Patents

Literature

265results about How to "Reduce sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for water treatment

InactiveUS7077963B2Low costEconomical and efficientWaste water treatment from quariesSolid waste disposalSufficient timeMagnesium ion

The invention provides compositions comprising bauxite refinery residues that have been reacted with sufficient calcium and magnesium ions that they have a reaction pH of less than 10.5, and one or more water treating additives. The invention also provides processes for treatment of water containing dissolved inorganic substances involving stepwise treatment of the water in which the reacted bauxite refinery residues are added after the addition of a pH-raising additive. The invention also provides processes for treatment of water containing dissolved inorganic substances in which the reacted bauxite refinery residues are added stepwise, with one or more water treating additives also being added in at least one of the steps. The invention also provides a process for the neutralisation of bauxite refinery residue by reacting it with a base amount and a treating amount of calcium ions and a base amount and a treating amount of magnesium ions for a time sufficient to produce an at least partially-neutralized residue exhibiting a reaction pH of less than 10.5.

Owner:NAUVEAU TECH INVESTMENTS

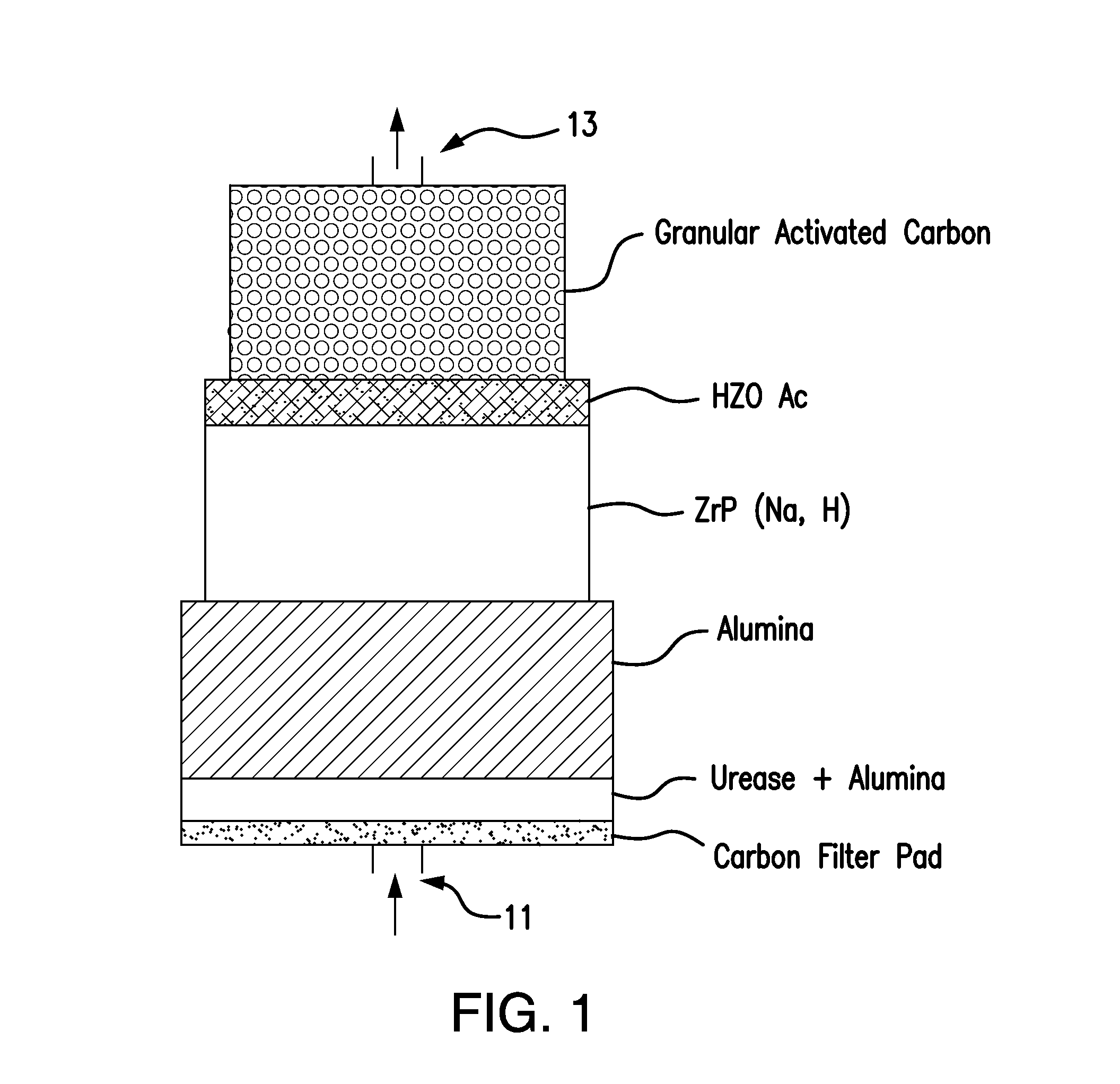

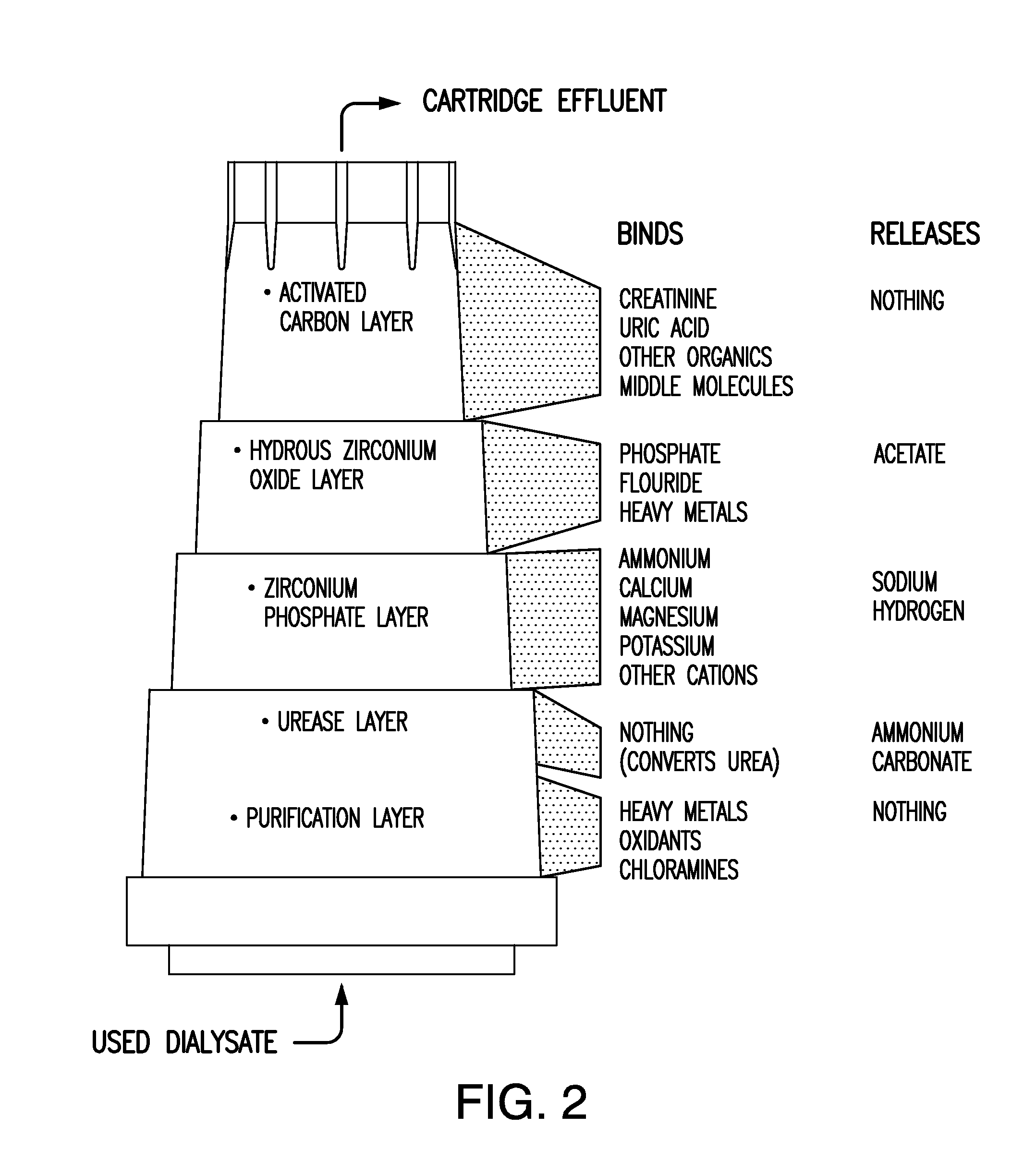

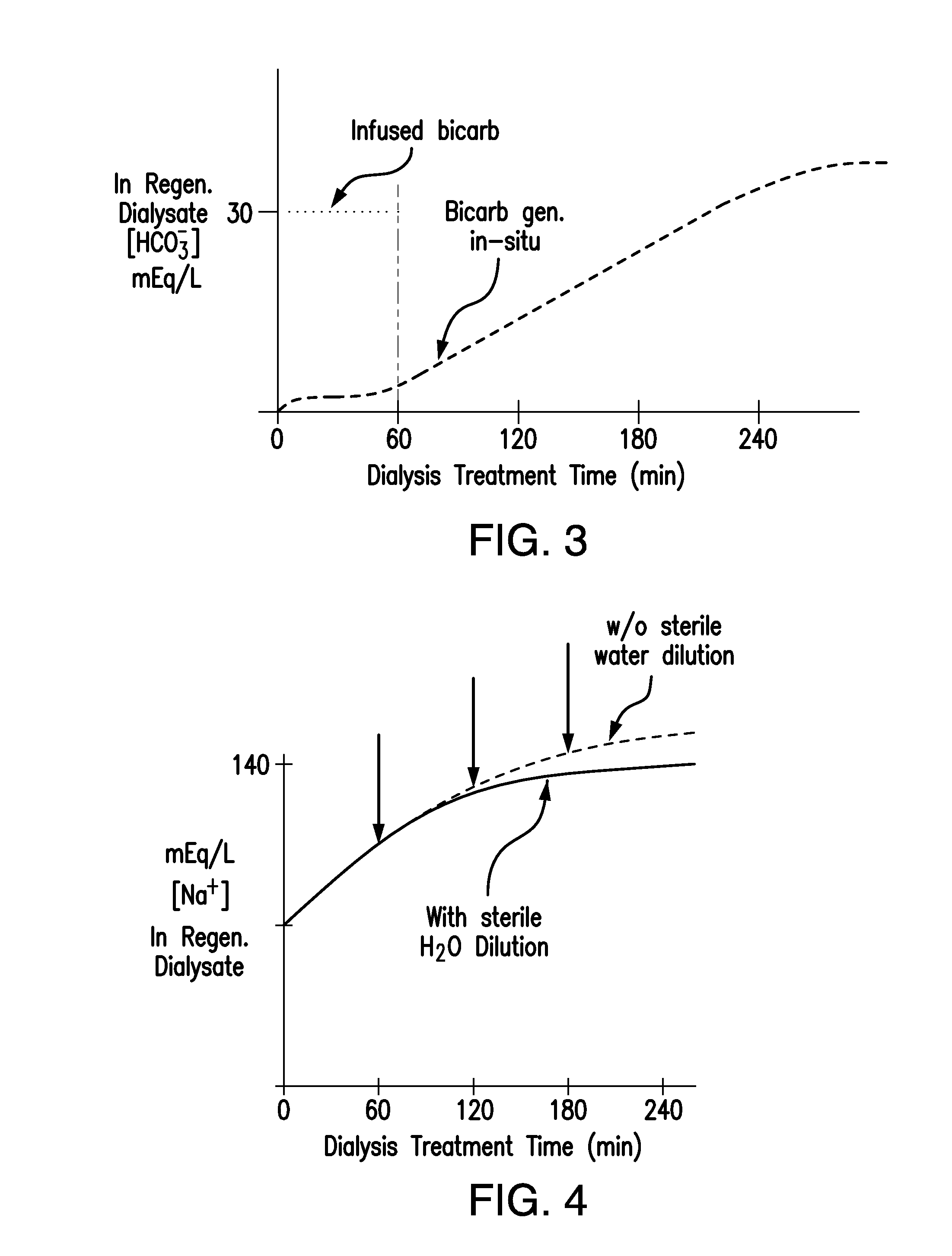

Method For Treating Dialysate, Dialysis System, And Method For Pre-Evaluating Dialysis Patients For Treatment With Same

ActiveUS20150343126A1Eliminate needReduce sodiumDialysis systemsSolid sorbent liquid separationSorbentDialysis fluid

A method for treating dialysate solutions used in dialysis wherein dialysate is treated in an early part of a dialysis treatment session by external infusion of bicarbonate solution into the dialysate circuit to eliminate the need for bicarbonate requirements in concentrates used for preparation of precursor dialysate (priming) solutions and / or for a solid bicarbonate layer in a sorbent cartridge. Dialysate is treated in a latter part of a dialysis treatment session by introduction of sterile dilution water to reduce sodium concentration in the dialysate. The method provides a more efficient and reduced use of dialysate fluids, electrolytes, sorbent cartridge materials, equipment scale, or any combinations of these, while maintaining purity standards and applicable physiological ranges for bicarbonate, sodium, and other dialysate solution components over the course of a dialysis treatment session.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Method for reducing content of sodium in aluminum hydroxide

InactiveCN102020302AReduce sodiumGood application effectAluminates/aluminium-oxide/aluminium-hydroxide purificationFire retardantLow sodium

The invention relates to a method for reducing the content of sodium in aluminum hydroxide, in particular to a method for preparing low-sodium aluminum hydroxide (Na2O is less than 0.1 percent) serving as a fire retardant or a raw material for calcining low-sodium aluminum oxide. The method is characterized by comprising the following steps of: after homogenizing the aluminum hydroxide by using pure water, performing hydro-thermal treatment, and filtering, washing and drying to obtain low-sodium aluminum hydroxide powder. In the method, the aluminum hydroxide prepared by a Bayer process or a sintering process is subjected to the hydro-thermal treatment, so that adherent alkali and lattice alkali in the aluminum hydroxide are dissolved in the water, and the low-sodium aluminum hydroxide powder is obtained by processes of solid-liquid separation, washing, drying and the like, wherein the powder can be used as the fire retardant or the raw material for calcining the low-sodium aluminum oxide. The method has the advantages that a process is simple, industrialization is easy to realize and the like, so the using performance of the aluminum hydroxide fire retardant can be improved effectively, and the low-sodium aluminum hydroxide can be used as the raw material for calcining low-sodium alpha-aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Salt replacing composition, process for its preparation and food systems containing such composition

InactiveUS20080199595A1Reduce sodiumIncrease PotassiumMilk preparationFood preparationPotassiumAmino acid

A salt replacing composition for replacing sodium chloride in food contains a major amount of potassium chloride, ammonium chloride and at least one of an amino acid and a salt of an amino acid. A reduced sodium chloride composition contains the salt replacing composition and sodium chloride. A food containing the salt replacing composition and a process for making the salt replacing composition.

