Patents

Literature

63 results about "Dry cured" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The duration of the curing process varies by the type of ham, with, for example, Serrano ham curing in 9–12 months, Parma hams taking more than 12 months, and Iberian ham taking up to 2 years to reach the desired flavour characteristics. Some dry cured hams, such as the Jinhua ham, take approximately 8 to 10 months to complete.

Simplified cultivating method for dry-cure pepper

ActiveCN103493664AEnsure constant temperature and humidityGrowth inhibitionHorticultureFertilizer mixturesSoil temperatureTillage

The invention discloses a simplified cultivating method for dry-cure pepper. The method improves the emergence rate, the planting percent and the strong seedling rate of direct-seeded seeds of pepper by covering and using direct-seeding nutrition balls and direct-seeding nutrition matrix. The method furhter solves the problems that surface layers in field direct seeding is prone to hardening due to the fact that soil temperature and humidity are affected by environment to be large in change to be unfavorable for seed emergence of pepper seeds and growth of seedlings. In addition, the method achieves practicability of pepper direct-seeding techniques and widens popularization and application ranges. By means of black film covering and direct seeding cultivation, the problems of weed growth in fields and serious pepper lodging are effectively solved, minimal tillage or zero tillage in fields are achieved, the use of weed killers is reduced, specific fertilizers are screened through tests to solve the problem of one-time fertilization in pepper production, additional fertilizers are avoided in pepper production on the premise of avoiding output reduction of peppers, and the problem of harvesting dry-cure scatter and fresh peppers at one time in a concentrated mode is solved. Thus, the purposes of achieving low cost production of peppers and improving pepper quality are achieved.

Owner:贵州省辣椒研究所

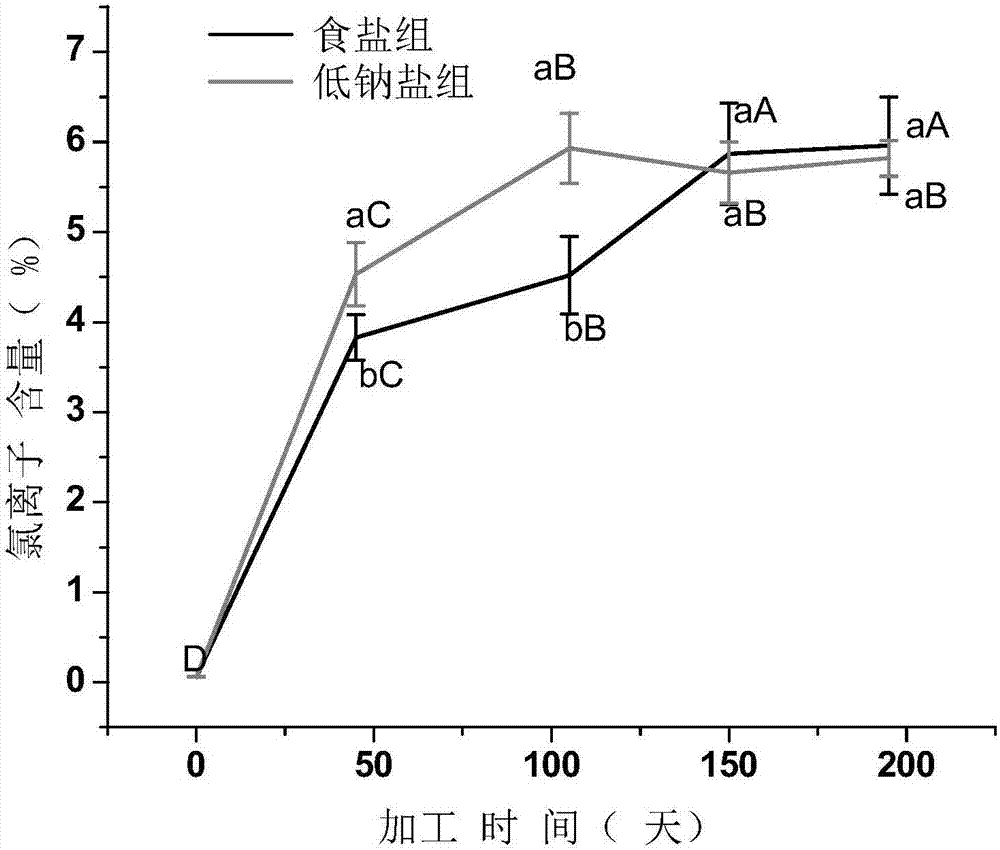

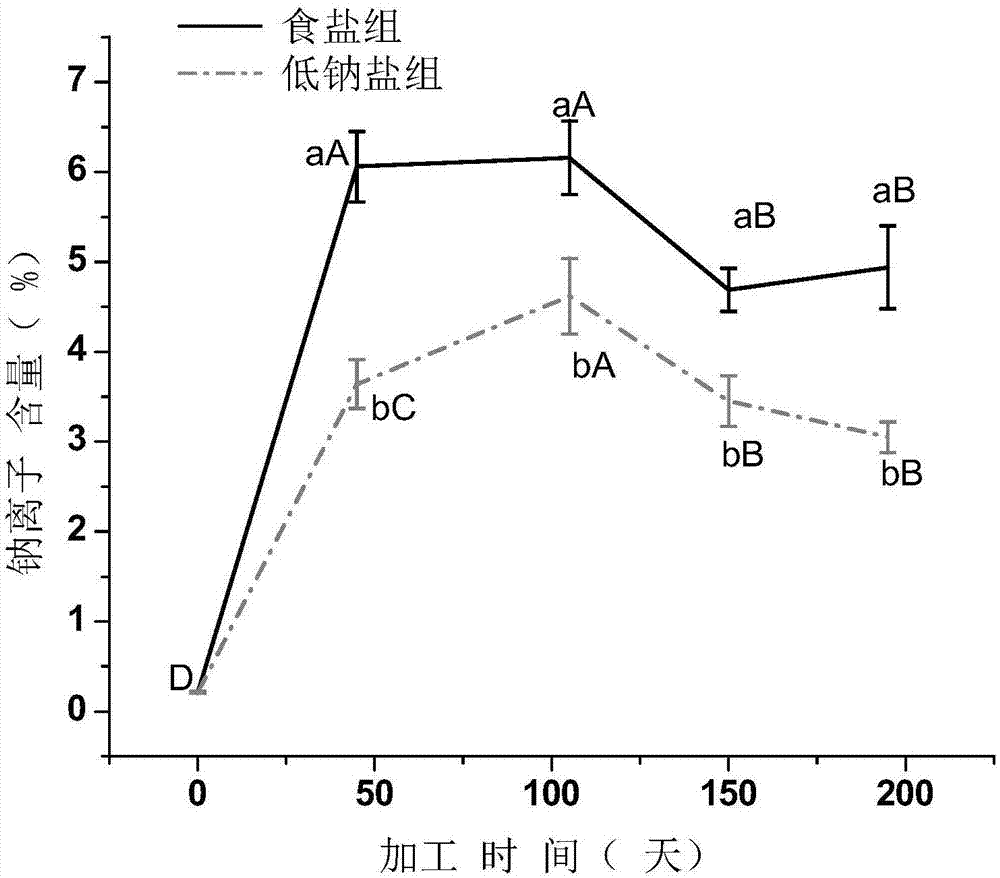

Processing method for naturally fermenting low-sodium dry cured meat product

InactiveCN103271365AEnsure hygiene and safetyReduce sodiumFood preparationTemperature controlFood flavor

The invention discloses a processing method for naturally fermenting a low-sodium dry cured meat product. The processing method comprises the following steps of: tumbling fresh meat and salt or low-sodium salt with the weight being 2%-5% of that of the fresh meat into a tumbling machine; statically curing, namely standing the tumbled meat for 2-5 days at the temperature of 0-4 DEG C; dehydrating, namely putting the pieces of cured meat for 3-5 days at the temperature of 8-12 DEG C, the humidity of 80%-90% and the wind speed of 1-2 m / s; and naturally fermenting, namely standing the dehydrated meat for 12-16 days at the temperature of 13-20 DEG C, the humidity of 75-85% and the wind speed of 2-3 m / s, and then standing the meat for 7-15 days at the temperature of 20-30 DEG C, the humidity of 65%-80% and the wind speed to be 3-4 m / s, thus obtaining the finished product when the weight loss ratio is 40%-45%. The processing method disclosed by the invention has the advantages that a new technology of temperature-controlled and humidity-controlled multi-stage low-temperature fermentation is adopted, all-natural low-sodium fermentation is adopted without any flavor and fragrance in the processing process, and the safety and the sanitation of the product are guaranteed. Compared with that of products with equal salt, the sodium content of the product can be reduced by 31.6%-50.87%, and thus the product conforms to the idea of low-sodium healthy eating of people.

Owner:郭秀云

Preparation method of high-efficient decay-promoting agent

InactiveCN106701603AHigh activityPromote degradationBio-organic fraction processingFungiSporeHigh fertility

The invention discloses a preparation method of a high-efficient decay-promoting agent. The preparation method comprises the three steps of activation and purification of bacteria, enlarged culture of a liquid shaking table and preparation of solid bacterial powder, and comprises the concrete steps of inoculating fungi, actinomycetes and bacteria on respective culture media, and carrying out streak culture; picking single colonies of the bacteria and the actinomycetes or mycelia or spores of the fungi to inoculate into respective prepared liquid culture media, and culturing through the liquid shaking table; finally inoculating each bacterium of each liquid culture medium into a prepared culture material according to the proportion, dry-curing, mixing the dry-cured bacteria according to the proportion, and preparing the high-efficient decay-promoting agent with high fertility. The invention provides the preparation method of the high-efficient decay-promoting agent, which has the characteristics of capability of enabling the decomposing speed of straw or farmyard manures to be improved remarkably, high degradation ability, high decay promoting efficiency, and good effect.

Owner:云南博隆生物科技开发有限公司

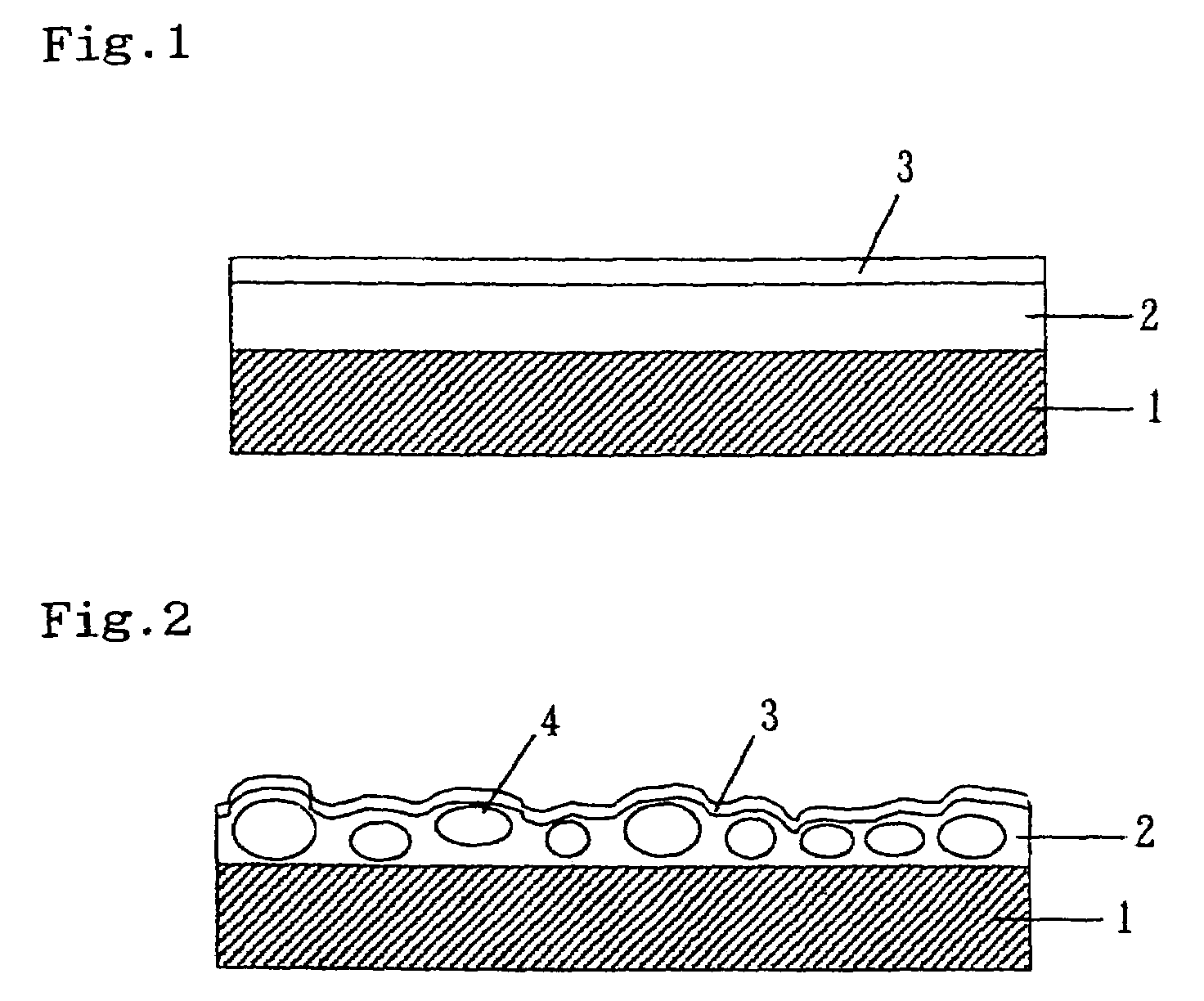

Antireflection film, optical element and visual display

InactiveUS7156530B2Excellent scratch roof property and stain resistanceSlow curingRoof covering using sealantsDiffusing elementsPartial hydrolysisOligomer

