Patents

Literature

53 results about "Azoxymethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Azoxymethane (AOM) is a carcinogenic and neurotoxic chemical compound used in biological research. It is the oxide of azomethane and is particularly effective for the induction of a colon carcinoma.

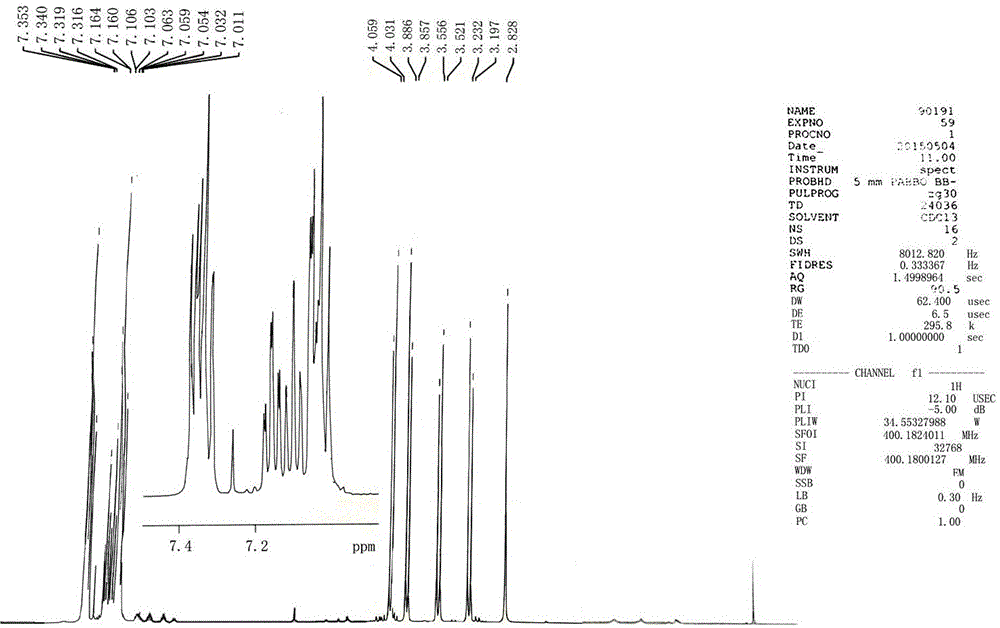

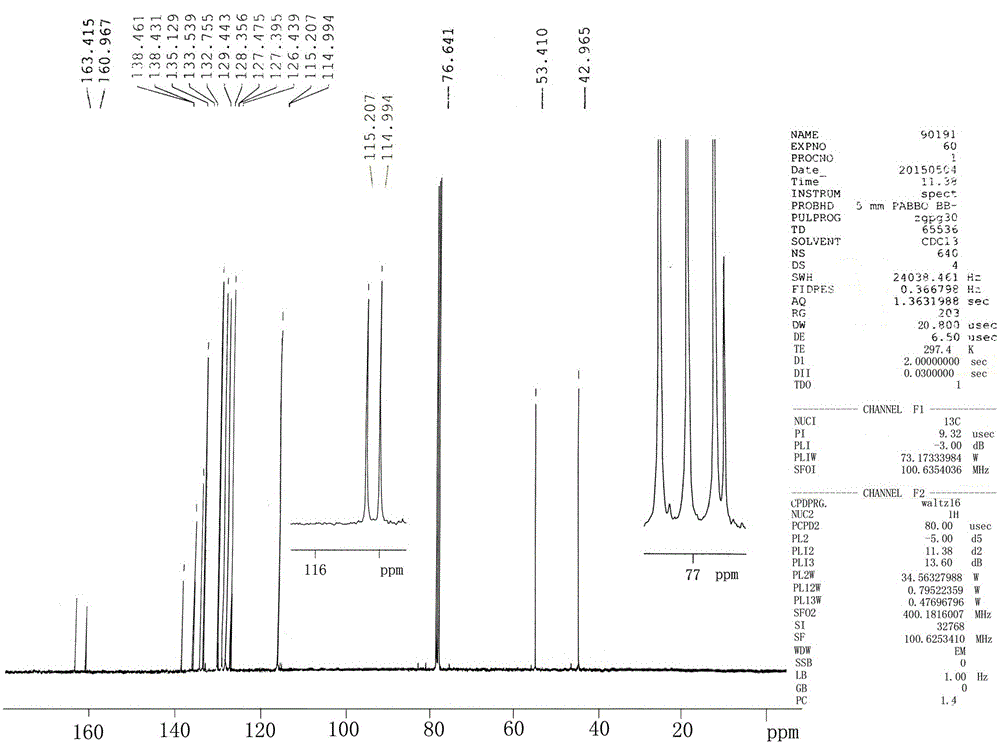

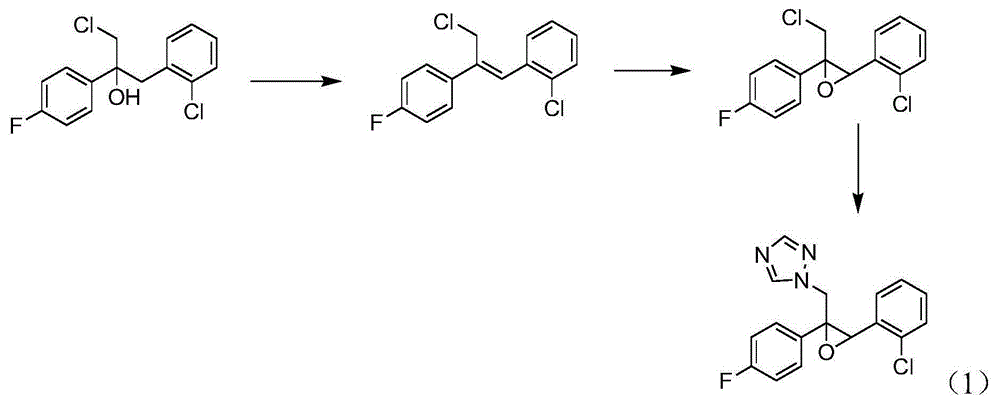

Epoxiconazole intermediate 1-chloro-3-(2-chlorophenyl)-2-(4-fluorophenyl)-2-propanol synthesis process

ActiveCN105130757AEasy to recycleProcess conditions are mild and controllableOrganic compound preparationHydroxy compound preparationPropanolChloride

The present invention discloses an epoxiconazole intermediate 1-chloro-3-(2-chlorophenyl)-2-(4-fluorophenyl)-2-propanol synthesis process, and belongs to the technical field of fine chemical industry. According to the process, 2-chlorobenzyl chloride and 2-chloro-4'-fluoroacetophenone are adopted as raw materials, diethoxymethane and toluene are adopted as solvents, and a two-step reaction comprising as a Grignard reaction and a nucleophilic addition reaction is performed to obtain the target product. According to the present invention, the high yield intermediate is obtained while the process operation is simplified, the raw material cost and the production cost are reduced, the environmental pollution is reduced, and the safety requirements of the industrial scale-up production are met.

Owner:内蒙古佳瑞米精细化工有限公司

Methanol gasoline mixed fuel and method of preparing the same

InactiveCN101508919ASolve the problems of poor stability, poor compatibility and easy delaminationCan be stored for a long timeLiquid carbonaceous fuelsGasolineSolvent

The invention relates to a methanol-gasoline blend fuel and a preparation method thereof, belonging to the technical field for preparing fuel gasoline. The methanol-gasoline blend fuel is made of the components with the weight percentage: 55-98% of gasoline, 1-44% of methanol and 1-10% of miscible solvent; wherein, the miscible solvent is more than one in dimethoxymethane, diethoxymethane and methoxyl ethoxy methane. The materials are put into a container to be evenly mixed together according to the mixture ratio, so that the product of the invention can be prepared. The invention has the advantages that as the miscible solvent with certain proportion is added into the methanol-gasoline, the problems of poor stability, bad intermiscibility and easy delamination can be effectively solved; the selected miscible solvent has the boiling range of 42-78 DEG C which is within the boiling range of main components of gasoline, thus not only effectively avoiding the Reid vapour pressure of the methanol-gasoline blend fuel rising and the risks such as remnant and the like, but also being safe and reliable in use.