Owner:MCCORMICK & CO INC

Method for simultaneously removing sulfur and phosphorus from semi-steel

The invention provides a method for simultaneously removing sulfur and phosphorus from semi-steel. The method comprises the following steps sequentially carried out on a semi-steel sulfur removal station: carrying out first-stage injection on the semi-steel by using a sulfur removal oxygen lance, wherein an injection material is injection-assisted powder taking an inert gas as a carrier; carrying out second-stage injection on the semi-steel by using the sulfur removal oxygen lance, wherein an injection material is a mixture of the injection-assisted powder taking the inert gas as the carrier and passivating magnesium powder; carrying out third-stage injection on the semi-steel by using the sulfur removal oxygen lance, wherein the injection material is the injection-assisted powder taking the inert gas as the carrier, the semi-steel is molten iron obtained after vanadium is extracted from vanadium-containing molten iron by using a converter, and the injection-assisted powder is prepared from 55-80 parts by weight of passivating lime, 5-15 parts by weight of ferric oxide and 20-30 parts by weight of sodium oxide. The method has the advantages that the semi-steel without the vanadium can be simultaneously subjected to pretreating sulfur and phosphorus removal; the corrosion on a lining of a vanadium extracting converter can be avoided, and meanwhile, the content of sodium in vanadium residues can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of high purity aluminium oxide powder

InactiveCN1903728AHigh chemical purityReduce sodiumAluminium oxide/hydroxide preparationWater bathsAluminium hydroxide

The present invention relates to a preparation method of high-purity aluminium oxide powder body. It is characterized by that it adopts aluminium sheet whose purity is 99.9999% and organic alkal; and makes them be mutually reacted in hot water bath to obtain the precipitate of aluminium hydroxide, then the precipitate is calcined at 1100-1200deg.C and ground so as to obtain high-purity ultrafine aluminium oxide powder body. The described organic alkal; includes any one of choline, hexamethohydrotetramine and dopamine.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

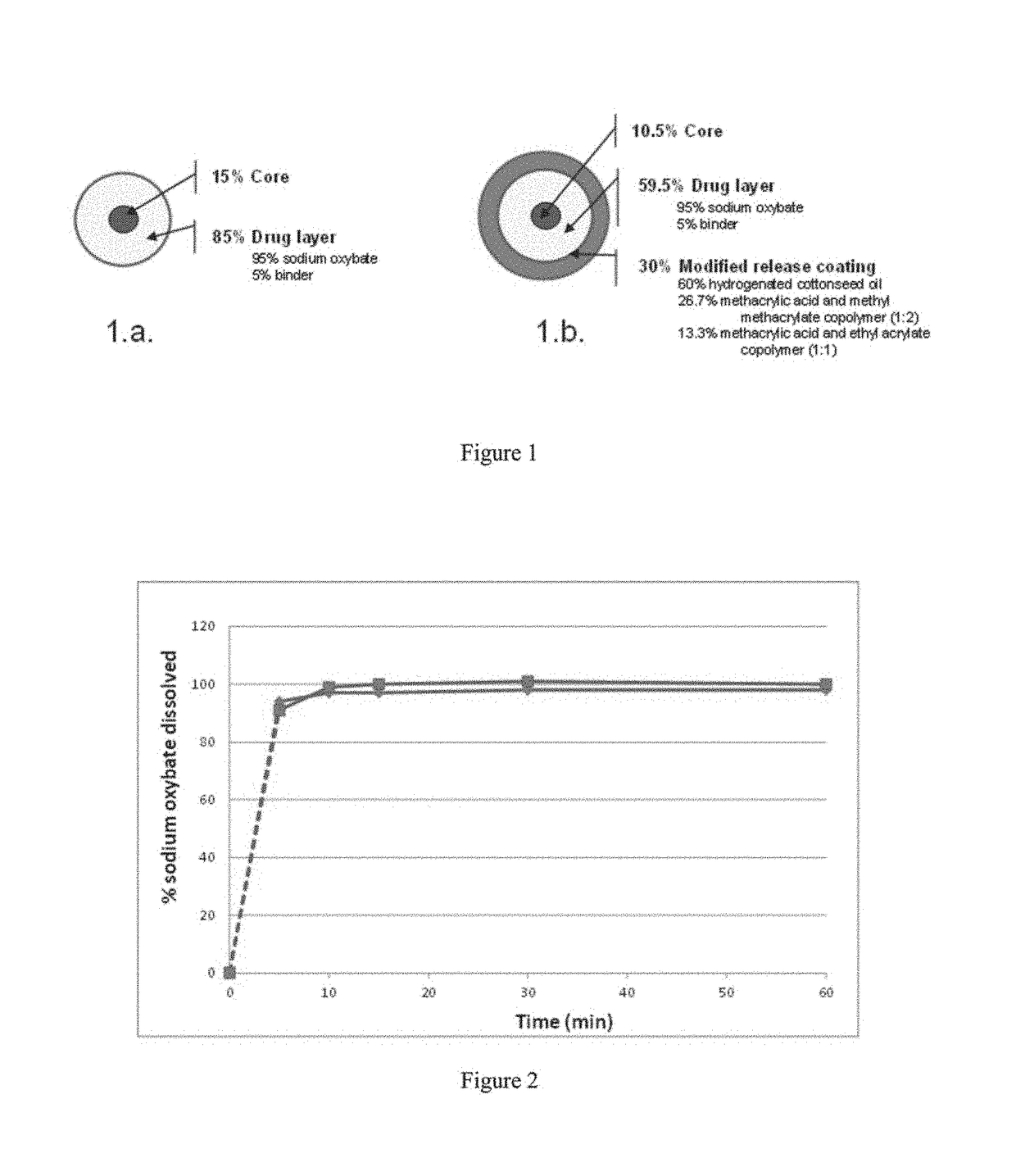

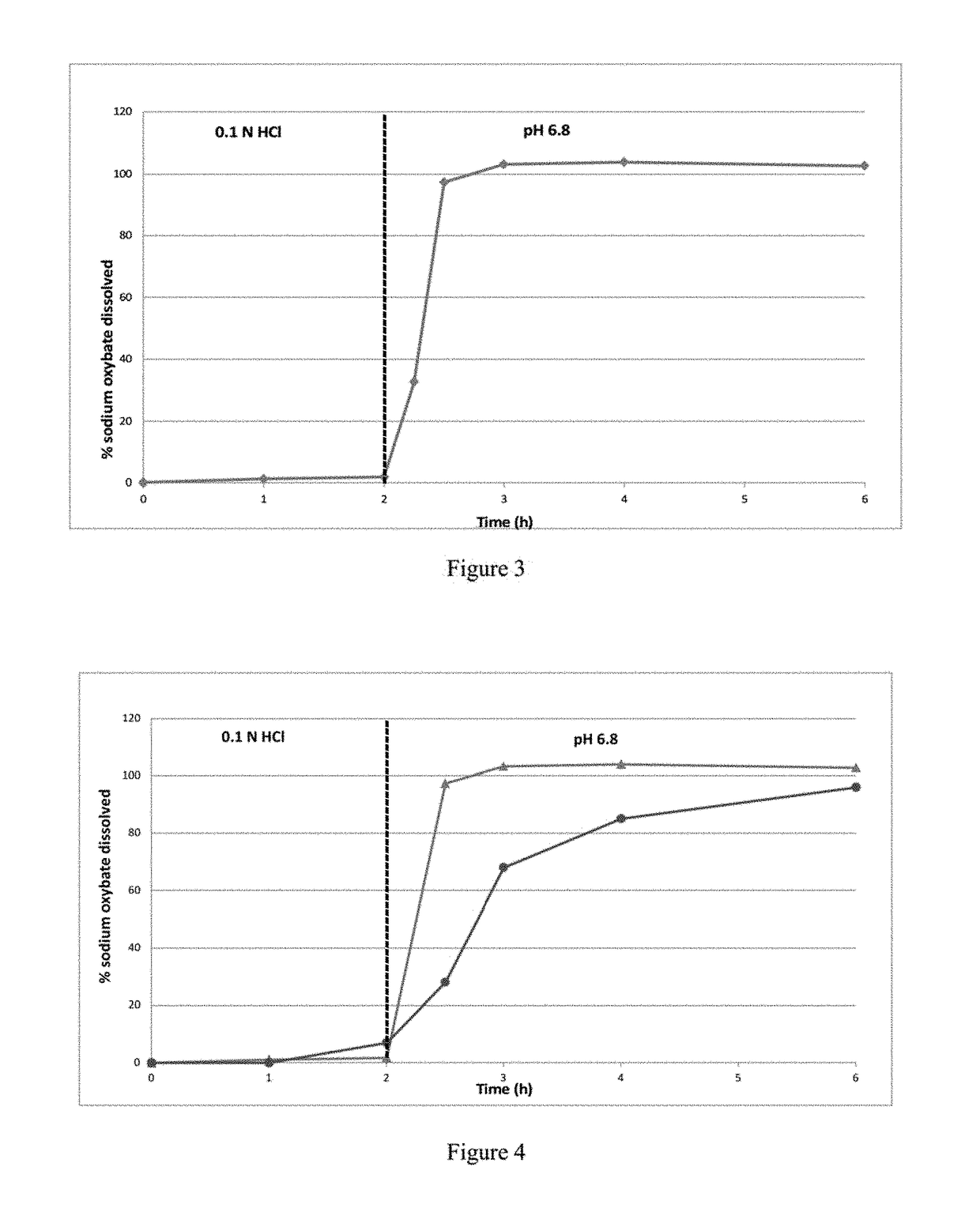

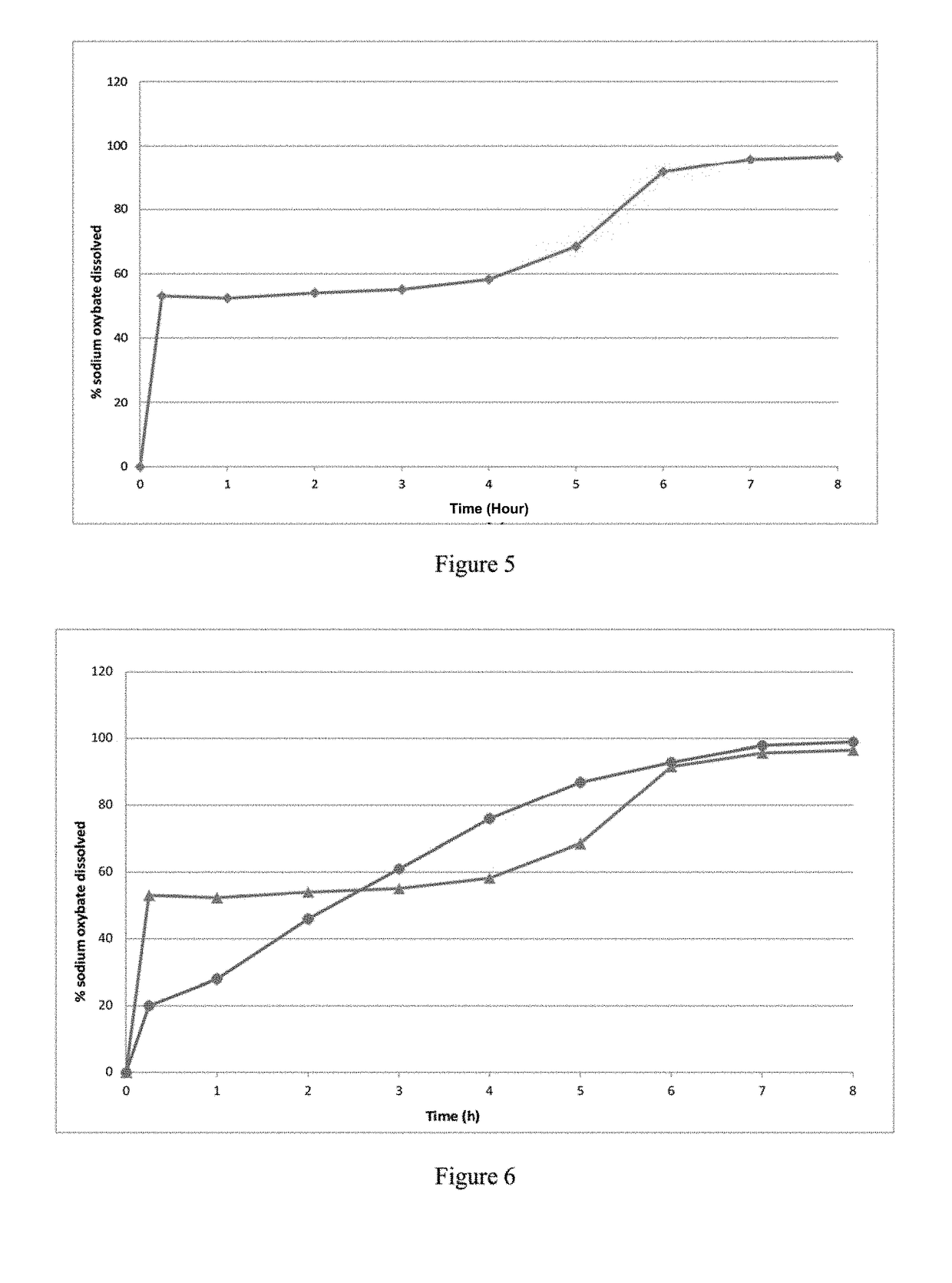

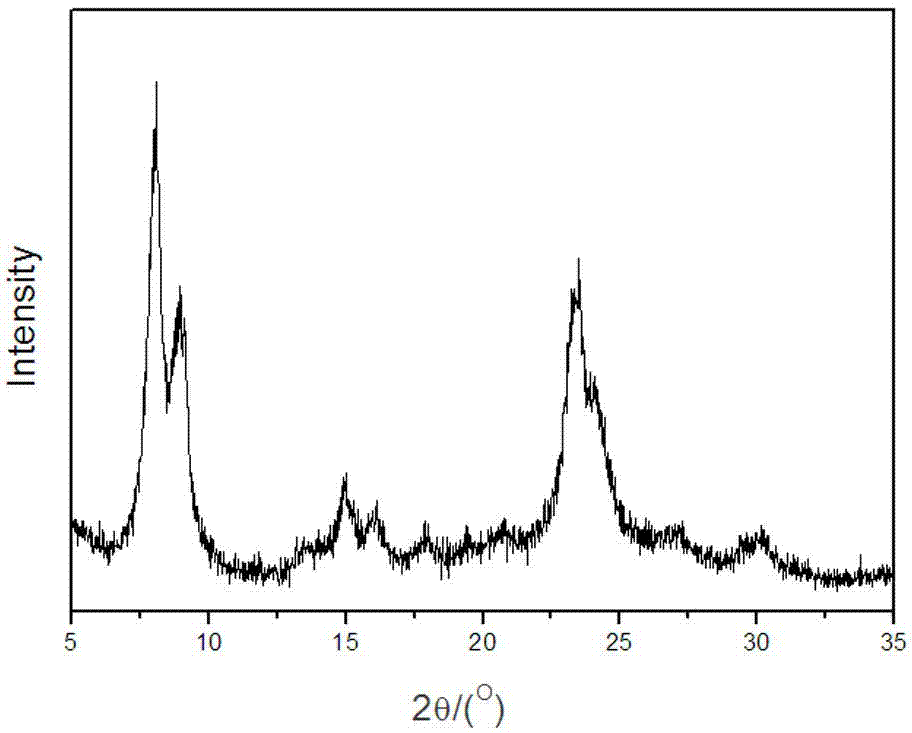

Modified release gamma- hydroxybutyrate formulations having improved pharmacokinetics