Owner:NITTO DENKO CORP

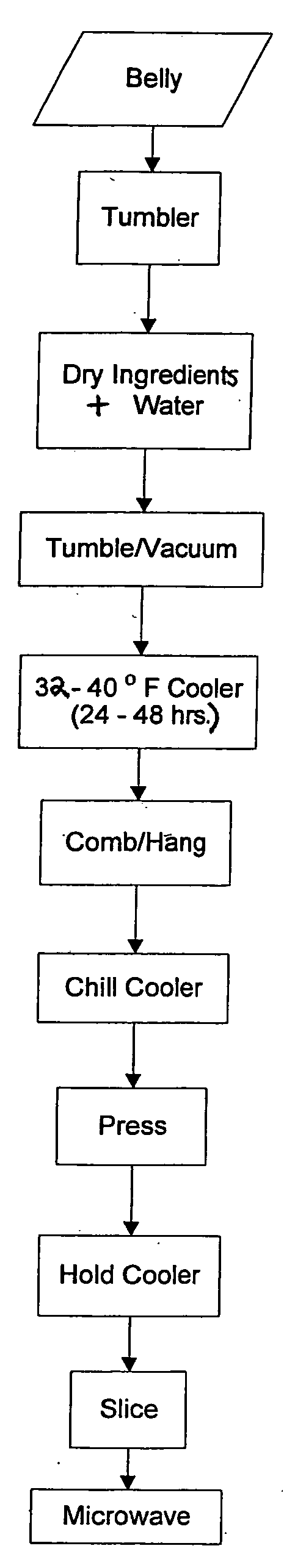

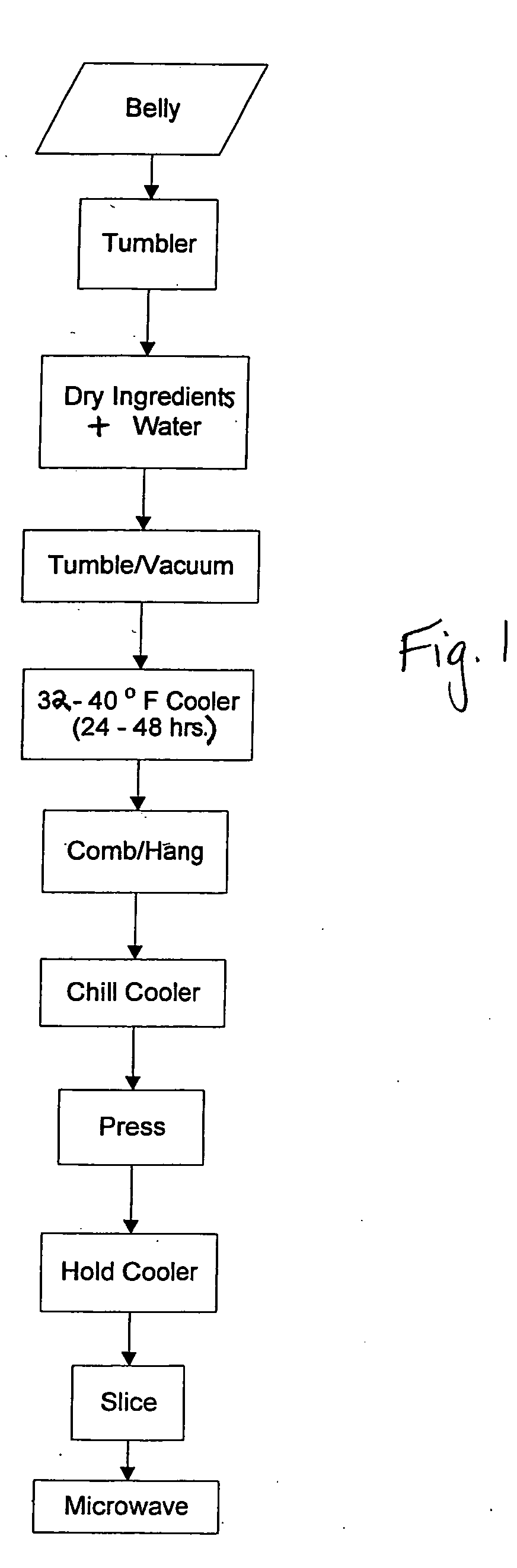

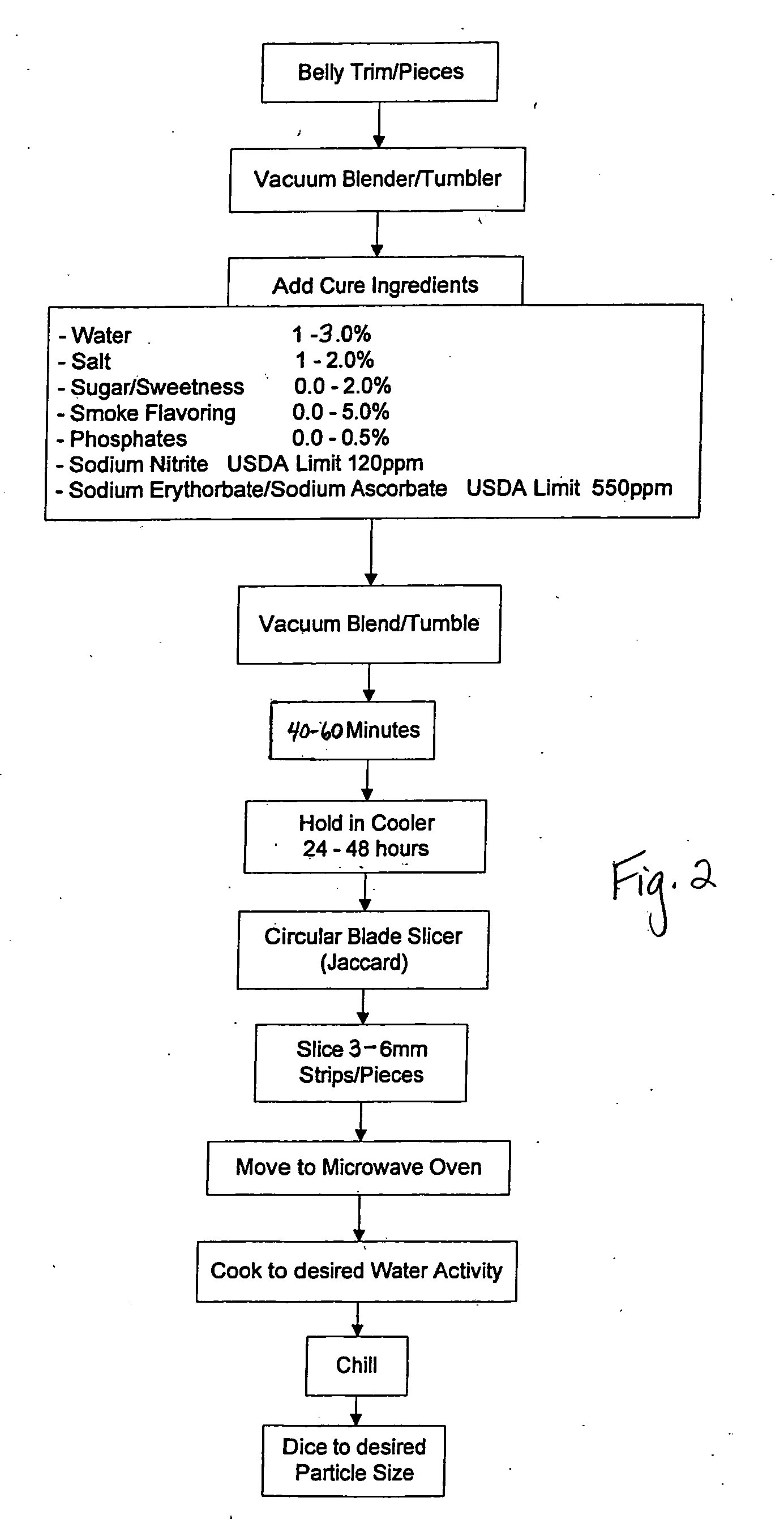

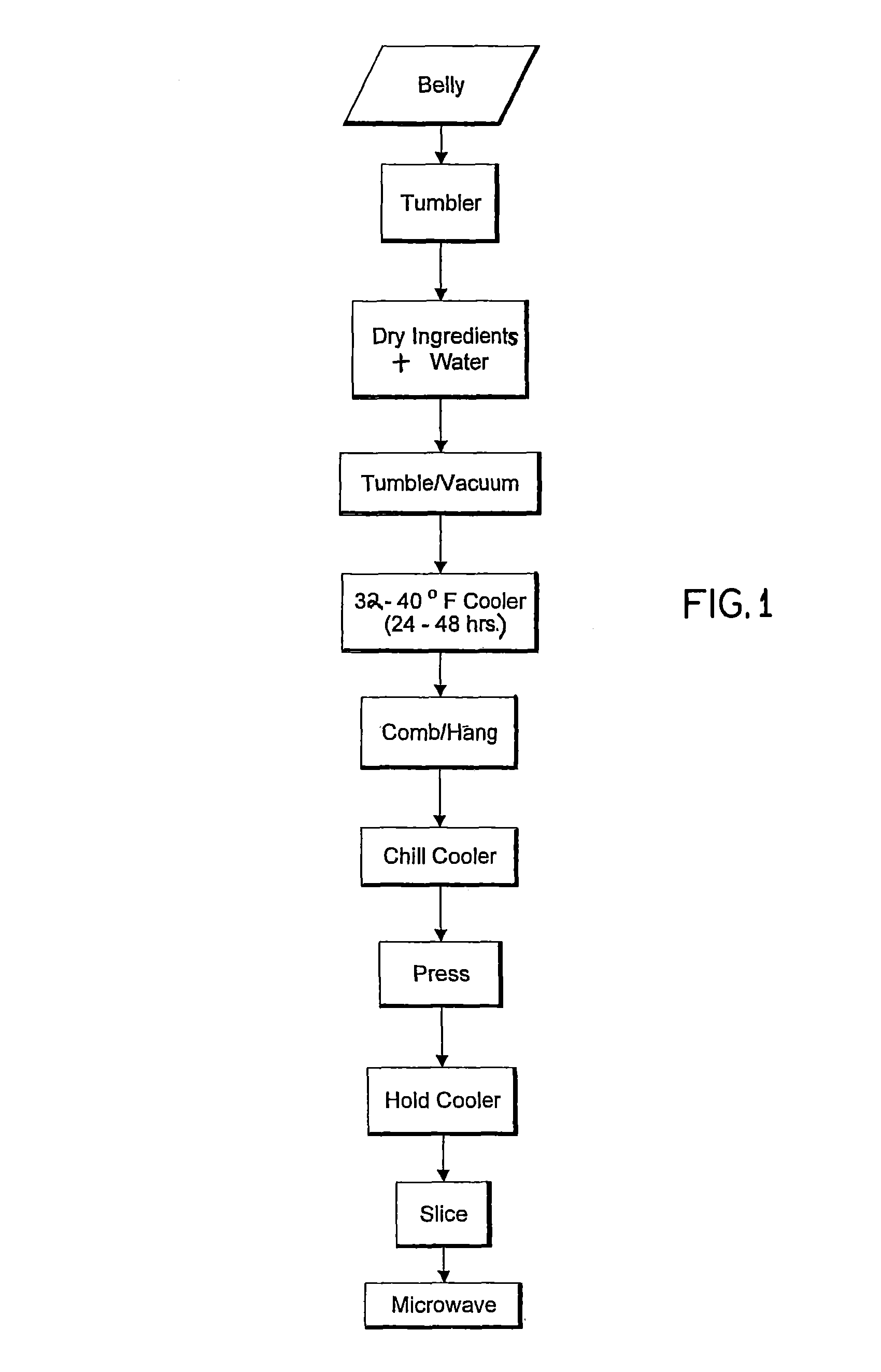

Method of making bacon pieces

Owner:HORMEL FOODS

Method for processing dry-cured beef food

The invention relates to a method for processing dry-cured beef food, and belongs to the technical field of food processing. The processing method comprises the following steps of: selecting ham of fresh beef, cleaning the ham, removing tendon, fascia and fat, cutting the ham into 500 grams of meat block according to straight shreds, uniformly coating 45 grams of sodium chloride, 0.1 gram of sodium nitrate, 5 grams of sweetener and 0.03 gram of sodium ascorbate on the surface of the meat block based on 1,000 grams of beef, and kneading the meat block till the meat block is soft; putting the meat block into a cylinder, sealing the cylinder mouth, salting the meat block for 10 to 15 days, and turning the meat block in the cylinder once in the meantime; and air-curing, stacking and extruding the meat block, airing the meat block to form a finished product, controlling the water content within 40 percent, then slicing the meat block, packing the slices with vacuum, and sterilizing the slices by irradiation with 8KGy dose to obtain the dry-cured beef food. Compared with the prior art, the method has the advantages of simple and reasonable process steps and capability of realizing industrialized production; and the product has the advantages of bright red and attractive color, good mouthfeel and long storage period. The method has great improvement on the traditional dry-cured beef production method, and has high market popularization value.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