Owner:张犀诚

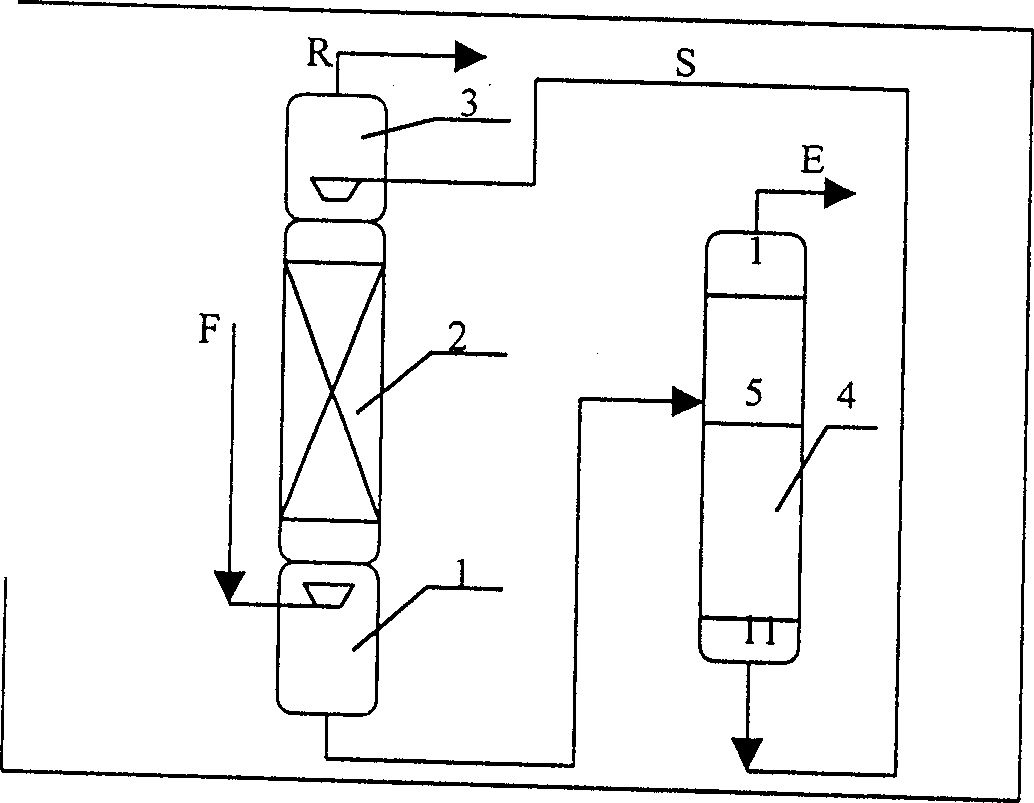

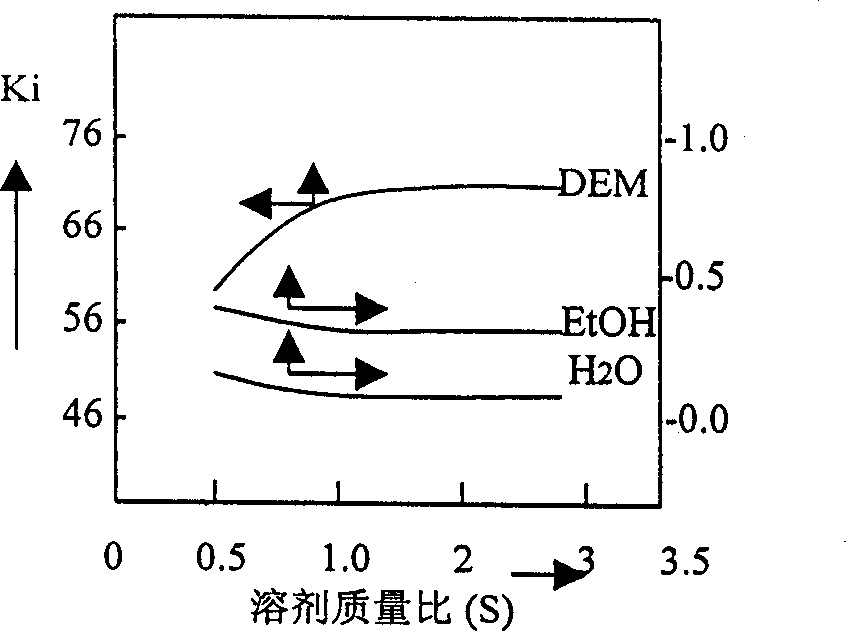

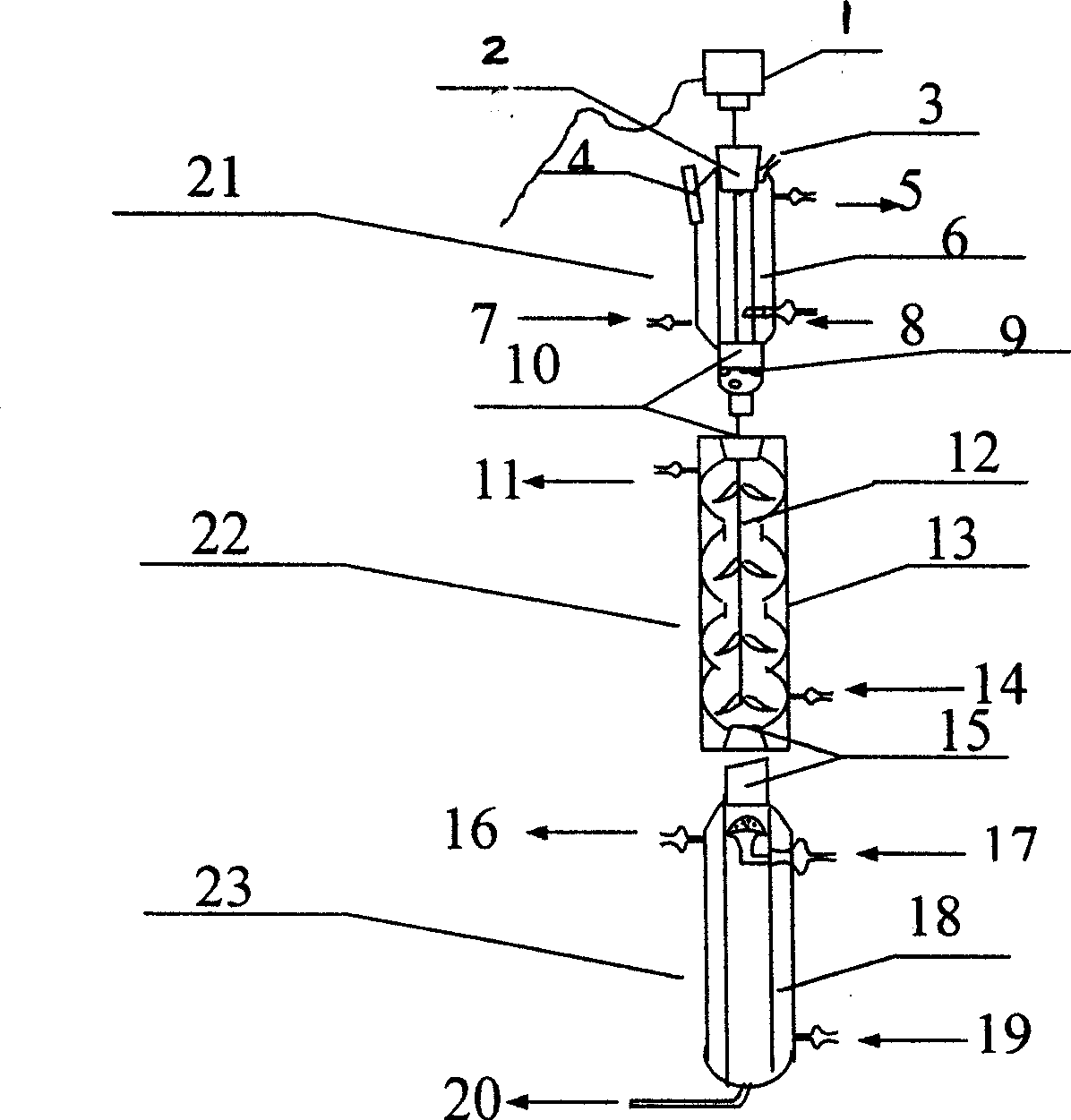

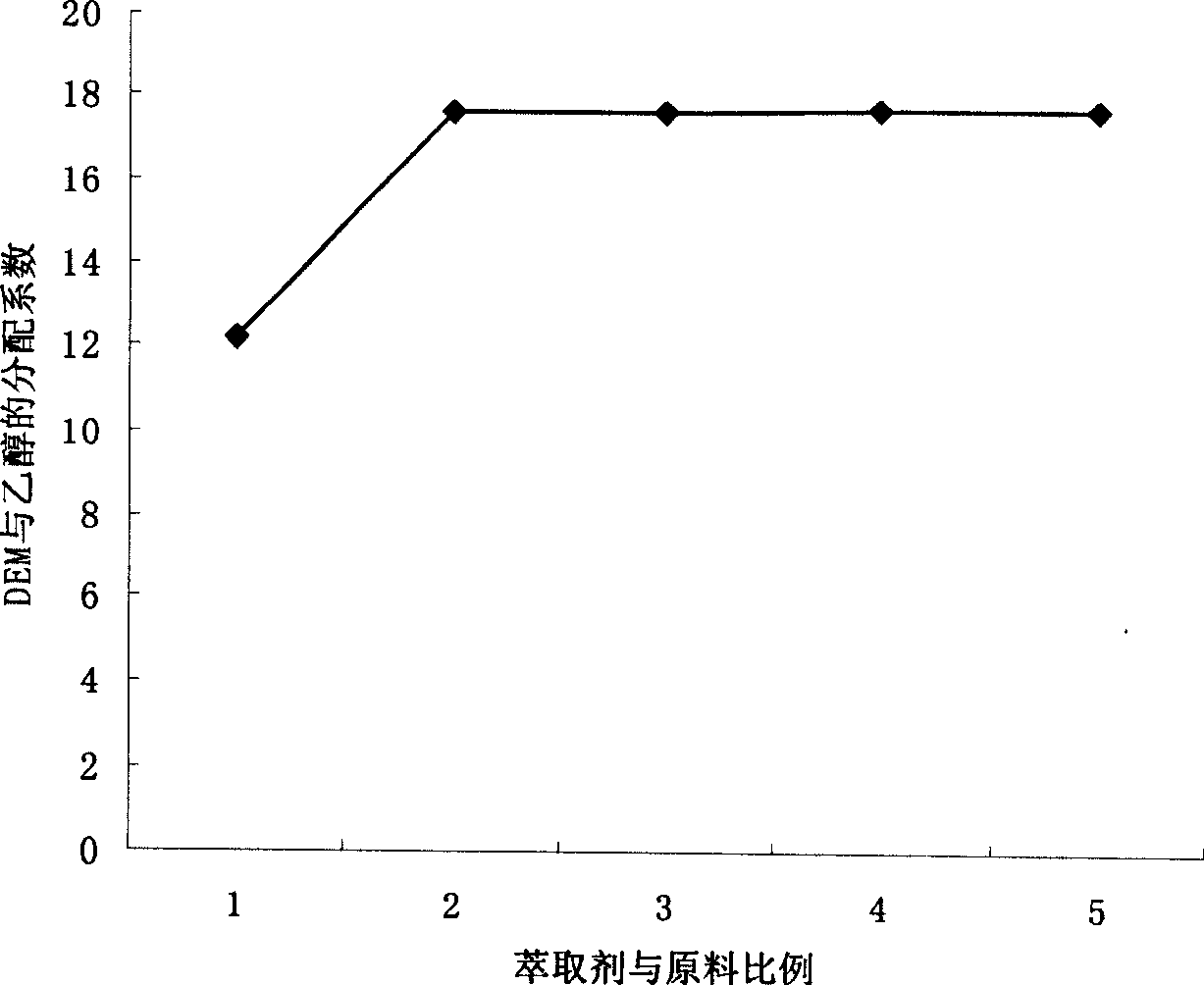

Liquid-liquid extraction process of dioxyethyl methane and water solution of ethanol

InactiveCN1388107AEfficient separationReduce energy consumptionEther separation/purificationPolyolTower

Dioxyethyl methane (DEM) and water solution of ethanol are liquid-liquid extracted with polyol as extractant, and after delaminating separation, the extraction phase is refined, the processed solvent is used circularly and the raffinate contains DEM in higher purity. The optimized scheme is cross current extraction and counter current extraction process, in which material DEM and water solution of ethanol are made to contact with extractant propanetriol flowing in reverse direction in an extracting tower, with the raffinate containing DEM over 99.6%, the mixed extractant liquid being separated in refining tower and the water solution of ethanol being obtained from the tower top. The said process can separate DEM and water solution of ethanol effectively.

Owner:NANJING NORMAL UNIVERSITY

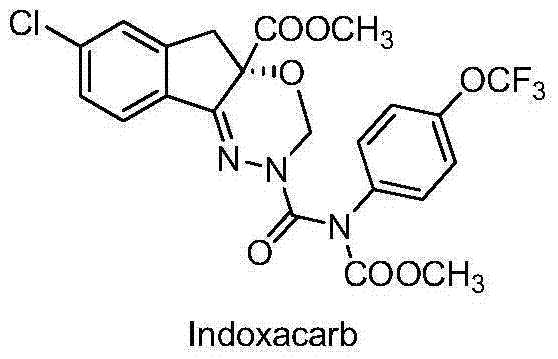

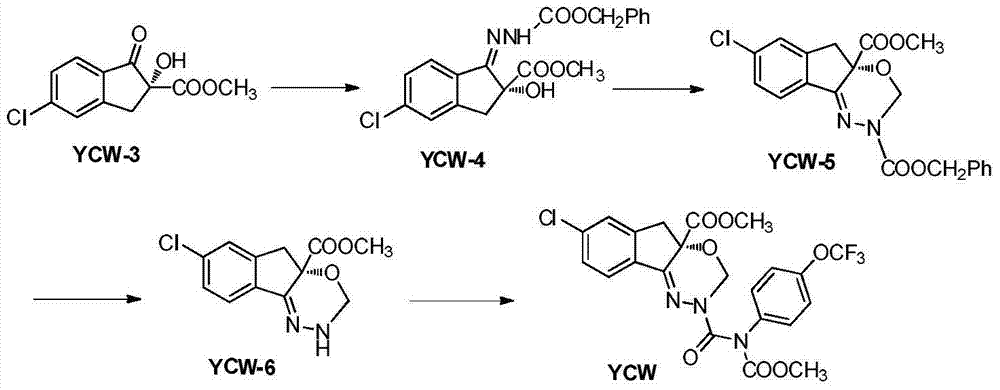

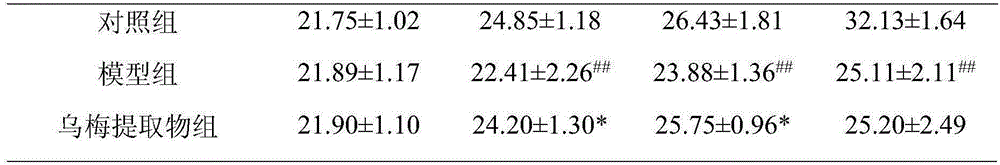

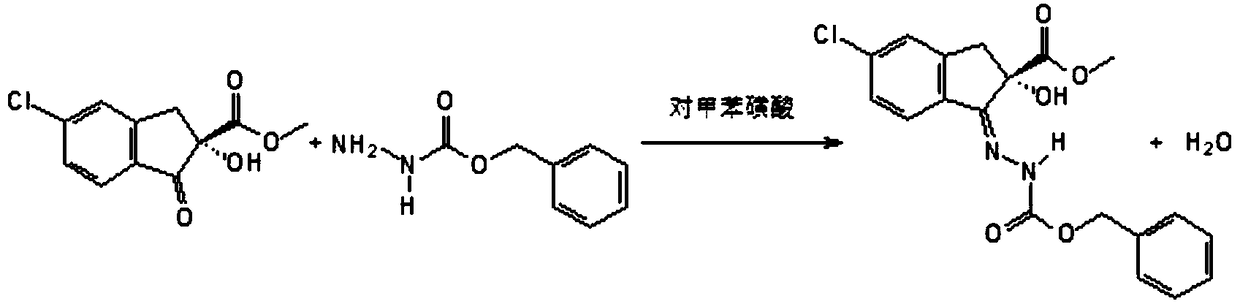

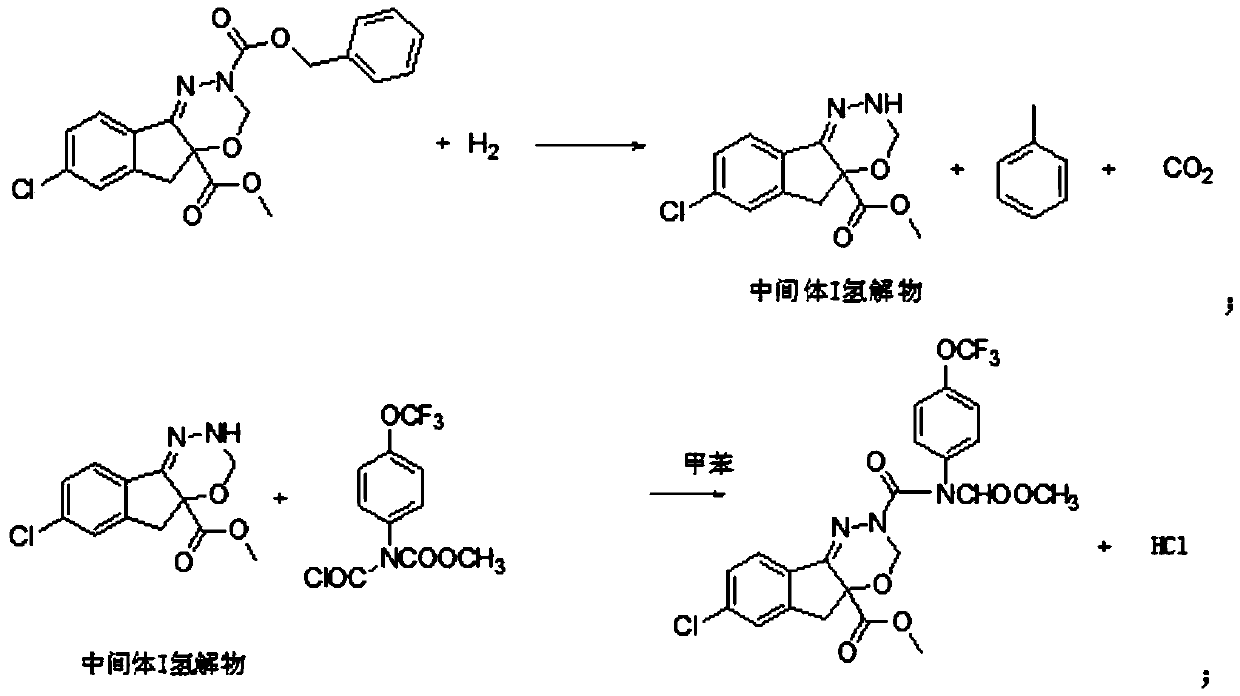

Method for synthesizing intermediate of agricultural insecticide indoxacarb

ActiveCN104262285AHigh yieldReduce decompositionOrganic chemistryRoom temperatureReaction temperature

The invention discloses a method for synthesizing an intermediate of agricultural insecticide indoxacarb. The method comprises the following steps: (1) putting YCW-4, Lewis acid and methylbenzene into a reaction container according to a proportion, stirring, heating to a reacting temperature of 105-110 DEG C, dripping a methylbenzene solution of diethoxymethane, adding benzyl carbazate, and reacting at the reacting temperature until the reaction is carried out completely, wherein azeotrope of ethanol and diethoxymethane serving as a byproduct is constantly vaporized and eliminated in the reacting process; (2) stopping heating after the reaction is finished, cooling to room temperature under a stirring condition, concentrating at reduced pressure to reclaim methylbenzene, cooling and crystallizing the concentrate at low temperature by using a crystallization solvent, suction-filtering, washing, and baking to obtain light yellow crystal which is a target product, namely the intermediate of agricultural insecticide indoxacarb. The synthesizing method has the technical advantage of high yield.

Owner:ZHEJIANG UNIV

Method for preparing diethoxymethane by using active carbon supported solid acid catalyst

ActiveCN102795976ACheap manufacturingEasy to handleOrganic chemistryOrganic compound preparationReaction temperatureSolid acid

The invention relates to a method for preparing diethoxymethane by using an active carbon supported solid acid catalyst. The method is characterized in that formaldehyde and ethanol are used as raw materials and reacted under normal pressure under the action of a solid acid catalyst at the temperature of 70 to 100 DEG C, the reflux ratio is controlled to be 1:1-4:1, distillate of 74 to 76 DEG C is collected on the top of a tower, and the diethoxymethane product is obtained; after the aqueous solution in a tower kettle is filtered, the solid acid catalyst is recycled in the kettle; the molar ratio of the formaldehyde to the ethanol is 1:2-1:5, the formaldehyde raw material is a formaldehyde solution at the concentration of over 37 weight percent, and the ethanol raw material is absolute ethanol or an ethanol solution at the concentration of 75-95 weight percent; the solid acid catalyst is the active carbon supported solid acid catalyst, the active acid ingredient is sulfuric acid, and the acid solid capacity is 15 to 25 mass percent; and the consumption of the solid acid catalyst is 0.3 to 10 percent of the total mass of the reactants. The method has the advantages that the catalyst is economic in preparation, easy to separate from the product and low in equipment corrosion, and the waste catalyst is easy and convenient to reclaim and treat.