ActiveUS20180021284A1Improve therapeutic effectivenessImprove safety profilePowder deliveryNervous disorderDissolutionHydroxybutyrates

Modified release formulations of gamma-hydroxybutyrate having improved dissolution and pharmacokinetic properties are provided, and therapeutic uses thereof.

Owner:FLAMEL IRELAND

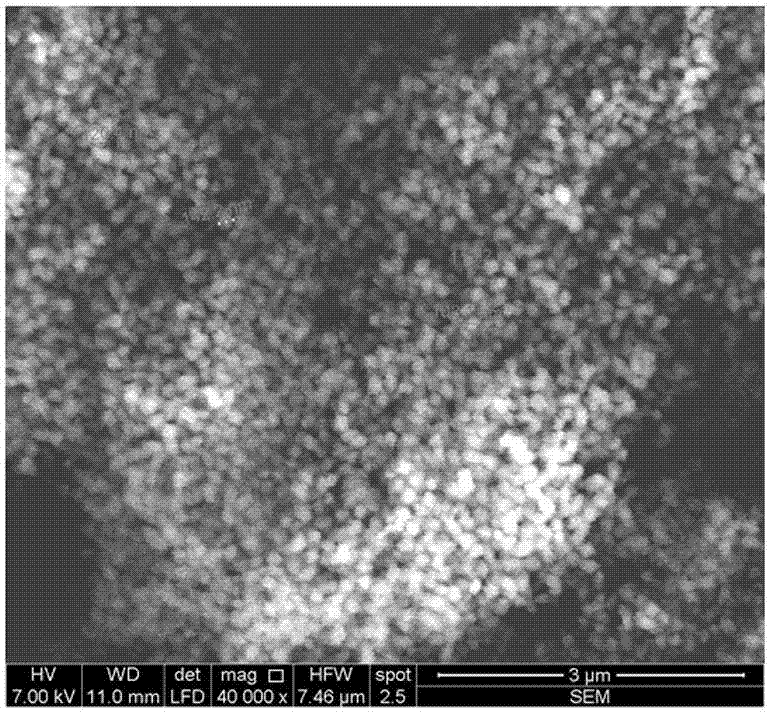

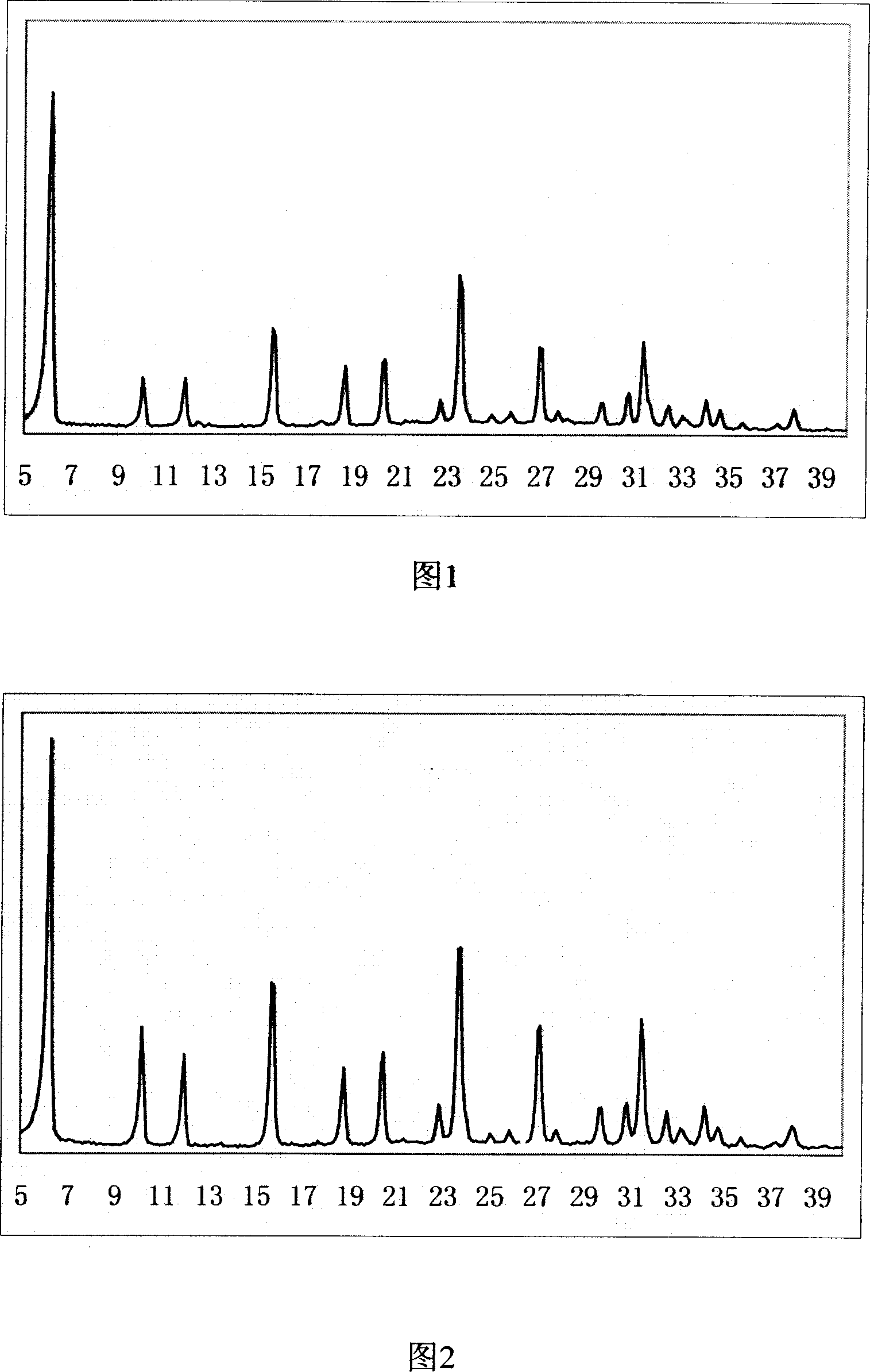

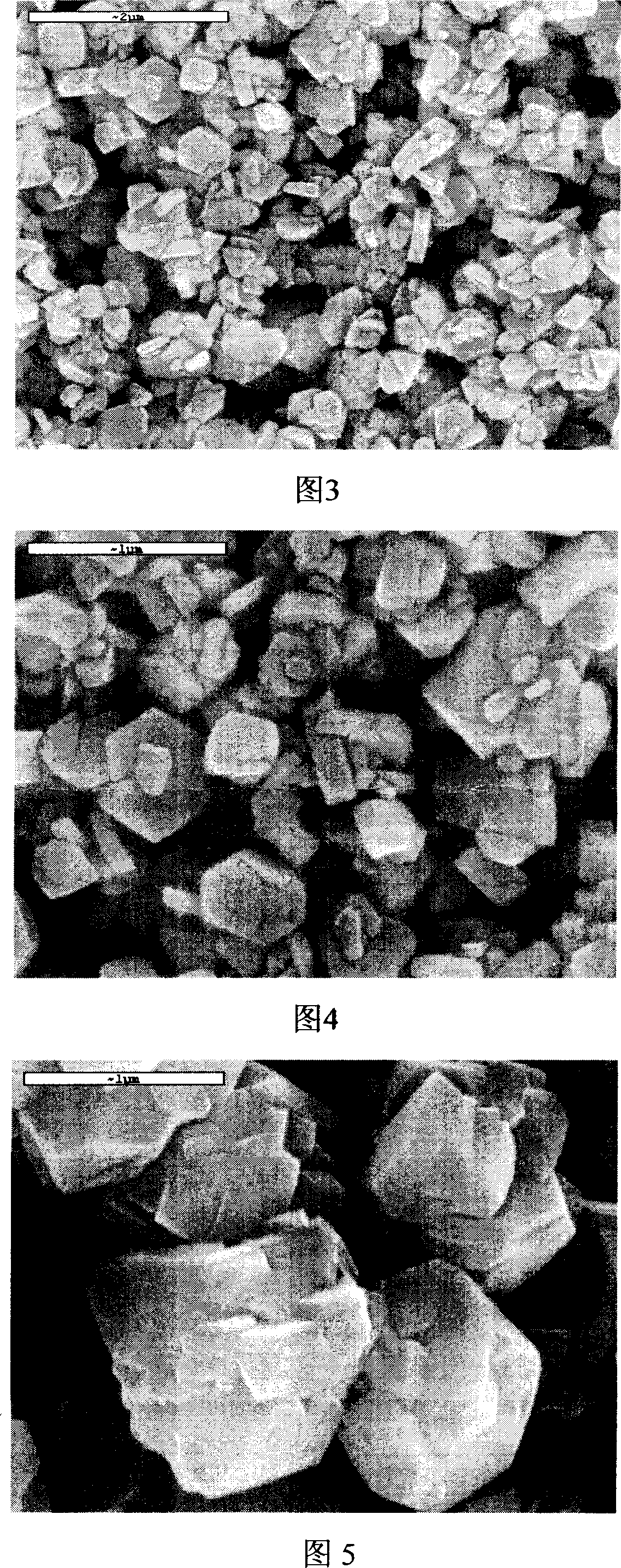

Method for rapidly synthesizing pure-phase small-grain ZSM-11 molecular sieve

ActiveCN103663488AReduce sodiumShort synthesis timePentasil aluminosilicate zeoliteMolecular sieveAmmonium hydroxide

The invention discloses a method for rapidly synthesizing a pure-phase small-grain ZSM-11 molecular sieve. According to the method, the synthesis time is short, and the process is simple. Tetrabutyl ammonium hydroxide (R1) and 1, 8-diaminooctane (R2) are taken as composite template agents, a silicon source, an aluminum source, the template agents and water are uniformly mixed and prepared into synthetic sol, and the molar ratio of the synthetic sol is that Al2O3: SiO2: R1: R2: H2O is equal to (0.001-0.2): (0.001-1.0): (0.05-0.5): (10-100); and the mixture is subjected to hydrothermal crystallization for 1-2 days at the temperature of 160-190 DEG C, centrifugal separation, washing and drying are performed after cooling, and a pure-phase small-grain ZSM-11 molecular sieve sample is obtained. According to the method, tetrabutyl ammonium hydroxide and 1, 8-diaminooctane are taken as the composite template agents, a seed crystal is not required to be added to the synthetic sol, and the molecular sieve is rapidly synthesized at a high temperature. The method id short in synthesis time, simple in process and simple and convenient to operate; and the content of sodium in the synthesized ZSM-11 molecular sieve is low.