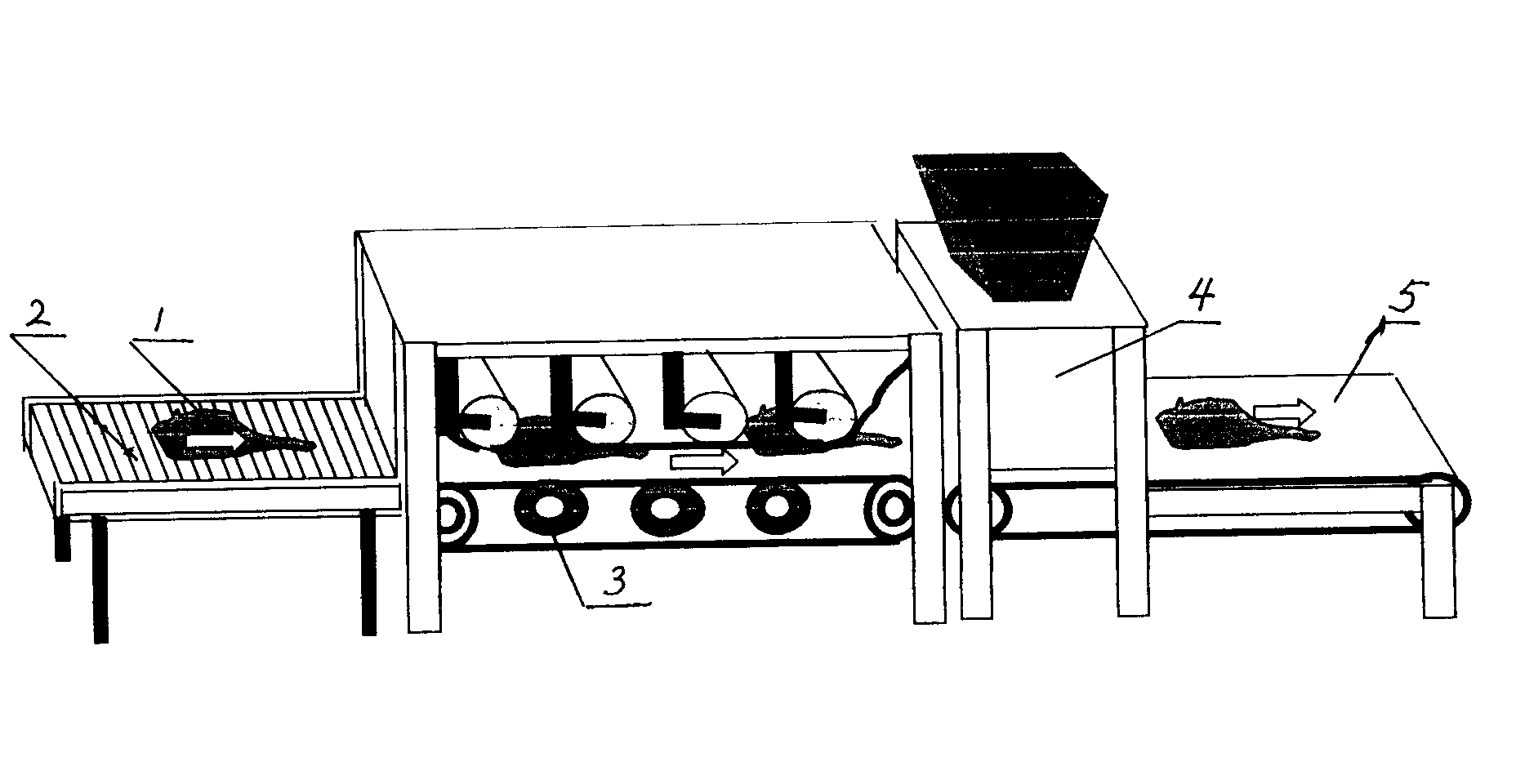

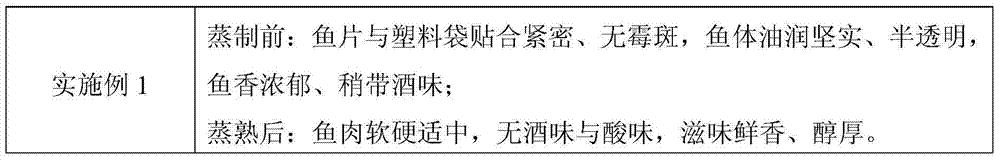

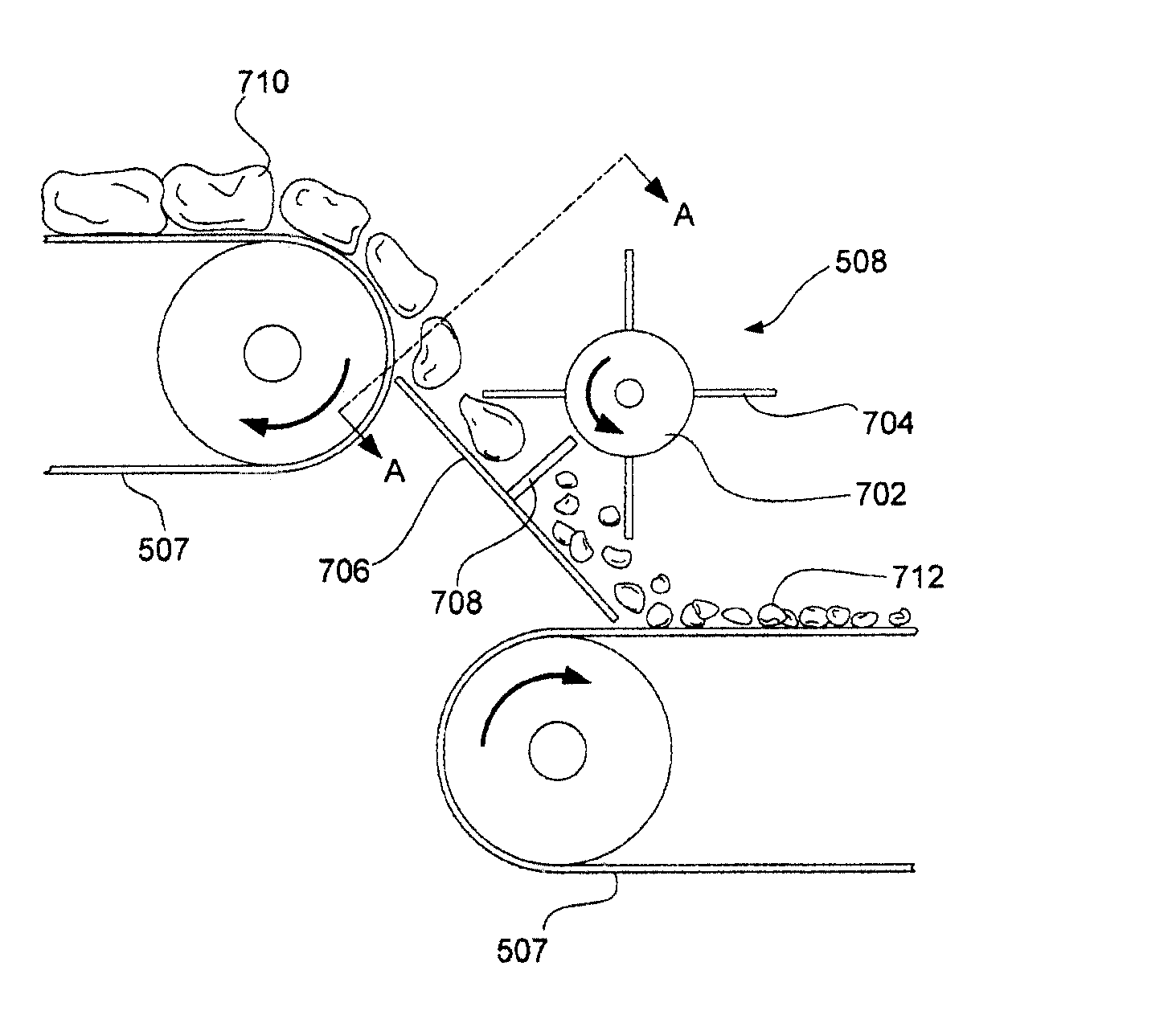

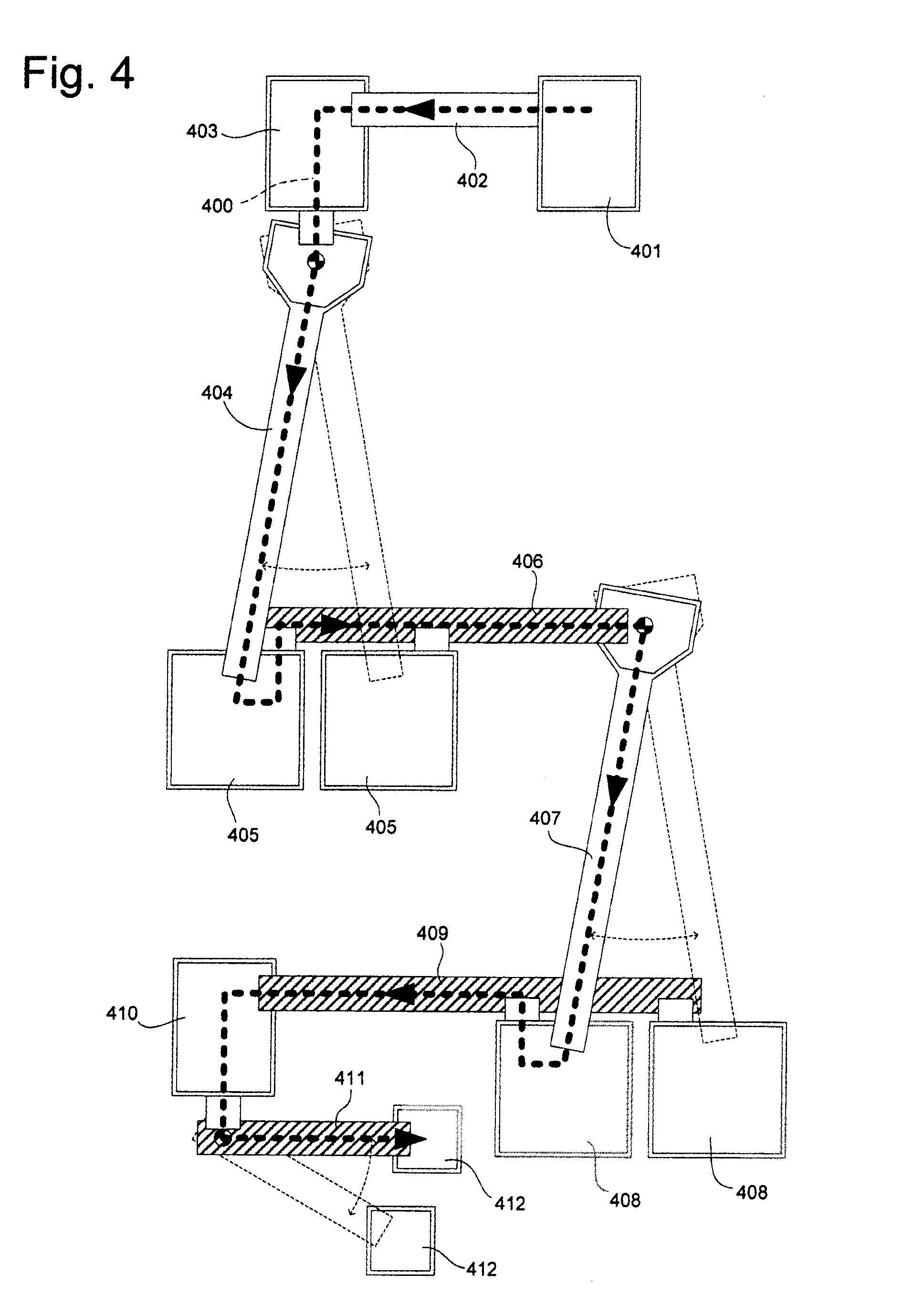

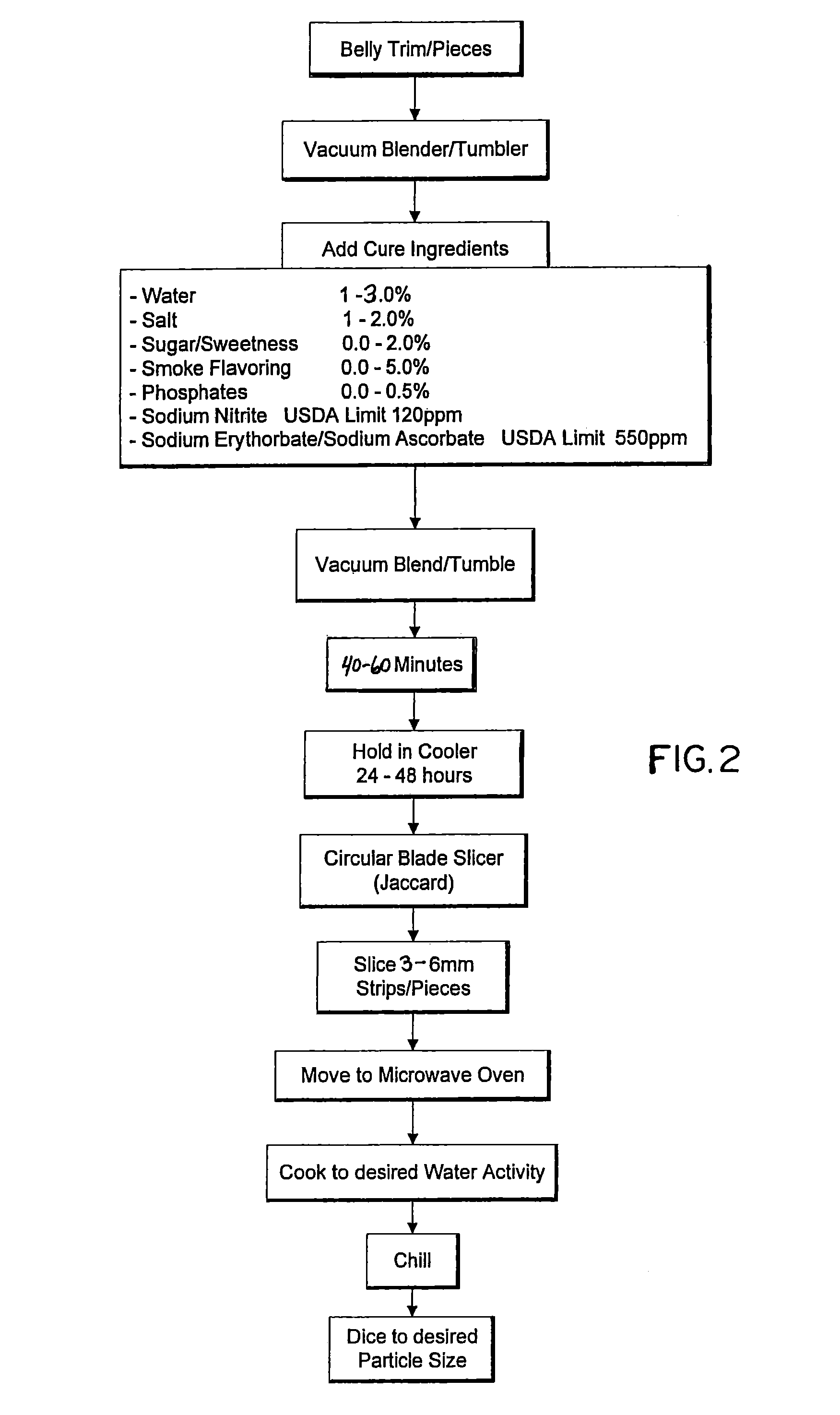

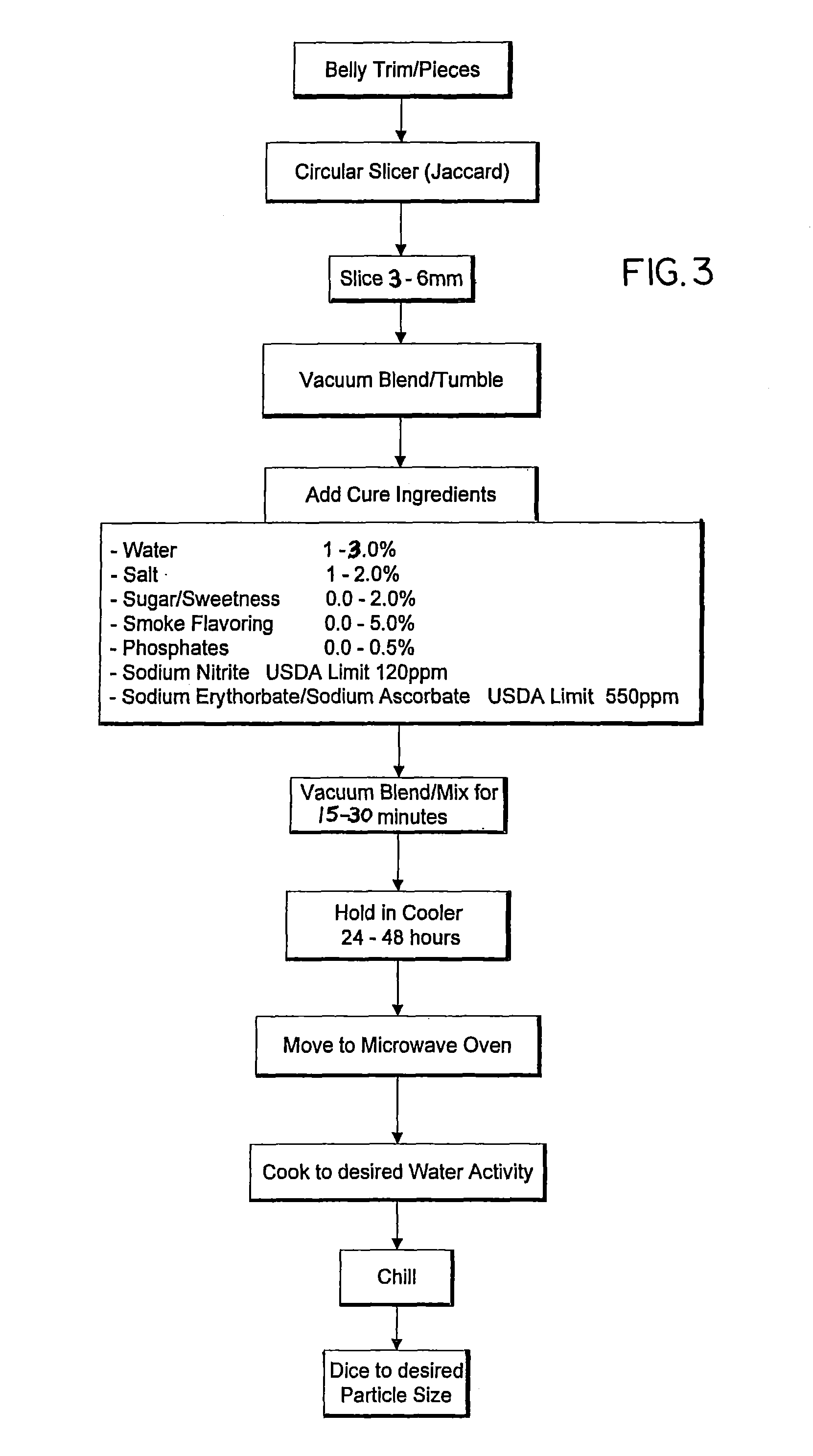

Method and apparatus for cooking meat

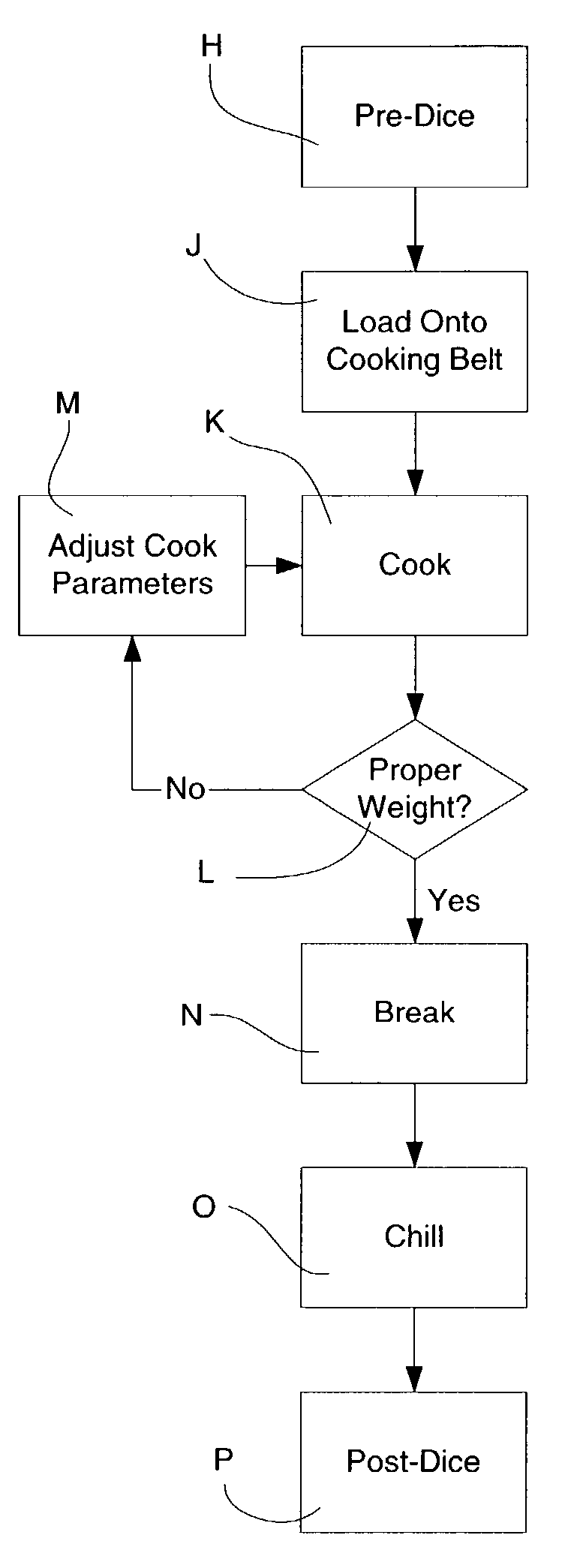

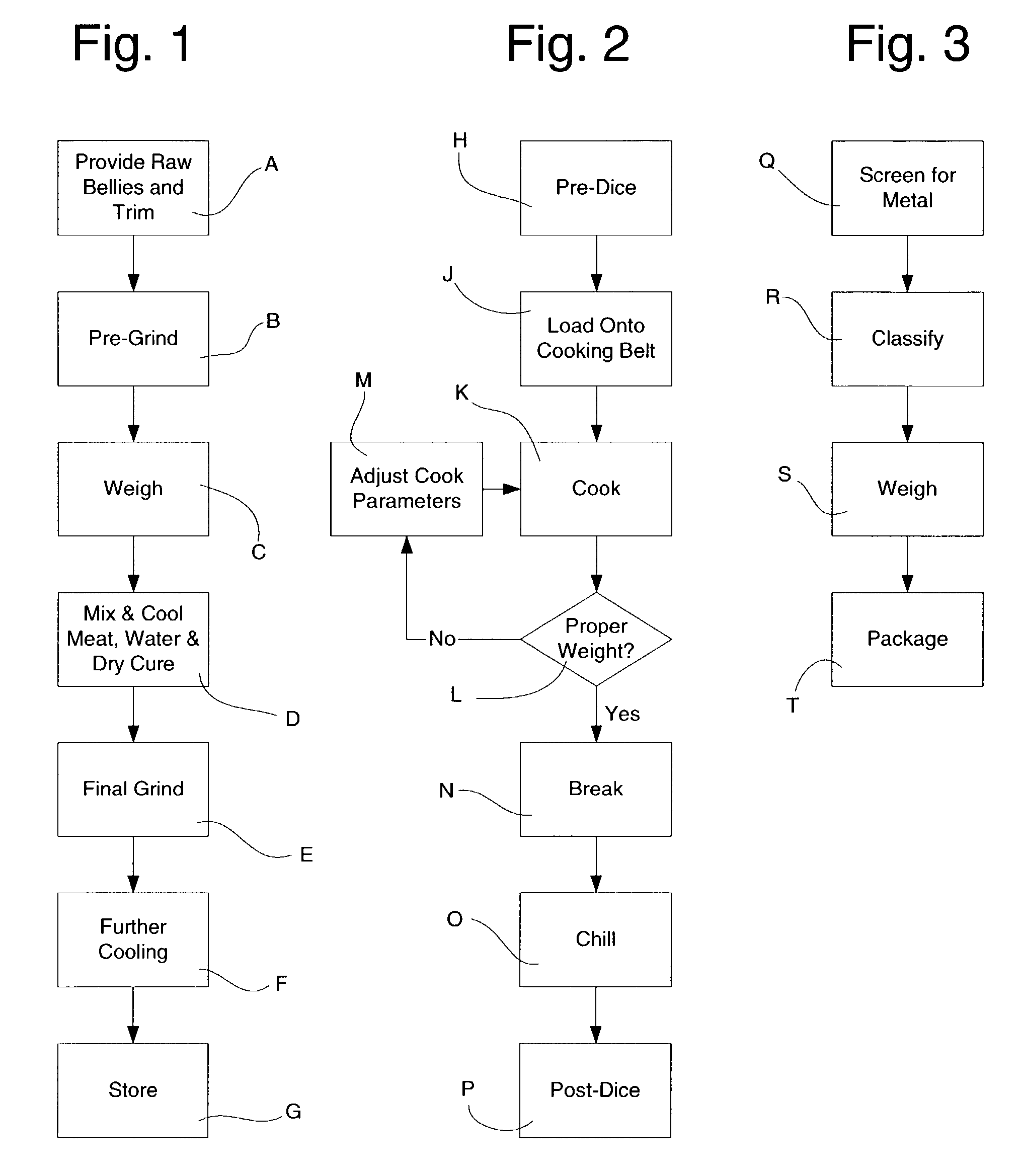

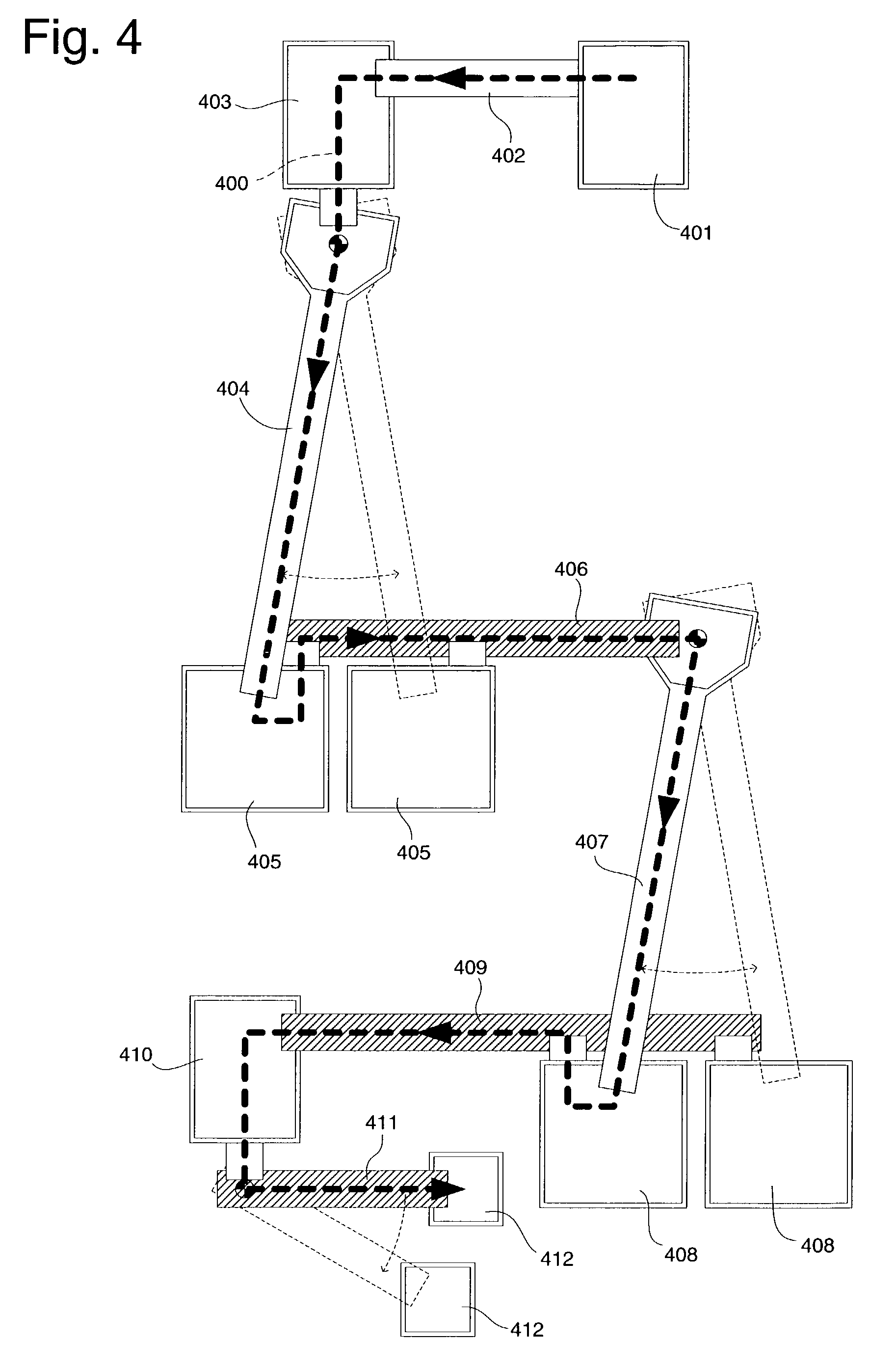

A method and apparatus for preparing cooked particulate meat products, such as bacon bits or other bacon seasonings and toppings. The raw meat is ground to a first size in a first grinder, mixing with dry cure and water to form a raw meat mixture, cooled and stored. The raw meat mixture is then diced to a second size in a first dicer, evenly spread onto a cooking belt, cooked in one or more continuous cooking ovens to form a cooked meat mixture and diced again to a third size in a second dicer.

Owner:SMITHFIELD PACKAGED MEATS CORP

Preparation method of solar cell back plate

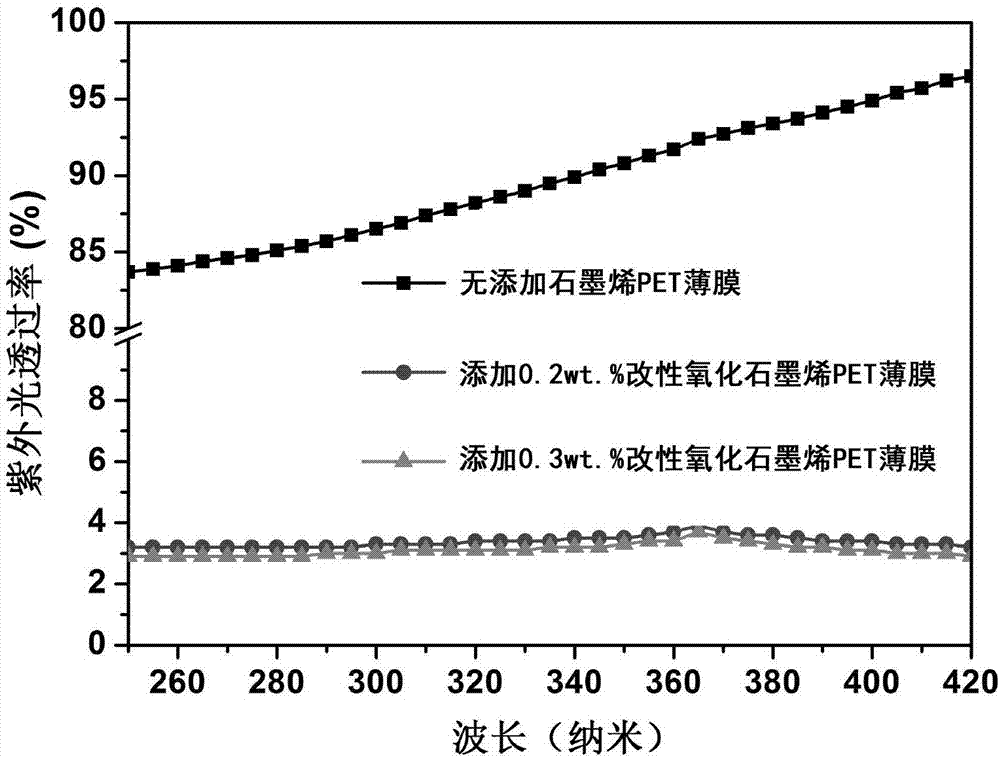

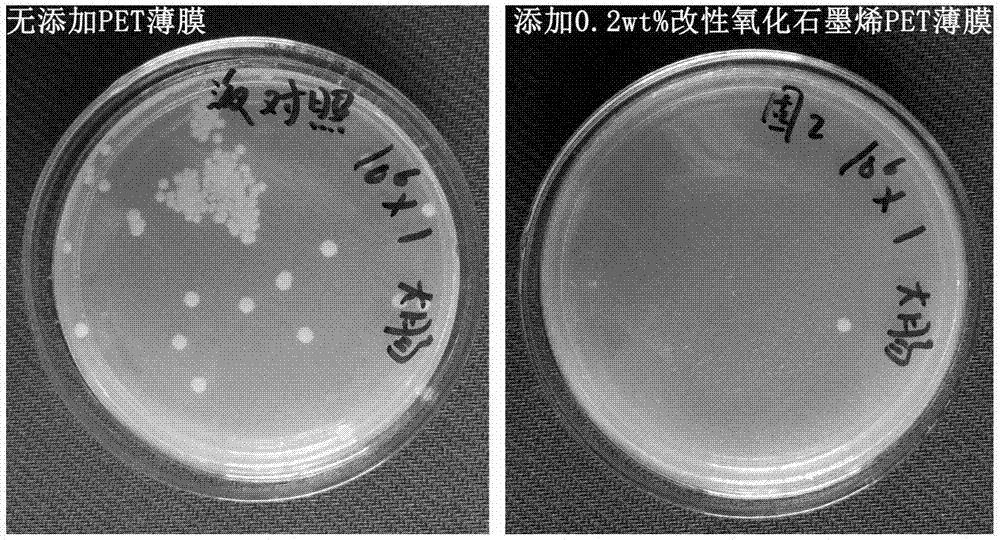

InactiveCN107230732AThermally stableSelf-cleaningPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a preparation method of a solar cell back plate. The method comprises the following steps of uniformly mixing a graphene filler and resin sections, performing mixing, extrusion, drum sizing and bidirectional stretching in sequence to obtain a solar cell back plate, carrying out the low-temperature plasma treatment on the surface of the solar cell back plate, coating the surface of the back plate of the solar cell by using a coating, and drying and solidifying to obtain the product. Compared with the same type of patents, through the grapheme modification of the PET slice, the invention can realize thermal stability, self-cleaning performance, anti-aging performance, gas / water resistance, and ultraviolet resistance of the PET substrate of the back plate of the solar cell.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

Method for preparing dry-cured goose through Lysostaphin co-fermentation of goose meat

The invention belongs to the field of the food processing technology and in particular relates to a method for preparing dry-cured goose through Lysostaphin co-fermentation of goose meat. The method comprises the following steps: I. curing goose meat preliminarily; II. inoculating, fermenting and airing; and III. packaging. According to the method for preparing dry-cured goose through Lysostaphin co-fermentation of goose meat, the defects that the existing goose meat is rough in meat quality and has poor mouthfeel and fragrance are overcome, the method disclosed by the invention has short fermentation period, and the prepared dry-cured goose has fine mouthfeel and is delicious in taste; and furthermore, the fermentation of the goose meat and airing are carried out simultaneously, the fermenting time and the airing time of the dry-cured goose are shortened, the goose meat has low oil oxidative rancidity and high protein decomposition in a low-temperature lysostaphin co-fermentation process; and besides, the lactobacillus fermentation quantity is low, the fermentation sour is reduced, the delicate flavor generated by amino acid is improved and the quality and the safety of the dry-cured goose product are improved.

