Patents

Literature

368 results about "Brix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degrees Brix (symbol °Bx) is the sugar content of an aqueous solution. One degree Brix is 1 gram of sucrose in 100 grams of solution and represents the strength of the solution as percentage by mass. If the solution contains dissolved solids other than pure sucrose, then the °Bx only approximates the dissolved solid content. The °Bx is traditionally used in the wine, sugar, carbonated beverage, fruit juice, maple syrup and honey industries.

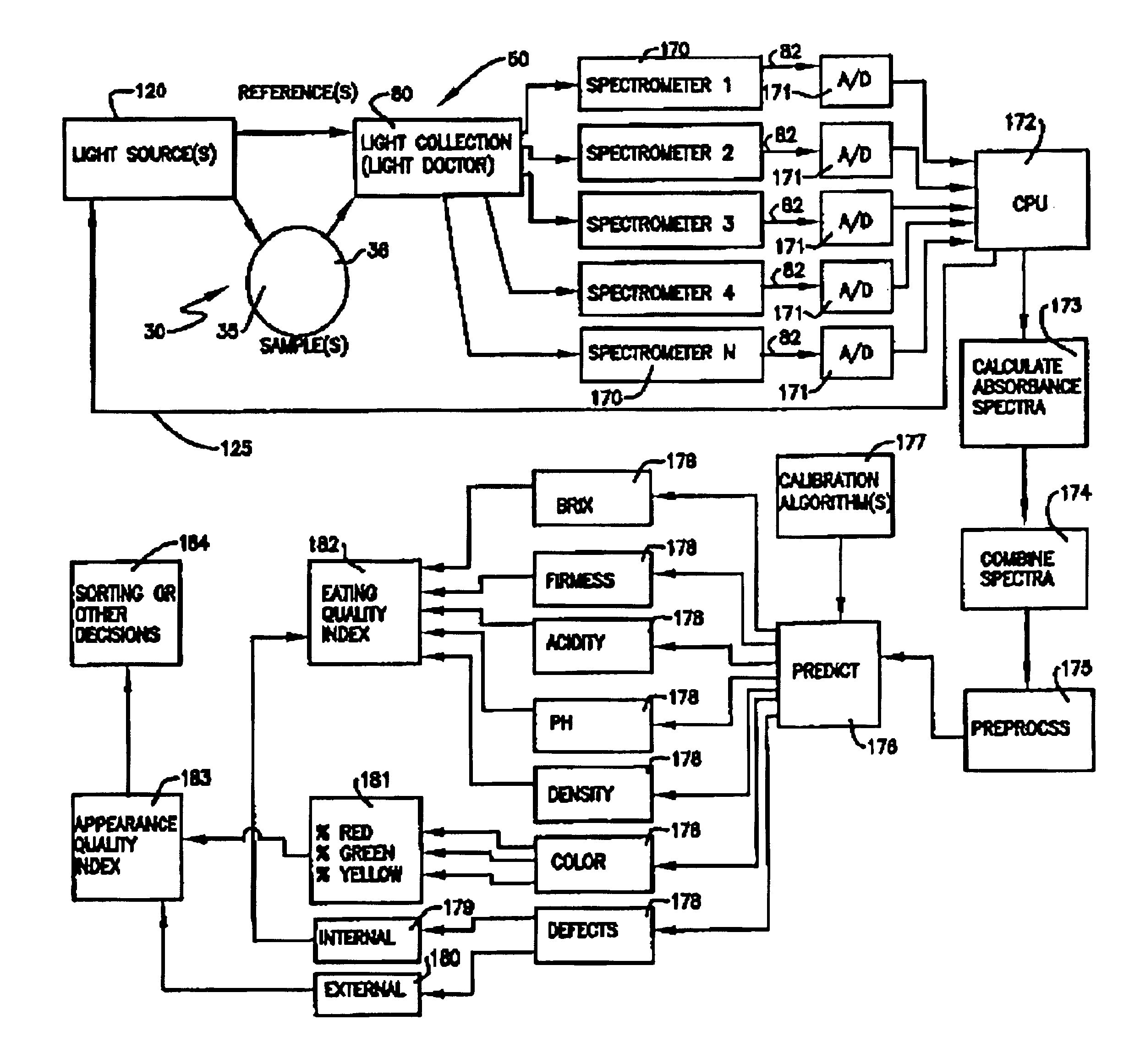

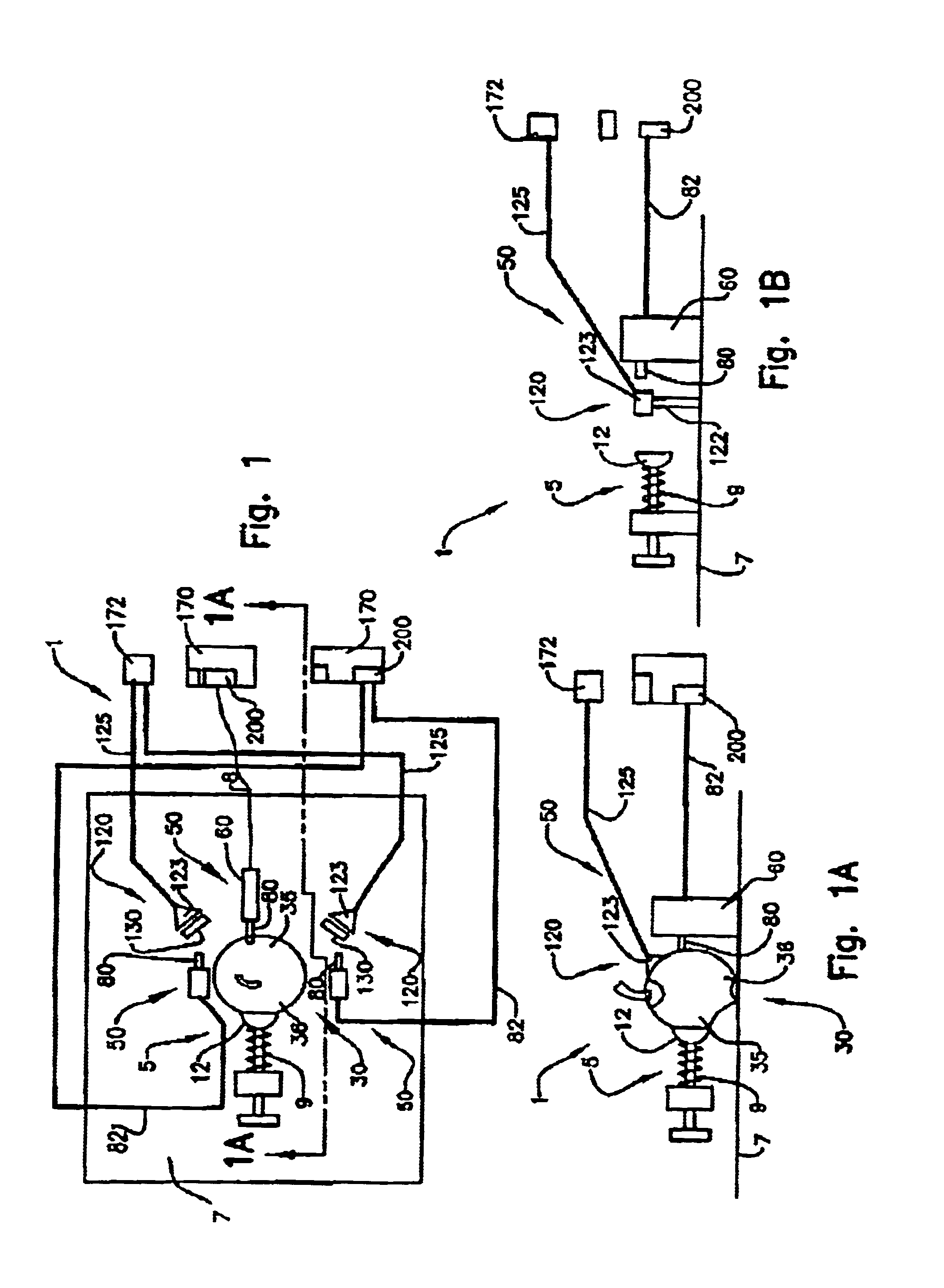

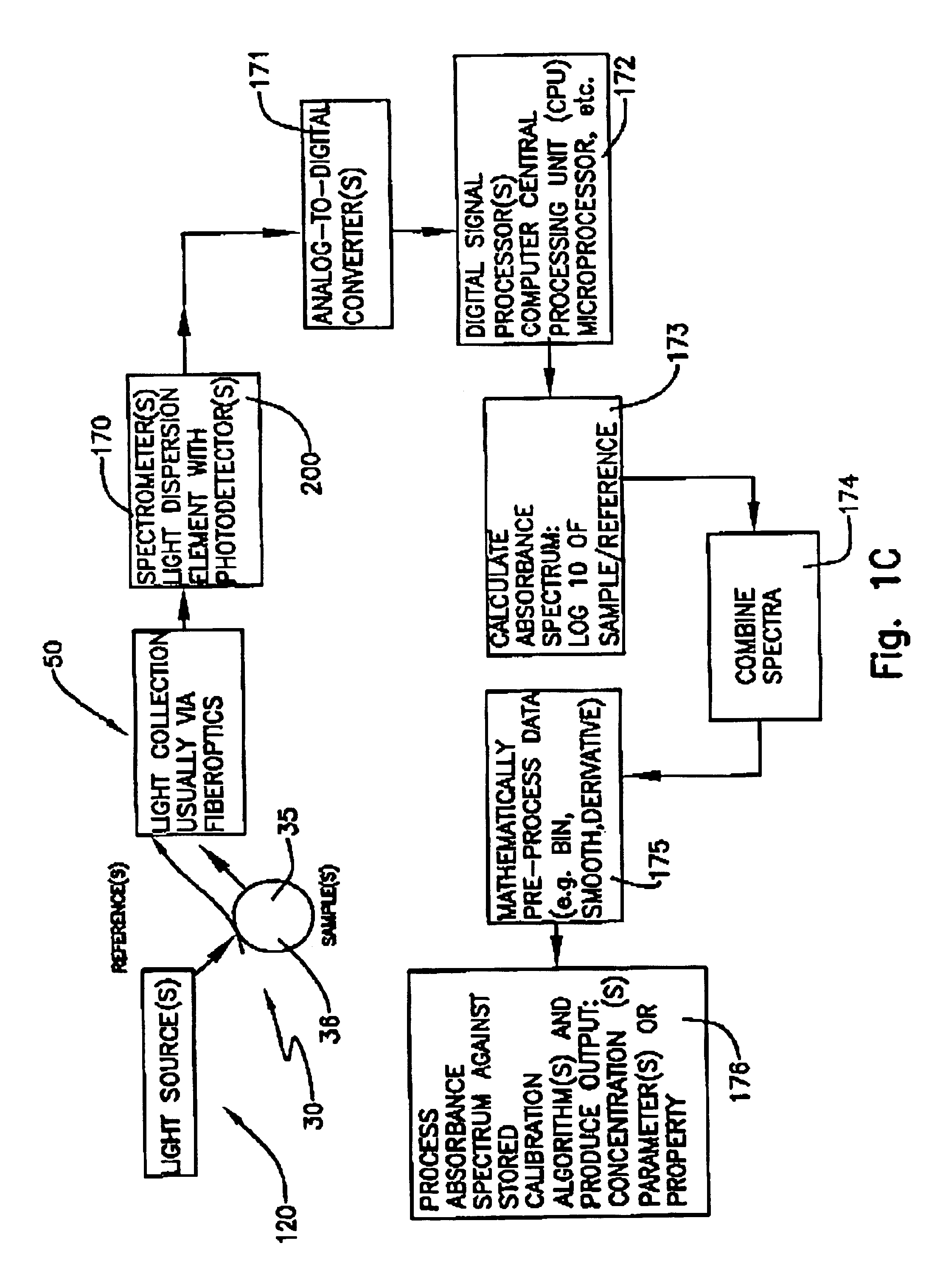

Apparatus and method and techniques for measuring and correlating characteristics of fruit with visible/near infra-red spectrum

InactiveUS6847447B2Better signal to noise ratioImproves Brix prediction accuracyRadiation pyrometryInvestigation of vegetal materialBrixPeak value

This disclosure is of 1) the utilization of the spectrum from 250 nm to 1150 nm for measurement of prediction of one or more parameters, e.g., brix, firmness, acidity, density, pH, color and external and internal defects and disorders including, for example, surface and subsurface braises, scarring, sun scald, punctures, in N—H, C—H and O—H samples including fruit; 2) an apparatus and method of detecting emitted light from samples exposed to the above spectrum in at least one spectrum range and, in the preferred embodiment, in at least two spectrum ranges of 250 to 499 nm and 500 nm; 3) the use of the chlorophyl band, peaking at 690 nm, in combination with the spectrum from 700 nm and above to predict one or more of the above parameters; 4) the use of the visible pigment region, including xanthophyll, from approximately 250 nm to 499 nm and anthocyanin from approximately 500 to 550 nm, in combination with the chlorophyl band and the spectrum from 700 nm and above to predict the all of the above parameters.

Owner:FPS FOOD PROCESSING SYST BV

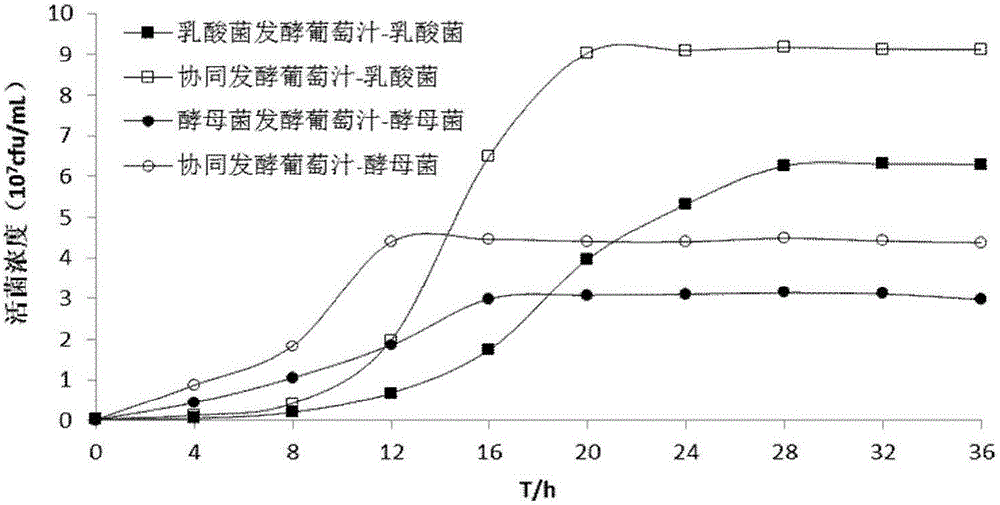

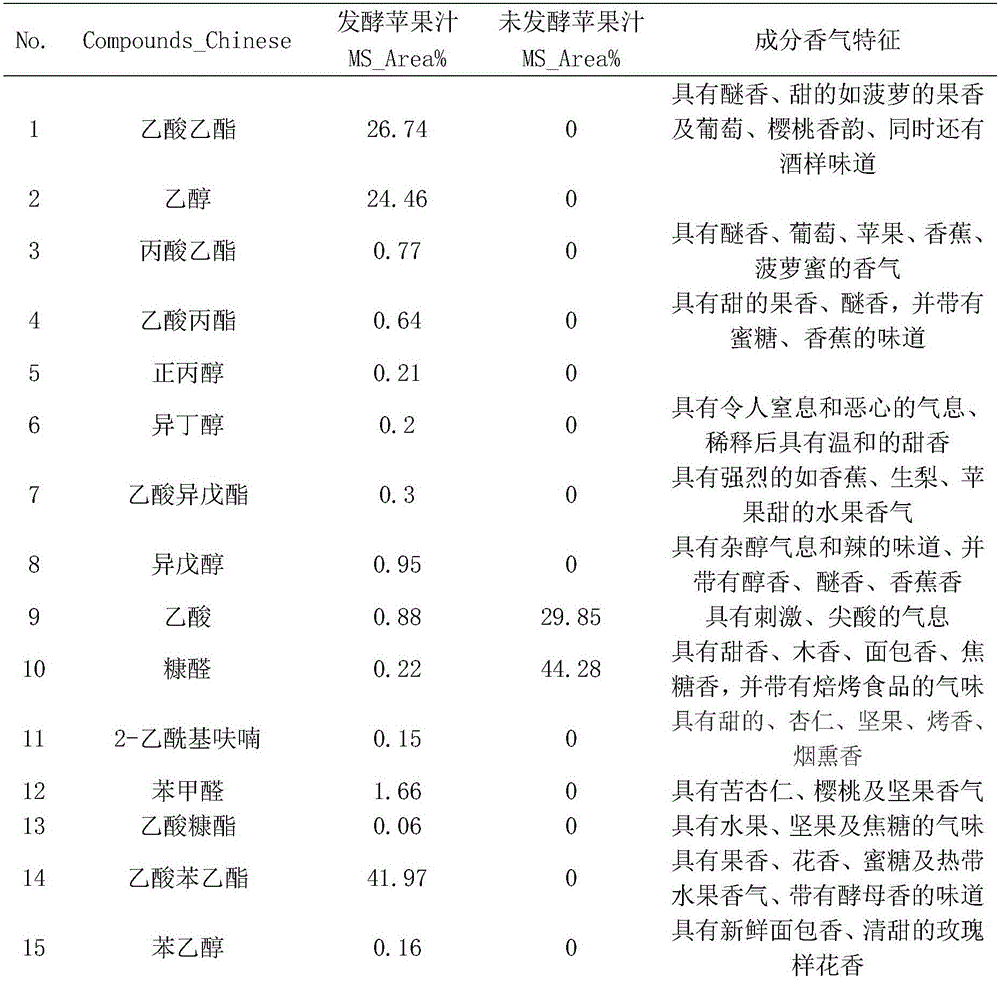

Method for preparing fermented fruit and vegetable juice and application of product obtained by method

InactiveCN106213095APromote fermentationPromote growthYeast food ingredientsFood ingredient functionsBrixAdditive ingredient

The invention discloses a method for preparing fermented fruit and vegetable juice and application of a product obtained by the method, and the method comprises the following steps: mixing fruits and vegetables to obtain a high-Brix-degree material with the Brix greater than or equal to 30 degrees, adding yeast for first-time fermentation, and adding lactic acid bacteria for secondary synergistic fermentation when the Brix is reduced to below 30 degrees. The fruit and vegetable juice is fermented by use of microorganism for metabolism to produce amino acids, organic acids, alcohols, esters, and other flavor substances to enhance fragrance and enrich the taste. The fermented fruit and vegetable juice prepared by the method can be directly eaten, can be added as a food ingredient into food can also be used as a raw material for preparing a concentrated main agent after blending and concentration. Compared with products on the market in prior art, the preparation method can solve the problem that high-Brix-degree fruit and vegetable juice is difficult to ferment, light in flavor and single in fragrance, and has the advantages of simple process, low cost, convenient transportation, broad market prospects, and the like.

