Patents

Literature

434 results about "Technical grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technical grade - containing small amounts of other chemicals, hence slightly impure; "technical-grade sulfuric acid". technical-grade. chemical science, chemistry - the science of matter; the branch of the natural sciences dealing with the composition of substances and their properties and reactions.

Instant recoverable slippery water for shale gas reservoir

ActiveCN102516975AHas instantMeet the needs of large-scale development and online formulationDrilling compositionPhosphatePotassium

The invention relates to instant recoverable slippery water for a shale gas reservoir. The slippery water consists of the following components in percentage by weight: 0.02-0.1 percent of a friction-reducing agent, 0.2-2.0 percent of potassium chloride, 0.1-0.5 percent of a cleanup additive, 0.1-0.5 percent of an anti-swelling agent and the balance of water, wherein the friction-reducing agent is polyacrylamide or a polyacrylamide derivative of which the molecular weight is 5*105-1*106; the cleanup additive consists of 0.5-2.0 percent by mass of a fluorocarbon surfactant, 10-15.0 percent by mass of a low molecular alcohol solvent, 3.0-5.0 percent by mass of a high molecular alcohol additive, 10.0-20.0 percent by mass of a technical grade hydrocarbon chain surfactant and the balance of water; and the anti-swelling agent is a cation polyquaternary salt, poly-quaternary phosphate or a poly-quaternary sulfate. The slippery water can be fully dissolved and swelled within 20-30 seconds for forming a uniform system without oxidizing a gel breaker, damage to the crack diversion capability can be reduced, a cracking reverse discharge liquid can be recycled, and waste liquid treatment cost is lowered.

Owner:PETROCHINA CO LTD

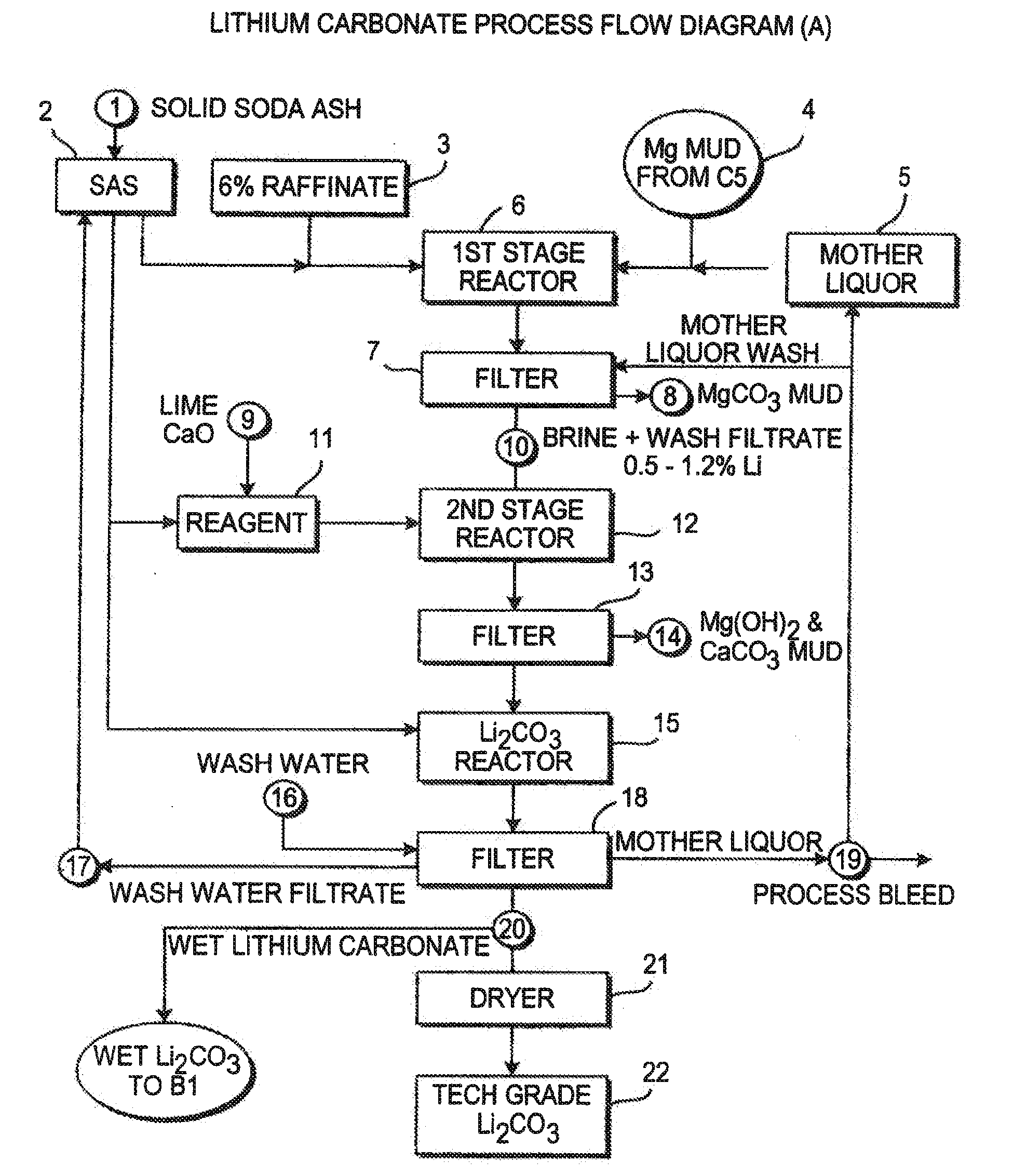

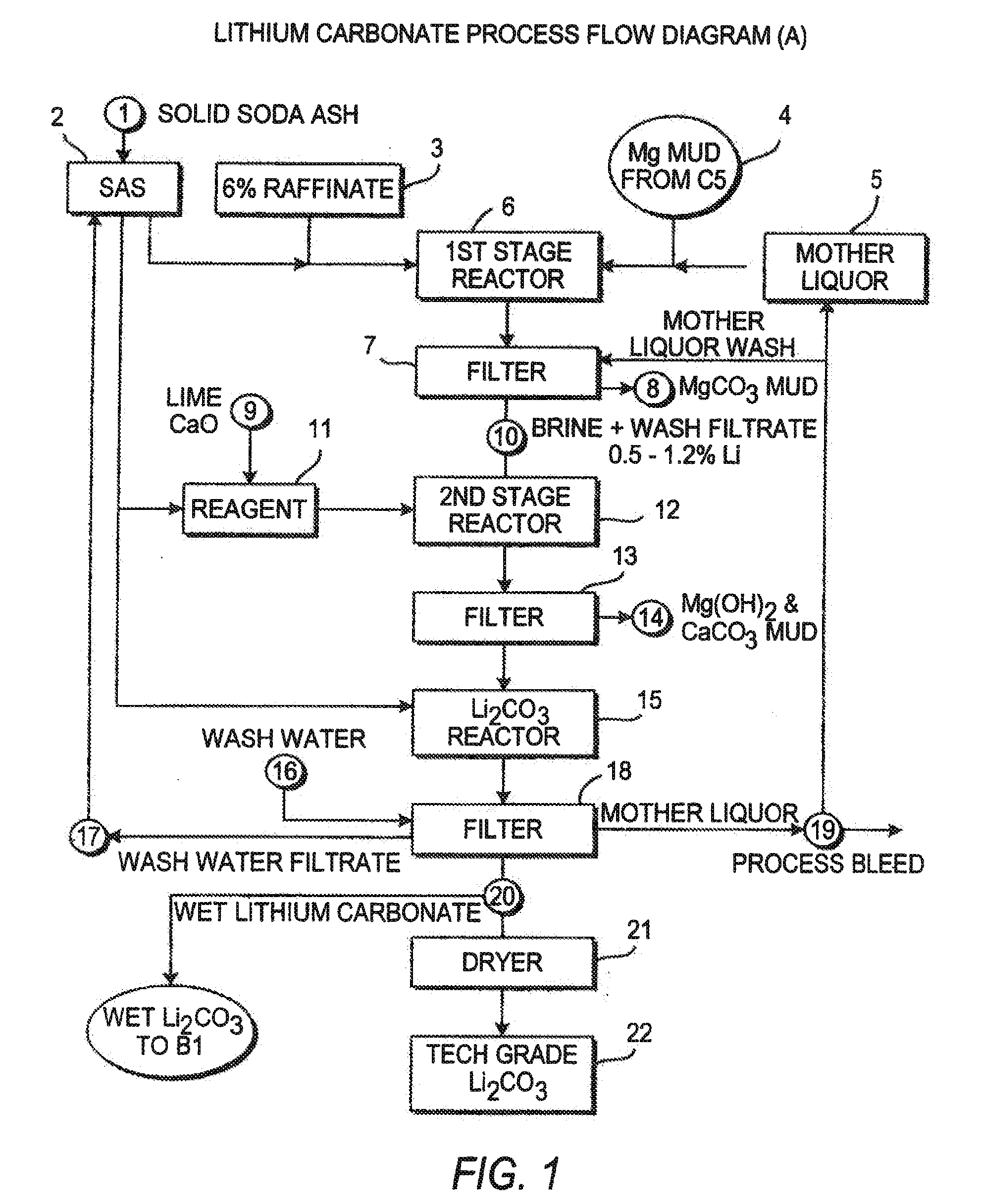

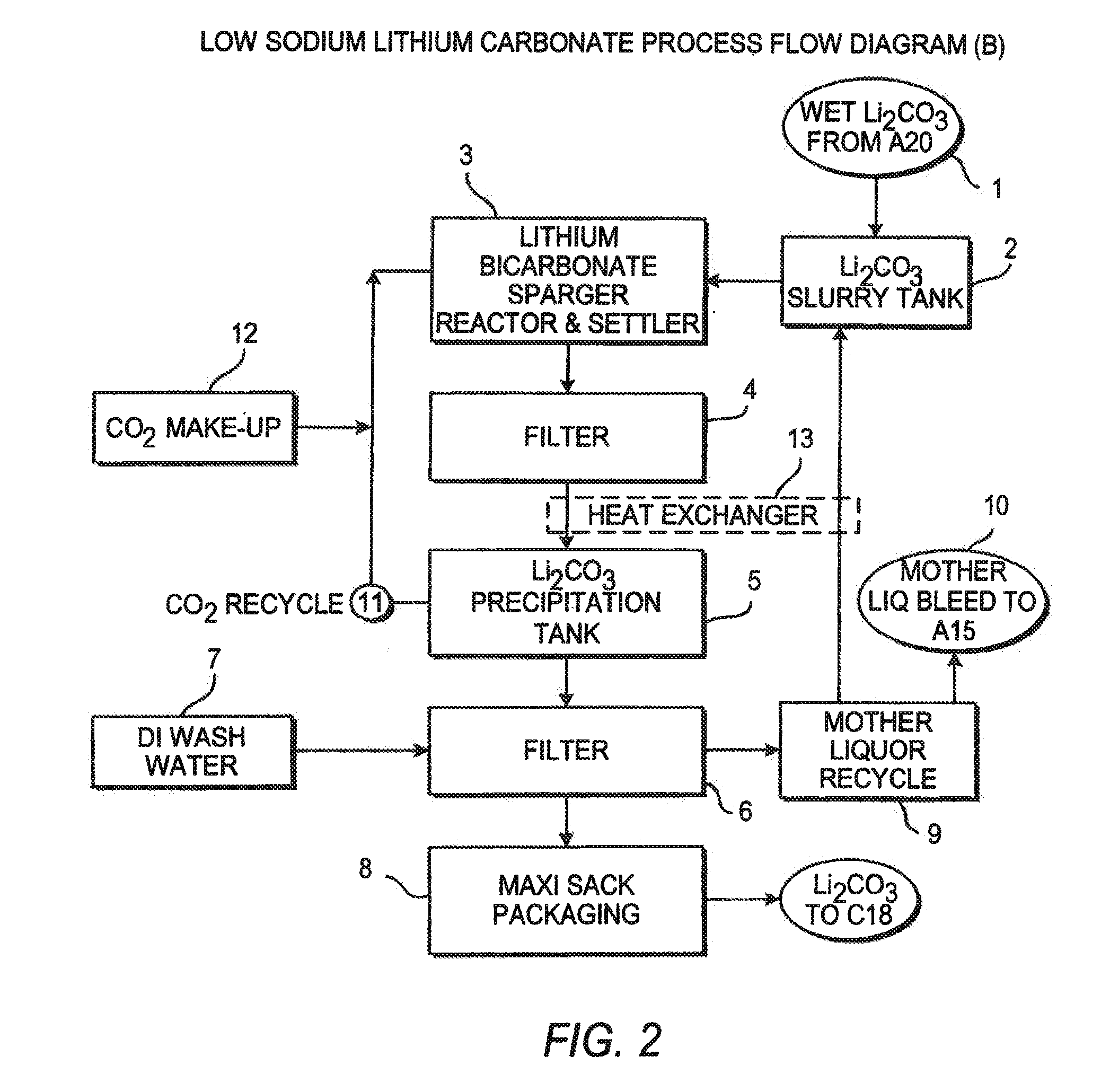

Production of lithium compounds directly from lithium containing brines

InactiveUS20110123427A1Reduce in quantityPromote absorptionVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

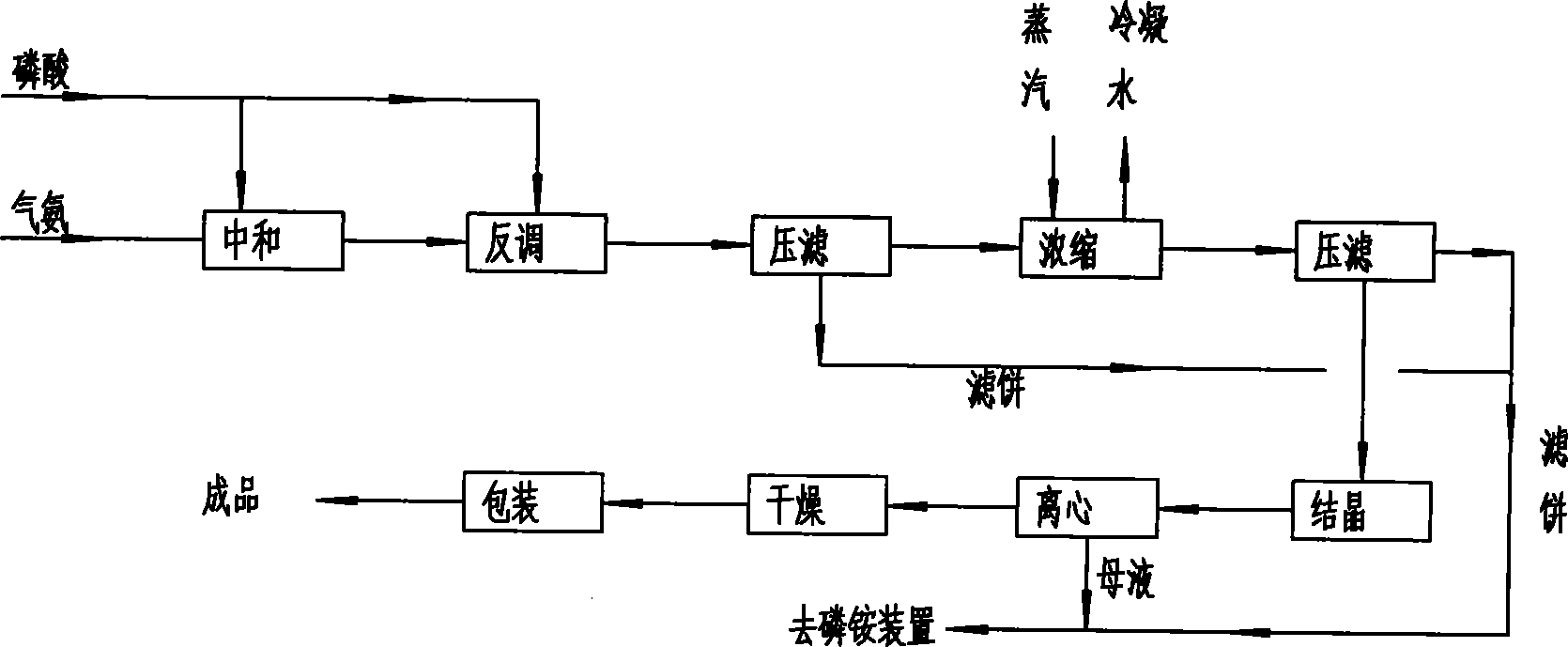

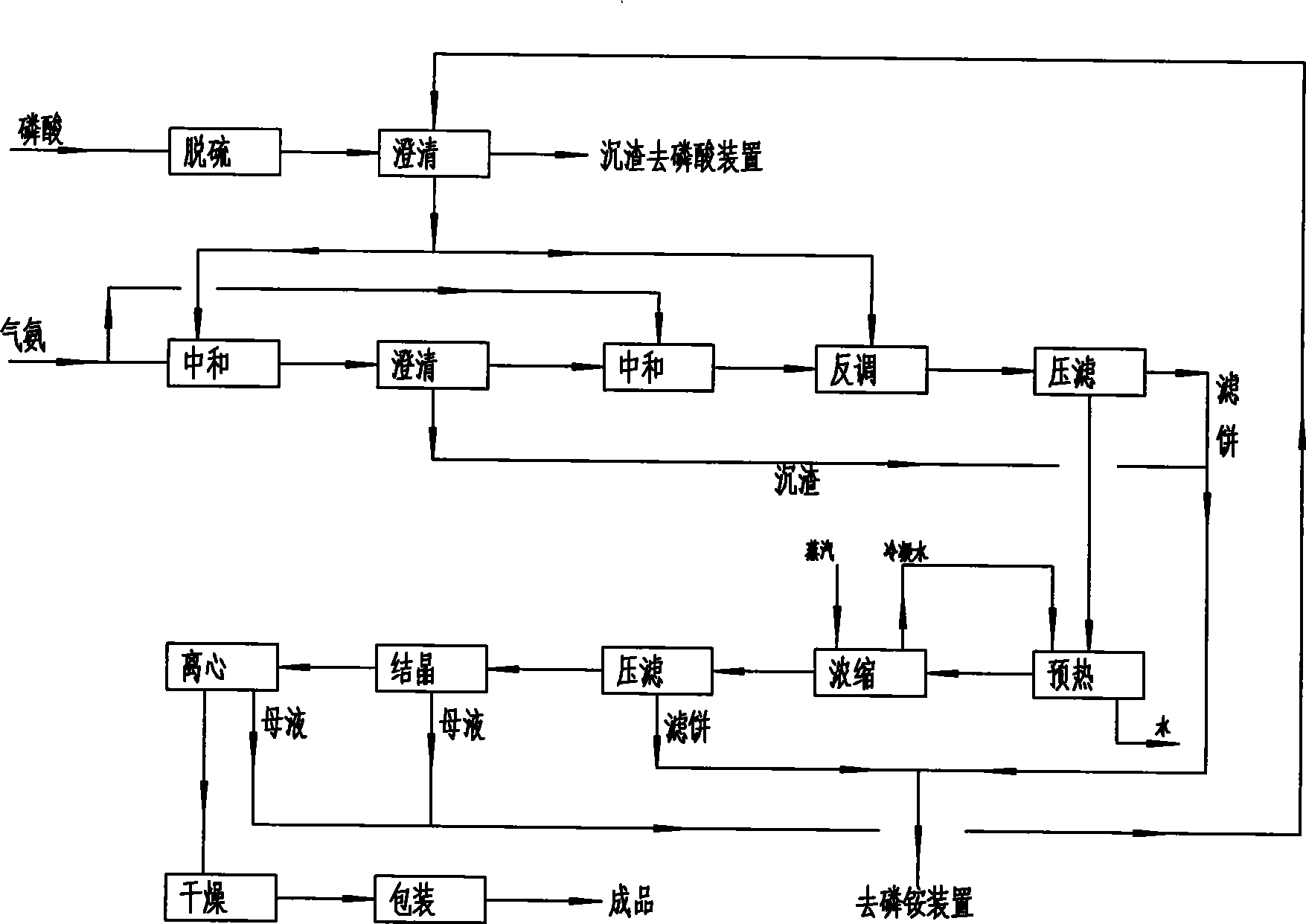

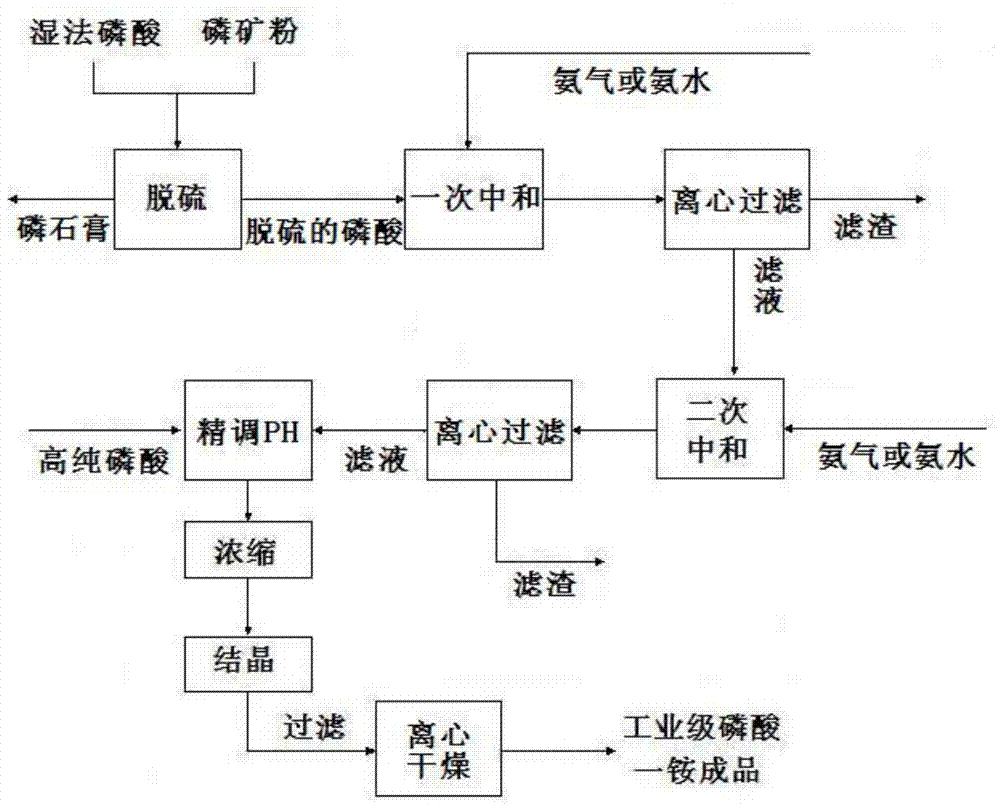

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

ActiveCN101367512AReduce labor intensityReduced pressure filter loadPhosphatesPhosphatePhosphoric acid