Owner:CHONGQING QINGSHUIWAN FOOD

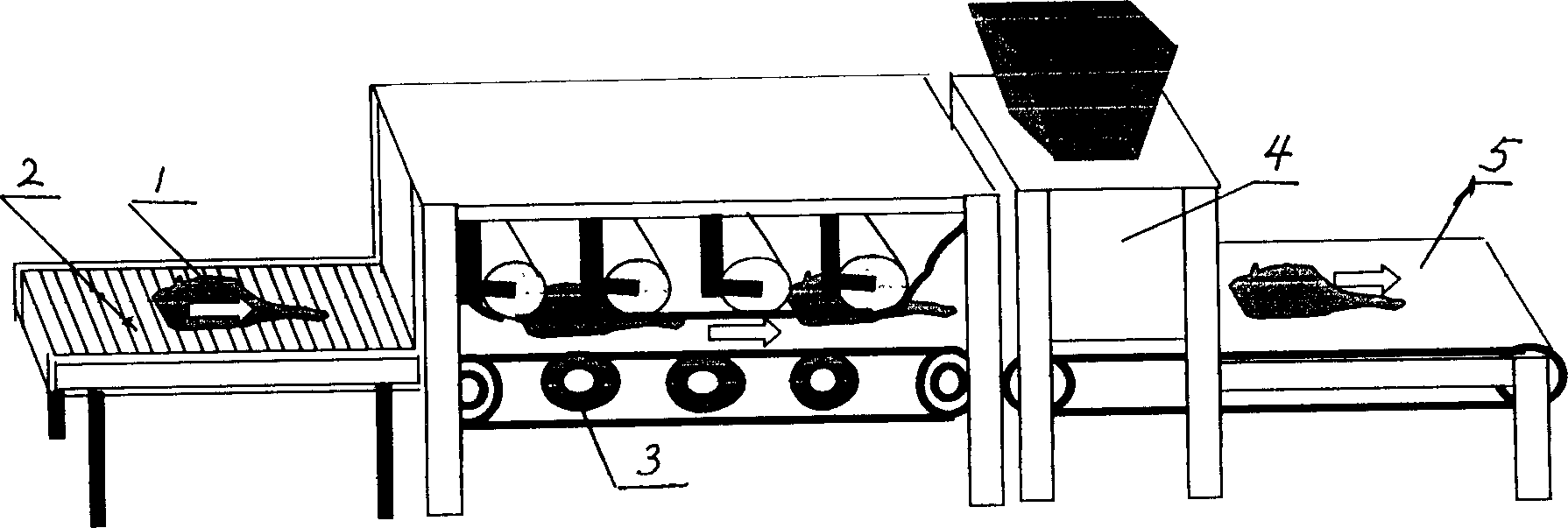

Curing and cleaning technology in the process of processing dry-cure ham

InactiveCN1524428AEffective regulationHigh degree of mechanizationMeat/fish preservation using liquidsElutionEngineering

The invention relates to a pickling and cleaning process in ham pickling procedure comprising the steps of, placing onto sprocket track for manual salt feeding onto the lateral position of the pig legs, rolling in rolling maching, automatically feeding into salt spraying apparatus for automatic salt addition, manual salt feeding, stacking and stewing, repeating the procedures for 3-4 times, feeding into a first cleaning pool for elution of surface coated salt, feeding into a second cleaning pool for removal of excess salt, water flush, and surface dewatering and weathering.

Owner:NANJING AGRICULTURAL UNIVERSITY

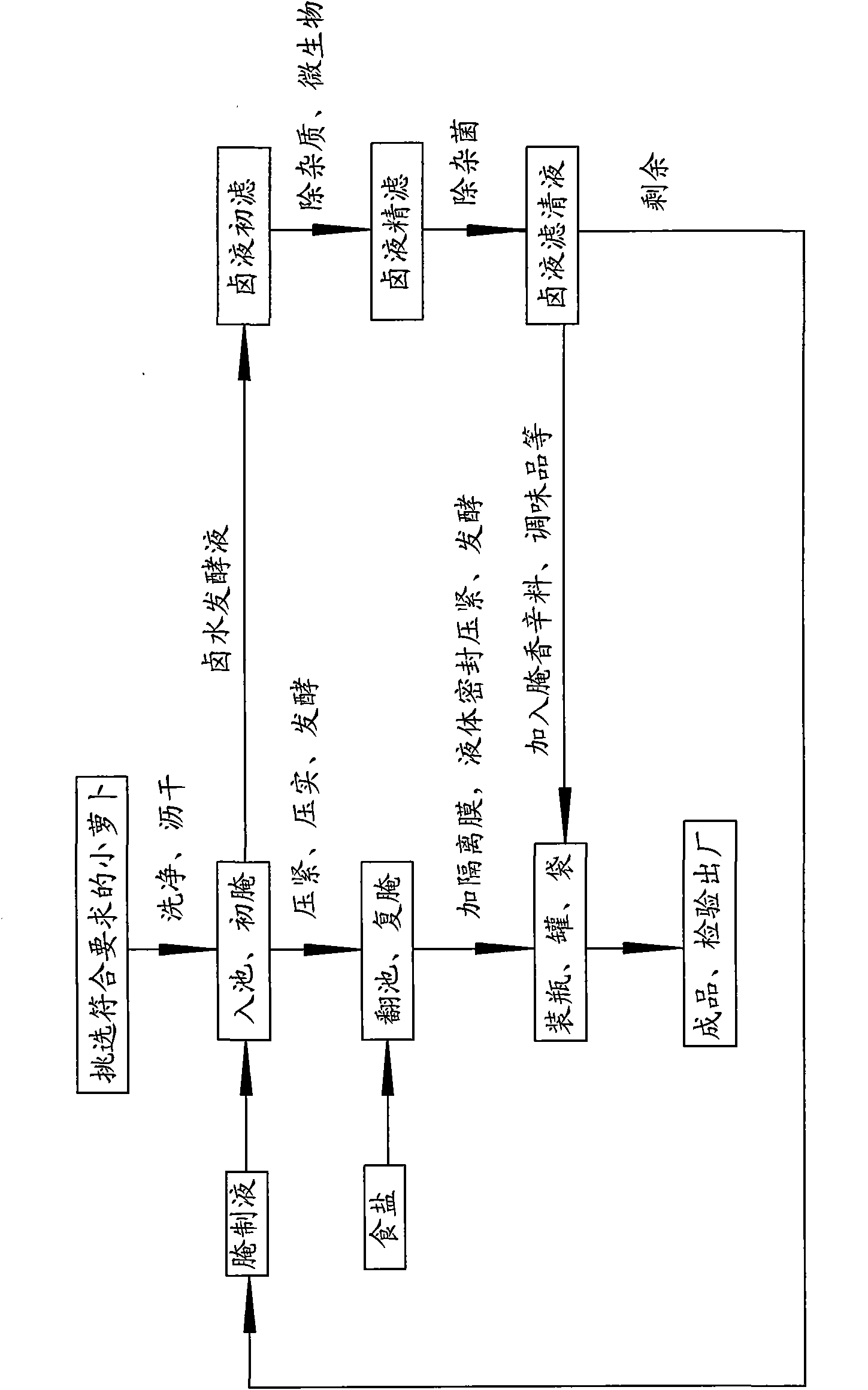

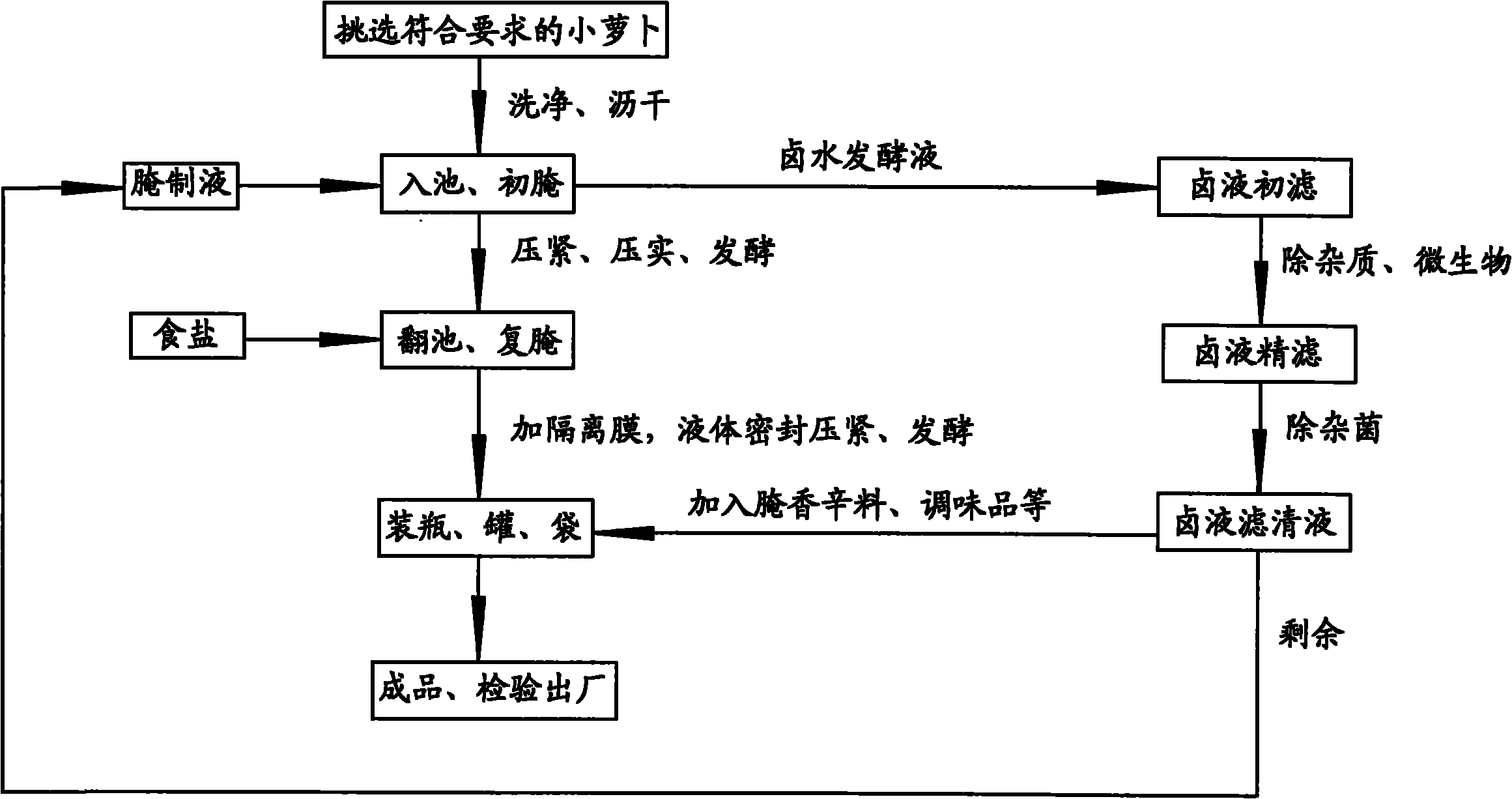

Bottled, canned or bagged salted and fermented radish with raw juice soup and preparation method thereof

InactiveCN102334664AKeep the natural flavorReduce dosageClimate change adaptationFood preparationFood flavorImpurity

The invention relates to bottled, canned or bagged salted and fermented radish with raw juice soup and a preparation method thereof, and the bottled, canned or bagged salted and fermented radish comprises radish, spices, seasonings, the soup, potassium sorbate or sodium benzoate and the like, wherein the soup is salt solution or saltwater brine filtered solution formed by filtering fermentation broth for salting and fermenting the radish and removing impurities and microbial thalli or mixed solution of the two. The preparation process is as follows: selecting the radish; performing low-salt welt salting; sealing and dry-salting; making the saltwater brine filtered solution; selecting, cutting and classifying; filling the saltwater brine filtered solution and the like; and sealing and packaging. Low-salinity salting solution is used for preliminary salting, thereby accelerating the fermentation speed and shortening the preliminary salting time; the salting solution is recycled as the saltwater brine filtered solution, thereby saving the using quantity of common salt and water; the re-salting adopts the dry-salting way, a plastic thin film is further used for isolating from air, and liquid is further used for sealing and compacting, thereby completing isolating the radish from the air and being capable of salting the radish for a long time without deterioration; and the saltwater brine filtered solution is used for replacing the seasoning soup in a finished product, thereby not only keeping the natural flavor of the salted radish, but also reducing the cost and reducing the environmental pollution caused by wastewater discharge.

Owner:兰溪市桃花雨粮蔬专业合作社

Processing method for producing cooked dry-cured geese

The invention discloses a processing method for producing cooked dry-cured geese and belongs to the field of food processing. The method comprises the steps of: killing geese, removing blood and eviscerating the geese to obtain goose bodies; injecting marinating juice into parts of the goose with more muscles and steeping the geese into the marinating juice for some time; after taking out the goose bodies, spreading the salting spice on the inner and outer surfaces of the geese bodies; drying in air; dry-steaming the watered dried goose bodies for 30-60min; cooling naturally; and, sterilizing and packing. The method provided by the invention combines slating with marinating and realizes preparation of cooked food by dry steaming. The cooked dried geese produced by the processing method provided by the invention have special flavor, dense, fresh and tender meat. The taste of the cooked dry-cured geese is mild relative to the existing uncooked dry-cured geese. The cooked dry-cured geese are eaten directly or cooked with other food, and thus the eating manner of the dry-cured geese is expanded.

Owner:句容市红掌食品有限公司

Method for preparing low-salt non-saltpetre dry cured goose

InactiveCN101243885ATaste delicate and tightReduce saltFood preparationMeat/fish preservation by dryingFlavorPre treatment

The invention relates to a low-salt nitrite free dry cured goose making method, which adopts the technical proposal of sorting and pretreating, injecting, immersion, tenderization, drying, blanching and secondary clearing, boiling, precooling and packaging and sterilizing; which is characterized in that the making method bases on meat texture theory, microbiology and edible enzyme technique, so that the formula and process design is scientific. The method has the advantages of modern processing method, low salt, tender and compact taste, nitrite free and traditional flavor.

Owner:吴松青

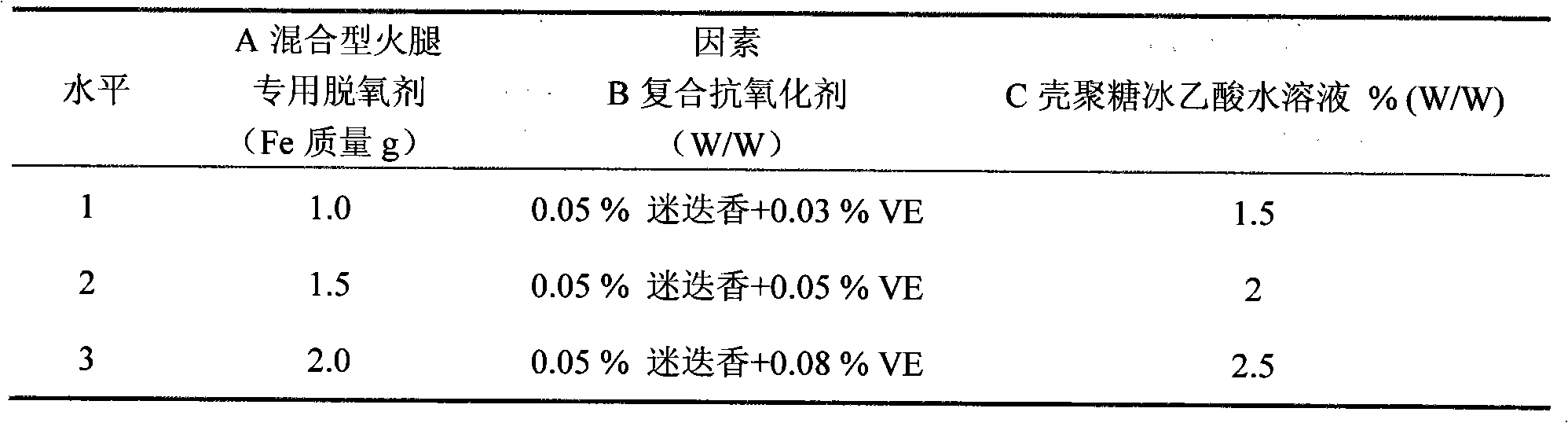

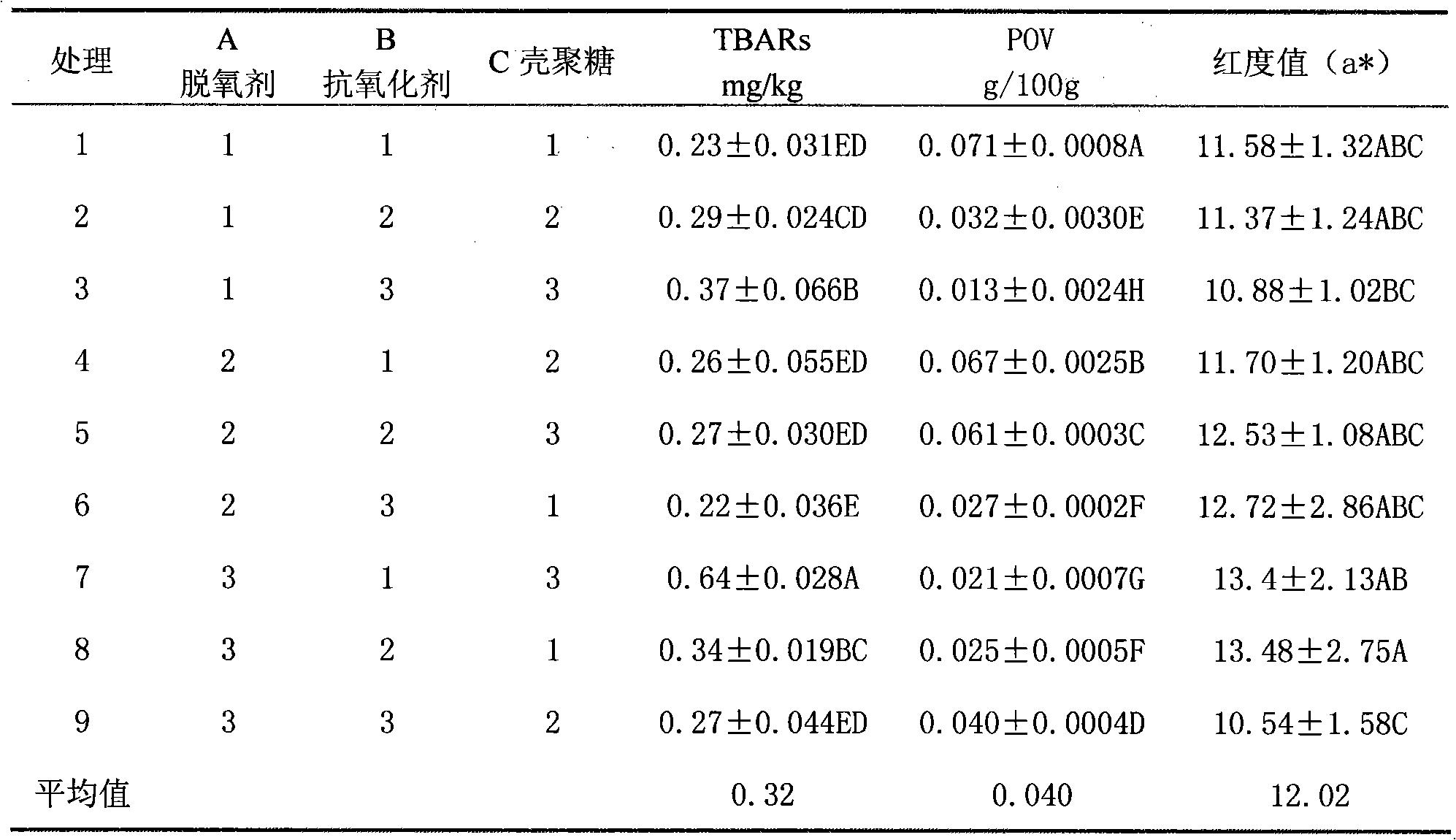

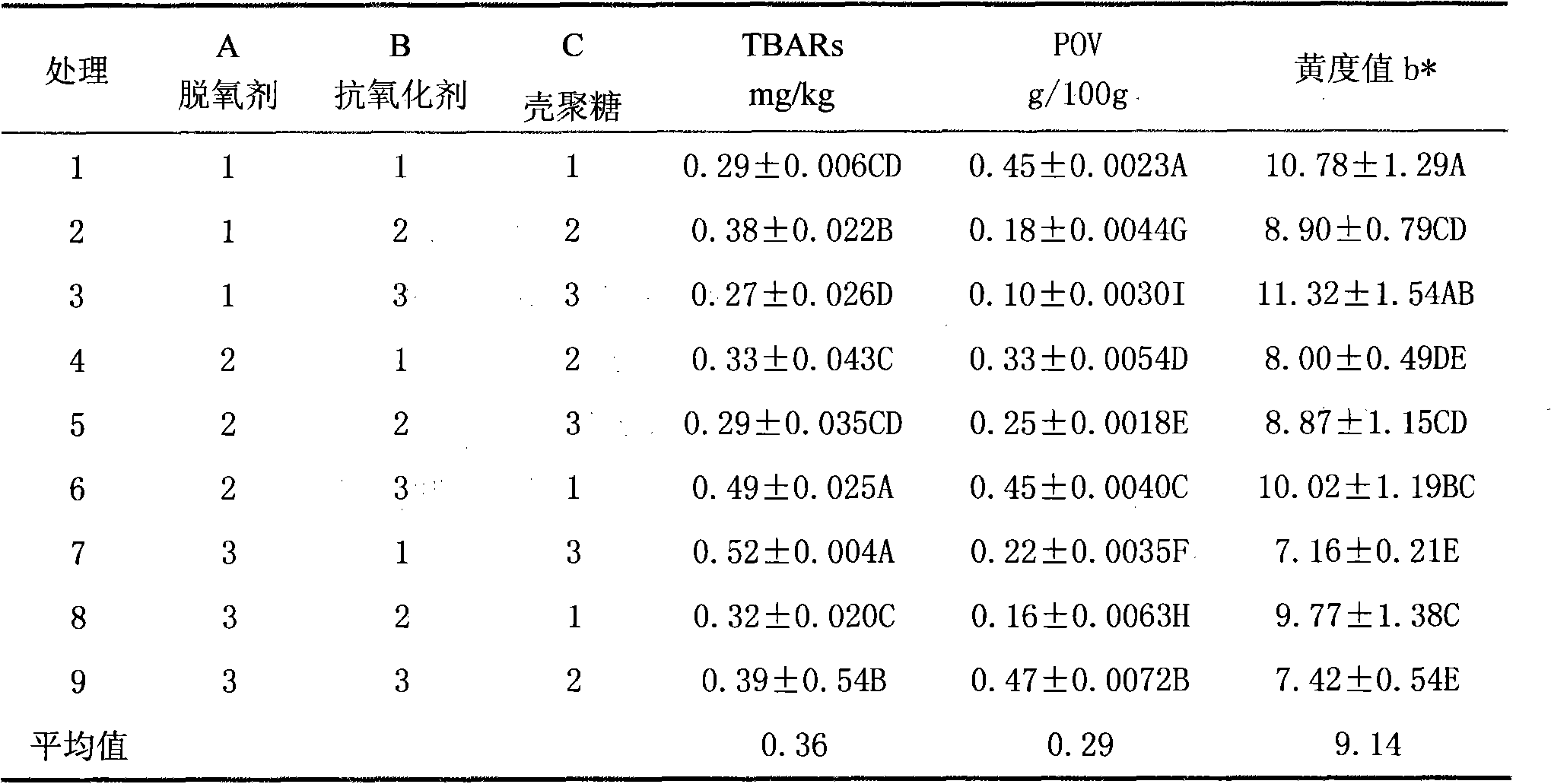

Method for comprehensively packaging and refreshing chopped dry-cured ham in anti-oxidation mode