Owner:NANJING FORESTRY UNIV +1

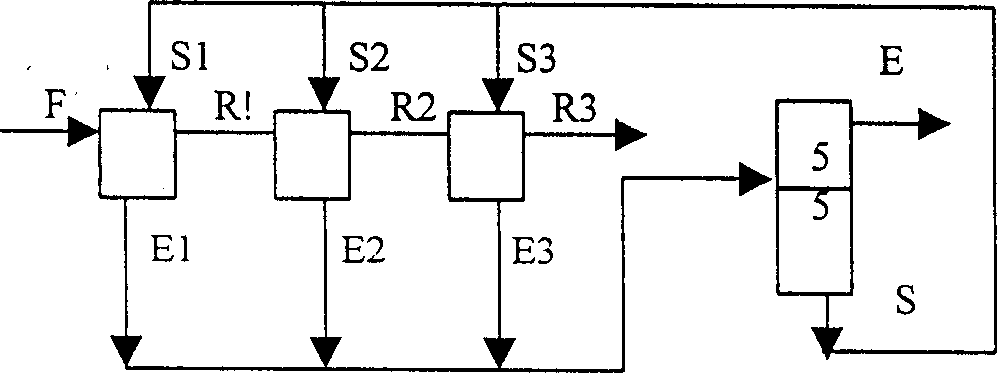

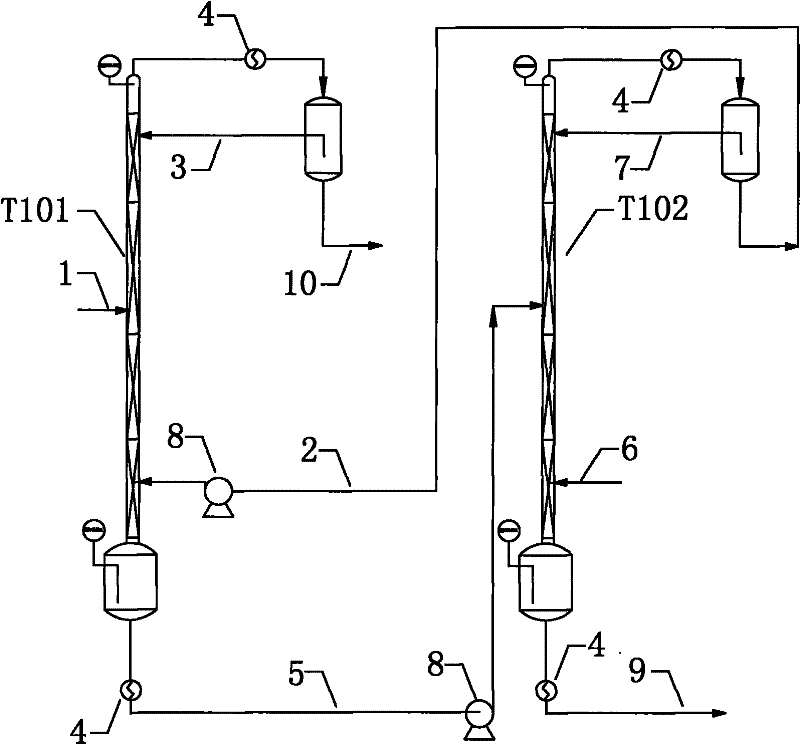

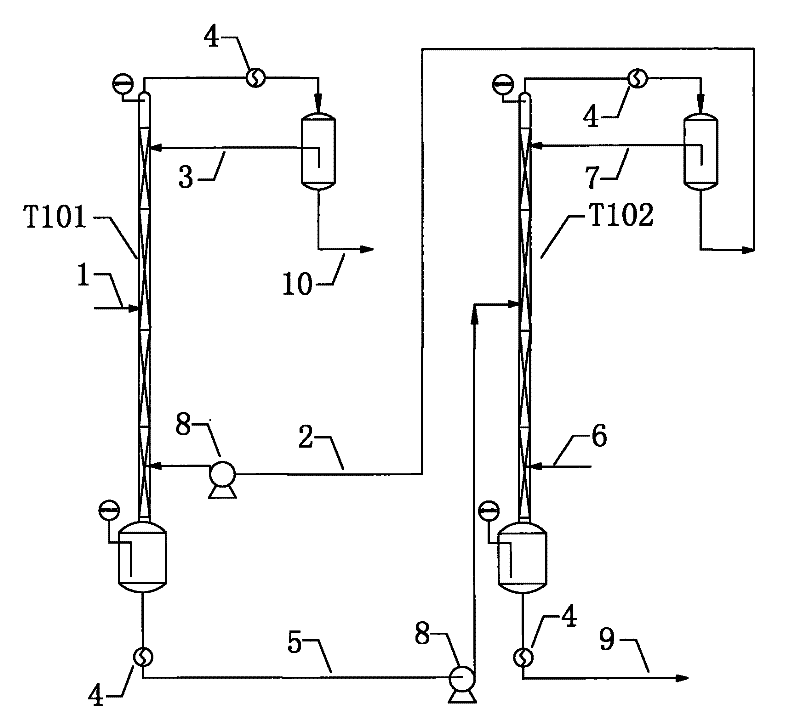

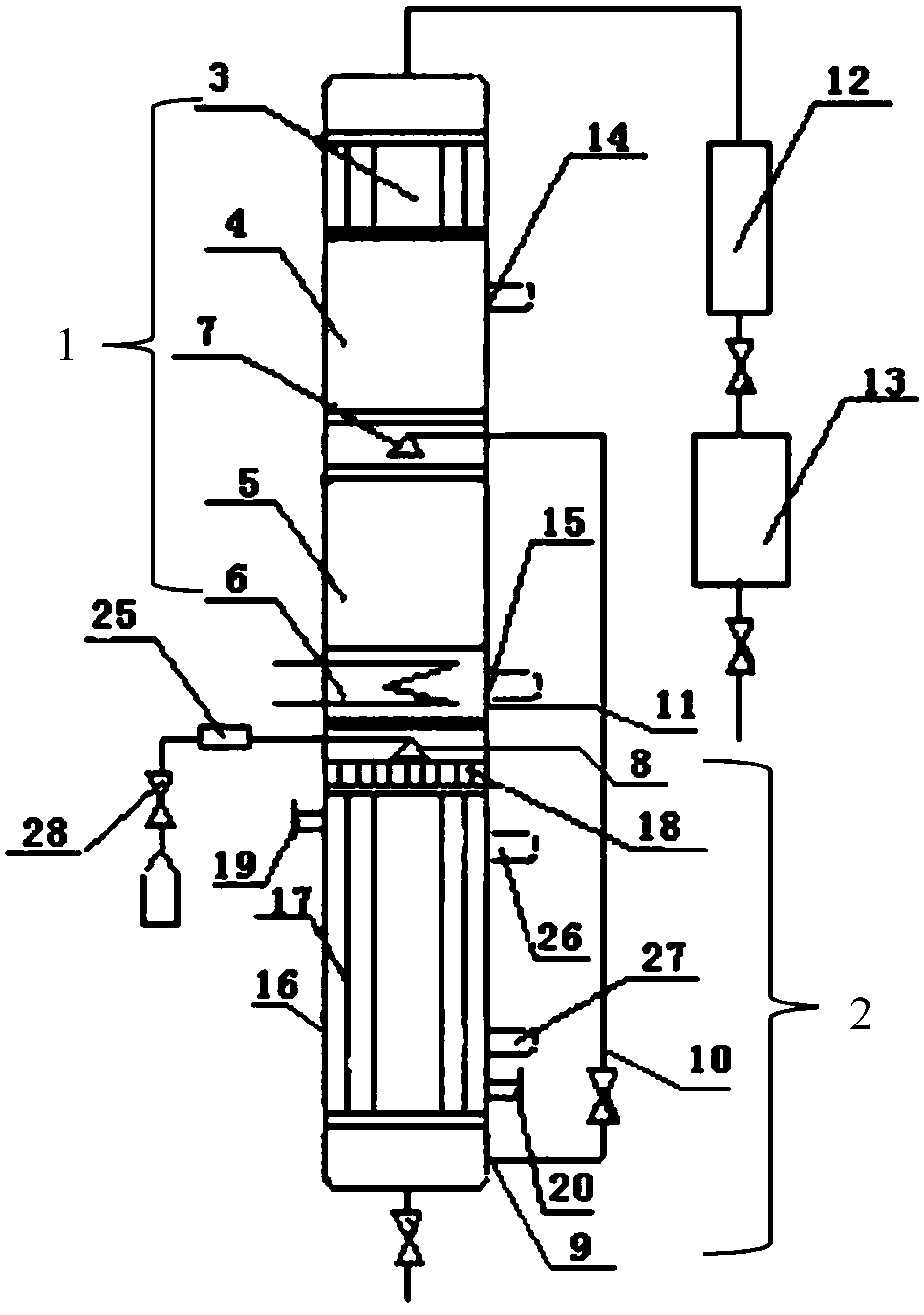

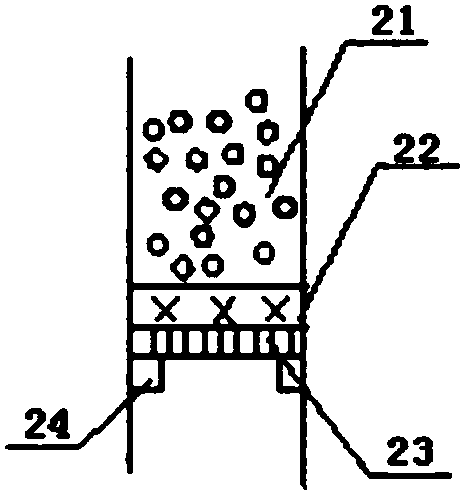

Continuous catalysis and rectification technology for synthesizing diethoxymethane

ActiveCN102206145AHigh purityShort reaction cycleOrganic chemistryOrganic compound preparationWastewaterHigh selectivity

The invention discloses a continuous catalysis and rectification technology for synthesizing diethoxymethane. According to the invention, formaldehyde and ethanol are adopted as raw materials, and a two-stage linkage catalysis rectifying tower composed of a first-stage reaction rectifying tower and a second-stage reaction rectifying tower is employed. Solid acid catalysts are loaded in both the first-stage and the second-stage reaction rectifying towers. The technology comprises the steps that: (A) formaldehyde is delivered to the first-stage reaction rectifying tower, while ethanol is delivered to the second-stage reaction rectifying tower; (B) formaldehyde discharged from the bottom of the first-stage reaction rectifying tower is delivered to the second-stage reaction rectifying tower, where formaldehyde is subject to a reaction with ethanol; and waste water is discharged from the bottom of the second-stage reaction rectifying tower; (C) material obtained from the top of the second-stage reaction rectifying tower is delivered to the first-stage reaction rectifying tower, where the obtained material is subject to a reaction with formaldehyde; and diethoxymethane, which is a target product, is obtained from the top of the first-stage reaction rectifying tower; (D) the steps from (A) to (C) are repeatedly circulated. The technology has advantages of short processing period, high selectivity, high yield, high product purity, and simple operation. Therefore, the technology is suitable for continuous industrial production.

Owner:石家庄一科发化工科技有限公司

Method for separating diethoxymethane and ethanol by glycerol and water multi-stage countercurrent liquid-liquid extraction

InactiveCN101503342AEfficient separationReduce energy consumptionOrganic compound preparationHydroxy compound preparationPolyolGlycerol

The invention relates to a method for liquid-liquid extracting and separating diethoxymethane (DEM) and ethanol by adopting glycerin and water in a way of multi-stage counter current, comprising the steps: polylol and the water are taken as extracting agent for liquid-liquid extracting the DEM and the ethanol solution; after extraction and hierarchical separation, extract phase is processed by rectifying, and then solvent can be recycled; the faffinate contains over 99.7% of DEM. The method has the prioritization scheme that liquid-liquid extraction with multi-stage counter current is adopted; the raw material DEM and the ethanol solution are sent to an extracting tower and contacted with extracting agent propanetriol and water which flow into the extracting tower along the reverse direction, the faffinate passes through a static hierarchical section 2 (the liquid stops at the section for more than 10min), and the faffinate contains more than 99.7% of DEM; the mixed liquid of extracting agent at the bottom of the extracting tower is separated by a rectifying tower, and ethanol water solution can be obtained on the top of the rectifying tower. The method can effectively separate the DEM and the ethanol solution, and the purity and one-time yield of the DEM respectively reaches over 99.7% and 98% after separation.

Owner:NANJING NORMAL UNIVERSITY

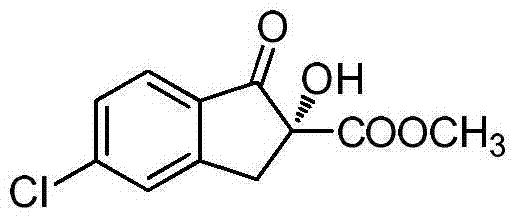

Preparation method of indoxacarb intermediate

ActiveCN106397351APromote decompositionThe reaction is easy to operateOrganic chemistryReaction temperaturePhosphoric acid

The invention relates to a preparation method of indoxacarb intermediate. The preparation method is characterized by comprising the following steps: dissolving intermediate 5-chloro-2-methoxycarbonyl-2-hydroxy-1-indanone into xylene, adding benzyl carbazate and phosphorus pentoxide, separating out phosphoric acid, adding diethoxymethane into reaction liquid, enabling the solvent xylene to flow back on a tower, dropping the obtained reaction liquid into xylene at a constant speed, gathering ethyl alcohol, performing negative pressure desolventizing on obtained reaction liquid, adding a crystallizing agent into the rest liquid, performing cooling crystallization, filtering, and drying, so as to obtain 7-chloroindeno [1,2-e][1,3,4] oxadiazine-2,4a (3H,5H)-dicarboxylicacid-4a-methyl-2-benzylester. The method is convenient to operate, increases the reaction temperature, accelerates the reaction speed, and obviously improves the content and the yield of the intermediate.

Owner:JINGBO AGROCHEM TECH CO LTD

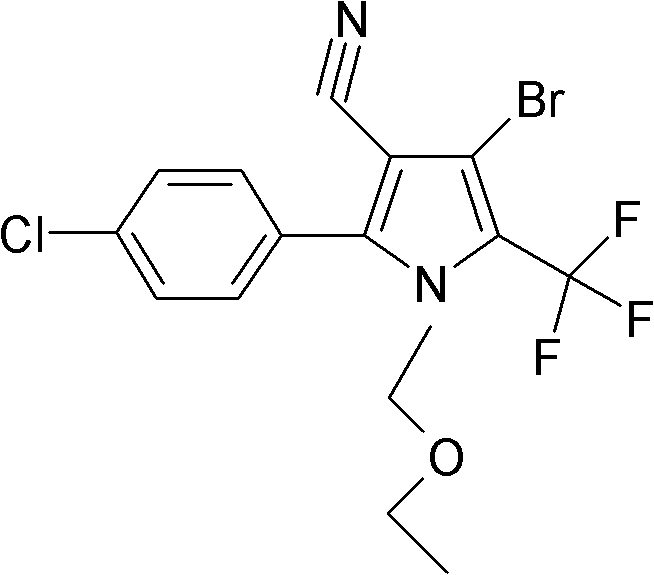

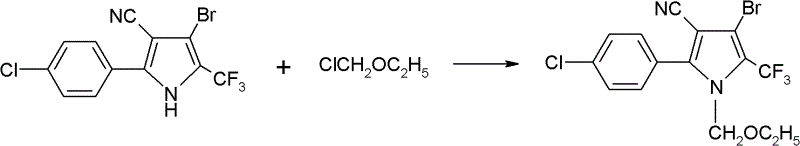

Preparation method of chlorfenapyr

InactiveCN102617439AReduce moisture contentReduce processing difficultyOrganic chemistryChlorfenapyrKetone solvents

The invention relates to a preparation method of chlorfenapyr, wherein, 4-bromine-2-(4-chlorphenyl)-5-trifluoromethyl pyrrole-3-nitrile and chloromethyl ethers are taken as raw material, alkali carbonate or organic amine is taken as acid-binding agents, and esters are taken as reaction solvent so as to prepare chlorfenapyr. The preparation method adopts ester solvent, reduces the treatment difficulty of waste water in the later period, lowers the manufacturing cost greatly, and reduces the environmental protection treatment pressure; the manufacturing cost is 20 percent lower than the diethoxymethane technology and is 10 percent lower than the ketones solvent technology; the wastewater quantity is only about 10 percent of the diethoxymethane technology and is about 25 percent of the ketones solvent technology; and unforeseen benefits can be achieved by compared with the traditional ketones solvent.