Owner:HANGZHOU EVER MAPLE FLAVOR & FRAGRANCE

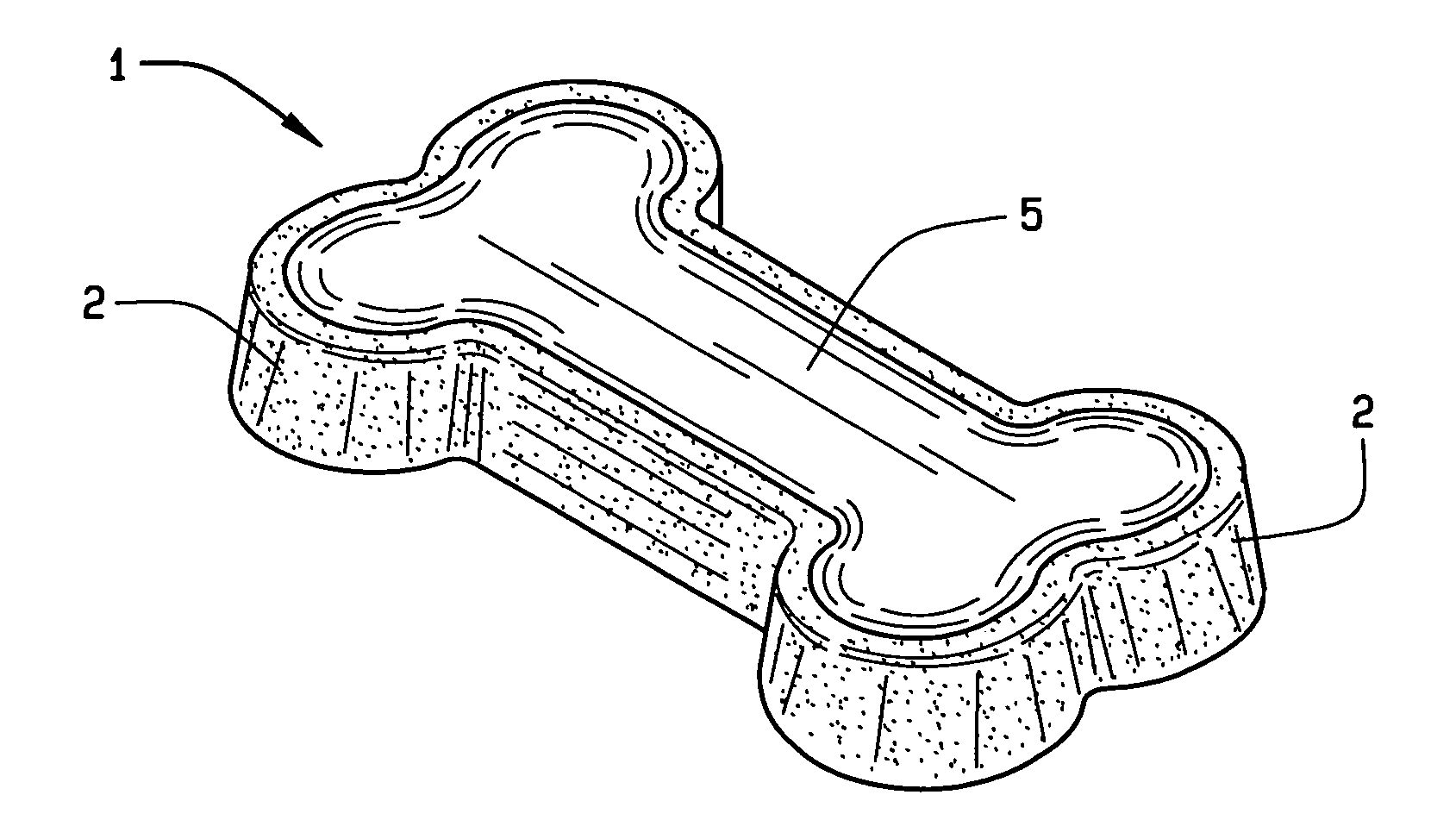

Foodstuff containing a moist meaty filling

ActiveUS7485330B2Improve palatabilityEnhanced edgeMeat/fish preservationBaking mixturesBrixWater activity

A biscuit treat for dogs has improved palatability by incorporating a highly palatable shelf stable meaty filling into a cavity formed upon the top surface of the biscuit. The meaty filling includes agar as a gelling agent in combination with sufficient soluble solids to yield a high Brix number and reduced water activity. Precise quantities of agar and of a soluble solids concentration exceeding 65% eliminate capillary transfer of moisture from the highly aqueous meaty filling to the low moisture dry biscuit. The resulting highly palatable two phase biscuit has a long shelf life suitable for commercialization in the pet treat market.

Owner:REDBARN PET PRODS

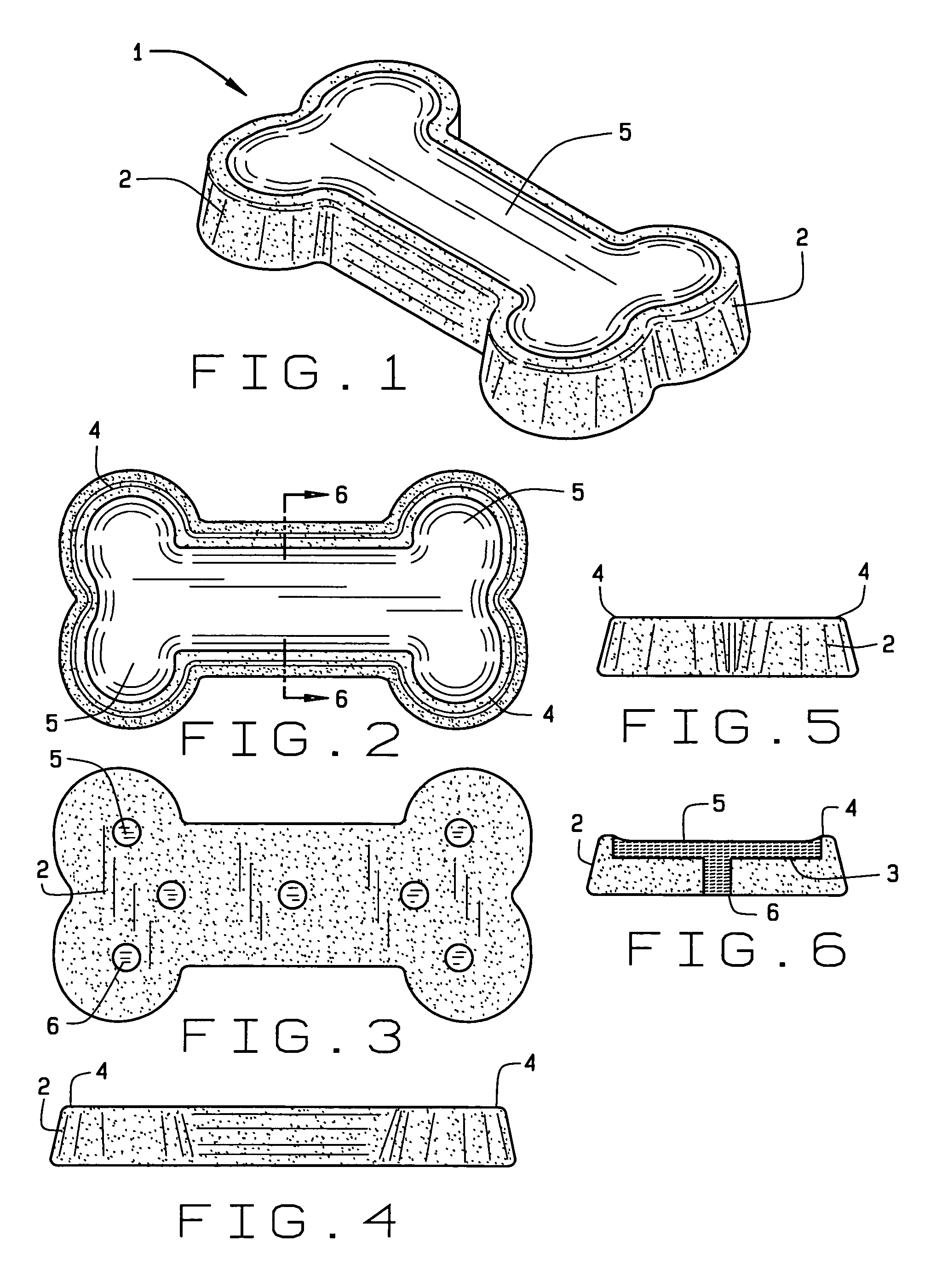

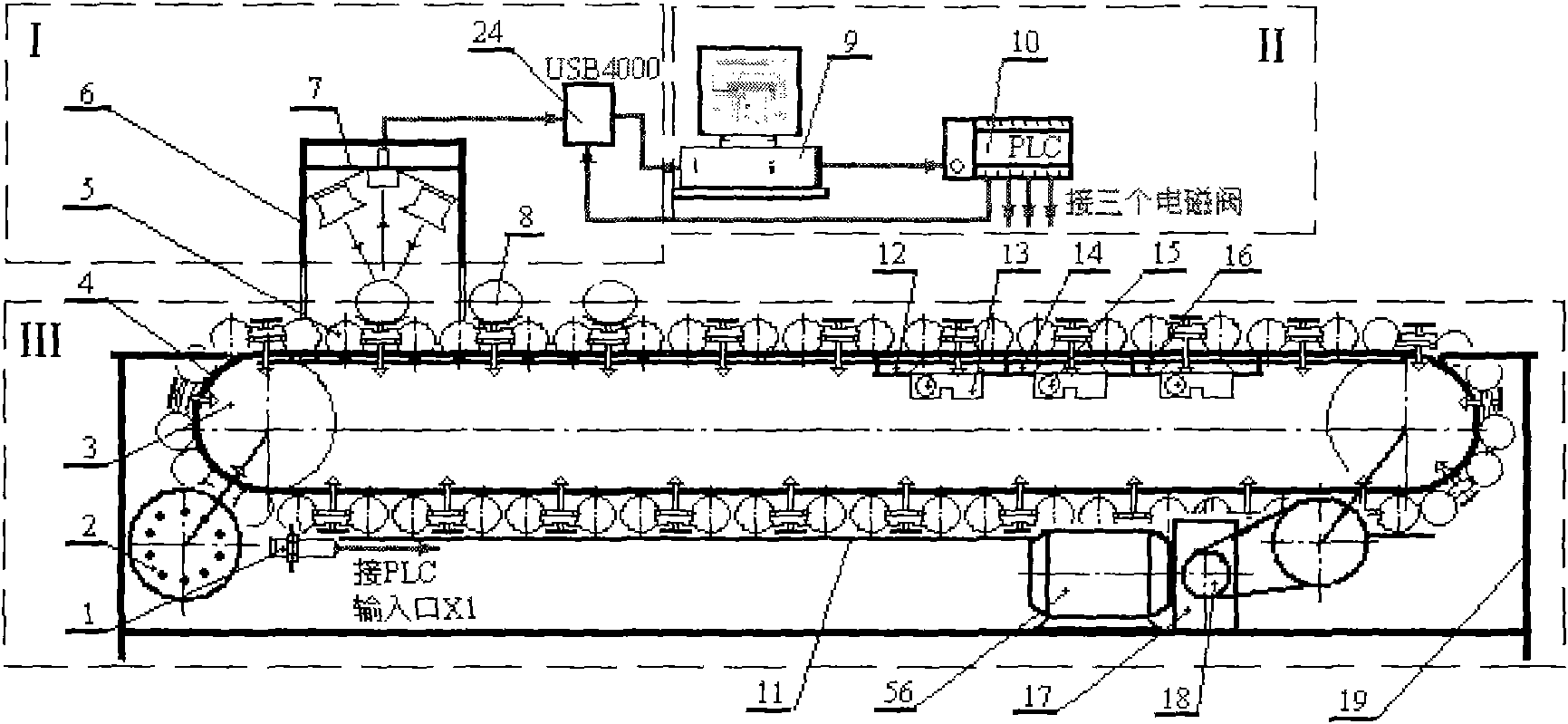

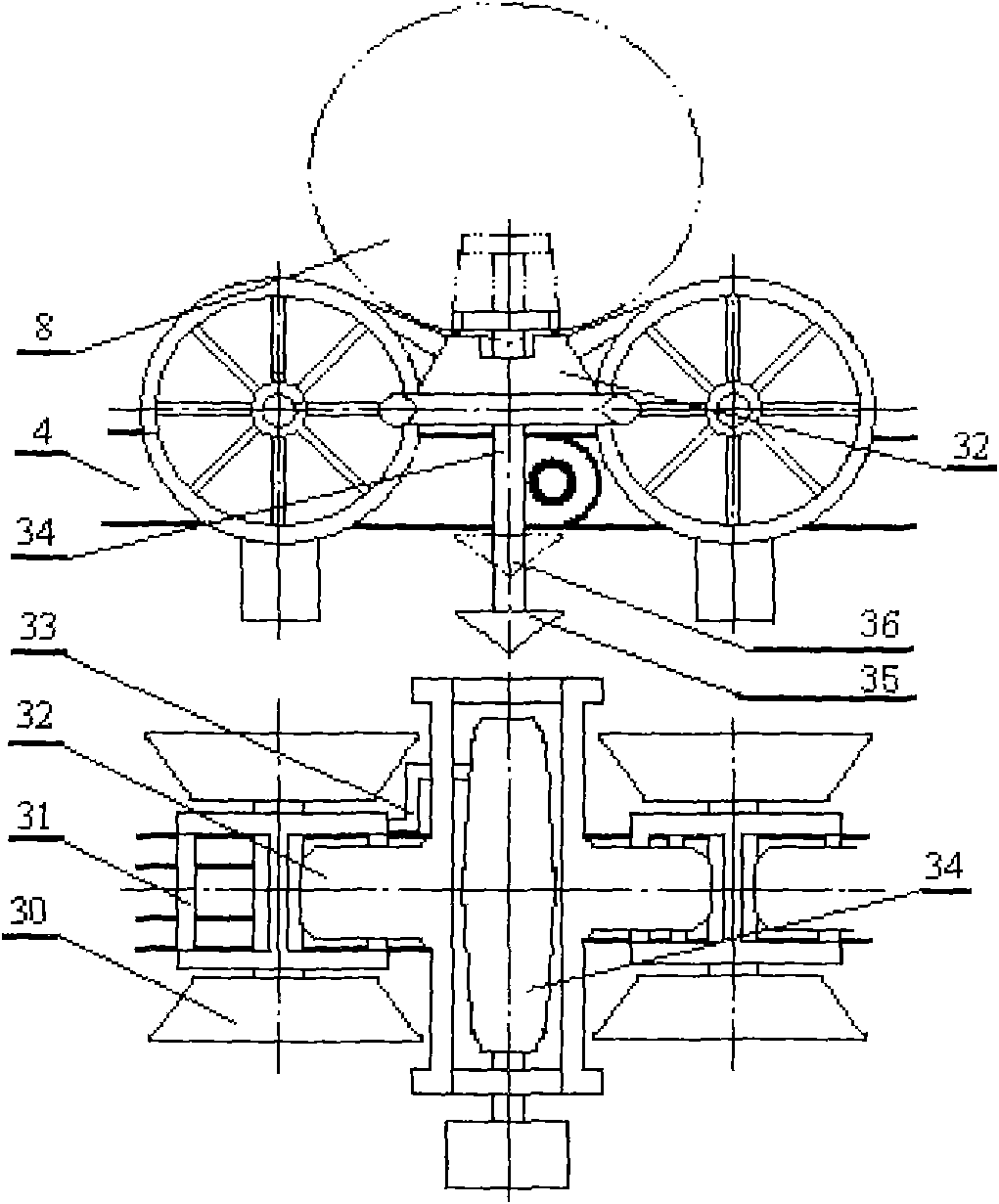

Visible near-infrared spectrum-based fruit brix/acidity online detection and separation production line

InactiveCN101920245AMeet the needs of large-scale commercial processingIncrease the level of automationColor/spectral properties measurementsSortingProduction lineBrix

The invention discloses a visible near-infrared spectrum -based fruit brix / acidity online detection and separation production line, which consists of a mechanical conveying device (III), a visible near-infrared spectrum detection device (I) and a separation control device (II). The work flow is as follows: the fruits are conveyed by the mechanical conveying device of the production line and enter a station of the visible near-infrared spectrum detection device (I) and a separation; a coding disc (2) and a proximity switch (1) installed on a chain wheel shaft detect the moving position information of the fruits and send the information to a spectrometer (24); the spectrometer is triggered by the proximity switch, acquires the visible near-infrared spectrum absorbed and reflected by the fruits and sends a spectrum signal to a fruit brix / acidity model of the computer software so as to calculate the content of the fruit brix / acidity and divides the grades of the fruit brix / acidity by segment; and the computer is communicated with a programmable controller PLC (10) through an interface, assigns the grade signals to the PLC and controls the execution element at each separation port to realize separation of the fruits of different grades. The invention is applicable to the online detection and separation of the inside brix / acidity of the fruits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