ActiveCN101803629AImprove antioxidant capacityImprove barrier propertiesMeat/fish preservation using chemicalsPeroxideDry cured

The invention relates to a method for comprehensively packaging and refreshing chopped dry-cured ham in an anti-oxidation mode and belongs to the field of food packaging. The method comprises the following steps: uniformly spraying a composite antioxidant consisting of rosemary and VE on the surface of chopped ham; coating aqueous solution of chitosan glacial acetic acid on the chopped ham; drying the ham and forming a uniform and dense protective film on the surface of the ham; and putting the ham into a small mixed deoxidant bag special for the ham which is formed by mixing and compounding a main agent consisting of reduced Fe powder and Na2S2O4 and an assistant consisting of active carbon and NaCl, and packaging the ham in a vacuum state. When the chopped ham is stored at normal temperature for six months, the TBARs and peroxide values of chopped ham muscles and subcutaneous fat are obviously reduced, the colors of fresh chopped ham muscles and fat are well kept, the oxidation degree of ham fat is remarkably reduced, the requirements on the storage of vacuum packaged chopped ham and anti-oxidation refreshment in circulation are met, and the circulation storage and shelf life of the ham are effectively prolonged.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

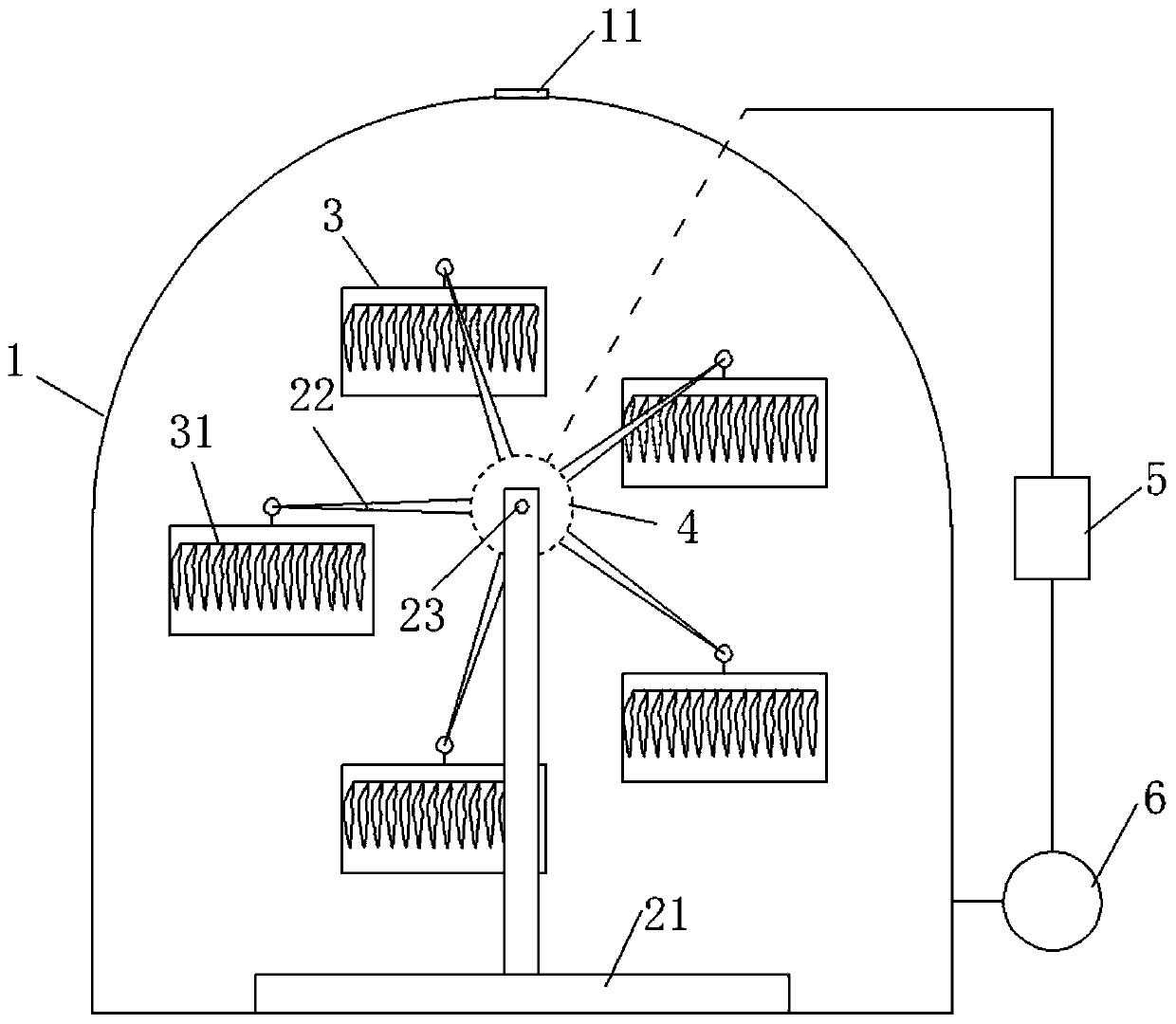

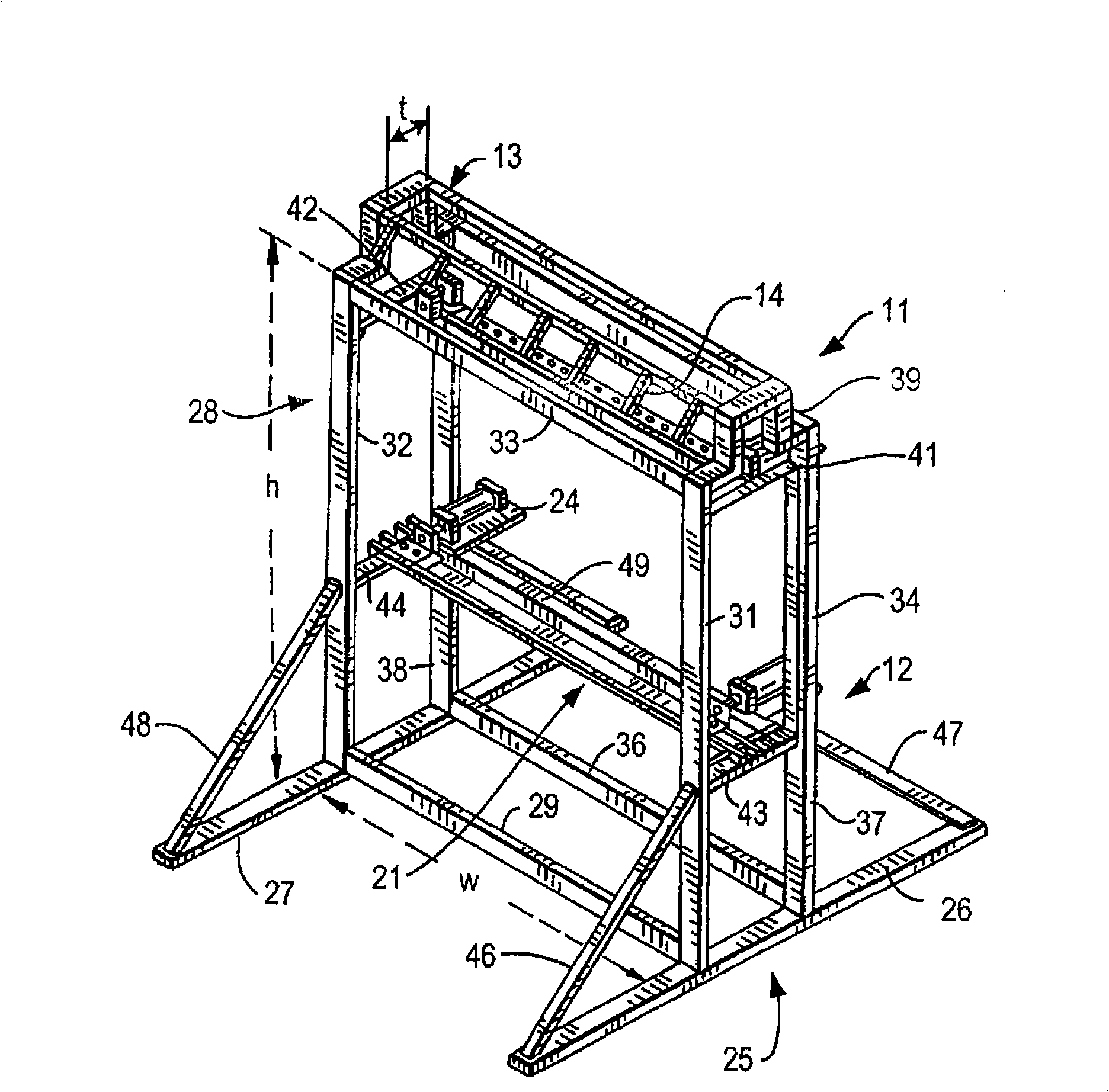

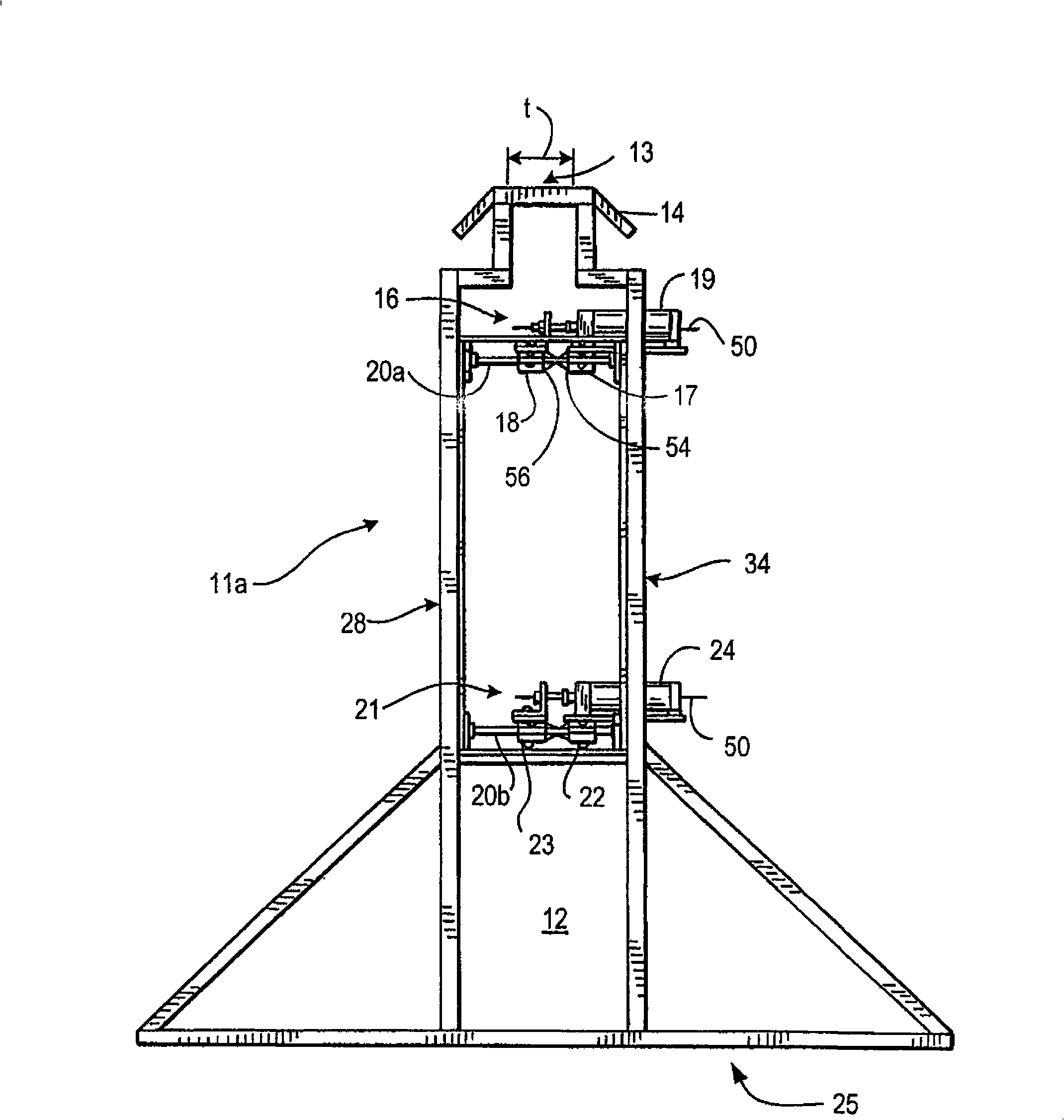

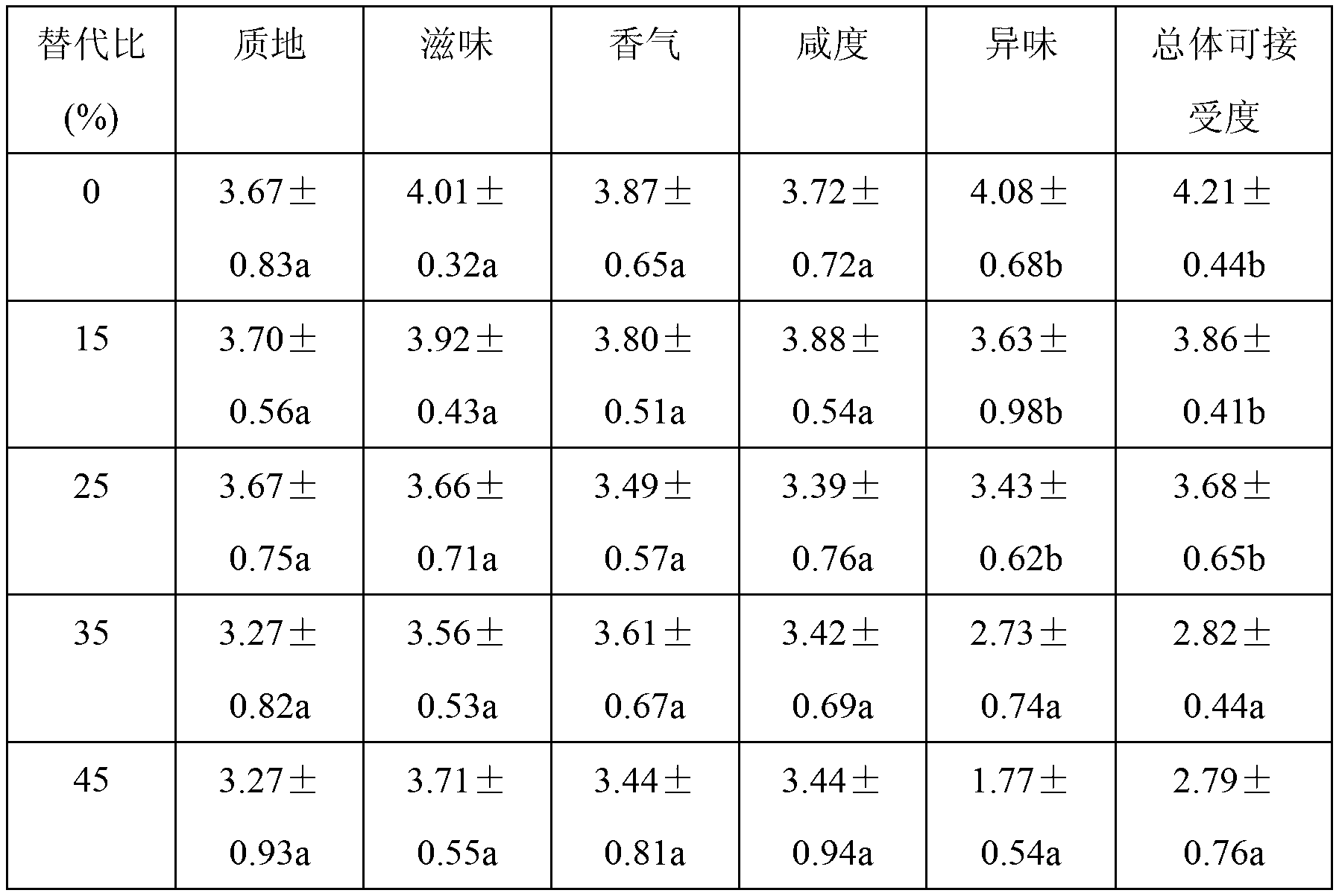

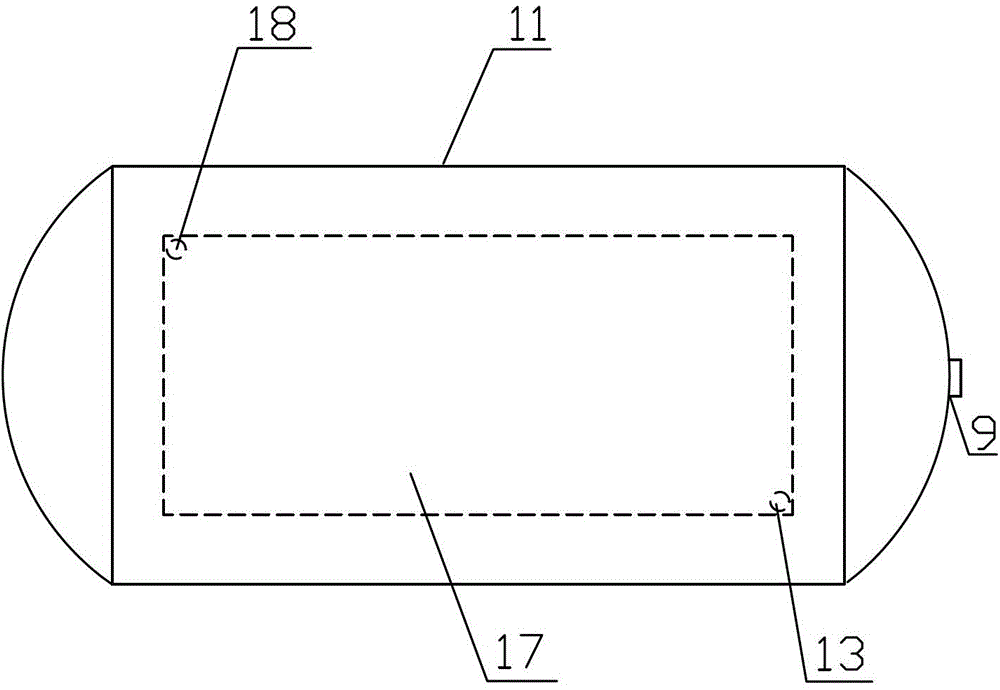

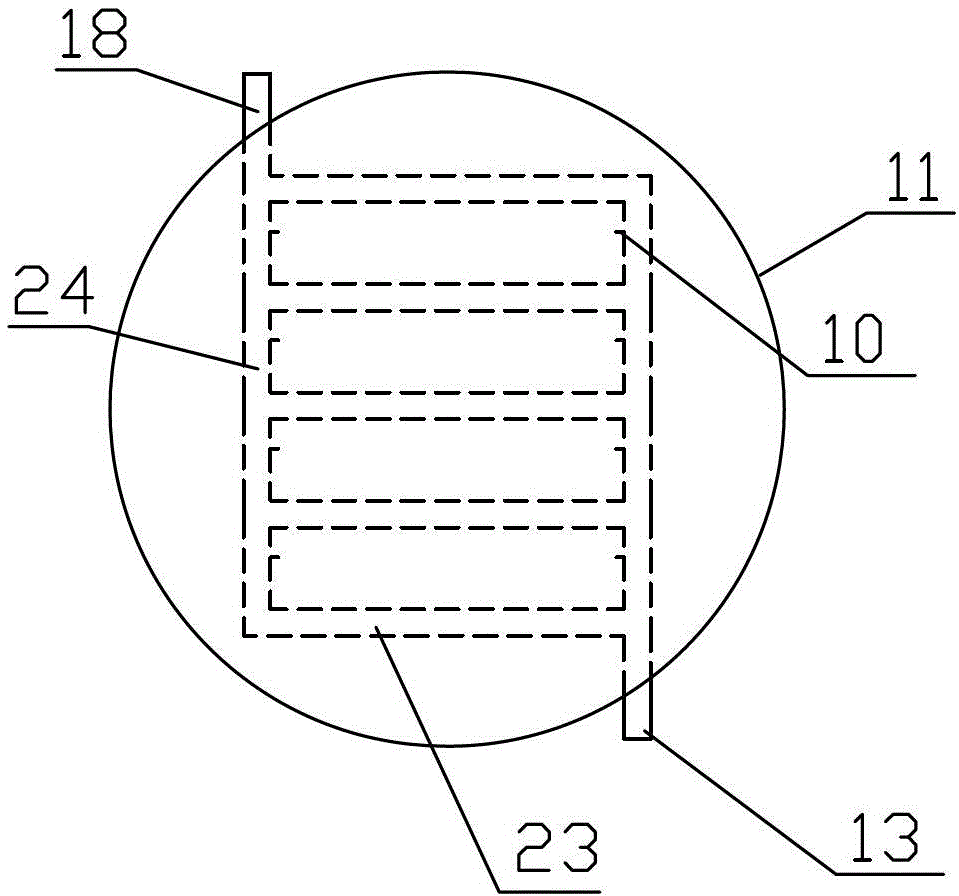

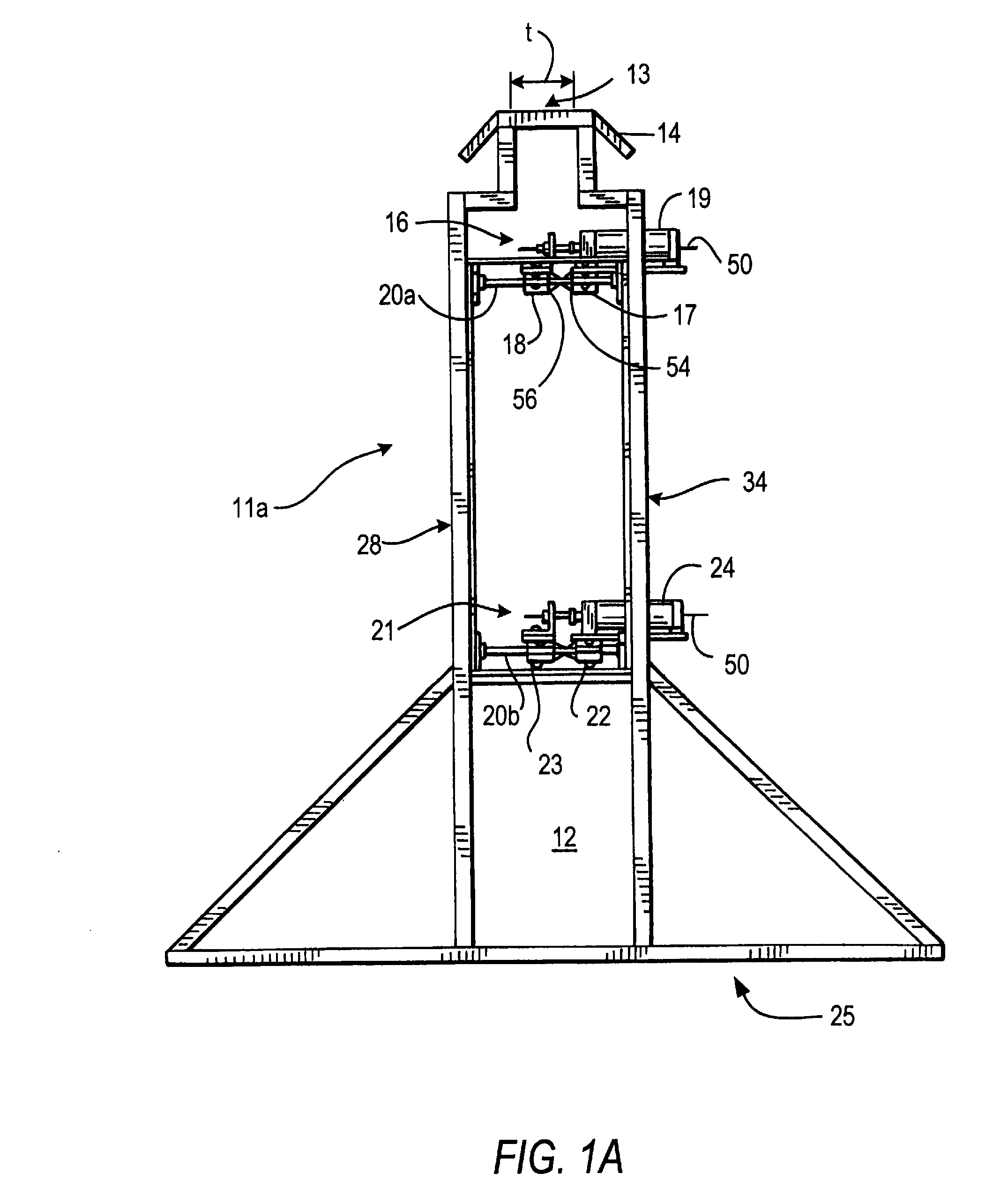

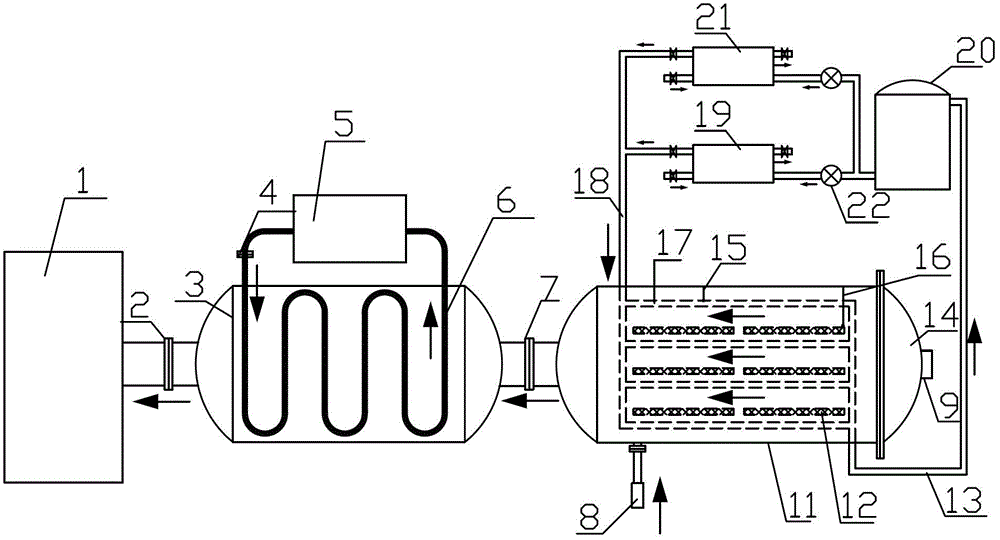

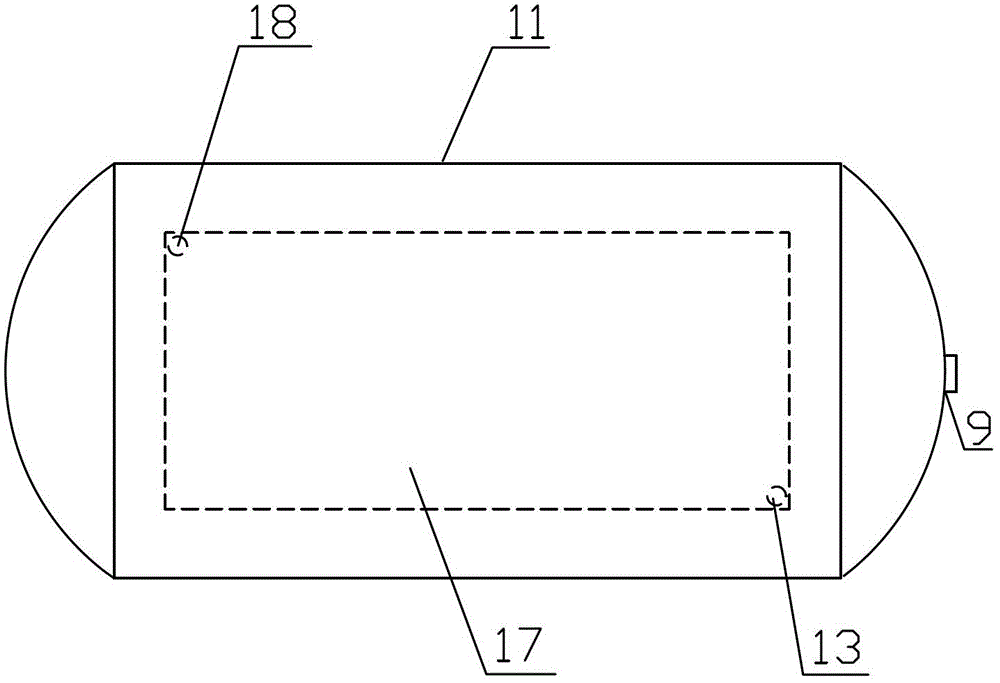

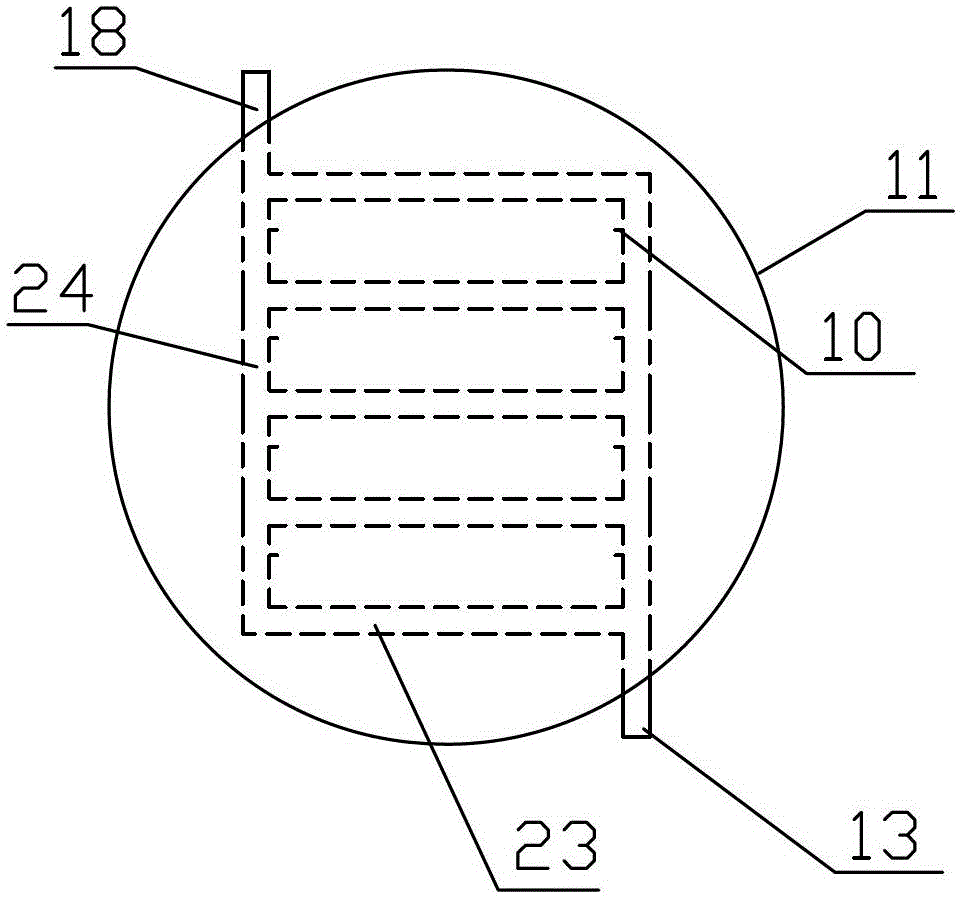

Rotating type hanging and drying curing barn

ActiveCN110542287ASame processing conditionsQuality improvementTobacco preparationBioreactor/fermenter combinationsVertical planeEngineering

The invention discloses a rotating type hanging and drying curing barn. The rotating type hanging and drying curing barn comprises a heat source, a circulating fan and a drying room. The rotating typehanging and drying curing barn is characterized in that a vertical rotating frame is arranged in the drying room and comprises a supporting base and rotating arms arranged on the supporting base, therotating arms can do circular motion on a vertical plane around a rotating shaft at the top of the supporting base, and a hanging bin is arranged at the free end of each rotating arm. Compared with the prior art, the rotating type hanging and drying curing bran has the beneficial effects that the high-humidity environment in the fermentation process can be ensured, meanwhile, the processing conditions of all the processed materials are the same, rich experience is not needed, replication and large-scale production are facilitated, and the quality of the processed products is stable.

Owner:绍兴柯桥瑞策纺织有限公司

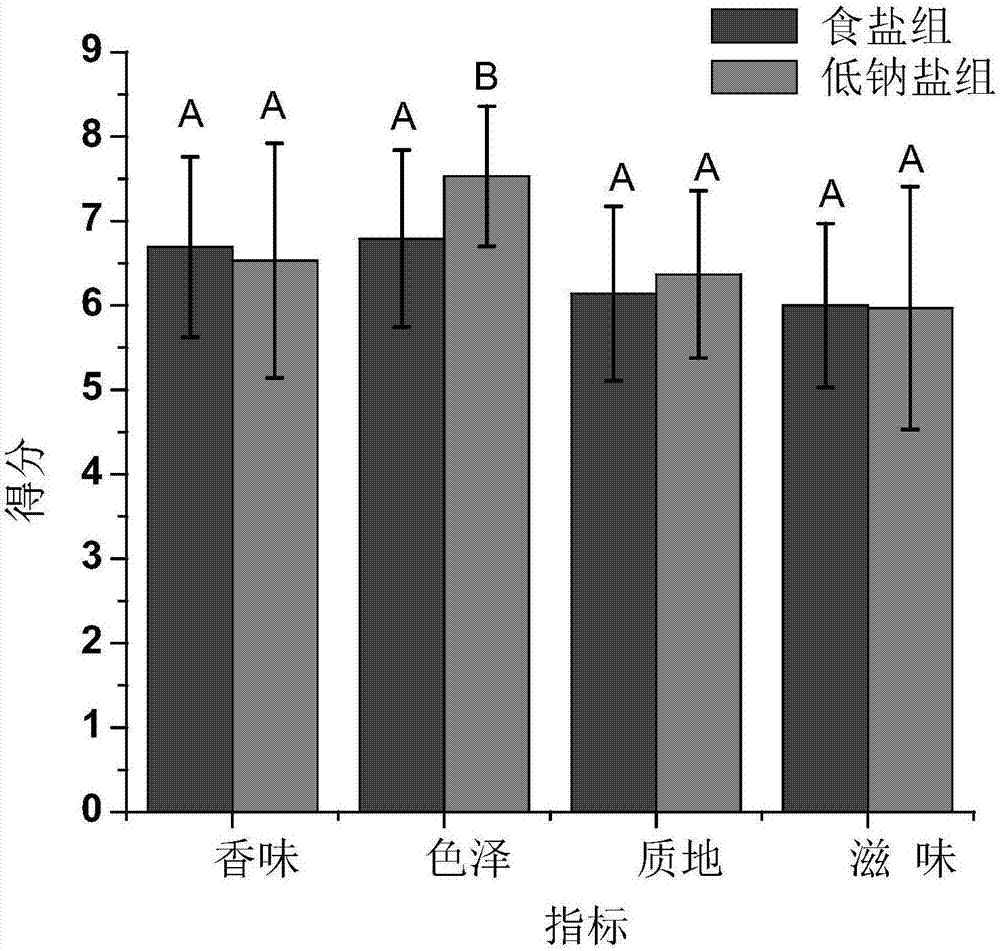

Processing method of quickly-ripe low-sodium-salt dry-cured ham

The invention discloses a processing method of a quickly-ripe low-sodium-salt dry-cured ham. The processing method comprises the following steps of (1) selecting raw materials; (2) performing trimming; (3) performing pickling; (4) performing hanging and performing cleaning; (5) performing low-temperature dehydration; and (6) performing fermentation: enabling dehydrated ham to be sequentially subjected to a low-temperature fermentation stage, a medium-temperature fermentation stage, a medium and high temperature fermentation stage and a high-temperature fermentation stage. Compared with the hamcured with conventional