Visible near-infrared spectrum-based fruit brix/acidity online detection and separation production line

A near-infrared spectroscopy, fruit candy technology, applied in the measurement of color/spectral characteristics, material analysis and sorting by optical means, etc., can solve the problems of high detection cost, unsuitability, long detection time, etc., to improve competitiveness. , the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

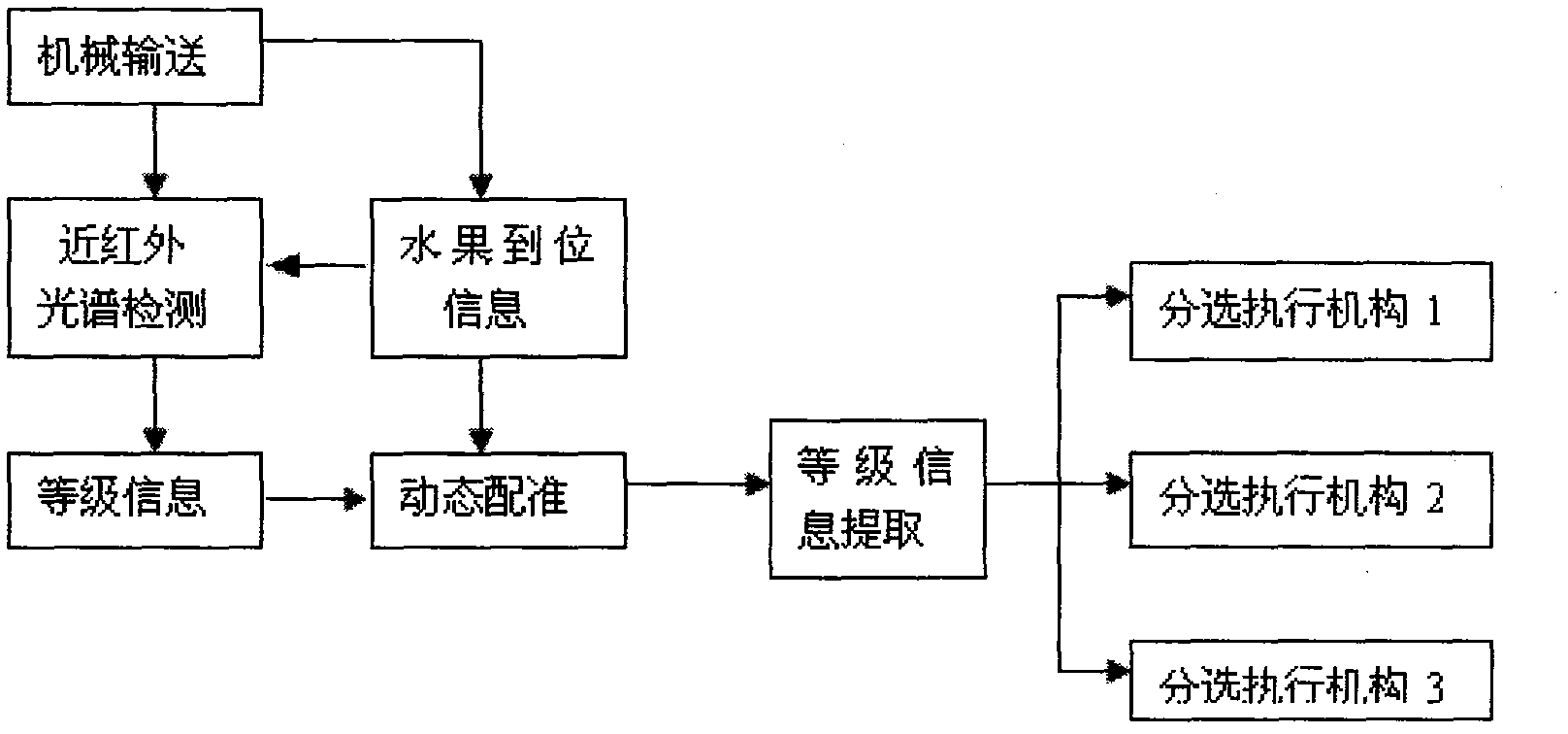

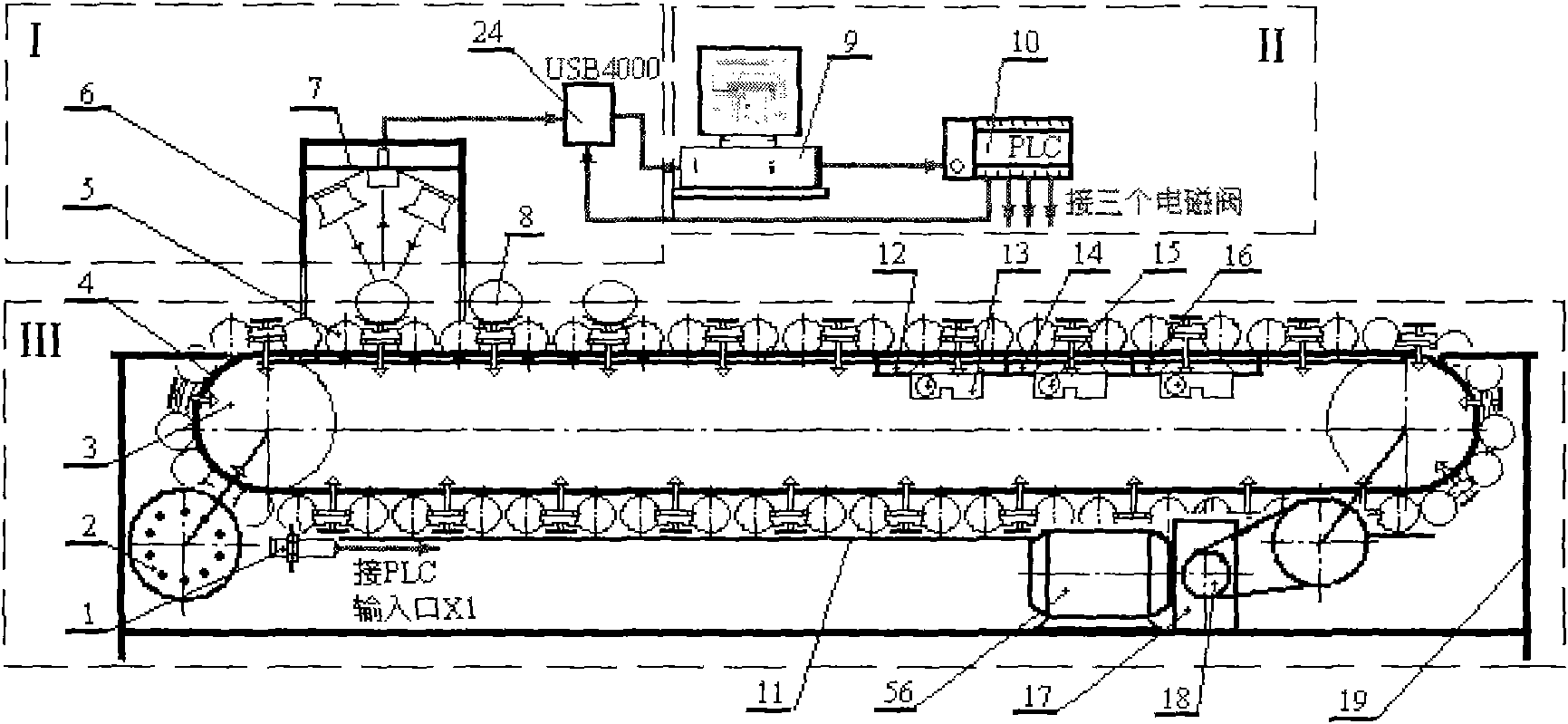