The invention relates to a craftwork for producing the industrial-level monoammonium phosphate consecutively with the phosphoric acid by wet process, which adopts the following steps: 1) phosphoric acid and phosphorite pulp are desulfurized to get the desulfurized phosphoric acid; 2) the acid is undertaken the first neutralization action to get a neutralized material pulp clarifying solution; 3) after the second neutralization reaction, the solution is reacted with the desulfrized phosphoric acid to get a secondary neutralized material pulp with the pH value being adjusted; 4) the secondary neutralized material pulp with the pH value being adjusted is primarily filtered to get a primary filtering solution and a primary filtering mass; 5) the primary filtering solution is secondarily concentrated and press filtered to get the secondary filtering solution; 6) the obtained secondary filtering solution is dissolved through the grain refining, is cooled down in vacuum, is crystallized, is centrifugally separated and dried to get the finished product of the industrial-level monoammonium phosphate. The invention has the advantages that the operation during the production process is consecutive; the labor intensity of the worker is reduced; the leakage rate of the ammonia is low and the loss is small; the secondary neutralized raw material solution is clear solution, so that the viscosity is low and the loss of the ammonia is small; the neutralization and the press filtering load is reduced; the crystallization production capacity is large; the heat energy is adequately used, thereby reducing the consumption of the vapor.

Owner:HUBEI XIANGYUN GROUP CHEM

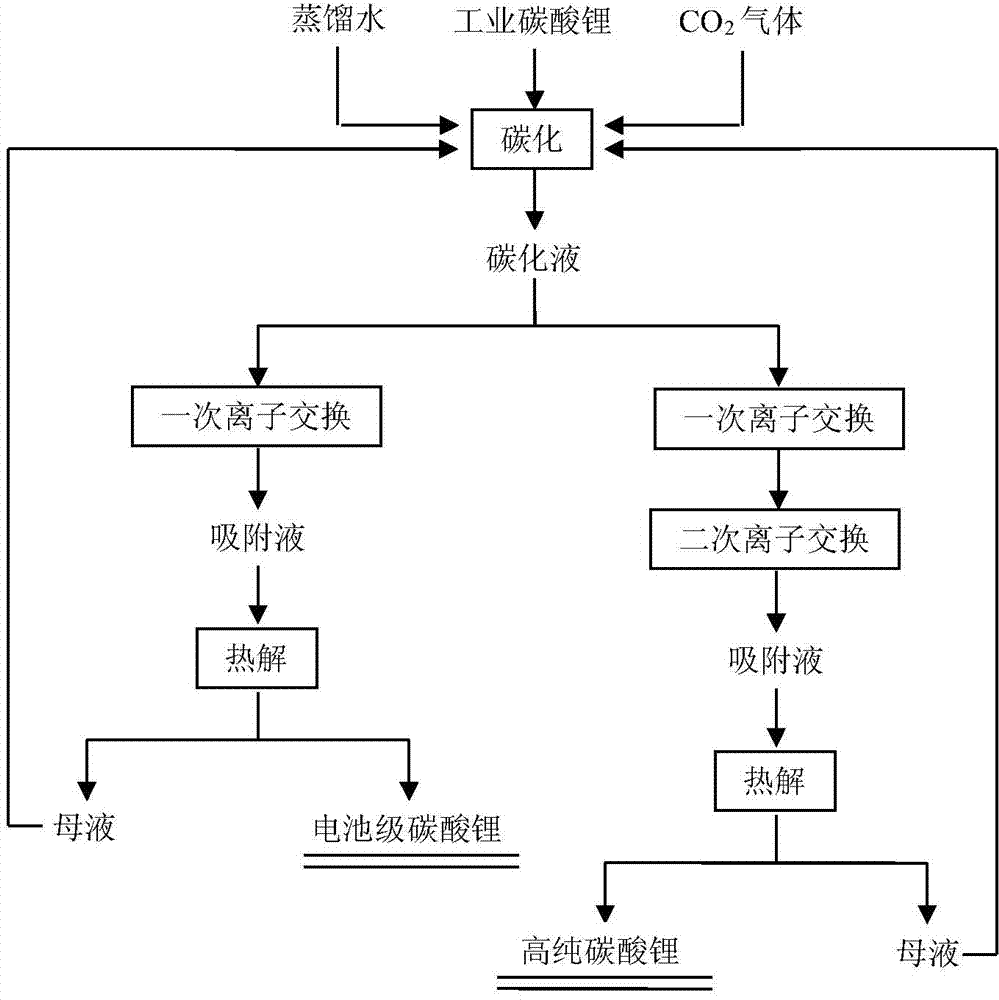

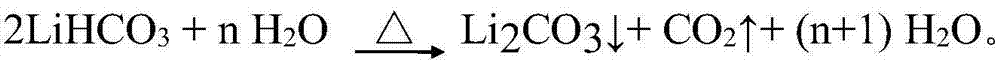

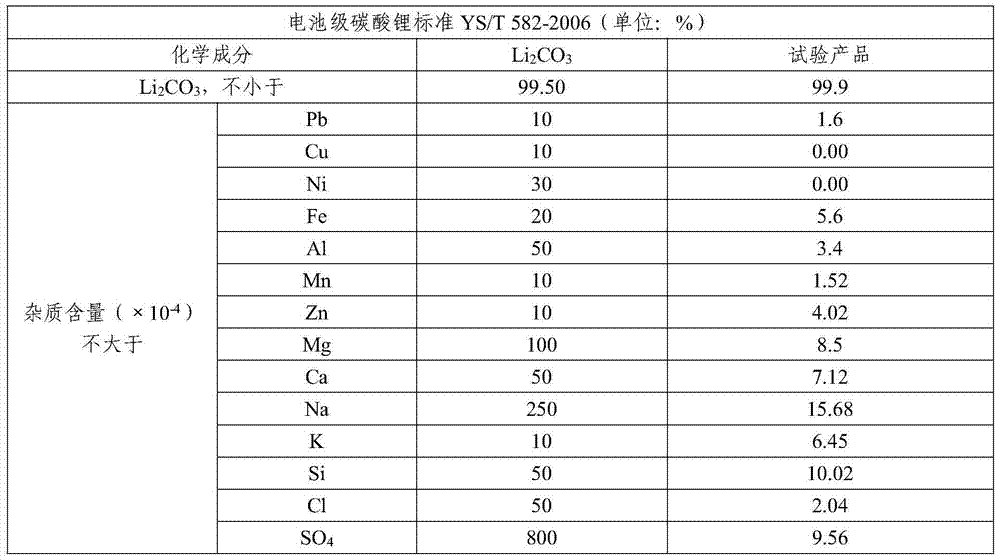

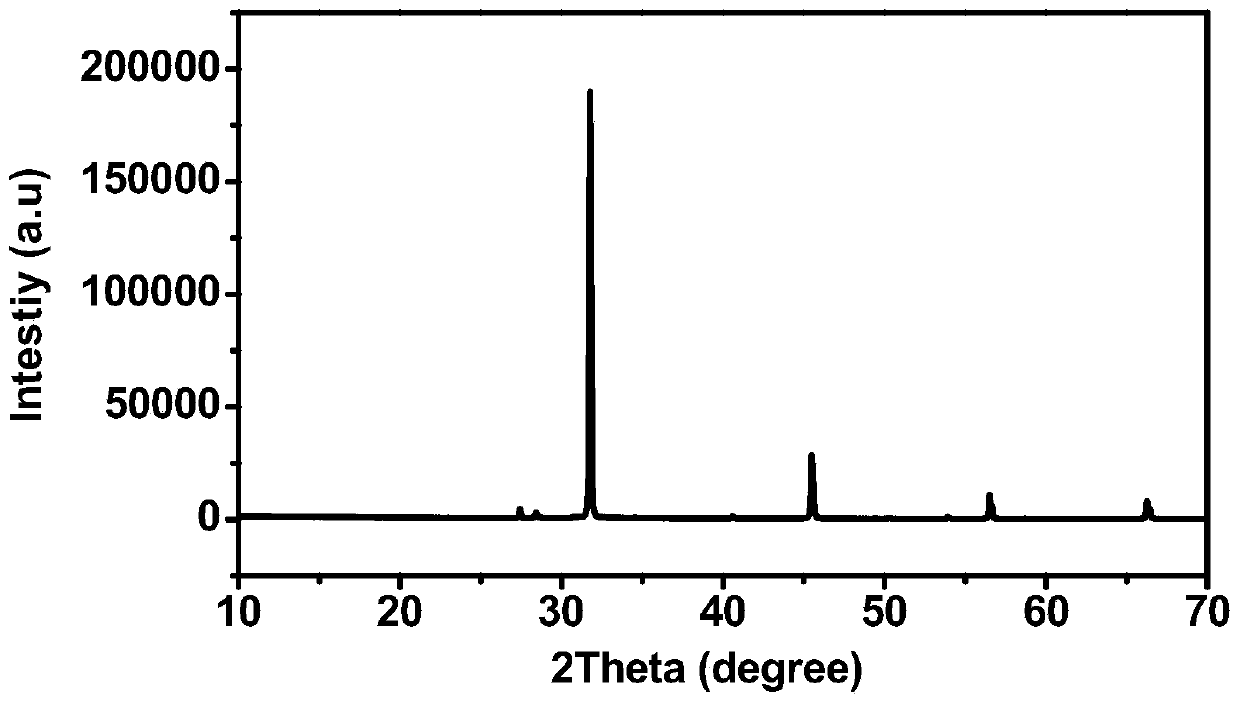

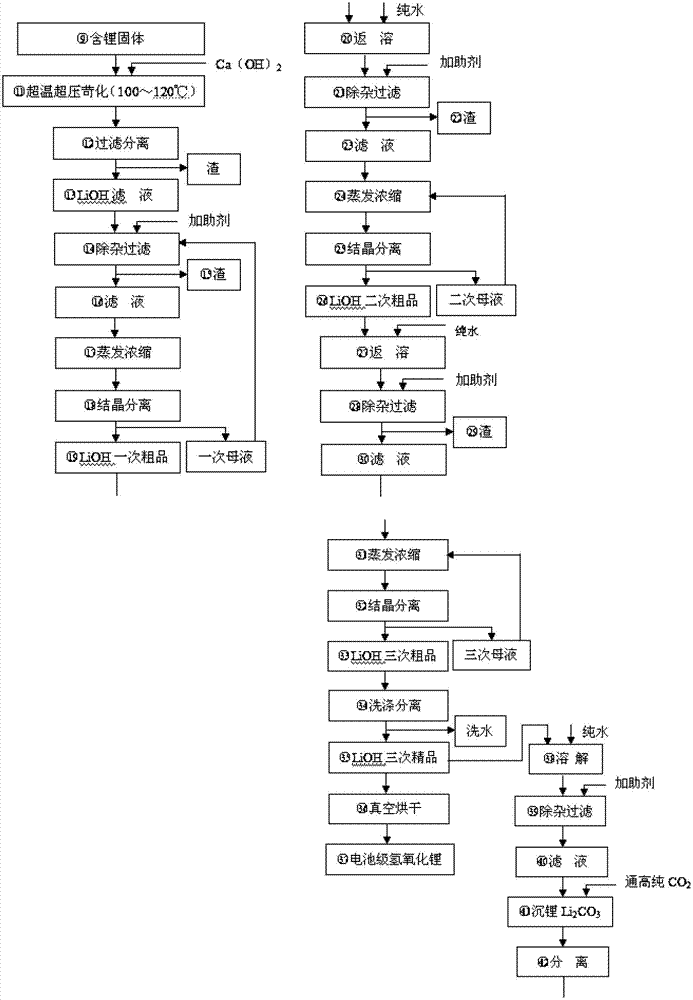

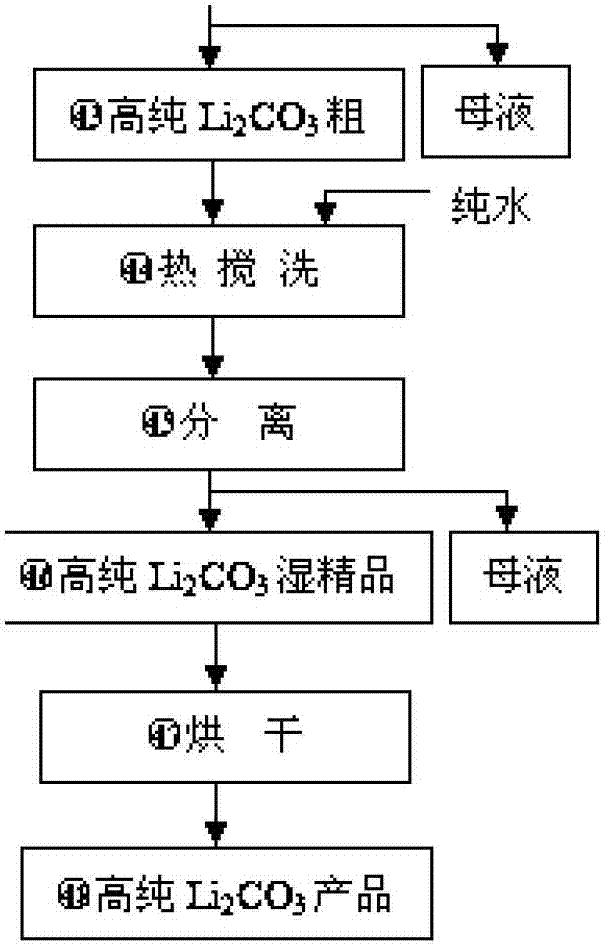

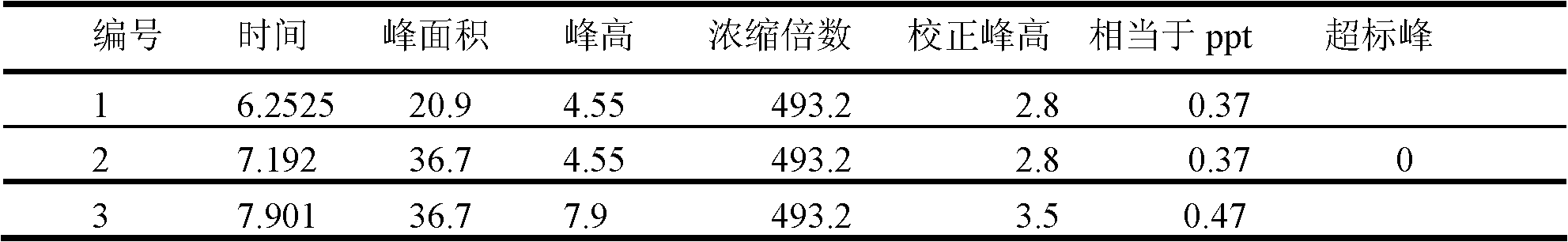

Method for preparing battery-grade lithium carbonate or high-purity lithium carbonate from industrial-grade lithium carbonate

InactiveCN103539169AHigh purityControl impurity contentLithium carbonates/bicarbonatesIon exchangeCarbonization

The invention discloses a method for preparing battery-grade lithium carbonate or high-purity lithium carbonate from industrial-grade lithium carbonate. The method comprises the following steps of: (1) carbonization: mixing the industrial-grade lithium carbonate with secondary distilled water to obtain slurry and then introducing carbon dioxide gas so that lithium carbonate solid is dissolved into a lithium bicarbonate solution; (2) ion exchange: removing main impurities such as calcium and magnesium out of the solution by using resin through carrying out ion exchange once or twice; and (3) pyrolysis: heating the solution subjected to ion exchange adsorption once for a certain time under the boiling condition, filtering, washing and drying to obtain the battery-grade lithium carbonate; and heating the solution subjected to ion exchange adsorption twice or more times for pyrolysis, filtering, washing and drying to obtain the high-purity lithium carbonate. The method provided by the invention is capable of effectively controlling the content of impurities, is short in process flow, low in energy consumption and friendly to environment, and also has high practical value.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