sodium salt or a 30% sodium salt replacement in a conventional report, the quickly-ripe low-sodium-salt dry-cured ham has the advantage that the dosage of the sodium salt is substantially reduced; and quick ripening is performed by a modern technology, so that the processing time of the ham is shortened to 5-6 months from 10-12 months consumed by a conventional dry-cured ham; and in the whole processing course, the temperature and the humidity can be automatically adjusted, and the quickly-ripe low-sodium-salt dry-cured ham can be produced all the year round. Finishedproducts of the quickly-ripe low-sodium-salt dry-cured ham are free from odorous and bad situations and homogeneous in quality, good flavor is kept, besides, the permeation rate of salinity is increased, the content of the sodium salt is notably reduced, the processing cycle is notably shortened, the quickly-ripe low-sodium-salt dry-cured ham meets the demands of consumers at present, the industrialization and the large scale of the dry-cured ham are also facilitated, and the industrialized process of conventional meat products is promoted.

Owner:NANJING AGRICULTURAL UNIVERSITY

Process for producing fired dry-cured beef

The invention discloses a process for producing fired dry-cured beef. The fired dry-cured beef is prepared from 1,000 parts of fresh cattle meat, 10 to 12 parts of salt, 1 to 2 parts of monosodium glutamate, 2 to 3 parts of pricklyash peel and 10 to 12 parts of red chili powder. The process comprises the following steps of: removing sundries from the fresh cattle meat to leave pure meat, shredding and salting; roasting the salted cattle meat shreds by using coke till thorough cooking; and mashing the roasted cattle meat to the thickness of 0.8 to 1 centimeter, cooling to normal temperature, performing quantitative packing, and thus obtaining a finished product. The produced fired dry-cured beef has the characteristics of high nutritional value, spicy and delicious taste, pure taste, freshness, mellowness, thick aftertaste, high protein content, low fat content and the like; and the dry-cured beef has unique fragrance, the protein content is 57.5 percent, and the fat content is 28.4 percent.

Owner:朱继云

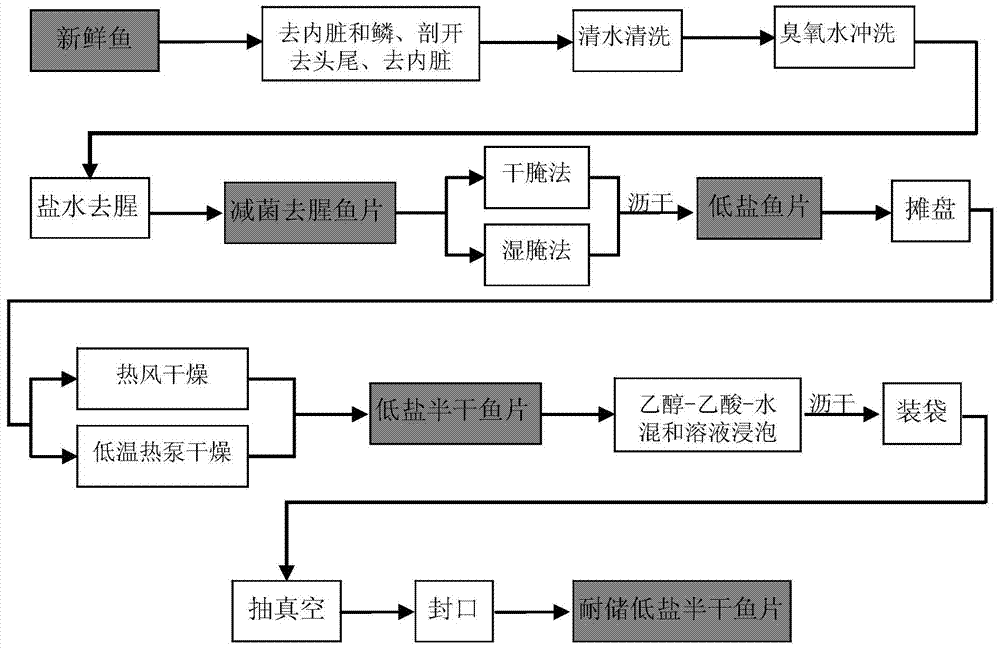

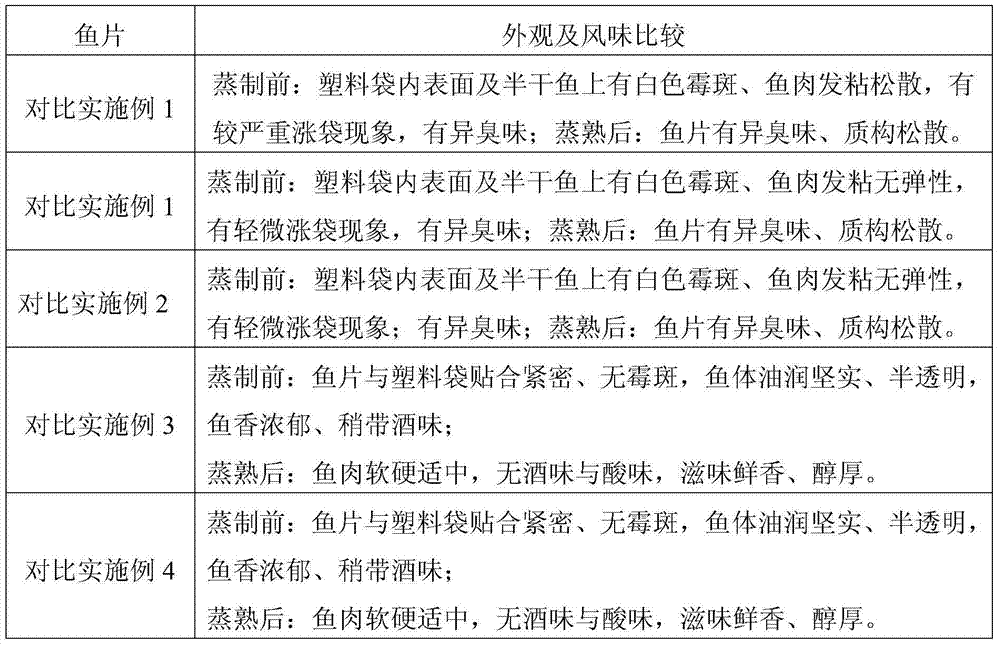

Storable low-salt half-dry fish fillet and processing method and application thereof

ActiveCN103931737AEasy to operateLow costFood processingMeat/fish preservation using chemicalsSteepingDry cured

The invention discloses a storable low-salt half-dry fish fillet and a processing method and application thereof. The method comprises the following steps: removing internal organs and scales of a fish, splitting along the back or the abdomen, opening and pressing to form the fish fillet which is nearly symmetrical except for the tail part; cleaning by clean water, and flushing by 2-10 ppm of ozone water, and then cleaning by saline water for removing fishy smell so as to obtain the fish fillet from which bacteria are reduced and fishy smell are removed; obtaining the low-salt fish fillet by a dry-cure process or a wet-cure process; drying by a low-temperature heat pump drying technology or a hot air drying technology; steeping the dried fish fillet for 0.5-1.0 min by an ethanol-acetic acid-water mixed solution; draining off excessive steeping liquor; packaging the tilapia fish fillet into a plastic bag, vacuumizing and enveloping to obtain the storable low-salt half-dry fish fillet. The fish fillet is lubricating in fish body, abundant in elasticity, and mellow and fragrant in taste. The processing method disclosed by the invention is simple to operate, low in cost, safe and sanitary, and can be applied to processing of fishes.