Owner:山东潍坊双星农药有限公司

Preparation method of indoxacarb technical concentrate

InactiveCN107235926ANo pollution in the processHigh response rateOrganic chemistrySodium methoxideEthylenediamine

The invention discloses a preparation method of an indoxacarb mother drug, comprising the following steps: using 5-chloroindanone as a raw material to synthesize: (S)-5-chloro-2,3-dihydro-2-hydroxyl-1- Methyl oxo-1H-indene-2-carboxylate; from (S)-5-chloro-2,3-dihydro-2-hydroxy-1-oxo-1H-indene-2-methyl carboxylate and Benzyl carbazate is first condensed and then synthesized with diethoxymethane: 2‑benzyloxycarboxy‑7‑chloroindeno[1,2‑P][1,3,4]oxadiazine‑2, 4a-methyl carboxylate; use p-trifluoromethoxyaniline as raw material and methyl chloroformate, 1,2-diphenylethylenediamine as acid-binding agent to generate 4-(trifluoromethoxy)phenyl Methyl carbamate is then photoacylated with sodium methoxide to generate chloroformyl (4-trifluoromethoxyphenyl) methyl carbamate; by 2-benzyloxycarboxy-7-chloroindeno[1,2 ‑P][1,3,4]Oxadiazine‑2,4a‑carboxylate methyl ester is deprotected by hydrogenation, and then synthesized with methyl chloroformyl (4‑trifluoromethoxyphenyl) carbamate prestige. The invention has the advantages of high reaction yield, greatly improved production efficiency, high product purity and no pollution to the environment.

Owner:NANTONG SHI ZHUANG CHEM

Anisodamine production method

The invention provides an anisodamine production method which comprises the following steps: S1, taking belladonna coarse powder, adding 25% to 28% concentration of ammonia for soaking for 15-20min; S2, adding diethoxymethane for percolation, extracting the percolation liquid with 2% sulfuric acid; S3, adding chloroform for cleaning, adding the ammonia to adjust pH to 9, adding carbon tetrachloride for extraction; S4, adding water for washing carbon tetrachloride layer, and adding anhydrous sodium sulfate into chloroform layer for drying; S5, filtering and recovering the chloroform, adding anhydrous benzene for dissolution, and precipitating crystal; and S6, adding benzene for washing, drying at 55-60 DEG C to obtain anisodamine. The anisodamine production method improves the collection rate and collection purity of the anisodamine, the purity reaches 98%, and the process parameters are optimized.

Owner:施佩蓓

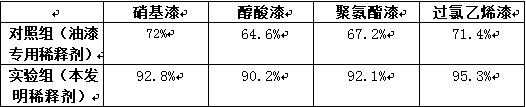

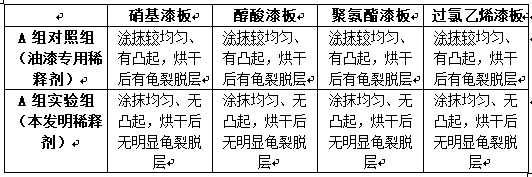

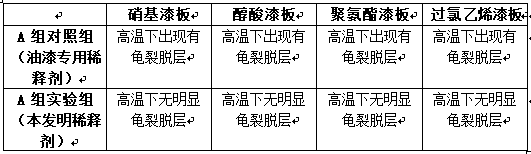

Multi-purpose paint diluting agent and preparation technology thereof

The invention discloses a multi-purpose paint diluting agent and a preparation technology thereof. The multi-purpose paint diluting agent is prepared from the following raw materials: ethylene glycolmonoethyl ether acetate, dichloropropane, pentaerythritol, cyclohexanone, tetrabutyl orthosilicate, ethyl cellosolve, diethoxymethane, methyl isopropyl ketone, turpentine and isophoron. The paint diluting agent prepared by the preparation technology does not contain benzene toxic substances, is safe and has no toxin, and has good stability and strong dissolubility; various types of paint can be dissolved through the multi-purpose paint diluting agent; the production flow is simple, the production cost is low and no three wastes are discharged, so that the multi-purpose paint diluting agent hasa good application prospect.

Owner:韩立志

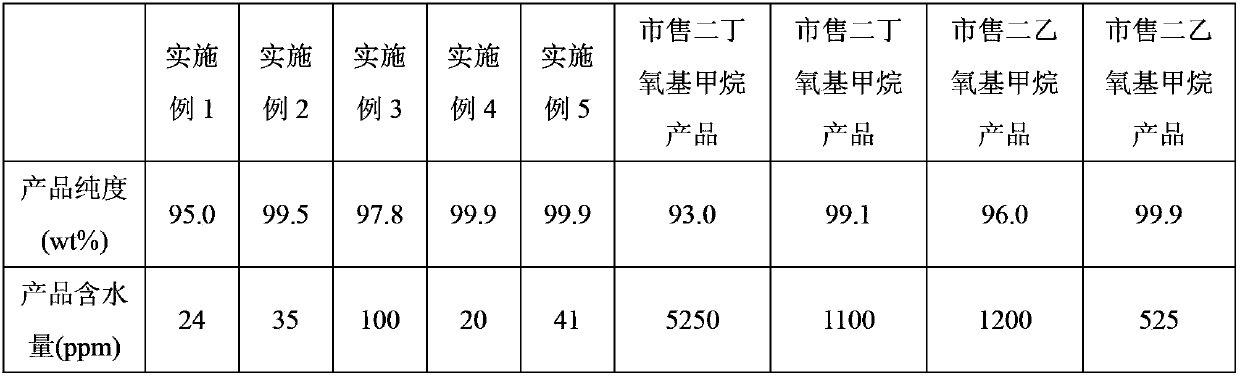

Production method of dibutoxymethane, diethoxymethane, dipropoxymethane or dipentyloxymethane

ActiveCN103965029AReduce moisture contentHigh purityOrganic chemistryOrganic compound preparationInternal pressureAlcohol

The invention provides a production method of dibutoxymethane, diethoxymethane, dipropoxymethane or dipentyloxymethane. The production method comprises the following steps of 1, taking formaldehyde or a formaldehyde derivative, mixing the formaldehyde or formaldehyde derivative and an alcohol raw material, and pre-heating the mixture to a temperature of 70-160 DEG C, 2, feeding the pre-heated mixture into a reactor, adding an acid catalyst into the reactor, carrying out heating until an alcohol-acid condensation reaction occurs and the materials in the reactor vaporize, and 3, releasing the produced gas from the reactor, directly feeding the gas into a rectifying tower communicated with the reactor, carrying out rectification, and taking out the product on the bottom of the rectifying tower, wherein the internal pressure of the rectifying tower is less than zero. The production method only adopts a rectifying tower-based treatment process, does not additionally use a dehydrating agent, and can produce a dibutoxymethane equimolecular quantity conditioning agent having water content less than 100ppm and purity more than 95%. The production method has simple processes and short production time, obviously reduces energy consumption and is suitable for industrial production.

Owner:李云勇 +2

Green environment-friendly diluent

The invention discloses a green environment-friendly diluent which mainly comprises the following components: 55-65% of dioxo ethyl methane, 8-12% of #120 solvent gasoline, 7-9% of dimethylbenzene, 11-13% of ethanol, 2% of ethylene glycol, 2% of butanol, 2% of butyl ester, 2% of ethyl ester and 2% of cyclohexanone. The green environment-friendly diluent adopts dioxo ethyl methane as the main component, and the use amount of benzene is small, so that the working security is facilitated, and the requirements on working environment improvement of departments and enterprises are met; and moreover the green environment-friendly diluent is remarkable in university, and the nitrolacquer paint series, the alkyd paint series, the crylic acid paint series, the epoxy paint series, the polyurethane paint series, the vinylidene chloride paint series, acetal paint series and like can be diluted; and meanwhile the production process is simple, and the production process is free of waste water and waste slag discharge and has small amount of gas volatilization, so that the national discharge standard is met.

Owner:吕金海

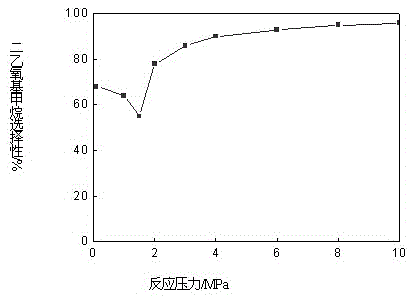

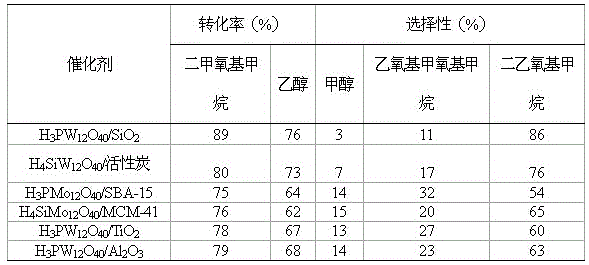

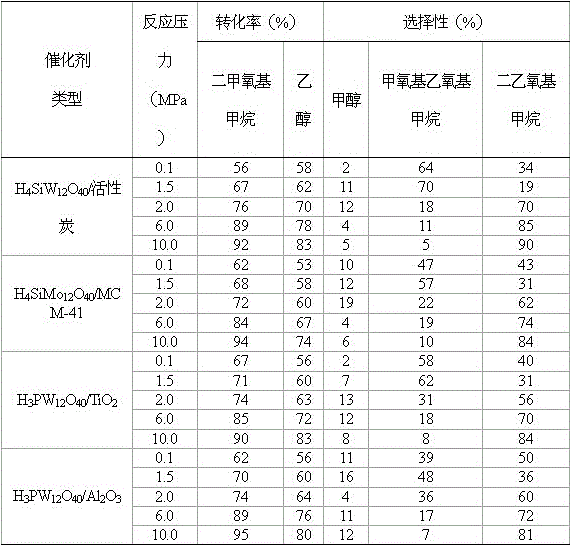

Method for preparing diethoxymethane by supported heteropolyacid catalyst

InactiveCN105622365AHigh selectivityEasy to operateOrganic chemistryMolecular sieve catalystsDimethoxymethaneAqueous solution

The invention relates to a method for preparing diethoxymethane, in particular to a method for for preparing diethoxymethane by a supported heteropolyacid catalyst. According to the method, dimethoxymethane and ethanol are taken as raw materials, liquid acid and supported liquid acid are taken as catalysts, the preparation method of the supported heteropolyacid catalyst, for example 33% of H3PW12O40 / SiO2, comprises the following steps that a phosphotungstic acid aqueous solution with the concentration of 33% by mass is used, SiO2 is taken as a carrier, the impregnation liquid volume is the approximate to the pore volume, a catalyst sample is obtained after the phosphotungstic acid aqueous solution and the SiO2 are mixed uniformly and stood at the normal temperature by 10h, the sample is dried at the temperature of 120 DEG C, and calcination is performed at the temperature of 350 DEG C to obtain the 33% of H3PW12O40 / SiO2 catalyst by the mass is prepared. According to the method, the product is relatively simple, the selectivity is high, and the method has an excellent application prospect. The raw materials required by the method are easy to obtain, the whole process operation is simple, at the same time, the method doesn't produce any chemical substances polluting the environment, and the method belongs to the environment-friendly technology route.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