Owner:DATONG COAL MINE GRP +1

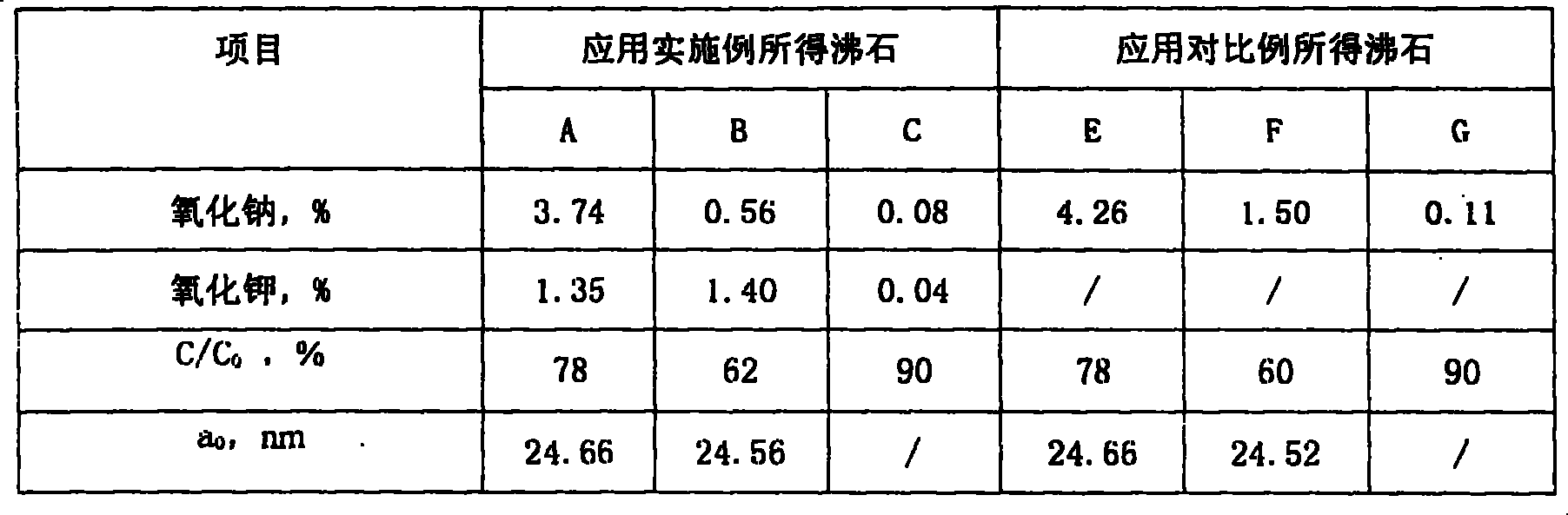

Method of reducing ammonia and nitrogen pollution in process of zeolite modification

ActiveCN100404432CLow modification costReduce usageWater/sewage treatment by ion-exchangeEnergy based wastewater treatmentReaction temperaturePotassium

This invention relates to a method to reduce ammonia nitrogen pollution during the modification process of zeolite. The method comprises, in the process, exchanging sodium in the zeolite with potassium compounds, and then exchanging zeolite with ammonium salts. The ratio of potassium compounds to zeolite is 0.01~0.5, reaction temperature is 5-100DEG C, and the reaction time is 0.1-6 hours. The method will not increase the modification cost and can reduce ammonium salt use by 50%, therefore reducing ammonia nitrogen pollution and the burden of ammonia nitrogen wastewater treatment process and investment. It is an environmental technology for zeolite modification. The prepared zeolite catalyst has lower sodium content with catalytic activity basically unchanged or increased.

Owner:PETROCHINA CO LTD

High silica/ aluminum ratio octagonal zeolite synthesizing method

ActiveCN1951812AHigh molar ratio of silicon to aluminumHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteHigh silicaSilicon

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting calcium chondroitin sulfate in shark cartilage

A method for extracting shark calcium chondroitin sulfate from a shark cartilage comprises the processes in sequence such as curing, alkalization, enzymatic hydrolysis, deproteinization, crystallization, resin pretreatment, resin exchange, ultrafiltration dehydration, calcification of filtrate and crystallization dehydration dying. Because secondary crystallization is adopted, the covalent binding of protein and shark chondroitin sulfate is broken by hydrogen peroxide to enable the chondroitin sulfate in the protein to be dissociated, impurities such as the protein and the like can be effectively removed to improve the purity and the content of shark sodium chondroitin sulfate; cation resin is adopted to complete the sodium removal process by column chromatography, the exchanged shark chondroitin sulfate is high in concentration and the shark chondroitin sulfate which is produced during ion exchange can be accurately controlled, and the sodium content in the product is low; with dehydration of ultrafiltration, not only the concentration can be realized, but also the small molecular impurities can be removed to improve the purity of the shark chondroitin sulfate, at the same time, to improve the content of calcium. The method also can save the using amount of ethanol and reduce the production cost.

Owner:王清荣

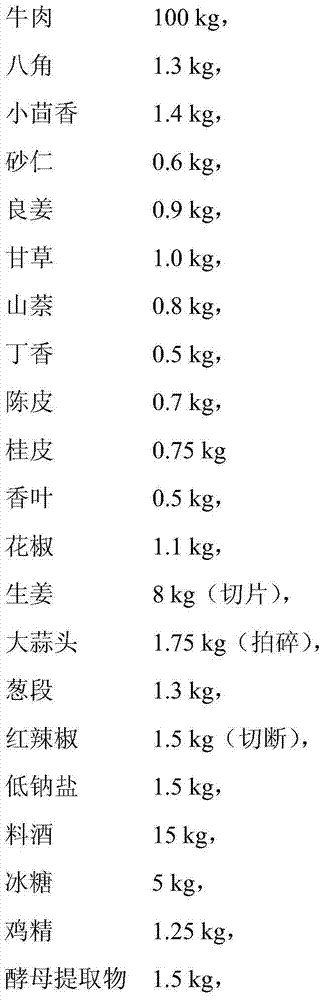

Preparation method for low-sodium-salt spiced beef leisure food

InactiveCN103478752AReduce sodiumReduce contentClimate change adaptationFood preparationReady to eatNitrite

The invention discloses a preparation method for low-sodium-salt spiced beef leisure food. The raw material for preparing low-sodium-salt spiced beef is fresh beef or frozen beef. The preparation method comprises the following steps of performing vacuum rolling and pickling on the fresh beef or the defrozen beef by using composite low-sodium salt, marinating the beef in boiled marinade, and finally slicing and packaging as well as sterilizing the beef to obtain the ready-to-eat spiced beef packaged products (leisure food). Compared with common spiced beef, the finished product prepared tastes delicious, and the sodium content is obviously reduced; nitrite is not used; the contents of potassium ions and calcium ions are also increased; nutrients of the food are strengthened; the health of a human body is facilitated; the preparation method is particularly suitable for nutrient healthy meat products eaten by people suffering from hypertension.

Owner:WUHAN POLYTECHNIC UNIVERSITY

High-silica octagonal zeolite and synthesizing method thereof

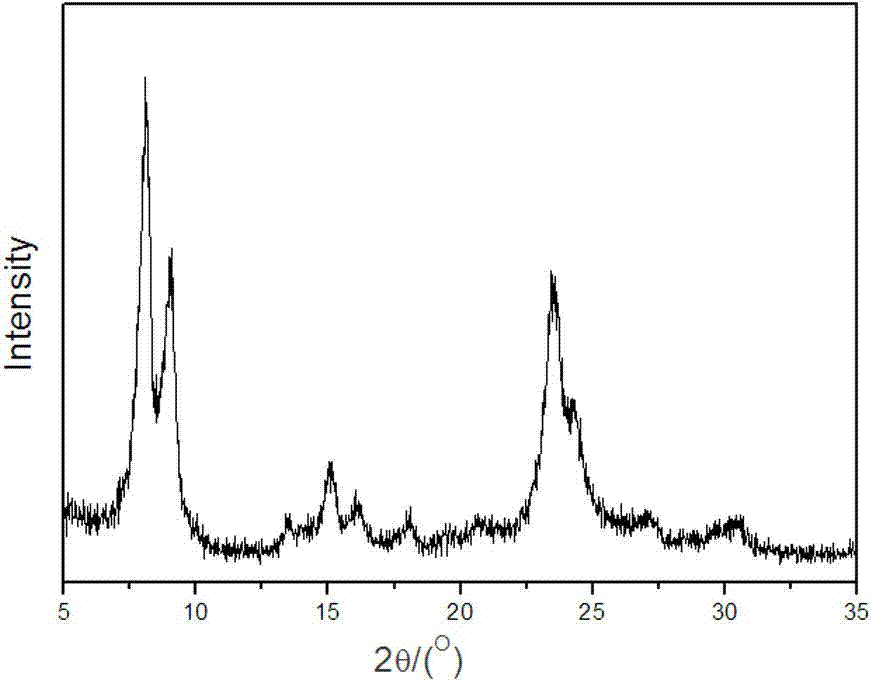

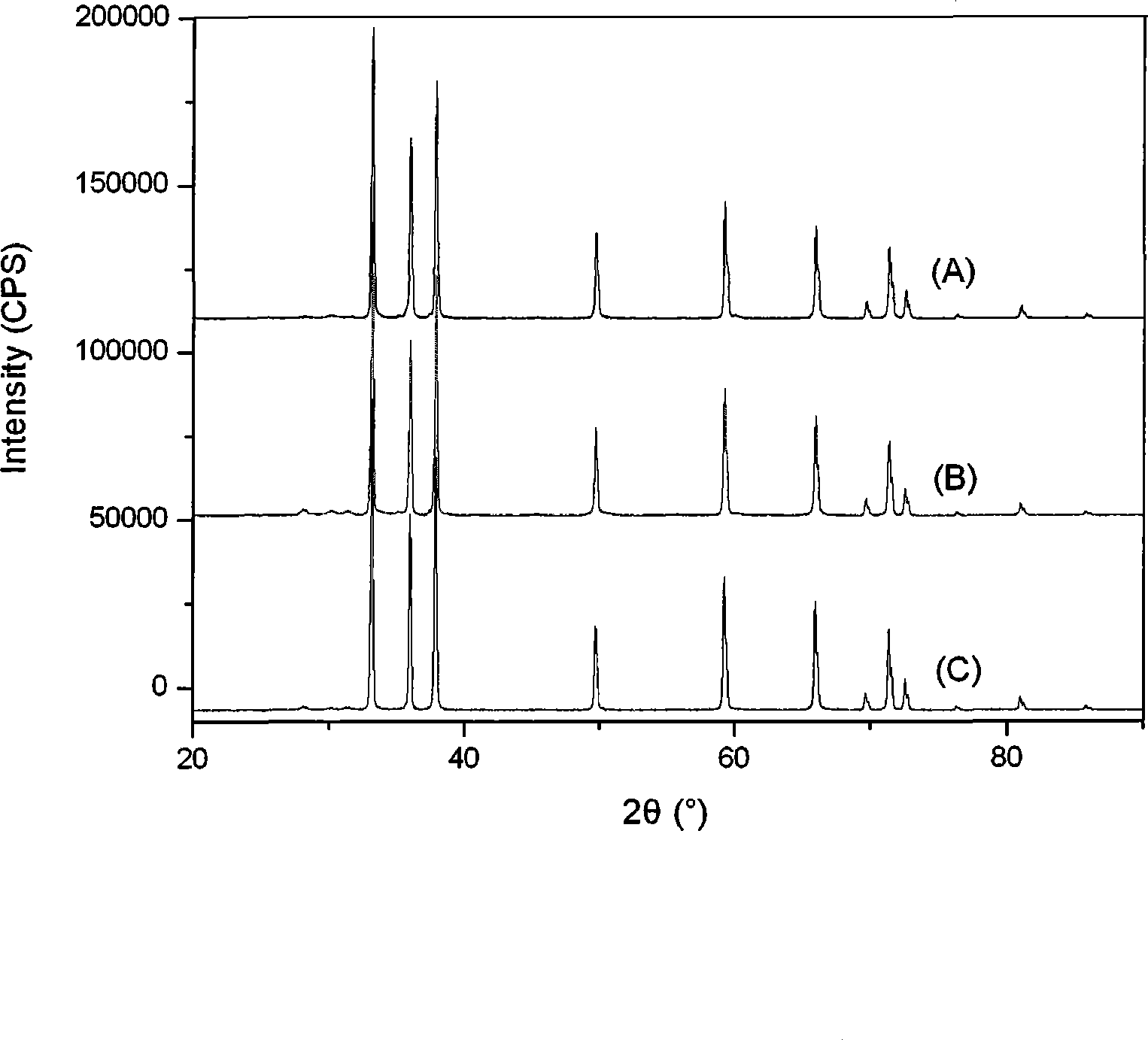

ActiveCN1951813AHigh crystallinityReduce sodiumFaujasite aluminosilicate zeoliteHigh silicaSpectral analysis

The invention discloses a high-silicon octahedra zeolite and preparing method with the molar rate of SiO2 / Al2O3 at 6-20, wherein the XRD spectral analysis belongs to Y-typed zeolite in the octahedra zeolite, whose crystal particle shape displays sheet appearance; producing the product under fitful moulding agent and low alkaline condition without guiding agent (zeolite seed).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing A1Npowder with microwave carbon thermoreduction cooling-down catalysis calcination

A method for preparing AlN powder by catalytic calcination, temperature reduction to a low temperature, and microwave carbon thermal reduction comprises the following steps: (1), aluminum hydroxide and ammonium chloride are mixed, wetly milled, filtered and dried, so as to obtain a mixture of the ammonium chloride and the aluminum hydroxide; (2), the product obtained in step (1) and acetylene black are mixed, aluminum powder is added to the mixture, and the wet milling and the drying are performed, so as to obtain precursor powder with uniform mixed carbon and aluminum; (3), the precursor obtained in step (2) is put into a high-temperature sintering furnace, and the nitrogen is introduced into the furnace, so as to carry out a microwave carbon thermal reduction-nitridation reaction; and (4), the product obtained in step (3) is calcined in dry air, so as to prepare the aluminum powder. The invention has the advantages of simple process, low synthesis temperature, low material cost, simple equipment, short process flow, simple operation, high purity of the product and environmental friendliness. Furthermore, the invention is suitable for the fields of precision ceramics, electrons, aviation / aerospace and the like, can realize mass industrial production, and has good market prospect.