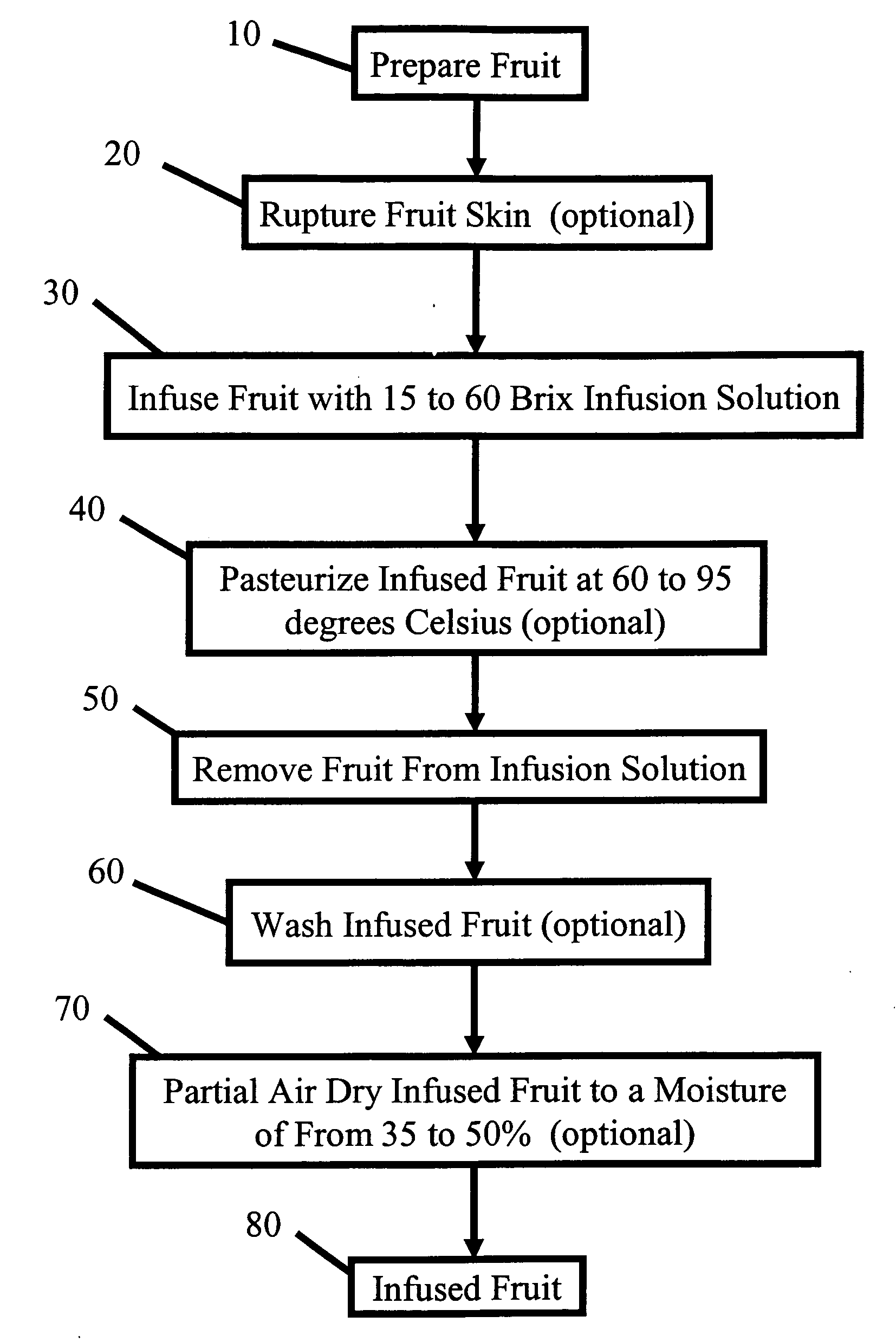

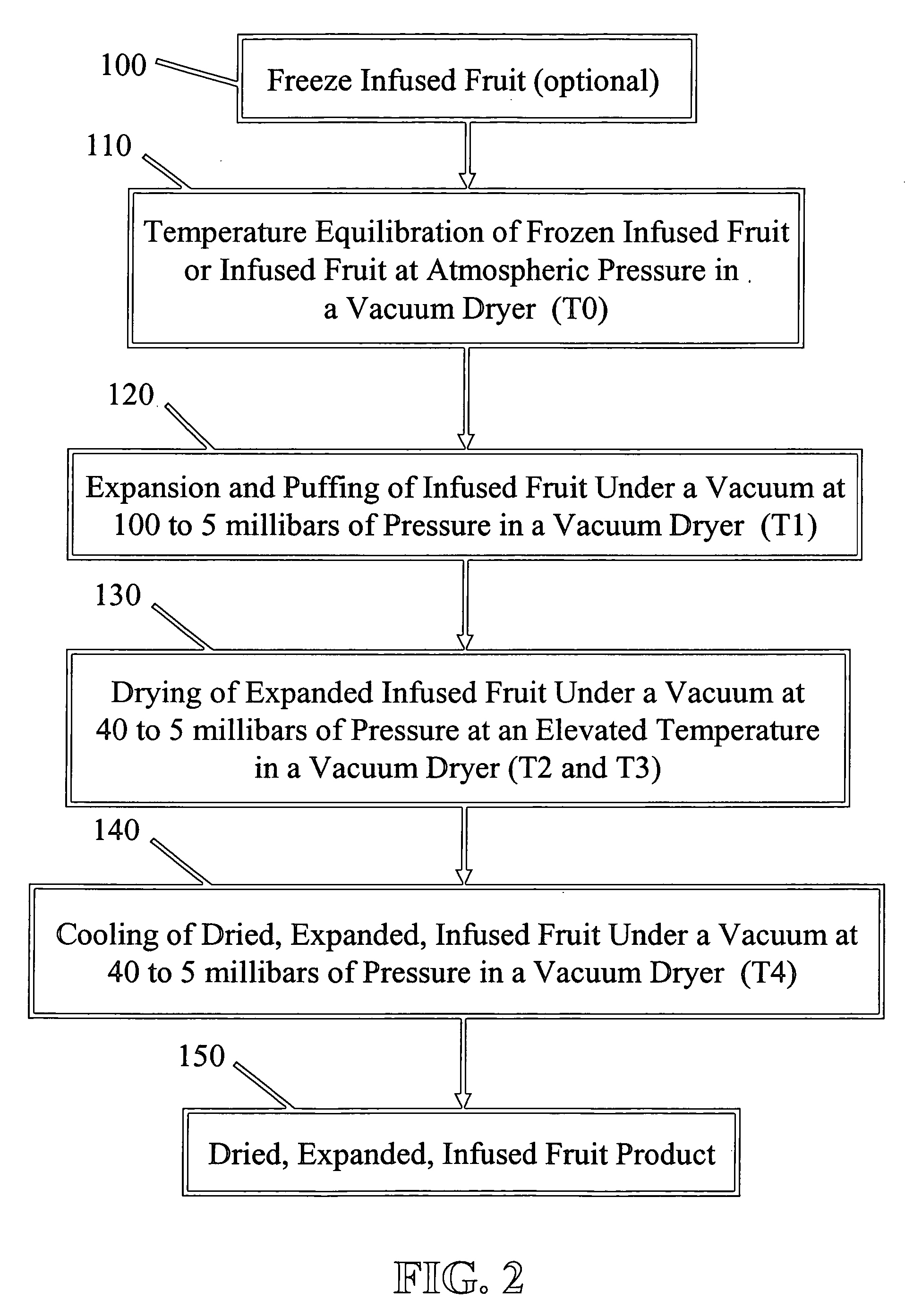

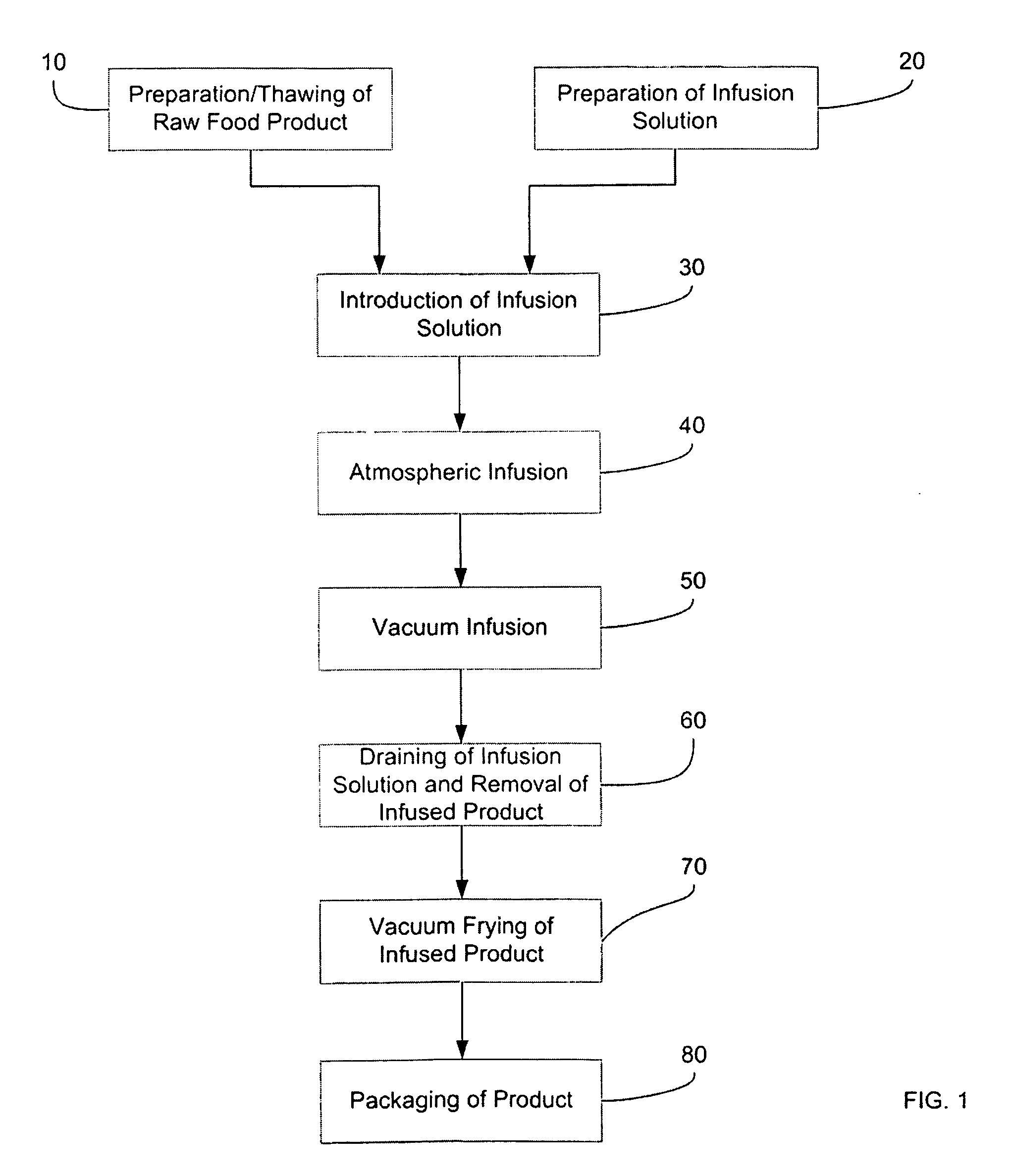

Vacuum puffed and expanded fruit

InactiveUS20060013925A1Light and crisp tasteLow buoyant densityFood shapingFruits/vegetable preservation by coatingWater activityDried fruit

A method is disclosed for preparing an expanded, vacuum puffed, dried fruit product. The method includes infusing the fruit with a low Brix infusion solution and then expanding the fruit by subjecting it to a vacuum at elevated temperature followed by drying of the fruit under a vacuum at elevated temperature and finally cooling of the fruit under lowered temperature while maintaining the vacuum. The product produced by the method is light, crisp, and has a low water activity and a low buoyant density.