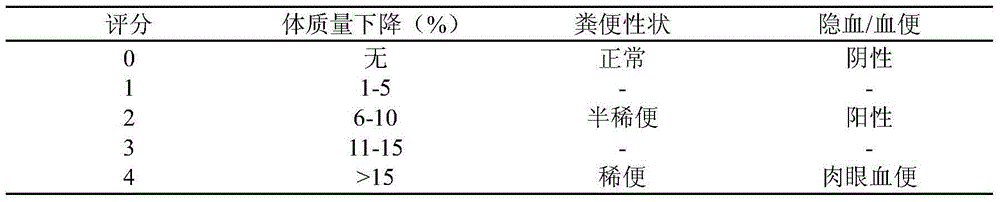

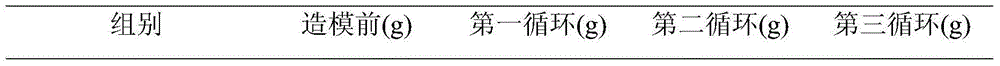

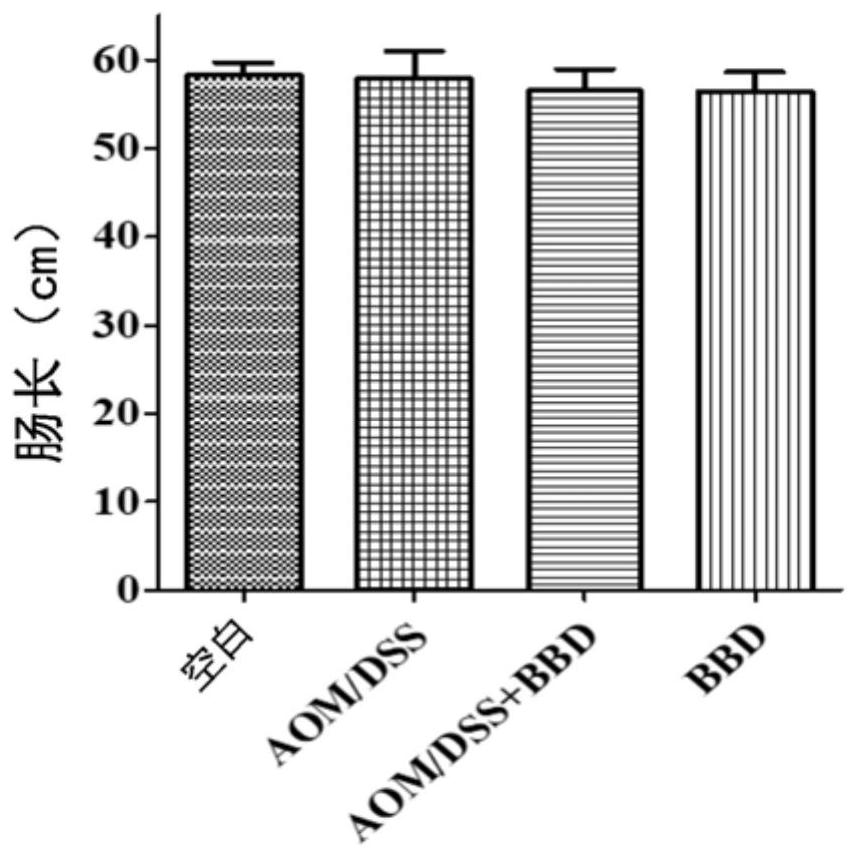

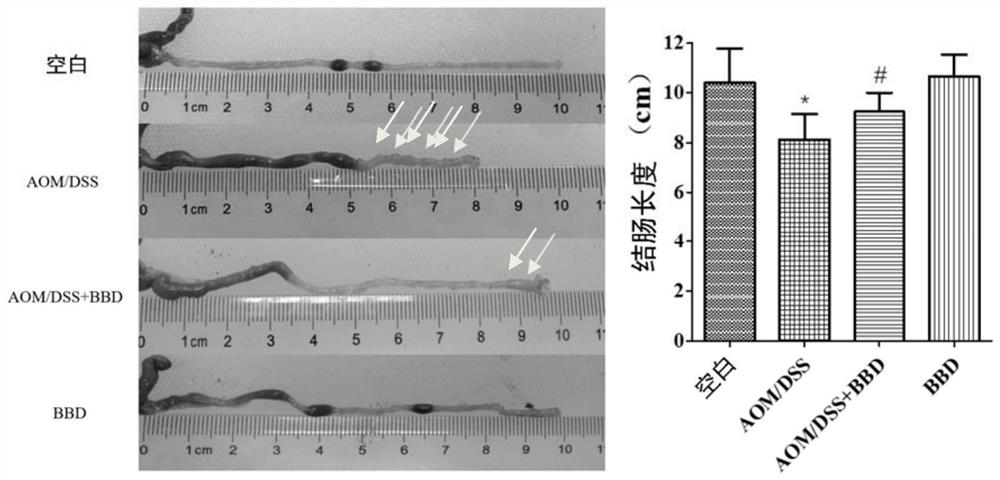

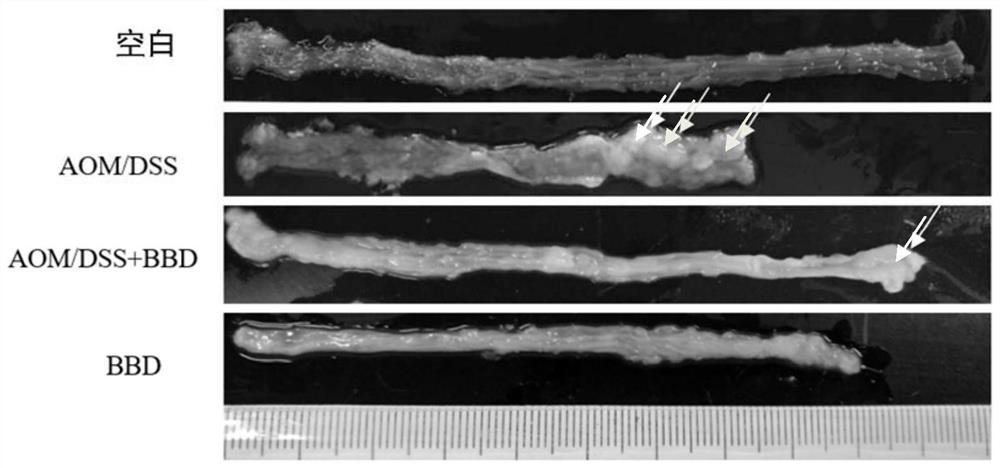

Application of dark plum fruit and extract of dark plum fruit in preparation of drug or health care product for controlling CRC (colorectal cancer)

ActiveCN104800321AImprove weight lossReduce tumor incidenceAntineoplastic agentsFood preparationBowels diseasesLoose Stool

The invention discloses an application of dark plum fruit and an extract of dark plum fruit in control of the CRC (colorectal cancer). On the basis of the conventional efficacy of dark plum fruit, a large quantity of experiments is adopted for intensive study, an AOM-DSS (azoxymethane / dextran sodium sulfate) induced mouse model suffering from bowel disease carcinogenesis is adopted, and study results show that the dark plum fruit and the extract of the dark plum fruit can substantially improve the condition of weight loss of the model mouse in a bowel disease carcinogenesis process, can substantially improve the continuously serious symptoms such as body mass loss, loose stools, hematochezia and the like of the mouse suffering from bowel disease carcinogenesis, can substantially reduce the colonic neoplasm incidence of the mouse suffering from bowel disease carcinogenesis and has very good CRC preventing and controlling efficacy.

Owner:JIANGSU PROVINCIAL HOSPITAL OF TCM

Indeno oxadiazine compound synthetic method

The invention relates to an indeno oxadiazine compound synthetic method. The method comprises the following steps: mixing toluene, methyl 5-chloro-2,3-dihydro-2-hydroxy-1-oxo-inden-2-carboxylate, benzyl carbazate and methylbenzenesulfonic acid, performing a reaction under vacuum condition at 60 DEG C to 70 DEG C, and removing water while the reaction is carried out to obtain a first reaction solution; mixing toluene and diethoxymethane, adding the first reaction solution dropwise, and removing the ethanol while the reaction is carried out to obtain a second reaction solution; and separating and purifying the second reaction solution to obtain high-purity methyl 7-chloro-2,3,4a,5-tetrahydro-2-(benzyloxy)carbonyl indeno(1,3,4)oxadiazine-4alpha-carboxylate. The reaction yield is also high.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

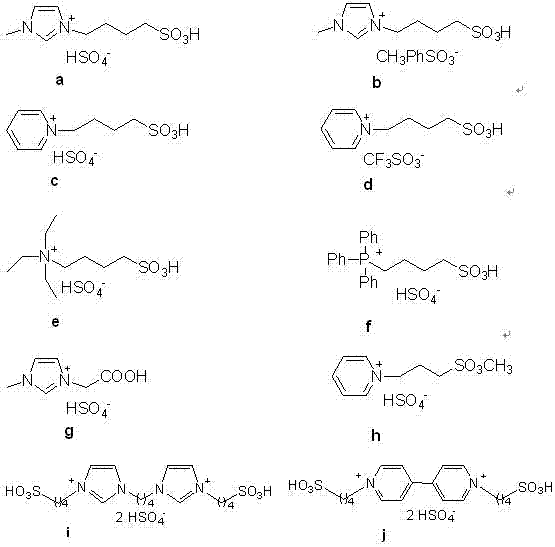

Continuous reaction rectifying synthesizing methylene diethyl ether technology

A process for synthesizing diethoxymethane (DEM) by continuous reactive rectification includes such steps as continuously adding formaldehyde and acid catalyst to reactor, adding ethanol from reactifying column, respectively controlling the internal temp and the top temp of reactive rectifying tower to 80 deg.C and 65 deg.C, reactive reactifying to obtain distilate from tower, extracting by propanetriol or diethanolamine in liquid-liquid extracting tower to obtain DEM from tower top, and regenerating extractant, ethanol and water by regenerating tower for cyclic use. Its advantages are high speed and high output rate (more than 76%).

Owner:NANJING NORMAL UNIVERSITY

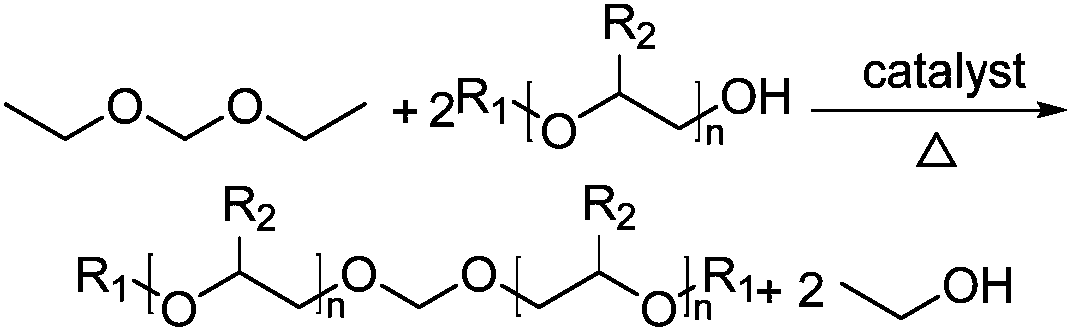

Bis-diol monoalkyl ether formaldehyde preparation method

ActiveCN107827717AReduce dosageHigh catalytic activityOrganic chemistryOrganic compound preparationWastewaterEther

The invention discloses a bis-diol monoalkyl ether formaldehyde preparation method. The bis-diol monoalkyl ether formaldehyde can be prepared by the steps: utilizing methylene diethyl ether and diolmonoalkyl ether as raw materials and performing transacetalation under the catalysis of phosphotungstic acid. According to the preparation method disclosed by the invention, the bis-diol monoalkyl ether formal is synthesized from a phosphotungstic acid catalyst; the catalyst has the advantages of small use amount, high catalytic activity, small corrosion to equipment and easiness in being separated from products; recycling the catalyst is achieved; the preparation method is a high-efficiency, green and environment-friendly production method. The methylene diethyl ether is utilized to replace formaldehyde as the raw material, so that pollution of the formaldehyde to the environment and harm of the formaldehyde to the human body are greatly reduced; wastewater emission is reduced, product quality is improved, and a green chemistry idea is met.

Owner:ANHUI XINYUAN CHEM

Method for preparing diethoxymethane from ethanol and paraformaldehyde

InactiveCN102180777AReduce energy consumptionSimple processOrganic chemistryOrganic compound preparationChemical industryParaformaldehyde

The invention discloses a method for preparing diethoxymethane from ethanol and paraformaldehyde, which relates to a synthesis method of chemical industry. The method comprises the following steps of: stirring ethanol and paraformaldehyde in a reaction kettle, adding sulfuric acid when heating to reach 70+ / -2 DEG C, preserving heat and undergoing a reaction at the temperature of 75-85 DEG C for 0.5-1 hour; and heating and distilling by using a rectifying tower, collecting distillate with the boiling range of 70-88 DEG C under the condition that the reflux ratio is (1-3):1, standing the distillate, distilling supernate and collecting distillate serving as diethoxymethane at the temperature of 80-88 DEG C. Ethanol directly reacts with paraformaldehyde under the condition that sulfuric acid is taken as a catalyst, so that a process is simplified, and a large amount of post-treatment equipment investment can be particularly saved; the method is easy to operate and control; and compared with the prior art, the method has the advantages of higher primary transformation ratio, short reaction time, low energy consumption and product purity of up to 99.6 percent.

Owner:YANGZHOU LIBANG CHEM

Oxygenation anticoagulant for diesel oil

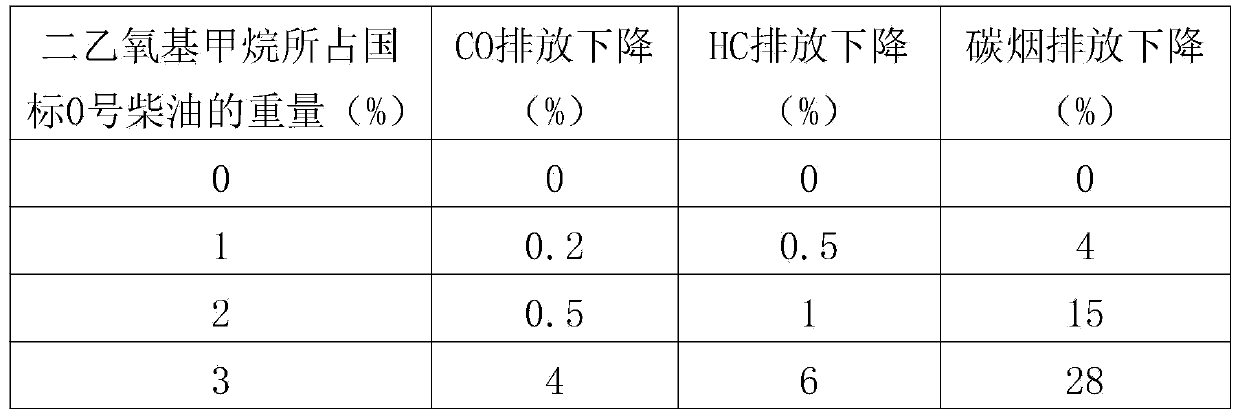

InactiveCN110564464AEasy to cleanMake up for the problem of reduced powerLiquid carbonaceous fuelsFuel additivesKeroseneDiesel combustion

The invention discloses an oxygenation anticoagulant for diesel oil, which relates to the field of fuels. The oxygenation anticoagulant is prepared by mixing Fischer-Tropsch synthesis kerosene, polyoxymethylene dimethyl ether, diethoxymethane and octanol according to a specific ratio; wherein polyoxymethylene dimethyl ether and diethoxymethane are used as oxygenating agents to improve the cleanness of diesel oil combustion; and the Fischer-Tropsch synthesis kerosene can make up the problem that the dynamic property of the diesel oil is reduced due to the addition of polyoxymethylene dimethyl ether and diethoxymethane, and play a role in maintaining or reducing the condensation point of diesel oil. The preparation of the oxygenation anticoagulant is simple, the main raw materials are from coal-to-methanol and ethanol, and the cost is low. Moreover, the comprehensive performance of the diesel oil can be effectively improved, and the economic value is relatively high.

