Patents

Literature

261results about How to "Prevent thermal degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

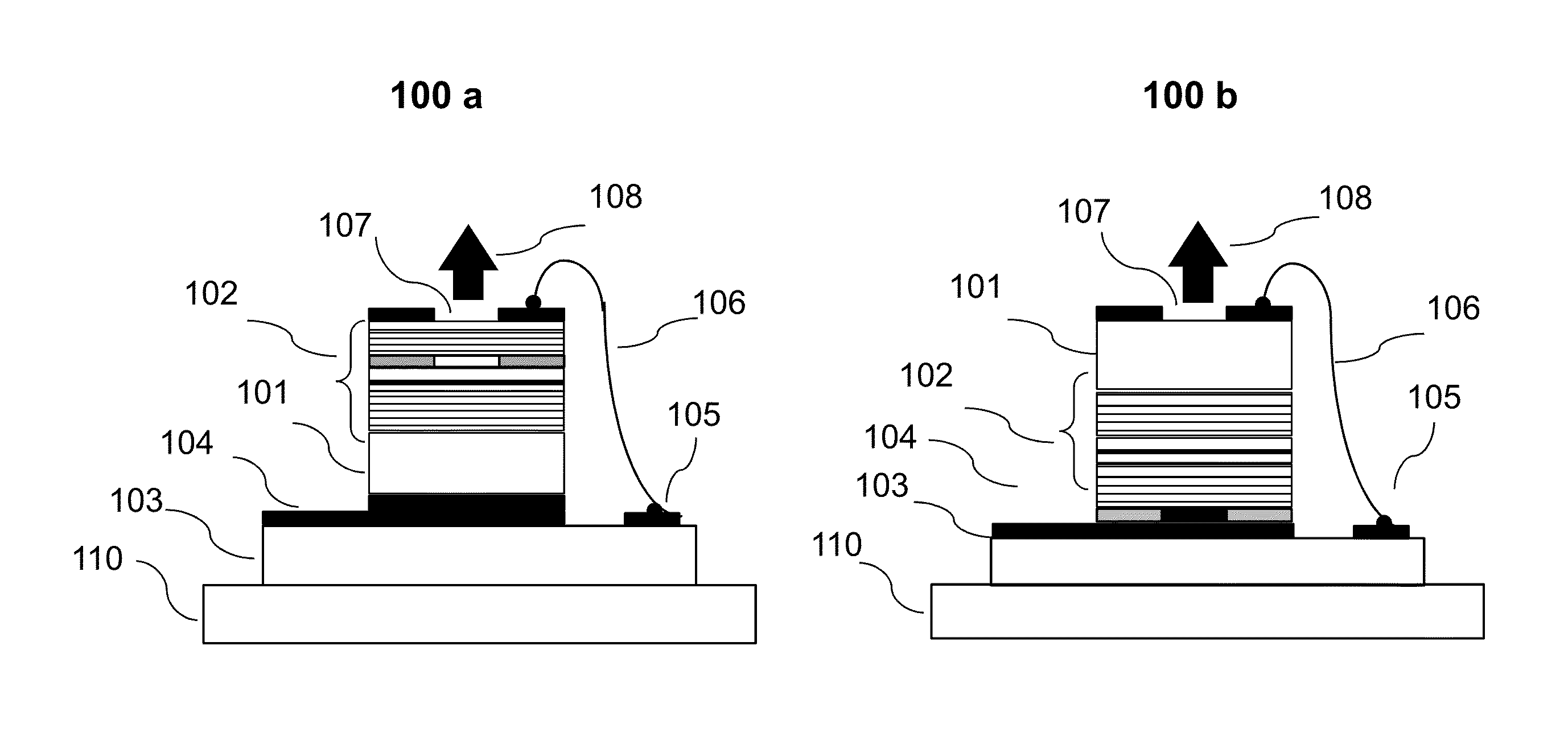

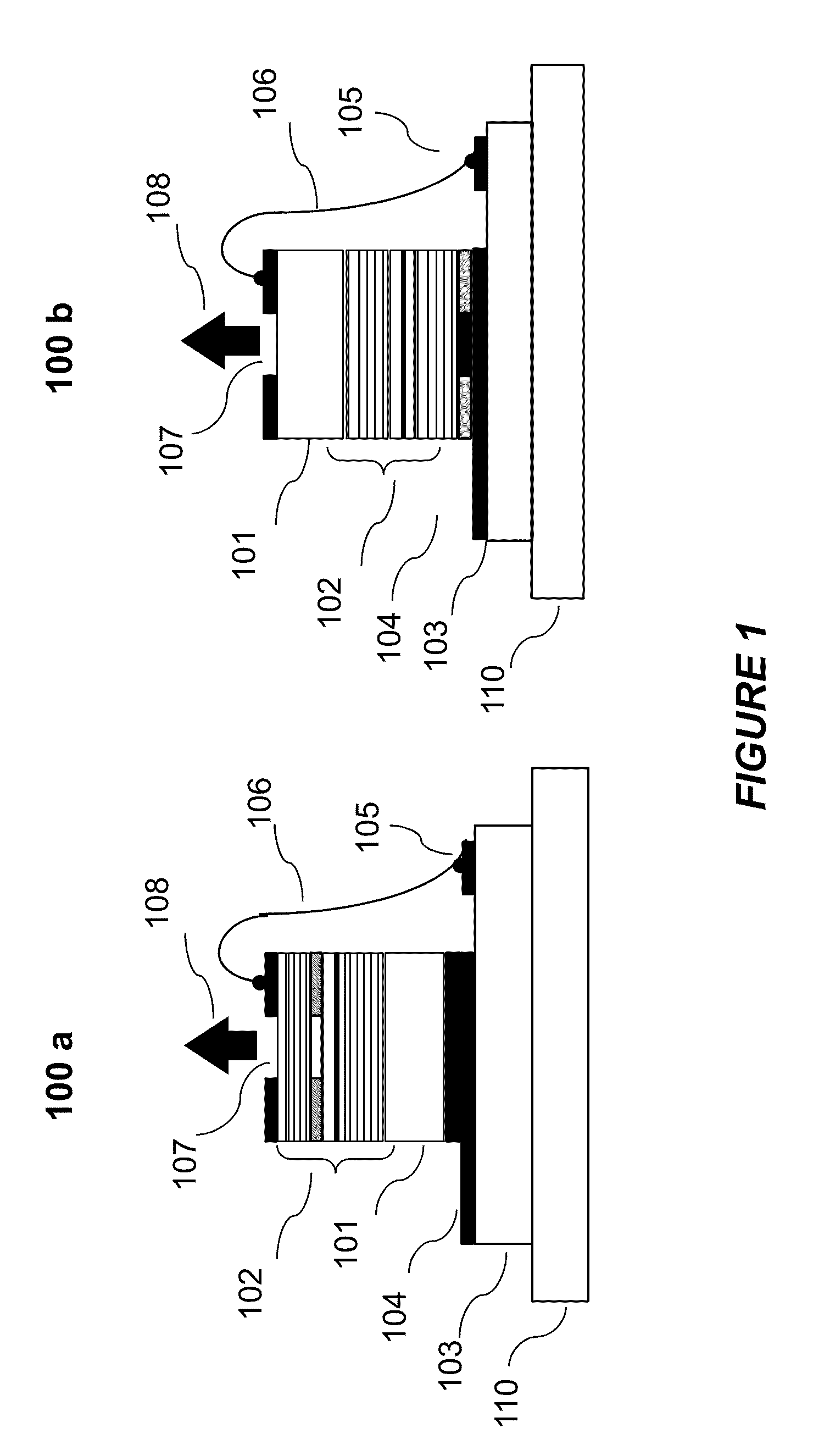

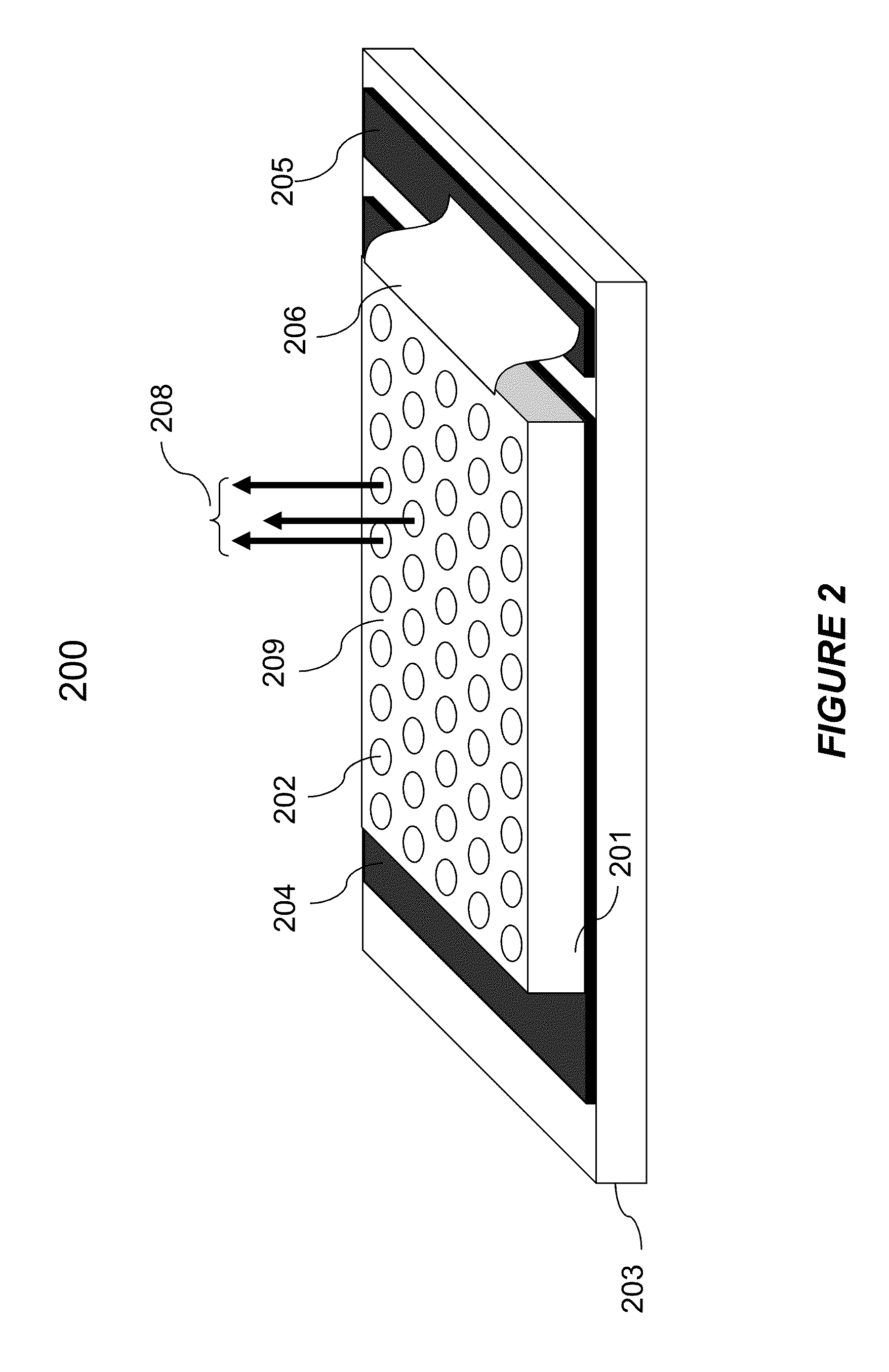

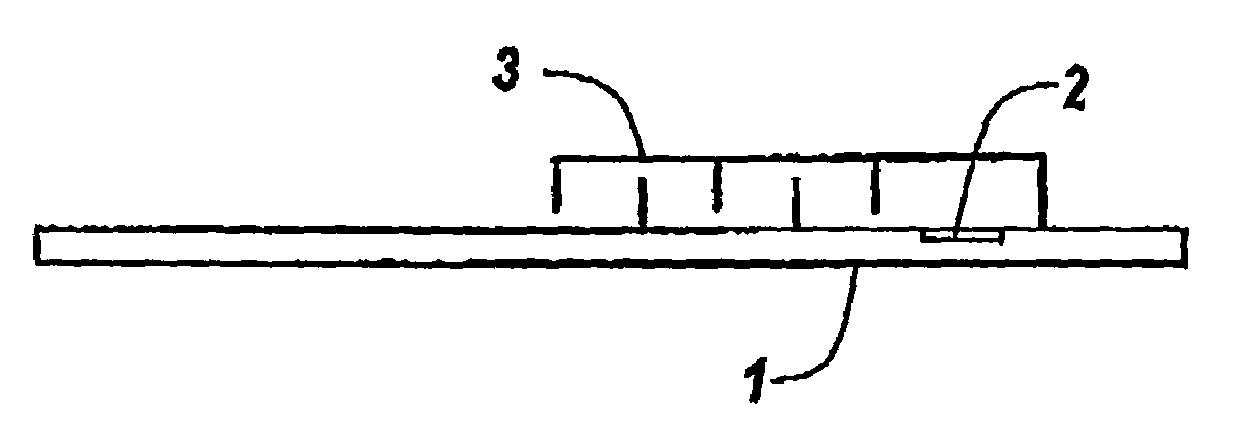

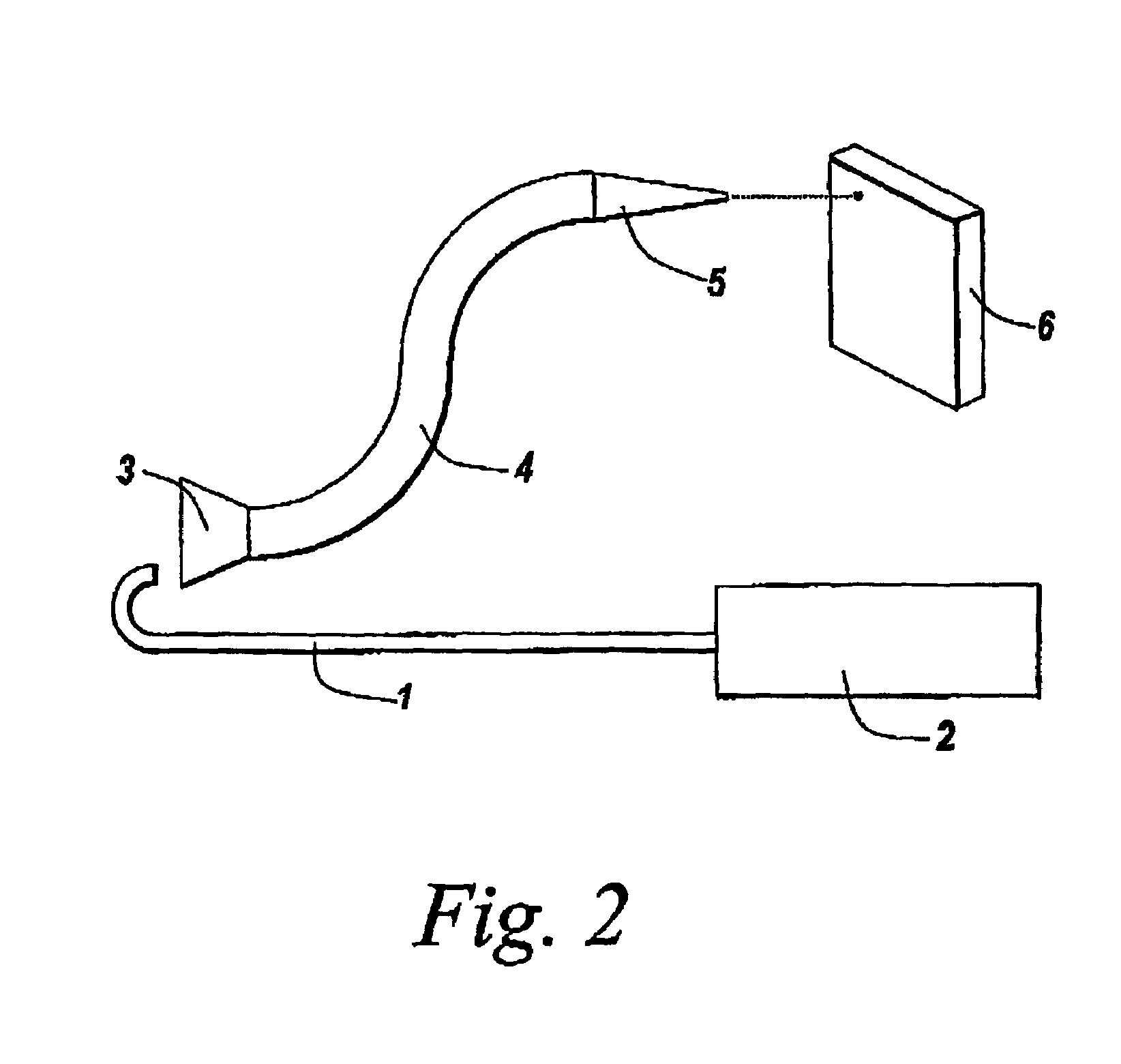

Laser Illuminator System

InactiveUS20130163627A1Improve thermal conductivityHeat dissipation fastSolid-state devicesSemiconductor lasersVertical-cavity surface-emitting laserLow inductance

An optical illuminator using Vertical Cavity Surface Emitting Laser (VCSEL) is disclosed. Optical modules configured using single VCSEL and VCSEL arrays bonded to a thermal submount to conduct heat away from the VCSEL array, are suited for high power and high speed operation. High speed optical modules are configured using single VCSEL or VCSEL arrays connected to a high speed electronic module on a common thermal submount or on a common Printed Circuit Board (PCB) platform including transmission lines. The electronic module provides low inductance current drive and control functions to operate the VCSEL and VCSEL array. VCSEL apertures are designed for a desired beam shape. Additional beam shaping elements are provided for VCSELs or VCSEL arrays, for desired output beam shapes and / or emission patterns. VCSEL arrays may be operated in continuous wave (CW) or pulse operation modes in a programmable fashion using a built-in or an external controller.

Owner:PRINCETON OPTRONICS

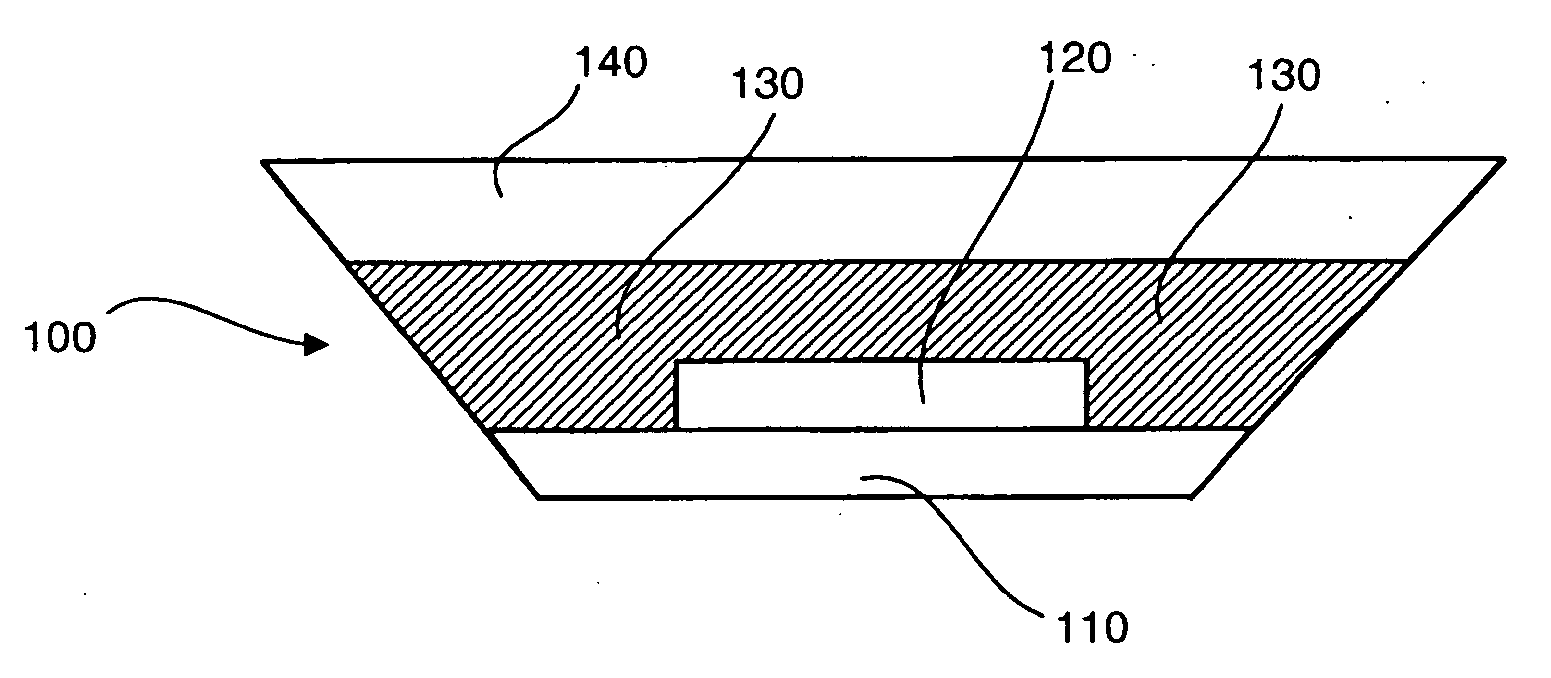

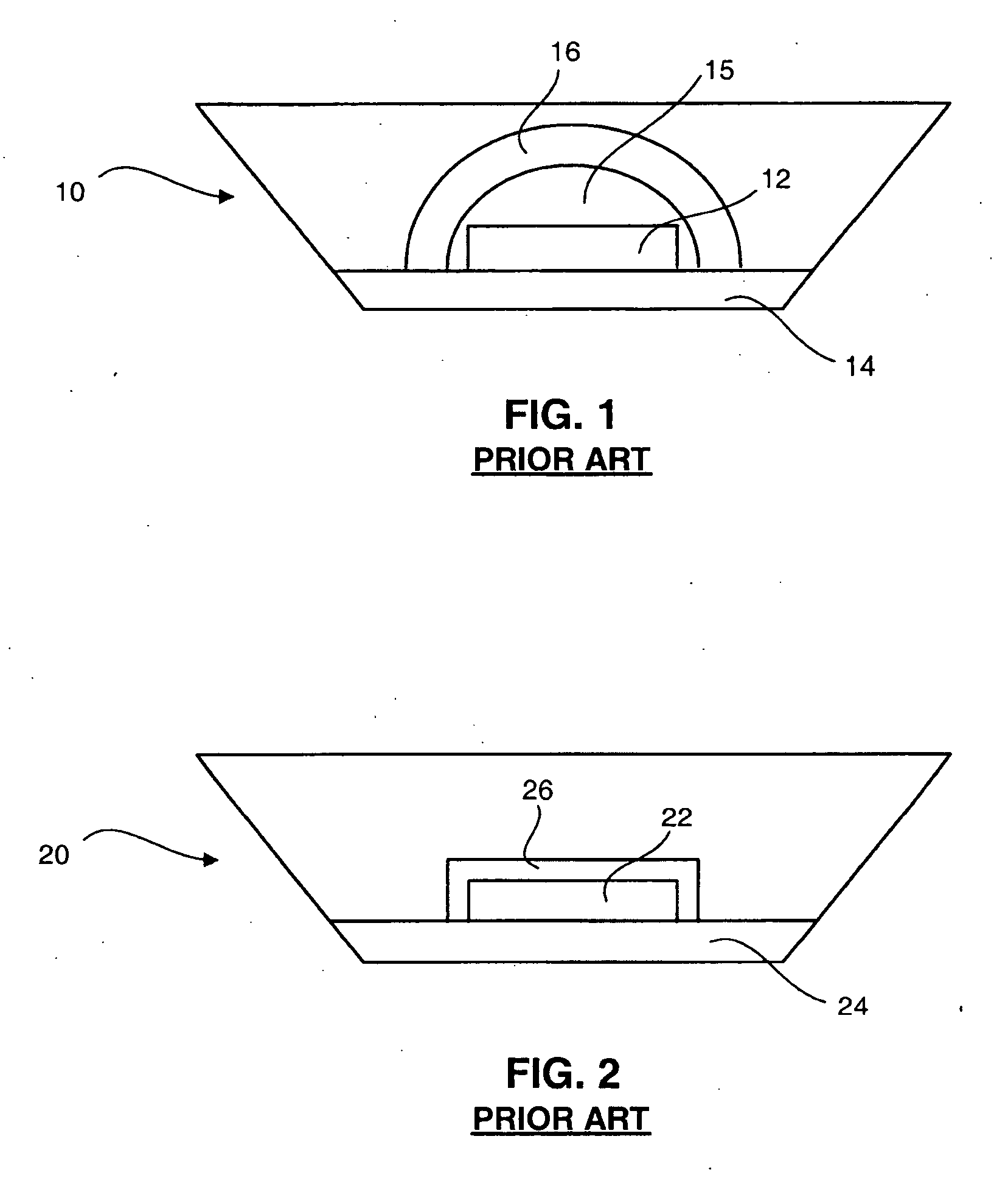

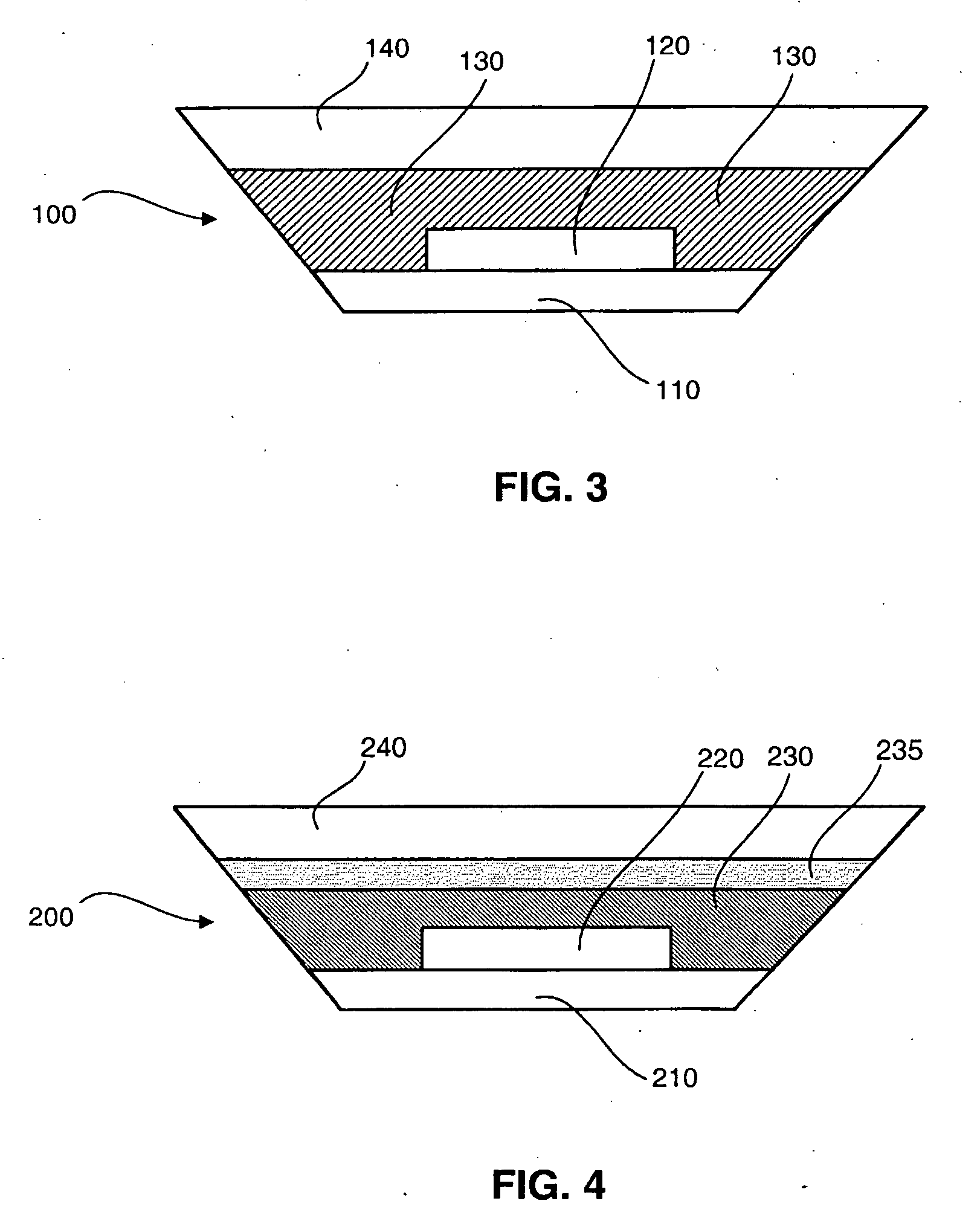

Light emitting device with a thermal insulating and refractive index matching material

ActiveUS20060091788A1Reduce heat transferPrevent thermal degradationDischarge tube luminescnet screensLamp detailsThermal insulationPhosphor

A light emitting device has a light emitting diode (LED) encapsulated by an encapsulant member. The encapsulant member includes a luminescent material, such as a phosphor, and a thermal insulating material. The thermal insulating material effectively insulates the luminescent material from the heat generated by the LED. A thermal conducting material is desirably placed in thermal contact with a back side of the LED to assist heat dissipation. The encapsulant member may be formed in two separate layers with the luminescent material forming a luminescent layer, and the thermal insulating material forming a thermal insulation layer disposed between the luminescent layer and the LED.