Owner:CENT SOUTH UNIV

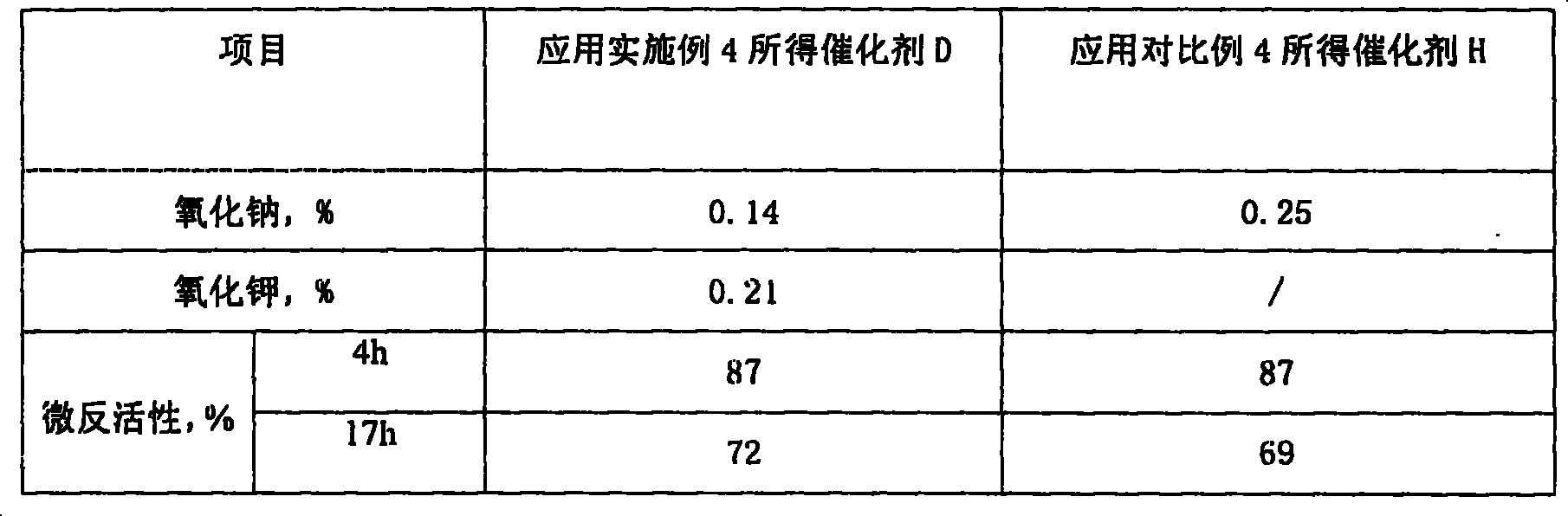

Modification treatment method of Y-type zeolite

ActiveCN104628010AReduce drynessHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteWater vaporStrong acids

The invention relates to a modification treatment method of a Y-type zeolite. The method comprises the following steps: carrying out ammonium exchange and direct burning on industrially-produced common NaY zeolite, repeating the ammonium exchange and direct burning for at least three times, then subjecting the NaY zeolite to a water steam treatment at a high temperature, and finally processing the NaY zeolite by a critic acid solution. The silicon / aluminum ratio of processed Y-type zeolite is in a range of 9 to 11, and the specific surface area of the processed Y-type zeolite is in a range of 550 to 650 m2 / g. Furthermore, the zeolite stability is improved, the sodium content is decreased, at the same time the amorphous aluminum out of the skeleton is removed, secondary mesopores (3-20 nm) are generated in the Y-type zeolite, strong acid centers are generated at the meantime, no environmental pollutant is generated during the treatment process, the efficiency is high, the modification treatment method is environment-friendly, the whole process is carried out on the basis of conventional modification treatments, and the provided method is suitable for massive preparation of Y-type zeolite with a high silicon / aluminum ratio through modification on NaY zeolite.

Owner:PETROCHINA CO LTD

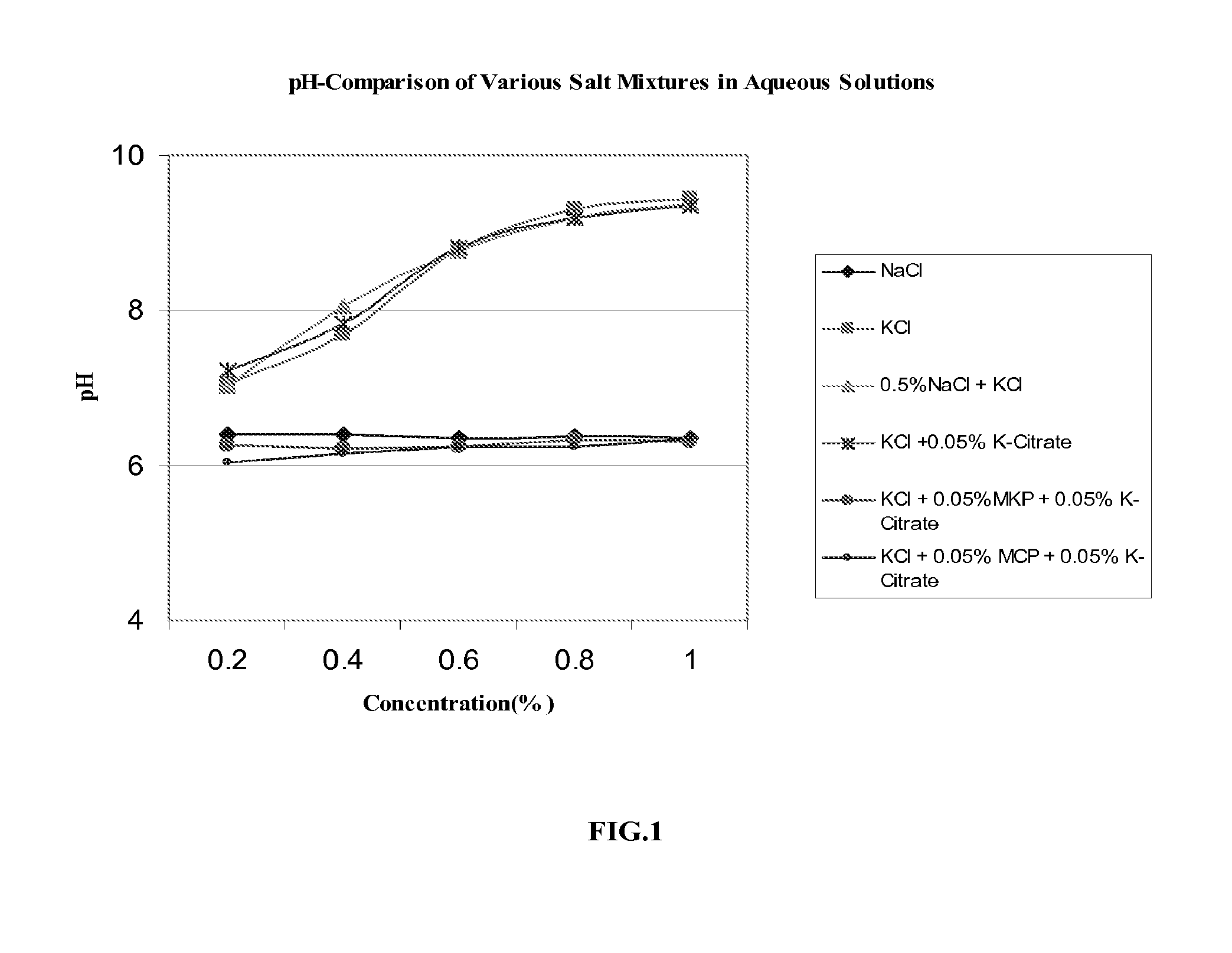

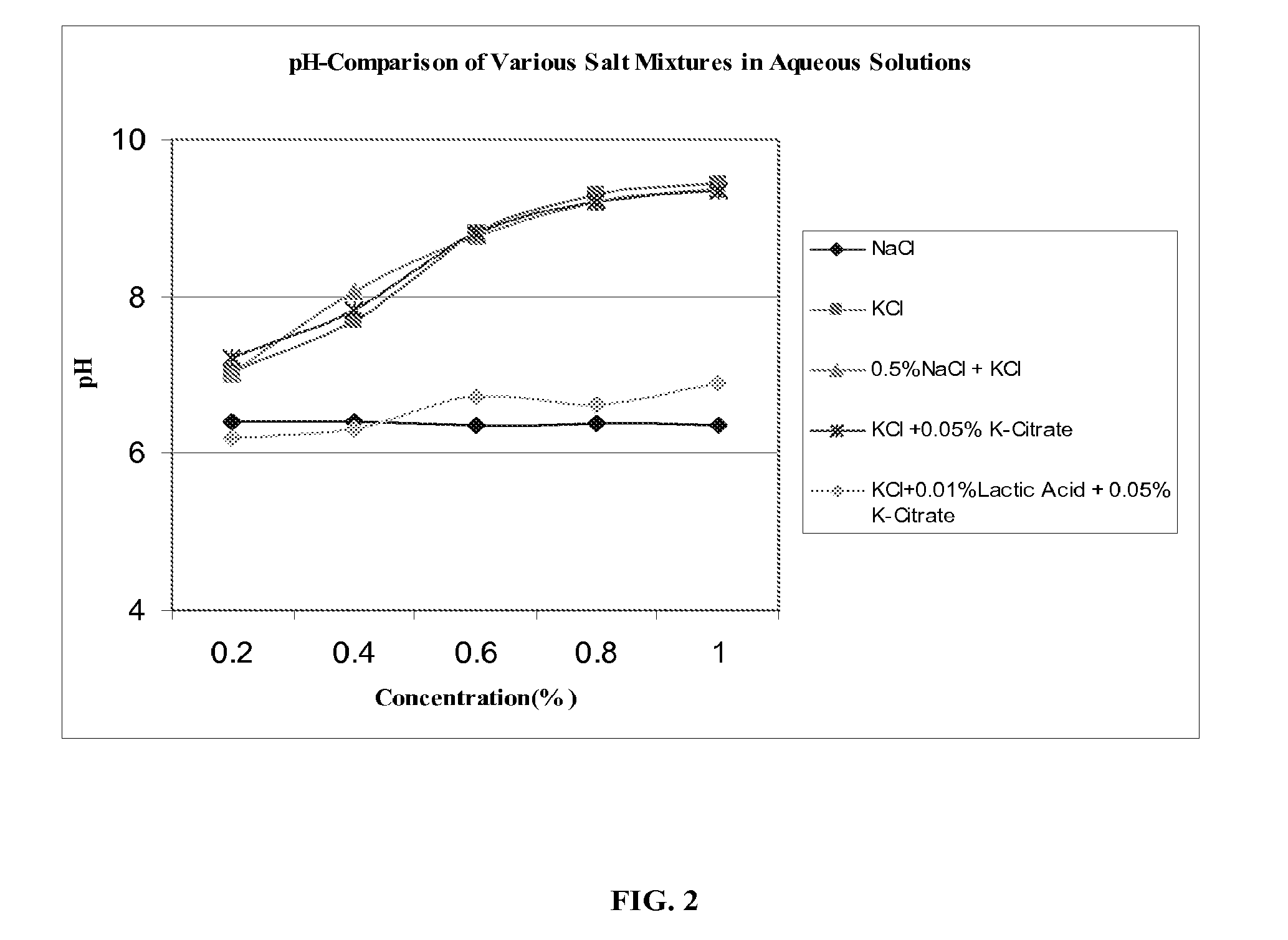

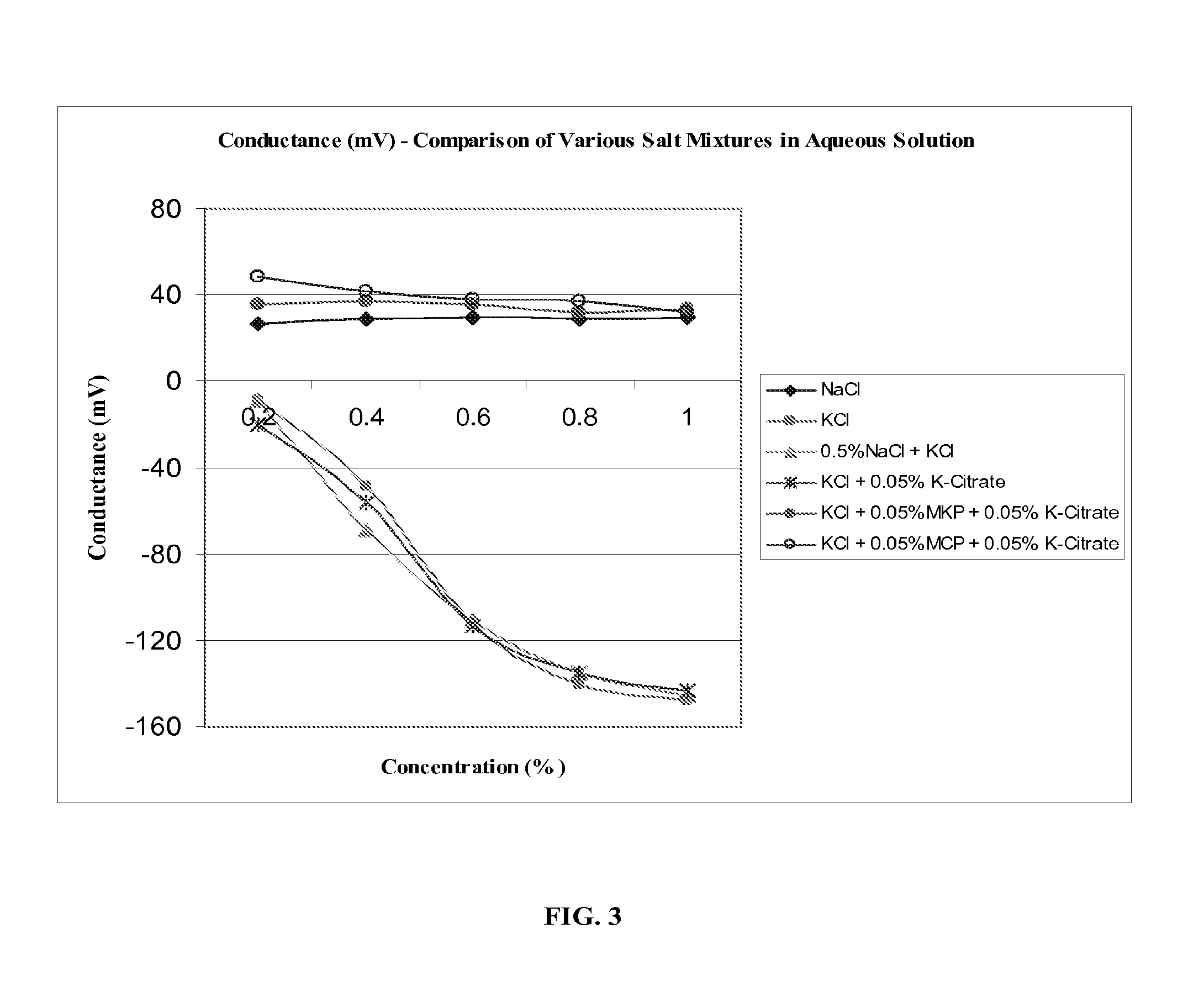

Methods and compositions for reducing sodium content in food products

InactiveUS20090196957A1Reduce sodiumEnhancing salt perceptionMilk preparationMeat/fish preservationOrganic acidMonopotassium phosphate

The invention provides compositions and methods for reformulating foodstuffs to reduce sodium content, while significantly enhancing salt perception and minimizing additional bitterness. In certain embodiments, the invention provides salt taste enhancing compositions including a blend of three potassium salts—namely, potassium chloride, monopotassium phosphate, and potassium citrate—which, when used in conjunction with sodium chloride, significantly enhances the salt perception in foods and beverages, while imparting no or limited bitter aftertaste. In other embodiments, the invention provides salt taste enhancing compositions including potassium chloride in combination with an organic acid and, optionally, an organic acid salt of potassium.