Owner:GRACELAND FRUIT +1

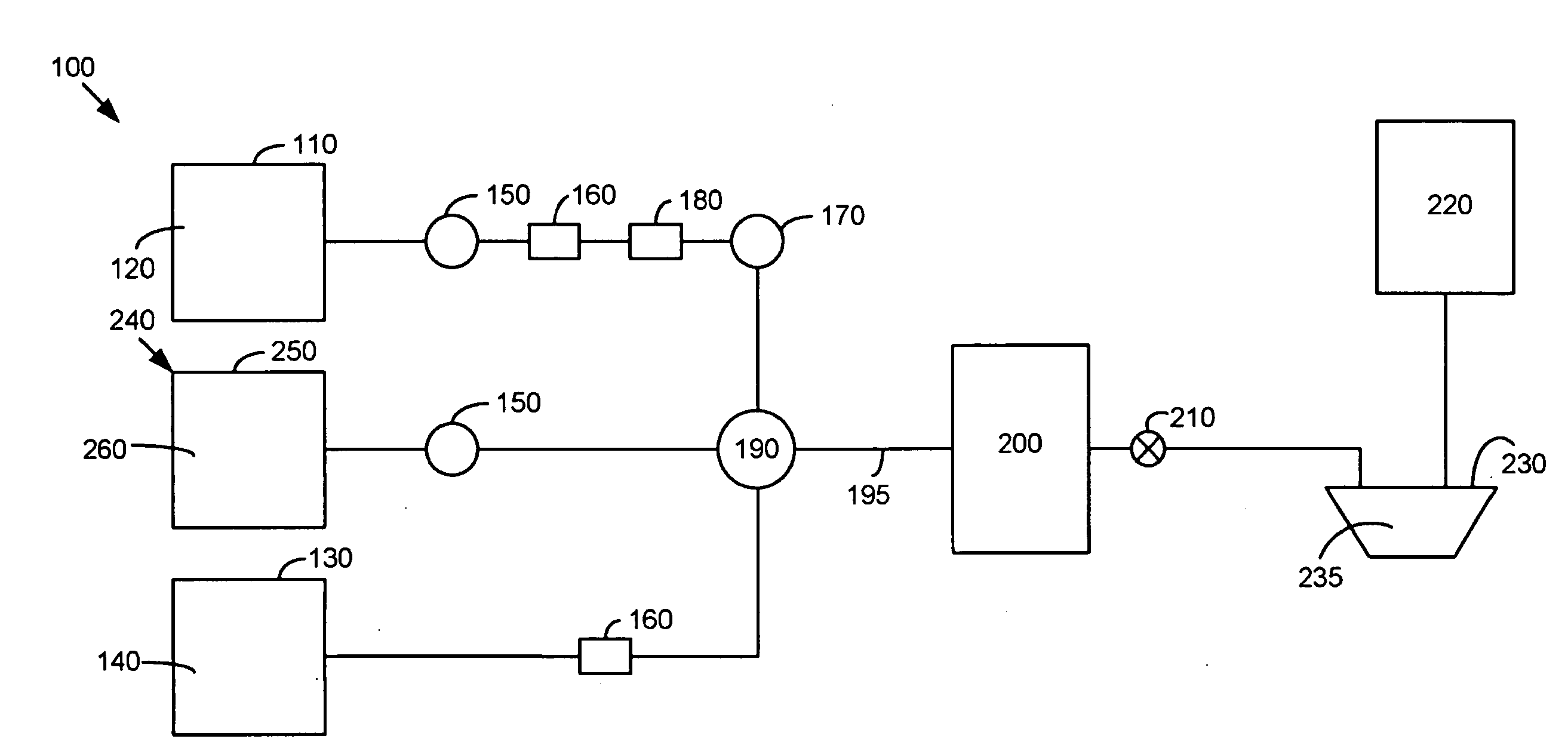

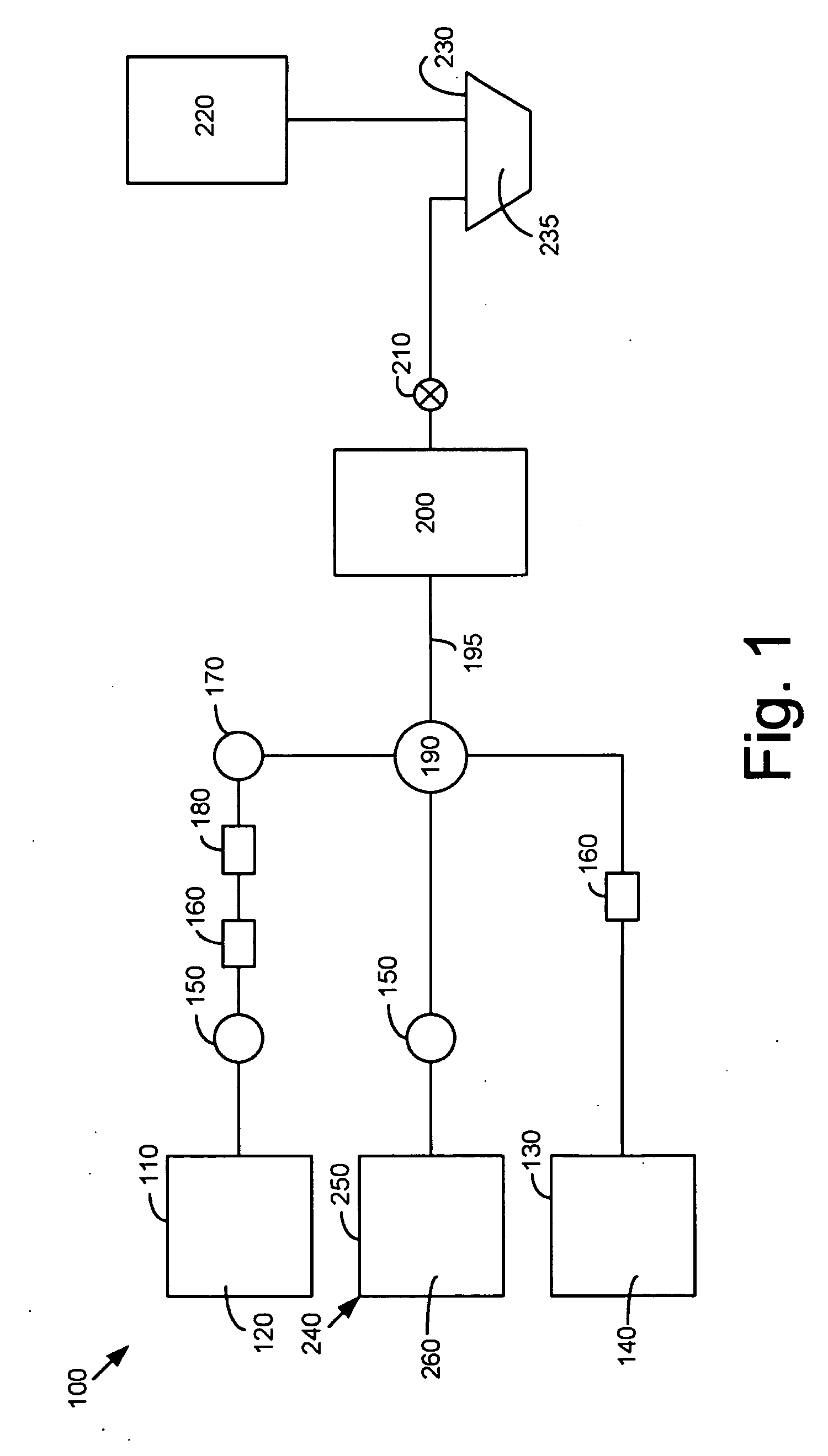

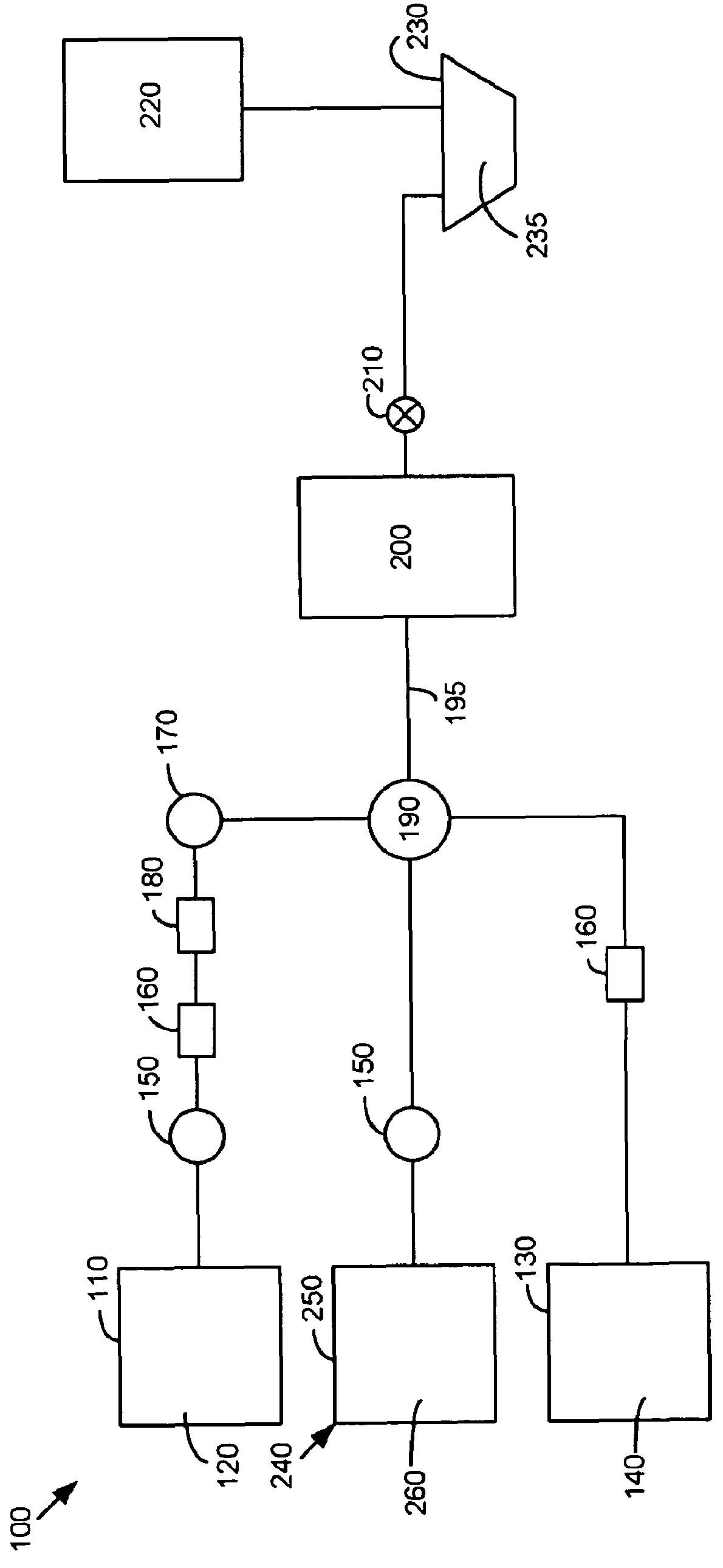

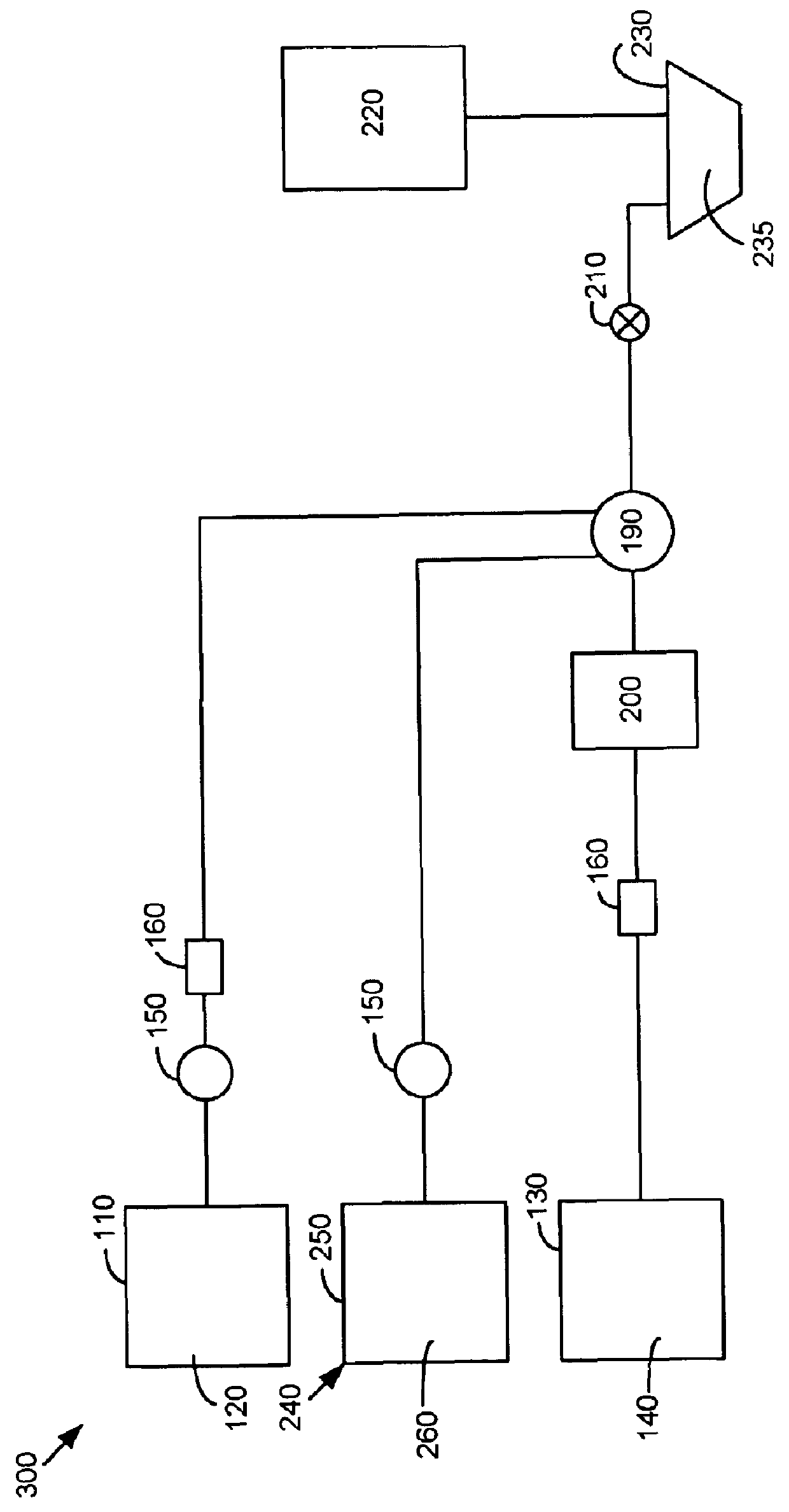

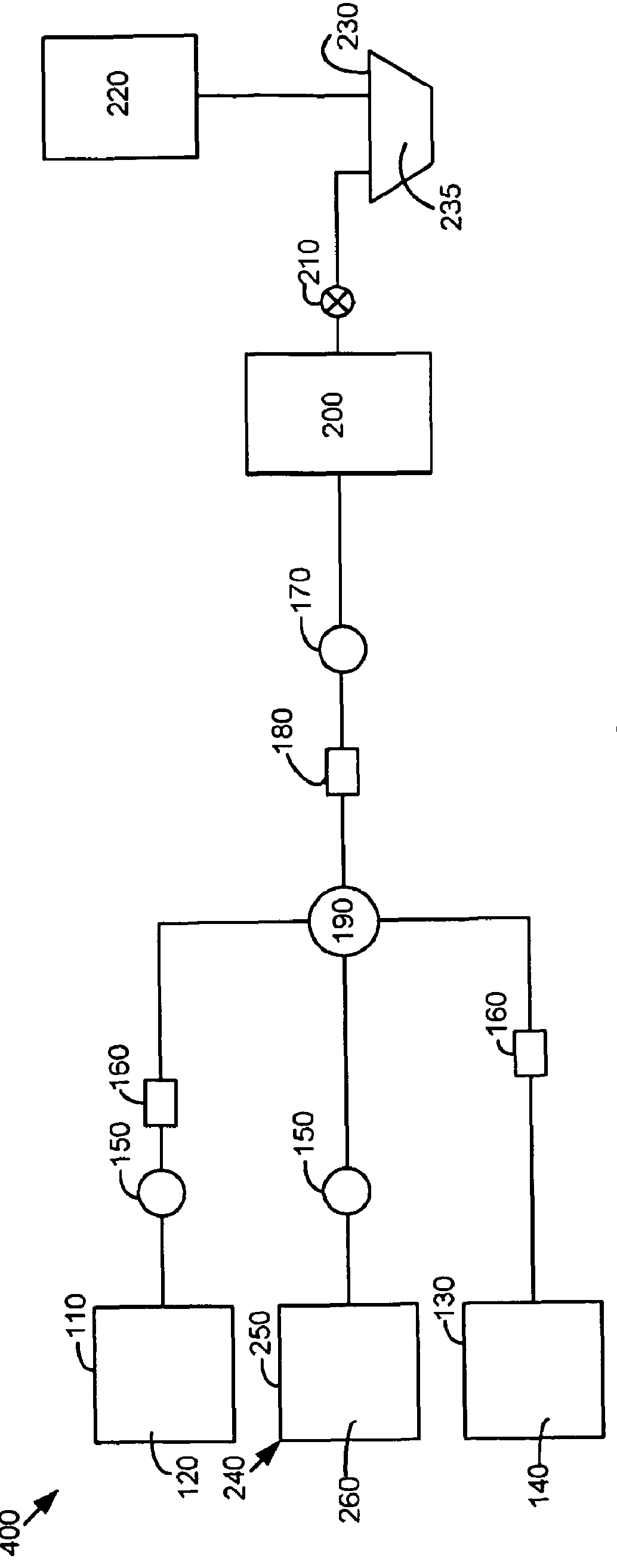

Systems and Methods for Predilution of Sweetener

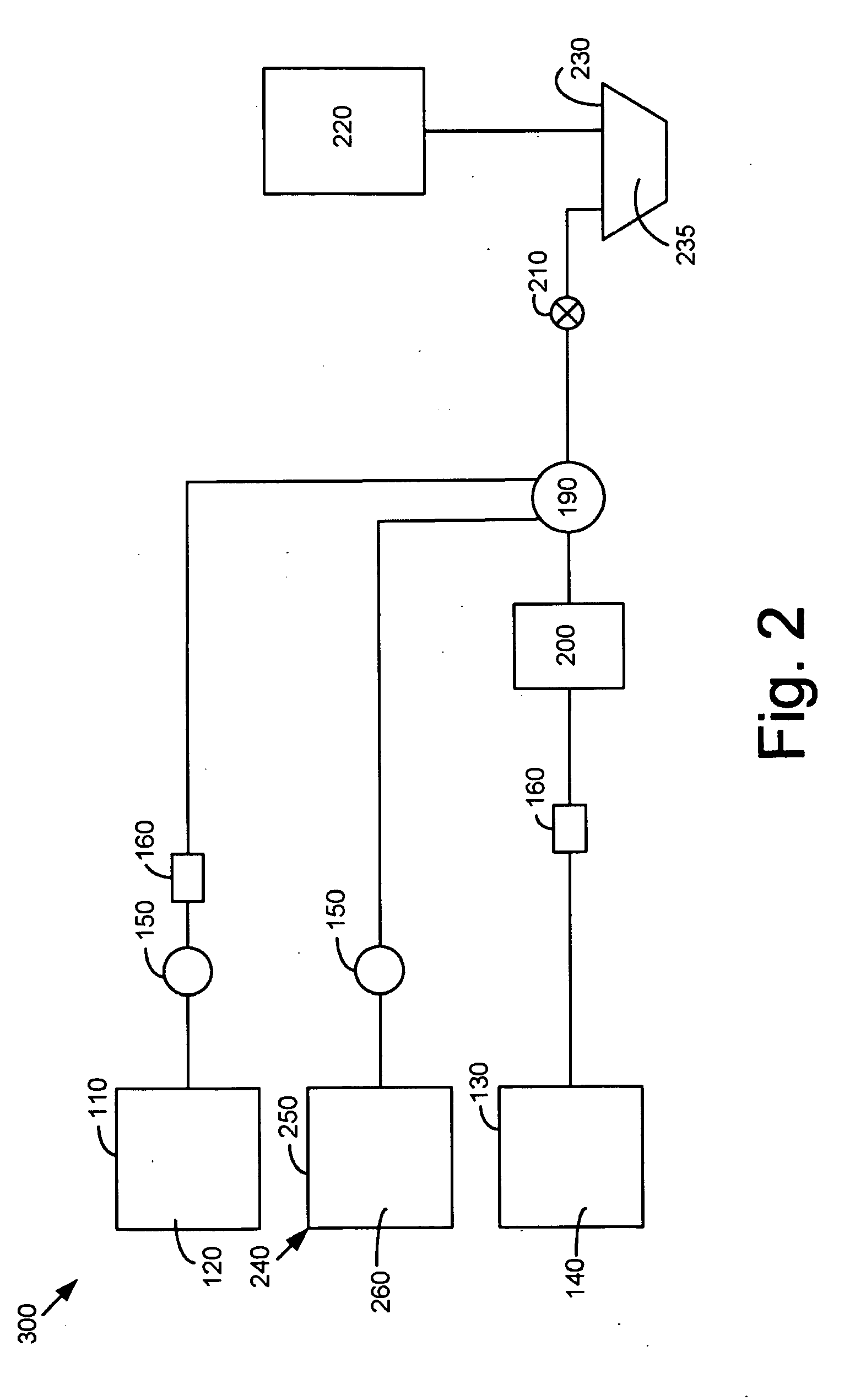

A beverage dispensing system using a sweetener. The beverage dispensing system may include a dispensing nozzle, a sweetener source with the sweetener at more than about 65° brix, a first diluent source with a first diluent, a mixing chamber in communication with the sweetener source and the first diluent source so as to dilute the sweetener to less than about 65° brix, and a second diluent source with a second diluent so as to dilute further the sweetener upstream of the dispensing nozzle.

Owner:THE COCA-COLA CO

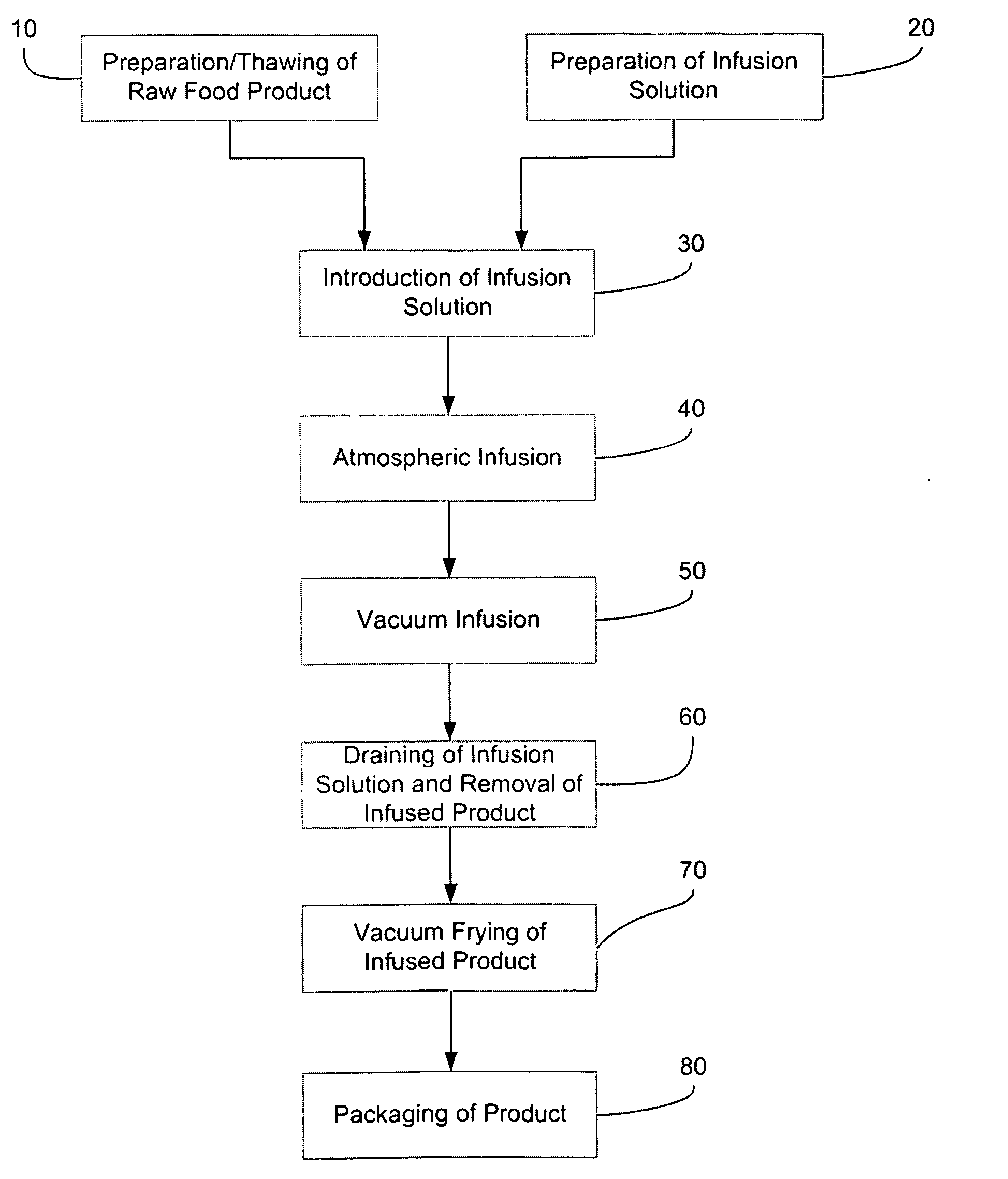

Infusion Method for Vacuum Fried Fruit Leveraging

InactiveUS20090297671A1Long shelf lifeHighly solubleMeat/fish preservation by freezing/coolingLipidic food ingredientsInfusion timeBrix

A method for infusing fruits and vegetables with prebiotic soluble fibers in the form of either short chain fructooligosaccharides or dextrins. Fruits and vegetables are submerged in an infusion solution of prebiotic soluble fiber, and undergo both atmospheric and vacuum infusion processes. The infusion solution is maintained at a temperature of between about 45° F. to about 50° F. and at a Brix of about 30° to about 60°. Vacuum (low pressure) pulses are applied to the product to expedite solids infusion (mass transfer) and thereby decrease infusion time and the product is subsequently vacuum fried to attain a great-tasting, fiber-enriched and aesthetically-pleasing fruit or vegetable product with reduced sweetness, good texture, and an enhanced natural taste with less than 2% moisture by weight and a significantly long shelf-life of up to 12 months.

Owner:FRITO LAY NORTH AMERICA INC

Sugarcane foliage medicinal fertilizer formulation

InactiveCN101186548AReduce dead heart seedlingsIncrease productionBiocideNitrogenous fertilisersBrixImidacloprid

The invention relates to a sugarcane foliar fertilizer formula: the following raw materials are added into a blender according to weight percentage of 10 percent of imidacloprid of concentration of 95 percent, 75 percent of monosultap of concentration of 95 percent and 15 percent of cartap hydrochloride of concentration of 98 percent, the materials are fully blended and added with the same amount of kaolin as filling agent and humectant, the amount of which equals to 2 percent of the raw materials, and the obtained material is ground and evenly stirred; zinc sulfate, borax, manganous sulfate and ammonium molybdate are ground respectively, and are added with, according to the weight percentage, 40 percent of zinc sulfate, 20 percent of manganous sulfate, 36 percent of borax, 3.5 percent of ammonium molybdate and 0.5 percent of gibberellin as growth regulator, then all the materials are evenly blended; the blended pesticide and the blended micronutrient fertilizer are mixed by ratio of 1 to 2, thus forming the fertilizer. The fertilizer is diluted by water by 200 times and sprayed on the plant leaves of the sugarcane. One day after the fertilizer is sprayed, control efficiency of woolly aphids is over 96 percent, and three days later, the control efficiency of woolly aphid reaches 100 percent; meanwhile, the fertilizer is efficient for egg of snout moth's larva and larvae of the sugarcane to some extent, and can reduce dead hearts in fields; after the fertilizer is absorbed by the leaves, the leaves turn green, with yield improved by 15 percent and brix improved by 0.2 percent in the fields.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