Owner:LED ENGIN

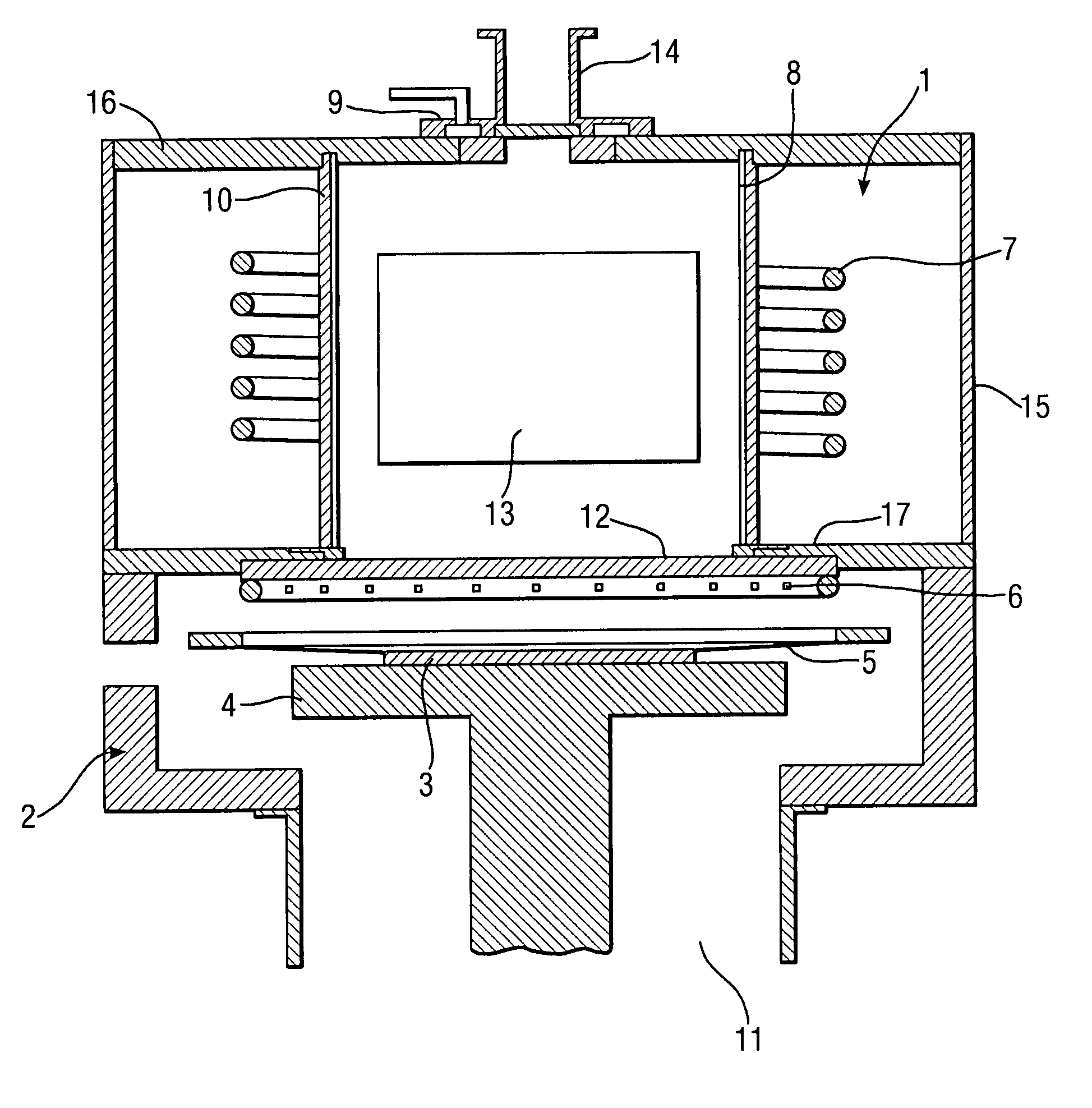

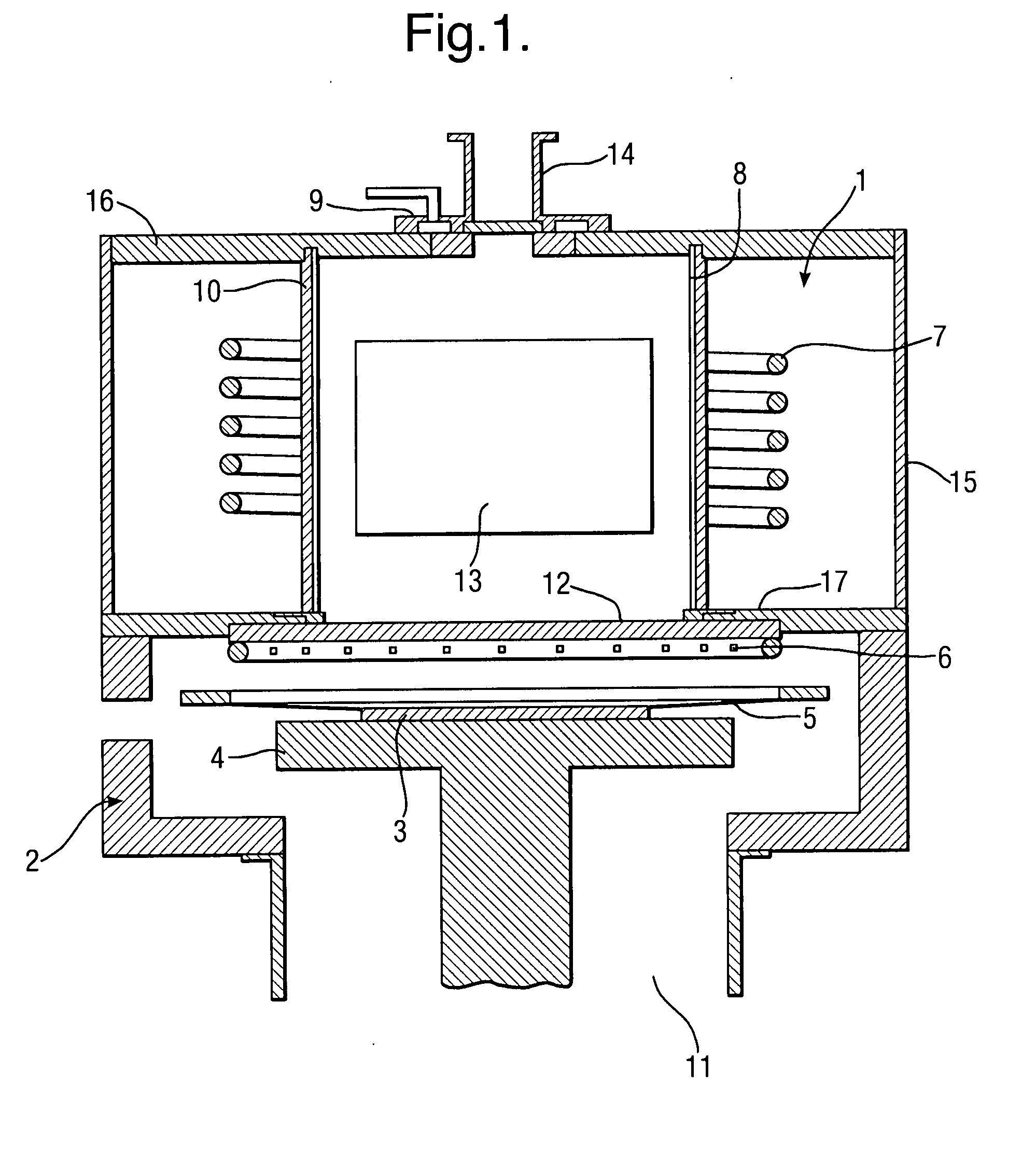

Surface processing apparatus

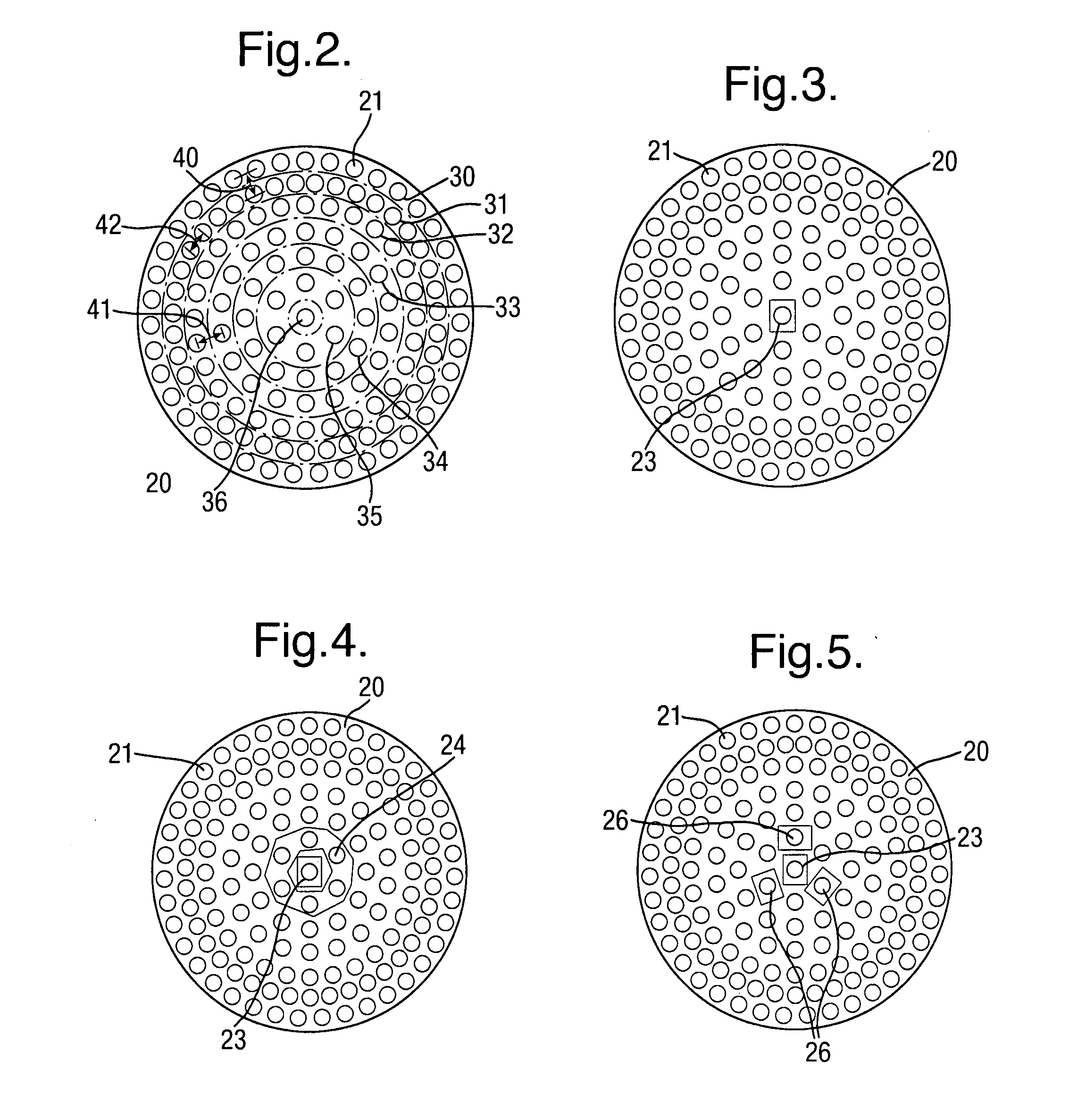

InactiveUS20080035608A1Uniform deposition and material removal ratePrevent thermal degradationElectric discharge tubesDecorative surface effectsEngineeringSurface processing

A surface processing apparatus is provided for use in the surface processing of a substrate. The surface processing apparatus comprises a plasma source and processing chamber in which a substrate is mounted in use. The processing chamber is operatively connected to the plasma source and the surface processing apparatus is characterised by a transmission plate for the transmission of plasma in use between the plasma source and processing chamber. The transmission plate comprises one or more apertures wherein the physical form of the one or more apertures and / or the distribution of the one or more apertures is adapted to provide a predetermined processing pattern upon the surface of the substrate. Typically the design of the apertures is adapted to provide a substantially uniform deposition rate across a wafer substrate.

Owner:OXFORD INSTR NANOTECH TOOLS

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

Method for production of modified water absorbent resin

InactiveUS20090298963A1Improve production efficiencyOutstanding propertyAbsorbent padsBandagesWater solublePolymer chemistry

This invention is to provide a method for producing a modified water absorbent resin excelling in water absorbing properties. This invention relates to a method for producing a modified water absorbent resin, which comprises a) mixing a water absorbent resin and a water-soluble radical polymerization initiator or a heat-degradable radical polymerization initiator without addition of an ethylenically unsaturated monomer and b) irradiating the resultant mixture with active energy rays. The method is particularly capable of exalting the absorbency against pressure and the saline flow conductivity.

Owner:NIPPON SHOKUBAI CO LTD

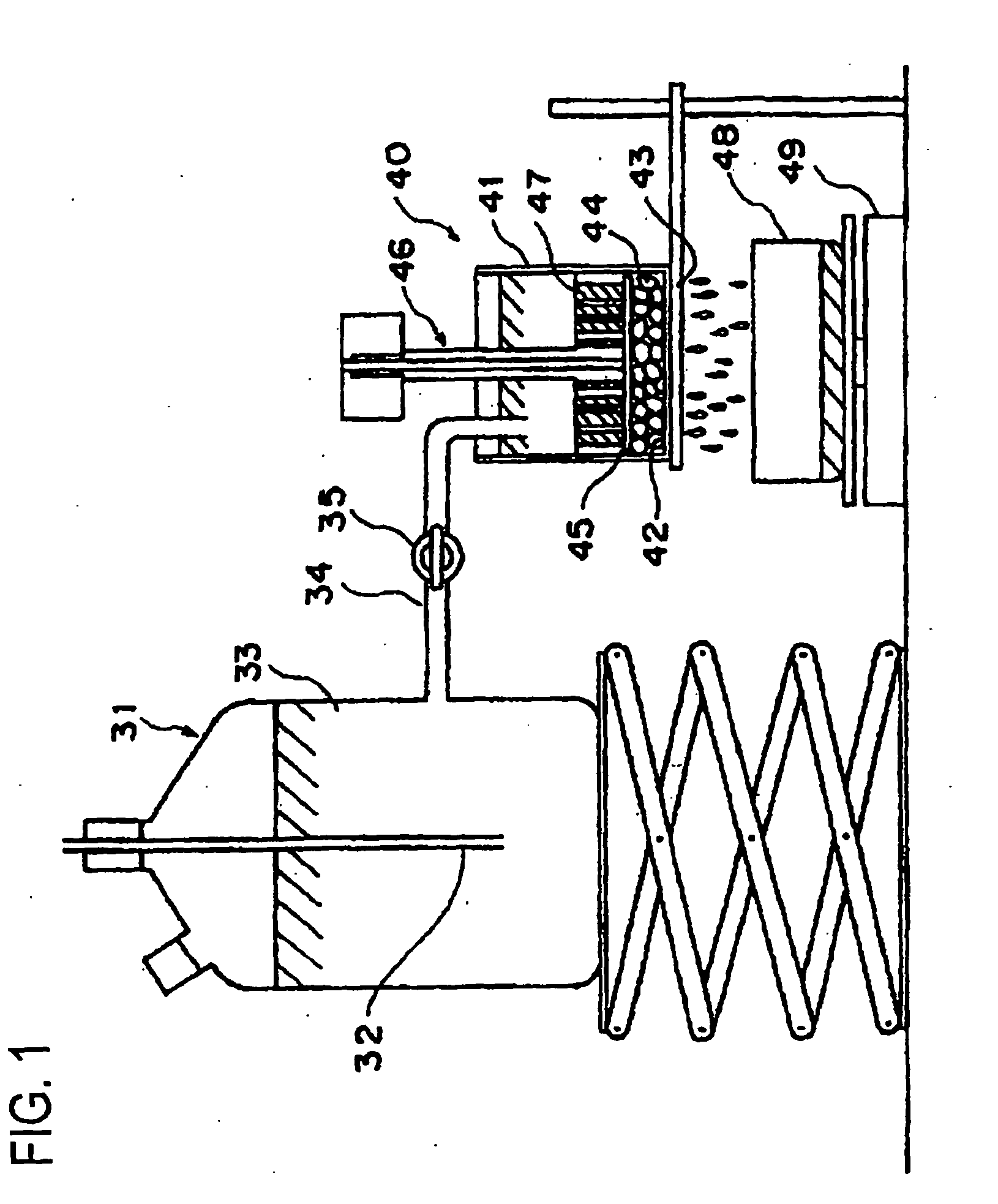

Macromolecular material polymerization reaction kettle

ActiveCN101596440AImprove the output effectReduce inventoryRotary stirring mixersChemical/physical/physico-chemical stationary reactorsInsulation layerElectric machinery

The invention discloses a macromolecular material polymerization reaction kettle. The kettle comprises a kettle body, an upper closed cover, a drive sealing device, a stirring device, a feed and discharge port, wherein the upper part of the kettle body is an inverted cone-shaped wide mouth; the middle part of the kettle body is of a bucket shape; the lower part of the kettle body is cone; the kettle body is provided with a heating jacket 14 with a spiral flow channel and a heat insulation layer 9; the upper closed cover 6 is provided with a heating jacket 7, a heat insulation layer 9, a vacuum port 8 and a feed port 12; the stirring device consists of a stirring shaft 5, an inner strip-shaped spiral stirring paddle 3, an outer strip-shaped spiral stirring paddle 2, a scraping blade 16 and a supporting oar 18; the drive sealing device consists of a motor, a retarder and a sealing machine; and the upper part of the stirring shaft is connected with the drive sealing device. The macromolecular material polymerization reaction kettle has good stirring effect and high heat and mass transferring efficiency, can solve the difficult problems of pole climbing and devolatilization of high-viscosity fusant and is in particular suitable for the polymerization reaction of a high-viscosity macromolecular material.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

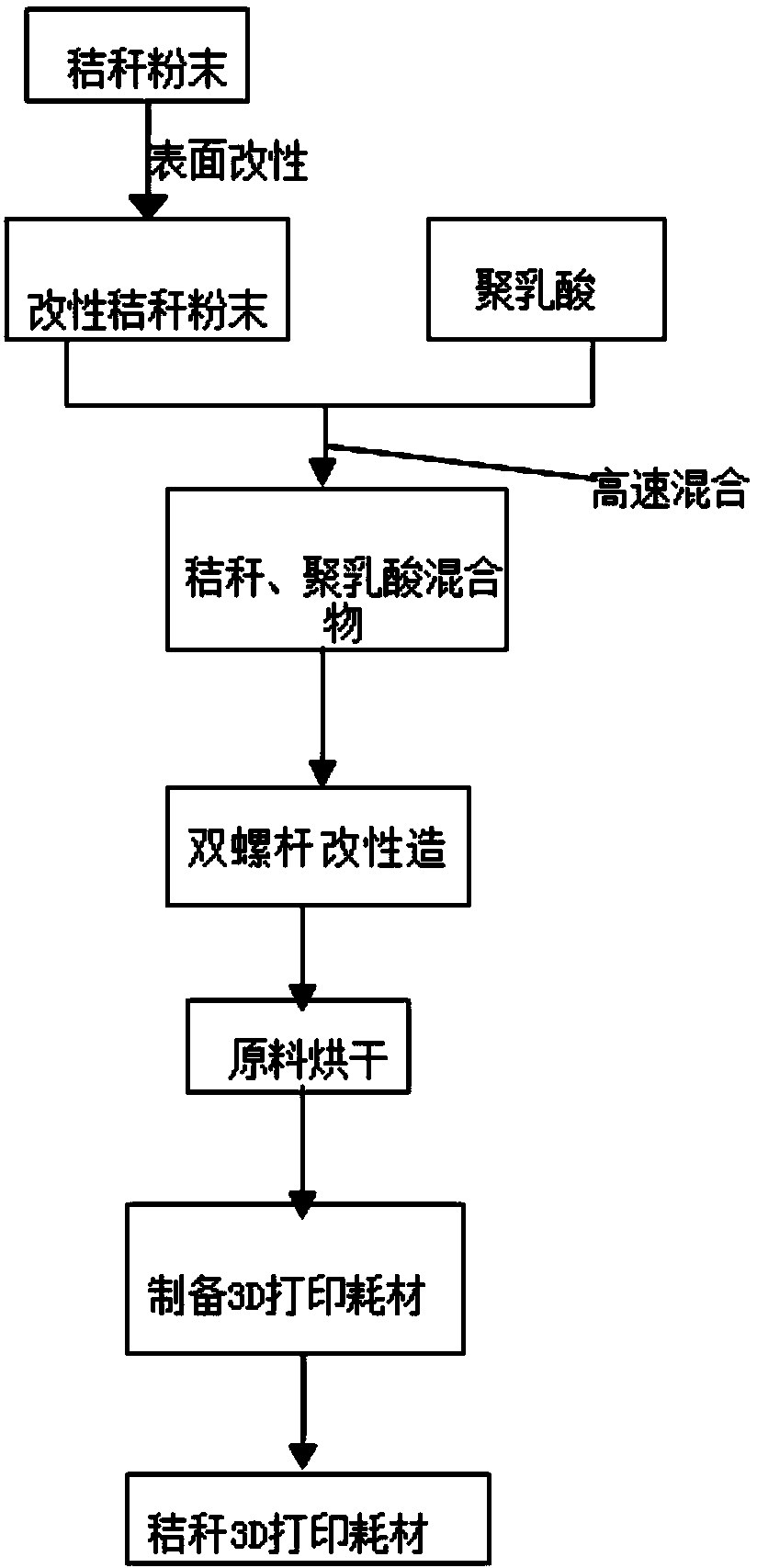

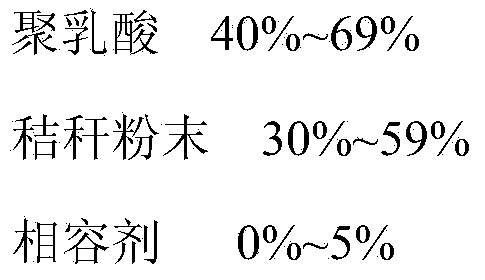

Straw 3D printing consumable and preparation method thereof

The invention provides a straw 3D printing consumable and a preparation method thereof. The formula includes the following raw materials in mass percentage: 40 to 69 percent of polylactic acid, 30 to 59 percent of straw powder, 0 to 5 percent of a compatilizer, and 0.2 to 3 percent of other additives. Straws, a crop byproduct, are fully utilized by the straw 3D printing consumable for surface modification, and the degradable material polylactic acid is added for melt blending. Compared with the prior art, the 3D printing material provided by the invention has stable performances, can replace common 3D plastic consumables in 3D printing, is non-toxic, low-carbon and environment-friendly, and has superior comprehensive performances, thereby achieving considerable economic value and broad market prospects.

Owner:芜湖瀚博电子科技有限公司

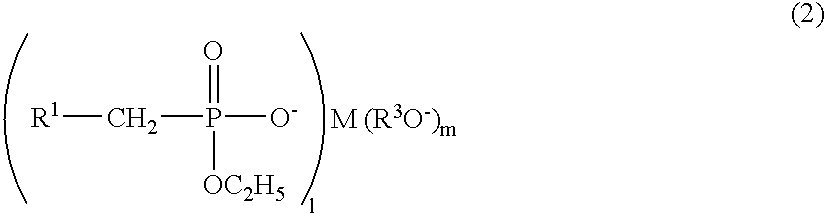

Polyester polymerization catalyst, polyester produced by using the same, and process for producing polyester

ActiveUS7144614B2Improve thermal stabilityPrevent thermal degradationWrappers shrinkageAnimal housingPolyesterFiber

This invention provides a novel polymerization catalyst other than antimony compounds, polyester produced by using the same and a process for producing polyester. The polycondensation catalyst of this invention is a polyester polymerization catalyst comprising an aluminum compound and a phosphorus compound having a specific structure. Further, this invention relates to polyester produced by using this polyester polymerization catalyst and a process for producing polyester. Further, this invention relates to fibers, films and hollow molded articles comprising the polyester.

Owner:TOYO TOYOBO CO LTD

Adsorption, detection and identification of components of ambient air with desorption/ionization on silicon mass spectrometry (DIOS-MS)

InactiveUS7564027B2Prevent thermal degradationOptical radiation measurementBioreactor/fermenter combinationsPhysicsMass spectrum analysis

The present invention provides a device, system, and associated methods to actively or passively sample air by directing it onto the surface of a porous light-absorbing semiconductor, for example, a desorption / ionization on porous silicon (“DIOS”) chip. Upon adsorption of an analyte, the surface may be analyzed directly by laser desorption / ionization time-of-flight mass spectrometry. Because the process of laser desorption / ionization and subsequent mass detection does not require elevated temperatures, thermal degradation of analytes is avoided.

Owner:WATERS TECH CORP

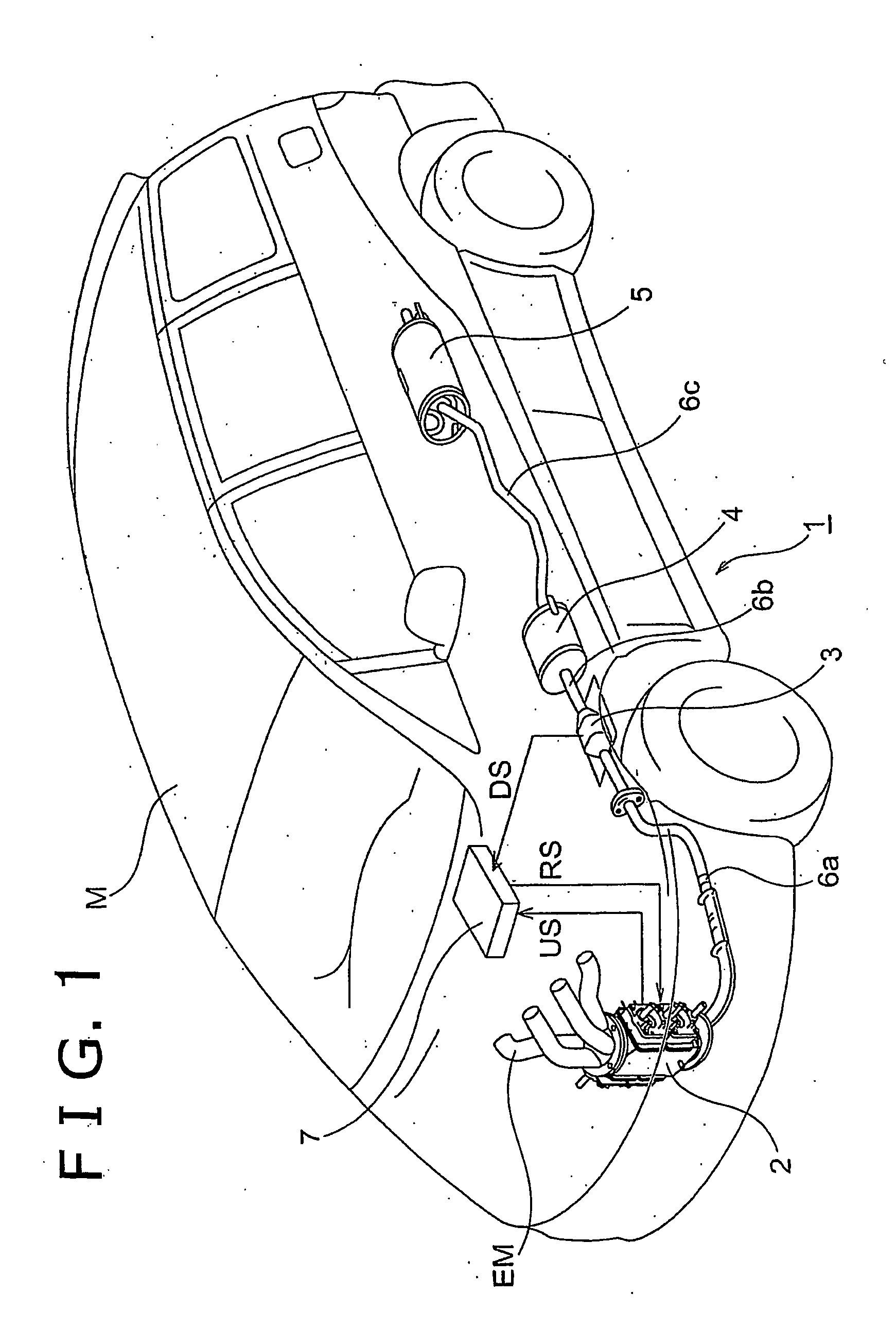

Exhaust system

InactiveUS20060053771A1Improve fuel efficiencyPrevent degradationInternal combustion piston enginesThermoelectric device with peltier/seeback effectThermal energyPulp and paper industry

An exhaust system (1) is provided with an exhaust passage that allows exhaust gas discharged from an internal combustion engine to pass therethrough, an exhaust emission control unit including a catalyst (2,3) such as a three-way catalyst (27) to purify the exhaust gas, and an exhaust heat collecting unit that converts thermal energy of the exhaust gas into electric energy. The exhaust passage (25) is formed in the center of the exhaust system provided with the exhaust emission control unit. By-pass passages (26) are formed at both sides of the exhaust passage (25) through which the exhaust gas flows without passing through the exhaust emission control unit. The exhaust heat collecting unit (29) is provided on the outer side of each of the by-pass passages (26).