Owner:CAMPBELL SOUP COMPANY

Low sodium salt of botanic origin

ActiveUS20050220975A1Affecting yieldAffecting qualitySurface-active detergent compositionsAnimal feeding stuffPotassiumIodine

The invention describes the cost effective process for the preparation of a mixture of salts having low sodium salt (health salt) contain and exclusively derived from vegetable sources which have desired sodium chloride: potassium chloride ratio and traces of micronutrients including iodine, said salt is white in color and free flowing in nature.

Owner:COUNCIL OF SCI & IND RES

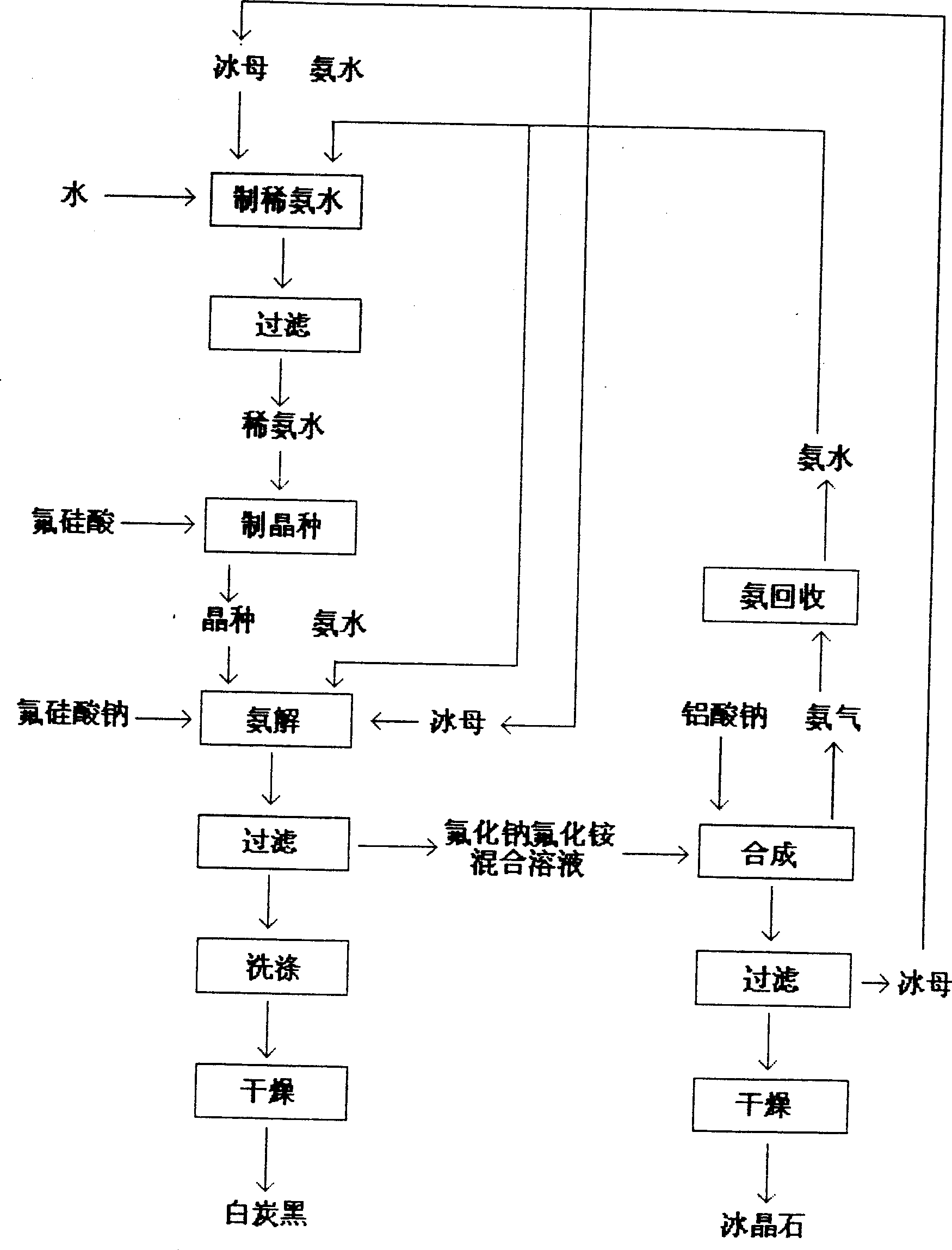

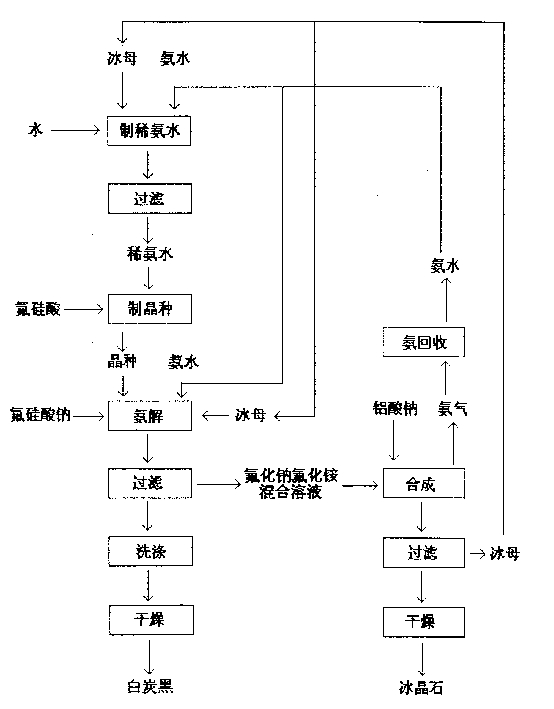

Method for simultaneously producing sodium aluminofluoride and silica white

InactiveCN1515493ALower molecular ratioHigh puritySilicon oxidesAluminium fluoridesReaction temperatureSodium aluminate

The method for producing ice spar and coproducing white carbon black includes the following steps: (1) adding ice mother and ammonia water in water to prepare dilute ammonia water, making fluorosilicic acid solution react with dilute ammonia water to obtain white carbon black crystal seed, controlling pH value of white carbon black in 6-8 and reaction temp. at 30-40 deg.C; (2). adding a certain quantity of white carbon black crystal seed into ammonolysis cell, in which the added quantity of crystal seed can be regulated according to the requirements, adding proper quantity of ice mother, in the presence of crystal seed making sodium fluorosilicate and ammonia water implement ammonolysis reaction at about 60 deg.C to obtain white carbon black slurry, filtering and washing to obtain white carbon black ointment, drying to obtain its finished product; (3). providing the steps for obtain ice spar product.

Owner:DO FLUORIDE CHEM CO LTD

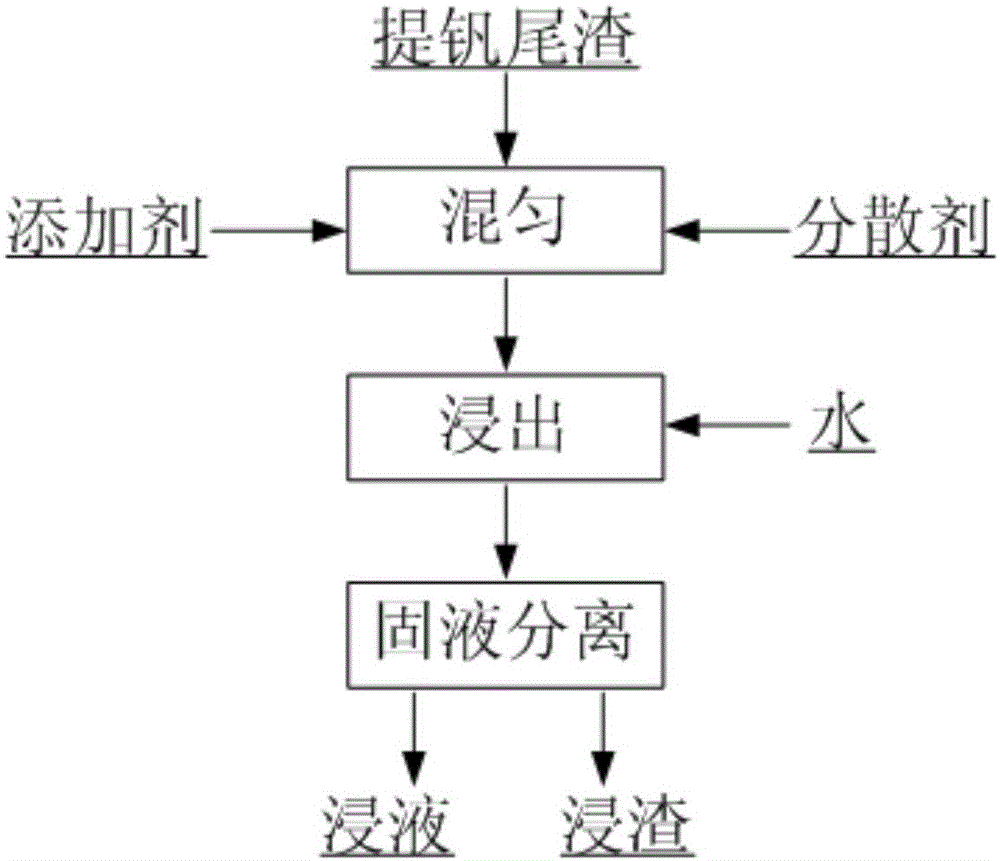

Treating method of tailings generated from vanadium extraction

ActiveCN105002367AEfficient use ofReduce usageProcess efficiency improvementAlkaline earth metalSlag

The invention discloses a treating method of tailings generated from vanadium extraction. The treating method adopts the technical scheme as follows: through the adoption of ions of alkaline-earth metals, sodium with stronger activity in the tailings generated from vanadium extraction is replaced to form sodium ions to enter a solution, so that the purpose of sodium removal is achieved; through the addition of a dispersing agent, the clustering phenomenon between particles is reduced, so that the removing rate of sodium is further improved. According to the treating method of the tailings generated from vanadium extraction, the sodium content can be significantly decreased, and sodium is replaced by alkaline-earth metals which have a less influence on smelting, so that the fact that the leaching residues are further subjected to blast furnace ironmaking is possible, and the efficient utilization of the tailings generated from vanadium extraction is achieved; a large amount of acid solution is avoided, and the recycle of a leaching solution is facilitated; the leaching solution can be used for leaching vanadium from vanadium slag; the removing rate of sodium in the leaching residues can be 40-70% above.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Residual stream upgrading in a propylene oxide-styrene monomer process

ActiveUS20100078391A1Reduce and eliminate formationGood removal effectLiquid degasificationHydrocarbon by hydrogenationLower gradeSlurry

In the co-production of propylene oxide and styrene monomer, there is produced a sodium-containing heavy residue stream previously suitable only as a low grade fuel. In accordance with the invention, the heavy residue stream is mixed with a hydrocarbon and an aqueous acid, and the resulting mixture is separated into an aqueous sodium salt-containing slurry phase and an organic phase reduced in sodium.

Owner:LYONDELL CHEM TECH LP

Production method of low-lipid salad dressing and vinegar-egg health salad dressing

The invention discloses a production method of low-lipid salad dressing and vinegar-egg health salad dressing and belongs to the technical field of health foods. The production method of the low-lipid salad dressing and vinegar-egg health salad dressing is characterized in that super-refined carbohydrate and microparticulated protein are utilized for simulating taste and physical properties of lipid, so that use amount of lipid is reduced, heat value of a product is reduced, and health function of a vinegar egg can be realized.

Owner:钱生球

Nutritious low-sodium composite salt and preparation method thereof

InactiveCN103584062AReduce sodiumSuppress high blood pressureFood ingredient functionsFood preparationBiotechnologyArginine

The invention discloses low-sodium nutritious composite salt and a preparation method thereof. The low-sodium nutritious composite salt is prepared from common salt, potassium chloride, L-histidine, L-arginine, L-lysine and sodium gluconate by the steps of stirring, dissolving, spraying and drying. The nutritious low-sodium composite salt disclosed by the invention is added with amino acid necessary for a human body when obviously reducing sodium content, not only is guaranteed to have the same salinity with the common salt, but also solves the problems of odor and bitterness of the common salt, and has an obvious health care effect.

Owner:NANJING AGRICULTURAL UNIVERSITY

Use of aldosterone antagonists to inhibit myocardial fibrosis

InactiveUS20020013303A1Prevent or otherwise inhibit myocardial fibrosisReduce sodiumOrganic active ingredientsNormal electrolytesSpironolactone

This invention discloses a method of using an aldosterone antagonist such as spironolactone, at a dosage which does not disrupt a patient's normal electrolyte and water-retention balance, to inhibit myocardial fibrosis, including left ventricular hypertrophy (LVH).