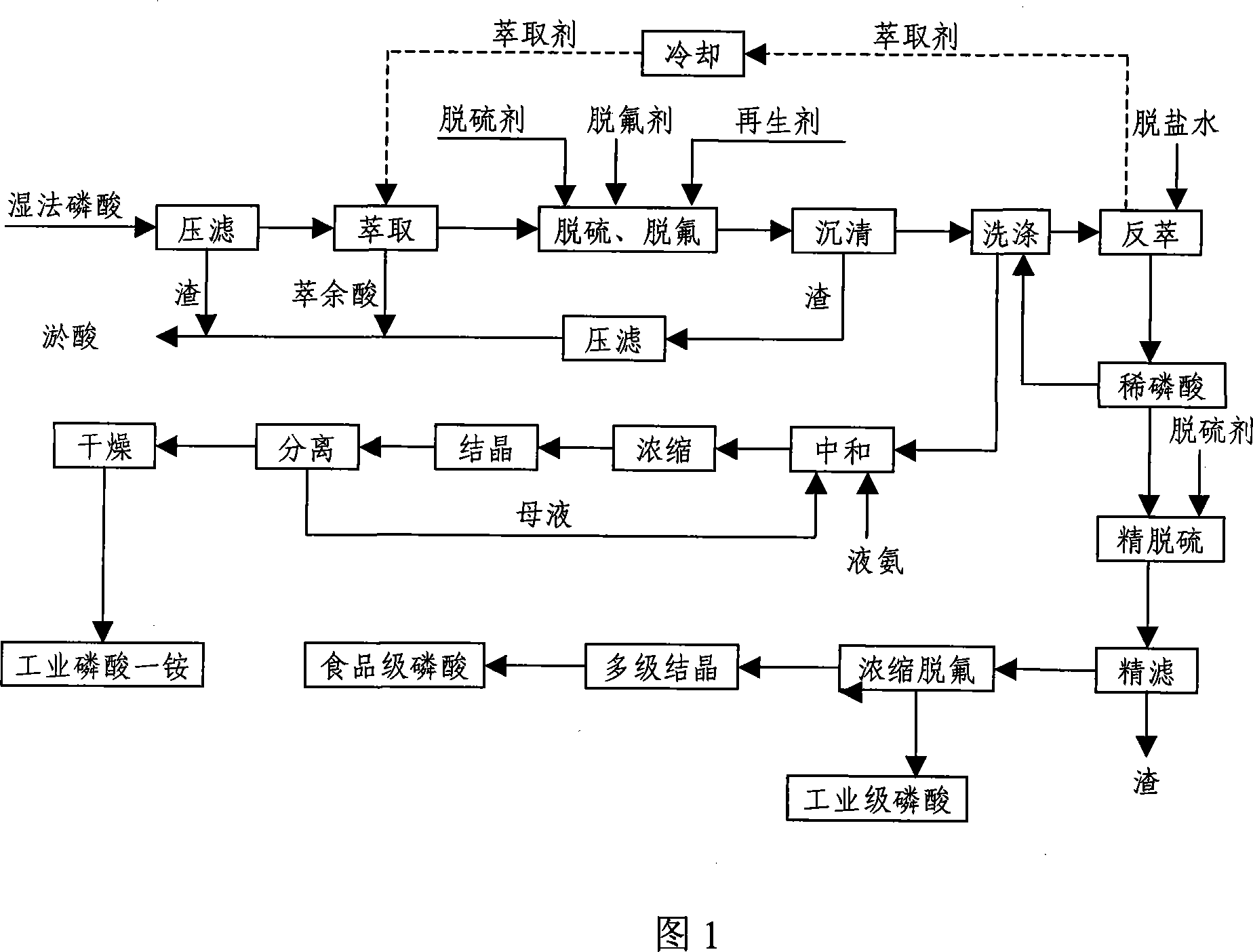

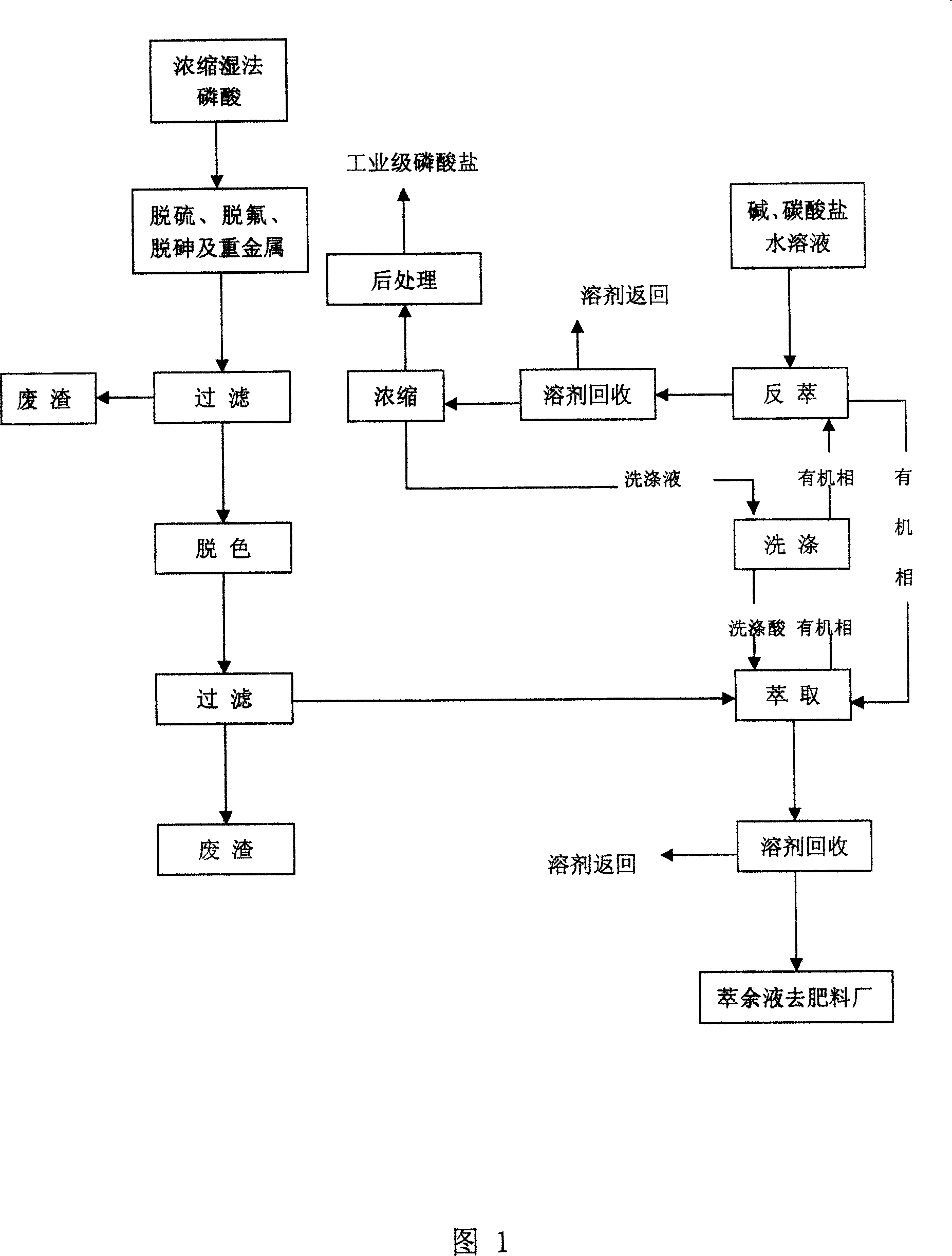

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

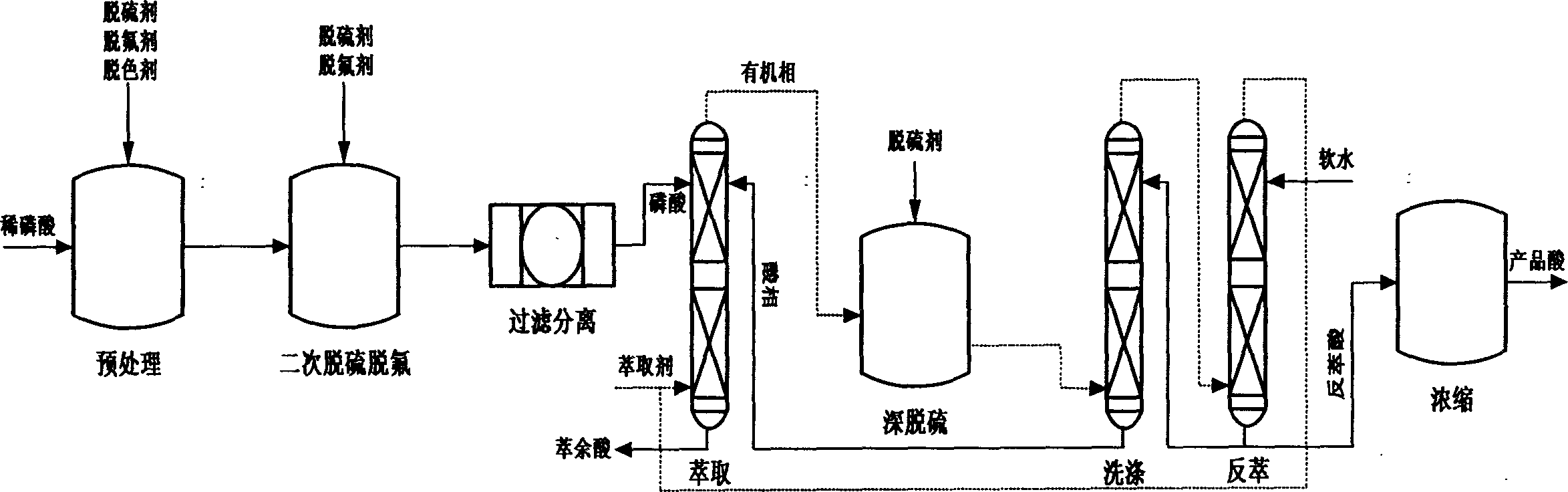

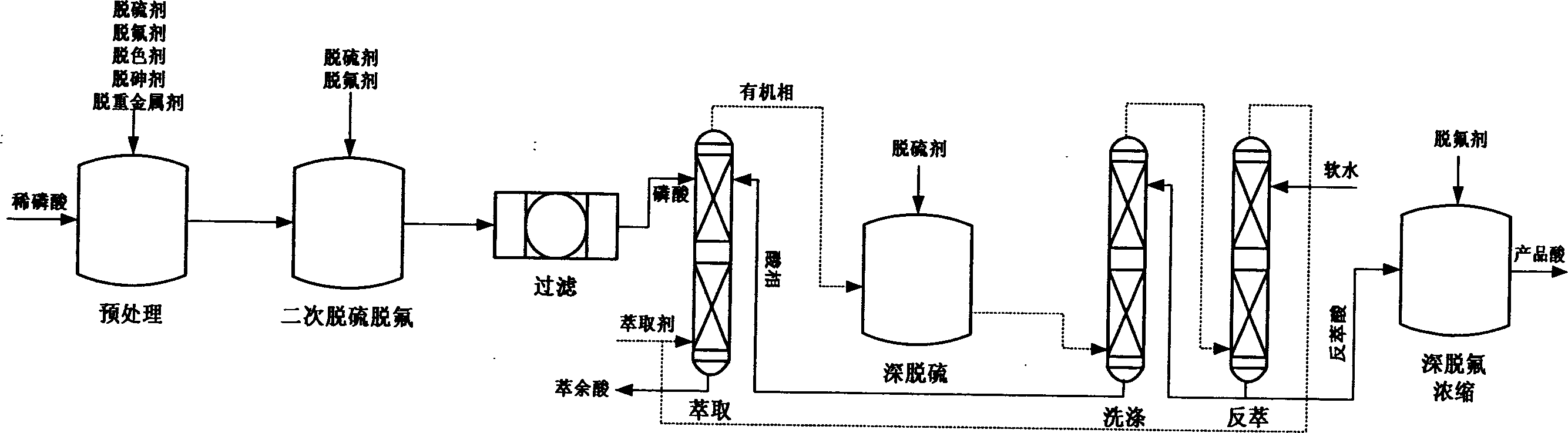

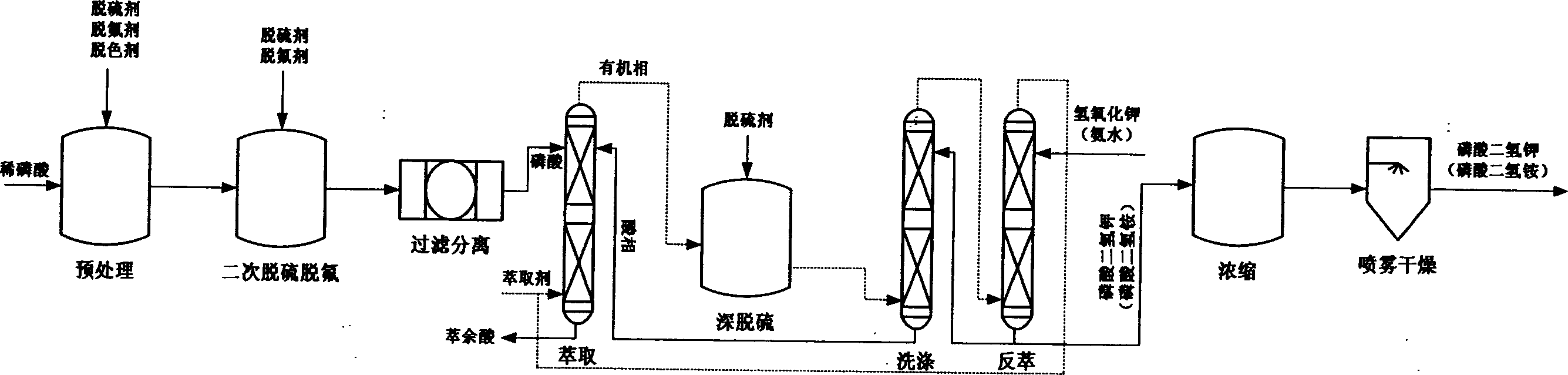

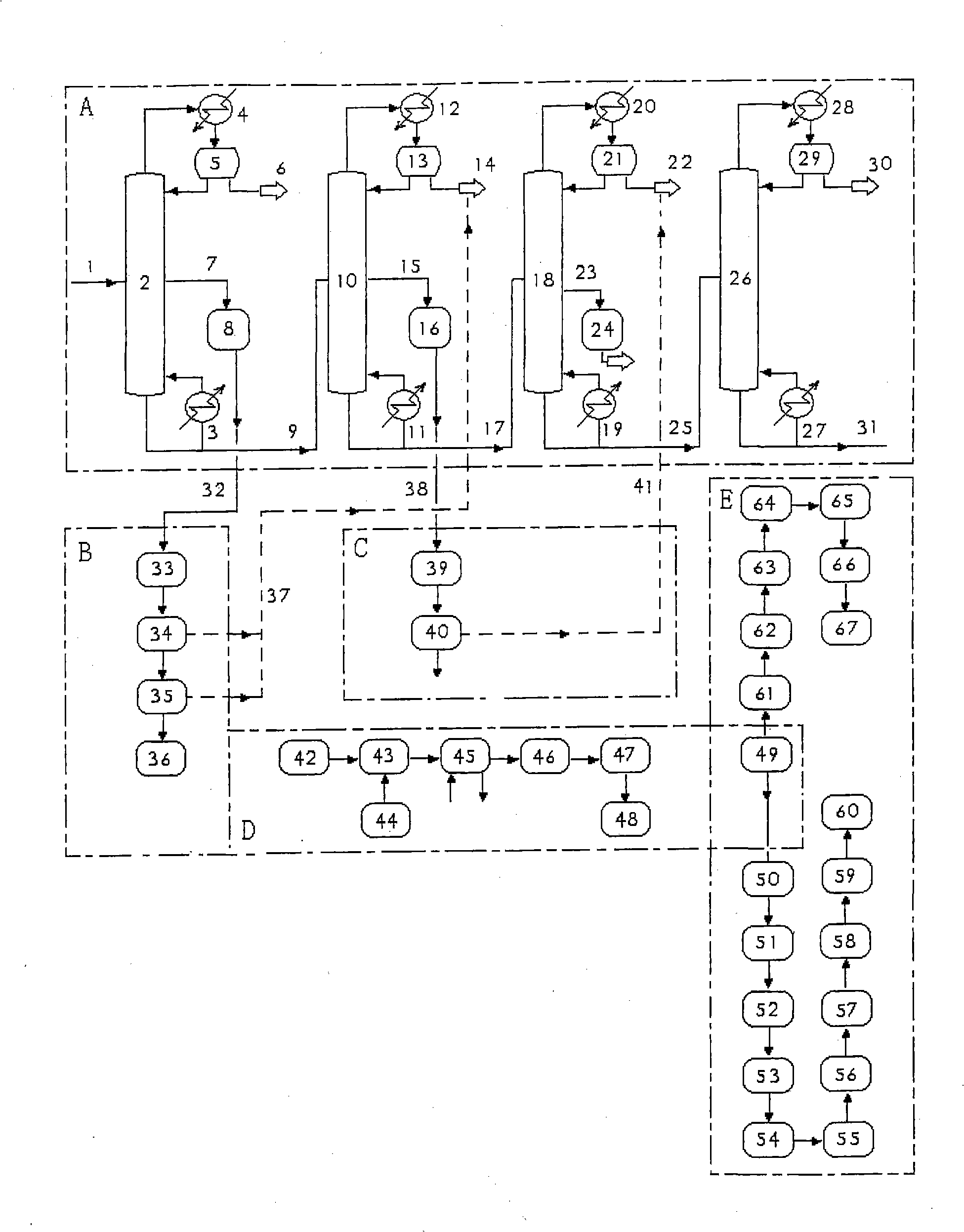

Method for preparing technical grade phosphoric acid, foodstuff grade phosphoric acid and phosphate using wet method and thin phosphoric acid

The invention discloses a method for preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid, which sequentially contains pretreation, secondary desulfurizion and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction and concentration. Different from method for preparation of food-grade phosphoric acid with wet-process diluted phosphoric acid, the pretreating contains not only desulfurization, defluorination, decoloring, but also de-arsenic, de-heavy metal, and defluorination and deep concentration proceeds parallelly after retrograde extraction. The process of preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid sequentially contains pretreation, secondary desulfurization and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction, concentration, spray drying or shotcrete granulation, the extractant using in the process of retrograde extraction being KOH saturated solution or NH4OH saturated solution. With said process, it can decrease the energy consumption and the production cost; and it can produce and purify phosphoric acid, and also directly produce plural of phosphonate with the same device.

Owner:SICHUAN JINGCUI CHEM TECH

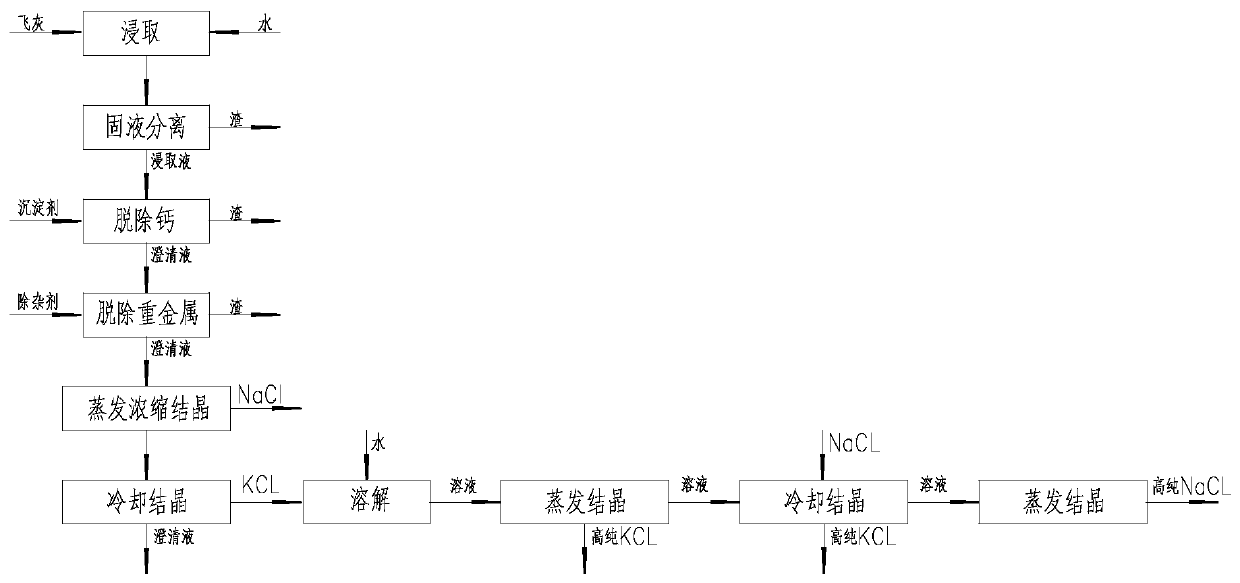

Method for producing potassium salt and sodium salt by using waste incineration fly ash

ActiveCN110040748AHigh purityEfficient use ofAlkali metal halide purificationTechnical gradeSodium salt

The invention discloses a method for producing potassium salt and sodium salt by using waste incineration fly ash, comprising the following steps: extracting waste incineration fly ash with water to obtain an extract; removing calcium ions and heavy metal impurities in the extract, and adjusting the pH of the solution to 6-8; heating and evaporating to concentrate the solution obtained in the previous step until crystallization, immediately filtering to obtain crystals sodium chloride, and naturally cooling the filtrate to room temperature for crystallization to obtain crystals crude potassiumchloride; dissolving the crude potassium chloride in water with a mass ratio of the crude potassium chloride to water is 1:1-1:1.9, heating and evaporating the solution until crystallization, and immediately separating the solid and liquid to get crystals pure potassium chloride and filtrate; and supplementing sodium chloride into the filtrate obtained in the previous step, cooling for crystallization, and filtering to obtain crystals pure potassium chloride. The invention can separate sodium salt and potassium salt in fly ash washing wastewater, and obtain high purity or industrial grade ofsodium chloride and potassium chloride crystals.

Owner:SINOMA INT ENG

Preparation method of ultrafine low-sodium alpha-alumina micropowder

ActiveCN103332718AReduce sodiumLower firing temperatureAluminium oxide/hydroxide preparationAluminium hydroxideTechnical grade

The invention relates to a preparation method of ultrafine low-sodium alpha-alumina micropowder, and belongs to the technical field of abrasive polishing and sintered body materials. The preparation method of ultrafine low-sodium alpha-alumina micropowder is provided for realizing the reduction of the content of sodium in a raw material aluminum hydroxide, so the sintering temperature is reduced, and the uniformity of the crystal grain granularity of a product is guaranteed. A technical scheme adopted in the invention is characterized in that the preparation method of ultrafine low-sodium alpha-alumina micropowder comprises the following steps: 1, precursor treatment: adding pure water to industrial-grade aluminum hydroxide to prepare a uniform slurry, and adding an acid for sodium removal; 2, calcining: adding the treated aluminum hydroxide to a chloride mineralizer, uniformly mixing, and calcining at 1100-1350DEG C for 1-8h to obtain alpha-alumina; and 3, grinding: crushing the obtained calcining product alpha-alumina to the original grain size in order to obtain alpha-alumina micropowder.