Owner:TOYOTA JIDOSHA KK

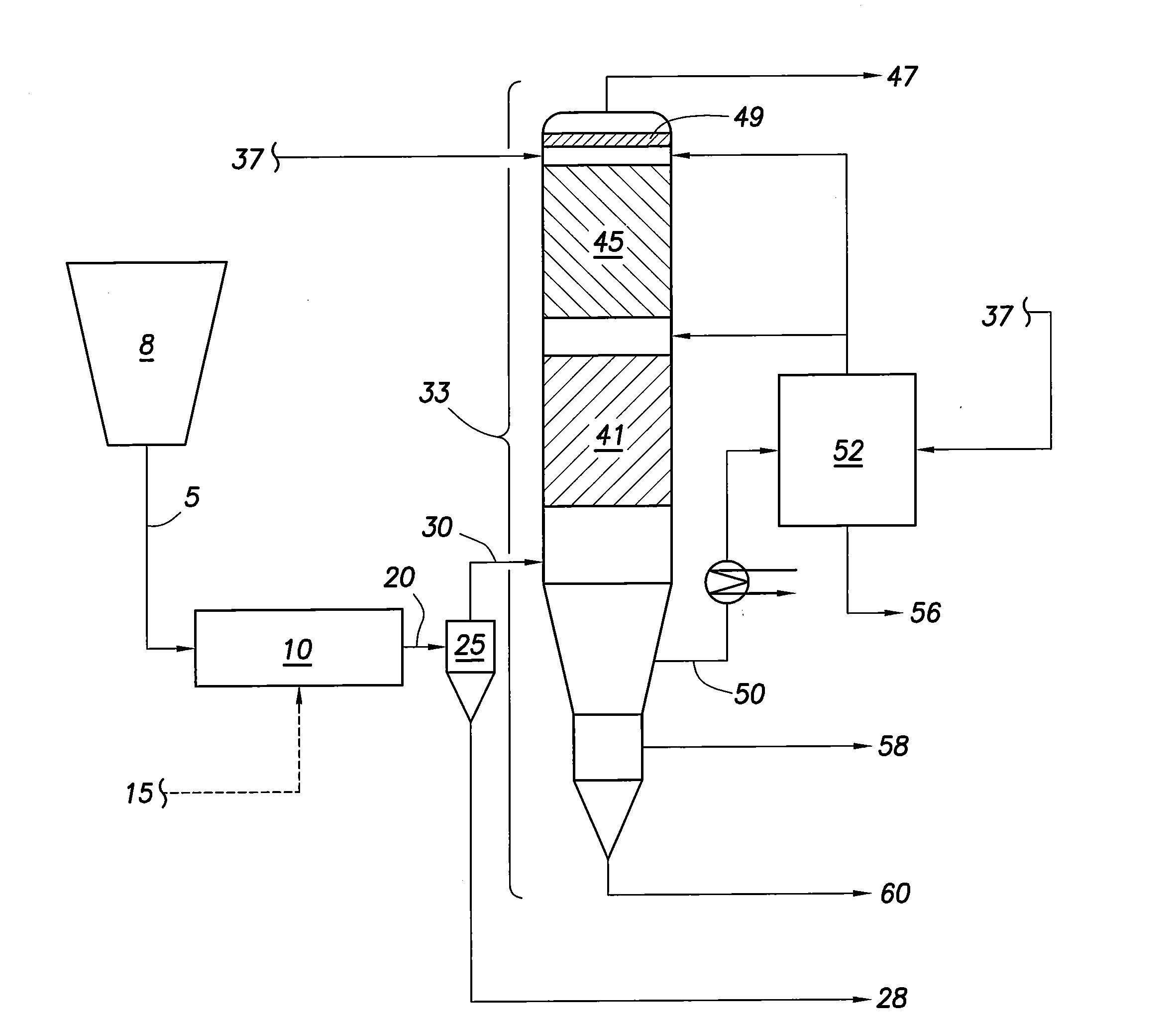

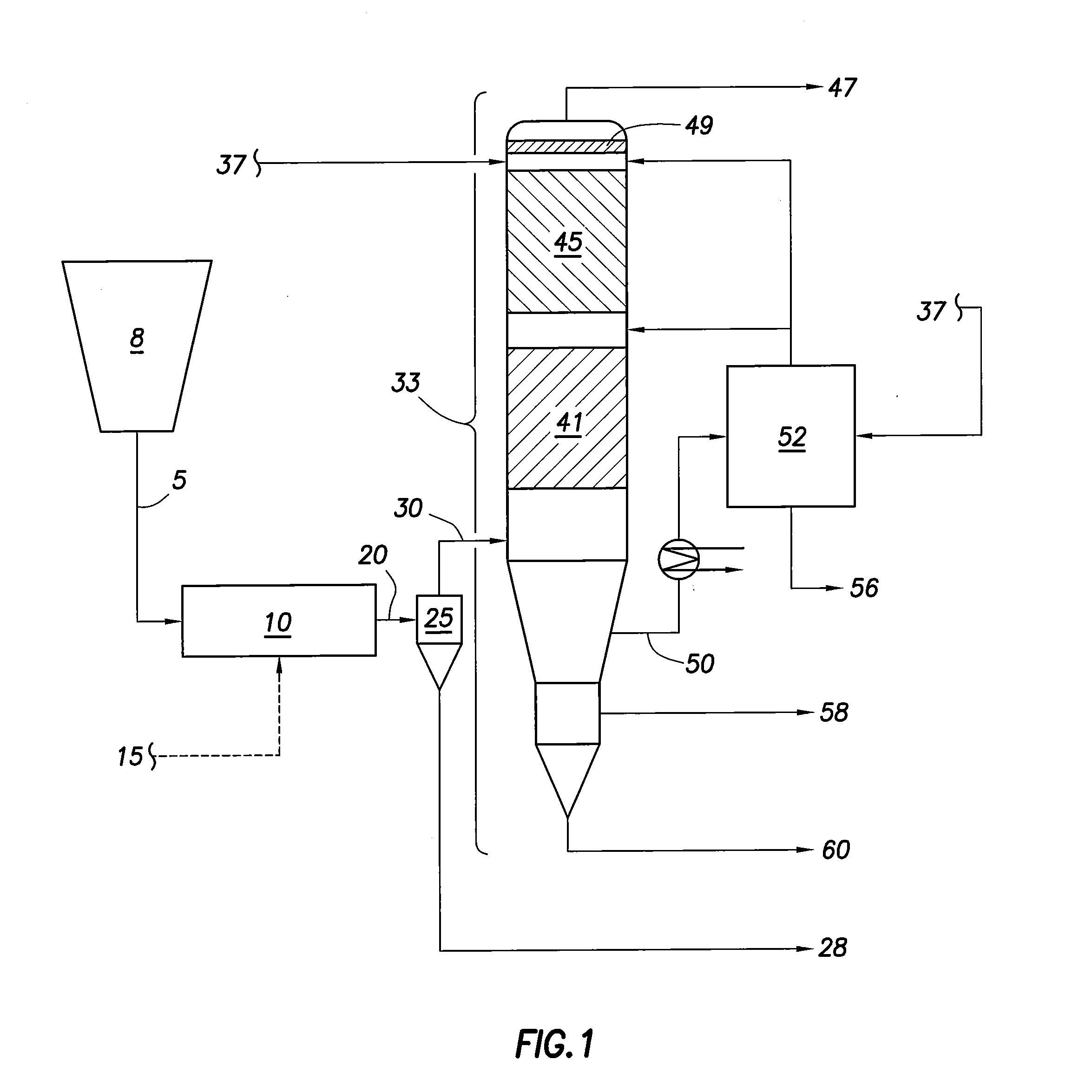

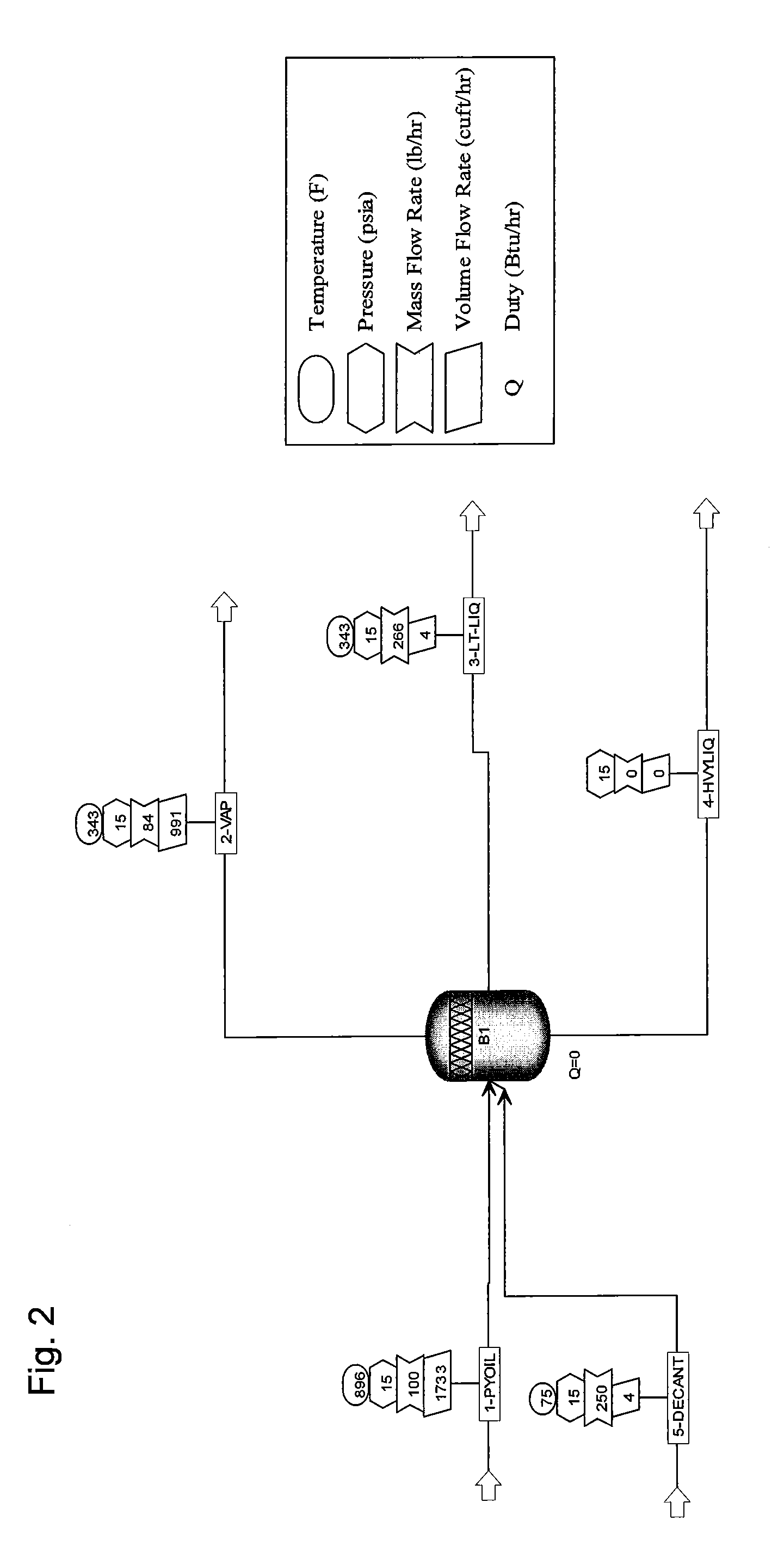

Absorption and quench method for biomass pyrolysis product

ActiveUS20120167452A1High aromatic contentFaster quenching rateGas treatmentOrganic chemistryBoiling pointBiomass

A biomass pyrolysis product is quenched by direct cooling with a cold quench fluid and initial product separation is performed based on boiling point and solubility in the quench fluid. A properly chosen quench fluid may act as a selective solvent, thus providing dilution of unstable precursors of pyrolytic lignin or other heavy by-products, and / or separation of certain undesirable pyrolysis oil components such as water and light acids.

Owner:PHILLIPS 66 CO

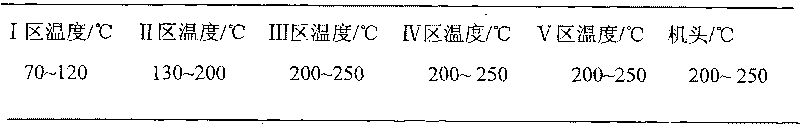

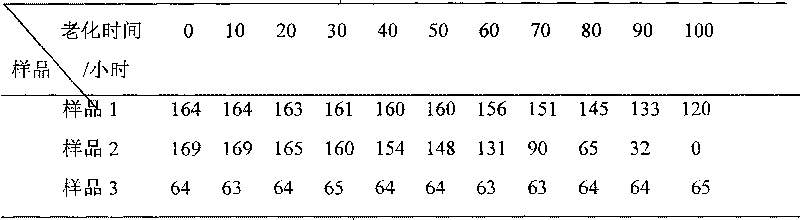

Method for preparing polyester film for photovoltaic cell backplane

InactiveCN101733925AGood aging resistanceHigh fluorine contentFlat articlesSemiconductor devicesChemistryBackplane

The invention relates to a method for preparing a polyester film for a photovoltaic cell backplane, which comprises:1, a process step of synthesizing polyester chips, which is to first add terephthalic acid, glycol and antimony acetate serving as a catalyst into a reaction kettle to perform esterification, then to add triethyl phosphate and antioxidant 1010 which are blended with glycol to perform an reaction and finally to discharge the products of the reaction; 2, a process step of preparing mother particles, which is to crush the polyester chips synthesized by the step 1, dry the crushed polyester chips, add polycarbodiimide, an ultraviolet absorber MV 3638, triethyl phosphate and antioxidant 1010, mix the mixture and extrude the mixture by a double-screw extruder to produce the particles; and 3, a process step of producing a film by biaxial tension, which is to place the polyester chips synthesized by the step 1, the mother particles prepared by the step 2 and SiO2 3,000+ / -100ppm PET polyester chips into the double-screw extruder for blending the mixture, melt and extrude the mixture in the double-screw extruder, casting a piece by a casting piece machine and prepare the film by biaxial tension. The method of the invention can change an active terminal carboxyl group into a stable group, so the polyester film has high aging resistance.

Owner:申达集团有限公司 +1

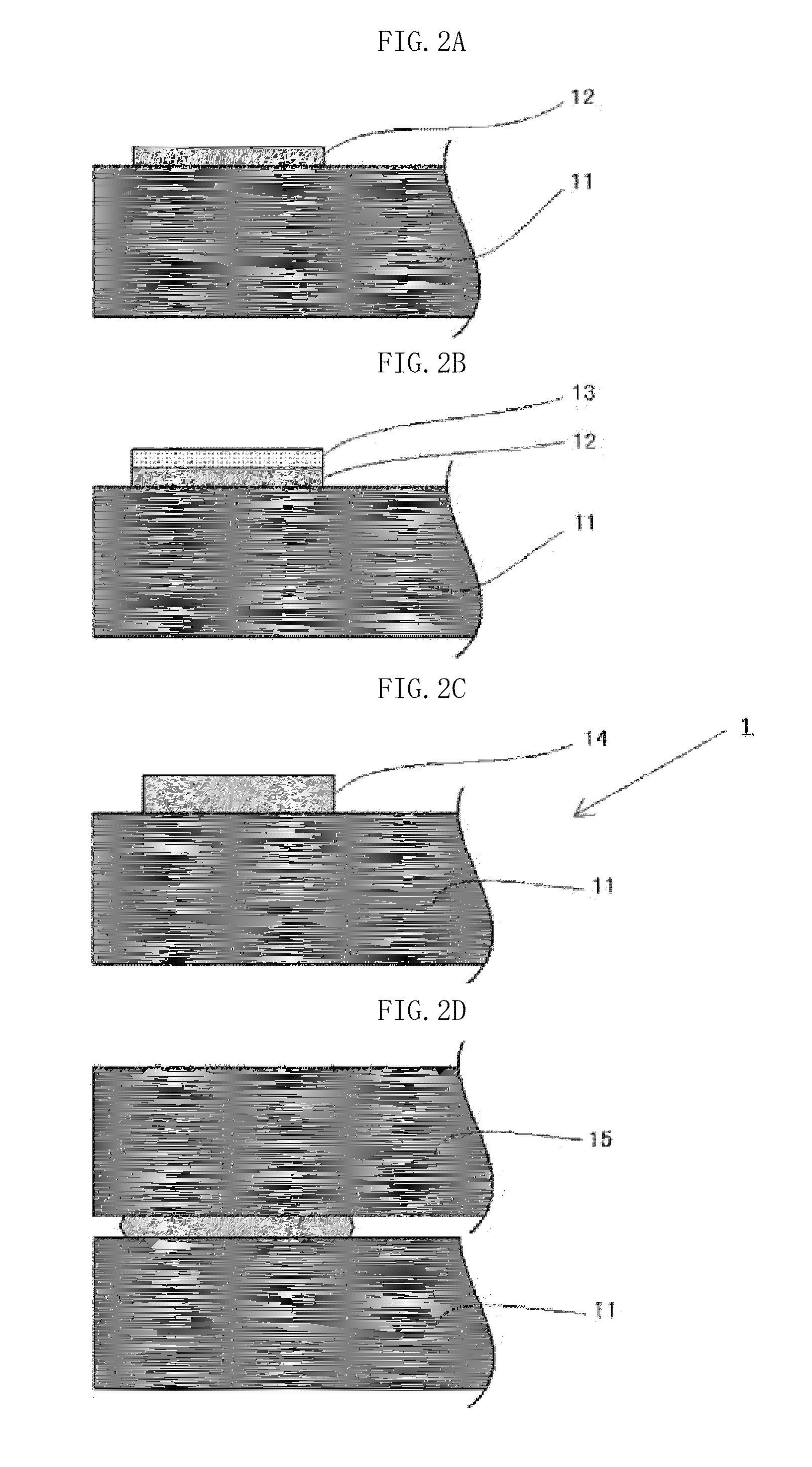

Glass substrate with sealing material layer, organic el device using same, and manufacturing method for electronic device

ActiveUS20140196502A1Reduce contentPrevent thermal degradationElectrical apparatusElectroluminescent light sourcesMetallurgySurface roughness

Provided is a glass substrate with a sealing material layer, including a sealing material layer formed by sintering a sealing material, in which: the sealing material includes at least inorganic powder; the inorganic powder includes glass powder and a refractory filler; the content of refractory filler in the inorganic powder is 10 to 35 vol %; and the sealing material layer has a surface roughness Ra of less than 0.5 μm.

Owner:NIPPON ELECTRIC GLASS CO LTD

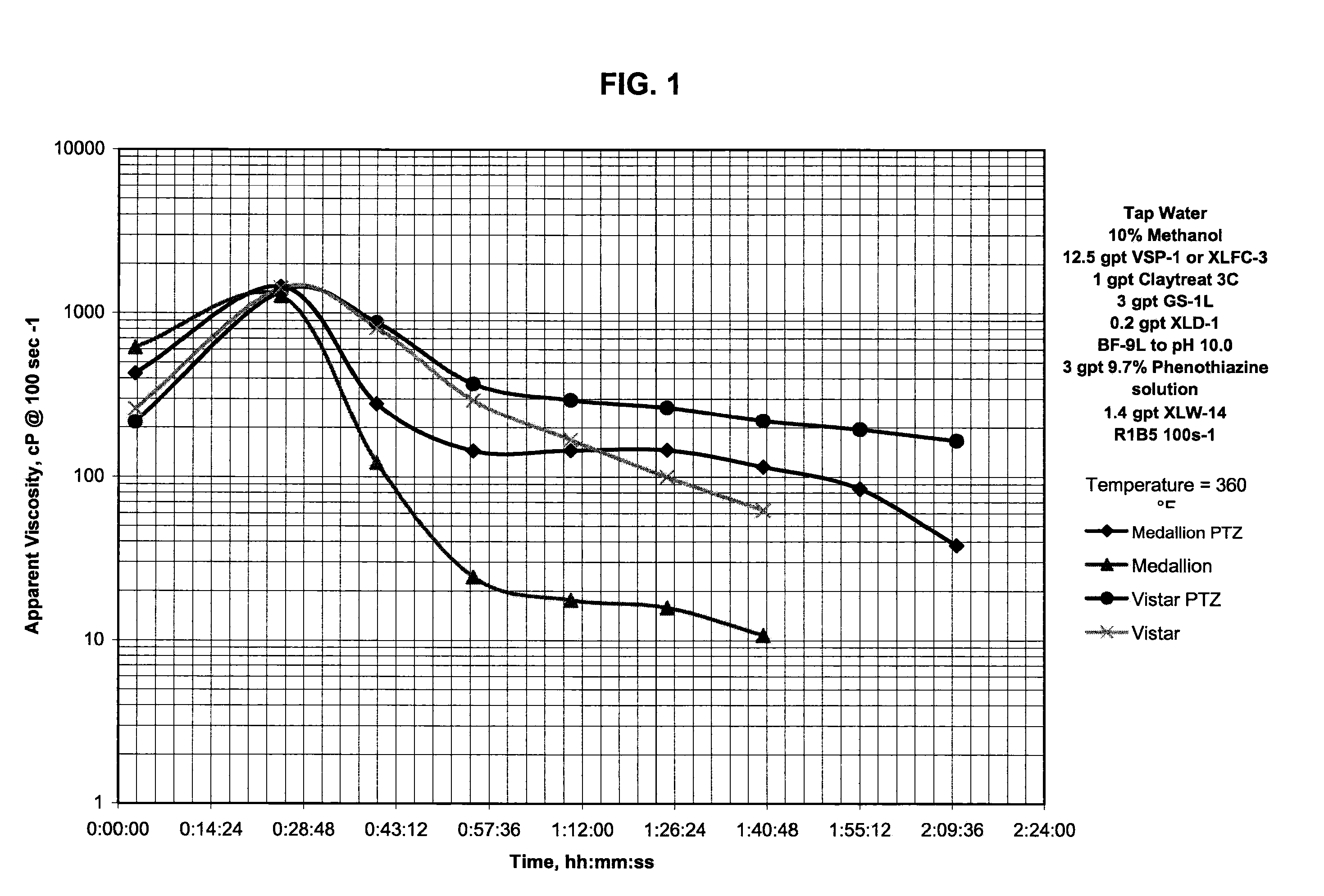

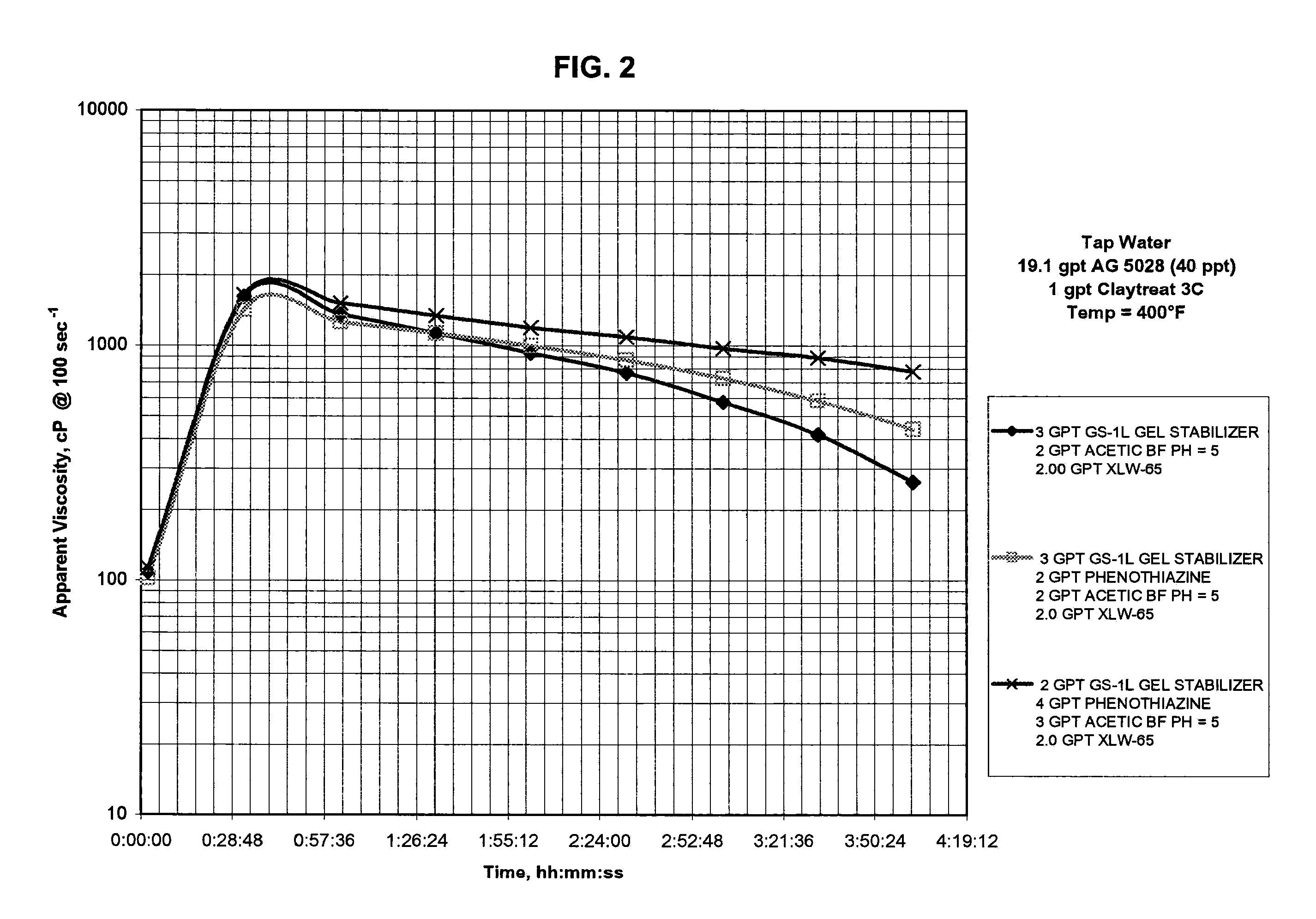

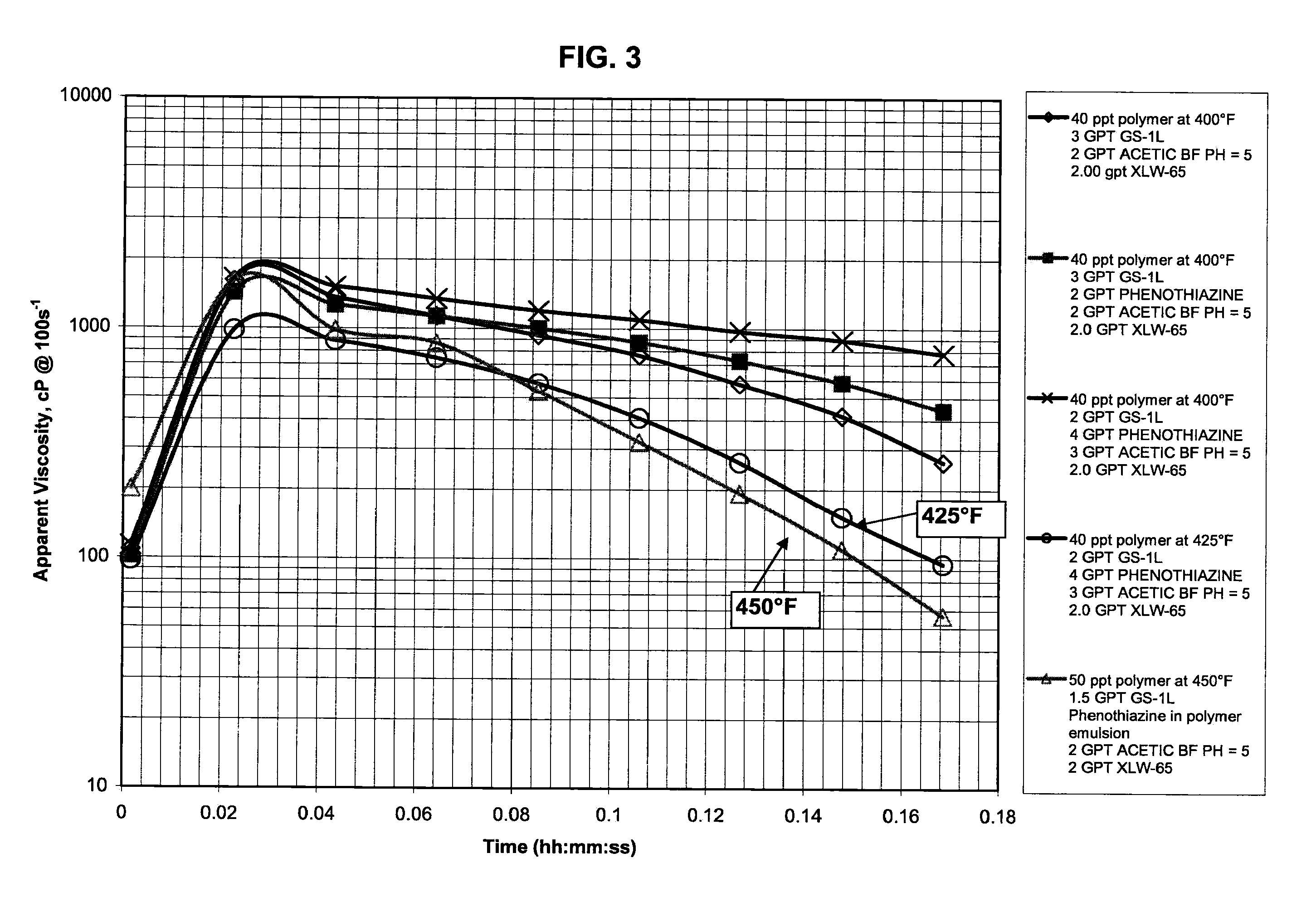

High temperature stabilizer for well treatment fluids and methods of using same

A high temperature well treatment fluid comprising an electron donating compound comprising phenothiazine as thermal decomposition reduction additives for gels used in well treatment fluids is provided. The electron donating compound comprising phenothiazine performs as a stabilizer in well treatment fluids at temperatures of up to about 500° F. (260° C.). Methods of treating wells having subterranean formation temperatures of up to about 500° F. (260 ° C.) using such high temperature well treatment fluids are provided.

