Method for preparing fermented fruit and vegetable juice and application of product obtained by method

A fruit and vegetable juice, fruit and vegetable technology, applied in the direction of bacteria used in food preparation, application, yeast-containing food ingredients, etc., can solve the problem of difficult survival of microorganisms, difficulty in preservation of fermented fruit and vegetable juice, transportation and industrial application, high Brix fruit and vegetable concentration Juice is difficult to ferment and other problems, to achieve the effect of promoting growth and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing fermented fruit and vegetable juice described in this example comprises the following steps: take 50 g of concentrated apple juice, add 50 g of secondary water, mix evenly, and sterilize at a temperature of 105° C. for 10 minutes; 5 cfu / mL inoculated with Kluyveromyces lactis, aerated and fermented at 28°C for 40 hours until Brix was at 25°, inoculated with complex lactic acid bacteria (Streptococcus thermophilus, Lactobacillus acidophilus, Lactococcus lactis, Lactobacillus bulgaricus) at a temperature of 42°C Ferment for 2 hours to pH 3.3, and standardize the fermented apple juice to obtain the finished product of fermented apple juice (live bacteria type). The standardized fermented apple juice is stored in a refrigerator at 0-4° C., and its shelf life is 21 days.

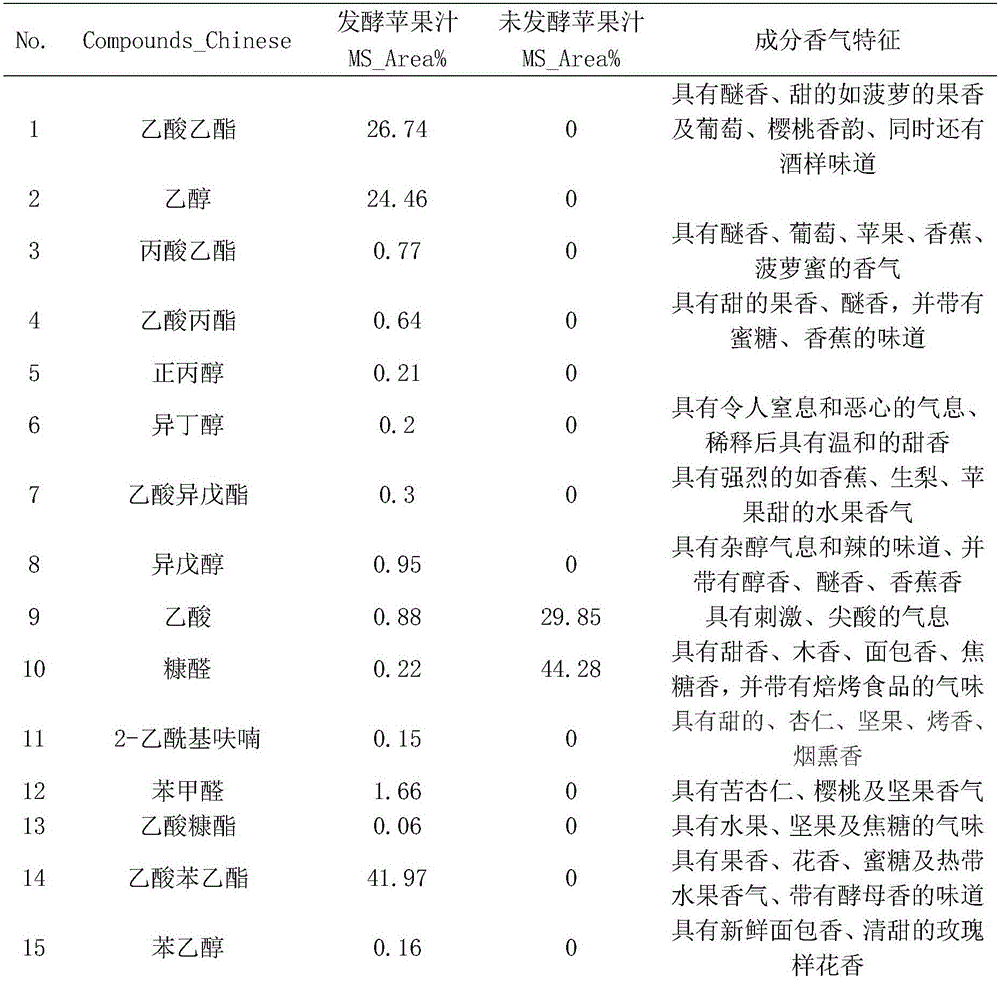

[0024] The following table shows the aroma components of fermented apple juice and unfermented apple juice in this example. The solid-phase microextraction method is used to analyze ...

