stable caramel color concentrate

Caramel color concentrates are prepared by subjecting a solution of caramel color to ultrafiltration through a semi-permeable membrane having a Molecular Weight Cut Off (MWCA) of no greater than 3000 Daltons to retain caramel solids, but remove 4 MeI and other salts. After ultrafiltration, the retentate is subjected to an acidifying step to convert remaining impurities into salts which are then removed. A shelf stable concentrate is obtained having color bodies with a wide range of molecular weight.

Owner:PEPSICO INC

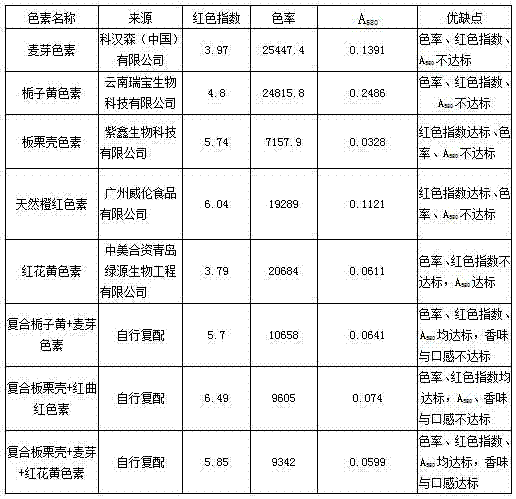

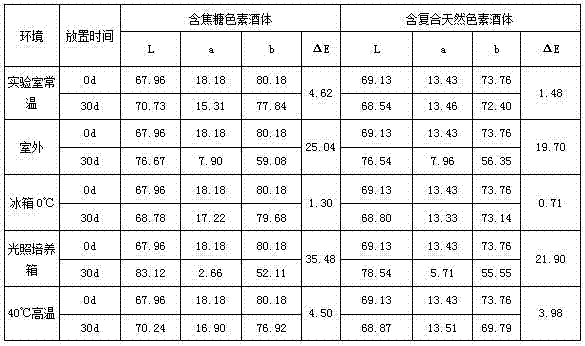

Compound natural pigment solution substituting for caramel pigment in compound wine

ActiveCN103937290ASimilar styleUnique fragranceAlcoholic beverage preparationNatural dyesCarcinogenFood flavor

The invention relates to a compound natural pigment solution substituting for caramel pigment in compound wine. The compound natural pigment solution is prepared from the following raw materials in mass fraction: 80%-90% of chestnut shell extract, 5%-10% of malt extract and 5%-10% of carthamin extract; after all the extracts are mixed, 0.5-1.0 time of water is further added for preparing concentrated liquid; the prepared compound natural pigment solution needs to simultaneously achieve the quality standard requirements of color index of 9000-11000, red index of 5.5-7.0 and absorbance of 0.04-0.07 at 580nm under the concentration of 0.1%. Compared with the wine prepared by the caramel pigment, the wine prepared by the compound natural pigment provided by the invention has similar color, similar style, unique flavor, soft taste, good stability and no carcinogen 4-methylimidazole, and can completely substitute for the caramel pigment in the existing compound wine.

Owner:JING BRAND

Chinese date buccal tablet and its preparing process

InactiveCN1653951ARetain nutritionKeep health careUnknown materialsPill deliveryMagnesium stearateSlurry

The present invention is buccal date tablet and its production process. The production process includes making date slurry with date and spray drying to obtain date powder; mixing data powder 25-35 wt%, glucose powder, dextrin, can sugar powder or milk powder 60-65 wt%, date powder essence, citric acid, menthol or ethyl maltol 4-7 wt% and caramel 1-3 wt%; pelletizing the mixture in pelletizing machine and stoving to obtain date pellet; mixing date pellet with magnesium stearate in 2-4 wt%; and tabletting in tabletting machine to obtain the buccal date tablet. The produced buccal date tablet has the nutrients and health functions similar to date and is small, light, and easy to carry and eat.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing oil-soluble and fat-soluble caramel pigments with edible safety