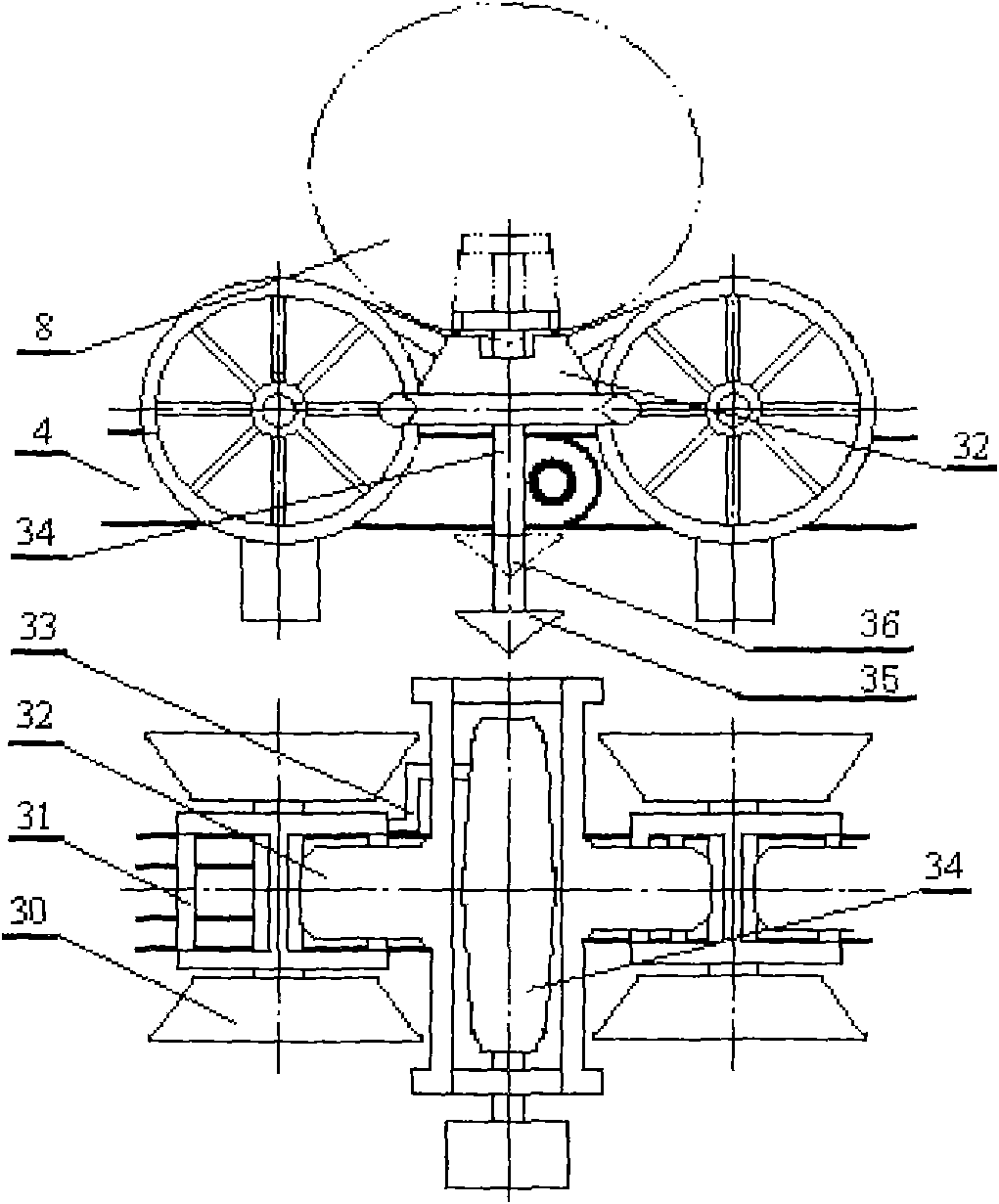

[0028] The overall structure of the on-line detection and sorting production line of fruit sugar acidity in the embodiment of the present invention is as follows: figure 1 As shown, the mechanical conveying device (III) includes: a sorting actuator (13), a motor (56), a reducer (17), a drive sprocket (18), a sprocket (3), a chain (4), and a support rail (11) and fixing brackets (1 9). The motor is connected with the reducer, the reducer is connected with the drive sprocket, and the sprocket and the chain form a circular conveying device. The visible-near-infrared spectrum detection device (1) comprises: an illumination box (6), an illumination unit (7), and an optical fiber spectrometer (24). The illumination unit is connected with the fiber optic spectrometer; the spectrometer is connected with the computer through a USB port. The sorting control device (II) includes: programmable logic controller PLC (10), photoelectric proximity switch (1), code disc (2), sorting ports (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com