Owner:BAKER HUGHES INC

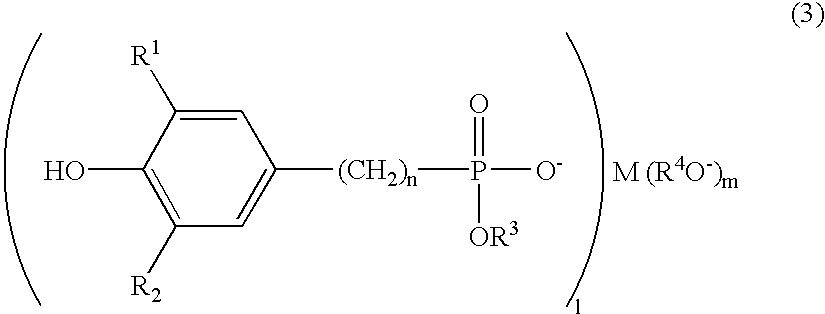

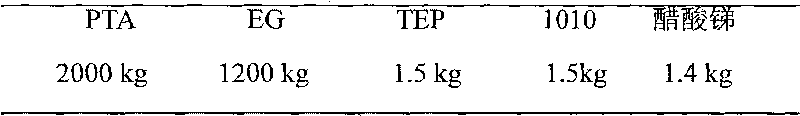

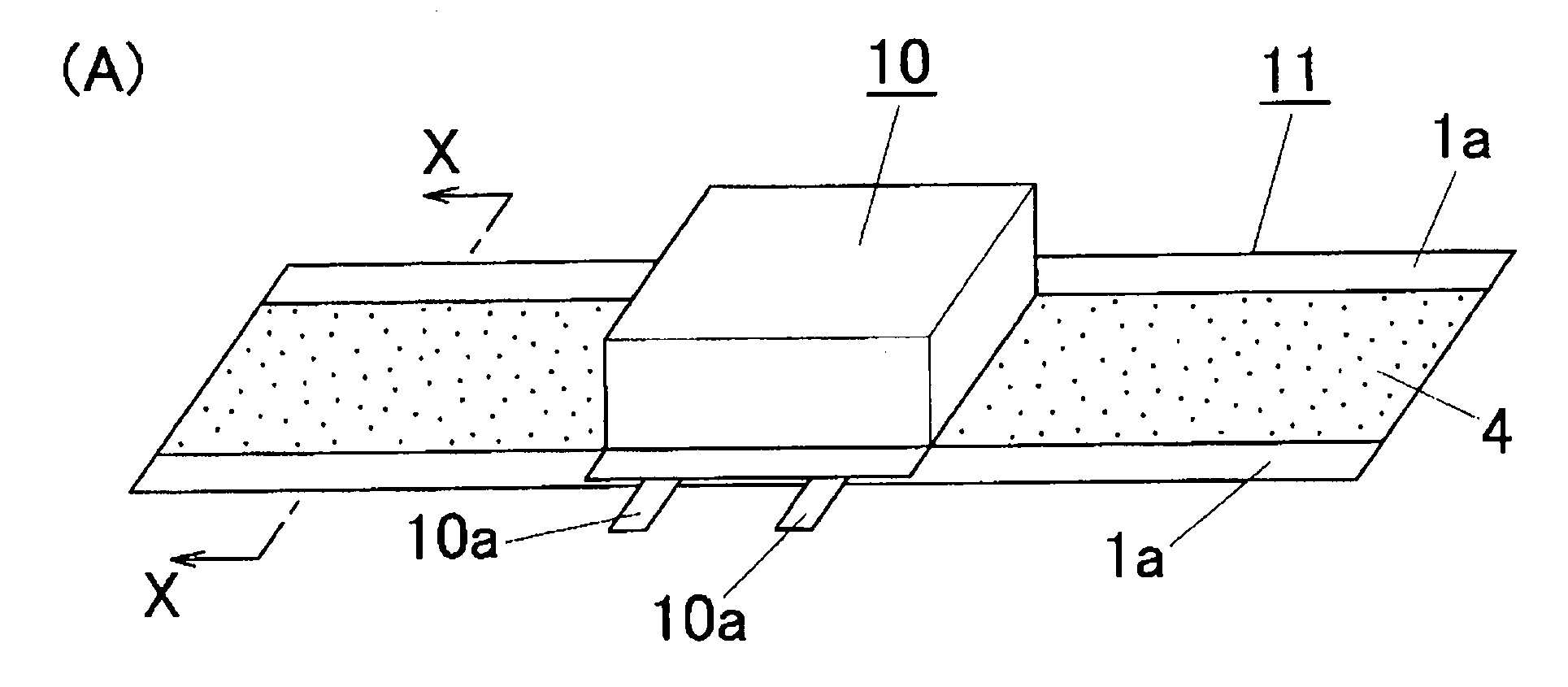

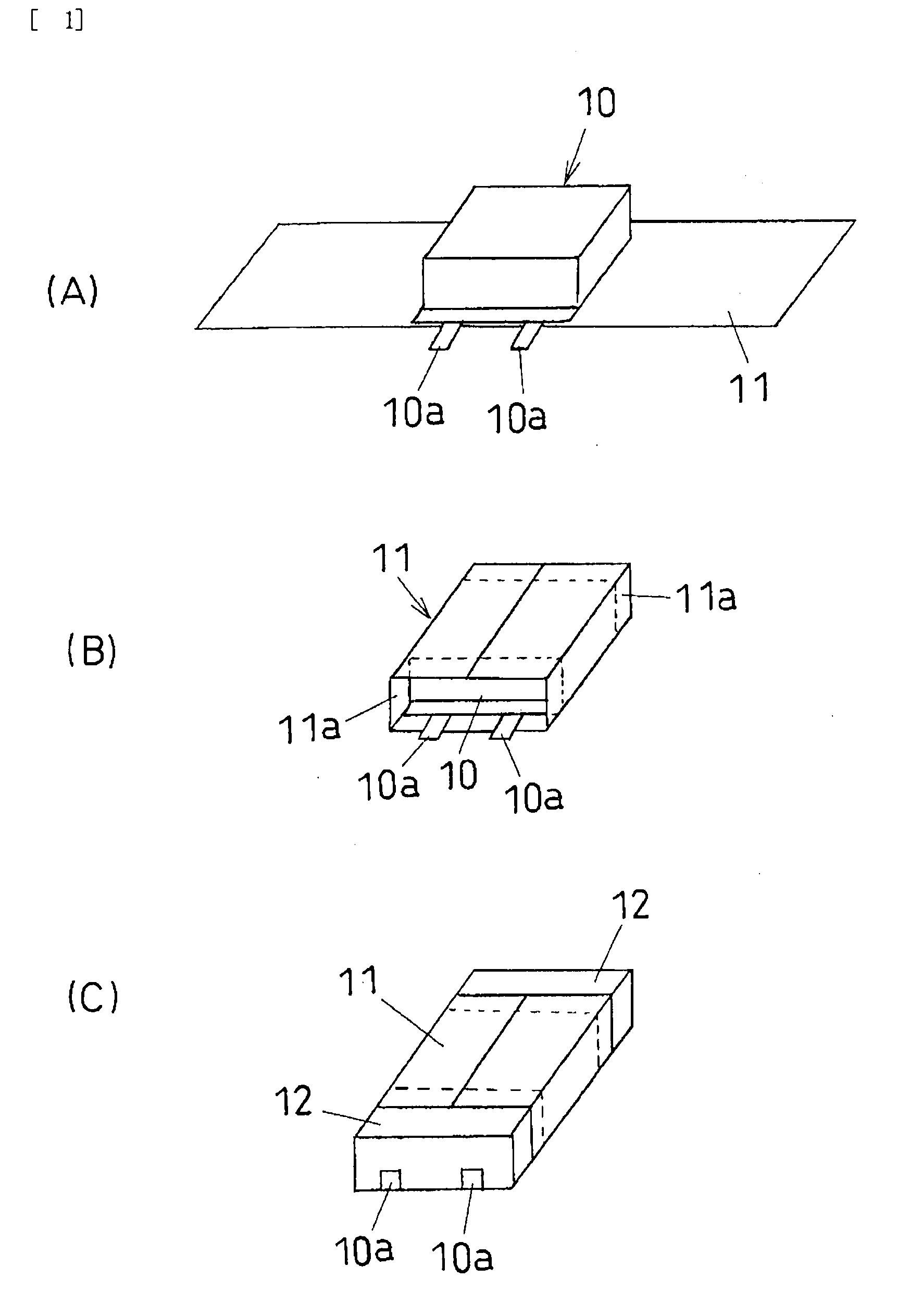

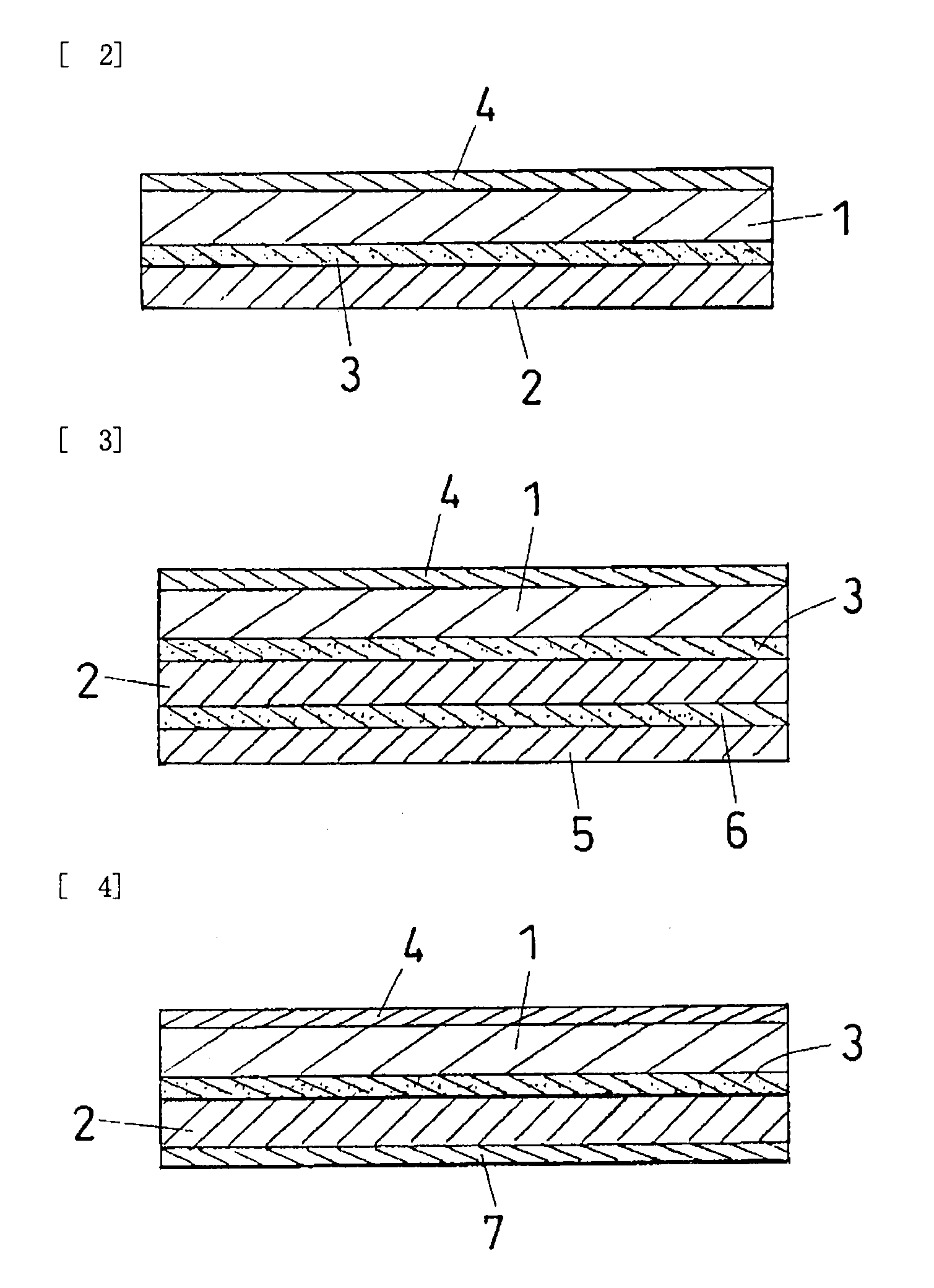

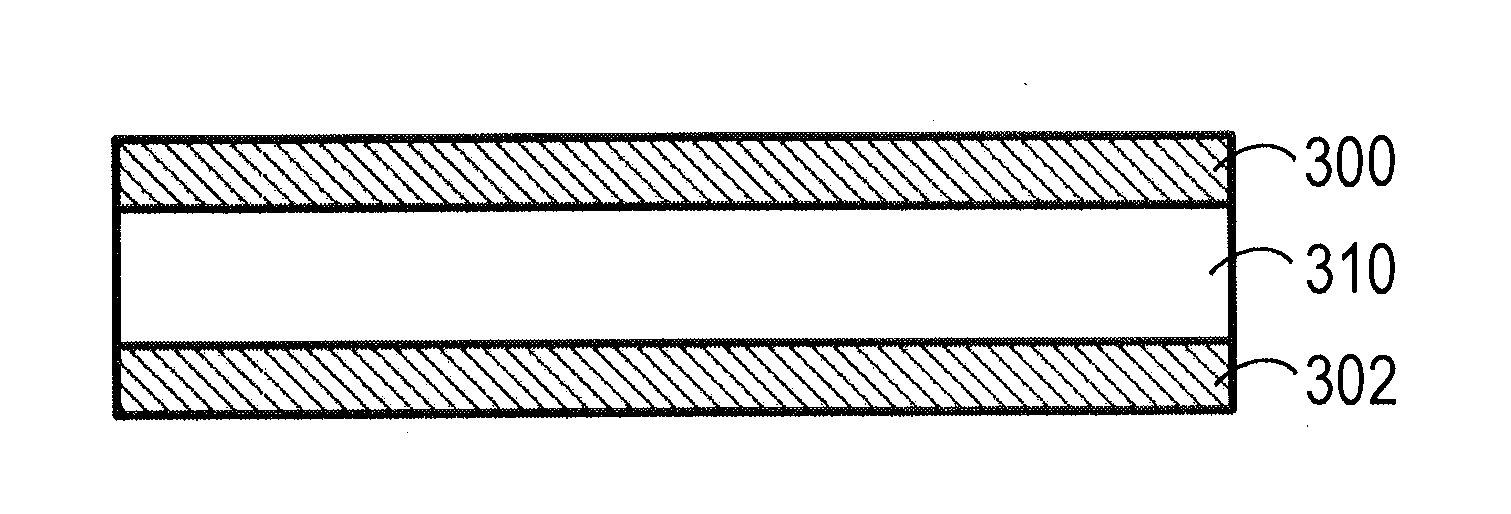

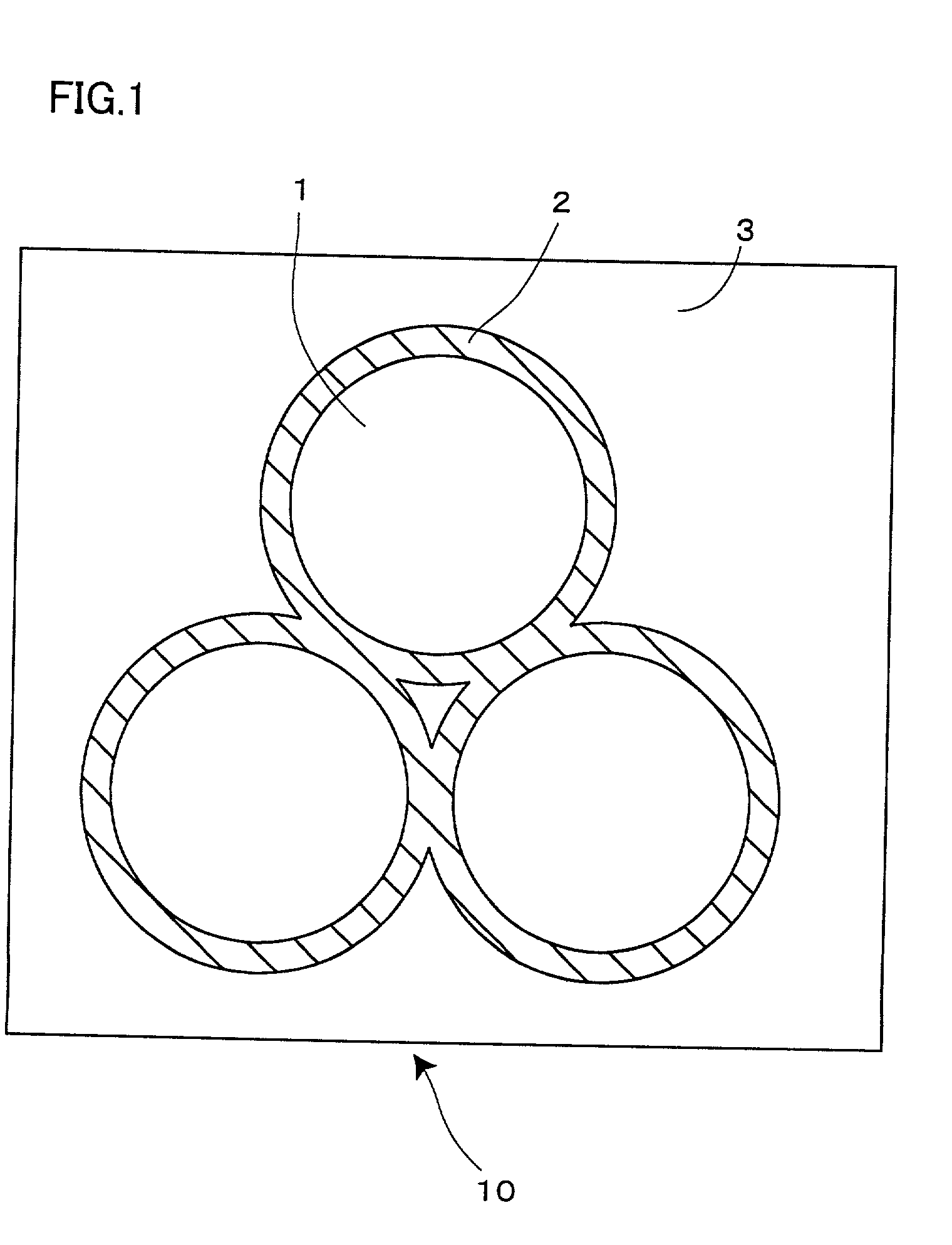

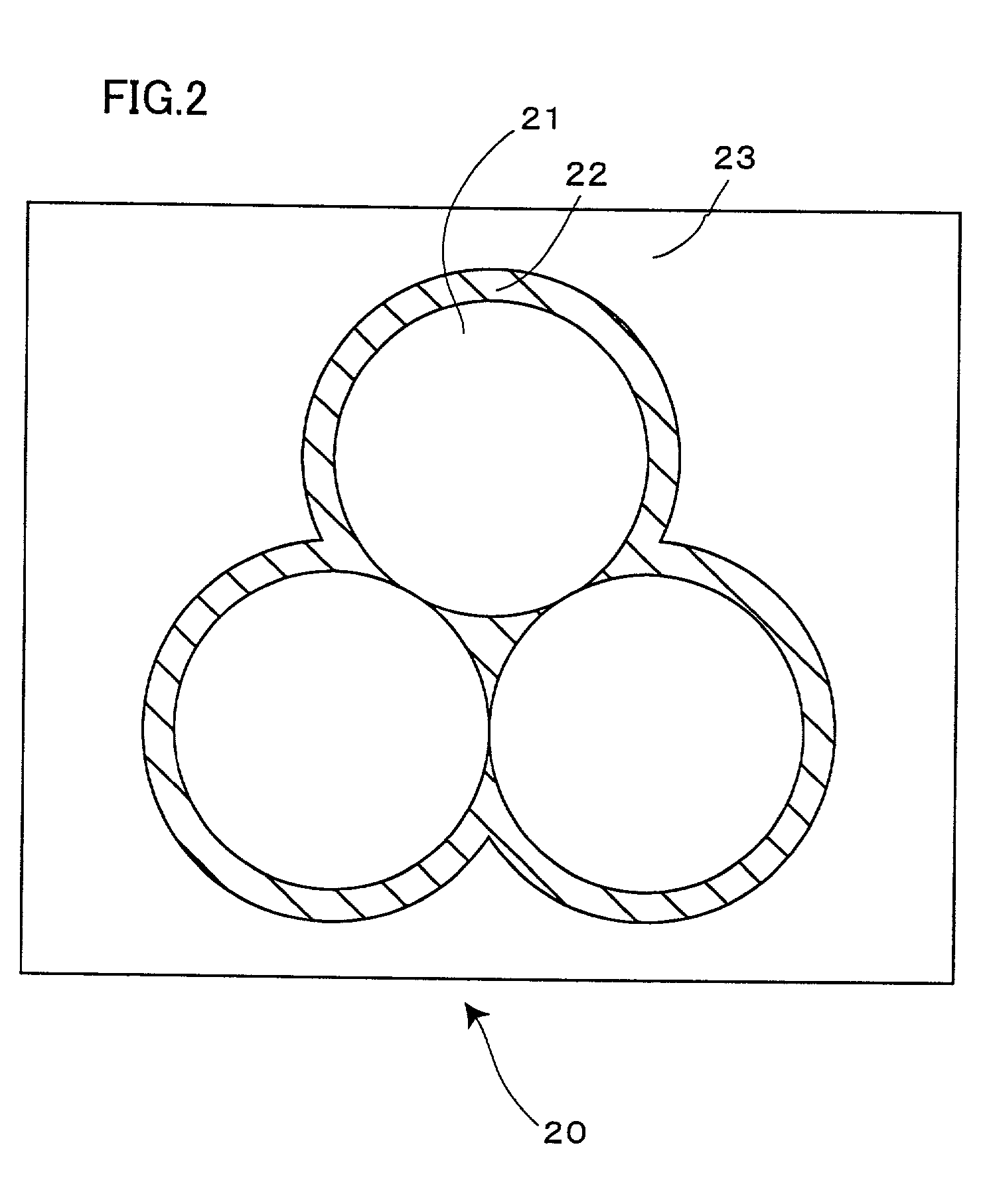

Laminate packing material for battery and laminate battery

ActiveUS20100040942A1Reduce in quantitySimplification of battery production lineSynthetic resin layered productsJackets/cases materialsMetallic foilThermal adhesive