The invention discloses a method for preparing oil-soluble and fat-soluble caramel pigments with edible safety. The method comprises the following steps: firstly, filling caramel pigment raw materials into an extraction kettle of a supercritical fluid extracting device; then, performing the supercritical CO2 fluid extraction on the caramel pigment raw materials under the following extraction conditions that: the extraction kettle pressure is between 10 and 40 MPa, the pressure of a separation kettle I is between 5 and20 MPa, the pressure of a separation kettle II is between 3 and 15 MPa, the extraction time is 10 to 90 min, the temperature of the extraction kettle is between 20 and 90 DEG C, the temperature of the separation kettle I is between 10 and 60 DEG C and the temperature of the separation kettle II is between 5 and 40 DEG C; and after the extraction is completed, concentrating or dehydrating the materials in the separation kettle II, and drying the materials to prepare an oil-soluble or fat-soluble caramel pigment product. The method has the characteristics of no pollution, simple process, high product yield and high edible safety.

Owner:QINGDAO RICHEN FOODS

High-stability chestnut shell brown pigment as well as refining method and application thereof

ActiveCN103232725AIntuitively reflect the color stateFacilitate the unification of standardsNatural dyesFood preparationBrown pigmentCoca

The invention relates to a high-stability chestnut shell brown pigment as well as a refining method and an application thereof. The high-stability chestnut shell brown pigment is a brown liquid made by refining by taking chestnut shell thick extract as a raw material, can be completely dissolved in an aqueous solution with pH of 4-14 and an ethanol solution with the concentration less than or equal to 65% and is in transparent brown; colour index of the brown pigment is 8000-12000, and the index of red is 5.0-7.0; and the brown pigment is added to 15-60% vol of alcoholic drink and cola type carbonated drink and is respectively placed for 30 days under the conditions of irradiation outside, inside and under a fluorescent lamp and temperatures of 4 DEG C and 40 DEG C, and the determined pigment loss ratio is lower than that of a caramel pigment under equal conditions. The chestnut shell brown pigment product prepared by the invention is high in purity, good in dissolubility, high in stability, low in pigment loss ratio and high in safety and can mix colour in the alcoholic drink and coca type carbonated drink by replacing the caramel pigment, and the chestnut shell brown pigment is represented by adopting the index of red and colour index for the first time.

Owner:湖北紫鑫生物科技有限公司

Method for preparing caramel pigment from molasses

The invention discloses a method for preparing caramel pigment from molasses. The method is characterized by comprising the following steps of: adding hydrochloric acid or phosphoric acid solution to the molasses prepared by the conventional process to adjust the pH of the molasses to 2.0-2.5, adding flocculant to the molasses for depositing impurities after the molasses is heated to be boiled, heating and stirring supernate for 1h-1.5h to prepare acidolysis solution, filtering the acidolysis solution by a filter bag, adding slaked lime milk to the filtered acidolysis solution for mixing, adjusting the pH of mixed solution to 8-10, heating and concentrating the mixed solution to 88-92 degrees Bx, filtering the mixed solution by a curved sieve, and storing the mixed solution in a molasses storage. The caramel pigment can be used for coloring a sugar product. The investment of the preparation method of the color matching agent is less, equipment is simple, the color and luster of the prepared color matching agent are deep, the color matching agent does not cause turbidity and sedimentation after being diluted, and the caramel pigment is used for coloring the sugar product and is capable of improving the appearance of the sugar product and enhancing the recovery ratio of sugar and the use ratio of the molasses.