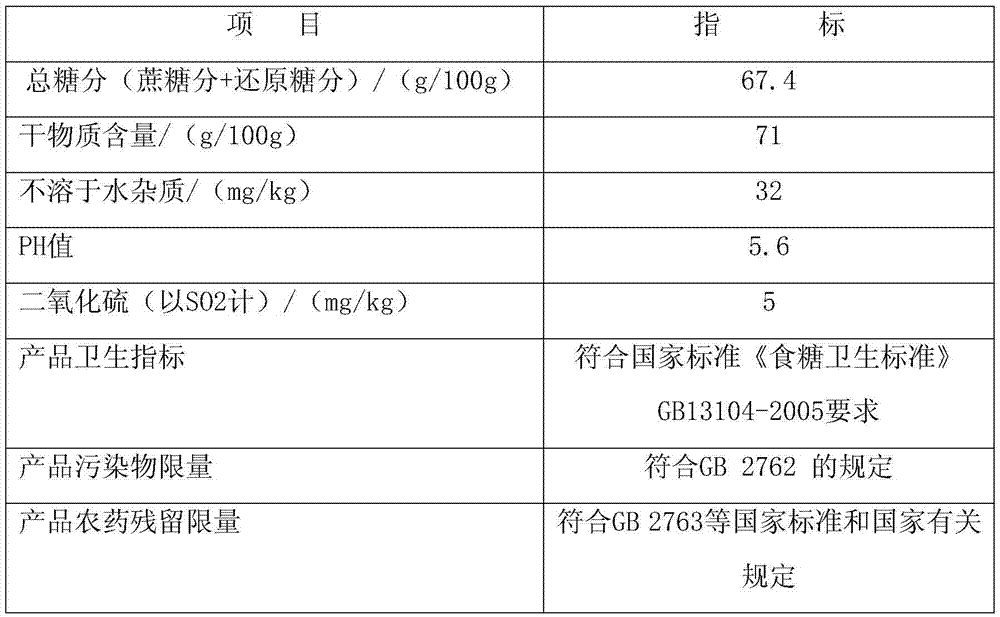

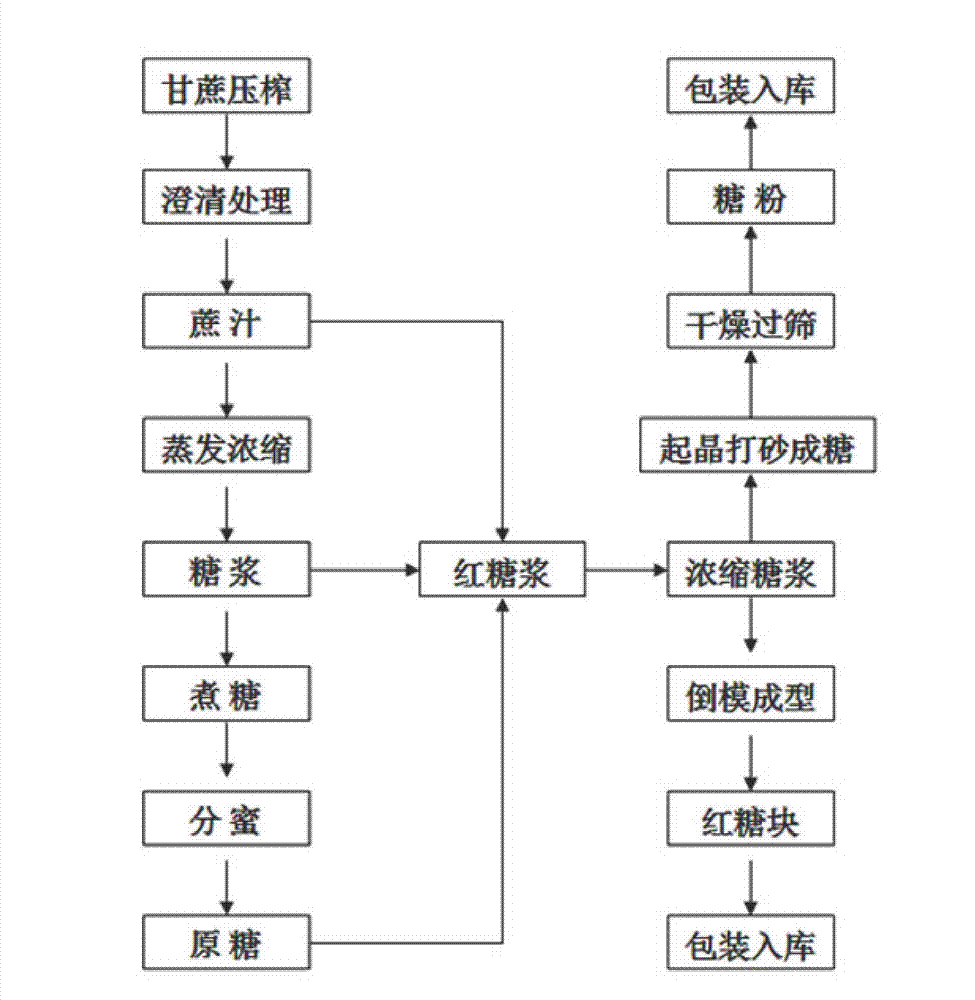

Method for producing raw juice brown sugar

The invention relates to a method for producing raw juice brown sugar and belongs to the technical field of food processing. The invention aims at solving the technical problem of providing a method for producing raw juice brown sugar with higher quality. The method for producing the raw juice brown sugar comprises the following steps: a, juicing sugarcane, and sieving, so as to obtain raw juice after sieving and screening residue; b, heating the raw juice after sieving, eliminating formed floating condensation products, so as to obtain clear juice, and filtering, so as to obtain filtrate I; c, standing the filtrate I for 2-3 hours, and removing fine silt impurities at the bottom layer, so as to obtain sugar juice clear liquid; d, evaporating and concentrating the sugar juice clear liquid obtained in the step c into syrup with the brix of 85-90 degree Bx, then carrying out sugar boiling to obtain massecuite, sanding, and moulding, so as to obtain lump sugar; or evaporating and concentrating the sugar juice clear liquid obtained in the step c into clear syrup with the brix of 55-60 degree Bx, and then carrying out sugar boiling at normal pressure, so that liquid brown sugar with the concentration of 68-78 degree Bx is obtained.

Owner:MIYI HUASENTY CO LTD

Preparation method of decolored fructus momordicae fruit juice and fruit juice prepared by the method

ActiveCN101283831APreserve natural nutrientsHigh sweetnessFood preparationBiotechnologyDiabetes mellitus

The invention discloses a method for preparing decolorized grosvenor momordica juice and the decolorized grosvenor momordica juice prepared by the method. The method comprises following steps: selecting materials and pre-processing, passing through a cation column, decolorizing, acidifying for the first time, concentrating and acidifying for the second time. The decolorized grosvenor momordica juice is white or yellow-like transparent liquid with Baume degree more than 10 or brix more than 60, wherein the juice contains, calculated by dry weight, mogroside with a volume content equal to or larger than 30%. The grosvenor momordica juice prepared by the method keeps the natural nutriment of grosvenor momordica and has high sweetness and low sugar content. Meanwhile, the method solves the color change problem of the grosvenor momordica juice, and the product is suitable for various consumers, in particular to patients with diabetes, hypertension, etc.

Owner:GUILIN NATURAL INGREDIENTS CORP

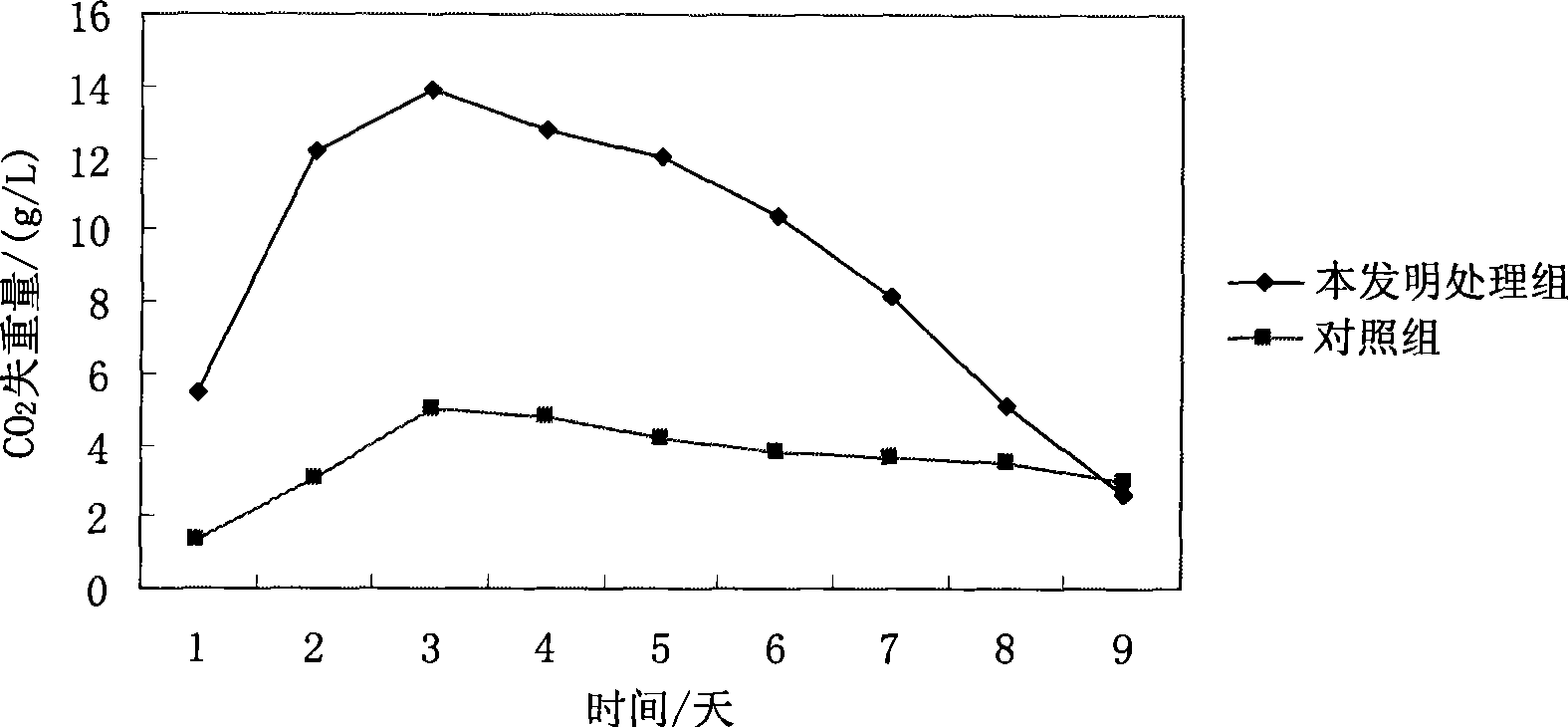

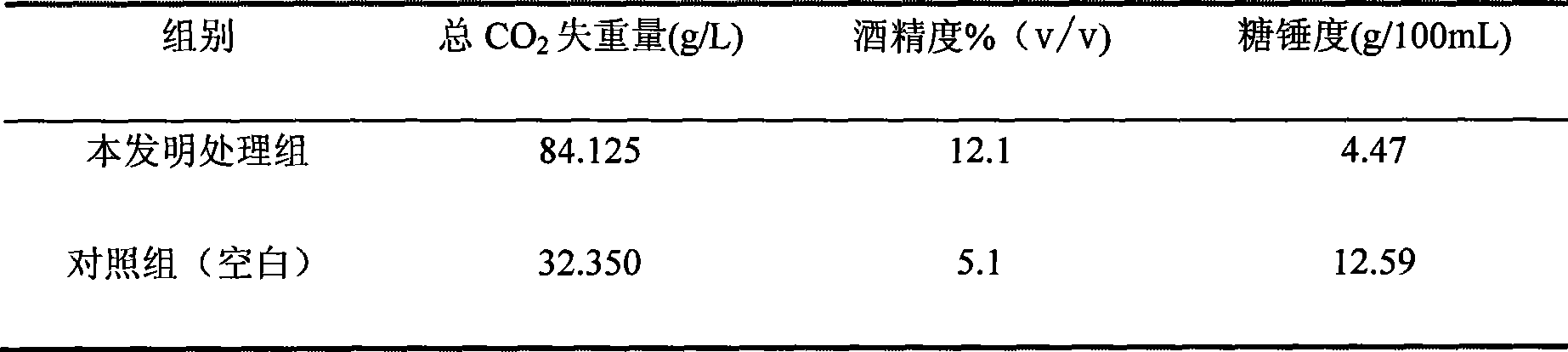

Method for producing honey wine

InactiveCN101362996AMeet the requirements of green and naturalSimple processAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a production method of honey fermented wine, and the production method belongs to the technical field of fruit wine. Natural acacia original honey is taken and diluted till the sugar Brix of 22 to 30 Brix by using pure water, yeast nutrients for promoting the growth of a yeast are added, the Angel wine high-activity dry yeast after the activation is further added for carrying out the primary fermentation for 20 days at 20 DEG C, and the honey fermented wine is prepared by low-temperature aging at 15 DEG C. The production method can solve the problem of muddy sediments of the honey fermented wine through adding appropriate amount of the yeast nutrients to improve the alcohol degree and simultaneously reduce the sugar degree of the honey and carrying out the heating treatment of wine body, the brewed honey fermented wine is characterized by rich and delicate taste, clarified and transparent appearance, fresh and elegant smell and natural and cool properties.

Owner:HUAZHONG AGRI UNIV

Systems and methods for predilution of sweetener

A beverage dispensing system using a sweetener. The beverage dispensing system may include a dispensing nozzle, a sweetener source with the sweetener at more than about 65° brix, a first diluent source with a first diluent, a mixing chamber in communication with the sweetener source and the first diluent source so as to dilute the sweetener to less than about 65° brix, and a second diluent source with a second diluent so as to dilute further the sweetener upstream of the dispensing nozzle.

Owner:THE COCA-COLA CO

Reduced sugar citrus juice beverages

InactiveUS20050058763A1Increases perceived sweetness sensory characteristicSolution value is not highFood scienceFruit juiceBrix

Citrus juice beverage products and their method of production are formulated to reduce the sugar content of the beverage while the beverage products have sensory, taste, mouth feel and texture characteristics that mimic those of whole citrus juice. Orange juice beverage products are especially preferred. The beverage products have a relatively low Brix, on the order of between about 7 and about 8 Brix. Also included in the beverage products is a sweetener which does not add a significant caloric load to the beverage product. A sinking pulp added to the beverage product in an amount to achieve texture and other sensory characteristics of a whole juice.

Owner:TROPICANA PROD INC

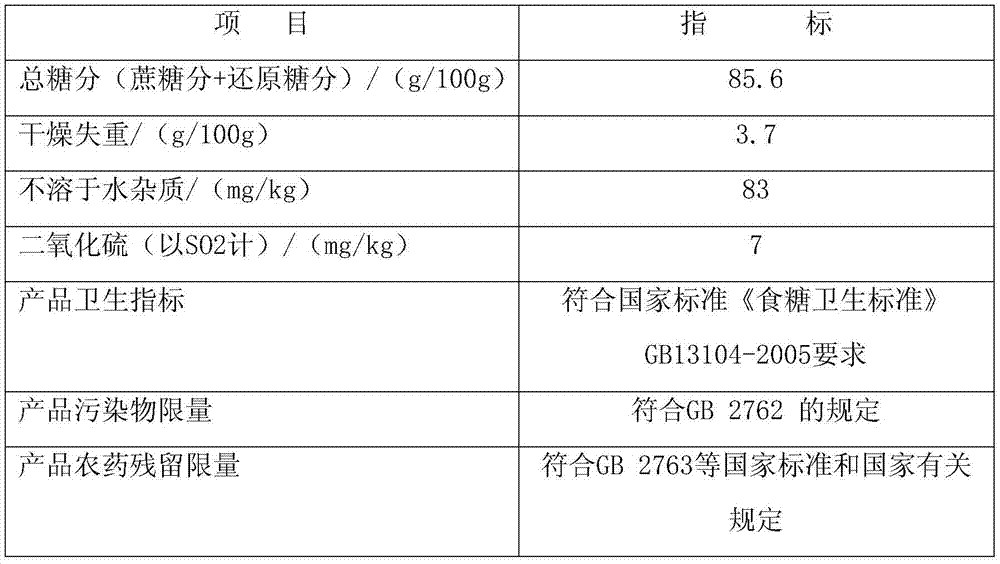

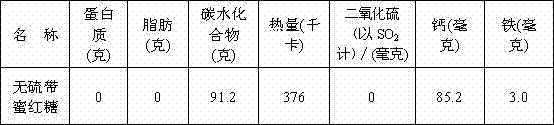

Method for producing sulfur-free honey-carrying brown sugar

The invention discloses a method for producing sulfur-free honey-carrying brown sugar. Cane juice, syrup and raw sugar are used as raw materials. The method comprises the following steps of: preparing brown syrup of which the cane sugar content is 85 to 95 percent according to a certain proportion, evaporating and concentrating into sugar paste of which the Brix is 92 to 98oBx, discharging, stirring, cooling, stimulating sugaring, drying, sieving, cooling to room temperature, finally obtaining the honey-carrying brown sugar of which the cane sugar content is 85 to 95 percent, metering and packing. By using the method for preparing the brown sugar, processing aids containing potential food safety hazard are not added in the production process, so the cane sugar content is high, the brown sugar has obvious advantages of original ecological and health-care food, crystallization and sugaring can be quickly realized, and the operation is convenient; and the finished sugar keeps the favor of original cane, is rich in nutritional components, and meets the requirement for original ecological sugar.

Owner:广西浦北县湘桂糖业有限责任公司

Preparation method of fructus momordicae extract applicable to industrial production

The invention discloses a preparation method of fructus momordicae extract applicable to industrial production. The preparation method comprises the following steps: (1) washing and crushing fresh fruits of fructus momordicae; (2) adding a hydrophilic solvent, heating, conducting reflux extraction and filtering to obtain extracted liquor; (3) heating the extracted liquor, conducting vacuum concentration, cooling, standing and filtering to obtain concentrated liquor; (4) conducting tubular centrifugation to the concentrated liquor and then ultrafiltering to obtain filtrate; (5) conducting column adsorption by connecting more than three macroporous resin chromatographic columns to the filtrate, standing and washing, eluting respectively through the hydrophilic solvent and respectively collecting eluent; (6) respectively conducting nanofiltration to the eluent through nanofiltering films, and then concentrating until the brix degree is about 25-30, to obtain concentrated liquor; and (7) spray-drying the concentrated liquor, to obtain the fructus momordicae extract. By utilizing the method, a plurality of specifications of mogroside V extract products can be produced at a time, resin can be efficiently utilized, energy consumption can be reduced, the quality of the product can be guaranteed, the cost can be lowered, and the fructus momordicae extract is applicable to industrial production.

Owner:HUNAN HUACHENG BIOTECH

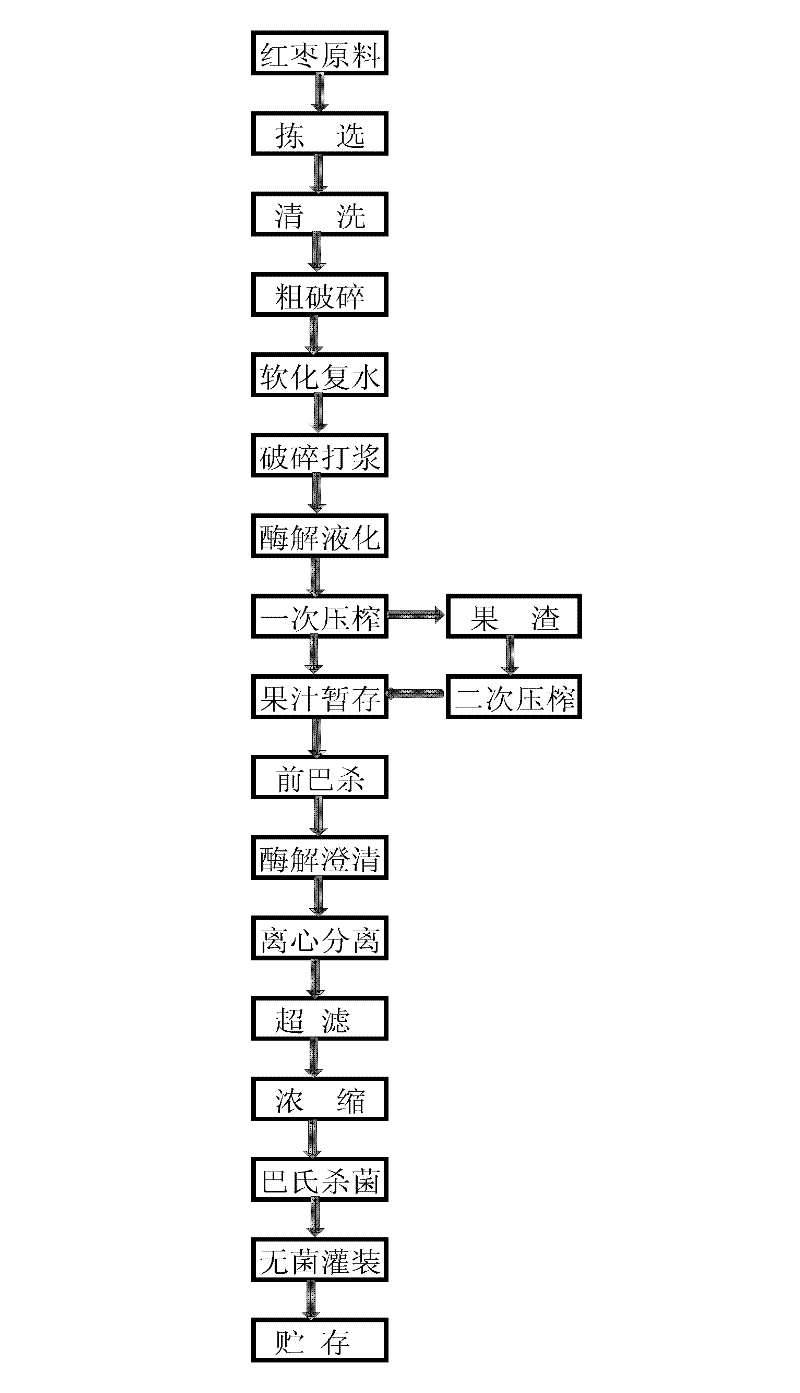

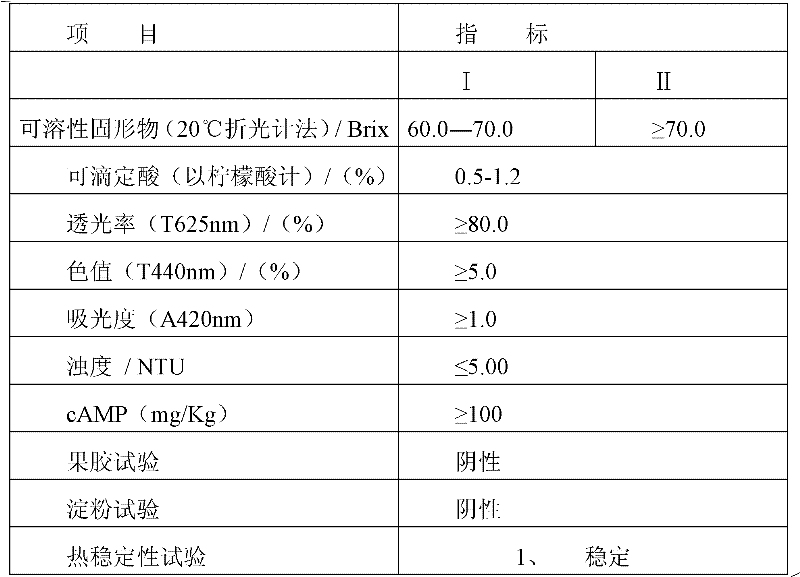

Method of preparing concentrated clear red jujube juice with high cAMP content

The invention discloses a method of preparing concentrated clear red jujube juice with high cAMP content, which comprises the following steps: taking out red jujube after rehydration, denucleating and then crushing pulp for preparing the red jujube thick liquid; conveying the red jujube after enzymolysis by pectinase into a juicer for squeezing, and filtering to obtain the red jujube juice; adding pectinase, amylase and cellulose into the red jujube juice for heat-preservation and enzymolysis for 60-90 minutes; and clearing, conducting concentration sterilization, and finally bulking. The concentrated clear red jujube juice prepared by the invention is clear and transparent, has the cAMP content being larger than or equal to 100 mg / Kg and soluble solid state material being larger than or equal to 60.0 Brix, is deposit-free and suspension-free, has brownish red color and does not have impurities which can be seen by naked eyes; and the concentrated juice is diluted to the soluble solidstate material being 60.0 Brix, and the juice has inherent fragrance and flavor of red jujubes and is free from extraneous odor.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