Owner:晋城市富基新材料股份有限公司

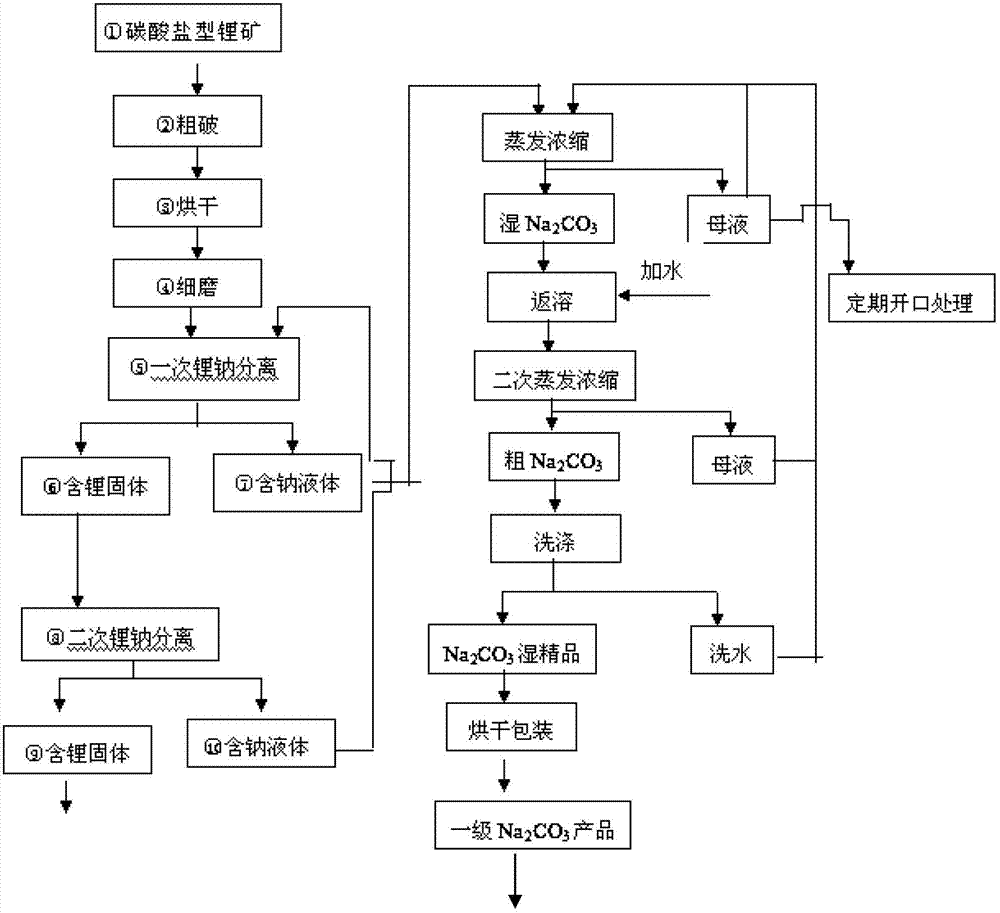

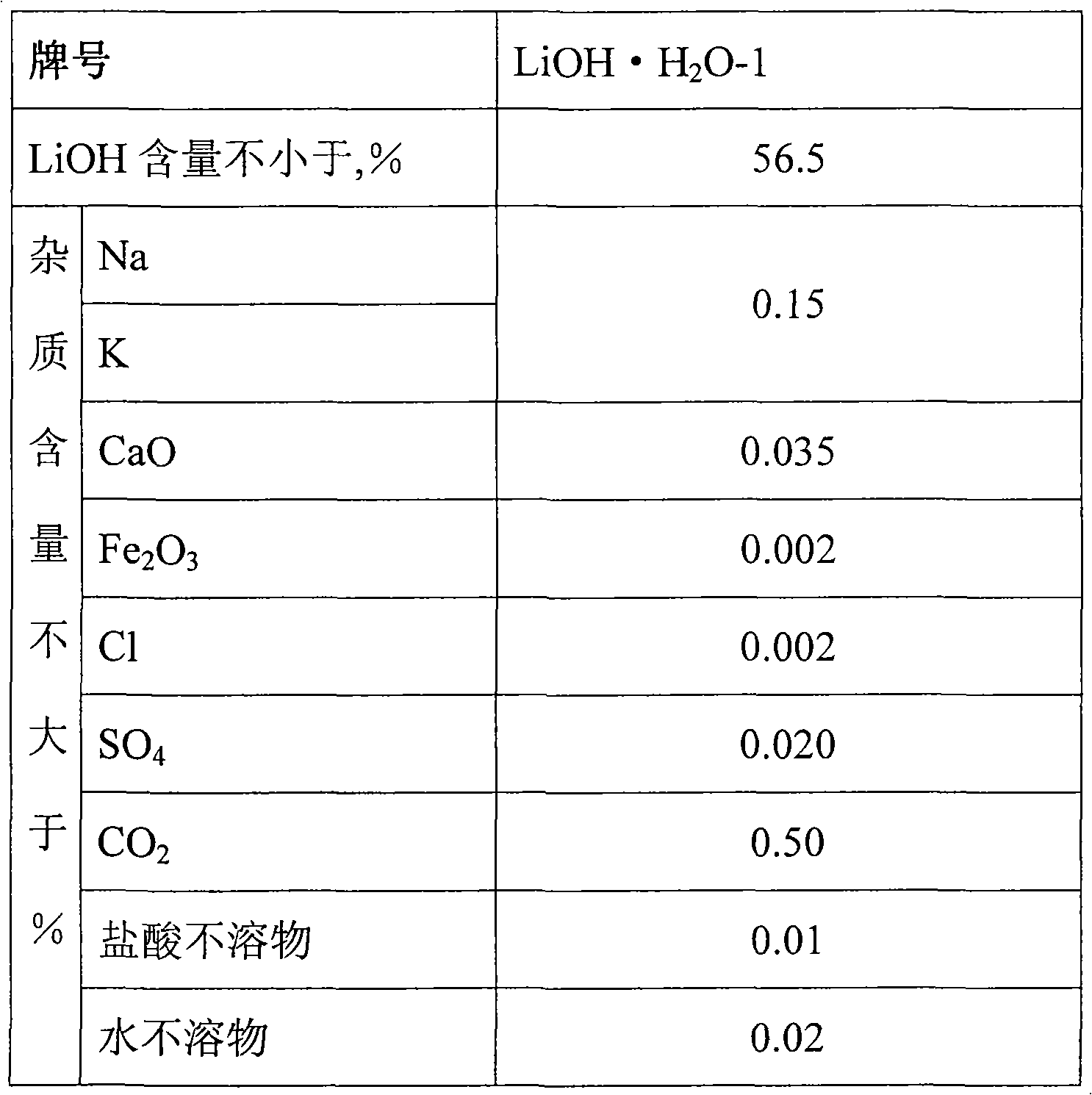

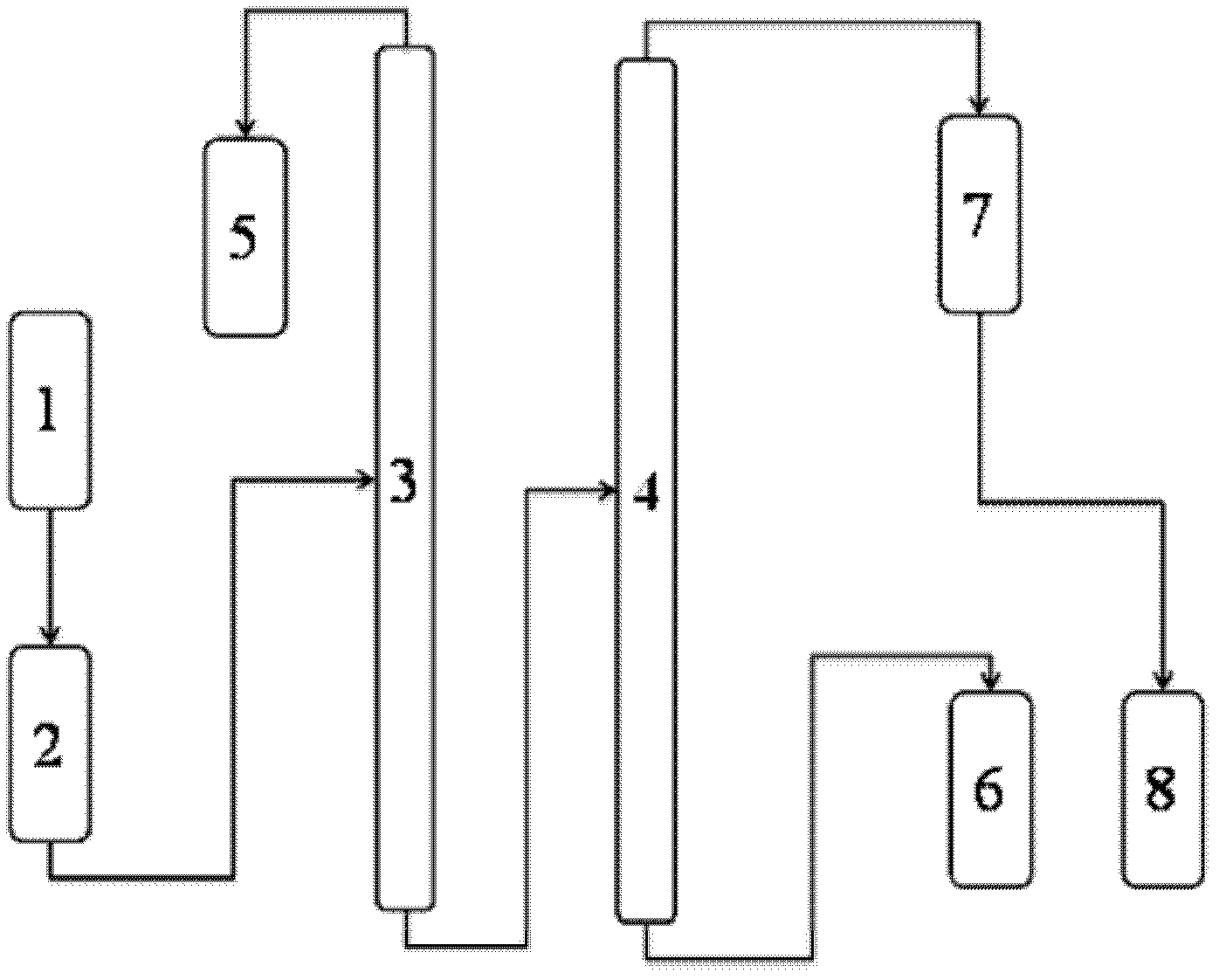

Method for industrially producing industrial, cell-grade or high-purity lithium hydroxide monohydrate

InactiveCN102826576AReduce consumptionReduce pollutionLithium oxides/hydroxidesLithium carbonateWater resources

The invention provides a method for industrially producing an industrial, cell-grade or high-purity lithium hydroxide monohydrate, which comprises the following steps of: (1) grinding; (2) removing impurities by a thermal precipitation method; (3) causticizing; and (4) removing impurities, crystallizing, washing, separating and drying. The invention also provides a method for preparing high-purity lithium carbonate. After causticizing reaction equipment and a reaction method which are provided by the invention are utilized, the feeding amount of the single causticizing production can be greatly improved and the large-scale industrial continuous production of the industrial and cell-grade lithium hydroxide monohydrate and the high-purity lithium carbonate is implemented; the consumption of water resources and energy can be effectively reduced and in the reaction, only a cheap precipitating agent or a cheap complexing agent needs to be used, so that the production cost is reduced; and the reaction is simple and convenient to operate and, the environment pollution is small, the obtained product has high quality and yield, the quality of the obtained product is stable and the product has wide industrial application prospect.

Owner:四川长和华锂科技有限公司

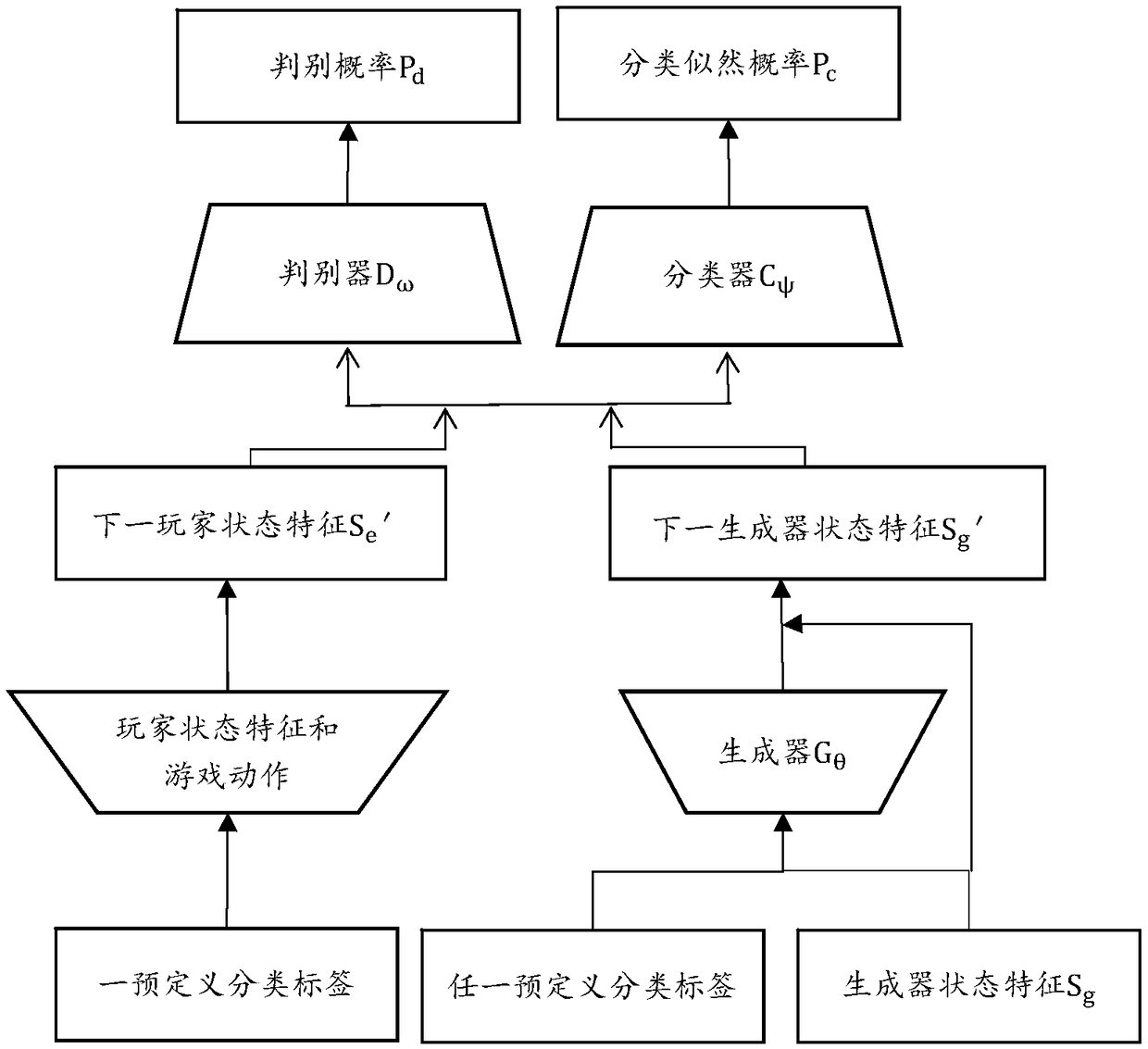

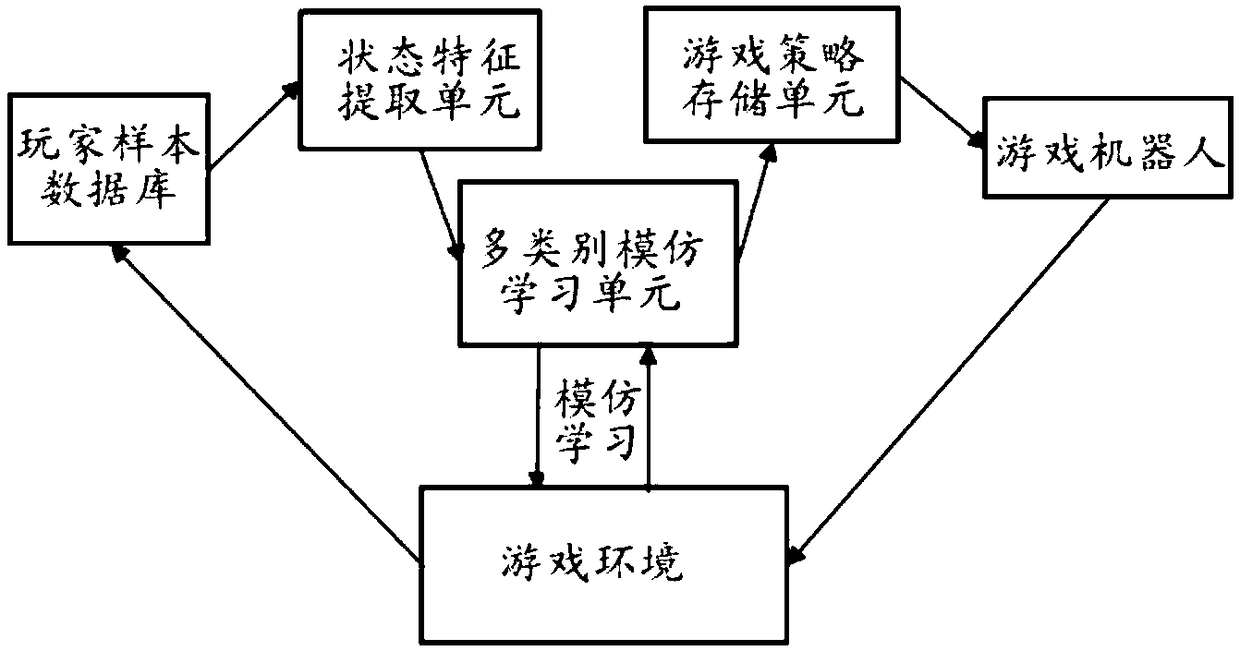

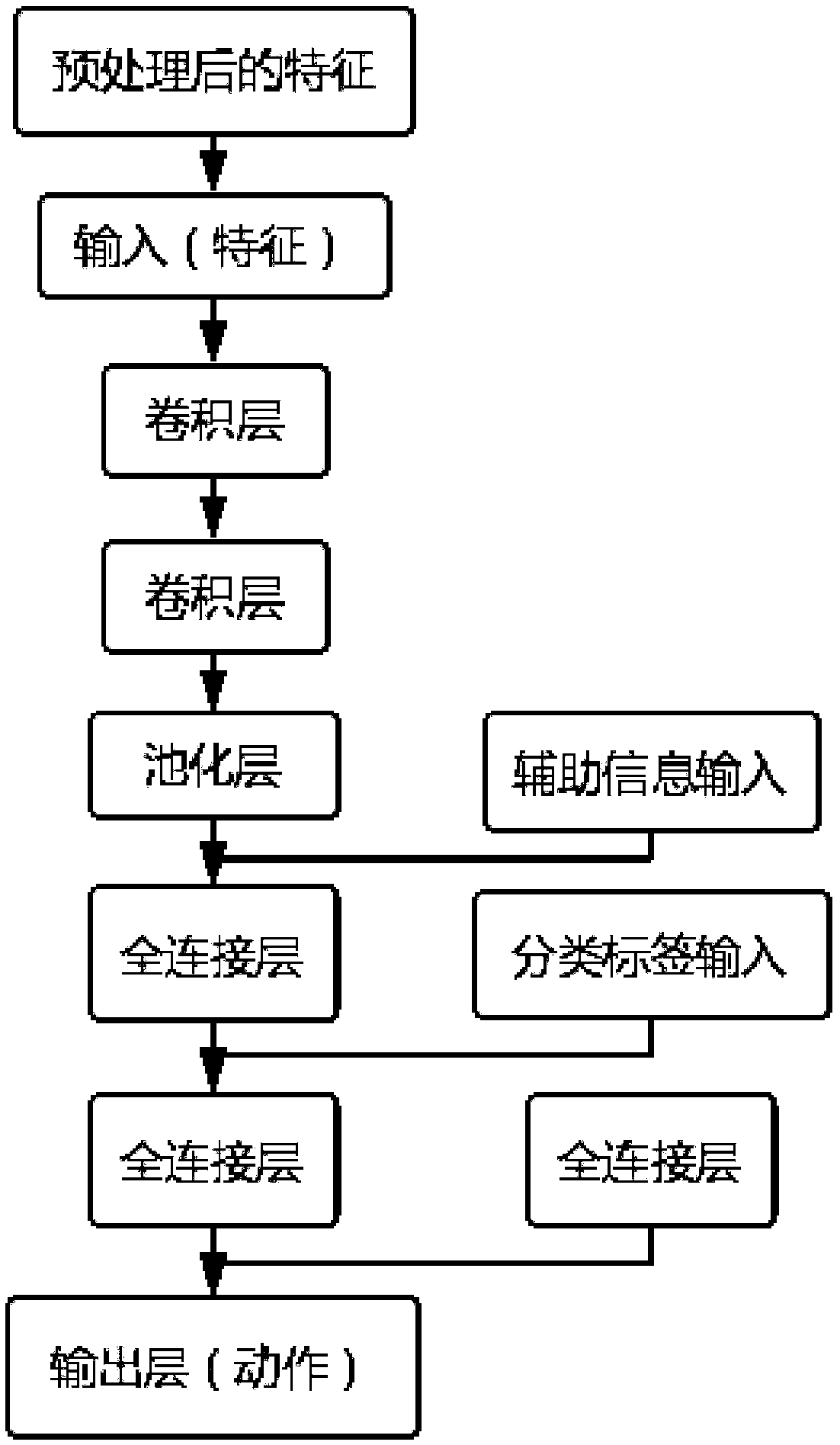

End-to-end game robot generation method and system based on multi-class imitation learning

