Method for preparing polyester film for photovoltaic cell backplane

A polyester film and photovoltaic cell technology, which is applied in applications, circuits, electrical components, etc., can solve the problems of reducing the aging resistance of polyester films, and achieve the effects of high fluorine content, good aging resistance, and high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with specific examples, which are easily grasped and verified by those skilled in the art. The present invention is illustrated by examples, but not limited thereto.

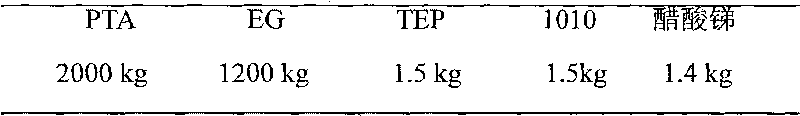

[0038] Terephthalic acid (PTA), ethylene glycol (EG), triethyl phosphate (TEP), antimony acetate and antioxidant 1010, the specific formula of the five substances is as follows:

[0039] Table 3 PET synthesis monomer ratio

[0040]

[0041] On the polyester batch polymerization device, first add terephthalic acid (PTA), ethylene glycol (EG) and antimony acetate into the reactor according to the above formula, and the temperature rises to 265°C for esterification reaction. At this time, triethyl Phosphate ester (TEP) and antioxidant 1010 are formulated with ethylene glycol (EG), and when the esterification rate reaches 95%, triethyl phosphate ester formulated with ethylene glycol and antioxidant 1010 are added. Under the pressure of 25Pa, react at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com