Owner:曹强 +1

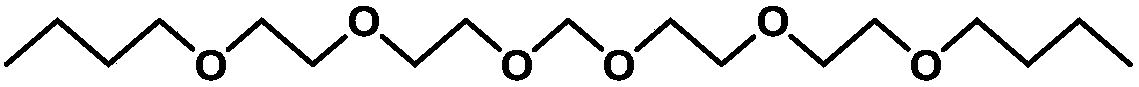

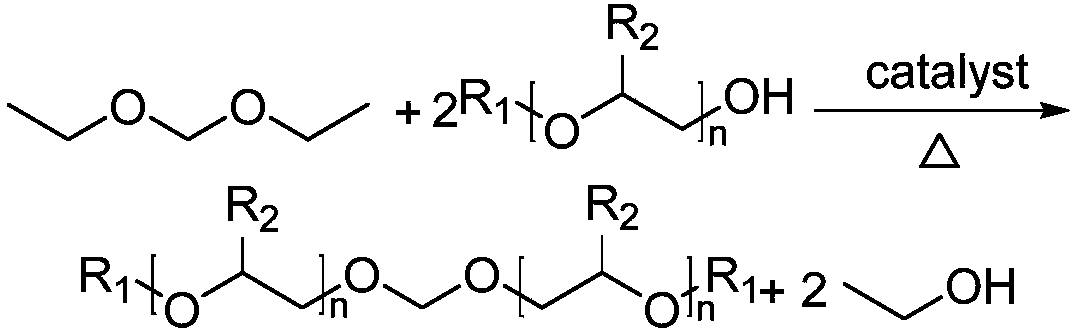

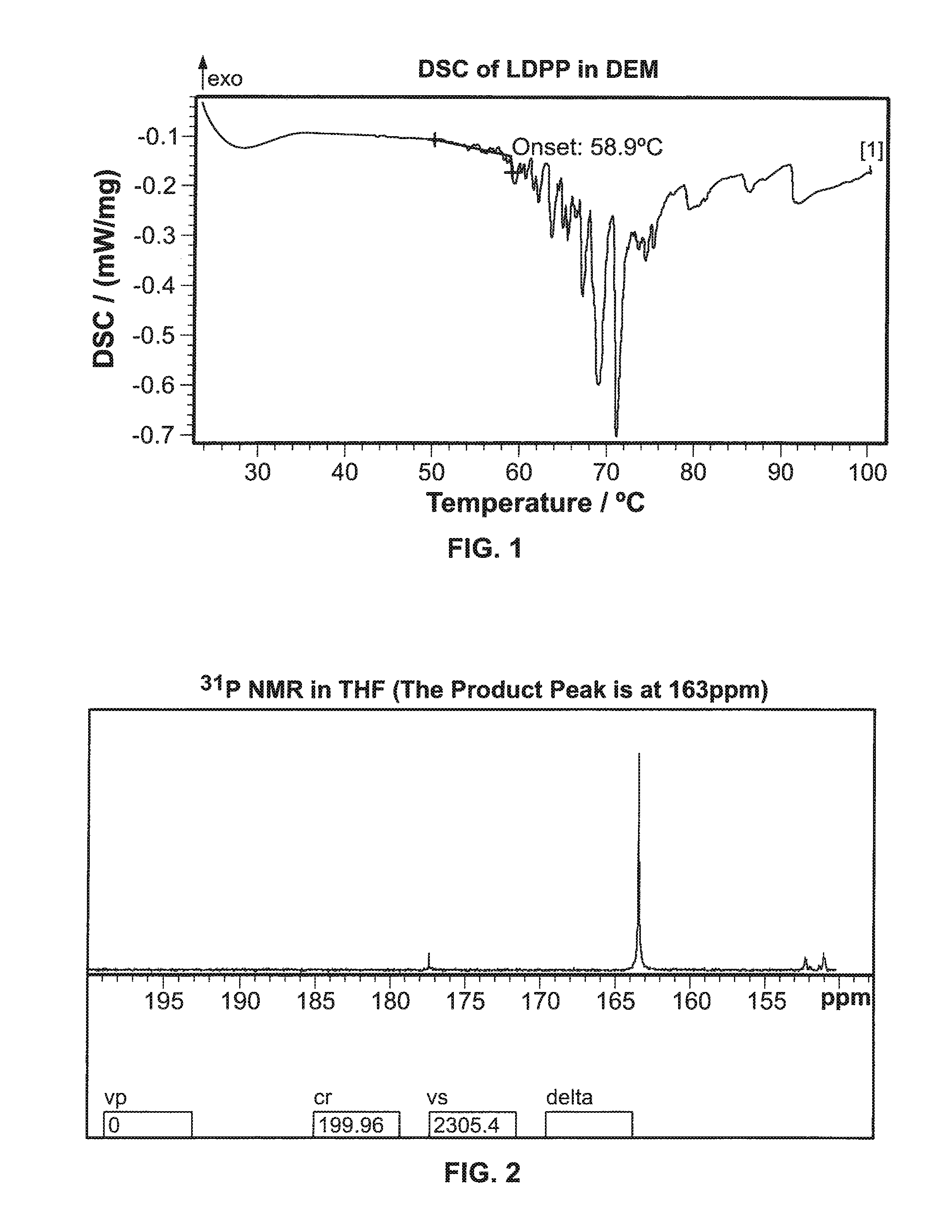

Production of lithium diphenylphosphide

InactiveUS20100298121A1Improved stability resultThe result is stableOrganic-compounds/hydrides/coordination-complexes catalystsLithium halidesLithium diphenylphosphideTetrahydrofuran

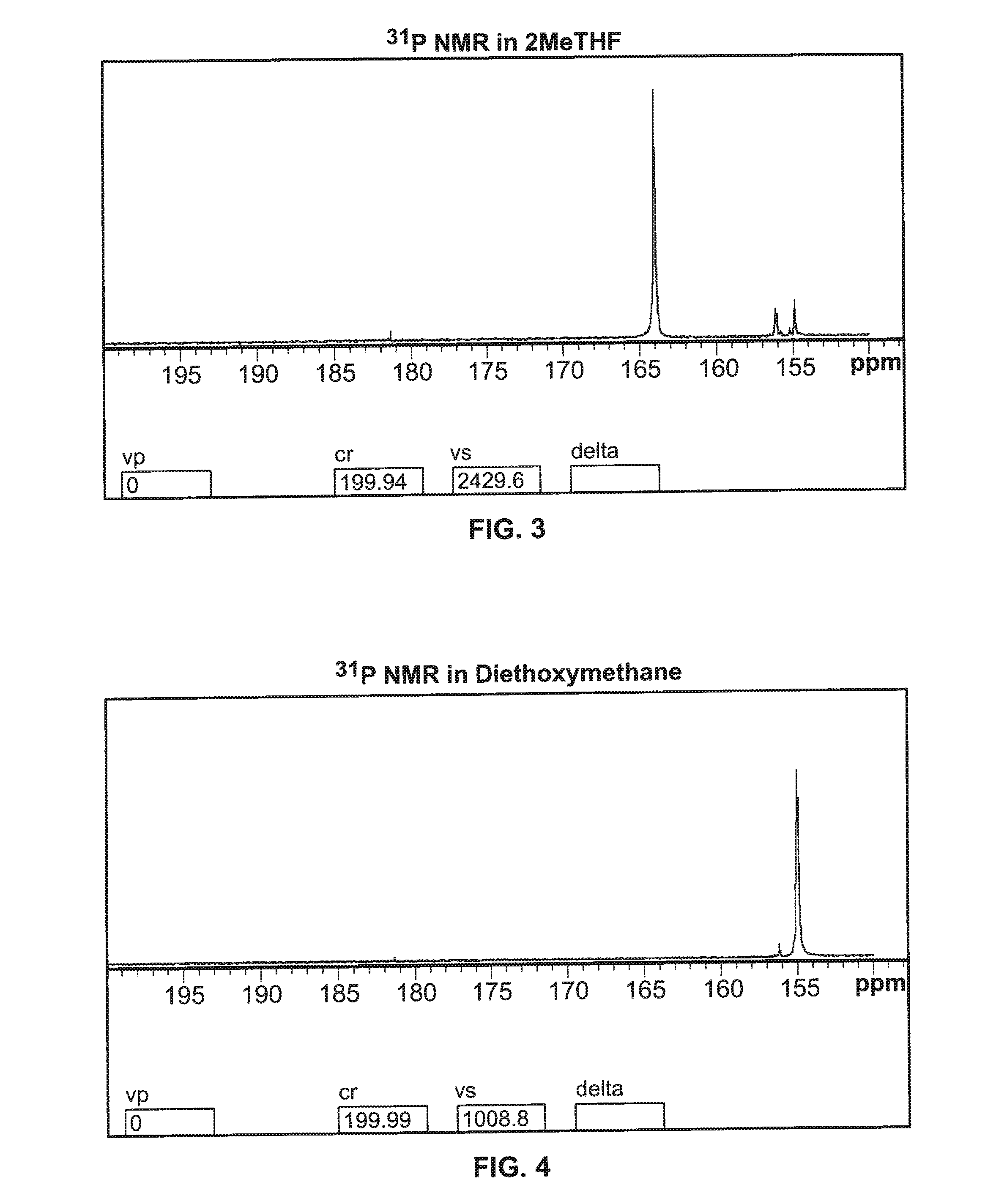

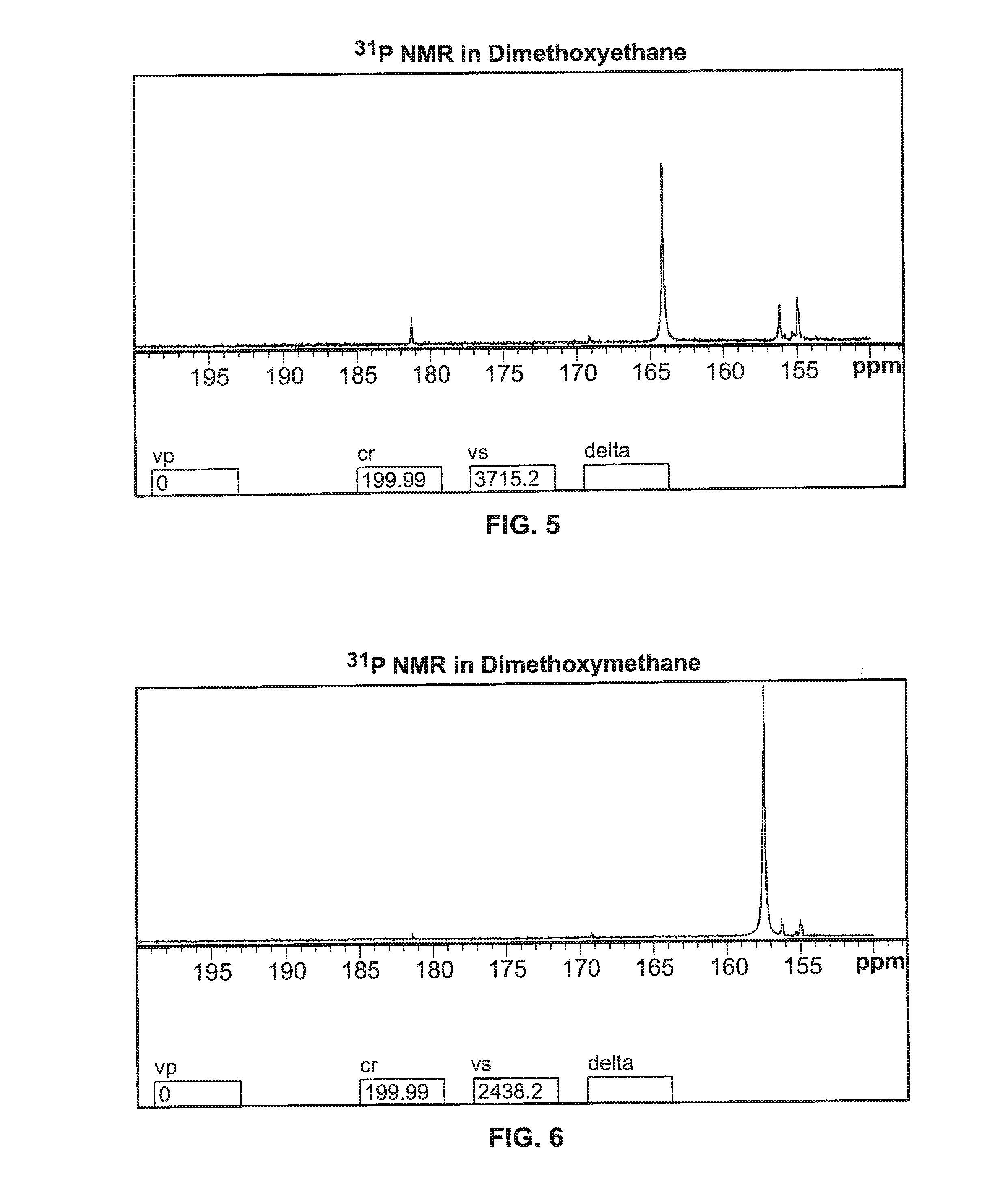

Lithium diphenylphosphide solutions in a solvent, e.g., diethoxymethane (DEM), that are more stable than when tetrahydrofuran (THF) is used as a solvent. Methods of producing them are also disclosed.

Owner:ROCKWOOD LITHIUM INC

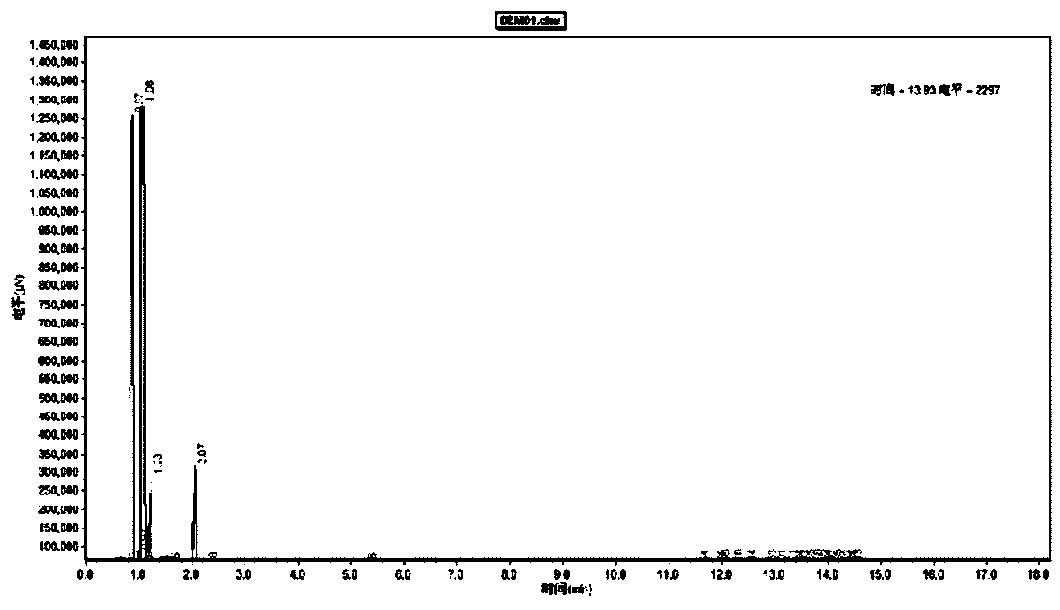

Method for preparing diethoxymethane

ActiveCN108047006AAvoid coke deactivationReduce generationOrganic chemistryOrganic compound preparationPolymer scienceAlcohol

The invention discloses a method for preparing diethoxymethane. The method comprises the following steps that an up-down integrated rectification device and a tube bundle reaction device are adopted,ethyl alcohol and formaldehyde are mixed according to the mass ratio of (1.15-1.25):1, the mixture is added into the tube bundle reaction device, a reaction is conducted at 101-103 DEG C, a diethoxymethane mixture is generated, the mixture is lifted to the rectification device to be rectified, and diethoxymethane can be obtained. The method has the advantages that the preparation method can make the generated diethoxymethane mixture continuously and timely guided out of the bottom of the tube bundle reaction device, condensation is not needed, the mixture directly enters the rectification device to be rectified, the phenomenon that a catalyst and the reaction are always in a high-temperature state, and coking deactivation is caused is avoided, a secondary reaction is avoided, producing ofmonoethoxymethane is lowered, the conversion rate of products is increased, the selectivity of the reaction process is improved, and convenience is brought to operation.