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

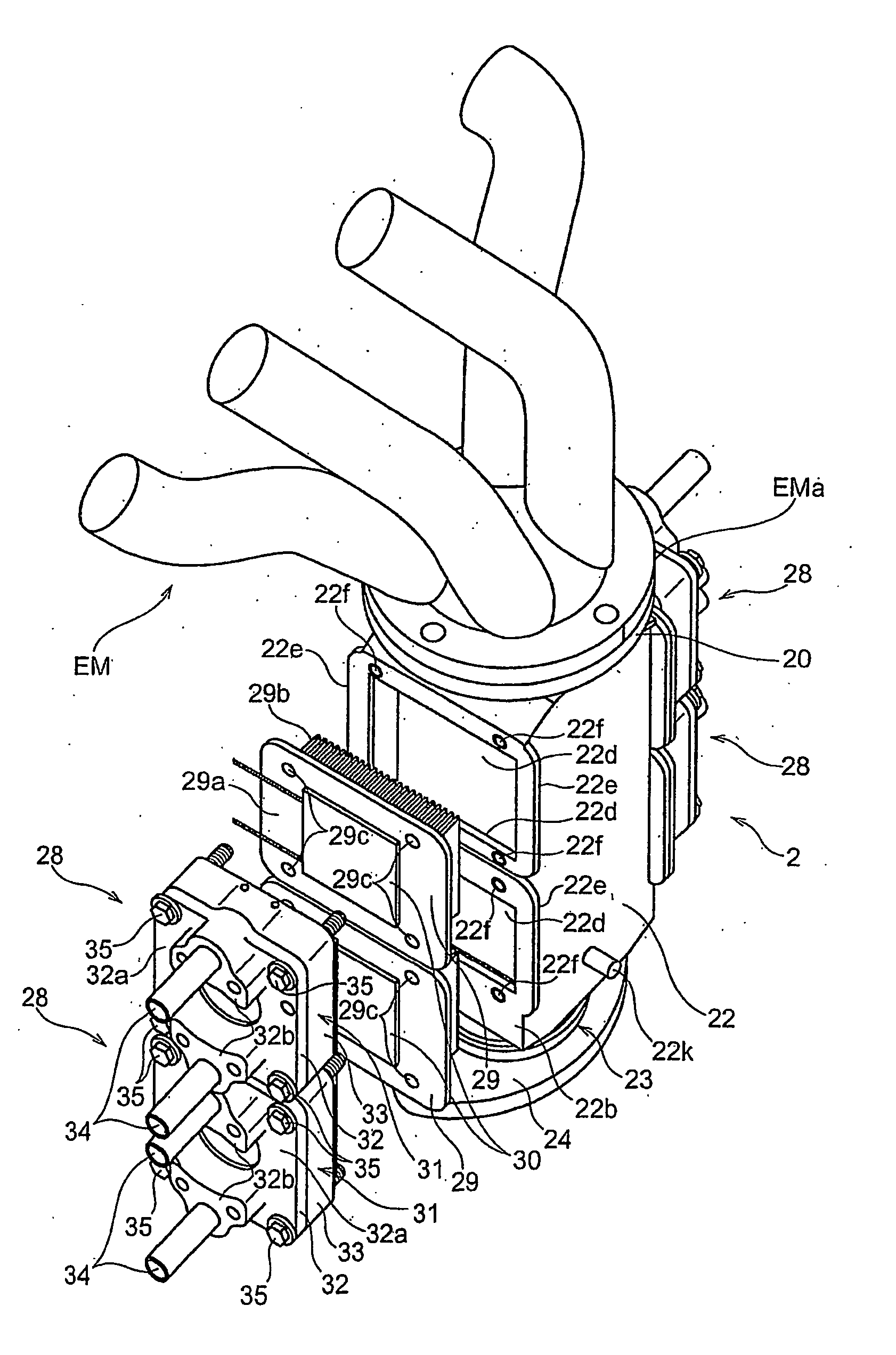

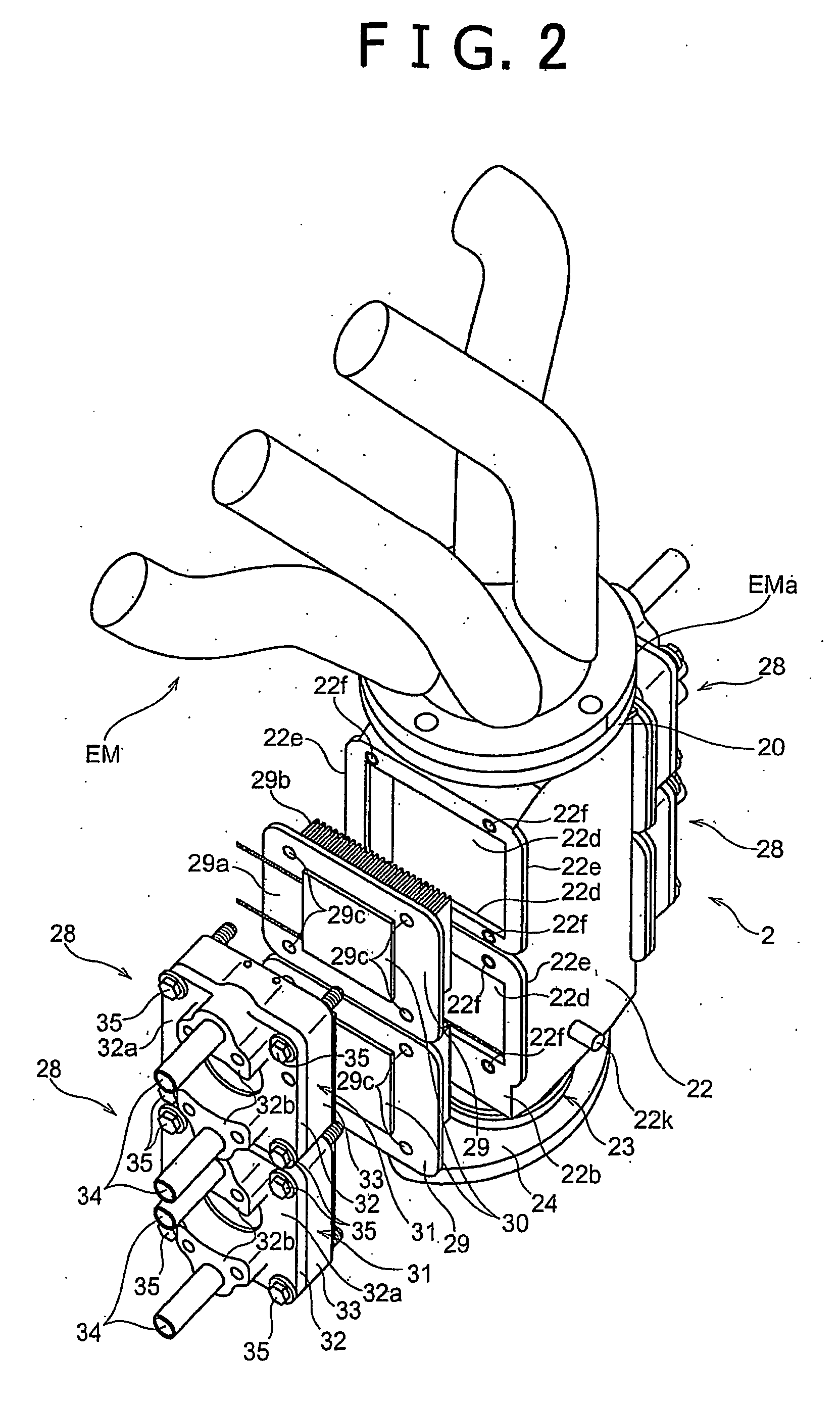

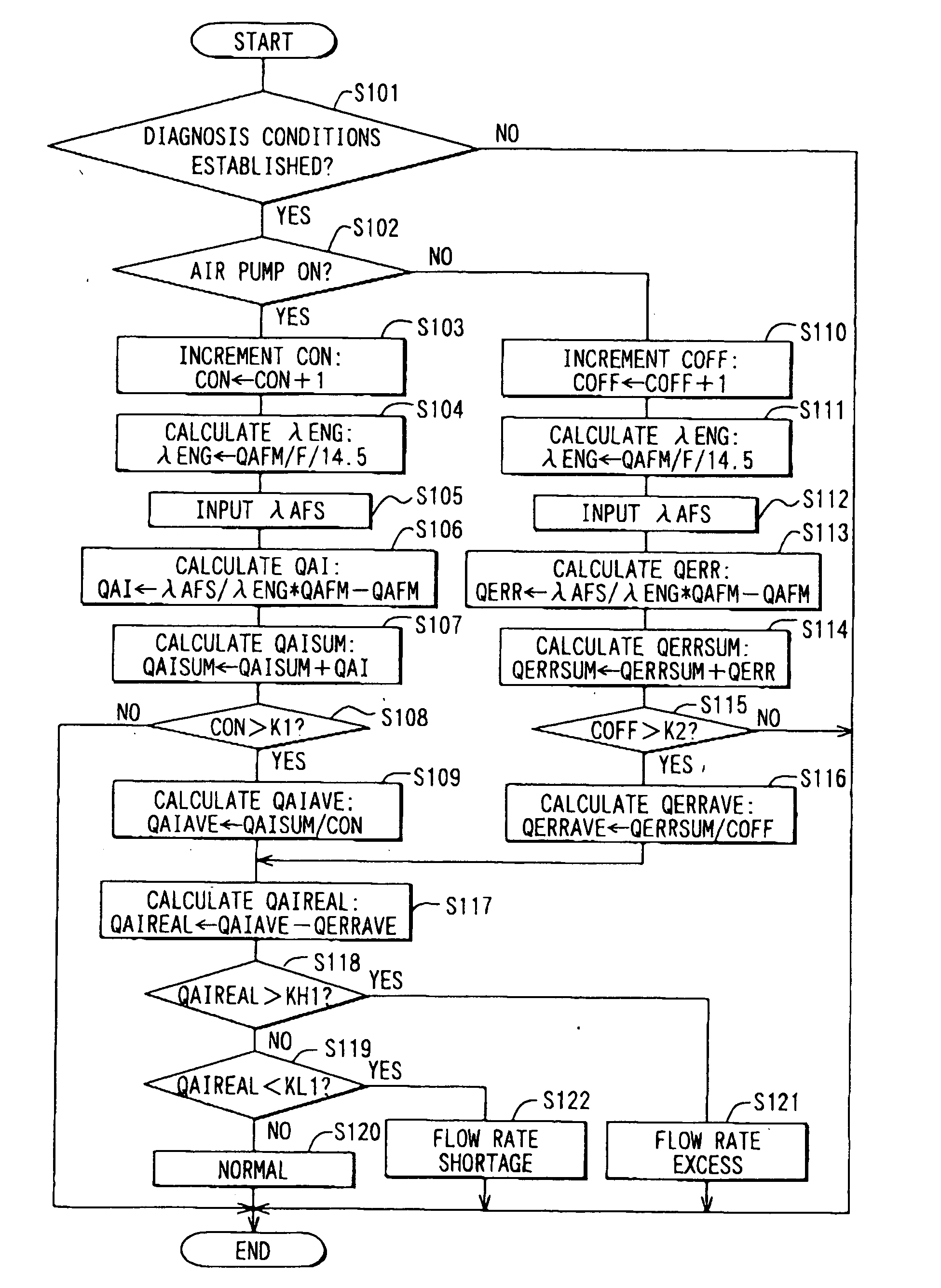

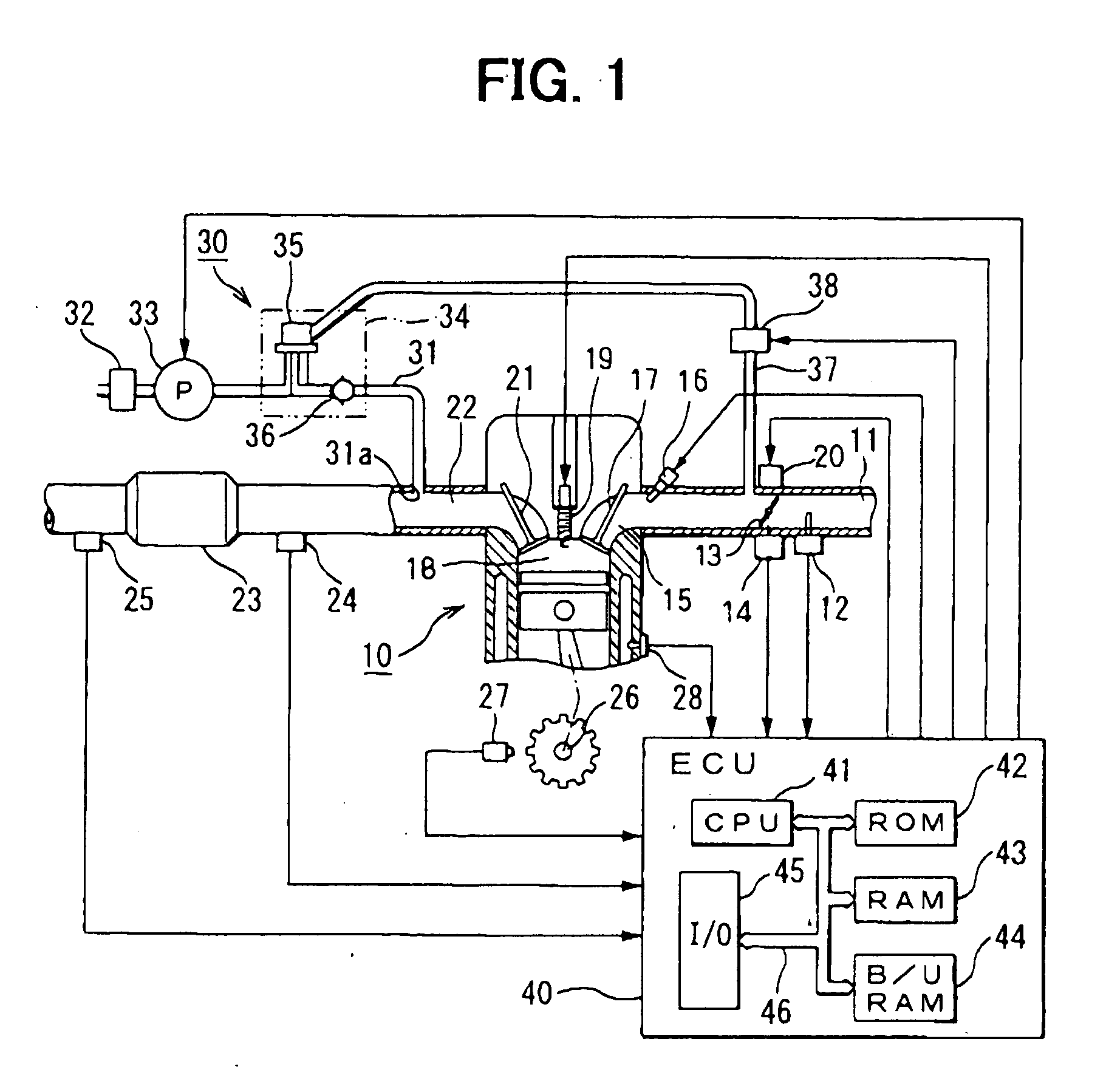

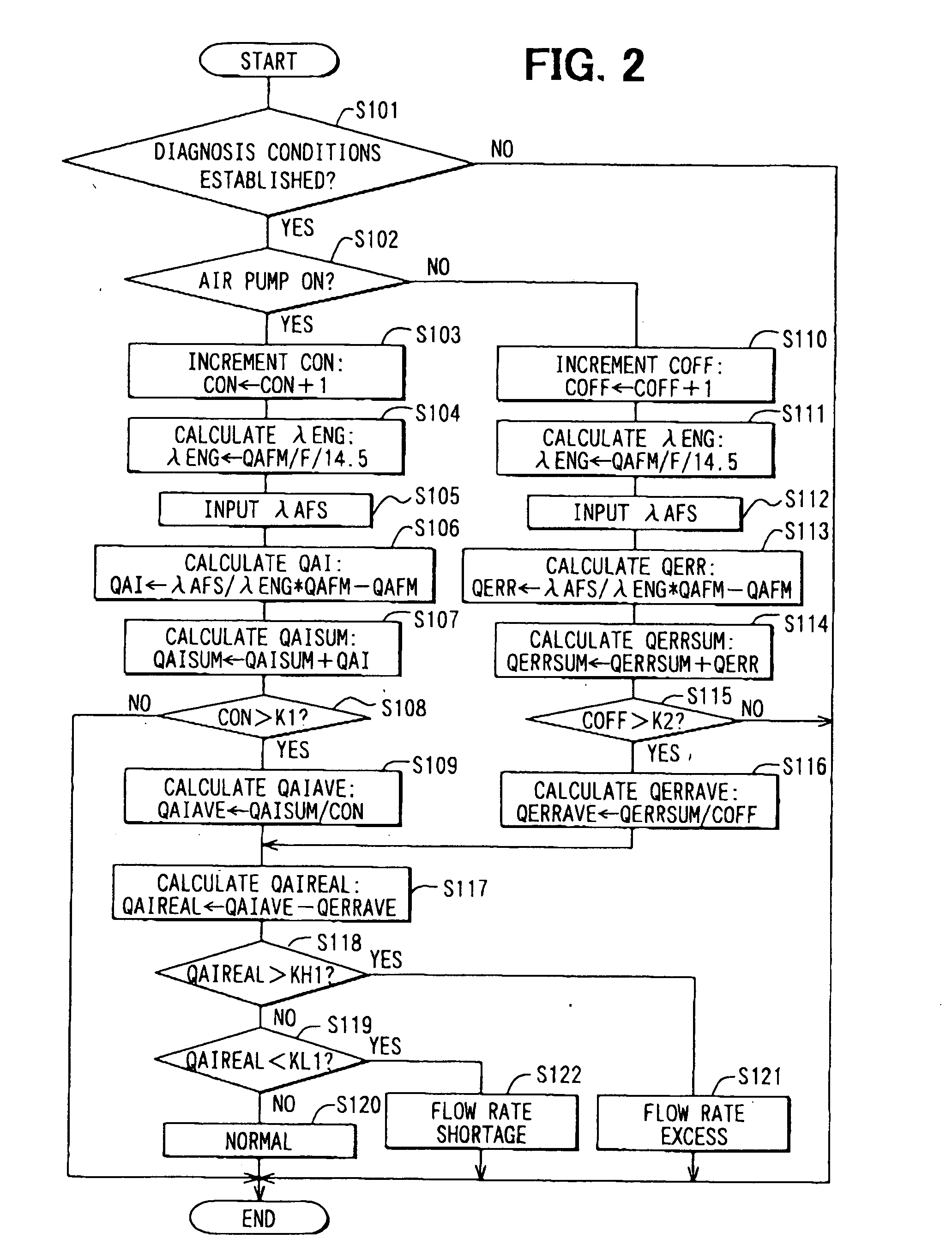

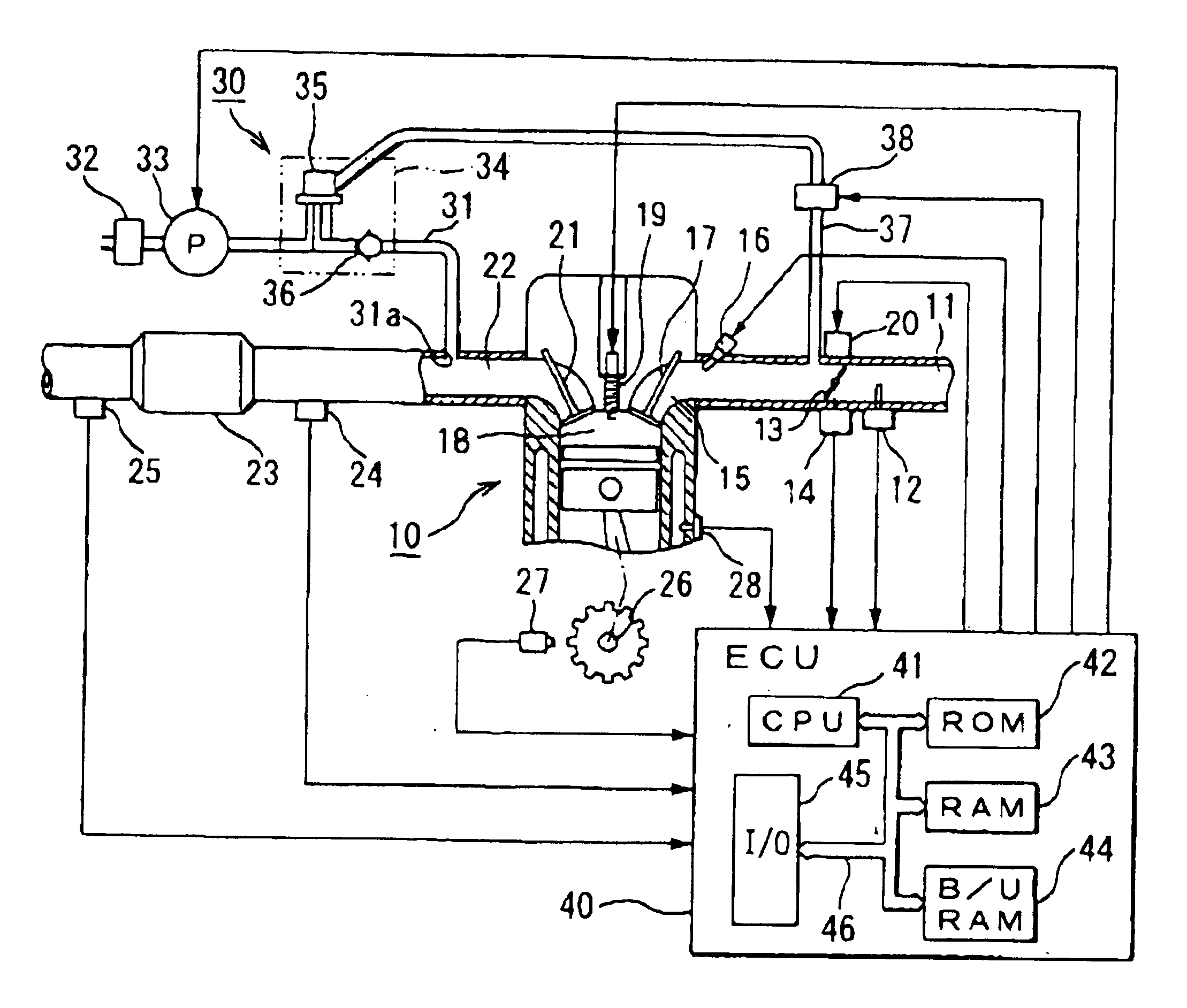

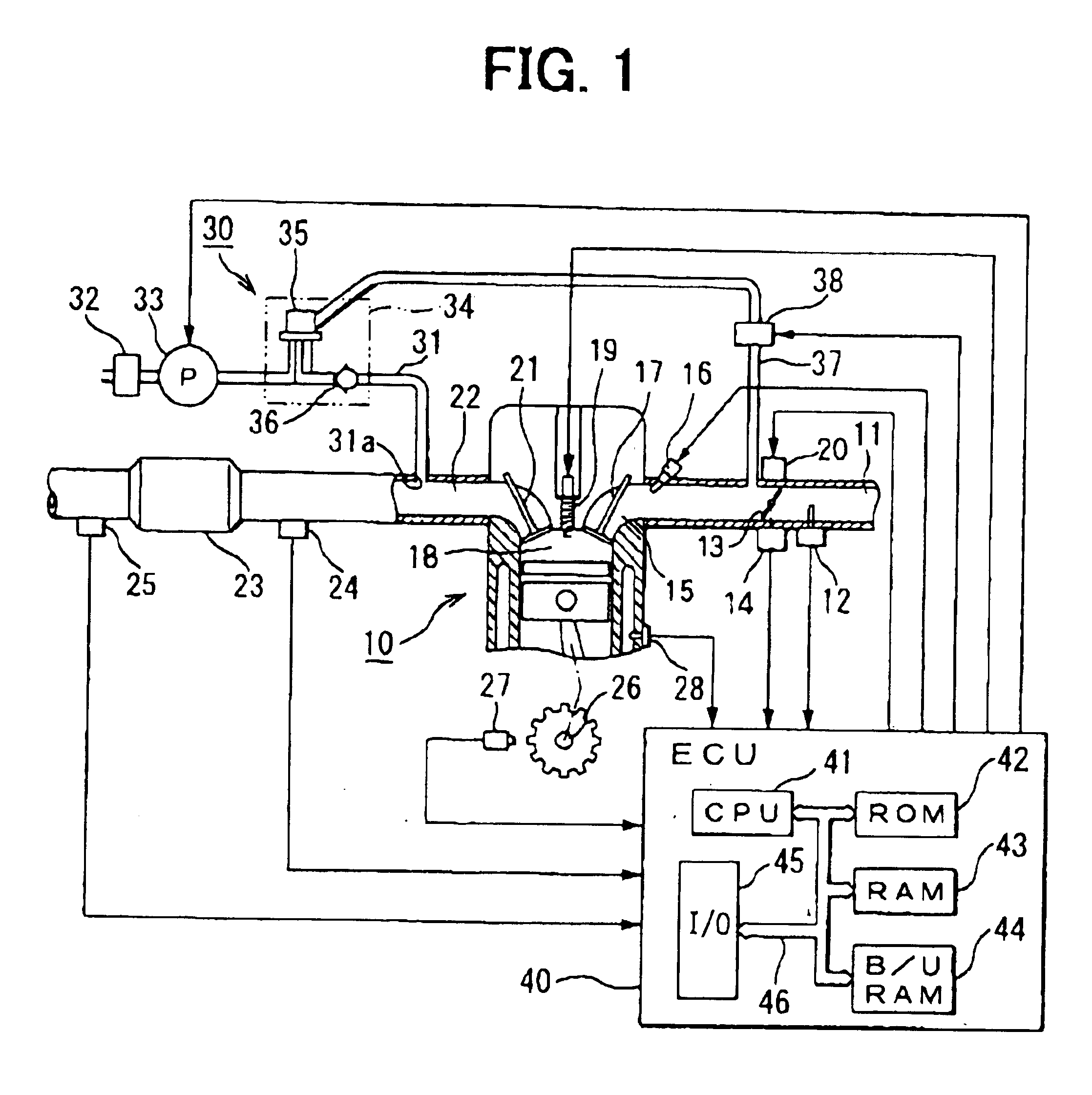

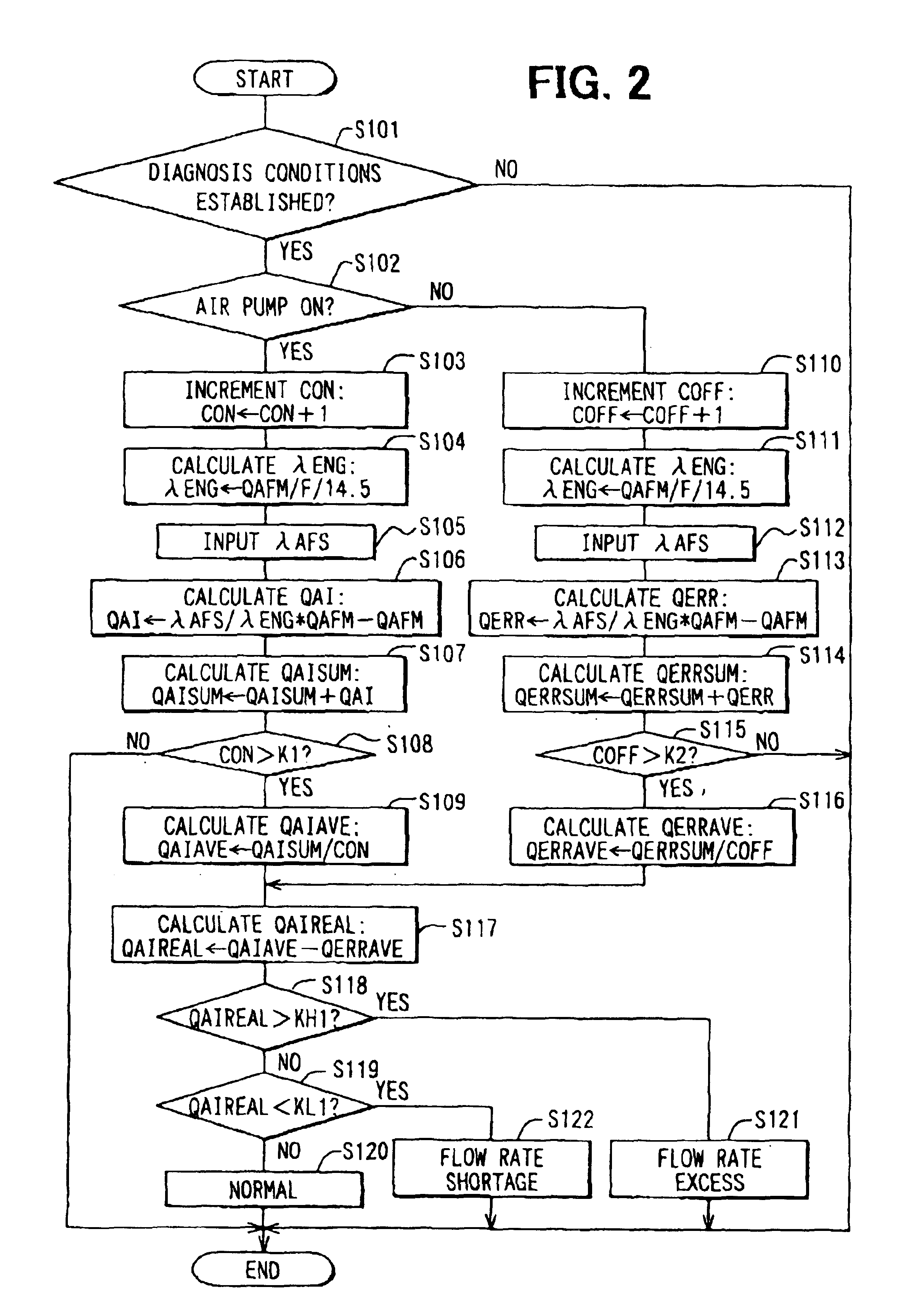

Secondary air supply abnormality detection system

InactiveUS20040148926A1Prevent thermal degradationAccurate calculationElectrical controlInternal combustion piston enginesAnomaly detectionAir pump

A secondary air supply abnormality detection system determines that an abnormality is generated in a system including a secondary air supply system if a true secondary air flow rate is out of a predetermined range. The true secondary air flow rate is calculated by subtracting a secondary air flow rate average at the time when an air pump is not operating from another secondary air flow rate average at the time when the air pump is operating. Thus, variation in the secondary air flow rate due to change with time or production tolerance can be suitably corrected. Since calculation accuracy of the true secondary air flow rate is improved, determination accuracy of the abnormality in the system including the secondary air supply system can be improved.

Owner:DENSO CORP

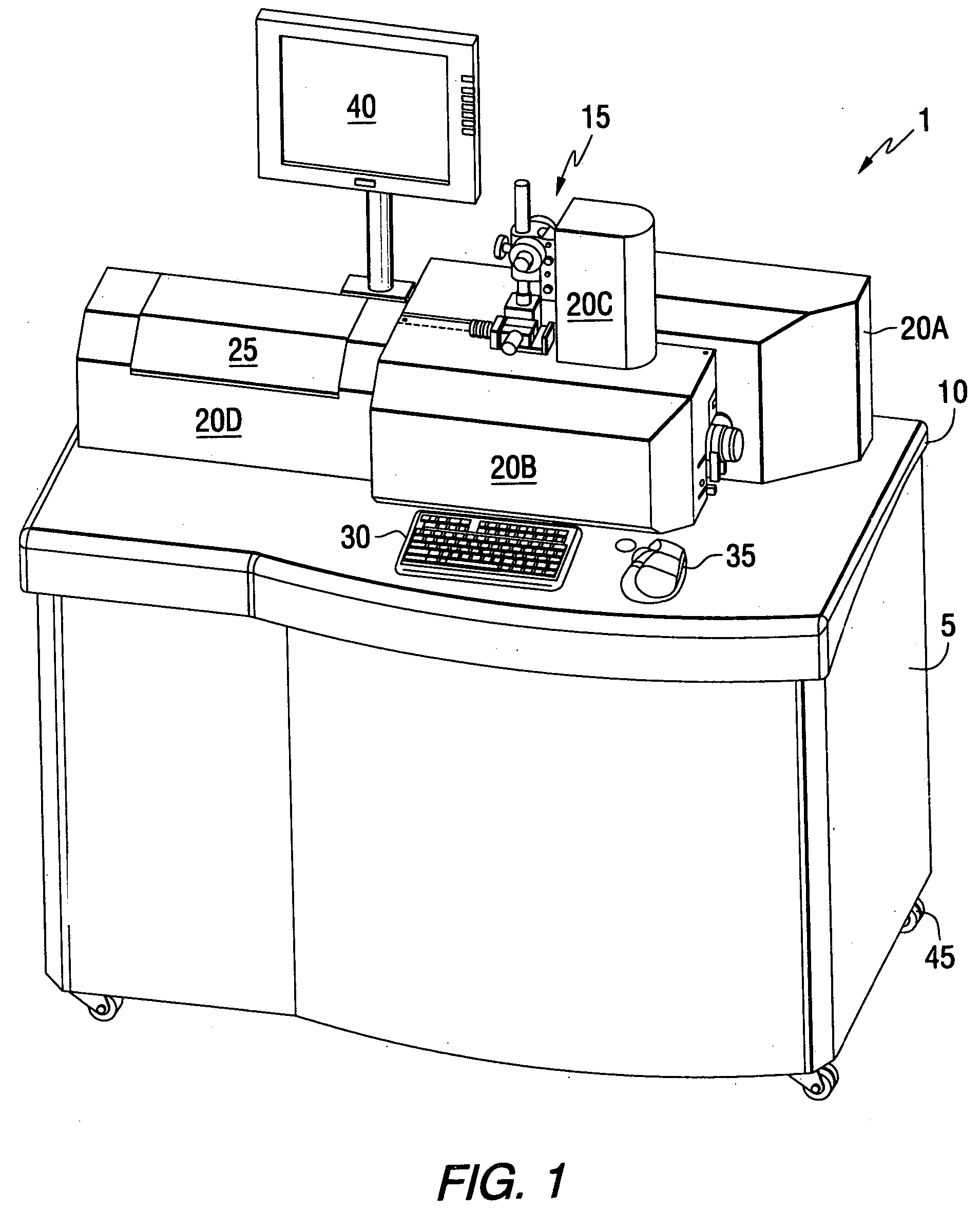

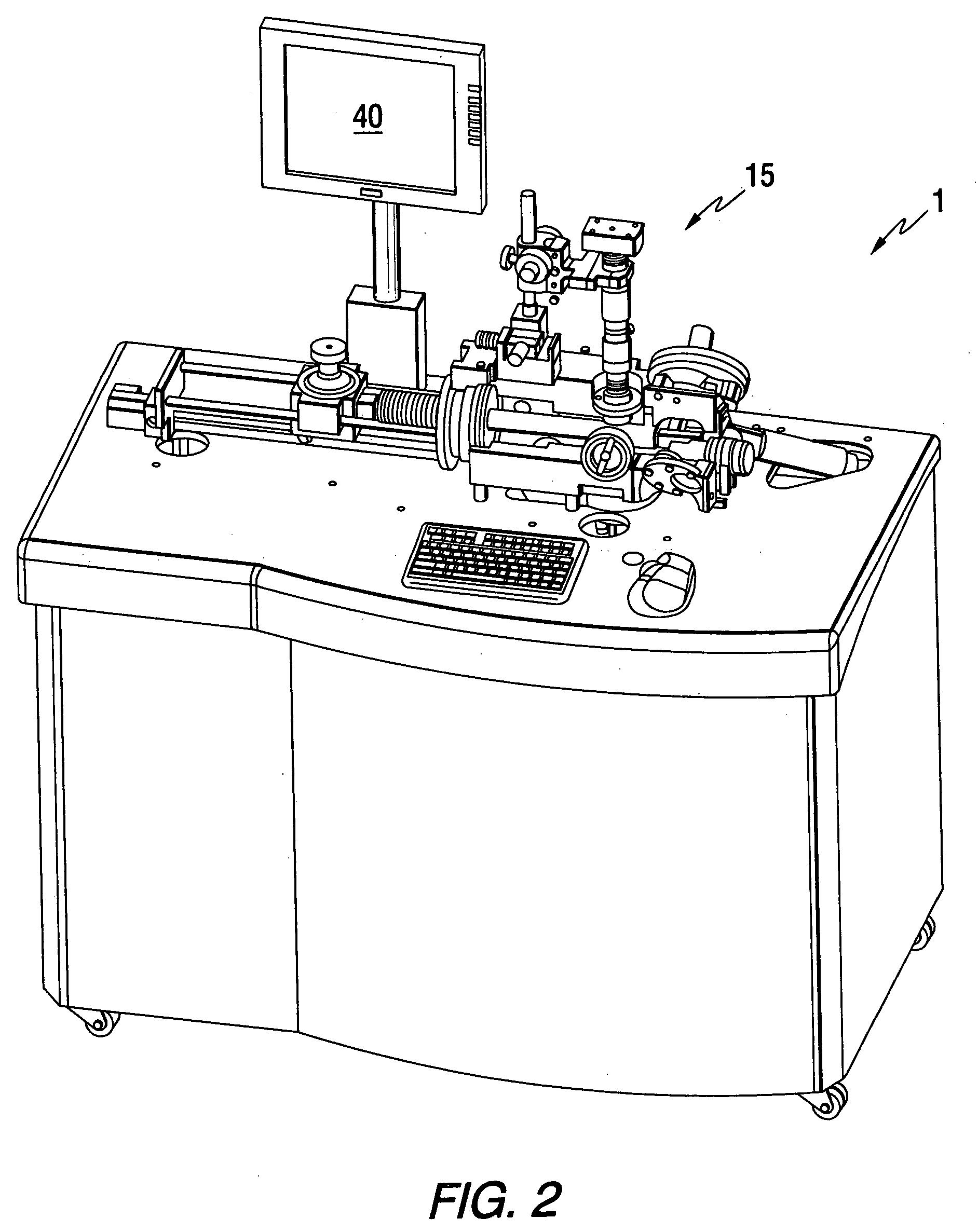

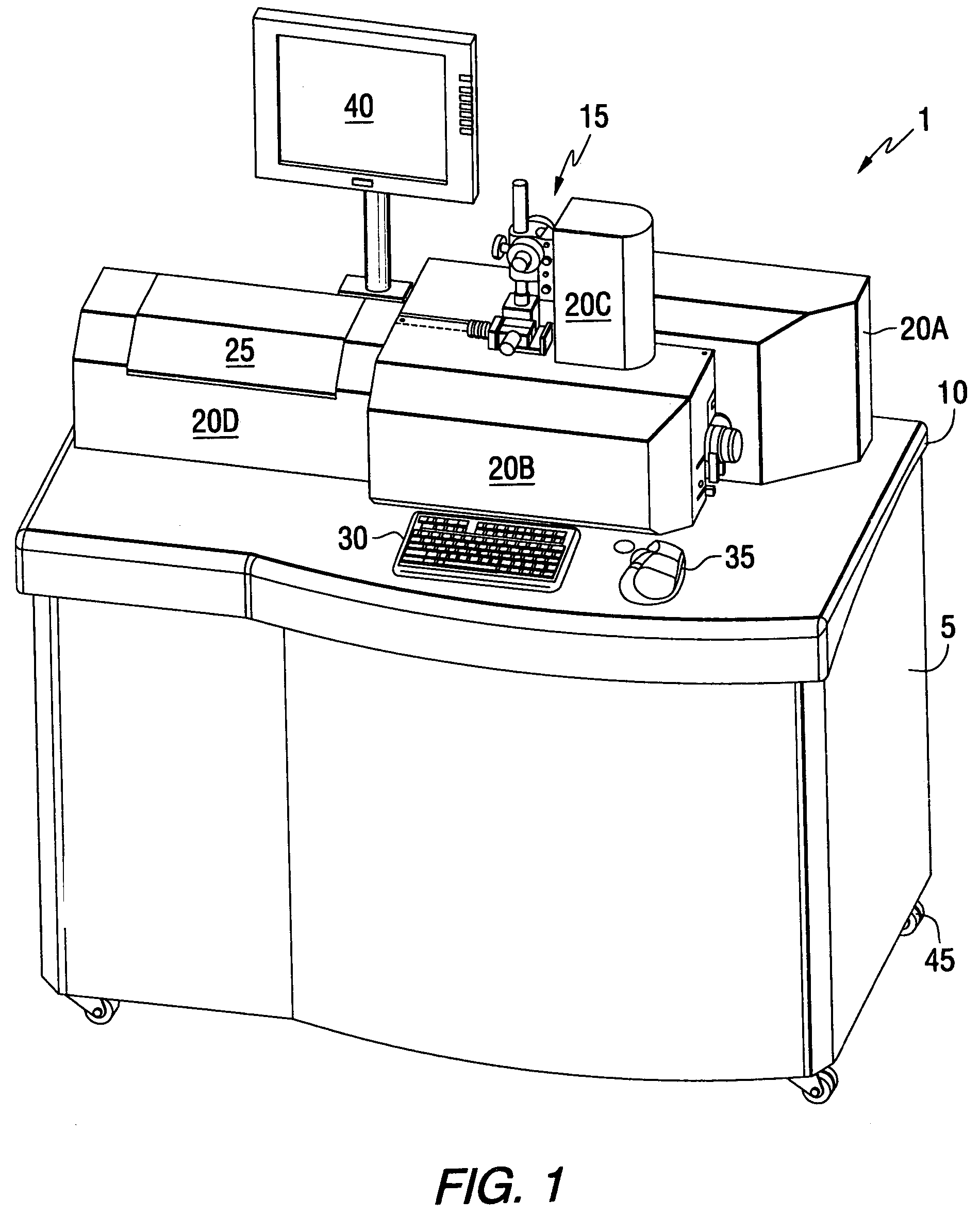

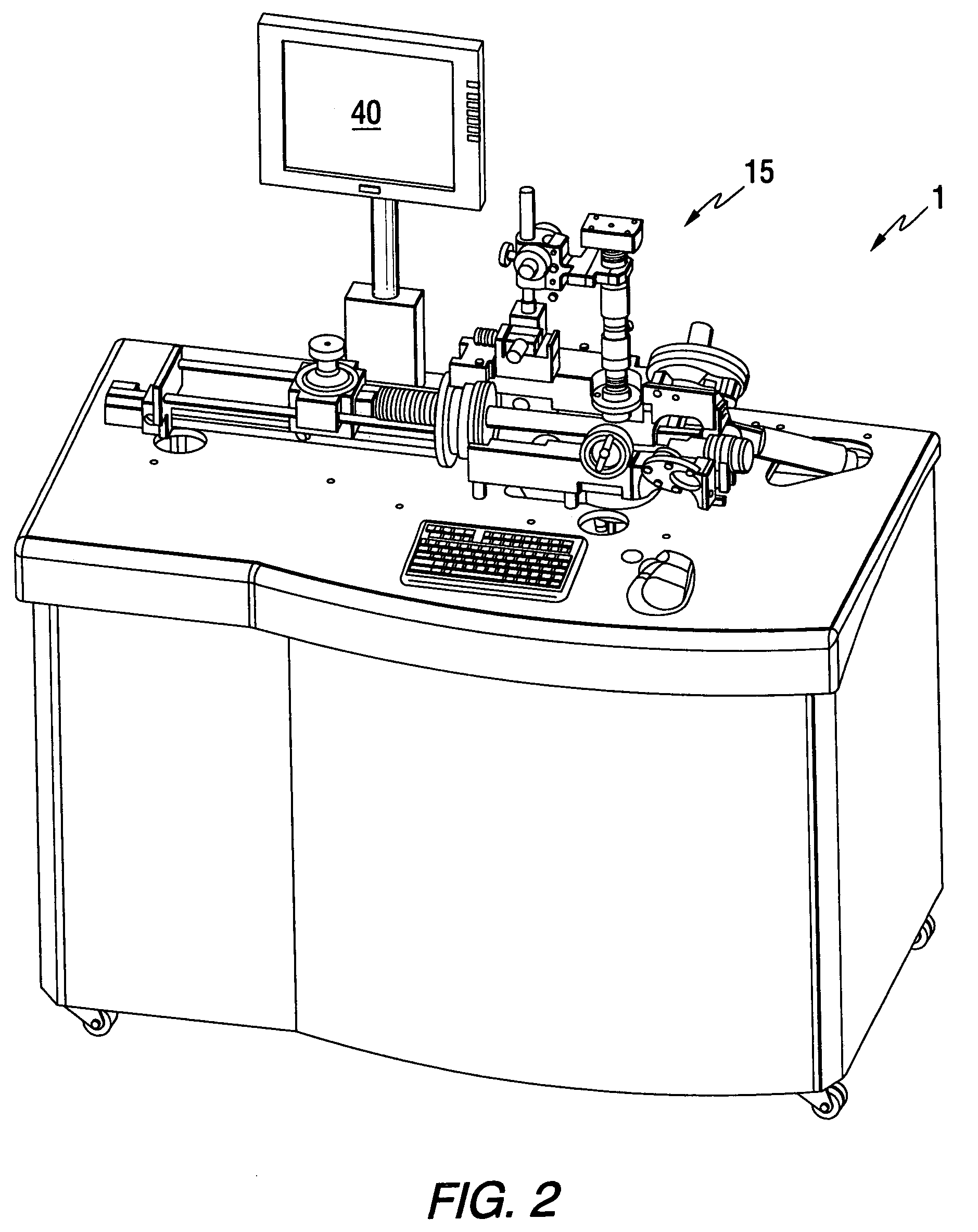

Device and method for milling of material using ions

ActiveUS20060022148A1Small beam spot sizeSmall diameterThermometer detailsDecorative surface effectsIon bombardmentLocking mechanism

A milling device is disclosed for the preparation of microscopy specimens or other surface science applications through the use of ion bombardment. The device provides the ability to utilize both gross and fine modification of the specimen surface through the use of high and low energy ion sources. Precise control of the location of the specimen within the impingement beams created by the ion sources provides the ability to tilt and rotate the specimen with respect thereto. Locational control also permits the translocation of the specimen between the various sources under programmatic control and under consistent vacuum conditions. A load lock mechanism is also provided to permit the introduction of specimens into the device without loss of vacuum and with the ability to return the specimen to ambient temperature during such load and unload operation. The specimen may be observed and imaged during all active phases of operation.