Embodiment 2

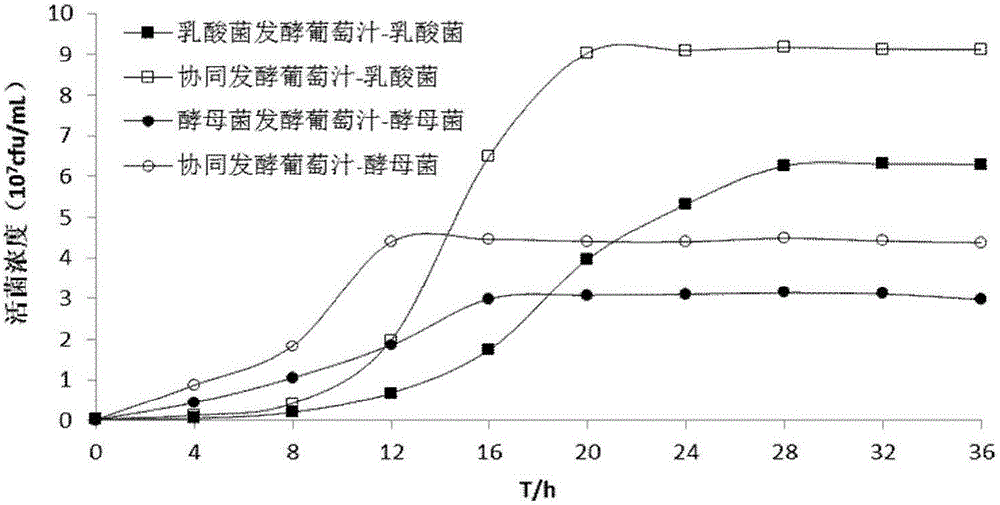

[0028] Such as figure 1 As shown, the preparation method of a fermented fruit and vegetable juice described in this example includes the following steps: take 33g of concentrated grape juice, add 66g of secondary water, mix well, and sterilize at 132°C for 3s; 7 cfu / mL inoculated with mixed fermentation strains (Kluyveromyces lactis, Debaryomyces hansenii, Lactobacillus plantarum, Lactobacillus paracasei, Lactobacillus helveticus, Lactobacillus bulgaricus) and fermented at 30°C for 56 hours, so that the pH dropped to 3.0 Finally, the fermentation end point is reached; the fermented grape juice concentrate is standardized, sterilized at 90°C for 10 minutes, and then filled to obtain the finished product of fermented grape juice. Its normal temperature shelf life is 6 months;

[0029] Yeast, lactic acid bacteria, and the concentration curve of live bacteria when yeast and lactic acid bacteria co-ferment grape juice, it can be clearly seen from the figure that when lactic acid b...

Embodiment 3

[0031] The preparation method of a fermented fruit and vegetable juice described in this example comprises the following steps: take 50 g of pumpkin puree, 30 g of pumpkin concentrated juice, and 20 g of secondary water, mix them evenly, and sterilize at 85° C. for 30 minutes; 5cfu / mL was inoculated with compound yeast (Kluyveromyces lactis, Kluyveromyces marx, and Dekker’s yeast) and fermented at 25°C for 6 hours, then inoculated with compound lactic acid bacteria (Streptococcus thermophilus, Lactobacillus acidophilus, Lactococcus lactis, Bulgaricus Lactobacillus) was fermented at 37°C for 36 hours, and the pH dropped to 4.2 as the end point of fermentation; after standardizing the fermented pumpkin pulp, it was pasteurized at 75°C for 30 minutes to obtain the finished product of fermented pumpkin juice, which has a shelf life of 6 months at room temperature . This method has a short yeast fermentation time and very little ethanol content, and can be used as an ingredient in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com