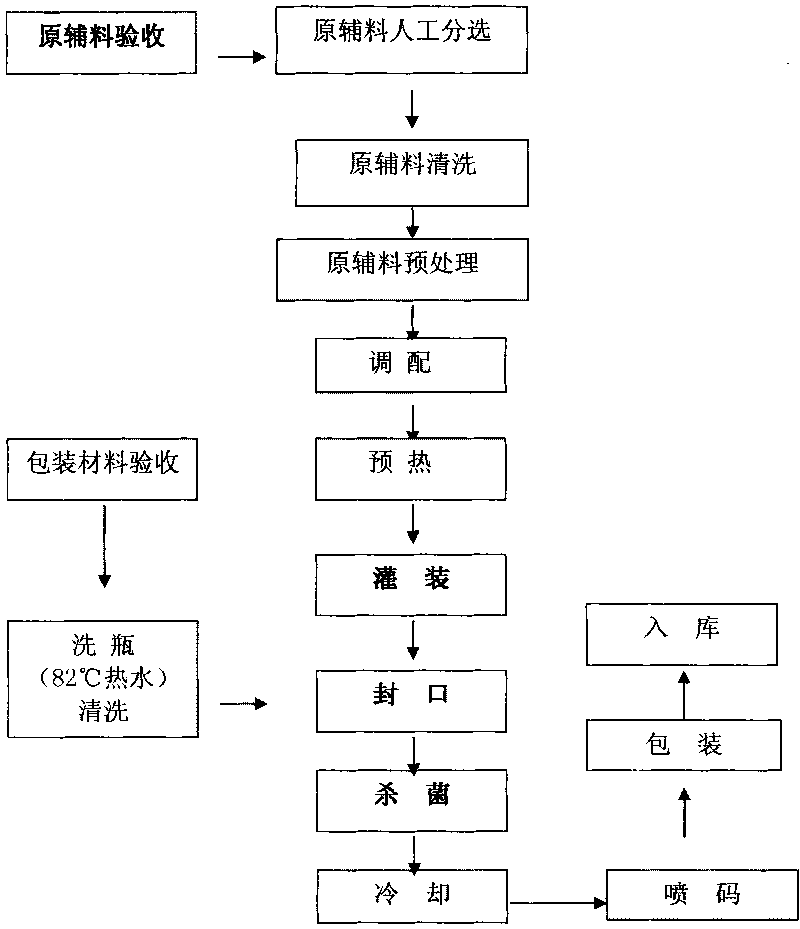

Tomato chili sauce

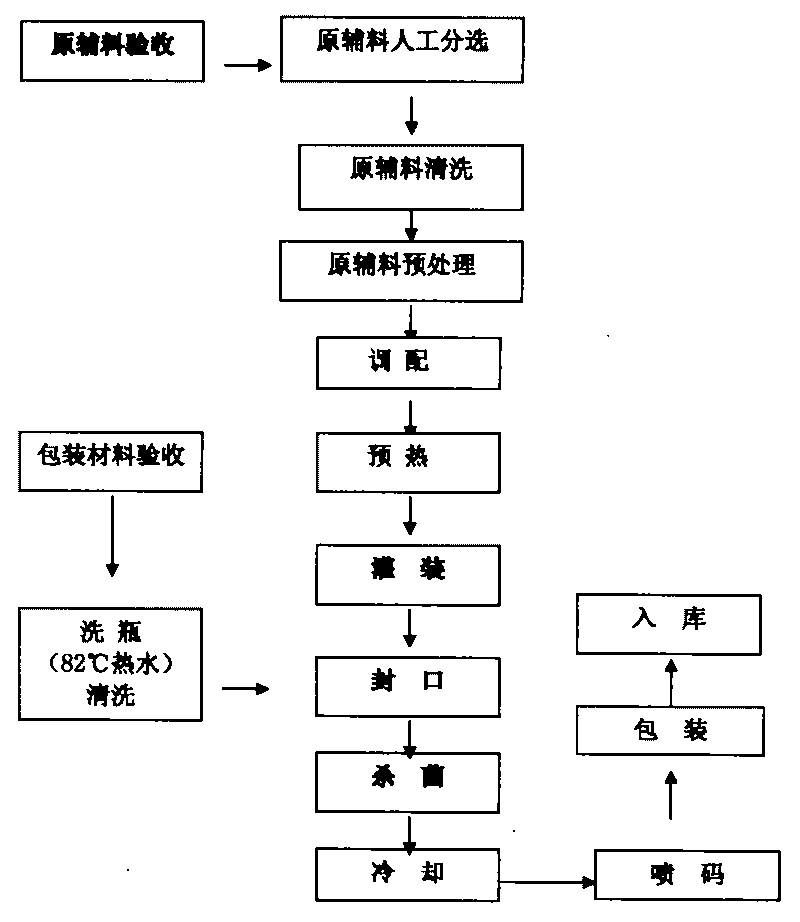

The invention relates to a tomato chili sauce which comprises the following raw materials in the formula by weight: 200-700kg of tomato, 200-700kg of colourful pepper, 50-300kg of garlic and 50-300kg of chili pepper. The preparation method comprises the following steps: grinding tomato, pepper and garlic with a meat grinder; then adding grinded raw and auxiliary materials in a concentrating pan, adding 5-25kg of table salt to fully mix, heating to 70-98 DEG C, adding 1-3L of acetic acid to ensure that the vacuum degree is 0.05-0.08MPa and the Brix is 9.5-11.5; after detecting the raw and auxiliary materials, performing hand-sorting, cleaning, pretreating; pumping the prepared sauce into a balance tank, using a tubular heater to perform circulating preheating; and filling and sealing, sterilizing, cooling, packaging and warehousing. Tomato and pepper are used as raw materials to prepare the chili sauce with special flavor, rich nutrition, moderate taste, scientific preparation technology and complete nutritional components and the tomato chili sauce of the invention is a nutrient and flavoured pepper composite seasoning which is applicable to extensive markets such as the Central Asia and the Eastern Europe.

Owner:陈其钢

Method for prolonging storage period of kiwi fruits

ActiveCN105994592ALong duration of actionReduce concentrationFruits/vegetable preservation by freezing/coolingDiseaseBrix

The invention discloses a method for prolonging the storage period of kiwi fruits and belongs to the technical field of agricultural food science. The storage period of the kiwi fruits is prolonged by adopting a method of combining timely harvesting, wound curing treatment after harvesting, spontaneous modified atmosphere PE freshness-keeping bag packaging, repeated low-dose 1-MCP treatment and low-temperature storage. The method comprises the following steps: the kiwi fruits are harvested when the content of soluble solids is between 6.0 Brix and 8.0 Brix, and the hardness is between 9.5-11 kg / cm<2>; after being harvested, the kiwi fruits are subjected to the wound curing treatment for 24-72 hours in the shade at a normal temperature to eliminate the fruits suffering from mechanical injury, defects and disease and pest damages, are sub-packed into PE freshness-keeping bags for ozone sterilization, are pre-stored for 5 days in a freshness-keeping storehouse with the temperature of 8 DEG C and the RH of 90 percent, are pre-cooled for 24 hours after the storehouse temperature is adjusted to 2+ / -0.5 DEG C, and the RH is adjusted to 85 percent, and then are laced for storage; when the storage time is 30, 60 and 90 days, the 1-MCP treatment with different concentrations is adopted. The method is a kiwi fruit storage and freshness-keeping method which is efficient, convenient, easy to operate and cheap.

Owner:GUIYANG UNIV

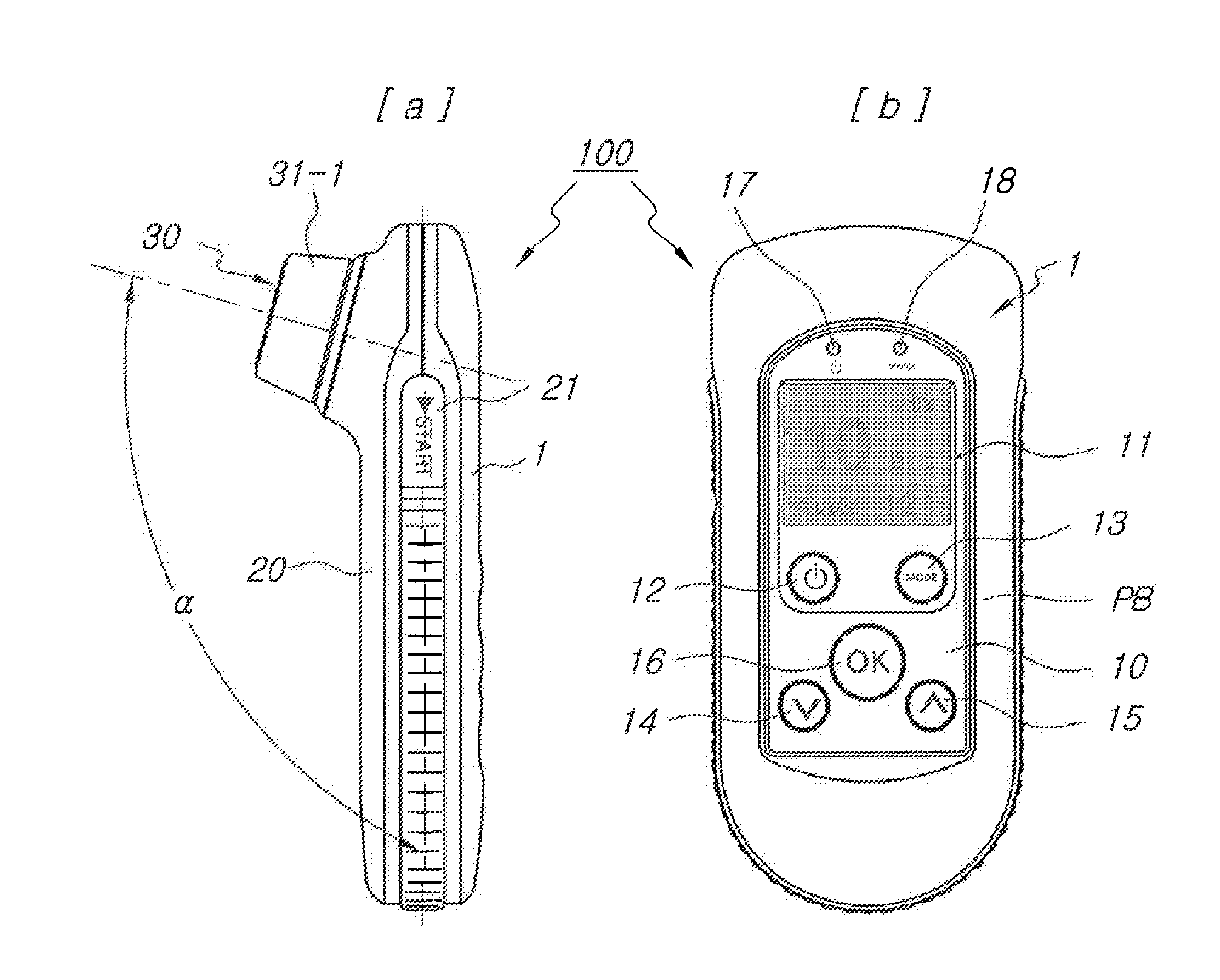

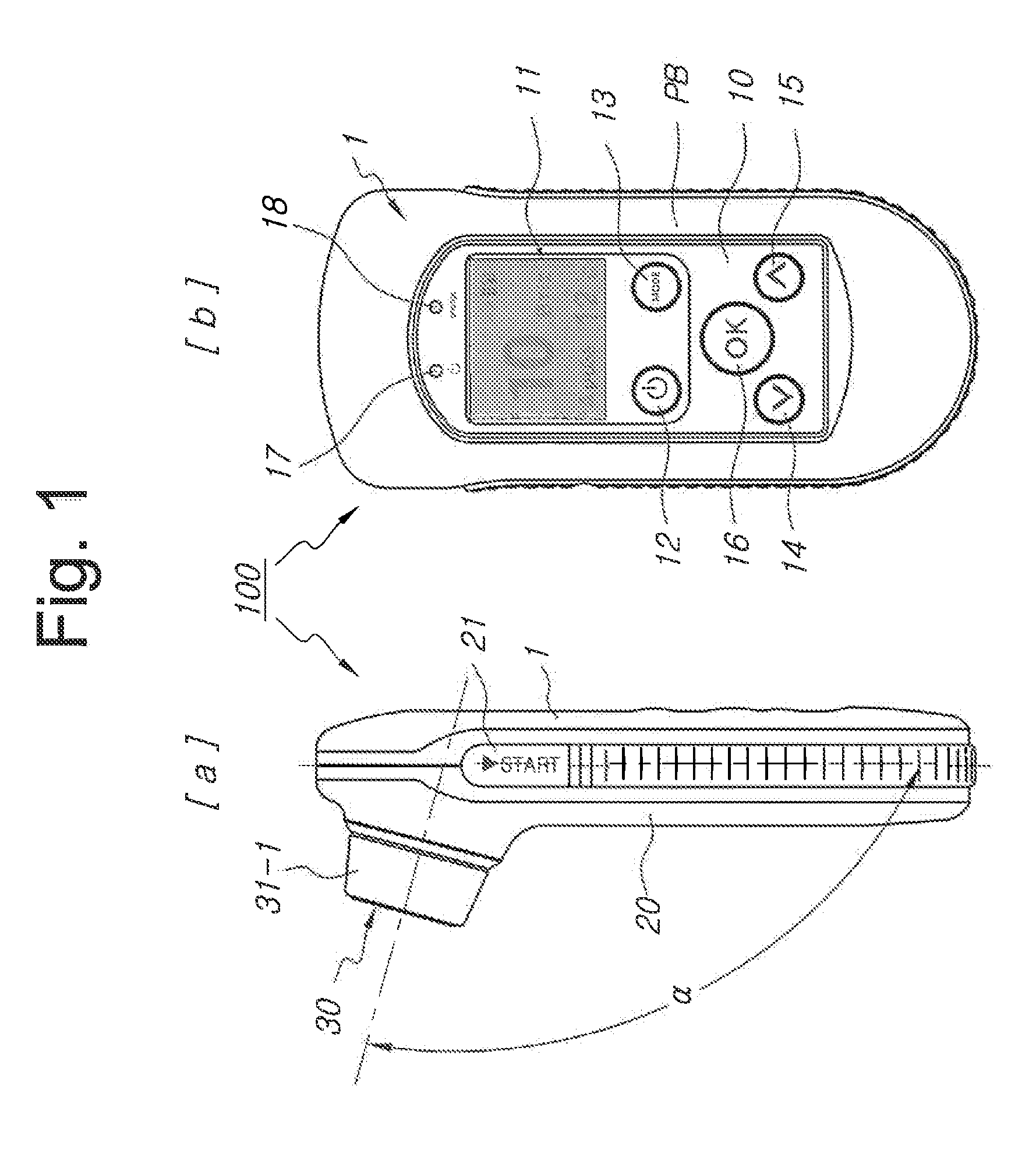

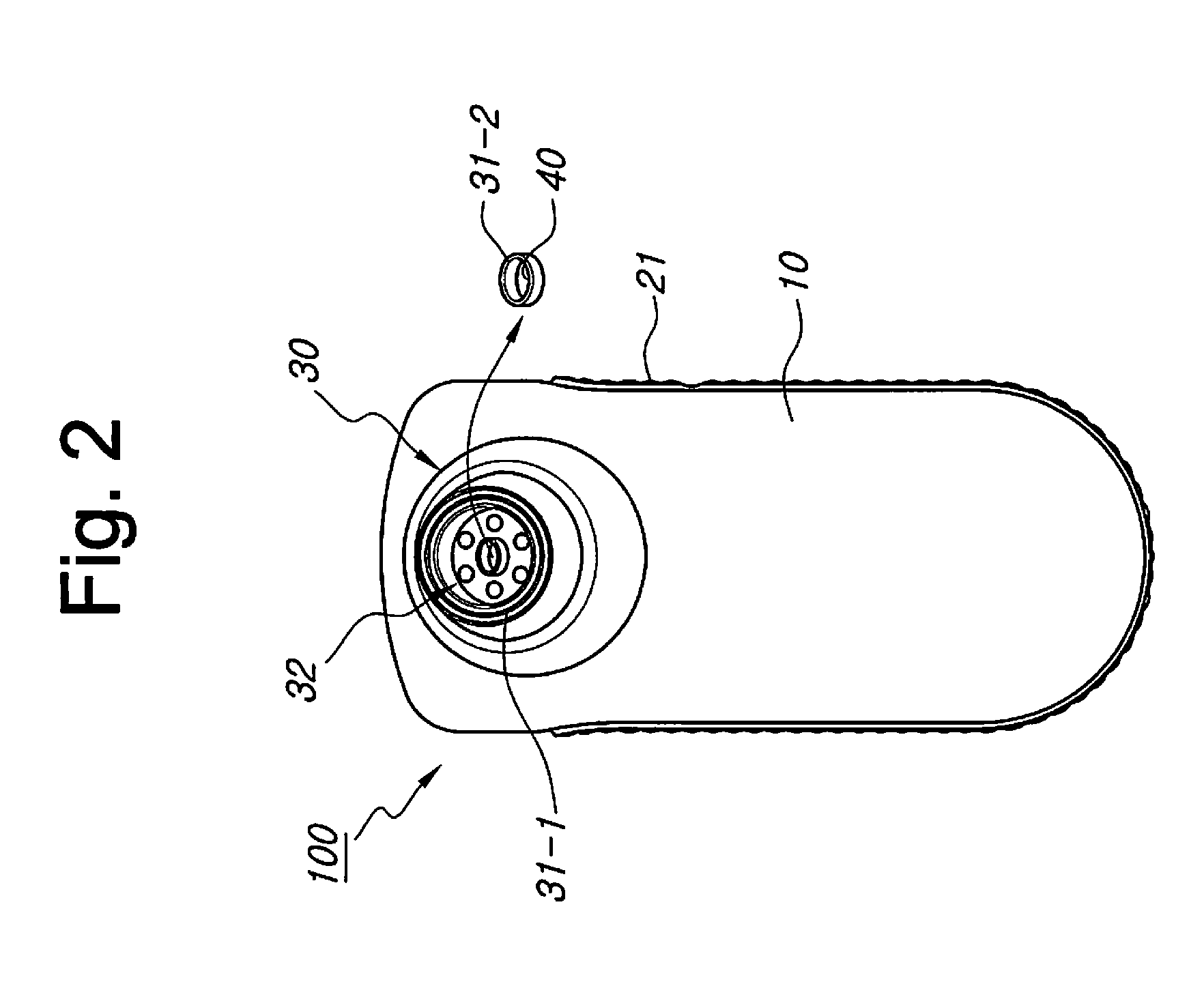

Non-destructive sugar content measuring apparatus

InactiveUS20150021478A1Improve portabilityHigh measurement accuracySolid-state devicesColor/spectral properties measurementsNon destructiveMeasurement device