ActiveCN108724182AScientific learning styleSmart learningProgramme-controlled manipulatorTechnical gradeHuman–computer interaction

The invention relates to an end-to-end game robot generation method and system based on multi-class imitation learning to obtain game robots which are more comparable to game levels of players of different technical grades. The end-to-end game robot generation method based on multi-class imitation learning comprises the following steps: establishing a player sample database; and forming an adversarial network by a policy generator, a policy discriminator and a policy sorter, wherein the policy generator carries out imitation learning in the adversarial network, the policy generator obtains game policies similar to game behaviors of the players of different technical grades to further generate game robots, and the policy generator, the policy discriminator and the policy sorter are multilayered neural networks. According to the method and system provided by the invention, the multi-class game robots can be obtained, and the robot of each class can simulate the game policy close to the player of corresponding class.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

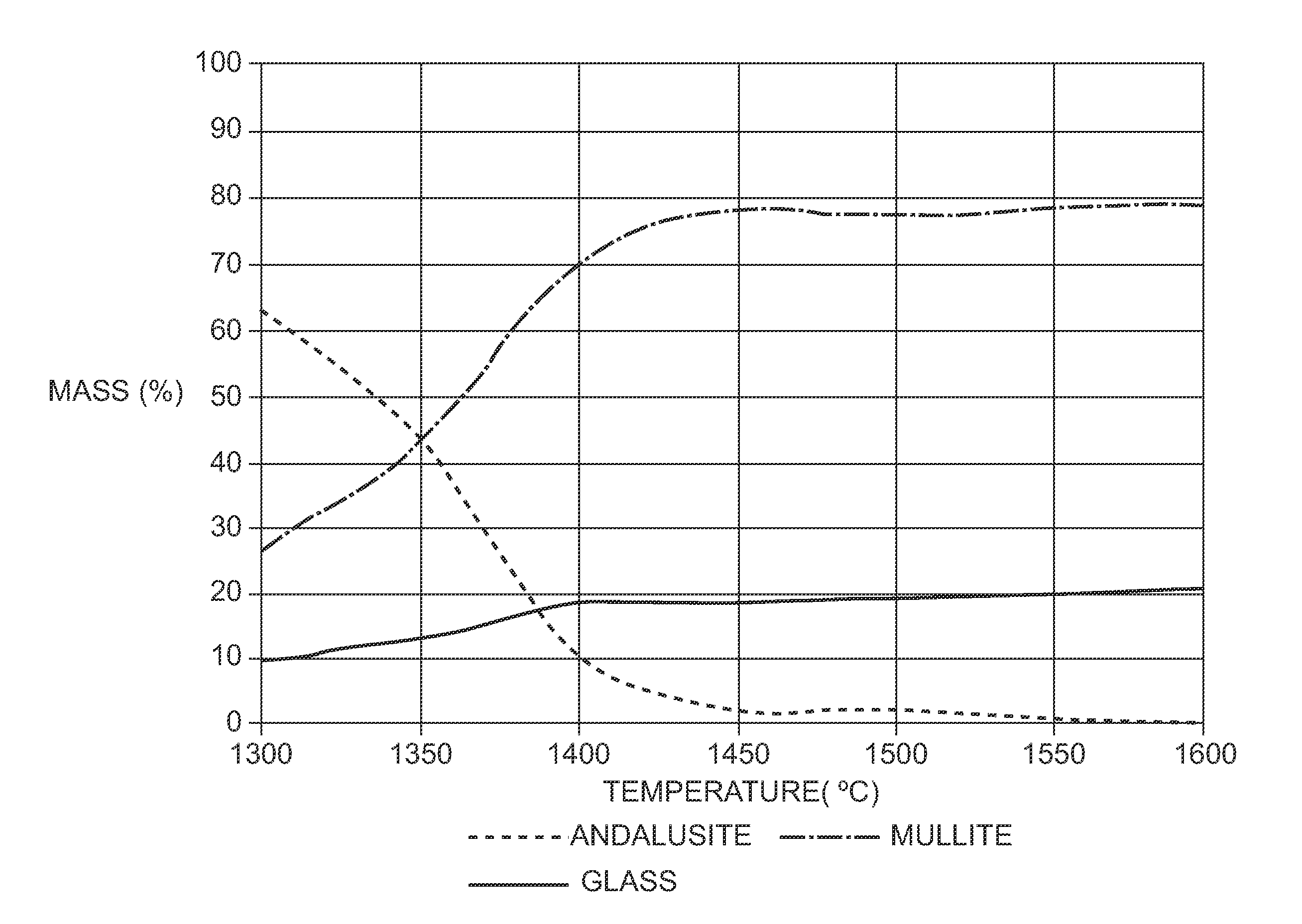

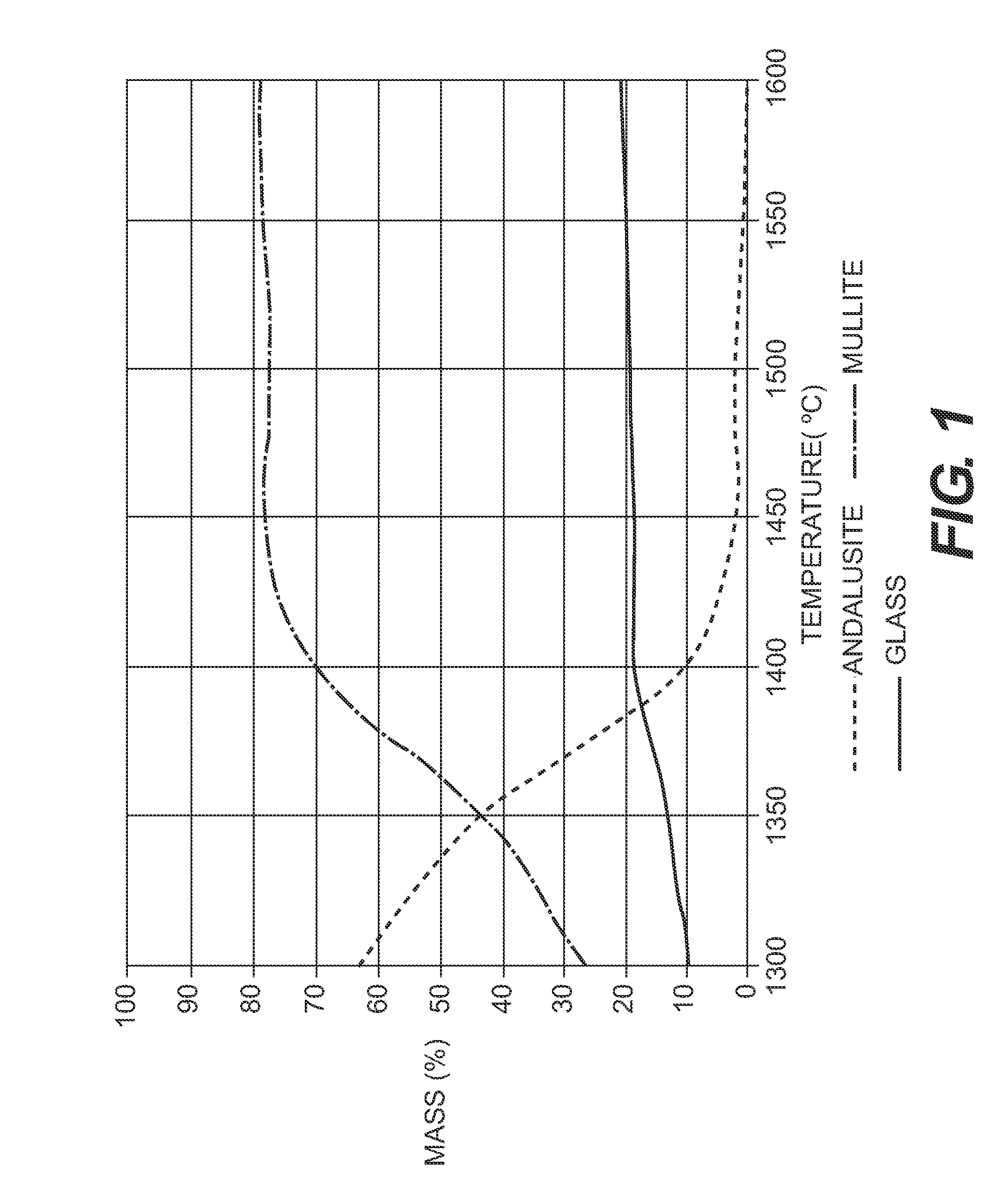

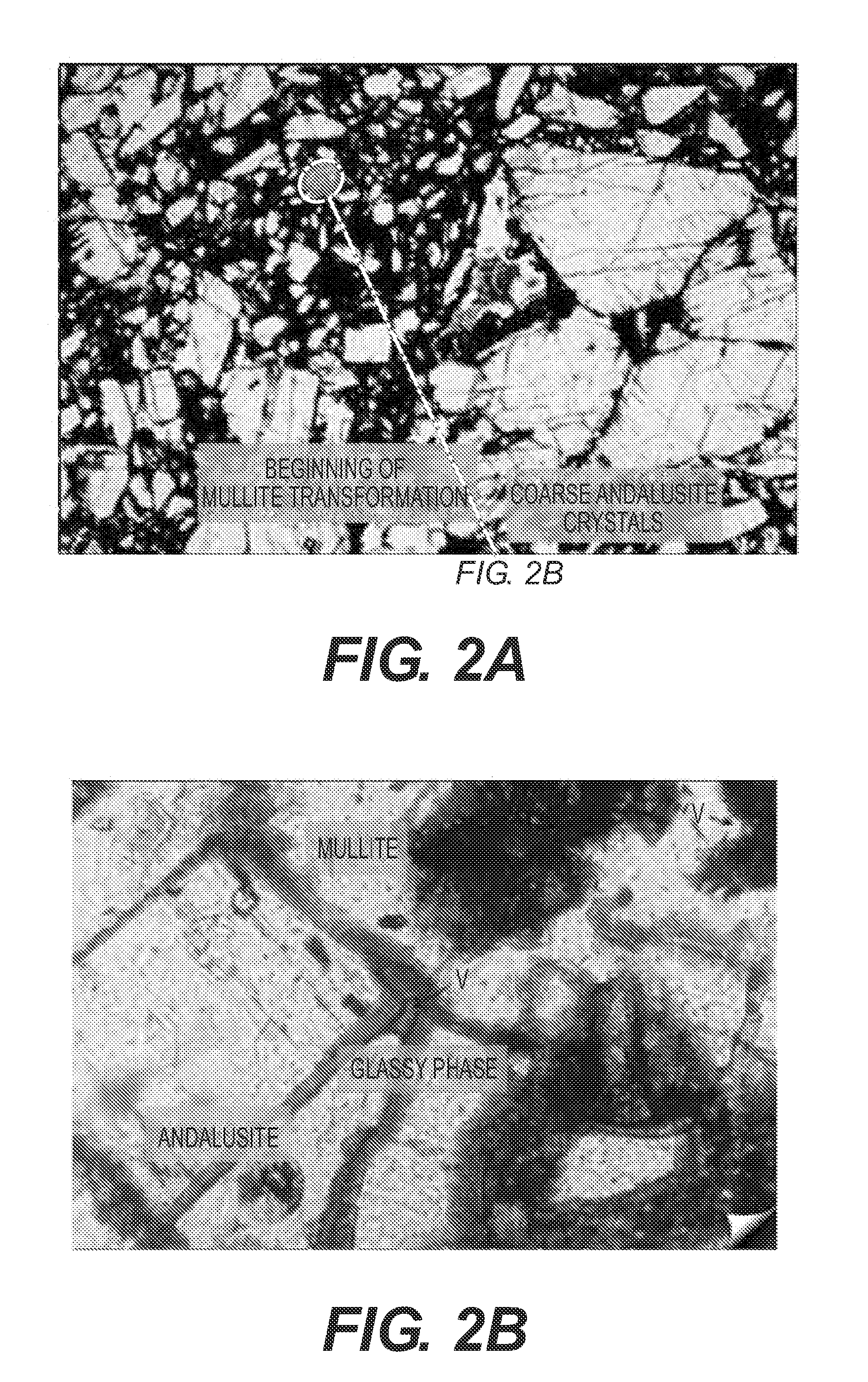

Proppants and Anti-flowback additives made from sillimanite minerals, methods of manufacture, and methods of use

Spherical and rod-shaped proppants and anti-flowback agents made from sillimanite minerals possess high strength and high conductivity. The sillimanite minerals may be selected from the group consisting of kyanite, sillimanite, and andalusite and may be used alone or in combination with other materials, such as bauxite, kaolin, meta-kaolin, pure or technical grade alumina (about 98%-99.9% alumina by weight), alumina-containing slag, zirconia, silica, iron, alkali elements (such as calcium, magnesium, and sodium), and virtually any other mineral containing alumina. The starting material may optionally be milled to achieve better compacity and crush resistance in the final proppant or anti-flowback agent. A fracturing fluid may comprise the rods or spheres alone, or in combination with each other or other proppants or anti-flowback agents of different shapes.

