Manufacturing method of novel semisolid quick-fermentation pickle

A production method and semi-solid technology, applied in the direction of bacteria used in food preparation, food science, food preservation, etc., can solve the problems of large salt and water consumption, high cost, short fermentation cycle, etc., to achieve short fermentation cycle , Long growth lag period, rich nutrition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

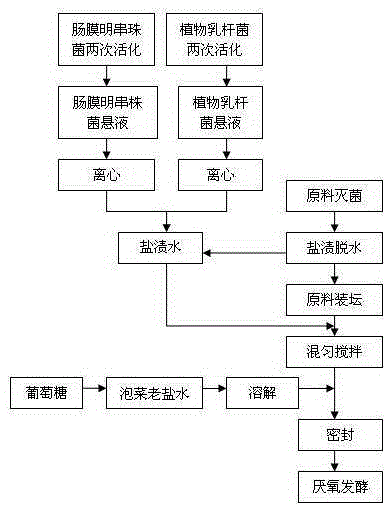

[0032] A kind of preparation method of novel semi-solid fast fermented pickles, the method comprises the following steps:

[0033] (1) Raw material pretreatment: Screen the cabbage used for fermentation, remove yellow leaves and rotten leaves, select fresh, moderately mature vegetables without impurities, wash them, drain them, put them in ultraviolet light for 30 minutes, and put them Sterilize both sides, trim and cut after sterilization, cut into 2-4*2-4cm size;

[0034] (2) Disinfection treatment of the kimchi jar: clean the kimchi jar, dry it, spray it with alcohol with a mass concentration of 75% for 15 minutes, and then add boiling water for another 30 minutes of disinfection treatment.

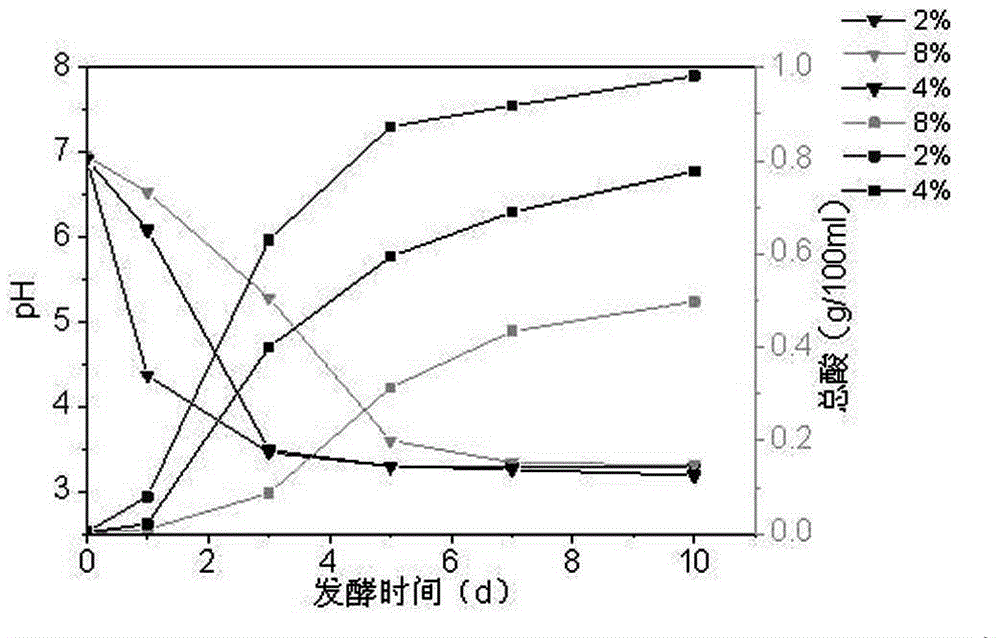

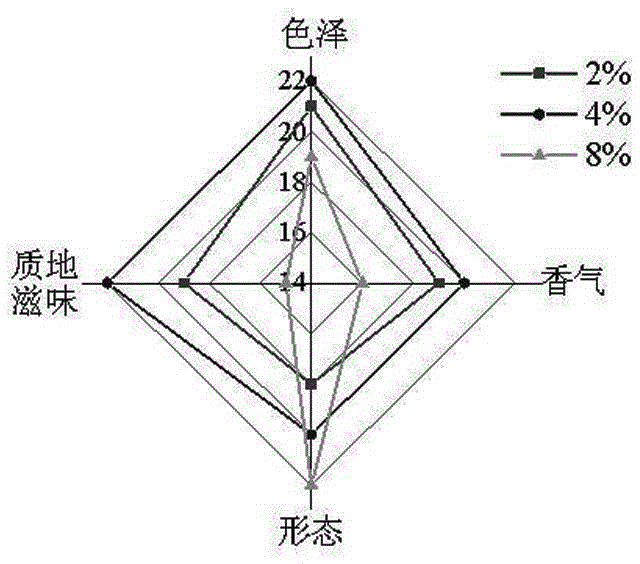

[0035] (3) Pickled cabbage salted dehydration: based on the mass of cabbage, add 4% of the cabbage mass of salt, after mixing, place the pickle altar at room temperature for sealing and pre-salted dehydration for 24 hours, and then pour out the salted water spare;

[0036] (4) Prepar...

Embodiment 2

[0042] A kind of preparation method of novel semi-solid fast fermented pickles, the method comprises the following steps:

[0043](1) Raw material pretreatment: Screen the fermented white radishes to remove black spots and rotten parts, select fresh, moderately mature radishes, and clean them without impurities. Trim and cut after bacteria, cut into 2-3×2-3×3-4cm size;

[0044] (2) Disinfection treatment of the kimchi jar: clean the kimchi jar, dry it, spray it with alcohol with a mass concentration of 75% for 15 minutes, and then add boiling water for another 30 minutes of disinfection treatment.

[0045] (3) Kimchi salting and dehydration: based on the mass percentage of white radish, add salt in a proportion of 4%, after mixing, put the kimchi jar at room temperature for sealing and pre-salting and dehydration for 24 hours, and then pour the salted water spare;

[0046] (4) Preparation of Lactobacillus and Leuconostoc Enteritidis bacteria sludge: Get the Lactobacillus pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com