A non-destructive sugar content measuring apparatus is provided and includes a measuring sensor portion for including a spectral sensor which receives a near infrared ray from the light which is reflected by the flesh FB of the fruit F of which the sugar content is measured, an LED light source which has LEDs circularly arranged, an optical sensor which receives light reflected by a flesh of a fruit F, and a temperature sensor; a casing including a measuring sensor portion and has a panel portion which has a digital display for displaying a brix value as a digital value and operational switches, the panel portion and the operational switches being mounted on a front face thereof; a main circuit board PB for including a Central Processing Unit (CPU) which is embedded in the casing and processes electric signals from the light sensor and performs a calculation and determination

Owner:DAESUNG TECH

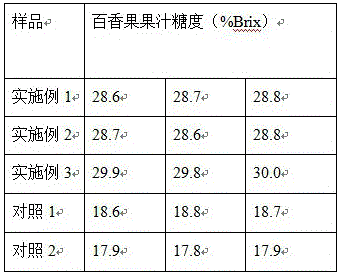

Planting method for improving sugar content of passion fruits

InactiveCN105474971AIncrease productionBright colorBio-organic fraction processingExcrement fertilisersDiseaseFruit juice

The invention relates to a planting method for improving the sugar content of passion fruits. The variety of the planted passion fruits is 'Tainong No.1', and the planting method comprises the steps of land selection, soil preparation, planting, frame erection, reshaping and pruning, fertilizer and water management, field management and prevention and control of diseases and insect pests. By the adoption of the planting method for improving the sugar content of the passion fruits, a fertilizer containing sugar and fermentation broth prepared through fermentation of human excrete and containing a sugar fertilizer are irrigated in a drop mode before blooming and during fruit forming, the average single-fruit weight of produced passion fruits is 63 g, the maximum weight is 125 g, fruit juice is reddish yellow and has heavy flavor, the acidity is 2.14%, the sweetness is up to 30% Brix, the fruit juice rate is up to 34%, color and luster are bright, the yield is high, no pollution exists, and five-time harvesting can be performed in one year.

Owner:广西绿希望农业发展有限公司

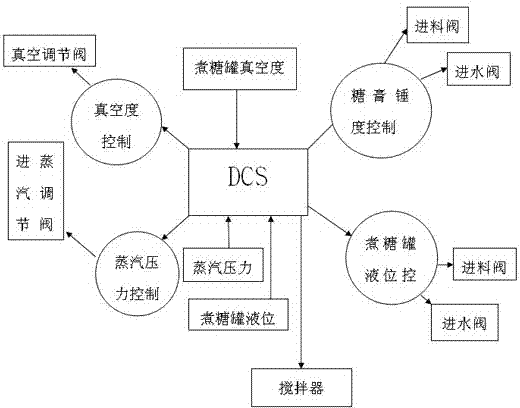

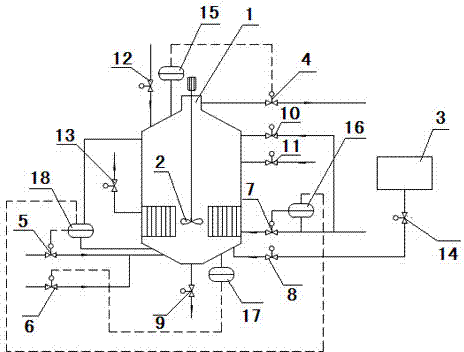

Sugar boiling automatic control device

ActiveCN102925593AImprove reliabilityImprove efficiencySugar juice boiling/evaporationThermodynamicsAutomatic control

The invention provides a sugar boiling automatic control device and relates to a device for controlling several main parameters of a sugar boiling pot automatically. The sugar boiling automatic control device comprises a vacuum control module, a massecuite brix control module, a heating steam pressure control module and a sugar boiling pot liquid level control module. The vacuum control module measures vacuum of the sugar boiling pot through a transmitter and uses a distributed control system (DCS) for regulating a condenser inlet circulating water regulating valve so as to control the vacuum. The massecuite brix control module measures brix of syrupy through a brix meter and controls a feed valve, a water inlet valve and sugar boiling time through the DCS. The heating steam pressure control module measures steam pressure of the sugar boiling pot through a pressure transmitter and uses a DCS for controlling amount of heating steam entering the sugar boiling pot. The sugar boiling pot liquid level control module measures liquid level of the syrupy of the sugar boiling pot through a liquid level transmitter and controls a feed valve and a water inlet valve of the sugar boiling pot through the DCS. The sugar boiling automatic control device achieves full-automatic sugar boiling, effectively improves reliability and economic benefit of sugar boiling control, greatly reduces consumption of water and steam, reduces faulty operation, lowers accident rate, and improves sugar output.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Method for processing preserved apricot

The invention discloses a method for processing preserved apricot, which belongs to the technical field of fruit and vegetable processing. The method is characterized by comprising the following steps of: cleaning and dissecting apricots and removing cores to obtain apricot bowls; performing superheated steam jet impact blanching for 30 to 180 seconds under the conditions that the airflow temperature is 100 to 150 DEG C, the air speed is 6 to 20m / s and the relative humidity is 10 to 90 percent; soaking the apricot bowls into 45 to 70-degree sugar solution of Brix in a material-liquid ratio of 1:3-1:10, soaking sugar in a vacuum pulsation pressure device, and performing pulsation in a pulsation ratio of 1-15min: 1-15min when the vacuum degree of a pulsation pressure chamber is between 0.080-0.098MPa and 0MPa, wherein the sugar soaking temperature is room temperature and the time is 1 to 6 hours; and drying the apricot bowls in a gas jet impact drying oven for 8 to 20 hours at the temperature of between 50 and 70 DEG C and the air speed of between 3 and 20m / s to obtain the preserved apricot. Because the superheated steam blanching technology is adopted, sulfur is not fumigated during processing, and any additive is not used; and because the vacuum pulsation pressure low-temperature quick osmosis technology is adopted, nutrition loss caused by repeated high-temperature hot boiling is avoided, and sugar osmosis can be greatly quickened.

Owner:CHINA AGRI UNIV

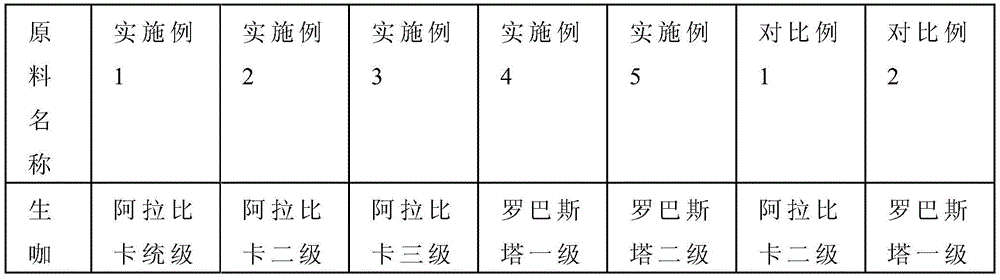

Low-caffeine instant coffee and preparing method thereof

The invention relates to a preparing method of low-caffeine instant coffee. The preparing method includes the steps that raw coffee beans are soaked in water for 0.5-1.5 h; the soaked raw coffee beans are steamed for 0.5-1.5 h at the temperature of 90 DEG C-110 DEG C; the steamed coffee beans are dried until the water content is 10-15%; the dried coffee beans are baked for 10-20 min and ground until the fineness is 5-30 meshes; the ground coffee powder is prewet for 10-30 min with water accounting for 20-50% of the mass of the ground coffee powder and is extracted with water for 5-20 min at the extracting temperature of 170 DEG C-180 DEG C and the extracting pressure of 0.9-1.2 Mpa; extract liquor is concentrated to 45-55 Brix, and subjected to spray drying to obtain the low-caffeine instant coffee. The caffeine content of the baked coffee beans and the instant coffee product is obviously reduced while the flavor of the product is not reduced obviously.

