Device for recycling industrial grade diethoxymethane and method for recycling industrial grade diethoxymethane

A diethoxymethane and chemical industry technology, applied in the field of diethoxymethane preparation, can solve the problems of the by-product ethanol not being effectively used, the by-products affecting the environment, and the energy consumption of the process, etc., to improve the purity of the product , environmental protection, high conversion rate of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

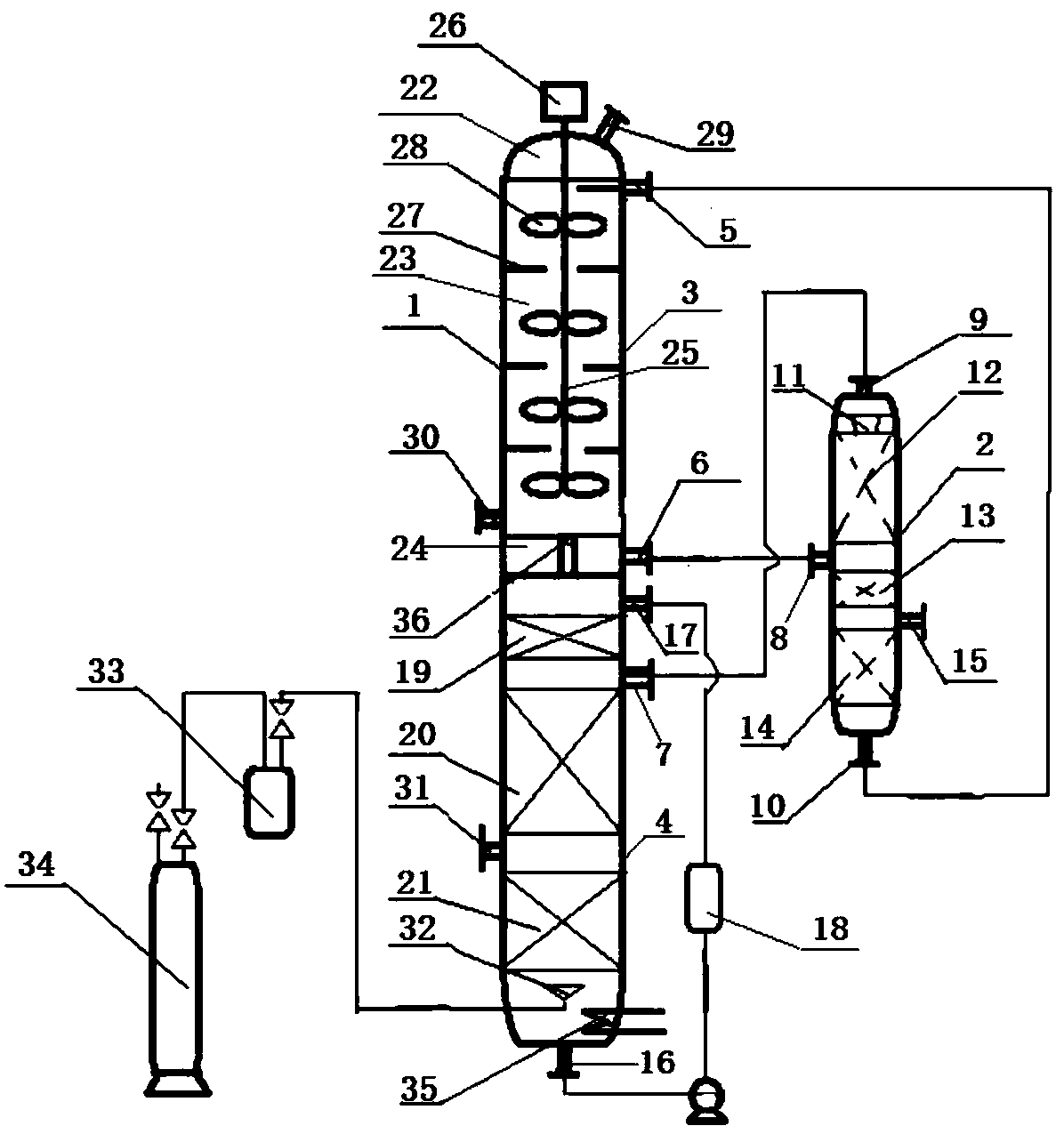

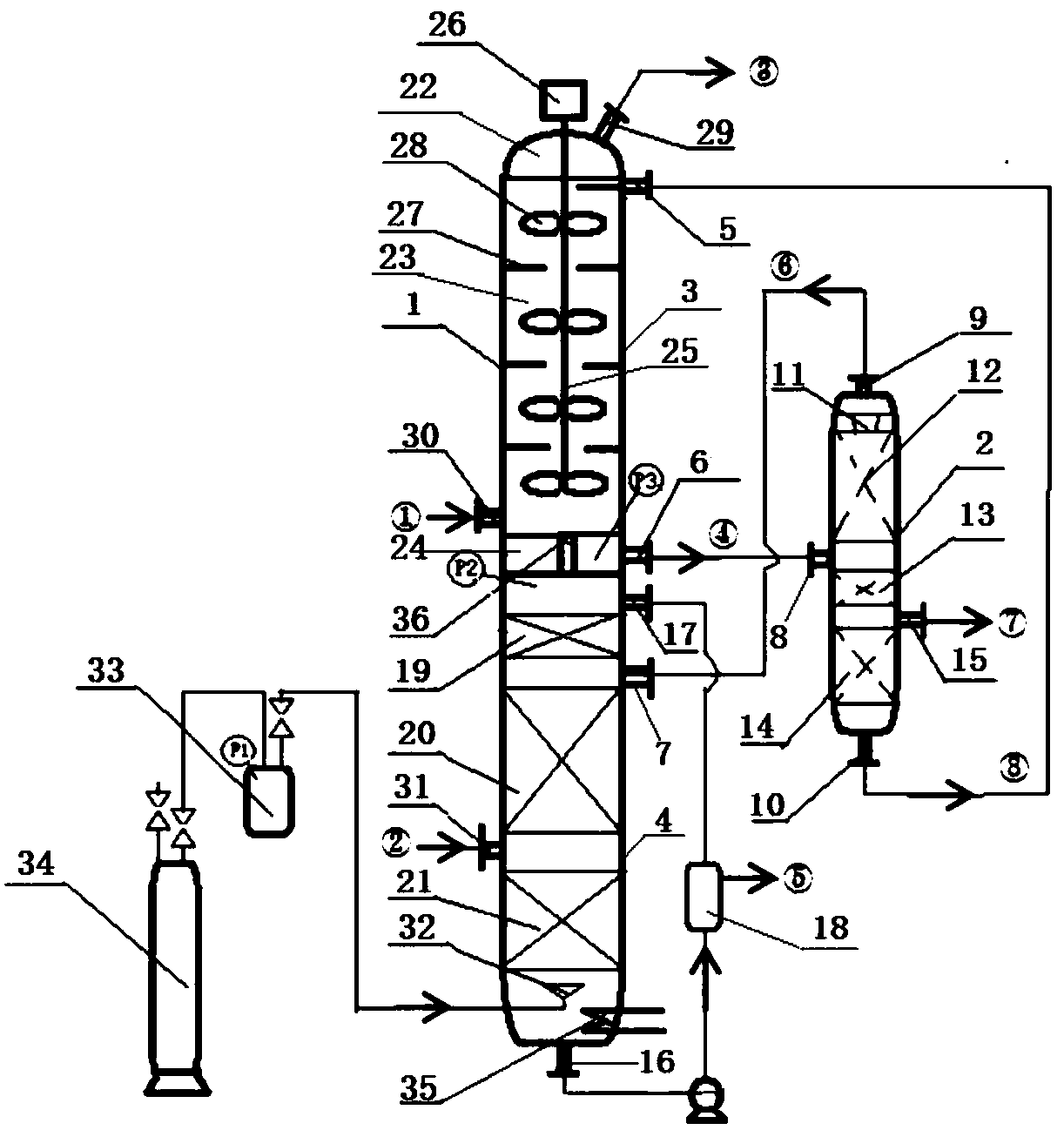

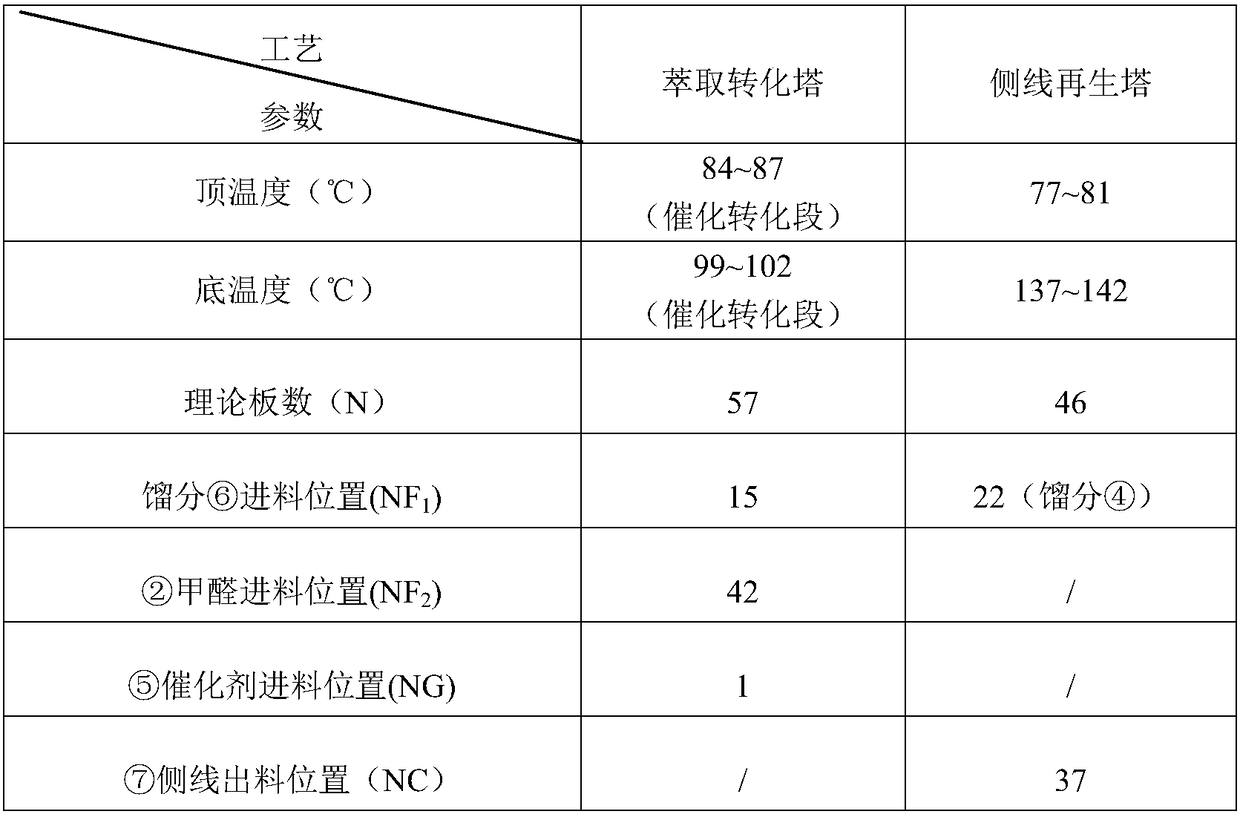

[0020] Such as figure 2 As shown, the method for refining and recycling industrial grade industrial grade diethoxymethane using the device of the present invention comprises the following steps:

[0021] (1) add extraction agent and industrial grade diethoxymethane (DEM) respectively by the industrial grade diethoxymethane feed inlet 30 of liquid-liquid extraction device and extractant inlet 5, this extractant and industrial grade The ratio of the DEM addition is 0.995:1, the starting motor 26 stirring speed 80rpm, by N 2 The gas cylinder adjusts the pressure P1 of the buffer