Owner:US CERAMICS LLC

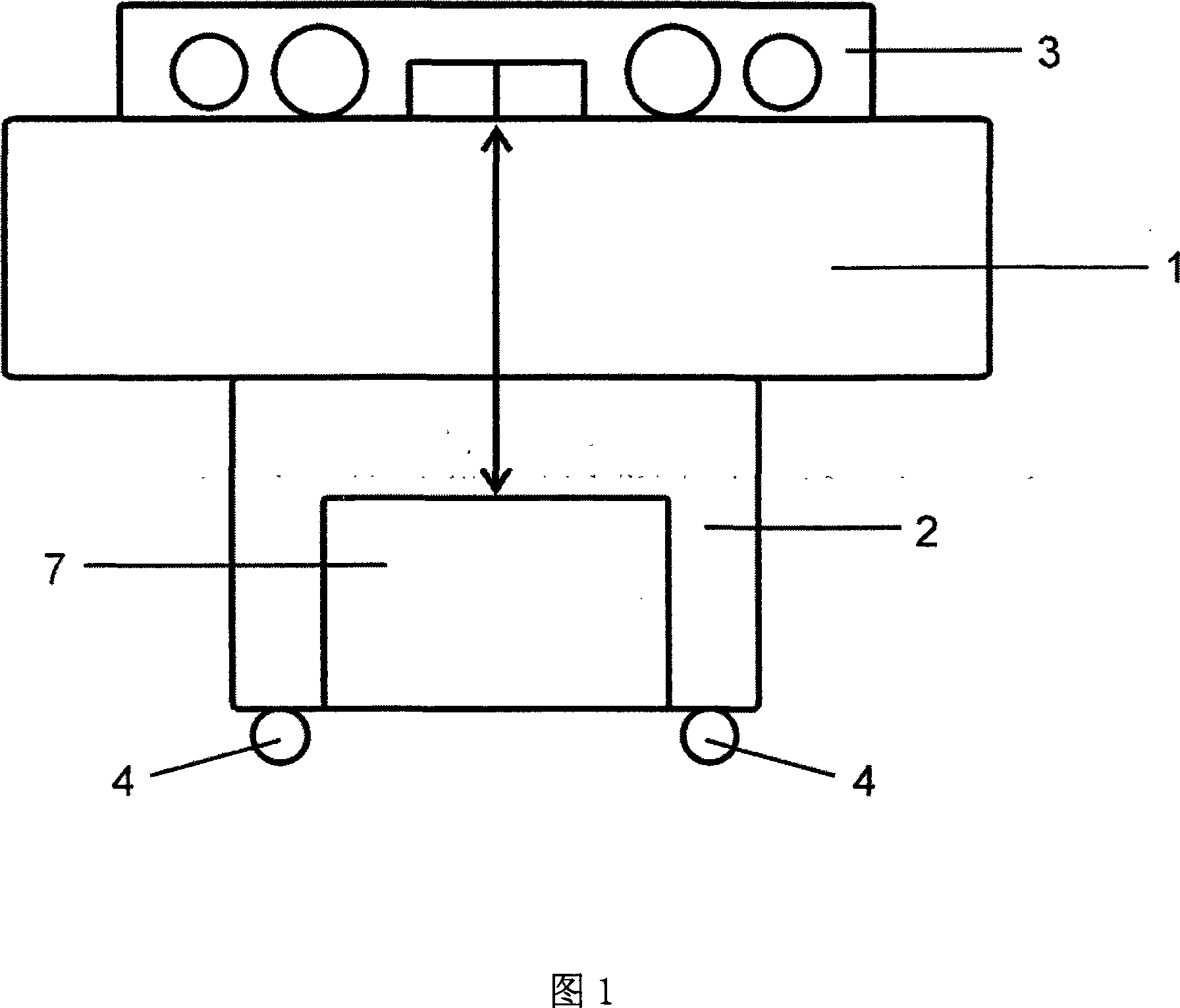

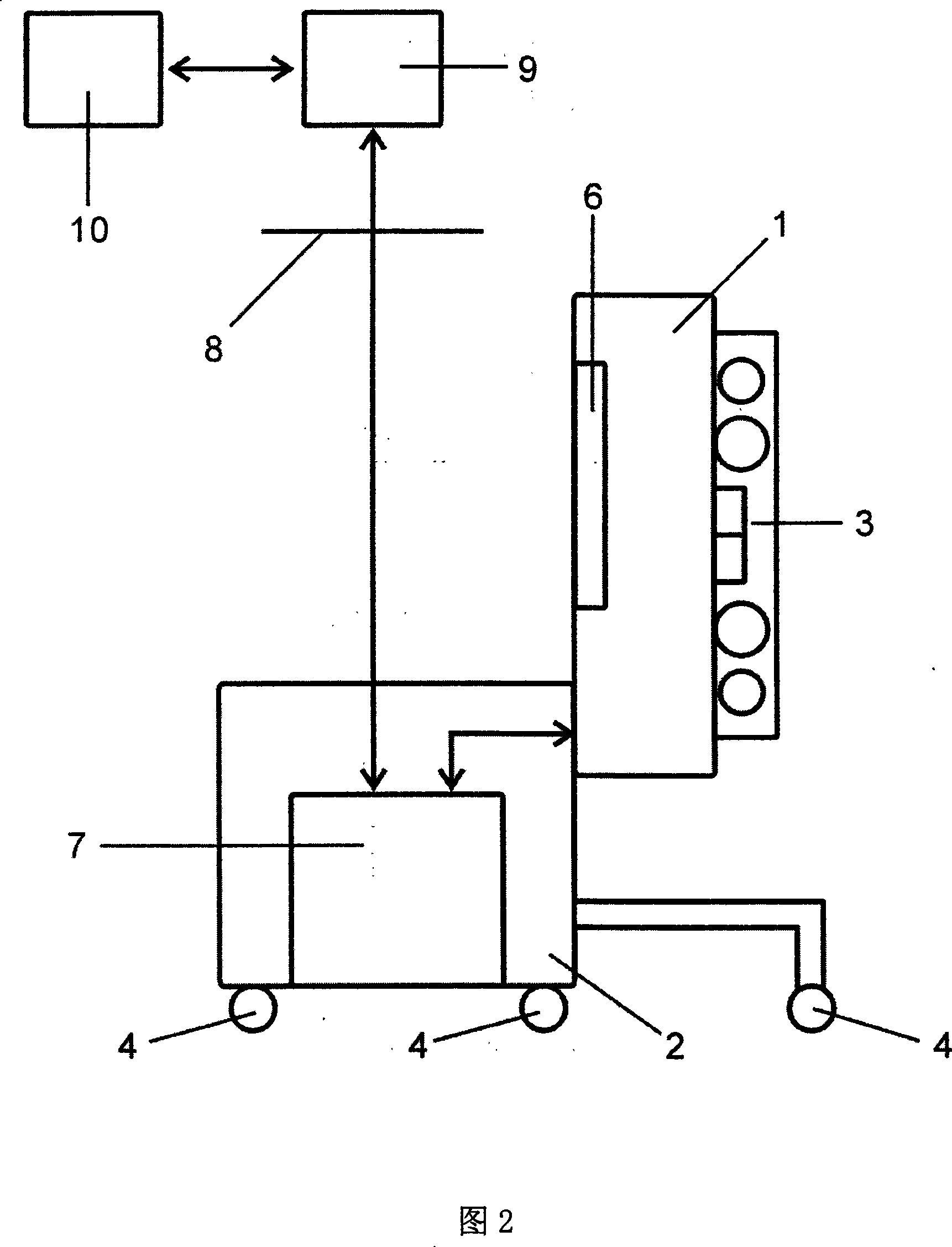

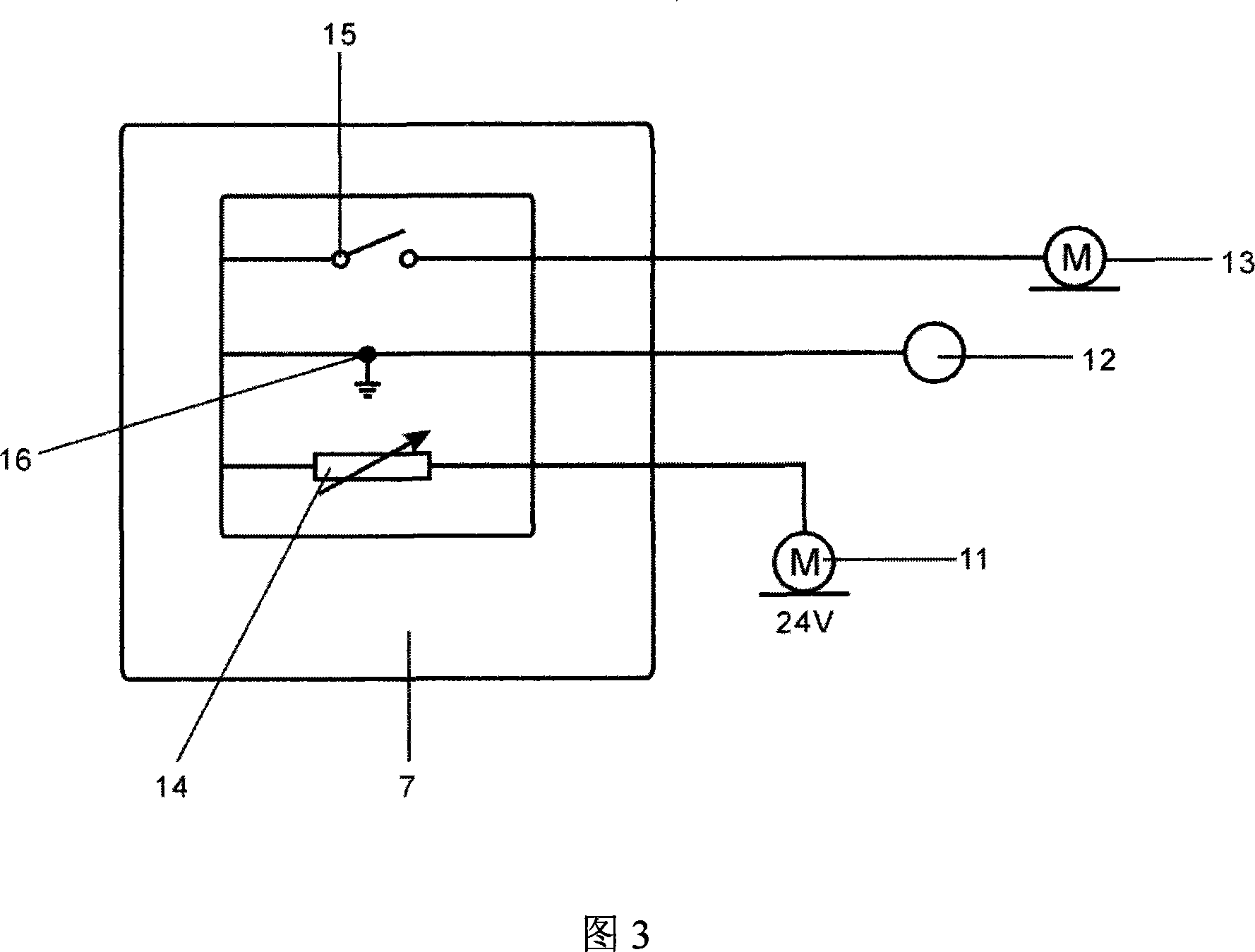

Method and apparatus for testing vehicle electric appliance circuit system equip guarantee skill

InactiveCN101206814AImplement virtual testingEducational modelsElectrical appliancesEngineeringTechnical grade

The invention relates to a method of equipment ensuring skill experiment for a vehicle electric circuit system and the device thereof. A real device can be especially combined with a computer through the invention, various single failures or combined failures are artificially arranged to the a vehicle electric circuit system by using a computer mouse, the invention can also perform on-line network with other computers, simultaneously the actual measurement or the virtual measurement on the screen of a real object or a computer is realized, evaluation contents are distributed in a regional network of computers, the operational situations are monitored. The invention is used for the quick and professional technique training, the skill evaluation, and the evaluation and the appraisal work of the technical grade on the overhaul of the vehicle electric circuit system.

Owner:TIANJIN UNITE AUTOMOBILE ELECTRONICS CONTROL TECH SERVICE

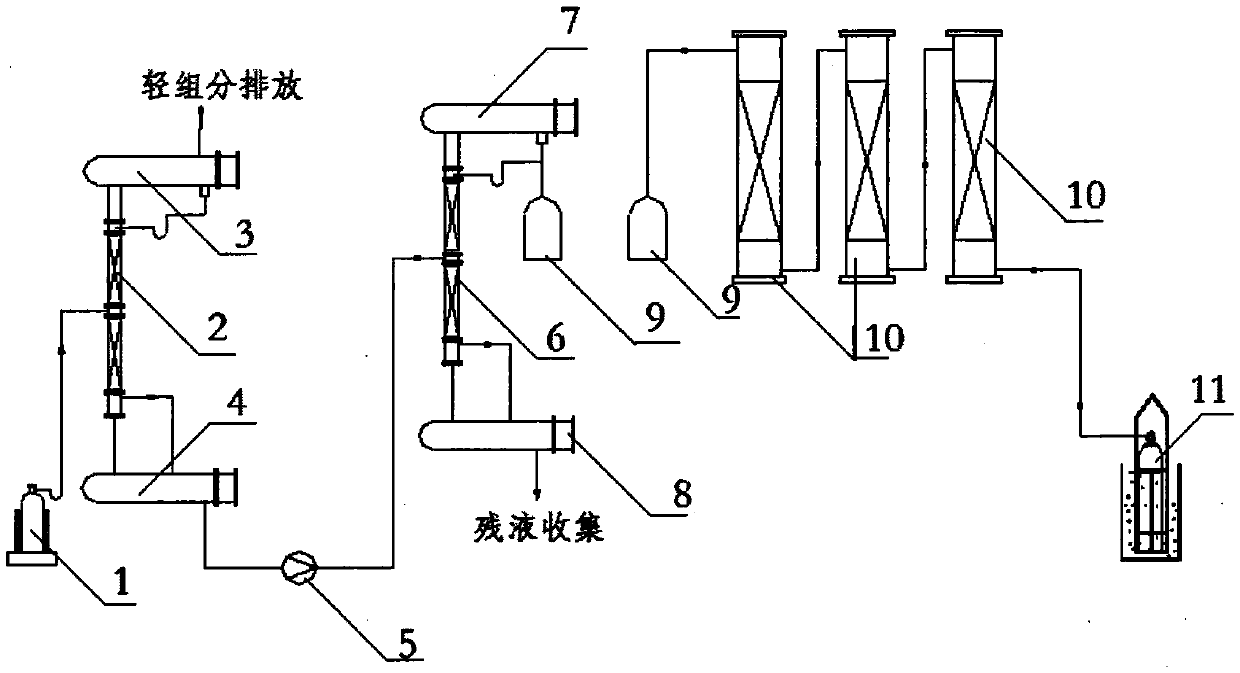

Electronic grade hydrogen chloride purification method

ActiveCN105502295AAvoid introducingReduce manufacturing costChlorine/hydrogen-chloride purificationComing outPurification methods

The invention provides an electronic grade hydrogen chloride purification method. The method is characterized by comprising the following steps: introducing industrial liquid hydrogen chloride with purity of 99% to the middle position of a first rectifying tower to be rectified so as to remove light components; introducing a liquid coming out from the bottom of a reboiler of the first rectifying tower to the middle position of a second rectifying tower by a pump to be rectified, condensing hydrogen chloride generated through heating by a second reboiler with a second condenser, controlling the reflux ratio, enabling part of hydrogen chloride to flow back to the second rectifying tower and transferring the other part of hydrogen chloride to middle storage tanks to be stored and pumping out residual liquid from the bottom of the second reboiler to a waste liquid storage tank so as to remove heavy components; and obtaining high-purity hydrogen chloride with purity above 99.9999% through adsorption and purification of at least an adsorption tower with a molecular sieve inside. The method has the effect of avoiding introduction of other impurity media, is simple to operate and is low in production cost.

Owner:SHANGHAI ZHENGFAN TECH +1

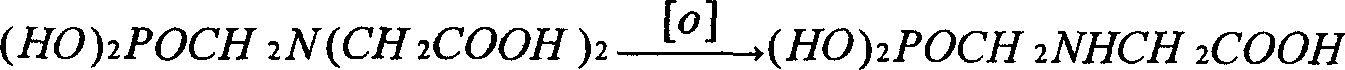

Glyphosate preparation and method for preparing same

ActiveCN1631894AReduce investmentReduce generationBiocideGroup 5/15 element organic compoundsWastewaterTechnical grade

Disclosed are a glyphosate and its preparing method oxidate oxidate to acquire mixed liquid of glyphosat; bifter hydration, add into glyphosate agent glyphosate preparation to change it into salt, then add surface active agent as assistant into the mixed liquid of salt and the surface active agent is one or several ones from nonion surface active agent or amphoteric surface active agent or organic silicon surface active agent, mix them to be average, acquiring the . In the course, there is no need to separate glyphosate technical grade, while preparation the with the glyphosate technical gradedirectly, which has decreased the amounts of equipment and worker, without drainage of glyphosate mother liquid, it completely makes use of glyphosate technical grade, as well as reduces waste water, benefiting for environmental protection.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

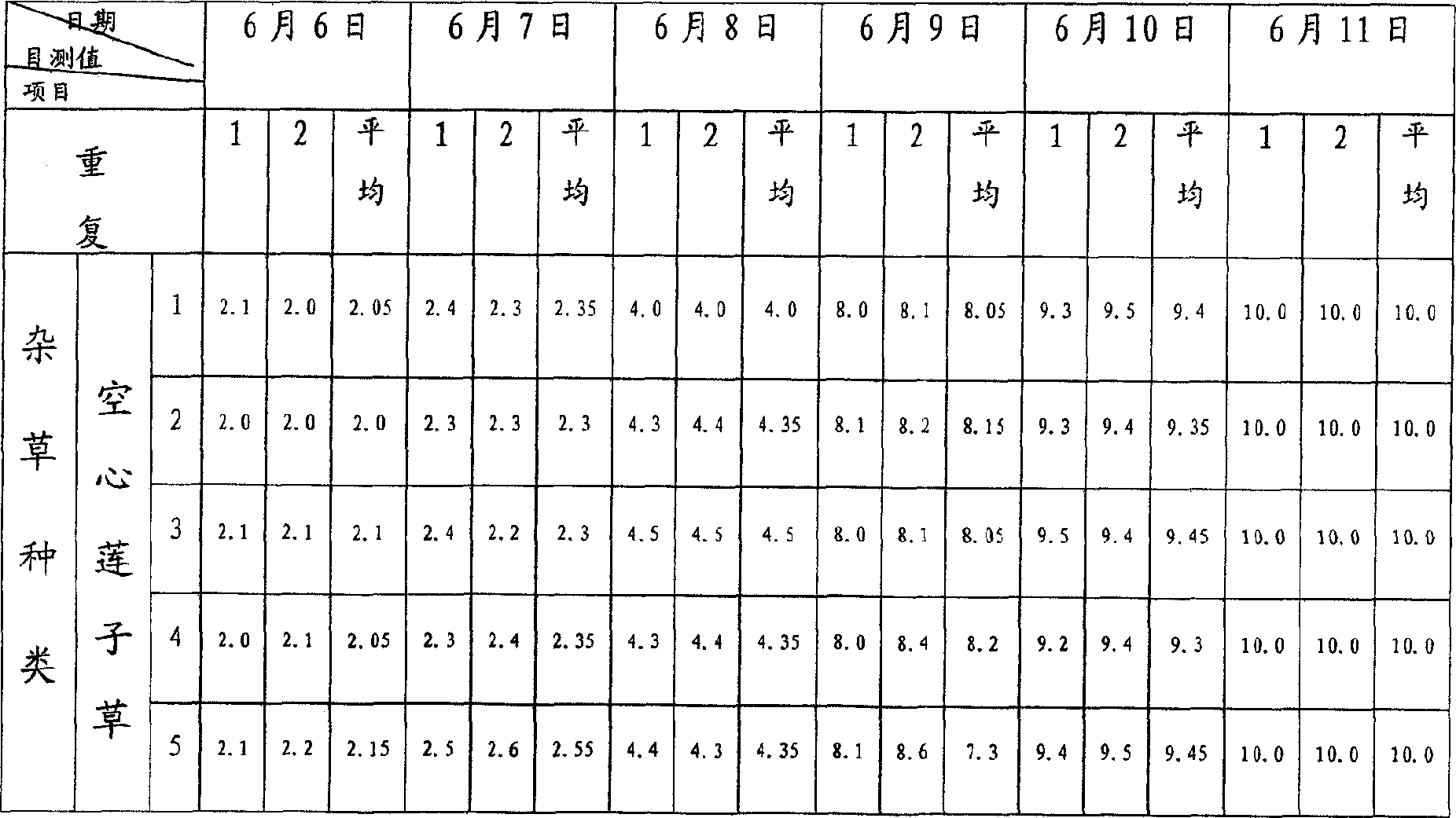

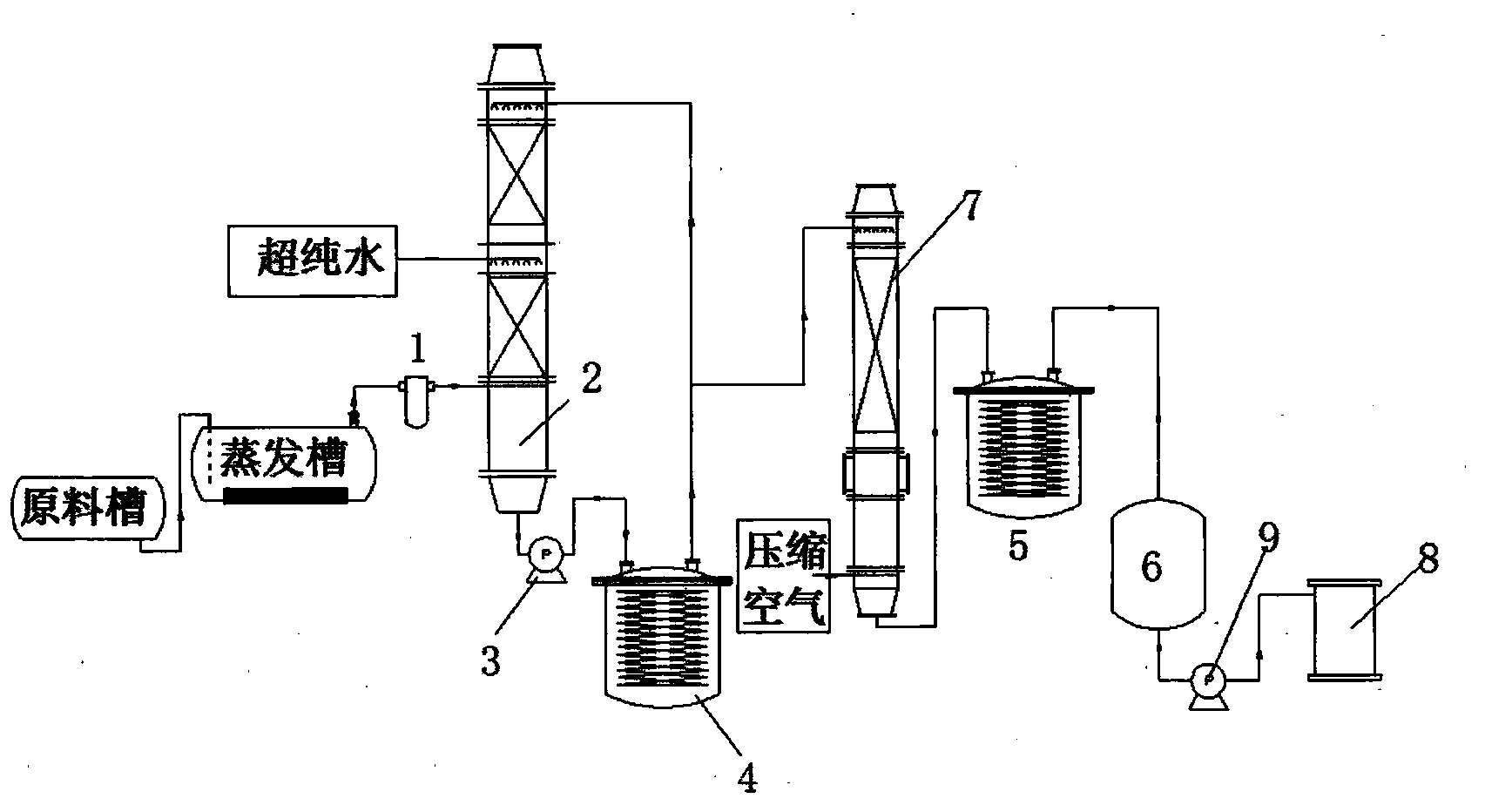

Production method of electronic-grade sulphuric acid

ActiveCN103407972AHigh temperature resistantBring pollutionSulfur compoundsUltrafiltrationDistillation

The invention discloses a production method of electronic-grade sulphuric acid. The production method comprises the following steps in sequence: industrial-grade sulfur trioxide raw materials are provided and placed into a raw material storage tank; the sulfur trioxide raw materials are conveyed into an evaporator tank; the evaporator tank is heated; sulfur trioxide steam generated by heating enters into an absorption tower through a filter; the sulfur trioxide steam is absorbed by electronic-grade ultrapure water in the absorption tower, the concentration of absorption liquid is controlled, and the absorbed solution enters into a degassing tower after cooled by a cooler; air stripping is performed on a sulfuric acid solution by the degassing tower through compressed air; the sulfuric acid solution enters into a finished product storage tank after cooled; finally, the final electronic-grade sulphuric acid applied to the integrated circuit industry is obtained after ultrafiltration to remove particles. The operating temperature of the technology, compared with a conventional technology, is lower than 120 DEG C. Therefore, the technology is safer than a high-temperature distillation technology which takes industrial-grade sulfuric acid as raw material, and in addition, compared with adopting equipment made of quartz glass, non-pollution to electronic-grade sulphuric acid products is guaranteed from equipment material.

