Multi-purpose paint diluting agent and preparation technology thereof

A diluent, multi-purpose technology, applied in coating and other directions, can solve the problems of harming human health, poor leveling, and easy whitening of the paint film, achieving no three waste discharge, simple production process, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

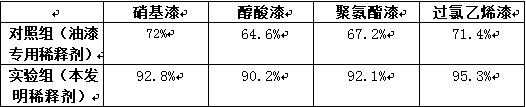

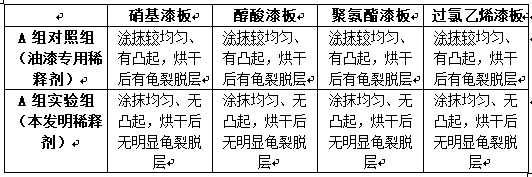

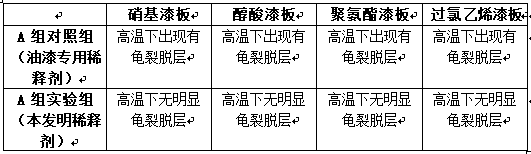

Examples

Embodiment 1

[0019] A kind of multi-purpose paint thinner and preparation technology thereof, the raw material and its mass parts of making multi-purpose paint thinner are 26 parts of ethylene glycol ethyl ether acetate, 25 parts of dichlorinane, 36 parts of pentaerythritol, cyclohexanone 18 parts, 18 parts of butyl orthosilicate, 16 parts of ethyl cellosolve, 12 parts of diethylamethane, 12 parts of methyl isopropyl ketone, 10 parts of turpentine and 8 parts of isophorone.

[0020] The preparation process for making the multi-purpose paint thinner comprises the following steps: mixing ethylene glycol ethyl ether acetate, dichlorinane, cyclohexanone, ethyl cellosolve and diacetylmethane, adding acid-base adjustment Adjust the pH value to between 4-5, and heat to 40-50°C, stir and react for 30 minutes, then add pentaerythritol, tetrabutyl orthosilicate, methyl isopropyl ketone, turpentine and isophorone to the reaction in sequence In the liquid, and add active diluent, coupling agent and st...

Embodiment 2

[0025] The raw materials and mass parts thereof for making multi-purpose paint thinner are 31 parts of ethylene glycol ethyl ether acetate, 28 parts of dichloronalane, 39 parts of pentaerythritol, 23 parts of cyclohexanone, 22 parts of orthobutyl silicate, 19 parts of base cellosolve, 15 parts of diacetylmethane, 14 parts of methyl isopropyl ketone, 12 parts of turpentine and 11 parts of isophorone.

[0026] The preparation process steps of this embodiment are as in embodiment 1.

Embodiment 3

[0028] The raw materials and mass parts thereof for making multipurpose paint thinner are 36 parts of ethylene glycol ethyl ether acetate, 32 parts of dichloroinyl alcohol, 42 parts of pentaerythritol, 27 parts of cyclohexanone, 26 parts of orthobutyl silicate, 22 parts of base cellosolve, 18 parts of diacetylmethane, 16 parts of methyl isopropyl ketone, 14 parts of turpentine and 13 parts of isophorone.

[0029] The preparation process steps of this embodiment are as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com