Owner:WEBER KARL T

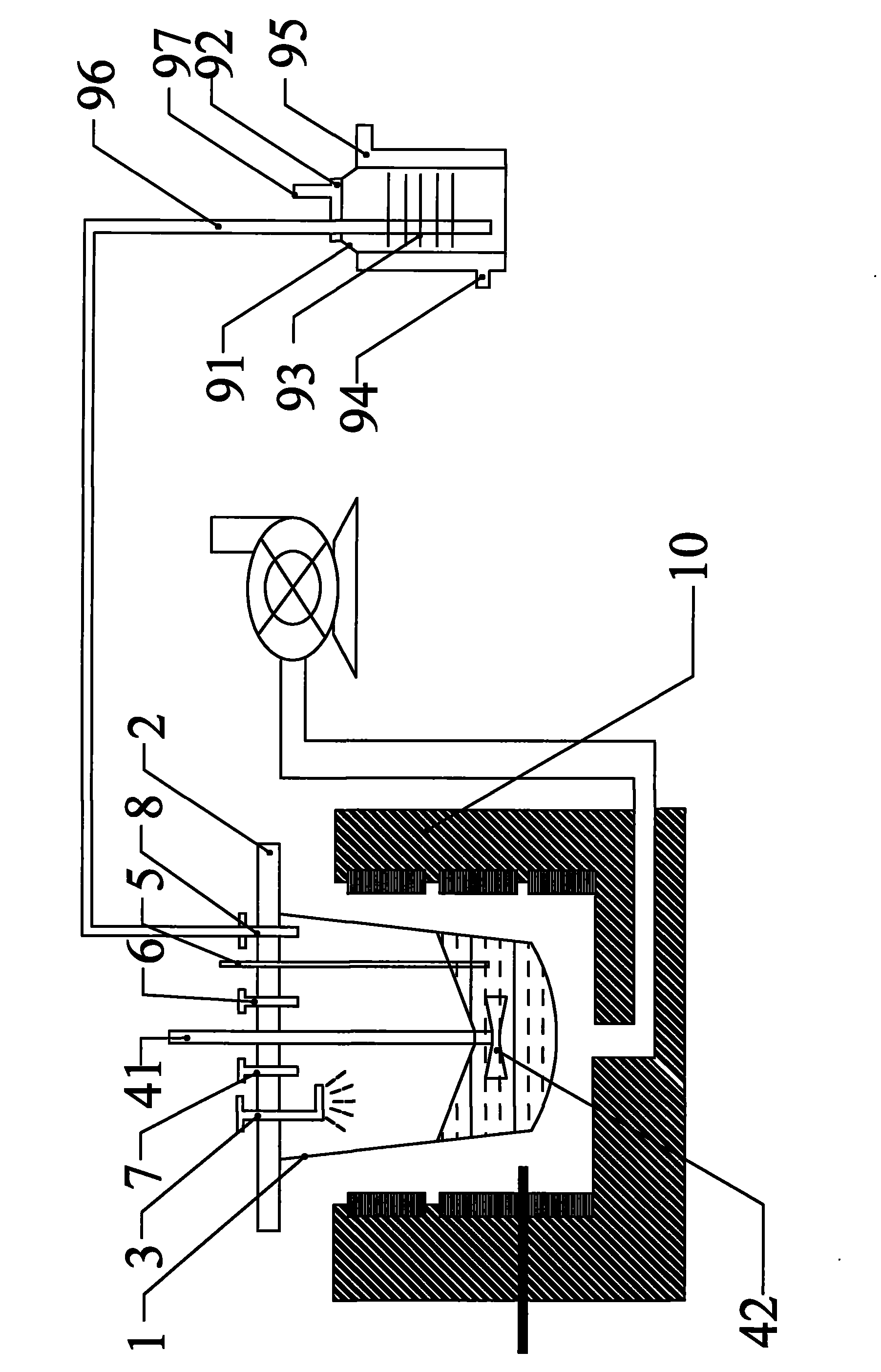

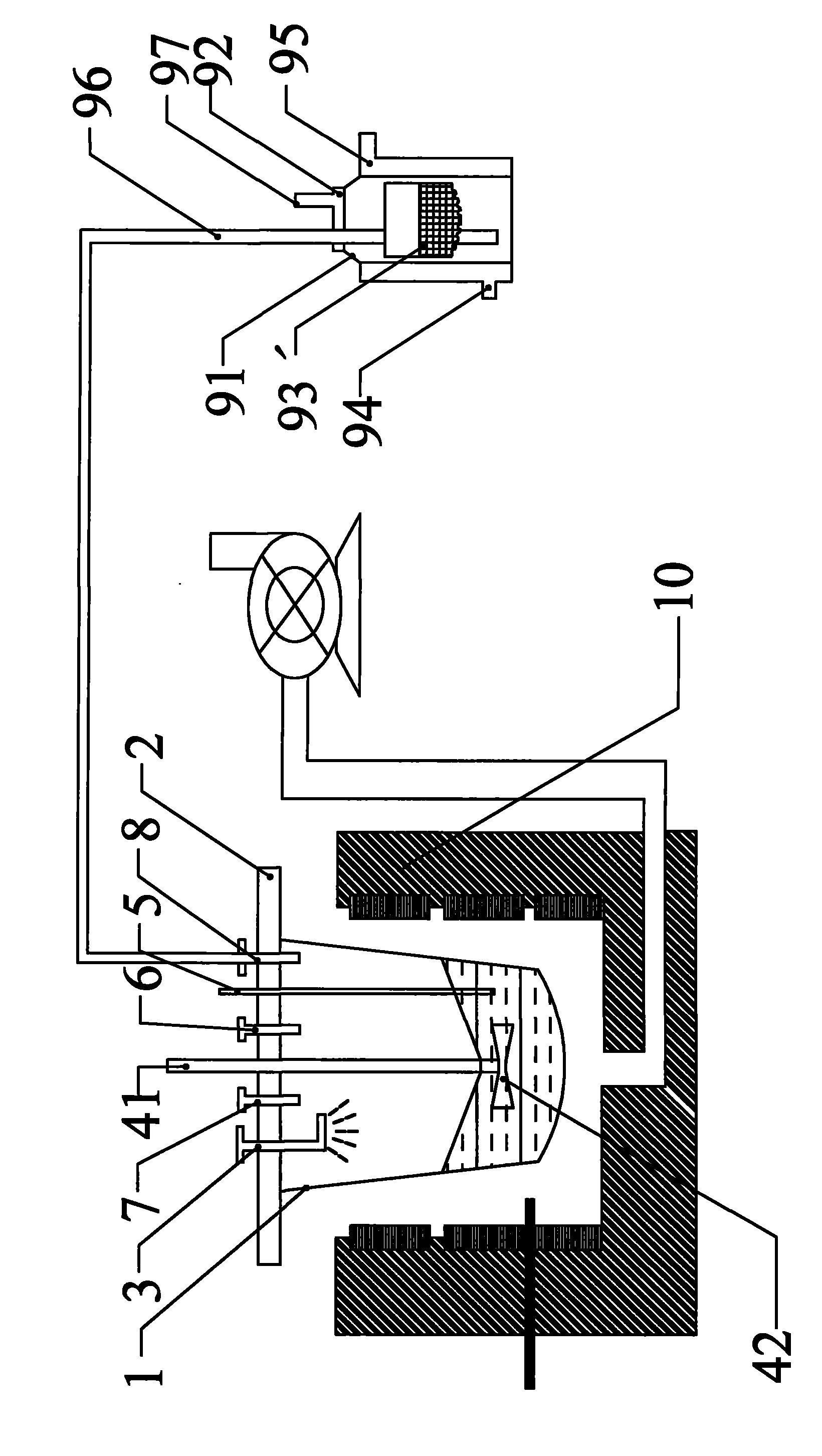

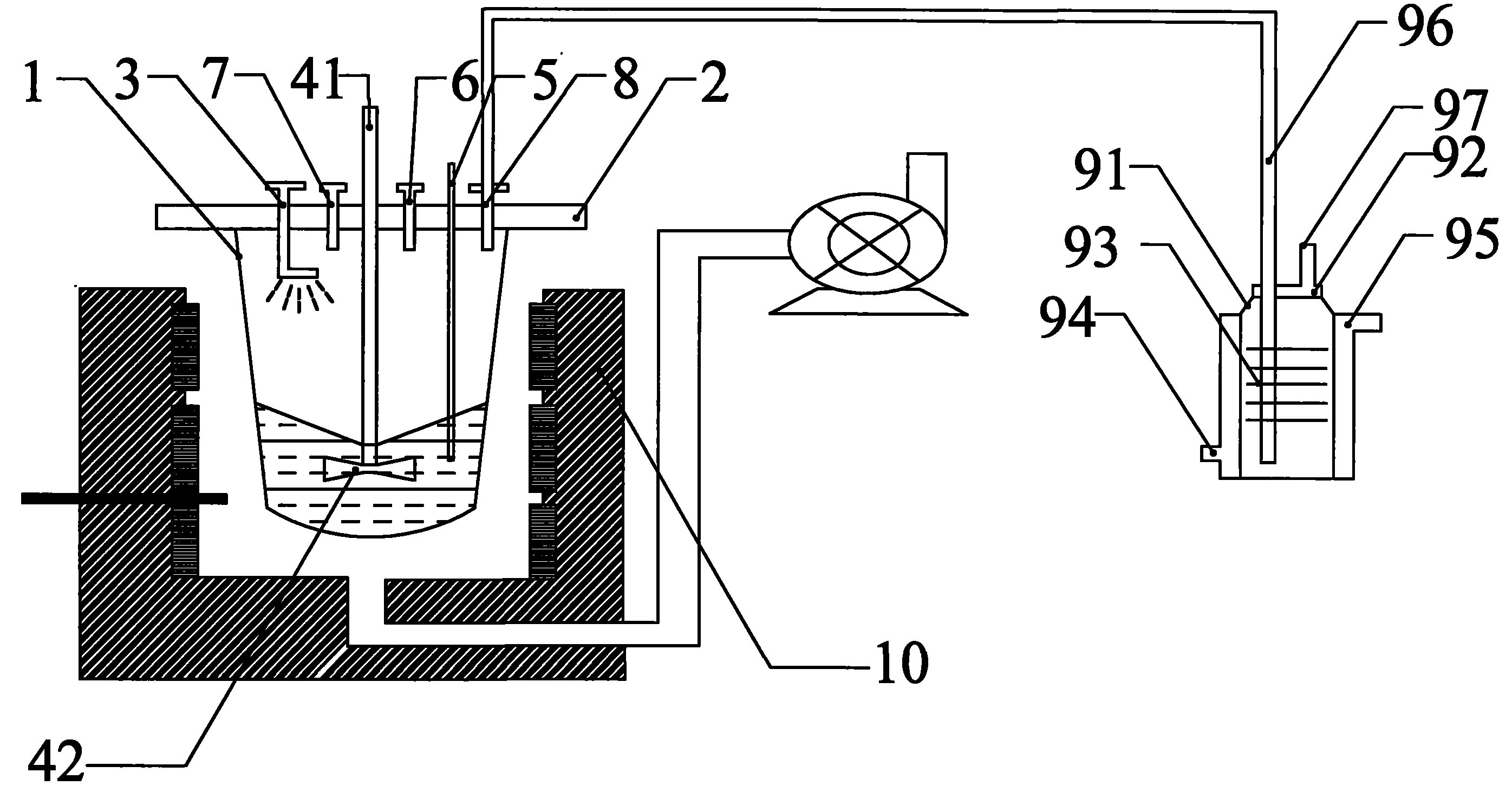

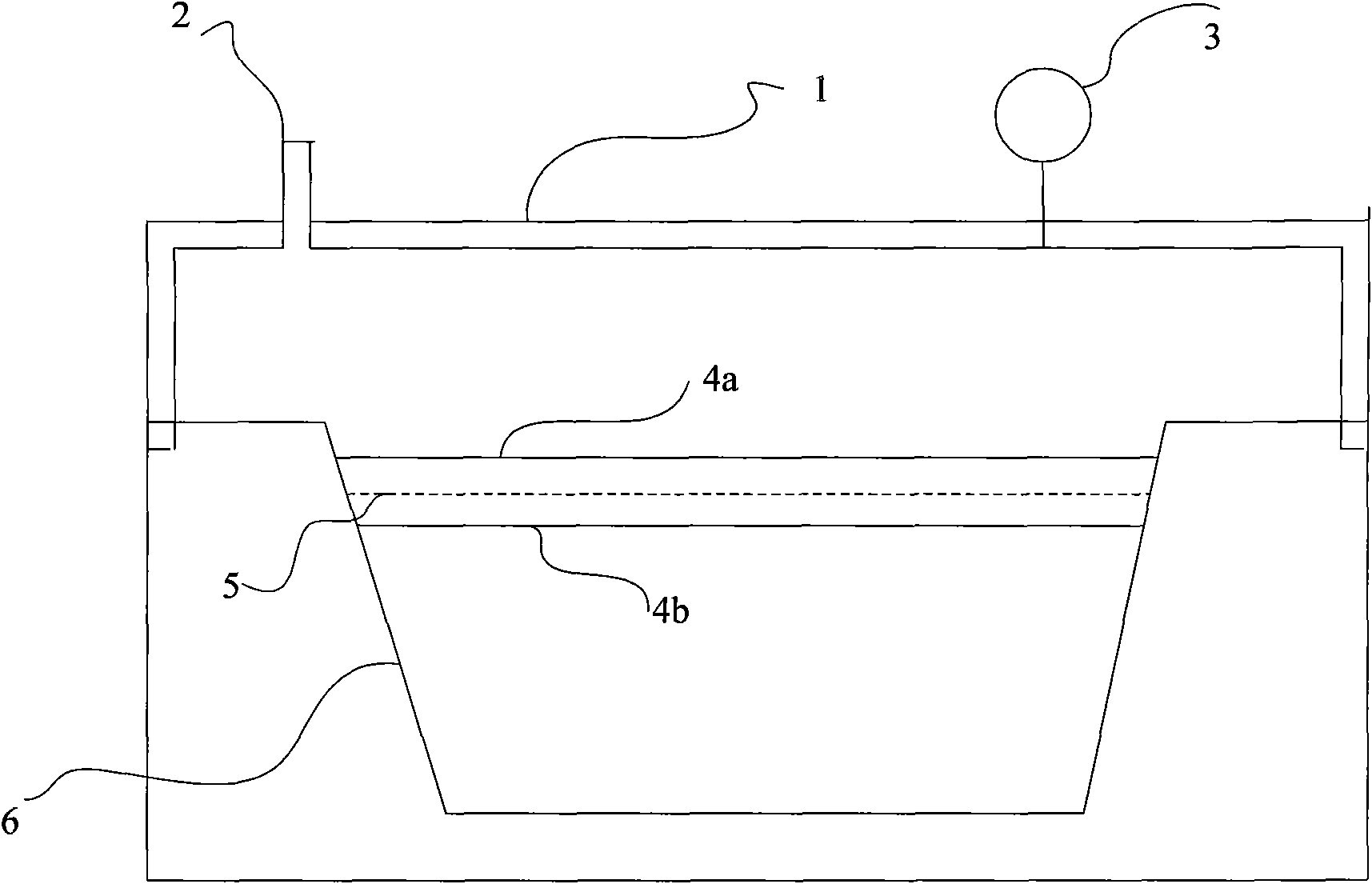

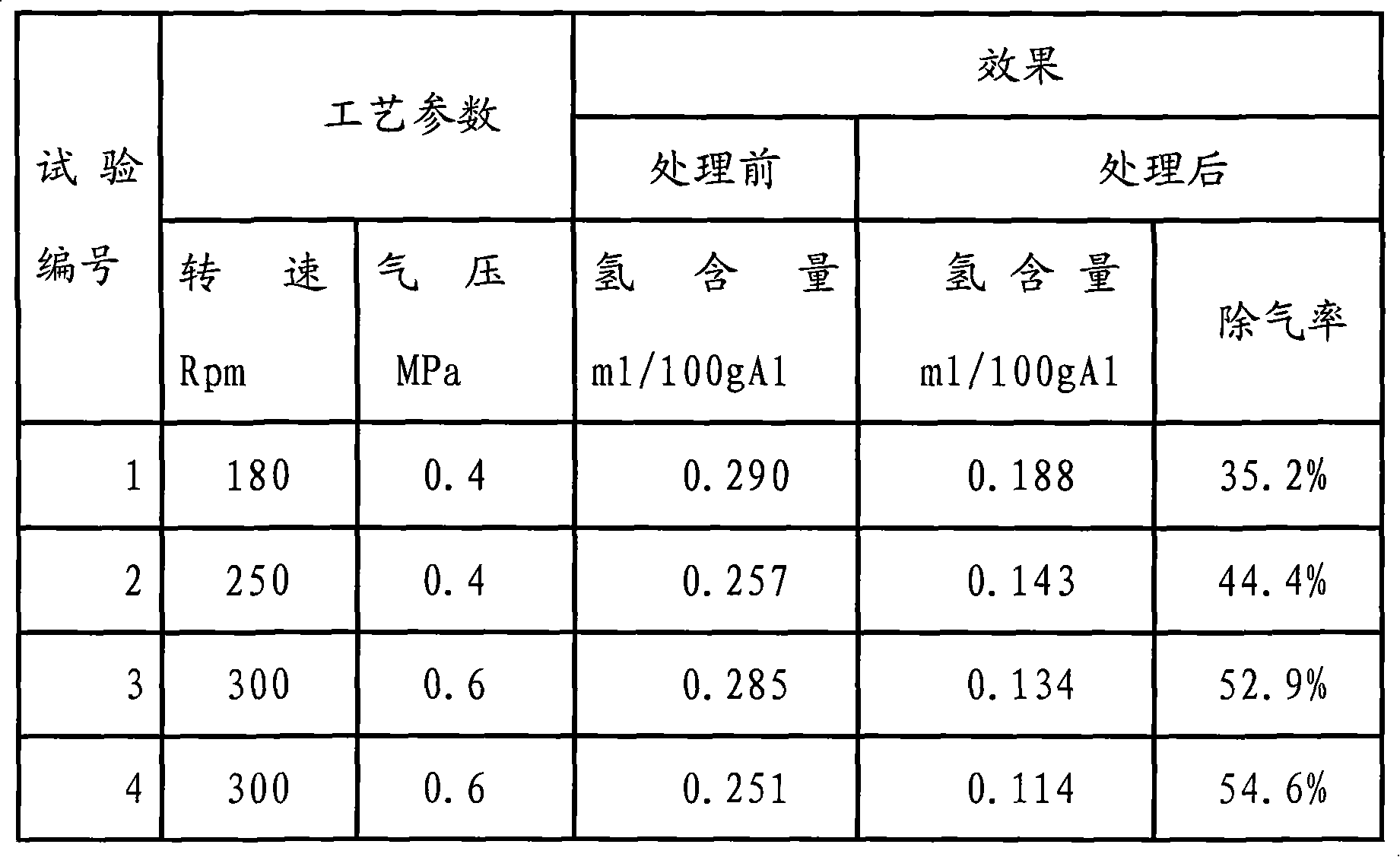

Production method and production device of tantalum powder

The invention discloses a production device of tantalum powder, which comprises a reaction vessel and a reaction vessel cover, wherein the reaction vessel cover is hermetically sealed with the reaction vessel; the reaction vessel cover is provided with a plurality of through holes; a thermocouple, a stirring device and a sodium injecting tube are respectively arranged in the through holes; a feed inlet, a gas inlet and an exhaust port are also arranged on the reaction vessel cover; and the production device also comprises an alkali metal collector. The invention also discloses a method for producing the tantalum powder by utilizing the device. The tantalum powder prepared by the method of the invention has low content of oxygen, potassium and sodium, and the alkali metal collector is used for collecting the discharged alkali metal vapor, thereby reducing the pollution on the atmosphere, recycling alkali metals and reducing the production cost.

Owner:江门富祥电子材料有限公司

High-temperature alterant and method for purifying fusant by adopting same

The invention discloses a high-temperature alterant, which comprises the following components in percentage by weight: 15 to 20 percent of chloride, 40 to 45 percent of chloride, 25 to 30 percent of rare earth metal compound, 3 to 8 percent of titanium dioxide, and 2 to 6 percent of graphite. The invention also discloses a method for purifying a fusant, wherein the high-temperature alterant is added into a smelting furnace. The high-temperature alterant can reduce the sodium content in an electrolytic molten aluminum fusant and effectively control the grain size to achieve good grain refining effect. The method for purifying the fusant can effectively reduce gas and foreign impurities in the fusant, optimize the production process, ensure the quality of aluminum and aluminum alloy fusants, improve the ingot yield, save the energy consumption, and reduce the discharge of pollutants.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Device and method of preparing pure lithium chloride solution by precipitating sodium through evaporation of mixed aqueous solution of lithium chloride and sodium chloride

ActiveCN106379920AEfficient separationHigh purityLithium halidesAlkali metal chloridesLithium chlorideEnvironmental effect

The invention discloses a device and a method of preparing pure lithium chloride solution by precipitating sodium through evaporation of a mixed aqueous solution of lithium chloride and sodium chloride and relates to the technical field of lithium chloride production. A raw material outlet of a condensate preheater is connected with a raw material inlet of an evaporation crystallizer through a pipeline; a raw material outlet of the evaporation crystallizer is connected with a feeding hole of a thickener through a pipeline; a lower part slurry outlet of the thickener is connected with a centrifugal machine; a centrifugal mother liquid outlet of the centrifugal machine is connected with a mother liquid groove; the mother liquid groove is connected with a mother liquid return hole of the evaporation crystallizer through a mother liquid pump; a sodium chloride crystal outlet is also formed in the centrifugal machine; and an upper part clear liquid outlet of the thickener is connected with a lithium chloride clear liquid groove. According to the device and the method, separation of the lithium chloride and the sodium chloride is more efficient, the purity of the obtained lithium chloride solution is high, and the sodium content is low; the equipment is simple and convenient to operate, low in running cost and little in investment and is feasible; and in addition, without using an external solution, new impurities are not introduced in the whole process, no waste liquid is drained, and environmental effect and economic benefit are good.

Owner:河北言明化工设备有限公司

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

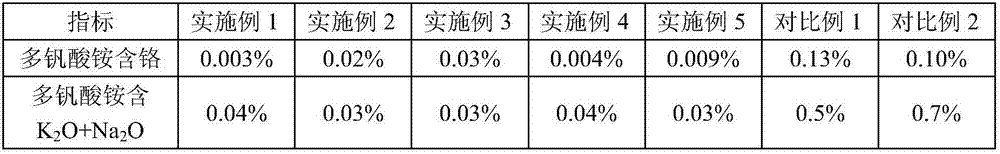

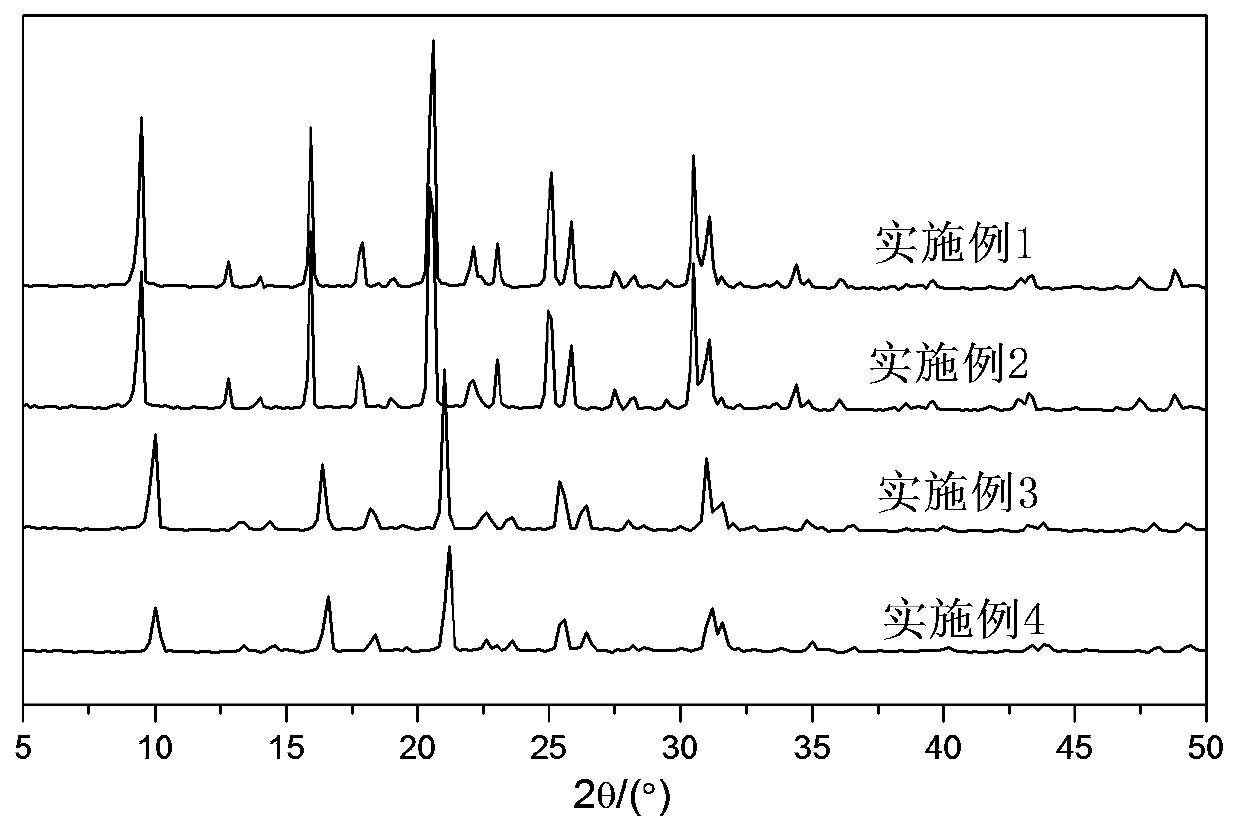

Method for producing low-chromium ammonium polyvanadate