Owner:GUANGXI CHONGZUO XIANGGUI SUGAR

Method for preparing gluconic acid from mother liquor of xylose crystalline liquid

InactiveCN101538591AReduce manufacturing costQuality improvementFermentationResource utilizationUltrafiltration

The invention discloses a method for preparing gluconic acid from mother liquid of xylose crystalline liquid, and relates to a preparation method of gluconic acid. The method takes industrial waste of mother liquor of xylose crystals as raw material and obtains the product by decolorization, enzymic oxidation, ultrafiltration, electrodialysis and concentration and drying. The invention is characterized by being capable of fully utilizing the industrial waste of mother liquor of xylose crystals to prepare various products including the gluconic acid, caramel pigment and protein feed, and good quality of the prepared gluconic acid with the purity being up to 98.6 percent; and also by simple method, convenient operation, low production cost, easy popularization and application and the like; and opens up a new way for the resource utilization of industrial waste of mother liquor of xylose crystals. The products prepared by the method can be widely applied as metal ion chelation agent, acid agent and coloring agent in the industries of food, medicine and electroplating and the like, as anti-aging agent in cosmetics and as feed additive and the like.

Owner:CHONGQING UNIV

Method for processing tuna instant seasoned dried-fish

The invention discloses a method for processing tuna instant seasoned dried-fish. The method comprises boiling the tuna after screening, so that fish and bones are convenient to separate and slicing is easy; immersing fillets into a flavor liquid consisting of soy and other components to pickle and season, and turning and mixing the fillets every 1 to 2 hours, so that the flavor liquid penetrates well and flavoring effect is relatively good; and drying the pickles and seasoned fillets with hot wind at a temperature of 50 to 75 DEG C for 3 to 5 hours, and turning the fillets every 0.5 to 1 hour, so that the air drying time is relatively few, water loss of the tuna fillets is small, the taste is good, and the fillets are uniformly dried to get the dried fish with uniform caramel color. Therefore, the method has advantages of well penetrated seasoned dried-fish, good-color dried-fish, relatively little drying time and relatively good drying effect.