Owner:SHANGHAI ZHENGFAN TECH +1

Process for joint production of aromatic solvent, stone oil naphthalin and durene line products with C10 heavy aromatic raw material

ActiveCN101318874ATake advantage ofSave resourcesDistillation purification/separationCrystallisation purification/separationAromatic solventGas phase

The present invention discloses a method for jointly preparing a series of products of an aromatic solvent, petronaphthalene and durene from a C10 heavy aromatics material, belonging to the C10 heavy aromatics complex utilization technical field. The method comprises the following steps of: A) separating the C10 heavy aromatics material; B)refrigerating and crystallizing an enrichment solution of durene; C)refrigerating and crystallizing an enrichment solution of naphthalene; D) gas phase catalytically oxidizing durene; and E) preparing technical grade PMA, technical grade PMDA and electronic grade PMDA from a crude product. The method has the advantages that the method can carry out joint production to obtain the series of products of aromatic solvent, petronaphthalene and durene by the C10 heavy aromatics material so that the C10 heavy aromatics material obtains sufficient utilization, thereby contributing to resource economizing.

Owner:常熟华虞环境科技有限公司

Production method of attapulgite loaded hydroxyapatite composite defluorination filter bulb

ActiveCN102502907AHigh fluoride removal capacityHigh yieldWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionSolubilityPhosphoric acid

The invention discloses a production method of an attapulgite loaded hydroxyapatite composite defluorination filter bulb, which comprises the following steps: preparing attapulgite loaded hydroxyapatite powder from industrial-grade calcium hydroxide, phosphoric acid, acetic acid and attapulgite as raw materials, regulating the solubility of calcium hydroxide using acetic acid, and controlling calcium-phosphorus ratio and pH value of the solution so as to ensure the purity and the defluorination capacity of the products; and fabricating the attapulgite loaded hydroxyapatite powder into pelletsof diameters 0.5-1.5mm, and drying and molding the pellets at a temperature ranging from 350 to 450 DEG C so as to obtain attapulgite loaded hydroxyapatite composite defluorination filter bulb. The composition of attapulgite and hydroxyapatite reduces cost, is helpful for pellet formation, and enhances defluorination of hydroxyapatite. The method of the invention uses cheap and easily-accessible raw materials, high capacity of defluorination filter bulbs, long service life and small fluent water resistance, , and is simple in preparation, easy for control and regeneration, and easy for large-scale industrial production and promotion.

Owner:JIANGSU YONGGUAN WATER & WASTERWATER EQUIP CO LTD +1

Method for thermally extracting coal

InactiveCN102512846AIncrease productionLow costCoke ovensSolid solvent extractionNitrogenNational standard

The invention relates to a method for thermally extracting coal, and the method comprises the following steps of: fully mixing crushed and dried coal granules with a solvent, and then adding the mixture into a high-pressure reaction kettle, raising the temperature to a specified temperature under a certain pressure after nitrogen metathesis; and thermally extracting, filtering, washing and drying to obtain black super-pure coal, wherein the solvent is industrial-grade national standard absorber oil or absorber oil produced by a coking plant. By utilizing the method, the coal thermal extraction rate can reach above 80%, the super-pure coal yield can reach above 70% and the super-pure coal ash content is less than 0.1%. The method has the advantages of high thermal extraction rate and good quality of the coal, and low production cost, as well as wide market application prospect because an extraction solvent can be recycled.

Owner:HEBEI IRON & STEEL GRP +1

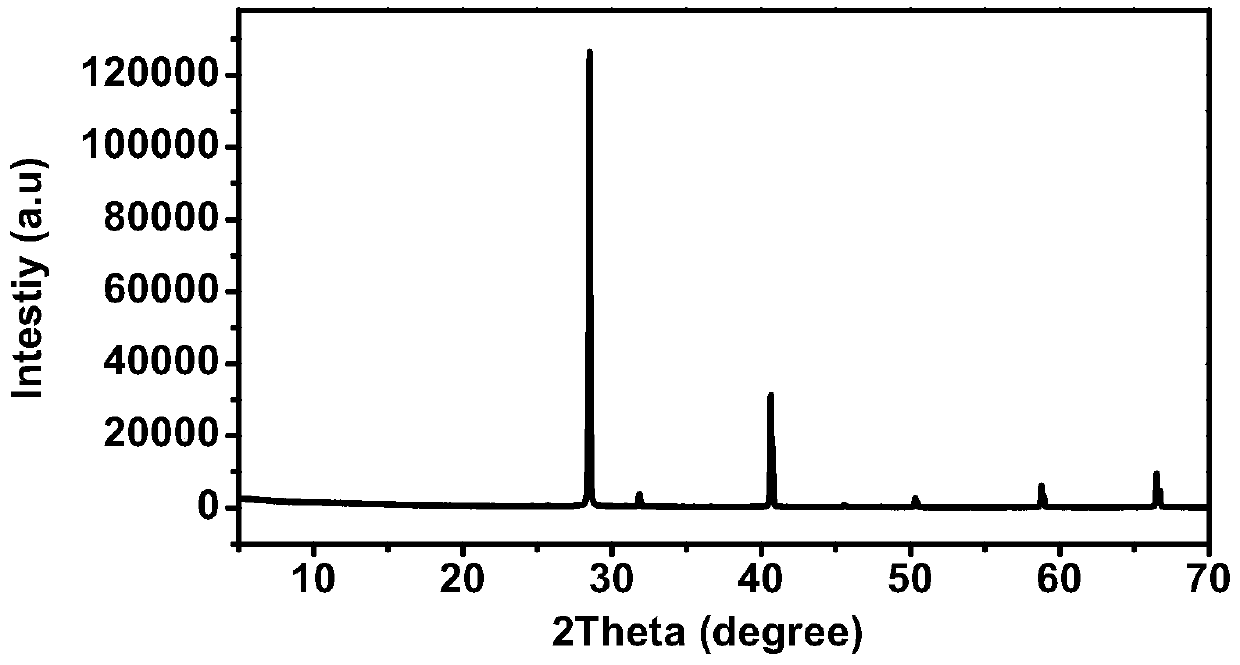

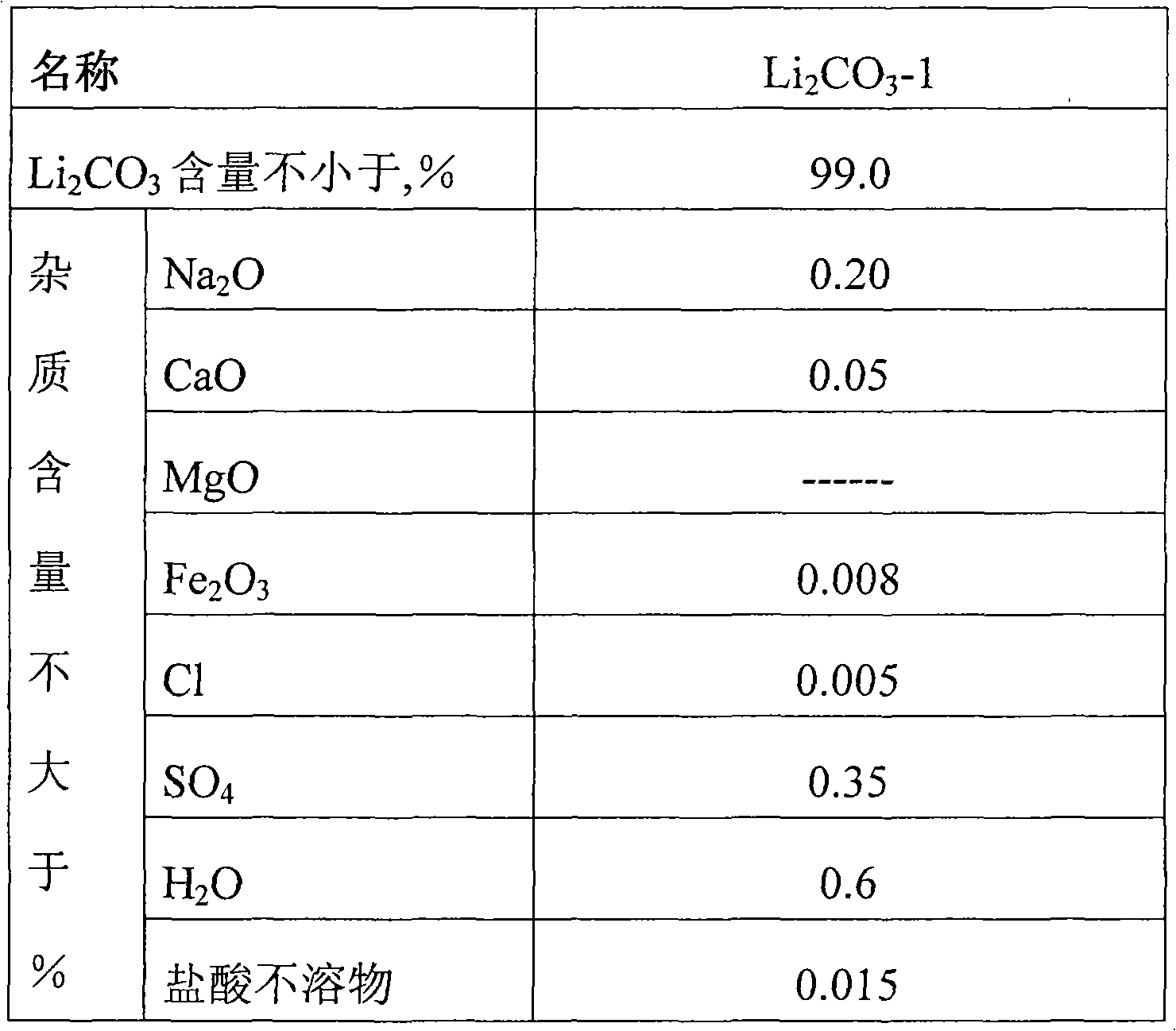

Preparation method for lithium carbonate

The invention provides a preparation method for lithium carbonate. The method comprises the following steps of: (1) mixing lithium hydroxide serving as a raw material and water for dissolving, adding a precipitating agent, and collecting filtrate of the lithium hydroxide, wherein the lithium hydroxide serving as the raw material is in an industrial grade; (2) introducing carbon dioxide into water, adding lithium carbonate serving as a raw material, adding a precipitating agent, introducing carbon dioxide until the pH is between 8 and 9, and collecting filtrate of solution of lithium hydrogen carbonate, wherein the lithium carbonate serving as the raw material is in an industrial grade; (3) mixing the solution of the lithium hydrogen carbonate obtained in the step (2) and the solution of the lithium hydroxide obtained in the step (1), heating the solution, and preserving the heat; (4) separating solid from liquid of a product in the step (3), and collecting the separated lithium carbonate wet material; and (5) drying a product in the step (4) in vacuum to obtain a product. By the process, the defects of the conventional process are better overcome, the product prepared from two industrial-grade raw materials can meet the requirement on 99.9 percent or higher-grade index, and the total yield of the product is over 95 percent.

Owner:SHANGHAI CHINA LITHIUM INDAL

Method and device for preparing mass spectrum level acetonitrile

InactiveCN102432498AMeet the requirements of high-purity solventsEasy to operateCarboxylic acid nitrile purification/separationPesticide residuePotassium hydroxide

The invention relates to a method and a device for preparing mass spectrum level acetonitrile. The method comprises the following steps of: performing oxidation reaction on acetonitrile to remove impurities, rectifying, and filtering to obtain the mass spectrum level acetonitrile, wherein an oxidant used in the oxidation reaction is potassium permanganate, sodium hydroxide, potassium hydroxide, calcium hydroxide and the like; the impurities such as residual trace hydrocyanic acid and acrylonitrile and the like in industrial acetonitrile are mainly removed; the using amount of the oxidation reaction agent is 1 to 50 weight percent of that of the acetonitrile; and oxidation reaction time is 3 to 24 hours. The impurity content of the mass spectrum level acetonitrile product prepared by the method is lower than 10 to 12, the requirement of pesticide residue analysis can be met, the method and the device are easy to operate, cost is saved, and wide market application prospects are achieved.

Owner:NAT INST OF METROLOGY CHINA

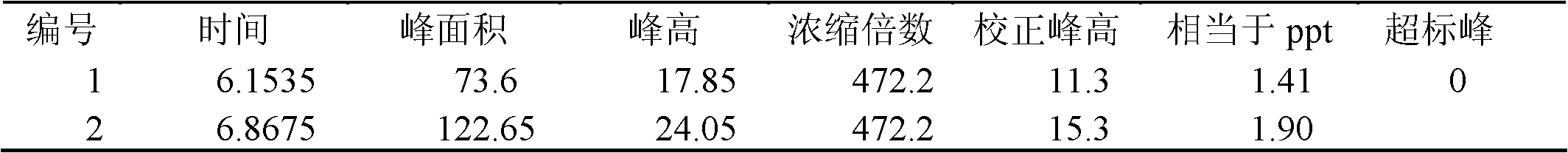

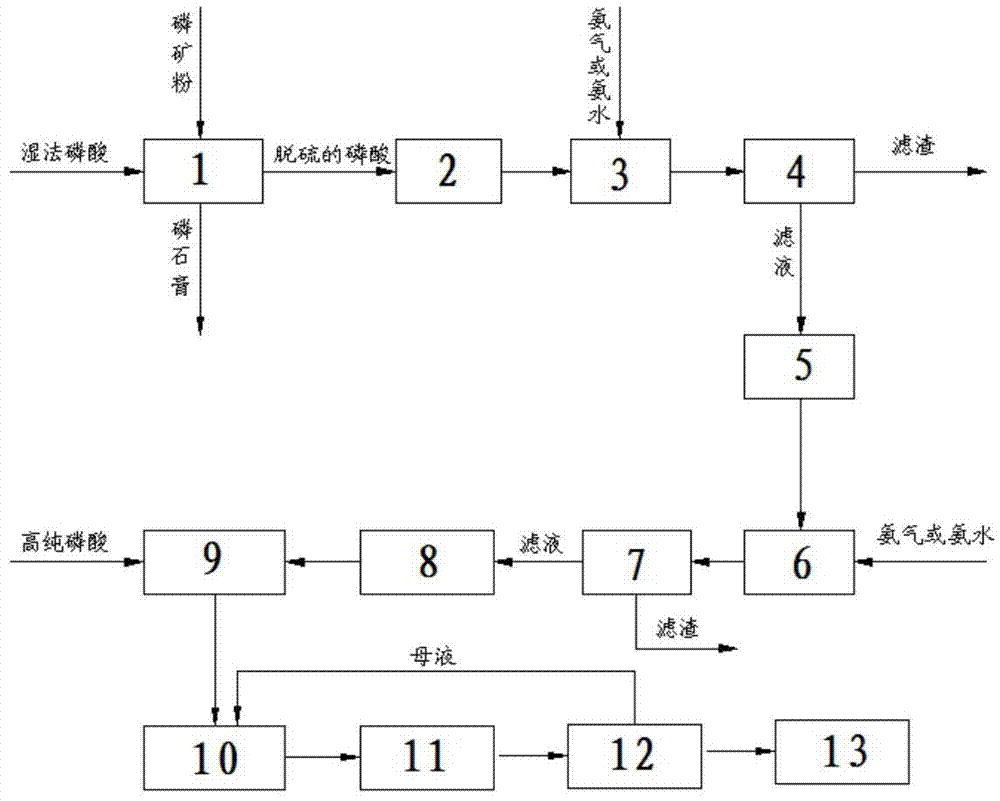

Method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid

The invention discloses a method for producing industrial grade monoammonium phosphate through combination of wet process phosphoric acid and high-purity phosphoric acid. The method comprises the steps of performing neutralization reaction for two times on filtrate and ammonia gas or ammonia water to obtain ammonium phosphate slurry, wherein the filtrate is obtained by performing desulfurization reaction on phosphate rock powder and wet process phosphoric acid; performing concentration, crystallization and drying by using filtrate which is obtained by adjusting the pH value with high-purity phosphoric acid to obtain an industrial grade monoammonium phosphate product; removing most of impurity ions when the pH value is neutralized to 4.0-5.0 by the first neutralization reaction, then performing the second neutralization reaction to remove impurities in the wet process phosphoric acid, finely adjusting the pH value to 3.9-4.4 by using the high-purity phosphoric acid, and performing concentration and crystallization to obtain the industrial grade monoammonium phosphate. The method disclosed by the invention reduces the production cost and energy consumption and is environment-friendly and pollution-free; the obtained product is stable in quality, the process flow is short, the device construction investment is saved, the needed operators are less, the energy consumption is reduced, the pollution is reduced, and the quality of monoammonium phosphate is ensured through effective impurity removal, so that the method has a very good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

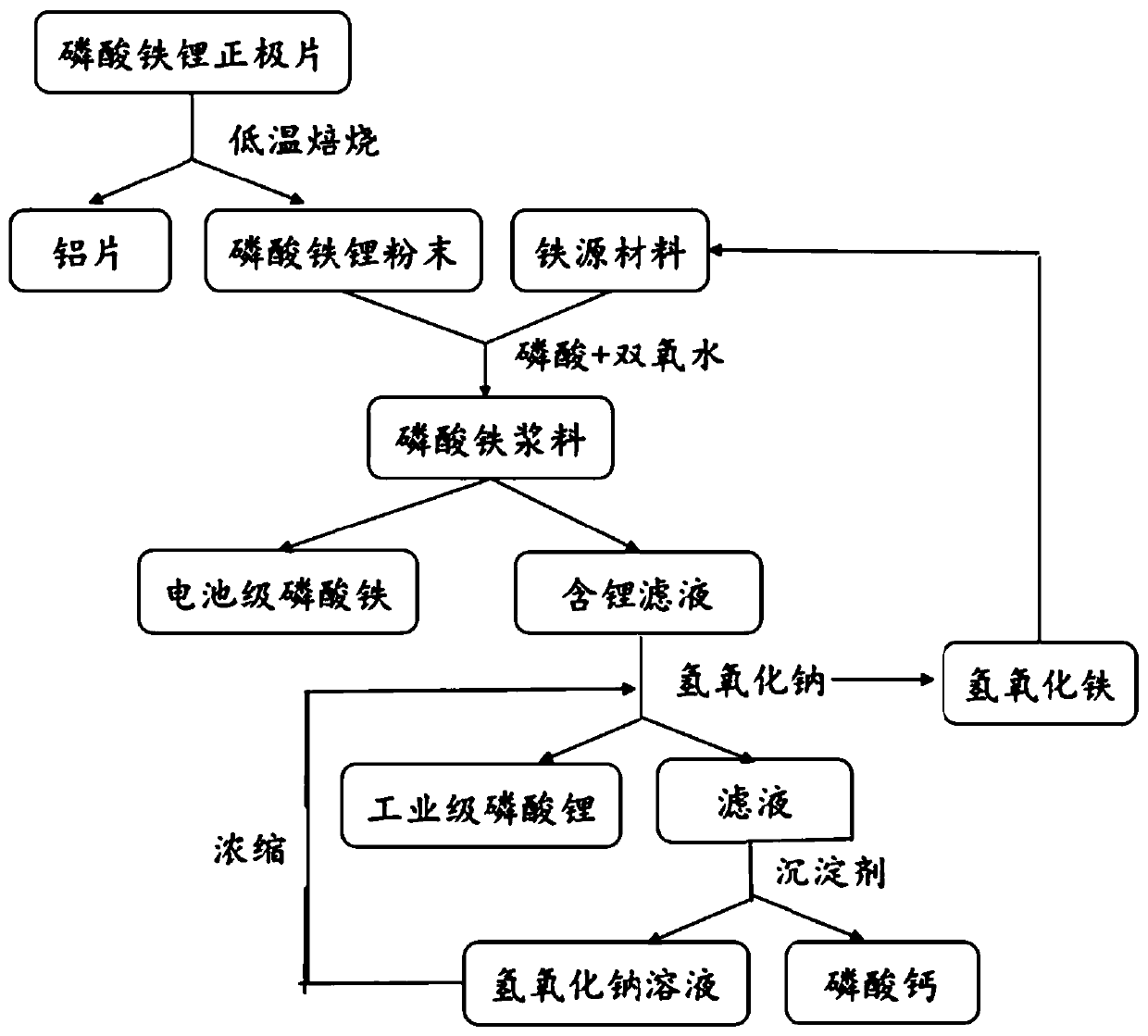

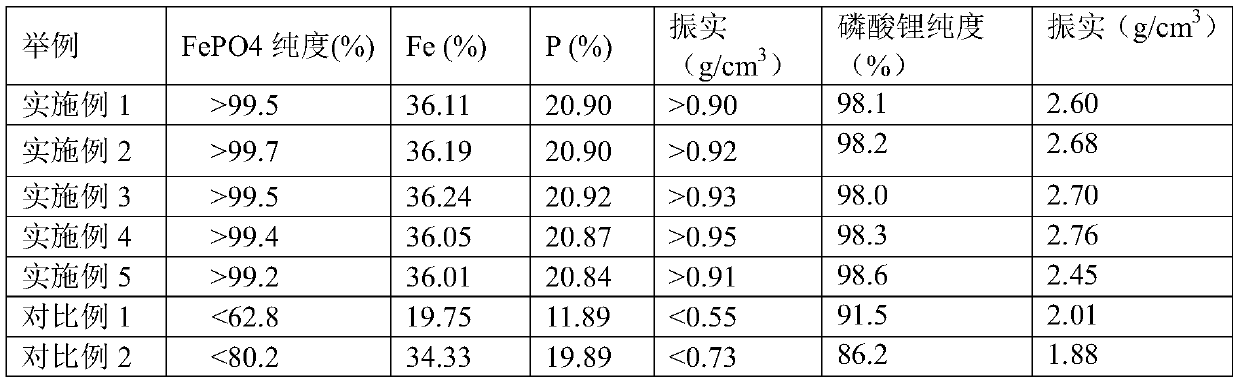

Method for preparing battery-grade iron phosphate and industrial-grade lithium phosphate in waste lithium iron phosphate battery