Owner:E A FISCHIONE INSTR

Secondary air supply abnormality detection system

InactiveUS6830043B2Prevent thermal degradationAccurate calculationElectrical controlInternal combustion piston enginesAnomaly detectionAir pump

A secondary air supply abnormality detection system determines that an abnormality is generated in a system including a secondary air supply system if a true secondary air flow rate is out of a predetermined range. The true secondary air flow rate is calculated by subtracting a secondary air flow rate average at the time when an air pump is not operating from another secondary air flow rate average at the time when the air pump is operating. Thus, variation in the secondary air flow rate due to change with time or production tolerance can be suitably corrected. Since calculation accuracy of the true secondary air flow rate is improved, determination accuracy of the abnormality in the system including the secondary air supply system can be improved.

Owner:DENSO CORP

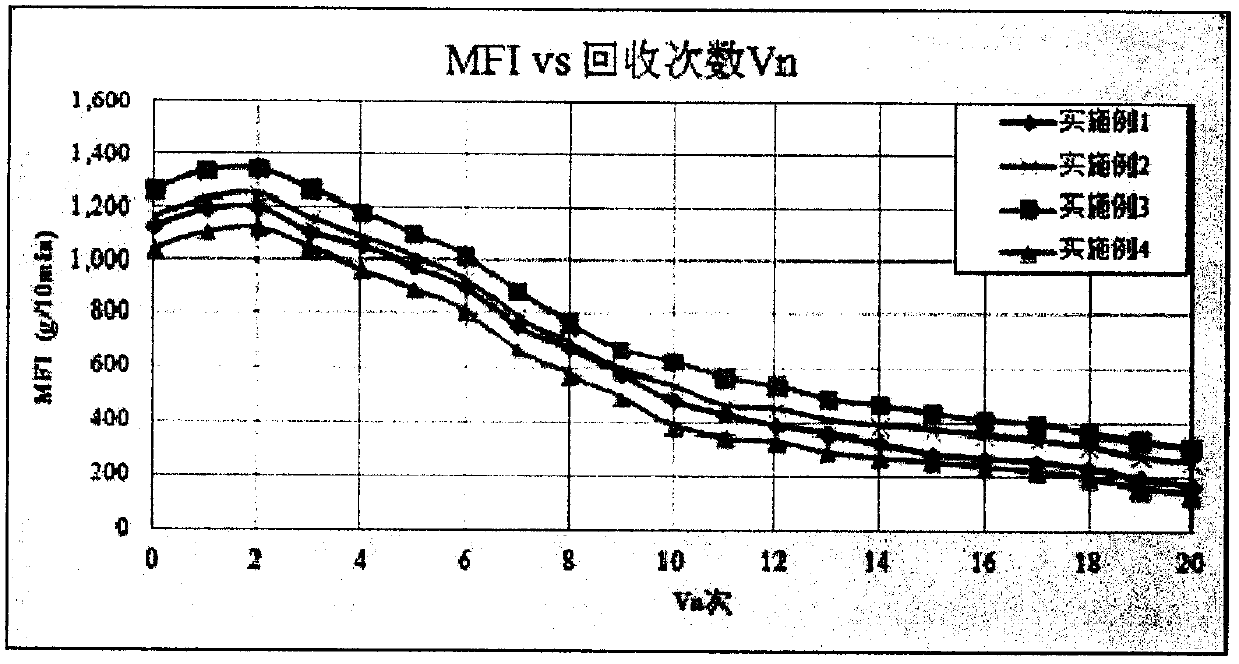

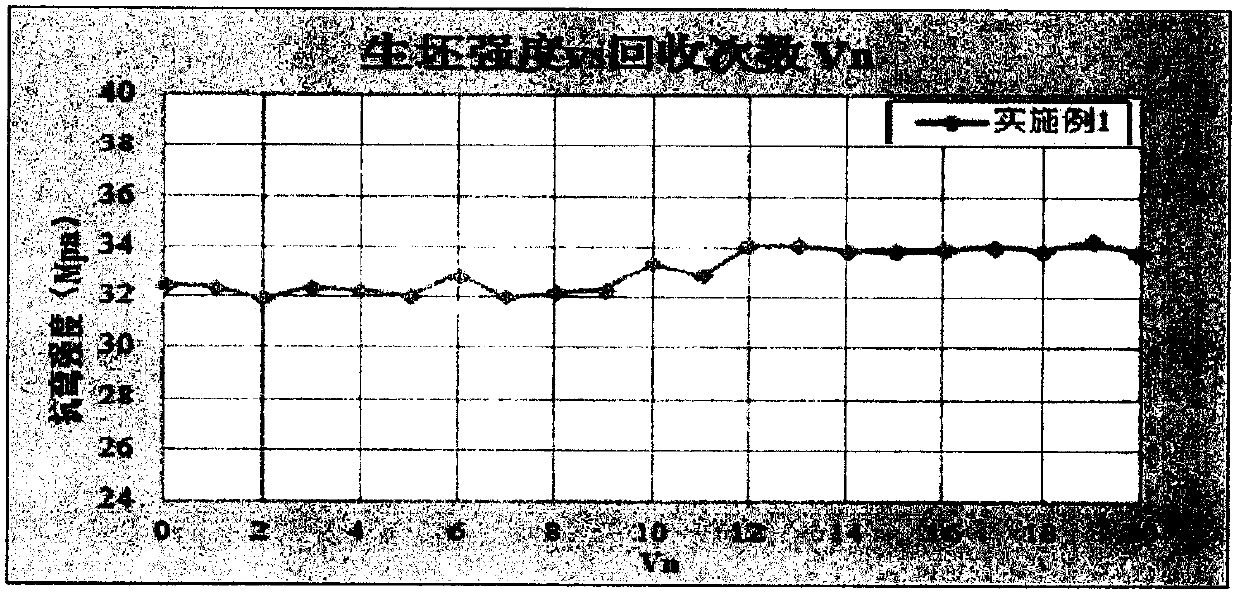

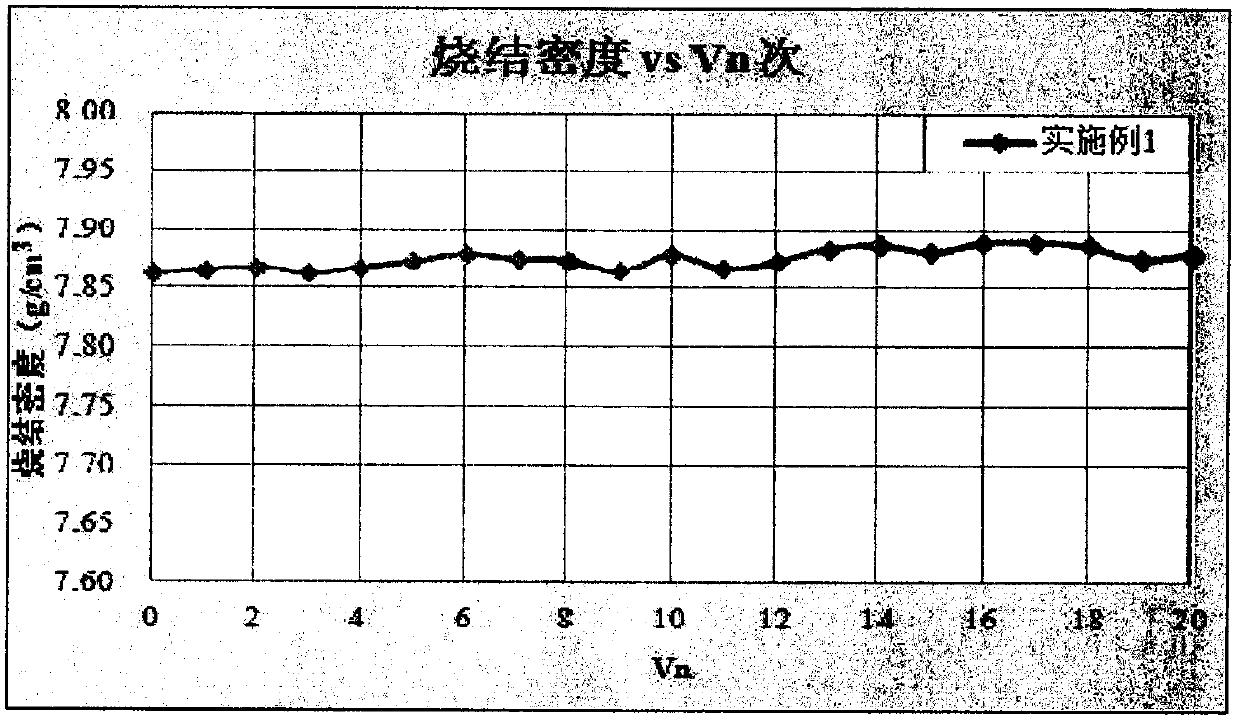

Stable type stainless steel feed for injection molding and preparation method of stable type stainless steel feed

InactiveCN107866559AImprove liquidityIncrease the number of recycling timesTransportation and packagingMetal-working apparatusTougheningLubricant

The invention discloses stable type stainless steel feed for injection molding and a preparation method of the stable type stainless steel feed, and belongs to the technical field of stainless steel injection molding. The stable type stainless steel feed for the injection molding is prepared by the following components of, by weight, 88-93 parts of stainless steel powder, 5-9 parts of kemata, 0.1-1 part of hardening agent, 0.1-0.6 part of compatibilizer, 0.1-0.4 part of lubricant, 0.1-0.3 part of dispersing agent, 0.1-0.2 part of toughening agent and 0.1-0.5 part of stabilizer, and the stabletype stainless steel feed is formed by adding the components to banburying equipment in different orders and blending. The stainless steel feed has excellent liquidity and stability, the number of recycling of the stainless steel feed in the injection molding is increased, a degraded material through multiple times of recycling still has stable liquidity, after the stainless steel feed is injectedinto a green body and is sintered, a product has the characteristics like stable performance and sintered density, the waste of raw materials in use is reduced, and the cost of an MIM piece can be lowered and the yield of an MIM product can be increased substantially.

Owner:KUNSHAN NANO NEW MATERIAL TECH

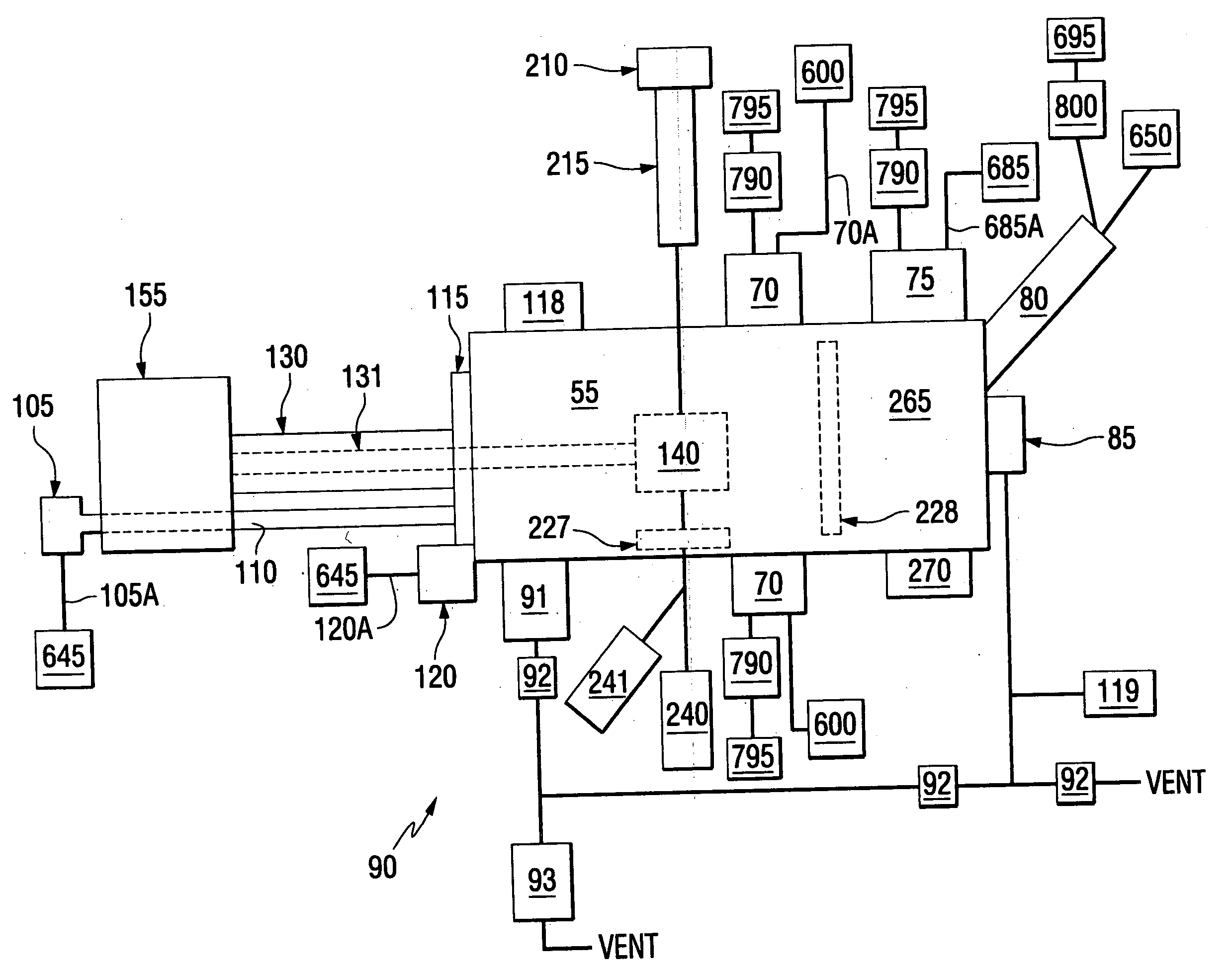

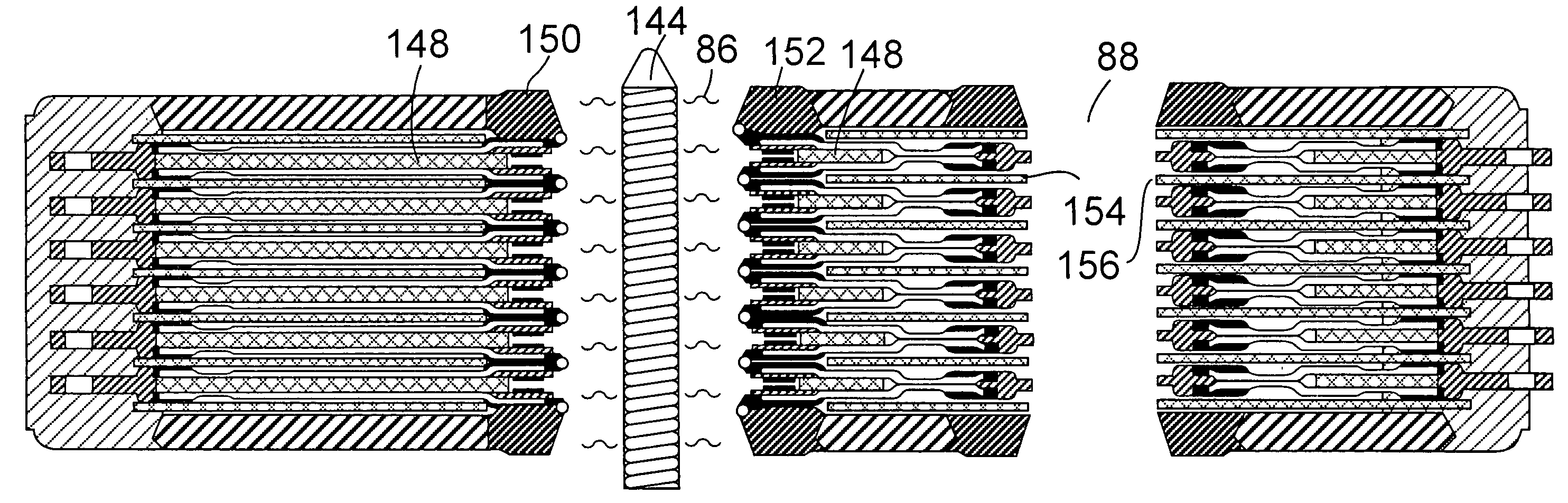

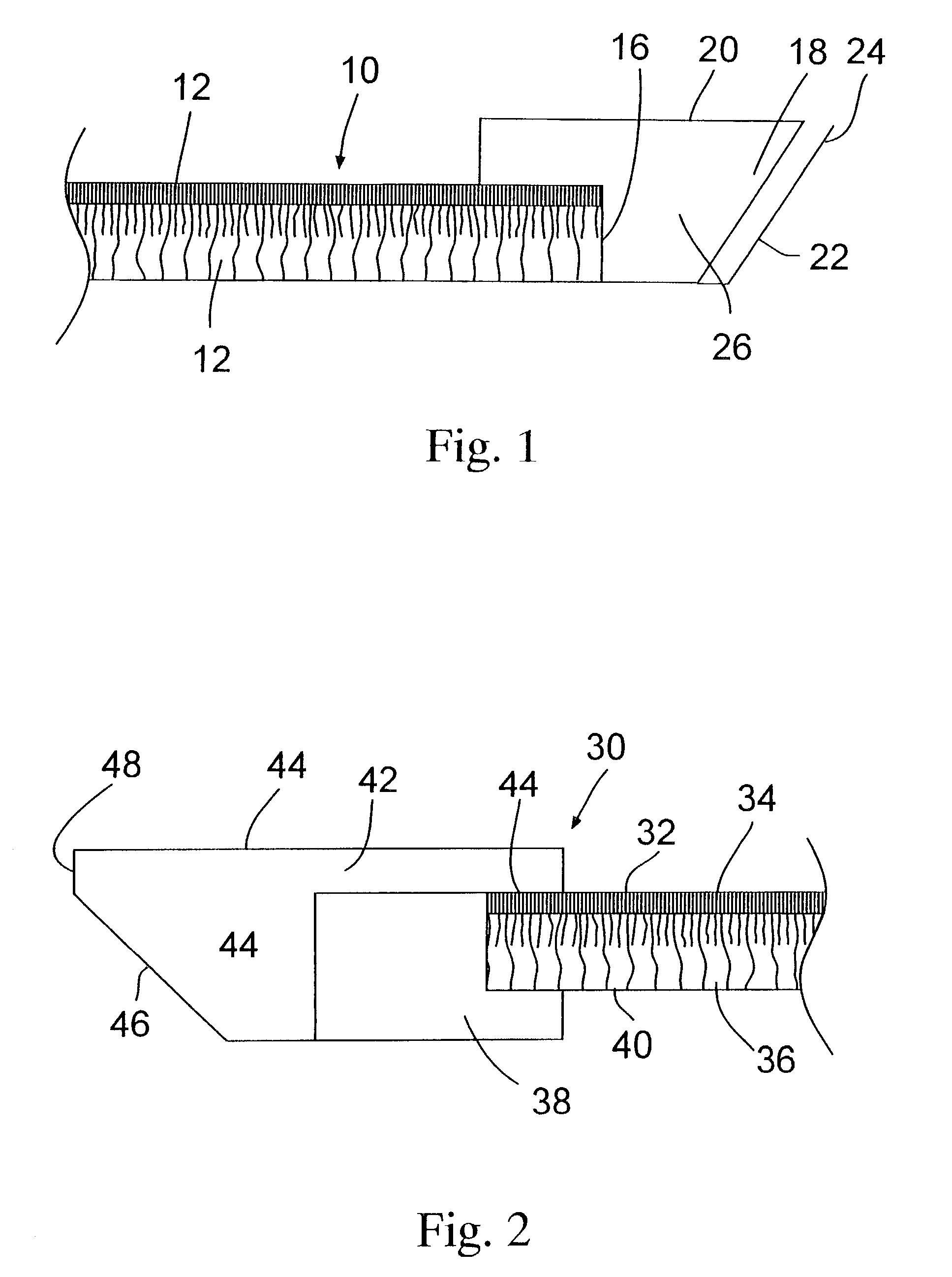

Process for making a fluid processing module

InactiveUS7097800B2Improve sealingAvoid degradation of mechanical propertiesSemi-permeable membranesOther chemical processesPorous layerFiltration

A process for making a fluid processing module is provided wherein a plurality of filtration elements is alternated with a fluid porous layer to form a stack. The filtration elements comprise a membrane sheet having a thermoplastic element bonded to a portion of an edge of the membrane. An opening is provided either through the membrane or through the thermoplastic element. A portion of the thermoplastic element extends into the opening and can be sealed to an adjacent positioned thermoplastic element to seal the porous sheet positioned between adjacently positioned membranes from fluid communication with the opening. Sealing can be effected by extending a heating element through the opening of the stack to effect simultaneous sealing of a plurality of thermoplastic elements.

Owner:MILLIPORE CORP

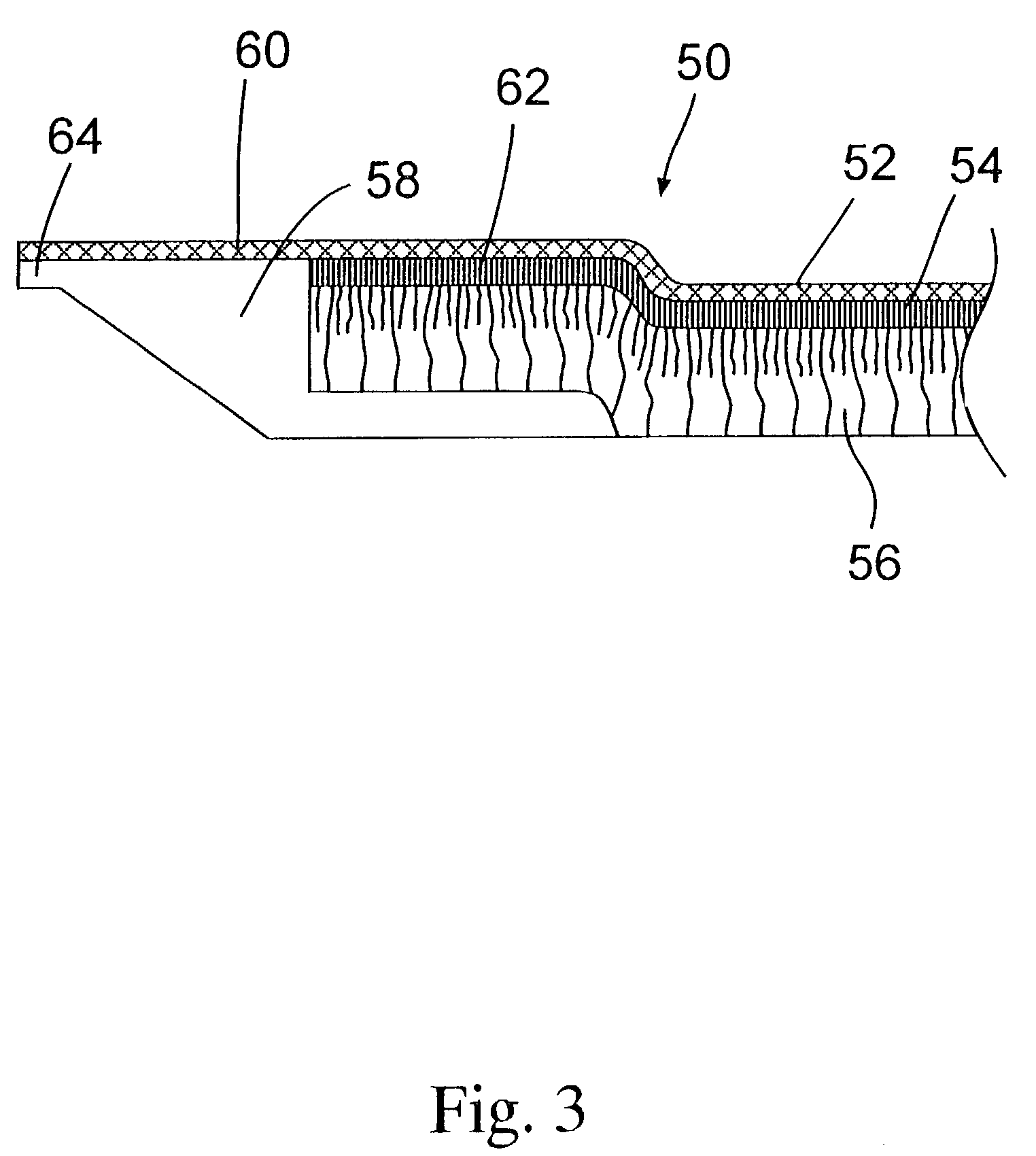

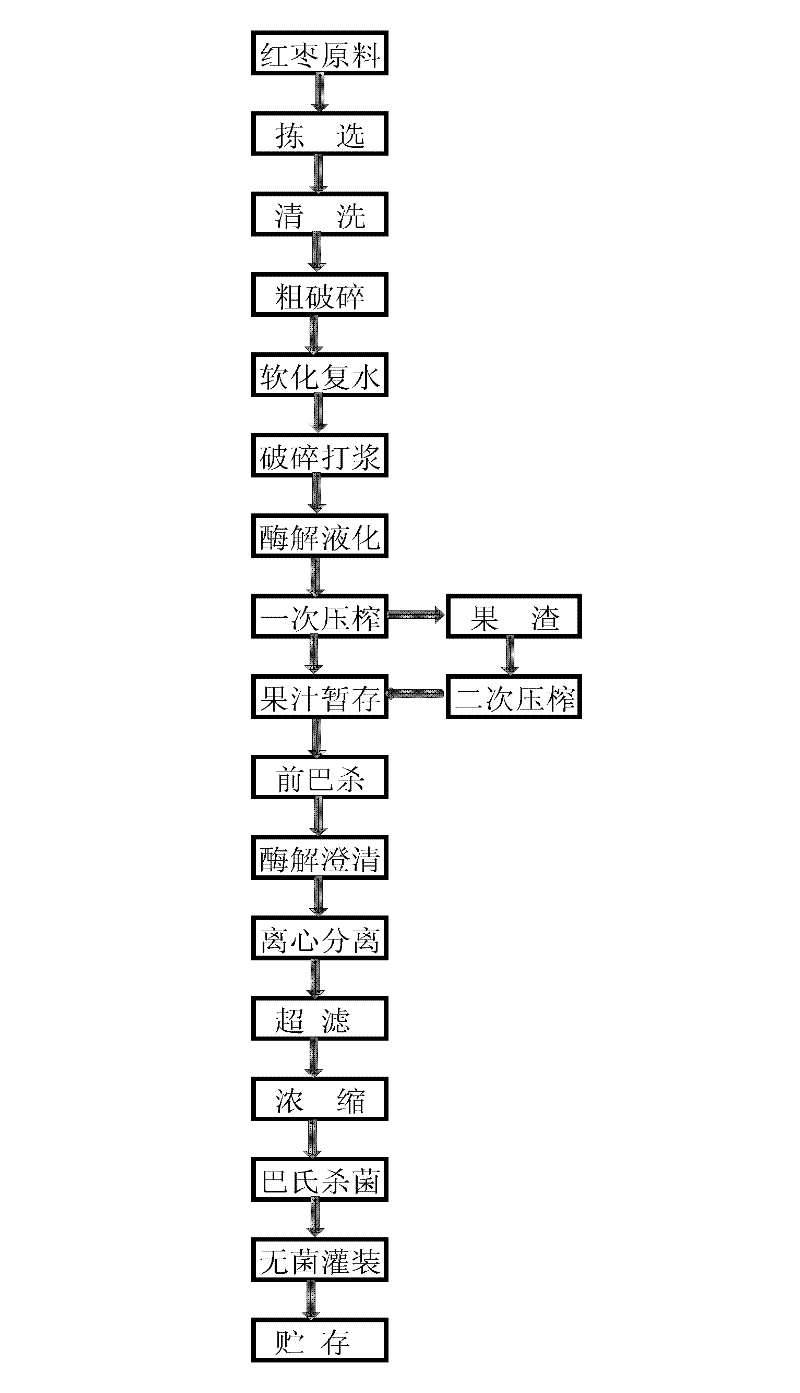

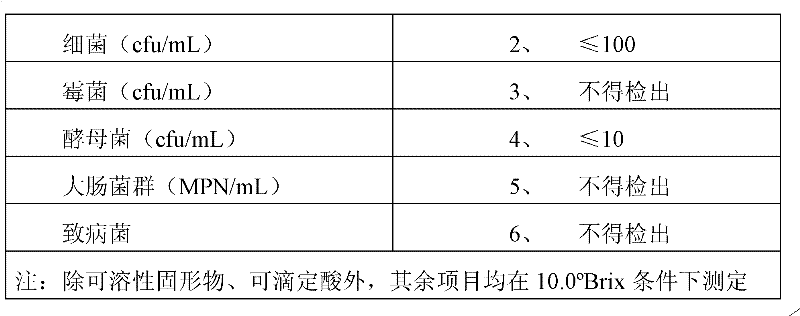

Method of preparing concentrated clear red jujube juice with high cAMP content

The invention discloses a method of preparing concentrated clear red jujube juice with high cAMP content, which comprises the following steps: taking out red jujube after rehydration, denucleating and then crushing pulp for preparing the red jujube thick liquid; conveying the red jujube after enzymolysis by pectinase into a juicer for squeezing, and filtering to obtain the red jujube juice; adding pectinase, amylase and cellulose into the red jujube juice for heat-preservation and enzymolysis for 60-90 minutes; and clearing, conducting concentration sterilization, and finally bulking. The concentrated clear red jujube juice prepared by the invention is clear and transparent, has the cAMP content being larger than or equal to 100 mg / Kg and soluble solid state material being larger than or equal to 60.0 Brix, is deposit-free and suspension-free, has brownish red color and does not have impurities which can be seen by naked eyes; and the concentrated juice is diluted to the soluble solidstate material being 60.0 Brix, and the juice has inherent fragrance and flavor of red jujubes and is free from extraneous odor.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