Owner:NINGBO UNIV +1

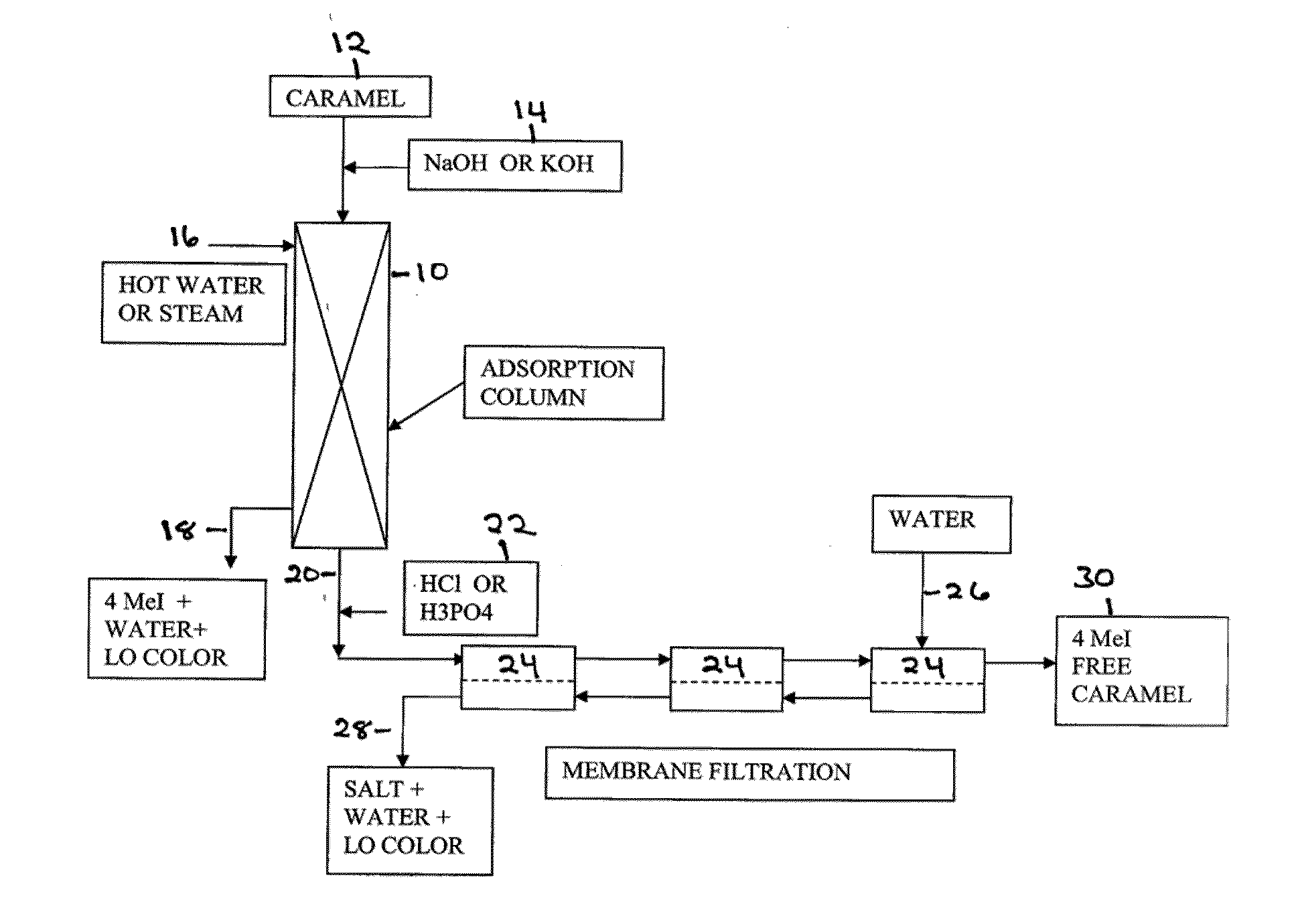

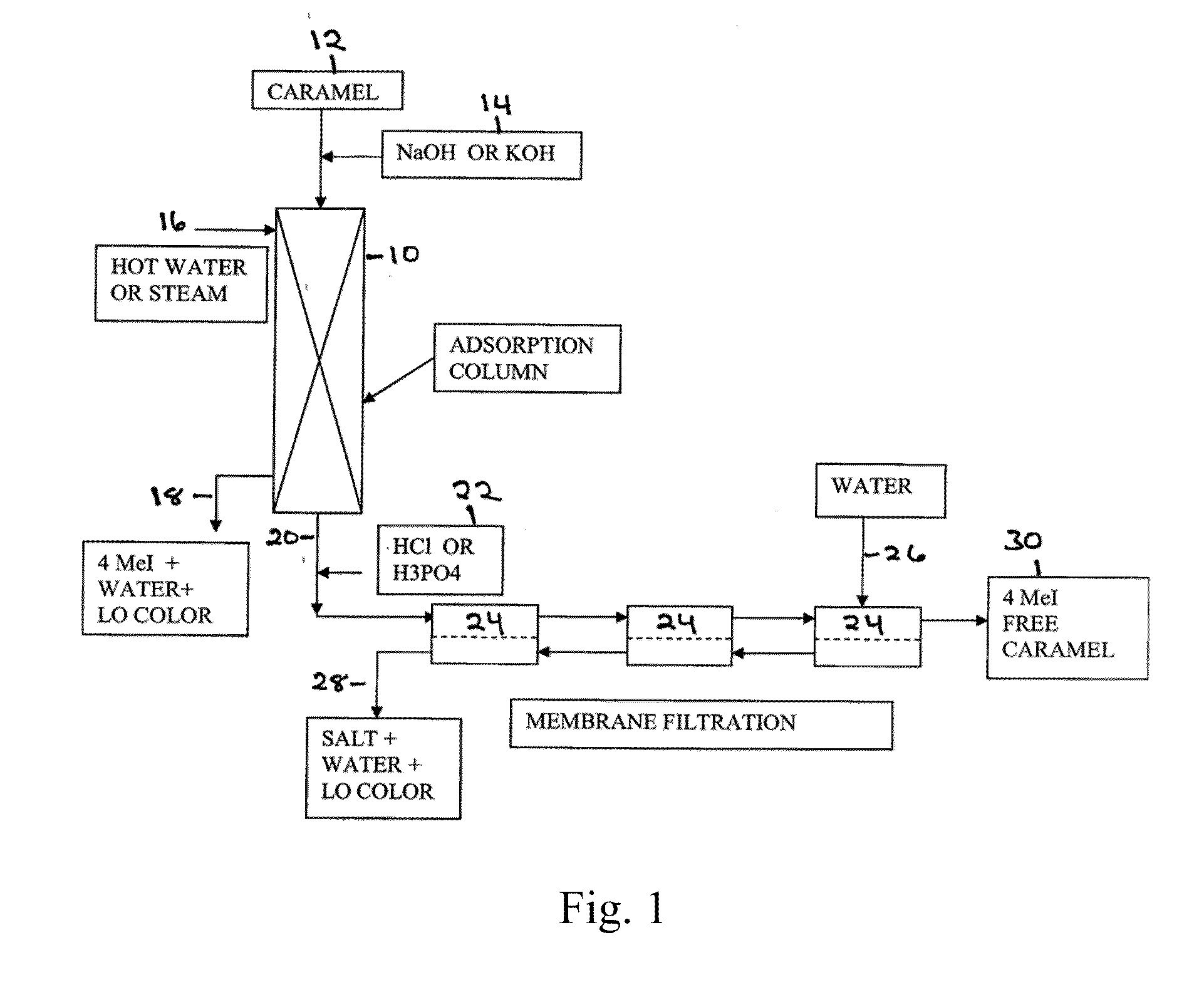

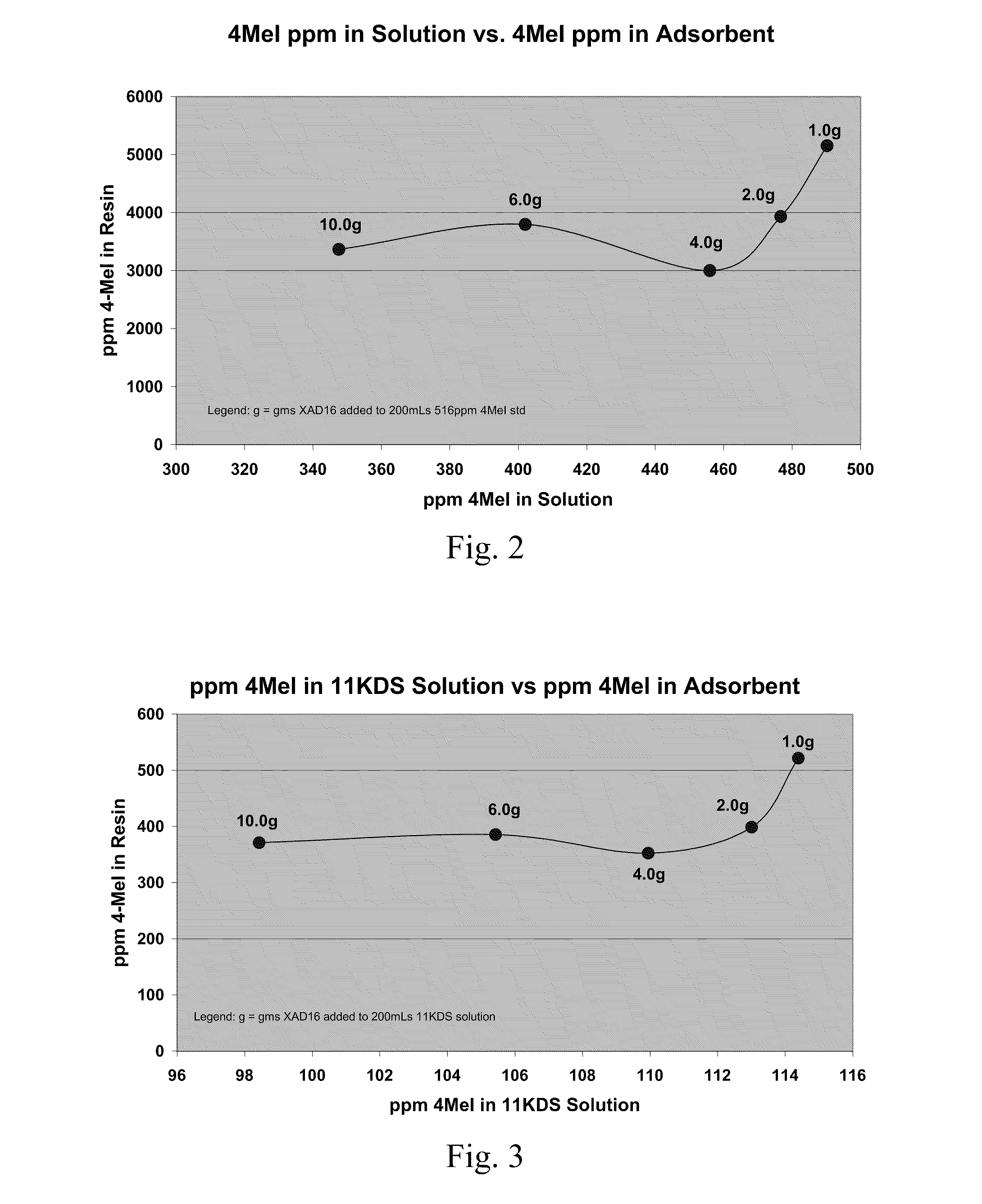

Adsorption Purification Of Caramel

A process of purifying a caramel color solution comprising introducing the caramel color solution into an adsorbent wherein the adsorbent adsorbs 4-MeI to form a purified caramel color solution, and adding an acid to the purified caramel color solution to lower the pH to less than 5.

Owner:PEPSICO INC

Crab flavor seasoning sauce prepared through enzymolysis method, and preparation method thereof

InactiveCN105533310AHas a mellow and fresh fragranceThick and long mouthfeelFood preparationMaillard reactionHydrolysate

The present invention discloses a crab flavor seasoning sauce prepared through an enzymolysis method, and a preparation method thereof, wherein the crab flavor seasoning sauce is prepared from the following raw materials by weight: 40 parts of a crab meat hydrolysate, 60 parts of a hypsizygus marmoreus hydrolysate, 10-20 parts of amino acids, 10-20 parts of reducing sugar, 5-15 parts of edible salt, 5-10 parts of disodium ribonucleotide, 5-10 parts of disodium succinate, 5-10 parts of caramel color, and 20-30 parts of water. The preparation method comprises: (1) preparing a crab meat hydrolysate; (2) preparing a hypsizygus marmoreus hydrolysate; (3) mixing the two hydrolysates and the remaining raw materials according to a certain ratio, and carrying out a Maillard reaction; and (4) sterilizing. According to the present invention, the prepared crab flavor seasoning sauce has characteristics of delicious and sweet odor of seafood, realistic crab flavor and mellow, delicious, thick and lingering taste, can be widely used for cooking of various types of seafood, and can be adopted as the appetizing sauce and the dish seasoning so as to provide effects of flavor increasing and fresh improving.