ActiveCN109775678ASolve the high cost of processing needsSimple recycling processPhosphorus compoundsLithium metalPhosphoric acid

The invention belongs to the technical field of recovery and comprehensive utilization of waste lithium ion power batteries, and particularly relates to a method for preparing battery-grade iron phosphate and industrial-grade lithium phosphate in a waste lithium iron phosphate battery, which comprises the following steps: carrying out low-temperature roasting treatment on a waste lithium iron phosphate positive plate disassembled from the battery to obtain lithium iron phosphate powder; mixing the powder with an iron source material, adding a mixed solution of phosphoric acid and hydrogen peroxide, and carrying out heating reaction to obtain battery-grade iron phosphate precipitate and lithium-containing filtrate; evaporating and concentrating the lithium-containing filtrate, adding an alkaline solution to remove impurities to generate industrial-grade lithium phosphate precipitate; adding a precipitant to generate a small amount of calcium phosphate precipitate, concentrating the filtrate, and recycling the filtrate; the method efficiently treats lithium iron and lithium metal materials in lithium iron phosphate by treating waste lithium iron phosphate and iron source materials byphosphoric acid to generate more industrially high value-added iron phosphate and lithium phosphate; the process is green and the cost is low.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

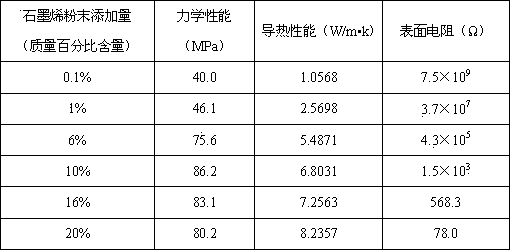

Preparation method of graphene

InactiveCN105366671AImprove conductivityImprove thermal conductivityBulk chemical productionHeat conductingTechnical grade

The invention discloses a preparation method of graphene. The method is simple in technology and easy to operate, and the obtained graphene is excellent in electric conduction, heat conduction and mechanical performances. With the method, the mechanical strength, heat-conducting property and anti-static function of polypropylene resin can be greatly improved, and the additional value of plastics is improved. The method belongs to physical exfoliation processes in which the treatment condition is mild and the quality of graphene cannot be damaged; and the exfoliation degree of the graphene is high through the two times of physical exfoliation processes. Therefore, the number of layers of graphene can be reduced; the yield of single-layer graphene is improved; and the high-quality graphene is finally obtained. Moreover, the influence of the preparation conditions of the method on the quality and yield of the graphene product is little; the product quality and yield are easy to control; and the method is suitable for large-scale production. Besides, the raw materials used in the method disclosed by the invention are all industrial products, and are easy to obtain and low in cost; and the production process is free of pollution.

Owner:JIANGSU JINJU ALLOY MATERIAL

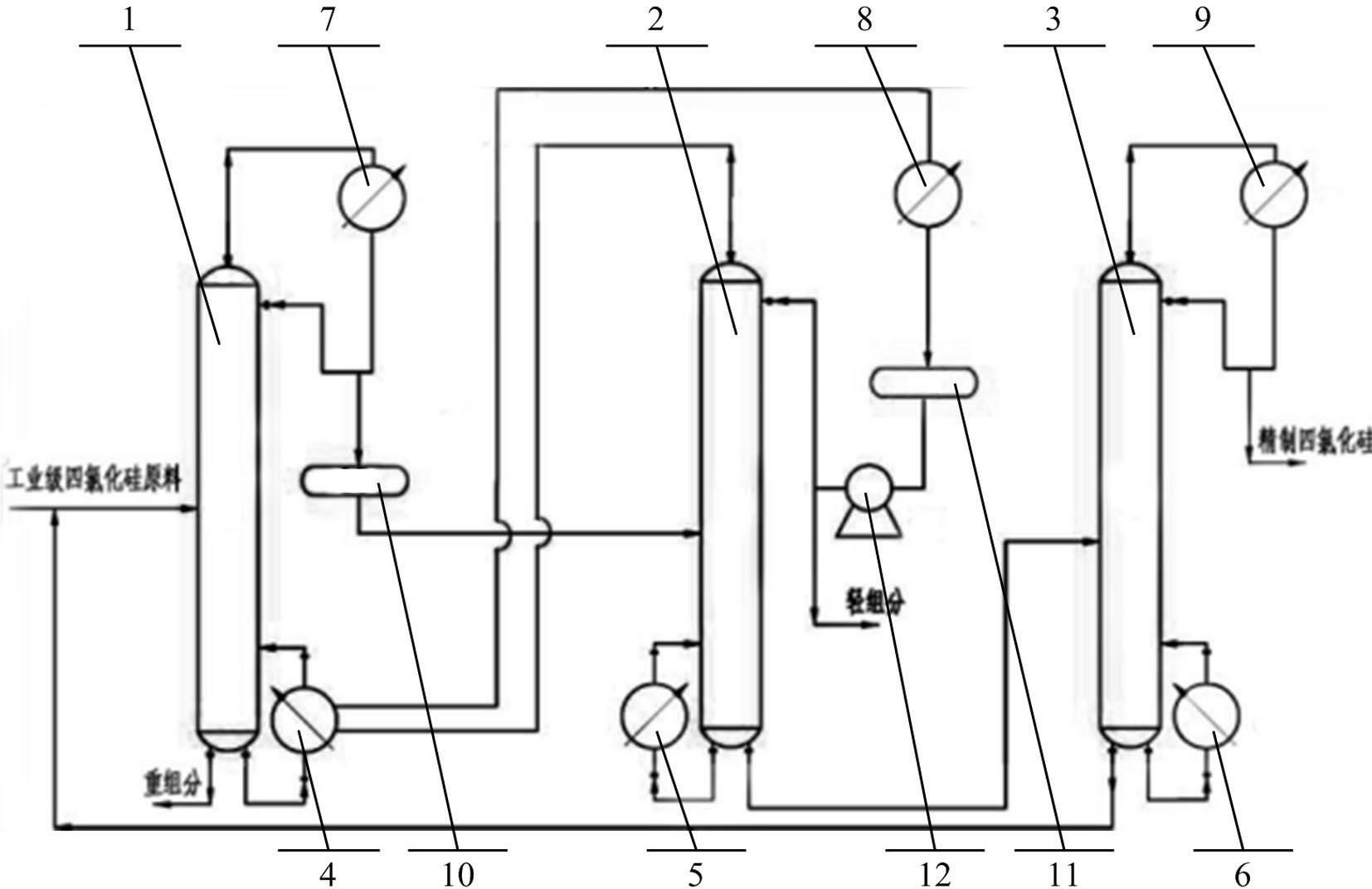

Processing process of industrial grade silicon tetrachloride

ActiveCN102642839ALower quality requirementsRealize refining and purificationHalogenated silanesDifferential pressureReboiler

The invention belongs to the field of chemical engineering purification and provides a process processing industrial grade silicon tetrachloride into high-purity silicon tetrachloride. The process comprises the following steps: coarse silicon tetrachloride enters a heavy-removing tower, a produced material at the top of the heavy-removing tower serves as a primary product to enter a buffer tank, and produced materials in a tower kettle of the heavy-removing tower are impurities with a high boiling point and solid impurities; the primary product in the buffer tank enters a light-removing tower, a gas phase material at the top of the light-removing tower serves as a heat source to enter a reboiler of the heavy-removing tower and then is cooled through a condenser, and a produced material ofthe light-removing tower enters a secondary heavy-removing tower by differential pressure; a produced material of the secondary heavy-removing tower flows back to serve as feed of the heavy-removing tower, and a produced material at the top of the secondary heavy-removing tower is a final product. The process can prevent the solid impurities and sticky materials with the high boiling point in a raw material from blocking a feeding pipe of a follow-up rectification tower, is low in requirements for raw material quality and suitable for processing industrial grade silicon tetrachloride of various different sources, and reduces energy consumption by thermal coupling rectification of the heavy-removing tower and the light-removing tower.

Owner:XINTE ENERGY

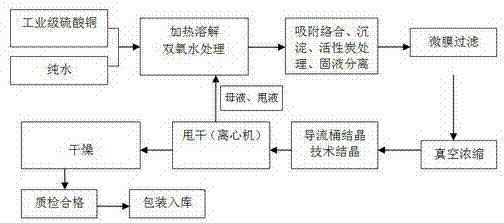

Production method of high-purity copper sulphate

InactiveCN102826584ASimple and fast operationImprove product qualityCopper sulfatesFiltrationTechnical grade

The invention discloses a production method of high-purity copper sulphate. The production method of high-purity copper sulphate comprises the following steps of: dissolving industrial grade copper sulphate into ultrapure water, heating to the temperature of 40-70 DEG C, dropwise adding sulphuric acid to regulate pH to be 1.0-2.0, stirring and dissolving, and then adding hydrogen peroxide; mixing polymeric ferric sulphate with basic copper carbonate in a mass ratio of 1: (2.5-4.5) to prepare a precipitation complexing agent, adding the precipitation complexing agent the weight of which is 0.5-2.5wt% of weight of the solution into the insulated solution, then adding activated carbon the weight of which is 0.5-2.5wt% of the weight of the solution, stirring for 3-7 hours, cooling to room temperature, and standing overnight; and carrying out rough filtration on the solution, then filtering with a microporous membrane with the size of 0.2mu m, and concentrating and crystallizing filtrate to obtain high-purity copper sulphate.

Owner:XILONG SCI CO LTD

Method for preparing technical grade phosphate using wet method phosphoric acid as raw material

InactiveCN1994871ATake full advantage of the combined utilityReduce lossesPhosphatesCompound organicAlkaline earth metal

The invention discloses a making method of industry-grade phosphate based on wet process phosphoric acid as raw material, which comprises the following steps: desulfurizing; defluorinating; stripping arsenic; removing heavy metal; decoloring; extracting predisposed wet process phosphoric acid through compound organic solvent of ketone and phosphate ester; washing; reextracting; condensing; post-processing to obtain the product; adopting alkali solution of potassium carbonate, sodium carbonate or alkaline-earth metal as extractor.

Owner:YUNNAN CHEM RES INST

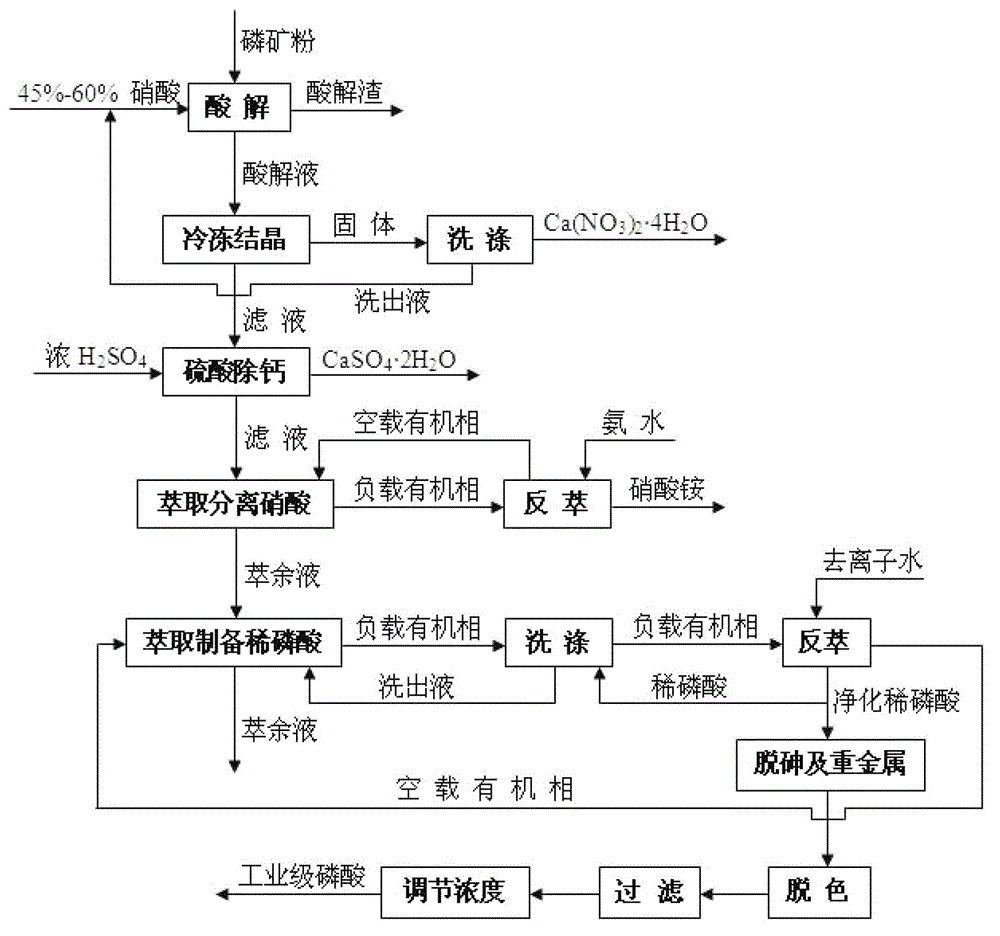

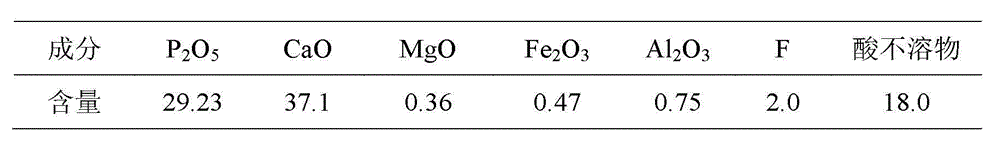

Method for preparing industrial-grade phosphoric acid by decomposing mid-low-grade phosphorite with nitric acid

The invention relates to a method for preparing industrial-grade phosphoric acid by decomposing mid-low-grade phosphorite with nitric acid. The method comprises the following processing steps: (1) decomposing phosphorite with nitric acid; (2) separating calcium nitrate through freezing crystallization; (3) carrying out deep deliming with sulfuric acid; (4) conducting countercurrent or cross current extraction of filtrate obtained in the step (3) by using a first mixed extractant to obtain raffinate which is coarse phosphoric acid; (5) conducting countercurrent or cross current extraction of the coarse phosphoric acid obtained in the step (4) by using a second mixed extractant, carrying out countercurrent washing on the load organic phase obtained by the countercurrent or cross current extraction by using dilute phosphoric acid for at least two times, and then conducting countercurrent reverse extraction by using deionized water to obtain strip liquor which is purified dilute phosphoric acid after removing impurities such as iron, magnesium, aluminum, calcium and fluorine; and (6) sequentially conducting evaporation concentration, dearsenification, heavy metal removal, decoloring, filtration and concentration adjustment on the purified dilute phosphoric acid obtained in the step (5) to obtain industrial-grade phosphoric acid.

Owner:CHINA BLUECHEMICAL +1

Rare earth and sodium humate compound feed additive and preparation method thereof

The invention discloses a rare earth and sodium humate compound feed additive and a preparation method thereof. The preparation method comprises the following steps: 1, carrying out alkali dissolution treatment after air-drying and crushing decomposed coal to obtain coal powder with particle size of above 40 meshes, carrying out acid-out treatment, and purifying humic acid to obtain sodium humate with particle size of 100 meshes; 2, blending industrial-grade rare earth chloride with edible-grade citric acid into a water solution, heating the water solution to about 40 DEG C, mixing according to a proportion of 10.5:8.9, regulating the pH value to 3.5-4.0, ageing for 6 hours, and then filtering, washing, drying and crushing to obtain rare earth citrate with particle size of 100 meshes; and 3, uniformly mixing the rare earth with the sodium humate according to a proportion of 1:27. According to the compound feed additive produced by adopting the preparation method, the cost is reduced, the yield and the weight of animals are promoted, the safety is realized, and the diseases are prevented and resisted.

Owner:HOHHOT YIYANGDA BIOTECH CO LTD

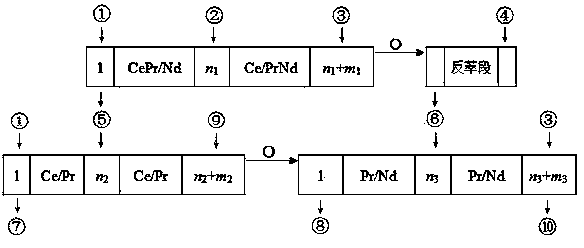

Technique for preparing high-purity praseodymium from industrial praseodymium raw material

InactiveCN103526058AEmission reductionWide variety of sourcesProcess efficiency improvementCeriumTechnical grade

The invention discloses a technique for preparing high-purity praseodymium from an industrial praseodymium raw material. According to the technique, a high-purity praseodymium (99.99%-99.9995%) product is prepared from industrial praseodymium (98%-99.9%). The technique consists of three fractional extraction systems: cerium-praseodymium / praseodymium-neodymium grouping separation, cerium / praseodymium separation and praseodymium / neodymium separation, wherein separation of cerium-praseodymium from neodymium is realized in an extraction section of the cerium-praseodymium / praseodymium-neodymium fractional extraction system; separation of cerium from praseodymium-neodymium is realized in a washing section of the cerium-praseodymium / praseodymium-neodymium fractional extraction system; the cerium / praseodymium separation fractional extraction system is directly serially connected to the praseodymium / neodymium separation fractional extraction system. Compared with an existing technique, the technique has the advantages that alkali consumption (including alkali for saponification and alkali for neutralization) is reduced by 13%, and acid consumption (including acid for washing and acid for reextraction) is reduced by 13%.

Owner:NANCHANG HANGKONG UNIVERSITY

Resource utilization method for titanium white by-product ferrous sulphate

InactiveCN102351231ASolve pollutionSolve the technical problem that the titanium dioxide by-product ferrous sulfate cannot be processed in large quantities at low costIron oxides/hydroxidesCalcium/strontium/barium sulfatesResource utilizationDihydrate Calcium Sulfate

The invention discloses a resource utilization method for titanium white by-product ferrous sulphate, which solves the technical problem of incomplete utilization of titanium white by-product ferrous sulphate with low cost in the prior art. The method of the invention comprises the following steps: a, purifying and processing titanium white by-product ferrous sulphate; b, introducing ammonia gas in a ferrous sulphate solution obtained by purifying and processing, fully reacting and filtering to obtain ferrous hydroxide deposition and an ammonium sulfate solution; c, adding calcium hydrate in the ammonium sulfate solution and fully reacting to obtain dihydrate calcium sulphate deposition and ammonia gas, recovering ammonia gas as a raw material of a step b, drying the dihydrate calcium sulfate deposition and processing to obtain the product gypsum. According to the invention, sulfur and iron resources in titanium white by-product ferrous sulphate are fully used for producing industrial grade gypsum and iron ore concentrate, the problem of titanium white by-product on environmental pollution is solved; The ammonia gas can be circularly used without consumption based on theory, the loss amount needs to be added in practical production, and the production cost is low.

Owner:攀枝花市尚亿科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com