Owner:NANJING NORMAL UNIVERSITY +1

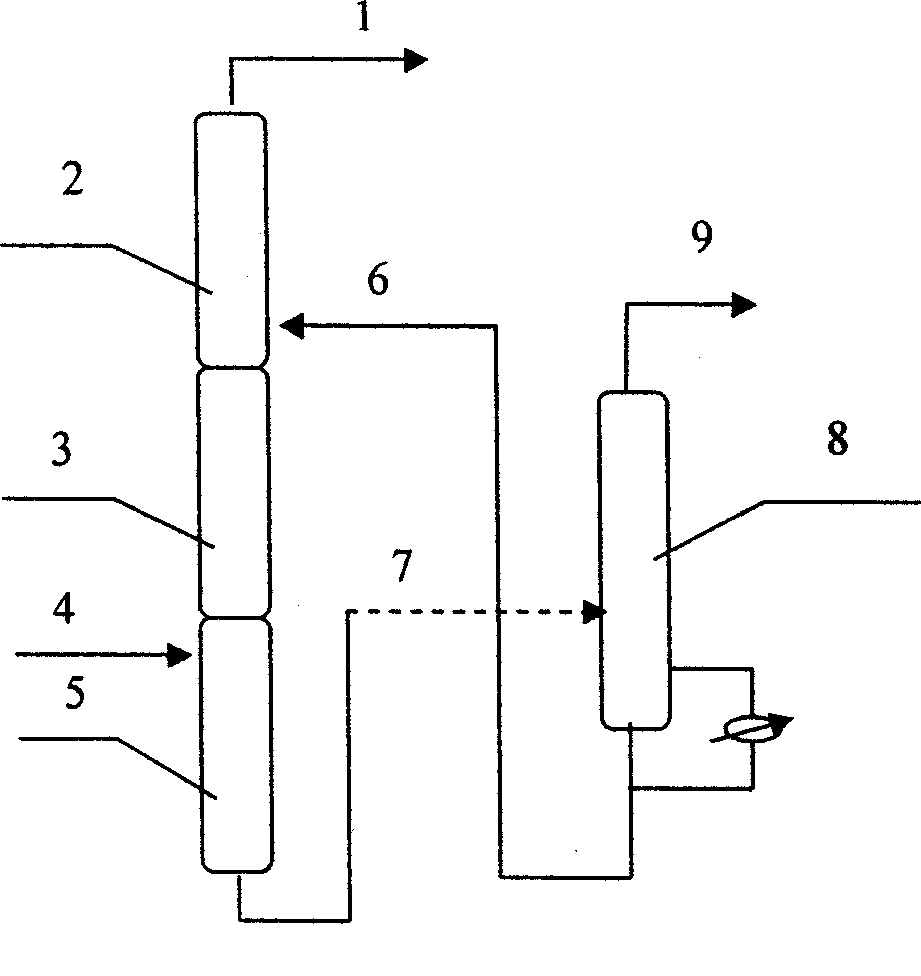

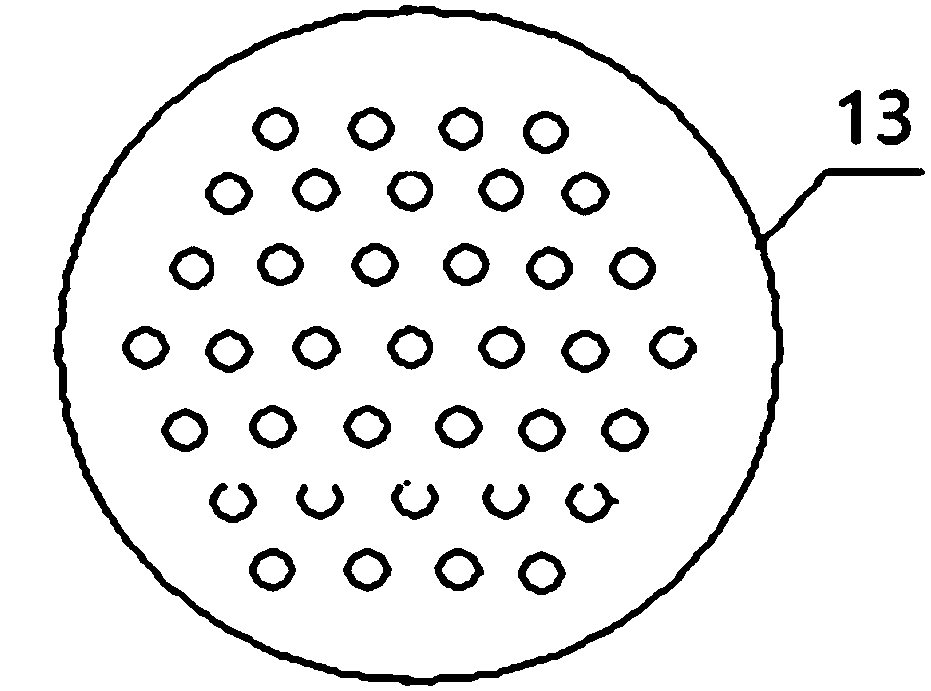

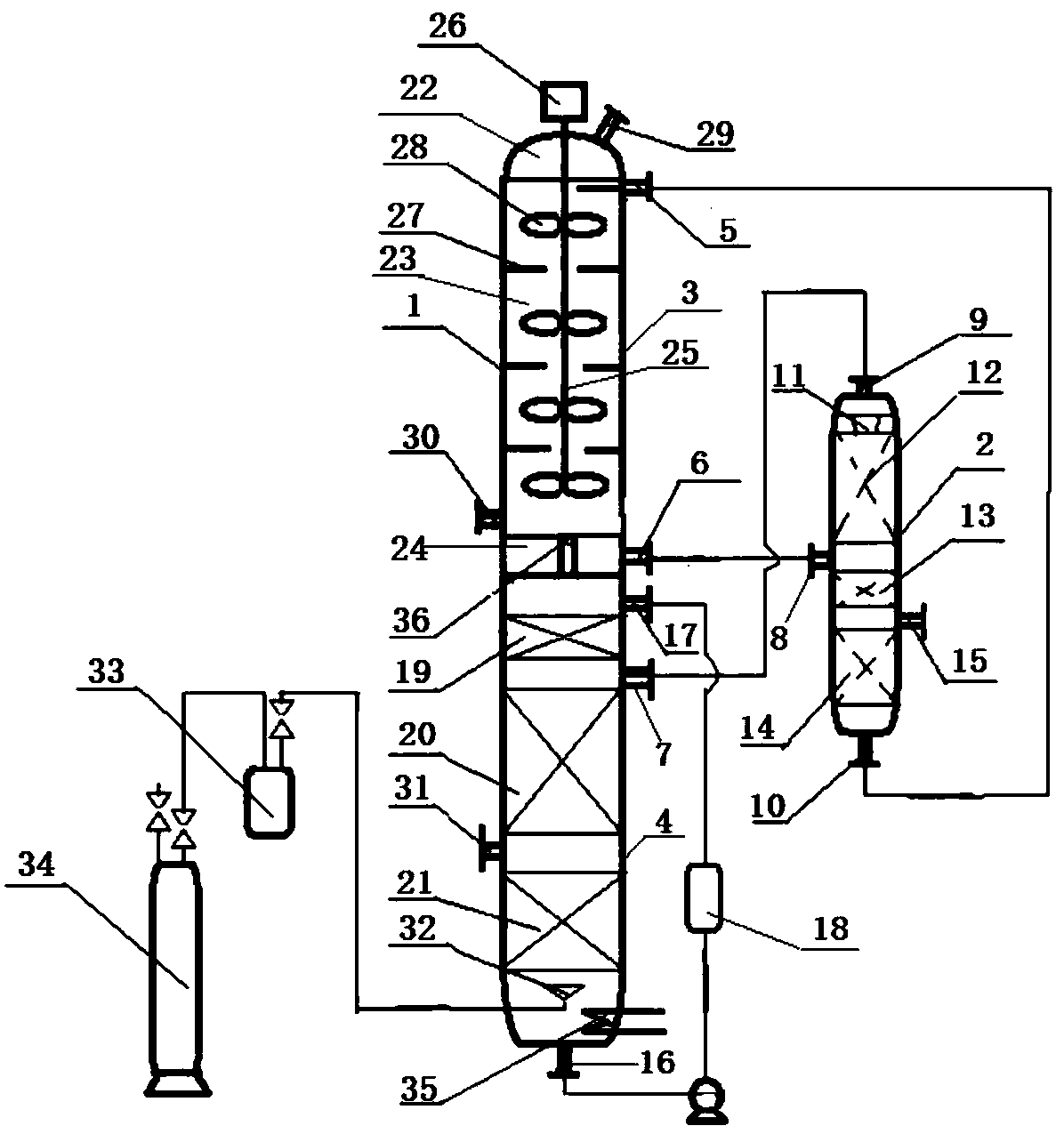

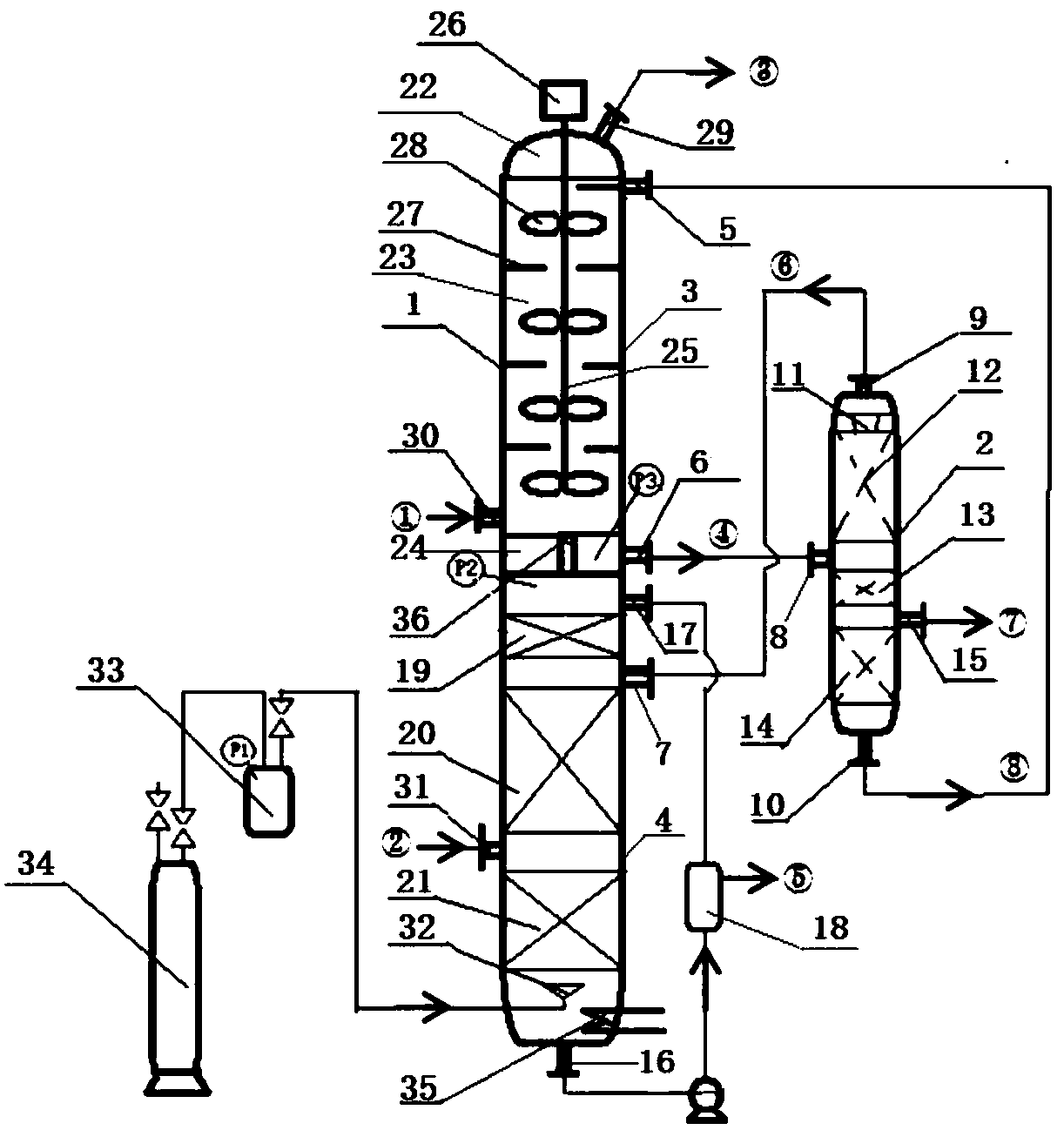

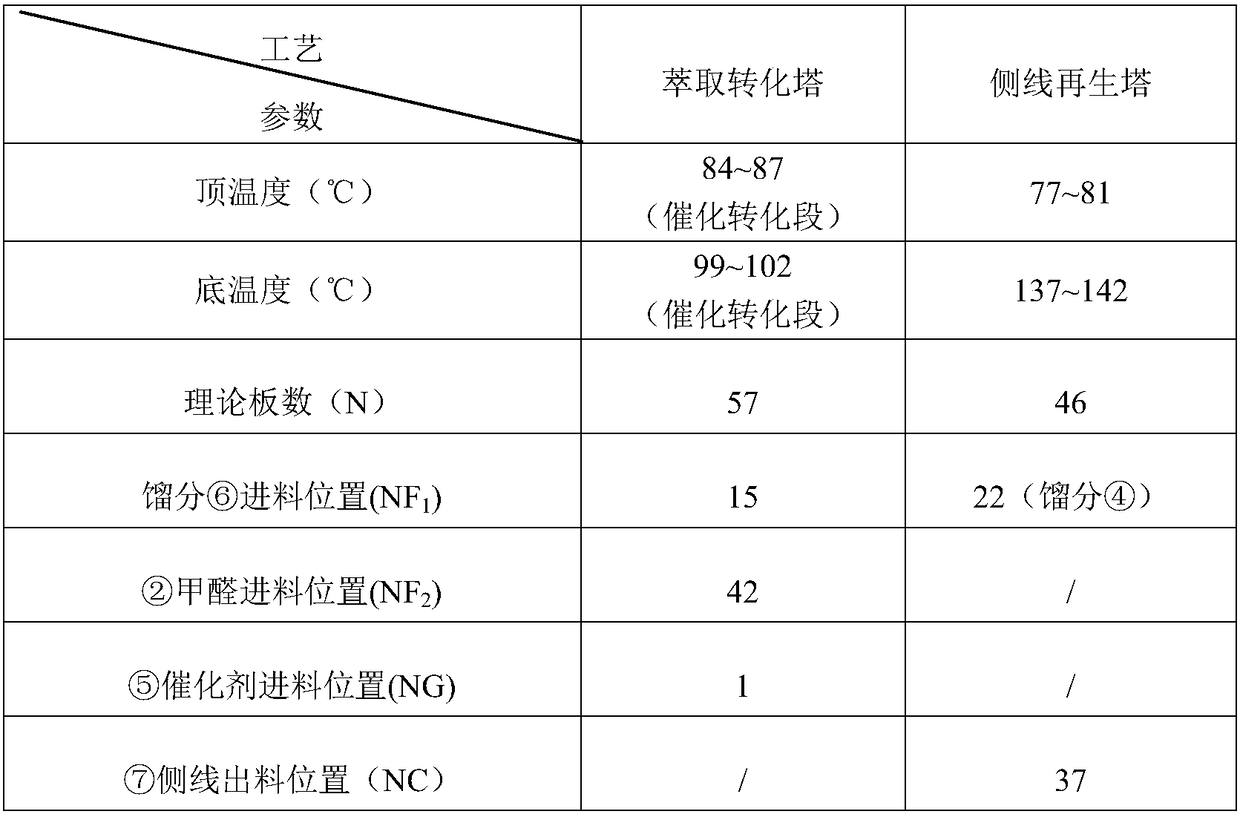

Device for recycling industrial grade diethoxymethane and method for recycling industrial grade diethoxymethane

InactiveCN108640823AHigh purityImprove conversion rateOrganic chemistryOrganic compound preparationEnvironmental engineeringTechnical grade

The invention discloses a device for recycling industrial grade diethoxymethane and a method for recycling the industrial grade diethoxymethane, the device comprises an extraction conversion tower anda side line regeneration tower connected with the extraction conversion tower, and the extraction conversion tower comprises a liquid-liquid extraction device and a catalytic conversion device whichare integrally arranged up and down. The method is as follows: the industrial grade diethoxymethane and an extractant are added into the liquid-liquid extraction device for reaction, and then a mixedsolution containing the extractant is sent to the side line regeneration tower for reaction; the mixed solution containing the extractant obtained at the bottom of the side line regeneration tower iscirculated to the liquid-liquid extraction device, an ethanol mixed solution obtained at the top of the tower is circulated to the catalytic conversion device, and a mixture of a formaldehyde solutionand a catalyst is added to the catalytic conversion device for catalytic conversion reaction. The significant advantage of the device is that the device can not only effectively recycle the industrial grade diethoxymethane, but also realize catalytic conversion of ethanol; the process is simple and the environment is protected.

