Preparation process of low 4-methylimidazole caramel pigment

A methyl imidazole caramel, preparation technology technology, applied in the direction of organic dyes, chemical instruments and methods, natural dyes, etc., can solve the problems of complicated operation, high cost of membrane filtration technology, high application pressure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

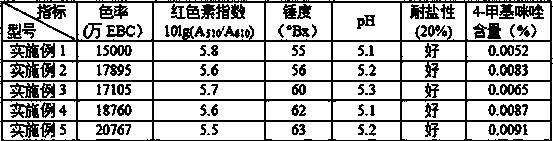

Examples

preparation example Construction

[0020] The preparation technology of low 4-methylimidazole caramel pigment of the present invention comprises the following steps:

[0021] (1) Dilute the molasses with an appropriate amount of water, settle, and take the supernatant liquid;

[0022] (2) Transfer the sugar liquid into the reaction kettle, add ammonium carbonate solution with 0.5-1% sugar liquid mass, and control the temperature at 115-120°C for 5-10 minutes; continue to add ammonium carbonate solution with 1-1.5% sugar liquid mass, Control the temperature at 120-122°C for 10-15 minutes; continue to add ammonium carbonate solution with a sugar solution mass of 1.5-2.0%, control the temperature at 122-125 °C for 15-20 minutes; continue to add sugar solution mass of 1-1.5% ammonium carbonate solution solution, control the temperature at 120-122°C for 10-15 minutes; then control the temperature at 115-120°C for 20-30 minutes, and end the reaction to obtain caramel pigment with low 4-methylimidazole content.

[00...

Embodiment 1

[0033] The preparation technology of low 4-methylimidazole caramel coloring:

[0034] (1) Pretreatment of molasses: Take 4kg of refined sugar molasses, add 1kg of water to dilute, add dilute sulfuric acid, adjust the pH value to 1.5, raise the temperature to 105°C and maintain it for 60min, cool down to about 80°C and put it into the settling tank, after settling Take the supernatant sugar solution for use;

[0035] (2) Brix adjustment: add an appropriate amount of water to adjust the Brix to 60°Bx, and pump it into the reactor;

[0036] (3) Reaction stage: first heat the sugar solution to 115°C quickly, then slowly add a saturated aqueous solution of ammonium carbonate with 1% of the mass of the sugar solution dropwise, and control the temperature at 115°C for 10min; , control the temperature at 120°C for 15 minutes; continue to add dropwise a saturated aqueous solution of ammonium carbonate with a mass of 2.0% of the sugar solution, and control the temperature to react at 1...

Embodiment 2

[0039] The preparation technology of low 4-methylimidazole caramel coloring:

[0040] (1) Pretreatment of molasses: Take 5kg of refined sugar molasses, add 1kg of water to dilute, add dilute sulfuric acid, adjust the pH value to 2.0, raise the temperature to 105°C and maintain it for 60min, cool down to about 60°C and put it into the settling tank, after settling Take the supernatant sugar solution for use;

[0041] (2) Brix adjustment: add an appropriate amount of water to adjust the Brix to 63°Bx, and pump it into the reactor;

[0042] (3) Reaction stage: first heat the sugar liquid to 120°C quickly, then slowly add 0.5% sugar liquid saturated ammonium carbonate aqueous solution dropwise, control the temperature at 120°C for 5 minutes; continue to drop the sugar liquid 1% ammonium carbonate saturated aqueous solution , control the temperature at 122°C for 10 minutes; continue to add dropwise a saturated aqueous solution of ammonium carbonate with a mass of 1.5% of the sugar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com