bottle 33, and the pressure P2 of the catalytic conversion device 4 is controlled to be greater than the pressure P3 of the liquid-liquid extraction device 3. After the extraction reaction, the raffinate phase outlet 29 at the upper end of the liquid-liquid extraction device 3 obtains a concentration of Up to 99.07% DEM;

[0022] (2) The mixed solution containing extractant and ethanol flowing out from...

Embodiment 2

[0029] Adopt the device of the present invention to carry out the method for refining and recycling industrial grade technical grade diethoxymethane comprising the following steps:

[0030](1) add extraction agent and industrial grade diethoxymethane (DEM) respectively by the industrial grade diethoxymethane feed inlet 30 of liquid-liquid extraction device and extractant inlet 5, this extractant and industrial grade The ratio of the DEM addition is 0.8:1, the starting motor 26 stirring speed 80rpm, by N 2 The gas cylinder adjusts the pressure P1 of the buffer bottle 33, and the pressure P2 of the catalytic conversion device 4 is controlled to be greater than the pressure P3 of the liquid-liquid extraction device 3. After the extraction reaction, the raffinate phase outlet 29 at the upper end of the liquid-liquid extraction device 3 obtains a concentration of Up to 99.02% DEM;

[0031] (2) The mixed solution containing extractant and ethanol flowing out from the extraction pha...

Embodiment 3

[0033] Adopt the device of the present invention to carry out the method for refining and recycling industrial grade technical grade diethoxymethane comprising the following steps:

[0034] (1) add extraction agent and industrial grade diethoxymethane (DEM) respectively by the industrial grade diethoxymethane feed inlet 30 of liquid-liquid extraction device and extractant inlet 5, this extractant and industrial grade The ratio of the DEM addition is 1.5:1, the starting motor 26 stirring speed 80rpm, by N 2 The gas cylinder adjusts the pressure P1 of the buffer bottle 33, and the pressure P2 of the catalytic conversion device 4 is controlled to be greater than the pressure P3 of the liquid-liquid extraction device 3. After the extraction reaction, the raffinate phase outlet 29 at the upper end of the liquid-liquid extraction device 3 obtains a concentration of Up to 99.09% DEM;

[0035] (2) The mixed solution containing extractant and ethanol flowing out from the extraction ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com