Owner:麦亚孙

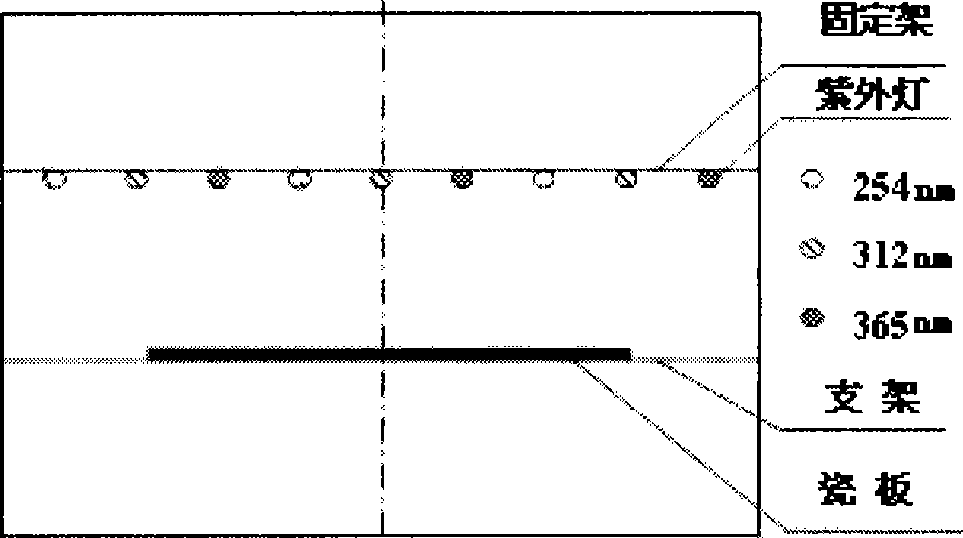

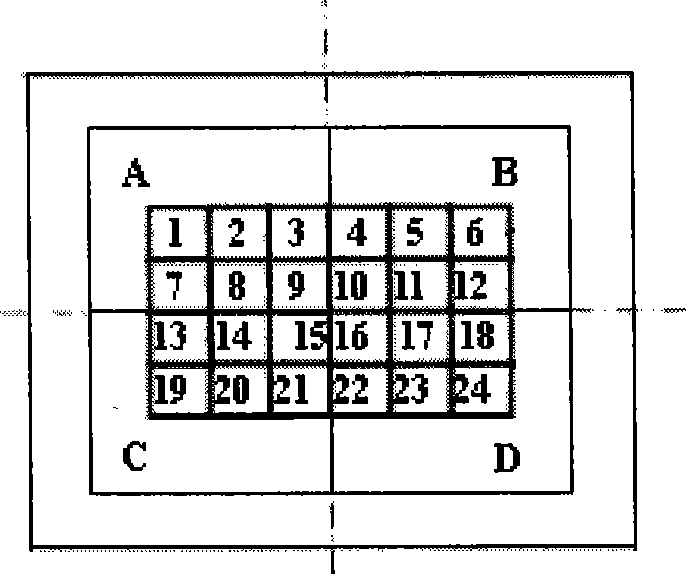

Artificial dirt, method for making same and aging processing method

InactiveCN101419211ASimulate the realObjective decontamination abilityPreparing sample for investigationUltravioletEngineering

The invention aims to provide artificial dirt, a method for preparing the same and a method for an aging treatment thereof. The artificial dirt is prepared from soybean oil, refined lard, refined butter, ammonia-free caramel color, wheat flour, and monostearin, and is used for simulating the actual dirt to measure the detergency of an oil stain cleaning agent. The invention use ultraviolet radiation to perform the aging treatment on the artificial dirt so that the artificial dirt falls off evenly in washing. The invention can factually simulate the common oil stains in daily life, can truly and objectively reflect the detergency of different oil stain cleaning agents, and can be applied to the formulation of a national standard or an industrial standard. The method for preparing the artificial dirt has the advantages of simple operation, good experimental repeatability and good reproducibility.

Owner:北京绿伞科技股份有限公司

Chocolate cookies and preparation method thereof

The invention relates to the technical field of food processing, and particularly discloses chocolate cookies and a preparation method thereof. The chocolate cookies are mainly prepared by sequentially coating powder materials and chocolate paste layers on the outer layers of cookies, wherein the cookies are mainly prepared from low gluten wheat flour, medium gluten wheat flour, high gluten wheat flour, rice meal, white granulated sugar, palm oil, cocoa powder, high fructose corn syrup, edible salt, soybean lecithin, span 65, caramel color and vanillin; the powder material is mainly prepared from white granulated sugar, malt extract, cocoa powder and maltodextrin; chocolate paste is mainly prepared from vegetable oil, white granulated sugar, cocoa powder, soybean lecithin, span 65, beta-cyclodextrin, hydroxypropyl-modified starch, oxidized starch and pullulan. The chocolate paste layers on the outer layers of the cookies is bright in color, smooth, free of cracks and delicate in taste; the cookies as the inner layers are crisp, and the chocolate paste layers on the outer layer are excellent in humidity resistance and can keep the cookies as the inner layers crispy for a long time.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com