Owner:SUZHOU KINGMAO COFFEE CO LTD

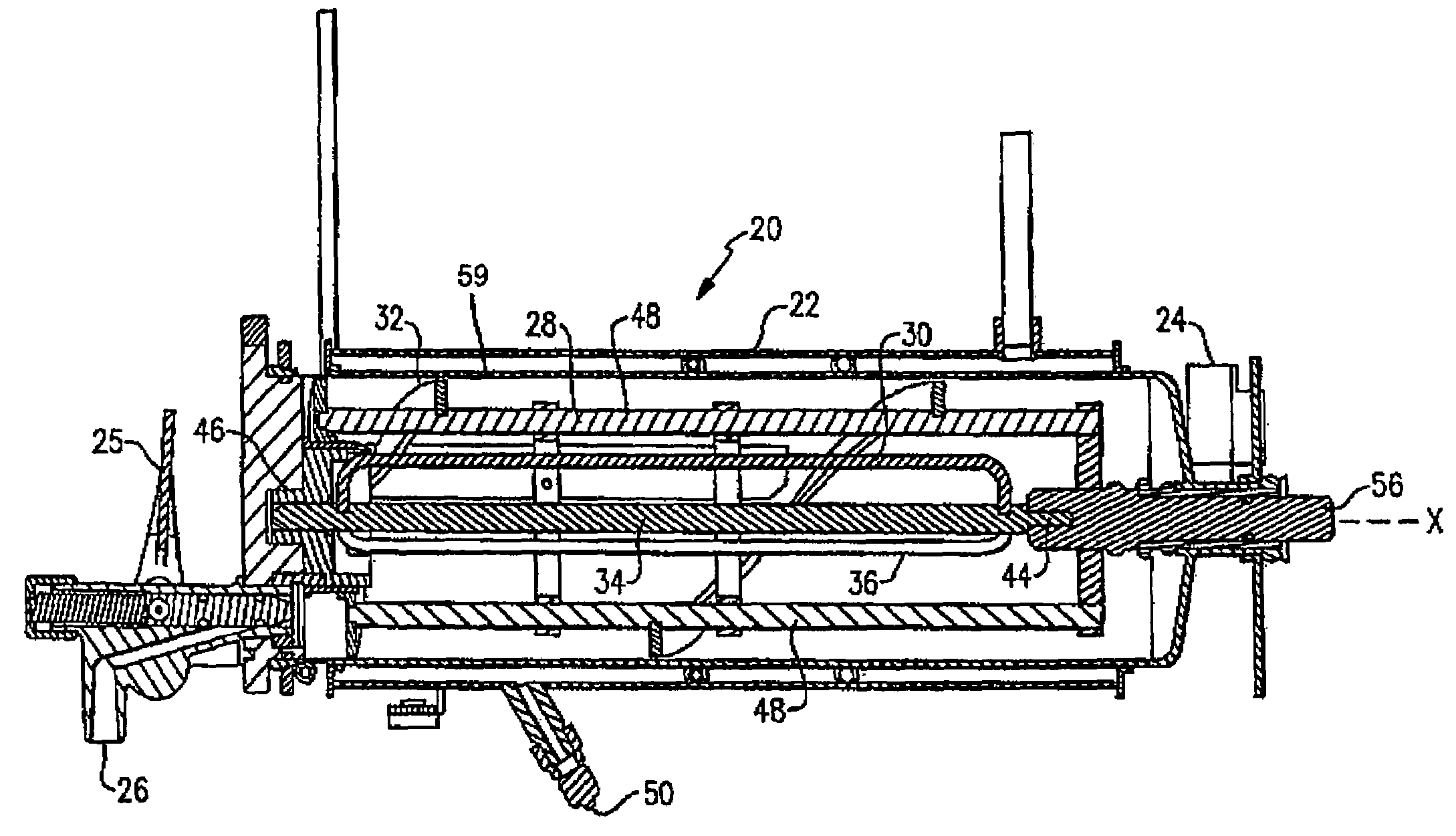

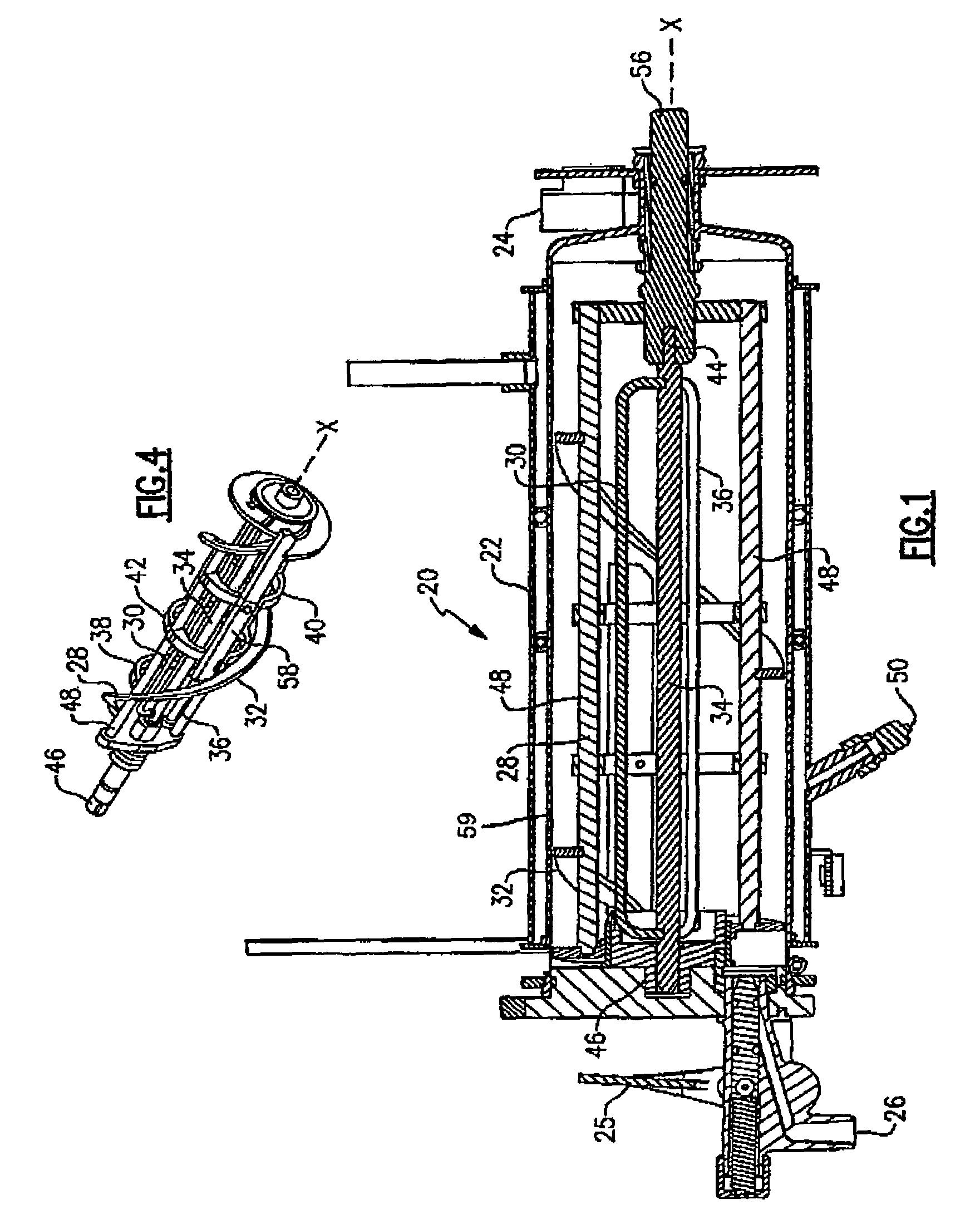

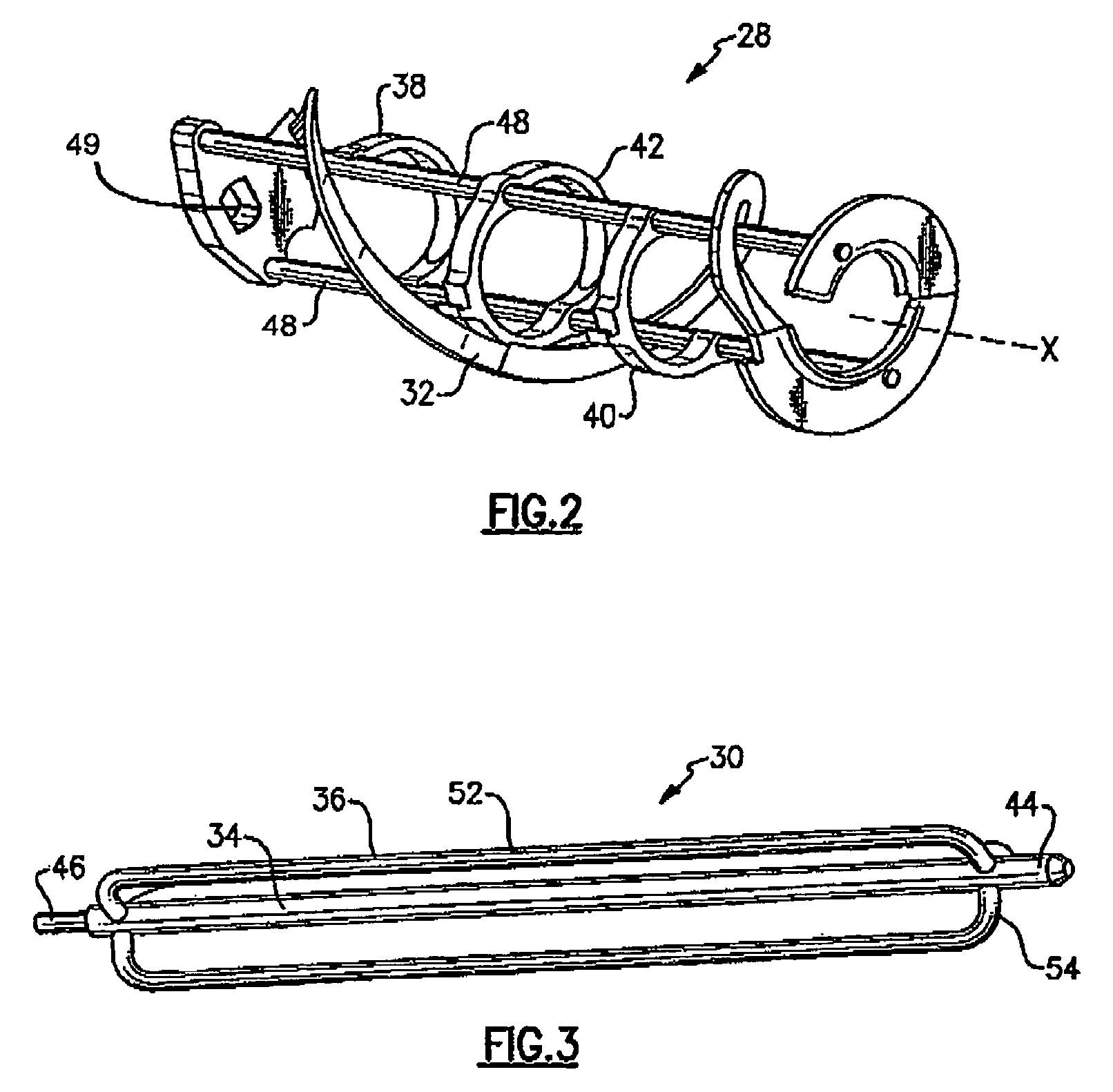

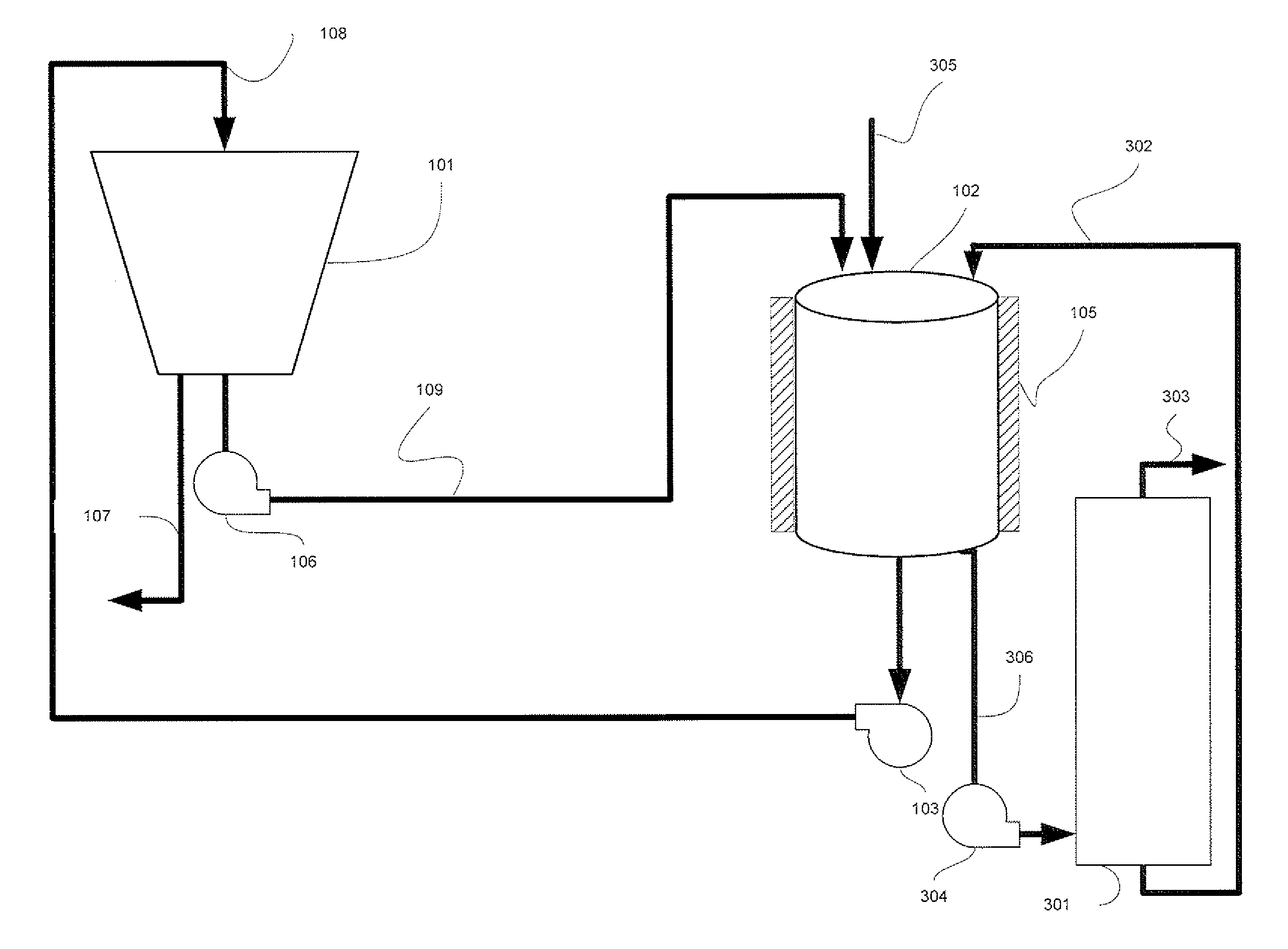

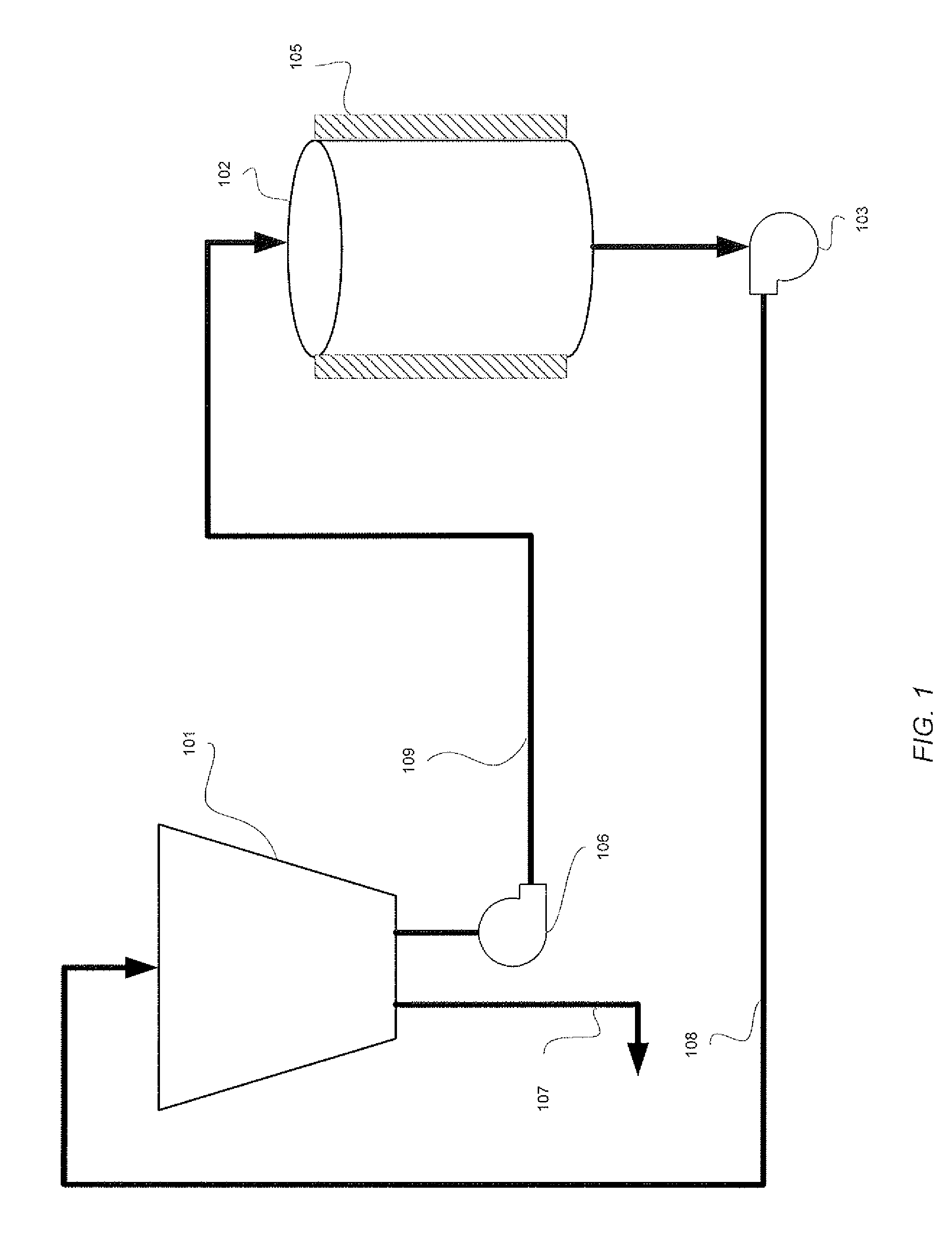

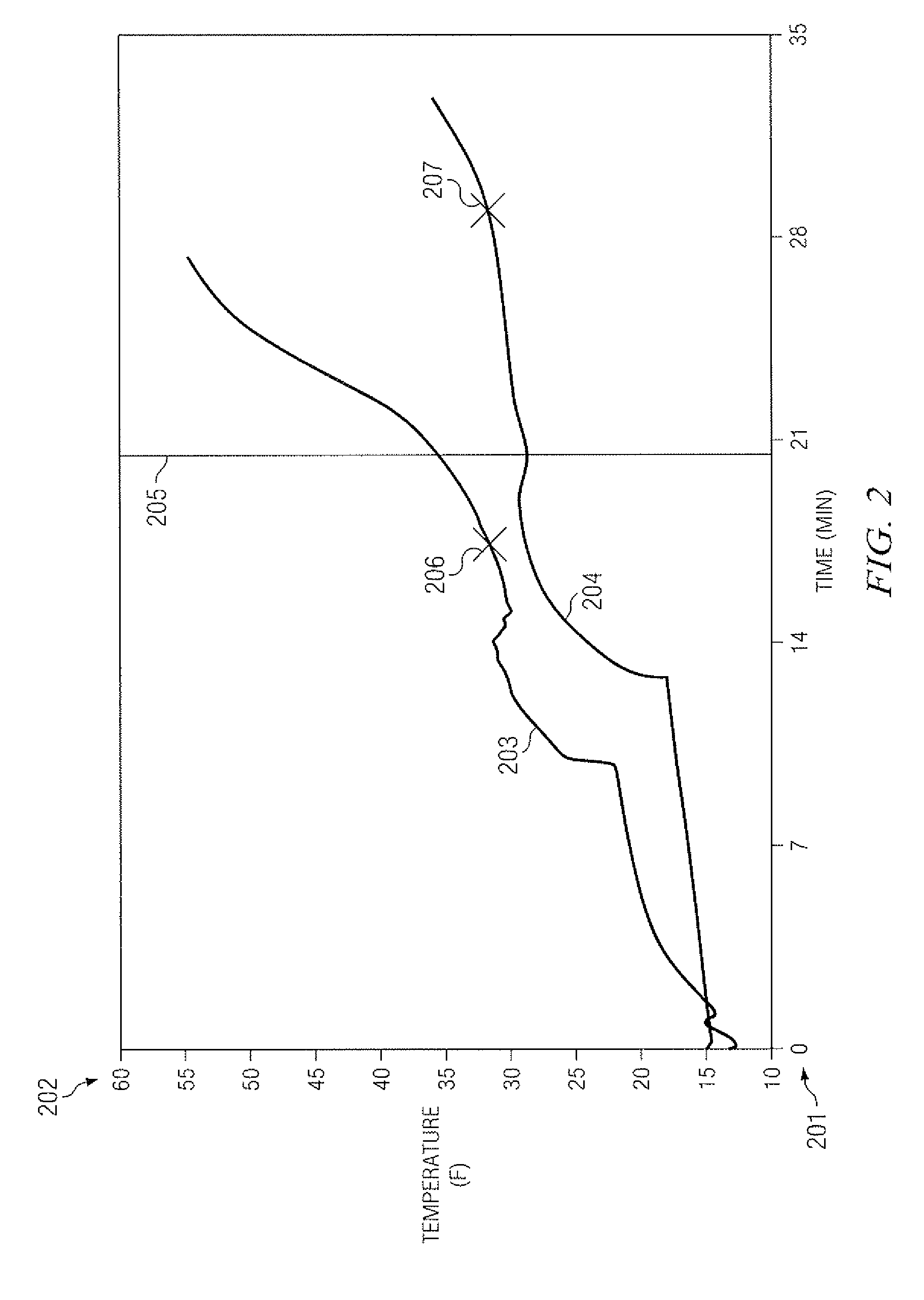

Frozen carbonated beverage apparatus for preparing a low Brix frozen carbonated beverage

ActiveUS7278276B2Improve consistencyQuality improvementDomestic cooling apparatusLighting and heating apparatusBrixEngineering

A frozen carbonated beverage apparatus includes a freezing cylinder that stores and freezes a low Brix frozen carbonated beverage. A beater including a helical member is moveable about an axis, and a stationary baffle is received within the beater. As the beater rotates, a scraper blade scrapes against the wall of the freezing cylinder to remove any frozen product from the wall. The helical member moves the frozen product within the freezing cylinder. The baffle prevents the mass of the product from collecting in the center of the helical beater and just rotating with the beater, assisting the blending of the frozen carbonated beverage and increasing the quality of the final product.

Owner:TAYLOR COMML FOODSERVICE LLC

Humilis juice and its processing method

The present invention relates to a common plum juice and its processing method. The described common plum juice is a natural one, it is a red clear transparent liquor, has the original frangrance of common plum furit, its soluble solid content is 8 deg.brix-10 deg. Brix, and its pH value is 3.4-3.8. Its processing method includes the following steps: using mature common plum fruit as raw material, circulating extraction, filtering, regulating pH value, high-temperature sterilizing, cooling, filling and packaging so as to obtain the invented product.

Owner:HEBEI AGRICULTURAL UNIV.

Method for preparing raw apple pulp

The invention discloses a method for preparing raw apple pulp, which comprises the following steps of: taking fresh and mature apples with sugar degree greater than or equal to 12-DEG Brix as a raw material, conveying the apples to a crushing machine, and crushing the apples into 1-3 cm particle size; beating the crushed apples in a beating machine, and adding VC (Vitamin C) accounting for 0.01-0.5% of the apples by weight for color protection during beating; heating the pulp to 80-100 DEG C, and maintaining the temperature for 5-10 min; then, beating the hot pulp in a double-way beating machine, temporarily storing the pulp for 10-30 min, and homogenizing the pulp under the pressure of 5-10 MPa; and degassing the pump by using a degassing machine after homogenizing, filtering the pulp, and performing pasteurization to obtain the raw apple pulp. The obtained raw apple pulp does not have obvious caking or layering and has white or slight yellow color, the apple pulp has unique taste and aroma of mature apples and palatable sweet and scour taste and does not have bad smell caused by fermentation or other causes, and no additive such as essence, pigments, preservatives and the like is added.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

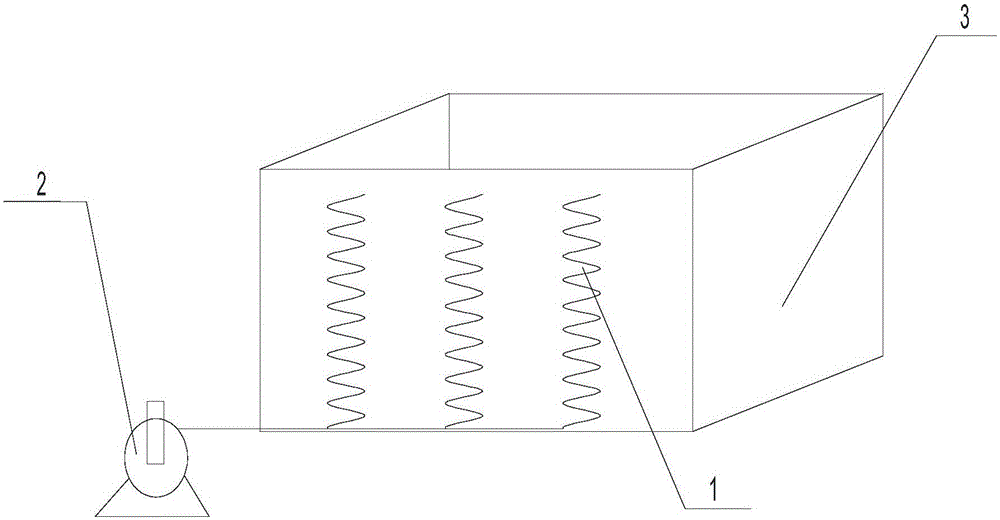

Processing technique to thaw partially frozen fruits and vegetables and incorporating solids

ActiveUS20090162504A1Avoid damageImprove infusion efficiencyMilk preparationDough treatmentInfusion timeHigh rate

A method for thawing and infusing partially frozen fruits or vegetables. Individually quick frozen fruits or vegetables are introduced into a mixing kettle. An infusion solution is circulated from a solution tank, through a bed of fruits or vegetables, and back to a solution tank. The infusion solution is maintained at a temperature of about 45° to about 50° F. and at a Brix of about 40° to about 50°. The infusion solution is pumped and circulated at a high rate which reduces thaw time but does not result in product degradation. After thawing, the pumping and re-circulating rate is decreased to allow for increased infusion efficiency. Pressure pulses are applied to the product in the mixing tank which decreases the infusion time. Thus, thawed and infused fruit and vegetables are produced quickly and with minimal product degradation.

Owner:FRITO LAY NORTH AMERICA INC

Preparation for humic-acid-contained water-soluble fertilizer by utilizing molasses alcohol fermentation liquid

The invention discloses preparation for a humic-acid-contained water-soluble fertilizer by utilizing molasses alcohol fermentation liquid. The preparation comprises the following steps: using molasses fermentation liquid with a brix of 45 to 75% as a main raw material, adding biological bacteria with a weight accounting for 0.5 to 5% of the weight of the molasses fermentation liquid, carrying out uniform mixing and then carrying out placing in a fermentation pool, carrying out fermentation at 30 to 60 DEG C for 32 to 40 hours, then carrying out high-temperature inactivation at 200 to 250 DEG C, adding a water-soluble nitrogen fertilizer, a water-soluble phosphate fertilizer and a water-soluble potash fertilizer with a total weight accounting for 15 to 40% of the weight of the molasses fermentation liquid, and carrying out filtering and removing sediments so as to obtained the humic-acid-contained water-soluble fertilizer. According to the invention, rich humic acid, organic matters, amino acid and plant-needed trace elements like nitrogen, phosphorus and potassium contained in the molasses fermentation liquid are utilized to effectively improve soil, so the organic matters are increased; fertilizer efficiency is strengthened; growth of plants is promoted; and requirements for integration of water and fertilizers in modern agricultural science and technology can be met; meanwhile, useful substances like the trace elements, the organic matters, amino acid and humic acid in the molasses fermentation liquid are fully utilized to return to a field, so wastes are turned into treasures.

Owner:广西中以水肥一体生物科技有限公司

Compound drink of papaya and passion fruit

The invention discloses a compound drink of a papaya and a passion fruit. The undiluted liquid content of the compound drink is 30-50%, the sugar content of the compound drink is 10-15%, the total acid content is 0.1-0.5%,and the brix degree of soluble solid is 8-15 degree Bx, wherein the undiluted liquid is formed by mixing of the papaya and the passion fruit as per the weight ratio of 7.5: (1-2); the compound drink further comprises Chinese herbal medicine concentrated juice accounting for 0.2-1 percent of the total weight. According to the compound drink, the papaya which is low in juice squeezing rata, and rich and unique in flavor and the passion fruit which is high in yield and short of flavor are mixed, and a little of Chinese herbal medicine concentrated juice is added at the same time, so that the compound drink of the papaya and the passion fruit has the mixing rich flavor of the papaya and the passion fruit, is excellent in taste, nutritionally endowed, quenches the thirst, wet the whistle, has the health care effects of maintaining beauty and keeping young, can be drunk at the moment the drink bottle is opened, and has a broad market prospect.

Owner:王正金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com