Owner:NANJING NORMAL UNIVERSITY

A kind of preparation method of indoxacarb insecticide

Owner:JINGBO AGROCHEM TECH CO LTD

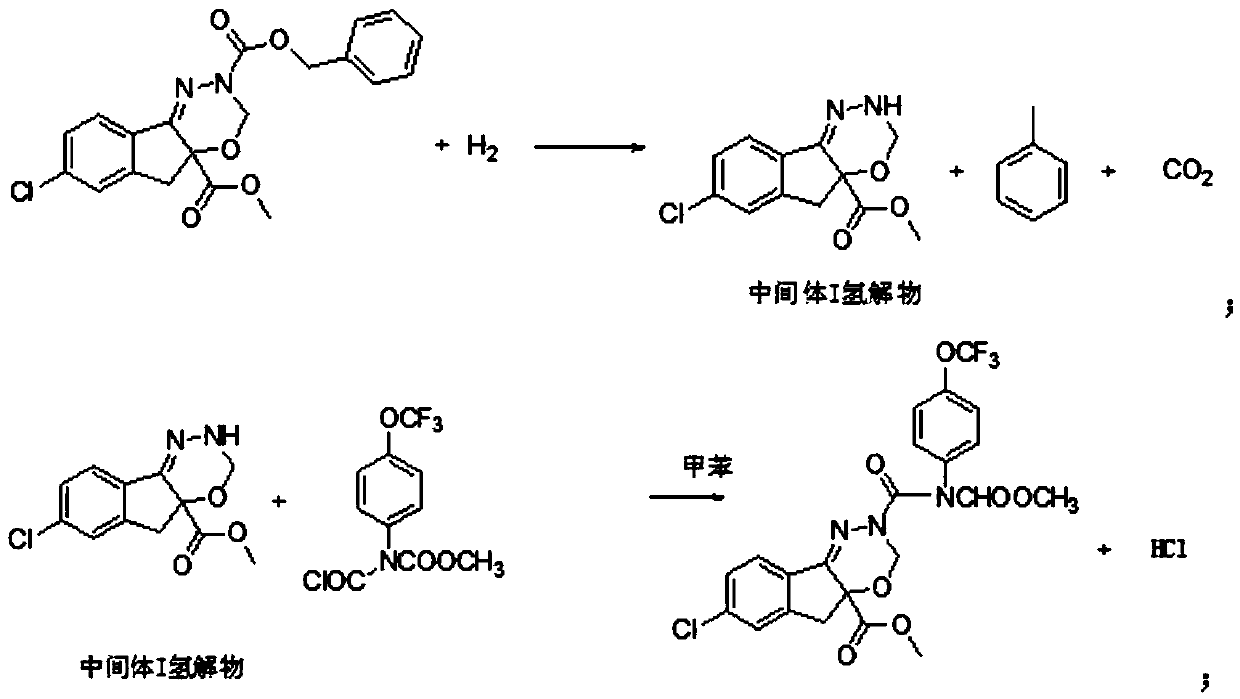

Method for catalytically synthesizing diethoxymethane by ionic liquid

InactiveCN106866388AReduce dosageHigh catalytic activityOrganic chemistryOrganic compound preparationReaction temperatureNitrogen gas

The invention discloses a method for catalytically synthesizing diethoxymethane by ionic liquid. The method takes the ionic liquid as a catalyst and takes formaldehyde and ethanol as reactants to react for 0.5h to 6h in a nitrogen atmosphere under conditions that the reaction temperature is 80 DEG C to 160 DEG C and the reaction pressure is 0.5Mpa to 5.0MPa; a positive ion part of the ionic liquid is selected from imidazole positive ions, pyridine positive ions, quaternary ammonium positive ions, quaternary phosphonate positive ions and heterocyclic positive ions. According to the method disclosed by the invention, raw materials are obtained from coal chemical industry and biomass and are cheap and easy to obtain; the catalyst has high activity, can be repeatedly used, has low corrosion and has no special requirements on equipment; reaction conditions are moderate, and reaction and separation processes are simple.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

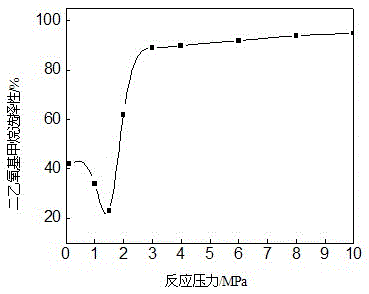

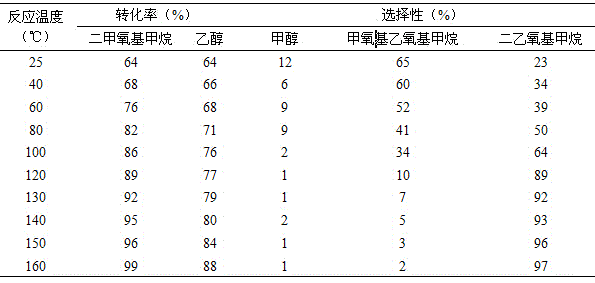

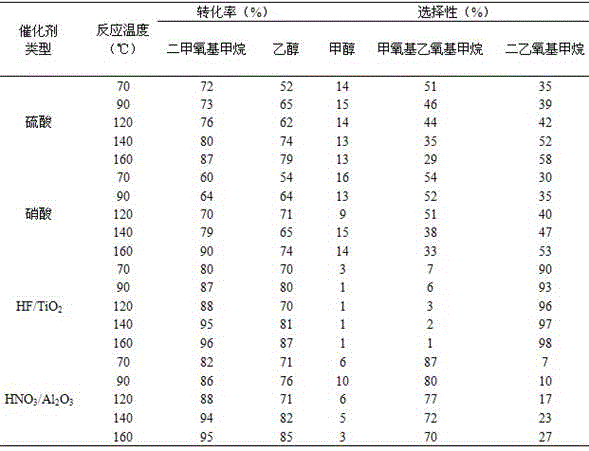

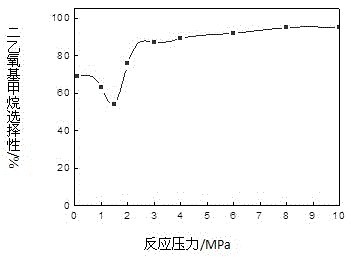

Method for preparing diethoxymethane

InactiveCN105585462AGood choiceCreate pollutionOrganic chemistryOrganic compound preparationReaction temperatureHigh selectivity

The invention provides a method for preparing diethoxymethane, relating to a method for preparing methane. The method comprises the following step: by using dimethoxymethane and ethanol as raw materials, reacting at 0-160 DEG C under the reaction pressure of 0.1-10.0 MPa by using a liquid acid and a supported liquid acid as catalysts to generate diethoxymethane. The liquid acid catalyst is one or more of inorganic acids from sulfuric acid, hydrochloric acid, nitric acid and hydrofluoric acid. The mass percent of the sulfuric acid catalyst is 0-98%, the hydrochloric acid catalyst is a 0-38% hydrogen chloride water solution, the mass percent of the nitric acid catalyst is 0-95%, and the mass percent of the hydrofluoric acid catalyst is 0-55%. The reaction temperature is 0-160 DEG C, and the reaction pressure is 0.1-10.0 MPa. The method has the advantages of single product and high selectivity, and has favorable application prospects. The required raw materials are cheap and accessible, and the whole process is simple to operate and can not generate the environment-polluting chemical substances. Thus, the method belongs to an environment-friendly technical route.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Application of eight-treasure pill to preparation of medicine for delaying occurrence and development of colitis-related colon cancer

PendingCN114869914AHeavy metal active ingredientsHydroxy compound active ingredientsStainingPharmaceutical drug

The invention relates to an application of Babaodan in preparation of a medicine for delaying occurrence and development of colitis-related colon cancer. Experimental results show that the eight-treasure pill can effectively slow down occurrence and development of azomethane oxide / dextran sodium sulfate induced colitis-related colon cancer. Meanwhile, HE staining results of the liver and the spleen show that compared with a blank control group, obvious histopathologic changes cannot be caused to the liver and the spleen after the mouse takes the eight-treasure pill for a long time, and the eight-treasure pill does not have obvious toxicity to the mouse after the mouse takes the eight-treasure pill for a long time.

Owner:XIAMEN TRADITIONAL CHINESE MEDICINE

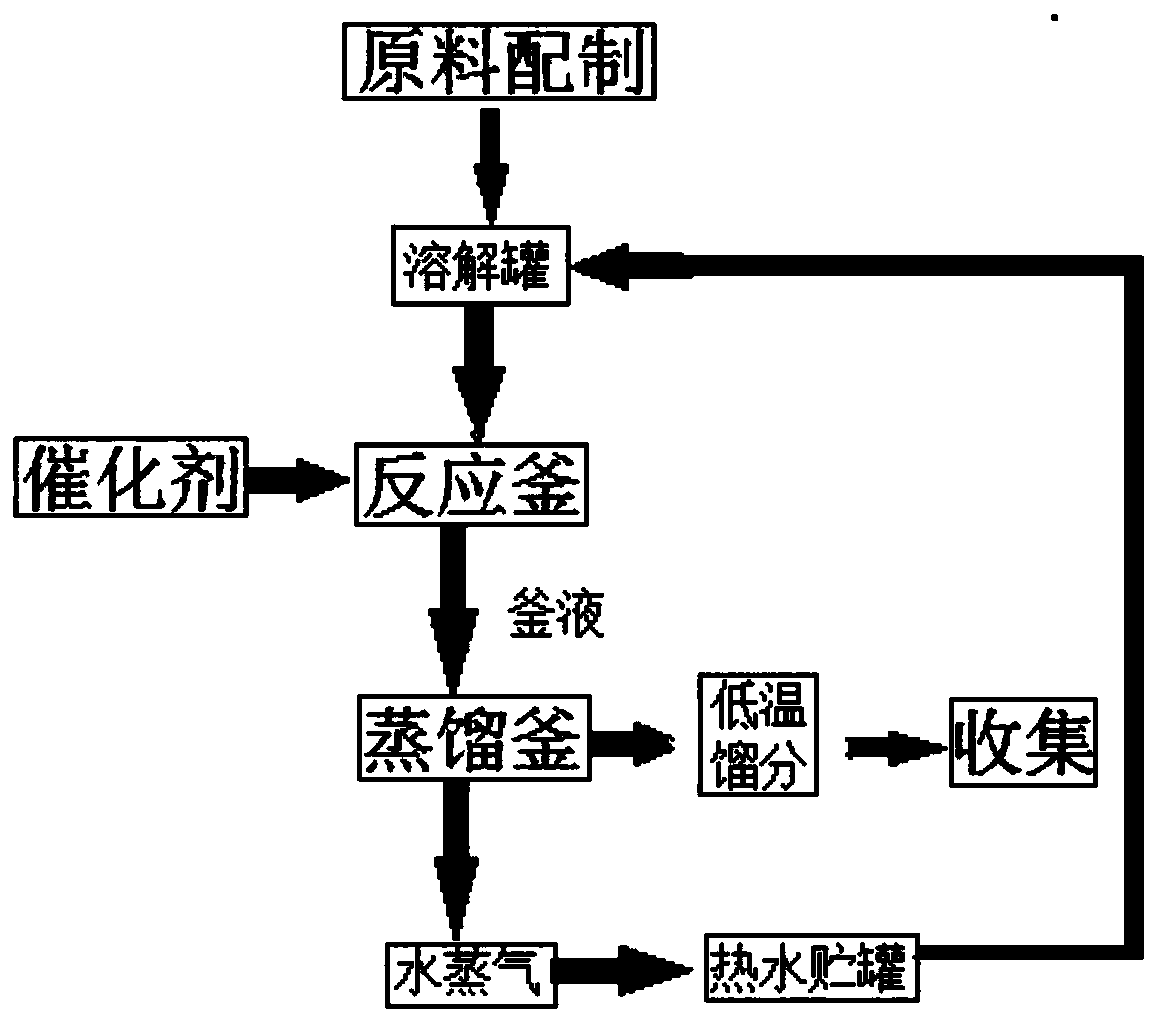

Preparation method of diethoxymethane

ActiveCN103739462AResidue will notReduce energy consumptionOrganic chemistryOrganic compound preparationSolubilityEthylenediamine

The invention relates to the field of preparation of chemical raw materials, and in particular relates to a preparation method of diethoxymethane. The preparation method comprises the steps of raw material preparation, dissolution, reaction and distillation, wherein a combinatorial catalyst of ethylenediamine tetraacetic acid and malic acid is used as an organic combinatorial catalyst, the characteristics of insolubility of ethylenediamine tetraacetic acid and solubility of malic acid in ethyl alcohol are utilized to ensure that an ethanol / formaldehyde solution reactant forms a heterogeneous and homogeneous phase reaction; meanwhile, in order to prevent residual formaldehyde in a product and resulted raw material wastes, the weight ratio of ethanol to formaldehyde is selected to ensure that the formaldehyde can not be remained in the product; moreover, through the recycling of water vapor during distillation, the energy consumption during production is reduced; meanwhile, the catalyst is recycled, so that the production cost is reduced, and the economical benefit is improved.

Owner:GUIZHOU QIANSHENG NEW ENERGY IND

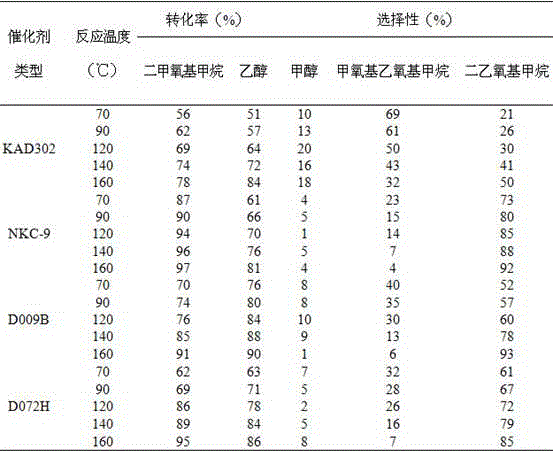

Method for synthesizing diethoxymethane from dimethoxymethane and ethanol

ActiveCN105669393AHigh selectivityEasy to operateOrganic chemistryOrganic compound preparationReaction temperatureAmberlyst-15

The invention provides a method for synthesizing diethoxymethane from dimethoxymethane and ethanol, relating to a method for preparing methane. The method comprises the following step: by using dimethoxymethane and ethanol as raw materials, reacting at 0-160 DEG C under the reaction pressure of 0.1-10.0 MPa by using a liquid acid and a supported liquid acid as catalysts to generate diethoxymethane at high selectivity. The resin catalyst is one or more of KAD302, KC107, NKC-9, DA-330, D009B, Amberlyst-15 and D072H containing sulfonic acid functional group. The reaction temperature is 0-160 DEG C, and the reaction pressure is 0.1-10.0 MPa. The filling gas is inert gas which is argon, helium, carbon dioxide or N2 mixture or a gas mixture thereof. The method has the advantages of single product and high selectivity, and has favorable application prospects. The required raw materials are cheap and accessible, and the whole process is simple to operate and can not generate any environment-polluting chemical substance. Thus, the method belongs to an environment-friendly technical route.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com