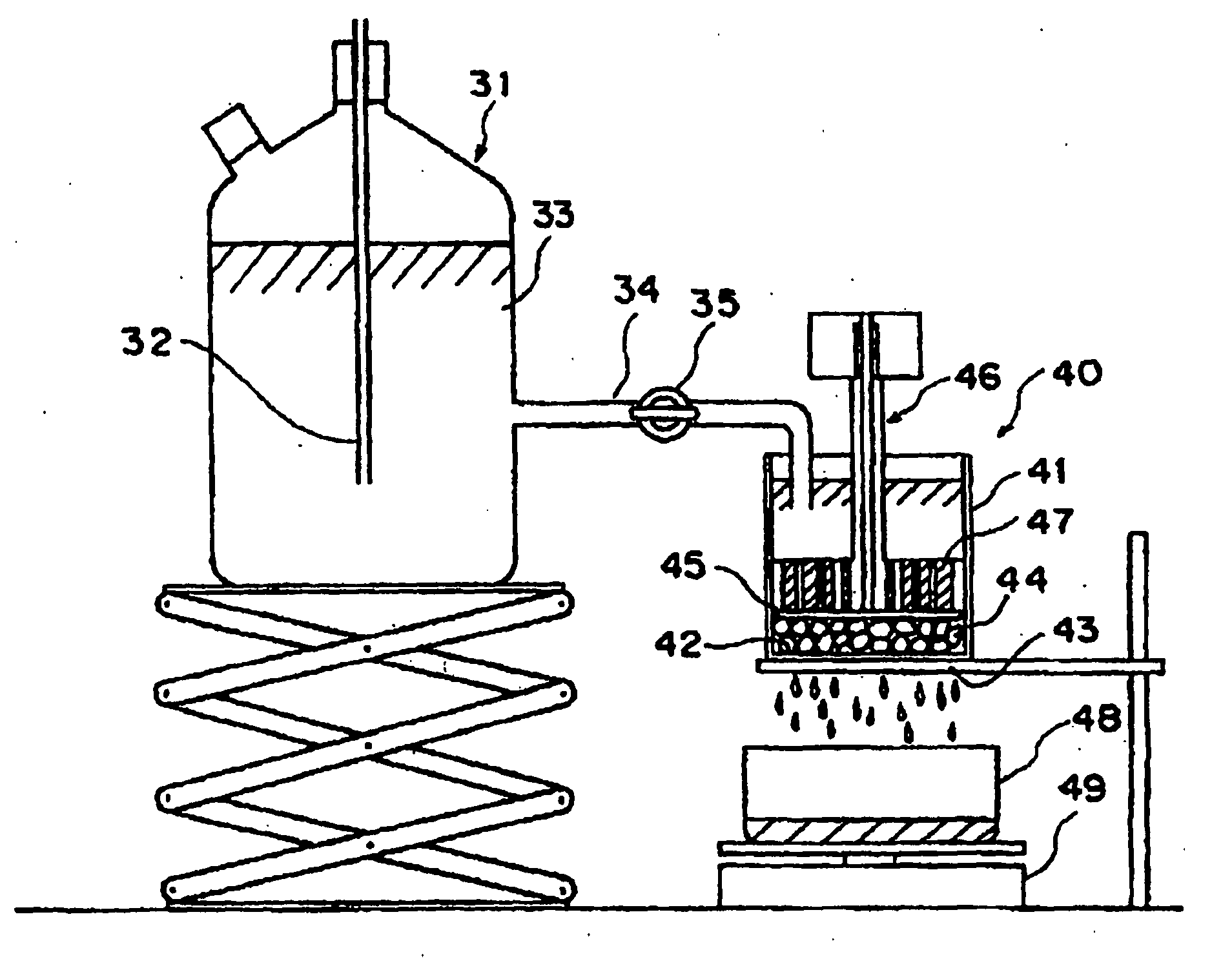

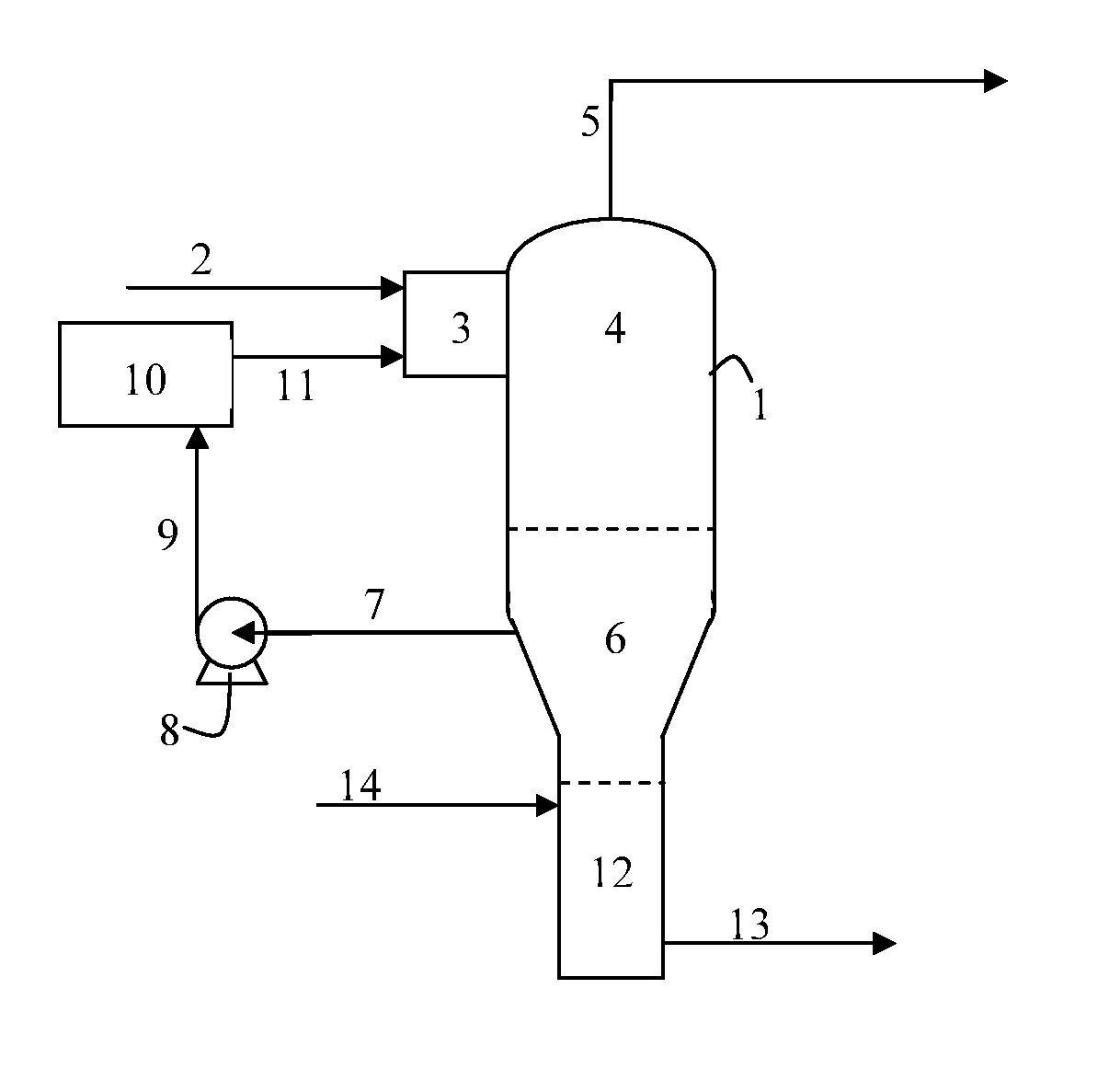

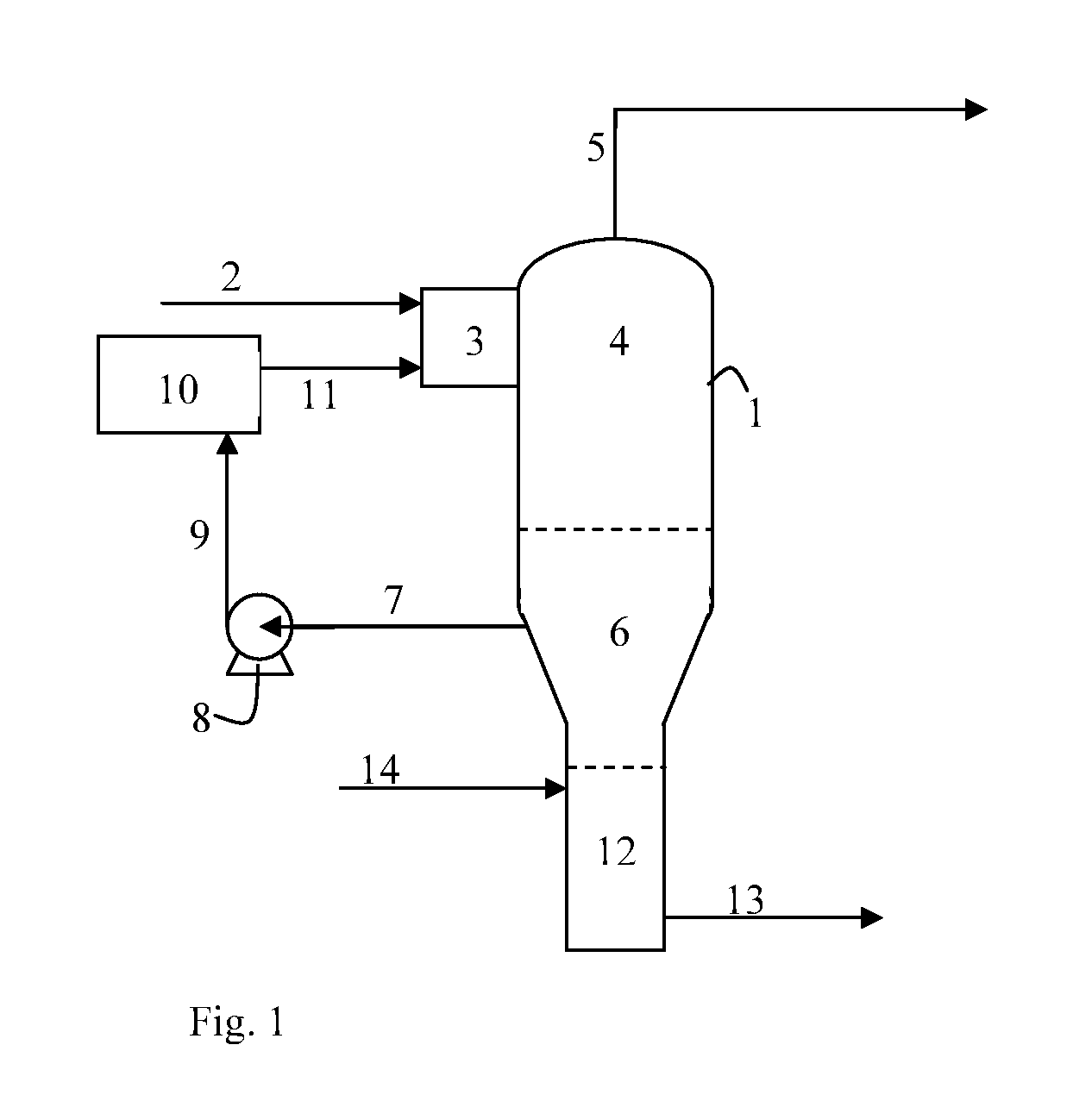

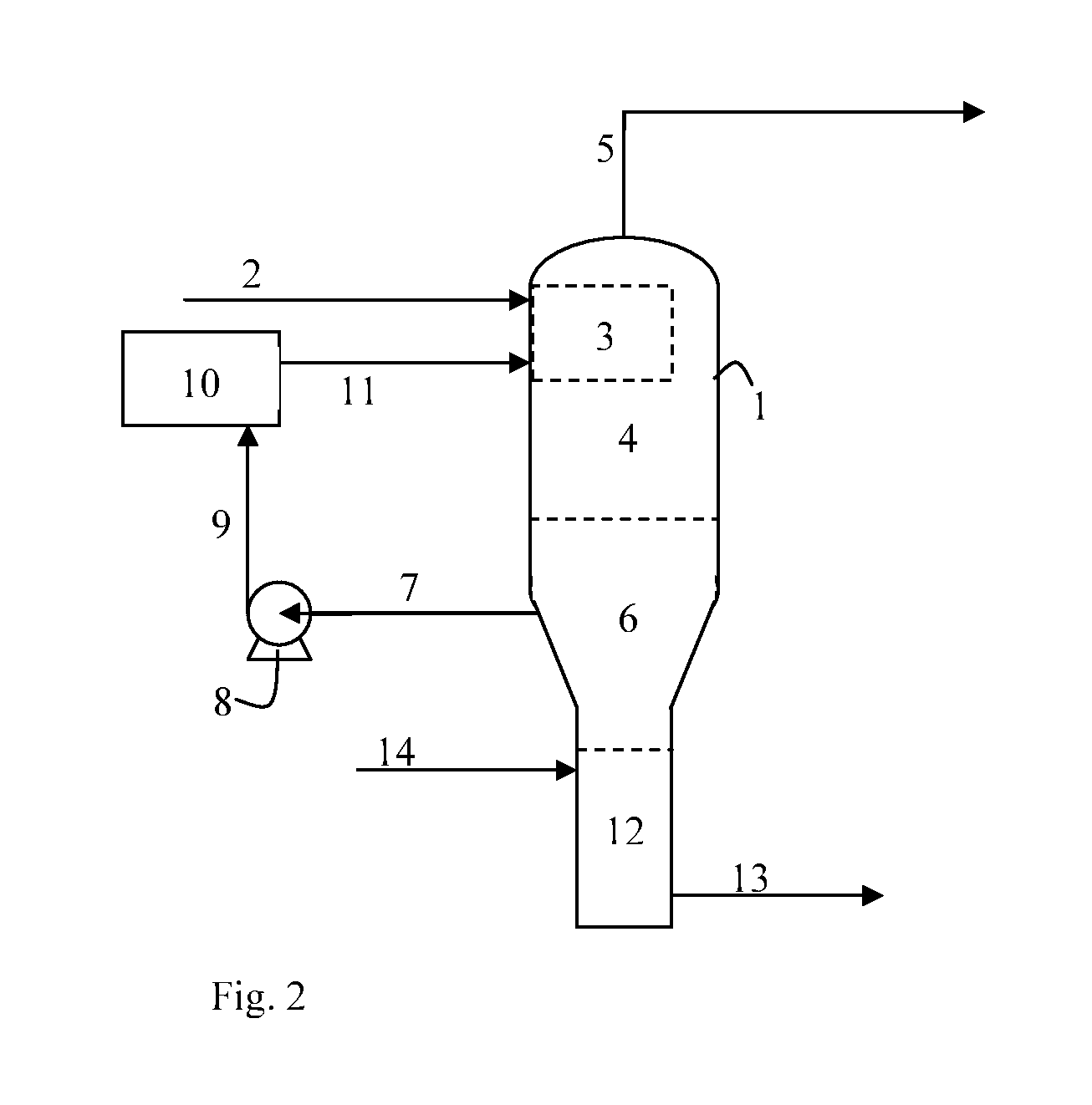

Process for separating solids from valuable or harmful liquids by vaporisation

ActiveUS8652304B2Prevent thermal degradationDrying using combination processesSolvent extractionOil and natural gasPetroleum

The present invention is directed to an enhanced process for separating dissolved and suspended solids from valuable or harmful liquids and more particularly to improving the operational aspects and separation efficiency of treating certain water miscible fluids including those used for oil and gas processing such as glycols, as well as automobile and aircraft fluids, that have become contaminated with dissolved and / or suspended solid matter.

Owner:PRIME SERVICES TRUSTEE

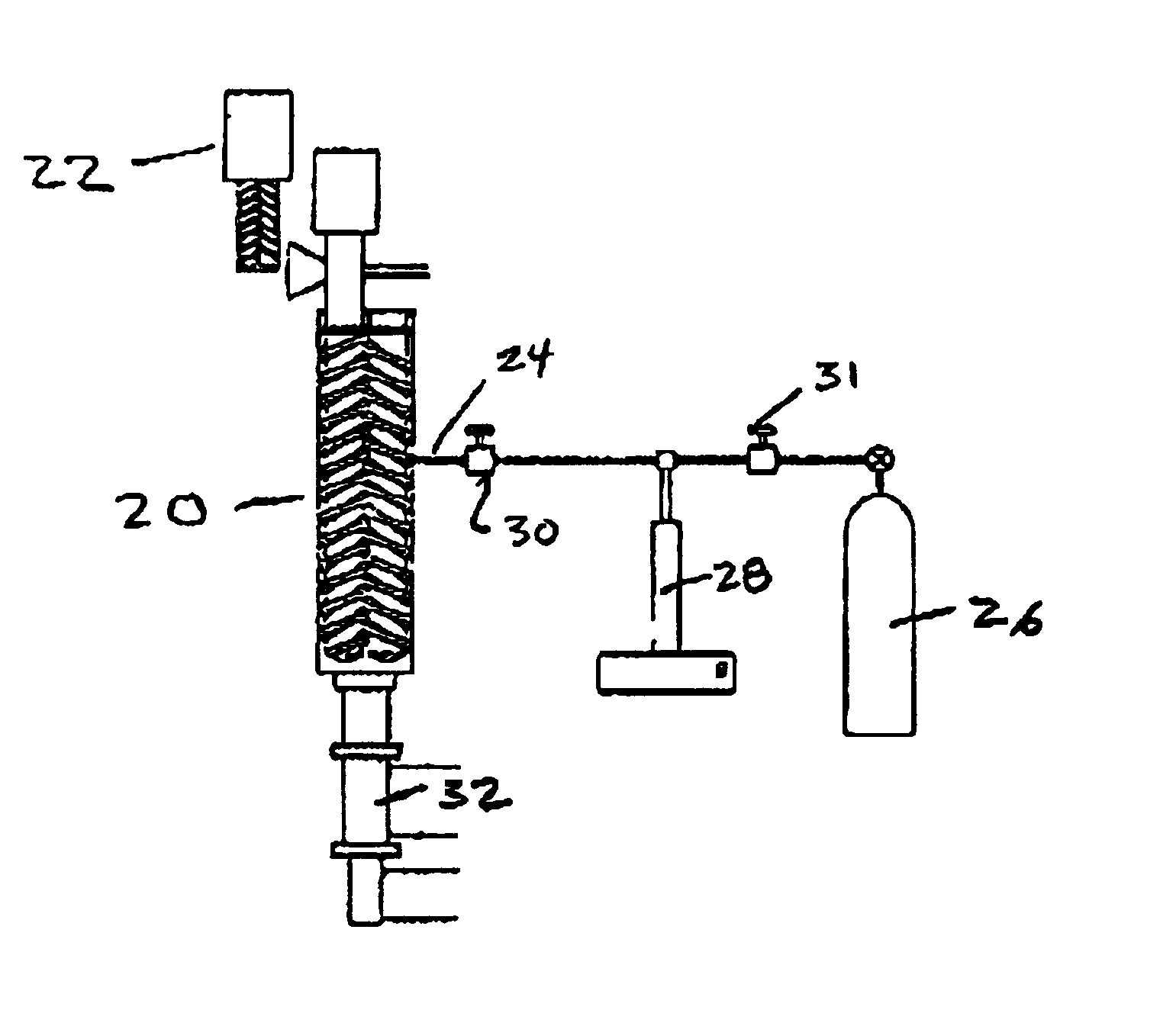

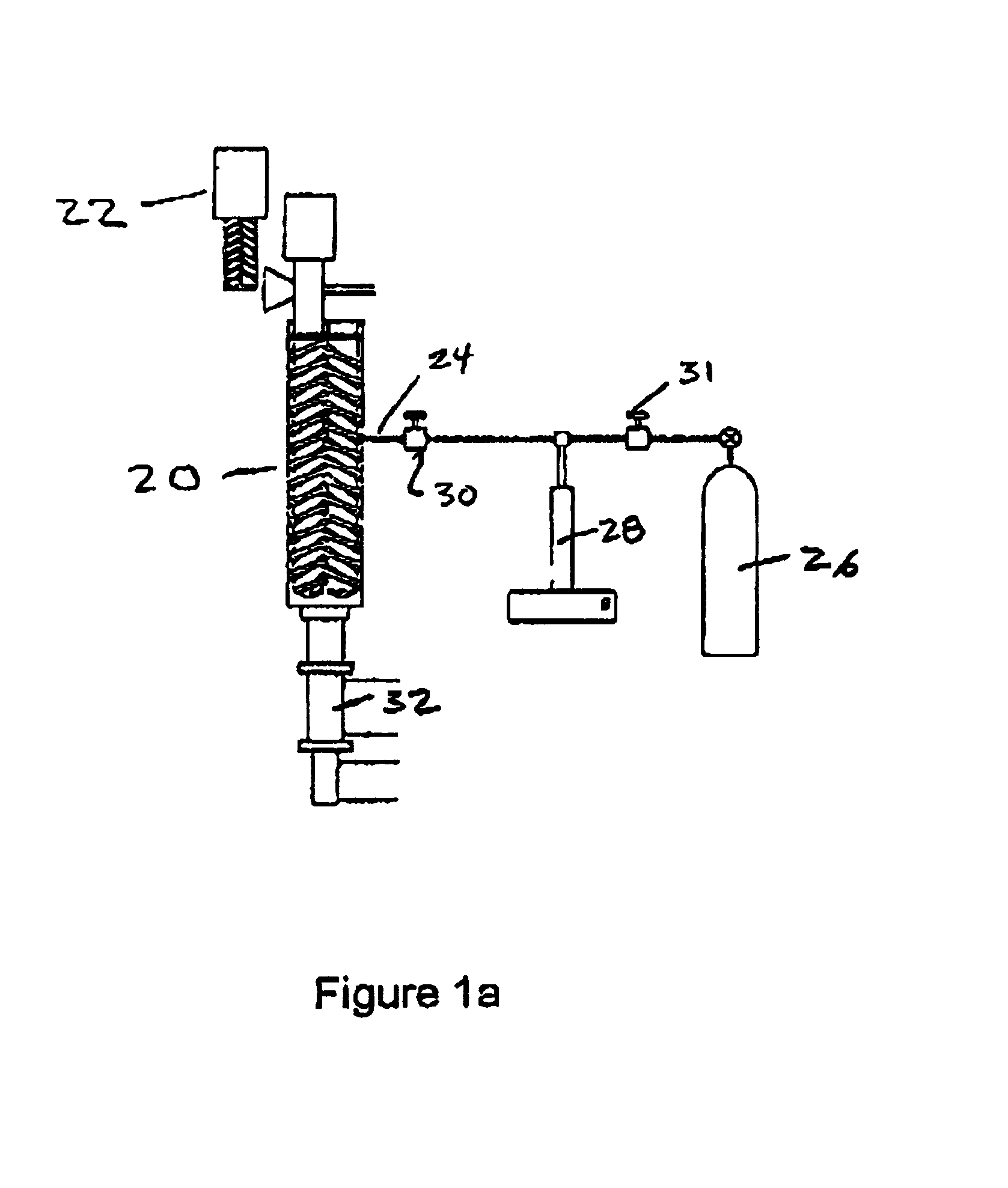

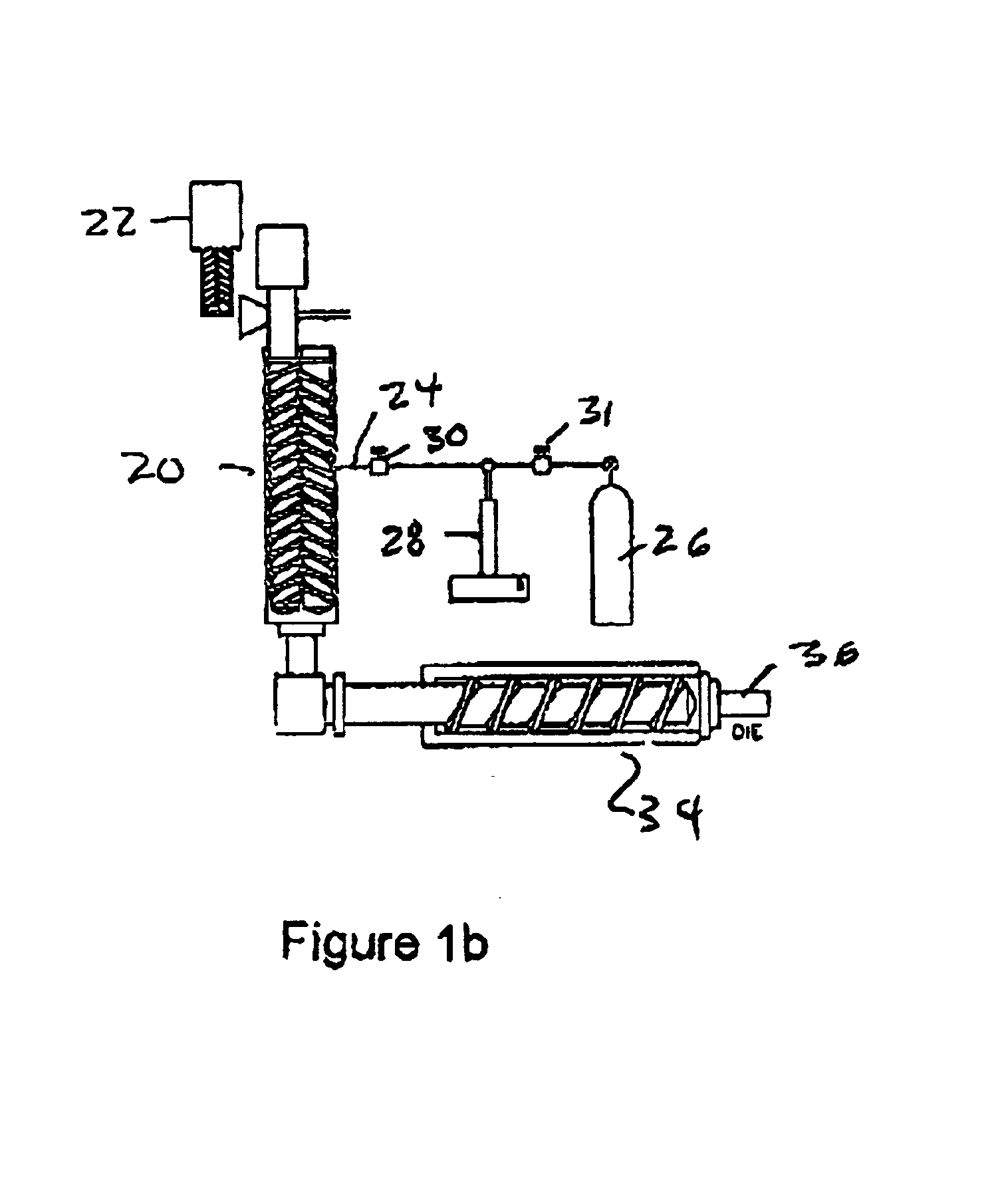

Plastic wood fiber foam structure and method of producing same

InactiveUS6936200B2Improve material performanceLow costDomestic articlesFlat articlesWood fibreMetallurgy

A process for producing plastic / wood fiber composite foamed structures includes the steps of pre-drying wood fiber filler; mixing it with plastic to form a mixture; feeding the mixture into an extruder; introducing and mixing a blowing agent; subject the mixture to high shear forces and extruding the mixture to produce a plastic / wood fiber composite foamed structure. The filler has a degradation temperature and an active volatization temperature. During the pre-drying step the temperature is maintained below the degradation temperature. During the mixing step the mixing temperature is maintained below the active volatilizing temperature. During the introducing and mixing step a blowing agent is introduced into the plastic / wood fiber mixture and is mixed therewith to produce a plastic / wood fiber / gas mixture. During the subjecting step the plastic / wood fiber / gas mixture is subjected to high shear forces in the presence of high pressures and the temperature is maintained below an active volatilizing temperature.

Owner:PARK CHUL +2

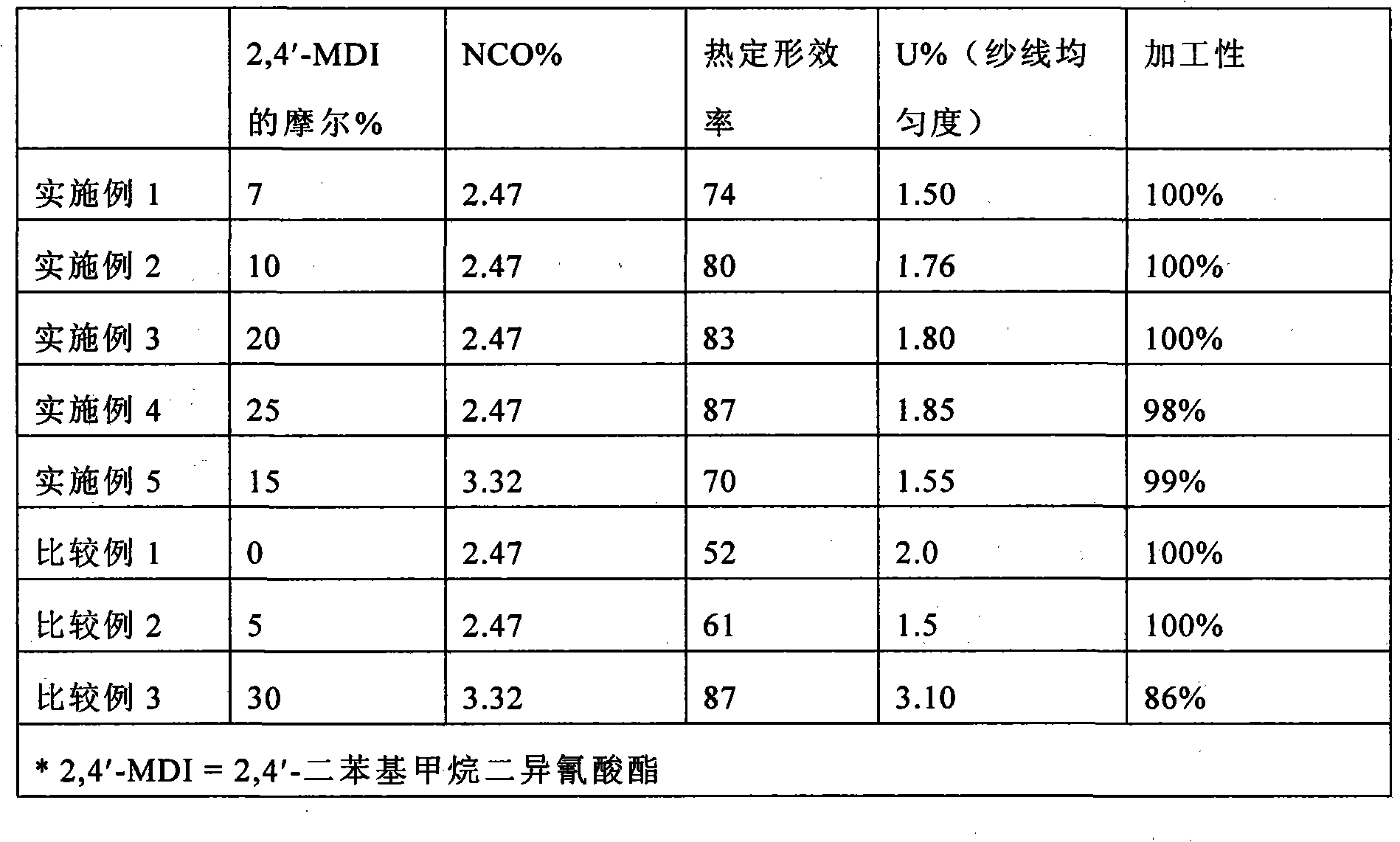

Method for preparing polyurethaneurea elastic fiber with improved heat settability and polyurethaneurea elastic fiber prepared by the same

InactiveCN101849048AHigh heat setting efficiencyPrevent thermal degradationMonocomponent polyurethanes artificial filamentPrepolymerIsocyanate

The present invention relates to a method for preparing polyurethaneurea elastic fiber, the method comprising reacting a mixture of at least one diisocyanate comprising 4,4'-diphenylmethanediisocyanate and 7 to 25 mole % of 2,4'-diphenylmethanediisocyanate with polyol to produce a prepolymer, and polyurethaneurea elastic fiber prepared by the same. The polyurethaneurea elastic fiber of the present invention has superior spinning workability, improved yarn evenness, and high heat-set efficiency even at low temperature.