Owner:JINAN UNIVERSITY

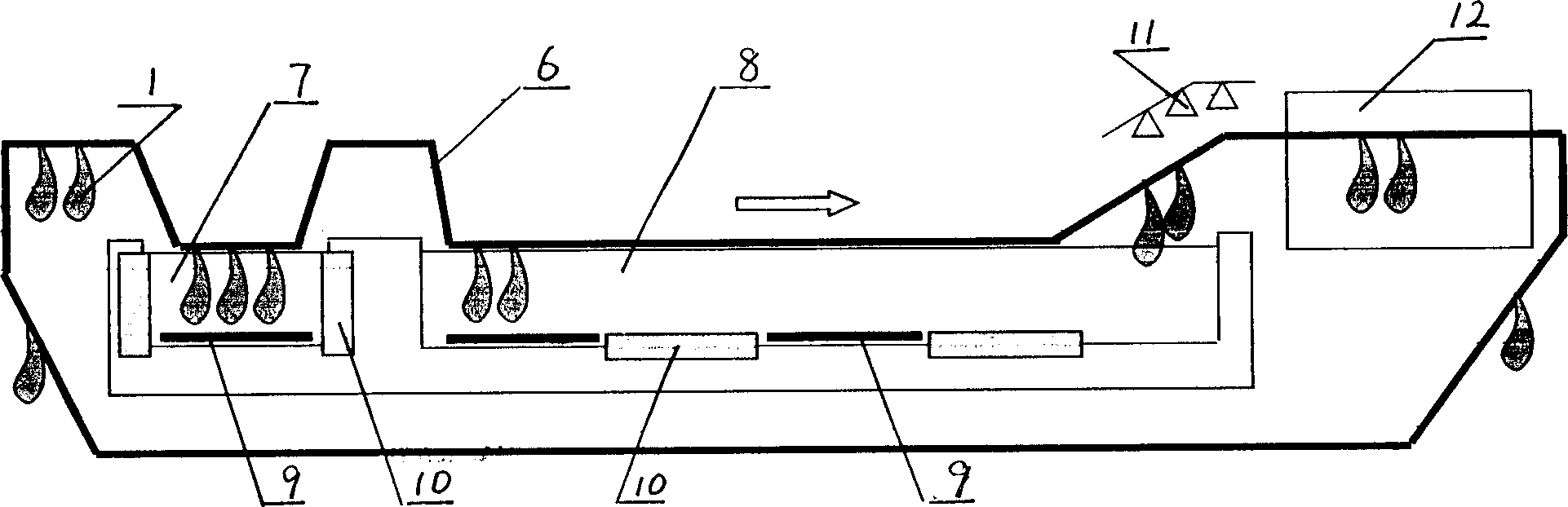

Method and Apparatus for Producing Cooked Bacon Using Starter Cultures

A method for preparing cooked particulate meat products using a starter culture, such as bacon bits or other bacon seasonings and toppings. The raw meat is ground to a first size in a first grinder, mixed with dry cure which includes a starter culture to form a raw meat mixture, cooled, and stored long enough to allow for partial fermentation. The raw meat mixture is then ground and diced to a second size in a first dicer, evenly spread onto a cooking belt, cooked in one or more continuous cooking ovens to form a cooked meat mixture and diced again to a third size in a second dicer.

Owner:PATRICK CUDAHY

A preparation method of dual enzyme hydrolysis ham essence base material and products produced thereby

InactiveCN101156676ASimplify the steps of eating methodIncrease varietyFood preparationWater bathsSide effect

The invention relates to a ham flavor base material preparation method and the product thereof, and belongs to the food processing technical field. A dry-cured ham preserved for a year and a half is ground by a meat grinder, and water is added, under the condition of ice bath, the ham is ground for 1 min by a high-speed organization bruiser at the speed of 6500 rpm, the pH value is adjusted to 6.48, then compound flavor protease and complex protease are added, the mixture is put in water with 44 DEG C for water bath for an hour, and is put in water with 100 DEG C for enzyme activity elimination for 10 min, and finally the process can be completed by filtering with a 40-mesh screen. The invention can produce more ham flavor base materials with less top-grade hams; and the steps of the traditional ham eating method is simplified; the ingredients of the product is safe, and has no toxic effect as well as side effect, and can provide upscale flavor for the other snack foods using savory flavor, thereby the type of the snack food is increased, as well as the grade is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

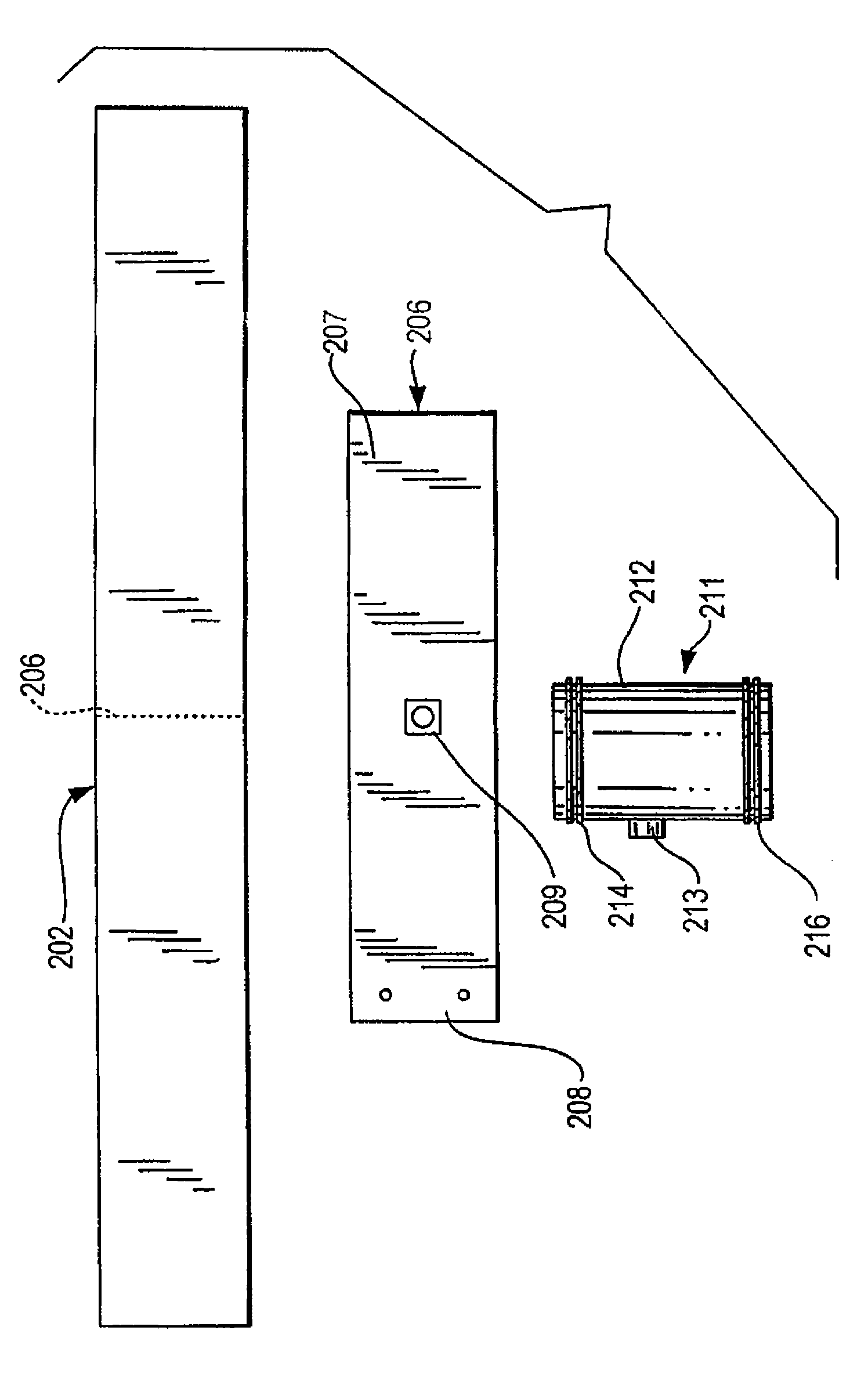

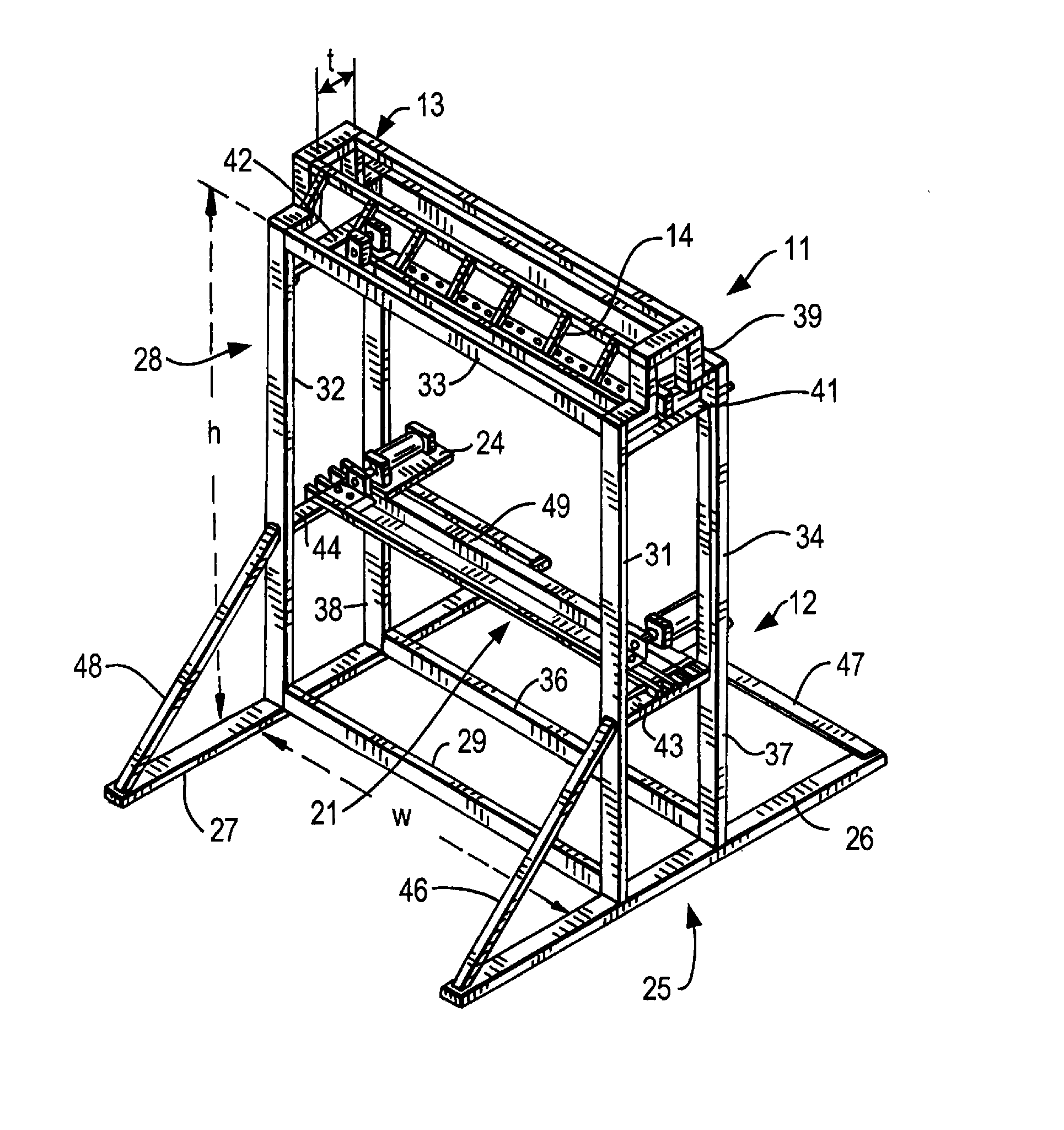

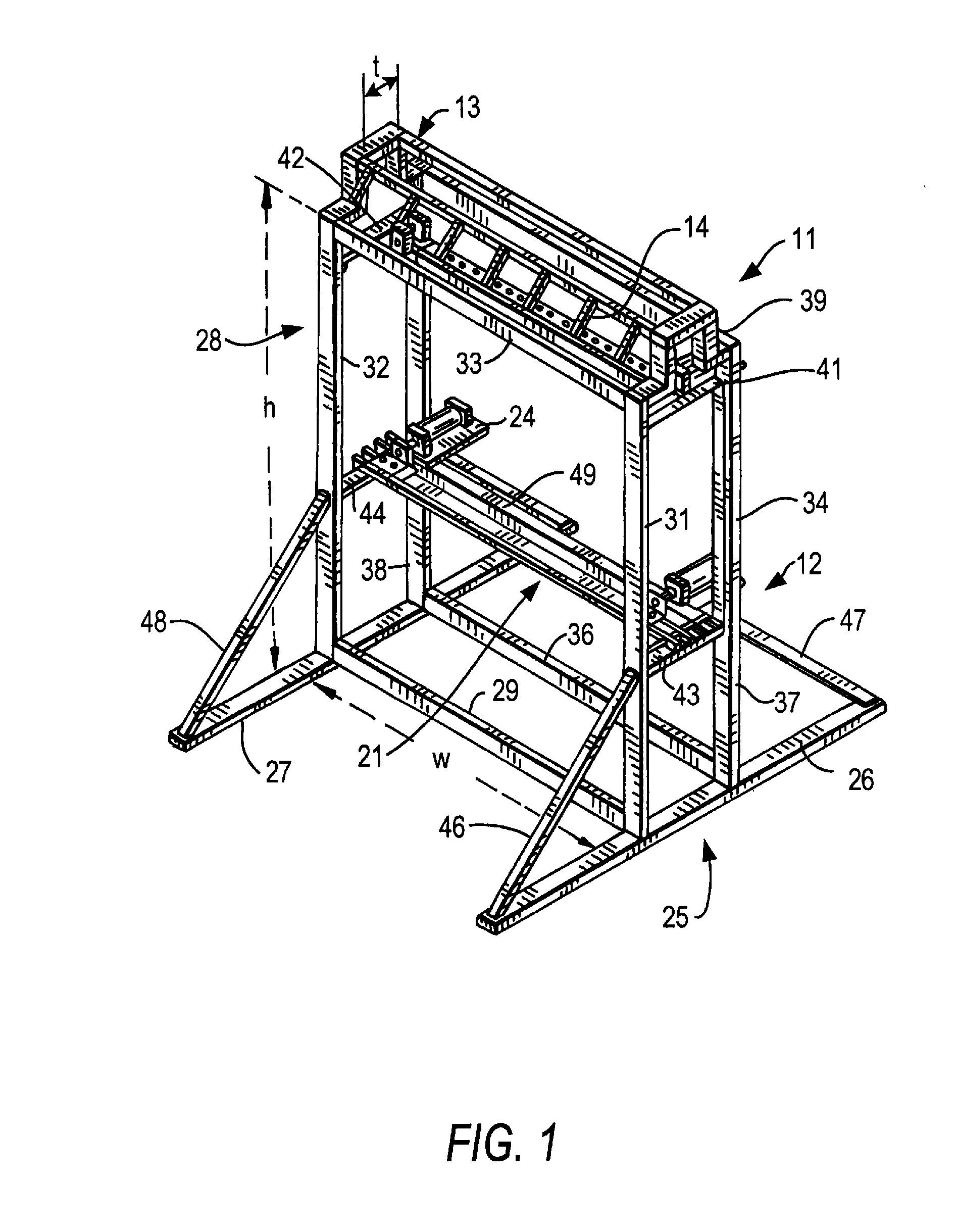

Reusable inversion sleeve assembly for inversion of cured in place liners

Installation of a flexible cured in place liner by inverting the liner utilizing an inversion sleeve assembly with an installation apparatus having at least one selectively operable rigid gland. The sleeve assembly includes a sleeve portion of an absorbable material secured in an apparatus with an inversion boot fitted at the distal end with an inlet port for inversion and / or curing fluid. The sleeve assembly and apparatus are particularly well suited for inverting with air and curing the liner with steam introduced through a perforated lay flat hose using an apparatus with two glands. The installation sleeve is the same dimension as the liner to be installed and is reusable thereby substantially reducing the set up time to install using the dual gland apparatus. Preferably, the flexible sleeve is a length of dry cured in place liner inverted on to itself to expose two impregnable surfaces. The sleeve may have a built in fluid inlet port for use with a dual gland apparatus.

Owner:INA ACQUISITION

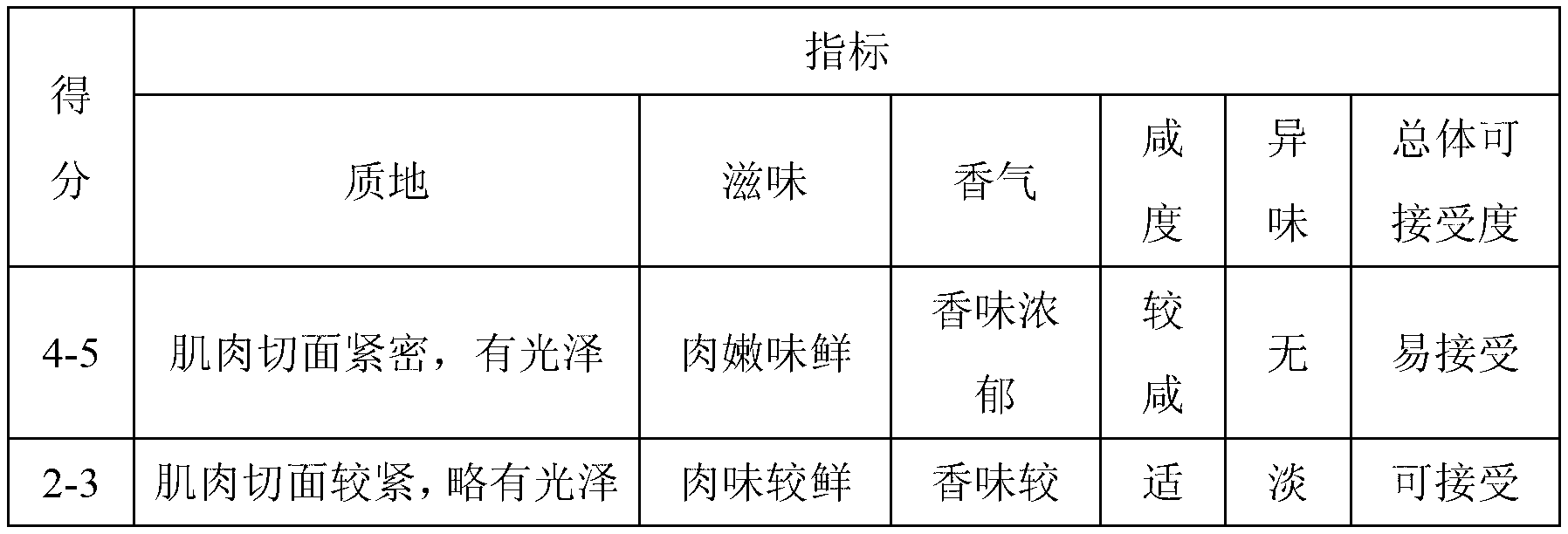

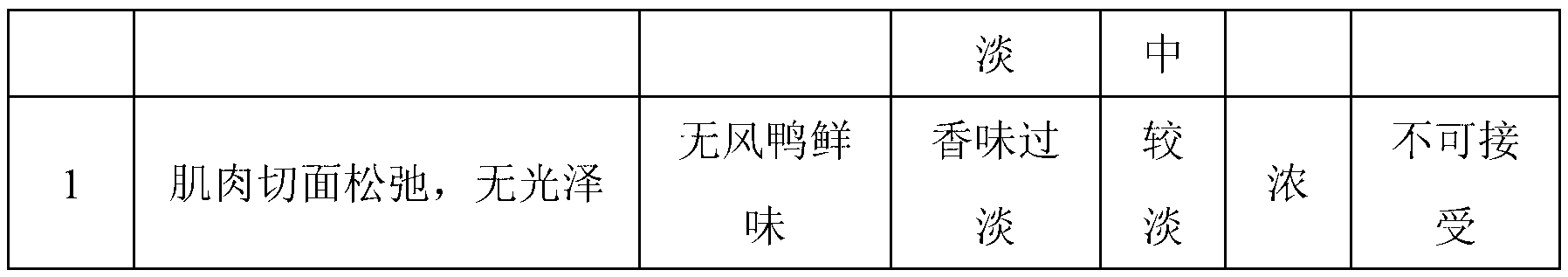

Mixed salt for preserving meat product and application thereof

ActiveCN103251026AStrong fragranceReduce contentMeat/fish preservationFood preparationCALCIUM LACTOBIONATESodium salt

The invention discloses a mixed salt for preserving a meat product and application thereof. The mixed salt is composed of potassium chloride, calcium chloride and calcium lactate. During preserving, the concentration of potassium chloride is 0.34 to 0.51 mol / L, the concentration of calcium chloride is 0.17 to 0.31 mol / L, and the concentration of calcium lactate is 0.17 to 0.31 mol / L. According to the invention, potassium chloride, calcium chloride and calcium lactate in fixed proportions are mixed to replace sodium chloride in traditional preserving liquid for dry-cured duck, so the content of a sodium salt in a dry-cured duck product is substantially reduced, unique sensory characteristics of preserved products are not changed, and the products are allowed to have the characteristics of rich fragrance, tender meat, fresh taste, a compact muscle section and luster; and the mixed salt can be extensively used for processing of food like the dry-cured duck, dry-cured chicken, dry-cured goose and preserved meat.