According to a method for producing low-chromium ammonium polyvanadate, ammonium polyvanadate produced from vanadium slag with an acidic ammonium salt precipitation method is used as a raw material and is added to a sodium carbonate solution, after a solution is produced through heating and reaction, polyacrylamide is added, the solution is left to stand for clarification, and a vanadium solution is obtained through filtration; the vanadium solution is diluted with water, sulfuric acid is added for adjustment of the pH value, ammonium sulfate is added, after the solution is heated to be boiling and the ammonium polyvanadate reacts, ammonium polyvanadate solids are obtained through filtration and then are washed with a mixed solution of sulfuric acid and ammonium sulfate, the ammonium polyvanadate is rinsed with water, and a low-chromium ammonium polyvanadate product with the chromium mass content being smaller than or equal to 0.03% is obtained. The method has the advantages as follows: the technology is simple, the prepared ammonium polyvanadate has the relatively high purity (V2O5% is larger than or equal to 99.6%), the content of potassium and sodium is low (the sum of the content of K2O and the content of Na2O is smaller than or equal to 0.05%), the chromium content is low, and the defect that ammonium polyvanadate prepared from the vanadium slag used as the raw material has the high chromium content is effectively overcome.

Owner:锦州钒业有限责任公司

Processing method for naturally fermenting low-sodium dry cured meat product

InactiveCN103271365AEnsure hygiene and safetyReduce sodiumFood preparationTemperature controlFood flavor

The invention discloses a processing method for naturally fermenting a low-sodium dry cured meat product. The processing method comprises the following steps of: tumbling fresh meat and salt or low-sodium salt with the weight being 2%-5% of that of the fresh meat into a tumbling machine; statically curing, namely standing the tumbled meat for 2-5 days at the temperature of 0-4 DEG C; dehydrating, namely putting the pieces of cured meat for 3-5 days at the temperature of 8-12 DEG C, the humidity of 80%-90% and the wind speed of 1-2 m / s; and naturally fermenting, namely standing the dehydrated meat for 12-16 days at the temperature of 13-20 DEG C, the humidity of 75-85% and the wind speed of 2-3 m / s, and then standing the meat for 7-15 days at the temperature of 20-30 DEG C, the humidity of 65%-80% and the wind speed to be 3-4 m / s, thus obtaining the finished product when the weight loss ratio is 40%-45%. The processing method disclosed by the invention has the advantages that a new technology of temperature-controlled and humidity-controlled multi-stage low-temperature fermentation is adopted, all-natural low-sodium fermentation is adopted without any flavor and fragrance in the processing process, and the safety and the sanitation of the product are guaranteed. Compared with that of products with equal salt, the sodium content of the product can be reduced by 31.6%-50.87%, and thus the product conforms to the idea of low-sodium healthy eating of people.

Owner:郭秀云

Method for synthesizing Cu-SSZ-13 in one step under sodium-free system

InactiveCN109999897AThe synthesis process is simpleBroaden the synthesis pathMolecular sieve catalystsFiltrationIon exchange

The invention relates to the technical field of molecular sieve synthesis and discloses a method for synthesizing Cu-SSZ-13 in one step under a sodium-free system. Initial gel is prepared from an aluminum source, a silicon source, a copper ammonia complex and a copper ion load regulator; the initial gel is crystallized and then subjected to filtration, washing, drying and calcination, and the Cu-SSZ-13 molecular sieve is obtained. No conventional sodium hydroxide is used as an alkali source, the sodium content of other raw materials is very low, so that synthesis of the Cu-SSZ-13 molecular sieve under the sodium-free system is guaranteed, and copper ion loading and improvement of stability of copper ions in the target product are facilitated; due to addition of the copper ion load regulator, the load of copper ions is regulated freely in a certain range, and different reaction technological condition requirements are met. The method is simple to operate, repeated ion exchange and calcination technologies are avoided, so that the traditional technological process is greatly simplified, the production cost is reduced effectively, and the method is energy-saving and environmentally friendly, and has enormous industrial application prospects.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com