Owner:HYOSUNG CORP

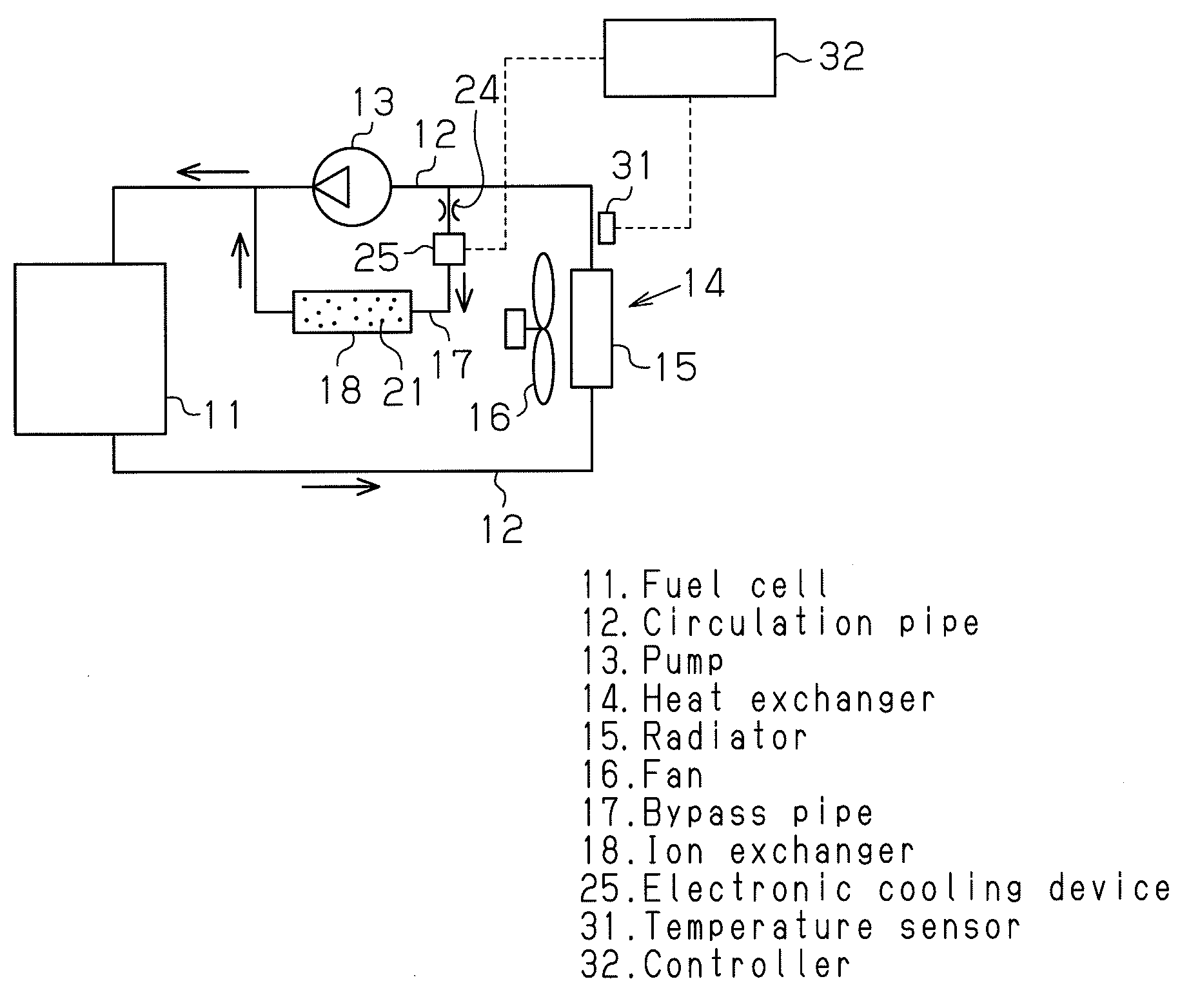

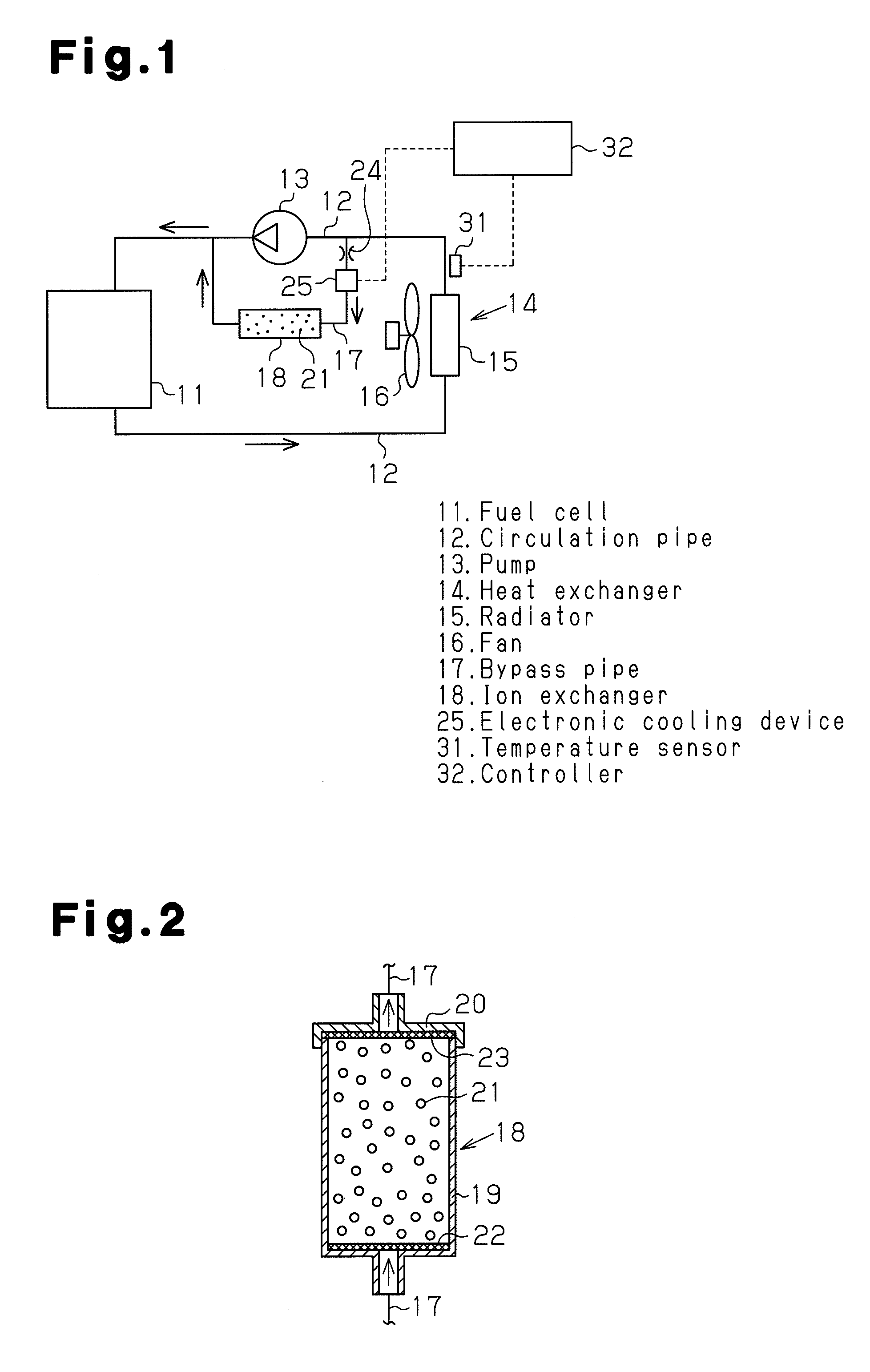

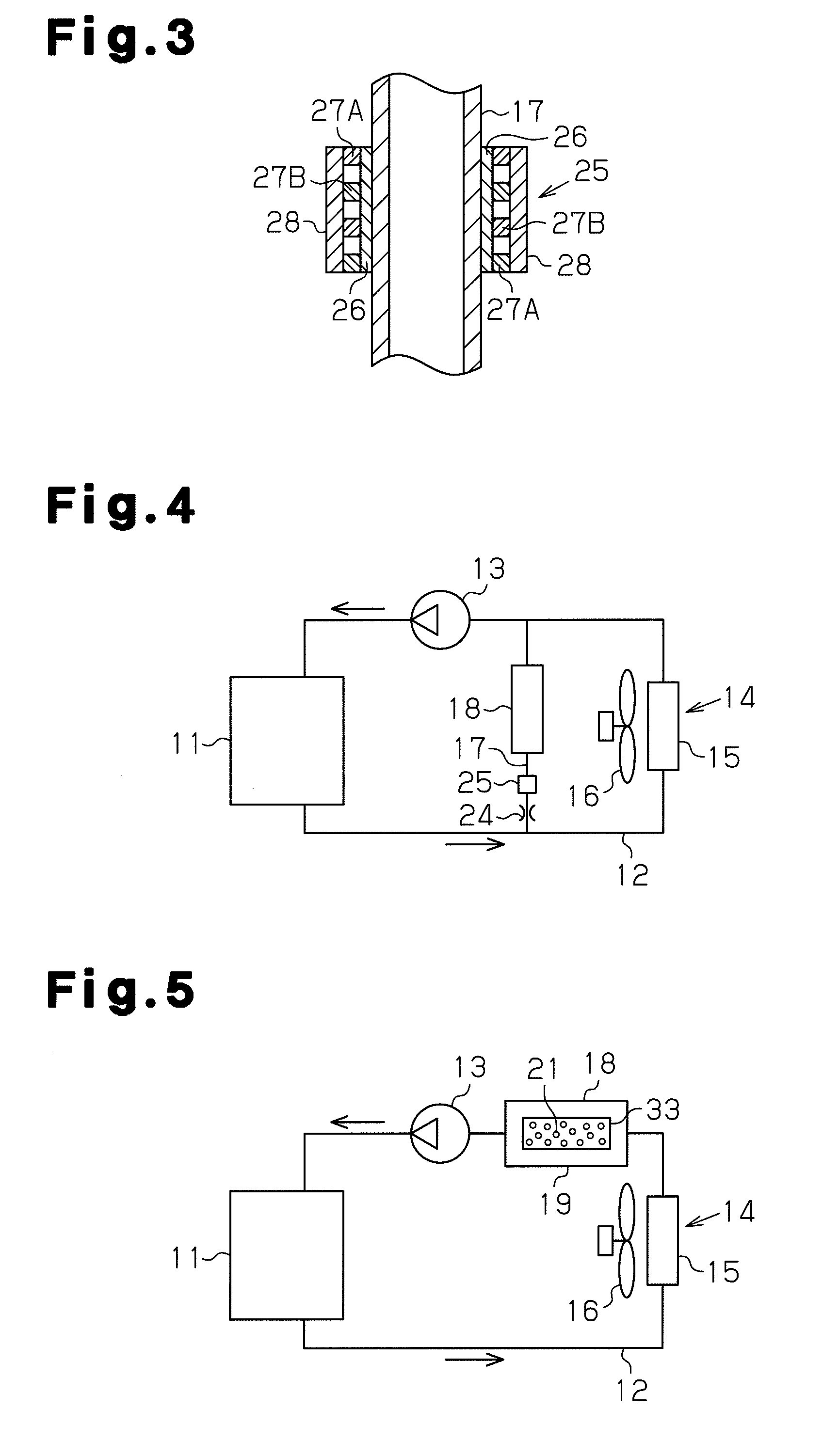

Fuel cell cooling system

InactiveUS20090317680A1Low heat resistanceAllowable temperature range can be increasedFuel cell auxillariesFuel cellsElectronics cooling

A circulation pipe for a coolant is connected to a fuel cell. A pump and a heat exchanger are connected to the circulation pipe. A bypass pipe is connected in parallel with the pump. An ion exchanger is connected to the bypass pipe. An electronic cooling device is connected to the bypass pipe on an upstream side of the ion exchanger. The coolant, which is supplied to the ion exchanger, is cooled by the electronic cooling device to a predetermined temperature, so that the ion-exchange resins are prevented from being abnormally heated by the coolant.

Owner:TOYOTA BOSHOKU KK

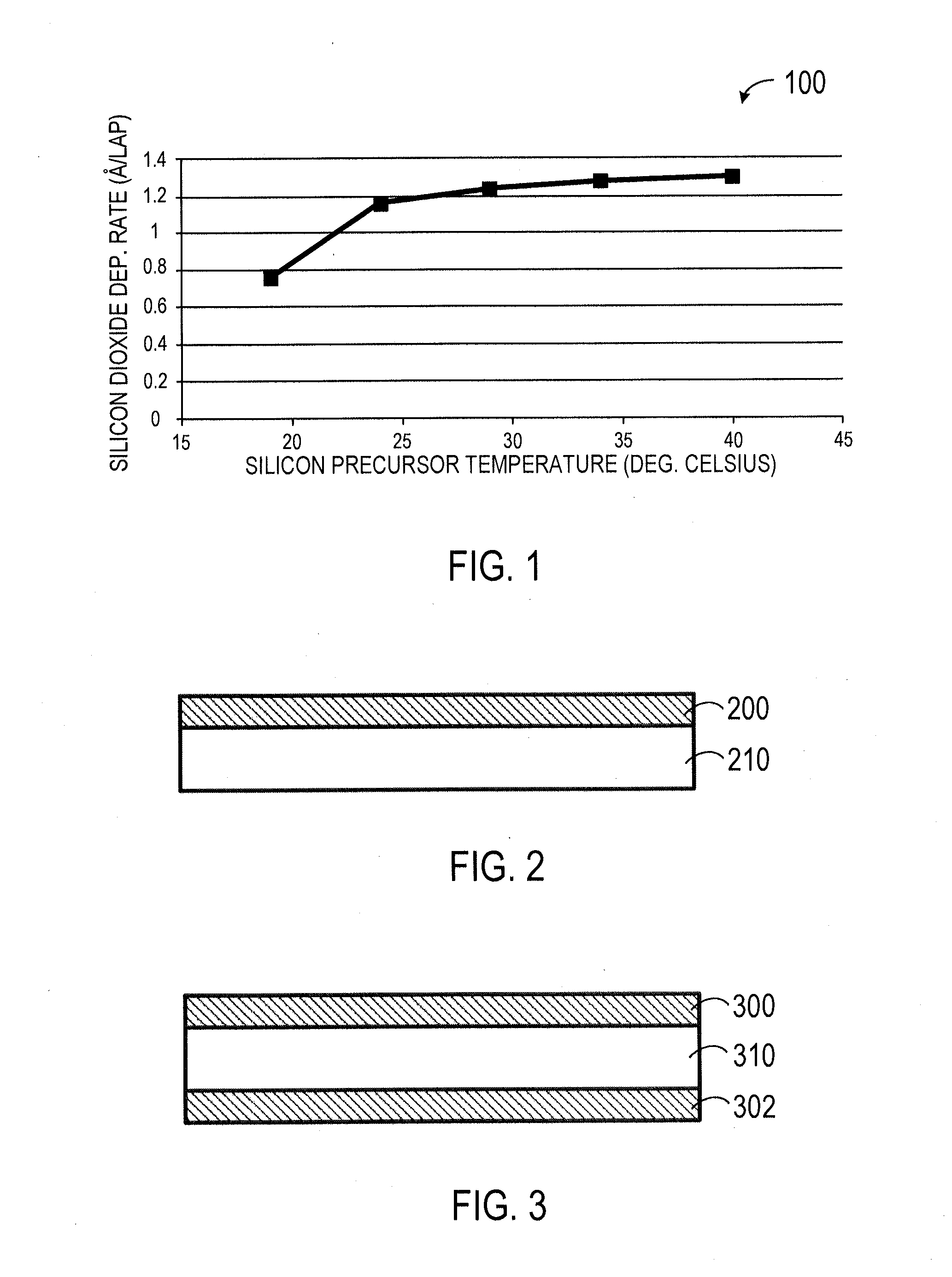

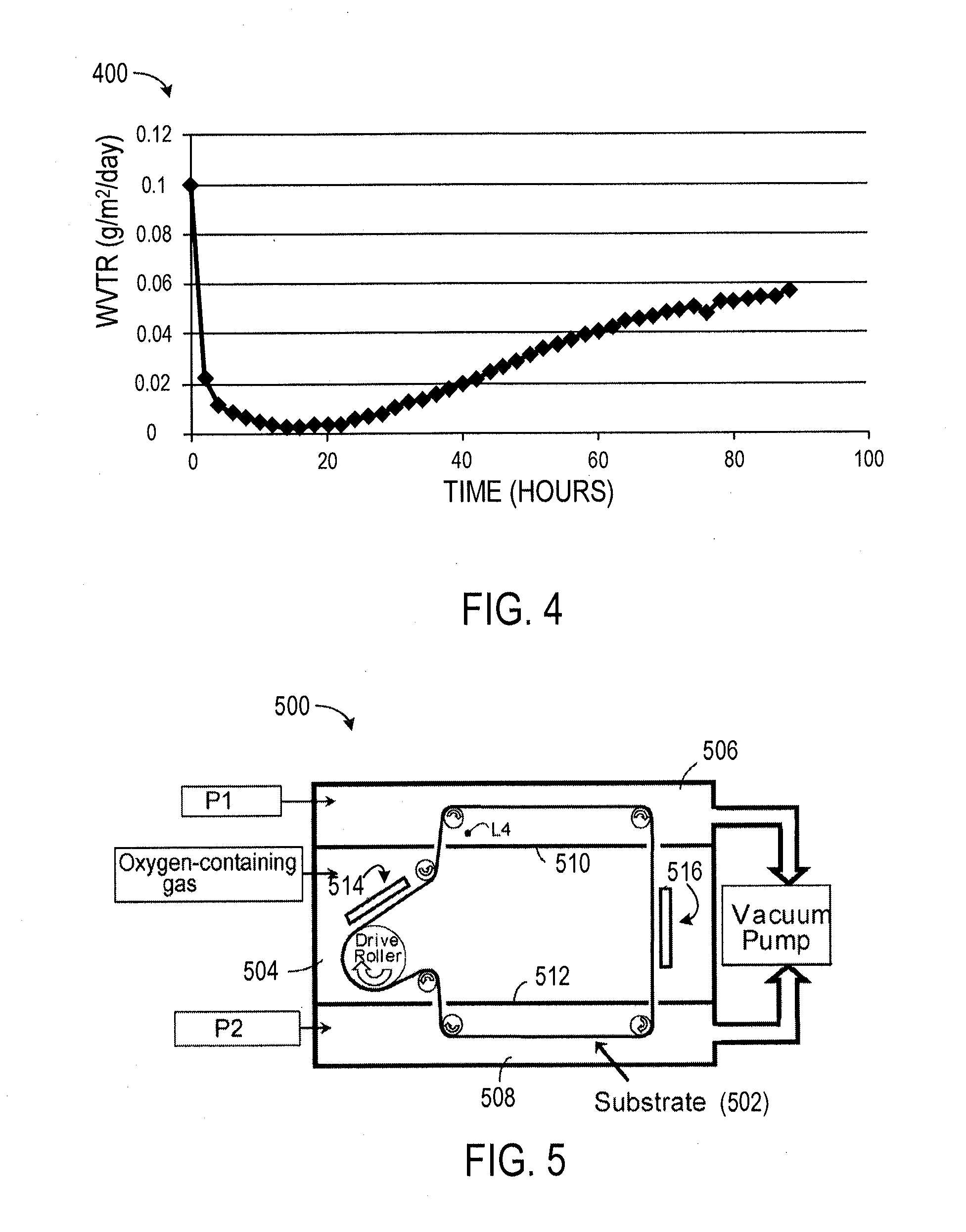

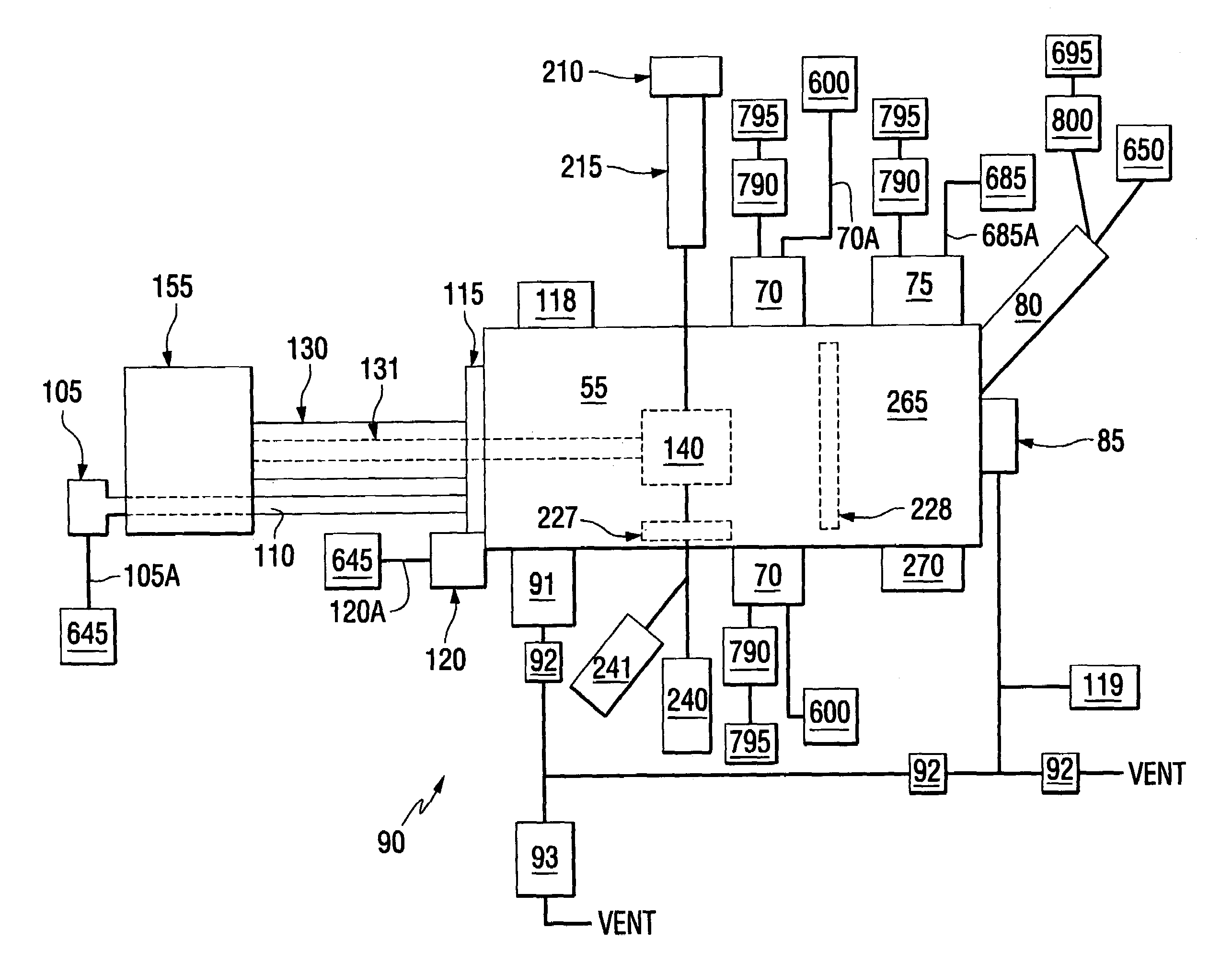

Mixed metal-silicon-oxide barriers

ActiveUS20140242736A1Lower refractive indexReduce transmissionSemiconductor/solid-state device detailsSolid-state devicesRefractive indexSilicon oxide

A method of forming a thin barrier film of a mixed metal-silicon-oxide is disclosed. For example, a method of forming an aluminum-silicon-oxide mixture having a refractive index of 1.8 or less comprises exposing a substrate to sequences of a non-hydroxylated silicon-containing precursor, activated oxygen species, and metal-containing precursor until a mixed metal-silicon-oxide film having a thickness of 500 Ångstroms or less is formed on the substrate.

Owner:LOTUS APPLIED TECH +1

Device and method for milling of material using ions

ActiveUS7132673B2Quantity minimizationPromotes ability to rasterThermometer detailsDecorative surface effectsIon bombardmentLocking mechanism

A milling device is disclosed for the preparation of microscopy specimens or other surface science applications through the use of ion bombardment. The device provides the ability to utilize both gross and fine modification of the specimen surface through the use of high and low energy ion sources. Precise control of the location of the specimen within the impingement beams created by the ion sources provides the ability to tilt and rotate the specimen with respect thereto. Locational control also permits the translocation of the specimen between the various sources under programmatic control and under consistent vacuum conditions. A load lock mechanism is also provided to permit the introduction of specimens into the device without loss of vacuum and with the ability to return the specimen to ambient temperature during such load and unload operation. The specimen may be observed and imaged during all active phases of operation.

Owner:E A FISCHIONE INSTR

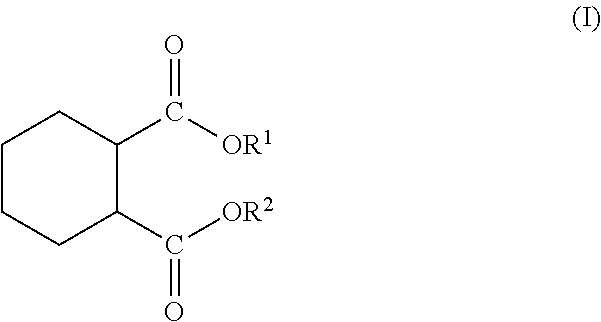

Thermoplastic polyurethanes composition and preparation processes thereof

This invention is directed to a thermoplastic polyurethanes composition comprising polyether-based thermoplastic polyurethane and 1,2-cyclohexane dicarboxylic acid ester and preparation processes thereof. The thermoplastic polyurethane composition has a good mold release behavior in injection molding without undesirably significant shrinkage and surface blooming of final product.

Owner:BASF SE

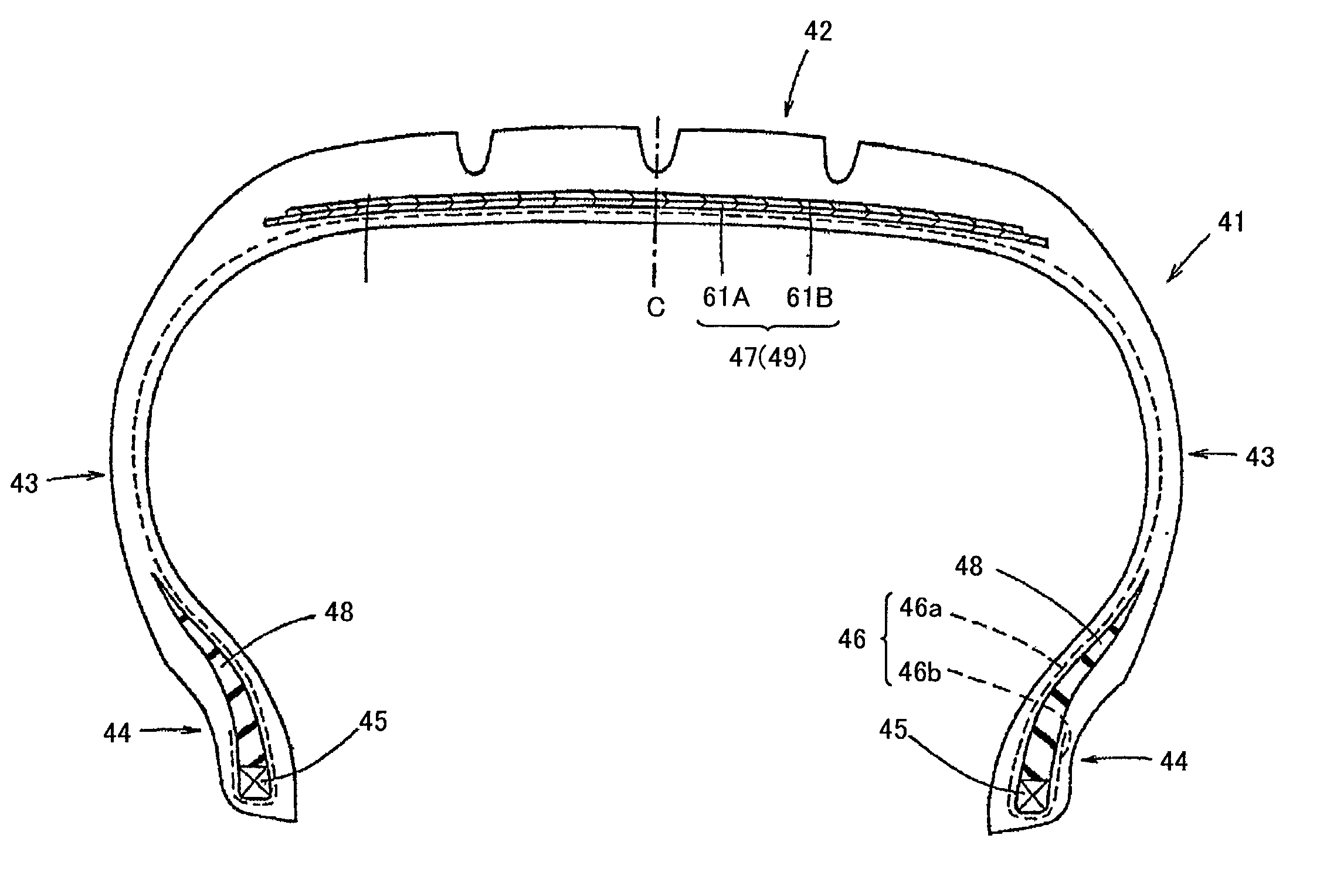

Composite of steel cord and rubber composition and tire using the same

A steel cord-rubber composite is provided, that has improved initial adhesion property and adhesion property against aging between the steel cord and the rubber composition with improved manufacturing cost efficiency. A steel cord-rubber composition composite includes a coating layer and a steel cord, and the coating layer includes an inner coating layer formed of a rubber composition containing a rubber component, a cobalt compound and sulfur and directly covering the steel cord, and an outer coating layer formed of a rubber composition of which contents of cobalt compound and sulfur are smaller than those of the inner coating layer and coating the outer portion of the inner coating layer.

Owner:SUMITOMO RUBBER IND LTD

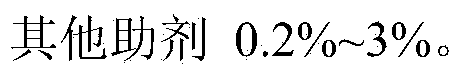

Compounds containing phosphorus, nitrogen and transition metal elements, and preparation method thereof

InactiveCN102153586AImprove thermal stabilityPrevent thermal degradationGroup 5/15 element organic compoundsHalogenEngineering plastic

The invention discloses compounds containing phosphorus, nitrogen and transition metal elements. The compounds with the structure also contain transition metal with a catalytic flame-retardant effect besides phosphorus and nitrogen elements required in the traditional flame retardant. A method for preparing the compounds with the structure is simple; and the obtained product has higher yield, does not contain halogen, is environment-friendly, has high thermal decomposition temperature, and can be used for flame-retardant engineering plastic. A general structural formula of the compounds is shown in the following formula (I).

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com