Owner:南京黄教授食品科技有限公司

Processing method for vacuum frozen puffed beef cube

InactiveCN103141858AIncrease added valueReduce manufacturing costFood preparationPreservative freeDrug biological activity

The invention discloses a processing method for vacuum frozen puffed beef cubes, and belongs to the dry-cure of beef cubes. The method comprises the following steps of: (1) pretreating raw materials, namely, washing fresh beef, cutting the washed fresh beef into meat blocks of 500-1000g, putting the meat blocks into a pot and boiling for 30-40min, fishing out, cutting the boiled meat blocks into beef cubes of 1cm by using a cuber, adding different soup bases with different recipes according to different tastes, boiling, soaking, boiling the soap till being dried, taking out the beef cubes and draining; (2) spreading the drained beef cubes in a single layer, uniformly distributing on material trays, putting the material trays with the beef cubes into an instant freezer, and instantly freezing for 4-6h at minus 40 DEG C so as to ensure that the moisture in the beef cubes is completely frozen; and (3) carrying out vacuum freezing puffing drying by using a vacuum freezing puffing drying machine. By utilizing the method, the original biological activity and the nutrition components of the beef cubes are maintained to the maximum extent, and moreover, the beef cubes have the characteristics of good crispness, completeness in appearance, additive or preservative free, low drying energy consumption, capacities of improving the taste and improving the production efficiency, and the like.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Reusable Inversion Sleeve Assembly for Inversion of Cured in Place Liners

ActiveUS20080072982A1Poor curingUnderground chambersLayered productsEngineeringMechanical engineering

Installation of a flexible cured in place liner by inverting the liner utilizing an inversion sleeve assembly with an installation apparatus having at least one selectively operable rigid gland. The sleeve assembly includes a sleeve portion of an absorbable material secured in an apparatus with an inversion boot fitted at the distal end with an inlet port for inversion and / or curing fluid. The sleeve assembly and apparatus are particularly well suited for inverting with air and curing the liner with steam introduced through a perforated lay flat hose using an apparatus with two glands. The installation sleeve is the same dimension as the liner to be installed and is reusable thereby substantially reducing the set up time to install using the dual gland apparatus. Preferably, the flexible sleeve is a length of dry cured in place liner inverted on to itself to expose two impregnable surfaces. The sleeve may have a built in fluid inlet port for use with a dual gland apparatus.

Owner:INA ACQUISITION

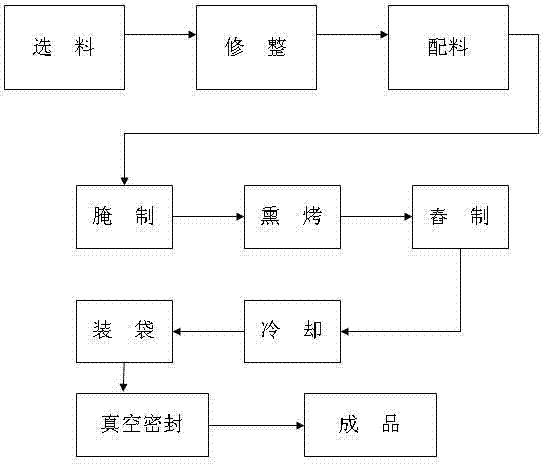

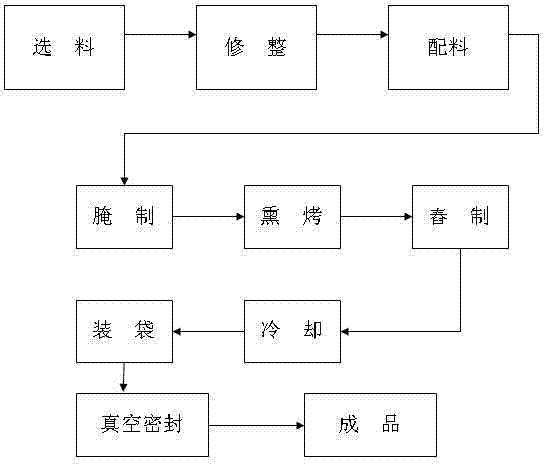

Rapid machining method of smoked old hen

InactiveCN102960757AGuaranteed qualityShort processing timeFood preparationTemperature controlRapid processing

The invention discloses a rapid machining method of a smoked old hen. The rapid machining method comprises the following steps of: directly drying dry-cured old for 1-12 hours and then hanging the old hen inside a smoking room; igniting by using a wooden material or charcoal, opening a furnace door, smoking for 4-5 hours with open fire, carrying out curing treatment by controlling a temperature within a range from 70 to 80 DEG C, and smoking for 1-5 hours with the open fire; and controlling the temperature within a range from 50 to 60 DEG C, manufacturing a finished product and freezing in time. The method provided by the invention has short machining time; chicken skin and chicken of the machined old hen are soft and elastic, and have no smoke smell, delicious taste and good taste sense.

Owner:陆超

Preparation method of tender dry-cured goose

The invention discloses a preparation method of tender dry-cured goose, which comprises the following steps: killing and preparing dry-cured gooses, injecting a tenderizer prepared from an aqueous solution of ficin and bromelain, carrying out rolling and kneading, mixing five spices powder, salt and liquor, coating a mixture in and out of the goose body for dry-curing, preparing a wet-curing material from clove, myrcia, dahurian angelica root, cassia, licorice, amomum tsao-ko, cardamom, netmeg, anise, common fennel fruit, dried orange peel, grosvenor momordica fruit, villous amomum fruit, ginger, scallion and black tea, carrying out a wet-curing for the goose body, carrying out air drying, boiling with sauce and sterilizing, and preparing the tender dry-cured goose. The preparation technology is simple, antiseptic is not added, preservation time is long, carrying and eating are convenient, and the prepared dry-cured goose has unique local flavor, delicious quality and salted fragrance with heavy flavor.

Owner:TIANCHANG BAITAHU FOOD

Composite antioxidant for inhibiting excessive oxidation of fatty fish lipid and pickling processing method

ActiveCN106982916AInhibit excessive oxidationHyperoxidation blockingFood ingredient as antioxidantAcidic food ingredientsLipid formationVitamin C

The invention discloses a composite antioxidant for inhibiting excessive oxidation of fatty fish lipid and a pickling processing method. The composite antioxidant comprises 2.0-3.5%v / w of lactobacillus plantarum liquid with the concentration of 108-1010cfu / mL, 0.03-0.05%w / w of rosmarinic acid, 0.03-0.05%w / w of bamboo leaf flavonoid and 0.01-0.02%w / w of vitamin C. The usage of the components is the percent ratio of the components to the weight of treated fish. The components are weighed according to the percent ratio of the weight of the treated fish, dissolved in normal saline and uniformly stirred into composite antioxidant solution, the pickled fish is soaked in the composite antioxidant solution, the volume weight ratio of the composite antioxidant solution to the fish is 1:1, soaking time is 1.5-2.5 hours, the fish soaked in the antioxidant is placed in a heat pump dryer until the water content of the fish is 38-42%, and the fish is packaged and stored. Moderate fat oxidation of the fatty fish in the pickling and low-temperature drying process is facilitated, the dry-cured fish has special flavor, the oxidation process is stopped after drying, further excessive lipid oxidation of dry-cured fatty fish products is effectively inhibited, and the guarantee period of the products is prolonged.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

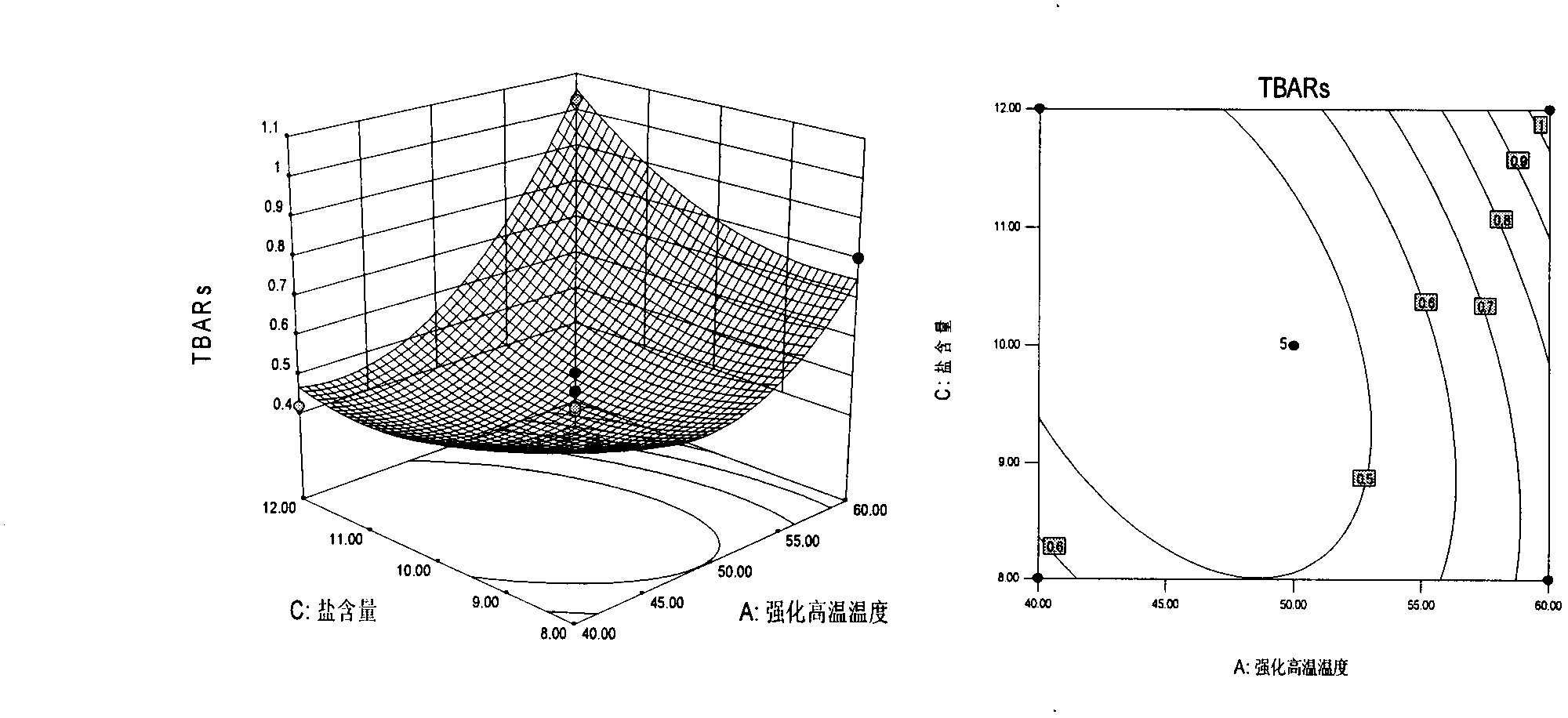

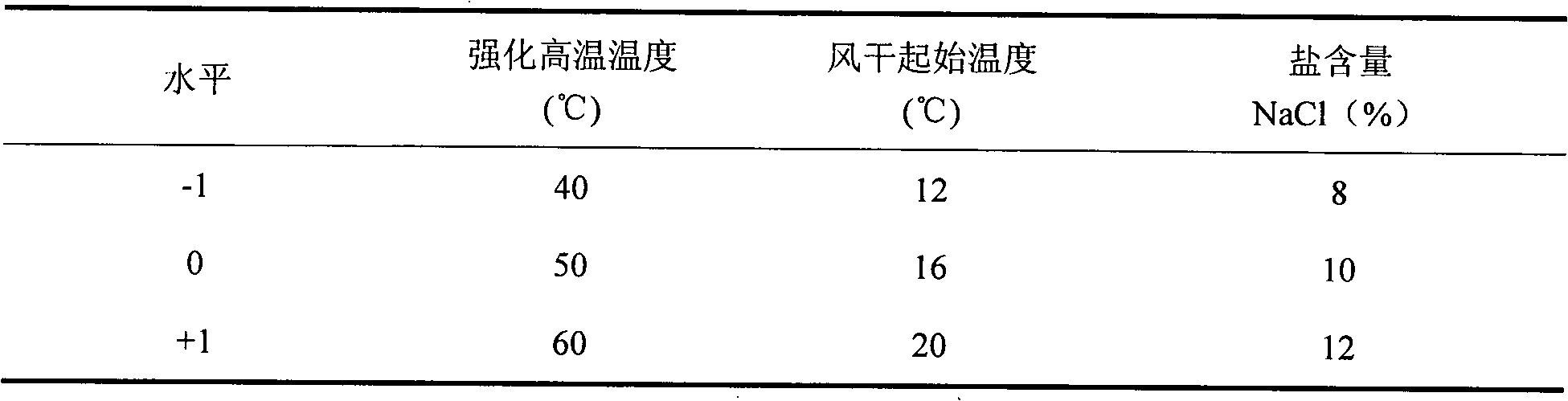

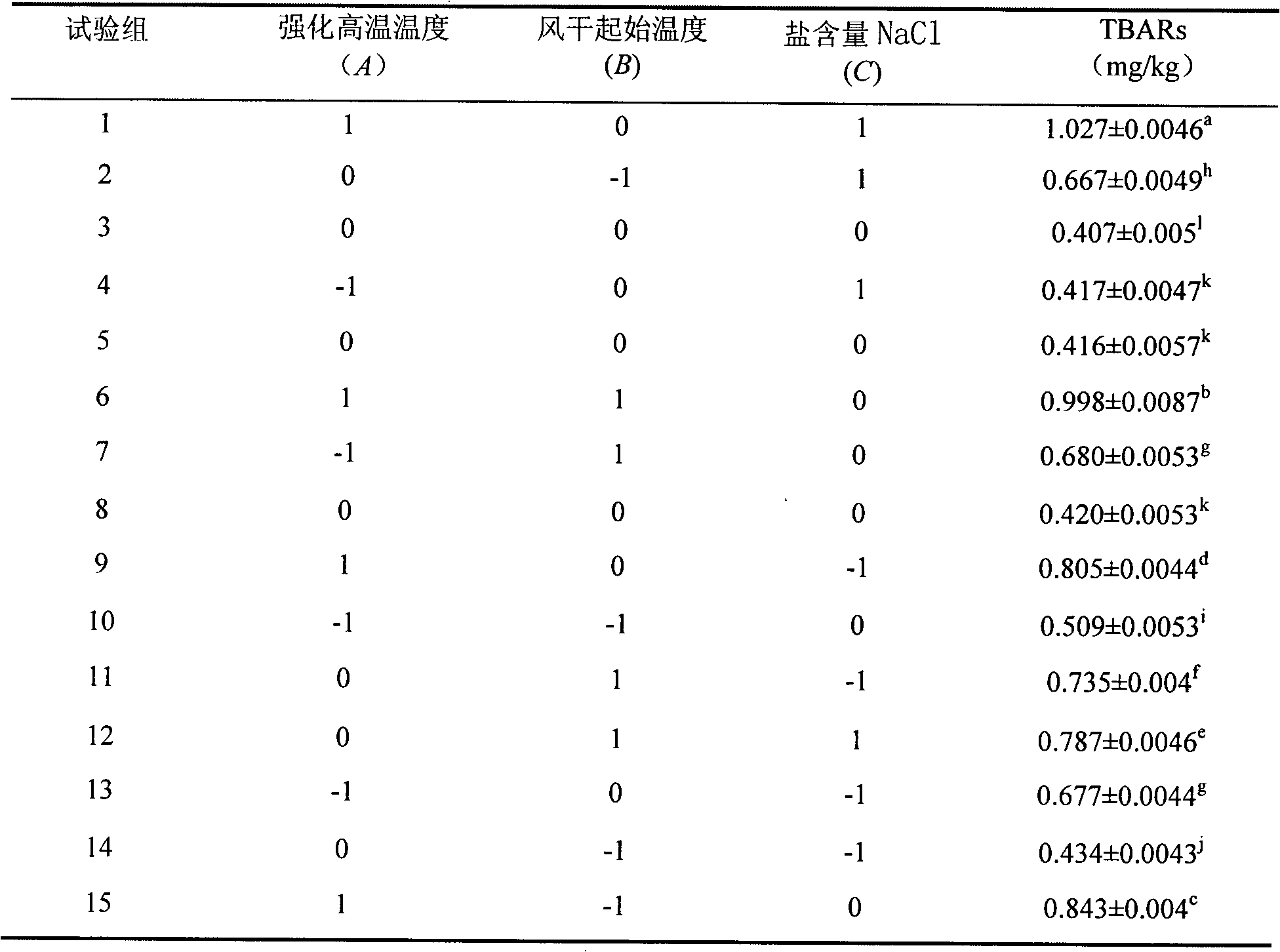

Lipidolysis oxidation controlling method in dry-cured duck processing process

InactiveCN102669703AIncrease vitalityImprove flavor qualityFood preparationLiquid temperatureRipening

The invention relates to a lipidolysis oxidation controlling method in a dry-cured duck processing process, and belongs to the deep processing technical field of animal products. The lipidolysis oxidation controlling method comprises the following steps of: wet-salting (salting liquid temperature of 5 plus (minus) 5 DEG C) a raw fresh duck in salting liquid with salt content of 9-12% for 24 hours; putting the salted duck at the temperature from 40 DEG C to 60 DEG C; high-temperature air-drying the salted duck in the environment with relative humidity of 58 plus (minus) 5% RH for 60 plus (minus) 20 minutes, and starting the air-drying and ripening for the salted duck; controlling the temperature to be 12 DEG C to 18 DEG C from the beginning of the air-drying and ripening; and air-drying ripening the salted duck for 68-78 hours at a heating rate of 0.2-0.3 DEG C per hour under the humidity of 58 plus (minus) 5% RH to obtain a dry-cured duck product. According to the invention, activity of lipase and lipoxygenase in dry-cured duck meat is controlled by a reinforced high-temperature air-drying process to quicken up lipidolysis oxidation and flavour formation in the product, so that fat oxidation indexes are effectively lowered, and flavour quality of the dry-cured duck product is improved; besides, the invention also provides a new process for controlling lipidolysis oxidation and quickening up the flavour formation for the large-scale production of the dry-cured duck.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method of making bacon pieces

Owner:HORMEL FOODS

Processing method for vacuum frozen dried puffed fresh golden silk jujube

ActiveCN103141559AIncrease added valueIncreased added value; drying energy consumptionFruit and vegetables preservationFood processingPreservative freeFreeze-drying

The invention discloses a processing method for vacuum frozen dried puffed fresh golden silk jujube, and belongs to the dry-cure of fresh golden silk jujube. The method comprises the following steps of: (1) pretreating the raw material, namely, selecting and washing fresh golden silk jujube and carrying out stone elimination treatment on the washed golden silk jujube; (2) steeping the treated golden silk jujube into a sugar liquid of which the sugar content is 40% for 8-12h, subsequently taking out the golden silk jujube to be sprayed, removing the sugar liquid on the surface of the golden silk jujube, and draining; (3) spreading the drained golden silk jujube in a single layer and uniformly distributing on a material tray, putting the golden silk jujube in the material tray into an instant freezer, and instantly freezing for 4-6h at minus 40 DEG C so as to ensure that the moisture in the golden silk jujube is completely frozen; and (4) carrying out vacuum freezing puffing drying by using a vacuum freezing puffing drying machine. By utilizing the method, the original biological activity and the nutrition components of the golden silk jujube are maintained to the maximum extent, and moreover, the fresh golden silk jujube has the characteristics of good crispness, completeness in appearance, additive or preservative free, lower drying energy consumption, capacities of improving the taste and improving the production efficiency, and the like.

Owner:山东鼎力枣业食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com